Page 1

Click here to get to our homepage:

http://www.gemultilin.com/

GEK-45404F

MULTILIN

GE Power Management

INSTRUCTIONS

OVERVOLTAGE RELAYS

TYPES IAV, 51D

K

52C

D

K

GE Power Management

205 Great Valley Parkway

Malvern, PA 19355, USA

Page 2

GEK-45404

DESCRIPTION................................................................................................................................................... 3

APPLICATION................................................................................................................................................... 4

RATINGS............................................................................................................................................................ 5

BURDENS.......................................................................................................................................................... 6

OPERATING CHARACTERISTICS................................................................................................................. 8

CONSTRUCTION.............................................................................................................................................. 9

RECEIVING, HANDLING, AND STORAGE ................................................................................................ 10

RECEIVING.................................................................................................................................................. 10

HANDLING.................................................................................................................................................. 10

STORAGE..................................................................................................................................................... 10

ACCEPTANCE TESTS.................................................................................................................................... 10

VISUAL INSPECTION ................................................................................................................................10

MECHANICAL INSPECTION..................................................................................................................... 11

ELECTRICAL TESTS.................................................................................................................................. 12

Drawout Relays - General.......................................................................................................................... 12

Power Requirements - General.................................................................................................................. 12

Pickup-voltage Test ................................................................................................................................... 12

Time-voltage Test...................................................................................................................................... 12

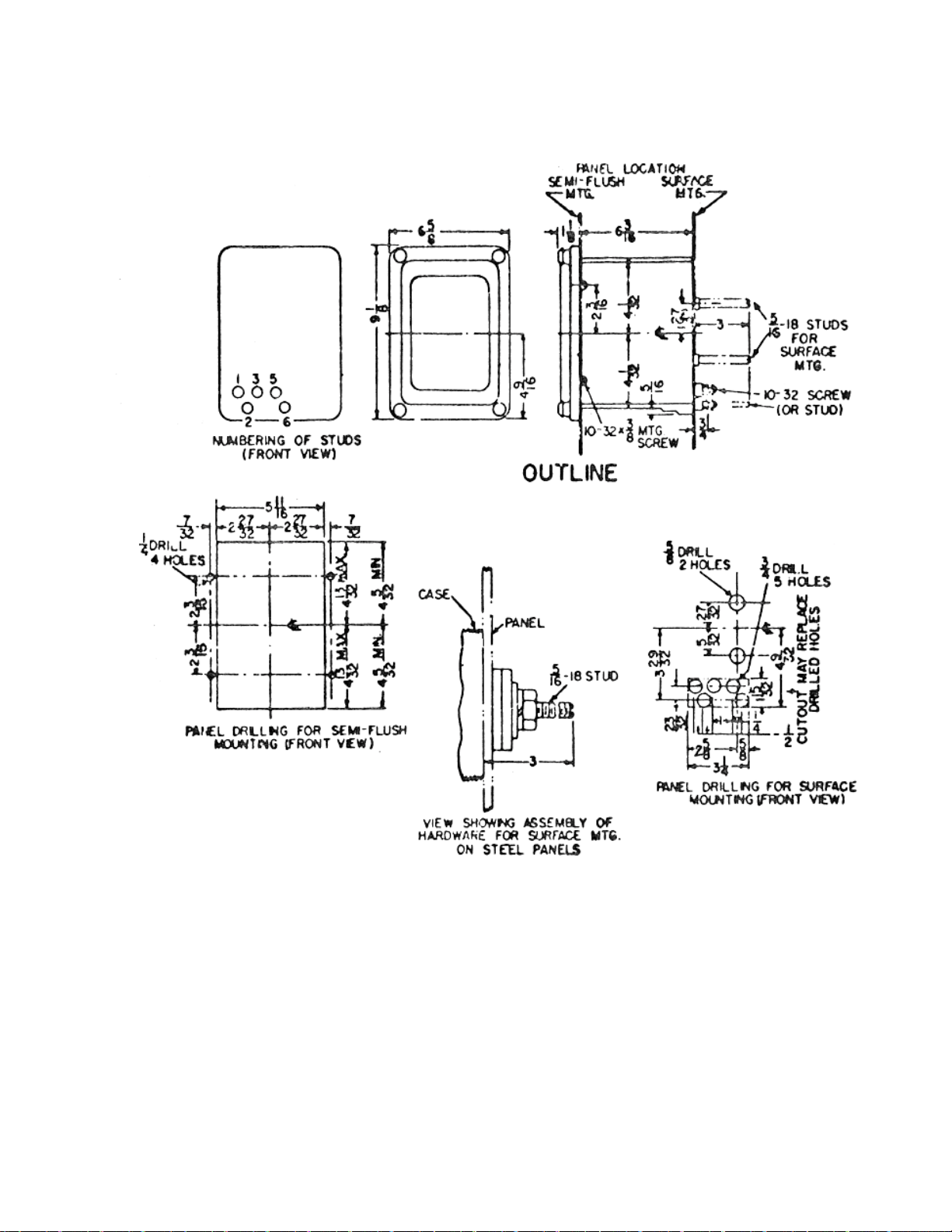

INSTALLATION.............................................................................................................................................. 13

INSPECTION................................................................................................................................................ 13

LOCATION................................................................................................................................................... 13

MOUNTING ................................................................................................................................................. 13

CONNECTIONS........................................................................................................................................... 13

GROUND CONNECTIONS......................................................................................................................... 13

OPERATION.................................................................................................................................................... 13

ADJUSTMENTS........................................................................................................................................... 14

Target and Seal-in Unit.............................................................................................................................. 14

Voltage Setting .......................................................................................................................................... 14

Time Setting............................................................................................................................................... 15

PERIODIC CHECKS AND ROUTINE MAINTENANCE.............................................................................. 15

MAINTENANCE.............................................................................................................................................. 15

DISK AND BEARINGS ............................................................................................................................... 15

CONTACT CLEANING............................................................................................................................... 16

SERVICING...................................................................................................................................................... 16

RENEWAL PARTS.......................................................................................................................................... 16

LIST OF ILLUSTRATIONS ............................................................................................................................ 17

Cover Photo(8043180)

These instructions do not purport to cover all details or variations in equipment nor provid e for every possible

contingency to be met in connection with installation, operation or maintenance. Should further information be desired

or should particular problems arise which are not covered sufficiently for t h e purchaser's purposes, the matter should be

referred to the General Electric Company.

To the extent required the products described herein meet applicable ANSI, IEEE and NEMA standards; but no

such assurance is given with respect to local codes and ordinances because they vary greatly.

OVERVOLTAGE RELAYS

TYPES IAV51D, IAV51K, IAV52C, IAV52D, IAV52K

2

Page 3

GEK-45404

DESCRIPTION

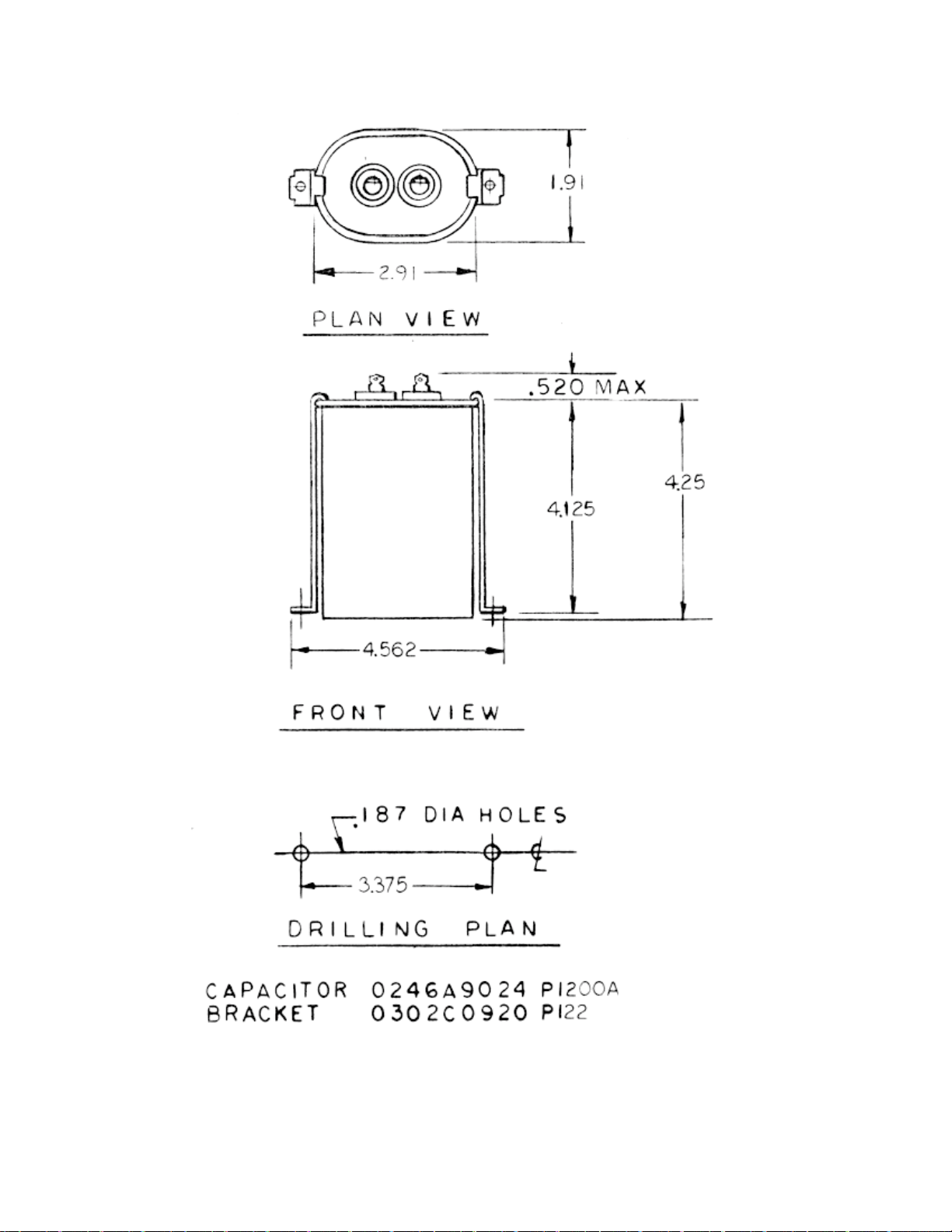

These are single-phase, sensitive overvoltage relays of the induction disk construction. They are

equipped with a time dial so as to provide adj ustable time delay i n their operation. The relays are

principally applicab le for sensitive overvoltage ground detection for high-impedance grounded

generators or for ungrounded power systems. The differences among the four rel ays are as indicated

in Table A below. Each relay is mounted in a standard size S1 drawout case and the outline and

panel drillings are shown in Figs. 14 and 15; Fig. 13 shows the outline for an external capacitor when

used. The internal connections of the relays are indicated in the table. Each relay contains a target

seal-in unit that is used to protect the relay m ain contact s and control spring from damage due to

breaker-trip current.

