Page 1

GE Oil & Gas

Becker* Rotary Piston Double

Acting (RPDA)

Heavy -duty, high performance applications

require RPDA Actuators

Page 2

2

Page 3

Becker RPDA Rotary Piston Double Acting

Actuators from GE Oil & Gas are ideally

suited for operations that demand a lock

last failure mode, including below ground

regulation and bleed-to-pressure

applications. These long-lasting, compact,

durable, and maintenance free actuators

can be retrofitted onto almost all pipeline

valves. RPDA Actuators are built to accept

high pressure power gas and can

incorporate options that eliminate

emissions and economically reduce

below-ground noise.

Features

Bleed to Pressure System* can

eliminate bleed gas emissions

Retrofits to almost any pipeline valve

High pressure RPDA actuator accepts

high pressure natural gas up to 500

psig (3447 kPa).

Upright actuator design saves space

and promotes longer actuator piston

seal life

Designed to be maintenance free

Comes equipped with a precision linear

scale that indicates valve position in ten

degree increments.

Crank-arm design actuators are

specifically suited for control valve

applications

May be mounted in any installation

orientation

3

Page 4

Technical Specifications

Actuator Mechanism Type

Rotation (Output)

Actuator Stops

Installation

Coating

Power Gas Requirements

Pneumatic crank arm

90° (standard)

Integral

Vertical (recommended),

Horizontal

Epoxy (standard)

Sweet natural gas

500 psig (3447 kPa) Models

Maximum Power Gas

10L and smaller 4

50 psig (3103 kPa) Models 12L

and larger

Minimum Power Gas

50 psig(345 kPa)

recommended

-20°F to +160°F (-29°C to

Operating Temperature

Range

+71°C) standard, -30°F to

+160°F (-34°C to +71°C)

(Optional low temp. spec.)

Torque Output

Dimensions

See Table 7

See Tables 3, 4, and 5

Filtered to 100μ nominal. Free

Sweet Natural Gas

Specification

of excessive moisture (< 7 lbs.

entrained H2O per 1.0 mmscf)

and liquid hydrocarbons.

If excessive moisture or hydrocarbon content is present, a

Filter-Dryer may be necessary. For adequate filtration and

elimination of moisture, a Becker Model FD-1500 Filter-Dryer

should be installed. Refer to Becker FD-1500 literature to

determine if a Model FD-1500 Filter-Dryer is necessary.

