Page 1

GE Oil & Gas

41005 Series

Masoneilan* Cage Guided, Balanced

Globe Valve Tech Spec

Technical Specifications

09/2013

Page 2

2 | GE Oil & Gas

Page 3

Contents

1. General .............................................................................4

1.2 Serial Plate ...............................................................................................4

1.3 After Sales Service .......................................................................................4

1.4 Spare Parts ..............................................................................................4

1.5 Actuator and Other Accessories ..........................................................................4

2. Numbering System ...................................................................5

3. Installation ..........................................................................6

3.1 Cleanness of Piping ......................................................................................6

3.2 Isolating By-Pass Valve ...................................................................................6

3.3 Heat Insulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.4 Hydraulic Test and Cleaning of Lines ......................................................................6

3.5 Flow Direction ...........................................................................................6

4. Disassembly .........................................................................7

4.1 Removal of Actuator .....................................................................................7

4.2 Opening of the Pressurized Chamber .....................................................................7

4.3 Disassembly of Valve Plug Stem ..........................................................................8

4.4 Disassembly of the Auxiliary Pilot Plug ....................................................................8

5. Maintenance – Repair ................................................................9

5.1 Packing Box ..............................................................................................9

5.2 Repair of Parts ...........................................................................................9

6. Valve Reassembly ...................................................................11

6.1 Pinning the Valve Plug Stem .............................................................................11

6.2 Assembly of Ring or Spring-Energized Seal Ring ..........................................................12

6.3 41405 Valve Plug and Cage Assembly ....................................................................13

6.4 Assembly of the Parts Inside the Valve Body .............................................................13

6.5 Assembly of Bonnet .....................................................................................13

6.6 Tightening of Body Stud Nuts ............................................................................14

6.7 Assembly of Packing Box ................................................................................15

7. Actuator ...........................................................................16

7.1 Coupling of Actuator Type 88 No. 6 ......................................................................16

7.2 Coupling of Actuator Type 87 No. 6 ......................................................................16

7.3 Coupling of Actuator Type 87 No. 10, 16 and 23 ..........................................................16

7.4 Coupling of Actuator Type 88 No. 10, 16 and 23 ..........................................................17

7.5 Coupling of Air-to-Extend Actuator (Type 37) .............................................................18

7.6 Coupling of Air-to-Retract Actuator (Type 38) .............................................................18

7.7 Other Types of Pneumatic Actuators .....................................................................18

Body Sub Assembly .....................................................................21

41005 Series Cage Guided, Balanced Globe Valve Tech Spec (September/2013) | 3

Page 4

1. General

Important

This document contains all the instructions required for the installation, operation and maintenance of the

equipment.

Regular maintenance, strict observance of these instructions and the use of manufacturer’s replacement parts will

guarantee optimum operation and reduce maintenance costs.

1.1 Scope

The following instructions are designed to guide the user

through the installation and maintenance of the 41005

series valves for all sizes and all pressure classes.

1.2 Serial Plate

The serial plate is usually fixed to the side of the actuator

yoke. It indicates, amongst other things, the type of valve,

the pressure class, the material used for the pressurized

chamber and the air supply pressure of the actuator.

1.3 After Sales Service

GE offers it clientele an After Sales Service comprising

highly qualified technicians, for the operation,

maintenance and repair of its equipment. To benefit from

this service, contact our local representative or the After

Sales Service of the factory whose address is given at the

end of the document.

1.4 Spare Parts

When carrying out maintenance operations, only

manufacturer’s replacement parts must be used,

obtained through our local representatives or our

Spare Parts Service.

When ordering spare parts, the model and serial

numbers indicated on the manufacturer’s serial plate

must be given.

The recommended spare parts are indicated in the parts

list included in this instruction manual on page 20.

1.5 Actuator and Other Accessories

The valve is equipped with an actuator; like all the other

valve accessories, actuators are the subject of special

instructions which provide information on the electric

and pneumatic connections. The instruction manuals

to be used for standard actuators are No. ER30004E for

types 37/38, No. ER8788 for types 87/88.

4 | GE Oil & Gas

Page 5

2. Numbering System

Actuator

(2 Digits)

Actuator Type

and Action on Air

Failure

Conventional

37 – Open

38 – Close

Cylinder

51– Double Acting

52 – Open

53 - Close

Multispring

87 – Open

88 – Close

Body

Series

41

Cage

guided

globe

Balanced Plug

Seal Type

0. Undefined

3. Pressure

energized

PTFE seal ring

4. With pilot

5. With seal ring

6. With PTFE

seal

9. Graphite seal

ring

Body S/A (5 Digits)

Trim Type/Characteristic

0. Undefined

1. Standard cage/Linear

2. Standard cage/Equal

percentage

3. Lo-dB

4. Lo-dB® single stage with

5. Lo-dB® double stage/Linear

6. VRT (stack) TYPE S/Linear

7. VRT (stack partial)/Type S/

®

/ anticavitation single

stage/Linear

diffuser/Linear

modified percentage

Design

Series

5 A. Angle Body

Optional Config.

EB. Extension

bonnet

C. Cryogenic

extension

bonnet

8. VRT (cage) TYPE C/Linear

9. Anticavitation

double stage/Linear (1)

Note: This instruction manual describes all the standard options in the 41005 valve series. To satisfy the particular

41005 Series Cage Guided, Balanced Globe Valve Tech Spec (September/2013) | 5

Page 6

conditions of your application, GE may have had to

develop a special option which is the subject of an

additional clause to this instruction manual. In this case,

the instructions given in the additional clause always take

precedence over the general instructions.

3. Installation

3.3 Heat Insulation

In case of heat insulated installation, do not insulate the

valve bonnet and take protection measures related to

personal safety.

3.4 Hydraulic Test and Cleaning of Lines

During this operation, the control valve must not be used

as an isolating valve.

3.1 Cleanness of Piping

Before installing the valve in the line, clean piping and

valve of all foreign material such as welding chips, scale,

oil, grease or dirt. Gasket surfaces must be thoroughly

cleaned to insure leak-free joints.

3.2 Isolating By-Pass Valve

To allow for in-line inspection, maintenance and

removal of the valve without service interruption,

provide a manually operated stop valve on each side

of the control valve and a manually operated throttling

valve in the by-pass line.

This means that the valve must always be opened before

carrying out pressure tests in the process line, cleaning of

pipes, etc., otherwise equipment damages or destroying

of seal rings could result.

3.5 Flow Direction

The valve must be installed so that the controlled

substance will flow through the valve in the direction

indicated by the flow arrow located on the body.

6 | GE Oil & Gas

Page 7

4. Disassembly

4.1 Removal of Actuator

(Figures 15 and 16)

A. Remove the packing flange nuts (3) then remove

the packing flange (4) and the packing follower (23).

