Page 1

GE Oil & Gas

H Series compressors

High-speed reciprocating compressors for natural gas applications

Our H Series compressors (formerly models HPD, HPDD, HPSS, HPDS)

are designed to run continuously for extended periods of time while

unattended. These high-speed units forgive non-reversals through

unique wrist-pin needle bearing design. GE’s comprehensive line-up of

double-acting and stepped cylinders offer maximum staging flexibility.

A workhorse in field gas applications, the H Series can also provide up

to 6,000 psig for CNG vehicle refueling. The compact, packager-friendly

design features a “through shaft” fan adapter that allows the cooler to

be driven by the pump end of the compressor, shortening overall skid

size, and simplifying the piping design.

Performance features

Type

Horizontal balanced opposed, one, two or four throws with double

acting and/or stepped cylinder sets to provide up to four stages of

compression.

Frame

Heavy-wall, one-piece alloy iron casting with reinforcing ribs. Removable

alloy iron crosshead guides are surrounded by large cooling passages.

Crankshaft

Forged-steel design has integral counterweights and force-lubricated

tri-metal sleeve type main bearings.

Cylinders

A wide range of gas-cooled cylinder options is available. Cylinder

arrangements include double-acting, tandem, and stepped-piston

designs. Non-lube designs are available for special applications.

Cylinders are available with MAWP up to 6,000 psig.

Compressor valves

Steel valve seats and guards; MTX or HTCX valve plates are standard.

Valve springs, lifts and plates can be tailored to meet your performance

conditions.

Compressor lubrication

Gear type lube oil pump is driven by the crankshaft. Lubrication system

includes a non-bypassing, spin-on lube oil filter, oil pump relief valve and

thermostat.

Packing and cylinder lubrication

Integral single-pump force-feed lubricator contains a block distribution

system, a cycle indicator and a no-flow shutdown switch. Stainless

steel tubing includes plated fittings piped to the cylinders and packing.

Lubrication feed rate is fully adjustable.

Standard testing

Compressor mechanical run test, hydrostatic test of all cylinders and

post-test inspection meet GE’s high standards.

Standard accessories

Specialized tools, where applicable, are included in the toolbox.

Optional items

Variable-volume clearance pockets, CSA or XP no-flow switches and

vibration switches, export boxing, immersion oil heaters, flywheels, drive

couplings, oil coolers and fan drives.

