Page 1

GE Energy

X$D IEC

IE2 High Efficient Extra Severe Duty Motors

90-280 Frame

0.55-220 kW

50 Hz or 60 Hz

200 V-690 V

Page 2

GE sets the standard...

EXCEED S

NEMA

MG1-31

IN VERTER

D

UTY

GEGARD2400

T

M

add ---period

Superior Performance

The X$D IEC meets or exceeds IE2 Nominal

• Overall vibration is 1.6 mm/sec. (0.063 in. per second). This

helps to extend the life of the motor and the connected

equipment.

• Total shaft runout is 0.025 mm (0.001 in.) for shaft diameters

p to 41 mm and 0.038 mm (0.0015 in.) for shaft diameters

u

greater than 41 mm for ball bearing machines.

• GEGARD2400™ insulation systems features Class H

insulation

against IGBT

materials. This system increases motor protection

drive voltage spikes that typically can reach

2,400 volts @ 0.1 microsecond rise time, which exceeds

NEMA MG1-31 standards.

efficiencies.

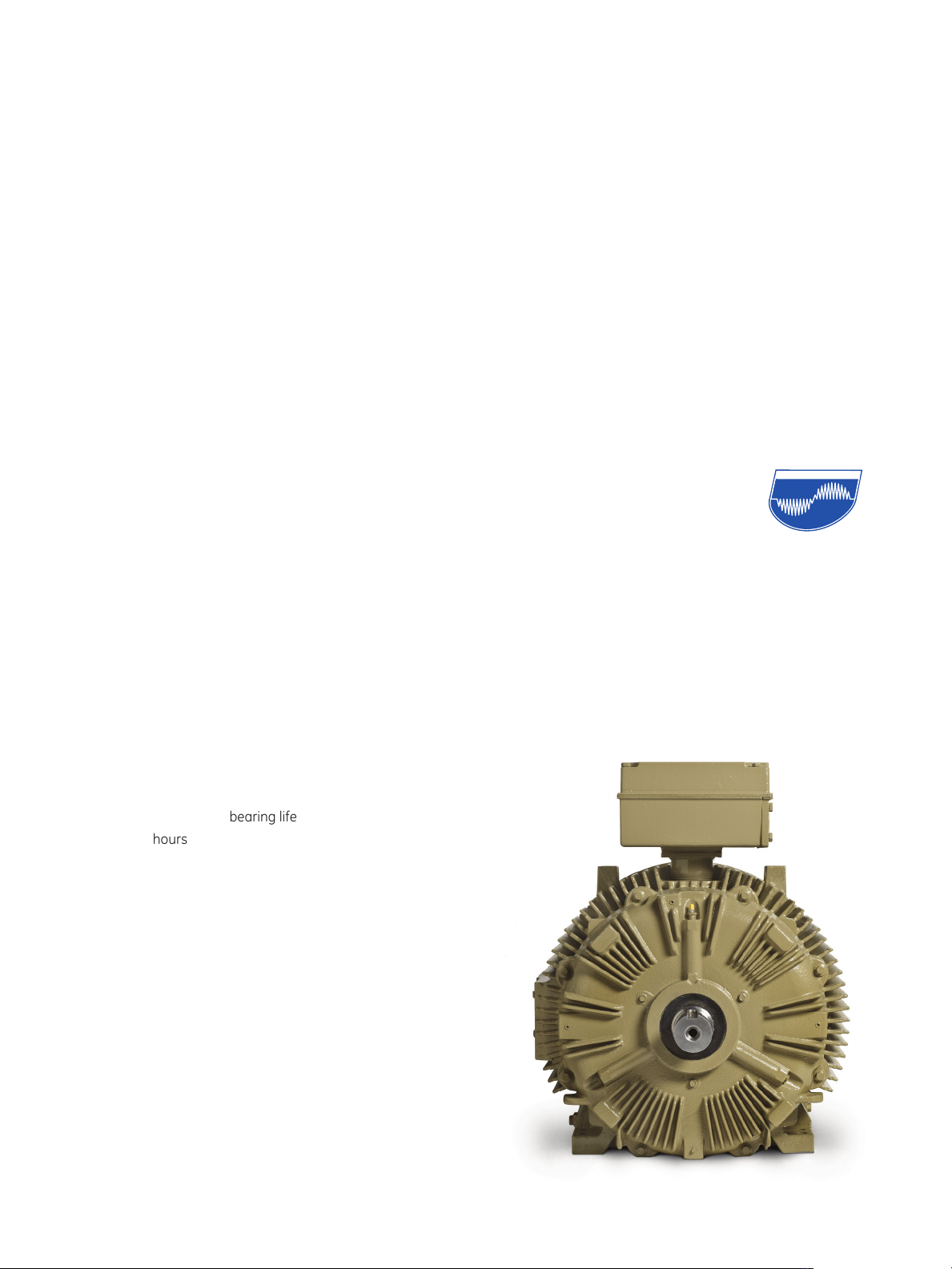

Bearings

GE’s Bearing System assures the maximum possible bearing

life when combined with a maintenance program. For optimum

performance, the same over-sized bearing is used on both

ends of the motor.

A steel-reinforced recessed slinger is integrated to both the

•

drive-end and opposite drive-end ensuring IP55 protection

• Fully charged lubrication system with a temperature-resistant

polyurea grease suitable for a wide temperature range

to +130°C).

(-40°C

.

Proven Reliability

For years severe duty motors from GE have proven their

performance and reliability in the most demanding process

industry environments.

