Page 1

g

GEH–6505A

POWER LEADER™

Ethernet Gateway

User’s Guide

Page 2

GEH–6505

WARNINGS, CAUTIONS, AND NOTES

AS USED IN THIS PUBLICATION

WARNINGS

CAUTIONS

NOTES

Warning notices are used in this publication to emphasize that hazardous voltages, currents, or other conditions that could cause personal injury exist in this equipment or

may be associated with its use.

Warning notices are also used for situations in which inattention or lack of equipment

knowledge could cause either personal injury or damage to equipment.

Caution notices are used for situations in which equipment might be damaged if care

is not taken.

Notes call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While

efforts have been made to ensure accuracy, the information contained herein does not

cover all details or variations in hardware and software, nor does it provide for every

possible contingency in connection with installation, operation, and maintenance.

Features may be described herein that are not present in all hardware and software

systems. GE Electrical Distribution & Control assumes no obligation of notice to

holders of this document with respect to changes subsequently made.

GE Electrical Distribution & Control makes no representation or warranty, expressed,

implied, or statutory, with respect to, and assumes no responsibility for the accuracy,

completeness, sufficiency, or usefulness of the information contained herein. No

warrantees of merchantability or fitness for purpose shall apply.

REFERENCES

POWER LEADER™ is a registered trademark of GE Company.

Modbus RTU is a registered trademark of AEG Schneider Automation.

For details of the Modbus RTU protocol, refer to PI-MBUS-300 Rev. E from

Modicon/AEG Schneider Automation.

For details of RS485 communications, refer to the EIA-485 standard.

©Copyright 1996 GE Company

All Rights Reserved

Page 3

POWER LEADER™ Ethernet Gateway

Table of Contents

Chapter 1 – Introduction ...........................................................................................1

1–1 Overview .................................................................................................................................. 1

1–2 Physical Description ............................................................................................................... 2

1-3 Operational Description.......................................................................................................... 3

Message Format................................................................................................................. 3

Gateway/Host Interface.................................................................................................... 3

1–4 Specifications .......................................................................................................................... 4

1–5 Environmental Requirements................................................................................................ 4

1–6 Terminology............................................................................................................................ 4

Chapter 2 – Installation .............................................................................................5

2–1 Mounting................................................................................................................................. 5

2–2 Control Power Connections................................................................................................... 5

2–3 Ethernet Connection.............................................................................................................. 5

2–4 Modbus Connection............................................................................................................... 6

2–5 Diagnostic Connection........................................................................................................... 6

2–6 Wiring Rules for Modbus Networks....................................................................................... 6

2–7 Modbus Equivalent Addresses............................................................................................... 7

Chapter 3 – Configuration.........................................................................................8

3–1 Configuration Procedure....................................................................................................... 8

3–2 Ethernet Gateway IP Address................................................................................................. 9

3–3 Baud Rate Specification......................................................................................................... 9

3–4 Message Monitoring ............................................................................................................. 10

3–5 Ethernet Driver ..................................................................................................................... 10

3–6 Gateway Diagnostics ............................................................................................................. 11

Display Socket, IP Address and Subnet Mask................................................................ 11

RS485 Loop-back Test..................................................................................................... 11

Ethernet Test ................................................................................................................... 11

Exit Diagnostics Program............................................................................................... 11

Network Test – FACTORY USE ONLY .......................................................................... 12

3–7 Advanced Options – Technical Support Personnel ONLY ............................................... 12

Updating the Gateway Software ..................................................................................... 12

Chapter 4 – Operation .............................................................................................13

Chapter 5 – Diagnostic Messages and Errors .......................................................14

5–1 Monitor Mode....................................................................................................................... 14

5–2 Processing Error Messages ................................................................................................... 14

Chapter 6 – Troubleshooting Guide .......................................................................15

RS485 Port Configuration Worksheets..................................................................16

i

Page 4

POWER LEADER™ Ethernet Gateway

Table of Contents

List of Figures

Figure 1. POWER LEADER Ethernet Gateway. ............................................................................................ 1

Figure 2. Typical use of Ethernet Gateway. ...................................................................................................2

Figure 3. Front view of Ethernet Gateway, showing dimensions. ................................................................ 2

Figure 4. Rear view of the Ethernet Gateway, showing Ethernet, RS485 and RS232 ports........................ 2

Figure 5. Ethernet headers on Modbus messages......................................................................................... 3

Figure 6. Mounting hole patter for Ethernet Gateway. ................................................................................ 5

Figure 7. Connecting control power to the Ethernet Gateway..................................................................... 5

Figure 8. Making the Ethernet connection to the Gateway. ........................................................................ 5

Figure 9. Connecting an RS485 network to the Ethernet Gateway.............................................................. 6

Figure 10. Termination of the RS485 network at the last Modbus device.................................................. 6

Figure 11. Connecting a dumb terminal to the RS232 port......................................................................... 6

Figure 12. Terminal communications settings. ............................................................................................8

Figure 13. Ethernet Gateway configuration menu........................................................................................ 8

Figure 14. Gateway diagnostics menu.......................................................................................................... 11

List of Tables

1. Examples of Modbus RTU compatible devices. .......................................................................................1

2. POWER LEADER Ethernet Gateway specifications. ................................................................................ 4

3. POWER LEADER Ethernet Gateway environmental requirements........................................................ 4

4. POWER LEADER commnet devices supported by the Modbus Concentrator...................................... 7

5. RS485 Port Settings.................................................................................................................................... 10

6. Diagnostic messages key............................................................................................................................ 14

7. Error message key...................................................................................................................................... 14