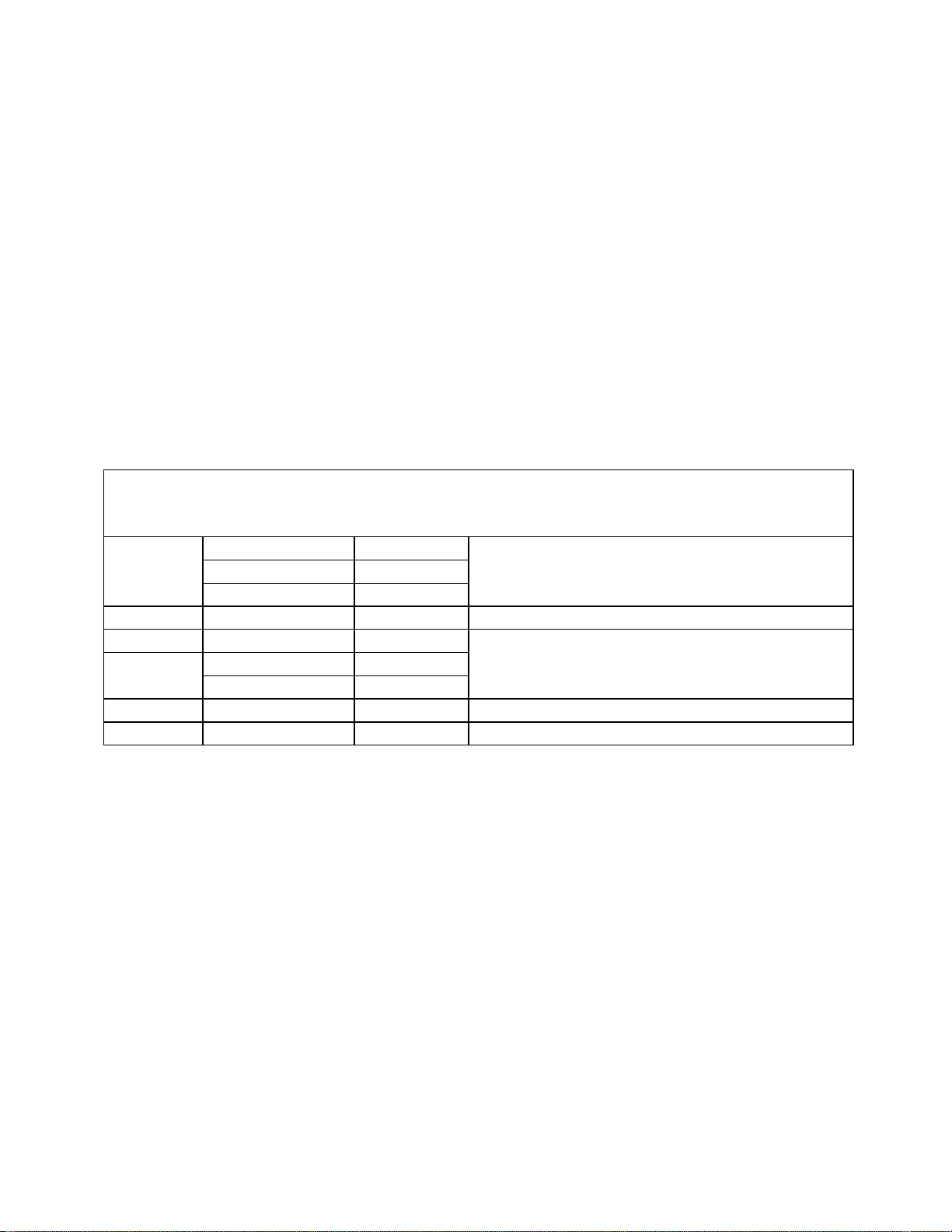

TABLE A

CONTINUOUS

RATING**

(VOLTS)

IAV51D 115 10-40

199 16-64 YES 1NO 1

345 28-112

IAV51K 67 5.4-20 YES 1NO 2

IAV52C 115 9.2

199 16 NO 2NO* 3

345 28

IAV52D 199 16-64 YES 2NO* 4

IAV52K 67 5.4-20 YES 2NO* 5

* The two normally-open contacts have a common connection; refer to the internal connections of

the relay.

** All relays have a 360 volt 10 second rating.

PICKUP

RANGE,

VOLTS

TAPS CONTACTS

INTERNAL

CONNECTIONS

FIGURE

3

Page 4

GEK-45404

APPLICATION

These are single-phase, sensitive, time-delay overvoltage relays. They are princip ally a pplicabl e for

sensitive overvoltage ground detection for high-impedance grounded generators or for ungrounded

power systems. These relays all have a capacitor in series with the operating coil. For the IAV51K

and IAV52K relays, this capacitor is external to the relay because o f its large size. The effect of the

capacitor is to tune the relay c oil circuit so that the relay pickup on third harmonic (180Hz) voltage is

approximately eight times the relay pi ckup at 60 Hz. Thi s is particularly important in overvoltage

ground detection for generators, since they produce a large third- harmonic component of voltage

during normal operation.

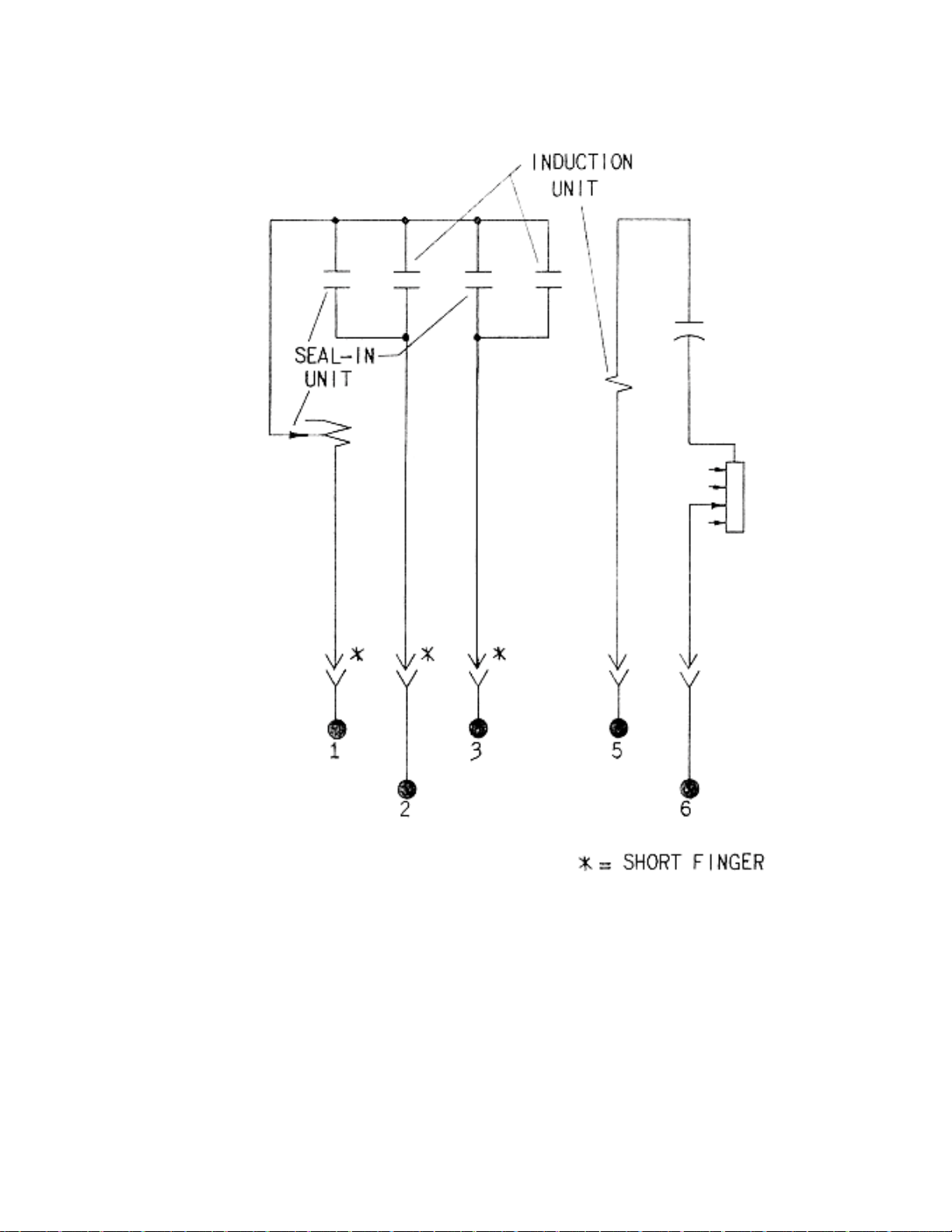

The external connection diagram for the IAV51K or the IAV52K relay for sensitive generator ground

detection is shown in Fig. 8. This is a typical protection scheme for a unit generator transformer

using a distribution transformer connected in the neutral with a resistor across the transformer

secondary. The IAV51K/52K relays are usually us ed for thi s application because they p rovide the

very s ens itive 5.4 volt pickup rating. This enables the relay to detect a ground fault within a few

percent of the wi nding from the neutral. Since the power transformer and the station service

transformer in a unit generator transformer scheme are both connected in delta on the generator side,

coordination with other protection is virtually unnecessary and the ground relay u sed can be very

sensitive. Some time delay in relay operation is usually us ed to coordinate with fuses protecting

against faults on the secondary side of potential transformers that are normally connected to the

generator terminals. The usual practice is to use these relays to trip the generator breaker and shut

down the machine. If the relay is used only t o sound an alarm when a ground fault is detected, the

application should be reviewed. It may be necessary to add another relay to provide ground

protection with good sensitivity simultaneously with a high continuous-voltage rating.

