Page 1

GE

Lighting

Installation Guide

12

Volt

®

Tetra

Wet Location MAX

LED Lighting System

GEMX71-W1, GEMX50-W1, GEMX41-W1, GEMX32-W1, GEMXH71-W1, GEMXH50-W1,

GEMXH41-W1, GEMXH32-W1, GEMXRD-W1, GEMXBL-W1, GEMXGL-W1, GEMXPO-W1,

GEMXRC-W1, GEMXYG-W1, GEMXHRD-W1

BEFORE YOU BEGIN

Read these instructions completely and carefully.

WARNING/AVERTISSMENT

RISK OF ELECTRIC SHOCK

• Turn power off before inspection, installation or removal.

• Properly ground Tetra® power supply enclosure.

RISK OF FIRE

• Use only UL approved wire for input/output connections.

Minimum size 18 AWG (0.82mm2)

• Follow all NEC and local codes.

Save These Instructions

Use only in the manner intended by the manufacturer.

If you have any questions, contact the manufacturer.

This device complies with part 15 of the FCC Rules. Operation is

subject to the following two conditions: (1) This device may not

cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause

undesired operation.

Note: This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant to part 15 of

the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment

is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required to

correct the interference at his own expense.

This Class [A] RFLD complies with the Canadian standard

ICES-003. Ce DEFR de la classe [A] est conforme à la NMB-003

du Canada.

RISQUES DE DÉCHARGES ÉLECTRIQUES

• Coupez l’alimentation avant l’inspection, l’installation ou le déplacement.

• Assurez-vous de correctement mettre à terre l’alimentation électrique Tetra®.

RISQUES D’INCENDIE

• N’utilisez que des ls approuvés par UL pour les entrées/sorties de connexion.

Taille minimum 18 AWG (0.82mm2)

• Respectez tous les codes NEC et codes locaux.

Prepare Electrical Wiring

Electrical Requirements

• Acceptable for use in dry, damp and wet locations.

• The grounding and bonding of the LED Driver shall

be done in accordance with National Electric Code (NEC)

Article 600.

• Follow all National Electric Codes (NEC) and local codes.

Tips

• For optimal light uniformity in halo-lit applications the Tetra® LED

modules should be mounted on UL recognized plastic and the light

output from the Tetra® LED system should be directed back into the

sign enclosure. This will allow for uniform backlighting of the sign

and will provide simple mounting for the Tetra® LED system.

• A best practice for the supply wire at the point at which it is brought

into the sign is to have a drip loop on the inside of the letter to keep

water from collecting on the Tetra® LED strip.

• These products are not required to be enclosed or protected from

weather.

This product is intended solely for the use of non-residential signage

lighting and is not intended for use in any other applications.