• A one-year warranty comes standard with every X$D IEC

motor. (12 months operational/18 months maximum from

hipment.)

s

• Cast-in vibration pads provide five-point vibration probe

mounting (four radial, one axial).

Rugged cast iron frame, conduit box, endshields, and fan cover.

•

Inverter Duty Application

The GEGARD2400™ insulation system exceeds

the NEMA MG1-31 specifications

requirements of the

IEC 60034-17

standards. It has the ability to withstand repeated 0.1 microsecond

rise time that typically can reach 2400 volt spikes for up to 575

line voltages.

• Infinite:1 variable torque speed range and 10:1 constant

torque* speed range available on request.

* Some exceptions apply to constant torque speed ranges. Contact

GE Energy to verify capability on specific ratings.

• All motors are tested to verify the Corona Inception Voltage

(CIV) at the factory before shipment.

and the

and

60034-18-41

• An oversized single-shielded bearing is open towards the

• 130,000 hours minimum bearing life for direct-drive loads,

• A gasketed cast-iron inner bearing cap retains lubricant and

• Finned endshield for improved heat dissipation and long

grease cavity for maximum lubricant circulation.

and 26,280 hours for L10 belt-driven loads.

protects the bearing system and interior of the motor from

contaminants.

bearing life (200-280 frame)

IE2 Efficiency

Page 3

...with powerful features

Serviceability

Even the best motors need service. Our design engineers have

made improvements to help make service easy.

• Stainless steel combination breather/drains allow

condensation to drain from motor.

• An over-sized gasketed conduit box, containing permanently

labeled non-wicking Class H leads to a terminal board, makes

onnection and installation easy.

c

• Dual mounting holes for application versatility and

reduced inventory.

• Stator core centered in frame for easy conversion of a top

or side mounted conduit box for power connections on either

side of the motor (except on some FF flange constructions).

• Raised-letter embossed 316 stainless steel nameplate

with superior operational and maintenance information.

Superior Corrosion Protection

The motor frame, fan cover, endshield, and conduit box are cast

iron for severe duty. Rotor surfaces are coated to resist interior

rust, which helps maintain performance.

• Epoxy ester paint system stands up to corrosive

environments.

• Non-sparking, corrosion-resistant bidirectional fan* is quiet

and energy efficient.

* Two-pole motor fans are unidirectional in 280 K and H frame sizes.

• Corrosion-resistant ISO Grade 8.8 metric hardware is

rugged and designed for ease of motor service.

• Embossed 316 stainless steel nameplate stamped with over

0 motor specification details and all applicable standards.

3

• Leads are sleeved and are compatible with an oil mist

lubrication system.

Safety

GE has added features that make this product safe to install,

operate, and maintain.

• Safer lifting is possible with a four-point lifting system

versus a single eyebolt.

• Cast-in lifting lugs eliminate eyebolts that may strip, shear,

get lost, or be improperly selected.

• Grease inlet fitting at twelve o'clock and outlet fitting at eight

o'clock or four o’clock position, which promotes safer

regreasing.

• A silicon bronze box lug earthing terminal is located in the

conduit box. Additional earthing terminal posts are

located toward the drive-end on both sides of the frame

for greater operational safety.

• Fan covers on frames 200-280 have axial mounting bolts

for more rugged installation.

X$D IEC meets these challenges.

Improved Customer Operating Performance

• The X$D IEC meets or exceeds the

industry specifications in IEC construction. With an advanced

insulation and bearing system, one-year warranty and all

the advanced features that come with it, the X$D IEC is the

most durable and reliable , to ensure high reliability and

durability over the life of the motor.

.

requirements for most

Page 4

X$D IEC 50 Hz (IE2 Efficiency – Type KFE)

Output

kW

Frame FL RPM

Cat

Number

N

P

Amps IN

(A)

S

tart/

F

ull

Load

Amps

I

S/IN

S

tart/

F

ull

Load

Torque

T

S/TN

Full

Load

Torque

TN (Nm)

S

tarting

Torque

TS (Nm)

B

reak-

d

own

Torque

Tmax

(

Nm)

N

P Eff.

Full

Load

7

5%

Load

Eff.

5

0%

Load

Eff.

N

P PF

Full

Load

Max

KVAR

Mo-

ment of

Inertia J

(Kgm2)

Approx

Motor

Mass

(kgs)

Sound

Pres-

sure

dB(A)

I

EC T

B

lock

(@460 V)

6 Stud

I

EC

0

.55 90S 2930 N902 1.3 7.8 2.8 1.8 5.0 6.5 77.2 82.3 79.0 78.5 0.4 0.0013 23 70 M4

0

.55 90S 1435 N901 1.2 6.6 3.0 3.7 10.8 12.9 79.9 85.2 84.1 79.5 0.4 0.0032 23 58 M4

0

.55 90S 945 N900 1.6 5.0 2.5 5.6 14.0 17.2 74.0 81.1 79.5 68.0 0.6 0.0043 23 55 M4

0

.5590L 700N9712.3 3.7 2.8 7.5 20.624.967.066.660.850.5 1.10.004823 60 M4

0

.75 90S 2910 N905 1.8 6.9 2.4 2.5 6.0 7.7 78.9 85.6 84.6 78.0 0.5 0.0013 23 70 M4

0

.75 90S 1425 N904 1.7 6.0 2.8 5.0 14.0 16.8 81.1 82.7 81.4 76.5 0.6 0.0029 23 58 M4

0

.75 90S 945 N903 2.1 5.3 2.8 7.6 21.1 25.5 76.0 81.3 79.6 66.5 0.8 0.0049 23 55 M4

0

.75 112S 725 N972 2.8 4.6 2.0 9.9 19.5 29.8 71.8 76.2 71.9 53.5 1.

