Page 1

ÿ

GE Power Management

Digital Breaker Failure Protection

Digital Breaker Failure Protection

Digital Breaker Failure ProtectionDigital Breaker Failure Protection

DBF

Instructions

Instructions

InstructionsInstructions

GEK 106168E

GEK 106168E

GEK 106168E GEK 106168E

Page 2

*(3RZHU0DQDJHPHQW

$Q\WKLQJ\RXFDQ·WILQG"

$Q\WKLQJQRWFOHDUHQRXJK"

,) <28 +$9( $1< &200(17 21 7+( &217(176 2) 7+(

35(6(17 0$18$/ .,1'/< )$; 86 $ &23< 2) 7+,6 3$*(

72*(7+(5 :,7+ $ &23< 2) 7+( 3$*( :+(5( <28 +$9(

)281' 7+( 352%/(0 72 7+( )$;180%(5

),//,1*,17+(48(67,21$,5(%(/2::(:,//%(+$33<72

62/9( <285 '28%76 $1' :( 7+$1. <28 )25 +(/3,1* 86

,03529(7+,60$18$/

&RPSDQ\

1DPH

$GGUHVV

3KRQH

(PDLO

'HVFULSWLRQRI\RXUTXHVWLRQRUVXJJHVWLRQ

0DQXDO*(.FRGH

)D[

Page 3

Page 4

TABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

1. GENERAL DESCRIPTION AND APPLICATION........................................................................................... 1

1.1. GENERAL DESCRIPTION................................................................................................................................. 1

2. OPERATION LOGIC...................................................................................................................................... 3

2.1. PROTECTION FUNCTIONS.............................................................................................................................. 3

2.1.1. Overcurrent units.......................................................................................................................................... 3

2.2. MONITORING AND RECORDING FUNCTIONS.............................................................................................. 5

2.2.1 Measurement............................................................................................................................................... 5

2.2.2 Associated Breaker Status........................................................................................................................... 5

2.2.3 Target Lamps ............................................................................................................................................... 5

2.2.4 Circuit Breaker Breaking Capacity Monitoring ............................................................................................. 9

2.2.5 Built-in Self-Checking Unit.......................................................................................................................... 10

2.3. ANALYSIS FUNCTIONS......................................................................................................................................... 10

2.3.1 Event Recorder........................................................................................................................................... 10

2.3.1 Oscillography .............................................................................................................................................. 10

2.4. CONTROL.......................................................................................................................................................... 12

2.4.1 Tables of Settings ...................................................................................................................................... 12

2.4.2 Time Synchronization.................................................................................................................................. 13

2.4.3 Configurable Inputs and Outputs ............................................................................................................... 13

2.5. MAN-MACHINE INTERFACE (HMI)........................................................................................................................ 15

EMOTE COMMUNICATIONS................................................................................................................................16

2.6. R

3. SETTINGS.................................................................................................................................................... 17

4. TECHNICAL CHARACTERISTICS.............................................................................................................. 21

4.1. M

4.2. TECHNICAL CHARACTERISTICS ............................................................................................................................ 22

5. HARDWARE DESCRIPTION....................................................................................................................... 25

5.1. P

5.2. OPERATING THEORY.......................................................................................................................................... 27

6. ACCEPTANCE TESTS................................................................................................................................. 29

6.1. C

6.2. V

6.3. P

6.4. R

6.5. I

6.6. P

6.7. C

6.8. I

6.9. FUNCTIONS......................................................................................................................................................... 33

ODEL LIST....................................................................................................................................................... 21

4.1.1. Special Models........................................................................................................................................... 21

HYSICAL DESCRIPTION..................................................................................................................................... 25

5.1.1. Case.......................................................................................................................................................... 25

5.1.2. Electrical Connections............................................................................................................................... 25

5.1.3. Internal Construction................................................................................................................................. 25

5.2.1. Magnetic Module....................................................................................................................................... 27

5.2.2. CPU Board................................................................................................................................................ 27

5.2.3 Power Supply ............................................................................................................................................. 28

5.2.4 Keyboard and Display................................................................................................................................ 28

ONNECTIONS AND NECESSARY EQUIPMENT...................................................................................................... 29

ISUAL INSPECTION ........................................................................................................................................... 29

ANEL INSULATION TESTS.................................................................................................................................. 29

ELAY SETTING................................................................................................................................................. 30

NDICATORS........................................................................................................................................................ 30

OWER SUPPLY................................................................................................................................................. 30

OMMUNICATIONS .............................................................................................................................................. 31

NPUTS............................................................................................................................................................... 32

6.8.1 Digital inputs................................................................................................................................................ 32

6.8.2 IRIG-B Synchronizing Input........................................................................................................................ 32

6.9.1 50BF 1P Unit Test...................................................................................................................................... 33

6.9.2 50BF 3P Unit Test...................................................................................................................................... 34

6.9.3 Internal Arc Test......................................................................................................................................... 35

6.9.4 3P NO I FUNCTION.................................................................................................................................... 35

GEK-106168E DBF Breaker Failure Protection i

Page 5

TABLE OF CONTENTS

6.9.5 Neutral Overcurrent Unit Test.....................................................................................................................35

6.10. RELAY MEASUREMENT TESTS ...........................................................................................................................37

6.10.1. Current Measurement..............................................................................................................................37

6.10.2. Timing Measurement...............................................................................................................................37

7. INSTALLATION AND MAINTENANCE........................................................................................................39

7.1. I

NSTALLATION.....................................................................................................................................................39

ONNECTION-TO-GROUND AND DISTURBANCES SUPPRESSION............................................................................39

7.2. C

7.3. M

AINTENANCE....................................................................................................................................................39

8. KEYBOARD AND DISPLAY........................................................................................................................41

8.1. M

8.2. S

8.3. I

8.4. C

8.5. S

8.6. C

ENU TREE. ......................................................................................................................................................42

ETTINGS GROUP (SET KEY) ..............................................................................................................................43

NFORMATION GROUP (INF KEY)..........................................................................................................................46

ONTROL GROUP (ACT KEY) .............................................................................................................................47

INGLE KEY MENU .............................................................................................................................................48

ONFIGURATION MENU.......................................................................................................................................49

FIGURES .................................................................................................................................................................51

ii DBF Breaker Failure Protection GEK-106168E

Page 6

LIST OF FIGURES

LIST OF FIGURES

Figure 1. Breaker Failure Logic (189C4114 Sheet 2)

Figure 2. External Connections (189C4114 Sheet 1)

Figure 3. Front View (226B7412 Sheet 9)

Figure 4. Rear View (226B7412 Sheet 10)

Figure 5. Dimensions Diagram (226B6086 sheet 10)

Figure 6. Panel drilling (226B6086H10)

Figure 7. RS232 Connection (DBF relay to PC)

Figure 8. RS232 Connection (DBF relay to MODEM)

GEK-106168E DBF Breaker Failure Protection iii

Page 7

LIST OF FIGURES

iv DBF Breaker Failure Protection GEK-106168E

Page 8

1. GENERAL DESCRIPTION AND APPLICATION

1.

1. GENERAL DESCRIPTION AND APPLICATION

1. 1.

GENERAL DESCRIPTION AND APPLICATION

GENERAL DESCRIPTION AND APPLICATIONGENERAL DESCRIPTION AND APPLICATION

1.1. GENERAL DESCRIPTION

The DBF system is a microprocessor based breaker failure protection, control and measurement unit that has

different algorithms to allow its use on a wide range of applications in power systems.

The functions and information management of the unit can be performed remotely (computer connected to the

serial port RS232, fiber-optic or modem) or locally using the man-machine interface (HMI), which includes a 20

keys keypad, and a two line liquid crystal display (LCD) on the front of the relay.

The system provides the following functions:

a) Protection

• Low current level breaker failure protection, following a single or three phases initiation, with up to

two time delayed steps.

• High current level breaker failure protection, following a two/three (selectable by setting) phases

initiation.

• No current breaker failure protection, following a two/three (selectable by setting) phases initiation.

• Breaker internal arc detection.

b) Monitoring

• Current measurements for each phase and ground.

• Breaker status

• 16 fully configurable LED indicators

• One fixed relay status LED

• Breaker health monitoring (ΣI2t).

• Built-in self-check functions.

c) Analysis:

• Event recorder

• Oscillography

d) Control:

• 3 settings’ tables

• Time synchronization using the communications program, the IRIG-B input or the HMI (keypad and

display).

• Configurable inputs and outputs.

• User can build logic schemes using AND, OR and NOT gates and the internal digital signals of the

relay.

GEK-106168E DBF Breaker Failure Protection 1

Page 9

1. GENERAL DESCRIPTION AND APPLICATION

e) Communication Interfaces

• Remote communications through three communication ports, one on the front of the relay and two

located on the rear.

• Human machine interface (HMI) consisting of 20 keys keypad and alphanumerical LCD (16

characters x 2 lines).

• Windows based GE-INTRO configuration software (for inputs, outputs, LEDs configuration) and

GE-LOCAL communications software (for relay monitoring, settings change, stored data retrieve, etc).

Both are part of the GE-NESIS software package (General Electric Network Substation Integrated

System).

2 DBF Breaker Failure Protection GEK-106168E

Page 10

2. OPERATION LOGIC

2.

2. OPERATION

2. 2.

(See f igur e 1 at the end of the Ins truc tion Manual)

OPERATION LOGIC

OPERATION OPERATION

LOGIC

LOGICLOGIC

2.1. PROTECTION FUNCTIONS

2.1.1. OVERCURRENT UNIT S

The DBF system incorporates the following overcurrent detectors:

• Three Single Phase Low-Level Overcur rent Detector s

(Used by the 50BF 1P function.)

• Three Single Phase High- Level Overcur rent Detector s.

(Used by the 50BF 3P function.)

• One G r ound Overcur rent Detector .

(Used by the 3P No I function.)

• Three Single-Phase current detectors for the internal arc function.

Low-Level Overcurrent Breaker Failure Unit – 50BF 1P

The breaker failure operation is star ted by detecting any single phase above a setpoint threshold (PH Lo-Set

Pickup setting), ANDed with a tripping signal (break er failure initiate signal) issued by the main feeder protection.

These breaker f ailure initiation signals can be s ingle-phas e or three-phase type at OR1, OR2 and OR3. There are

four digital signals available (50BF Initiate A, 50BF Initiate B

any digital input (contact converter). The factory digital input conf igur ation is the following (as shown in f igur e 1):

Digital Signal Input # Terminals

50BF Initiate A Input #1 C9 – D10

50BF Initiate B Input #2 D9 – D10

50BF Initiate C Input #3 C10 – D10

3P BF Initiate Input #7 E7 – E8

The AND1, AND2 and AND3 gates thus fully armed m ay perform (depending on settings) one or two time delayed

tripping steps. Use 50BF_1P setting ( permitted/Not permitted) and number of output stages (N. of Output

Stages) setting to enable this f unc tion and to set the number of steps. Timers T1 and T2nd control t he timing of

the f ir s t and second step respec tively (1_Phase T imer T 1 and 2nd Stage Timer settings).

If the tr ipping signal is three-pole type (digital input E7-E8 for the default factor y configuration), the s ignal will be

placed at the same time in OR1, OR2 and OR3 and then to AND1, AND2 and AND3.

High-Level Overcurrent Breaker Failure Unit – 50BF 3P

, 50BF Initiate C and 3P BF Initiate) assignable to

This func tion operates if high-Level overc urr ent is detected on 2 phases (or 3 phases if se tting BF Logic (3P/2P)

is set to 3P) and if 2 break er failure initiation inputs are energized (or j us t the 3P BF Initiate input, if Severe Fault

3P setting is set to permitted) .

The starting of this function is similar to the 50BF 1P, but in this case the current level setting range is higher (PH

Hi-Set Pickup s etting) and the output is controlled by the energization of two single pole initiation signals. This

function can also operate ener gizing the 3P BF Initiate signal, if Severe Fault 3P setting is set to ‘permitted’.

Other diff er enc e with res pect to the 50BF 1P f unc tion, is that the current in all the three phases must exceed the

setpoint, or at least one pair of phases. This is selected with BF Logic (3P/2P) setting. In the first case (BF Logic

(3P/2P) s et to 3P) the signal should progress through AND11 and AND12. If BF Logic (3P/2P) issetto2P,then

the signal will go through AND8, AND9 or AND10 and then AND13. The outputs of AND12 or AND13 ar e sent via

GEK-106168E DBF Breaker Failure Protection 3

Page 11

2. OPERATION LOGIC

OR5 to the bottom input of AND4. Any pair of single BF initiation signals placed at AND5, AND6,orAND7 will

activate the top input of AND4. This input to AND4 can also be ON if there is a 3P BF Initiation and Severe Fault

3P setting is set to ‘permitted’.

Ground Overcurrent Breaker Failure Unit.

The breaker failure action based in this ground overcurrent function basically performs an additional breaker

failure function through AND19, when the 3P BF Initiate (or 2 Single Pole BF Initiate, if Low Load 2P

set to ‘permitted’) is present at OR10 and a ground current higher than Neutral Pickup setting is detected.

Breaker Failure without current (or very low current).

DBF includes internal logic to cover also no-current, or very low fault current BF applications. This function will

issue an output if the 3P BF Initiate input is energized (or 2 Single Pole BF Initiate, if Low Load 2P

to ‘permitted’), and at least one pole of the circuit breaker is still closed.