B. Check that the exposed part of the valve plug

stem (1) is clean enough for the bonnet (7) to be

removed easily.

Access to the internal components of the body should be

accomplished with the actuator removed. To carry out

this operation, follow the instructions below and refer

to the specific actuator instructions, reference ER 8788

for a type 87/88 actuator and ER 30004 E for the type

37/38 actuator.

4.1.1 Disconnection of instruments

Disconnect all mechanical couplings between the

positioner and the other instruments on the one hand

and the valve stem/actuator stem coupling on the

other hand.

4.1.2 Plug stems screwed into the actuator stem

In the case of air-to-retract actuators, apply sufficient air

pressure on the diaphragm to retract the stem completely.

Loosen the counter-nut, unscrew the stem.

Caution: During this operation, make sure that the

plug does not turn when it is seated. If the plug travel

is very small and there is a large amount of plug stem

inside the actuator, it may be necessary to remove

the yoke nut and lift the actuator so that the plug is

not touching the seat.

C. Remove the body stud nuts (8).

D. By means of a pad eye secured instead of the

actuator, lift the bonnet (7) up and separate it from

the valve body (18). During this operation, the valve

plug stem (1) must be pushed downwards so that

the valve plug remains in the valve body (18).

E. Remove the spring washer (17) and the body

gasket (10).

F. In the case of type 41305, 41375, 41505, 41605 and

41905 valves, remove the valve plug stem (1) and

valve plug (15) assembly from the cage by pulling the

valve plug stem upward, then remove the cage (16)

and “stack” (37) assembly for 41375 type valve.

Caution: Because of the cage gasket (31), the cage

can sometimes be lifted along with the valve plug. If

this should happen, press down on the cage so that it

remains in the body. If the cage is lifted along with the

valve plug, it could slip during handling and fall

In the case of a 41905 series valve [equipped with

a graphite ring (45)], make sure that the ring is not

damaged during the operation.

4.1.3 Stems attached with a stem connector

In the case of air-to-retract actuators, apply sufficient

air pressure on the diaphragm to retract the stem

completely.

Loosen the screws and remove the stem connector.

4.1.4 Removal of actuator

Disconnect all the ingoing and outgoing air and electrical

connections from the actuator. Loosen the yoke nut or

attachment screws and lift the actuator, making sure

that the concentricity and/or the thread of the bonnet is

not damaged.

4.2 Opening of the Pressurized Chamber

(Figures 17, 18 and 19)

Danger: Prior to disassembly, vent the process

pressure and isolate the valve if necessary.

Note: The valve must always be reassembled with new

packing rings and gaskets; before disassembly, make

sure that the appropriate parts are available.

G. In the case of a 41405 valve, remove the valve

plug and body cage assembly by pulling the valve

plug stem upward; in this case, the valve plug has

a shoulder which prevents the cage from falling.

Remove the valve plug from the cage by pulling on

the end of the valve plug stem.

H. Remove the seat ring (13) and the seat ring gasket

(14) from the valve body (18).

I. Remove the packing (6), the packing spacer (5) and

the guide bushing (22) from the bonnet (7).

Note: A packing spacer (5) is only mounted when the

bonnet has a side connection.

41005 Series Cage Guided, Balanced Globe Valve Tech Spec (September/2013) | 7

Page 8

4.3 Disassembly of Valve Plug Stem

The valve plug stem is screwed and pinned into the

valve plug (15).

To dismount the stem, the valve plug must be held as

indicated below, taking care not to damage the guiding

surfaces; the plug stem pin (9) is then removed. By means

of flats or using a nut and counter-nut on the end of the

stem, unscrew the stem taking care not to apply

a bending moment which could deform it.

Cylindrical machining diameter of the jaw =

plug shank diameter: Dia. A

Tight only on

this no guiding

surface

Soft metal

vise draw

4.4 Disassembly of the Auxiliary Pilot Plug

When the valve is of the 41405 type.

In the case of 50, 80 or 100 mm (2”, 3” or 4”) valves

(Figure 17).

Exert a sufficient force on the auxiliary pilot plug (20) to

compress the spring washers (12). The retaining ring (19)

can then be removed, releasing the auxiliary pilot plug

and spring washers.