20.012846 62 M6

1

.1 90S 2905 N908 2.4 7.7 2.7 3.6 9.8 11.9 80.8 88.1 88.0 83.0 0.5 0.0018 23 70 M4

1

.1 90L 1420 N907 2.3 6.4 2.8 7.4 20.9 24.1 82.7 86.9 87.3 84.0 0.5 0.0052 23 58 M4

1

.1 112S 970 N906 3.0 7.2 2.3 10.8 24.5 42.4 78.3 87.5 86.1 68.5 1.0 0.0151 46 62 M6

1

.1 112S 715 N973 3.7 4.4 1.9 14.7 27.3 38.8 74.7 77.6 74.6 58.0 1.5 0.0146 46 62 M6

1.5 90L 2915 N911 3.3 8.0 3.1 4.9 15.5 18.0 82.6 86.6 85.3 78.5 0.9 0.0020 23 70 M4

1

.5 90L 1410 N910 3.1 6.2 2.8 10.2 28.9 32.7 83.9 86.2 86.9 83.5 0.8 0.0052 23 58 M4

1

.5 112M 960 N909 4.0 6.4 2.2 14.9 32.5 53.7 79.9 84.1 82.3 67.5 1.5 0.0113 46 62 M6

1

.5 112M 700 N974 4.6 4.1 1.6 20.4 33.6 47.7 74.4 76.8 75.2 63.0 1.8 0.0165 46 62 M6

2

.2 112S 2940 N914 4.7 7.3 2.0 7.1 14.1 23.5 84.0 89.8 88.6 80.5 1.2 0.0062 46 75 M6

2.2 112S 1455 N913 5.0 6.5 2.4 14.4 34.4 45.8 85.3 88.4 87.6 74.0 1.6 0.0113 46 64 M6

2

.2 112M 960 N912 5.6 6.6 2.2 21.9 48.9 79.2 81.9

8

4.7 83.5 69.5 2.1 0.0151 46 62 M6

2

.2 132S 725 N975 6.6 5.3 2.2 29.1 64.7 98.7 82.9 82.8 80.2 58.0 2.9 0.0347 100 63 M6

3

112S 2935 N917 6.1 6.9 1.9 9.8 18.2 29.8 85.3 90.6 90.0 83.0 1.3 0.0073 46 75 M6

3112S1460N9166.76.72.519.648.562.486.389.488.574.52.10.014246 64 M6

3

132S 975 N915 7.3 6.4 2.1 29.4 62.4 90.0 83.5 88.7 87.8 71.0 2.5 0.0321 100 65 M6

3

132M 720 N976 9.2 5.3 2.3 39.8 91.6 136.1 81.3 82.6 80.3 58.0 3.9 0.0420 100 63 M6

3

.7 112M 2930 N920 7.3 6.7 1.8 12.1 22.2 35.7 86.4 91.0 90.8 84.5 1.5 0.0083 46 75 M6

3

.7 112M 1455 N919 8.3 6.6 2.5 24.2 60.7 76.9 87.3 89.2 88.4 74.0 2.6 0.0161 46 64 M6

3.7 132M 970 N918 8.5 5.8 1.9 36.5 67.7 96.8 84.7 88.4 88.2 74.5 2.6 0.0340 100 65 M6

3

.7 160M 725 N977 9.5 5.0 1.8 48.5 85.4 129.7 82.4 86.9 85.8 68.5 3.4 0.0668 130 63 M6

4112M2925N9238.0 6.6 1.813.123.938.286.490.990.883.51.70.008346 75 M6

4112M1450N9228.8 6.2 2.326.360.776.987.