Conforms to the following standards: IP66 rated

imagination at work

Page 2

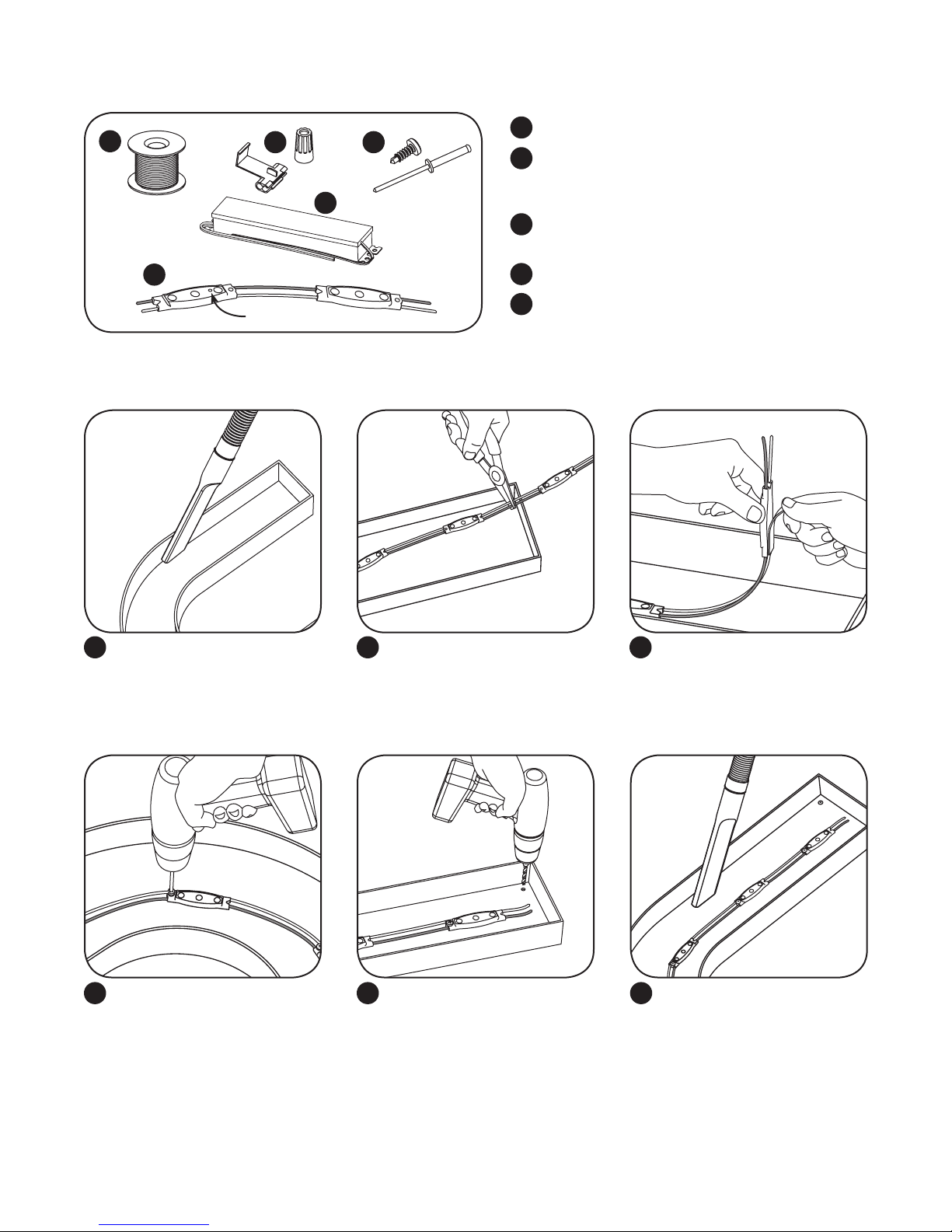

Components

1

5

Layout Modules

2 3

4

TC Measure Point

UL approved 18 AWG supply wire (0.82 mm2)

1

UL approved 22-14 AWG twist-on wire connectors

2

(0.33 - 2.08 mm2) or 18-14 AWG In-line/IDC

connectors (0.82 - 2.08 mm2)

#6 or #8 (M3 or M4) screws, 1/8 inch (3.2 mm)

3

rivets, or electronic grade silicone or equivalent

Tetra® 12 Volt Power Supply

4

Tetra® Wet Location MAX LED Modules

5

Clean and remove all debris

1

from the inside of the channel

letter before you begin.

4 5 6

Use rivets, screws, or silicone

to secure at least every fth

LED module within the channel

letter. Use #6 (M3) or #8 (M4)

pan headed metal screws,

1/8-inch (3.2 mm) rivets, or

silicone.

Measure and cut Tetra LED

2 3

strip to the appropriate length

for each letter. Cuts can be

made between any of the

modules.

Drill a 1/4” (6.4 mm) hole near

the LED strip and grommet the

hole for supply wire access.

NOTE: For halo-lit applications LED modules should be mounted on UL

recognized clear acrylic or polycarbonate. The light output from the LED

system should be directed back into the sign enclosure. This will allow for

uniform backlighting of the sign and will provide simple mounting.