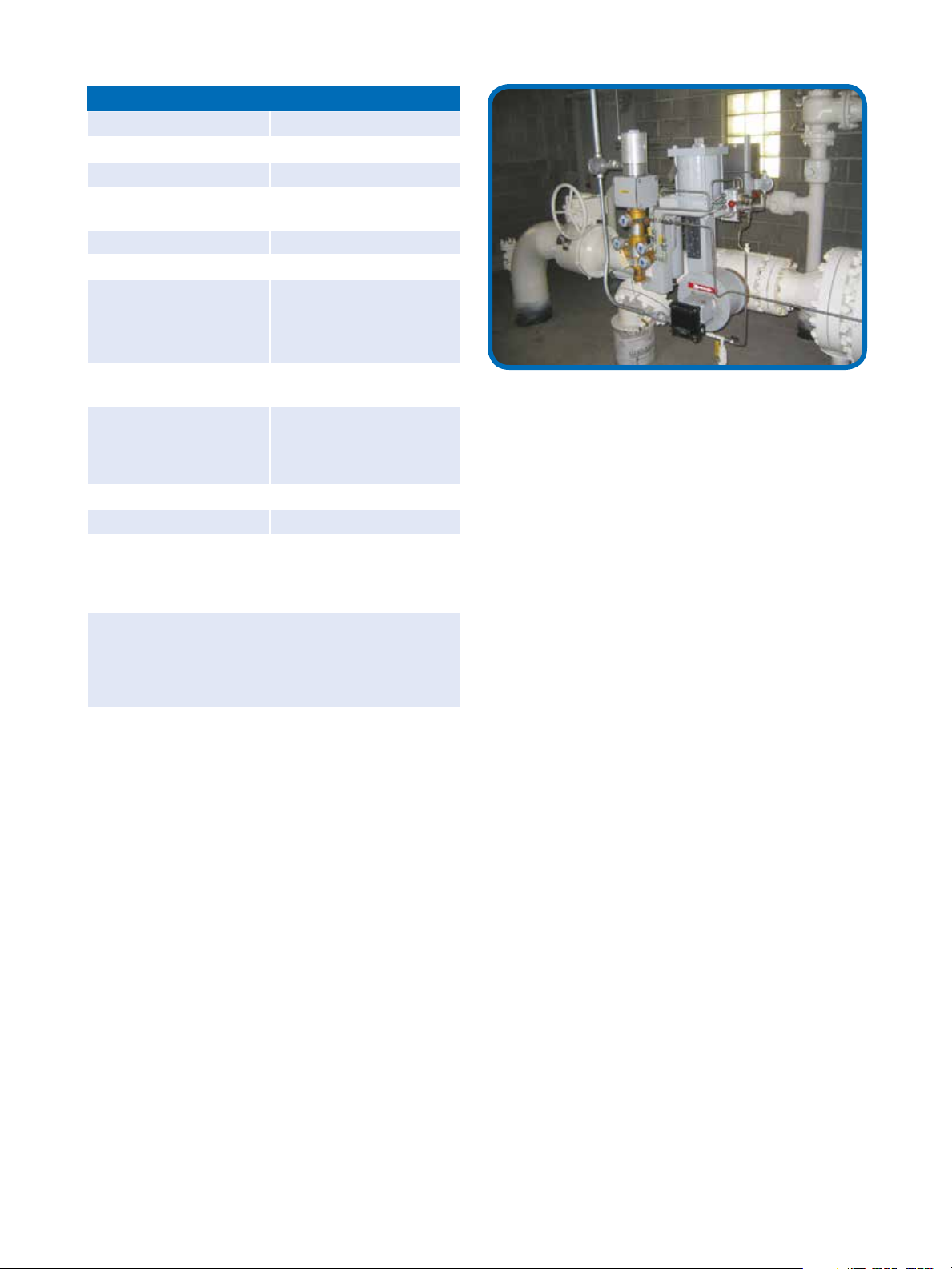

Figure 2 - Becker RPDA Actuated Control Valves

A pressure control regulator station is shown here with Becker RPDA

actuators and T-Ball Control Valves. The RPDA actuators are equipped

with Becker VRP-CH Valve Regulator Pilots (VRP). The VRP is capable

of providing extremely accurate pressure control with fast response

necessary for power plant type applications. Additionally, note that

the VRP-CH pressure control pilots are equipped with Model VB-250

Volume Boosters to increase stroking speed. The primary regulator is equipped with a QTCV-T2 Quiet Trim Control Valve to provide

decreased noise during operation. The monitor regulator is equipped

with a FPCV-T0 Full Port Control Valve that ensures bubble tight shutoff with class VI shutoff.

4

Page 5

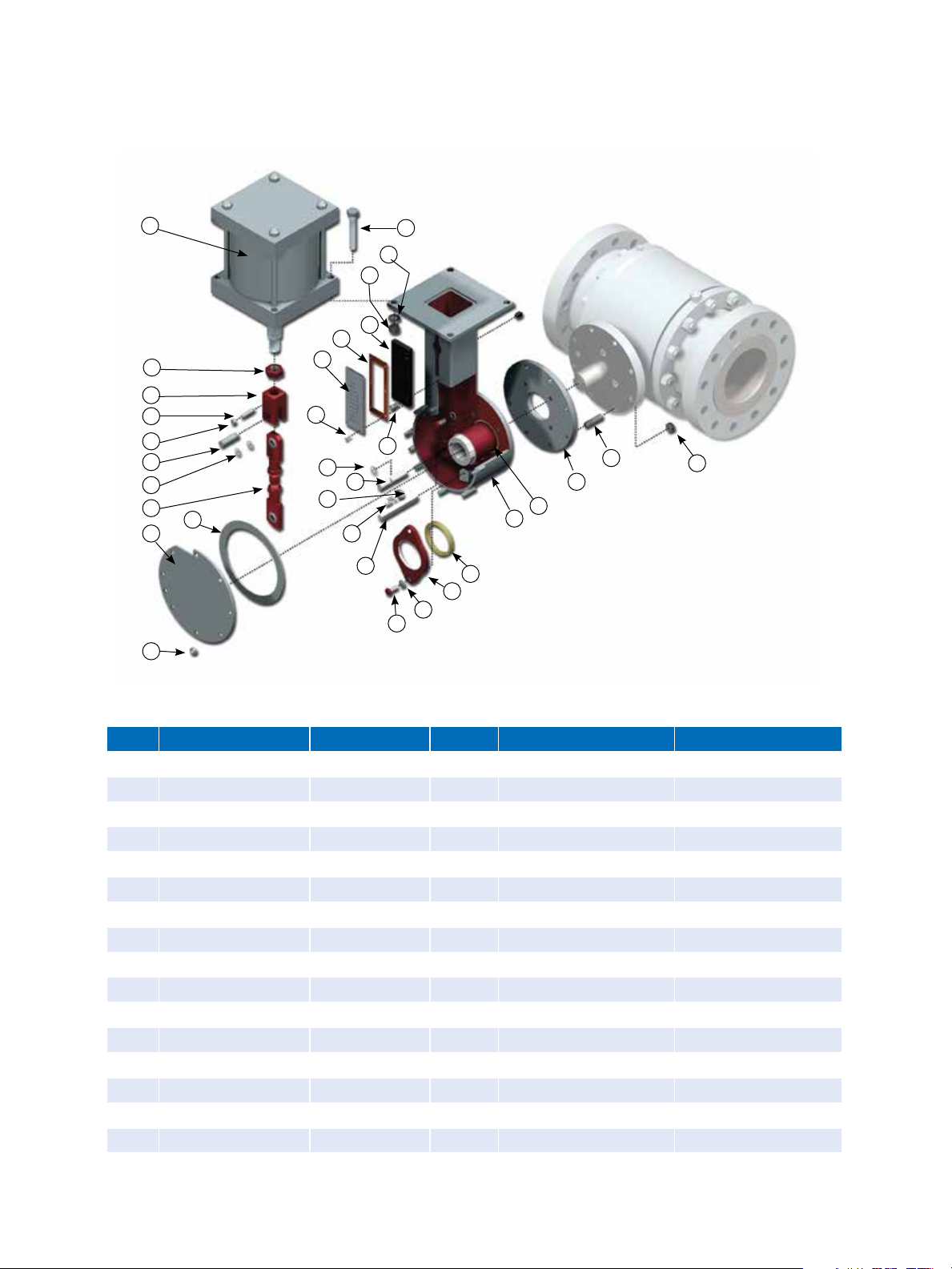

RPDA Rotary Piston Double Acting Actuator Components

1

16

2

3

4

5

6

7

8

9

10

11

17

18

20

21

22

23

12

13

14

15

19

30

29

24

25

28

27

26

32

31

33

Table 1 - RPDA Rotary Piston Double Acting Actuator parts description and materials

