Page 1

GE Oil & Gas

Becker* 35000 and 36000 Series

V-0 Control Valves

Page 2

2 | Dresser

Page 3

GE’s Becker V-0 Control Valve is a segmented

type rotary control valve designed for mild duty

natural gas regulation.The V-0 features a high

capacity, cost effective design in a very compact

package.

The 35000 Series V-0 valve incorporates flangeless end connections for installation

between flanges. The 36000 Series V-0 valve incorporates raised face flange end

connections in accordance with ISA S75.04. The 35000 Series valves are offered

in 150, 300, and 600 ANSI ratings and the 36000 Series valves are offered in 150

and 300 ANSI ratings. The V-0 Control valve utilizes the Becker RSD Rotary Spring

and Diaphragm actuators. When paired with GE environmentally friendly control

instrumentation, the V-0 is the ideal high capacity valve for mild duty pressure and

flow regulation, and on/off service in natural gas piping systems.

Features

High capacity ball valve design allows low wide open

pressure differential

Extended turndown in excess of 300:1 with v-notch segmented ball

Soft seat design for bubble tight shutoff or stainless

steel seat for erosive process

Spring and diaphragm actuators require low supply pressure

and reduced transient consumption

Easy maintenance minimizes downtime

Versatile design allows for simple field actuator

mounting change

Becker ZERO BLEED* instrumentation reduces costly

atmospheric gas emissions in steady state

Proven Becker VRP Valve Regulator Pilot and DNGP Digital

Natural Gas Positioner offer accurate steady-state control

Use in control or ON/OFF applications

3

Page 4

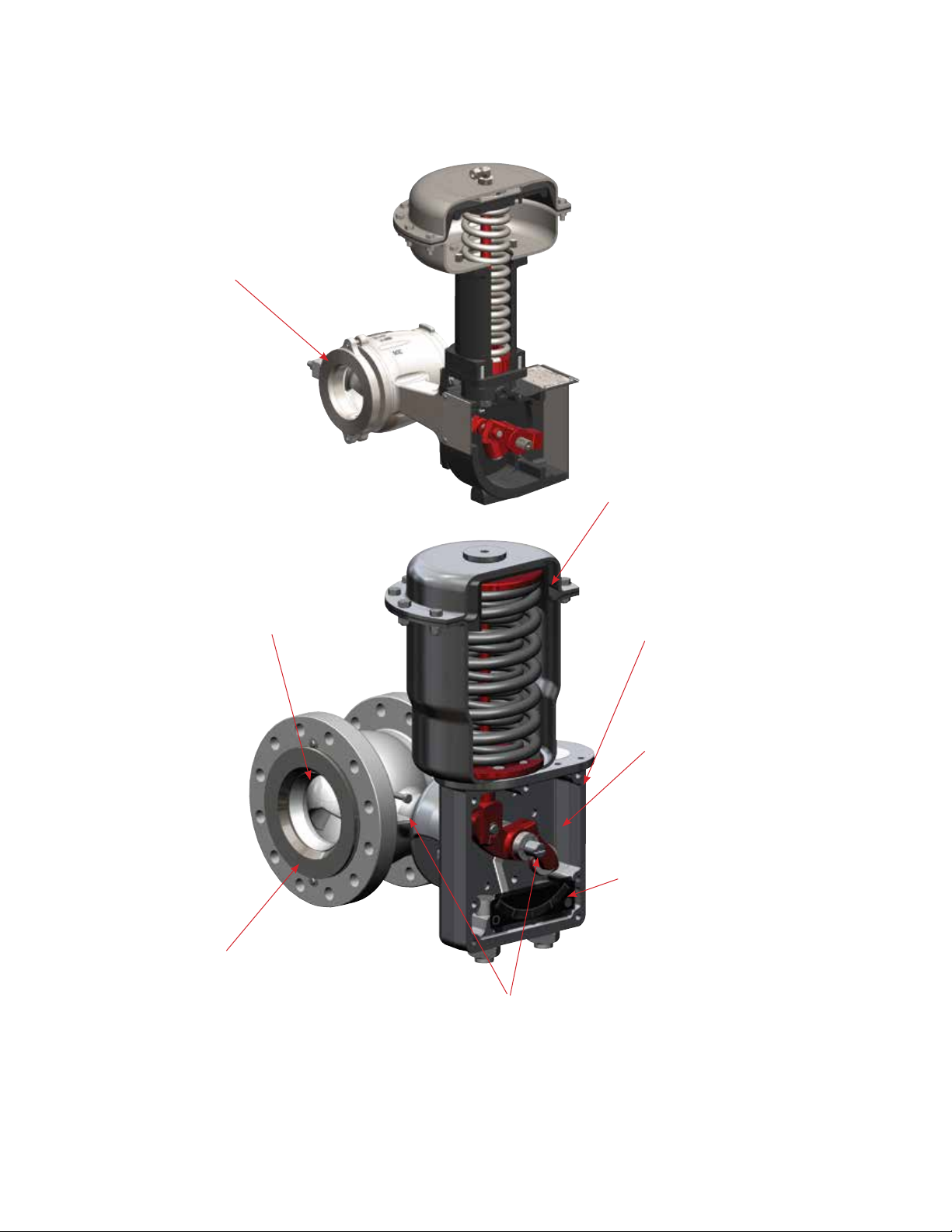

Simple Rugged Versatile Design

Flanged or Flangeless Design

Integral flange (150 and 300 Class) and

flangeless (150, 300, and 600 Class) end

connections available

High Turndown

The segmented ball design with the

v-notch characteristic offers high wideopen capacity and optimal low-end control

resulting in total turndown in excess of

300:1

Spring and Diaphragm

Actuator

Large diaphragm area requires low

supply pressure and low transient

consumption.Spring loaded fail safe

is easily field reversible

Simple Enclosed Housing

Enclosed actuator housing protects

linkage from the elements and is

safer for station personnel

Blowout-Proof Shaft

The shaft is designed so that it can

