Page 1

,

GEK-36150

,r

O,P,ERATOR'S

'.

~

'

/MANUAL

GENERAL

fl

ELECTRIC

Page 2

The

information

contained herein does

not

purport

to

cover

all details

or

variations in

equipment

nor

to

provide

for

every

possible contingency

to

be

met

in connection

with

installation,

operation,

or

maintenance. Should

further

in-

formation

be desired

or

should particular

problems

arise

which

are

not

covered

sufficiently

for

the purchaser's pur-

poses,

the

matter should

be

referred

to

General Electric

Company, USA.

TermiNet

is a trademark

of

General Electric Company, USA

©Copyright

General Electric Company, USA 1973

Page 3

TermiNet

300

and

Operator's

1200 Printers

Manual

- GEK-36150

Printed July, 197 4 (SM)

Page 4

Page 5

GEK-36150

PREFACE

This manual shows

the

operator

how

the

TermiNet Printers are operated. Sections 1 through 5

describe what

the

controls and indicators do,

the

operation

of

the

keyboard,

the

loading

of

paper

and ribbon, and

other

information pertaining

to

the

operation and care-of

the

TermiNet Printer.

Because of

the

many communication systems

that

exist, no

attempt

is

made

to

show

how

the

TermiNet Printer may be used

in

a specific system. Consult your supervisor

or

application

specialist for special instructions on how

to

use

the

TermiNet Printer with

your

communications

system. Section 6

is

primarily for

the

application specialist who must know certain operating

characteristics

of

the

TermiNet Printer

in

order

to

understand how it should operate

in

your

communications system.

This manual covers

both

the

TermiNet

300

and 1200 Printers. Information

that

pertains only

to

a

specific model Printer

will be identified.

The term

"jumper"

will appear occasionally in

the

following text. Basically,

the

removal or

installation of a jumper

is

an optional wiring change

that

will change particular operating

characteristics of

the

TermiNet Printer. Most jumpers can be installed and removed by a TermiNet

Printer serviceman

at

the

TermiNet Printer site.

Because many TermiNet Printer

problems are simple and can be easily avoided

or

corrected

by

the

operator, read Section 5, "TAKING CARE OF YOUR TermiNet PRINTER," before calling for

service. You may avoid an unnecessary interruption

of

your

operation and an unnecessary service

call.

In

most

cases,

the

word

"Printer"

will be used instead

of 11TermiNet Printer" in

the

following text.

Preface

iii/iv

Page 6

Page 7

GEK-36150

TABLE OF CONTENTS

Table

of

Contents

SECTION 1

SECTION 2

SECTION 3

SECTION 4

INTRODUCTION

PREPARING THE PRINTER FOR OPERATION

Paper

Installation . . . . • . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper

Required . . . . • . . . . . . . . . .

Ribbon Required

Ribbon

OPERATION

Switches, Controls,

Audlble Indicators

Keyboard Operations . . . . . . . . . . . . • . . . . . . . . . . . . . . . . . . .

Interrupt Conditions

Escape

Horizontal Tabulation

Vertical Tab

Split Platen Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

OPTIONS

Answerback

Automatic Answerback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Automatic Carriage Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Automatic Motor Control

High

Line Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parity Error Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Red/Black Ribbon Option

Transparency

Installation

Sequence

AND

Speed

...................................

.................................

and

Indicators . . . . . . . . . . . . . . . . . . . . . . . . .

..................................

.................................

and

Control

and

Form

ACCESSORIES

......................................

Transmission ·

Switch

.............•..................

Codes

.............•..................

Feed

(VTFF)

..............................

.....................

.............................

."

. . . . . . . . . . . . . . . . . . . . 2-5

. . . . . . . . . . . . . . . . . . . . . . . . 3-8

.·

......................

-

........

2-1

2-6

2-6

3-1

3-1

3-1

3-3

3-9

3-9

4-1

4-1

4-1

4-1

.4-1

4-1

4-1

4-2

.4-2

SECTION 5

SECTION 6

TAKING

Things

Cleaning the Printer

Replacing Pushbutton Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Avoiding Unnecessary Service

TermiNet PRINTER OPERATING CHARACTERISTICS

Data Transmission

CARE OF YOUR TermiNet PRINTER

to

Remember

Interface

Speeds

Character Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

ASC

TermiNet Character

......................................

........................................

11

Code

.•...............•...............

.................................

Calls

........................

and

Reception

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Codes

... ; .....................

............................

Continued

5-1

5-1

5-1

5-1

6-1

6-1

6-3

6-3

6-4

v

Page 8

Table

of

Contents

GEK-36150

SECTION 6 (Continued)

Timing Characteristics and

TermiNet

TermiNet

Using your Local TermiNet Paper Tape Accessory, Printing

or Transmitting

Using

A1

Using

Accessory (TCA) A3

TABLE

the

TermiNet

and A2 Models

the

TermiNet 1200 Printer with

OF CONTENTS (Continued)

Fill Characters

300

Printer

1200 Printer

to

..............................

..............................

a Remote Printer

300

Printer with

...............................

Model . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

.................

.....................

the

Cassette Accessory (TCA),

the

TermiNet Cassette

Locally

·

...

6-5

6-5

6-8

6-12

6-13

vi

Page 9

GEK-36150

Accessories, Options and

...............

Accessory, Magnetic Tape Cassette (TCA)

Accessory, Paper Tape

ALARM (Indicator)

ALL

CAPS (Switch)

Answerback

.....................

Answerback, Automatic

................

..............

.................

...............

...

3-2,3-4

4-1

.4-2

4-2

3-2

.4-1

4-1

Anti-Curl Device . . . . . . . . . . . . . . . . 2-2,2-3

ASC

11

Code . . . . . . . . . . . . . . . . . . . . . . 6-3

Audible Indicators

AUTO

L.

F.

(Switch)

Automatic Answerback . . . . . . . . . . . . . . .

Automatic Carriage Return

Automatic Motor Control . . . . . . . . . . . . . .

BS

(Backspace) Key

Carriage Return, Automatic . . . . . . . . . . . . .

Character Codes, TermiNet

..................

.................

.............

.................

.............

3-1

3-2

4-1

4-1

4-1

3-7

4-1

6-4

Character Composition . . . . . . . . . . . . . . . . 6-3

Characters, Printable . . . . . . . . . . . . . . . . .

Character Spacing, Horizontal

Cleaning

Code, ASCII

the

Printer . . . . . : . . . . . . . . . . .

......................

Codes, Escape Sequence and

Codes, TermiNet Character

............

Control . . . . . . . . 3-8

.............

1-1

1-1

5-1

6-3

6-4

Control Codes, Escape Sequence and . . . . . . . . 3-8

Panel

Control

.....................

Controls and Indicators, Switches

Copy

..........................

Cover Interlock (Switch)

...............

.........

1-Q

3-1

1-1

3-5

Cover Latch . . . . . . . . . . . . . . . . . . . . . . 3-5

Cover Release Latch

Cover, Top

.......................

Covers, Tractor

CTL (Control)

.................

....................

Key

..................

Data Transmission and Reception

DEL (Delete) Key

Dimensions, Paper Hole

Dimensions, Ribbon and

..................

...............

SpQol

.........

...........

1-2

1-2

2-3

3-7

6-1

3-7

2-6

2-7

INDEX

Index

11

11

Fill

Character Chart

Printer, Time Delay and

11

11

Fill

Character Chart for TermiNet 1200

Printer, Time Delay and

Fill characters, Timing Characteristics and

FORM FEED (Switch)

Feed, Vertical Tab and (VTFF)

Form

for

TermiNet

.............

.............

................

300

.......

.....

6-6

6-9

6-5

3-4

3-9

Forms Tractor . . . . . . . . . . . . . . . . . . 1-2,2-3

HERE

IS

(Switch)

Speed Transmission (300 Printer)

High

Horizontal Character Spacing

Horizontal Tabulation

HT

(Horizontal Tab} Key

..................

............

................

..............

......

3-2

4-1

1-1

3-9

3-7

Indicator,

ALARM . . . . . . . . . . . . . . . . . . . 3-2,3-4

Print Position . . . . . . . . . . . . . . . . 1-2,3-2

READY

...................

3-2,3-4

Indicator/Switch,

INTERRUPT

LOCAL

MOTOR

MOTOR

ON

LINE

STANDBY

................