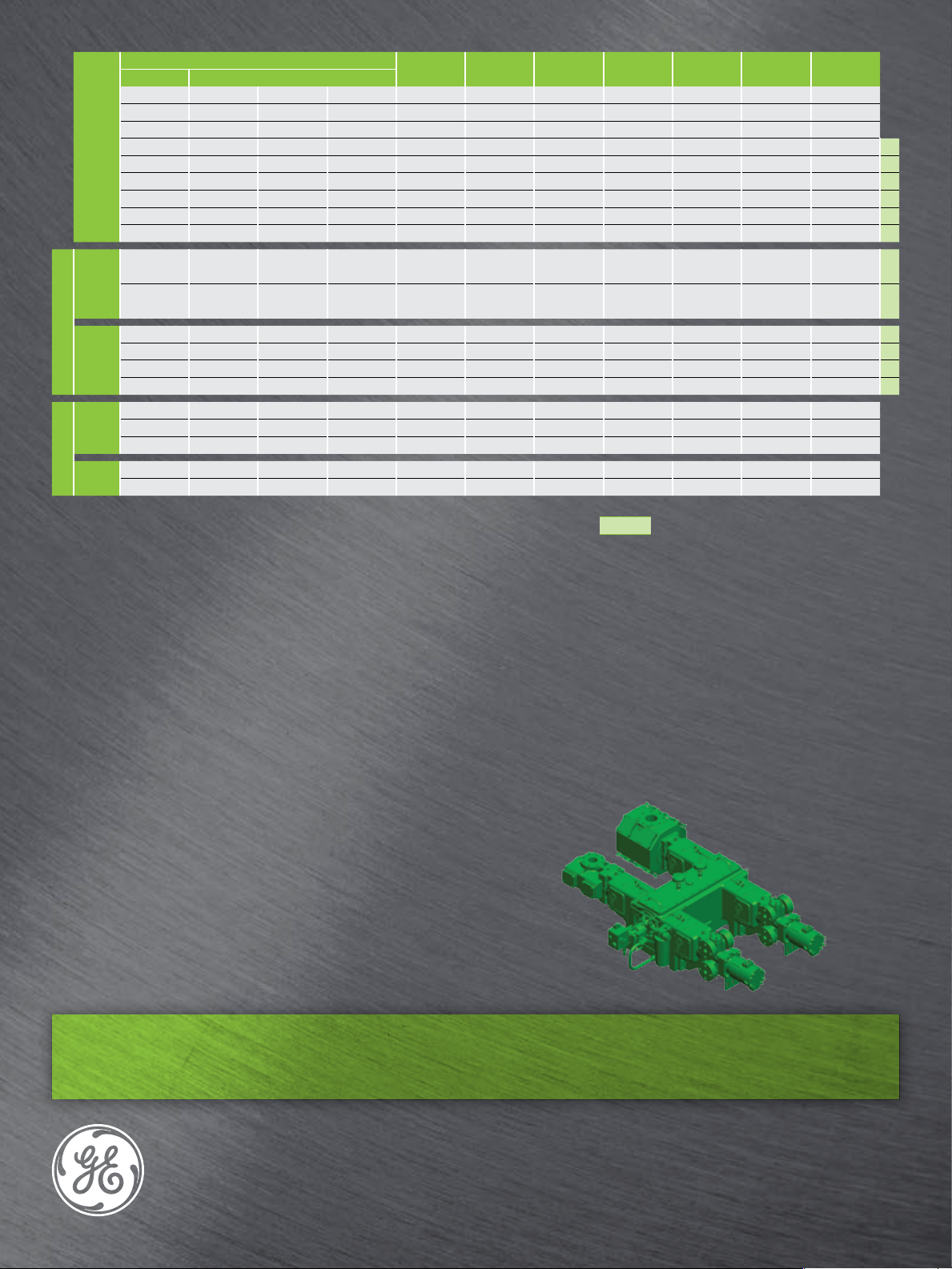

Throw configurations

Compressor throws

Max. BHP (kW)

Frame weight lbs (kg) dry*

Frame length inches (cm)*

Frame width inches (cm)*

Frame height inches (cm)

1

100 (75) 200 (149) 400 (298)

1,050 (476) 1,050 (476) 2,350 (1,066)

26.3 (66.8) 26.3 (66.8) 57.6 (146.3)

49.5 (125.7) 49.5 (125.7) 49.5 (125.7)

28.9 (73.4) 28.9 (73.4) 25 (63.5)

2 4

Stroke configuration

Stroke inches (mm)

Max. rated speed (rpm)

3.0 (76.2)

1,800

Piston/piston rods

Hard anodized aluminum alloy or cast iron pistons. Weight is precisely

controlled during manufacturing to eliminate the need to match parts

in the field. Carbon-filled Teflon piston rings are standard for most

applications. Piston rods are 4140 steel with rolled threads. Full-floating

vented sealing and wiper packing.

Connecting rods

Ductile iron with precision insert type bearings on crank end and roller

bearings on pin end.

Crossheads

One-piece ductile iron crossheads have babbitted faces, cast iron

crosshead guides and steel crosshead pin.

Heavy duty running gear

Rod load - tension

Rod load - compression

Combined rod load

Piston rod diameter

Crankshaft material

Connecting rod material

Crankpin bearing diameter

Crankpin bearing width

Main bearing diameter

Main bearing width

Connecting rod pin

* without cylinders F.S. = Forged Steel D.I. = Ductile Iron

10,000 lbs-f

10,000 lbs-f 44.48 kN

20,000 lbs-f 88.96 kN

1.125 inches 28.6 mm

3.25 inches 82.6 mm

1.5 inches 38.1 mm

3.0 inches 76.2 mm

1.875 inches 47.6 mm

44.48 kN

F.S .