not blow out, even with the actuator

and packing follower removed

Position Indication

Visible rotary indicator allows quick

visual inspection of valve position

Soft or Metal Seat Design

Easily interchangeable soft seat

(standard) offering Class VI shutoff, or

stainless steel seat (optional) offering

Class IV shutoff

4

Splined Stem Connections

A durable and accurate involute spline

connects the stem to the ball and

torque arm. Unlike pins or keys, concentrated stresses are avoided to ensure long

trouble-free service

Page 5

High Capacity with Optimal Low-End Control

Flanged Body Design (Available in Classes 150 and 300)

Valve Size V-0 Control Valve (Degrees Open)

(in) (mm) 10 20 30 40 50 60 70 80 90

1 25 0.2 1.2 2.9 5.2 8.2 12.1 17.3 25.6 55.0

1.5 40 0.4 2.7 6.5 11.9 18.8 27.5 39.4 58.1 125

2 50 0.5 3.7 8.8 16.1 25.5 37.4 53.5 79.0 170

3 80 1.3 9.4 22.9 41.8 66.0 96.8 138.6 205 440

4 100 2.2 15.9 38.5 70.3 111 163 233 344 740

6 150 3.8 26.9 65 119 188 275 394 581 1250

8 200 5.6 40 97 177 279 409 586 865 1860

10 250 9 64.9 157 287 453 664 951 1404 3020

12 300 13.2 95 229 418 660 968 1386 2046 4400

Flangeless Body Design (Available in Classes 150, 300 and 600)

Valve Size V-0 Control Valve (Degrees Open)

(in) (mm) 10 20 30 40 50 60 70 80 90

2 50 0.3 4.7 12.7 23.3 39.0 58.2 81.5 112 163

3 80 1.5 7.4 22.3 44.6 73.7 114 164 242 372

4 100 2.3 17.3 40.3 74.2 121 178 247 371 575

6 150 4.6 30.2 78.9 148 231 331 463 664 1160

8 200 5.7 47.8 120 225 354 512 749 1180 1770

Capacity Curve for 6” (150 mm) Flangeless V-0

1200

1000

800

600

400

200

Flow Coefficient (Cv)

0

0

10

20 50

30

40

60 70

Degrees Travel (Open)

High Rangeability

The V-0 Control Valve offers a modified equal percentage capacity curve

allowing optimal control at both the low end and high wide-open capacity

80 90

5

Page 6

Equipped with Environmentally Friendly

Instrumentation

Pressure Control with VRP Valve Regulator Pilot

The Becker Model VRP-SB-CH Single-Acting Pilot provides pressure control when utilized with

the V-0 Control Valve. The VRP-SB-CH pilot measures process sensing pressure and

positions the single-acting V-0 actuator to maintain the pressure setpoint. The VRP-SB-CH pilot

may be utilized for pressure control applications with setpoints ranging from 1.0 psig

(6.9 kPa) to 1480 psig (10204 kPa). The VRP-SB-CH pilot features ZERO BLEED™ in steady state.

