Page 1

POWER LEADER

PMCS 6.11a

Interface Toolkit

TM

Installation Guide

GEH-6513

GE Power Management Control System 6.11a

PMCS Interface Toolkit Back to Main Menu •••• i

Page 2

Notice

The information contained in this document is subject to change without notice. GE makes no warranty of any

kind with regard to this material, including, but not limited to, the implied warranties of merchantability and

fitness for a particular purpose. GE shall not be liable for errors contained herein or incidental consequential

damages in connection with the furnishing, performance, or use of this material.

This document contains proprietary information which is protected by copyright. All rights are reserved. No part

of this document may be photocopied or otherwise reproduced without consent of GE.

Copyright ©2000 - 2002 by GE. Published in a limited copyright sense, and all rights, including trade secrets,

are reserved.

Document Edition - First 5/96

Second 5/97

Third 1/98

Fourth 06/98

Fifth 03/99

Sixth 07/99

Seventh 03/00

Eighth 10/00

Ninth 02/01

Tenth 06/01

Eleventh 01/02

The following are products of General Electric Company:

POWER LEADERTM Meter 239 Motor Protection Relay GE Fanuc Series 90/30 PLC

POWER LEADER Modbus Monitor 269 Plus Motor Management Relay GE Fanuc Series 90/70 PLC

POWER LEADER Electronic Power

Meter

Spectra MicroVersaTrip SR469 Motor Management Relay EPM 7300 Electronic Power Meter

EPM 7600 Electronic Power Meter EPM 7500 Electronic Power Meter EPM 7330 Electronic Power Meter

Enhanced MicroVersaTrip-C SR489 Generator Management Relay EPM 7700 Electronic Power Meter

Enhanced MicroVersaTrip-D 565 Feeder Management Relay EPM 3710 Electronic Power Meter

MDP Overcurrent Relay 735 Feeder Relay EPM 3720 Electronic Power Meter

SR750/SR760 Feeder Management Relay SR745 Transformer Management Relay Spectra Electronic Control Module

Universal Relay EPM7430D/EPM7450D Motor Manager II (MMII)

GE-Zenith MX200 (Microprocessor

Controller)

EPM5350P (DMMS350) EPM5000P (DMWH300) EPM9450Q/EPM9650Q

369 Motor Management Relay Power Quality Meter (PQM)

GE-Zenith Generator PLC (Series 90-

70)

EPM5300P/EPM5200P

Electronic Power Meter 3710 , Electronic Power Meter 3720, Electronic Power Meter 7300, Electronic Power

Meter 7330, Electronic Power Meter 7500, Electronic Power Meter 7600, and Electronic Power Meter 7700 are

products of Power Measurement Limited.

Multilin 269+ Motor Management Relay® is a registered trademarks of Multilin Inc., and Multilin SR489

Generator Management Relay™ and Multilin SR745 Transformer Management Relay™ are trademarks of

Multilin Inc.

Microsoft, Microsoft Access, Microsoft Excel, Microsoft PowerPoint, Microsoft Visual Basic, and MS-DOS are

registered trademarks, and Windows NT is a trademark of Microsoft Corporation.

Wonderware is a registered trademark of WonderWare Corporation. Wonderware InTouch and NetDDE are

trademarks of WonderWare Corporation.

US Pat Nos 5,768,148; 5,764,155; 5,862,391

ii •••• Back to Main Menu PMCS Interface Toolkit

Page 3

Back to Main Menu

Contents

INTRODUCTION.............................................................................................................................................................. 1

W

ELCOME......................................................................................................................................................................... 1

H

OW SHOULD I USE THIS MANUAL? .................................................................................................................................. 2

C

ONVENTIONS .................................................................................................................................................................. 3

A

BOUT THE INTERFACE TOOLKIT...................................................................................................................................... 3

I

NSTALLATION .................................................................................................................................................................. 3

USING AND CONFIGURING PMCS WIZARDS ......................................................................................................... 5

A

BOUT THE WIZARDS ....................................................................................................................................................... 5

S

MALL FACEPLATE WIZARDS ........................................................................................................................................... 6

Usage ........................................................................................................................................................................... 6

Configuration............................................................................................................................................................... 6

L

ARGE FACEPLATE WIZARDS............................................................................................................................................ 8

Usage ........................................................................................................................................................................... 8

Configuration............................................................................................................................................................... 9

Special Considerations ................................................................................................................................................ 9

T

ABULAR DATA SCREEN WIZARDS................................................................................................................................. 11

Usage ......................................................................................................................................................................... 11

Configuration............................................................................................................................................................. 11

O

NE-LINE WIZARDS........................................................................................................................................................ 16

Usage ......................................................................................................................................................................... 16

Configuration............................................................................................................................................................. 17

Circuit Breaker One-Line Wizards............................................................................................................................. 21

E

LEVATION WIZARDS ..................................................................................................................................................... 22

Usage ......................................................................................................................................................................... 22

Configuration............................................................................................................................................................. 22

F

LOOR PLAN WIZARDS ................................................................................................................................................... 23

Usage ......................................................................................................................................................................... 23

Configuration............................................................................................................................................................. 23

T

OOLBAR WIZARD .......................................................................................................................................................... 24

Usage ......................................................................................................................................................................... 24

Configuration............................................................................................................................................................. 24

A

NNUNCIATOR PANEL WIZARD ...................................................................................................................................... 25

Usage ......................................................................................................................................................................... 25

Configuration............................................................................................................................................................. 29

PMCS Interface Toolkit Back to Main Menu •••• iii

Page 4

Troubleshooting Tips for the Annunciator Panel Wizard .......................................................................................... 34

C

USTOM TABLE WIZARD ................................................................................................................................................ 35

Usage ......................................................................................................................................................................... 35

Configuration............................................................................................................................................................. 35

S

YSTEM STATISTICS WIZARD .......................................................................................................................................... 40

Usage ......................................................................................................................................................................... 40

Configuration............................................................................................................................................................. 40

L

OCKOUT/TAGOUT WIZARD ........................................................................................................................................... 42

Usage ......................................................................................................................................................................... 42

Supported Devices...................................................................................................................................................... 42

Configuration............................................................................................................................................................. 43

Example of Lockout/Tagout Wizard........................................................................................................................... 44

S

PECIAL SCRIPTING CONSIDERATIONS FOR THE EPM 7700............................................................................................. 48

Installing the Application Script ................................................................................................................................ 49

EPM 7700 Tabular Data Screen Scripting ................................................................................................................ 54

CREATING FLOOR PLANS, ELEVATION VIEWS, AND ONE-LINE DIAGRAMS ........................................... 55

I

NTRODUCTION ............................................................................................................................................................... 55

E

LEVATION VIEWS .......................................................................................................................................................... 55

F

LOOR PLANS.................................................................................................................................................................. 57

E

LECTRICAL ONE-LINE DIAGRAMS ................................................................................................................................. 58

C

REATING A BASIC INTERFACE ........................................................................................................................................ 61

FEATURES OF GE LARGE FACEPLATE WIZARDS.............................................................................................. 67

A

BOUT THE LARGE FACEPLATE WIZARDS ...................................................................................................................... 67

POWER LEADER EPM................................................................................................................................................ 68

S

PECTRA MICROVERSATRIP TRIP UNIT .......................................................................................................................... 71

E

NHANCED MICROVERSATRIP-C TRIP UNIT .................................................................................................................. 72

E

NHANCED MICROVERSATRIP-D TRIP UNIT .................................................................................................................. 74

POWER LEADER M

S

PECTRA ECM................................................................................................................................................................ 78

EPM 3710 M

EPM 3720 M

EPM 7700 M

269 P

LUS MOTOR MANAGEMENT RELAY ....................................................................................................................... 87

565 F

EEDER MANAGEMENT RELAY ................................................................................................................................92

ETER.......................................................................................................................................................... 80

ETER.......................................................................................................................................................... 82

ETER.......................................................................................................................................................... 84

ETER............................................................................................................................................. 76

FEATURES OF TABULAR DATA SCREEN WIZARDS........................................................................................... 99

I

NTRODUCTION ............................................................................................................................................................... 99

F

EATURES OF TABULAR DATA SCREENS ......................................................................................................................... 99

P

OWER LEADER EPM ................................................................................................................................................... 101

S

PECTRA MICROVERSATRIP ......................................................................................................................................... 102

E

NHANCED MICROVERSATRIP-C TRIP UNIT ................................................................................................................ 103

E

NHANCED MICROVERSATRIP-D TRIP UNIT ................................................................................................................ 104

POWER LEADER M

S

PECTRA ECM.............................................................................................................................................................. 106

MDP D

IGITAL OVERCURRENT RELAY .......................................................................................................................... 107

ETER........................................................................................................................................... 105

Monitoring Tab ........................................................................................................................................................ 107

Command Tab .......................................................................................................................................................... 108

Setup Tab ................................................................................................................................................................. 109

PQM (P

OWER QUALITY METER) .................................................................................................................................. 110

Metering Tab............................................................................................................................................................ 111

Status Tab................................................................................................................................................................. 112

Demand Tab............................................................................................................................................................. 113

IV Range Tab ........................................................................................................................................................... 114

iv •••• Contents PMCS Interface Toolkit

Page 5

P Range Tab............................................................................................................................................................. 115

Analysis Tab............................................................................................................................................................. 116

IO Tab ...................................................................................................................................................................... 117

Setpoints Tab............................................................................................................................................................ 118

M

OTOR MANAGER II (MMII) ....................................................................................................................................... 119

EPM 3710 M

EPM 3720 M

EPM 7300 M

ETER........................................................................................................................................................ 120

ETER........................................................................................................................................................ 121

ETER........................................................................................................................................................ 122

Metering Tab............................................................................................................................................................ 123

Min/Max Tab............................................................................................................................................................ 124

Setup Tab ................................................................................................................................................................. 125

EPM 7330 M

ETER........................................................................................................................................................ 126

Metering Tab............................................................................................................................................................ 127

Min/Max................................................................................................................................................................... 128

Setup Tab ................................................................................................................................................................. 129

EPM 7500/7600 M

ETER............................................................................................................................................... 130

Metering Tab............................................................................................................................................................ 130

Min/Max Tab............................................................................................................................................................ 132

Power Quality Tab................................................................................................................................................... 133

Demand Tab............................................................................................................................................................. 134

Inputs Tab ................................................................................................................................................................ 135

Setup 1 Tab .............................................................................................................................................................. 136

Setup 2 Tab .............................................................................................................................................................. 138

EPM 7700 M

ETER........................................................................................................................................................ 140

Metering Tab............................................................................................................................................................ 140

Min/Max Tab............................................................................................................................................................ 142

Power Quality Tab................................................................................................................................................... 143

Demand Tab............................................................................................................................................................. 144

Inputs Tab ................................................................................................................................................................ 145

Setup 1 Tab .............................................................................................................................................................. 146

Setup 2 Tab .............................................................................................................................................................. 148

U

NIVERSAL RELAY ....................................................................................................................................................... 150

Metering Tab............................................................................................................................................................ 151

Power Quality Tab................................................................................................................................................... 152

Protection Control Tab ............................................................................................................................................ 153

Power System Configuration Tab ............................................................................................................................ 154

Transformer Tab ...................................................................................................................................................... 156

Elements Tab............................................................................................................................................................ 157

Digital Counter Tab................................................................................................................................................. 158

Virtual Inputs Tab.................................................................................................................................................... 159

Virtual Outputs Tab ................................................................................................................................................. 160

Contact Inputs Tab................................................................................................................................................... 161

Contact Output Tab.................................................................................................................................................. 162

DCMA Tab ............................................................................................................................................................... 163

Source Tabs.............................................................................................................................................................. 164

Demand Tab............................................................................................................................................................. 165

Line Tab ................................................................................................................................................................... 166

Breaker Tab ............................................................................................................................................................. 167

Contact Output Current States Tab.......................................................................................................................... 168

Remote Temperature Detection Tab ........................................................................................................................ 169

Bus Tab .................................................................................................................................................................... 170

239 M

OTOR PROTECTION RELAY.................................................................................................................................. 171

Metering tab............................................................................................................................................................. 171

Status Tab ................................................................................................................................................................ 172

Trip Data.................................................................................................................................................................. 173

PMCS Interface Toolkit Contents •••• v

Page 6

Setpoints Tab............................................................................................................................................................ 174

269 P

LUS MOTOR MANAGEMENT RELAY ..................................................................................................................... 175

369 M

OTOR MANAGEMENT RELAY .............................................................................................................................. 176

Metering Tab............................................................................................................................................................ 176

Alarms Tab............................................................................................................................................................... 178

Demand Tab............................................................................................................................................................. 179

Local RTD Tab......................................................................................................................................................... 180

Remote RTD Tab...................................................................................................................................................... 181

Control Tab.............................................................................................................................................................. 182

Setup Tab ................................................................................................................................................................. 183

SR469 M

OTOR MANAGEMENT RELAY.......................................................................................................................... 184