The resistor, shown in Fig. 8 connected across the broken delta secondary of the PT's, or alternatively

connected in series in the primary neutral connection, is usually required to prevent the occurrence of

ferro-resonance. Thi s phenomenon could occur due to the int eraction of the PT inductance with the

distributed capacitance-to-ground of the primary power system.

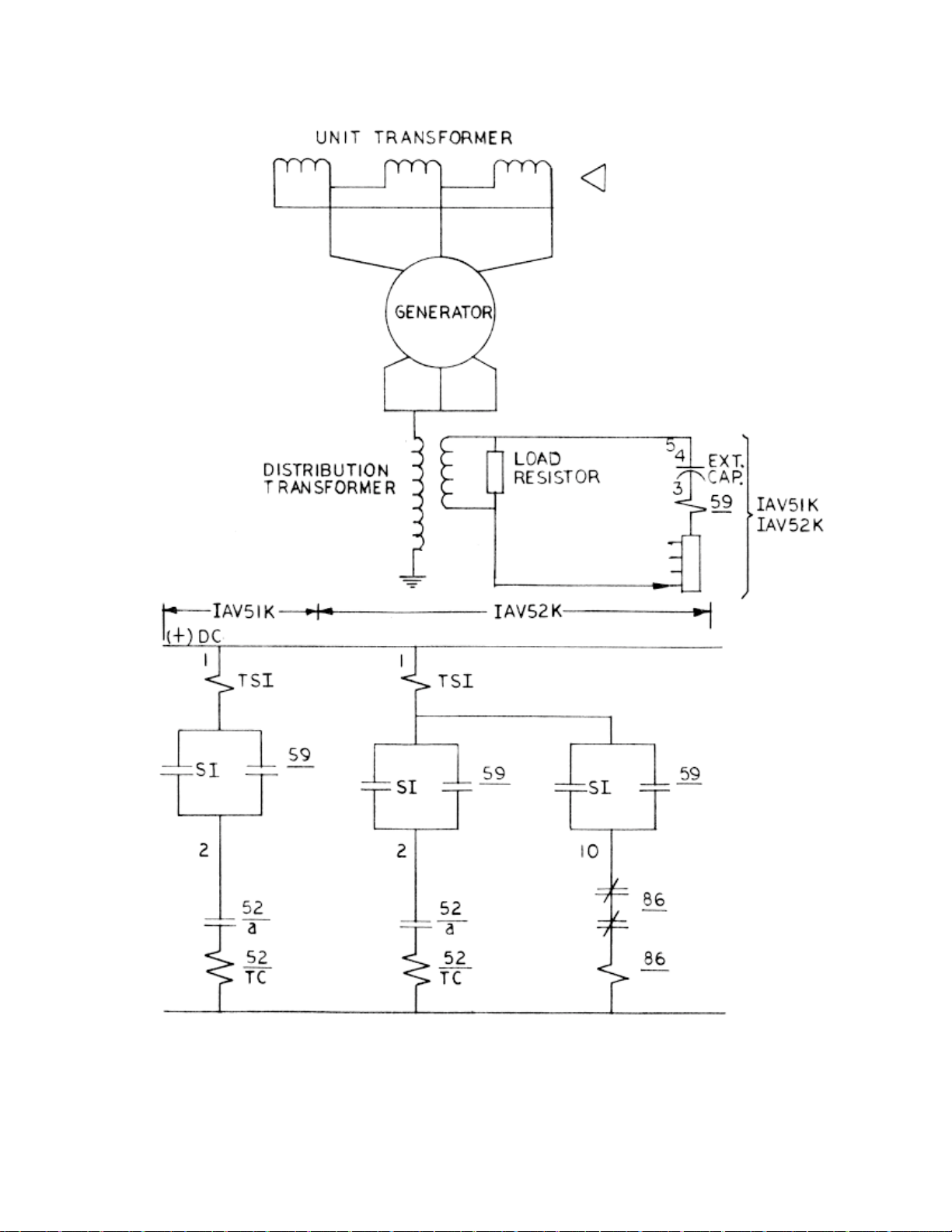

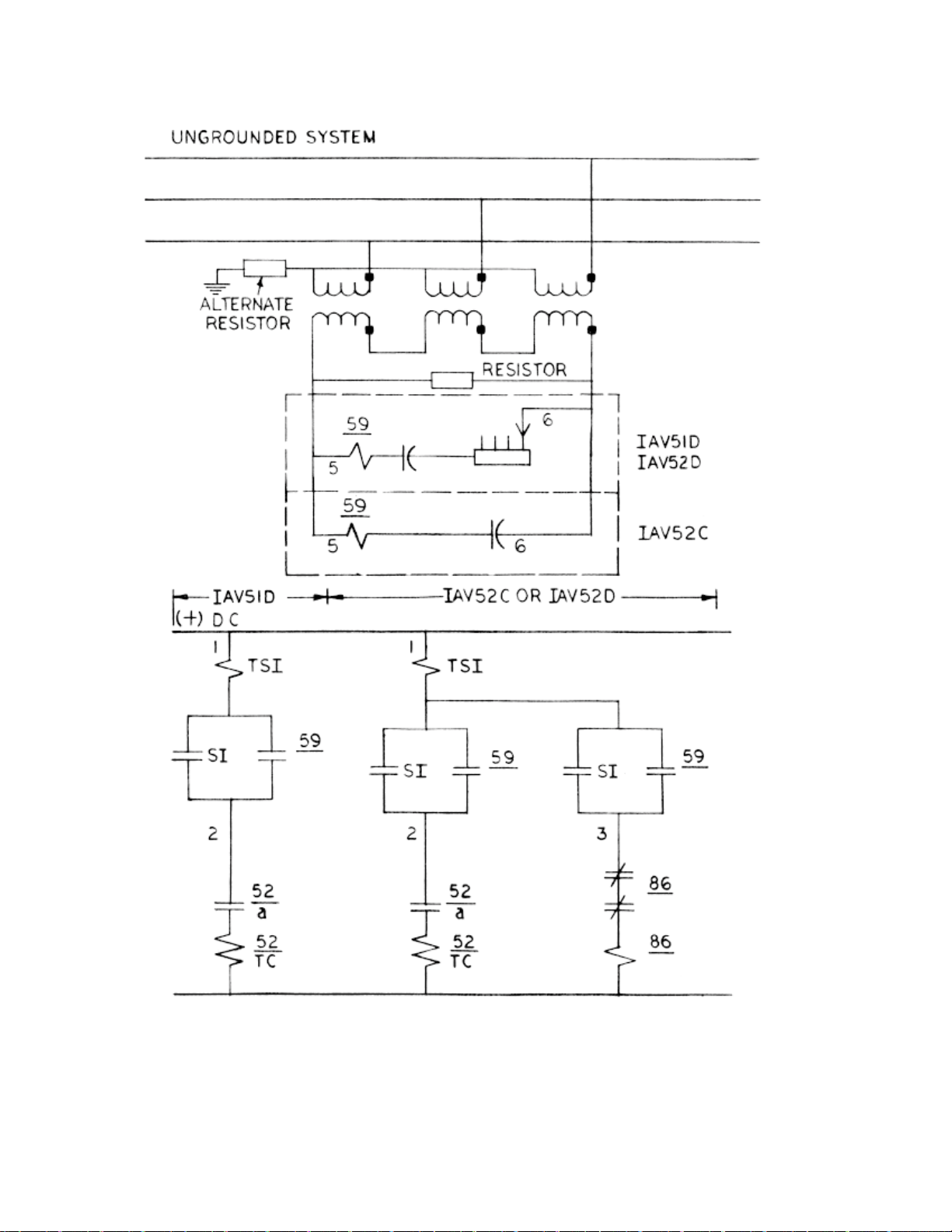

The external connection diagram for the IAV51D, 52D, or the IAV52C relay for ground-fault

detection on an ungrounded power system is shown in Fig. 9. The relay operates to detect the first

ground fault that occurs on the system, connections so that it can be removed before a second

ground occurs, causing a double phase-to-ground fault, which requires a service interruption. Since

the relay ma y b e applied merely to sound an alarm in this application, it is necessary that it be

continuously rated for the full broken-delta voltage expected for a single phase-to-ground fault

located right at the potential transformers, or some automatic means must be employed to disconnect

the relay from the voltage supply.

When this fault occurs it is equivalent to shorting out one phase of the pot ential transformer primary.

The other two unfaulted phases of the PT primaries now have full phase-to-phase voltage applied

and their corresponding dJelta secondaries will be supplying √ 3 times their normal rated voltage.

The broken delta equivalent voltage will be these two voltages added in series at a 60o angle and the

4

Page 5

GEK-45404

broken delta voltage will therefore be three times the normal delta phase-to-phase voltage with no

fault.

RATINGS

The operating-circuit ratings available are shown in Table I. The operating coil will stand rated

voltage continuously on any tap.