Remove tape backing and

stick LED modules into place.

Continue until you have

reached the end of the strip.

Clean and remove all debris

from the inside of the channel

letter. Replace sign face.

Page 3

Electrical Connections

White (-)

Red (+)

Connect LED strips using in-line (IDC) connectors or

1 2

twist-on wire connectors.

To Tetra LED System

Red (+)

Run a wire from the Power Supply to each channel

3

Black or blue (-)

Power

Supply

letter and connect to the rst LED module on the

strip.

Must be used with Tetra® 12 Volt Power Supplies.

Cap wires

Must cap all exposed wires with appropriate wire

connectors.

Red (+)

White (-)

Connect the red wire (+) of the LED strip to the red

4

Red (+)

To power

supply

Black or blue (-)

wire (+) of the power supply. Connect the white

wire (-) of the LED strip to the black or blue wire (-)

of the power supply.

NOTE: All electrical connections should be made

within the letter.

Retrot Instructions

1. (Existing Signs Only) Prior to installation, survey the site for information regarding power and accessibility inside and outside the building. Ensure

that the branch circuit supplying the existing transformer or ballast will be within the voltage ratings of the new LED power supply, and have

a current rating not exceeding 20A, or that permitted by applicable local, state, or country electrical codes (whichever is less).

2. (Existing Signs Only) Remove the existing lighting equipment to be replaced, such as neon tubing or uorescent tubes; and associated

transformers and ballasts. Care should be taken not to break the existing neon or uorescent tubes.

NOTE: Follow all federal and local regulations when disposing of neon tubing, uorescent tubes, transformers and ballasts.

3. (Existing Signs Only) If removal of the existing lighting equipment eliminates the disconnect switch, as required by applicable local, state, or

country electrical codes; a new disconnect switch must be installed.

4. (Existing Signs Only) Make sure the removal of lighting equipment does not compromise the integrity of the sign body (i.e. water intrusion). Fill in

all holes 0.5 in. (13 mm) or smaller with the appropriate amount of rated caulk or sealant. For holes greater than 0.5 in. (13 mm), use an aluminum

or zinc coated steel patch with rivets and sealant.

5. (Existing Signs Only) A clean and dry mounting surface ensures optimum adhesion if the self-adhesive method of mounting is chosen. Follow

the manufacturer’s directions when using a non-oil based solvent, such as rubbing alcohol to clean the surface area where you intend to mount

the module. Before installing, ensure the surface is dry.

6. Using the layout guidelines above, determine required number of LED modules required to illuminate the sign.

7. A Tetra® 12VDC Class 2 Power Supply, as listed below, must be used with this retrot kit. Using the Maximum Loading chart below, determine the

number of Tetra® Class 2 Power Supplies required to power the number of LED modules required to illuminate the sign, so as not to overload

the Tetra® Class 2 Power Supply chosen.

8. Follow the instructions above to properly mount the LED modules.

9. Connect the DC output of the power supply to the LED modules using the Electrical Connections instructions above.

10. Connect the power unit to the supply in accordance with the applicable local, state, and country electrical codes, and the instructions found in the

power supply installation guide.

11. If required, the disconnect switch shall be installed by qualied personnel, in accordance with applicable local, state, and country electrical codes.

Page 4

Troubleshooting

Symptom Solution

All letters are OFF • Check AC input connection and/or check circuit breaker.

• Check wire connection(s) at the Tetra® LED System and power supply for improper termination(s) or short circuits.

Properly terminate or replace the wire connection(s).

• Check that connections are the red striped wire (+) of the LED strip to the red wire (+) of the power supply and the

white wire (-) of the LED strip to the black or blue wire (-) of the power supply.

Some LEDs

appear dim

Some of the letters are

not illuminated

Shadows • Re-route supply wire and secure to the back of the can with silicone. Adjust wire connector orientation so that it

• Ensure the overall length of the Tetra® LED System does not exceed the maximum load.