388.988.675.5 2.60.016146 64 M6

4132M970N9219.3 5.9 1.939.476.7108.984.788.387.973.03.00.0359100 65 M6

4

160M 730 N978 10.6 5.2 2.0 52.4 103.4 154.6 84.1 86.1 84.4 65.0 4.2 0.0668 130 63 M6

5

.5 132S 2920 N926 10.6 6.1 2.0 18.0 36.1 46.4 87.5 89.9 90.0 86.0 2.3 0.0137 100 77 M6

5

.5 132S 1465 N925 11.5 6.5 2.0 35.8 70.8 100.1 88.2 90.9 90.5 78.5 3.2 0.0340 100 67 M6

5.5 132M 960 N924 12.3 5.6 1.9 54.6 101.4 139.9 86.1 88.3 88.6 75.0 3.7 0.0434 100 65 M6

5.5 160M 730 N979 14.5 5.4 2.2 72.0 155.6 225.9 84.7 86.9 85.2 64.5 5.9 0.0891 130 63 M6

7

.5 132S 2940 N929 13.7 8.5 3.1 24.3 75.0 81.1 88.5 92.6 92.5 89.0 2.7 0.0217 100 77 M6

7

.5 132M 1460 N928 15.2 5.9 1.8 49.1 88.4 123.1 89.1 90.8 91.0 80.0 3.8 0.0397 100 67 M6

7

.5 160M 970 N927 16.3 5.6 2.0 73.9 150.8 200.7 87.3 89.4 88.9 76.0 5.2 0.0737 130 65 M6

7.5 160L 725 N980 18.2 5.0 1.9 99.0 186.8 268.7 86.1 87.5 86.8 69.0 6.7 0.1069 130 63 M6

11 160M 2955 N932 20.4 6.6 2.2 35.6

78.5 91.5 89.6 92.2 92.2 87.0 3.9 0.0457 130 79 M6

1

1160M1470N93121.1 5.7 2.1 71.5149.4184.190.191.992.083.5 5.30.0869130 69 M6

1

1160L965N93021.75.5 2.0109.0213.1263.088.791.392.082.55.00.1335130 65 M6

11 180M 735 N981 25.2 7.0 2.3 142.9 333.0 478.7 86.8 90.2 89.7 72.5 8.3 0.3132 200 68 M6

15 160M 2945 N935 26.9 6.4 2.3 48.6 113.5 117.8 90.5 92.6 93.1 89.0 4.1 0.0571 130 79 M6

1

5160L1470N93427.5 6.0 2.297.5219.1246.790.993.393.786.55.40.1326130 69 M6

1

5180L975N93328.46.3 2.1147.1302.9370.889.791.492.185.06.50.2900200 69 M6

1

5200M725N98235.0 4.5 1.7197.4337.4449.790.291.090.668.512.00.4313365 71 M8

18.5 160L 2965 N938 32.8 9.1 3.8 59.6 226.1 194.0 91.0 94.3 94.3 89.5 5.4 0.0828 130 79 M6

18.5 180M 1480 N937 37.0 6.8 2.0 119.4 234.1 341.5 91.4 93.1 92.7 79.0 10.9 0.1926 200 72 M6

18.5 200L 985 N936 39.1 6.3 1.8 179.4 314.0 513.4 90.4 93.4 92.8 75.5 11.9 0.4458 365 72 M8

18.5 225S 740 N983 41.

