Page 1

g GE Energy

GEI-M1025-B

Motor Installation

And Maintenance Instructions

Vertical AC Small Industrial Motors

NEMA Frame Sizes: 213 to 449

NEMA Type P Base, Weather Protected Type 1

High Thrust, Hollow and Solid Shaft

Ball Type Non-Reverse Couplings

And Bolted Couplings

Models: 5KXXXDTTXXXX

Models: 5KEXXXDTTXXXX

© Copyright 2012 General Electric Company 2012/07/02

Page 2

GEI-M1025-B

Table of Contents

I. General Information ................................................................................................................................................. 1

A. How to Properly Use this Instruction Manual ................................................................................. 1

B. Safety Symbols ............................................................................................................................................. 1

C. Safe Motor Operation Information ...................................................................................................... 2

D. Description of Labels and Nameplates ............................................................................................. 3

E. Model and Serial Numbers ...................................................................................................................... 3

F. Relevant Industry Standards .................................................................................................................. 3

II. Receiving ....................................................................................................................................................................... 3

A. Unpacking ....................................................................................................................................................... 4

B. Temporary Storage ..................................................................................................................................... 4

C. Extended Storage ........................................................................................................................................ 4

D. Handling .......................................................................................................................................................... 4

III. Installation .................................................................................................................................................................... 4

A. Location ........................................................................................................................................................... 4

B. Mounting .......................................................................................................................................................... 5

C. Power Supply and Connections ............................................................................................................ 5

IV. Operation…………………………………………… .................................................................................................................... 6

A. Steps Prior to Starting ................................................................................................................................ 6

B. Initial Start ....................................................................................................................................................... 7

C. Jogging and Repeated Starts ................................................................................................................. 7

V. Maintenance ................................................................................................................................................................ 8

A. General ............................................................................................................................................................. 8

B. General Cleanliness .................................................................................................................................... 8

C. Insulation and Windings ........................................................................................................................... 8

D. Vacuum and Compressed Air Cleaning ............................................................................................ 8

E. Cleaning with Water and Detergent.................................................................................................... 9

F. Bearings and Lubrication ......................................................................................................................... 9

G. Couplings ...................................................................................................................................................... 11

H. Re-Assembling the Upper End ............................................................................................................. 12

VI. Operational Difficulties ......................................................................................................................................... 13

VII. Failure ........................................................................................................................................................................... 14

VIII. Repair ............................................................................................................................................................................ 14

IX. Renewal Parts ........................................................................................................................................................... 14

X. Fastener Torques ..................................................................................................................................................... 15

XI. Coupling Assembly ................................................................................................................................................. 16

A. 210 – 280 Frame Non-reverse and Bolted Coupling ................................................................. 16

B. 320 – 449 frame Non-Reverse and Bolted Coupling ................................................................. 18

Page 3

GEI-M1025-B

The use of a lightning bolt within an

arrowhead symbol, enclosed in a yellow

triangle warns of dangerous electrical

voltage that could cause an electric shock to

a person.

This symbol identifies a terminal, which

is intended for connection to an

external grounding conductor for

protection against electric shock in

case of a fault.

The use of an exclamation point within a

yellow triangle indicates to the user that

important installation, operating and

maintenance instructions must be followed.

The use of a small case “i” enclosed in

a square indicates a general note.

The use of wavy lines, enclosed in a yellow

triangle, indicates that the motor can be hot

and should not be touched without taking

proper precautions.

WARNING:

Indicates a procedure or condition that,

if not strictly observed, could result in

personal injuries or death.

This symbol instructs one to read the

manufacturer’s instruction manual before

installation, operation and maintenance.

CAUTION:

Indicates a procedure or condition that,

if not strictly observed, could result in

minor injuries to personnel.

This symbol indicates the need to wear

hearing protection.

I. GENERAL INFORMATION

A. How to Properly Use this Instruction Manual

This installation and maintenance manual has been written to assist the user with proper procedures when handling,

installing, operating and maintaining the equipment. All of the safety warnings and instructions in this manual must

be followed to prevent injury to personnel.

This manual must be kept for future reference during installation, operation and maintenance.

B. Safety Symbols

Below is a safety symbol table that identifies the safety symbols that appear in this manual and on the motors.

1

Page 4

GEI-M1025-B

WARNINGS: High voltage and rotating parts can cause serious or fatal injuries. Qualified

personnel should perform installation, operation and maintenance of electrical machinery. For

equipment covered by this instruction manual, it is important to observe safety precautions to

protect personnel from possible injury. Be sure to keep the installation and maintenance

information for future reference. All warnings and cautions must be followed.

Installation

Avoid contact with energized circuits and rotating parts.

Avoid bypassing or rendering inoperative any safeguards or protective devices.

Avoid use of automatic-reset thermal protection where unexpected starting of equipment might be hazardous to

personnel.

Avoid contact with capacitors until safe discharge procedures have been followed.

Be sure the motor shaft key is captive before the motor is energized.

Avoid long exposure in close proximity to machinery with high noise levels.

When the motor is coupled to equipment, ensure that system vibrations are within acceptable limit (per ISO 10816-

1) to avoid failure of the motor.

Use proper protective gear, care and procedures when handling, lifting, installing, operating and maintaining the

motor.