ii

Page 5

POWER LEADER™ Ethernet Gateway

Chapter 1 – Introduction

Chapter 1 – Introduction

1–1 Overview

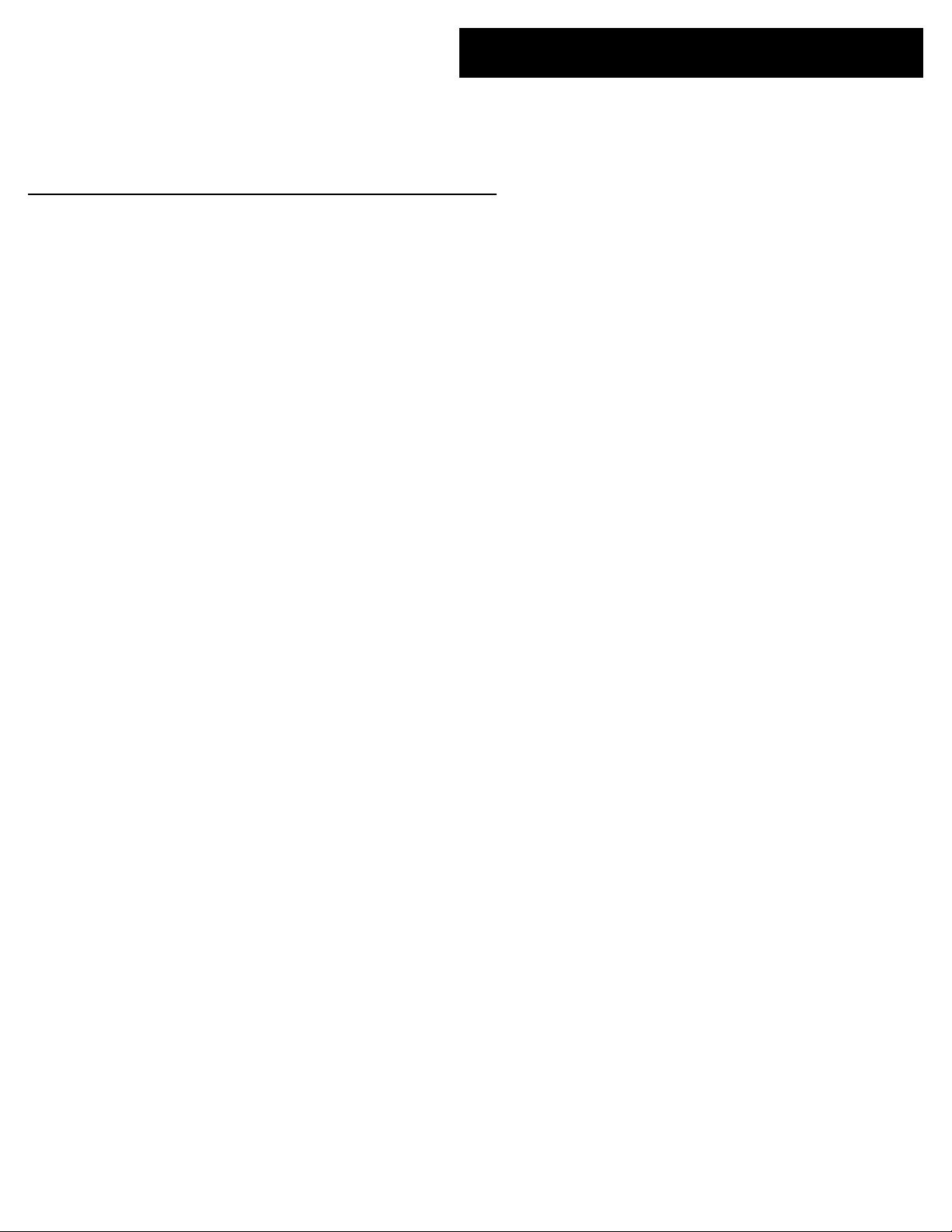

The GE POWER LEADER™ Ethernet Gateway

(catalog number PLENETG01), shown in Figure 1,

is a microprocessor-based device that connects one

to four RS485-based Modbus Remote Terminal Unit

(RTU) networks to an industry-standard, highspeed Ethernet network. Up to 31 Modbus RTU

devices can be connected to each of the Modbus

RTU networks.

Figure 1. POWER LEADER Ethernet Gateway.

The Ethernet Gateway works with GE’s Power

Management Control System (PMCS), a

comprehensive power management software

platform that acts as the ‘host’ to RS485 networks

attached to the Ethernet Gateway. A special part of

the PMCS called the Dynamic Data Exchange

(DDE) server is a database that records the

addresses and configurations of all attached

devices. The Ethernet Gateway serves as a passthrough device, interpreting the addressing

information and routing queries from the host to

the Modbus RTU networks and passing answers to

those queries from the attached devices back to the

host.

The Ethernet Gateway strictly conforms to the

Modbus RTU protocol, providing the capability to

tie the supported Modbus RTU devices into an

Ethernet network. Table 1 contains a partial list of

devices that are compatible with the Ethernet

Gateway and conform to the Modbus RTU

standard.

Device Description

EPM 3710 Full-function, three-phase electronic

meter with optional pulse initiation,

waveform capture, data logging, and

protective relay outputs.

EPM 3720 Full-function, three-phase electronic

meter with optional pulse initiation,

waveform capture, data logging,

protective relay outputs, and harmonic

distortion measurements.

Multilin 269 Plus

Motor Management

Relay

Multilin 565 Feeder

Management Relay

Fanuc 90/30 PLC Programmable logic controller (PLC)

Fanuc 90/70 PLC Programmable logic controller with

Modbus

Concentrator

Table 1. Examples of Modbus RTU compatible devices.

Protection for medium-voltage

industrial motors and associated

mechanical systems.

Complete time-overcurrent phase and

ground protection by monitoring feeder

phase current and ground current.

for applications from simple relay

replacement to midrange process

control.

multiple processors and programming

capabilities for large, high-speed

applications.

Maps addresses of up to 32 attached

POWER LEADER communications

network (commnet) devices to

equivalent Modbus addresses for use

with the Ethernet Gateway.

NOTE: PMCS is certified for use with power

management components manufactured 5/13/96

or later. If your system interfaces to: 1) any trip

units, meters, or relays manufactured prior to

5/13/96, or 2) any Spectra RMS™ Circuit Breakers

with MicroVersaTrip PM™ Trip Units, please

contact the POWER LEADER Customer Support

Center at 1-800-843-3742.

As mentioned in Table 1, the Modbus Concentrator

allows integration of POWER LEADER commnet

devices with Modbus RTU-compatible networks for

use with the Ethernet Gateway. See Section 3–5 for

more details on the integration of commnet devices

into Modbus networks.