Metering Tab............................................................................................................................................................ 184

Status Tab................................................................................................................................................................. 185

Alarms Tab............................................................................................................................................................... 186

Trip Tab.................................................................................................................................................................... 187

IO Tab ...................................................................................................................................................................... 188

Maintenance Tab...................................................................................................................................................... 189

Analog Tab............................................................................................................................................................... 190

RTD HI Tab.............................................................................................................................................................. 191

Setpoints Tab............................................................................................................................................................ 191

SR489 G

ENERATOR MANAGEMENT RELAY.................................................................................................................. 192

Metering Tab............................................................................................................................................................ 192

Pickup Tab ............................................................................................................................................................... 193

Alarms Tab............................................................................................................................................................... 193

Trip Data Tab........................................................................................................................................................... 194

IO Tab ...................................................................................................................................................................... 195

Maintenance Tab...................................................................................................................................................... 196

Setpoints Tab............................................................................................................................................................ 197

565 F

EEDER MANAGEMENT RELAY .............................................................................................................................. 198

735 F

EEDER RELAY ...................................................................................................................................................... 200

Metering Tab............................................................................................................................................................ 200

Trip Data Tab........................................................................................................................................................... 201

Setpoints Tab............................................................................................................................................................ 202

SR745 T

RANSFORMER MANAGEMENT RELAY.............................................................................................................. 203

Metering Tab............................................................................................................................................................ 203

Flags Tab ................................................................................................................................................................. 204

IO Tab ...................................................................................................................................................................... 204

Demand Tab............................................................................................................................................................ 205

Harmonic Tab .......................................................................................................................................................... 206

Setpoints Tab............................................................................................................................................................ 207

Power Tab................................................................................................................................................................ 208

SR750/760 F

EEDER MANAGEMENT RELAY .................................................................................................................. 209

Metering Tab............................................................................................................................................................ 210

Status Tab................................................................................................................................................................. 211

Fault Tab.................................................................................................................................................................. 211

Trip Tab.................................................................................................................................................................... 212

Demand Tab............................................................................................................................................................. 213

Logic Tab ................................................................................................................................................................. 214

IO Tab ...................................................................................................................................................................... 214

Setpoints Tab............................................................................................................................................................ 215

F

ANUC 90/30 ................................................................................................................................................................ 216

F

ANUC 90/70 ................................................................................................................................................................ 216

F

ANUC MICRO 90.......................................................................................................................................................... 217

MX200 ......................................................................................................................................................................... 218

Metering Tab............................................................................................................................................................ 218

vi •••• Contents PMCS Interface Toolkit

Page 7

Setup Tab ................................................................................................................................................................. 220

GEN PLC..................................................................................................................................................................... 223

Master Tab............................................................................................................................................................... 223

Generator Tab.......................................................................................................................................................... 224

PSG .......................................................................................................................................................................... 225

EPM5300P ................................................................................................................................................................... 227

Metering Tab............................................................................................................................................................ 227

Setup One Tab.......................................................................................................................................................... 229

Setup Two Tab.......................................................................................................................................................... 230

EPM5200P ................................................................................................................................................................... 232

Metering Tab............................................................................................................................................................ 232

Setup One Tab.......................................................................................................................................................... 233

EPM5350P ................................................................................................................................................................... 235

Metering Tab............................................................................................................................................................ 235

Setup One Tab.......................................................................................................................................................... 236

Setup Two Tab.......................................................................................................................................................... 237

EPM5000P ................................................................................................................................................................... 239

Metering................................................................................................................................................................... 239

Setup......................................................................................................................................................................... 240

EPM9450Q/EPM9650Q .............................................................................................................................................. 241

Metering................................................................................................................................................................... 241

Min/Max................................................................................................................................................................... 242

Demand.................................................................................................................................................................... 243

Thermal Average...................................................................................................................................................... 244

Digital Inputs ........................................................................................................................................................... 245

Setup......................................................................................................................................................................... 246

EPM7430D/EPM7450D .............................................................................................................................................. 247

Metering................................................................................................................................................................... 247

Min/Max................................................................................................................................................................... 248

Limits........................................................................................................................................................................ 249

Setup......................................................................................................................................................................... 251

TROUBLESHOOTING ................................................................................................................................................ 252

A

SSERTION ERROR........................................................................................................................................................ 252

EPM 3710/EPM 3720 –

EPM 3720 – KVAH

L

ONG UPDATE WHEN CHANGING SETPOINTS.................................................................................................................. 252

PLEPM – W

I

NTOUCH APPLICATIONS – WINDOWS NOT DISPLAYED PROPERLY................................................................................. 253

RONG METERING TAB DISPLAYED............................................................................................................. 252

NO DATA OR INCORRECT DATA DISPLAYED ............................................................................ 252

IMPORT VALUES INCORRECT ........................................................................................................ 252

APPENDIX A: EPM 3720 SLIDING WINDOW DEMAND KEYS ......................................................................... 255

D

OWNLOADING SLIDING DEMAND WINDOW KEYS TO THE EPM 3720 ......................................................................... 255

APPENDIX B: AUTOMATIC WAVEFORM CAPTURE AND WAVEFORM RETRIEVAL ON EPM3720.... 263

U

SING A SETPOINT TO TRIGGER WAVEFORM CAPTURE OR RECORD ON THE EPM 3720 ................................................. 263

APPENDIX C: EPM 7700 - SPECIAL CONSIDERATIONS ................................................................................... 279

EPM 7700 T

AGS SUBJECT TO DEACTIVATION BY TABULAR DATA SCREEN WIZARD ................................................... 279

INDEX............................................................................................................................................................................. 293

PMCS Interface Toolkit Contents •••• vii

Page 8

Page 9

Introduction

Welcome

The PMCS Interface Toolkit is a POWER LEADER Power Management Control

System (PMCS) version 6.11a tool that provides a custom toolkit to efficiently create

flexible, accurate, and friendly user interfaces to your power management data. With

the PMCS Wizards (accurate graphical representations of power management

devices and other commonly encountered objects), you can create applications to

provide a customized interface that accurately represents physical, electrical, and

geographical plant layouts. The wizards can significantly cut new system

development time, providing results in less than an hour.

The PMCS Interface Toolkit allows you to create one-line diagrams, elevation views,

and floor plans that you can combine with tabular data screens and three-dimensional

device wizards to create a virtual representation of your facility and equipment. With

this graphical user interface, you actually see and control devices on the screen,

without having to make a trip out to the meter or trip unit.

The Toolkit, which consists of the Wonderware InTouch development environment

coupled with GE’s wizards, is easy to use, taking advantage of state-of-the-art dragand-drop technology. Wizards are provided for all the devices most commonly used

with the PMCS DDE Server. Creating a custom interface is as easy as selecting

wizards for the devices installed in a facility and placing them on the screen.

Here’s what you’ll find in this guide:

• Chapter 2 explains the kinds of PMCS Wizards, their use and

configuration – Small Faceplate wizards, Large Faceplate wizards,

Tabular Data Screen wizards, One- Line wizards, Elevation wizards,

and Floor Plan wizards.

• Chapter 3 illustrates the use of the GE wizards described in Chapter 2

to create animated displays of the facility floor plan, switchgear

elevations, and system one- line diagrams.

• Chapter 4 gives an example of application development, using the

wizards described in Chapters 2 and 3 to create an actual PMCS

application.

• Chapter 5 describes the functions available with each of the GE Large

Faceplate wizards. These wizards are accurate graphical representations

1

Page 10

of power management devices, complete with working controls that are

linked to the corresponding devices in your facility.

• Chapter 6 describes the Tabular Data wizards. These wizards list the

data and setpoints of power management devices in a tabular format.

Simply point and click to select the appropriate tab of information to

display and view the related data.

The examples and references in this guide enable you to create custom interfaces for

your PMCS system, and allow you to access power management data in the way that

best suits you.

How should I use this manual?

How you use this book depends on your level of expertise with Wonderware

InTouch. Consult the table below to determine where you should start.

If this describes you… Start here:

I’ve never seen this stuff before! What’s

Wonderware InTouch? What are

“Wizards”?

I’ve just opened this package – where do I

go first?

I’m familiar with Wonderware InTouch

and I’d like to build a custom application

for some GE power management devices.

The GE PMCS Wizards are already

installed on my system, I’m already

experienced with InTouch, and I’m ready

to start building custom applications.

Just tell me about the wizards; I’m an old

pro and ready to go!

Refer to the documentation that came with your

Wonderware InTouch package. Start with the

introduction and tutorial sections, which will teach you

about Wonderware InTouch and how to use it to create

custom applications. When you understand what wizards

are and how to use them, come back here.

Go to Chapter 1, Introduction. Chapter 1 explains what

the User Screen Configurator is, what it’s good for, and

where to go after that.

Go to Chapter 1 for installation instructions, then to

Chapter 2 for descriptions of the wizards and how to use

them. Chapter 4 provides a demo of actual application

development. This package contains wizards for the

power management devices supported by GE’s PMCS

6.11a software.

Turn to Chapter 2 for information on how to use the GE

PMCS Wizards, and Chapter 4 for a quick example of

application development. For detailed descriptions of

the Large Faceplate wizards or the Tabular Data Screen

wizards, refer to Chapters 5 and 6 respectively.

Skim through Chapters 2 and 3 for an overview of

what’s in the package, then Chapter 4 for a quick

example of application development. Chapter 5

describes the GE Large Faceplate wizards and Chapter 6

the associated Tabular Data Screen wizards.

2 PMCS Interface Toolkit

Page 11

Conventions

You will find this book easy to use if you look for these simple conventions:

About the Interface Toolkit

The Interface Toolkit consists of the Wonderware InTouch development

environment and a special set of wizards developed for use with the power

management devices supported by PMCS.

Installation

To install the Interface Toolkit from the CD-ROM, refer to the instructions provided

in GEH-6514, Read This Book First.

When InTouch is successfully installed, you must add the PMCS wizards to

InTouch’s library of available wizards.

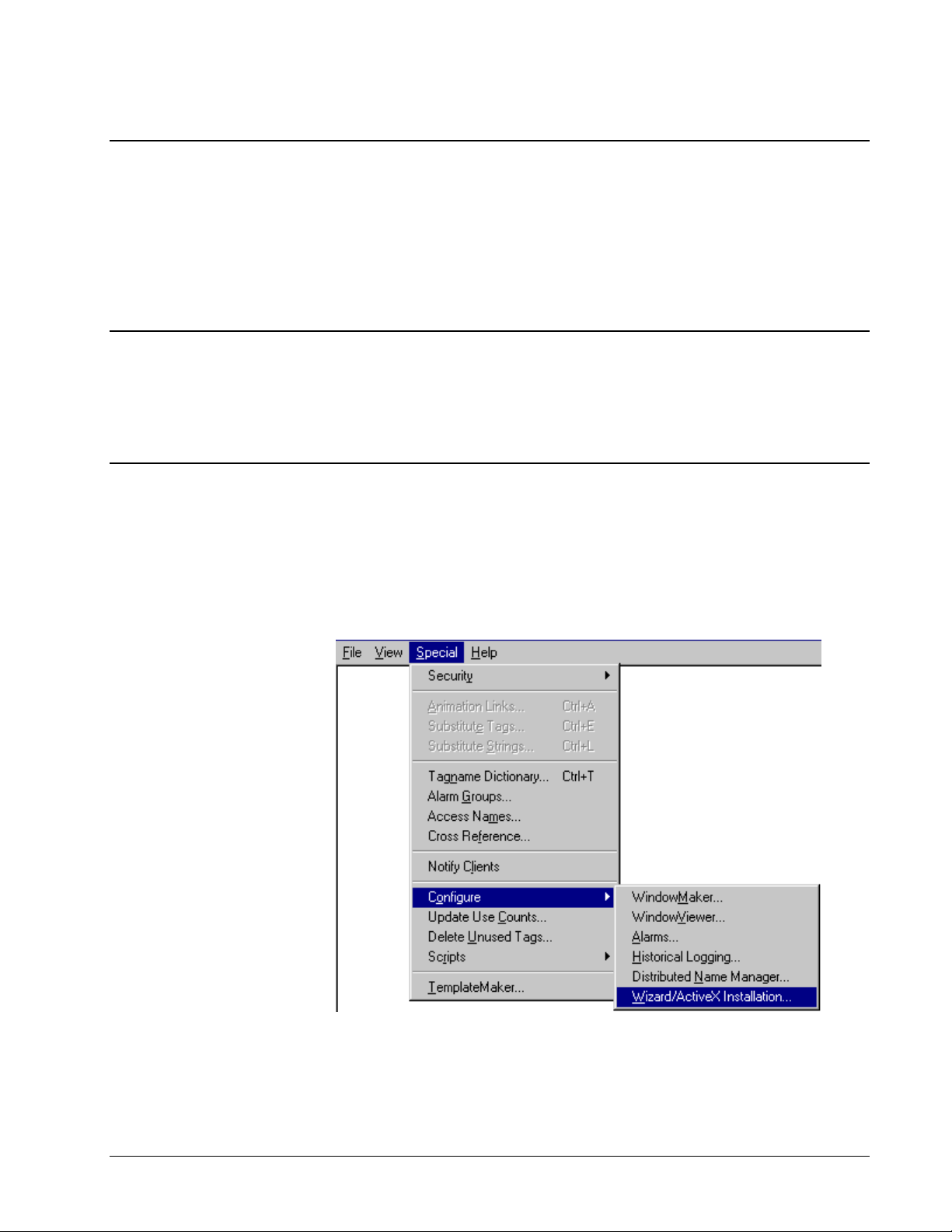

To add the wizards to InTouch, start InTouch and enter Development mode. Pull

down the Special menu and select Configure > Wizard.