If eyebolts are used for lifting motors, they must be securely tightened, and the direction of the lift must not

exceed a 15° angle from the shank of the eyebolt. Do not use eyebolts in an ambient below 0°F. At temperatures

below 0° F, the eyebolt could fail resulting in injury to personnel and/or damage to equipment. Drop-forged

eyebolts per American Society of Testing Materials A489 or equivalent must be used.

Do not use the motor shaft as a means for lifting.

Do not lift both the motor and driven equipment with the motor lifting means.

Do not stand on or place objects on the motor.

Maintenance

Safe maintenance practices performed by qualified personnel are imperative. Before starting maintenance

procedures, be positive that:

Equipment connected to the shaft will not cause mechanical rotation.

Main motor windings and all accessory devices associated with the work area are disconnected from electrical

power sources.

The motor has been given time to cool.

Failure to properly ground the frame of the motor can cause serious injury to personnel. Grounding should be in accordance with National and local

Standards and consistent with sound practice.

These instructions do not purport to cover all the details in motors nor to provide for every possible contingency to be met in connection with installation,

operation or maintenance. Should further information be desired or should particular problems arise which are not covered sufficiently for the

purchaser’s purposes, the matter should be referred to the General Electric Company.

This document contains proprietary information of General Electric Company, USA and is furnished to its customer solely to assist that customer in the

installation, testing, operating and/or maintenance of the equipment described. This document shall not be reproduced in whole or in part, nor shall its

contents be disclosed to any third party without the written approval of GE Energy.

C. Safe Motor Operation Information

2

Page 5

GEI-M1025-B

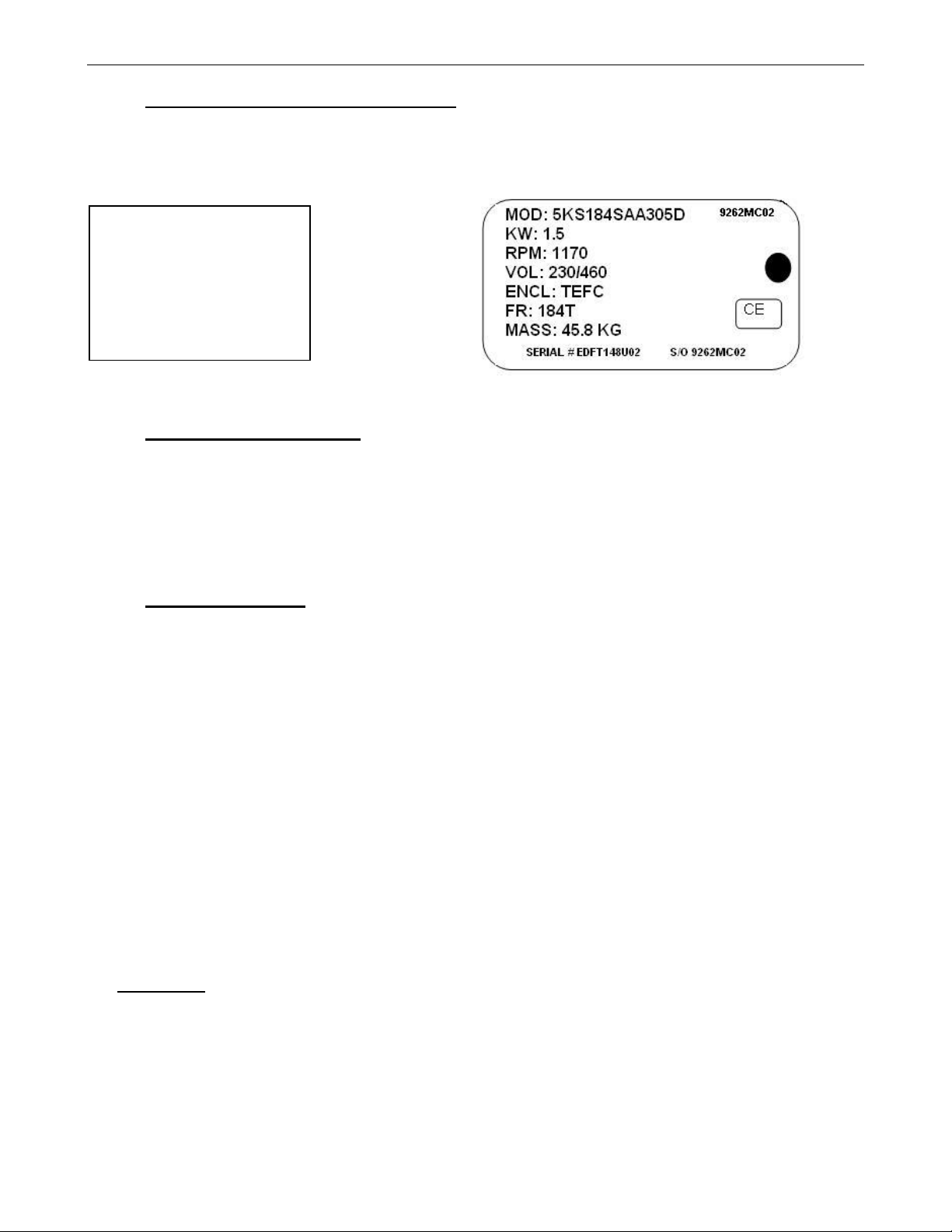

MOD – GE model number

RPM = Motor speed at full

MASS = Motor mass

Typical Packing Label

D. Description of Labels and Nameplates

Motor rating and identification data are furnished on packing labels and motor nameplates. Motor nameplates

provide a permanent record of motor characteristics, plant identification and date of manufacture. Below is an

example of a label that is attached to the shipping package.