Breaker Arc Detection Device.

This function may close one output of the relay when it detects that: the circuit breaker is open and some amount

of current is present in any phase. There are two settings available for this function: ‘Internal Arc Pickup’toset

the current threshold and ‘Internal Arc Timer’ to coordinate the operation time of the unit with the time it takes for

the breaker and auxiliary elements to open.

setting is

setting is set

If the circuit breaker is open, then the 52/b contacts will energize the digital inputs corresponding to the circuit

breaker status (terminals C11-D12, D11-D12 and C12-D12 for the factory default configuration), and then the

upper input of AND16, AND17 and AND18. The other input will be energized if the DBF detects a current higher

than Internal Arc Pickup setting. The outputs of these AND gates are sent to OR8 and then to timer T4 (Internal

Arc Timer setting) to complete the arc detection function, this will close the auxiliary relay D2-C2 (according to the

factory default output configuration).

Reset of Latching Relays

The DBF breaker failure protection may be ordered with an expansion board, which includes two latching relays

that are operated in different ways depending on the number of steps selected (for additional reference see Figure

1), and will fix the tripping output once the breaker failure function has operated. A digital input through F11-F12

(factory default inputs configuration) (pulse signal, not sustained) resets these latching relays to its steady-state

position.

4 DBF Breaker Failure Protection GEK-106168E

Page 12

2. OPERATION LOGIC

2.2. MONITORING AND RECORDING FUNCTIONS

2.2.1 MEASUREMENT

The DBF system provides the continuous measurement of phase and ground current values.

These measurements can be accessed directly on the liquid crystal display (HMI) on the front of the relay, or via

the GE-LOCAL communication software.

2.2.2 ASSOCIATED BREAKER STATUS

The DBF system monitors the associated breaker status through the digital inputs 52/b (or 52/a), and it is

displayed on the local HMI or through the communications software.

2.2.3 TARGET LAMPS

The DBF incorporates 17 LED target lamps, one fixed LED (two colors) assigned to the system ready function,

and 16 user configurable red LEDs. These configurable LEDs are arranged in two columns of 8 LEDs each. The

configuration is done using the GE-INTRO software, and it consists on assigning an internal event (or an AND

gate of internal events) to an LED. The LED can be configured to have memory (if Vdc is removed or the event

causing the operation of the LED gets deactivated) or not and to blink or to be steady. The internal events must

be previously defined using the internal signals of the relay. It is possible to use AND, OR and NOT logic gates to

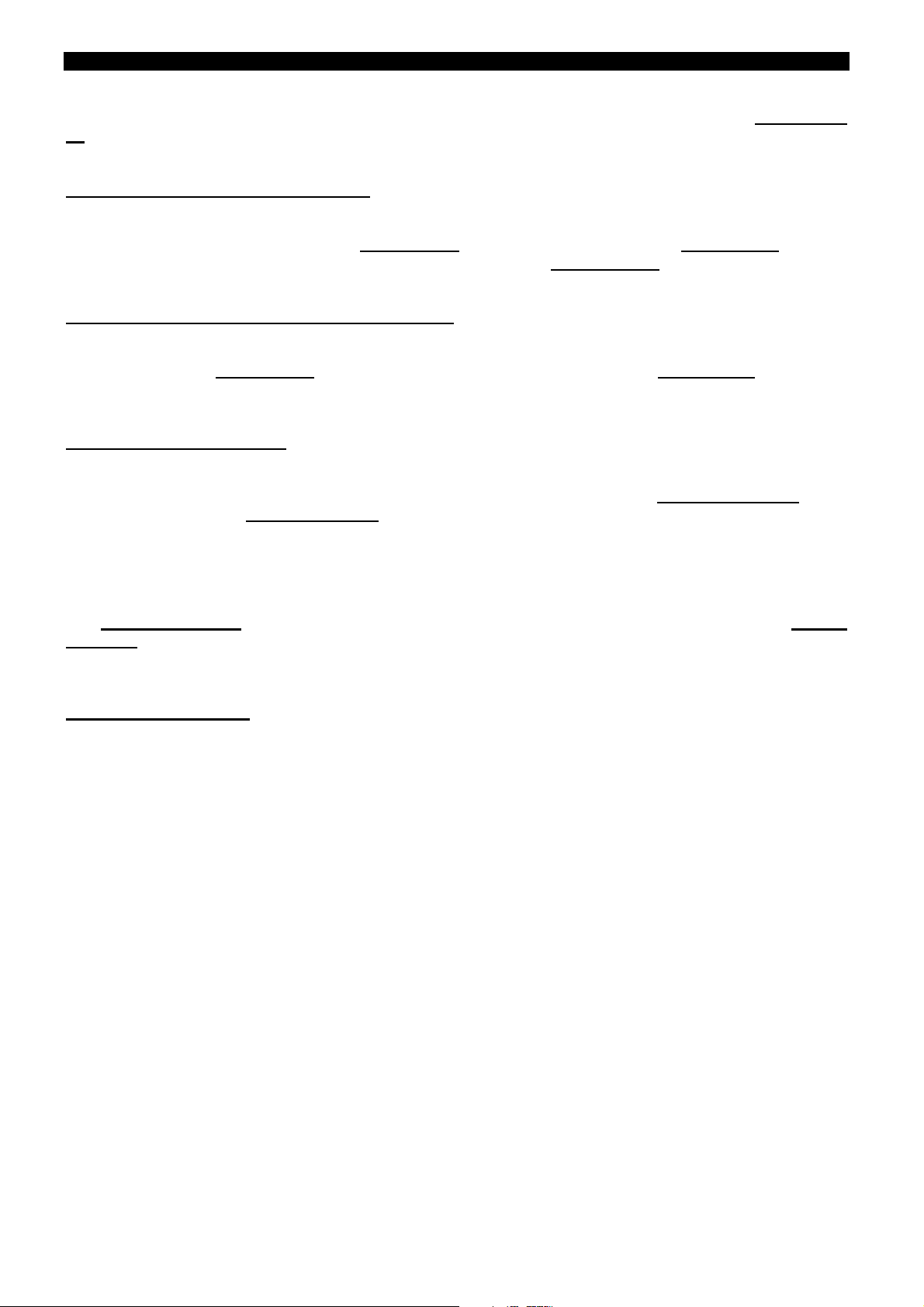

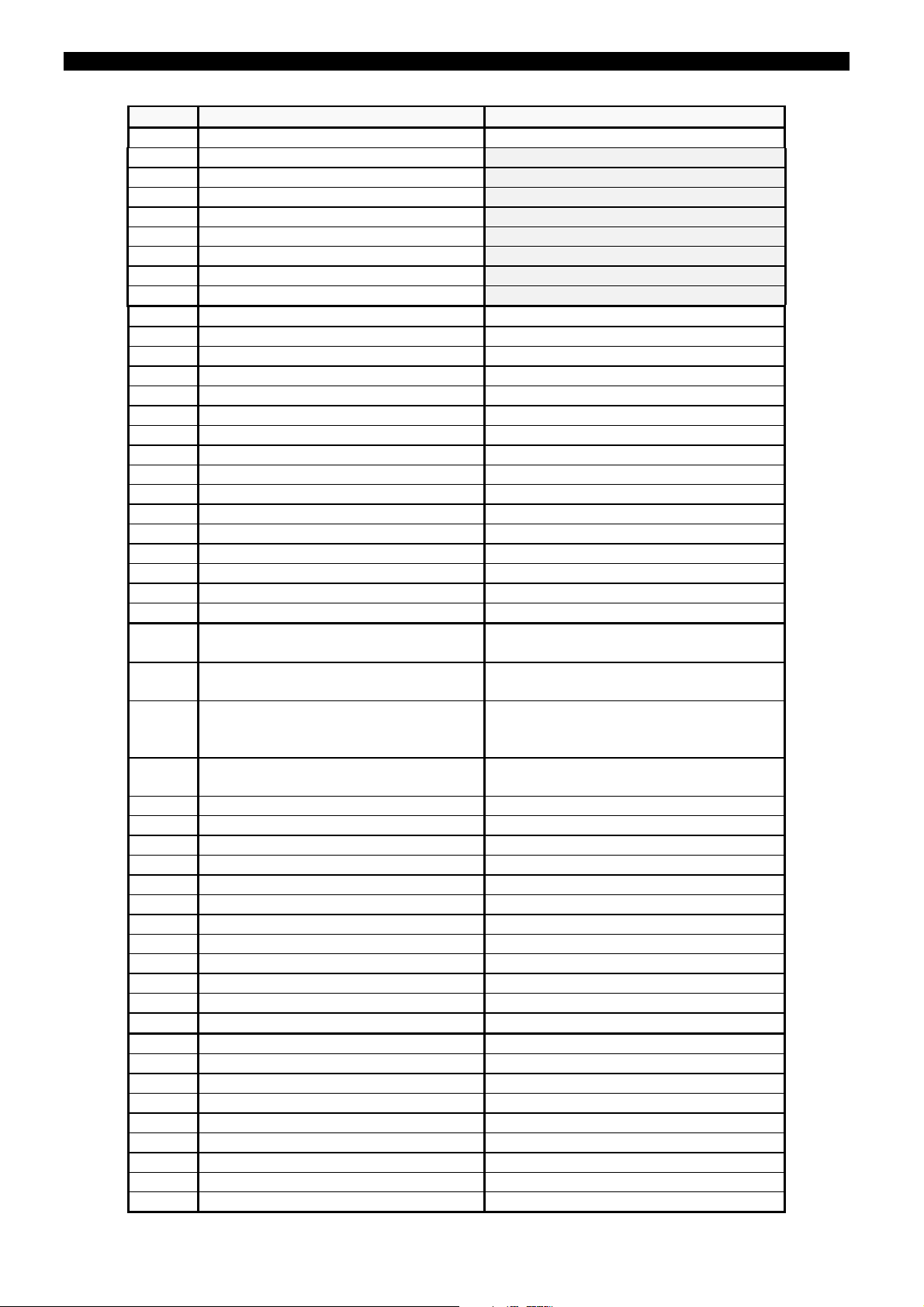

define these events. The available internal signals are listed in the following table.

The TARGET RESET button allows testing all target lamps if it is pushed for a short time (lighting up all of them),

or resets the sealed-in targets if it remains pressed for three seconds or more.

Please refer to GE_INTRO (configuration software) Instruction book (GEK-105594) for further information.