• Boldface type indicates the name of an item you need to select.

• Monospace type indicates an example or text that is displayed on the

screen.

• UPPERCASE type indicates a file name, command name, or acronym.

3

Page 12

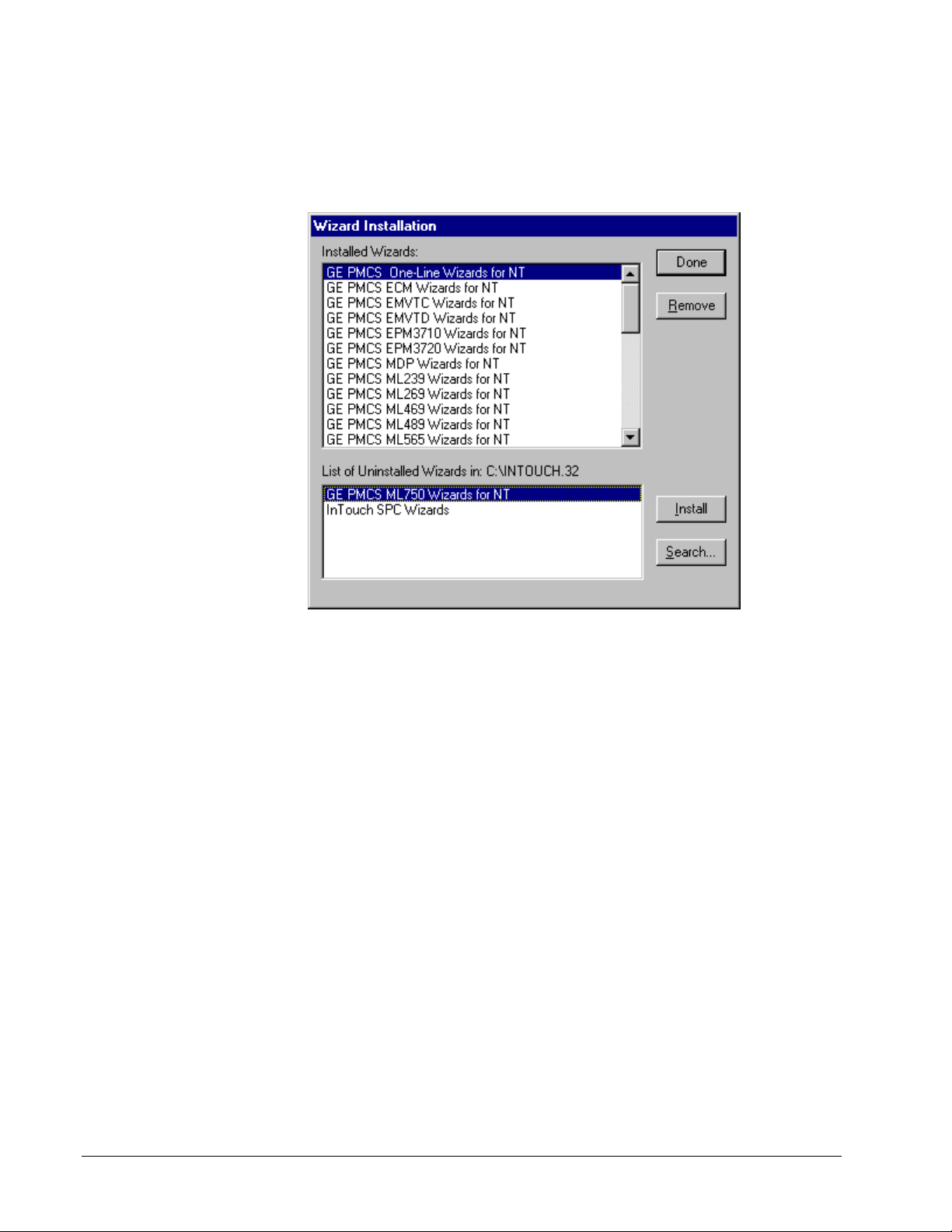

From the InTouch Configuration menu, select Install Wizards.

The Wizard Installation dialog displays two list boxes, showing the currently

installed wizards and the wizards available for installation. Select the desired wizards

from the bottom box and click Install. When the installation is complete, click Done.

Exit from the InTouch Configuration dialog box by clicking OK. The PMCS wizards

should now be loaded and ready for use.

4 PMCS Interface Toolkit

Page 13

Using and Configuring PMCS Wizards

About the Wizards

The wizards contained in the PMCS Interface Toolkit allow you to quickly build

accurate and friendly user interfaces with InTouch. In addition to the various wizards

standard with InTouch development systems, the Interface Toolkit provides six types

of powerful GE wizards:

• GE Small Faceplates

• GE Large Faceplates

• GE Tabular Screens

• GE One-Line Tools

• GE Elevation Wizards

• GE Floor Plan Wizards

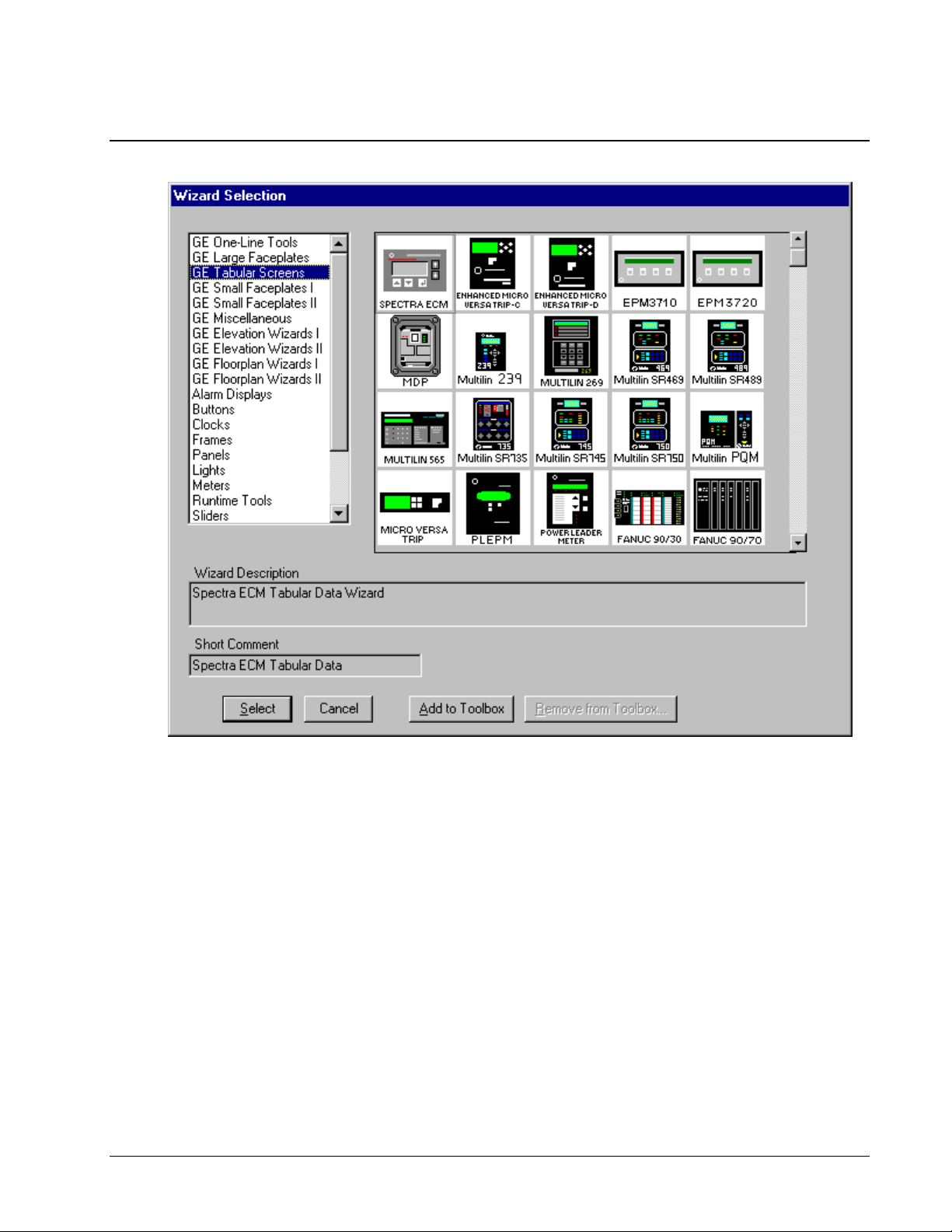

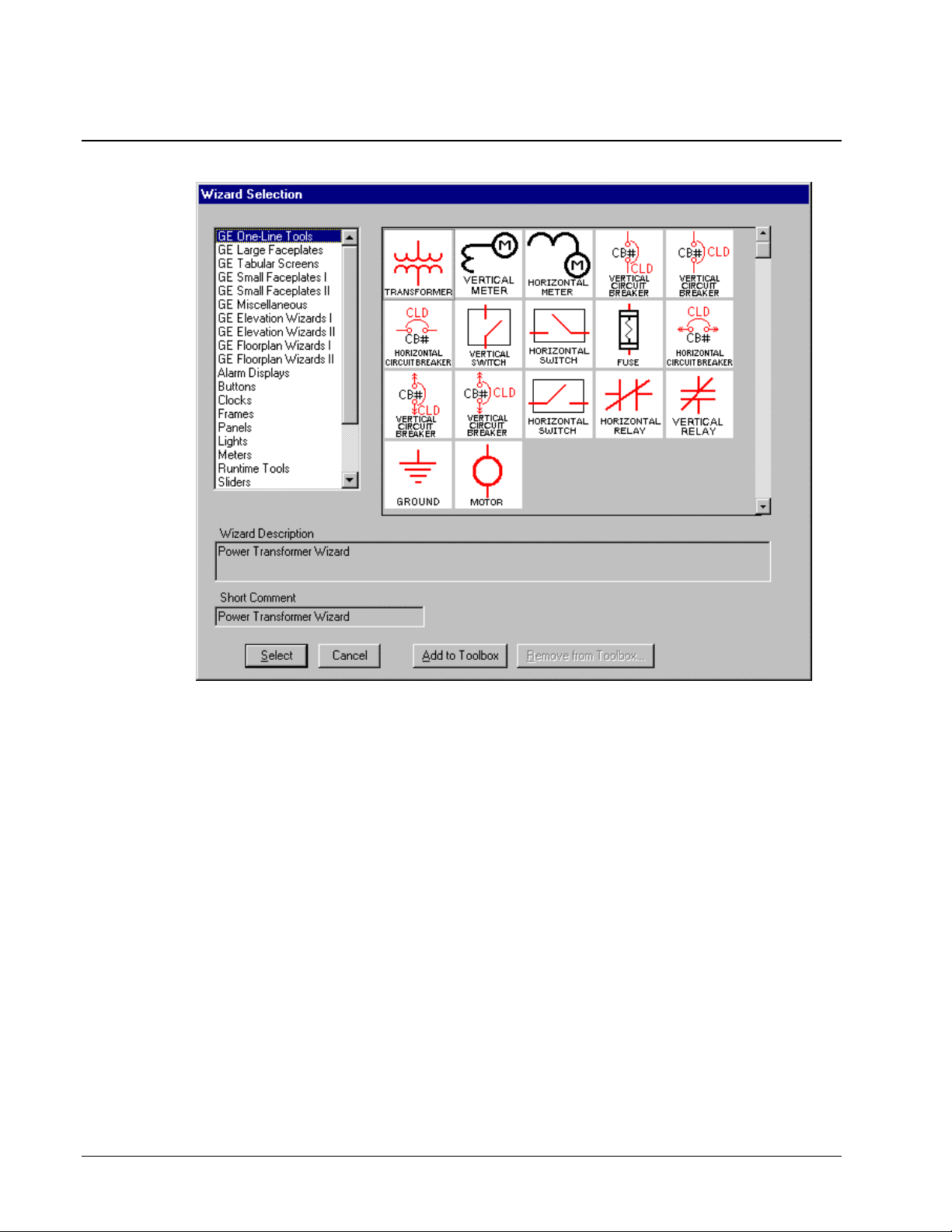

The five-step procedure below outlines how to use InTouch wizards.