KW = Motor power rating

load

VOL – Motor voltage

ENCL = Enclosure code

FR = Frame size

E. Model and Serial Numbers

As discussed in section D, every motor that is manufactured by GE Energy has a model number and a serial number,

which are permanently marked on the motor nameplate. When contacting a GE Energy Service Shop or

representative, please provide the model and serial numbers.

Data and information regarding an individual motor model number can be obtained from the Data Pack for the motor

or through EliteNet or by contacting your local GE Energy representative.

F. Relevant Standards

1. Motors shipped with this Installation and Maintenance Instruction have been designed and built to the

2. Motors that have the IECEx designation have also been designed to meet the requirements of the

3. Motors with the CE Mark have also been designed to meet the requirements of the following EU

II. RECEIVING

Each motor should be carefully inspected upon receipt. Motor rating and identification data are furnished on a

packing label for verification purposes. Any damage should be reported promptly to the carrier and a claim filed. The

nearest GE Energy sales office may provide additional guidance.

latest revision of the following standards:

a. NEMA MG-1

following standards:

a. IEC and/or BS/EN 60079-0

b. IEC and/or BS/EN 60079-15

directives:

a. Machinery safety

b. Low Voltage

c. Electromagnetic Compatibility

d. Conformity Assessment

3

Page 6

GEI-M1025-B

WARNING: Lifting lugs on the motor are designed for handling only the motor. They are not to be

used to lift the motor plus additional equipment such as pumps, compressors or other driven

equipment. In the case of assemblies on a common base, lugs or eyebolts provided on the motor are

not to be used to lift the assembly and base. The assembly should be lifted by a sling around the base

or by other lifting means provided on the base

WARNING: Installation should be in accordance with the ‘USA-National Electric Code’ or ‘BS/EN 602041’ and ‘BS/EN 60204-11’ and consistent with sound National and local practices. Coupling, belt and

chain guards should be installed as needed to protect against accidental contact with moving parts.

Motors accessible to personnel should be further guarded by screening, guard rails, etc., to prevent personnel

from coming in contact with the equipment.

A. Unpacking

If the motor has been exposed to low temperatures, unpack it only after it has reached the temperature of the room in

which it will be unpacked. Otherwise the motor windings will be exposed to condensing moisture.

B. Temporary Storage (Up to 6 Months)

If the motor will not be put into service immediately, certain precautions should be taken to protect the motor while in

storage. It is recommended the motor be placed under cover in a clean, dry location.

During storage, windings should be protected from excessive moisture by some safe and reliable method of heating,

such as space heaters, to keep the temperature of windings above the temperature of the surrounding air. It is

recommended that the motor in storage be inspected at periodic intervals, the windings meggered and a log kept of

pertinent data. (Refer to the OPERATION section.) Any significant drop in insulation resistance should be investigated.

Precautions are taken by the factory to guard against corrosion. The machined parts are coated to prevent rust

during shipment. If the equipment is to be stored, examine the machined parts carefully for rust and moisture and

recoat where necessary.

Motors with oil-lubricated or oil-mist lubricated bearings are normally operated and tested in the factory with a rustinhibiting oil in the lubrication system. A rust-inhibiting film remains on critical bearing surfaces during transit and for

up to six months in storage.

Rotate the shaft of all grease-lubricated motors 10-20 revolutions at two-month intervals.

If the purchaser has specified the machine be packaged for long-term storage, the foregoing recommendations do

not apply and the packing should be left intact during the period of storage.

C. Extended Storage (Longer than 6 months)

In the event the motor is to be stored longer than six months, please refer to GE Instruction Manual GEK-97427.

D. Handling

III. INSTALLATION

A. Location

Locate the motor in a clean, well ventilated area. The motor enclosure is designed such that dripping, windblown and splashing water will not damage the motor. Under conditions of extreme weather and moisture,

additional protection, such as a pump house, is recommended. The free flow of air around the motor must

not be obstructed. The ambient air temperature should not exceed the value on the motor Nameplate.

4

Page 7

GEI-M1025-B

Coupling halves should have a close sliding fit on their mating parts and must be

securely locked to avoid damage in operation. If it is necessary to drive the coupling

into position, it is important that the other end of the shaft be supported so the force of

driving on the coupling does not damage the lower end bearing. Failure to comply may

result in extensive damage to the bearing.

B. Mounting

1. Motors with Oil-Lubricated bearings must be mounted on a level surface to prevent oil leakage and for

proper operation of the oil sight glass.

2. The motor base should be bolted down square with the pump head and at right angles with the pump

shaft. Bolt the motor to the pump head using bolts of the largest size permitted by the clearance holes in

the motor base.