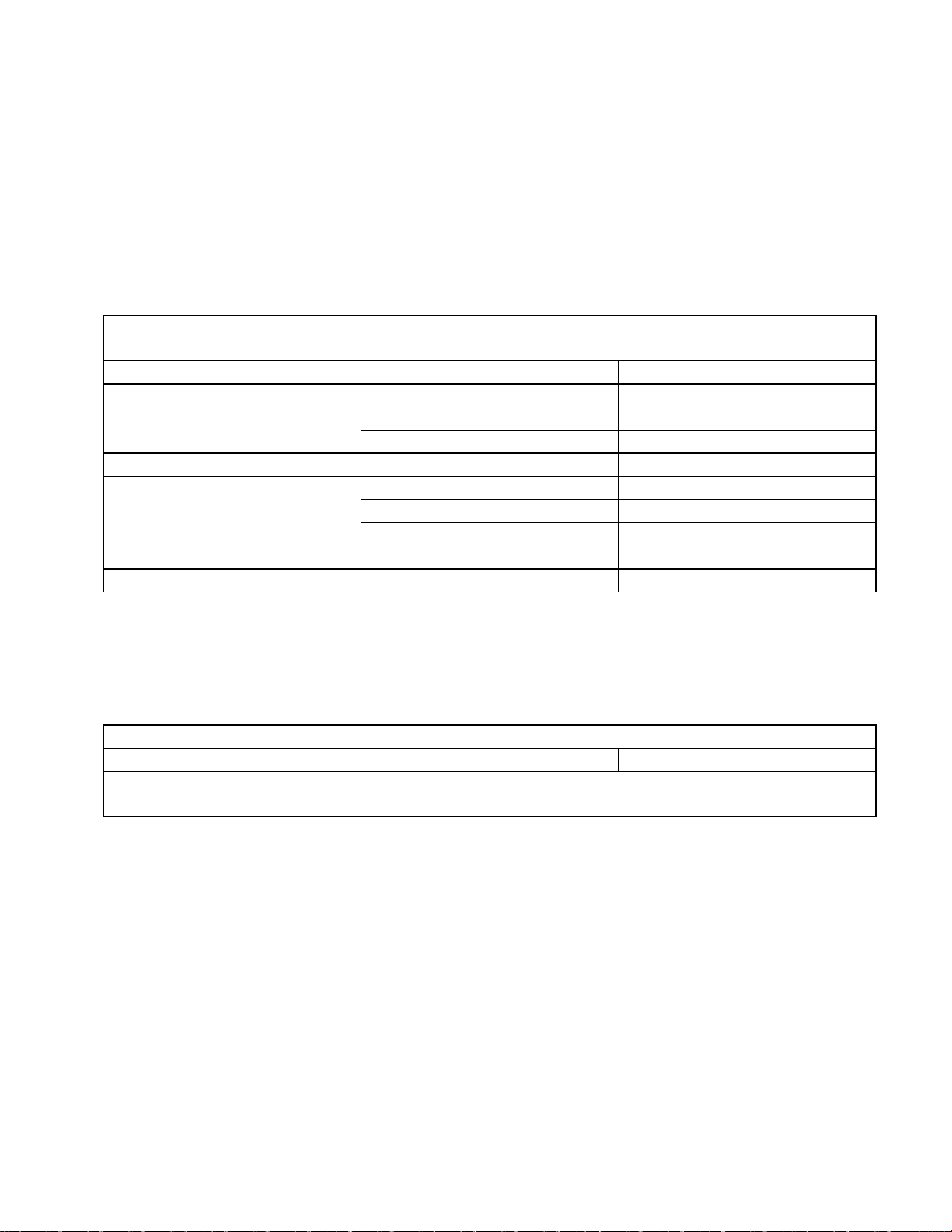

RELAY VOLTAGE RATINGS

60HZ 50HZ

IAV51D 115 115

199 199

345 345

IAV51K 67 67

IAV52C 115 115

199 199

345 345

IAV52D 199

IAV52K 67 67

The current-closing rating o f the contacts is 30 amperes for voltage not exceeding 250 volts. The

current-carrying ratings are affected by t he selection of the tap on the seal-in coil, as indicated in

Table II.

TABLE II

FUNCTION AMPERES

2-Amp Tap 0.2-Amp Tap

Tripping Duty Carry

Continuously

The 2-ampere tap has a DC resistance of 0.13 ohms and a 60 cycle impedance of 0.53 ohms, while

the 0.2-ampere tap has a 7-ohm DC resistance and a 52-ohm 60 cycle impedance. The tap setting

used on the seal-in element is determined by the current drawn by the trip coil.

The 0.2-ampere tap is for use with trip coils that operate on currents ranging from 0.2 up to 2.0

amperes at the minimum control voltage. If this tap is used with trip coils requiring more than two

amperes, there is a possibility th a t the 7-ohm resistance will reduce the current to so low a v alue t hat

the breaker will not be tripped.

The 2-ampere tap should be us ed with trip coils that take 2 amperes or more at minimum control

voltage, provided the tripping current does not exceed 30 amperes at the maximum control voltage.

If the tripping c urrent exceeds 30 amperes an auxiliary r e l a y s hould be used, the connections being

30

3

0

0.3

5

Page 6

GEK-45404

such that the tripping current does not pass through the contacts of the target and seal-in coil of the

protective relay.

BURDENS

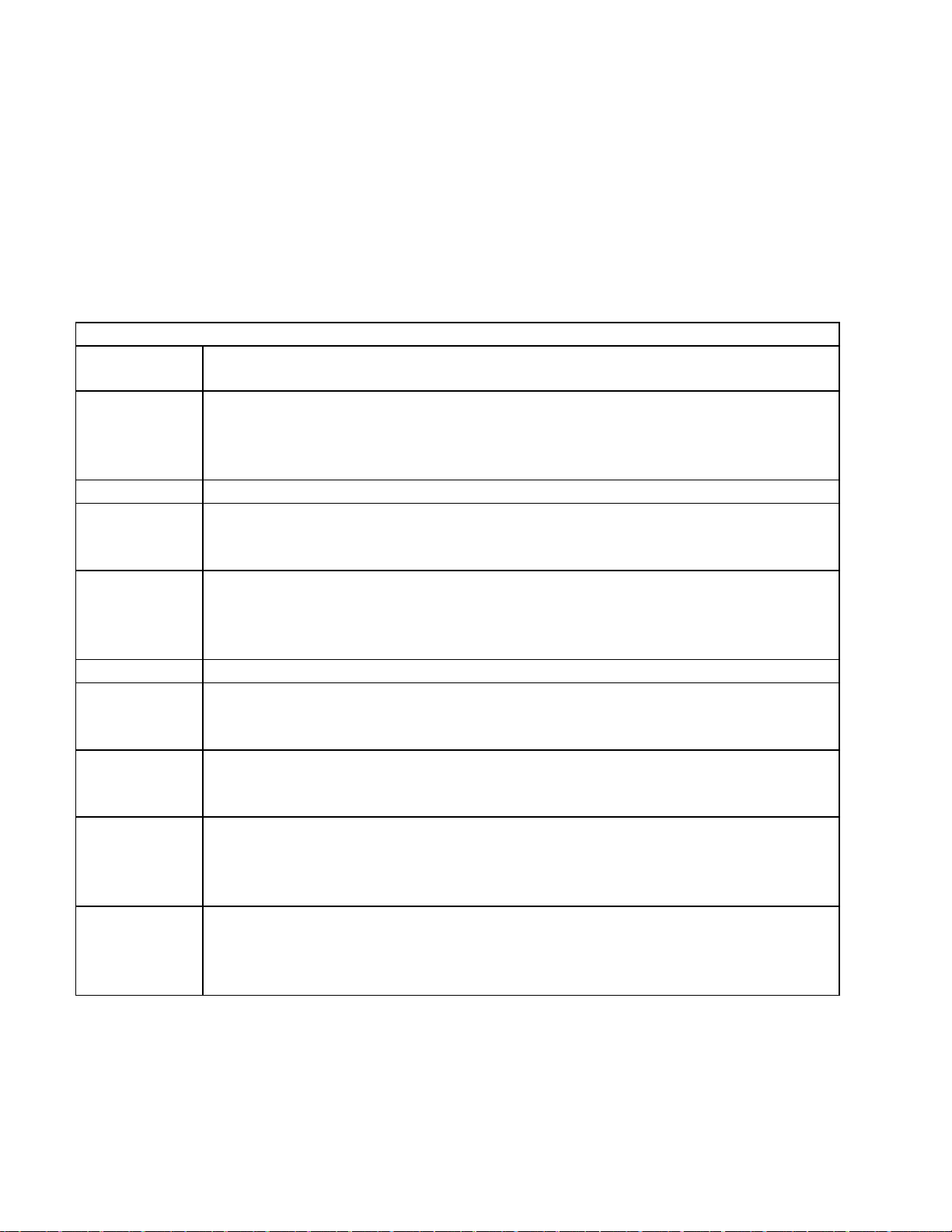

Burdens for the various relay types are give in Tables IIIA and B.