1. From InTouch, either create a new window or open an existing window

to modify.

2. Select the wizards button

Selection dialog box pops up.

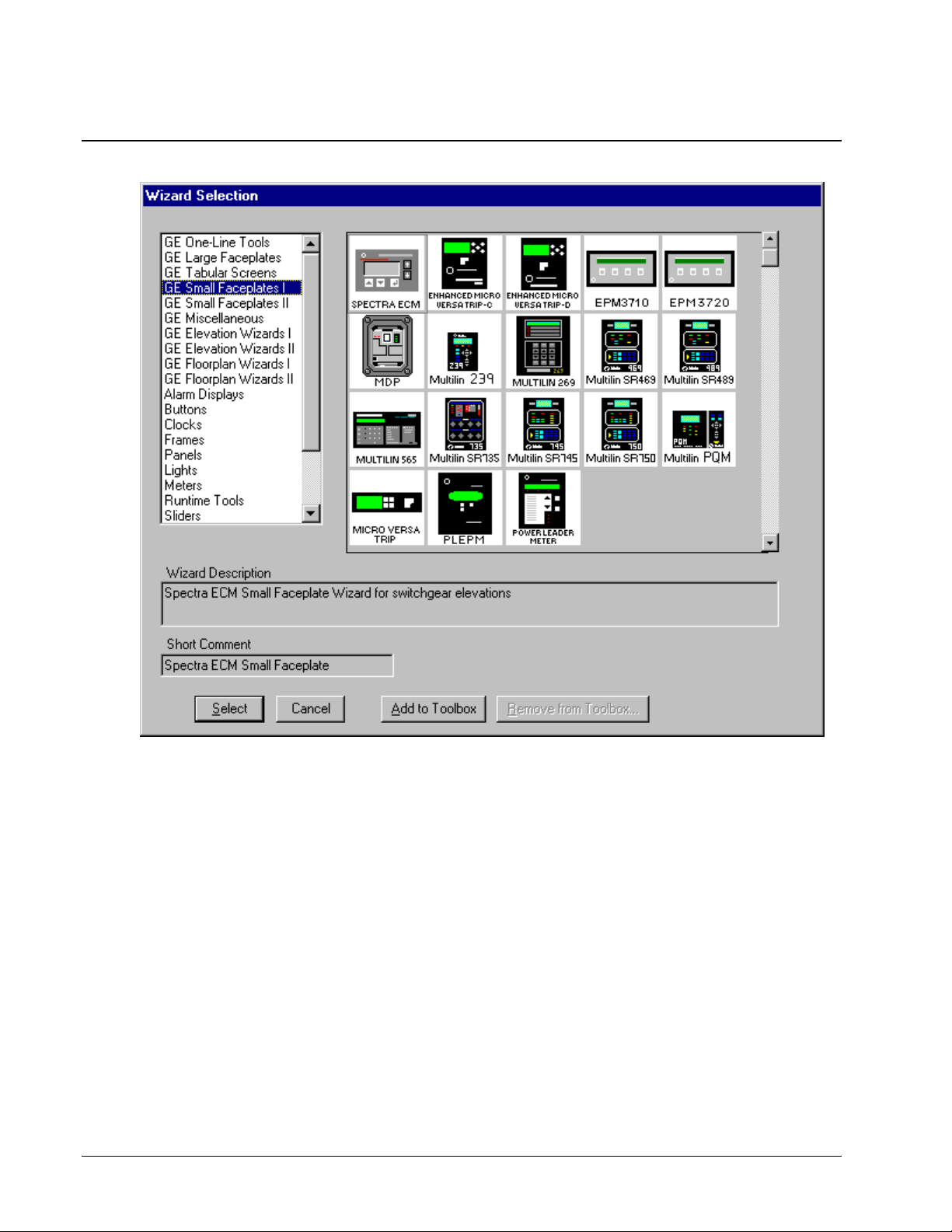

3. Select the class of wizard from the list of wizards on the left side of the

Wizard Selection dialog. Several classes contain too many devices to fit

on one palette and have been broken up into several palettes; for

example; Small Faceplates 1 and Small Faceplates 2.

4. Double-click on the desired wizard, then click on the window to place

the wizard.

5. Once the wizard has been placed, double-click anywhere on the wizard

to open a configuration dialog (if appropriate), and complete any

necessary configuration based on the instructions later in this chapter.

The remainder of this chapter is devoted to describing and illustrating the various

kinds of wizards included in the PMCS Interface Toolkit.

5

from the floating toolbars. The Wizard

Page 14

Small Faceplate Wizards

Usage

The Small Faceplate wizards are icon-sized graphics typically used to create accurate

elevation views and one-line diagrams. These wizards are provided with logic to

open another window, typically either a Large Faceplate or Tabular Data Screen

wizard. There are two palettes of Small Faceplates to choose from.

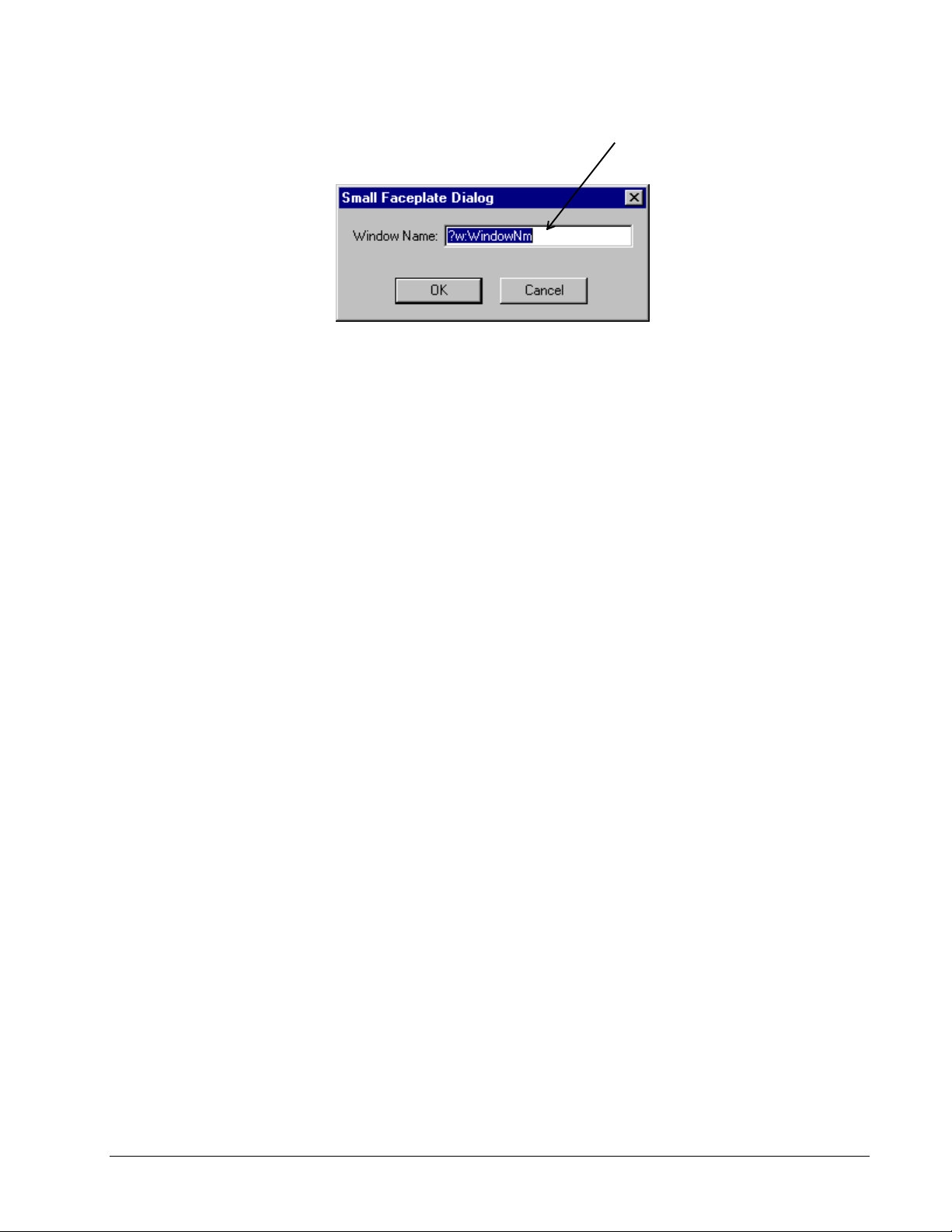

Configuration

In development mode, after placing the Small Faceplate, double-click on the icon to

open the Small Faceplate Dialog box, as illustrated below. Typically, a Small

Faceplate wizard is linked to a window containing either a Large Faceplate or a

Tabular Data Screen wizard. You can move or resize Small Faceplate wizards in the

window as desired.

6 PMCS Interface Toolkit

Page 15

Enter the name of the window

to open when the icon is

clicked on during runtime.

7

Page 16

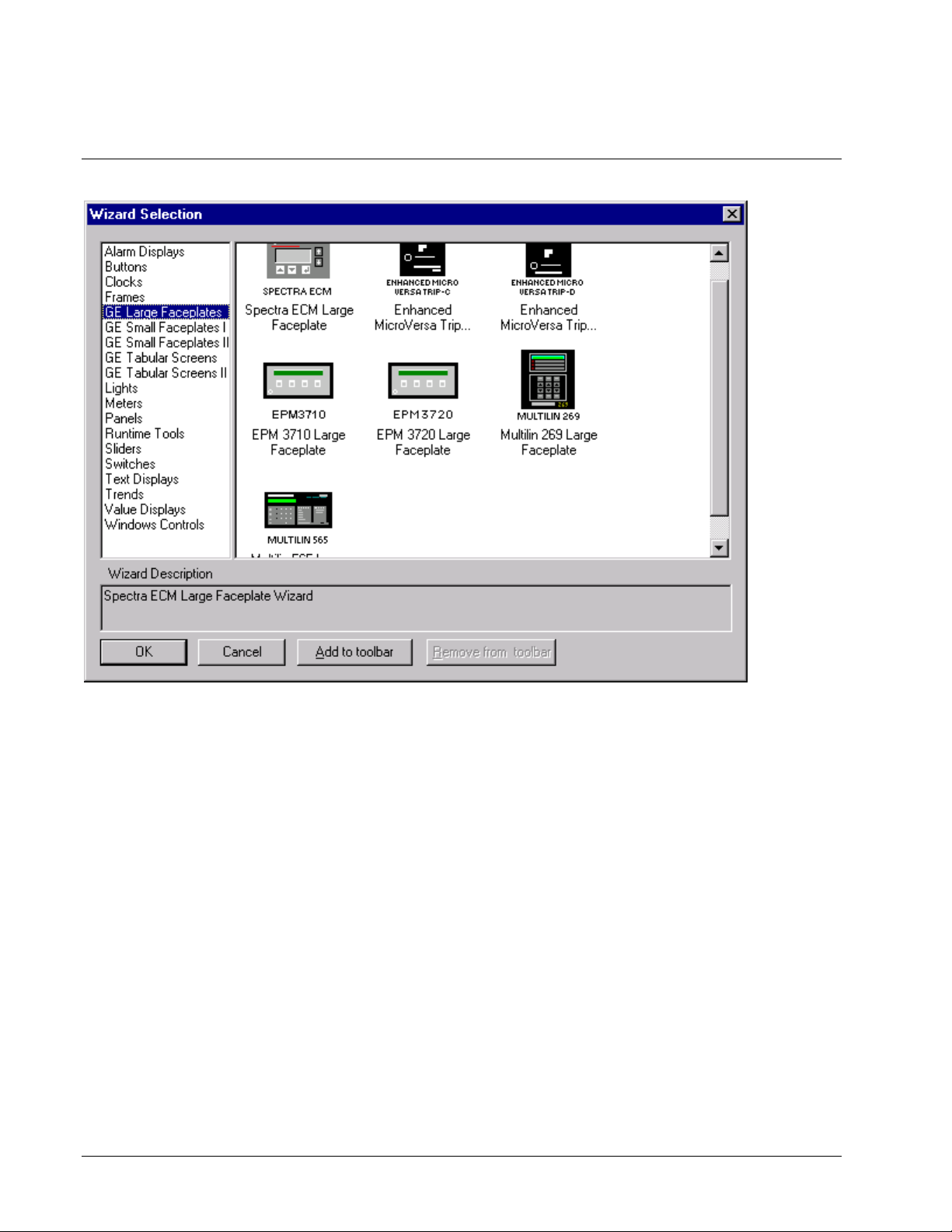

Large Faceplate Wizards

Usage

Large Faceplate wizards are three-dimensional representations of device faceplates

that can be used to display data from the device. These three-dimensional wizards

include extensive logic that provides an accurate reproduction of the actual display

and keys of the device. Large Faceplate wizards are typically placed in overlay

windows.