.......................

OFF

...................

ON

....................

......................

.......

·

..............

3-2,3-4

3-2

3-4

3-4

3-2

3-2

Indicators,

Audible . . . . . . . . . . . . . . . . . . . . . . .

Switches, Controls, and . . . . . . . . . . . . . .

3-1

3-1

Indicators and Switches,

KSR

Printer . . . . . . . . . . . . . . . . . . . . 3-2

RO

and SR Printers

INHIBIT (Switch)

Install

at

ion, paper . . . . . . . . . . . . . . . . . .

Installation, Ribbon

Interface . . . . . . . . . . . . . . . . . . . . . . . .

Interface Connections . . . . . . . . . . . . . . . .

................

..................

.................

3-4

3-2

2-1

2-6

6-1

6-1

Interlock Switch, Cover . . . . . . . . . . . . . . . 3-5

INTERRUPT (Indicator/Switch)

Interrupt Condition Table

Introduction

......................

.......

..............

3-2,3-4

3-3

1-1

Error Detection, Parity . . . . . . . . . . . . . . . .

ESC

(Escape) Key

..................

Escape Sequence and Control Codes

External Paper

Handler . . . . . . . . . . . . 1-2,2-5

External Paper Handler, Paper

External Paper Rack . . . . . . . . . . . . . . . .

Fan-Fold Paper Widths

FF (Form Feed) Key

................

.................

........

Installation

....

4-1

3-7

3-8

2-5

.2-3

2-6

3-7

Keyboard . . . . . . . . . . . . . . . . . . . . . . . 1-2

Keyboard Operations . . . . . . . . . . . . . . . . .

3-1

Key,

BS

(Backspace)

CTL (Control}

DEL (Delete)

ESC

(Escape}

FF

(Form Feed)

..................

...................

...................

...................

..................

3-7

3-7

3-7

3-7

3-7

vii

Page 10

Index

INDEX {Continued)

Key (Continued)

HT

(Horizontal

LF (Line Feed)

(Shift Lock)

LOK

RPT (Repeat)

RETURN

SHIFT

VT (Vertical Tab)

Operation

Keys,

Knob, Platen . . . . . . . . . . . . . . . . . . 1-2,3-5

Lamps,

Latch, Cover

Lever, Paper

LF (Line Feed) Key

Line

LINE

Line Lengths,

LINE SPACE (Switch)

Line Spacing, Vertical

LOCAL

LOK (Shift Lock) Key

Replacing

Control

FEED

(Indicator/Switch)

Tab)

.•.............

..................

.................

................

..............

.......................

.................

....................

Pushbutton

......................

Release

. . . . . . . . . . . . . . . . . . . . . . 4-1

(Switch)

Print

........

.................

................

..................

.............

................

.............

................

- -

............

- . . . . . 1-2,3-5

......

-

..

3-2,3-4

3-7

3-7

3-7

3-7

3-7

3-7

3-7

3-7

5-1

3-5

3-7

3-4

1-1

1-1

3-2

3-7

.

Magnetic

Manual Controls, Switch Locations

Motor

MOTOR

MOTOR ON (Indicator/Switch)

Tape

Control,

OFF

Cassette Accessory (TCA)

and

Automatic

(Indicator/Switch)

..............

..........

..........

.....

4-2

. . . . . . 3-5

4-1

3-4

3-4

GEK-36150

Paper

Tape

Accessory

Tape

Paper

Paper

Paper Widths, Fan-Fold

Parity Error

Platen

Power

Preparing

Print

Print

Printable Characters . . . . . . . . . . . . . . . . .

Printing Speeds

RATE (Switch) . . . . . . . . . . . . . . . . . 3-2,3-4

READY

Reception, Data Transmission and . . . . . . .

Red/Black

Release Lever, Paper

Replacing

RETURN Key

Ribbon

·Ribbon

Ribbon

Ribbon, Red/Black

Ribbon Required

RPT

Rubber

Accessory, Using Printer

Tube

Line Lengths

Position Indicator . . . . . . . . . . . . 1-2,3-2

(Repeat)

. . . . . . . . . . . . . . . . . . . . . . 2-2

Detection

Knob

. . . . . . . . . . . . . . . . . . . 1-2,3-5

ON

Switch

the

Printer

(Indicator)

Ribbon

Pushbutton

.....................

and

Spool

Installation

Out

Sensor

Key

Feet

- Paper Rack

.............

with

...............

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . 1-2,3-5

for

Operation

..................

....................

..............

Option

Dimensions

...................

..............

.................

Lamps . . . . . . . . . .

..................

..................

Option

..................

..............

.........

...........

.............

4-2,6-12

....

3-2,3-4

..

..

6-12

2-6

4-1

2-1

1-1

1-1

1-1

6-1

4-2

3-5

5-1

3-7

2-7

2-6

2-7

4-2

2-6

3-7

2-3

ON LINE (Indicator/Switch)

Operating Characteristics,

OPERATION

Operation

Operation,

Operations, Keyboard . . . . . . . . . . . . . . . . 3-1

Options

Panel, Control

Paper Handler, External . . . . . . . . . . . . 1-2,2-5

Paper Handler, External, Paper Installation

Paper Hole Dimensions (Fan-Fold)

Installation

Paper

Paper Pan . . . . . . . . . . . . . . . . . . . . . . . 2-3

Paper Rack, External . . . . . . . . . . . . . . . . . . 2-3

Paper Rack,

Paper Release Lever . . . . . . . . . . . . 1-2,2-5,3-5

Out

Paper

Paper

Out

Paper Required

Paper

Roll Dimensions

Shield

Paper

Paper

Shield Switch

.....................

Keys . . . . . . . . . . . . . . . . . . . . 3-7

Preparing

and

Accessories . . . . . . . . . . . . . . .

Rubber

Switch (External) . . . . . . . 2-3,2-5,3-6

Switch (Internal)

the

.....................

...................

Feet

....................

......................

.................

............

TermiNet

Printer for . . . . . . . .

..............

................

..........

Printer

.........

....

....

2-2,3-5

3-2

6-1

3-1

2-1

4-1

1-2

2-5

2-6

2-1

2-3

2-5

2-5

1-2

3-5

Sensor,

Shield, Paper . . . . . . . . . . . . . . . . . . .

SHIFT

Space Bar . . . . . . . . . . . . . . . . . . . . . . . 3-7

Spacing, Horizontal Character

Spacing.Vertical Line

Speed (Data Transmission

Speeds, Printing . . . . . . . . . . . . . . . . . . . .

Split

STANDBY (Indicator/Switch)

Switch,

Ribbon

Key

Platen

ALL

AUTO L. F. .

Cover

FORM FEED

HERE

INHIBIT

LINE FEED

LINE SPACE

Paper

Paper

Paper

Out

.................

......................

............

.................

and

Reception)

Printer

CAPS

Interlock . . . . . . . . . . . . . . . . . . 3-5

IS

Out

Out

Shield

.................

.....................

...................

...................

......................

......................

....................

................

(External)

(Internal)

....................

..........

............

...........

2-7

..

1-2

3-7

1-1

1-1

.....

6-3

1-1

3-10

3-2

3-2

3-2

3-4

3-2

3-2

3-4

3-2,3-4

2-3,2-5,3-6

2-2,3-5

3-5

viii

Page 11

GEK-36150

Index

Switch (Continued)

Power On

RATE

TRANSPARENCY ·

....

...........

.

.

...

.

Switch/Indicator,

INTERRUPT

LOCAL

MOTOR

MOTOR ON

ON

LINE

STANDBY

................

.......................

OFF

...................

....................

......................

.....................

Switches and Indicators,

KSR

Printer

RO

and SR Printers . . . . . . . . . . . . . . . . 3-4

Switches, Controls, and Indicators

....................

.........

Switch Locations and Manual Controls

Tabulation, Horizontal

Taking Care

of

your

Tape Accessory, Paper

Tape Cassette Accessory (TCA)

Tape Cassette Accessory (TCA), A

Models, Using

................

TermiNet Printer

................

the

300

With,

....

1"

and A2

..........

.......

.4-2,6-13,6-14

Tape Cassette Accessory (TCA), A3 Model,

Using

the

1200

Printer With,

..........