Purely pneumatic pressure control

ZERO BLEED™ technology eliminates

atmospheric emissions in steady state

Design specifically suited for natural

gas production, midstream, distribution, and transmission

Setpoint ranges from 1 to 1480 psig

Rugged design is vibration resistant

and suitable for demanding pipeline

applications

Flow or Pressure Control with DNGP Digital Natural Gas Positioner

The Becker DNGP Digital Natural Gas Positioner is used with the V-0 control valve to provide

an accurate valve stem position that is proportional to the electronic command input signal

received from an electronic controller. The DNGP eliminates the need for an I/P transducer

™

and features ZERO BLEED

consumption at steady state. Additionally, the DNGP features

easy, menu driven setup along with PC interfaced diagnostic and setup features. Most

importantly, the DNGP offers multiple fail safe modes to protect your gas pipeline.

4-20 mA analog and 12 or 24 VDC pulse input

ZERO BLEED™ technology eliminates atmospheric emissions in

steady state

Design specifically suited for natural gas production, midstream,

distribution, and transmission

Explosion proof design may be installed in hazardous locations

Illuminated display and navigational menus for easy

field configuration

Split range control for multiple runs

Push-button manual local positioning of valve

6

Page 7

ON/OFF Over/Under-Pressure Protection with VRP-SB-GAP Controller

The Becker Model VRP-SB-GAP Single-Acting Controller provides on-off control when

utilized with the V-0 Control Valve. The VRP-SB-GAP controller measures the process

sensing pressure and closes the actuated valve upon pressure rising to the high

pressure setpoint. Conversely, VRP-SB-GAP controller will re-open the actuated valve

upon pressure falling to the low pressure setpoint. The action of the VRP-SB-GAP

controller may be reversed to open an actuated valve upon rising pressure while

closing on falling pressure. The VRP-SB-GAP controller may be utilized for gap control

applications with setpoints ranging from 1.0 psig (6.9 kPa) to 1480 psig (10204 kPa).

The VRP-SB-GAP controller features ZERO BLEED™ in steady state.

Purely pneumatic over/under-pressure protec-

tion

for on/off applications

Automatic reset when trip condition removed

ZERO BLEED™ technology eliminates atmospheric

emissions in steady state

Design specifically suited for natural gas

production, midstream, distribution,

and transmission

Setpoint ranges from 1 to 1480 psig

Rugged design is vibration resistant

and suitable for demanding pipeline

applications

Easy, intuitive adjustment and maintenance

techniques greatly minimize training

Specifications

35000 and 36000 Series V-0 Control Valve

Classification

Valve Type

Applications

Shut Off Class

Flow Characteristics

Size Range

Flange End

Flangeless

Pressure Ratings

Flange End

Flangeless

End Connections

Compatible Actuators

Rotary Control Valve

Segmented Ball Valve

Monitoring, mild service, or on/off

applications

Class VI with soft seats (standard) or

Class IV with metal seats (optional)

Modified Equal Percentage (high gain)

Range of Product

1” (25 mm) to 12” (300 mm)

2” (50 mm) to 8” (200 mm)

150 and 300 ANSI

150, 300 and 600 ANSI

RFFE, Flangeless

Becker RSD Series - Rotary Spring and

Diaphragm

Body Material

Flange End

Flangeless

Ball Material

Seat Seal Material

Flange End

Flangeless

Prep/Coating

Maximum Control Cv

Minimum Control Cv

Maximum Noise

Pipe Velocity (Gas)

Pipe Velocity (Liquid)

Face to Face

Operating

Temperature

Flange End

Flangeless

Materials of Construction

ASTM A216 Gr WCB Carbon Steel

ASTM A352 Gr LCC Carbon Steel

ASTM A351 Gr CG8M Type 317

PTFE (standard soft seat), 317 SS (metal seat)

TFE (standard soft seat), 316 SS (metal seat)

Sandblast per SP-10 and standard Becker

topcoat

General Design Specifications

90% of Maximum Cv

0.33% of Maximum Cv

100 dBA

100 ft/sec

30 ft/sec

Conforms to ISA Standard S75.04

soft seat: -20ºF to 425ºF (-29ºC to 218ºC)

metal seat: -20ºF to 500ºF (-29ºC to 260ºC)

soft seat: -50ºF to 450ºF (-46ºC to 232ºC)

metal seat: -50ºF to 550ºF (-46ºC to 287ºC)