94.7 1.5238.7351.3570.091.093.592.870.014.10.8853524 71 M8

22 180M 2960 N941 39.0 7.5 3.1 71.0 217.3 221.0 91.4 93.6 93.3 89.0 7.8 0.1170 200 80 M6

22 180L 1475 N940 43.8 6.4 1.9 142.2 264.8 376.8 91.7 92.6 92.2 79.0 12.9 0.2000 200 72 M6

22 200L 980 N939 47.9 5.5 2.2 214.8 475.0 574.2 90.9 92.4 91.8 73.0 15.4 0.4829 365 72 M8

22 225S 740 N284 47.8 4.6 1.4 284.0 399.4 645.7 91.6 94.1 93.6 72.5 14.8 1.0750 524 71 M8

30 200M 2965 N944 56.0 5.2 1.5 96.5 140.5 220.6 92.1 94.3 93.7 84.0 12.2 0.1769 365 82 M8

30 200M 1475 N943 57.2 4.8 1.5 193.9 292.2 428.3 92.4 94.6 94.6 82.0 13.5 0.3611 365 75 M8

30 225M 985 N942 57.6 5.4 1.5 290.0 430.6 709.6 91.7 95.0 94.8 82.0 13.9 1.2420 524 72 M8

30 250S 735 N985 66.5 5.7 1.9 388.7 726.3 1231.6 92.4 93.6 92.7 70.5 23.8 1.4548 721 72 M8

37 200M 2960 N947 67.5 5.1 1.5 119.2 176.0 256.5 92.5 94.5 94.3 85.5 12.9 0.2010 365 82 M8

37 200L 1480 N946 71.5 5.7 1.8 238.5 432.3 616.4 92.8 95.0 94.8 80.5 18.8 0.4581 365 75 M8

37

250M 995 N945 75.2 5.9 1.6 355.6 571.9 957.2 92.2 94.9 94.2 77.0 22.4 1.3482 721 74 M10

37 250M 735 N986 77.9 5.4 1.7 480.7 827.0 1382.5 92.7 94.0 93.6 74.0 25.5 1.7558 721 72 M10

45 225S 2970 N950 85.3 5.4 1.4 144.7 205.0 350.1 92.9 94.8 94.2 82.0 21.3 0.2805 524 84 M8

45 225S 1480 N949 83.5 5.6 1.6 290.0 453.4 711.0 93.1 94.9 95.0 83.5 19.9 0.5991 524 76 M8

45 280S 995 N948 88.7 6.3 1.4 432.2 617.4 1231.3 92.7 94.7 93.9 79.0 25.3 2.7867 998 77 M10

45 280S 740 N987 94.2 4.9 1.4 580.1 803.3 1434.7 93.2 93.7 93.0 74.0 29.7 2.2933 998 74 M10

55 225M 2970 N953 98.4 5.9 1.6 176.8 280.7 433.5 93.3 95.6 95.2 86.5 19.9 0.3569 524 84 M8

55 225M 1480 N952 101.0 5.7 1.6 354.4 570.9 875.5 93.5 94.9 94.8 84.0 23.6 0.6878 524 76 M8

55 280M 995 N951 107.0 6.3 1.5 528.4 777.7 1500.1 93.1 95.0 94.3 79.5 29.8 3.2154 998 77 M10

55 280M 740 N988 112.0 4.8 1.4 709.9 958.5 1666.1 93.4 94.2 93.7 76.0 32.2 2.7103 998 74 M10

75 250M 2975 N956 129.0 7.6 2.0 240.7 481.6 742.3 93.9 95.9 95.8 89.5 23.5 0.6219

721 84 M8

75 250M 1485 N955 137.0 4.8 1.4 482.0 664.0 1048.7 94.0 96.1 96.1 84.0 29.3 1.2281 721 77 M8

75 280M 990 N954 141.0 5.9 1.4 721.3 992.5 1854.9 93.7 95.4 95.0 82.0 34.9 3.8585 998 77 M10

75 280M 740 N989 151.0 5.3 1.6 967.1 1511.4 2490.5 93.7 94.8 94.3 76.5 44.1 3.9612 998 74 M10

90 280M 2985 N958 155.0 7.3 1.7 287.9 483.7 896.7 94.2 95.8 95.2 89.0 29.2 1.1939 998 86 M16

90 280S 1480 N957 160.0 4.9 1.6 580.0 946.0 1361.7 94.4 96.0 95.9 86.0 31.9 2.9820 998 80 M16

90 280K 900 N967 168.0 5.9 1.5 865.8 1268.2 2424.2 94.2 95.4 95.2 82.0 41.4 4.3549 1430 80 M16

90 280K 740 N990 176.0 5.4 1.6 1161.4 1861.7 3003.0 94.1 95.0 94.8 78.5 47.3 5.2121 1430 74 M16

110 280M 2975 N960 187.0 5.7 1.3 352.7 461.2 849.5 94.5 95.7 95.5 90.0 27.5 1.1598 998 86 M16

110 280M 1490 N959 193.0 6.1 1.2 704.6 826.1 1812.6 94.7 96.4 96.4 87.0 38.0 3.2802 998 80 M16

110 280K 990 N968 199.0 5.6 1.4 1059.1 1481.3 2739.8 94.5 95.6 95.7 84.5 42.3 5.3918 1430 80 M16

110 280H 740 N991 221.0 6.3 2.0 1415.8 2827.3 4429.6 94.5 95.2 94.

876.067.87.29701430 74 M16

132 280K 2980 N961 221.0 6.2 1.4 422.9 587.4 1185.3 94.9 95.9 95.8 91.0 30.3 1.4520 1430 88 M16

132 280K 1490 N963 233.0 5.5 1.1 845.6 921.0 2073.9 94.9 96.5 96.5 86.0 45.8 3.3897 1430 80 M16

132 280K 990 N969 241.0 5.9 1.5 1270.6 1904.1 3477.0 94.8 95.8 95.7 83.5 54.0 6.2214 1430 80 M16

160 280H 2980 N962 264.0 6.5 1.6 512.5 795.6 1473.7 95.2 96.2 96.2 92.0 33.5 1.8480 1430 88 M16

160 280H 1490 N964 276.0 6.0 1.2 1024.2 1272.6 2642.4 95.2 96.9 96.8 88.0 49.0 4.7601 1430 80 M16

160 280H 995 N970 289.0 6.6 1.7 1538.5 2659.0 4660.1 95.1 96.2 96.1 84.0 65.8 8.9173 1430 80 M16

200 280H 1490 N965 349.0 6.2 1.3 1279.9 1659.8 3402.4 95.1 96.6 96.4 87.0 66.2 5.1928 1430 89 M16

220 280H 1490 N966 380.0 6.6 1.4 1407.5 1958.2 3916.4 96.0 96.7 96.4 87.0 75.1 5.7698 1430 89 M16

Typical Performance Data at 400 Volts

690 V Ratings are also available - Contact GE for details

Page 5

Contact GE for details on additional ratings

Output

k

W

Frame FL RPM

Cat

N

umber

NP

Amps IN

(

A)

Start/

Full

Load

A

mps

IS/IN

Start/

Full

Load

T

orque

TS/TN

Full

Load

T

orque

TN (Nm)

Starting

Torque

T

S (Nm)

Break-

down

Torque

T

max

(Nm)

NP Eff.

Full

L

oad

75%

Load

E

ff.

50%

Load

E

ff.

NP PF

Full

L

oad

Max

K

VAR

Mo-

ment of

I

nertia J

(

Kgm2)

Approx

Motor

M

ass

(

kgs)

Sound

Pres-

s

ure

d

B(A)

IEC T

Block

(@460 V)

6

Stud

IEC

0.55 90S 3520N350 1.1 7.6 2.2 1.5 3.3 4.7 74.0 86.4 84.8 82.0 0.30.0013 23 75 M4

0

.55 90S 1730N356 1.1 6.9 2.9 3.0 8.9 11.5 81.5 83.0 80.9 74.5 0.5 0.002423 63 M4

0

.55 90S 1145N364 1.4 5.2 2.5 4.6 11.5 15.0 78.5 79.0 76.2 64.5 0.60.0028 23 60 M4

0

.55 90L 845N372 1.9 3.8 2.2 6.2 13.417.467.071.467.255.5 0.90.004023 60 M4

0.75 90S 3515N351 1.5 7.6 2.3 2.0 4.7 6.6 80.0 87.2 86.0 81.0 0.40.0013 23 75 M4

0.75 90S 1720N357 1.5 6.9 2.9 4.2 12.2 15.2 82.5 84.5 83.3 78.0 0.50.0028 23 63 M4

0

.75 90S 1140N365 1.7 5.3 2.4 6.3 15.2 19.7 80.0 81.6 79.9 68.5 0.70.0042 23 60 M4

0

.75 112S 875 N373 2.5 5.0 2.0 8.2 16.0 27.0 74.0 78.7 74.2 50.5 1.