8 PMCS Interface Toolkit

Page 17

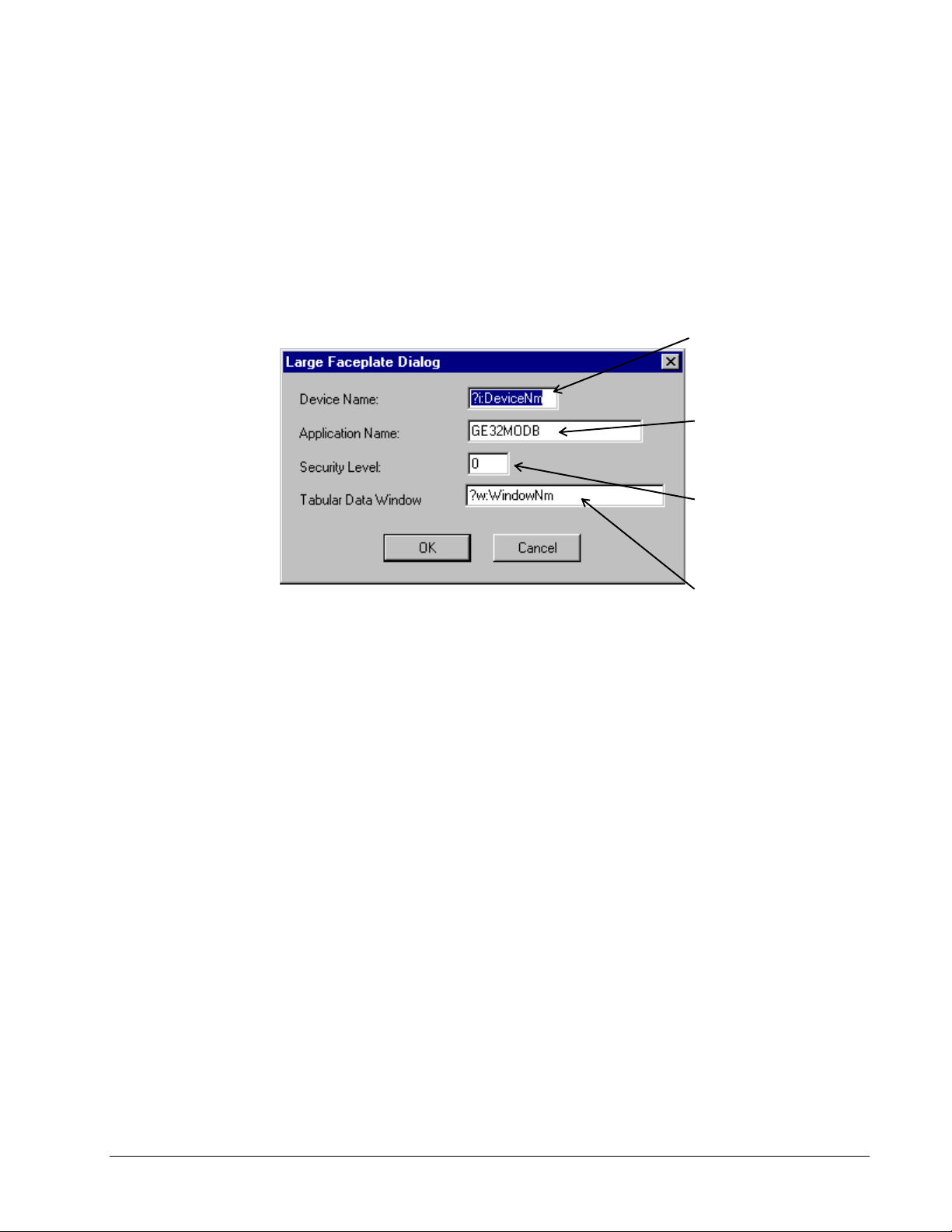

Configuration

Place the Large Faceplate wizard into an open window, then double-click on it to

display the Large Faceplate Dialog box. Configure the wizard by entering the

appropriate information into each of the boxes.

The figure shown below is the dialog for a typical wizard. Some wizards have

additional features which may be configured. See the section titled Features of GE

Large Faceplate Wizards for more details.

Enter the unique eight-character

name matching the appropriate Topic

in the PMCS DDE Server.

Enter the application name of the

PMCS DDE Server (GE32MODB or

GE32MTCP) for most PMCS

devices; ION_LINK for EPM 7700

devices).

Enter the minimum security

level for enabling remote

command functions.

Enter the name of the window to

open when the device display is

clicked on during runtime.

You can move and resize Large Faceplate wizards as desired.

Special Considerations

The button controls on the 3-D representation emulate the controls of the actual

device. This may be useful for reducing software training time for personnel already

familiar with device operation. The detailed features of each of the Large Faceplate

wizards are described in the section titled Features of GE Large Faceplate

Wizards .

EPM 7700

The EPM 7700 Large Faceplate Dialog box contains an extra field, which must be

completed during configuration. The Node Name field requires that you enter the

name of the computer running the Communications Server that connects to this

particular device. Depending on the configuration of the EPM7700 network, this can

be either the Primary node computer, or a computer setup as a "Full Station"

Secondary node. Refer to DEH-40035, the GE 7700 Gateway Users Guide, and

GEH-6514, PMCS Read This Book First, for more information on network

configuration. The Node Name field is required because the EPM7700 does not use

the same DDE server as the rest of the standard PMCS devices, and the wizard must

be directed to the location of the correct Communications Server for proper

configuration of DDE topic names.

9

Page 18

Also, the Application Name field must be completed as ION_LINK rather than

GE32MODB or GE32MTCP for the EPM7700 device. The ION LINK program is

installed during initial PMCS 6.11a setup if the EPM7700 software option is selected.

When configuring Wizards on Secondary nodes, the Application Name field entry

does not follow the PMCS wizard convention of “\\RemoteComputer\ION_LINK”.

EPM7700 Secondary nodes run a local copy of the ION LINK server, thus the

application name for EPM7700 Large Faceplate wizards is always “ION_LINK”

whether the wizard is installed on the Primary node or a Secondary node. The Node

Name entry determines if the wizard is on a Secondary node.

Finally, the EPM 7700 device type requires special InTouch scripting for the large

faceplate wizard. Refer to the section at the end of this chapter titled Special

Scripting Considerations for the EPM 7700.

10 PMCS Interface Toolkit

Page 19

Tabular Data Screen Wizards

11

Usage

Tabular Data Screen wizards contain organized, comprehensive, tabular layouts of

device parameters including additional configuration and remote control features.

Depending on the device, there may be multiple file-tabs beneath the tabular data

section. These switch among various pages relating to data and setpoints.

Each Tabular Data Screen wizard contains buttons for activating the help file, trend

window, setup window (if applicable), Event Logger, Waveform Capture, and for

closing the window.

You can move and resize Tabular Data Screen wizards as desired.

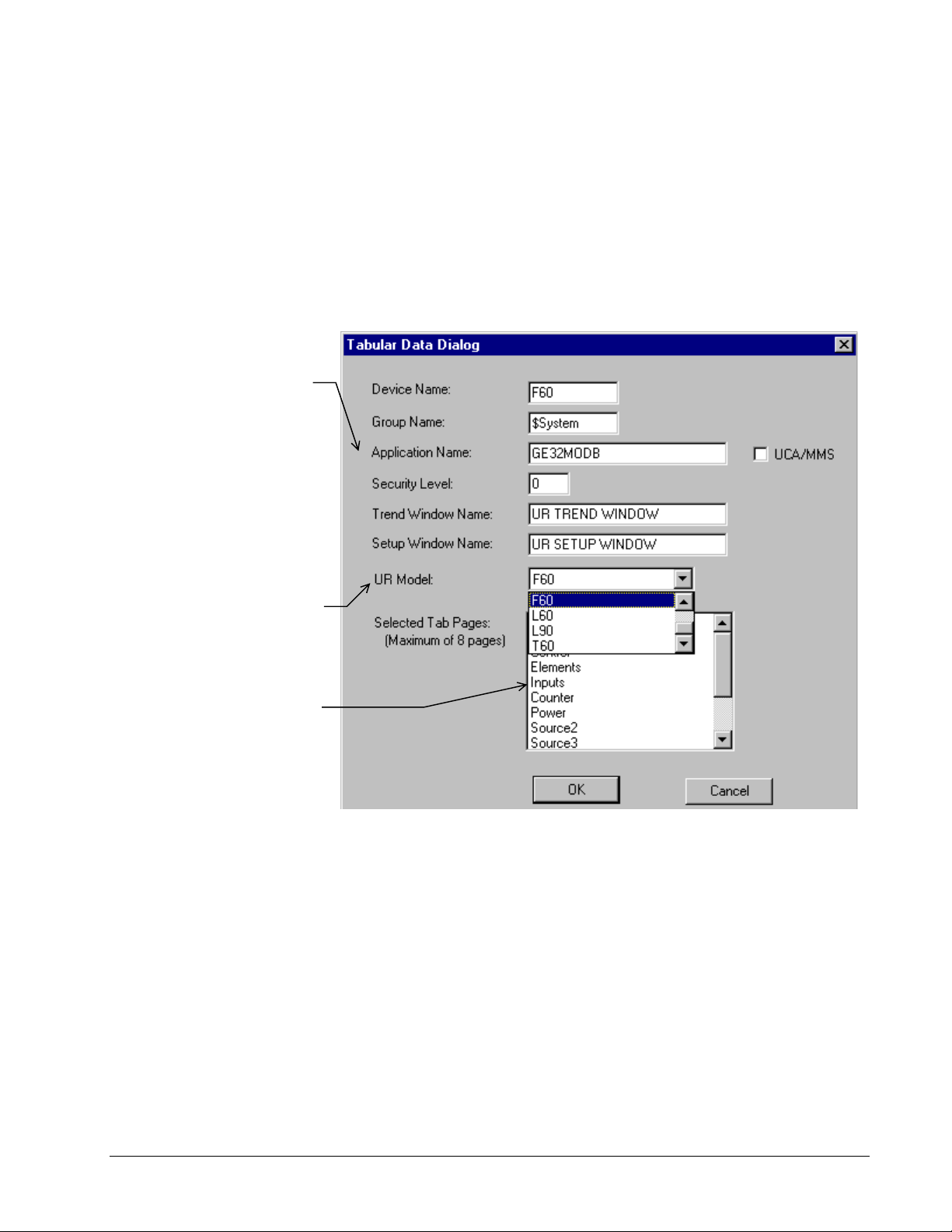

Configuration

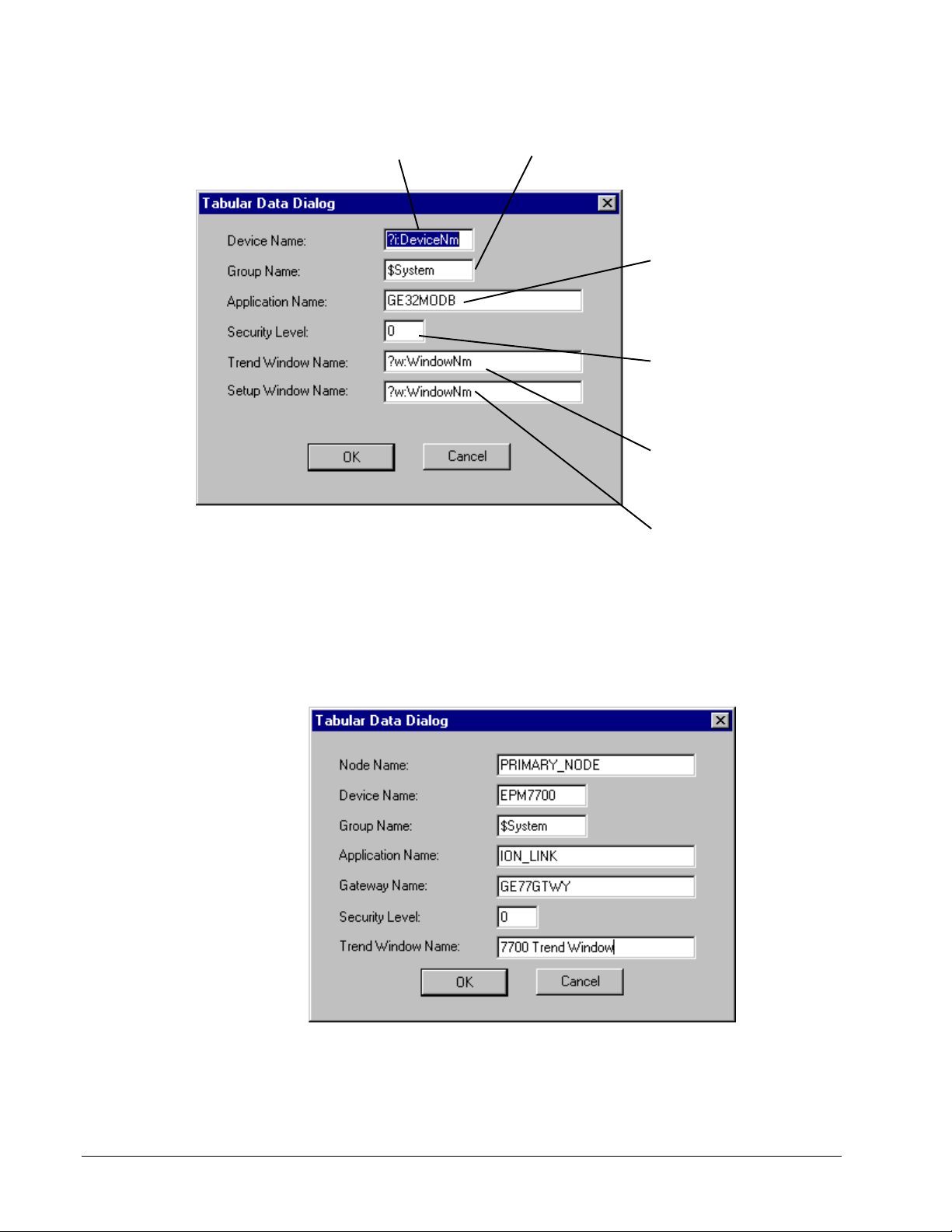

In development mode, after placing a wizard into an open window, double-click on it

to display the Tabular Data Dialog box. The figure below shows the dialog box for a

typical Tabular Data wizard. Some wizards have additional features which may be

configured. See the section titled Features of Tabular Data Screen Wizards for

more details.