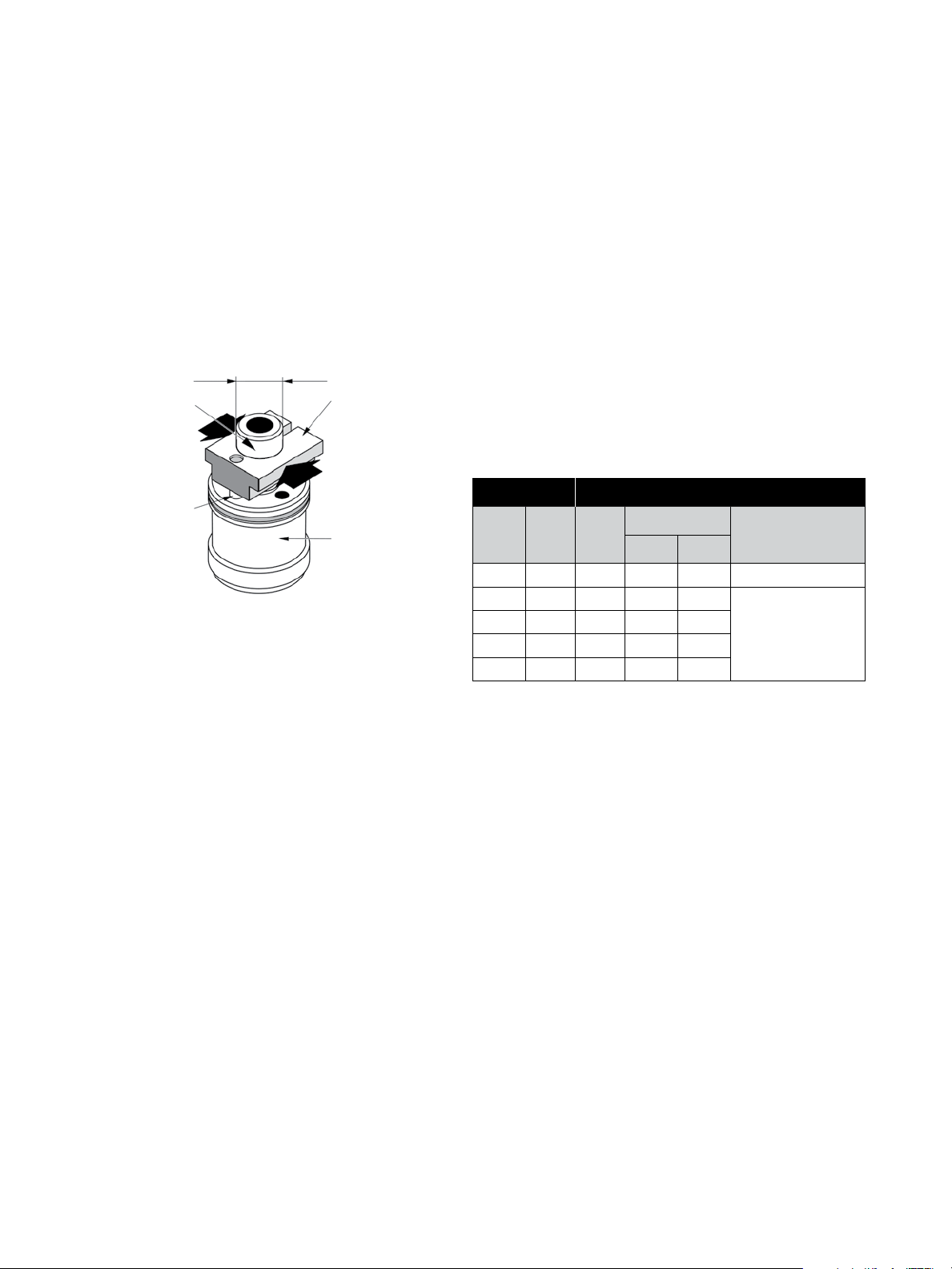

In the case of 150 to 400 mm (6” to 16”) valves (Figure 17).

To carry out this operation safely, screws of the diameter

and length indicated in the table in Figure 2 must be used.

Thread the socket head cap screws through the holes

in the auxiliary pilot plug (20). Tighten until the retainer

ring (19) can be removed. Loosen the screws gradually.

Remove the auxiliary pilot plug and the spring (12).

Stop pin

integrated in

vise jaw and

inserted into a

plug hole

Figure 1

Do not tight

on the plug

skirt

Valve size Pilot Dismounting Screws Size

Length

mm in. Qty.

Dia.

mm in.

150 6 2 57 2.25 1/4” – 20 UNC 2A

200 8 2 70 2.75

250 10 2 63.5 2.5

300 12 3 101.5 4

3/8” – 16 UNC 2A

400 16 3 63.5 2.5

Figure 2

8 | GE Oil & Gas

Page 9

5. Maintenance – Repair

5.1 Packing Box

Tightness of the packing box is obtained by compression

of the packing (6). Compression must be achieved by

evenly tightening the packing flange nuts (3) on the

packing flange (4). Periodical retightening of the packing

flange nuts is required to maintain tightness.

Make sure that the packing is not over tightened as this

could prevent smooth operation of the valve. If a leak

persists after the packing has been compressed to a

maximum, the packing needs to be changed.

A packing spacer (5) is only mounted when the bonnet

has a side connection.

5.1.1 Carbon/PTFE and pure PTFE packing rings

Carbon/PTFE and pure PTFE packing rings are cut in

such a way that they can be replaced without having to

separate the valve plug stem from the actuator stem.

A. Unscrew and remove the packing flange nuts (3).

B. Lift the packing flange (4) and packing follower (23)

up along the valve stem.

C. By means of a puller, remove the packing (6) and

packing spacer (5), taking care not to damage the

sealing surface of the packing box lantern or the

valve plug stem.

D. Replace the packing rings, with the cut in each ring

placed about 120° from the next, pressing them

down one at a time and respecting the table below:

G. Put the valve back into service and check for

tightness. Tighten packing flange nuts (3) as required.

5.1.2 Graphite packing ring

To carry out this operation, the valve plug stem must be

removed. See chapter on actuator disassembly.

A. Loosen and remove packing flange nuts (3).

B. Remove packing flange (4), and packing follower (23)

from the plug stem.

C. By means of a puller, remove packing rings (6),

insuring not to damage the sealing surface of

packing box or plug stem.

D. Replace new packing set (6); first one back-up ring

(Carbon/Graphite braided ring), then expanded

graphite rings (smooth rings), at last, one other

braided back-up ring; it is important to press the

rings down one at a time in the packing box.

Number of

packing set

N.D. mm (in.) Braided Graphite Braided

50 (2”) 1 4 1

80 – 100

(3” – 4”)

150 to 600

(6” to 24”)

Number of rings

1 6 1

1 5 1

Figure 4

Carbon/PTFE and pure PTFE packing box

Number of rings

with side connection

N.D. mm (in.)

50

(2”)

80 – 100

(3” – 4”)

150 to 600

(6” to 24”)

E. Put the follower (23) and the packing flange (4)

back on.

F. Screw and tighten the packing flange nuts (3) without

cramming the packing rings.

without side

connection

6 2 4

8 3 5

7 2 5

Figure 3

on top of

packing

spacer

under

packing

spacer

41005 Series Cage Guided, Balanced Globe Valve Tech Spec (September/2013) | 9

E. Put the follower (23) and packing flange (4) back on.

F. Screw and moderately tighten the packing flange

nuts (3).

G. Reassemble the valve plug stem (see chapter on

actuator re-assembly).

H. Open and close the valve several times then tighten

the packing.

I. Put the valve back into service and check for

tightness. Tighten packing flange nuts (3) as required.

5.2 Repair of Parts

Before re-assembly, the parts must be carefully

examined in order to eliminate any scratched, worn or

damaged parts.

5.2.1 Guiding surfaces

The guiding surfaces of the cage and valve plug, the

guide bushing, and the guiding surfaces of the plug stem

and auxiliary pilot plug must be checked in particular. If

Page 10

there is only slight damage, a light abrasive can be used.

Otherwise the part must be replaced as soon as possible

(see paragraph “Spare parts”).

However, not more than 0.25 mm (0.010”) of metal must

be removed in the case of a 50, 80 or 100 mm (2”, 3” or 4”)

valve or more than 0.4 mm (0.015”) in the case of a 150 to

400 mm (6” to 16”) valve. Make sure that the seating angle

indicated in Figure 6 is respected.

Guiding

surface

Cage

Figure 5

5.2.2 Sealing surfaces (Figure 6)

Guiding surface

Seating surface

31°30'

32°30'

Valve Plug

Seat Ring

Seating surface

Pilot

62°30'

57°30'

Guiding

surface

Guiding

surface

Seating

surface

If a slight defect exists on any of the above seating

surfaces, lapping can be envisaged, in which case the

following must be respected:

• Spreadafinelayerofhighqualitysealingcompound

on the seating surface.

• Puttheseatring(13)inthebody,notingtheangle.