3

0.0128 46 65 M6

1

.1 90S 3500N352 2.0 7.7 2.4 3.0 7.2 9.8 82.5 88.1 87.6 82.5 0.50.001523 75 M4

1

.1 90L 1720N358 2.1 7.4 3.2 6.1 19.5 23.5 84.0 86.4 85.8 80.0 0.70.0039 23 63 M4

1

.1 112S 1170 N366 2.4 7.6 2.1 9.0 19.0 36.2 85.5 88.4 86.7 68.5 1.0 0.0146 46 65 M6

1.1 112S 870 N374 3.3 5.0 2.0 12.0 23.6 36.6 77.0 79.9 76.3 54.0 1.6 0.0146 46 65 M6

1

.5 90L 3500N353 2.7 7.4 2.4 4.1 9.8 12.9 84.0 85.5 84.2 84.0 0.70.0017 23 75 M4

1

.5 90L 1725N359 2.8 7.3 3.2 8.3 26.3 31.0 84.0 86.6 85.9 79.5 1.00.0043 23 63 M4

1

.5 112M 1165 N367 3.0 6.9 1.9 12.3 23.9 43.5 86.5 87.8 86.7 71.5 1.2 0.0128 46 65 M6

1

.5 132S 875 N375 3.9 5.1 1.7 16.4 28.3 49.2 82.5 83.1 80.5 59.0 1.9 0.0219 100 68 M6

2.2 90L 3480 N203 3.9 7.1 2.4 6.0 14.6 18.6 85.0 86.1 85.5 83.0 1.1 0.0020 23 75 M4

2

.2 112S 3540 N202 4.0 7.6 2.0 5.9 11.8 20.2 85.5 91.3 90.5 80.0 1.2 0.0057 46 80 M6

2

.2 112S 1765 N201 4.1 7.5 2.7 11.9 31.9 41.2 87.5

9

0.7 89.7 77.0 1.4 0.0123 46 67 M6

2.2 112M 1165 N300 4.5 7.5 2.3 18.0 41.1 71.2 87.5 88.3 87.1 70.0 1.8 0.0180 46 65 M6

2.2 132S 880 N376 6.0 5.9 2.3 23.9 54.9 90.4 84.0 84.4 81.4 55.0 3.1 0.0347 100 68 M6

3

112S 3540 N206 5.2 7.5 2.0 8.1 16.1 26.4 87.5 90.4 89.1 83.5 1.3 0.0073 46 80 M6

3

112S 1755 N205 6.0 6.5 2.4 16.3 39.5 51.2 87.5 88.1 86.7 71.5 2.4 0.0113 46 67 M6

3132M1170N2045.9 6.3 1.924.446.070.087.788.787.872.52.30.0264100 68 M6

3

132M 875 N377 7.8 5.7 2.2 32.8 72.5 117.1 84.5 84.7 82.2 57.0 3.9 0.0420 100 68 M6

3

.7 112M 3540 N395 6.3 7.6 2.1 10.0 20.5 32.8 87.5 91.1 90.0 84.0 1.5 0.0083 46 80 M6

3.7 112M 1755 N394 7.2 6.6 2.4 20.1 49.2 62.5 87.5 89.4 88.4 74.0 2.6 0.0132 46 67 M6

3.7 132M 1170 N207 7.2 6.4 1.9 30.2 57.1 84.2 87.5 89.5 88.9 74.0 2.6 0.0321 100 68 M6

3.7 160M 880 N378 8.3 5.5 1.9 40.1 75.4 119.6 85.5 88.2 86.4 65.5 3.7 0.0668 130 67 M6

4

112M 3535 N398 6.9 7.5 2.0 10.8 22.1 35.2

8

7.5 91.2 90.2 83.5 1.7 0.0083 46 82 M6

4

112M 1750 N397 7.3 6.2 2.2 21.8 48.0 60.7 88.5 89.9 89.5 77.5 2.3 0.0137 46 67 M6

4132M1170N3967.6 6.4 1.932.661.890.488.589.689.174.52.70.0340100 68 M6

4160M880N3799.4 5.8 2.143.391.6143.685.587.685.362.54.50.0668130 67 M6

5.5 132S 3535 N315 9.1 7.1 2.1 14.9 30.6 43.4 88.5 90.5 89.6 86.0 2.3 0.0137 100 82 M6

5

.5 132S 1770 N314 10.0 7.2 2.2 29.6 66.0 91.2 89.5 91.4 90.4 77.5 3.3 0.0321 100 70 M6

5

.5 132M 1175 N313 10.9 7.0 2.3 44.8 103.2 142.8 89.5 90.0 89.1 71.0 4.4 0.0434 100 68 M6

5.5 160M 885 N380 13.0 6.0 2.3 59.5 138.0 209.5 85.5 88.3 86.2 62.0 6.2 0.0891 130 67 M6

7.5 132M 3525 N318 11.8 7.0 2.1 20.3 43.1 55.6 89.5 91.4 91.2 89.0 2.4 0.0171 100 82 M6

7.5 132M 1760 N317 12.9 6.2 1.9 40.6 75.4 103.0 89.5 91.5 91.4 81.5 3.5 0.0378 100 70 M6

7

.5 160M 1170 N316 13.4 6.5 2.2 61.1 137.3 175.4 89.5 90.4 89.8 78.5 4.6 0.0737 130 68 M6

7

.5 160L 880 N381 15.9 5.6 2.0 81.5

1

65.3 248.4 88.5 89.2 88.0 67.0 7.1 0.1069 130 67 M6

11 160M 3555 N321 17.5 6.7 2.0 29.5 58.0 76.1 90.2 92.1 91.6 87.5 3.6 0.0428 130 84 M6

11 160M 1770 N320 17.9 5.9 2.1 59.4 121.7 147.6 91.0 92.6 92.6 85.0 4.5 0.0823 130 72 M6

1

1160L1175N31920.3 7.3 2.889.5250.3298.890.290.589.675.57.80.1013130 68 M6

1

1180M885N38220.9 6.9 2.0118.7238.9359.588.591.591.174.5 7.20.3132200 71 M6

1

5160M3550N32423.5 7.0 2.3 40.390.7103.390.293.092.889.0 4.10.0542130 84 M6

15 160L 1770 N323 24.3 6.6 2.4 80.8 196.2 219.9 91.0 93.4 93.3 85.0 6.2 0.1097 130 72 M6

15 180L 1180 N322 28.4 5.8 1.7 121.2 202.4 328.0 90.2 91.6 90.7 73.5 10.8 0.2471 200 72 M6

1

5200M880N38331.4 5.1 1.8162.7300.6411.589.592.091.067.012.80.4313365 74 M8

1

8.5 160L 3550 N327 28.5 7.4 2.5 49.7 126.6 131.9 91.0 93.3 93.3 89.5 5.0 0.0628 130 84 M6

1

8.5 180M 1775 N326 30.3 6.4 1.8 99.4 174.9 256.0 92.4 93.5 93.3 83.0 8.6 0.1704 200 75 M6

18.5 200L 1180 N325 35.