7

Page 8

35000 Series Flangeless V-0 Valve Dimensions

35000 Series V-0 Valve Dimensions (in)

Valve

4 (100) 40 149 24.38 26.63 19.88 2.12 6.19 4.50 13.12 13.88 7.62

4 (100) 60 252 34.25 30.31 29.50 2.50 6.19 4.75 18.62 14.81 7.62

6 (150) 60 282 34.25 33.06 29.50 2.50 7.44 4.75 18.62 16.31 9.00

8 (200) 60 332 34.25 36.62 29.50 2.50 9.12 4.75 18.62 18.19 9.56

Valve

4 (100) 40 68 619 676 505 54 157 114 333 353 194

4 (100) 60 115 870 770 749 64 157 121 473 376 194

6 (150) 60 128 870 840 749 64 189 121 473 414 229

8 (200) 60 151 870 930 749 64 232 121 473 462 243

Actuator

Size

2 (50) 30 86 17.87 21.45 13.31 1.31 4.38 4.56 11.38 11.38 4.88

2 (50) 40 115 24.38 22.26 19.88 2.12 4.38 4.50 13.12 11.32 4.88

2 (50) 60 218 34.25 25.94 29.50 2.50 4.38 4.75 18.62 12.25 4.88

3 (80) 30 100 17.87 24.51 13.31 1.31 5.50 4.56 11.38 13.32 6.50

3 (80) 40 129 24.38 25.32 19.88 2.12 5.50 4.50 13.12 13.26 6.50

3 (80) 60 232 34.25 29.00 29.50 2.50 5.50 4.75 18.62 14.19 6.50

Size

Weight

lbs

A B C D E F G H I

35000 Series V-0 Valve Dimensions (mm)

Actuator

Size

2 (50) 30 39 454 545 338 33 111 116 289 289 124

2 (50) 40 52 619 565 505 54 111 114 333 288 124

2 (50) 60 99 870 659 749 64 111 121 473 311 124

3 (80) 30 45 454 623 338 33 140 116 289 338 165

3 (80) 40 59 619 643 505 54 140 114 333 337 165

3 (80) 60 105 870 737 749 64 140 121 473 360 165

Size

Weight

kg

A B C D E F G H I

35000 Series Valve Tie Rod Length (in)

Valve Size Class 150 Class 300 Class 600

2 (50) 8.25 8.50 9.25

3 (80) 10.12 11.12 11.50

4 (100) 11.44 12.12 13.62

6 (150) 13.62 14.38 16.50

8 (200) 13.62 15.38 17.12

35000 Series Valve Tie Rod Length (mm)

Valve Size Class 150 Class 300 Class 600

2 (50) 210 216 235

3 (80) 257 282 292

4 (100) 291 308 346

6 (150) 346 365 419

8 (200) 346 391 435

8

Page 9

36000 Series Flanged V-0 Valve Dimensions

Actuator Model 33, Size AC – inches [millimeters]

Actuator Model 33, Size B and C – inches [millimeters]

9

Page 10

36000 Series Flanged V-0 Valve Dimensions (in)

Valve

Size

Actuator Size A

in. DN Size Sq. In.

ANSI

150

ANSI

300

ANSI

300

Face-to-Face

D

Standard ISA

(2)

S75.04

E F G

(1)

C

B

ANSI

150

Center-to-

Face

H

Standard ISA

S75.04

1 25 AC 30 2.74 2.74 8.06 4.25 4.88 4.00 10.70 8.50 10.53 2.12

1.5 40 AC 30 3.13 4.08 8.33 5.00 6.12 4.47 10.70 8.50 10.80 2.43

AC 30 3.92 5.05 8.74 6.00 6.50 4.93 10.70 8.50 11.21 2.56

2 50

B 70 3.92 5.05 8.52 6.00 6.50 4.93 11.45 13.00 11.21 2.56

B 70 4.64 4.64 10.24 7.50 8.25 6.54 11.45 13.00 12.93 3.59

3 80

C 140 4.64 4.64 10.24 7.50 8.25 6.54 15.07 17.50 12.93 3.59

B 70 5.48 5.48 10.87 9.00 10.00 7.61 11.45 13.00 13.56 3.95

4 100

C 140 5.48 5.48 10.87 9.00 10.00 7.61 15.07 17.50 13.56 3.95

6 150 C 140 6.76 6.76 12.09 11.00 12.50 8.99 15.07 17.50 14.78 4.85

8 200 C 140 7.88 7.88 13.81 13.50 15.00 9.59 15.07 17.50 16.50 5.03

10 250 C 140 9.46 9.46 15.75 16.00 17.50 11.69 15.07 17.50 18.44 6.09

12 300 C 140 10.63 10.63 16.92 19.00 20.50 13.33 15.07 17.50 19.61 7.52

(2)