Page 20

Enter the unique eight- character

l

name matching the appropriate

Topic in the PMCS DDE Server.

Use the Group Name field to logically group devices,

if desired. Enter the name of the group to which the

device belongs.

Enter the application name of

the PMCS DDE Server

(GE32MODB or GE32MTCP).

Enter the minimum security leve

for enabling remote command

and setup functions.

Enter the name of the window to

be opened when the Trend

button is clicked on during

runtime.

Enter the name of the window to

be opened when the Setup

button is clicked on during

runtime.

EPM 7700

The EPM 7700 Tabular Data Dialog box is slightly different from the other PMCS

device types, containing two extra fields and requiring minor differences in

configuration. The Tabular Data Dialog for the EPM 7700 is shown below, followed

by the special configuration requirements.

The Node Name field requires that you enter the name of the computer running the

Communications Server that connects to this particular device. Depending on the

configuration of the EPM7700 network, this can be either the Primary node

computer, or a computer setup as a “Full Station” Secondary node. Refer to DEH-

12 PMCS Interface Toolkit

Page 21

40035, the GE 7700 Gateway Users Guide, and GEH-6514, PMCS Read This Book

First, for more information on network configuration. The Node Name field is

required because the EPM7700 does not use the same DDE server as the rest of the

standard PMCS devices, and the wizard must be directed to the location of the

correct Communications Server for proper configuration of DDE topic names.

Also, the Application Name field must be completed as ION_LINK rather than

GE32MODB or GE32MTCP for the EPM7700 device. The ION LINK program is

installed during initial PMCS setup if the EPM7700 software option is selected.

When configuring Wizards on Secondary nodes, the Application Name field entry

does not follow the PMCS wizard convention of “\\RemoteComputer\ION_LINK”.

EPM7700 Secondary nodes run a local copy of the ION LINK server, thus the

application name for EPM7700 Tabular Data Wizards is always “ION_LINK”

whether the wizard is installed on the Primary node or a Secondary node. The Node

Name entry determines if the wizard is on a Secondary node.

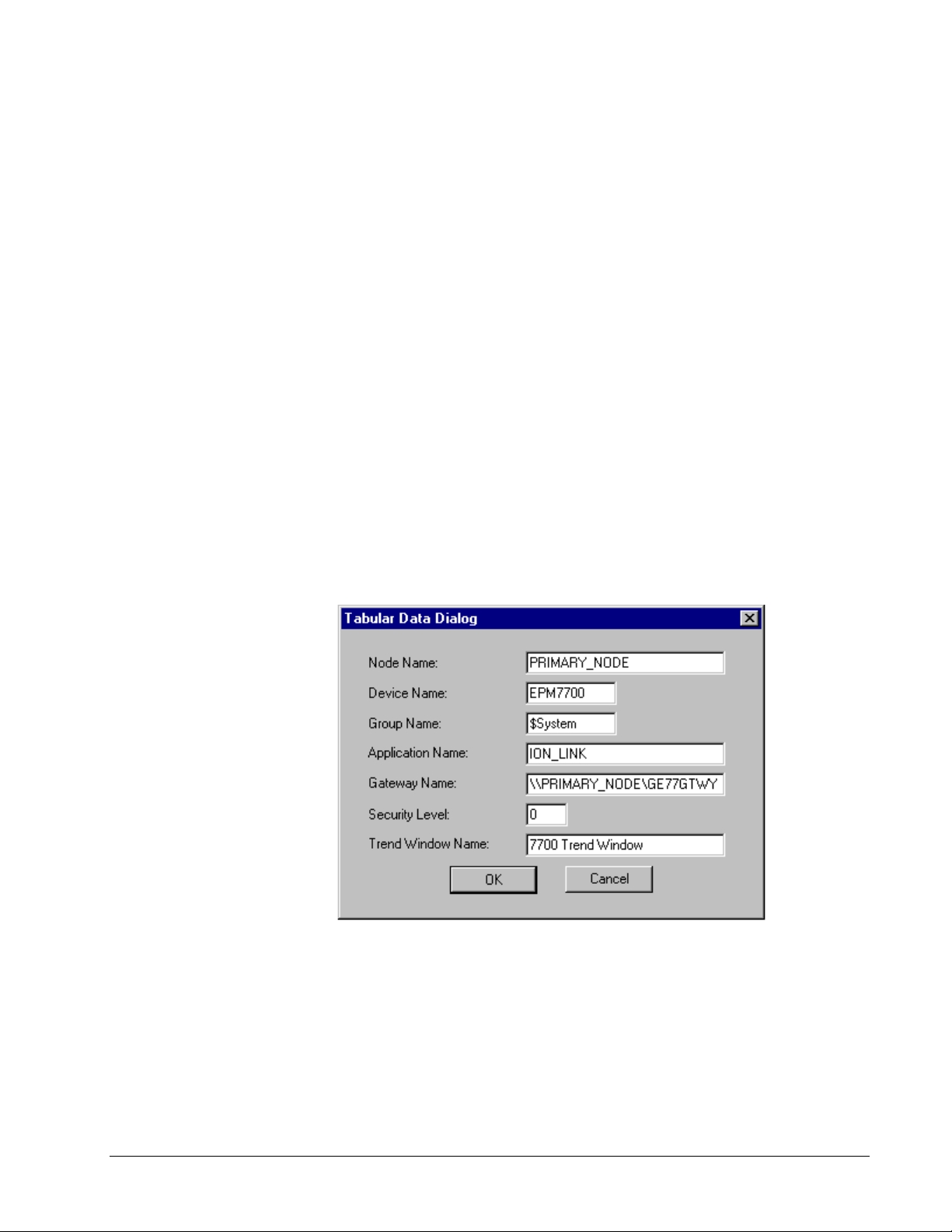

The Gateway Name field must be completed with GE77GTWY, the application name

of the GE 7700 Gateway Server program. When configuring the EPM7700 Tabular

wizard on a Secondary node, the Gateway Name does follow the PMCS wizard

convention of “\\RemoteComputer\GE77GTWY” in the Gateway Name field, where

‘RemoteComputer’ is the name of the PC where the GE 7700 Gateway application is

running – the Primary Node. The following example shows a Tabular Data Dialog

box as it would appear when configuring a Tabular Data wizard on a Secondary

node. The Node Name field contains the name of the Primary Node computer, the

Application Name field is ION_LINK (as it is for ALL EPM7700 wizards on ANY

node) and the Gateway Name field points to the GE 7700 Gateway Server running on

the Primary Node PC.

13

Finally, the EPM 7700 device type requires special InTouch scripting for the tabular

data screen wizard. Refer to the section at the end of this chapter titled Special

Scripting Considerations for the EPM 7700.

Refer to DEH-40035 for information on the Communications Server and 7700

Gateway Server.

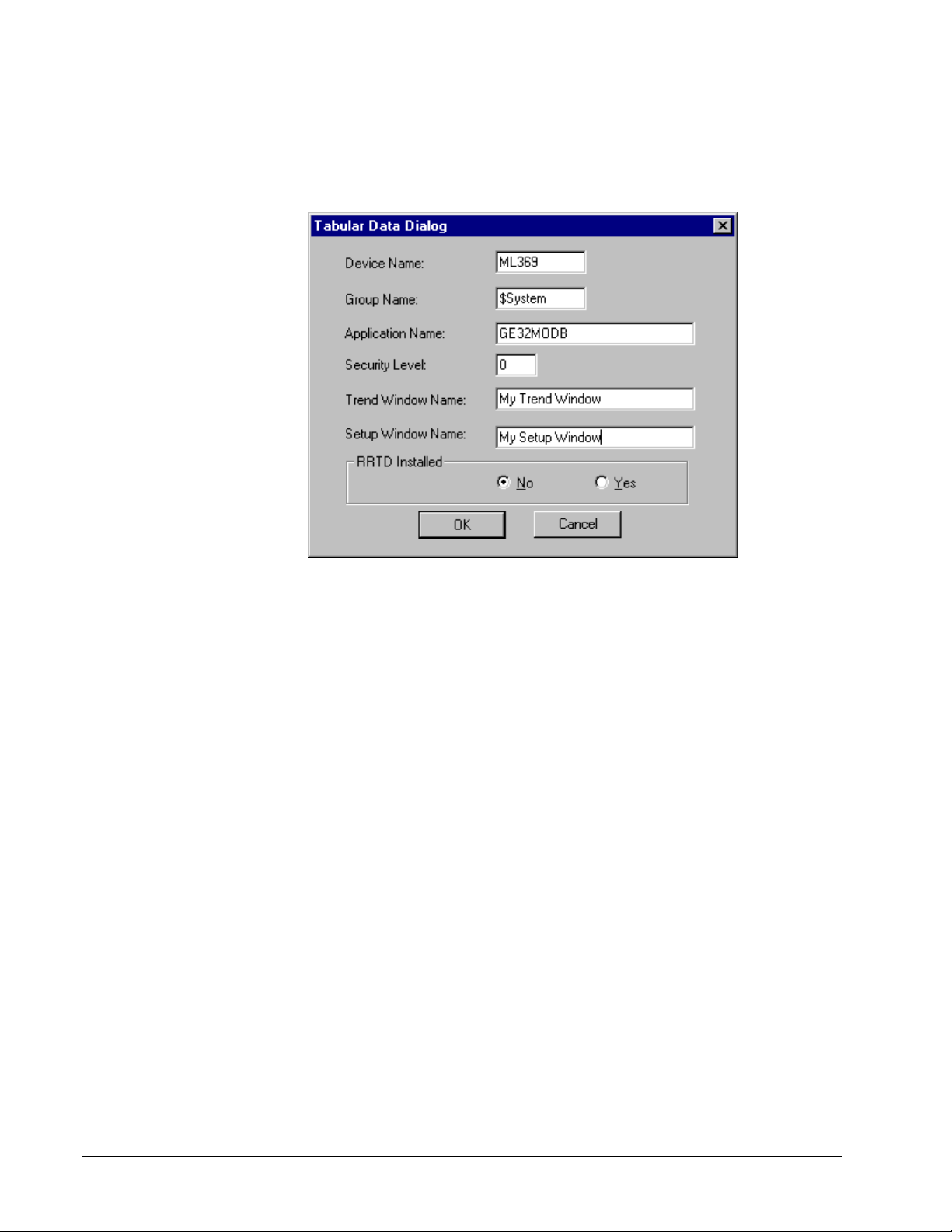

369 Motor Management Relay

The 369 Motor Management Relay offers an optional Remote RTD module, which

can provide support for up to 12 additional RTDs. Accordingly, the 369 Tabular

Page 22

Data Dialog box has an extra field for indicating when the RRTD option is installed.

Be sure to select the correct RRTD option when completing the 369's Tabular Data

Dialog window. If you are not planning to use an RRTD module with your relay,

select the "No" button. This minimizes the number of I/O tags created by the wizard,

providing better performance.

14 PMCS Interface Toolkit

Page 23

Complete the Application Name

field; typically GE32MODB or

GE32MTCP.

Special Note:

The UCA/MMS is not supported in

this version. So don’t Check this

checkbox.

Universal Relay

The Universal Relay device comes in several different models, and each model

supports different capabilities, which are reflected by the various tabs available for

each model. When configuring a Universal Relay device, you first select the UR

Model, then choose which tabs will be displayed for the particular device.