TABLE IIIA

60 - Cycle Burdens Rated Voltage

RELAY

TYPES

1AV51D 115 A(10) 31.4 0.33 10.2

IAV51D 199 A(16) 32.0 0.31 9.9

IAV52D B(24) 27.9 0.56 15.6

IAV51D 345 A(28) 41.5 0.37 15.5

IAV51K 67 A(5.4) 34.0 0.31 10.5

IAV52K B(7.5) 31.0 0.52 15.9

IAV52C 199 No Taps 32.0 0.31 9.9

1AV51D 115 A(10) 36.8 0.34 12.6

IAV51D 199 A(16) 25.4 0.28 7.0

VOLTAGE

RATING

115 No Taps 24.2 0.21 5.0

345 No Taps 41.5 0.37 15.5

TAP**SETTING VOLT-AMPS POWER

FACTOR

B(15) 27.2 0.57 15.6

C(25) 19.0 0.82 15.6

D(40) 12.3 0.93 11.4

C(40) 20.0 0.81 16.2

D(64) 13.2 0.92 12.2

B(42) 35.0 0.62 21.6

C(70) 23.9 0.85 20.3

D(112) 13.6 0.95 12.9

C(12.5) 23.1 0.77 17.7

D(20) 16.0 0.9 14.4

B(15) 30.8 0.62 19.0

C(25) 20.3 0.86 17.4

D(40) 12.7 0.95 12.0

B(24) 23.1 0.5 11.5

C(40) 17.8 0.74 13.3

D(64) 12.4 0.88 11.0

WATTS

TABLE IIIA (CONTINUED)

6

Page 7

GEK-45404

50 - Cycle Burdens at Rated Voltages

RELAY

TYPES

IAV51D 345 A(28) 31.9 0.36 11.4

IAV51K 67 A(5.4) 28.8 0.29 8.4

IAV52K B(7.5) 26.6 0.45 12.1

IAV52C 199 No Taps 25.4 0.28 7.0

**Minimum pickup volts

VOLTAGE

RATING

115 No Taps 25.0 0.41 10.1

345 No Taps 31.9 0.36 11.4

TAP**SETTING VOLT-AMPS POWER

FACTOR

B(42) 28.3 0.56 15.8

C(70) 21.0 0.79 16.6

D(112) 12.8 0.93 11.9

C(12.5) 21.1 0.71 14.9

D(20) 16.0 0.86 13.7

TABLE IIIB

WATTS

60 - Cycle Burden at Rated Voltages

RELAY

TYPES

1AV51D 115 A(10) 0.46 0.99 0.46

IAV51D 199 A(16) 0.41 0.94 0.38

IAV52D B(24) 0.56 0.98 0.55

IAV51D 345 A(28) 0.48 0.86 0.41

IAV51K 67 A(5.4) 0.43 0.91 0.39

IAV52K B(7.5) 0.57 0.96 0.55

VOLTAGE

RATINGS

TAP**SETTINGS VOLT-AMPS POWER

FACTOR

B(15) 0.62 1.0 0.62

C(25) 0.96 1.0 0.96

D(40) 1.48 1.0 1.48

C(40) 0.89 0.99 0.88

D(64) 1.38 1.0 1.37

B(42) 0.66 0.95 0.62

C(70) 1.02 0.98 1.01

D(112) 1.4 0.99 1.4

C(12.5) 0.92 0.98 0.91

D(20) 1.47 0.99 1.46

WATTS

115 No Taps 0.36 0.78 0.28

IAV52C 199 No Taps 0.41 0.94 0.38

345 No Taps 0.48 0.86 0.41

TABLE IIIB

7

Page 8

GEK-45404

50 - Cycle Burden at Rated Voltages

RELAY

TYPES

1AV51D 115 A(10) 0.52 0.98 0.52

IAV51D 199 A(16) 0.32 0.85 0.27

IAV51D 345 A(28) 0.39 0.96 0.37

IAV51K 67 A(5.4) 0.38 0.91 0.34

IAV52K B(7.5) 0.52 0.95 0.5

IAV52C 199 No Taps 0.32 0.85 0.27

VOLTAGE

RATINGS

115 No Taps 0.27 0.98 0.27

345 No Taps 0.39 0.96 0.37

TAP**SETTINGS VOLT-AMPS POWER

FACTOR

B(15) 0.67 0.99 0.67

C(25) 1.0 1.0 1.0

D(40) 1.52 1.0 1.52

B(24) 0.5 0.93 0.46

C(40) 0.83 0.97 0.81

D(64) 1.33 0.99 1.32

B(42) 0.58 0.98 0.57

C(70) 0.96 0.99 0.95

D(112) 1.35 1.0 1.35

C(12.5) 0.87 0.98 0.85

D(20) 1.42 0.99 1.41

WATTS

**Minimum pickup volts

OPERATING CHARACTERISTICS

The Type IAV51D relay is a low-pickup voltage relay normally u s e d for ground fault protection on

AC rotating machines. It has single-circuit closing contacts that close when the voltage increases to

pickup value, as set on the tap block. The time delay in closing the contacts is determined by th e

se tting of the time dial at the top of the shaft. The IAV51D has a capacitor and tapped resistor

connected in series with the operating coil. The capacitor is added to tune the circuit, giving a low

pickup voltage at rated frequency. At rated voltage the operating U magnet is highly saturated,

increasing the impedance of the circuit, thus limiting the current to a s afe value. The taps on the

resistor are connected to the tap block to provide a four-to-one range of pickup. As shown in the

typical external connection diagram, Fig. 8, this relay is connected to the machine neu tral potential

transformer through a closed contact on the auxiliary tr i pping r elay, hence is energized only w h e n a

ground occurs. To obtain still-lower pickup than the normal calibration, it is permissible to insert an

inverted potential transformer between the machine neutral transformer and the relay c oil circuit.

The IAV51D has a seal-in element. Time curves are shown in Fig. 11.

The IAV51K relay is similar to the IAV51D except that it has an external capacitor. Time curves are

shown in Fig. 11.

8

Page 9

GEK-45404

The IAV52K relay is similar to the IAV51K except that it has two, instead of one, normally-open

contacts.

The IAV52C is a low-pickup, time-overvoltage relay with two normally-open contacts. It has a sealin element. It has a capacitor connected in series with the operating coil but, unlike the IAV51D

relay, it does not have a tapped resistor connected in series with the operating c oil. The time-voltage

characteristics at the #1, #5, and #10 time-dial settings are the same as for the "A" taps of the

IAV51/52D and K relays shown in Fig. 11.

CONSTRUCTION

These relays are the induction disk construction. The disk is actuated by a potential operating coil on

a laminated U-magnet. The disk shaft carries the moving c ontact, which completes the trip or al arm

circuit when it touches the stationary contact or contacts. The disk shaft is restrained by a spiral

spring to give the proper contact-closing voltage, and its motion is retarded by per ma ne nt magnets

acting on the disk to give the correct time delay.

There is a seal-in unit mounted to the left of the shaf t. This unit has its coil in series and its contacts

in parallel with the main contacts, such that when the main contacts close, the seal-in unit picks up

and seals in. When the seal-in unit picks up, it raises a target into view that latches up and remains

exposed until released by pressing a button beneath the lower-left corner of the cover.

The case is suitable for either surface or semi-flush panel mounting and an assortment of hardware is

provided for either mounting. The cover attaches to the case and also carries the reset mechanism

when one is required. Two of the cover screws have provision for a sealing wire.

The case has studs or screw connections at the bottom for the external connections. The electrical

connections between the relay units and the case studs are made through spring-backed contact

fingers mounted in stationary, molded inner and outer blocks, between which nests a removable

connecting plug that completes the circuits. The outer blocks, attached to the case, have the st uds for

the external connections, and the inner blocks have the terminals for the internal connections.

The relay mechanism is mounted in a s teel framework called the cradle and is a complete unit, with

all leads being terminated at the inner block. This cradle is held firmly i n the cas e by a latch at the

top and the bottom and by a guide pin at the back of the case. The case and cradles are so contructed

that the relay cannot be ins erted in the case upside down. The connecting p lug, besides making the

electrical connections between the respective b locks of the cradle and case, also locks the latch in

place. The cover, which is fastened to the case by thumbscrews, holds the connecting plug in place.

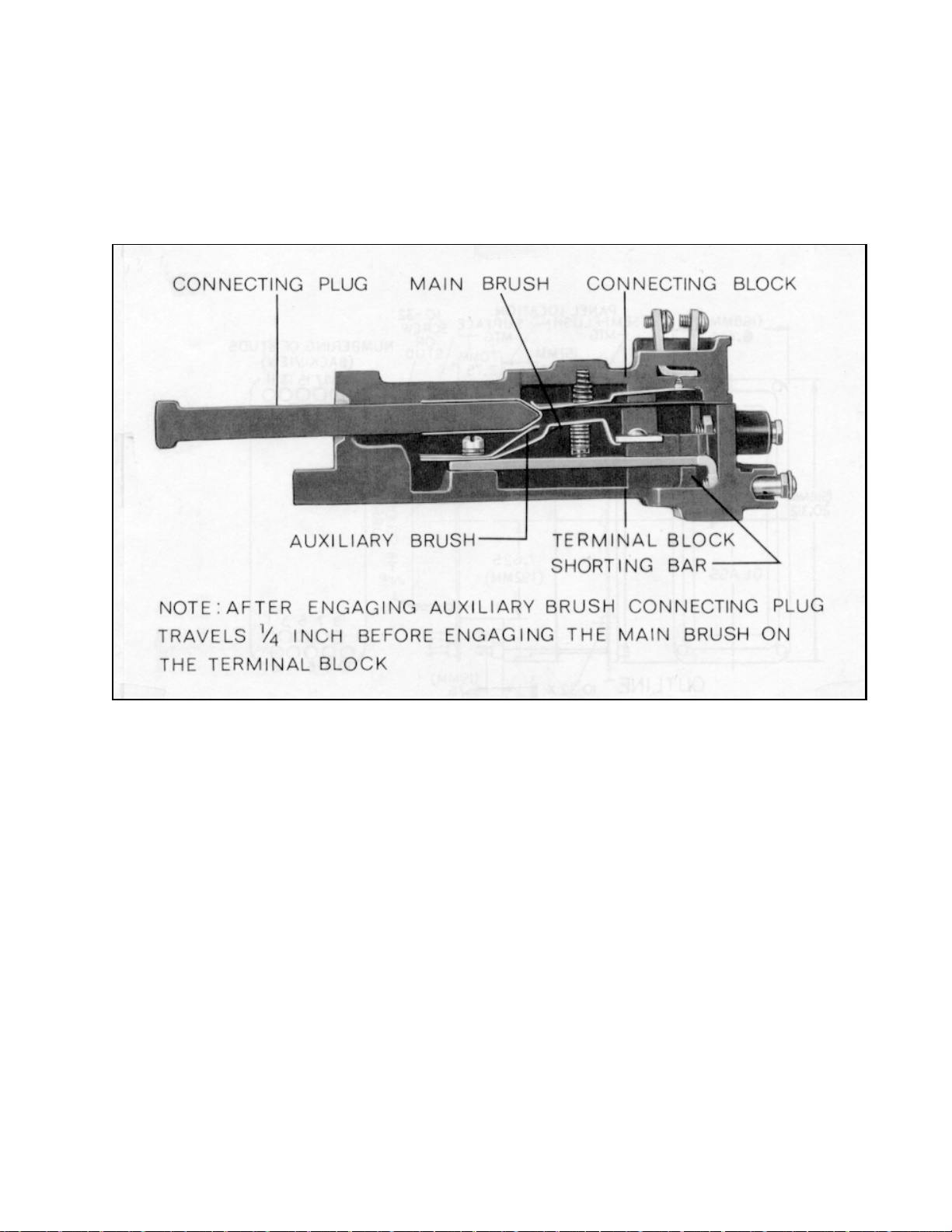

To draw out the cradle from a single-ended case, the cover must first be removed. Then the

