Page 1

GEI-M1026

Vertical Motor Non-Reverse/

Bolted Coupling

Installation Instructions

GE Motors

(For 5KXXXXDTTXXXX Models)

High Thrust

Hollow Shaft

Frames 213-449 NEMA Type P-Base

Weather Protected Type - I

Ball Type NRC (Non Reverse Coupling) & Bolted Coupling

Page 2

GEI-M1026

juries.

performed by qualified personnel.

High voltage and rotating parts can

cause serious or fatal in

Installation, operation and mainte-

nance of electric machinery should be

• Avoid extended exposure in close proximity

with high noise levels.

• Use proper care and procedures in handling,

lifting, installing, operating and maintaining

Familiarization with NEMA Publication MG-2,

Safety Standard for Construction and Guide

for Selection, Installation and Use of Electric

Motors and Generators, the National Electrical

Code and sound local practices is

recommended.

For equipment covered by this instruction

book, it is important to observe precautions to

protect personnel from possible injury. Among

the many considerations, personnel should be

instructed to:

• Avoid contact with energized circuits or

rotating parts.

• Avoid bypassing or rendering inoperative

any safeguards or protection devices.

• Avoid use of automatic-reset thermal

protection where unexpected starting of

equipment might be hazardous to

personnel.

• Avoid contact with capacitors until safe

discharge procedures have been followed.

• Be sure the shaft key is fully captive before

the motor is energized.

the equipment.

• The motor should be lifted by the lugs

provided. Do not lift anything but the motor

with the motor lifting means.

Safe maintenance practices by qualified

personnel are imperative. Before starting

maintenance procedures, be positive that:

• Equipment connected to the shaft will not

cause mechanical rotation.

• Main machine windings and all accessory

devices associated with the work area are

disconnected from electrical power sources.

If a high potential insulation test is required,

procedures and precautions outlined in NEMA

Standard MG-1 and MG-2 should be followed.

Failure to properly ground the frame of this

machine can cause serious injury to personnel

or death. Grounding should be in accordance

with the National Electrical Code and consistent

with sound local practice.

These instructions do not purport to cover all of the details or variations in equipment nor to provide for every possible

contingency to be met in connection with installation, operation, or maintenance. Should further information be desired or

should particular problems arise which are not covered sufficiently for the purchaser's purposes, the matter should be

referred to the General Electric Company.

© Copyright 2006 General Electric Company

2

Page 3

GEI-M1026

Lock Washers

Coupling

INSTRUCTION DIAGRAMS FOR MOUNTING 210 TO 280 FRAME

NON-REVERSE AND BOLTED COUPLINGS

(FOR 5KXXXXDTTXXXX MODELS)

Upper Half Coupling 1

Coupling Bolts 3

Coupling Lock Washers 3

Cover Plate 1

Cover Plate Bolts 5

Cover Plate Lock Washers 5

Steel Balls 10

Gib Key 1

Instructions 1

Part Name Frame Size Item Torque (Ft-Lbs) Torque (N-M)

Cover Plate Bolts 210 thru 280 1/4 - 20 UNC x 1/2 Bolt 8 11

Coupling Bolts 210 5/16 - 18 UNC x 1-3/4 Bolt 17 23

Coupling Bolts 250/280 3/8 - 16 UNC x 2-1/4 Bolt 30 41

It shall be the installer’s responsibility in all cases to ascertain these torque values are used

and maintained. This shall include those instances when the coupling comes mounted in the

motor. Failure to comply may cause the coupling bolts to break, with resultant, extensive

damage to the equipment.