Item Description Material Item Description Material

1 Cylinder Carbon Steel 18 Indicator Screw Stainless Steel

2 Jam Nut Carbon Steel 19 Indicator Frame Screw Carbon or Stainless Steel

3 Rod Clevis Carbon Steel 20 Tru-Arc Ring Carbon Steel

4 Indicator Bar Stainless Steel 21 Torque Arm Pin Stress Proof Steel

5 Position Indicator Aluminum 22 Pin Clamp Carbon Steel

6 Rod Clevis Pin Stress Proof Steel 23 Pin Clamp Hardware Carbon Steel

7 Tru_Arc Ring Carbon Steel 24 Square Key Carbon Steel

8 Connecting Link Carbon Steel 25 Outboard Bearing Belt Carbon Steel

9 Cover Plate Gasket Rubber 26 Outboard Bearing Washer Carbon Steel

10 Cover Plate Carbon Steel 27 Outboard Bearing Plate Carbon Steel

11 Cover Plate Nut Carbon Steel 28 Outboard Bearing Duralon

®

12 Cylinder Bolt Carbon Steel 29 Actuatot Housing Carbon Steel

13 Cylinder Lockwasher Carbon Steel 30 Torque Arm Carbon Steel

14 Cylinder Nut Carbon Steel 31 Adapter Plate Carbon Steel

15 Indicator Frame PVC 32 Stud Carbon Steel

16 Indicator Gasket Rubber 33 Nut Carbon Steel

17 Lexan Cover Lexan 34 Vent Elbow Plastic

5

Page 6

Becker RPDA Rotary Piston Double Acting Actuator Cylinder Components

1

Table 2 - Components & Materials for construction of RPDA

2

3

4

5

8

9

10

11

12

13

14

5

6

7

Rotary Piston Double Acting Actuator Cylinder

Item Description Material

1 Hex Nut Steel

2 Cylinder Tie-Rod High Strength Steel

3 Piston Head (top) Steel

4 Tube Seal (top) Buna-N O-Ring

5 Piston U-Cup Seal (top) Buna-N

6 Rod Clevis Pin Stress Proof Steel

7 Piston Wear Strip Reinforeced Teflon

8 Piston Nodular Iron

9 Piston Rod Hard Chrome Plated Steel

10 Tube Steel (bottom) Buna-n O-RIng

11 Piston Head (bottom Steel

12 Piston Rod Seal Polyurethane

13 Piston Rod Bearing Duralon

14 Gland Plate Steel

15 Gland Plate Screws (SHCS) Alloy Steel

16 Piston Tube Alloy Steel

Teflon is a registered trademark of Dupont Company

Duralon is a registered trademark of Rexnord, Inc.

®

®

15

15

Figure 4 - RPDA Rotary Piston Double Acting Actuator Cylinder

Exploded View

RPDA Actuators Standard Mounting Configurations

FLOW

FLOW

Figure 5.1

Mount #1 - Left Hand (Standard)

with clean sweep feature

Actuator located on left hand

side of valve when looking in

directionof flow (actuator

vertical/valve stem horizontal).

Figure 5.2

Mount #2 - Right Hand

Actuator located on right hand

side of valve when looking in

direction of flow (actuator

verticle/valve stem horizontal).

FLOW

Figure 5.3

Mount #3 - Vertical Stem

(Actuator Downstream)

Actuator located on downstreamside of valve when looking in direction of flow (actuator

horizontal/valve stem vertical).

FLOW

Figure 5.4

Mount #4 - Vertical Stem

(Actuator Upstream)

Actuator located on up-stream

side of valve when looking in

direction of flow (actuator

horizontal/valve stem vertical).

6

Page 7

RPDA high pressure actuator built

solid for all your control valve needs

Bleed to Pressure System* Can Eliminate

Bleed Gas Emissions

GE’s Becker RPDA Actuators feature the unique ability

to incorporate the Bleed to Pressure System feature.

GE’s Becker RPDA Actuators and control instrumentation can accept high pressure power gas and discharge

bleed gas to lower pressure systems.Bleed to Pressure

Systemeliminates all atmospheric emissions!

Maintenance Free

The RPDA actuator is designed to be maintenance free,

no regular lubrication is required for the piston cylinder

or the actuator mechanism.

High Pressure Capability

The RPDA actuator is specifically

constructed to accept high

pressure natural gas up to

500 psig (3448 kPa). Higher

pressure power gas allows use

of smaller actuators and

implementation of Becker

products’ unique Bleed to

Pressure System.

Below Ground Actuator Option Reduces Noise

Attenuation up to 37 dBA

Becker RPDA actuators are available with a unique

below ground option that provides superior noise

attenuation in regulator stations at minimal cost.

Additionally, below ground stations minimize ambient

heat loss by maintaining piping systems below ground.

We can retrofit to almost any valve in

your pipeline

We can provide high quality actuators to mate to almost any quarter turn valve, regardless of manufacturer

or age. We have years of experience successfully adapting our actuators to fit a multitude of valves.

U-Cup Seals

U-cup Piston Seals are designed to provide superior

sealing capabilities with minimal friction. This design

allows accurate positioning of the control valve actuator

with very slight pressure differential to the piston.

Vertical Advantage

Upright actuator promotes

longer actuator piston seal life,

saves space, and requires less

maintenance than other actuators.