3. The mounting bolts must be tightened to prevent changes in alignment and possible damage to the

equipment. It is recommended that a washer be used under each nut or bolt head to get a secure hold

on the base. As an alternative, flanged nuts or bolts may be used. The recommended torques are listed

in the FASTENER TORQUES section below.

4. Vertical Hollow Shaft Motors (VHS)

Remove the hood or top hat and the upper half-coupling from the motor. Lower the motor onto the

pump head with the pump shaft extending through the motor’s hollow shaft. The pump shaft should be

centered within the motor’s hollow shaft.

Non-Reverse Coupling (NRC) – See the Coupling Assembly Section below.

These motors are typically equipped with a Non-reverse coupling (NRC) that permits rotation in the

CCW direction viewed from the coupling end of the motor. The NRC system consists of a stationary

ratchet plate with slotted ramps and a rotating ball carrier that retains several steel balls. When the

motor starts in the forward (CCW) direction, the slotted ramps in the ratchet plate lift the balls above

the ratchet plate where they are held in place by centrifugal force as the motor speed increases.

When the motor speed decreases, the balls move down due to the decreasing centrifugal force and

then prevent CW (reverse) rotation by locking against the vertical edge of the slots in the ratchet

plate.

Fit the upper half-coupling onto the motor and key it to the pump shaft with the gib key. Put on the

adjusting nut supplied with the pump and draw up on the impellers. Lock the adjusting nut in place

with a screw through the nut into a tapped hole in the coupling.

5. Vertical Solid Shaft Motors (VSS)

These motors are provided with a shaft extension suitable for direct coupled loads. Use flexible couplings

if possible.

Accurate mechanical lineup is essential for successful operation. Mechanical vibration and roughness in

running the motor may be an indication of poor alignment. In general, lineup by straight edge across,

and feeler gauges between coupling halves is not sufficiently accurate. It is recommended that the

lineup be checked with a dial indictor and checking bars connected to the motor and load-machine

shafts. The space between coupling hubs should be maintained as recommended by the coupling

manufacturer. Shaft offset should not exceed 0.002”. Angular misalignment should be less than 0.002”.

C. Power Supply and Connections

1. Nameplate voltage and frequency should agree with the power supply. Motors will operate satisfactorily

on line voltage within ±10% of the nameplate value or frequency within ±5%, combined variation not to

exceed ±10%.

2. Dual voltage motors can be connected for the desired voltage using instructions on the nameplate or the

connection diagram.

5

Page 8

GEI-M1025-B

WARNING: Motor and control wiring, overload protection and grounding should be in

accordance with the USA –‘National Electric Code’ or ‘BS/EN 60204-1’ and/or ‘BS/EN 60204-11’ and

consistent with sound local practices.

WARNING: If the motor has been in a damp location, dry it out thoroughly before operating.

Before energizing the motor for the first time or after an extended shut down, it is advisable to

check the insulation resistance, power supply and mechanical freedom of the motor.

3. When mounting conditions permit, the conduit box may be rotated so that the conduit entrance can be

made upward, downward, or from either side.

IV. OPERATION

A. Steps Prior to Starting

1. Oil lubricated bearings

Drain any oil from the oil reservoir that was put in upon receipt of the motor or during long term storage

by removing the drain plug located at the bottom of the oil sump.

Replace the drain plug.

Refer to the lubrication nameplate on the motor.

With the motor at standstill, fill the oil reservoir per the information on the lubrication nameplate.

Replace the filler plug.

2. Insulation Resistance

In accordance with established standards, the recommended minimum insulation resistance for the

stator winding when measured with a 500 volt DC direct indicating ohmmeter with self-contained power

supply (megger), shall not be less than 5 mega-ohms at 40C for a motor rated under 1000 volts, and not

less than 100 mega-ohms at 40C for a motor rated over 1000 volts. If the insulation resistance is lower

than this value, it is advisable to eliminate the moisture in one of the following ways.

a. Dry the winding in an air-circulating oven with the air surrounding the winding at 110C, +5/-15C

until the winding has been above 90C for at least four hours. Then the air temperature may be

raised to 150C, +5C/-15C. Continue to heat until the insulation resistance is constant for a onehalf-hour period.

b. Enclose the motor with canvas or a similar covering. Leave a hole at the top for moisture to escape.

Insert heating units or lamps and leave them on until the insulation resistance is constant for a onehalf hour period.

c. With the rotor locked mechanically and using approximately 10% of rated voltage, pass a current

through the stator windings. Increase the current gradually until the winding temperature reaches

90C. Do not exceed this temperature. Maintain a temperature of 90C until the insulation

resistance becomes constant for a one-half hour period.

6

Page 9

GEI-M1025-B

WARNING: Be sure the motor is not running and the power supply is disconnected before performing

the final checks.

CAUTION: Repeated starts and/or jogs of induction motors greatly reduce the life of the winding

insulation. The heat produced by each acceleration or jog is much more than that dissipated by the

motor under full load. If it is necessary to repeatedly start or jog a motor, it is advisable to check the

application with the local GE Energy sales office.

B. Initial Start

1. Whenever possible, examine the interior of the motor for loose objects or debris and remove any such

foreign material.

2. If possible, turn the rotor by hand to ensure that it rotates freely.

3. Check all connections with the connection diagram(s) including auxiliary devices. Check all accessible

factory made connections for tightness to make sure none has become loose during shipment.