25.5 2.0149.8303.1394.491.792.191.172.013.50.3715365 75 M8

18.5 200L 875 N384 38.2 4.8 1.8 201.6 352.9 477.2 89.5 91.3 90.5 68.0 15.1 0.4493 365 74 M8

22 180M 3555 N330 34.1 6.9 2.6 59.1 153.6 165.0 91.0 93.1 92.5 89.0 7.3 0.0975 200 85 M6

22 180L 1775 N329 35.8 6.7 1.9 118.2 220.6 309.1 92.4 93.8 93.6 83.5 10.0 0.2000 200 75 M6

22 200L 1175 N328 39.6 5.6 2.1 178.4 370.8 445.2 91.7 93.1 92.6 76.0 13.1 0.4458 365 75 M8

22 225S 890 N385 43.0 5.0 1.6 235.9 369.7 585.1 91.0 94.1 93.3 70.5 16.3 0.9486 524 74 M8

30 200M 3570 N263 48.2 5.9 1.6 80.2 125.8 203.5 93.0 93.9 92.8 84.0 12.7 0.1769 365 87 M8

30 200M 1780 N262 50.6 5.1 1.6 161.0 254.3 375.1 93.0 94.4 94.0 80.0 15.2 0.3055 365 78 M8

30 225M 1185 N261 49.4 5.3 1.4 241.3 346.7 558.3 93.0 94.8 94.5 82.0 13.2 1.0459 524 75 M8

30 225M 885 N386 55.9 4.4 1.3 322.8 420.7 656.7 91.0 94.1 93.7 74.0 18.0 1.0750 524 74 M8

37 200M 3565 N266 58.4 5.4 1.5 99.1 144.5 221.4 92.4 94.3 93.6 86.0 12.8 0.1930 365 87 M8

37

200L 1780 N335 60.9 5.2 1.7 198.6 329.0 455.7 93.0 94.9 94.7 82.0 16.5 0.3888 365 78 M8

37 250M 1195 N264 65.3 6.1 1.6 296.0 477.1 811.1 93.0 94.6 93.6 76.5 22.9 1.1926 721 77 M10

37 250M 890 N387 75.0 6.4 2.2 397.7 864.0 1445.9 91.7 93.6 92.2 67.5 33.1 1.5551 721 75 M10

45 225S 3570 N269 71.0 6.0 1.5 120.3 174.9 302.1 93.0 95.0 94.1 85.5 17.5 0.2933 524 89 M8

45 225S 1780 N338 71.4 5.1 1.4 241.5 333.8 525.8 93.6 94.9 94.9 84.5 17.2 0.5325 524 79 M8

45 280S 1195 N337 73.6 6.5 1.4 359.8 514.2 995.0 93.6 94.5 93.4 82.0 21.2 3.1082 998 80 M10

45 280S 890 N388 84.4 5.6 1.6 481.6 752.8 1325.9 91.7 94.0 92.9 73.0 31.1 2.2933 998 77 M10

55 225M 3570 N342 86.3 6.1 1.6 147.0 232.4 372.0 93.0 95.4 94.7 86.0 20.4 0.3315 524 89 M8

55 225M 1780 N341 86.8 5.8 1.7 294.8 487.0 720.7 94.1 95.4 95.3 84.5 22.1 0.6656 524 79 M8

55 280M 1195 N340 92.8 6.3 1.4 439.9 630.4 1234.1 93.6 94.5 93.5 79.5 30.2 2.7867 998 80 M10

55 280M 890 N389 107.0 5.6 1.7 588.7 994.0 1715.2 93.0 93.4 92.0 69.5 44.8 2.3976

998 77 M10

75 250M 3570 N345 112.0 7.1 1.7 200.4 339.8 575.1 93.6 95.7 95.3 89.5 21.6 0.5830 721 89 M8

75 250M 1785 N344 119.0 4.6 1.3 401.1 541.1 848.7 94.5 96.0 95.9 83.5 29.1 1.0527 721 80 M8

75 280M 1190 N343 123.0 5.9 1.4 600.3 820.2 1532.0 94.1 95.0 94.3 81.5 35.6 3.3226 998 80 M10

75 280M 890 N390 141.0 5.9 1.8 803.0 1431.7 2337.7 93.0 94.3 93.2 72.0 53.9 3.3358 998 77 M10

90 280M 3580 N347 135.0 6.4 1.3 239.9 322.4 656.5 94.5 95.7 95.2 88.5 28.4 0.9551 998 91 M16

90 280S 1785 N346 141.0 5.8 1.6 481.7 780.9 1232.6 94.5 95.5 95.2 85.0 36.4 1.9383 998 83 M16

90 280K 1195 N368 145.0 6.3 1.6 720.1 1139.0 2093.1 94.1 95.5 95.0 83.0 39.8 4.3549 1430 82 M16

90 280K 890 N391 154.0 5.5 1.6 965.4 1540.0 2459.7 93.6 95.2 94.8 78.5 46.4 4.4824 1430 77 M16

110 280M 3580 N349 163.0 5.9 1.2 293.4 362.4 725.6 94.5 95.8 95.6 89.5 30.3 1.0575 998 91 M16

110 280M 1790 N348 167.0 6.3 1.2 586.4 697.1 1537.0 95.0 96.3 96.1 87.0 38.2 3.0566 998 83 M16

110 280K 1190 N369 173.0 6.1 1.6 880.5 1378.4 2464.8 95.0 95.6 95.

384.045.25.08081430 82 M16

110 280K 890 N392 184.0 5.2 1.5 1181.7 1767.2 2767.4 93.6 95.3 95.2 80.0 50.0 5.6291 1430 77 M16