• Inthecaseof41305,41505,41605and41905valves,

put the cage (16) on the seat ring.

• Incaseof41375valves,putthestack(48)ontheseat

ring and the cage (16) on the stack.

• Inthecaseof41405valves,assemblethevalveplug,

cage and stem (15)-(16)-(1).

• Incaseof41305,41505,41605,41375and41905,

assemble the valve plug (15) and stem (1).

• Assemblethebonnet(7)anditsguidebushing(22).

• Placeanappropriatetoolonthevalveplugstem(1)to

turn it.

• Lapbyslightlyrotatingthevalveplugortheauxiliary

pilot plug in alternative directions. After several

rotations, lift the valve plug, turn it 90°, and start again.

• Lappingcanberepeated,butmustbelimitedasmuch

as possible so that the seat remains sufficiently narrow

to guarantee tightness.

Plug seating

surface

29°30'

30°30'

Seat ring seating surface

Pilot seating

surface

(41405 only)

Figure 6

If the surface of the auxiliary pilot plug (20) is damaged,

the auxiliary pilot plug must be replaced (see paragraph

“Spare parts”).

The seat ring (13), plug and auxiliary pilot plug (20)

seating surfaces must be completely free of dents,

wear and scratches.

If the auxiliary pilot plug seat in the valve plug (15) and/or

other valve plug or seat ring seating surfaces show signs

of slight deterioration, they can be touched up on a lathe.

10 | GE Oil & Gas

• Disassembletheparts,cleanthemandputthemback,

respecting the initial angle.

5.2.3 Gasket seating surfaces

Gasket seating surface must be free of dents, scratches

and corrosion; otherwise, they will need to be repaired.

5.2.4 Seal rings and gaskets

Spiral-wound gaskets (10), (14) and (36) must always be

changed after disassembly. Seal rings (11A), (11C) or (11E)

can be reused if they are free of scratches, erosion and

corrosion.

5.2.5 Valve plug, valve plug stem

If the valve plug has to be changed, then the stem must

also be completely changed to guarantee correct pinning

of the assembly. If only the valve plug stem has to be

changed, then the valve plug can be reused.

Page 11

6. Valve Reassembly

Two flats of wrench size “E”

6.1 Pinning the Valve Plug Stem

The valve plug (15) and stem (1) assembly consists of a

rod threaded into the valve plug and pinned in place.

If the valve plug (15) [or the auxiliary pilot plug (20)

in the case of a 41405 valve] needs to be replaced,

it is recommended using a new stem. The hole of the

original pin in an old stem often prevents satisfactory

results being obtained and can seriously impair the

mechanical strength of the stem-valve assembly.

Assembly is carried out as follows:

6.1.1 Reference marking on the

valve plug stem

Make a reference mark on the valve plug stem at a

distance “X” (Figures 7 and 8), equivalent to the stem

recess in the valve plug.

Note: For shouldered plug stems with two flats, the

above marking is unnecessary.

6.1.2 Tightening of the plug stem

To carry out this operation, the valve plug must be

prevented from moving by holding the plug shank with an

appropriate tool.

Screw two nuts on to the end of the new plug stem and

lock them together. Screw the valve plug stem solidly into

the plug, checking that the reference mark is level with

the end of the plug shank.

If the stem has flats, apply a torque “T” using a wrench of

dimension “E” (see Figure 7).

6.1.3 Drilling the pin hole (Figures 7 and 8)

Note: For this operation, it is recommended clamping

the valve plug-stem assembly by the plug shank to avoid

damaging the guiding surfaces; particular care must be

taken so that the pin hole goes through the valve plug axis.

If the valve plug is new, drill a hole of diameter “C” at a

distance “D” from the end of the valve plug; choose the

diameter “C” from the table according to the type of pin

used (metric or Anglo Saxon pin).

If the hole is already drilled in the valve plug, use the hole

as a guide to drill through the valve plug stem.

Non-

stem

Torque T

Shouldered

stem

Standard

stem

Valve

plug stem

diameter B

mm (in.) mm (in.) mm In. mm (in.) mm (in.) mm (in.) mm (in.) N.m (Ft.lbs) N.m (Ft.lbs)

12.7 (1/2) 20 (.79) 3.5 0.14 18 (.70) 18.5 (.73) 6 (.24) 17 (11/16) 50 (37) 60 (44)

15.87 (5/8) 25.5 (.98) 5.0 0.2 24 (.95) 28 (1.1) 8 (.30) 22 (7/8) 50 (37) 160 (118)

19.05 (3/4) 35 (1.38) 5.0 0.2 30 (1.2) 45 (1.77) 19 (.75) 27 (11/16) 160 (118) 160 (118)

25.4 (1.0) 44.5 (1.66) 8.0 5/16 40 (1.58) 47.5 (1.88) 25 (.98) 30 (11/4) 160 (118) 250 (184)

31.75 (1 1/4) 58 (2.28) 8.0 5/16 55 (2.20) 70 (2.76) 31.5 (1.24) 40 (1 5/8) - 800 (590)

38.1 (1 1/2) 70 (2.76) 10.0 - 65 (2.56) 90 (3.54) 33 (1.30) 50 (2) - 1 500 (1100)

Diameter

A

Metric

pin,

diameter

C

B

Anglo-

Saxon

pin dia.

C

Plug shank

D

F D

Figure 7

Distance

X

Shouldered

stem

E

Shouldered

X

Shouldered stem

X

A

F

Standard stem

B

Dia. CStem pin

Figure 8

41005 Series Cage Guided, Balanced Globe Valve Tech Spec (September/2013) | 11

Page 12

6.1.4 Pinning

Pushing

Direction

FTOFTC

Pushing

Direction

By means of a hammer, introduce the pin into the hole.

Complete the pinning operation, taking care to ensure that

the pin is recessed by the same amount at both sides.

Using a ball tooling and hammer, caulk the pin hole edge

of the plug.

Place the assembly in the soft jaw chuck of a lathe to check

alignment of the two parts; correct any alignment defects.

6.2 Assembly of Ring or

Spring-Energized Seal Ring

6.2.1 41305 valve

(Figures 9, 18 and 19)

These valves have a spring-energized seal rings

composed of a PTFE-based jacket maintained expanding

by a spring.

To insert the ring into the plug groove:

• Lubricatetheentrychamber.

• Placetheringovertheconicaltopoftheplugsothat

the lips of the ring face to the pressure (see Figure 9).

Caution to the assembly direction of the radial ring

(11F) on the plug (see Figure 9).

Flow Tends to Open: the open side is in the top.

Flow Tends to Close: the open side is in the lower part.

• Sliptotheringintothegroove(withoutspinningit)as

shown in Figure 9. This operation can be facilitated by

heating the ring. The temperature of the ring should

not exceed 150°C.