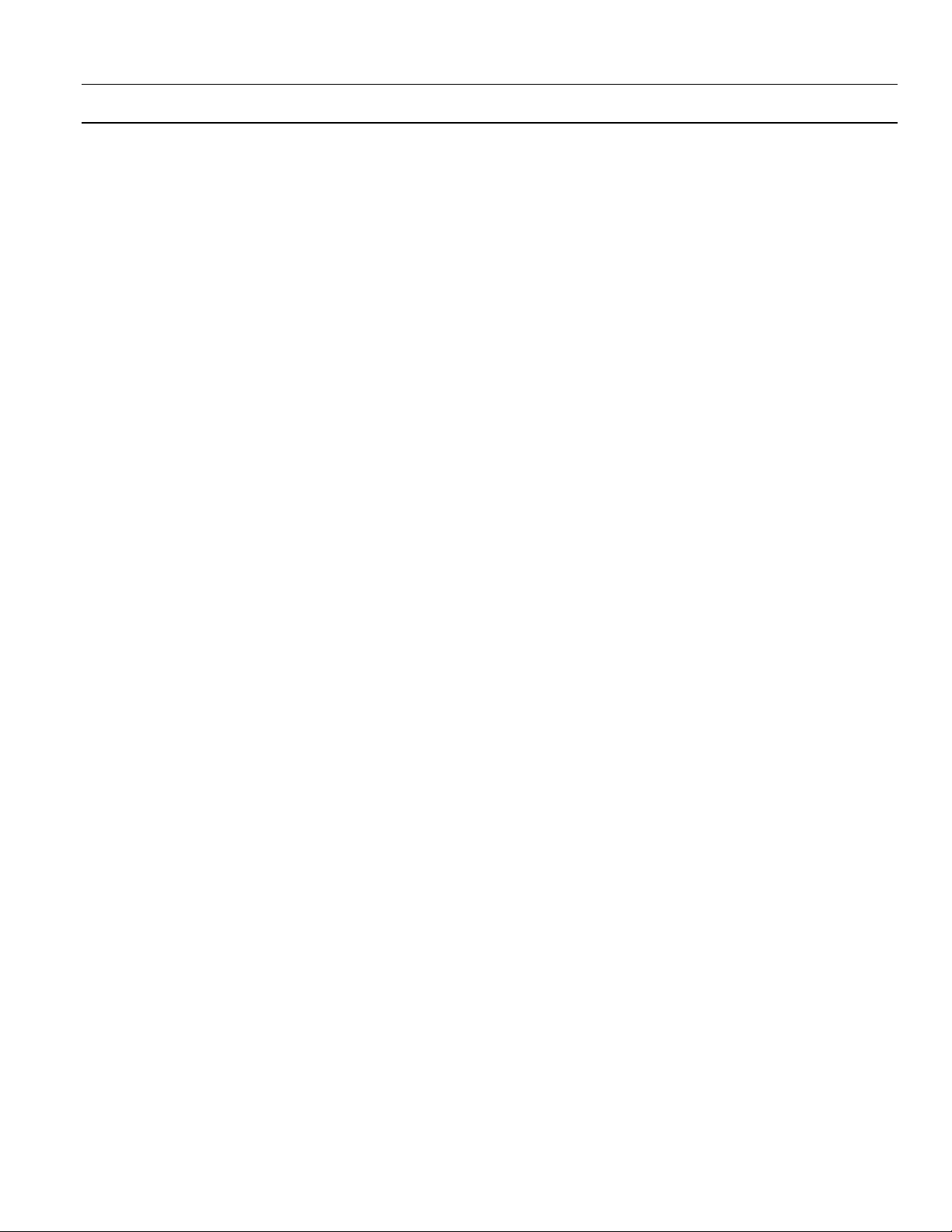

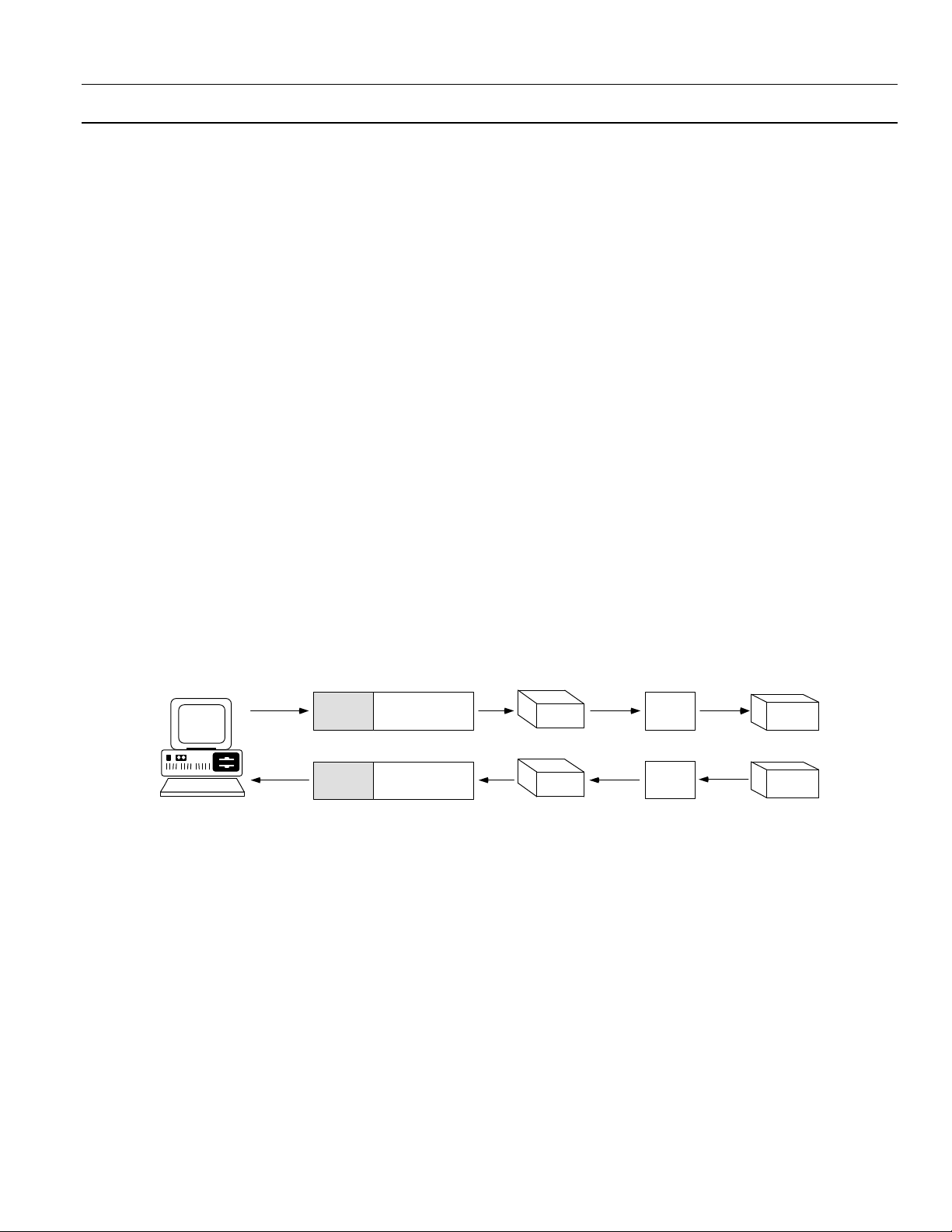

Figure 2 illustrates a typical Modbus RTU network

connected to a high-speed Ethernet through an

Ethernet Gateway.

1

Page 6

POWER LEADER™ Ethernet Gateway

Chapter 1 – Introduction

Ethernet

E PM

37 2 0

Host

PMCS

E PM

37 10

Ethernet

Gateway

PL EPM

RS485 Modbus RT URS485 Modbus RTU

PO WE R

LEADE R

Met er

Other

Mod bus

Concentr ator

Figure 2. Typical use of Ethernet Gateway.

1–2 Physical Description

Figure 3 is an outline drawing showing the

dimensions of the Ethernet Gateway. Figure 4 is a

rear view of the Gateway showing its control power,

Ethernet, RS485 and RS232 connections.

The following ports and connections are provided

on the Gateway:

• A pair of Ethernet ports provides input and output

connections to the either a 10BaseT or a 10Base2

Ethernet network.

• Four RS485 ports support up to four Modbus RTU

networks, labeled Network 1 to Network 4, with as

P C

Spectra

E CM

MVT - PM

Tri p Unit

PL C

90 /30

Mult i l in

26 9+

commnet devi ces

Mult il in

56 5

Other

P C

PLC

90 /70

many as 31 Modbus devices each and up to 247

Modbus addresses each. RS485 ports are DB-9 (9-pin

D shell) connectors with the following pin

assignments:

Data - Pin 1

Data + Pin 2

Ground Pin 5

• One RS232 port (also DB-9 style) allows connection

of a dumb terminal for configuration and

troubleshooting of the Ethernet Gateway.

• A standard PC-style power connector for AC control

power input.

6.7 in.

170.0 mm

0.32 in.

8.0 mm

7.5 in.

166.0 mm

Power

HDD Reset

7.32 in.

196.0 mm

Figure 3. Front view with dimensions.

Status

LEDs

Power

on/off

switch

Length:

15.5 in.

393.0 mm

2

Control power

connection

1

3

4

2

Four

RS485

ports

10Base2 and

10BaseT

Ethernet ports

Figure 4. Rear view showing ports.