D.I.

Roller bearing

Model nomenclature

H304 = H 30 4

Model = Frame Stroke (in) Throws

Page 2

Cylinders for the H Frames

Series Cylinder bore - inches

H30 2.50 3 1,440 Gas D.I. 1.5 1,500 4 No

H30 2.50 3 1,250 Gas D.I. 1.5 600 4 No

90 3.50 1,725 Gas D.I. 2 1,500 4 Yes

H30 3.50 4 1,250 Gas D.I. 3 600 4 Yes a

H30 4.50 5 1,250 Gas D.I. 3 600 4 Yes a

Double acting

H30 5.50 1,000 Gas D.I. 3 600 4 Yes a

H30 6 6.50 500 Gas D.I. 4 300 4 Yes b

H30 7.50 8 500 Gas D.I. 4 300 8 Yes b

H30 8 9 300 Gas D.I. 4 300 8 Yes b

H30 2.50 3 1,250 Gas C.I. 1.5 600 2 No c

MAWP

PSIG

Cylinder

cooling

Material

Flange

dia inch

Flange

rating PSIG

Valves VVCP

Crank end

Stepped

Head and

Tandem (CNG)

L = Nitrided Liner - field replaceable D.I. = Ductile Iron SAHE = Tandem cylinder - Single Acting Head End a, b, c, etc. Designates cylinders having identical XYZ flange

NL = No Liner F.S. = Forged steel SACE = Tandem cylinder - Single Acting Crank End dimensions to assist interchangeability and package

C.I. = Cast Iron piping standardization

(1) The 1.25" piston can be trimmed to add 14% or

25% additional clearance

(1) The 1.50" piston can be trimmed to add 10% or

20% additional clearance

Designed for flexibility

• The H Series is backed by 100 years of GE compressor design

experience

• Part of a complete line of reciprocating compressors featuring

advanced technology and work-proven designs

• Many cylinders have identical X, Y, and Z flange locations, allowing

packages to be reconfigured without any changes to the piping and

bottles

H30 3.50 4 5 1,250 Gas C.I. 1.5 600 2 No c

single acting

H30 4 5 1,250 Gas D.I. 1.5 600 2 Yes d

H30 5.50 750 Gas D.I. 1.5 600 2 Yes d

H30 6.50 7.50 500 Gas D.I. 3 300 4 Yes e

single acting

H30 8 300 Gas D.I. 3 300 4 Yes e

H30 2.50 3 3,500 Gas F.S. 1 6,000 2 No

H30 2.50 3 2,500 Gas D.I. 1.5 1,500 2 No

SACE

H30 3.50 4 3,500 Gas F.S. 2 6,000 2 No

H30 1.25 1.50 6,000 Gas F.S. 1 6,000 1 No

SAHE

H30 1.75 2 6,000 Gas F.S. 1.25 6,000 1 No

Operating benefits

• Compressor is easily reconfigured to meet your changing

requirements

• Reduces lifecycle cost and increases production

• Reduces required inventory of machinery and spare parts

• Higher efficiency, lower fuel or electricity consumption

• Lower cost of reconfiguration

• Greater utilization of driver power over a wide range of conditions

• Over 18,000 GE high-speed reciprocating compressors have been

built to date

All GE high-speed reciprocating compressors are packaged, serviced

and maintained by a worldwide network of authorized packagers and

distributors.

Compressor Sales

HSR_Sales@ge.com

T +1 713 683 2400

24 Hour Technical Support

HSR_Support@ge.com

T +1 832 978 9780

GE imagination at work

OEM Replacement Parts

OilGasTeamBox@gexpro.com

T +1 866 565 2303

4425 Westway Park Blvd

Mail Stop 3

Houston, TX 77041

geoilandgas.com/hsr

© 2013 General Electric Company. All rights reserved.

GE_HSRC_H_FS-012413

Loading...

Loading...