INDEX

......

1-2,3-5

3-2,3-4

3-2,4-2

3-2,3-4

3-2

3-4

3-4

3-2

3-2

3-2

3-1

3-5

3-9

5-1

4-2

6-13

6-14

(Continued)

Tension Limiter

TermiNet Character Codes

TermiNet Printer Operating Characteristics

Time Delay and 11Fill

TermiNet

Time Delay and 11Fill

TermiNet

Timing Characteristics

Timing Characteristics and Fill Characters,

TermiNet

Timing Characteristics and

TermiNet

Top

Tractor Covers

Tractor, Forms . . . . . . . . . . . . . . . . . 1-2,2-3

Transmission and Reception, Data

Transmission, High Speed (300 Printer)

TRANSPARENCY (Switch)

Vertical Line Spacing

Vertical Tab and Form Feed (VTFF)

VT (Vertical Tab) Key

Cover

....................

11

Character Chart for

300

Printer

1200

...............

11

Character Chart for

Printer

and

300

Printer

1200

...............

Printer

.......................

....................

.................

................

..............

..............

Fill Characters

Fill Characters,

..............

.........

..........

.......

.....

.....

....

3-2,4-2

2-2

6-4

6-1

6-6

6-9

6-5

6-5

6-8

1-2

2-3

6-1

.4-1

1-1

3-9

3-7

ix/x

Page 12

Page 13

GEK-36150

Introduction

SECTION 1

INTRODUCTION

Your TermiNet Printer

is

a high speed data

communications

printer

used primarily for

communicating with computer systems or

other

printers. The TermiNet Printer

is

compact for

operation

on

a desk

top

or

on

its optional Pedestal.

Operation

is

quiet compared

to

similar equipment.

The Printer can print and transmit information

that

is

received from its keyboard or from an external source

(for

example, a paper

tape

reader).

NOTE

For convenience, reference

to

the TermiNet

Printer,

in

most cases, will be "Printer".

Your Printer

will be one of

two

basic models; the

TermiNet

300

or TermiNet

1200

Printer (Figures

1-1

and 1-2). The TermiNet

300

and 1200 Printers print

maximum speeds of

30

and 120 characters per second

respectively.

The

KSR

(Keyboard, Send, and Receive) version of

the Printer has a keyboard similar

to

a standard office

typewriter. The

KSR

Printer can

print

and transmit

information generated

locally by the keyboard or a

local device (e.g., paper tape reader}.

It can receive

and print information from a remote terminal,

computer, or

other

communication device. ·

NOTE

When a

KSR

Printer

is

combined with a

recording and reading device such as a paper

tape punch and reader,

the

combined

configuration

is

normally called an ASR.

The SR (Send and Receive) version of

the

Printer has

no keyboard. The

SR Printer operates similar

to

the

KSR

except for

the

absence of the keyboard.

The

RO

(Receive Only) version

of

the Printer has no

keyboard and can print received information only.

Although this manual

is

written primarily for the

KSR

Printer,

the

SR and

RO

Printers operate

in

a

similar manner except for

the

major differences

previously explained.

The

general operating characteristics of the TermiNet

Printer are

as

follows:

PRINTABLE

CHARACTERS

All

of

the

94

printable characters

in

the

American

Standard Code for

Information Interchange (ASCII)

can

be

printed by the TermiNet Printer.

PRINTING SPEEDS

300

Printer,

the

standard

front

panel

RA

TE

switch

will select speeds

of

10, 15, and

30

characters per second (cps). An optional

speed

of

20

cps

is

available

as

a substitute for

one of the standard speeds.

1200 Printer, the standard

front

panel RATE

switch

will select speeds of

10;

30, or

120

characters per second. Optional speeds of 15,

20

or

60

cps are available

as

a substitute for

one

of the standard speeds.

HORIZONTAL CHARACTER SPACING

10 characters per inch (2.5 cm).

VERTICAL LINE SPACING

6 lines per inch (2.5 cm) with the LINE SPACE

switch in the

11111

position. 3 lines per inch (5.1 cm)

with

the

LINE SPACE switch

in

the

"2''

position.

PRINT LINE LENGTHS

300

Printer - 75,

80

or 118 print positions.

1200 Printer -

80

or 120 print positions.

COPY

The Printer

is

capable of handling up

to

a six-part

form set with a maximum form set thickness of

0.025

11

(0.64 mm). Recommended paper weights are:

1 part

2, 3 or 4

part

6

part

15 lb. paper

13.5

lb. paper, 8 lb. carbon

12

lb. paper, 8 lb. carbon

Multiple copies are only

possible with pin

or

tractor

feed paper.

1-1

Page 14

Introduction

GEK-36150

/ POWEFl SWITCH

PAPER

RELEASE

LEVER

PRINT

POSITION

INDICATOR

CONTROL

PANEL

RELEASE

LATCH

PKM-4007

Fiaure 1-1. TermiNet 300 Printer tKSR). Friction

Feed

PAPER

HANDLER

FORMS

TRACTOR

PKH-4005

i=igure

1-2. TermiNet 1200 Printer (KSR)

with

External

Paper

Handler

1-2

Page 15

GEK-36150

Preparing the Printer for Operation

SECTION 2

PREPARING THE PRINTER FOR OPERATION

PAPER

INSTALLATION

FRICTION

FEED (300 PRINTER)

a.

Press

the

Printer cover release latches and lift

cover (Figure

2-1

).

I WARNING I

POWER

IS

STILL

ON

WHEN THE COVER

IS

LIFTED. KEEP YOUR HANDS

ONLY

IN

AREAS NEEDED TO

INSTALL

THE

PAPER.

b.

Remove paper tube (Figure 2-2) from Printer.

c. Place the paper tube

in

the center of the new

paper

roll.

PLATEN

KNOB

d. Set the paper roll and tube

in

place.

e.

Lift the paper shield (Figure 2-1).

f. Feed the paper from the bottom of the

roll,

over the tension limiter, and under the platen

(Figure 2-3).

NOTE

It may be necessary

to

press the tension

limiter down while routing the paper under

the platen.

Make

certain

the

anti-curl device

(Figure 2-4)

is

positioned

in

the

middle of

the paper width.

g.

Push the Platen Knob (Figure 2-1)

in

and rotate

to

advance the paper.

PAPER

RELEASE

LEVER

in

the rear (normal) position

PAPER

SHIELD

....--RIGHT

COVER

RELEASE LATCH

PKM-4008

Figure 2-1. Paper Handling

2-1

Page 16

Preparing

the

Printer for Operation

GEK-36150

PAPER

TUBE

Figure 2-2. Paper Tube

PKM-4009

i.

To align the paper, move the Paper Release

Lever (Figure 2-1)

to

its forward (toward

the

keyboard) position and align

the

left edge of

the

paper with the vertical line on

the

paper

shield.

j.

Move

the Paper Release Lever

to

its most rear

(toward the

bustle) position.

PIN FEED (300 PRINTER)

a. Align the paper supply container, holder, etc.,

behind the Printer. The paper

supply should

be lower than the Printer's

top

surface.

b. Route the paper over

the

back of the Printer

toward the platen.

h.

Lower

the

paper shield carefully.

Do

not let

the

shield snap down.

c.

Insert the paper under the platen and align

paper holes with the sprocket pins.

2-2

ANTI-CURL

DEVICE

TENSION

LIMITER

PRESS

HERE

TO

RELEASE

LOW

PAPER

SWITCH

IF.