4. Some motors are designed for unidirectional rotation. Rotation of these motors must be in accordance

with the rotation indicated on the motor’s nameplate and the outline furnished with the equipment.

Connection plates on the motor have been furnished to assist in obtaining the proper rotation.

5. It is best to run the motor uncoupled from its load during the initial start to make certain it rotates in the

correct direction. Vibration, noise, voltage and current unbalance can also be checked.

To run a VHS motor uncoupled, it is recommended that the pump head-shaft be removed. If this cannot

be done, remove the upper half-coupling and be sure the pump shaft is well centered in the motor shaft.

Rotate the motor by hand to ensure there is no interference between the shafts. Do not try to run the

motor uncoupled by just removing the gib key.

If it is necessary to change rotation, interchange any two line leads.

6. After inspecting the motor carefully, make the initial start by following the regular sequence of starting

operations in the motor starter control instructions.

7. Check motor operation under load for an initial period of at least one hour to observe whether any

unusual noise or hot spots develop.

8. In the event of excessive vibration or unusual noise, disconnect the motor from the load and check the

mounting and alignment.

9. Check the operating current against the nameplate value. Do not exceed the value of nameplate current

multiplied by the motor service factor (if any) under steady continuous load.

10. Space heaters (if supplied) should be de-energized during motor operation.

C. Jogging and Repeated Starts

7

Page 10

GEI-M1025-B

WARNING: Before initiating maintenance procedures, disconnect all power sources to the motor

and accessories. For motors equipped with surge capacitors, do not handle the capacitors until

they are discharged by a conductor simultaneously touching all terminals and leads including

earth. This discharge conductor should be insulated for handling. Replace all normal grounding connections prior

to operating.

WARNING: To prevent injury to the eyes and respiratory organs, safety glasses and suitable

ventilation or other protective equipment should be used.

CAUTION: Care must be taken to make sure the air is dry and that the air pressure is not more than 21

x 103kg/m2 (30 psi).

WARNING: Operator must not use compressed air to remove dirt or dust from his or her person and

clothing.

V. MAINTENANCE

A. General

If the motor is dismantled during maintenance, sealing compounds (if any) need to be removed from the machined

rabbets (spigots). When reassembling the motor, all machined surfaces forming metal-to-metal joints should be

sealed with watertight sealing compound (Tite-Seal, GE Spec. A50CD427A or equivalent).

Inspect the motor at regular intervals, depending on service. Keep the motor clean and the ventilation openings clear.

In addition to the daily observation of the overall condition, it is recommended that a general inspection routine be set

up to check periodically the following items:

1. General cleanliness

2. Insulation and windings

3. Lubrication and bearings

4. Coupling Bolt tightness

B. General Cleanliness

The interior and exterior of the motor should be kept free from dirt, oil, grease and conducting dust. Debris and/or

dust may build up and block off ventilation. Any of these contaminants can lead to early motor failure.

C. Insulation and Windings

To obtain a long life and satisfactory operation of insulated windings, they should be kept clean from dirt, oil, metal

particles and other contaminants. A variety of satisfactory and acceptable methods are available for keeping the

windings clean. The choice of method will depend greatly on time, availability of equipment and on the insulation

system. Vacuum cleaning with non-metallic hose tips should precede cleaning with water and detergent or witt

solvents. Tightly adhering dirt will require removal by gentle brushing or wiping.

D. Vacuum and Compressed Air Cleaning

Compressed air should be used to remove loose dirt and dust from air passages.

Suction should be used to remove dirt from the windings to avoid damaging the coils.

8

Page 11

GEI-M1025-B

CAUTION: To minimize possible damage to varnish and insulation, a fairly neutral non-conductive

type of detergent such as DuBois Flow should be used. A pint of detergent to 76 liters (20 gallons) of

water is recommended.

E. Cleaning with Water and Detergent

This method is very effective in cleaning windings when used with a low-pressure steam jenny with maximum steam

pressure 30 psi and 90C.

If a steam jenny is not available, the cleaning solution may be applied with warm water by a spray gun. After the

cleaning operation, the windings should be rinsed with water or low-pressure steam.

Dry the windings. Refer to the Insulation Resistance section above, for instructions on how to proceed.

F. Bearings and Lubrication

1. Grease Lubricated Bearings

The grease used as a lubricant in grease-lubricated anti-friction bearings loses its lubricating ability over

a period of time. For a given bearing construction and assembly, the lubricating ability of a grease over

time depends primarily on the type of grease, the size of the bearing, the speed at which the bearing

rotates and the severity of operating conditions. As a result, it is not possible to accurately predetermine

when new grease must be added. Good results can be obtained if the general recommendations stated

in this manual are followed.

The primary function of grease is to supply the essential lubrication oil from the sponge-like reservoir of

its soap structure. Grease-lubricated bearings consume only a small amount of lubricant. This lubricant

must always be present to avoid rapid wear and bearing failure. Excessive or too frequent lubrication

may also damage the motor.

Grease lubricated bearings are lubricated at the factory. Motors with grease fittings should be lubricated

in accordance with these instructions to provide maximum bearing life.

2. Type of Grease

Motors are assembled with Shell Alvania R3 grease in the factory.