Easy to Read Travel Indicator

All RPDA actuators come equipped

with a precision linear scale that

indicates valve position in ten

percent increments.

Crank Arm Designed

for Control Valves

Crank arm design actuators are specifically

suited for control applications. The crank arm provides

an increasing torque curve that develops high torque

output where it counts. Additionally, the crank arm

design minimizes friction and lost motion.

Torque Arm Bearings

RPDA Actuators feature two large Torque Arm

Bearings to eliminate side load to control valve stem.

Both inboard and outboard torque arm bearings are

manufactured from non-metallic Duralon™ material to

ensure maximum load bearing capacity.

Duralon is a registered trademark of Rexnord, Inc.

Figure 6 - Cutaway view of RPDA Actuator and Cylinder.

Custom Coatings Available

Standard preparation of Becker RPDA actuators includes sandblast per SP-10 and epoxy coating for above

ground actuators and coal tar epoxy for below ground

actuator portions. RPDA actuators are available with

custom coatings to suit application needs

7

Page 8

E

A

C

B

D

G

F

I

Figure 7 - RPDA Single Cylinder Actuator up to 12 inch stroke

Table 3 - RPDA Single Cylinder Actuator Dimensions up to 12 inch stroke

H

Dimensions in inches (mm) Weight Volume

Model A B C D E F G H I

4D

5D

6D

6F

8F

8H

8L

10F

10H

10L

12L

14L

9.25

(235)

9.56

(243)

10.19

(259)

12.19

(310)

11.69

(297)

13.06

(332)

17.69

(449)

13.06

(332)

15.06

(383)

19.06

(484)

19.06

(484)

20.94

(532)

14.13

(359)

14.13

(359)

14.63

(371)

18.19

(462)

18.81

(478)

19.81

(503)

25.06

(637)

19.25

(489)

20.25

(514)

25.50

(648)

25.50

(648)

25.75

(654)

28.63

(727)

28.94

(735)

30.06

(764)

34.81

(884)

36.50

(927)

36.75

(933)

51.50

(1308)

38.56

(979)

42.44

(1078

53.31

(1354)

53.81

(1367)

55.56

(1411)

2.38

(60)

2.38

(60)

2.38

(60)

3.63

(92)

3.63

(92)

4.75

(121)

7.25

(184)

3.63

(92)

4.75

(121)

7.25

(184)

7.25

(184)

7.25

(184)

6.25

(159)

7.63

(194)

8.63

(219)

6.50

(165)

8.50

(216)

8.50

(216)

8.50

(216)

10.63

(270)

10.63

(270)

10.63

(270)

12.75

(324)

14.75

(375)

4.50

(114)

5.50

(140)

6.50

(165)

6.50

(165)

8.50

(216)

8.50

(216)

8.50

(216)

10.63

(270)

10.63

(270)

10.63

(270)

14.75

(375)

14.75

(375)

0.38

(10)

0.38

(10)

0.38

(10)

1.38

(35)

1.38

(35)

1.50

(38)

4.00

(102)

1.38

(35)

1.50

(38)

4.00

(102)

4.00

(102)

4.00

(102)

5.38

(137)

5.38

(137)

5.38

(137)

7.00

(178)

7.00

(178)

7.00

(178)

8.50

(216)

7.00

(178)

7.00

(178)

8.50

(216)

8.63

(219)

8.63

(219)

NOTE: Dimensions “B” and “C” will change for below ground units according to depth of burial

2.13

(54)

2.13

(54)

2.13

(54)

2.75

(70)

2.75

(70)

2.75

(70)

3.50

(89)

2.75

(70)

2.75

(70)

3.50

(89)

3.63

(92)

3.63

(92)

lbs

(kg)

120.00

(54)

125.00

(57)

150.00

(68)

210.00

(95)

245.00

(111)

295.00

(134)

440.00

(200)

345.00

(157)

390.0

(177)

545.00

(247)

655.00

(297)

850.00

(386)

3

in

(cm3)

50.2

(823)

78.5

(1,286)

113.0

(1,852)

169.6

(2,779)

301.4

(4,940)

401.9

(6,576)

602.9

(9,879)

471.0

(7,718)

628.0

(10,291)

942.0

(15,437)

1846.3

930,256)

1846.3

(30,256)

8

Page 9

E

A

C

C

B

K

G

D

F

J

I

Figure 8 - RPDA Single Cylinder Actuator greater than 12 inch stroke

Table 4 - RPDA Single Cylinder Actuator Dimensions greater than 12 inch stroke

H

Dimensions in inches (mm) Weight Volume

Model A B C D E F G H I J K L

12T

12X

12Z

14T

14X

14Z

29.56

(751)

33.56

(852)

35.56

(903)

30.94

(786)

34.94

(887)

36.94

(938)

41.00

(1041)

47.63

(1210)

48.63

(1235)

41.63

91057)

48.00

(1219)

49.00

(1245)

86.56

(2199)

100.38

(2550)

103.38

(2626)

88.31

(2243)

101.94

(2589)

104.94

(2665)

12.00

(305)

14.50

(368)

15.75

(400)

12.00

(305)

14.50

(368)

15.75

(400)

12.75

(324)

12.75

(324)

12.75

(324)

14.75

(375)

14.75

(375)

14.75

(375)

12.75

(324)

12.75

(324)

12.75

(324)

14.75

(375)

14.75

(375)

14.75

(375)

3.63

(92)

3.63

(92)

3.63

(92)

3.63

(92)

3.63

(92)

3.63

(92)

12.00

(3050

12.00

(305)

12.00

(305)