IN

LOCKED

POSITION

PRESS

DOWN

HERE

TO

"LOCK

OUT

11

LOW

PAPER

SWITCH

----

--

-

-

\

--

CD

PAPER OUT SWITCH IN LOCKED POSITION

-DEFEATS

ALARM -ENABLES

OPERATION

@ PAPER OUT SWITCH

IN

FULL

ROLL RANGE -

ENABLES

OPERATION

@ PAPER OUT SWITCH IN LOW PAPER

POSITION

PKM-4010

Figure 2-3. Paper Installation - Friction Feed

Page 17

GEK-36150

Preparing

the

Printer for Operation

l

PTM-3009

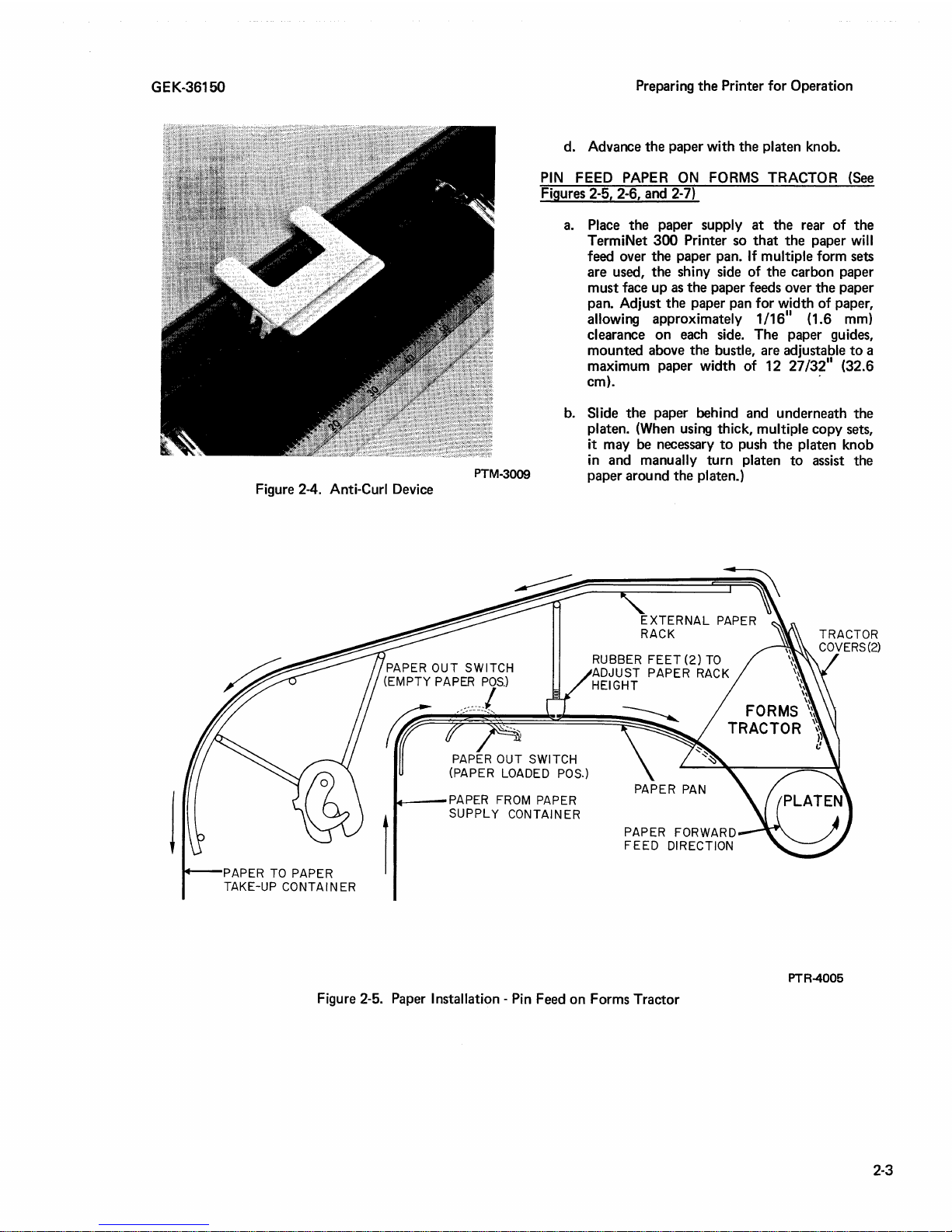

d. Advance the paper with the platen knob.

PIN

FEED PAPER

ON

FORMS TRACTOR (See

Figures 2-5, 2-6, and 2-7)

a.

Place

the

paper supply

at

the rear of

the

TermiNet

300

Printer so

that

the

paper will

feed over the paper pan.

If

multiple form sets

are used, the shiny side of the carbon paper

must face up

as

the

paper feeds over

the

paper

pan. Adjust

the

paper pan for width of paper,

allowing approximately

1/16

11

(1.6 mm)

clearance

on

each side. The paper guides,

mounted above the bustle, are adjustable

to

a

maximum paper width of 12 27

/32

11

(32.6

cm).

·

b.

Slide

the

paper behind and underneath the

platen. (When using thick, multiple copy sets,

it may be necessary

to

push

the

platen knob

in

and manually

turn

platen

to

assist the

paper around the

platen.)

Figure 2-4. Anti-Curl Device

PAPER TO

PAPER

TAKE-UP

CONTAINER

PAPER

OUT

SWITCH

(EMPTY

PAPER

POS.)

rr

/'

l

PAPER

OUT

SWITCH

(PAPER LOADED POS.)

w---PAPER

FROM PAPER

SUPPLY

CONTAINER

RUBBER

FEET

(2)

TO

ADJUST

PAPER

RACK

HEIGHT

PAPER

FORWARD

FEED

DIRECTION

Figure 2-5. Paper Installation - Pin Feed on Forms Tractor

PTR-4005

2-3

Page 18

Preparing the Printer for Operation

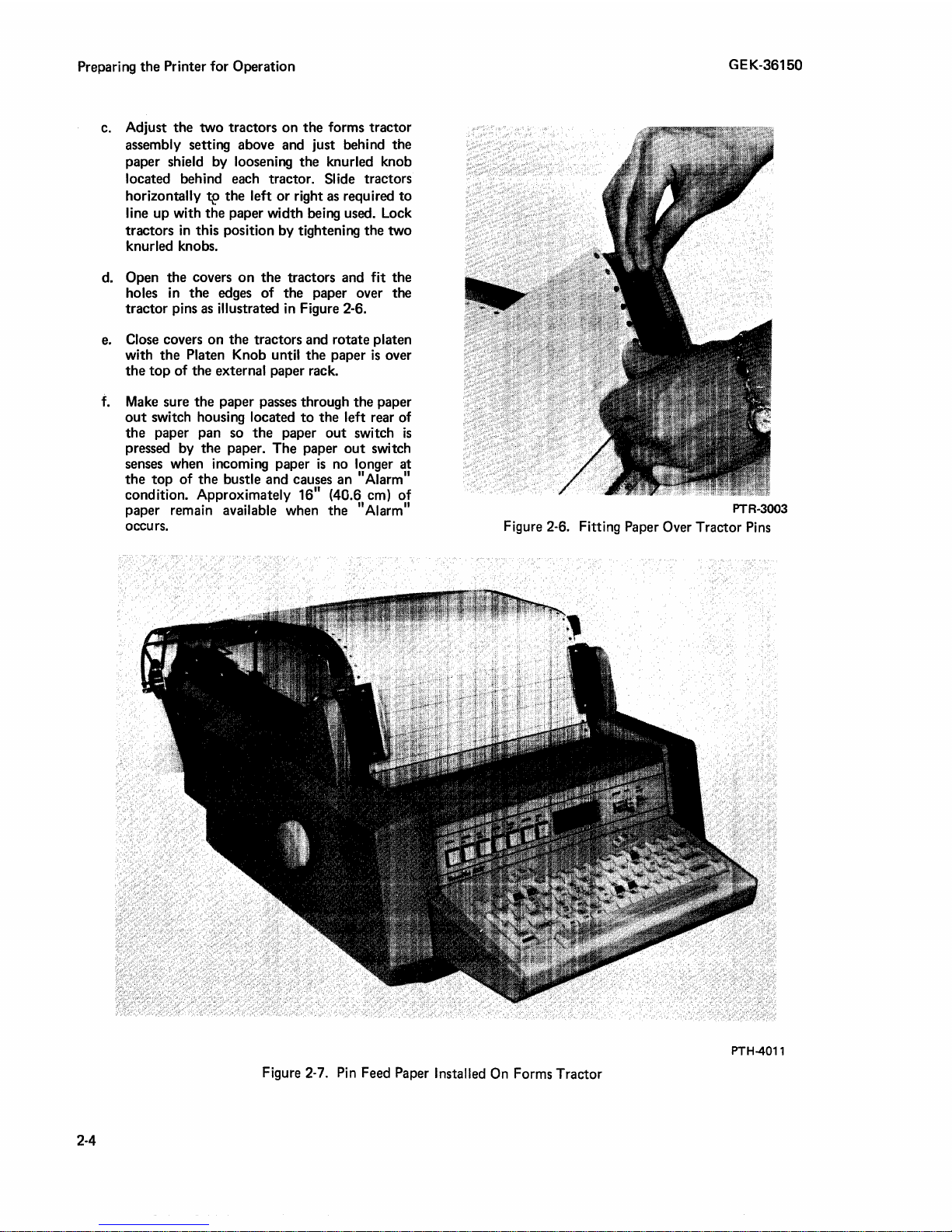

c.