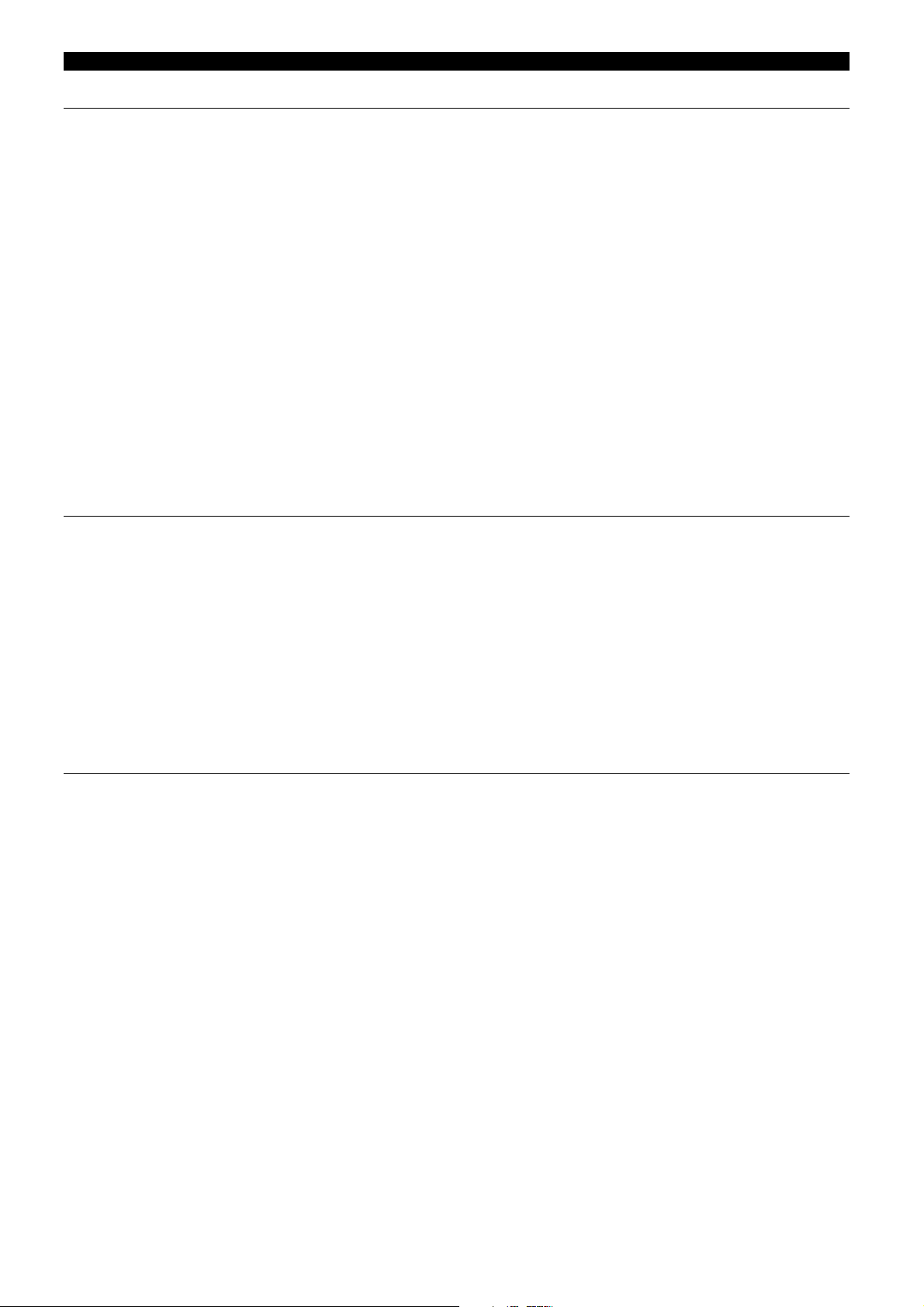

INTERNAL PROTECTION STATUS SIGNALS

Group Status Comment

1.0 Program Initiate Relay starts running (Vdc just applied).

1.1 Settings change User changes any setting

1.2 Write Counters User sets a value for any counter

1.3 Configuration Change User changes relay configuration

1.4 External Trigger Oscillography triggered by Dig. Input

1.5 Communications Trigger Osc. triggered by HMI or GE_LOCAL

1.6 Reset Operation Latched Relays Reset received

1.7

1.8

1.9

1.10

1.11

1.12

1.13

1.14

1.15

2.0 Input Nº 1 Digital Input #1 Status

2.1 Input Nº 2 Digital Input #2 Status

2.2 Input Nº 3 Digital Input #3 Status

2.3 Input Nº 4 Digital Input #4 Status

2.4 Input Nº 5 Digital Input #5 Status

2.5 Input Nº 6 Digital Input #6 Status

2.6

GEK-106168E DBF Breaker Failure Protection 5

Page 13

2. OPERATION LOGIC

Group Status Comment

2.7 Optional Exp. Board

2.8 Input Nº 7 Digital Input #7 Status

2.9 Input Nº 8 Digital Input #8 Status

2.10 Input Nº 9 Digital Input #9 Status

2.11 Input Nº 10 Digital Input #10 Status

2.12 Input Nº 11 Digital Input #11 Status

2.13 Input Nº 12 Digital Input #12 Status

2.14 Input Nº 13 Digital Input #13 Status

2.15 Input Nº 14 Digital Input #14 Status

3.0 Breaker Failure Logic BF Logic = 3P

3.1 Hi-Set A Pickup Output of Hi-Set current detector ph A

3.2 Hi-Set B Pickup Output of Hi-Set current detector ph B

3.3 Hi-Set C Pickup Output of Hi-Set current detector ph C

3.4 50BF Pole A Initiate CC1 Dig. Input ON (default configuration)

3.5 50BF Pole B Initiate CC2 Dig. Input ON (default configuration)

3.6 50BF Pole C Initiate CC3 Dig. Input ON (default configuration)

3.7 Lo-Set A Pickup Output of Lo-Set current detector ph A

3.8 Lo-Set B Pickup Output of Lo-Set current detector ph B

3-9 Lo-Set C Pickup Output of Lo-Set current detector ph C

3.10 50BF 3 Phase Initiate CC7 Dig. Input ON (default configuration)

3.11 50BF Neutral Initiate Output of Neutral current detector

3.12 Internal Arc A Pickup Output of AND 16 in figure 1

3.13 Internal Arc B Pickup Output of AND 17 in figure 1

3.14 Internal Arc C Pickup Output of AND 18 in figure 1

3.15

4.0 Pickup

4.1 Trip 1

4.2 Trip 2

4.3 Internal Arc

4.4

4.5

4.6

4.7

4.8

4.9

4.10

4.11

4.12

4.13

4.14

4.15

5.0 Phase A Trip Output of Timer 1 phase A in figure 1

5.1 Phase B Trip Output of Timer 1 phase B in figure 1

5.2 Phase C Trip Output of Timer 1 phase C in figure 1

5.3 Three-Pole Trip with Current Output of Timer 2 in figure 1

5.4 Three-Pole Trip without Current Output of Timer 3 in figure 1

5.5 Second Stage Trip Output of AND 14 / 15 in figure 1

5.6

5.7

5.8

Any BF signal is activated. Output of OR

7infigure1

Any unit (except Internal Arc) has tripped.

Output of OR 6 in figure 1

Same as Trip 1 when 1 step is selected.

2ndstage when 2 steps are selected.