The UR devices are also capable of communicating with a different type of PMCS

DDE Server than the other PMCS Advanced Wizards. By selecting the UCA/MMS

checkbox, you indicate that you wish the UR wizard to retrieve its data for display

from the MMS Server whose name is entered in the Application Name field.

Select the Model of UR which you are

configuring. This determines the

contents of the Available Tabs list.

Highlight the tabs you wish to display

on the Tabular Data Screen wizard.

Use the control key to select multiple

tabs.

15

Page 24

One-Line Wizards

Usage

You can use one-line wizards to create animated one-line diagrams that represent an

electrical schematic of the devices monitored by the software. These wizards are

provided with logic to either open another window or display device status.

One-Line wizards are divided into five functional groups according to the type of

animation:

• Horizontal and Vertical Meter wizards display another window, such as

a 3-D faceplate.

• Transformer, Fuse, Ground Symbol, and Motor Symbol wizards have a

discrete color-change animation indicating the On/Off state of the

device.

• Horizontal and Vertical Relay wizards also have discrete color-change

animation indicating the On/Off state of the device.

• Horizontal and Vertical Switch wizards have four discrete animations;

two are color changes indicating the On/Off state of the device and two

are used for a three-state display (Open, Closed, and Error conditions).

16 PMCS Interface Toolkit

Page 25

• Circuit Breaker wizards have two discrete color-change animations for

On/Off status display and one analog animation for a five-state display

(Open, Closed, Out, Trip, and Error conditions).

• Lockout/Tagout symbols have discrete visibility animations for various

tags. Refer to the section Using and Configuring PMCS Wizards:

Lockout/Tagout Wizard for more information.

Configuration

In development mode, after placing the one-line device icon, double-click on the icon

to open its configuration dialog box. All one-line wizards have two configuration

items in common:

•

Line Size is a number between 1 and 20 that sets the pixel width of

the lines in the wizard.

• Size configuration consists of three radio buttons (Small, Medium,

and

Large) that determine the overall size of the wizard on the screen.

Use the snap-to-grid feature in InTouch to quickly align One-Line wizards.

Configuration of each of the five classes of One-Line wizards is described below.

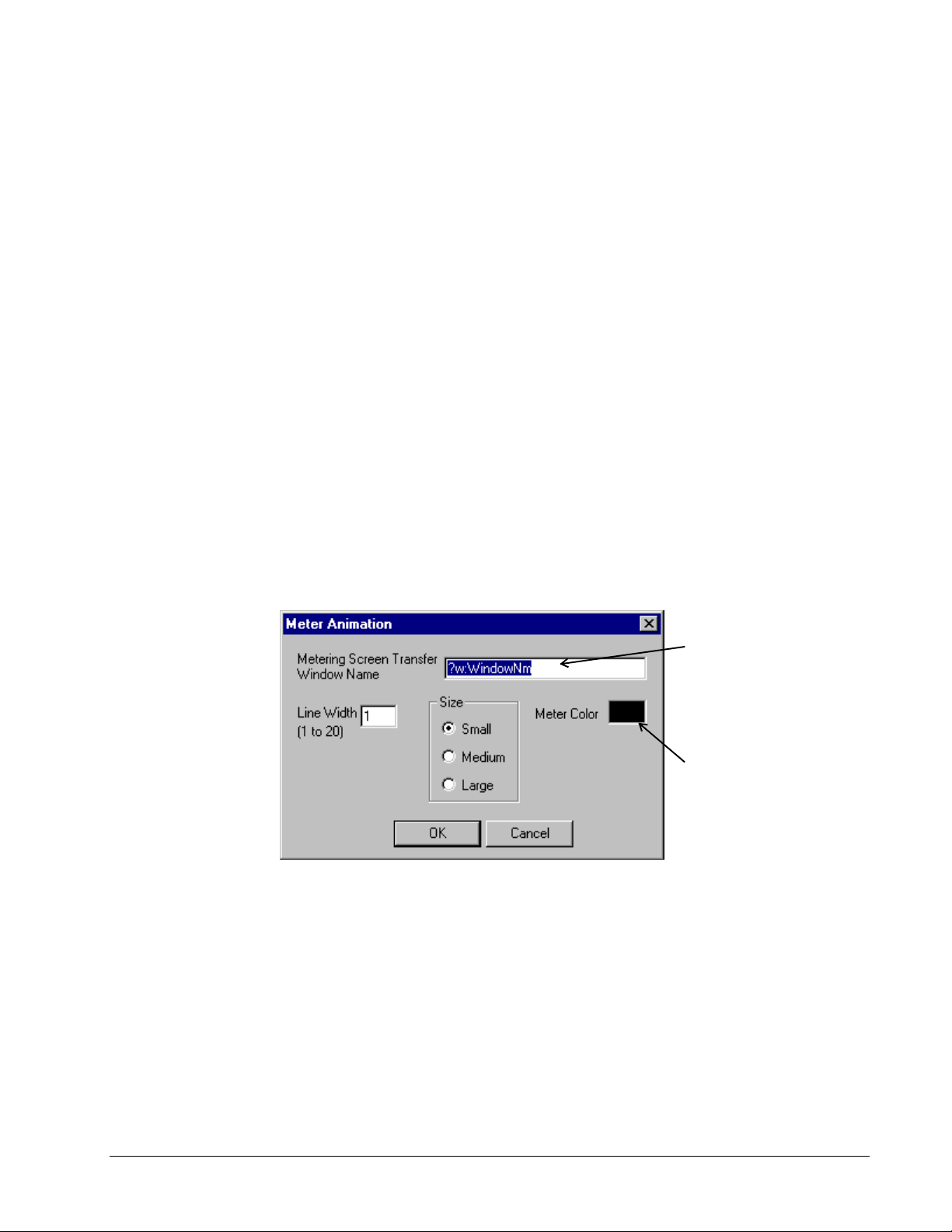

Meter One-Line Wizards

After placing a meter wizard in a window, double-click on it to display the dialog

box shown below. Configure the wizard by entering the appropriate information into

each of the boxes.

Enter the name of the

window to open when the

icon is clicked on during

runtime.

Select the color of the meter

wizard.

17

Page 26

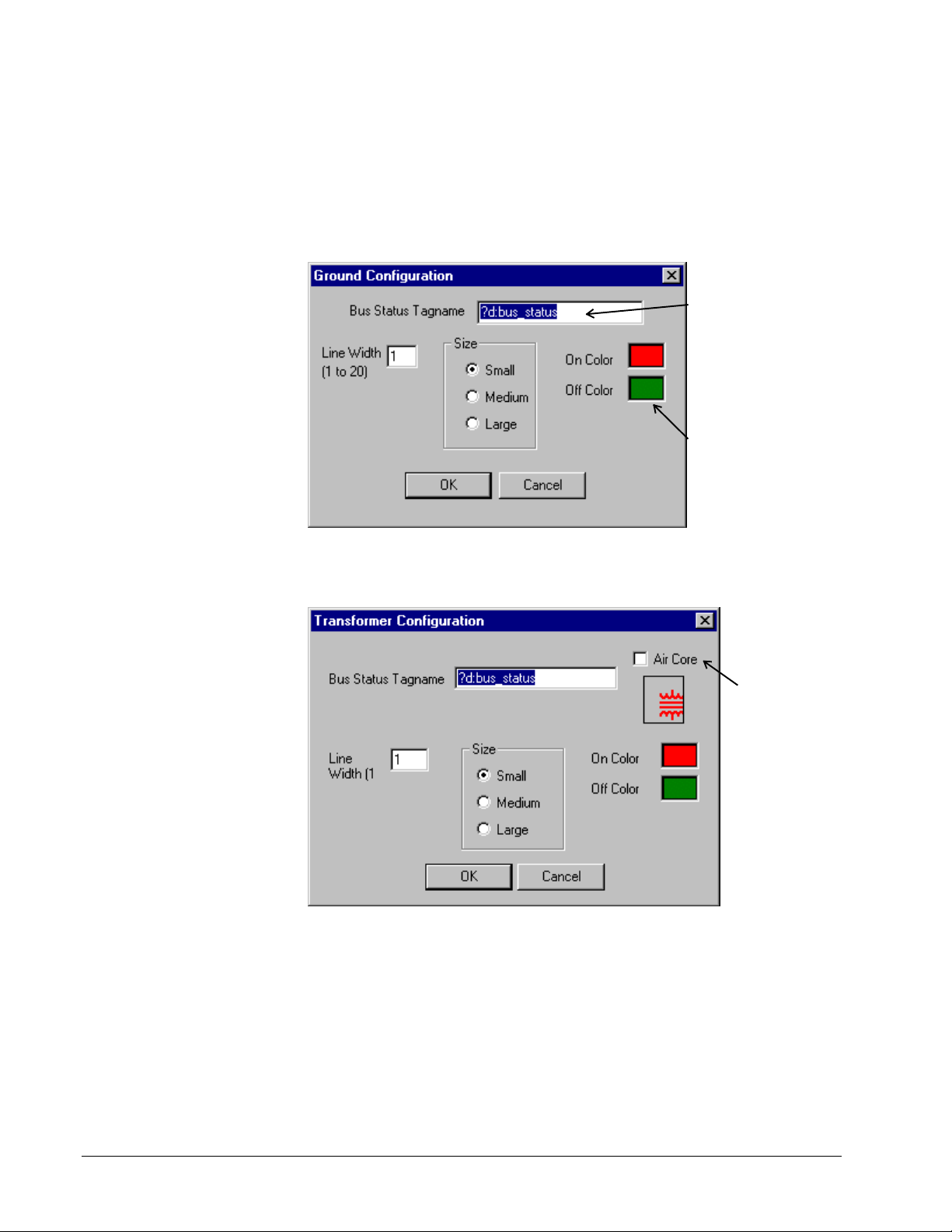

Transformer, Fuse, Ground, and Motor One-Line Wizards

After placing a Fuse, Ground, or Motor wizard in a window, double-click on it to

display the dialog box shown below. Configure the wizard by entering the

appropriate information into each of the boxes.

Enter the name of the

InTouch discrete tag that

determines the state of the

line colors during runtime.

Specify the colors of the lines

when the Bus Status is On and

Off. The wizard is displayed in

the On Color when the Bus

Status Tagname = 1, Off Color

when the Bus Status Tagname =

0.

The dialog box for the Transformer wizard has an extra check box that specifies

either an air-core or iron-core transformer, as shown below.

Click on the check

box to specify an

air-core

transformer.

18 PMCS Interface Toolkit

Page 27

Horizontal and Vertical Relay One-Line Wizards

After placing a Horizontal or Vertical Relay wizard in a window, double-click on it

to display the dialog box shown below. Configure the wizard by entering the

appropriate information into each of the boxes.

Enter the name of the InTouch discrete

tag that determines the color of the line

to the right (or top) of the relay symbol

during runtime.

Enter the name of the InTouch discrete tag that

determines the color of the line to the left (or bottom)

of the relay symbol during runtime.

Click the check box to

display a slash through the

contacts (normally closed

contact).

Specify the colors of the

wizard elements when the

contact status and

connection discrete tags

are On or Off.

Enter the name of the InTouch discrete tag

that determines the color of the relay

symbol during runtime.

19

Page 28

Horizontal and Vertical Switch One-Line Wizards

r

r

r

After placing a Horizontal or Vertical Switch wizard in a window, double-click on it

to display the dialog box shown below. Configure the wizard by entering the

appropriate information into each of the boxes.

Enter the name of the InTouch discrete tag

that determines the color of the line to the

right (or top) of the switch symbol during

runtime.

Enter the name of the InTouch discrete

tag that determines the color of the line

to the left (or bottom) of the switch

symbol during runtime.

Enter the names of the

InTouch discrete tags that

determine the state of the

switch during runtime.