6.2.2 41405 and 41505 valves

(Figures 17 and 19)

These valves are equipped with metal rings; the inner ring

has a straight cut while the outer ring has a staggered cut.

To insert the rings into the cage groove, open the rings

slightly by hand and slide them, one after the other, along

the plug making sure that the parts are not damage.

Note: The cuts in the outer and inner rings are to be

placed at about 180° from each other.

6.2.3 41605 valve

(Figure 19)

These valves are equipped with an inner elastomeric ring

and a PTFE gasket.

Insert the elastomeric ring (11D) in the groove.

Place the PTFE gasket (11C) at a temperature of 100°C

(boiling water) to 160°C for a few minutes to facilitate

insertion, then slide along the plug until it slips into the

groove.

For optimum insertion of the ring, a Serflex type ring

compressor can be used to compress the ring in the

groove for several minutes.

6.2.4 41905 valve

(Figure 19)

These valves are equipped with rings; the inner metal ring

has a straight cut and the outer ring is made of graphite.

The new graphite seal ring (11A) is supplied in the form of

a closed ring in which a notch must be cut before being

inserted.

• Keeptheringretaineduntilitreturnstoroom

temperature and goes back in place within the groove.

Clamping with a collar (SERFLEX type) will help to

properly position the ring.

Figure 9

12 | GE Oil & Gas

Caution: Graphite seal rings are fragile and the

following operations must be carried out very carefully.

Using a sharp blade, carry out two V notches on the two

opposite faces. Hold the ring on either side of the notch

between the thumb and index and bend until it breaks.

Using a very fine file, adjust each end of the ring so that

its external circumference corresponds to the internal

circumference of the inside diameter of the cage (16).

To adjust the length of the ring correctly, insert the new

graphite ring into the cage, with the ring against the

inner wall of the hole in the cage, allowing minimum play

between the two ends of the ring.

To insert the inner ring, then the graphite ring into the

cage groove, slightly open the rings by hand and slide

them one after the other along the plug, taking care not

to damage the parts.

Page 13

Note: The cuts on each ring are to be placed at about

180° from each other.

6.2.5 41375 high temperature valve

(232°C to 316°C)

(Figure 19)

These valves are equipped with a seal ring composed of a

jacket and a metallic spring and two backup rings (11G).

Assemble the different parts as shown in Figure 19,

starting by the backup rings.

Caution: put these parts as shown in Figure 19,

the angle of 90° of the backup ring in front of the

extrusion gap between cage and plug.

Caution: for the double-cage assembly, carry out the

following operations:

• Puttheinnercage(16)upsidedown,

• Encasetheoutercage(75)ontheinnercage,maintain

them together with the two pins (76).

• Inthecaseofvalvesotherthan41405valves,insert

the valve plug/stem/ring assembly into the cage taking

particular care as it goes past the ring or springenergized seal ring.

• InthecaseofvalveswithaN.D.lessthan150(6”),place

the body/cage gasket in the valve body, making sure

that it is centered as well as possible.

6.3 41405 Valve Plug and

Cage Assembly

(Figure 17)

6.3.1 Assembly of valve plug and auxiliary pilot plug

Assemble, as appropriate, the flat spring or the coil

springs then the valve plug/plug stem assembly.

Using the same tools as those used for disassembly

(see chapter “Disassembly”), compress the springs so

that the retaining ring can be inserted in the groove of

the main plug.

6.3.2 Assembly of cage

Place the cage over the valve plug assembly via the top

of the plug stem. When doing so, take particular care to

position the ring correctly.

6.4 Assembly of the Parts Inside

the Valve Body

(Figures 17, 18 and 19)

Proceed as follows:

• Aftercheckingthatthesurfacesareperfectlyclean,

place the seat gasket (14) in the valve body, making

sure that it is centered as well as possible.

• Forvalvesizes150to400mm(6to16”),inserteither

the cage gasket (24) or the flat spring washer (17).

• Forvalvesizes450,600and750mm(18,20and24”),

insert either the first cage gasket, the cage washer and

the second cage gasket or the flat spring depending

on the type of valve, then place the body gasket (10) in

the valve body making sure that it is centered as well

as possible.

Caution to the direction of assembly of spring washer:

• ND150(6”)to450(18”)valves,theconcavefaceis

upwards,

• ND500(20”),and600(24”),theconcavefaceis

downwards and the tapped holes are visible.

6.5 Assembly of Bonnet

Check that the packing ring (6), the spacer (5) and the

guide bushing (22) have been removed from the bonnet.

Position the bonnet (7) above the valve, so that the

packing flange studs (2) are perpendicular to the flow

direction of the valve.

Thread the bonnet (7) onto the valve stem (1) and push it

down carefully until it goes into the valve body studs (21)

and takes up its correct position.

• Mounttheseatringorthediffuserseat(13).

• Mount:

– The cage (16) for 41305, 41605 and 41905 valves,

– The cage/plug/stem assembly for 41405 valves,

– TheSTACKassembly(makingsurethatthefacewith

the smallest number of holes is in contact with the

seat ring), and cage (16) for 41375 valves.

41005 Series Cage Guided, Balanced Globe Valve Tech Spec (September/2013) | 13

Grease the threads of the valve body studs (21) and the

bearing surfaces of the body stud nuts (8).

Screw on the body stud nuts by hand. Tighten the nuts

lightly and evenly so that the internal parts are held in

place. The face of the bonnet should be parallel to the

upper face of the body.

Slide the guide bushing (22) onto the valve plug stem and

let it drop to the bottom of the packing box housing.

Page 14

6.6 Tightening of Body Stud Nuts

Alignment of internal parts

In order to achieve perfect alignment of the seat ring and

the valve plug, a force must be applied to the plug stem

during tightening of the bonnet which results in correct

relative positioning of the two parts.

The force can be applied with the pneumatic actuator

as follows:

Place the actuator on the valve bonnet (7) by means of

the yoke nut (33) or attachment screws and connect the

valve plug stem to the actuator stem. See chapter on

actuators for installation instructions.

Caution: During this operation, make sure that the

plug does not turn when it is seated. If the plug travel

is very small and there is a large amount of plug stem

inside the actuator, it may be necessary to remove

the yoke nut and lift the actuator so that the plug is

not touching the seat.

Align the internal parts as follows:

In the case of air-to-extend actuators, supply air to the

actuator at the maximum pressure indicated on the

serial plate and in the case of spring-to-extend actuators,

do not supply air to the actuator, so that the optimum

positioning of the valve plug and seat can be obtained.

Single bolting circle:

Evenly tighten the nuts (8) by applying the torque

indicated in table in Figure 10 and the tightening

sequence in Figure 11.