Output of AND 14 / 15 in figure 1

Trip from Internal Arc unit. Output of

Timer 4 in figure 1

6 DBF Breaker Failure Protection GEK-106168E

Page 14

2. OPERATION LOGIC

Group Status Comment

5.9

5.10

5.11

5.12

5.13

5.14

5.15

6.0

6.1 Parallel EEPROM Alarm Failure in parallel EEPROM

6.2 Serial EEPROM Alarm Failure in serial EEPROM

6.3 Out-of-Service Relay out of service

6.4 Default General Settings Relay with factory default settings

6.5 Default Table 1 Settings Table 1 with factory default settings

6.6 Default Table 2 Settings Table 2 with factory default settings

6.7 Default Table 3 Settings Table 3 with factory default settings

6.8

6.9

6.10

6.11 52 A Maintenance Alarm Accumulated I2t above limit for Phase A

6.12 52 B Maintenance Alarm Accumulated I2t above limit for Phase B

6.13 52 C Maintenance Alarm Accumulated I2t above limit for Phase C

6.14

6.15

7.0

7.1 Active Table 1 Setting Table #1 is the active Table

7.2 Active Table 2 Setting Table #2 is the active Table

7.3 Active Table 3 Setting Table #3 is the active Table

7.4

7.5

7.6 New Events There are new events stored in the DBF

7.7 Two Stages Set BF Logic set to 2 timed stages

7.8 Breaker Pole A Status CB Pole A Closed

7.9 Breaker Pole B Status CB Pole B Closed

7.10 Breaker Pole C Status CB Pole C Closed

7.11 Latching Relay 1 Status Optional Exp. Board: Latched#1

Closed

7.12 Latching Relay 2 Status Optional Exp.Boar: Latched#2 Closed

7.13

7.14

7.15

8.0

8.1

8.2

8.3

8.4

8.5

8.6

8.7

8.8

GEK-106168E DBF Breaker Failure Protection 7

Page 15

2. OPERATION LOGIC

Group Status Comment

8.9

8.10

8.11

8.12

8.13

8,14

8.15

9.0

9.1

9.2

9.3

9.4

9.5

9.6

9.7

9.8

9.9

9.10

9.11

9.12

9.13

9.14

9.15

10.0 AND1 Output of internal AND gate #1

10.1 AND2 Output of internal AND gate #2

10.2 AND3 Output of internal AND gate #3

10.3 AND4 Output of internal AND gate #4

10.4 AND5 Output of internal AND gate #5

10.5 AND6 Output of internal AND gate #6

10.6 AND7 Output of internal AND gate #7

10.7 AND8 Output of internal AND gate #8

10.8 AND9 Output of internal AND gate #9

10.9 AND10 Output of internal AND gate #10

10.10 AND11 Output of internal AND gate #11

10.11 AND12 Output of internal AND gate #12

10.12 AND13 Output of internal AND gate #13

10.13 AND14 Output of internal AND gate #14

10.14 AND15 Output of internal AND gate #15

10.15 AND16 Output of internal AND gate #16

INTERNAL COMMUNICATION STATUS SIGNALS

Group Status Comment

1.0 Remote/Local Mode Relay in remote mode

1.1 Rear Connection Rear communication port in use

1.2 Front Connection Front communication port in use

2.0 Date/Time alarm Synch. Signal not received in setting t Timeout

2.1 Serial EEPROM Alarm Failure in serial EEPROM

2.2 Comm. Settings Relay with factory default settings

2.3 Protection Link Status of internal comm. with protection CPU

2.4 IRIG_B Link Relay synchronized by IRIG_B

3.0 - 3.15

8 DBF Breaker Failure Protection GEK-106168E

Page 16

Group Status Comment

4.0 - 4.15

5.0 -5.15

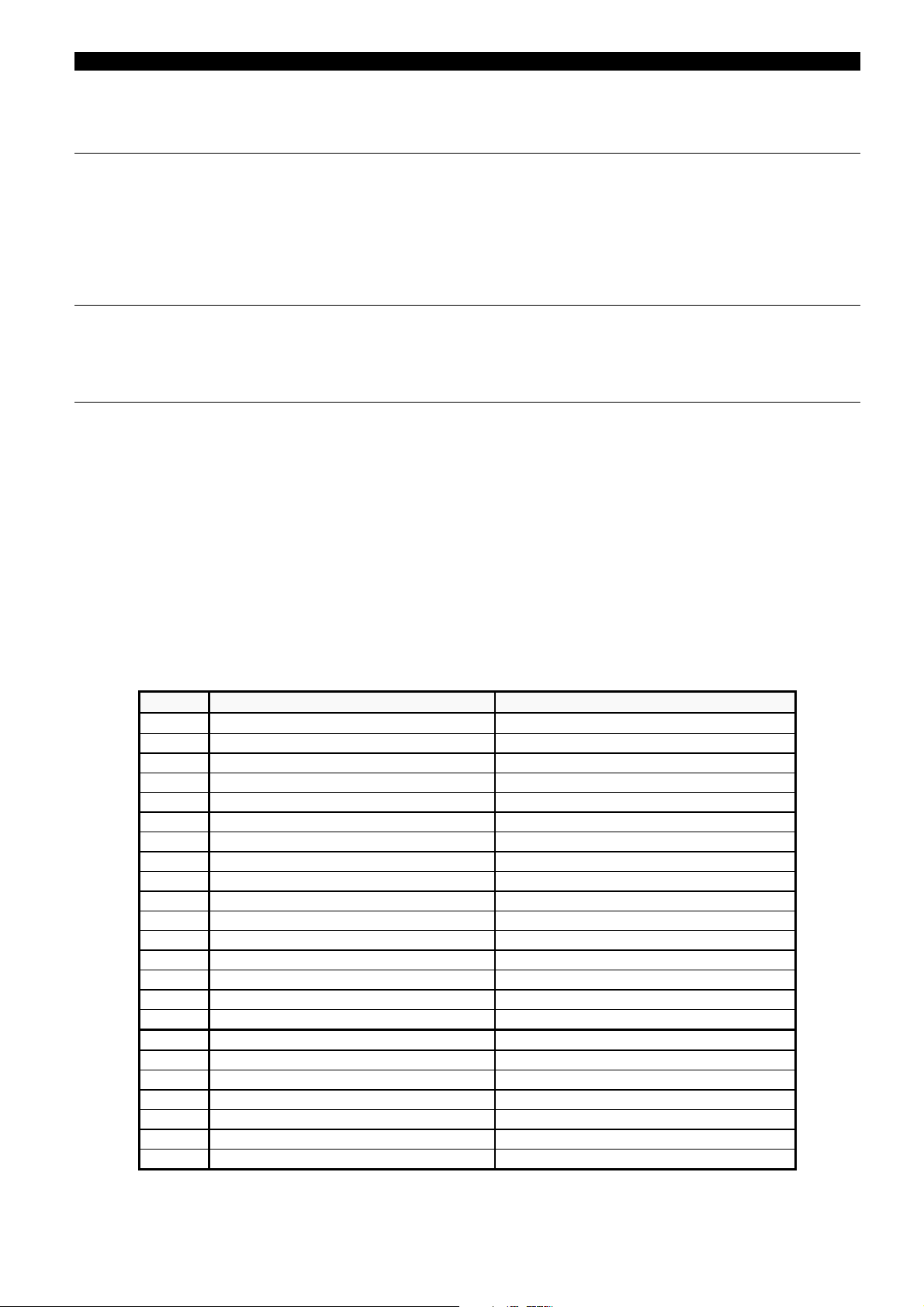

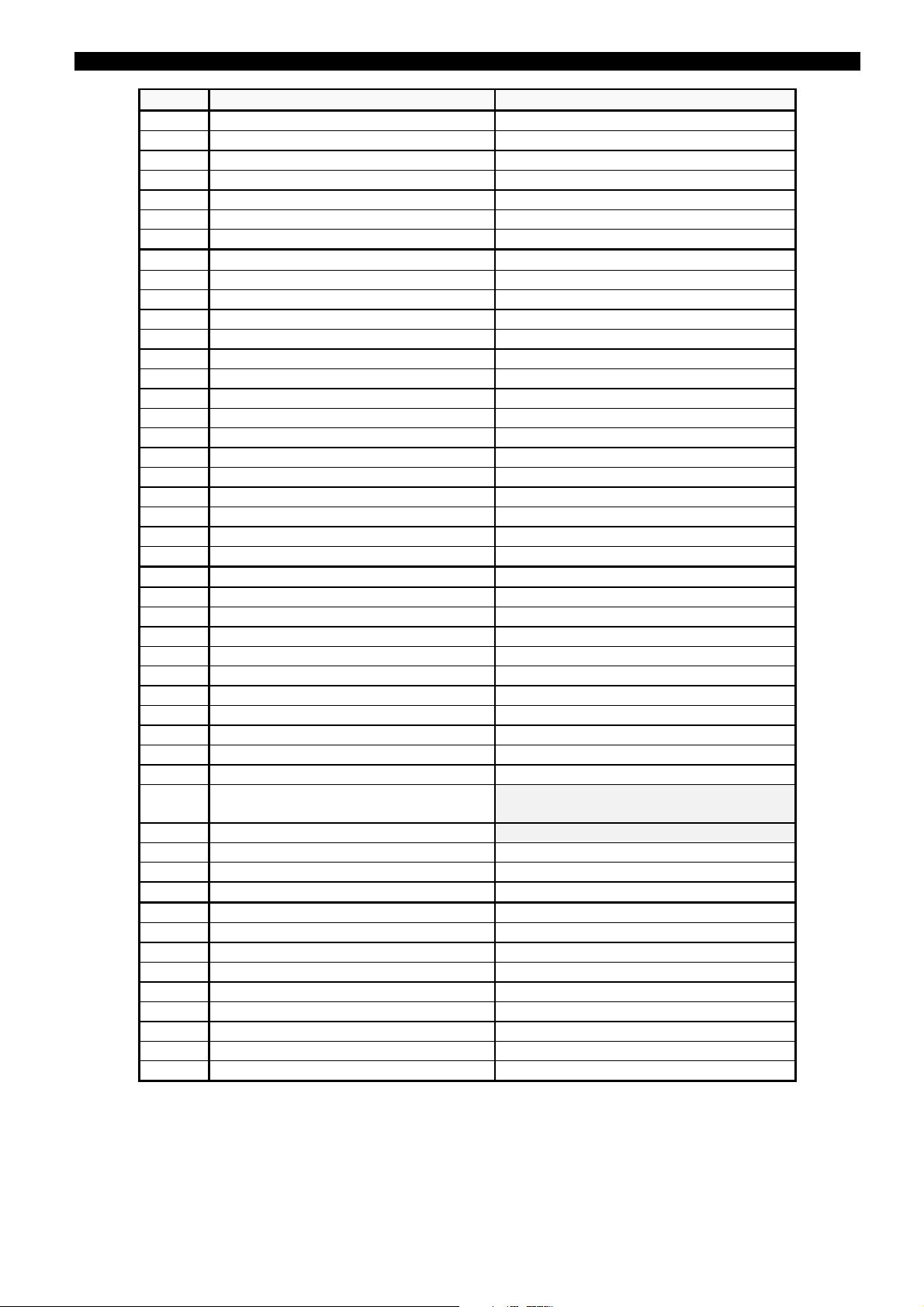

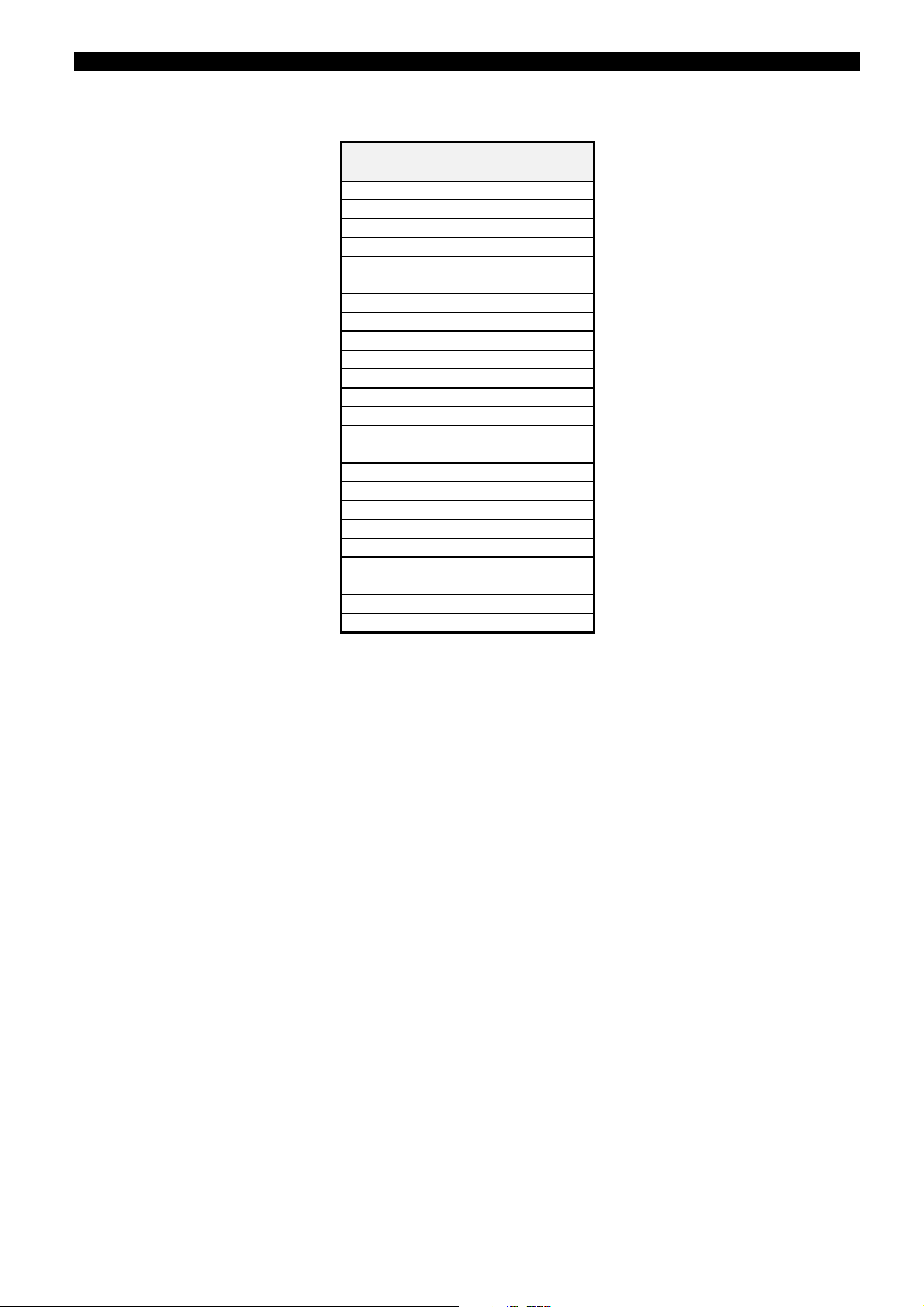

The DBF units are supplied with the following target LED’s default configuration:

2. OPERATION LOGIC

LED

LEFT COLUMN LED

RIGHT COLUMN

1 TRIP STAGE 1 9 LOW SET PICKUP

2 TRIPSTAGE2 10 50BFPOLEAINIT

3 PHASEATRIP 11 50BFPOLEBINIT

4 PHASEBTRIP 12 50BFPOLECINIT

5 PHASE C TRIP 13 INT. ARC A POLE

6 3PTRIPNOI 14 INT.ARCBPOLE

7 INT. ARC TRIP 15 INT. ARC C POLE

8 HIGH SET PICKUP 16 REMOTE COMMUNICATIONS

2.2.4 CIRCUIT BREAKER BREAKING CAPACITY MONITORING

To supervise the breaker health, the DBF system calculates and stores, for each operation, the accumulated

values of the square of the current multiplied by the opening time of the breaker (I

expressed in kA

The value I

2

sec.

2

t is accumulated and stored independently for each phase. These values can be accessed either by

2

t) on each phase. I2tis

the local HMI or by the GE-LOCAL communications software.

The function has an

Integration Time Selector

setting (kI2tOPMODE)whichcanbeusedtoassignafixed

opening time (given by another setting (kI2tINTTIME)). Otherwise the unit measures the time between the

tripping signal of the main feeder protection and the change of the status contacts of the circuit breaker (52/b).

The total

Breaking Current Limit

(kI2t LIMIT) setting fixes the maximum life breaking capability (it is recommended

to set this to the limit supplied by the manufacturer). When this threshold is reached in any phase, the system

may be configured to close an output, if the appropriate internal signal (52 A Maintenance Alarm, 52 B

Maintenance Alarm, 52 C Maintenance Alarm) is assigned to an output. In addition, the system also has a

counter for the tripping operations.

The purpose of these functions is to provide accurate data to perform the circuit breaker maintenance, based on

the actual breaking time and current values. Once this maintenance operation has been done, the values for both

2

t and number of opening operations, can be reset.

the I

In order to be able to take into account the history of the breaker, in the case where the breakers were already in

use before the installation of the relay, the system allows to set an initial value for the I

2

t and the number of the

previous breaking operations. Similarly, these values can be adjusted to a given value in order to take into account

operations carried out during protection testing.

GEK-106168E DBF Breaker Failure Protection 9

Page 17

2. OPERATION LOGIC

2.2.5 BUILT-IN SELF-CHECKING UNIT

The digital technology of the DBF system allows providing a built-in self-checking function which guarantees the

correct performance of the unit, and provides an external alarm in case of error detection.

Two built-in self-checking functions are performed, one when the unit is started up and the other during normal

operation. Internal tests are provided for power supply, program memory (ROM), working memory (RAM),

oscillography memory (RAM), and settings and calibration memory (EEPROM).

In addition, there is a hardware test for the Target LEDs, which lights them all up when the button TARGET

RESET is pressed. The sealed-in targets (latched) reset if the TARGET RESET button is kept pressed during

three seconds.

2.3. ANALYSIS FUNCTIONS.

The DBF system includes an event recorder and an oscillography waveform recorder with a resolution of 1 ms for

the first one, and 1 sample for the second one (1.04 ms at 60 Hz and 1.25 ms at 50 Hz). To avoid the loss of

date/time and oscillography records during any Vdc power failure, the unit is equipped with a capacitor, which

allows the information to be kept for at least 24 hours after power loss.

2.3.1 EVENT RECORDER.

The DBF system keeps a record of the last 144 events and stores for each one the following information: date and

time (accurate to one millisecond), the type of event, current RMS values during the event, and the state of the

unit (set of digital signals that describes the status of the relay at any given moment in time).

This event recorder is stored in a non-volatile memory and can be maintained indefinitely, even with no power

supply.

The list of events that the relay stores are factory fixed, and corresponds to standard relevant

situations/operations, like Settings Change, Program initiate, Active Table 1, Opening 52 phase C, Closing

52 phase C, Digital Input 1 Activated, etc.

2.3.1 OSCILLOGRAPHY

The DBF unit stores up to 4 oscillography records, with a resolution of 16 samples per cycle. Each record has a

maximum capacity of 66 cycles. The number of pre-fault cycles can be selected from 2 to 10 cycles. Each record

includes the following information:

• Date and time.

• Name of the signal that triggered the oscillography.

• Active settings table when recording

• Digital information (Status of internal digital signals)

• Instantaneous rms values of currents (I

A,IB,IC

and IN)

A configurable

mask

is available for selecting which functions or internal signals are able to trigger the

oscillography. It can either be triggered by a configurable digital input, by a command received from the

communication program (GE_LOCAL), or directly from the HMI.

10 DBF Breaker Failure Protection GEK-106168E

Page 18

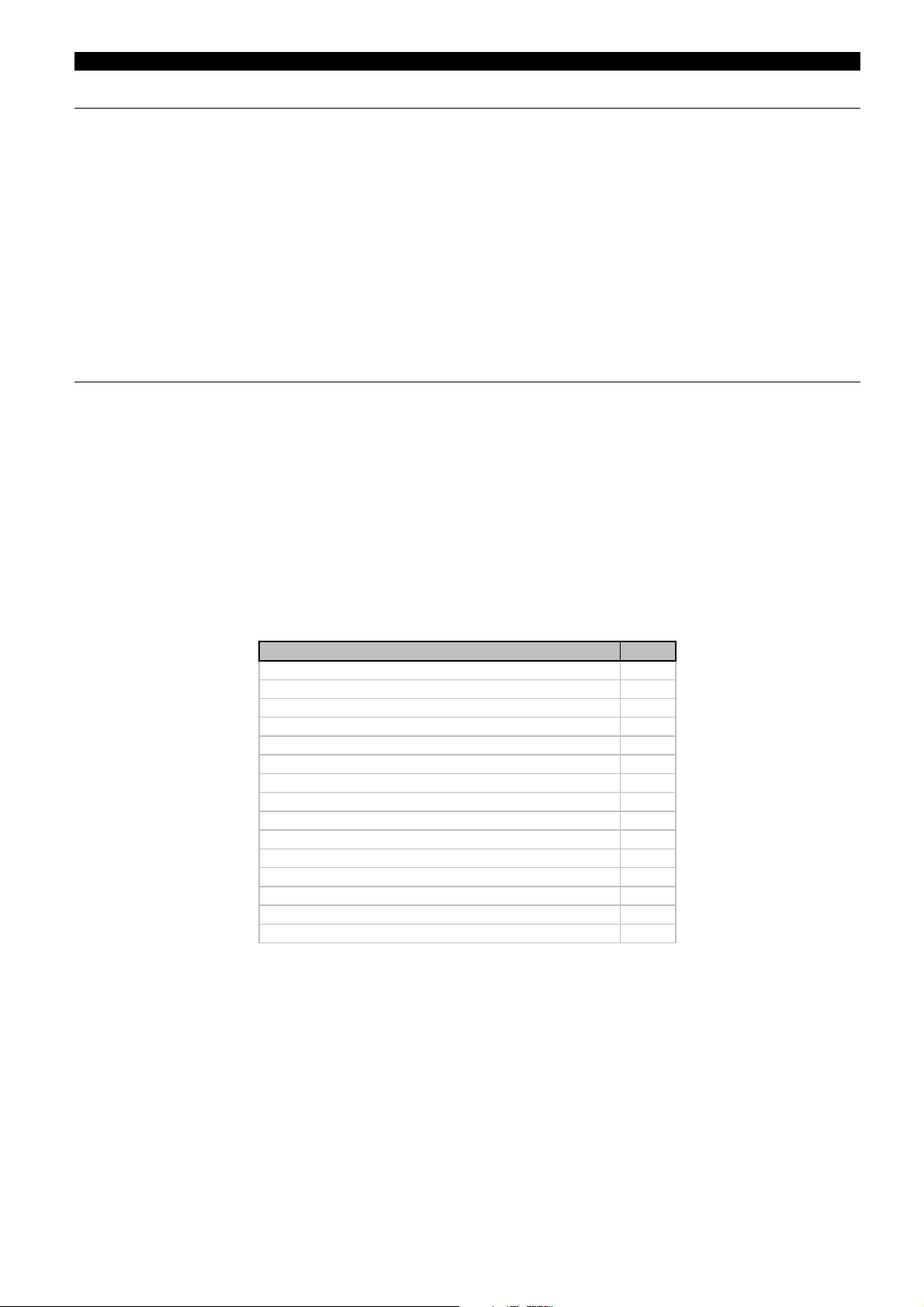

The user can select from the following list which signals may trigger the oscillography:

Events to Trigger the

Oscillography

PICKUP

1ST STAGE TRIP

2ND STAGE TRIP

INTERNAL ARC

50BF A TRIP

50BF B TRIP

50BF C TRIP

50BF 3P TRIP

EXTERNAL TRIGGER

COMM. TRIGGER

HI-SET A PICKUP

HI-SET B PICKUP

HI-SET C PICKUP

50BF A INIT

50BF B INIT

50BF C INIT

LO-SET A PICKUP

LO-SET B PICKUP

LO-SET C PICKUP

3 POLE 50BF INIT

NEUTRAL PICKUP

ARC A PICKUP

ARC B PICKUP

ARC C PICKUP

2. OPERATION LOGIC

The oscillography records are retrieved from the relay to the computer in COMTRADE international standard

format using the GE_LOCAL communications program. To draw the waveforms, digital flags, phasors and postfault analysis in general, it is suggested to use the GE_OSC oscillography program or any other that accepts

COMTRADE international format (IEEE-C37.111-1991). It is also possible to import the waveforms with

mathematical or spreadsheet programs (for example EXCEL

TM

).

GEK-106168E DBF Breaker Failure Protection 11

Page 19

2. OPERATION LOGIC

2.4. CONTROL

2.4.1 TABLES OF SETTINGS

The DBF system has two types of settings stored in non-volatile memory (information is kept even when there is

no auxiliary voltage):

• Generic Settings.

• Specific Settings.

The

Generic

settings are grouped as follows:

GENERAL SETTINGS

BREAKER SETTINGS

ACTIVE TABLE SETTINGS

OSCILLOGRAPHY MASK

FUNCTION PERMISSION

For the

grouped as follows:

Only one setting table is active at a given time, and this is the table used by the system to run the different

functions included in it.

There is an "ACTIVE TABLE" setting that determines the settings table that is active at a given moment.

The active settings table can be changed by means of up to 2 digital inputs, referred to as "ACTIVE TABLE

SELECT 0" and "ACTIVE TABLE SELECT 1" which allow up to 4 combinations from 0 to 3. To do this it is

necessary to configure (using GE-INTRO software) two inputs to have these meanings. For applications which

require less tables (up to 2) it is possible to use only one input.

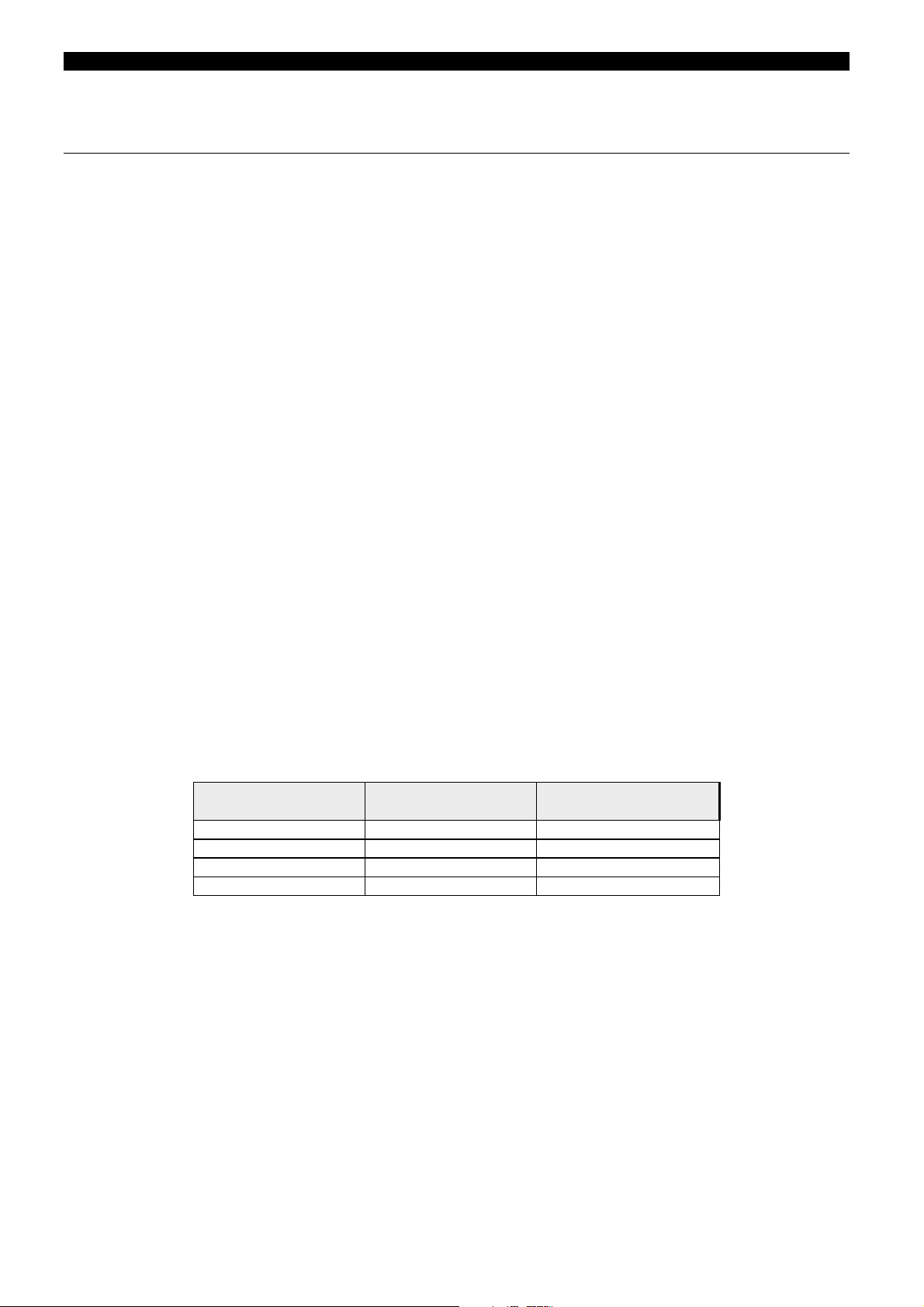

The selected combination is obtained from the binary coding of the 2 inputs mentioned (see following table). The

0-0 means selecting the table indicated in the "ACTIVE TABLE" setting, and numbers 0-1 to 1-1 select tables 1 to

3 respectively

specific

settings, the DBF allows to have up to 3 independent setting tables. These specific settings are

50BF SETTINGS

INTERNAL ARC SETTINGS

Table Selection

INPUT-1

0 0 Selected by setting

01 1

10 2

11 3

Table Selection

INPUT-0

Active Table

NOTE: if the inputs are programmed and used, energizing them, this selection has priority over the "ACTIVE

TABLE" setting and the table which is in fact used is determined by the status of the digital inputs.

12 DBF Breaker Failure Protection GEK-106168E

Page 20

2. OPERATION LOGIC

2.4.2 TIME SYNCHRONIZATION.

The DBF system includes an input for time synchronization. This input requires the connection of a device

to supply a demodulated IRIG-B output. In this way coordinated universal time is measured to a high degree of

accuracy and makes possible to tag events generated by the unit with a resolution of one millisecond.

The use of this input makes it possible to correlate data obtained from different units thanks to

synchronization with GPS satellites. In this way it is possible to obtain very useful information for analysis, crossreferencing the information provided by different units for a given incident.

Alternatively, it is possible to synchronize units by means of communications, using the GE-LOCAL

communications software, or manually by means of the HMI. If the IRIG-B input is used it has priority over time

setting by communications, since the time read by IRIG-B is much more accurate.

2.4.3 CONFIGURABLE INPUTS AND OUTPUTS

2.4.3.1 Digital Inputs

The DBF system has 6 digital inputs (two groups of 3 inputs with one common in each group). The inputs

can be configured by the user by means of the GE-INTRO configuration program. Using the optional expansion

board it is possible to increase the number of inputs up to a total of 14 (2 groups of 3 inputs with one common in

each group and 4 groups of 2 inputs with one common in each group). See the external connections diagram for

additional reference.

One of the following meanings can be assigned to any input: (For more detail about the configuration of the

inputs, see GE-INTRO Instruction Book).

Function P/L

Unused input

50BF Initiate A L

50BF Initiate B L

50BF Initiate C L

3P BF Initiate L

52a pole A L

52a pole B L

52a pole C L

52b pole A L

52b pole B L

52b pole C L

Latching Relays Reset P

External Trigger P

Active Table Select 0 L

Active Table Select 1 L

(L) indicates Level input

(P) indicates Pulse input

GEK-106168E DBF Breaker Failure Protection 13

Page 21

2. OPERATION LOGIC

2.4.3.2 O utputs

The basic DBF system has 10 outputs as follows:

• 2 tripping contacts (A12-B12 and C1-D1)

• 1 Breaker failure pickup signaling (A11-B11)

• 1 Internal arc detection (C2-D2)

• 1 Equipment alarm (C3-D3)

• 5 configurable contacts (C4-D4 to C8-D8)

The optional expansion board for the DBF provides 6 additional latched contacts (E1-F1 to E6-F6). This outputs

are not configurable and are assigned as follows:

• 3 tripping contacts (TRIP 1st Stage) (E1-F1 to E3-F3)

• 3 tripping contacts (TRIP 2nd Stage) (E4-F4 to E6-F6)

The configurable outputs can be programmed using logic based on the internal protection states (pick-ups, trips,

alarms, etc.). The DBF has 66 different internal states, and these can be used to carry out logical operations NOT,

AND and OR, which gives the unit a great flexibility.

The output configuration is done using different levels. At the first level it is possible to use AND gates of up to 16

signals. The output is incorporated into the states matrix so that it can then be used in other AND gates of up to 16

inputs. This process can continue until the 16 ANDs are used.

Once the AND gates have been configured it is possible to create a second level with OR gates of 16 inputs

limited to the established groups of bytes, and whose logical outputs are assigned to physical outputs of the unit.

This means that we can configure the physical outputs with any internal signal from the status or any combination

of them made by means of the AND logic gates.

14 DBF Breaker Failure Protection GEK-106168E

Page 22

2. OPERATION LOGIC

2.5. MAN-MACHINE INTERFACE (HMI)

The DBF system includes as standard a 20 key keyboard and a 2-line liquid crystal display (LCD) with 16

characters per line. This display has highly reliable LED diode back lighting (the screen brightness can be adjusted

on the rear of the front board).

By means of this interface the user can change the settings, display measurements, carry out operations

and access information stored in the unit. The functions of this local interface and how to use it are described in

the section KEYBOARD AND DISPLAY.

GEK-106168E DBF Breaker Failure Protection 15

Page 23

2. OPERATION LOGIC

2.6. REMOTE COMMUNICATIONS

The relay has 2 serial gates and three connectors. Gate 1 can be reached from the front of the relay in connector

1 (PORT 1 connector) or from the rear (PORT 2 connector). The second gate can be reached from connector 3

(PORT 3 connector) which is located on the rear.

There are different models, each with a different physical connection for the PORT 3 connector (RS-232/RS-485

or fiber-optic). In the "RS232" models the three connectors are RS232. In the "RS232 and fiber-optic" models the

PORT1 and PORT2 connectors are RS232 while the PORT3 connector is replaced by a fiber-optic connector.

The PORT 1 connector has priority over the PORT 2 connector and is selected when the DCD (Data Carrier

Detect) signal is activated. Figure 8 shows how to make the connections to a personal computer.

Gate 1 (PORT 1 and PORT 2 connectors) and 2 (PORT 3 connector) are independent and the unit can serve

them simultaneously.

The communications protocol is the same used for the rest of the GE digital protection systems and requires the

use of the GE-LOCAL software. PORT 3 protocol can be chosen between M-LINK and ModBus RTU. The

protocol is highly reliable and allows communication with different protection systems. It guarantees very efficient

data transfer (especially for the oscillography and other large files) along with error detection and automatic

communication recovery.