Com 1

RS232 port for

dumb terminal

Com 2

RS232 port

not used

keyboard port

not used

Page 7

POWER LEADER™ Ethernet Gateway

Chapter 1 – Introduction

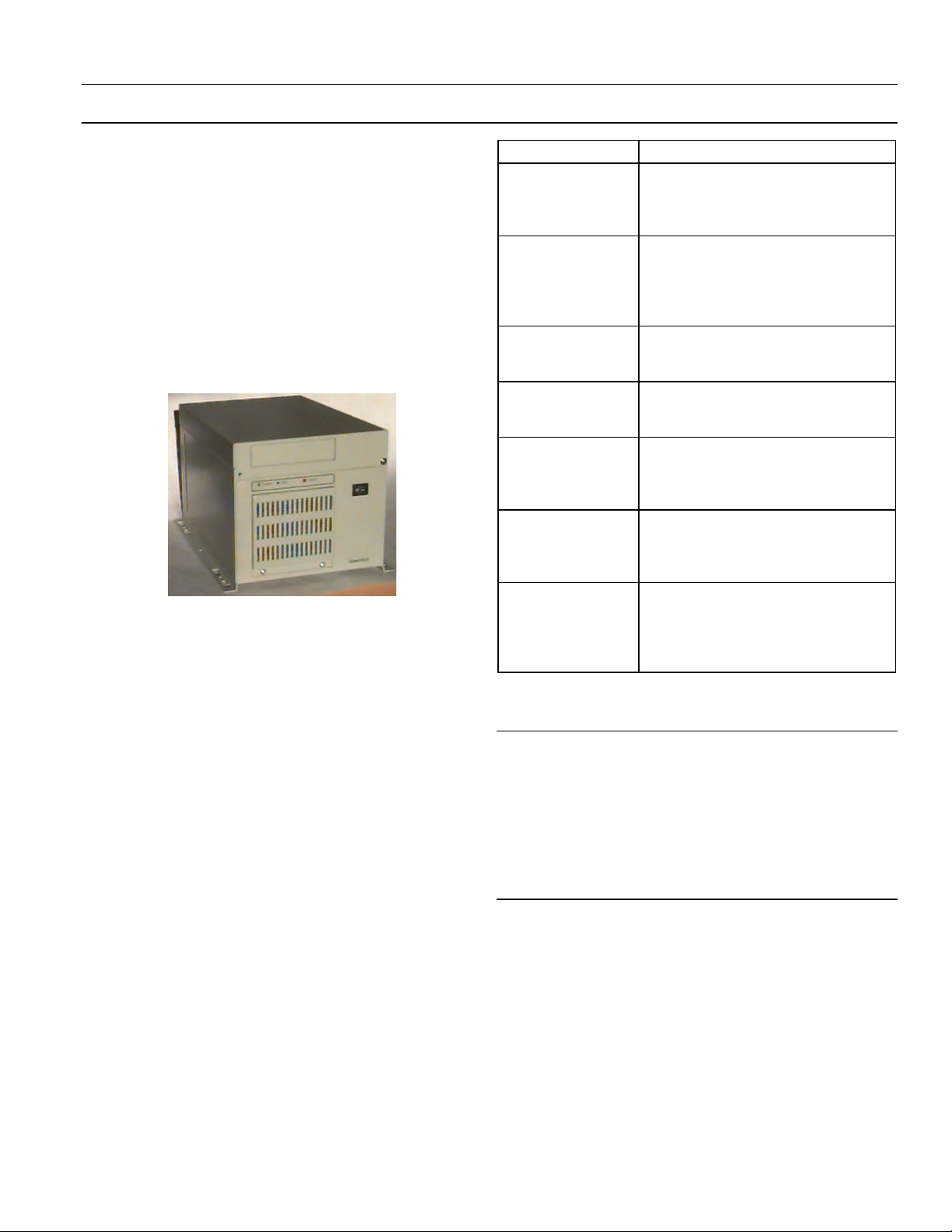

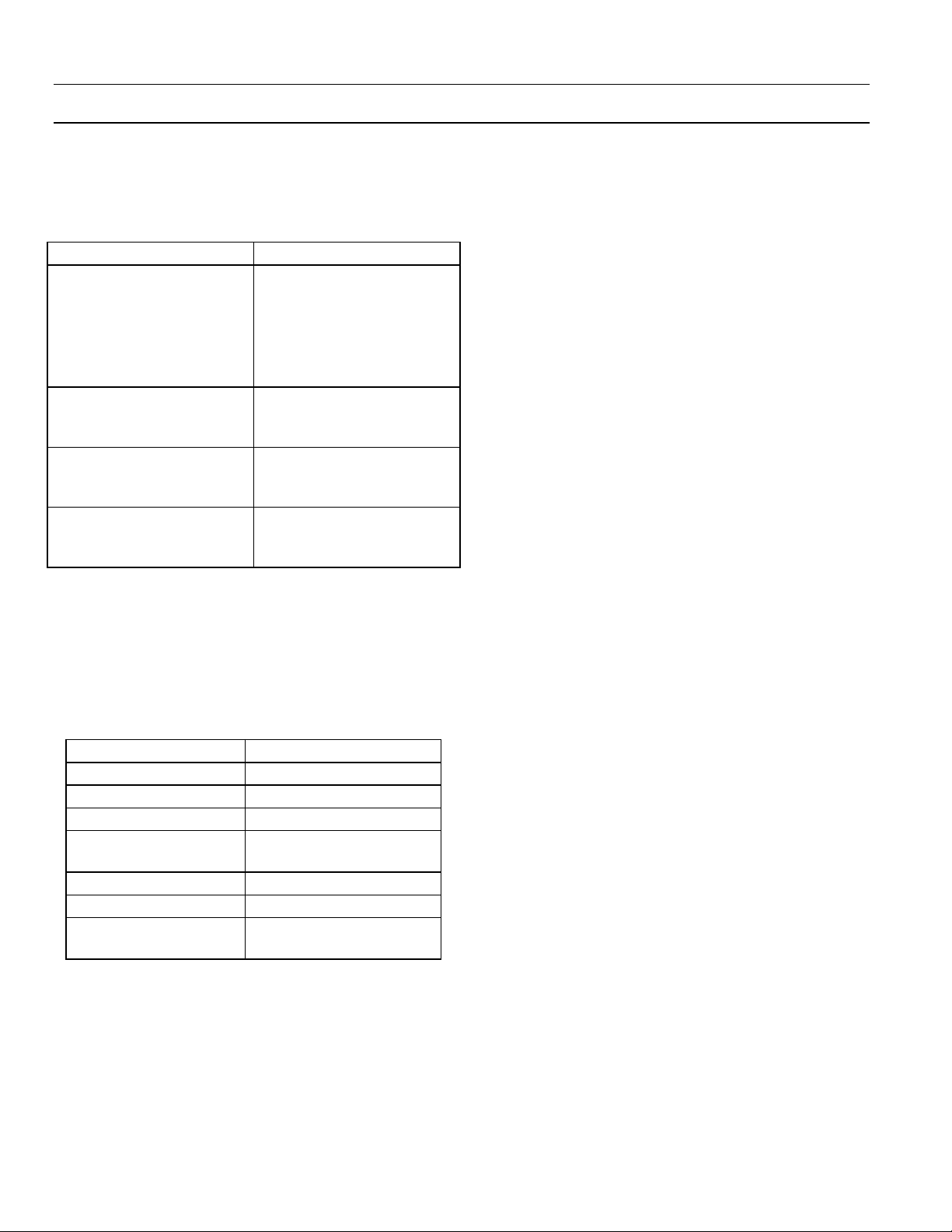

1-3 Operational Description

The Ethernet Gateway transparently passes message

between the host and devices attached to the

Gateway. Figure 5 illustrates the stripping or adding

of Ethernet headers to the Modbus messages. This

section describes the nature of these messages and

how the Gateway routes them. The following

information is not necessary for configuration and use of

the Ethernet Gateway, but is provided for users who may be

developing custom applications and need such

information.