132 280K 3585 N354 194.0 7.0 1.6 351.6 545.7 1122.2 95.0 95.5 94.8 90.0 36.8 1.3860 1430 91 M16

132 280K 1790 N360 202.0 6.3 1.3 703.3 886.1 1933.6 95.0 96.4 96.2 86.5 47.7 3.3176 1430 85 M16

132 280K 1190 N370 205.0 6.1 1.6 1056.8 1662.7 2870.4 95.0 95.9 95.7 85.0 48.4 6.8435 1430 82 M16

132 280H 890 N393 220.0 5.1 1.5 1418.8 2100.5 3231.8 93.6 95.5 95.5 80.5 56.3 7.2970 1430 77 M16

160 280H 3580 N355 230.0 6.8 1.7 426.5 743.5 1263.8 95.0 95.9 95.5 92.0 33.2 1.8480 1430 91 M16

160 280K 1790 N361 239.0 6.1 1.3 852.7 1073.2 2189.9 95.0 96.6 96.6 88.5 47.2 4.2552 1430 85 M16

160 280H 1195 N371 249.0 6.5 1.7 1280.5 2208.4 3714.2 95.0 96.1 95.8 85.0 61.3 8.3988 1430 82 M16

200 280H 1795 N362 305.0 7.0 1.5 1064.8 1566.4 3198.8 95.0 96.3 95.7 86.5 73.7 5.0485 1430 89 M16

220 280H 1790 N363 329.0 6.6 1.4 1171.7 1633.3 3229.3 95.4 96.4 95.9 88.0 68.9 5.6255 1430 89 M16

X$D IEC 60 Hz (IE2 Efficiency – Type KFE)

Typical Performance Data at 460 Volts

Page 6

Complete

Product

O

ffering

Innovative

Technology

Proven

Experience

World-Class

Service

The GE

Advantage

With GE, you have a single

point of responsibility for

all your motor needs. GE

offers a complete portfolio

of equipment from which to

choose, including:

• Motors from 1 to 100,000 HP

(0.75 to 75,000 kW)

• Generators up to 75 MVA

• Low and medium voltage

variable frequency drives

• Multiple product lines

covering all enclosures: WPI,

WPII, TEFC, TEAAC, TEWAC

• GE motors can adhere to

these industry standards

among others: NEMA, IEC,

CSA, API 541, 546, 547, and

661; IEEE 841, GOST, DIV 2,

Ex-n for Zone 2, Ex-p for

Zone 1 or 2, ATEX

GE has over 125 years of

experience in the electrical

industry with successful

global installations spanning

a wide variety of applications.

Very few competitors can

claim the depth and breadth

of experience that GE has

in creating and executing

solutions for its customers.

With GE’s wealth of global

experience comes a full

coverage offering for its

products along with leading

experts in the industries

they serve. Additionally,

GE experience and

innovation brings:

• Experienced sales force

• Engineering support

optimized for your

application

• Project management tools

GE is constantly innovating

product technologies to

meet and exceed customer

expectations. Founded by

world renowned inventors,

General Electric continues to

be a company made up of

individuals striving to design,

create, and build products

and solutions that improve

people’s lives. Among the

many tools used to produce

innovative products are:

• Electromagnetic finite

element analysis

• 3D solid modeling

• Virtual motor “building”

while in design phase

GE Energy

Fort Wayne, IN. 46802

800 541 7191

www.gemotors.com

For more information, please contact your GE sales representative

GE, ecomagination, X$D, GEGARD2400 are trademarks and a service mark of General Electric Company.

Copyright © 2011 General Electric Company. All rights reserved.

GEA18201A (2/2011)

Loading...

Loading...