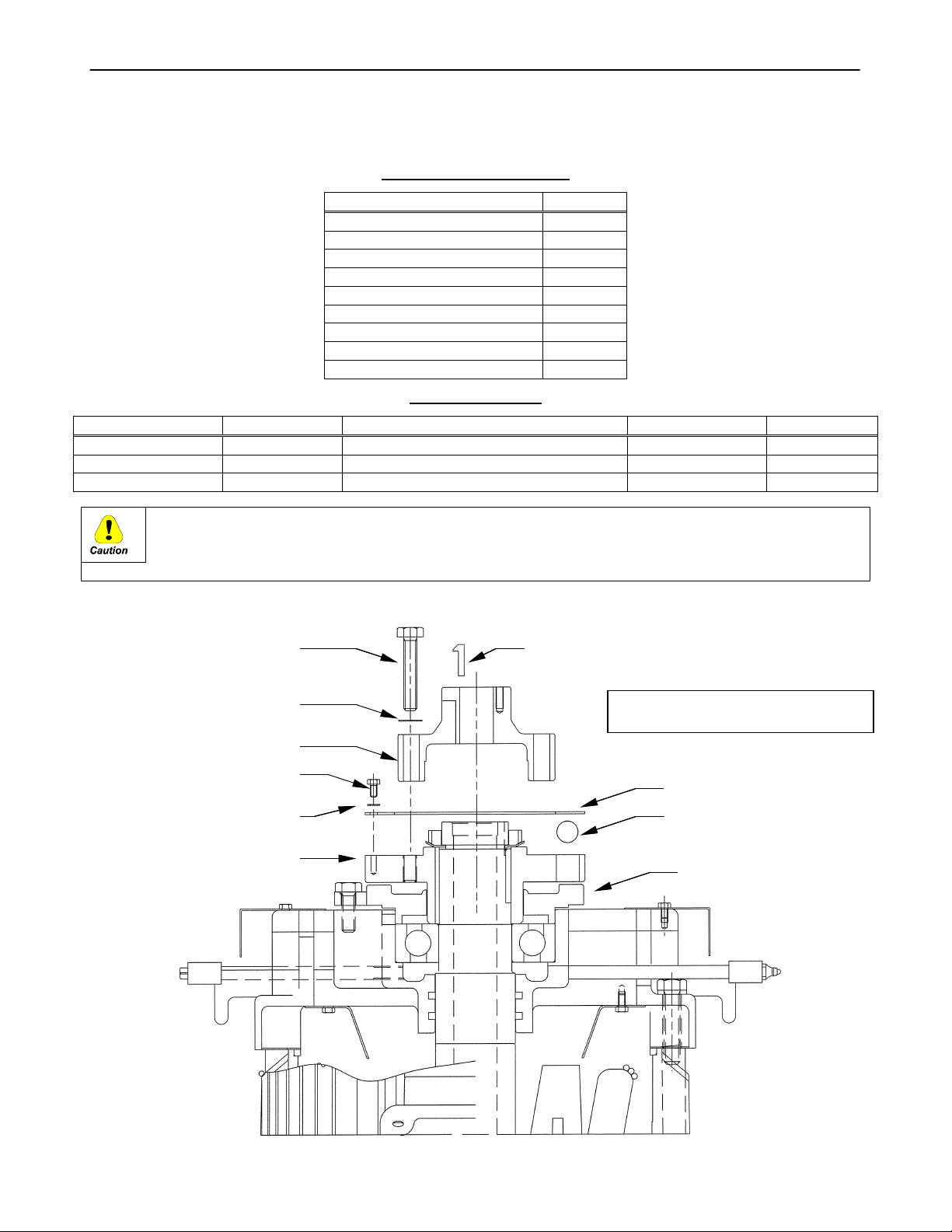

NON-REVERSE COUPLING (NRC ASSEMBLY)

Coupling Bolts

Coupling Kit Packing List

Item Quantity

Bolt Torque Chart

Figure 1

Gib Key

Coupling Lock Washers

Upper Half-Coupling

Cover Plate Bolts

Cover Plate

Lower Half-

(Located on motor)

NOTE: Thoroughly clean coupling & all

related components prior to mounting on motor.