Some equivalent greases are:

Polyrex EM – Exxon

BRB-2 - Chevron

AeroShell #5 – Shell Oil Company,

Hi Temp - Texaco, Inc.

3. The table below lists relubrication intervals for motors under normal, steady running conditions, in a

relatively clean atmosphere at 40C ambient temperature or less.

A standard 10,000 PSI (68.950 kPa) 16 ounce (473 mL) grease gun delivers approximately 0.04 oz. (1.18

mL) of grease with each pump, and a 24 oz. (710 mL) gun delivers approximately 0.06 oz. (1.77 mL) of

grease.

9

Page 12

GEI-M1025-B

Frame

Size

Upper

Thrust

Brg

Number of Pumps

Lower

Guide

Brg

Number of Pumps

Lubrication Intervals

(days)

16 Oz.

Gun

(Approx.

473 mL)

24 Oz.

Gun

(Approx.

710 mL)

16 Oz.

Gun

(Approx.

473 mL)

24 Oz.

Gun

(Approx.

710 mL)

2 Pole

4 Pole

6 Pole

213-215

7309

25

17

6209

25

17

120

180

180

254-256

7311

25

17

6309

25

17

120

180

180

284-286

7311

25

17

6311

25

17

120

180

180

324-326

Oil Lube

Oil Lube

Oil Lube

6312

25

17

120

180

180

364-365

Oil Lube

Oil Lube

Oil Lube

6313

25

17

120

180

180

404-405

Oil Lube

Oil Lube

Oil Lube

6314

44

29

80

180

180

444-445

Oil Lube

Oil Lube

Oil Lube

6314

44

29

N/A

180

180

447-449

Oil Lube

Oil Lube

Oil Lube

6218

44

29

N/A

180

180

WARNING: Lubrication maintenance should be performed with the motor stationary and

disconnected from the power source. Extreme caution must be exercised to avoid contact with

rotating parts or electrical wiring if the motor must be lubricated while running. Failure to observe

these precautions may result in damage to the equipment, injury to personnel, or both.

CAUTION: Failure to observe the foregoing instructions for re-greasing may result in over greasing,

grease leakage and/or bearing damage. To avoid damage to equipment, bearings and grease must be

kept free of dirt.

Amount and Interval Table

for Grease Lubricated Bearings

4. Procedure for Regreasing

a. Stop the motor and disconnect it from the power supply.

b. Clean dirt and debris from around the grease inlet fitting and the grease outlet plug.

c. Remove the grease outlet plug and clean the opening and outlet tube of hardened grease. This may

be accomplished with a twisted wire brush or sturdy pipe cleaner.

d. Add grease with a hand-lever operated gun only. Add only the amount of grease specified in the

table above.

e. Run the motor for about ten minutes before replacing the outlet plug.

Because this method of greasing bearings tends to purge the housing of used grease over a period

of time, removal of all grease should be required infrequently. A GE Energy Authorized Service Shop

can clean the bearing cavity and replace the bearings and grease when the motor is removed from

service for maintenance or reconditioning.

5. Oil Lubricated Bearings

Maintain proper lubrication by checking the oil level periodically and adding oil when necessary. Because

of the clearing action of the bearing as it accelerates, and the expansion of the oil as it gets hotter, the oil

level at the sight glass will be higher after the motor has been in operation for a while than it is with the

motor at standstill and cold. The normal level, with the motor stopped and the oil cold, is marked

STANDSTILL LEVEL on the sight gage.

Overfilling should be avoided not only because of the possibility that expansion may force the oil over the

oil sleeve and into the motor, but also because operating with the oil level too high prevents the bearing

from clearing itself of excess oil. The resultant churning can cause extra loss, high temperatures and

oxidized oil.

10

Page 13

GEI-M1025-B

NOTE: Warranty may be voided if internal maintenance or repairs are not performed by a GE Energy

Authorized Service Shop

If during operation, the oil level goes above the maximum shown on the sight gage, drain enough oil to

bring the level back within the operating range. To drain the oil, remove the drain plug below the sight

gage. Do not permit the operating oil level to fall below the minimum shown on the gage.

If it ever becomes necessary to add excessive amounts of make-up oil, investigate for oil leaks.

Change oil at regular intervals. The time between oil changes depends upon the severity of operating

conditions and, hence, must be determined by the motor user. One or two changes a year is average, but

special conditions, such as high ambient temperature, may require more frequent changes. Avoid

operating the motor with oxidized oil. Use only best grade, oxidation and corrosion inhibited turbine oil

produced by reputable oil companies. The lubrication nameplate on each motor specifies the viscosity

range of oil suitable for average conditions.

Operation in ambient temperatures that are near or below freezing may require preheating the oil or the

use of a special oil.

Too viscous an oil could cause the following:

a. Increased fluid friction losses resulting in higher operating temperatures. Higher temperatures will

cause the oil to oxidize and break down at an accelerated rate.

b. Oil tends to churn or foam more than a less viscous oil.

c. Bearings may run warmer because of reduced oil circulation through and around the bearings.

Too light an oil may allow the oil film to wipe or break down.