• Ensure the length of supply wire is equal to or below the recommended remote mounting distance.

• Check wire connection(s) at the Tetra® LED System and power supply for improper termination(s) or short circuits.

Properly terminate or replace the wire connection(s).

• Check that connections are the red striped wire (+) of the LED strip to the red wire (+) of the power supply and the

white wire (-) of the LED strip to the black or blue wire (-) of the power supply.

does not cover any LEDs.

• Adjust LED layout to ensure uniformity of illumination on the face of the letter.

Specications

Maximum Loading per Tetra 12 VDC Power Supply

180W Power Supply

Note: Load shall not exceed 5A per

each (of 3) output channels

128 modules/64 ft. (19.51 m)

per output channel

384 modules/192 ft. (58.52 m)

per power supply

80 modules/40 ft. (12.20 m)

per output channel

240 modules/120 ft. (36.59 m)

per power supply

120 modules/60ft. (18.29m)

per output channel

360 modules/180ft. (54.86m)

per power supply

160 modules/80ft. (24.38m)

per output channel

480 modules/240ft. (73.15m)

per power supply

200 modules/100ft. (30.48m)

per output channel

600 modules/300ft. (91.44m)

per power supply

106 modules/53ft. (16.15m)

per output channel

318 modules/159ft. (48.46m)

per power supply

100 modules/50ft. (15.24m)

per output channel

300 modules/150ft. (45.72m)

per power supply

SKU Rating

GEMX71-W1,

GEMX50-W1,

GEMX41-W1,

GEMX32-W1

GEMXH71-W1,

GEMXH50-W1,

GEMXH41-W1 ,

GEMXH32-W1

GEMXRD-W1

GEMXBL-W1

GEMXGL-W1

GEMXPO-W1

GEMXRC-W1

GEMXYG-W1

GEMXHRD-W1

12VDC, 38mA/module

0.456W/module

12VDC, 60mA/module

0.720W/module

12VDC, 40mA/module

0.48W/module

12VDC, 32mA/module

0.384W/module

12VDC, 30mA/module

0.36W/module

12VDC, 24mA/module

0.29W/module

12VDC, 45mA/module

0.54W/module

12VDC, 47mA/module

0.564W/module

25W Power Supply

Note: Load shall not exceed 2A

48 modules/24 ft. (7.31 m) 128 modules/64 ft. (19.51 m)

30 modules/15 ft. (4.57 m) 80 modules/40 ft. (12.20 m)

45 modules/22.5ft.(6.86m) 120 modules/60ft.(18.29m)

60 modules/30ft.(9.14m) 160 modules/80ft.(24.38m)

74 modules/37ft.(11.28m) 200 modules/100ft.(30.48m)

40 modules/20ft.(6.09m) 106 modules/53ft.(16.15m)

36 modules/18ft.(5.48m) 100 modules/50ft.(15.24m)

60W Power Supply

Note: Load shall not exceed 5A

Maximum Remote Mounting Distance

25W Power Supply 120 ft./36.6 m – – –

60W Power Supply 20 ft./6.1 m 30 ft./9.1 m 50 ft./15.2 m 86 ft./26.2 m

180W Power Supply 20 ft./6.1 m 30 ft./9.1 m 50 ft./15.2 m 86 ft./26.2 m

NOTE: For linear runs longer than 40ft, center connection to the LED strip is recommended to minimize voltage drop.

www.gelighting.com

GE and the GE Monogram are trademarks of the General Electric Company. All other trademarks are the property of their respective owners. Information provided is subject to

change without notice. All values are design or typical values when measured under laboratory conditions. GE Lighting is a business of the General Electric Company. © 2016 GE.

SIGN177 (Rev 11/17/16)

GE2027-8675

18 AWG/0.82 mm2

Supply Wire

16 AWG/1.31 mm2

Supply Wire

14 AWG/2.08 mm2

Supply Wire

12 AWG/3.31 mm2

Supply Wire

Loading...

Loading...