The status of the local/remote communication is indicated on the front of the unit by LED indicator 16 (the last LED

in the right-hand column, according to the default configuration.) Local communication refers to communication via

the keyboard/display (local display showing any information except for the initial DBF GENERAL ELECTRIC

screen), or via communications gate 1 (PORT 1, PORT2 connectors), and remote communication refers to

connection via gate 2 (PORT 3 rear connector).

Local and remote communications can exist at the same time, although there is only one possibility for changing

settings and carrying out operations, since this can only be done with the communication which has priority (local

communication) while the other is limited only to accessing information. When the local communication is

interrupted, either by the disconnection of PORT 1 connector or because the HMI is on the initial screen (a

situation which can be caused intentionally, or automatically if no key has been pressed for 15 minutes), the

remote communication recovers the ability to modify settings and carry out operations.

16 DBF Breaker Failure Protection GEK-106168E

Page 24

3. SETTINGS

3.

3. SETTINGS

3. 3.

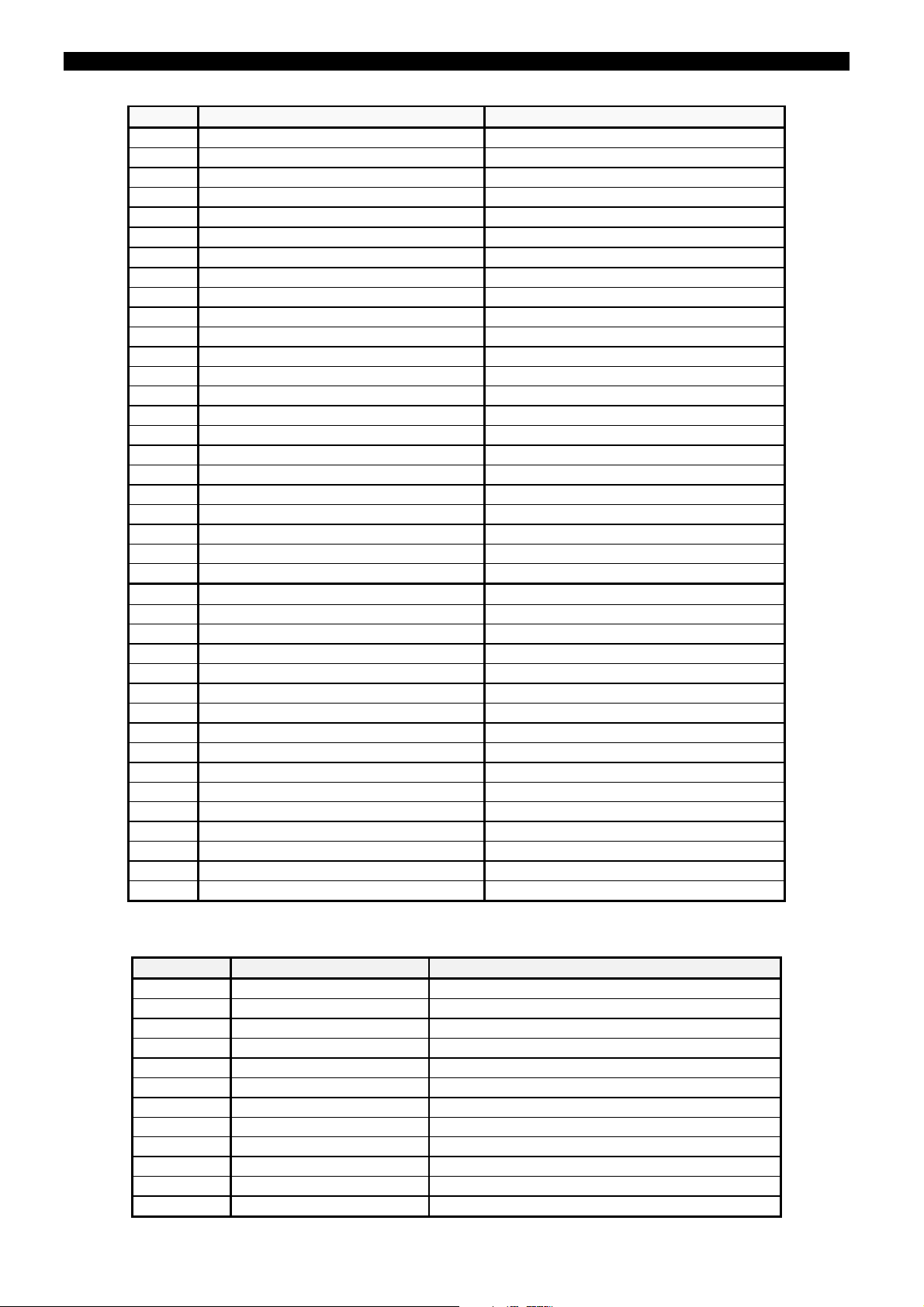

This section describes the settings of the DBF relay and the procedure to modify them. Table 3 shows the list of

DBF settings, their range and resolution, and the factory default settings.

To view or to modify settings using the GE_LOCAL program connected to PORT 1, PORT 2 or PORT 3 the user

has to perform the following steps:

• Check that the available connection cable is in accordance with the diagram in Figure 7.

Check correspondence between DB-9 connector in the cable with available connector at PC

port (could be DB-9 or DB-25)

• Connect the cable between the relay (or modem) and the serial port of your computer.

• Run the GE-LOCAL software. For more details on the installation and use of the GE-LOCAL

software see instruction book GEK-105568.

• Make sure that the communication parameters in GE_LOCAL match with those set on the

DBF. Specifically, the parameters on the configuration of the local HMI are:

SETTINGS

SETTINGSSETTINGS

COMMUNICATION SPEED

∗

through PORT 1 or PORT 2 (means LOCAL), or PORT 3 (means NET)

∗

STOP BIT

NET

To modify or view the DBF communication parameters refer to Chapter 8, Section 8.1 “Menu Tree”.

IMPORTANT: It should be noted that in order to simplify the setting of the unit and for safety reasons, all settings

related with the configuration of the unit (configurable inputs and outputs, internal status events and target LED’s)

have been removed from the HMI facilities and also from the communications software GE_LOCAL. To perform

these configurations the GE_INTRO software (described in instruction book GEK-105569) must be used.

Common to all tables Range Default Step

Relay status In/out of service In-service

Identification 20 ASCII characters No ID

Frequency 50 / 60 Hz 50 Hz

Phase CT Ratio 1-4000 1 1

Neutral CT Ratio 1-4000 1 1

: Stop-bit corresponding to each one of the communication ways: LOCAL or

TABLE 3. Settings Table

: On the relay depending on whether communication is:

General Settings Group

Breaker Setting Group

Breaker Number 4 ASCII characters 0000

kI2t Operation Mode Fixed-Measured Fixed

Integration Time for kI2t 0.03-0.25s 0.06s 0.01s

kI2t Maximum Limit 1-999999 99999 1

Active table setting group

Active setting table # 1 - 3 1 1

GEK-106168E DBF Breaker Failure Protection 17

Page 25

3. SETTINGS

Common to all tables Range Default Step

Oscillography Mask

Prefault Cycles 2-10 4 1

Arc Detection Enable-Disable Enable

Pickup Enable-Disable Enable

1stStage trip Enable-Disable Enable

2ndStage Trip Enable-Disable Enable

50BF A Trip Enable-Disable Enable

50BF B Trip Enable-Disable Enable

50BF C Trip Enable-Disable Enable

50BF 3P Trip Enable-Disable Enable

External Trigger Enable-Disable Enable

Communications Trigger Enable-Disable Enable

Hi-Set A Pickup Enable-Disable Enable

Hi-Set B Pickup Enable-Disable Enable

Hi-Set C Pickup Enable-Disable Enable

50BF A Init. Enable-Disable Enable

50BF B Init. Enable-Disable Enable

50BF C Init. Enable-Disable Enable

Lo-Set A Pickup Enable-Disable Enable

Lo-Set B Pickup Enable-Disable Enable

Lo-Set C Pickup Enable-Disable Enable

3P 50BF Init. Enable-Disable Enable

Neutral Pickup Enable-Disable Enable

Arc A Pickup Enable-Disable Enable

Arc B Pickup Enable-Disable Enable

Arc C Pickup Enable-Disable Enable

Functions Permitted

50BF 1P function Permitted-Non-Permitted Non-Permitted

50 BF 3P Function Permitted-Non-Permitted Non-Permitted

3P No I Function Permitted-Non-Permitted Non-Permitted

Independent for each table Range Default Step

50BF Settings

PH Hi-Set Pickup 1-12A 2A 0.01A

PH Lo-Set Pickup 1-12A 1A 0.01A

Neutral Pickup 0.50-6A 1A 0.01A

1 Phase Timer T1 0.05-2s 0.5s 0.01s

3 Phase Timer T2 0.05-2s 1s 0.01s

3P No I Timer T3 0.05-2s 2s 0.01s

BF Logic (3P/2P) 2-Phases/3 Phases 2-Phases

Severe Fault 3P Permitted-Non-Permitted Non-Permitted

Low Load 2P Permitted-Non-Permitted Non-Permitted

Output Stages number 1-2 1 1

2nd Stage Timer 0.05-2s 2s 0.01s

Internal Arc Settings

Internal Arc Pickup 0.05-1A 1A 0.01A

Internal Arc Timer 0.10-2s 1s 0.01s

18 DBF Breaker Failure Protection GEK-106168E

Page 26

3. SETTINGS

COMMENTS ON SETTINGS:

1. The Identification setting allows the user to input a name for the unit (for example the name of the line or

feeder) with a maximum of 20 ASCII characters.

2. The Active Table setting allows selecting the table to be active during normal operation among the three

tables available on the DBF. This selection can also be done by means of digital inputs configured for this

purpose. The table input selection has priority over the table setting selection (if the input has been configured

to perform change of tables).

3. To set the breaker monitoring function it is necessary to set first the kI2t OP. Mode setting. If this is selected

as "measured" no other setting is required, since the time used for the calculation is the time taken by the unit

during the interval: trip order-52/b contact to close. If the “fixed” mode is selected it is necessary to set then the

kI2t Integration Time. In this case the time used will be always the set time (should be the rated operating

time of the circuit breaker provided by the manufacturer).

4. The Pre-Fault Cycles to be shown in every oscillography record may be adjusted from two to ten (2-10). In

any case the total number of cycles for any oscillography record is 66, regardless of pre-fault cycles setting.

5. The difference between the function permission and permitted trips settings is:

• The function permission setting enables or disables the function

• The trip permission setting allows to enable or disable any specific function to trip, but keeping always

active the function, providing thus capability to generate events, alarms and signals.

6. The overcurrent ranges shown in Table 3 correspond to models of 1-12A for phase and 0.5-6A for ground for

5A rated CT’s. Only PH Lo-Set Pickup, PH Hi-Set Pickup

range.

7. Sometimes the names used to describe the settings for both the local HMI and the communications program

are short or abbreviated. This is because of the space limitation imposed by text windows in the program.

and Neutral Pickup settings change with the

GEK-106168E DBF Breaker Failure Protection 19

Page 27

3. SETTINGS

20 DBF Breaker Failure Protection GEK-106168E

Page 28

4. TECHNICAL CHARACTERISTICS

4.

4. TECHNICAL CHARACTERISTICS

4. 4.