12.00

(305)

12.00

(305)

12.00

(305)

5.00

(127)

5.00

(127)

5.00

(127)

5.00

(127)

5.00

(127)

5.00

(127)

3.75

(95)

3.75

(95)

3.75

(95)

3.75

(95)

3.75

(95)

3.75

(95)

20.00

(508)

20.00

(508)

20.00

(508)

20.00

(508)

20.00

(508)

20.00

(508)

NOTE: Dimensions “B” and “C” and K” will change for below ground units according to depth of burial

9.56

(243)

9.56

(243)

9.56

(243)

9.56

(243)

9.56

(243)

9.56

(243)

lbs

(kg)

985

(447)

1135

(515)

1295

(588)

1165

(529)

1335

(606)

1425

(647)

3

in

(cm3)

2262.0

(37,068)

2715.0

(44,491)

2941.0

(48.194)

3079.0

(50,456)

3695.0

(60,550)

4003.0

(65,597)

9

Page 10

E F

A

L

C

K

G

D

Figure 9 - RPDA Double Cylinder Actuator Dimensions greater than 12 inch stroke

Table 5 - RPDA Double Cylinder Actuator Dimensions greater than 12 inch stroke

B

J

I

H

Dimensions in inches (mm) Weight Volume

Model A B C D E F G H I J K L

D12T

D12X

D12Z

D14T

D14X

D14Z

29.56

(751)

33.56

(852)

35.56

(903)

30.94

(786)

34.94

(887)

36.94

(938)

41.00

(1041)

47.63

(1210)

48.63

(1235)

41.63

91057)

48.00

(1219)

49.00

(1245)

86.56

(2199)

102.19

(2550)

106.19

(2697)

91.31

(2319)

103.94

(2589)

107.94

(2742)

12.00

(305)

14.50

(368)

15.75

(400)

12.00

(305)

14.50

(368)

15.75

(400)

12.75

(324)

12.75

(324)

12.75

(324)

14.75

(375)

14.75

(375)

14.75

(375)

12.75

(324)

12.75

(324)

12.75

(324)

14.75

(375)

14.75

(375)

14.75

(375)

3.63

(92)

3.63

(92)

3.63

(92)

3.63

(92)

3.63

(92)

3.63

(92)

12.00

(3050

12.00

(305)

12.00

(305)

12.00

(305)

12.00

(305)

12.00

(305)

5.00

(127)

5.00

(127)

5.00

(127)

5.00

(127)

5.00

(127)

5.00

(127)

3.75

(95)

3.75

(95)

3.75

(95)

3.75

(95)

3.75

(95)

3.75

(95)

20.00

(508)

20.00

(508)

20.00

(508)

20.00

(508)

20.00

(508)

20.00

(508)

NOTE: Dimensions “B” and “C” and K” will change for below ground units according to depth of burial

9.56

(243)

9.56

(243)

9.56

(243)

9.56

(243)

9.56

(243)

9.56

(243)

lbs

(kg)

2097

(952)

2375

(1078)

2565

(1165)

2110

(958)

2380

(1081)

2580

(1171)

3

in

(cm3)

4524

(74,135)

54300

(88,982)

5882.0

(96,389)

6158.0

(100,912)

7390.0

(121,100)

8006.0

(131,195)

10

Page 11

Table 6 - Becker RPDA Actuator Selection Table

T-Ball

Valve Size

500 (3447 kPa) = ΔP 1000 (6895 kPa) = ΔP 1500 (10342 kPa) = ΔP

Double Acting Double Acting Double Acting

2” (50 mm) 5D 5D 5D

3” (80 mm) 5D 5D 6D

4” (100 mm) 6F 6F 6F

6” (150 mm) 8F 8F 8H

8” (200 mm) 10F 10F 10H

10” (250 mm) 10H 10H 10L

12” (300 mm) 10L 10L 12L

Temperature -20° F (-28.9° C) 100 psig (689 kPa) Power Gas

Choose the Perfect Rotary Control

Valve for your Application

FPCV-T0 Series Full Port Control Valve:

High turndown capability up 100:1

High pressure drop shutoff capability to

Class VI

T-Ball

Valve Size

500 (3447 kPa) = ΔP 1000 (6895 kPa) = ΔP 1500 (10342 kPa) = ΔP

Double Acting Double Acting Double Acting

2” (50 mm) 5D 5D 5D

3” (80 mm) 5D 5D 6D

4” (100 mm) 6F 6F 6F

6” (150 mm) 8F 8F 8H

8” (200 mm) 10F 10F 10H

10” (250 mm) 10H 10H 10L

12” (300 mm) 10L 10L 12L

Temperature -20° F (-6.7° C) 100 psig (689 kPa) Power Gas

T-Ball

Valve Size

500 (3447 kPa) = ΔP 1000 (6895 kPa) = ΔP 1500 (10342 kPa) = ΔP

Double Acting Double Acting Double Acting

2” (50 mm) 5D 5D 5D

3” (80 mm) 5D 5D 6D

4” (100 mm) 6F 6F 6F

6” (150 mm) 8F 8F 8H

8” (200 mm) 10F 10F 10H

10” (250 mm) 10H 10H 10L

12” (300 mm) 10L 10L 12L

Temperature -20° F (-28.9° C) 125 psig (861 kPa) Power Gas

QTCV-T1 Series Quiet Trim Control Valve:

Noise attenuation up to 7 dBA

High turndown capability up to 200:1

High pressure drop shutoff capability to

Class V

QTCV-T2 Series Quiet Trim Control Valve:

Noise attenuation up to 17 dBA

High turndown capability up to 300:1

High pressure drop shutoff capability

to Class IV

T-Ball

Valve Size

500 (3447 kPa) = ΔP 1000 (6895 kPa) = ΔP 1500 (10342 kPa) = ΔP

Double Acting Double Acting Double Acting

2” (50 mm) 5D 5D 5D

3” (80 mm) 5D 5D 6D

4” (100 mm) 6F 6F 6F

6” (150 mm) 8F 8F 8H

8” (200 mm) 10F 10F 10H

10” (250 mm) 10H 10H 10L

12” (300 mm) 10L 10L 12L

Temperature -20° F (-6.7° C) 125 psig (861 kPa) Power Gas

1. Contact GE representative for valve sizes over 12” bore.

2. T-Ball valves are comprised of the following: FPCV-TO, FPBV, QTCV-T1, QTCV-T2, and QTCV-T4

3. For power gas pressures greater/less than 100 psig (689 kPa) contact GE.

4. For higher ΔP applications contact GE representative.

5. Power Gas = P

supply

- P

for applications that utilize Bleed to Pressure System™ Feature.

discharge

QTCV-T4 Series Quiet Trim Control Valve:

Noise attenuation up to 25 dBA

High turndown capability up to 200:1

High pressure drop shutoff capability to

Class IV

11

Page 12

Table 7 - Becker RPDA Actuator Output Torque Table

RPDA Actuator

Model Number

5D

6F

8F

8H

10F

10H

10L

12L

14L

12T

12X

14T

14X

14Z

D12T

D12X

D12Z

D14T

D14X

D14Z

NOTES:

1. See graph to right.

2. Power Gas = Psupply when discharge (vent to atmosphere).

3. Power Gas = Psupply- Pdischarge when utilizing Bleed to Pressure System™ feature.

4. Consult Becker when Psupply > 150psig to ensure satisfactory operation

12

Angular

Position

1

100 psig (689 kPa) 125 psig (862 kPa) 150 psig (1034 kPa)

RDPA Actuator Output Torque/ Power Gas

Ending 3600 in-lb (24821 n-m) 4500 in-lb (31026 n-m) 5400 in-lb (37232 n-m) 500 psig

Running 5334 in-lb (36777 n-m) 6669 in-lb (45978 n-m) 8002 in-lb (55173 n-m)

Ending 7557 in-lb (52104 n-m) 9446 in-lb (65128 n-m) 11336 in-lb (78159 n-m) 500 psig

Running 11377 in-lb (78442 n-m) 14221 in-lb (98050 n-m) 17066 in-lb (117668 n-m)

Ending 13761 in-lb (94879 n-m) 17201 in-lb (118597 n-m) 20642 in-lb (142322 n-m) 500 psig

Running 20717 in-lb (142839 n-m) 25896 in-lb (178547 n-m) 31076 in-lb (214264 n-m)

Ending 18117 in-lb (124912 n-m) 22646 in-lb (156139 n-m) 27176 in-lb (187372 n-m) 500 psig

Running 26253 in-lb (181009 n-m) 32816 in-lb (226259 n-m) 39380 in-lb (271519 n-m)

Ending 21477 in-lb (148079 n-m) 26846 in-lb (185097 n-m) 32216 in-lb (222121 n-m) 500 psig

Running 32334 in-lb (222932 n-m) 40417 in-lb (278662 n-m) 48501 in-lb (334403 n-m)

Ending 28277 in-lb (194963 n-m) 35346 in-lb (243702 n-m) 42416 in-lb (292448 n-m) 500 psig

Running 40976 in-lb (282519 n-m) 51220 in-lb (353146 n-m) 61465 in-lb (423783 n-m)

Ending 41501 in-lb (286139 n-m) 51876 in-lb (357672 n-m) 62252 in-lb (429212 n-m) 500 psig

Running 61222 in-lb (422109 n-m) 76527 in-lb (527634 n-m) 91833 in-lb (633169 n-m)

Ending 58760 in-lb (405136 n-m) 73450 in-lb (506420 n-m) 88140 in-lb (607704 n-m) 400 psig

Running 93781 in-lb (646595 n-m) 117226 in-lb (808244 n-m) 140671 in-lb (969893 n-m)

Ending 79642 in-lb (549112 n-m) 99553 in-lb (686394 n-m) 119463 in-lb (823668 n-m) 400 psig

Running 127108 in-lb (876381 n-m) 158886 in-lb (1095481 n-m) 190662 in-lb (1314571 n-m)

Ending 100412 in-lb (692316 n-m) 125515 in-lb (865395 n-m) 150618 in-lb (1038475 n-m) 400 psig

Running 156116 in-lb (1076381 n-m) 195145 in-lb (1345476 n-m) 234174 in-lb (1614571 n-m)

Ending 120017 in-lb (827488 n-m) 150021 in-lb (1034358 n-m) 180026 in-lb (1241236 n-m) 400 psig

Running 187277 in-lb (1291230 n-m) 234096 in-lb (1614035 n-m) 280916 in-lb (1936851 n-m)

Ending 136093 in-lb (938328 n-m) 170116 in-lb (1172908 n-m) 204140 in-lb (1407496 n-m) 400 psig

Running 211591 in-lb (1458868 n-m) 264488 in-lb (1823582 n-m) 317387 in-lb (2188307 n-m)

Ending 162665 in-lb (1121536 n-m) 203331 in-lb (1401918 n-m) 243998 in-lb (1682307 n-m) 400 psig