Double bolting circle:

Beginning by the internal nuts, manually screw all the

bolts. Screw the internal nuts in order indicated by the

Figure 2 and screw them by successive, uniform and

progressive levels. During the tightening, make sure

that the bonnet face stays parallel at that of the body.

When the torque values given in the following table are

reached, the bonnet face must be in contact with that

of the body. Screw the external nuts in order indicated

by the Figure 2 and screw them by successive, uniform

and progressive levels until the torque values given in the

following table.

Torque Valve body stud/Bonnet

Body Nuts (21) Torque

Nominal

size (in)

2

3 x 2

4 x 2

2

3 x 2

4 x 2

3

4 x 3

6 x 2

3 2500 1 1/2 – 8 6 1050 775

4

6 x 4

8 x 4

4 2500 1 5/8 – 8 8 1250 930

6

8 x 6

10 x 6

6 2500 1 7/8 – 8 8 1900 1400

8

10 x 8

12 x 8

8 2500 1 3/4 – 8 12 1650 1220

10

12

16 x 12

12 2500 1 7/8 – 8 20 2200 1630

16

20

24

30 300 1 3/4 – 8 28 2000 1500

ASME

Pressure

classe

300/600 3/4 – 10 6 150 110

900/1500 7/8 – 9 8 250 180

2500 1 1/4 – 8 6 550 410

900/1500 1 – 8 8 400 300

300/600 3/4 – 10 8 150 110

900 /

1500

900/1500

300/600 7/8 – 9 8 250 180

900 1 1/2 – 8 6 1200 900

1500 1 1/2 – 8 6 1400 1000

300 1 – 8 8 400 300

600 1 – 8 12 350 250

900/1500 1 3/4 – 8 8 1800 1300

300/600 1 1/4 – 8 8 700 500

900 1 3/4 – 8 8 1900 1400

1500 1 3/4 – 8 8 2300 1700

300 1 1/2 – 8 8 1200 900

600 1 1/2 – 8 12 1200 900

900 1 3/4 – 8 12 1800 1300

1500 1 3/4 – 8 12 2000 1500

2500 2 – 8 12 2800 2070

300 1 1/2 – 8 8 1300 950

600 1 1/2 – 8 12 1200 900

900 1 1/2 – 8 16 1200 900

1500 1 3/4 – 8 16 2000 1500

300 1 1/2 – 8 12 1300 950

600 1 1/2 – 8 16 1300 950

900 1 1/2 – 8 20 1400 1000

1500 1 3/4 – 8 20 2300 1700

2500 2 – 8 24 2650 1960

300 1 3/8 – 8 24 900 650

600 1 3/4 – 8 24 2000 1500

900 1 7/8 – 8 24 2700 2000

300 1 3/4 – 8 20 1900 1400

600 1 3/4 – 8 26 2200 1600

Size (in) No. m.N ft.lb

1 1/4 – 8 6 800 600

14 | GE Oil & Gas

Figure 10

Page 15

6.7 Assembly of Packing Box

To assemble the packing box, proceed as indicated in the

“maintenance” chapter, paragraph 5.1.1 or 5.1.2.

Figure 11. Tightening sequence of nuts (8)

41005 Series Cage Guided, Balanced Globe Valve Tech Spec (September/2013) | 15

Page 16

7. Actuator

Caution: for coupling operations of actuators on

valves, it is necessary as a preliminary:

• topositiontheplug(15)onitsseatring(13).(Inno

case, one should not turn the plug on its seat, to

avoid any deterioration of tightness seat).

• connectatemporaryairsupplylinetotheactuator.

7.1 Coupling of Actuator Type 88 No. 6

(Figure 15)

A. Tightly screw the two hex nuts (1) onto the plug stem.

B. Push down the actuator and, at the same time, screw

on the yoke nut (33), then the bottom stem connector

(2). As soon as it becomes possible, insert the valve

stem into the actuator stem. The stem must be

inserted far enough so that when there is no air in

the actuator, the valve plug does not touch the seat.

C. Tighten the yoke nut.

D. Unscrew the valve plug stem until the valve plug

comes into contact with the seat. Do not turn the

valve plug on the seat as this could damage the

sealing surfaces.

E. Supply air to the actuator until the stem has travelled

at least 10 mm.

F. Unscrew the plug stem the number of turns N1

specified in Figure 13.

D. Supply air to the actuator at the initial pressure of

spring range.

E. Use the pointer (7) to set the travel scale (9) to the

open valve position.

F. Supply the actuator with air at a high enough

pressure to obtain a travel equal to the nominal

travel of the valve.

Caution: in the case of the 41405 valves, reduce the

travel by value A indicated in Figure 14.

G. Unscrew the plug stem until the valve plug is in

contact with the seat. Do not turn the valve plug on

the seat as this could damage the sealing surfaces.

H. Screw the 2 nuts (1) as far as they will go and check

that operation is correct.

7.3 Coupling of Actuator Type 87

No. 10, 16 and 23

(Figure 15)

A. Tightly screw hex nut (1) onto the plug stem.

B. Screw the top stem connector assembly tightly onto

the actuator stem.

C. Push down the actuator and, at the same time, screw

on the yoke nut (33), then the bottom stem connector

assembly by screwing until they come into contact

with the hex nut (1).

Caution: in the case of 41405 valves, use the N2 valve

so ensure tightness of the pilot plug.

G. Screw the 2 nuts (1) as far as they will go and check

that operation is correct.

H. Use the pointer (7) to set the travel scale (9) to the

closed valve position.

7.2 Coupling of Actuator Type 87 No. 6

(Figure 15)

A. Tightly screw the two hex nuts (1) onto the plug stem.

B. Push down the actuator and, at the same time, screw

on the yoke nut (33), then the bottom stem connector

(2). As soon as it becomes possible, insert the valve

stem into the actuator stem. The stem must be

inserted far enough so that, when there is air in the

actuator, the valve plug does not touch the seat.

C. Tighten the yoke nut.

16 | GE Oil & Gas

D. Push down the actuator and tighten the yoke nut.

E. Supply the actuator with air at the initial pressure

indicated on the spring scale.

F. Position the stem connector assembly at distance “X”

indicated in Figure 12.

G. Use the pointer (7) to set the travel scale (9) to the

open valve position.

H. Supply the actuator with air at a high enough

pressure to obtain a travel equal to the nominal

travel of the valve

Caution: in the case of the 41405 valves, reduce the

travel by value A indicated in Figure 14.

I. With the plug correctly positioned on the seat,

unscrew the bottom stem connector assembly until

it comes into contact with the top stem connector.