connecting plug can be drawn out. In so doing, the trip circuit is the first one opened, then the

voltage circuits are opened. After the connecting plug has been removed, the lower latch can be

released and the cradle easily drawn out. To replace the cradle, the reverse ord er should be fo llowed.

The internal connections of the relays are shown in Figs. 3, 4, 5, 6, and 7.

9

Page 10

GEK-45404

RECEIVING, HANDLING, AND STORAGE

RECEIVING

These relays, when not shipped as a part of a control panel, will be shipped in cartons designed to

protect them against damage. Immediately upon receipt of the relay, an examination should be made

for an y damage su stai ned during s hipment. If injury o r damage resulting from rough handling is

evident, a damage claim should be filed at once with the transportation company a nd the nearest

General Electric Sales Office should be notified promptly.

HANDLING

Reasonable care should be exercised in unpacki n g the relay in order that none of the p art s are in j u red

nor the adjustments disturbed.

STORAGE

If the relays are not to be installed immediately, they should be st ored in their original cartons in a

place that is free from moisture, dust, and metallic chips. Foreign matter collected on the outside of

the case may find its way inside when the cover is removed and cause trouble in the operation of the

relay.

ACCEPTANCE TESTS

Immediately upon receipt of the relay an inspection and acceptance test should be made to make sure

that no damage has been sustained in shipment and that the relay calibrations have not been

disturbed.

VISUAL INSPECTION

Check the nameplate stamping to make sure that the model number and rating of the relay agree with

the requisition.

Remove the relay from its case and check that there are no broken or cracked molded parts or other

signs of physical damage, and that all screws are tight.

10

Page 11

GEK-45404

CAUTION:

Every circuit in the drawout case has an auxiliary brush. It is especially important on current

circuits and other circuits with shorting bars that the auxiliary brush be bent hig h enough to

engage the connecting plug or test p lug b efore the main brushes do. This will preven t Curren t

Transformer (CT) secondary circuits from being opened.

MECHANICAL INSPECTION

On relays that have time dials, the dials will be set at zero before the relay l eaves the factory. It is

necessary to change this setting to open the relay contacts.

On all relays with locked time dials, make sure the two time-dial locking scre ws are tight. These

locking screw s are to prevent the dial from moving when the relay is subjected to high operating

torque.

The moving contact should be fastened securely in its support, and should engage the stationary

contact about in the middle, or at least 1/16 inch inside the periphery of the stationary contact.

The stop-arm leaf spri ng should deflect about 1/64 inch and the stop arm should clear the molded

block by at least 0.020 inch.

Any foreign material must be cleaned out of stator air gaps. Clearance between the di sk and either

the drag magnet or U magnet should be at least 0.010 inch for any position of the disk.

End play of the disk should be from 0.005 inch to 0.010 inch. End play should not be so great as to

allow the disk to strike the U magnet or the drag magnet. Check that top and bottom pivot and

bearing screws are tight.

There should be no noticeable friction in the rotating structure.

Rotate the time dial to the zero position. Check by means of a neon lamp that the contacts just close;

there should be approximately 1/32 inch wipe on the stationary contact. If the contact does not close,

adjust the disk position by backing off the t w o clamping screws on the stop arm and rotating the stop

arm relative to the cutout in the disk. This is a coarse adjustment. Retighten the clamping screws.

For fine adjustment of contact closing, run the stationary c ontact brush in or out by means of its

adjusting screw; after this adjustment, check that the screw is held firmly in its support.

11

Page 12

GEK-45404

ELECTRICAL TESTS

Drawout Relays - General

Since all drawout relays in service operate in their cases , it is recommended that they be tested in

their cases or an equivalent steel case. In this way an y ma gne tic effects of the enclosure will be

accurately duplicated during testing. A relay m a y b e tes ted without removing it from the panel by

using a 12XLA13A test plug. This plug makes connections only with the relay and does not disturb

any shorting bars in the cas e. Of course, the 12XLA12A test plug may als o be us ed. Although this

test plug allows greater testing fl exi bility, it also requires CT shorting ju mper s and the exercise of

greater care since connections are made to both the relay and the external circuitry.

Power Requirements - General

All alternating-current-operated devices are affected by frequency. Since non-sinusoidal waveforms

can be analyzed as a fundamental frequency plus harmonics of the fundamental frequency, it follows

that alternating-current devices (relays) will be affected by the applied waveform.

Therefore, in order to test alternating-current relays properly it is essential to use a sine wave of

current and/or voltage. The purity of the sine wave (i.e. its freedom from harmonics) cannot be

expressed as a finite number for any p a r ticular relay; however, and relay us i ng tuned circuits, RL o r

RC networks, or saturating electromagnets (such as time-overcurrent relays) would be especially

affected by non-sinusoidal waveforms.

Similarly, relays requiring DC control power should be test ed using di rect current and not full-wave

rectified power. Unless the rectified supply i s well filtered, many re la ys will not operate properly

due to the dips in the rectified power. Zener diodes, for example, can turn off during these dips. As a

general rule the DC source should not contain more than 5% ripple.

Pickup-voltage Test

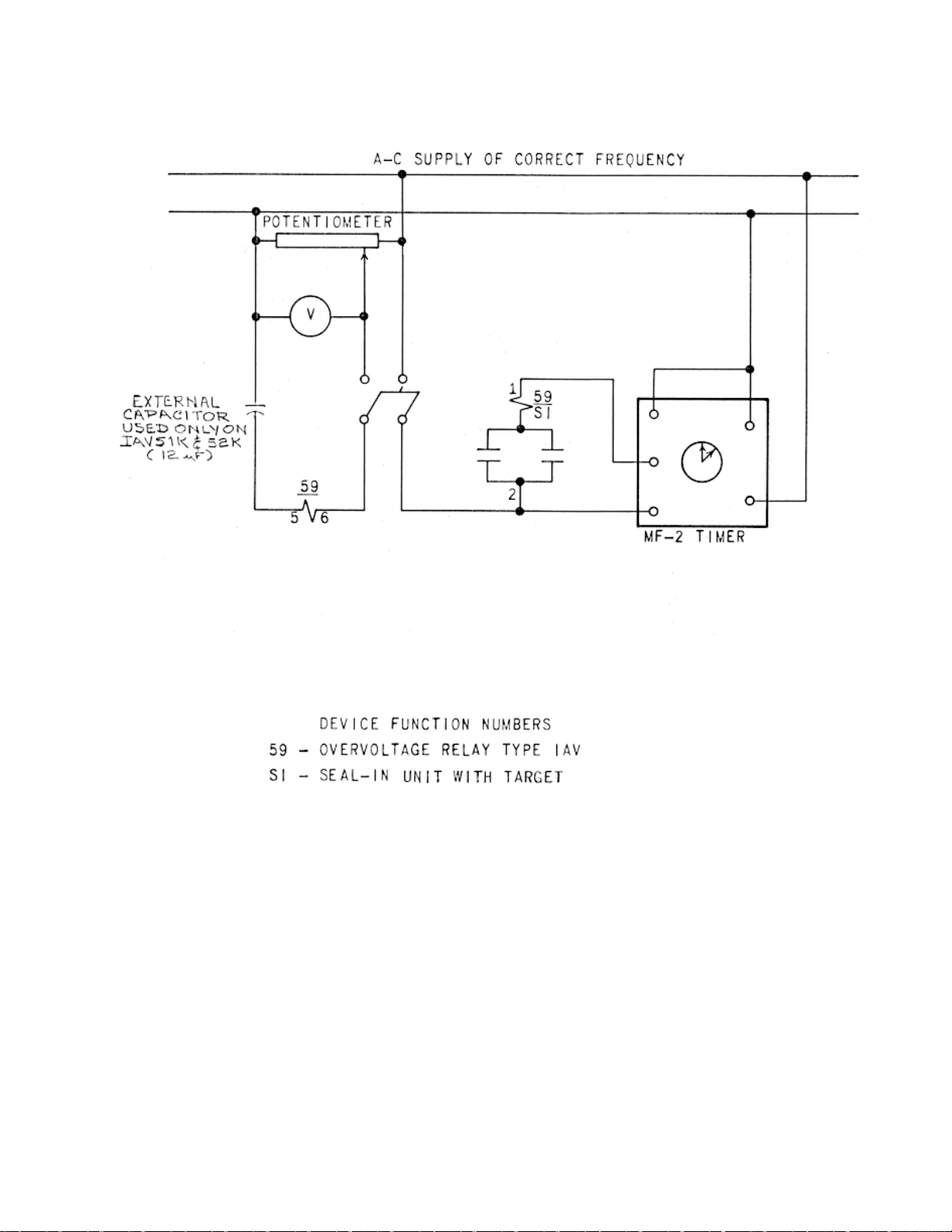

The pickup voltage should be checked; for the IAV51D, IAV51K, and IAV52K, the pickup voltage

should be checked on more than one tap. See relay n am e p la t e for value of pickup voltage (closing

volts). Test connections, Fig. 10, are the same as for the time-voltage test except that the timer is not

required.