Specify the colors of the wizard

elements when the connection

and switch discrete tags are On

and Off and when there is an

Error condition. The switch

symbol color is determined by

the following logic:

SwOpen SwClosedColo

0 0 erro

0 1 on

1 0 off

1 1 erro

20 PMCS Interface Toolkit

Page 29

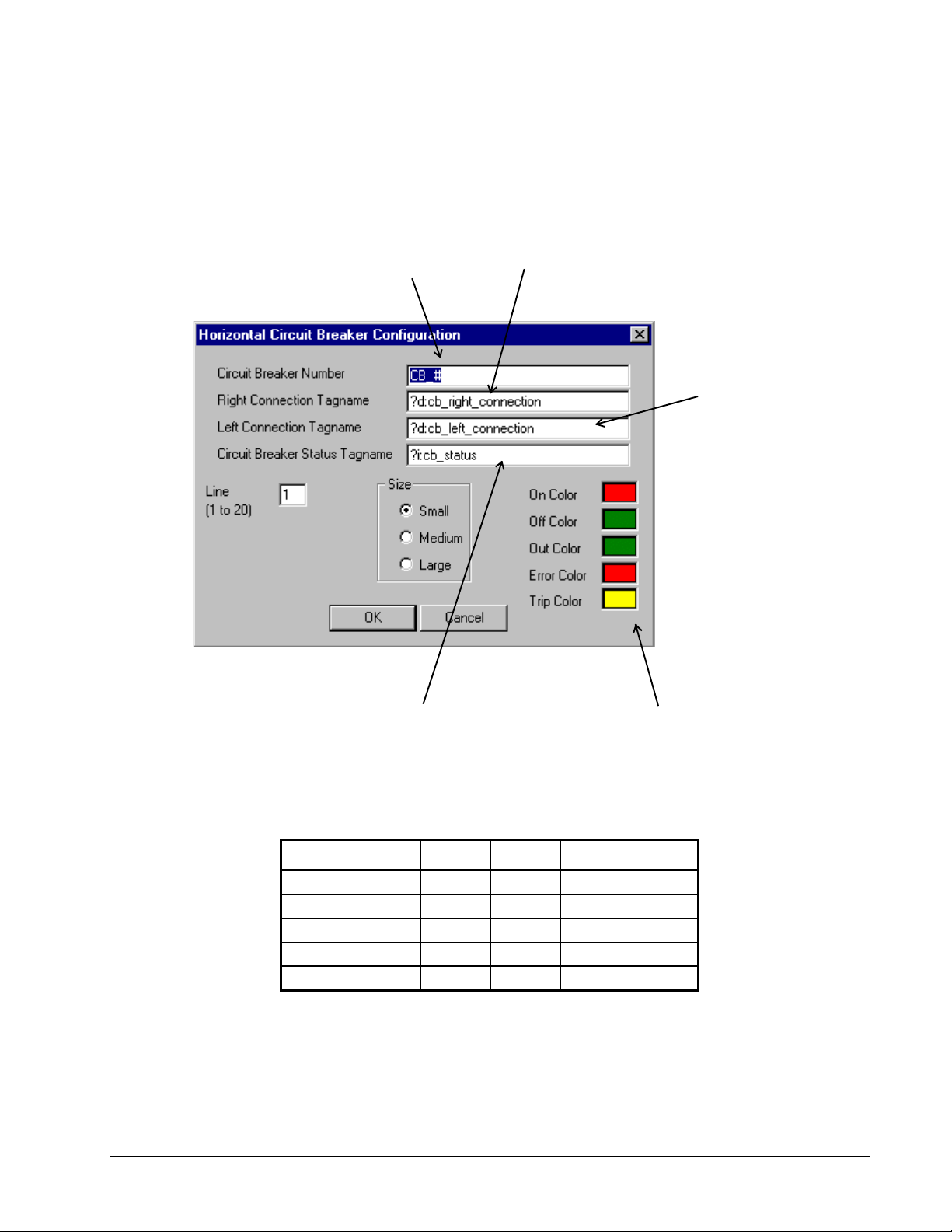

Circuit Breaker One-Line Wizards

After placing a Horizontal or Vertical Circuit Breaker wizard in a window, doubleclick on it to display the dialog box shown below. Configure the wizard by entering

the appropriate information into each of the boxes.

Enter text to display next to the

breaker graphic during runtime

(optional).

Enter the name of the InTouch analog tag that

determines the color of the circuit breaker

symbol, the state of the breaker, and the status

text displayed next to the breaker icon during

runtime.

Enter the name of the InTouch discrete tag that

determines the color of the line to the right (or

top) of the breaker symbol during runtime.

Enter the name of

the InTouch discrete

tag that determines

the color of the line

to the left (or bottom)

of the breaker

symbol during

runtime.

Specify the colors of the wizard

elements and status text for the

breaker states during runtime.

See the table below for default

status/color mappings.

21

The breaker status values and the associated default colors are listed in the table

below. Error status indicates that the breaker status inputs create an indeterminate

state for the breaker.

Breaker Status Value Text Default Color

Open 1 OPN Green

Closed 3 CLD Red

Drawn Out 5 OUT Green

Tripped 7 TRP Yellow

Error 9 ERR Flashing Red

Breaker status values & display colors.

Page 30

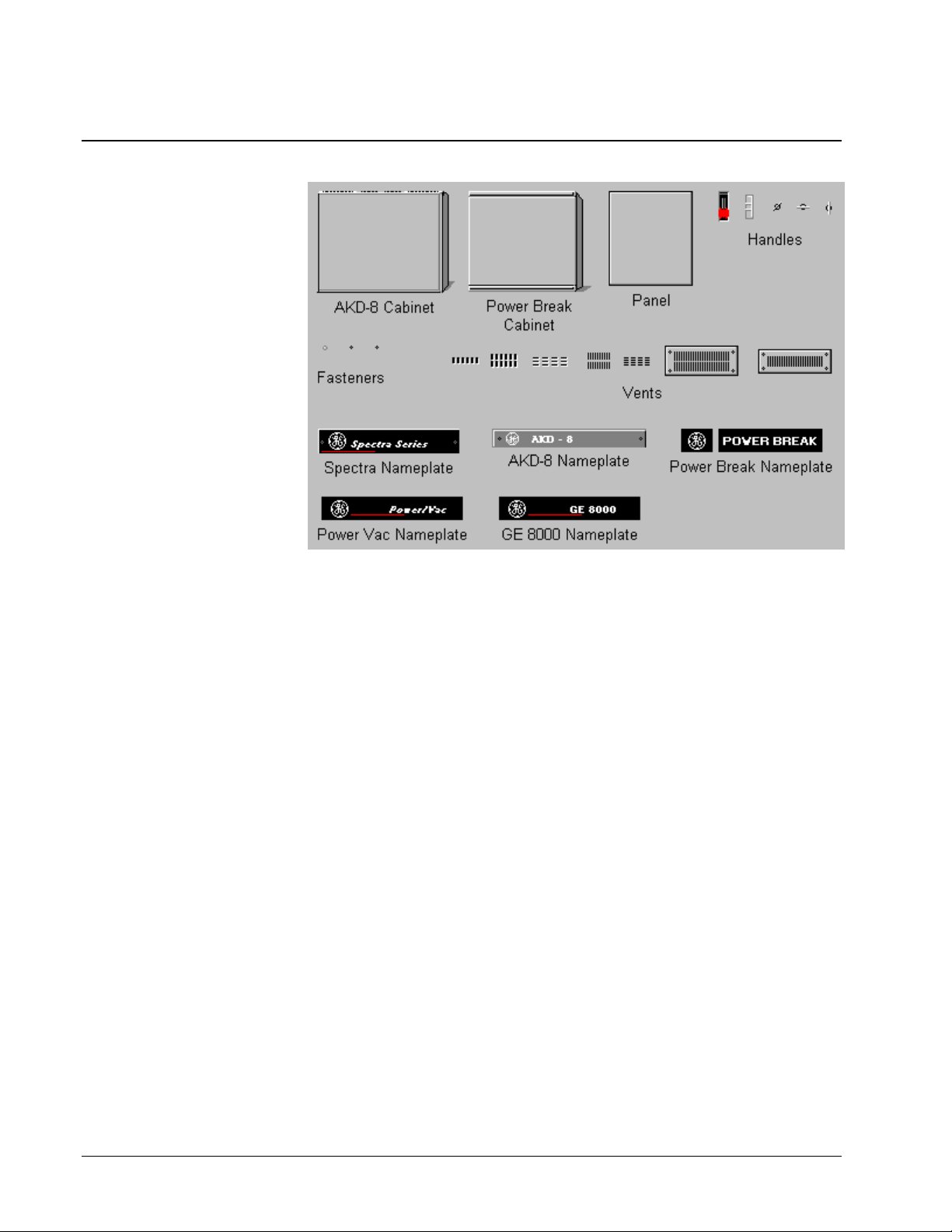

Elevation Wizards

Usage

Elevation wizards are graphical elements that represent switchgear components

useful for creating 3-D elevation views. These wizards are not associated with any

logic or animation, but are provided to create more visually accurate screens and

representations of equipment. Device icon wizards are typically placed on the

Elevation wizards to show the breakers, trip units, and meters and provide navigation

to device 3-D wizards, tabular displays, or arbitrary windows.

Configuration

After placing an Elevation wizard in an open window, it may be moved or resized,

but no other configuration is possible. Elevation wizards are not provided with logic

for opening another window.

22 PMCS Interface Toolkit

Page 31

Floor Plan Wizards

23

Usage

Floor Plan wizards are graphical elements that are useful for creating accurate

representations of a facility layout. You can use a floor layout as an overview display

of an entire plant, with animated areas for navigation to various switchgear elevation

views or one-line diagrams. You can paste miniature elevation views as bitmap

objects onto the floor layout, sized to fit, and then animate them as push buttons to

display elevation views or one-line diagrams (see Chapter 3).

Configuration

After placing a Floor Plan wizard in an open window, it may be moved or resized,

but no other configuration is possible. Floor Plan wizards are not provided with logic

for opening another window.

Page 32

Toolbar Wizard

Usage

The Toolbar wizard is a navigational tool which allows the user to move between

recently-used or frequently-used windows, and provides a clock for quick reference.

The first/last arrows jump to the first or last window in the windows list (see

Configuration below); the inner forward and back arrows move to the next or

previous window in the list. The window buttons to the right of the arrows provide

quick access to the windows assigned to each button.

Configuration

The arrow buttons on the Toolbar wizard operate by maintaining a list of windows

for access by the toolbar navigational controls. To allow a window to be added to the

windows list when viewed by a user, a call to WLAddWindow( ) must be placed in

the OnShow window script. This call must be placed in each window that you want to

have on the window list.

The eight hot buttons are configured by double clicking on the wizard, and

completing the Toolbar Wizard Edit dialog box:

For each button, you can set the top and bottom caption, and specify the window to

be opened when that button is clicked.

24 PMCS Interface Toolkit

Page 33

Annunciator Panel Wizard

Usage

The Annunciator Panel wizard provides an industrial-style annunciator display panel,

consisting of a bank of 48 indicator lights which change colors and blink to indicate

various device conditions. For instance, a circuit breaker could be associated with an

annunciator panel wizard to display grey when closed and change to red if it trips.

This wizard requires the PMCS Event Logger software to be installed and properly

configured before it can be used, because it operates by monitoring special DDE tags

which change state based on alarms or events recorded by the Event Logger.

The panel consists of an array of 48 buttons (six columns by eight rows), each of

which may be labeled with up to three lines of text, and each of which is associated

with a particular device (topic) at the PMCS DDE Server.

The annunciator panel wizard provides buttons for acknowledging alarms, resetting

acknowledged alarms, and for viewing an alarm summary via the PMCS Event

Logger.

Annunciator Panel Theory of Operation

The Annunciator Panel wizard provides a screen full of indicator tiles, each relating

to a particular device, event, or group of events. These tiles are displayed in different

colors to indicate different alarm conditions. The Annunciator Panel wizard monitors

selected DDE items in the Event Logger and responds to changes of state in these

items by changing the colors of individual indicator tiles. For example, you might

configure a relay trip event to have a tile in the Annunciator Panel wizard. The

wizard monitors a DDE tag at the Event Logger corresponding to the trip status of

the relay and displays a grey indicator if the relay is operating properly, and a red

indicator if the relay has tripped.

25

Page 34

From the Event Logger’s perspective, there are two parts to configuring the

Annunciator Panel. First, each DDE Item that will be displayed on the Annunciator

Panel wizard must be added (using the Add Items dialog). For the example we’re

discussing, we’ll assume you’ve created a DDE Item named Trip1. Each DDE item

will connect to an individual tile in the Annunciator Panel wizard.

The second part consists of defining events which will turn individual DDE items ON

or OFF. Each DDE item (or Annunciator Panel tile) can be turned on or off by any

number of device events you define. The events are logically ORed together to

determine ON or OFF conditions; i.e., if any of the events occurs, the DDE item is

ON; if none of the events have occurred, the DDE item remains OFF.

We’ll continue the relay example we began above. For example, you might configure

the Trip1 DDE Item to be ON if any of the following events occurs: the relay is

tripped, or the relay reports an error condition, or the relay senses an overvoltage

condition. The Annunciator Panel wizard displays a grey indicator tile for the relay

for as long as the DDE item remains in the OFF condition. If the Annunciator Panel

wizard sees the DDE Item change from OFF to ON, it reacts by changing the

indicator tile from grey to red. The Event Logger Annunciator Panel logic will also

change the state of a DDE Item in response to actions performed at the Annunciator

Panel Wizard. The user can both acknowledge and reset individual Annunciator DDE

Items. The following diagram shows the relationship of the Annunciator Panel

wizard, the Event Logger, and the PMCS DDE Server.

26 PMCS Interface Toolkit

Page 35

Annunciator Pan el W izard m onitors DDE Item s at Event Logger

Relay 1

(green)

Relay 1

(red)

Relay 2

(green)

Annunciator Panel Wizard

Annunciator Pan el W izard m onitors DDE Item s at Event Logger

Relay 2

(green)

Annunciator Panel Wizard

Relay 3