Tighten the socket head cap screws (5), nuts (1) and

(32) and check that operation is correct.

Page 17

Actuator

No

10 20 0.8 130 5.12

10 38 1.5 138.2 5.44

16 20 0.8 203.2 8.00

16 38 1.5 228.6 8.50

16 51 2.0 235.7 9.28

16 63.5 2.5 241.3 9.50

23 20 0.8 209.5 8.25

23 38 1.5 218.9 8.62

23 51 2.0 231.6 9.12

23 63.5 2.5 243.6 9.59

Figure 12. Position of top stem connector

Travel

mm inches mm inches mm inches

“X”

Actuator 87

“X”

Actuator 88

117.3 4.62

178.3 7. 02

J. Shut off the supply pressure in the actuator and use

the pointer (7) to set the travel scale (9) to the closed

valve position and check that operation is correct.

Valve

size

(in)

2

2 900 to 2500 3.25

3 and 4 150 to 1500

4 and 6 2500

6 150 to 1500

8 2500

8 150 to 1500

10 2500

ASME

class

150, 300 or

600

Plug stem

diameters

mm (in)

12.7

(1/2”)

15.87

(5/8”)

19.05

(3/4”)

N2

N1

41405

(turn)

(turn)

3.5

1.5

1.5 3.5

1.25 4.25

4.5

a

mm

(in)

1.9

(0.075)3 2500

2.0

0.08)

2.0

(0.08)

7.4 Coupling of Actuator Type 88

No. 10, 16 and 23

(Figure 15)

A. Tightly screw hex nut (1) onto the plug stem.

B. Tightly screw the top stem connector assembly onto

the actuator stem.

C. Push down the actuator and, at the same time, screw

on the yoke nut (33), then the bottom stem connector

assembly by screwing until they come into contact

with the hex nut (1).

D. Push down the actuator and tighten the yoke nut.

E. Unscrew the top stem connector to respect

dimension “X” in Figure 12.

F. With the plug correctly positioned on the seat,

unscrew the bottom stem connector assembly to

bring it into contact with the top stem connector.

G. Supply air to the actuator until the stem has travelled

at least 15 mm.

H. Unscrew the bottom stem connector the number of

turns N1 specified in Figure 13 then lock manually

with hex nut (1).

Caution: for 41405 valves, use the N2 valve so ensure

tightness of the pilot plug.

I. Release the pressure in actuator so that the two

parts of connector come into contact and tighten the

socket head cap screws and nuts (1) and (32).

41005 Series Cage Guided, Balanced Globe Valve Tech Spec (September/2013) | 17

10, 12

and 16

12 and 16 2500

18 150 to 1500

20 150 to 900

24 150 to 600

Figure 13. Reverse actuators – seating values for

Valve size

3 and 4 150 to 1500

4 and 6 2500

10, 12 and 16 150 to 1500

150 to 1500

25.4

(1”)

41305 – 41505 – 41605 – 41905 valves

ASME

(in)

2 150, 300 or 600

3 2500

2 900 or 2500 2 (0.08) 3.9 (0.15)

6 150 to 1500

8 2500

8 150 to 1500

10 2500

18 150 to 1500

Figure 14. Seating value for 41405 valves

class

A = Pilot plug travel

1.25

Value A

mm (in)

2.5 (0.1) 4.4 (0.17)

3 (0.12) 5 (0.2)

5 (0.2) 7 (0.27)

6 (0.24) 8.3 (0.33)

7 (0.275) 9.3 (0.37)12 and 16 2500

5

—

Value a1

mm (in)

2.3

(0.09)

Page 18

7.5 Coupling of Air-to-Extend Actuator

(Type 37)

(Figure 16)

7.6 Coupling of Air-to-Retract Actuator

(Type 38)

(Figure 16)

A. Push down on the plug stem (1) until the plug rests

is seated.

B. Attach the actuator to the valve bonnet with the

yoke nut (33) or attachment screws. Apply a sufficient

pressure to the diaphragm to extend the actuator

stem by the normal valve travel for valves 41305,

41505, 41605 and 41905 and the travel minus the

value of A in Figure 14 for 41405 valves.

C. Assemble the two parts of the stem connector (51)

and the point (58). The number of threads inside the

stem connection must be approximately equal for

each stem. Tighten screw(s) (52).

D. Check that the travel of the actuator stem

corresponds to the normal travel of the valve and

that the closed position is obtained for the maximum

spring range indicated on the serial plate.

E. Shut off the air pressure. Use the pointer (58) to set

the travel scale (56). The pointer (58) must indicate

“open” when the air pressure is off.

A. Connect a temporary air supply line to the actuator.

Apply sufficient pressure to the diaphragm to

retract the actuator stem completely. Attach the

actuator to the valve bonnet with the yoke nut (33)

or attachment screws.

B. Shut off the air pressure completely. Increase the air

pressure to retract the actuator stem by the value of

a in Figure 13.

Caution: For 41405 valves, use value a1 of Figure 14.

C. Assemble the two stem connectors (51) and the

pointer (58). The number of threads inside the stem

connection must be approximately equal for each

stem. Tighten screw(s) (52).

D. Check that the travel of the actuator stem

corresponds to the effective travel of the valve and

that the closed position is obtained for the minimum

spring range indicated on the serial plate.

E. Shut off the air pressure then use the pointer (58)

to set the travel scale (56). The pointer (58) must

indicate “closed” when the air pressure is nil.

7.7 Other Types of Pneumatic Actuators

For other type of actuators which the coupling valve

actuator is realized by coupling parts (see Figure 16)

follow the procedure:

• §7.5.foractuatoropensbyairfailure.

• §7.6.foractuatorclosesbyairfailure.

18 | GE Oil & Gas

Page 19

10

5

31

3

7

9

32

4

2

10

9

8

8

6

1

7

2

6

31

5

32

4

3

1

Model 87

No. 10-16-23

3

7

9

8

2

Detail of 87/88 Model

No. 6

33

31

10

33

33

Model 88

No. 10-16-23

Parts Reference

Ref. Designation

1 Hex nut

2 Bottom stem connector

3 Pointer screw

H

4 Top stem connector

H

5 Cap screw, soc, head

H

6 Connector Insert

1

7 Pointer

8 Screw, Pan head (travel scale)

9 Travel scale

10 Actuator stem

31 Yoke

H

32 Lock nut

33 Drive nut

H

Not provided for size 6 actuator

Figure 15. Spring diaphragm actuators – types 87/88 multispring

41005 Series Cage Guided, Balanced Globe Valve Tech Spec (September/2013) | 19

Page 20

36

56

33

1/4” NPT

26

Plug stem coupling

part the size

(see detail)