6. Inspecting Thrust bearings and Couplings

The parts should be removed in the following order: (1) top hat, (2) drive nut on the pump shaft, (3) upper

half coupling, (4) ball carrier, (5) ratchet balls, (6) locknut and washer, (7) ratchet plate, (8) lower half

coupling and bearing. When the thrust bearing is removed, the upper bracket can be lifted off the frame

after removing the bracket bolts. If required, the rotor and shaft can be lifted out with the upper bracket

by removing the lower bearing cap bolts.

G. Couplings

The condition of non-reverse couplings should be checked periodically. If dirt has caused the action of the

balls to become sluggish, the ball carrier should be removed, disassembled and thoroughly cleaned with a

suitable solvent. The parts should then be dried and reassembled. See the Coupling Assembly section below.

Sometimes, after a long period of operation with frequent stops and starts, the surface of the holes in the ball

carrier becomes polished, so that friction forces will no longer hold the balls clear of the ratchet plate when

the motor is running. This condition can be remedied by roughening these surfaces with a piece of emery

paper wrapped around a rod.

Bolts on both bolted couplings and non-reverse couplings should be checked periodically to be sure they are

tight. See FASTENER TORQUES below.

11

Page 14

GEI-M1025-B

H. Re-Assembling the Upper End

The lower guide bearing is restrained to take momentary up thrust. When reassembling the upper bearing

and coupling, it is important to avoid a preload stress on the guide and thrust bearings. The following

assembly procedure should be used.

1. Leave the shaft locknut loose.

2. Tighten the lower bearing cap bolts.

3. Tighten shaft locknut and raise the shaft until the bearings are just starting to preload. When slight

preloading is experienced, there is no endplay and the rotor will not turn as freely by hand.

4. After slightly preloading the bearings, back off the shaft locknut approximately 1/4 turn.

5. If the equipment is available, it is desirable for the shaft endplay be checked using a dial indicator to

measure movement as the rotor and shaft are raised and lowered. Shaft endplay should be 0.005 in. to

0.020 in. (0.127 mm to 0.508 mm).

6. When proper endplay is established, lock the nut in place with the shaft lock washer.

12

Page 15

GEI-M1025-B

Affected Parts

Difficulty

What to Check

Windings

Overheating

Bearings

Overheating

Worn out or dirty grease

Motor

Excessive Vibration

Winding Insulation

Low insulation resistance

or insulation failure

windings

VI. OPERATIONAL DIFFICULTIES

Some operating difficulties may occur. Common causes are given in the table below and should be corrected as

soon as possible.

Trouble Shooting Table

13

Page 16

GEI-M1025-B

WARNING: An extreme overload or electrical failure may result in heating or arcing which can

cause the insulation to give off noxious fumes. All power should be removed from the motor

circuit as a precaution even though the circuit has overload protection. Personnel should not

approach the motor until adequate ventilation of the area has purged the air of fumes. When covers of a motor

are removed after a failure, care should be observed to avoid breathing fumes from inside the motor. Preferably,

time should be allowed for the motor to cool before attempting any examination or repair.

WARNING: Water should not be applied to any electrically energized equipment because electric

shock could result in serious or fatal injury. In case of fire, disconnect all power and use a carbon

dioxide extinguisher to quench the flame. Before operating any motor after a suspected failure,

it should be inspected for damage.

WARNING: When burning off old insulation materials or when welding near insulation during

rewinding, adequate ventilation must be provided to avoid exposing personnel to noxious fumes.

Combustion of exhaust must be complete and adequately vented to the outside atmosphere in

compliance with acceptable standards. Exposure of personnel to air-borne inorganic fibers must be avoided by

adequate ventilation or by wetting the remaining insulation components following the burning of the organic

materials.

VII. FAILURE

VIII. REPAIR

If a motor is marked with IECEx or ATEX designation and repairs are required, the motor must be repaired by

operators trained in the understanding of BS/EN 60079-1 and BS/EN 60079-15 standards. The motor has been

designed to meet the rigid requirements of these standards. Repair or alteration of the motor may result in the motor

no longer meeting the requirements of these standards. If major repairs are undertaken (such as rewinding a stator),

proper facilities should be made available and suitable precautions observed.

IX. RENEWAL PARTS

The use of only GE Energy renewal parts is recommended. When ordering, specify the model number and the serial

number of the motor (complete nameplate data is desirable). Specify quantity and describe the part.

For information and service, refer to the nearest GE Energy Sales Office or a GE Energy Authorized Service Shop.

14

Page 17

GEI-M1025-B

Screw/Bolt Size

Typical Application

Torque

(Inch-Lb)

Torque

(N-M)

#10 Low Carbon Steel

Bearing Cap

15 - 25

1.7 – 2.8

¼” Low Carbon Steel (M6)

Bearing Cap

35 - 60

4.0 – 6.8

¼” (M6)

All Parts, except Bearing Cap and Fan Cover

70 – 96

7.9 – 10.8

¼” Grade 8 (M6)

Fan Cover Mounting

100 - 145

11 – 16

5/16” (M8)

Bearing Cap

78 - 120

8.8 – 14

5/16” (M8)

All Parts, except Bearing Cap

170 - 250

19 – 28

3/8” Low Carbon Steel

(M10)

Conduit Box Cover

180 – 240

20 – 27

3/8” (M10)