Message Format

Messages sent from the software to RS485 devices

via the Ethernet Gateway have a 15-byte header

inserted in front of the message. The header tells

the Gateway where to send the message, how long

the message is, and if parity errors were

encountered. This header has the following format:

SS DD EE NN CC

SS Sequence of ten AA hex bytes indicating the start

of a message

DD Destination device port number – the Gateway

RS485 port to which the message should be

routed (0 - 3)

EE Error status byte (0 = no parity errors, 1 = parity

errors encountered)

NN Number of bytes in the Modbus message

CC A one byte checksum calculated by adding the

first 14 bytes in the header

The header is stripped off the message by the

Gateway and the remainder of the message is sent

without changes to the destination device (or

interpreted by the Gateway if a configuration

message).

Messages from the RS485 devices to the host are

processed by adding the 15-byte header onto the

start of the message. For messages from devices to

the host, the byte in the DD position contains the

RS485 port from which the message came.

Cyclic redundancy check (CRC) handling is done

by the host on the Ethernet and the RS485 device

on the Modbus. The Gateway does not check the

CRC when receiving messages from the host or

from RS485 devices.

Hos t

PMC S

Modbus messages fr om host to device - Ethernet Gateway str ips off header

Ethernet

header

information

Message tr aveli ng on Ether net

Ethernet

header

information

Mod bus

mess a ge

Mod bus

mess a ge

Modbus messages f rom device to host - Ether net Gateway adds header

Ethernet

Gateway

Ethernet

Gateway

Figure 5. Ethernet headers on Modbus messages.

Gateway/Host Interface

The Gateway uses TCP/IP (Transmission Control

Protocol/Internet Protocol) to interface with the

host on the Ethernet.

The Gateway initially opens a socket and waits for a

host device to attempt to connect with the socket.

Once a connection is established, data messages

may be transmitted to the Gateway (and ultimately

the RS485 devices) and messages from RS485

devices passed to the host.

Mod bus

message

Message t ravel ing on RS485

Mod bus

message

RS485

device

RS485

device

3

Page 8

POWER LEADER™ Ethernet Gateway

Chapter 1 – Introduction

1–4 Specifications

The specifications of the Ethernet Gateway are

listed in Table 2.

Parameter Value

Control power 90–132 Vac or 180–264 Vac,

47–63 Hz; autoranging

Power supply =150 VA min

(contact your GE sales

representative for additional

voltage options.)

Modbus communications Four RS485 ports, 1200 baud,

2400 baud, 4800 baud, 9600

baud and 19.2 Kbaud.

Ethernet communications One PCL-843 16-bit Ethernet

card; supports 10BaseT or

10Base2 transport mediums.

Standards

UL Listed

CSA Certified

Table 2. POWER LEADER Ethernet Gateway specifications.

508 & 840

C22.2 No. 14

1–5 Environmental Requirements

The environmental requirements of the Ethernet

Gateway are listed in Table 3.

Parameter Value

Operating temperature 0° C to +50° C

Storage temperature –20° C to +80° C

Relative humidity 10% to 95% noncondensing

Vibration response and

endurance

Fast transient surge ANSI C37.90.1

Radiated EMI withstand ANSI C37.90.2

Electrostatic discharge IEC 801–2

Table 3. POWER LEADER Ethernet Gateway environmental

IEC 255–21–1

Severity Class 1

Severity Class 4

requirements.

1–6 Terminology

Following are definitions of some of the terms used

in this document.

POWER LEADER – The GE family of comprehensive

power management devices and system software used

to minimize downtime and overall power cost.

PMCS – Power Management Control System software.

SCADA (supervisory control and data acquisition) – A group

of systems including power management and control

systems.

DCS (distributed control system) – A group of systems

including building automation and status

monitoring systems.

Ethernet – An open, industry-standard, high-perform-

ance network communications protocol that operates

on 10BaseT or 10Base2 transport mediums and

yields communications rates up to 10 megabits per

second.

Modbus RTU (Remote Terminal Unit) – An open, industry-

standard, high-performance network communications protocol developed by Modicon/AEG

Schneider Automation.

Modbus-compatible device – Any device equipped with a

Modbus RTU communications port.

Modbus master – A host computer running PMCS

software.

RS485/EIA485 – A physical standard for multi-drop,

high-speed, noise-tolerant communications over a

twisted pair network; often used with the Modbus

RTU protocol.

Commnet – A GE proprietary communications network

standard.

Commnet-compatible device – Any meter, relay, trip unit, or

other device equipped with a commnet communications port.

Commnet segment – A group of one to four commnet-

compatible devices (including at most one waveformcapturing meter) with all communication ports wired

to a single Concentrator commnet port.

4

Page 9

Chapter 2 – Installation

m

2–1 Mounting

The Ethernet Gateway may be mounted on a

horizontal surface or on a wall, preferably inside an

enclosure or switchgear lineup. The Gateway should

be mounted so that it is spaced from enclosure walls

or from other components in the enclosure. A

minimum of two inches clearance should be

allowed along the long sides of the Gateway, and at

least six inches clearance on the ends to allow for

ventilation and cable access. To wall mount the

Ethernet Gateway, attach the brackets to the chassis

using six of the provided screws through the six

holes on the inner edges of the mounting brackets.

Then use the remaining four screws to secure the

chassis to the wall through the holes in the outer

edges of the brackets. Be sure that the chassis is

mounted securely. The hole pattern for the

mounting flanges of the Ethernet Gateway is shown

in Figure 6.

12 i n. 1 in.

305. 0 mm 23.0 m

POWER LEADER™ Ethernet Gateway

Chapter 2 – Installation

Figure 7. Connecting control power to the Ethernet Gateway.

2–3 Ethernet Connection

10BaseT and 10Base2 connections are provided on

the back of the Ethernet Gateway to connect the

Gateway to the Ethernet network, as shown in

Figure 8. The Gateway is equipped with a PCL-843

16-bit Ethernet card.

7 - 1/8"

190. 6 mm

8 - R5 4 - R2.5

Figure 6. Mounting hole pattern for Ethernet Gateway.

2–2 Control Power Connections

Connect the control power cable included with the

Ethernet Gateway to the standard PC-style power

outlet on the rear of the enclosure, as shown in

Figure 7. See Section 1–4 for appropriate control

power voltage ranges.

The ON switch for the Ethernet Gateway is located

on the front panel. Make sure the Gateway is

mounted in a location where the power switch is

not likely to be accidentally hit or switched off.

Figure 8. Making the Ethernet connection to the Gateway.

5

Page 10

POWER LEADER™ Ethernet Gateway

Chapter 2 – Installation

2–4 Modbus Connection

The Modbus RTU networks should be connected to

the RS485 ports on the back of the Ethernet

Gateway, as shown in Figure 9.

Figure 9. Connecting an RS485 network to the Ethernet

Gateway.

Per the EIA-485 standard, the RS485 networks must

be terminated at both ends. Position the Ethernet

Gateway at one end of the RS485 networks, as it is

internally terminated. The user must ensure that

the final device on each network is terminated

correctly, as shown in Figure 10.

2–5 Diagnostic Connection

The RS232 port on the back of the Ethernet

Gateway is provided for connection of a dumb

terminal to the Gateway. The terminal may be used

for configuring the Ethernet Gateway’s settings or

for diagnostic purposes. For diagnostic purposes,

the Gateway may be set to display all messages and

traffic on the terminal so that problems may be

tracked down and corrected. To connect a terminal

(usually a laptop computer running Windows’

Terminal accessory software) to the Gateway, plug

its RS232 cable into the RS232 port on the back of

the Ethernet Gateway, as shown in Figure 11.