Adjust the two tractors

on

the

forms tractor

assembly setting above and just behind the

paper shield by loosening the knurled knob

located behind each tractor.

Slide tractors

horizontally

tp

the

left

or

right as required

to

line up with the paper width being used. Lock

tractors

in

this position by tightening the two

knurled knobs.

d. Open the covers

on

the

tractors and fit the

holes in

the

edges of the paper over the

tractor pins

as

illustrated in Figure 2-6.

e.

Close covers

on

the

tractors and rotate platen

with

the

Platen Knob until

the

paper

is

over

the

top

of the external paper rack.

f.

Make sure

the

paper passes through

the

paper

out

switch housing located

to

the

left rear of

the

paper pan so

the

paper

out

switch

is

pressed by

the

paper. The paper

out

switch

senses when incoming paper

is

no longer at

the

top

of

the

bustle and causes an "Alarm"

condition. Approximately 16

11

(40.6 cm) of

paper remain available when the

11

Alarm"

occurs.

GEK-36150

PTR-3003

Figure 2-6. Fitting Paper Over Tractor Pins

PTH-4011

Figure 2-7.

Pin

Feed Paper Installed

On

Forms Tractor

2-4

Page 19

GEK-36150

Preparing the Printer for Operation

EXTERNAL

PAPER

HANDLER

(OPTION)

Similar to Forms Tractor except

use

Figure

2-8

as

a

reference.

PAPER

REQUIRED

ROLL

(300 PRINTER)

Figure

2-9

shows the dimensions of the paper

roll

required for the Printer.

PAPER

OUT SWITCH

FOR

EXTERNAL

PAPER

EXTERNAL

PAPER

HANDLING SYSTEM-OPTIONAL

~TERNAL

FAN FOLD

PAPER

SUPPLY

FOR

PIN FEED

PLATEN

MACHINES

----.ARROWS

INDICATE ROUTE

FOR

FEEDING

PAPER

TRANSPARENT SHIELD

OPH-4003

Figure

2-8.

Paper Installation with External Paper Handler

1

••

l

2

.s

c\\J\)

coRE

S\Z.E

..

4cM)

8 7 /'\6'' l2

•.

'IJ\O'T\-\

Figure

2-9.

Paper

Roll

Dimensions

PTM-4025

2-5

Page 20

Preparing the Printer

SINGLE SHEET

A single

(12.7 cm) may

FAN FOLD

sheet

with

be

for

Operation

a minimum length

used

in Printers using paper rolls.

of

5 inches

~----"t'--

1

(6.35 MM)

GEK-36150

/4"

Your Printer may

consists

each

the Printer. A pin feed Printer

in one

tractor Printer can

(7.6 cm)

determine the

distance

Use

Paper

Multiple copy paper consisting

to

thick

of

either a platen having a row

end, or a forms feed tractor mounted on

of

the

to

across

"overall"

hole dimensions

five copies

may

be

have

a pin

feed

will

sizes

shown in the table. A forms feed

use

any paper

12 27/32 inches (32.6 cm). You

size

your

Printer

the

width

size

when ordering

are

not

exceeding 0.025 in. (0.64 mm)

used.

width

uses

of

the platen between pins.

shown in Figure 2-11.

of

option

of

pins around

use

fan-fold paper

from

by

measuring the

(see

Figure 2-10).

an

original

top

3 inches

and

WIDTH

I

which

of

can

up

I

1/2"

150

shows

(12.7 MM)

FS

Underwood

ribbon

5/32"

(39.6 MM)

Figure 2-11.

Replacement Ribbons must

type double spools. (Figure 2-12

·spool dimensions.) The following ribbons

recommended.

Columbia

Curtis Young DUO PAK, Nylon 44, Black

Medium

Labelon Underwood Scriptor Duet, Black

Medium,

Paper

Hole Dimensions

RIBBON REQUIRED

have

#3202-2005

#4

#430

Nylon

PTR-4007

and

are

PIN FEED PAPER WIDTHS

Pin-to-Pin Overall

11

(20.3 cm)

8

11

/2

(21.6 cm)

8 1

11

9

(22.9 cm) 9 1

11

11

/32

12

3

2-6

11

(7.6 cm)

(31.3 cm)

Split Platen - Right Hand

Figure 2-10. Fan-Fold

l

8

1/2

11

9

(22.9 cm)

/2

12

27

3

1/2

Paper

11

(21.6 cm)

11

(24.1 cm)

11

/32

(32.6 cm)

11

(8.9 cm)

PTR-4006

Widths

Buckeye #130-2070-115 Paquette, Black

Record

General Ribbon,

Computer Black,

Install

ink

technique shown pictorially

Figure 2-14.

On

certain the ribbon

platen

(metal tab

platen).

#5

G.

Heavy

RIBBON

ribbons

Printers

and

INSTALLATION

as

shown by Figure 2-13,

NOTE

with

a forms tractor,

is

not routed between the

the anti-snag device paper holder

holding the paper against the

E.

TermiNet 300, Silk,

by

steps

1 through 6 in

make

using

Page 21

GEK-36150

Figure 2-12. Ribbon

and

Spool Dimensions

Preparing the Printer

PTR-4008

for

Operation

1.

SLIDE

EMPTY SPOOL

RIBBON OUT SENSOR MUST

DO NOT

FORCE

UNWIND

TAPE

ON

SPOOL

ALREADY

RIBBON OUT

LEFT

ON . DO

ON

SENSOR

3.

HUB.

ENGAGE

NOT

SPOOL.

BEFORE

IN

DIRECTION

DOES

RIBBON INSTALLATION

SLOT.

OPERATING

NOT

INTERFERE

PRINTER

INCORRECT

OF

ARROW

CAN

PRINTER

TO

WITH PRINT

CAUTION:

BE

DAMAGED

INSTALLATION

2.

ROUTE

INSTALL

SPOOL TO TAKE OUT SLACK .

ONE SPOOL

ROTATE

INSURE THAT RIBBON

FINGERS.----_,

Figure 2-13. Ribbon Installation

DO

BELT

BY

RIBBON

AS

FULL

NOT

BY

SHOWN

SPOOL.ROTATE ONE

Will

TURN

FORCE)

HAND

AND

(ONLY

MANUALLY

(

\11

-

~

'

44(902924

PrR-3001

2-7

Page 22

Preparing the Printer for Operation

2-8

GEK-36150

Place

Empty

Spool

On

Hub

First

0

~\~~~t~~

,~J1R9~

"YVm·.

~f:l~~.r

on

Hub

Place

Full

Spool

On

Other

Hub

. Align Slot In Spool With

Sensor

On

Hub

.

;.

. . . .

,,,_,,

. .

·---........

PTR-4009

Figure 2-14. Ribbon Installation Procedure

Page 23

GEK-36150

Operation

SECTION 3

OPERATION

SWITCHES, CONTROLS,

AND

INDICATORS

Figures 3-1, 3-2, and 3-3 point

out

the

locations

of

the

switches, controls, and indicators and explain

their basic functions.

AUDIBLE

INDICATORS

Beep

tone

each time a key

is

pressed.

High

pitch

tone

when ALARM indicator

lights.

High

pitch

tone

when INTERRUPT indicator

lights.

High

pitch

tone

indicating near end

of

line

and end of line. The

tone

will sound

at

print

positions 67, 72,

110, and 112 on 75, 80,

118,

and 120 print position Printers

respectively. The

tone

will also sound after

the

last print position

of

the

Printer.

NOTE

The

volume

of

all

the

audible indicators

is

adjustable by

the

serviceman

if

the

preset

volume does

not

satisfy your particular need.