TECHNICAL CHARACTERISTICS

TECHNICAL CHARACTERISTICSTECHNICAL CHARACTERISTICS

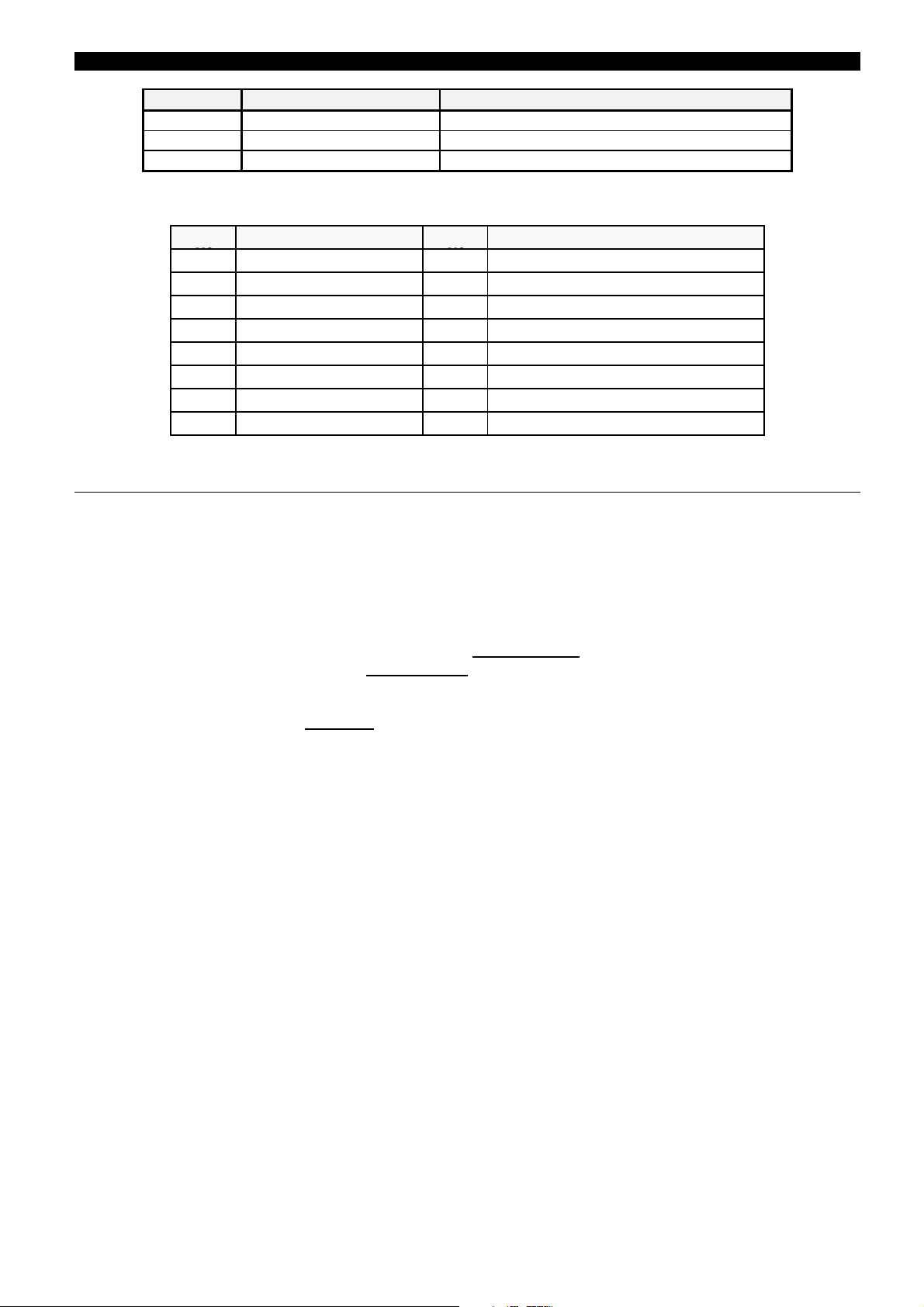

4.1. MODEL LIST

Position DBF 1 - - - - 1 1 - - 0 0 A Description

Comm. Interface

0

51

2

3

6 Ranges

[[[[1]]]] See Table [1R]

71

2

8M

D

11 0

1

12 G

H

13,14 0 0 Special Models

15 A Revision

P2: RS232 + P3: RS232

P2: RS232 + P3: Plastic F.O.

P2: RS232 + P3: Glass F.O.

P2: RS232 + P3: RS485

Comm. Protocols

P1, P2, P3: Mlink

P1, P2: Mlink; P3: ModBus

Language

Spanish

English

Model

Basic Model

Enhanced Model (Expansion

board)

Power Supply

48-125 VDC

110-250 VDC

TABLE [[[[1R]]]] -RANGES

MODELS ABCDEFG

DBF PHASE

GROUND

The input voltage of the standard model corresponds to the Power Supply voltage. The following models have

been developed to allow the selection of an input voltage independently of the Power Supply.

The following codes should be placed as two last digits before A in the ordering code for selecting the desired

characteristics:

MOD 04: V inputs: 48 Vdc ±20%

MOD 05: V inputs: 110 Vdc ±20%

MOD 06: V inputs: 125 Vdc ±20%

MOD 07: V inputs: 250 Vdc ±20%

Example: If we want to order a relay model with a digital input voltage of 48 Vdc, the model should be:

DBF1*****11**04A.

1-12 A 0.2-2.4 A 1-12A 1-12 A 1-12 A 0.5-6 A 0.5-6 A

1-12 A 0.2-2.4 A 0.2-2.4 A 0.5-6 A 0.1-1.2 A 0.2-2.4 A 0.1-1.2 A

4.1.1. SPECIAL MODELS

GEK-106168E DBF Breaker Failure Protection 21

Page 29

4. TECHNICAL CHARACTERISTICS

4.2. TECHNICAL CHARACTERISTICS

MECHANICAL

• Metal 19” rack case, 2 units high

• IP51 Protection (as per IEC 529)

• Local HMI: LCD (2 rows, 16 characters) and 20 key keyboard

• Rear connection for wiring: 4 blocks, 12 terminals each (6 blocks when optional expansion board)

• Dimensions: 437 x 164 x 88 mm

• Weight: Net 6 kg. Shipping 7 kg.

ELECTRICAL

• Frequency: 50 or 60 Hz (selectable by setting)

• Rated current: 1 or 5 A (different models)

• DC Power Supply 48/125 Vdc or 110/250 Vdc (different models)

• Operational range 80% to 120% of rated values

• Digital Input Voltage For standard models: 48-125, 110-250 VDC

• Thermal Capacity

Current circuits

- Permanent 4 x In

- 3s duration 50 x In

- 1 s duration 100 x In

• Temperature ranges

-Operation -20º C to + 55ºC

-Storage -40ºC to + 70ºC

• Humidity Up to 95% without condensation

• Trip contacts:

(according to selected model). For special models,

please refer to section 4.1.1.

AC

-Continuous Capacity 16A

-Rated Breaking Capacity 4000VA

-Make 25A for 4 sec

-Operating Time 8 ms or less

DC Breaking Capacity

- Resistive 9A at 30V

- Resistive 0.65A at 100V

- Inductive(L/R=40 ms) 0.5A at 30V

• Burden

-Current circuits 0.5 VA at I

• Consumption:

-At DC rated voltage 12 W idle state

-Digital inputs 8 mA (1 W at V

• Accuracy

-Current 5%

-Time 5% or 30ms (whichever is greater)

- Error index Class E-5 as per IEC 255-4

• Repeatability

-Operating value 1%

-Operating time 2% or 30 ms (whichever is greater)

=5A

r

0.1 VA at I

=1A

r

16 W all relays activated

= 125 VDC)

rated

22 DBF Breaker Failure Protection GEK-106168E

Page 30

4. TECHNICAL CHARACTERISTICS

COMMUNICATIONS

-RS232 using DB9 female connector (2/3 connectors depending on model)

- Mode: Half duplex

-1 mm plastic fiber-optic (depending on model)

Typical power output : -8dBm

Receiver sensitivity -39dBm

Numeric aperture N.A. 0.5

Wave length 660 nm (visible red)

HFBR-4516 type connector

-Glass fiber-optic 62.5/125 (depending on model):

Typical power output: -17.5 dBm

Receiver sensitivity -25.4 dBm

Numeric aperture N.A. 0.2

Wave length 820 nm (near infrared)

SMA type connector

STANDARDS

The DBF system complies with the following standards, which include the GE insulation and electromagnetic

compatibility standard and the standards required by Community Directive 89/336 for the EC market, in line with

European standards. It also complies with the European directive requirements for low voltage, and the

environmental and operating requirements established in ANSI standards C37.90, IEC 60255-5, IEC 60255-6 and

IEC 68.

Test Standard Class

Insulation test voltage IEC 60255-5 600V, 2kV

50/60 Hz 1 min.

Impulse voltage IEC 60255-5 5kV,0.5 J

1 MHz interference IEC 60255-22-1 III

Electrostatic discharge IEC 60255-22-2 IV

EN 61000-4-2 8kV

Immunity to radio interference IEC 60255-22-3 III

•Electromagnetic fields radiated with ENV 50140 10 V/m

amplitude modulation

•Electromagnetic fields radiated with ENV 50141 10 V/m

amplitude modulation. Common mode

•Electromagnetic fields radiated with ENV 50204 10 V/m

frequency modulation

•Fast transients IEC 60255-22-4 IV

EN 61000-4-4

•Magnetic fields at industrial EN 61000-4-8 30 Av/m

frequency

•RF emission EN 55011 B

GEK-106168E DBF Breaker Failure Protection 23

Page 31

4. TECHNICAL CHARACTERISTICS

24 DBF Breaker Failure Protection GEK-106168E

Page 32

5. HARDWARE DESCRIPTION

5.

5. HARDWARE DESCRIPTION

5. 5.

CAUTION

The DBF contains electronic components that can be damaged by electrostatic discharge if currents flow

through some terminals of the internal components. The main source of electrostatic discharge currents

is the human body, especially in conditions of low humidity, carpeted floors and isolated footwear. Under

these conditions it is important to have special care when removing and handling the modules or some of

their internal components. Personnel handling the relay should check that their body is free from

electrostatic charge, either by touching a surface at ground potential or by using an electrostatic

wristband connected to earth.

HARDWARE DESCRIPTION

HARDWARE DESCRIPTIONHARDWARE DESCRIPTION

5.1. PHYSICAL DESCRIPTION

5.1.1. CASE

The DBF case is made of stainless steel and consists of the main body and a covering lid. The main body of the

case contains the blocks of terminals necessary to carry out the external connections and guides to support the

trays that contain the internal parts of the relay. The trays can be pulled out in order to make easy the

maintenance and servicing of the relay.

5.1.2. ELECTRICAL CONNECTIONS

All the electrical connections for current channels, digital input and output relays are made using the terminal

blocks fixed to the rear part of the case. The connections required for communications are made using three DB-9

serial connectors, one on the front and two on the rear when using communication option RS-232. One of these

connectors is replaced by the corresponding fiber-optic connector in models including this option.

5.1.3. INTERNAL CONSTRUCTION

Internally the DBF unit is divided into 2 trays and a case. The case with the blocks of terminals is described above.

The lower tray carries the magnetic module and a printed circuit board which contains the power supply, the digital

inputs and also the trip outputs and auxiliary outputs on the basic version (model without expansion board).

The upper tray carries the board with the protection system CPU and the communications. This tray can also carry

as an option the input and output expansion board.

The front panel consists of a covered keyboard and a board which carries the alphanumeric display, the LEDs and

the Reset button. The model number (see list of models in Chapter 4) and the technical characteristics of the unit

are situated on the front panel of the relay.

The 16 indicator LEDs can be identified using labels which can be placed beside them, inside available plastic

holders.

A frontal bus is responsible for the connections between the lower and upper trays described above. Both trays

can be pulled out. To do so you first have to release the front panel which is fixed to the case with two screws and

pull it out, removing the flat cable which connects it to the CPU. It is then possible to remove the frontal bus.

The blocks of terminals situated on the rear of the case are identified with the letters A, B, C and D, and optionally

E and F, as shown in figure 9. In addition, each terminal is identified with a number.

GEK-106168E DBF Breaker Failure Protection 25

Page 33

5. HARDWARE DESCRIPTION

The communications connectors are situated on left-hand side of the front and on the right-hand side of the rear of

the case. The front port is PORT 1 and the rear ports are PORT 2 and PORT3. The IRIG-B connection is made

using a block of two additional terminals.

26 DBF Breaker Failure Protection GEK-106168E

Page 34

5. HARDWARE DESCRIPTION

5.2. OPERATING THEORY

The DBF unit measures current signals, performs complex calculations using internal data, stores relevant

incidents, pick-up tripping relays and generates information that can be used to determine the state of the

associated electrical system. The DBF functionality is related to the following modules:

- Magnetic module

- CPU board

- Power supply

- Keyboard and display

5.2.1. MAGNETIC MODULE

The magnetic module performs two essential functions: galvanic insulation and scaling analog input signals. In the

case of current transformers the input current for the primary winding is converted into a scaled voltage in the

secondary winding. Each current transformer must be linear in the whole measurement range of the relay.

5.2.2. CPU BOARD

The DBF uses two 16-bit microprocessors operating at a clock frequency of 20 MHz. One of these

microprocessors is used to perform the relay communications and the other performs the necessary calculations

for protection functions. In general the microprocessors are responsible to perform the input and output

calculations and operations at very high speed. The use of two microprocessors is especially recommendable to

make the protection and communication functions independent of each other inside the unit itself, and therefore

increase the reliability of the system.

The analogue-digital converter converts the voltage inputs into their digital equivalent with a resolution of 10 bits.

The unit code is stored in non-volatile EPROM memory while the settings and events are stored in EEPROM

memory. The data related to the oscillography is stored in RAM memory which is maintained using a capacitor,

thus avoiding the loss of information when the unit is disconnected.

A high-resolution real time clock is used to ensure that the date and time of all incidents can be time-tagged, with

a resolution of one millisecond. This clock can be synchronized externally using an IRIG-B demodulated signal..

The input and output functions are divided between the two microprocessors. The serial ports, the keyboard and

the display are controlled by the communications microprocessor. External communications are processed by a

serial communications controller circuit which contains a universal asynchronous transceiver (DUART). The digital

inputs and outputs are processed by the protection microprocessor.

The DBF contains 6 independent circuits to process digital inputs. These circuits check the presence or absence

of input voltage and are designed to isolate them electrically from the microprocessor, thus increasing the

reliability of the system.

On the front of the relay there is a set of 17 Target LED’s, one of which is fixed and indicates the operating state of

the unit. The rest are user-configurable using GE_INTRO software.

The button situated on the front is designed to check the state of the Target LED’s and to reset them by keeping it

pressed during 3 seconds.

GEK-106168E DBF Breaker Failure Protection 27

Page 35

5. HARDWARE DESCRIPTION

5.2.3 POWER SUPPLY

The DBF power supply can be 48-125 VDC or 110-250 VDC rated. The operating margin of the power supply is +

20%, and is galvanically isolated from the rest of the relay's circuits. The power supply provides ± 12 VDC to the

analog circuitry and the output relays, and ± 5 VDC for the digital circuits.