56

33

72

36

1/4” NPT

26

Parts Reference

Ref. Designation

1 Valve Plug Stem

26 Actuator stem

27 Stem nut

33 Drive nut

36 Spring adjustor

51 Coupling

52 Coupling screw

53 Coupling nut

55 Frein de tige

56 Travel indicator scale

57 Machine screw

58 Travel indicator

72 Spring barrel cap

Typ e 37

Air-to-extend actuator

53

26

51

58

1

52

57

Coupling parts

(No 18 and 18L actuators)

Typ e 38

Air-to-retract actuator

58

1

57

Coupling parts

(No 24 actuator)

26

51

52

1

20 | GE Oil & Gas

Detail of coupling types of plug stem

Figure 16. Spring diaphragm actuator 37/38 types

Page 21

Body Sub Assembly

19

20

16

15

13 13

41405 TRIM : 2" to 4" 41405 TRIM : 6" to 18"

41405 TRIM: 2” to 4” 41405 TRIM: 6” to 18”

12

14 15

19

20

16

12

14

Diffuser Option

diffuser option

Figure 17. Internal parts of pilot plug valve – 41405 type

31

16

15

37

14

13

Figure 18. Internal parts of VRT anticavitation valves – 41375 type

41005 Series Cage Guided, Balanced Globe Valve Tech Spec (September/2013) | 21

Page 22

22 | GE Oil & Gas

Page 23

1

2" to 4" ≤ 1500 lb

10

Without spring washer

6" to 16" ≤ 1500 lb

and 8" to 16" 2500 lb

10

With spring washer

6" to 18" ≤ 1500 lb

and 8" to 16" 2500 lb

Packing with lateral

2" to 6" 2500 lb

10

18", 20" and 24"

10

24

20" and 24"

connection

2

3

5

24

24

25

16

Double cage

4

23

6

22

7

8

21

10

24

9

16

15

13

14

18

75

76

ac

11G28 29

11A

17 17

Valve working in

Flow to closeFlow to open

11B11B11C11D 11E11F 11F

41095

4160541405 & 4150541305

High

temperature

4130541375

Parts Reference

Ref. Designation Ref. Designation Ref. Designation

1 Valve plug stem

2 Packing flange stud

3 Packing flange nut

4 Packing flange

5 Packing spacer

●

6 Packing 13 Seat/diffuser seat

7 Bonnet

H ●

■ ●

▲ ●

❍

❖

11D Elastomer seal ring 21 Valve body stud

11E Metallic seal ring 22 Guide bushing

11F Tec seal 23 Packing follower

11G Seal ring and backup ring 24 Cage gasket

12 Spring (or spring washers set) 25 Cage washer

●

14 Seat ring gasket

❍

❍

28 Retaining ring

29 Retainer ring

8 Valve body nut 15 Valve plug 37 Stack

●

●

o ●

o ●

H ●

On 41405 series valves only

❖

On 6” to 24” valves sizes only (150 to 600 mm)

♦

On 41605 series valves only

H

9 Plug stem pin 16 Cage 50 Washer (body nuts)

10 Body gasket

♦

17 Spring washer 75 Double cage

11A Graphite seal ring 18 Valve body 76 Pin

11B Metallic ring

11C U PTFE seal ring

❖

❖

●

o

■

19 Retaining ring

20 Auxiliary pilot plug

Recommended spare part

On 41905 series valves only

On 41405/505 Series valves only

On 41305 series valves only

▲

On 41375 high temperature valves only

❍

23 | GE Oil & Gas

41005 Series Cage Guided, Balanced Globe Valve Tech Spec (September/2013) | 23

Page 24

DIRECT SALES OFFICE LOCATIONS

AUSTRALIA

Brisbane

Phone: +61-7-3001-4319

Fax: +61-7-3001-4399

Perth

Phone: +61-8-6595-7018

Fax: +61-8-6595-7299

Melbourne

Phone: +61-3-8807-6002

Fax: +61-3-8807-6577

BELGIUM

Phone: +32-2-344-0970

Fax: +32-2-344-1123

BRAZIL

Phone: +55-11-2146-3600

Fax: +55-11-2146-3610

CHINA

Phone: +86-10-8486-4515

Fax: +86-10-8486-5305

FRANCE

Courbevoie

Phone: +33-1-4904-9000

Fax: +33-1-4904-9010

GERMANY

Ratingen

Phone: +49-2102-108-0

Fax: +49-2102-108-111

INDIA

Mumbai

Phone: +91-22-8354790

Fax: +91-22-8354791

New Delhi

Phone: +91-11-2-6164175

Fax: +91-11-5-1659635

ITALY

Phone: +39-081-7892-111

Fax: +39-081-7892-208

JAPAN

Chiba

Phone: +81-43-297-9222

Fax: +81-43-299-1115

KOREA

Phone: +82-2-2274-0748

Fax: +82-2-2274-0794

MALAYSIA

Phone: +60-3-2161-0322

Fax: +60-3-2163-6312

MEXICO

Phone: +52-5-310-9863

Fax: +52-5-310-5584

THE NETHERLANDS

Phone: +0031-15-3808666

Fax: +0031-18-1641438

RUSSIA

Veliky Novgorod

Phone: +7-8162-55-7898

Fax: +7-8162-55-7921

Moscow

Phone: +7 495-585-1276

Fax: +7 495-585-1279

SAUDI ARABIA

Phone: +966-3-341-0278

Fax: +966-3-341-7624

SINGAPORE

Phone: +65-6861-6100

Fax: +65-6861-7172

SOUTH AFRICA

Phone: +27-11-452-1550

Fax: +27-11-452-6542

SOUTH & CENTRAL

AMERICA AND THE CARIBBEAN

Phone: +55-12-2134-1201

Fax: +55-12-2134-1238

SPAIN

Phone: +34-93-652-6430

Fax: +34-93-652-6444

UNITED ARAB EMIRATES

Phone: +971-4-8991-777

Fax: +971-4-8991-778

UNITEDKINGDOM

Wooburn Green

Phone: +44-1628-536300

Fax: +44-1628-536319

UNITED STATES

Massachusetts

Phone: +1-508-586-4600

Fax: +1-508-427-8971

Corpus Christi, Texas

Phone: +1-361-881-8182

Fax: +1-361-881-8246

Deer Park, Texas

Phone: +1-281-884-1000

Fax: +1-281-884-1010

Houston, Texas

Phone: +1-281-671-1640

Fax: +1-281-671-1735

* Masoneilan is a registered trademark of the General Electric Company.

Other company names and product names used in this document are the registered trademarks

or trademarks of their respective owners.

© 2013 General El ectric Comp any. All rights r eserved.

GEA19369A 09/2013

Loading...

Loading...