All Parts, except Conduit Box Cover

250 – 370

28 – 42

½” (M12)

All Parts

610 – 920

70 – 100

5/8” (M16)

All Parts

1440 - 2160

163 - 244

¾” (M20)

All Parts

2150 – 3200

240 – 360

Screw/Bolt Size

Typical Application

Torque

(Inch-Lb)

Torque

(N-M)

#10

Bearing Cap

15 – 25

1.7 – 2.8

¼” (M6)

Bearing Cap

35 – 60

4.0 – 6.8

¼” (M6)

All parts, except Bearing Cap

60 - 75

6.8 – 8.5

5/16” (M8)

Bearing Cap

78 – 120

8.8 – 14

5 /16” (M8)

All parts, except Bearing Cap

130 – 155

15 – 18

3/8” (M10)

All Parts

230 – 275

26 – 31

½” (M12)

All Parts

550 - 670

62 – 76

5/8” (M16)

All parts

1100 – 1340

120 – 150

¾” M20)

All Parts

2000 - 2360

230 - 270

X. FASTENER TORQUES

A. Medium carbon steel fasteners per ASTM A449 Type 1.

B. Stainless steel fasteners per ASTM F593.

C. Threaded holes in parts for fasteners are per System 21, ASME/ANSI B1.3

D. SAE Grade 5 bolts have 3 radial marks on the head.

E. SAE Grade 8 bolts have 5 radial marks on the head.

F. Low carbon steel bolts have no marks on the head.

G. Low carbon steel bolts - Use 50% of the Grade 5 Torque.

Medium Carbon Steel SAE Hardware Grade 5 Fastener Torques

(Unless otherwise specified)

Stainless Steel SAE Hardware Property Class 50 Fastener Torques

15

Page 18

GEI-M1025-B

GIB KEY

BALLS

NOTE: Thoroughly clean coupling & all

related components prior to mounting on motor.

COUPLING BOLTS

COUPLING LOCK WASHERS

UPPER HALF-COUPLING

COVER PLATE BOLTS

COVER PLATE

LOCK WASHERS

COVER PLATE

RATCHET PLATE

LOWER HALF-COUPLING

(LOCATED ON MOTOR)

Item

Quantity

Coupling

1

Coupling Bolts

3

Coupling Lock Washers

3

Cover Plate

1

Cover Plate Bolts

5

Cover Plate Lock Washers

5

Steel Balls

10

Gib Key

1

Instructions

1

Frame Size

Item

Torque (Ft-Lb)

Torque (N-M)

210

5/16 - 18 UNC x 1-3/4 Coupling Bolt

17

23

250 - 280

3/8 - 16 UNC x 2-1/4 Coupling Bolt

30

41

210 - 280

1/4 - 20 UNC x 1/2 Cover Plate Bolts

8

11

It is the installer’s responsibility in all cases to ensure these torque values are used and maintained.

This includes those instances when the coupling comes mounted in the motor. Failure to comply may

cause the coupling bolts to break, with resultant, extensive damage to the equipment.

Typical TEFC Construction

Typical Dripproof Construction

XI. COUPLING ASSEMBLY

A. 210 - 280 Frame Non-Reverse and Bolted Coupling

Coupling Kit Packing List

Bolt Torque Chart

1. Non-Reverse Coupling

16

Page 19

GEI-M1025-B

NOTE: Thoroughly clean coupling & all

related components prior to mounting on motor.

COUPLING BOLTS

COUPLING LOCK WASHERS

UPPER HALF-COUPLING

COVER PLATE BOLTS

COVER PLATE

LOCK WASHERS

COVER PLATE

GIB KEY

RATCHET PLATE

LOWER HALF-COUPLING

(LOCATED ON MOTOR)

2. Bolted Coupling - Steel balls not used on Bolted Coupling assemblies.

Note: Steel balls not used on bolted coupling assembly.

17

Page 20

GEI-M1025-B

Item

Quantity

Upper Half Coupling

1

Coupling Bolts

6

Coupling Lock Washers

6

Cover Plate

1

Cover Plate Bolts

5

Cover Plate Lock Washers

5

Balls

10

Gib Key

1

Instructions

1

Part Name

Frame Size

Item

Torque (Ft-Lb)

Torque (N-M)

Cover Plate Bolts

320/440

1/4 - 20 UNC x 5/8 Bolt

8

11

Coupling Bolts

320/360

1/2 - 13 UNC x 2-1/2 Bolt

75

102

Coupling Bolts

400/440

5/8 - 11 UNC x 3-1/2 Bolt

150

203

It is the installer’s responsibility in all cases to ensure these torque values are used and maintained.

This includes those instances when the coupling comes mounted in the motor. Failure to comply may

cause the coupling bolts to break, with resultant, extensive damage to the equipment.

NOTE: Thoroughly clean coupling & all

related components prior to mounting on motor.

B. 320 - 449 Frame Non-Reverse and Bolted Coupling

Coupling Kit Packing List

Bolt Torque Chart

1. Non-Reverse Coupling

18

Page 21

GEI-M1025-B

NOTE: Thoroughly clean coupling & all

related components prior to mounting on motor.

2. Bolted Coupling - Steel balls not used on Bolted Coupling assemblies.

19

Loading...

Loading...