5.2.4 KEYBOARD AND DISPLAY

The DBF display at the front of the relay is liquid crystal type and consists of two rows of 16 characters each. The

display has background light with variable lightness adjustable by a potentiometer located on the rear of the front

cover plate.

28 DBF Breaker Failure Protection GEK-106168E

Page 36

6. ACCEPTANCE TESTS

6.

6. ACCEPTANCE TESTS

6. 6.

ACCEPTANCE TESTS

ACCEPTANCE TESTSACCEPTANCE TESTS

6.1. CONNECTIONS AND NECESSARY EQUIPMENT

Necessary equipment:

• One current source

• One DC voltage source

• Precision timer for testing timed events

• One AC/DC voltmeter/ammeter

Connect the relay as indicated in the external connections diagram, Figure 2.

For safety reasons, the external protection earth should be securely grounded.

Apply dc rated voltage to terminals A10-B10

6.2. VISUAL INSPECTION

Check that the relay has not suffered any kind of damage due to transport and handling.

Check that all the screws are tight and the terminal blocks have not been damaged in any way.

6.3. PANEL INSULATION TESTS

!

If any insulation test would be performed on the panel where the relay is installed, the ground terminals

A9-B9 must remain ungrounded.

Do the following groups in the terminals of the relay:

Group 1: A10, B10

Group 2: A1 to A4, B1 to B4

Group 3: C9, C10, D9, D10, C11, C12, D11, and D12

Group 4: A11, B11, A12, and B12

Group 5: C1, D1, C2, D2, C3, and D3

Group 6: C4, C5, C6, C7, C8, D4, D5, D6, D7, and D8

If the relay has expansion board, then the following groups must be added:

Group 7: E7, F7, E8, F8, E9, F9, E10, F10, E11, F11, E12, and F12

Group 8: E1, F1, E2, F2, E3, F3, E4, F4, E5, F5, E6, and F6

Apply 2000V gradually between case and groups.

Apply 2000V gradually between groups.

GEK-106168E DBF Breaker Failure Protection 29

Page 37

6. ACCEPTANCE TESTS

6.4. RELAY SETTING

Introduce the following settings in the relay (by means of HMI or GE_Local software):

General Settings Group Value

Relay Status IN SERV

Identification N/A

Frequency 50 Hz / 60 Hz

Phase CT Ratio 1

Neutral CT Ratio 1

Breaker Settings Value

Breaker Number N/A

KI2t Op. Mode Fixed

KI2t INT. Time 0.06s

KI2t LIMIT 99999

Active Table Set Value

Active Table 1

Function Permit Value

50BF 1P Function No Per

50BF 3P Function No Per

3P NO INT Funct No Per

50BF Settings Table 1 Value

PH Hiset Pickup 2A

PH Loset Pickup 1A

Neutral Pickup 1A

1 Phase Timer T1 1s

3 Phase Timer T2 1s

3P No I Timer T3 2s

BF Logic (3p/2P) 2 PHASE

Severe Fault 3P Per

Low Load 2P No Per

Nº Output Stages 1

2ndStage Timer 2s

Internal Arc Settings Table 1 Value

Int Arc Pickup 1A

Int Arc Timer 1s

The specific settings required for each test are indicated; other settings do not affect the tests.

6.5. INDICATORS

Check that pressing the TARGET RESET button (with relay fed with rated dc power supply) all target LEDs light

up.

6.6. POWER SUPPLY

The relay operates with a dc power supply within ± 20% of the rated value. Check that the READY target LED in

the front of the relay lights up showing green color.

1. Apply dc rated voltage to terminals A10-B10

2. Change setpoint FUNCTION PERMIT/50BF 1P FUNCTION to PERM.

3. Apply 2A to terminals A1-A2.

4. Energize digital input CC1 PHASE A BF INITIATE (C9-D10).

5. Wait 1second.

6. Check that the READY target LED in the front of the relay lights up showing green color.

7. Check the dc burden (see table below)

30 DBF Breaker Failure Protection GEK-106168E

Page 38

8. Remove the current from terminals A1-A2. Remove voltage from digital input CC1.

9. Repeat these steps with minimum and maximum voltages depending on the range of the relay.

Test voltages and typical burdens are listed below:

Model "G" (48/125 VDC)

Voltage (Vdc) Without Expansion Board With expansion Board

38 340 440

125 250 320

150 225 300

Model "H" (110/250 VDC)

Voltage (Vdc) Without Expansion Board With expansion Board

88 300 370

110 250 320

300 150 220

6. ACCEPTANCE TESTS

DC Battery (mA)

DC Battery (mA)

6.7. COMMUNICATIONS

The object of this test is to check the communication ports of the relay (PORT1, PORT2 and PORT3). To do this

it is necessary to use a computer and the communications software GE_LOCAL. Figure 7 shows the series cable

and connection accessories necessary to establish the connection between the PC and the relay. Figure 8 shows

the cable and connectors necessary for remote connection (by MODEM) through PORT3.

The PC communication parameters necessary to match the relay default setting parameters are:

Relay number: 1

Remote port speed: 19200

Local port speed: 19200

Remote stop bit: 1

Local stop bit: 1

By using GE_Local communications software establish the connection and check that the relay communicates

through the three communication ports. Repeat this test with different baud rates and different power supply

voltages.

GEK-106168E DBF Breaker Failure Protection 31

Page 39

6. ACCEPTANCE TESTS

6.8. INPUTS

6.8.1 DIGITAL INPUTS

Log into the relay using the GE_LOCAL software and press INPUTS / OUTPUTS button on the first general

screen.

• Check that applying dc rated voltage between terminals:

C9 and D10 (CC1)

D9 and D10 (CC2)

C10 and D10 (CC3)

C11 and D12 (CC4)

D11 and D12 (CC5)

C12 and D12 (CC6)

their corresponding status windows turn red while the applied voltage remains present.

If the relay has the optional expansion board, check the same for the following contact converter inputs:

E7 and E8 (CC7)

F7 and E8 (CC8)

E9 and F8 (CC9)

F9 and F8 (CC10)

E10 and E11 (CC11)

F10 and E11 (CC12)

E12 and F11 (CC13)

F12 and F11 (CC14)

6.8.2 IRIG-B SYNCHRONIZING INPUT

Connect the output of an IRIG-B unit with decoded output to the IRIG-B input at the rear of the DBF. Special care

must be taken when making the connection because the input is polarized.

Check that the time measured by the two units is the same.

32 DBF Breaker Failure Protection GEK-106168E

Page 40

6. ACCEPTANCE TESTS

6.9. FUNCTIONS

6.9.1 50BF 1P UNIT TEST

1. Change setpoint GENERAL/FUNCTION PERMIT/50BF 1P FUNCTION to PER.

2. Change setpoint GENERAL/FUNCTION PERMIT/50BF 3P FUNCTION to NO PER.

3. Change setpoint TABLE 1/FUNCTION PERMIT/3P No INT FUNCT to NO PER.

4. Change setpoint 50BF SETTINGS/Nº OUTPUT STAGES to 2.

5. The precision timer will be started at the same time than the corresponding contact converter (digital input) is

energized. The timer stop input will be wired to any DBF contact under test, i.e. contact C4-D4.

6. Apply 2A to terminals A1-A2 (phase A).

7. Energize digital input CC1 PHASE A BF INITIATE (terminal C9-D10).

8. Check that after T1 time delay (1s), the following contacts are closed:

A12-B12

C4-D4

C5-D5

In case the relay under test includes an expansion board, check also the operation of the following contacts:

E1-F1

E2-F2

E3-F3

9. Check that after 2nd Stage Timer delay (2s), the following contacts are closed:

C1-D1

C6-D6

C7-D7

and if the relay is equipped with an expansion board also the following contacts must be closed:

E4-F4

E5-F5

E6-F6

10. Repeat steps 7, 8, 9 and 10 using phase B current (B1-B2 terminals) and CC2 PHASE B BF INITIATE (D9D10 terminals) to start the breaker failure operation.

11. Repeat steps 7, 8, 9 and 10 using phase C current (A3-A4 terminals) and CC3 PHASE C BF INITIATE (C10D10 terminals) to start the breaker failure operation.

12. Change setpoint TABLE 1/50BF SETTINGS/Nº OUTPUT STAGES to 1.

13. Repeat steps 7 to 12 to check that in this case contacts C1-D1, C6-D6, C7-D7, E4-F4, E5-F5 and E6-F6 close

at the same time than contacts: A12-B12, C4-D4, C5-D5 and E1-F1, E2-F2, E3-F3 (if an expansion board is

available).

GEK-106168E DBF Breaker Failure Protection 33

Page 41

6. ACCEPTANCE TESTS

6.9.2 50BF 3P UNIT TEST

The DBF relay outputs are factory set with the default settings shown in the external connections drawing (Figure

2).

1. Change setpoint GENERAL/FUNCTION PERMIT/50BF 1P FUNCTION to NO PER.

2. Change setpoint GENERAL/FUNCTION PERMIT/50BF 3P FUNCTION to PER.

3. Change setpoint GENERAL/FUNCTION PERMIT/3P No INT FUNCT to NO PER.

4. Change setpoint TABLE 1/50BF SETTINGS/Nº OUTPUT STAGES to 2.

5. Change setpoint TABLE 1/50BF SETTINGS/BF Logic (3P/2P) to 3 PHASE.

6. The precision timer will be started at the same time than the corresponding contact converter (digital input) is

energized. The timer stop input will be wired to any DBF contact under test, i.e. contact C4-D4.

7. Apply 3A to terminals A1-A2 (phase A), B1-B2 (phase B) and A3-A4 (phase C).

8. Energize digital input CC7 3 POLE BF INITIATE (if the relay has not an expansion board, energize digital

inputs CC1 PHASE A BF INITIATE and CC2 PHASE B BF INITIATE simultaneously).

9. Check that after T2 time delay (1s), the following contacts are closed:

A12-B12

C4-D4

C5-D5

10. Check that after 2nd Stage Timer delay (2s), the following contacts are closed:

C1-D1

C6-D6

C7-D7

11. Change setpoint TABLE 1/50BF SETTINGS/Nº OUTPUT STAGES to 1.

12. Repeat steps 8 to 9. Check that after T2 time delay (1s), all the contacts are closed:

A12-B12 C1-D1

C4-D4 C6-D6

C5-D5 C7-D7

13. Change setpoint TABLE 1/50BF SETTINGS/BF LOGIC (3P/2P) to 2 PHASE.

14. Apply 3A to terminals B1-B2 (phase B) and terminals A3-A4 (phase C).

15. Energize digital inputs CC2 PHASE B BF INITIATE and CC3 PHASE C BF INITIATE.

16. Check that after T2 time delay (1s), the following contacts are closed:

A12-B12 C1-D1

C4-D4 C6-D6

C5-D5 C7-D7

17. Repeat steps 15 to 17 choosing any other pair of phases to apply ac current and any other pair of BF initiation

inputs.

34 DBF Breaker Failure Protection GEK-106168E

Page 42

6. ACCEPTANCE TESTS

6.9.3 INTERNAL ARC TEST

1. Change setpoint GENERAL/FUNCTION PERMIT/50BF 3P FUNCTION to NO PER.

2. Change setpoint TABLE 1/INTERNAL ARC SETTINGS/INT ARC TIMER to 2s.

3. Energize digital input CC4 52/b A

4. Apply 2A to terminals A1-A2 (phase A).

5. Check that after INT ARC TIMER time delay, contact C2-D2 is closed.

6. Repeat steps 3, 4 and 5 for phases B (terminals B1-B2) with digital input CC5 52/b B and C (terminals A3-A4)

with digital input CC6 52/b C.

6.9.4 3P NO I FUNCTION

1. Change setpoint GENERAL/FUNCTION PERMIT/50BF 1P FUNCTION to NO PER.

2. Change setpoint GENERAL/FUNCTION PERMIT/50BF 3P FUNCTION to NO PER.

3. Change setpoint GENERAL/FUNCTION PERMIT/3P No INT FUNCT to PER.

4. Change setpoint TABLE 1/50BF SETTINGS/Nº OUTPUT STAGES to 1

5. Change setpoint TABLE 1/50BF SETTINGS/ 3P NO I TIMER T3 to 1s

6. Change setpoint TABLE 1/50BF SETTINGS/LOW LOAD 2P to PER.

7. Energize digital input CC7 3P BF INITIATE. If the relay has not an expansion board, energize CC1 PHASE A

BF INITIATE and CC2 PHASE B BF INITIATE.

8. Check that after 3P NO I TIMER T3 (2s), the following contacts are closed:

C4-D4 A12-B12

C5-D5 C1-D1

C6-D6 C7-D7

9. If the relay is provided with an expansion board, check that also the following contacts are closed:

E1-F1 E2-F2

E3-F3 E4-F4

E5-F5 E6-F6

6.9.5 NEUTRAL OVERCURRENT UNIT TEST

1. Change setpoint GENERAL/FUNCTION PERMIT/50BF 1P FUNCTION to NO PER.

2. Change setpoint GENERAL/FUNCTION PERMIT/50BF 3P FUNCTION to NO PER.

3. Change setpoint GENERAL/FUNCTION PERMIT/3P No INT FUNCT to PER.