KEYBOARD OPERATIONS

The keyboard

is

similar

to

that

on a standard electric

typewriter. The keyboard has a total

of

62

keys

including

the

space bar, and

is

capable

of

generating

all

128

ASCII characters. The keys are electronically

interlocked

so

that

it

is

not

possible

to

generate

two

or

more codes simultaneously. A beep

tone

sounds

each time a key

is

pressed (with

the

exception

of

the

SHIFT, LOK, CTL, and RPT keys). Because actual

printing may

not

occur

at

the

same instant you press

a key (as with

most

typewriters),

the

beep

tone

allows

you

to

maintain your normal typing rhythm.

For descriptions

of

the

Printer operation keys, see

Figure 3-5.

3-1

Page 24

LOCAL · Lights whep prnssed, Starts

motor

and

onables' local Printer operation

but

does

not

al.low

the

transmission

or

reception of data.

STANDBY

~

· Ughts

when

pressed.

Tums

motor

oft

but

leaves electronics

i\.lmed

on

which enables

the

transmission

and

reception

of

data.

ON

UNE • Lights

When

pressed.

Tums

Printer

motor

on

.arid

enable~.

the

transmission and reception of

data.

READY·

Indicates data set

Is

ready

for

transmission.

Held

ofl

!f

INTER.RUPT

lamp

is

on

.

. 1200 Printer only - Used as

farnp

self test.

When· pre$sed,

all

lamps should light. The

HERE

lS

pushbutton ·does·

not

have a lamp.

ALARM • The ALARM lamp lights when the following alarm conditions occur (remains

on

until

the

alarm condition has been corrected):

Low paper or paper

out

Paper Shield

up

{not

on

forms tractor model)

Paper punch

out

of

paper or end

of

magnetic tape

in

"Write" mode if

in

optional

ASR configuration.

Problem

in

the Printer.

Also,

when the ALARM lamp lights, the following occurs:

An Alarm tone sounds

An

Interrupt

or

Break

is

automatically transmitted

to

alert

the

other end of

the

line

(if

on line)

The

motor

turns off

The following

are alarm conditions

that

do

not

light the ALARM lamp

but

sounds

the

Alarm tone, causes

an

Interrupt or Break

to

be transmitted, and turns off

the

motor.

Cover

up

(300 Printers only)

Undervoltage

to

Printer.

Print

belt

underspeed.

ALL

CAPS · When placed in

the

ON

position, all

alphabetic printing caused by the keyboard only will

be

upper

case.

AUTO

LF.

·When

in the ON position,

the

paper

is

advanced automatically when the RETURN

key

fa

pressed. (Has no effect

on

incomfng data.)

PKM-4011

Figure 3-1. Switches

and

Indicators, KSR Printer

G)

m

A

w

(J)

-

CJ1

0

Page 25

GEK-36150

CONDITION OF

INTERRUPT

LAMP

Unlit

Lit

CONDITION OF

INTERRUPT

LAMP

Unlit

Lit

TABLE3-1

INTERRUPT CONDITION

TABLE

RESULTS FROM PRESSING

INTERRUPT PUSHBUTTON

An

11

lnterrupt

11

or 11Break

11

signal

is

transmitted.

INTERRUPT lamp

does

not light.

1.

INTERRUPT lamp

goes

out.

2.

11

lnterrupt

11

or 11Break

11

is

not

transmitted.

3.

KEYBOARD

is

unlocked (KSR Printer).

4.

READY lamp

is

restored

to

normal.

RESULTS FROM RECEIVING

AN

INTERRUPT

SIGNAL

1.

INTERRUPT lamp lights.

2.

Alarm

sounds.

3. Keyboard

is

locked

out

(KSR Printer).

4.

Optional

Reader

(if

on)

is

turned off.

5.

Optional

Reader

may then

be

restarted

either

locally or remotely.

6.

Data may still

be

received.

7.

Motor

does

not turn

off.

8. READY lamp

is

held

off.

1.

Optional

Reader

(if

on)

is

turned off.

2.

Optional

Reader

may then

be

restarted

either

locally or remotely.

3.

Data may still

be

received.

4.

Motor

is

not turned off.

5.

READY lamp

is

held off.

NOTE

Operation

An

11

INTERRUPT

11

or 11Break

11

signal

transmitted by a TermiNet Printer

is

always 268 milliseconds long.

(It

is

a

constant

zero

(spacing) condition.)

The minimum duration

of a received 11INTERRUPT11or11Break

11

signal

must

be

240 milliseconds

to

insure detection

by a TermiNet Printer.

3-3

Page 26

INTERRUPT· Se1.1INTERRUPTCONDtTION TABLE 3·1.

READY, Indicates

data set

is

ready

for

reception

of

data. Held off if INTERRUPT tamp is on.

1200 Printer Only

'.

U~ed

as lainp self test.

When

pressed,

all

lamps should light. The

FORM

FEED and

LINE FEED pushbuttons do

not

have lamps.

MOTOR

OFF·

Lights when pressed.'Turns

motor

off

hut leaves electronics turned' on.

ALARM· The

ALARM

lamp lights when the foltowing alarm condition occurs (remains

on

until the alarm condition has been corrected):

low

paper or paper

out

Paper shield up (not on forms tractor model)

Problem

in Printer

Also, when the

ALARM

lights, the following occurs:

An

Alarm tone sounds

An

Interrupt or Break

is

automatically transmitted

to

alert the other end

of

the

tine

Motor turns

off

The following are alarm conditions that do not light the

ALARM

lamp but sound the

Alarm tone, cause an Interrupt or Break

to

be transmitted (SR Printer only}, and turn off

th•e

motor,

Cover up

(300 Printer only}

Undervoltage

to

Printer

Print

belt underspeed

When

the Alarm condition

is

corrected,

MOTOR

ON

must be pressed

to

start the motor.

Figure 3-2. Switches

and

Indicators, RO

and

SR

Printers

PTR-4010

Set

on

::1::.

single

H~e-fcied.

Set

on

2 , double ltne-feed,

0

"O

Cl)

OJ

..+

5·

::s

Page 27

FF

(Form Feed),

Option·

This key

causes

the·paper

to

advance

to

the

beginning

of

the

nei1t

form".

Also,

the

FF

character

code

is

generated

and

transmitted.

VT

!Vertical Tab).

Option·

This key cau$es

the

paper

to

advance to a pr1Jdetermined line*. Also,

the

VT

character

code

is

generated

and

transmittoo.

CTL (Control)

Th

ls

key

is

~sed

in conjun.ctl?,n wit.h

to

generate Control Codes ; See

(WENCE

AND

CONiROL

CODES"

In

ESC

{Escape) ·

ThiSk~y

is

used in

conjunctio~.

with

other

keys

to

generate Escape Sequence Codes • See

''ESCAPE SEQUENCE ANO CONTROL CODES"

in

this

section.

HT

\Hodzo~tal

Tab),

Option.

1'his

key

moves'.th~~ptint

Pi:>sitj0,i!

tti aprf!Qeterinlried

position*. Also,

the.HT

charapter .code is generateq

af1d.

tre~s~itted.

· ' ' · •

•:

*Refer

to

page

3-9 for a more detailed description on the

use

of

these

keys.

**If

it

is

a Split Platen Printer,

pressing

the

BS

key

moves

the

print position

to

the first print position

on

the right platen.

The normal backspacing function

is

not operable.

Figure 3-5. Operation

Keys

PTM-4026

RETURN •

Toi~

key generates

ttie

CR

code.With

the;·

AUTO LF switch in

the

OFF

position, pressing

~he

RETURN

key

returns

the

Printer

to

the

left

hand

margin

or

the 1irst horiwrita.!

tab

if

this option

.ls

present

With

1he

AUTO

LF

switch

Jn

the

ON

position,

pressing

th.e RETURN

key

'retµrns the.

Printer

to

toe

left

hand margin

and

also c'ause;\ a

Une

feed; • · · · · · •

G'>

m

7'

w

en

-

~

Page 28

Operation

ESCAPE SEQUENCE

AND

CONTROL

CODES

GENERATING ESCAPE SEQUENCE CODES

By

momentarily pressing

the

ESC

(Escape) key and

then

momentarily pressing

the

appropriate related

key, an escape sequence code

is

generated (the

character

following

the

ESC

code

does

not

print).

