Page 1

GE Oil & Gas

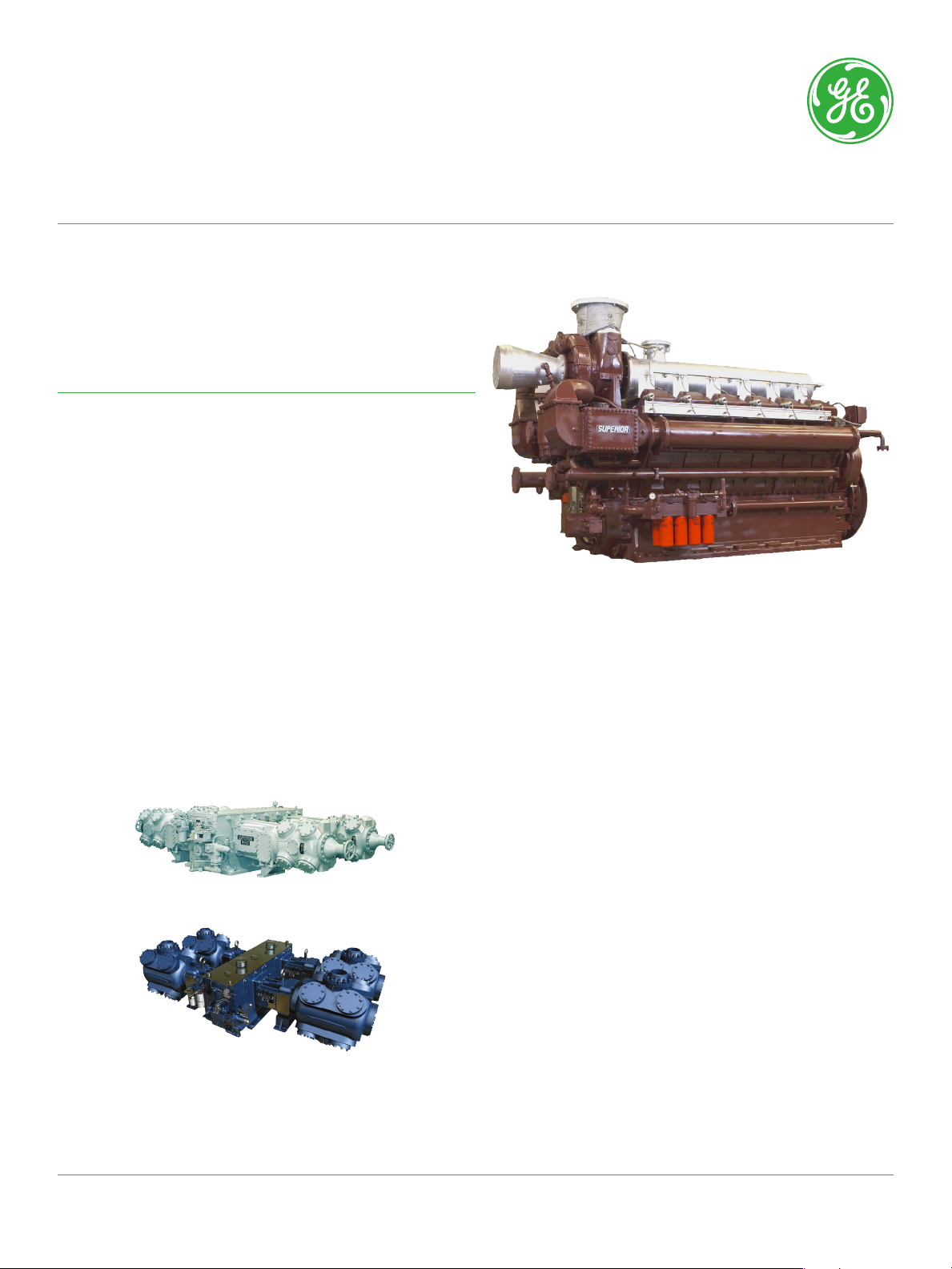

Superior* SGTD Engines

Hit the sweet spot for medium-speed gas drivers

Superior SGTD 12- and 16-cylinder gas engines

reach peak power and efficiency when packaged

with Superior MH, WH or WG separable

compressors operating at 900 RPM.

Superior Engines Since 1889

The Superior brand name has a long-standing reputation for high

quality engine and compressor products, dating back to 1889. Since

1976 alone, more than 10,000 Superior engines and compressor

frames have been manufactured and installed worldwide in a

variety of high- and medium-speed applications.

Superior turbocharged gas engines are medium-speed and built

for continuous, heavy-duty service. Optimal fuel/air mixing in

the cylinder, timed fuel injection, and air-charged intercooling

result in reduced fuel consumption and lowered emissions. The

low compression (8.75:1) pistons keep dynamic stresses at a

conservative level, provide for more stable operation and enhance

engine tolerance to variations in quality of fuel.

The conservative horsepower rating of Superior engines provides

ample reserve for emergency situations. Intercooling with optimal

valve overlap results in cooler combustion chamber parts while

assuring lower fuel consumption, greater efficiency, longer service

life and trouble-free operation.