36000 Series V-0 Valve Dimensions (mm)

Valve

Size

in. DN Size Sq. cm

1 25 AC

1.5 40 AC

2 50

3 80

4 100

6 150 C

8 200 C

10 250 C

12 300 C

Actuator Size A

ANSI

150

194 69.60 69.60 204.72 107.95 123.95 101.60 271.78 215.90 267.46 53.85

194 79.50 103.63 211.58 127.00 155.45 113.54 271.78 215.90 274.32 61.72

AC

194 99.57 128.27 222.00 152.40 165.10 125.22 271.78 215.90 284.73 65.02

B

452 99.57 128.27 216.41 152.40 165.10 125.22 290.83 330.20 284.73 65.02

B

452 117.86 117.86 260.10 190.50 209.55 166.12 290.83 330.20 328.42 91.19

C

903 117.86 117.86 260.10 190.50 209.55 166.12 382.78 444.50 328.42 91.19

B

452 139.19 139.19 276.10 228.60 254.00 193.29 290.83 330.20 344.42 100.33

C

903 139.19 139.19 276.10 228.60 254.00 193.29 382.78 444.50 344.42 100.33

903 171.70 171.70 307.09 279.40 317.50 228.35 382.78 444.50 375.41 123.19

903 200.15 200.15 350.77 342.90 381.00 243.59 382.78 444.50 419.10 127.76

903 240.28 240.28 400.05 406.40 444.50 296.93 382.78 444.50 468.38 154.69

903 270.00 270.00 429.77 482.60 520.70 338.58 382.78 444.50 498.09 191.01

ANSI

300

Center-to-

Face

H

Standard

ISA

(2)

S75.04

ANSI

300

Face-to-Face

D

Standard

ISA

(2)

75.04

E F G

(1)

C

B

ANSI

150

Notes:

1. Conforms to ASME/ANSI Standard B16.5 - 1996 “Pipe Flanges and Flange Fittings”

2. Conforms to ISA Standard S75.04

3. Conforms to ASME Standard B16.10 - 1992 (formerly ANSI Standard B16.10 - 1973)

Short Pattern Ball. Available for ANSI 150 Class Valves ONLY

10

Page 11

36000 Series Flanged V-0 Valve Dimensions (continued)

Assembly Weights

Valve and Actuator Assembly Weights (without

Valve Size Actuator

ANSI Class 150

in DN Model Size lbs Kg lbs Kg lbs Kg

1 25 33 AC 50 22 53 24 7 3

1.5 40 33 AC 54 24 61 27 7 3

2 50

3 80

4 100

6 150

8 200

10 250

12 300

33 AC 60 27 81 37 7 3

33 B 101 46 122 55 27 12

33 B 124 56 134 61 27 12

33 C 182 82 192 87 27 12

31/32 D 227 103 237 107 12 5

33 B 147 67 166 75 27 12

33 C 205 93 224 101 27 12

31/32 D 250 113 269 122 12 5

33 C 250 114 288 131 27 12

31/32 D 295 134 333 151 12 5

33 C 303 137 359 163 27 12

31/32 D 348 158 404 183 12 5

33 C 393 178 416 189 27 12

31/32 D 438 199 461 209 12 5

33 C 520 236 540 245 27 12

31/32 D 565 256 585 265 12 5

Manual Override)

Standard ISA S75.04 Face-to-Face

Flanged

ANSI Class 300

Flanged

Manual Override

Add to Valve/Actuator

Weight

11

Page 12

GE Oil & Gas

16250 Port Northwest

Houston TX 77041

+1 866 754 3562

www.geoilandgas.com

*Denotes trademakr of General Electric Company.

© 2014 Genera l Electric Com pany. All Rights Res erved.

GEA31409 09/2014

Loading...

Loading...