Figure 10. Terminating an RS485 network at the last device.

Figure 11. Connecting a dumb terminal to the RS232 port.

2–6 Wiring Rules – Modbus Networks

When wiring Modbus RTU devices to an Ethernet

Gateway, follow the wiring rules below to ensure

proper configuration. Refer to GEH-6502, the PMCS

Network Architecture Guide, for specific examples of

correct and incorrect configurations.

1. Up to 31 Modbus devices may be attached to a

single Modbus network. RS485 repeaters do not

have Modbus addresses, but do count as devices

toward the 31 physical devices per network limit.

2. Every device on a single Modbus network must

have a unique address. (Devices on different

networks may use the same Modbus address,

i.e., it is acceptable to have a device addressed as

device 10 on Network 1 and another device

addressed as device 10 on Network 2.) Use the

Modbus address worksheets (at the end of this

6

Page 11

POWER LEADER™ Ethernet Gateway

Chapter 2 – Installation

manual) to record the devices attached to each

network and verify that each device on each

network has a unique address.

3. Modbus Concentrators may be used to add

POWER LEADER commnet devices to a

Modbus network. The Concentrator assigns a

Modbus-equivalent address to each commnet

device attached to it. See Section 2-7 for a

discussion of commnet and Modbus-equivalent

addresses.

NOTE: While Modbus Concentrators are counted

as regular Modbus devices, the commnet devices

attached to Modbus Concentrators do NOT count

toward the 31 device/network limit, but ARE

considered in the 247 address/network limit.

4. No connections between Modbus networks are

permitted, either directly or through repeaters.

5. Modbus networks are constrained to a

maximum 4,000 feet of communication cable

without repeaters.

6. RS485 repeaters may be used to extend the

wiring length of a Modbus network or to

provide isolation between runs of cable in a

Modbus network. Refer to GEH-6502 for

appropriate wiring lengths with repeaters.

2–7 Modbus Equivalent Addresses

A maximum of 31 Modbus devices can be

supported on a single RS485 network of the

Ethernet Gateway. However, the Modbus RTU

protocol permits up to 247 individual addresses to

be recognized. These additional 216 addresses may

be utilized by commnet devices attached to a special

Modbus device, the Modbus Concentrator.

Commnet is a communications protocol utilized by

many of the devices from GE’s POWER LEADER

family of power management devices. The Modbus

Concentrator is a Modbus RTU device that permits

commnet devices to be assigned Modbus-equivalent

addresses. Each Modbus Concentrator keeps track

of up to 32 commnet devices and directs traffic

between the Modbus network and the commnet

devices. To the Modbus network, the commnet

devices appear as valid Modbus addresses.

To provide seamless integration of commnetcompatible devices into the Modbus RTU network,

the Concentrator directly maps commnet addresses

to equivalent Modbus addresses. The valid range of

commnet addresses recognized by the concentrator

is 300–514. These addresses are one-to-one mapped

to the equivalent Modbus address range of 33–247.

For a more detailed discussion of commnet devices

and the function of the Modbus Concentrator, see

GEH-6491, the Modbus Concentrator Users Guide.

Table 4 lists commnet devices supported by the

Modbus Concentrator (and the Ethernet Gateway).

Device Description

POWER LEADER EPM Full-function, three-phase electronic

meter with optional pulse initiation;

simple retrofit to existing

electromechanical installations. See

GEH–6302 for a full description.

POWER LEADER Meter Full-function three-phase meter with

optional protective relaying and

waveform capture. See GEH–5892.

POWER LEADER MDP

Overcurrent Relay

Spectra ECM™ Advanced motor protection in full-

MicroVersaTrip PM™ trip

unit in Spectra RMS™

molded-case circuit

breakers

MicroVersaTrip PM™ trip

unit in AKR, Power

Break® and Power

Break® II insulated-case

circuit breakers.

Table 4. POWER LEADER commnet devices supported by the

Three-phase and ground protection

against overloads and rapid

detection of short circuits.

See GEK–100682.

voltage-nonreversing (FVNR) and

full-voltage-reversing (FVR)

combination starter applications.

See GEH–6435.

Overcurrent protection and optional

full-function metering and protective

relaying. See GEH–5934.

Overcurrent protection and optional

full-function metering and protective

relaying. See GEH–6273.

Modbus Concentrator.

7

Page 12

POWER LEADER™ Ethernet Gateway

Chapter 3 – Configuration

Chapter 3 – Configuration

The Ethernet Gateway needs to be properly

configured to communicate with your RS485

networks. Two items are critical to proper

performance of your Gateway: the Gateway’s

Ethernet address and the RS485 port

communication settings. The Gateway’s Ethernet

address should be set so that the host software will

know how to address messages to the Gateway. You

must configure the Ethernet Gateway with the

appropriate baud rate and communications settings

for each RS485 port to match attached RS485

network. After initial setup, you should only need to

make changes to the Gateway’s settings after adding

devices or making system changes.

Follow the instructions in Section 3-1 to perform the

initial configuration. After the network is

operational, you may make configuration changes

through the dumb terminal. These procedures are

described in the following sections.

In all cases, be sure to save any configuration

changes to the Gateway’s hard drive (option 12) for

safe retrieval in the event of a power loss.

3–1 Configuration Procedure

Figure 12. Terminal communications settings.

You are now ready to configure the Gateway, as

outlined below:

1. Type SET (must be typed in capital letters)

then press <ENTER> to bring up the

configuration menu. If you make an error

typing in this string, wait ten seconds and try

again.

Configuration of the Gateway requires a dumb

terminal with RS232 port set to 19.2 Kbps, 8 data

bits, no parity, and 1 stop bit. The easiest way to do

this is to use a portable computer with an RS232

port, and run the Terminal accessory program from

Windows.

Use a null modem cable to attach the laptop to the

RS232 port of the Gateway, power up the laptop

and launch the Terminal program (located in the

Accessories program group in the Windows

program manager). Click on the Settings menu,

then choose Communications. Set your

communications options to look like figure 12.

When you have set your communications options,

close the options window and power up the Gateway

(the ON switch is located on the front panel).

When the Gateway finishes powering up, the

following message is transmitted to the terminal:

2. The terminal displays the configuration

menu:

Figure 13. Ethernet Gateway configuration menu.

8

Page 13

POWER LEADER™ Ethernet Gateway

Chapter 3 – Configuration

Enter the setting number you want to change,

then press <ENTER>.

NOTE: The lower portion of the Configuration Menu is

labeled Advanced Options. These options are for use

ONLY by GE technical support personnel. Do NOT select

any of these options. IF YOU ACCIDENTALLY SELECT

ANY ADVANCED OPTION FROM THE

CONFIGURATION MENU, PRESS <ESC> TO EXIT,

THEN PRESS <ENTER> TO RETURN TO THE

CONFIGURATION MENU.

3. At the prompt, enter the new setting, then

press <ENTER>. If you enter an invalid value,

the following message will be displayed:

Pressing <ENTER> returns you to the

configuration menu.

NOTE: Pressing <ESC> while entering a new value for a

setting discards the changes and redisplays the

configuration menu.

3–2 Ethernet Gateway IP Address

Ethernet Gateway’s IP address must be properly set

for it to receive messages sent by the host software.

Consult your LAN personnel or system

administrator for assistance in selecting the correct

IP address. Follow Section 3–7 to modify the IP

address.