Designed Specifically for Natural Gas

Compression Applications

• Built for continuous, heavy- duty service

• Medium speed, four-cycle, spark ignited natural gas engine

• Turbocharged and intercooled

• ATEX compliant to Group II, Category 3, Zone 2 (G)

• CE mark

SGTD Engine

MH / WH Compressors

WG Compressors

GE Oil & Gas offers a wide range of compressor solutions for your

unique gas applications. All of our Superior compressor packages are

designed for application flexibility and engineered to provide rugged,

reliable service and value.

Designed for Reduced Fuel Consumption

and Lower Emissions

• Optimal fuel/air mixing in cylinder

• Timed fuel injection

• Charge air intercooling

Designed for Variation in Fuel Quality

and Long Life

• Low compression pistons and low BMEP to maintain a

conservative level of dynamic stresses

• Based on original 825 Series (147 BMEP)

• Uncomplicated design for ease of maintenance without special

tools or specialized training

Page 2

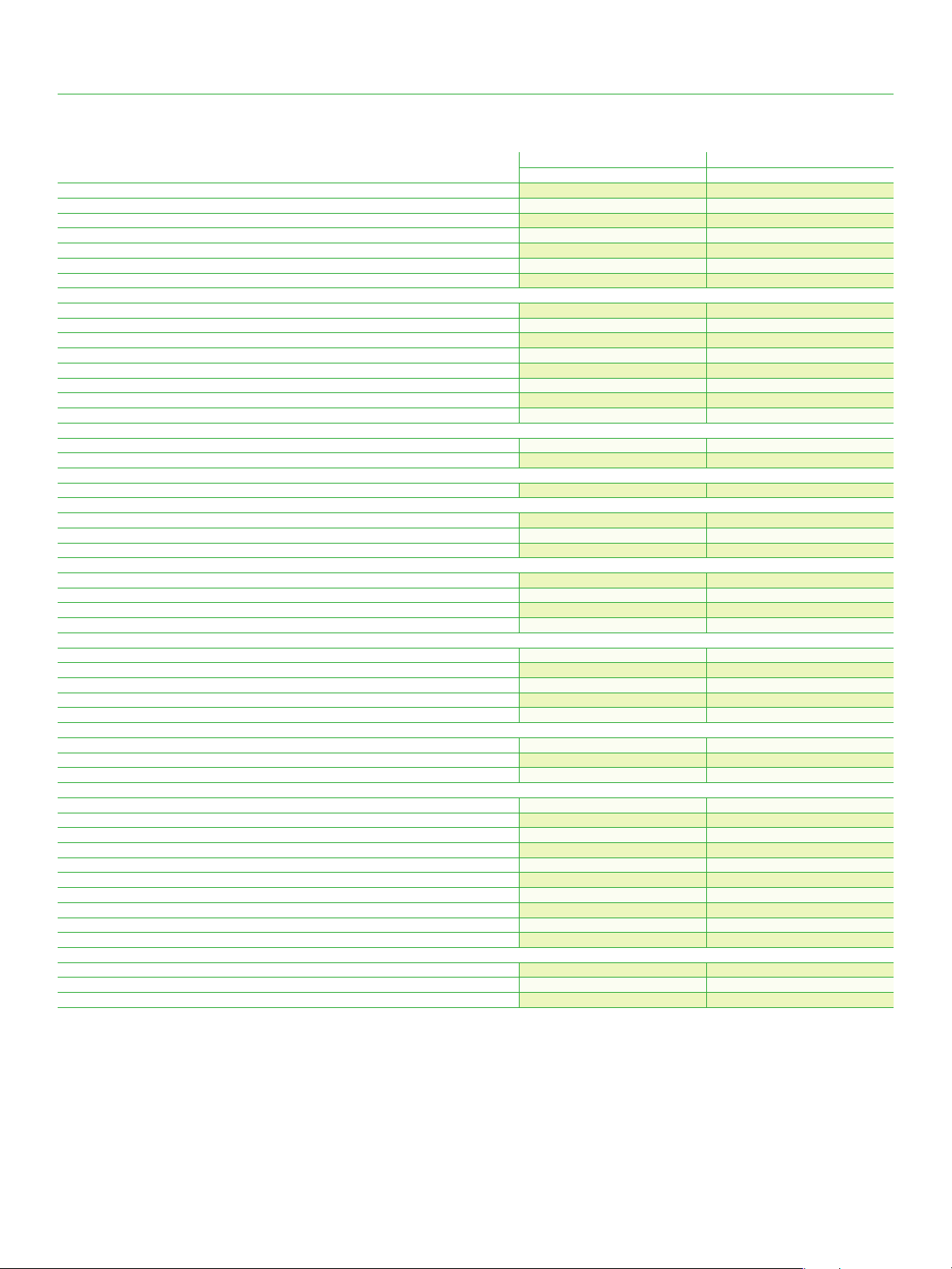

Superior Engine Technical Data

Engine Specifications

No. of Cylinders 12 16

Bhp [kW] 2,000 (1,490) 2,650 (1,975)