Time-voltage Test

The time-voltage curves should be checked for one or more settings. Recommended test connections

for this test are shown in Fig. 10.

12

Page 13

GEK-45404

INSTALLATION

INSPECTION

At the time of installation, the relay should be inspected for tarnis hed contact s , loose s crews , or o t her

imperfections. If any t rouble is found, it should be corrected; see MAINTENANCE. Check the

nameplate for model number and rating.

LOCATION

The location should be clean and dry, free from dust and excessive vibration, and well lighted to

facilitate inspection and testing.

MOUNTING

The relay should be mounted on a vertical surface. The outline and panel drilling dimensions are

shown in Fig. 14 for relay Types IAV51D, IAV52D, and IAV52C. Fig. 15 shows outline and panel

drilling for relay Types IAV51K and IAV52K.

CONNECTIONS

Internal connections are shown in Figs. 3 to 7 for the various relays.

GROUND CONNECTIONS

One of the mounting studs or screws should be perm anently gr ounded by a conductor not less than

No. 12 B&S gage copper wire or its equivalent.

OPERATION

Before the relay is put in service, the pickup-voltage and time-voltage tests described under

ACCEPTANCE TESTS (ELECTRICAL TESTS) should be made to determine that factory

adjustments have not been disturbed.

The relay may be tested while mounted on the panel, either from its own or another source of power,

by inserting a separat e t esting plug in place of the connecting p lug. Or, the cradle can be drawn out

and replaced by another that has been laboratory tested.

13

Page 14

GEK-45404

ADJUSTMENTS

Target and Seal-in Unit

For trip coils operating on current ranging from 0.2 up to 2.0 amperes at the minimum control

voltage, set the target and seal-in tap plug in the 0.2- ampere tap.

For trip coils operating on currents ranging from 2 to 30 amperes at the minimum control voltage,

place the tap plug in the 2.0-ampere tap.

The tap plug is the screw holding the right-hand stationary contact of t he seal-in element. To change

the tap setting, first remove the connecting pl ug. Then, take a screw from the left-hand stationary

contact and place it in the desired t ap. Next, remove the s crew from the ot her t ap, and place it in the

left-hand contact. This procedure is necessary to prevent the right- hand stationary c ontact from

getting out of adjustment. Screws should not be in both taps at the same time, as pickup for DC will

be the higher tap value and AC pickup will be increased.

Voltage Setting

The voltage at which the contacts operate may be changed by changing the tap of the IAV51D,

IAV52D, and IAV51K relays.

The pickup of any of the relays, when set for minimum pickup, can be adjusted by m eans of the

spring adjusting ring. The ring may be tur ned by inserting a tool in the notches around the edge. By

turning the ring, the operating voltage o f the IAV52C relay may be brought into agreement with the

nameplate value, and in the same way th e IAV51D, IAV51K, and IAV52K relays may b e brought

into agreement with the minimum tap setting.

For taps other than minimum, the slide band on the adjustab le resistor associated with the selected

tap, in series with the operating c oil, should be moved until the pickup is at tap voltage. This

adjustment should not be made until the spring ad justment for minimum pickup is made, since t he

spring adjustment sets the basic torque level of the relay.

Adjustments for pickup between calibrated taps can be made by selecting the tap closest to the

desired voltage and then adjusting the resistor band associated with the tap selected.

The relay is adjusted at the factory to operate from any time-dial position at a minimum voltage that

is 8% of rated voltage. The relays reset at 90% or more of the operating value. Operating voltage for

the IAV51D, IAV52D, IAV51K, and IAV52K relays is the minimum voltage for a given tap setting

at which the contacts just make.

14

Page 15

GEK-45404

Time Setting

The time of operation of the overvoltage relay is determined primarily by the setting o f th e time di al.

Further adju stment is obtained by moving th e permanen t magnet along its supporting shelf; moving

the magnet in toward the back of the relay decreases the time, while moving it out increases the time.

Fig. 11 shows the time-voltage characteristics of the IAV51D, IAV52D, IAV51K and IAV52K for

the four tap settings for the Number 1, 5, and 10 time- dial positions. The time-voltage characteristic

of the 1AV52C, which has no taps, is the same as for the "A" tap in the D & K relays.

To make time settings, set the time dial to the number required (to give the desir ed characteristic) b y

turning it until the number lines up with the notch in the adjacent frame. The time indicated by t h e

cu rv e s is the time required to close the relay c ontacts when the voltage is suddenly increased from a

value below pickup to the value on the curve (expressed in multiples of tap setting). The time

obtained should be the value on the curve ± 15%.

PERIODIC CHECKS AND ROUTINE MAINTENANCE

In view of the vital role of protective relays in the operation of a power system, it is important that a

periodic t est program be followed. It is recognized that the interval between periodic checks will

vary de pending upon environment, type of relay and the user's experience with periodic testing. Until

the user has accumulated enough experience to select the test interval best suited to his individual

requirements, it is suggested that the points listed under INSTALLATION PROCEDURE be

checked every six months.

* Revised since last issue

MAINTENANCE

These relays are adjusted at the facto ry a nd it is advisable not to disturb the adjustments. If for any

reason, they have been disturbed, the following points should be observed in restoring them.

DISK AND BEARINGS

The lower jewel may be tested for cracks by exploring its surface with the point of a fine needle. If it

is necessary to replace the jewel, the new jewel should be turned up until the disk is centered in the

air gap, after which it should be locked in position by the set screw provided for the purpose.

15

Page 16

GEK-45404

CONTACT CLEANING

For cleaning fine silver contacts, a flexible burnishing tool should be used. This consists of a

flexible strip of metal with an etched roughened surface, resembling i n effect a superfine file. The

polishing action is so delicate that no scratches are left, yet corroded material will be removed

rapidly and thoroughly. The flexibility of the tool ensures the cleaning of the actual points of

contact.

Fine silver contacts should not be cleaned with knives, files, or abrasive pap er or cloth. Knives or

files may leave scratches, which increase caring and deterioration of the contacts. Abrasive pap er or

cloth may leave minute particles of insulating ab ra si ve material in the contacts and thus prevent

closing.

The burnishing tool described above can be obtained from the factory.

SERVICING

For servicing and adjustments see applicable instructions under ACCEPTANCE TESTS,

INSTALLATION, AND MAINTENANCE.

RENEWAL PARTS

It is recommended that sufficient quantities of renewal parts be carried in stock to enable the prompt

replacement of any that are worn, broken, or damaged. Parts bulletin number GEF-3897 gives a list

of t hose most subject to wear in ordinary operation, or to damage due to possible abnormal

conditions.

When ordering renewal parts, address the nearest Sales Office of the General Electric Company,

specify quantity required, and give name of part wanted, complete nameplate data, including serial

number. If possible give the General Electric Company's requisition on which the relay was

furnished.