The

ESC

key and its related keys are shaded

on

their

front

edges. The Printer can react

to

escape sequence

codes from

the

keyboard or received from a remote

source.

NOTE

To

generate escape sequence codes with

early production

300

Printers, press and

hold

the

ESC

key,

then

simultaneously press

the

related key. Release

the

keys.

GENERATING CONTROL CODES

To

generate a control code, press and hold

the

CTL

(control) key,

then

simultaneously press

the

desired

control function key. Release

the

keys. Most control

function keys are identified on their

front

edges.

DESCRIPTION OF ESCAPE SEQUENCE AND

CONTROL CODES

In

the

descriptions following,

"receipt"

or

"when

received" refers

to

codes received,

not

those

Renerated

at

the

keyboard or

on

local tape.

Recognition" refers

to

codes received

or

to

codes

generated

locally. The following

is

a list

of

codes

most encountered

in

the

average system.

NOTE

In

some cases, the codes are stored. There

is

no permanent memory in

the

TermiNet

Printer, and stored codes

will be lost if

power

is

completely removed from

the

Printer.

ESCAPE

SEQUENCE CODES

The

ESCAPE code

is

used

in

sequence (Escape

is

first

code) with

other

codes

to

accomplish

the

following:

ESC

0 (Zero) RDR REV - This

code

when recognized

causes an

optional reading device

to

reverse.

ESC

1 -

HT

Set

(Option) -

If

the

horizontal

tab

option

is

present, recognition

of

ESC

1 will set a

tab

at

the

print column position where this code

is

recognized.

ESC

2 · Horizontal Tab Clear (Option) -

If

the

horizontal

tab

option

is

present, recognition

of

ESC

2

will clear

all

tabs which have been set.

3-8

GEK-36150

ESC

3 -

In

a Split Platen Printer, recognition

of

ESC

3

causes

the

right platen

to

advan~e

paper when

the

LF

code

is

recognized.

- When

the

Red and Black Printing

option

is

installed, recognition

of

ESC

3 will raise

the

ribbon

to

allow red printing (Red and Black Printing

option

is

not

available on

the

Split Platen Printer).

ESC

4 -

In

a Split Platen Printer, recognition of

ESC

4

causes

the

left platen

to

advance paper when

the

LF

code

is

recognized.

- When

the

Red and Black Printing option

is

installed, recognition

of

ESC 4 will lower

the

ribbon

to

allow black printing (Red and Black Printing

option

is

not

available

on

the

Split Platen Printer).

ESC

; - When received, this

code

places

the

Printer in

a suppress print mode and

allows two-way

simultaneous

data

flow. Locally generated data

is

transmitted

but

not

printed while received data

is

being printed. A jumper change can

be

made so

that

the

Printer will respond

to

a recognized

ESC

;.

ESC

: - Receipt

of

this

code

cancels

the

effect

of

ESC

;

and

restores

the

Printer

to

its normal condition.

That

is,

printing occurs

whether

data

is

being received

or

locally generated. Normal operation may

be

restored under local control

by

momentarily moving

the

INHIBIT switch

on

the

front

panel

to

the

PRINT

or

TRANS position,

by

pushing

the

LOCAL

pushbutton,

or

by turning

off

AC

power.

ESC

H (h) - Printer Motor On - Used, when

recognized,

to

turn

the

Printer

motor

ON. A jumper

change can be made so

that

only a received

ESC

H

will

turn

the

motor

on.

ESC

J m - Printer Motor Off - Used, when

recognized,

to

turn

the

Printer

motor

OFF.

A jumper

change can be made so

that

only a received

ESC

J will

turn

the

motor

off.

CONTROL CODES

CTL-C ETX (End-of-Text) - This code causes an

action

only if

the

Printer has

the

Line Control option.

When

the

Printer

is

in

a transmit mode, local

generation

of

ETX places

it

in a receive mode. ETX,

when received, turns the Printer

to

the

transmit

mode. A jumper change can

be

made so

that

ETX

code has no effect.

CTL-D.

EQT

(End-of-Transmission) - When

recognized, this code causes

the

Printer

to

go

to

"Standby"

if

the

Printer was

"On

Line".

If

the

Printer was in "Local",

the

EQT code will stop

the

Printer.

If

the

Printer has

the

line control option, a

jumper change can be made so

that

EQT will cause

the

same action

as

ETX. Also, a jumper change can be

made so

that

EQT has no effect.

Page 29

PAPER OUT (Internal Paper Supply) - Detects low

paper

condition and causes

an

alarm. Switch can be

placed in a Jocked

out

position (see Figure 2-3).

flt.ATEN KNOB -

To manually

rotate

the

platen,

push Pfaten

Knob in and turn. With the forms tractor

the

paper can only be advanced. · '

PTR-4011

Figure 3-3. Switch Locations

and

Manual Controls

0

"'C

(I)

OJ

...+

a·

:::::s

Page 30

Operation

3-6

...

PAP~R.·

.•.

·OUT

SWITCH.

•

Detects; a ·paper

o~t

conditio~.

and

causes

an

ararm. ·

··

· · · · · · ·

Figure 3-4. External Paper Out Switch

GEK-36150

PTR-4012

Page 31

GEK-36150

CTL-E, ENO (Enquiry) - This

code

causes an

action

if

your

Printer has

the

Answerback

or

Line Control

option.

Receipt

of

ENO triggers

the

answerback

message

that

can

contain

up

to

20

characters. If

the

Printer has

the

Line Control

option,

the

status

of

the

Printer

is

indicated

by

the

transmission

of

the

ACK

or

NAK

code

(following

the

Answerback

messa~e)

and

the

line

turns

around.

Status

excludes

the

Motor

Off"

state

of

the

Printer.

CTL-F, ACK

(Acknowledgment) - This

code

causes

an

action

only

if

the

Printer has

the

Line

Control

option.

Recognition

of

ACK

turns

the

line

around.

A

Printer

transmits

ACK as a response

to

ENO if

the

Printer

is

not

out

of

paper,

and

it

is

capable

of

receiving a message.

CTL-G, BEL

(Bell

or

Alarm) - When recognized,

this

code

causes

an

audible alarm

to

sound

for

approximately

0.5

seconds.

Any

BEL

code

received

during

the

0.5

second alarm will be ignored; i.e.,

successive BEL codes

do

not

generate

a cumulative

time

value

of

tone.

CTL-P, OLE (Data Link Escape) - OLE

is

used in

combination

with

the

following codes. These

codes

cause an

action

only

if

the

Printer has

the

Line

Control

option.

D

LE

EQT - When recognized,

these

codes

initiate

the

automatic

disconnect,

and

the

Printer

is

placed in

the

"Standby"

mode. (Data

Terminal Ready signal (circuit CD)

to

the

Data

Set

turns

off

for

67

milliseconds.)

- D

LE

? - When

these

codes

are received,

the

Printer assumes a "Wait Before

Transmit"

condition,

and

the

READY lamp goes

out.

The

Printer automatically responds

to D LE ? with

the

code

ENO.

Subsequent

receipt

of

ACK

lights

the

READY lamp.

CTL-0,

RDR ON,

DC1

(Reader On) -

The

Reader On

code

is

used, when received,

to

turn

on

an optional

reader device.

CTL-R,

PCH

ON, DC2 (Punch On) -

The

Punch On

code

is

used, when received,

to

turn

on

an

optional

recording device.

CTL-S, RDR

OFF,

DC3 (Reader Off) -

The

Reader

Off

code

is

used,

when

received,

to

turn

off

an

optional reading device. A

jumper

change

can

be

made

so

that

DC3

is

ignored

when

received.

CTL-T,

PCH

OFF,

DC4 (Punch Off) -

The

Punch

Off

code

is

used, when received,

to

turn

off

an optional

recording device.

CTL-U, NAK (Negative Acknowledgment) - This

code

causes an

action

only

if

the

Printer has

the

Line

Control

option.

Receipt

of

NAK

turns

the

line

Operation

around, I ights

the

INTERRUPT

lamp,

and

de-activates

the

keyboard.

The

Printer

transmits

NAK

on

receipt

of

ENO if

the

Printer

is

out

of

paper

and

is

used

with a data

set

which

does

not

disconnect

when

the

Data Terminal Ready lead (circuit CD)

is

turned

OFF.