Rated Speed [ rpm* ] 900 900

Bore / Stroke [ in (cm) ] 10 x 10.5 (25.4 26.7) 10 x 10.5 (25.4 26.7)

Displacement [ in3 (liter) ] 9,896 (162) 13,195 (216)

BMEP [psi (bar)] 177.8 (12.4) 177.8 (12.4)

Piston Speed [ fpm (m/s) ] 1,575 (8) 1,575 (8)

Bearing Diameters

Main [ in (cm) ] 8 (20.3) 8 (20.3)

Crankpin [ in (cm) ] 6.375 (16.2) 6.375 (16.2)

Piston Pin [ in (cm) ] 3.5 (8.9) 3.5 (8.9)

Camshaft [ in (cm) ] 2.75 (7.0) 2.75 (7.0)

Starting Air System

System Pressure [ psi (kg/cm2) ] 150 150

Consumption Rate (Air) [ scfm (liters/sec) ] 1500 (708) 1500 (708)

Consumption Rate (Gas) [ scfm (liters/sec) ] 1781 (841) 1781 (841)

Air Intake System

Air Intake Flow Rate [ scfm (m3/min) ] 4,895 (139) 6,526 (185)

Air Intake Pressure Drop (Max.) [ in H2O (cm H2O) ] 10 (25.4) 10 (25.4)

Fuel Gas System

Fuel Gas Pressure [ psi (bar) ] 50 - 55 (3.4 - 3.8) 50 - 55 (3.4 - 3.8)

Exhaust System

Exhaust Temperature [ °F (°C) ] 760 (404) 760 (404)

Exhaust Flow [ lbs./min. (kg/min) ] 385 (175) 514 (233)

Exhaust Back Pressure (Max.) [ in H2O (cm H2O) ] 10 (25.4) 10 (25.4)

Cooling Water System

Jacket Water System Capacity [ Gal (liters) ] 146 (553) 186 (704)

Jacket Water Outlet Temperature [ °F (°C) ] 165 - 180 (74 - 82) 165 - 180 (74 - 82)

Design Flow Rate at Rated Speed [ gpm (liters/min) ] 750 (2,838) 775 (2,933)

Intercooler Water Pump Flow [ gpm (liters/min) ] 200 (757) 340 (1,287)

Lube Oil System

Lube Oil System Capacity [ gallons (liters) ] 165 (625) 220 (835)

Lube Oil System Flow [ gpm (liters/min) ] 70 (265) 90 (341)

Lube Oil Consumption [ gal/day (liters/day) ] 3.30 (12.5) 5.28 (20)

Lube Oil Outlet Temperature [ °F (°C) ] 165 - 175 (74 - 79) 165 - 175 (74 - 79)

Lube Oil Filters Micron 15 15

Brake Specic Fuel Consumption

100% Load [ btu/Bhp-hr (kcal/kW-hr) ] 7100 (2400) 7100 (2400)

75% Load [ btu/Bhp-hr (kcal/kW-hr) ] 7400 (2500) 7400 (2500)

50% Load [ btu/Bhp-hr (kcal/kW-hr) ] 7900 (2670) 7900 (2670)

Engine Emissions†

NOx [ grams/Bhp-hr (mg/Nm3) ] 0.7 (300) 0.7 (300)

CO [ grams/Bhp-hr (mg/Nm3) ] 2.5 (1100) 2.5 (1100)

NMHC [ grams/Bhp-hr (mg/Nm3) ] 0.75 (330) 0.75 (330)

Dry Weight [ lbs (kg) ] 42,500 (19,280) 54,000 (24,494)

Heaviest Lift (Cylinder Block) [ lbs (kg) ] 10,400 (4,717) 11,000 (4,990)

Exhaust Manifold [ lbs (kg) ] 1,210 (549) 1,530 (694)

Turbocharger Assembly [ lbs (kg) ] 1,170 (531) 1,170 (531)

Cylinder Head [ lbs (kg) ] 250 (113) 250 (113)

Piston and Connecting Rod [ lbs (kg) ] 198 (90) 198 (90)

Overhead Clearance to Remove Piston and Connecting Rod [ in (cm) ] 89 (226) 89 (226)

Dimensions‡

Length [ ft - in (cm) ] 15 - 4 (467) 18 - 5 (560)

Width (without platforms) [ ft - in (cm) ] 7 - 4 (224) 7 - 9 (235)

Height [ ft - in (cm) ] 8 - 10 (269) 9 - 2 (279)

* Minimum permissible operating speed is 600rpm. Corresponding Bhp and kW values are available within these speed ranges.

† Qualifying conditions:

Pipeline quality gas with a methane content > 90% with a LHV of 900 btu/scf ± 15%130°F manifold temperature, intercooler water temperature < 120°F, ambient temperature = 100°F, altitude < 4,000ft.

Refer to factory for all other conditions

‡ Dimensions are approximate and not to be used for construction.

Model Model

12SGTD 16SGTD

GE Oil & Gas

16250 Port Northwest

Houston, TX 77041

24/7 customer support: +1 866 754 3562

geoilandgas.com

© 2014 Genera l Electric Com pany. All rights re svered.

GEA31212 (07/2014)

Loading...

Loading...