16

Page 17

GEK-45404

LIST OF FIGURES

FIG. 1 (8043181) TYPE IAV51D RELAY, REMOVED FROM CASE, FRONT VIEW

FIG. 2 (8043182) TYPE IAV51D RELAY, REMOVED FROM CASE, REAR VIEW

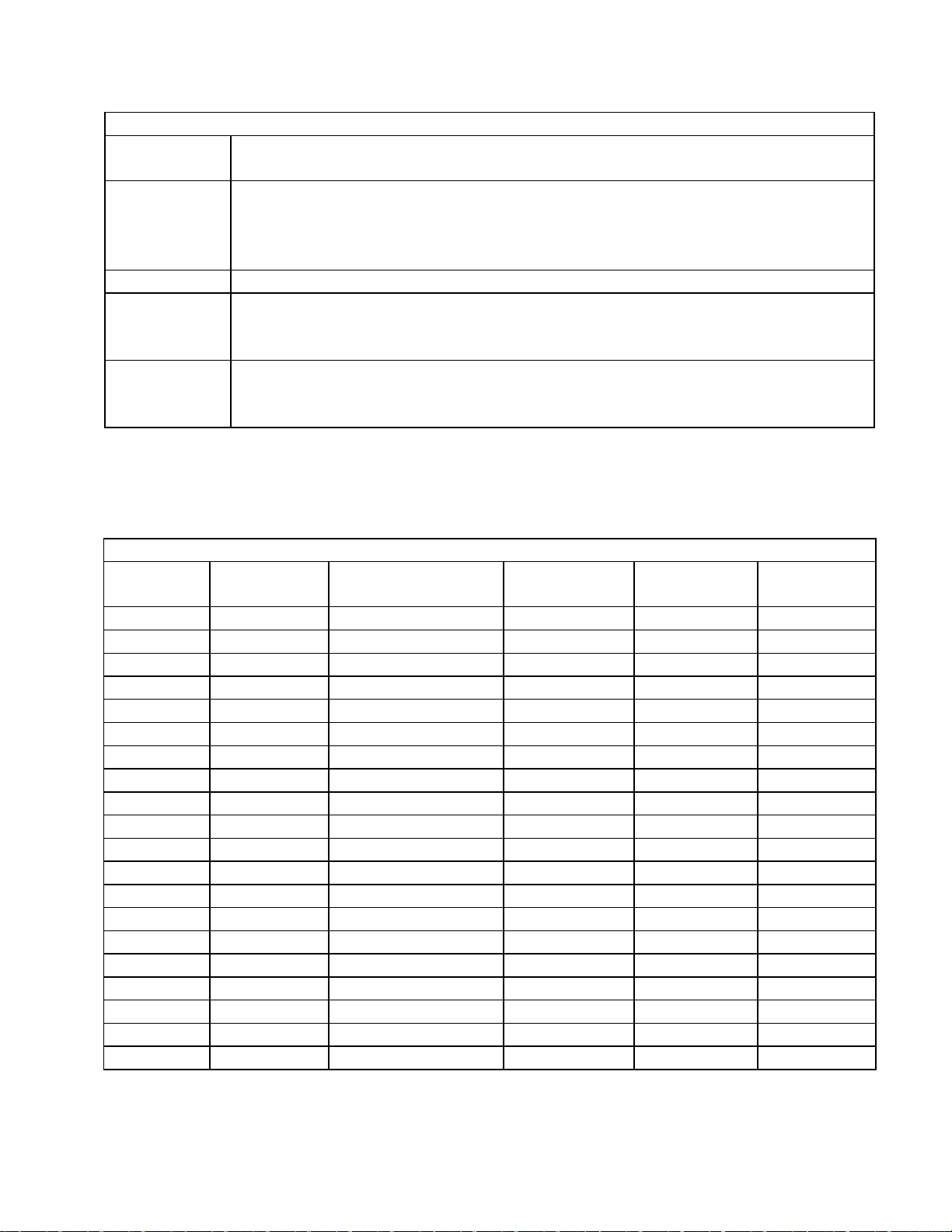

FIG. 3 (K6400439-5) INTERNAL CONNECTIONS OF THE TYPE IAV51D RELAY,

FRONT VIEW

FIG. 4 (0362A514-3) INTERNAL CONNECTIONS OF THE TYPE IAV51K RELAY,

FRONT VIEW

FIG. 5 (K6556505-0) INTERNAL CONNECTIONS OF THE TYPE IAV52C RELAY,

FRONT VIEW

FIG. 6 (0418A790-0) INTERNAL CONNECTIONS OF THE TYPE IAV52D RELAY,

FRONT VIEW

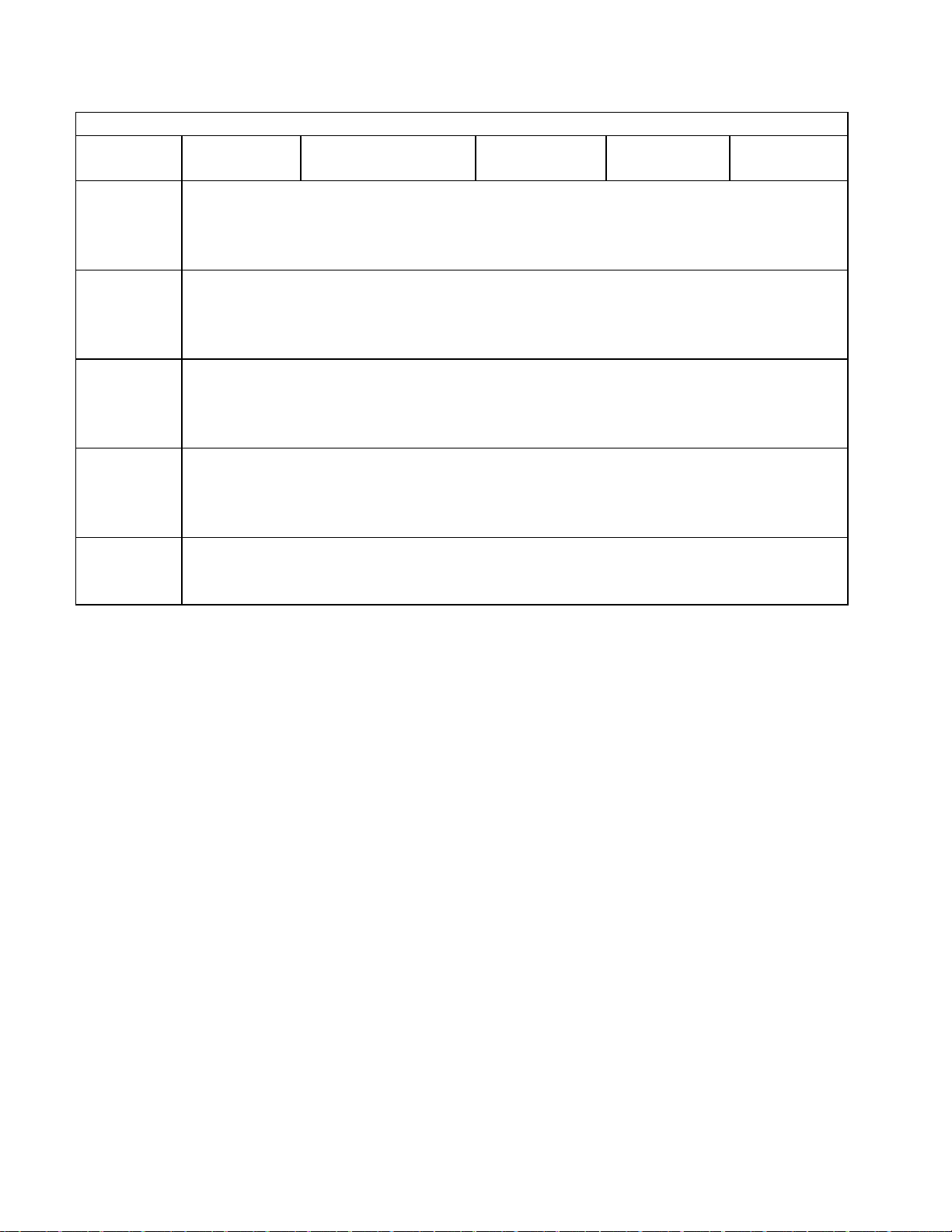

FIG. 7 (0257A8379-0) INTERNAL CONNECTIONS OF THE TYPE IAV52K RELAY,

FRONT VIEW

FIG. 8 (0275A2004-0) EXTERNAL CONNECTION DIAGRAM OF TYPES IAV51K AND

IAV52K FOR GENERATOR GROUND-FAULT PROTECTION

Fig. 9 (0275A2003-0) EXTERNAL CONNECTION DIAGRAM OF TYPE IAV51D AND

IAV52C FOR GROUND-FAULT DETECTION ON AN UNGROUNDED SYSTEM

FIG. 10 (K6154391-3) TEST CONNECTIONS FOR OVERVOLTAGE RELAYS

FIG. 11 (0178A8140-0) TIME VOLTAGE CURVES FOR TYPES IAV51D, 51K, 52D, AND

52K RELAYS

FIG. 12 (8025039) CROSS SECTION OF DRAWOUT CASE SHOWING POSITION OF

AUXILIARY BRUSH

FIG. 13 (0275A4399-0) OUTLINE OF IAV51K AND IAV52K EXTERNAL CAPACITOR

FIG. 14 (K6209270-2) OUTLINE AND PANEL DRILLING FOR RELAY TYPES IAV51D,

52D AND IAV52C

FIG. 15 (K6209271-7) OUTLINE AND PANEL DRILLLING FOR RELAY TYPES IAV51K

AND IAV52K

17

Page 18

GEK-45404

FIG. 1 (8043181-0) TYPE IAV51D RELAY, REMOVED FROM CASE, FRONT VIEW

18

Page 19

GEK-45404

FIG. 2 (8043182-0) TYPE IAV51D RELAY, REMOVED FROM CASE, REAR VIEW

19

Page 20

GEK-45404

FIG. 3 (K-6400439-5) INTERNAL CONNECTIONS OF THE TYPE IAV51D RELAY, FRONT

VIEW

20

Page 21

GEK-45404

FIG. 4 (362A514-3) INTERNAL CONNECTIONS OF THE TYPE IAV51K RELAY, FRONT

VIEW

21

Page 22

GEK-45404

FIG. 5 (K-6556505-0) INTERNAL CONNECTIONS OF THE TYPE IAV52C RELAY, FRONT

VIEW

22

Page 23

GEK-45404

FIG. 6 (418A790-0) INTERNAL CONNECTIONS OF THE TYPE IAV52D RELAY, FRONT

VIEW

23

Page 24

GEK-45404

FIG. 7 (0257A8379-0) INTERNAL CONNECTIONS OF THE TYPEIAV52K RELAY, FRONT

VIEW

24

Page 25

GEK-45404

FIG. 8 (0275A2004-0) EXTERNAL CONNECTION DIAGRAM OF TYPES IAV51KAND

IAV52K FOR GENERATOR GROUND-FAULT PROTECTION

25

Page 26

GEK-45404

FIG. 9 (0275A2003-0) EXTERNAL CONNECTION DIAGRAM OF TYPE IAV51D, IAV52C

AND IAV52D FOR GROUND-FAULT DETECTION ON AN UNGROUNDED SYSTEM

26

Page 27

GEK-45404

FIG. 10 (K6154391-3) TEST CONNECTIONS FOR OVERVOLTAGE RELAYS

27

Page 28

GEK-45404

NOTE: TD=Time Dial setting

FIG. 11 (0178A8140-0) TIME VOLTAGE CURVES FOR TYPES IAV51D, 51K,

52D, AND 52K RELAYS

28

Page 29

GEK-45404

FIG. 12 (8025039-0) CROSS SECTION OF DRAWOUT CASE SHOWING POSITION OF

AUXILIARY BRUSH

29

Page 30

GEK-45404

FIG. 13 (0275A4399-0) OUTLINE OF IAV51K AND IAV52K EXTERNAL CAPACITOR

30

Page 31

GEK-45404

FIG. 14 (K6209270-2) OUTLINE AND PANEL DRILLING FOR RELAY TYPES IAV51D, 52D

AND IAV52C

31

Page 32

GEK-45404

* FIG. 15 (K6209271-8) OUTLINE AND PANEL DRILLLING FOR RELAY TYPES IAV51K

AND IAV52K

32

Loading...

Loading...