Running 253826 in-lb (1750068 n-m) 317282 in-lb (2187583 n-m) 380740 in-lb (2625108 n-m)

Ending 174886 in-lb (1205796 n-m) 218608 in-lb (1507249 n-m) 262329 in-lb (1808695 n-m) 400 psig

Running 275168 in-lb (1897216 n-m) 343961 in-lb (2371525 n-m) 412752 in-lb (2845824 n-m)

Ending 200824 in-lb (1384633 n-m) 251030 in-lb (1730791 n-m) 301236 in-lb (2076949 n-m) 400 psig

Running 312232 in-lb (2152761 n-m) 390290 in-lb (2690951 n-m) 468347 in-lb (3229142 n-m)

Ending 240034 in-lb (1654976 n-m) 300043 in-lb (2068724 n-m) 360051 in-lb (2482464 n-m) 400 psig

Running 374554 in-lb (2582460 n-m) 468194 in-lb (3228081 n-m) 561831 in-lb (3873690 n-m)

Ending 258066 in-lb (1779302 n-m) 322583 in-lb (2224131 n-m) 387099 in-lb (2668954 n-m) 400 psig

Running 406044 in-lb (2799577 n-m) 507556 in-lb (3499477 n-m) 609067 in-lb (4199366 n-m)

Ending 272187 in-lb (1876663 n-m) 340234 in-lb (2345831 n-m) 408281 in-lb (2814998 n-m) 400 psig

Running 423183 in-lb (2917747 n-m) 528980 in-lb (3647186 n-m) 634776 in-lb (4376626 n-m)

Ending 325331 in-lb (2243078 n-m) 406664 in-lb (2803849 n-m) 487997 in-lb (3364621 n-m) 400 psig

Running 507653 in-lb (3500147 n-m) 634567 in-lb (4375187 n-m) 761481 in-lb (5250226 n-m)

Ending 349772 in-lb (2411593 n-m) 437215 in-lb (3014491 n-m) 524658 in-lb (3617389 n-m) 400 psig

Running 550336 in-lb (3794431 n-m) 687920 in-lb (4743039 n-m) 825504 in-lb (5691647 n-m)

(3447) kPa

(3447) kPa

(3447) kPa

(3447) kPa

(3447) kPa

(3447) kPa

(3447) kPa

(2758 kPa)

(2758 kPa)

(2758 kPa)

(2758 kPa)

(2758 kPa)

(2758 kPa)

(2758 kPa)

(2758 kPa)

(2758 kPa)

(2758 kPa)

(2758 kPa)

(2758 kPa)

(2758 kPa)

Running

Ending

Torque Output

0° 45° 90°

Actuator Position (Degrees Travel)

MAOP

3

Page 13

Below Ground Regulator Options Additional Noise Attenuation

40

Noise Attenuation (dBa)

Below Ground Depth (ft.)

The Becker Below Ground Ball Valve Regulator option

is unique to GE and provides a multitude of benefits by

direct burial of the control valve. The valve actuator,

lubrication lines,and drain lines are extended above

ground while the ball valve remains below ground. The

primary advantage of Becker Below Ground Regulators

is inexpensive noise attenuation in excess of 25 dBA.

More than 25 dBA noise attenuation

Less ambient heat loss

May use smaller adjacent piping diameter

Smaller station footprint

Most economical noise attenuation

May eliminate need for buildings/enclosures by

utilizing the fiberglass cabinet

35 dBa

37 dBa

30

30 dBa

25 dBa

20

10

3 ft Depth

4 ft Depth

5 ft Depth

6 ft Depth

0

Figure 10 - Below Ground Noise Attenuation Compared to Depth.

Typical below ground depths range from 3 feet to 6 feet burial.

The below ground depth is measured from centerline of pipe to

ground. Below ground usually provides from 25 dBA to 37 dBA noise

attenuation

Figure 12 - Installation of Becker Below Ground Regulators

(After Backfill)

The customer was able to achieve up to 25 dBA noise attenua-

tion over conventional above ground control valves with minimal

costs. The RPDA actuator utilizes an extended linkage to throttle the

control valve below ground. Many GE customers have utilized the

below ground concept for many years with great success and minimal maintenance. The topworks of the control valve actuators are

enclosed with Becker CAB Series Fiberglass Cabinets (green) after

backfill of regulator station. 16” Below Ground Ball Valve Regulators

are located at left, while 30” Below Ground Ball Valve Regulators

are located at right. A masonry wall has been installed at the

perimeter of the station. Upstream station isolation valves are

located in the foreground of the picture.

Figure 11 - Installation of Becker Below Ground Regulators

(Prior to Backfill) A large natural gas transmission/distribution

company based in Southern California installed Becker Below

Ground Ball Valve Regulators to achieve maximum noise attenuation, minimal maintenance, and optimum cost effectiveness. The

Below Ground Regulator can provide up to 37 dBA additional noise

attenuation with minimal additional cost. Two different size Below

Ground Ball Valve Regulators are show here. 16” Bore Below Ground

Regulators are shown in background, while 30” bore Below Ground

Ball Valve Regulators are shown in foreground. The Below Ground

Ball Valve Regulators are shown during installation, prior to backfill

of the regulator station.

13

Page 14

Accessories

GE’s Becker Control Valve Actuators provide reliability and accuracy for all of your

control valve applications

Limit Switches

Limit switches provide an indication of valve status and are commonly utilized on both on-off

and control valves. A limit switch assembly will close a contact at both the full-open and at

the full-closed position of valve travel. The switches provide a remote indication to gas control,

RTU or a flow computer as to the status of a valve. Limit switch assemblies are available with a

variety of configurations.