WARNING: Setting the Ethernet Gateway to an incorrect

or conflicting IP address can cause SERIOUS network

problems. ALWAYS consult your LAN personnel or system

administrator before making any changes to the IP

address.

3–3 Baud Rate Specification

You must configure the baud rate and

communications settings on each RS485 port to

match the baud rate on the attached RS485

network. The Gateway supports RS485 speeds of

1200 baud, 2400 baud, 4800 baud, 9600 baud and

19.2 Kbaud. Default settings are 19.2 Kbaud, 8 data

bits, no parity, 1 stop bit.

4. Configure parameters as desired, by repeating

steps 2 and 3.

5. When you are finished making changes, select

option 12, .

The configuration file on drive A is modified

with the new parameters and the terminal

displays the following message:

If an error has been made, select option 13,

The

currently displayed settings are discarded and

the following message is displayed on the

terminal:

Correct the error by repeating steps 1–3.

6. When you have saved the configuration and

exited, the Ethernet Gateway is ready for

operation. Turn off the unit until the rest of

the network is ready for operation.

Each network’s baud rate depends on the devices

attached to it – see GEH-6502, the PMCS Network

Architecture Guide, for more details on this.

To configure the baud rate and communications

settings for any of the four RS485 ports, follow

Section 3-1, referencing the special instructions

given below regarding the communications options.

Table 5 lists the valid entries for options 1 through

8 of the Configuration menu, relating to the baud

rate and communications settings of RS485 ports.

9

Page 14

POWER LEADER™ Ethernet Gateway

Chapter 3 – Configuration

Option Number: Valid Entries at Prompt:

1 = RS485 Port 1

3 = RS485 Port 2

5 = RS485 Port 3

7 = RS485 Port 4

2 = RS485 Port 1

4 = RS485 Port 2

6 = RS485 Port 3

8 = RS485 Port 4

1. Follow the procedure outlined in Section 3-1

to configure the Gateway.

2. At the Configuration menu, select the option

number, then press <ENTER>. At the prompt,

enter the new setting, then press <ENTER>. For

options 1, 3, 5, and 7, enter the new setting

from the options in Table 5, then press

<ENTER>. For options 2, 4, 6, and 8, enter each

new parameter as prompted, using the correct

entries from Table 5. If you enter an invalid

value, the following message display:

Press <ENTER> to return to the Configuration

menu.

NOTE: Pressing <ESC> while entering a new value for a

setting discards the changes and redisplays the

Configuration menu.

0 = 1200 baud 4 = 19200 baud

1 = 2400 baud 5 = 38400 baud

2 = 4800 baud 6 = 57600 baud

3 = 9600 baud

Data Bits: 0 = 7 data bits

1 = 8 data bits

Stop Bits: 0 = 1 stop bit

1 = 2 stop bits

Parity: 0 = None

1 = Even

2 = Odd

Table 5. RS485 Port Settings .

3–4 Message Monitoring

For diagnostic purposes, you may want to monitor

message traffic across the RS485 ports. This can be

done on a terminal connected to the RS232 port.

You may monitor messages on any single RS485

port or on all four ports simultaneously.

Selecting menu item 14 allows you to select whether

or not messages are sent to the RS232 port in

monitor mode and which RS485 ports are to be

monitored. The following prompt appears:

Enter your selection from the above choices.

3–5 Ethernet Driver

Menu item 10 permits the Ethernet driver to be

selected. Most systems utilize DIX Ethernet; a

handful use IEEE Ethernet. The Gateway defaults

to the DIX Ethernet driver. If your network does not

function under DIX Ethernet and you have

eliminated all other potential sources of trouble,

change the driver setting to IEEE Ethernet and retry

communications. If this does not resolve the

problem, contact Customer Service.

3. Follow steps 5 and 6 of Section 3-1 to save any

changes and exit configuration mode.

10

Page 15

POWER LEADER™ Ethernet Gateway

Chapter 3 – Configuration

3–6 Gateway Diagnostics

Selecting menu item 11 exits the Gateway software

and runs the Gateway diagnostics program. The

Gateway Diagnostics menu shown in Figure 14 is

displayed on the terminal.

Figure 14. Gateway Diagnostics menu.

Display Socket, IP Address and Subnet

Mask

Select menu item 1 to display the IP address and

subnet mask for the Gateway.

RS485 Loop-back Test

Enter the port to be tested: 1, 2, 3, or 4. The

following message displays:

(where X is the port being tested).

If the loop-back is successful, the following message

will be displayed:

(where Y is the loop-back port).

If the loop-back is unsuccessful, the following

message displays:

Default settings on the RS485 ports for the loopback tests are 115.2 Kbps, 8-N-1.

Ethernet Test

Select menu item 3 to test the Gateway’s internal

Ethernet connections. This performs a self-test of

the Gateway’s Ethernet card to ensure that it is

functioning correctly. The following message

displays:

If the test passes, the following message displays:

Select menu item 2 to perform a loop-back test on

an RS485 port. The loop-back test is useful for

identifying the RS485 ports and for testing

communications on an RS485 port. To complete

this test, you will need a short RS485 cable, available

at an electronics retailer.

The RS485 port being tested is connected to

another RS485 port and a test message is

transmitted from the port being tested. The

following prompt appears:

If the test fails, the following message displays:

In either case, pressing <ENTER> returns you to the

diagnostics menu.

Exit Diagnostics Program

Select menu item 4 to exit the Gateway diagnostic

software and reload the Gateway software.

11

Page 16

POWER LEADER™ Ethernet Gateway

Chapter 3 – Configuration

Network Test – FACTORY USE ONLY

NOTE: A client program may be requested from GE to

run on the host when performing the network test. The

client attempts to establish a connection to a server (the

Gateway) with the specified IP address, subnet mask and

port number.

Menu item 5 is for factory testing of the network.

End users should NOT select this option. This test

attempts to communicate with a host across the

Ethernet. To complete this test, you will need an

RS232 null modem cable, available at an electronics

retailer. Before performing this test, the host PC

must be running the client software mentioned

above, and must be connected to the Ethernet

Gateway via the null modem cable.

When you select menu item 4, the following

message is displayed:

3–7 Advanced Options – Technical

Support Personnel ONLY

Ordinarily these options will have been configured

by the system integrator or direct from the factory;

you should NOT alter any of the settings from the

advanced options area of the Configuration menu.

WARNING: ALTERING ANY OF THESE SETTINGS

MAY RENDER THE ETHERNET GATEWAY

INOPERABLE. IF YOU ACCIDENTALLY SELECT ANY

OPTION FROM THE ADVANCED SETTINGS, PRESS

<ESC> TO EXIT, THEN PRESS <ENTER> TO RETURN

TO THE CONFIGURATION MENU.

Select menu item 15 to modify the Gateway socket

identifier. The format is: ####.

Select menu item 16 to modify the Gateway Internet

Protocol (IP) address. Enter the IP address in dot

notation, e.g., 123.145.51.126.

Select menu item 17 to modify the Gateway subnet

mask. Enter the subnetwork mask in dot notation,

e.g., 255.255.255.0.

If the network test passes, the following message is

displayed:

If the network test fails, the following message is

displayed:

In either case, pressing <ENTER> returns you to the

diagnostics menu.

Select menu item 18 to modify the FTP PC/TCP

kernal serial number. The number has the

following format: 1234-5678-9012.

Select menu item 19 to modify the FTP PC/TCP

kernal authentication key. The number has the following format: 1234-5678-9012.