Cover Plate

Balls

Ratchet Plate

3

Page 4

GEI-M1026

Cover Plate Lock

Washers

pling

BOLTED COUPLING ASSEMBLY

Figure 2

Coupling Bolts

Gib Key

Coupling Lock Washers

Upper Half-Coupling

Cover Plate Bolts

NOTE: Thoroughly clean coupling & all

related components prior to mounting on motor.

Cover Plate

Lower Half-Cou

(Located on motor).

Ratchet Plate

Note: Steel balls are not used on bolted coupling assembly.

4

Page 5

GEI-M1026

INSTRUCTION DIAGRAMS FOR MOUNTING 320 TO 440 FRAME

NON-REVERSE AND BOLTED COUPLINGS

(FOR 5KXXXXDTTXXXX MODELS)

Upper Half Coupling 1

Coupling Bolts 6

Coupling Lock Washers 6

Cover Plate 1

Cover Plate Bolts 5

Cover Plate Lock Washers 5

Balls 10

Gib Key 1

Instructions 1

Part Name Frame Size Item Torque (Ft-Lbs) Torque (N-M)

Cover Plate Bolts 320/440 1/4 - 20 UNC x 5/8 Bolt 8 11

Coupling Bolts 320/360 1/2 - 13 UNC x 2-1/2 Bolt 75 102

Coupling Bolts 400/440 5/8 - 11 UNC x 3-1/2 Bolt 150 203

It shall be the installer’s responsibility in all cases to ascertain these torque values are used

and maintained. This shall include those instances when the coupling comes mounted in the

motor. Failure to comply may cause the coupling bolts to break, with resultant, extensive

damage to the equipment.

NON-REVERSE COUPLING (NRC) ASSEMBLY

Coupling Kit Packing List

Item Quantity

Bolt Torque Chart

Figure 3

NOTE: Thoroughly clean coupling & all

related components prior to mounting on motor.

5

Page 6

Note: Steel balls are not used on bolted coupling assembly.

NOTE: Thoroughly clean coupling & all

related components prior to mounting on motor.

GEI-M1026

BOLTED COUPLING ASSEMBLY

Figure 4

6

Page 7

GEI-M1026

Attn: Industrial Engineering

To:

g

Reader Comments

General Electric Company

GE Motors

Technical Publications Editor

1030 Swinney Ave, Bldg 26-2

Fort Wayne IN 46802-4332

Fax: 260-439-3881

(GE Internal DC: 8*380-3881)

We welcome comments and suggestions to make this publication more useful.

Your Name Today’s Date If needed, how can we contact you?

Your Company’s Name and Address Job Site Fax No.

GE Requisition No. Phone No.

Your Job Function / How You Use This Publication Publication No. E-Mail

General Rating

Contents

Organization

Technical Accuracy

Clarity

Completeness

Drawings / Figures

Tables

Referencing

Readability

Excellent Good Fair Poor Additional Comments

Specific Suggestions (Corrections, information that could be expanded on, and such.)

Page No.

Comments

Other Comments (What you like, what could be added, how to improve, and such.)

Overall Grade (Compared to publications from other manufacturers of similar products, how do you rate this publication?)

Superior Comparable Inferior Do not know Comment

Detach and fax or mail to the address noted above.

Publication Issue / Revision Date

Address

7

Page 8

GEI-M1026

……………………………………………….…………………Fold here and close with staple or tape………………………………….………………….

Place

Stamp

Here

GE MOTORS

INDUSTRIAL ENGINEERING TECHNICAL

PUBLICATIONS EDITOR

1030 SWINNEY AVE, BLDG 26-2

FORT WAYNE IN 46802-4332 USA

…………………………………………………..………….………………..Fold here first……………………………………………………………….

8

Page 9

Document Revision History

Rev # Date Author ISAAC # Description

0 03/27/06 Futter 06-0644 New manual for Ball NRC 320-440 frame motors.

GEI-M1026

9

Loading...

Loading...