HORIZONTAL TABULATION (OPTION)

TAB

SET

A

tab

is

set

when

the

"Escape"

and 111

11

(HT set)

codes

are generated

from

the

keyboard

or

received

from a remote

source.

Any

number

of

tabs

can

be

set

on a print

line.

TAB CLEARING

All

tabs

are cleared

when

the

"Escape"

and

112'1

(HT

CLR) codes

are

generated from

the

keyboard

or

received from a

remote

source.

NOTE

When AC

input

power

is

turned

off,

all

tabs

are cleared. The

tabs

do

not

clear when

the

Printer goes

to

the

"Standby"

status.

OPERATING CHARACTERISTICS

When

the

HT key

is

pressed

or

a Horizontal

Tab

-

control

code

is

received,

the

print

position moves

to

the

next

tab

set

to

the

right.

If

no

tabs

are set,

the

print

position moves

to

one

position

past

the

last

print

position.

When

the

RETURN key

is

pressed

or

a Carriage

Return

control

code

is

received,

the

print

position

moves

to

the tab

set

farthest

left. This

tab

becomes

the

left margin.

If

no

tabs

are set,

the

print

position

moves

to

1 (one).

VERTICAL TAB AND FORM FEED (VTFF),

OPTION

DESCRIPTION

This

option

allows

the

Printer

to

rapidly feed

paper

(6

3/4

inches

per

second)

to a predetermined

line

position

upon

recogniton

of

a locally

or

remotely

generated form feed (FF)

or

vertical

tabulation

(VT)

code.

A programmable disc

is

used

to

program

the

VTFF.

The

Printer

can

have

VTFF

for

use

with

forms

of

8,

8

1

/2,

or

11

inches. The corresponding discs

contain

48,

51,

and

66

divisions respectively. Figure 3-6

shows

the

disc

for

use

with

the

11

inch form. It has

66

divisions corresponding

to

the

number

of

print

lines

on a 11

inch

sheet

of

paper

(6

print

lines per

inch).

3-9

Page 32

Operation

GEK-36150

For form-feed operation, this disc can be punched

with

the

recognition

disc punch (see Figure 3-6) so

run quickly

of

a FF

to

the

code

causes

first line

the

line feed drive

of

printing

that

on

the

to

a new

form.

The vertical tabulation operates in

as

the

form feed. The programmable disc controls

response

operation

of

the

Printer

to

is

used for rapid consecutive line-feeds

a recognized VT code. This

the

same manner

the

within a particular form.

The

VTFF

is

designed

a form if you should inadvertently press

rather

than

the

causes either vertical

indexing, depending

the

programmed disc. If

in

the

disc or

mechanism, a timer will

to

help prevent mis-indexing of

FF key. Recognition

tabulation

on

which hole appears next

there

are no holes punched

there

is

a malfunction

stop

paper feeding within a

of

a VT code

or

form feed

in

the

the

VT

sensing

on

few seconds.

PROGRAMMING THE DISC

a. Mount

disc-key protrudes through

the

disc

on

the

punch so

the

disc key hole

that

the

(see Figure 3-7).

b.

By

rotating

line with

should coincide with

the

form

is

the

the

to

disc, set

VT

the

desired number

and FF holes. This number

the

line position where

be started.

in

SPLIT

PLATEN

The

Split Platen (Pin Feed) Printer configuration

{Figure 3-9)

SR,

RO

is

capable

is

available with

and ASR Printers. This Printer configuration

of

printing dissimilar information

separate, standard size forms by using

independently operated platens.

prints up

the

to

75

columns

right hand platen prints

PRINTER

the

TermiNet

The

on

8 1 /2-inch wide paper and

up

to

300

left hand platen

26 columns on 3

on

KSR,

two

two

1 /2-i nch wide paper. Each platen has its own

independently-operated manual paper advance knob,

paper supply and paper

When

the

LINE

Split Platen Printer

or

LOCAL mode,

energized first while

out

sensor.

is

first placed

the

left hand platen

the

right hand platen remains

in

ON

idle.

In

this mode, when

only

the

recognition

local

left hand form will advance. Upon

of

or

remote source),

deactivated and

energized; linefeed will now advance

. form only. To return

the

Printer must recognize

ESC

4.

All

option

normal Printer operations and standard

functions (except Backspace

below) remain operable

the

linefeed {LF) key

the

character sequence ESC 3 {from

the

the

left hand platen will be

right hand platen

to

left hand platen operation,

the

character sequence

the

is

right hand

{BS),

in

conjunction with

pressed,

will

as

noted

the

Split

Platen Printer configuration.

is

be

c. Press

in

the

the

disc

punch

in

in

the

line with

FF hole

the

position.

d. Rotate

position where

the

disc and punch a hole

the

form

is

to

stop.

OPERATING THE VTFF OPTION

a. Press a pre-punched disc over

the

disc wheel until it can be rotated (see

Figure 3-8). Rotate

the

wheel protrudes

b. Press

c. Using

the

on

RO

or SR Printer).

to

the

first line position

the

first line

characters

ready

to

print.

FF key (or FORM FEED

Platen Knob, advance

to

on

be printed

the

disc until

through

The

that

is

under

the

fingers. The Printer

to

punch

a hole

desired numbered

at

have a vertical

the

the

each VT

tab

keyed

hub

of

the

key on

disc keyhole.

pushbutton

Printer will line feed

is

to

be printed.

the

form so

the

the

embossed

is

now

Pressing

first

current

provides a

hand platen. THEREFORE,

PLATEN

BACKSPACING FUNCTION

Whenever

again {or whenever power

hand platen

print

column

the

BS

key moves

position

on

location. This use

method

to

the

the

print

right platen regardless of

of

the

automatically

ON

PRINTER,

the

Printer

is

automatically energized when power

is

turned

THE

NORMAL

IS

NOT OPERABLE.

off

is

interrupted),

position

BS

character

tab

to

the

THE SPLIT

briefly,

then

the

to

right

the

BS

on

left

restored, regardless of which platen was energized

previously.

On Printers employing

Feed (VTFF) option,

the

Vertical Tab and Form

the

VTFF controls the left

hand platen only.

is

3-10

Page 33

GEK-36150

Operation

PROGRAMMABLE

Of

SC

DISC

PUNCH

OVT-3002

Figure 3-6. Programmable Disc and Disc Punch

OVT-3001

Figure 3-7. Programmable Disc On

Disc Punch

(11

11

Form)

OVT-3000

Figure 3-8. Programmed Disc

Mounting

3-11

Page 34

Operation

GEK-36150

OSP-4013

Figure

3-9.

Split Platen Printer

3-12

Page 35

GEK-36150

Options and Accessories

SECTION 4

OPTIONS

This section gives a brief description

common Printer options.

are technical

the

application specialist. Consult your local specialist

if

you should have questions on these options.

in

nature, and are written primarily for

ANSWER BACK

When the HERE

control

message, up

transmitted.

code

to

The

ENO

20

message

Some of

IS

pushbutton

is

received, an answerback

characters,

can-

be changed by

local serviceman.

AUTOMATIC ANSWERBACK

Similar

except when

automatically

to

the

answerback

the

print

Printer

(if

the

option

is

called,

motor

its answerback message.

AUTOMATIC CARRIAGE RETURN

Any character which causes

advance beyond

converted

to

print position

the

a carriage return

to

automatically return

the

last print position will be

The character causing this carriage return

of

the

the

descriptions

is

pressed

is

printed and

described above

the

Printer will

is

on) and transmit

column

code

count

and cause

to

column one:

will be lost.

more

or

your

AND

the

to

the

ACCESSORIES

The

following functions

1. Line

codes

of

the

control codes cause this function:

ACK

NAK

ETX (by making a

not

EOT (optional,

EQT may be used

2. Wait before transmit:

Control

ENO exchange.

3. Mandatory Disconnect - Forced Disconnect

when Printer recognizes D

LINE CONTROL

take

place with this option:

Control - Printer recognizes control

to

make a line change (change

data

set

lead CA).

jumper

change, ETX will

The

the

state

following

cause a line change).

by

making a jumper change.

also

to

make a line change).

"READY"

lamp by DLE?

LE-EOT.

AUTOMATIC MOTOR CONTROL

It allows use of

Send)

to

control

the

interface circuit