Housing NEMA 4, 4X, 7, Class I, Groups C & D,

Division 1 & 2

Switches 2 or 4

Option 2 or 4 Hermetically Seales Switches

Position Transmitter

The Valve Position Feedback assembly provides a quantitative indication of the exact position

of a control valve. The Valve Position Feedback assembly provides 4-20 mA analog remote position feedback proportional to the control valve position. The feedback signal may be utilized

as an integral portion of the control loop or merely as an additional feedback signal to gas

control for monitoring valve status. Valve Position Feedback is typically utilized on flow control

valves

Transmitter 4-20 mA Output

Housing NEMA 4, 4X, 7, Class I, Groups C & D,

Division 1 & 2

Switches 2 or 4

Option 2 or 4 Hermetically Seales Switches

SPDT Single Pole, Double Throw

DPDT Double Pole, Double Throw

up to 125 V D.C. at .5 amps

up to 250 V A.C. at 15 amps

SPDT Single Pole, Double Throw

DPDT Double Pole, Double Throw

up to 125 V D.C. at .5 amps

up to 250 V A.C. at 15 amps

Trip Valve

The Trip Valve protects double-acting actuators from loss of supply gas pressure. In the event

that the supply gas pressure falls below a minimum level, the trip valve can be configured to do

one of the following: lock the valve in last position, stroke the valve to the full-open position*,

Stroke the valve to the full-closed position*

*These applications require an additional volume tank to perform the operation

Max Allowable 150 psig 91034 kPa)

Weight 4.5 lbs (2.0 kg)

Body Connections 1/4” FNPT

Temp. Limits -40°F to + 180 F

(-40°C to +82°C)

Hydraulic Operator override

The Hydraulic pump override is utilized for manual operation of large control valves when

pneumatic power is not available. The Hydraulic pump override utilizes a hydraulic pump and

reservoir to develop necessary torque to close/open the control valve. Hydraulic pump overrides are typically utilized on ball control valves larger than 16” bore.

Trip Point Adjustable from 40 psig (276 kPa)

to 70% of supply pressure

Volume Tank Required for fail-open or fail closed modes. DOT approval

LP Tank (240 psig (1655 kPa) Max

with DOT Stamp). Size based on

application

14

Page 15

Let GE help select the perfect rotary control valve actuator

Table 8- Selection table for Becker Control Valves and Actuators

RPDA (Small Models)

RPDA (Large Models)

SYDA (Small Models)

SYDA (Large Models)

RPSR

SYSR

LPDA (Small Models)

LPDA (Large Models

LPSR

LD

Actuator Instrumentation

VRP-CH-Pilot

VRP-B-CH Pilot

VRP-SB-CH-Pilot

VRP-SB-PID Pilot

HPP-4 Positioner

HPP-5 Positioner

HPP-SB Positioner

DNGP Positioner

VRP-SB-GAP

FPCV-T0

QTCV-T1

QTCV-T2

QTCV-T4

Globe Series

Bleed to Pressure System BPS

AB Series Atmospheric Bleed

Control

NBV Series No-Bleed Valve

DPS-2 Series Non-Bleed Sensor

PS-2 Series Non-Bleed Sensor

SP Series Setpoint Pump

RSM Series Remote Setpoint Module

Panel Mounting

Stainless Steel Option

VB Series Volume Booster

QEV Series Quick Exhaust Valve

I/P Transducer

SLV Series Signal Lock Valve

™

• • • • • •

• •

• • • •

• • • •

• • • • • •

• • •

• • • •

• • • • • • • • • •

• • • • • • • • • •

Compatible Valves

• • • • • •

• • • • • •

• • • • • •

• • • • • •

• • •

Actuator Options

• • • • • • •

• • • • • • •

• • • •

• • • •

• •

• • • • •

• • • • •

• • • • • •

• • • • • • • •

• • • • •

• •

• • •

• • •

GE has a wide variety of control valve

actuators with a variety of features that

ensure the optimum solution for your

application needs. Refer to the figures

to the left to assist you in selecting the

proper control valve actuator and

accessories.

Figure 13 - Becker RPDA Rotary Piston Double Acting

Actuator

The Becker RPDA Actuator is a rugged, quarter-turn

actuator design for the rigors of aggressive throttling

service. The RPDA features a high pressure crank-arm

design specifically geared for control valve service.

The high pressure capability of the RPDA allow power

gas pressures up to 500 psig. This extended power

gas range permits the implementation of GE’s unique

“bleed to pressure system” that eliminates all atmospheric emissions. Additionally, the RPDA is available

with a Below Ground Option to substantially reduce

noise with minimal additional expense.

1. RPSR, SYDA, and LPDA Small Models are defined as actuator size <2000 in³ (0.333m³).

2. RPSR, SYDA, and LPDA Large Models are defined as actuator size >2000 in³ (0.333m³).

3. LD Series Actuators are limited to Becker Series Globe Valves

TM

is limited to discharge pressure systems below 300 psig (2068 kPa). Consult Becker for

4. BPS

application assistance.

*CAUTION: This information is intended as a guideline for application

of Becker Control Valve products. GE strongly recommends consulting

Becker product Engineering prior to application of any product.

15

Page 16

GE Oil & Gas

16250 Port Northwest

Houston TX 77041

+1 866 754 3562

www.geoilandgas.com

*Denotes trademakr of General Electric Company.

© 2014 Genera l Electric Com pany. All Rights Res erved.

GEA19651 09/2014

Loading...

Loading...