Select menu item 21 to modify the Gateway Router.

This item has the following format: 0.0.0.0, 0.0.0.0,

0.0.0.0 Note that the Router numbers may have

multiple digits in each placeholder, and each set of

four numbers represents one router; for example,

205.109.43.11, 0.0.0.0, 0.0.0.0 is configured for one

router. The Gateway may be configured with a

maximum of three routers.

Updating the Gateway Software

Option 20 of the Configuration menu allows updating of the Ethernet Gateway’s operating software

and is for use ONLY by factory service personnel.

12

Page 17

Chapter 4 – Operation

The Ethernet Gateway, once properly configured,

requires no user intervention for operation.

During normal operation, the Ethernet Gateway

passes messages to and from the attached Modbus

devices and translates these messages between the

Ethernet and Modbus RTU protocols.

Should power to the Ethernet Gateway be interrupted, communications between the host and the

RS485 networks will resume automatically and

immediately when power is restored.

Likewise, if the Ethernet connection or any of the

RS485 connections are broken, communications

will be immediately resumed when the connections

are restored.

Any errors encountered by the Ethernet Gateway

will result in a message being sent back to the host,

where it will be interpreted and displayed for corrective action by the operator.

POWER LEADER™ Ethernet Gateway

Chapter 4 – Operation

All processing error messages are sent to the RS232

port. Processing error messages are listed in Section

5-1 of this manual.

13

Page 18

POWER LEADER™ Ethernet Gateway

Chapter 5 – Errors and Diagnostic Messages

Chapter 5 – Diagnostic Messages and Errors

5–1 Monitor Mode

The Ethernet Gateway can be set to send diagnostic

messages to the RS232 port to be displayed on a

terminal (see Chapter 3). These diagnostic

messages can be very useful in tracking down errors

in configuration or device addressing.

Diagnostic messages sent to the RS232 port in monitor mode have the following format:

Table 6 explains what each field means:

Field Meaning

The relative time of the message in timer

ticks. This rolls over every

1,000,000,000 timer ticks.

Indicates the direction of the message:

E-n (n = 1,2,3 or 4) indicates a message

sent from the Ethernet Gateway to

RS485 port number 1,2,3 or 4

n-E indicates a message sent from

RS485 port number 1,2,3 or 4 to the

Ethernet Gateway

Header byte added to regular Modbus

message. Printed as two hex digits.

Binary data of regular Modbus message.

Printed as two hex digits.

5–2 Processing Error Messages

Table 7 gives error messages that may be generated

by the Gateway and displayed at the PMCS host.

Message Meaning

Error - Buffer Overflow One or more buffers have

overflowed.

Error - Writing to Flash

ROM

Error - Reading Flash

ROM

An attempt to write to flash ROM

(drive A) has failed.

An attempt to read the flash ROM

(drive A) has failed.

Table 7. Error message key.

Table 6. Diagnostic messages key.

14

Page 19

POWER LEADER™ Ethernet Gateway

Chapter 6 – Troubleshooting Guide

Chapter 6 – Troubleshooting Guide

The following guide is provided for troubleshooting

and isolating common problems. It does not cover

every possible condition. Contact the ED&C

Customer Support Center at 800-843-3742 if the

problem is not resolved by these procedures.

Symptom Possible Cause Corrective Action

1. No response at either

host PC or dumb

terminal from the

Ethernet Gateway.

Lack of power.

Ethernet Gateway internal

failure.

Check that control power cable is working and

correctly connected.

Remove and reapply power to the Ethernet

Gateway to see if the failure clears itself

(possibly caused by external noise). Contact

Customer Support if the problem persists.

WARNING:

Voltages hazardous to personnel and equipment may

be present at the power connection.

2.

No response at host

PC from the Ethernet

Gateway, but terminal

connection is OK.

3.

Ethernet connections

OK, but no response

from RS485

device(s).

4.

Some devices on

RS485 networks not

recognized at host.

Faulty Ethernet wiring

between Ethernet Gateway

and host PC

Ethernet driver may be

incorrect.

Faulty RS485 wiring between

Ethernet Gateway and

RS485 networks.

Lack of control power at

RS485 device(s).

Addressing problems or too

many devices on segment

Check that the Ethernet connector is properly

wired and firmly seated. Test wiring for

continuity and polarity to host PC.

Check with your system administrator as to

which Ethernet driver is being used (DIX or

IEEE). Make sure Gateway is set accordingly

(Section 3-5).

Check that the RS485 connector is properly

wired and firmly seated. Test wiring for

continuity and polarity on RS485 wiring.

Check that control power present and correctly

connected at device(s).

Refer to Section 5-1 to diagnose the precise

problem and correct accordingly.

15

Page 20

POWER LEADER™ Ethernet Gateway

Configuration Worksheets

RS485 Port Configuration Worksheets

Use the following worksheets to record the devices

attached to the Ethernet Gateway for reference and

troubleshooting. Record the Ethernet Gateway’s

Ethernet address on the first page only, then fill in

the information on the Modbus devices attached to

RS485 Port 1 Worksheet

Baud Rate for RS485 Port 1

Modbus

Network

1 1

1 2

1 3

1 4

1 5

1 6

1 7

1 8

1 9

1 10

1 11

1 12

1 13

1 14

1 15

1 16

1 17

1 18

1 19

1 20

1 21

1 22

1 23

1 24

1 25

1 26

1 27

1 28

1 29

1 30

1 31

Device

Number Device Type & Physical Location / Notes

each network: device type and physical location,

and the Modbus address assigned to it.

Ethernet Gateway Address:

Modbus

Address

16

Page 21

Baud Rate for RS485 Port 2

POWER LEADER™ Ethernet Gateway

Configuration Worksheets

RS485 Port 2 Worksheet

Modbus

Network

2 1

2 2

2 3

2 4

2 5

2 6

2 7

2 8

2 9

2 10

2 11

2 12

2 13

2 14

2 15

2 16

2 17

2 18

2 19

2 20

2 21

2 22

2 23

2 24

2 25

2 26

2 27

2 28

2 29

2 30

2 31

Device

Number Device Type & Physical Location / Notes

Modbus

Address

17

Page 22

POWER LEADER™ Ethernet Gateway

Configuration Worksheets

RS485 Port 3 Worksheet

Baud Rate for RS485 Port 3

Modbus

Network

3 1

3 2

3 3

3 4

3 5

3 6

3 7

3 8

3 9

3 10

3 11

3 12

3 13

3 14

3 15

3 16

3 17

3 18

3 19

3 20

3 21

3 22

3 23

3 24

3 25

3 26

3 27

3 28

3 29

3 30

3 31

Device

Number Device Type & Physical Location / Notes

Modbus

Address

18

Page 23

Baud Rate for RS485 Port 4

POWER LEADER™ Ethernet Gateway

Configuration Worksheets

RS485 Port 4 Worksheet

Modbus

Network

4 1

4 2

4 3

4 4

4 5

4 6

4 7

4 8

4 9

4 10

4 11

4 12

4 13

4 14

4 15

4 16

4 17

4 18

4 19

4 20

4 21

4 22

4 23

4 24

4 25

4 26

4 27

4 28

4 29

4 30

4 31

Device

Number Device Type & Physical Location / Notes

Modbus

Address

19

Page 24

g

GE Electrical Distribution & Control

General Electric Company

41 Woodford Ave., Plainville, CT 06062

GEH-6505A 0996 © 1996 General Electric Company

Loading...

Loading...