Page 1

OWNERS MANUAL

faucet and

base

%)”

a

GENERAL ELECTRIC

UNDERCOUNTER

REVERSE OSMOSIS

SYSTEM

I

b---u-d”

Safety Guides

model

GE/18 ●

Maintenance

..

installation

Repair Parts

Operation

GENERAL ELECTRIC Appliance Park

XXXXX (-/96)

71

Page 2

TABLE OF CONTENTS

PAGE NO.

Specifications

What the Drinking Water System will do

Components of the system

Checks to make before installing

Installing

3

3

4 Maintenance

4

5-8

SAFETY GUIDES

Read all steps, guides and rules carefully before

installing and using the Undercounter RO System.

Follow all steps exactly to correctly install.

BE SURE TO FOLLOW APPLICABLE STATE AND LO-

CAL PLUMBING AND SANITATION CODES when

installing the Undercounter RO system. Using a quali-

fied installer is recommended.

The Undercounter RO System works on water pres-

sures of 40 psi minimum, to 125 psi maximum (seethe

table on page 3). If house water pressure is over the

maximum, install a pressure reducing valve in the water suppiy line to the Undercounter RO System.

PAGE NO.

Pressure testing

How the Drinking Water System works

Sanitizing the RO System

Repair parts

DO NOT install the Undercounter RO System outside,

or in extreme hot or cold temperatures. Temperature

of the water supply to the Undercounter RO System

must be between 40”F (minimum) and 80 or 100°F

(maximum) ...see the table on page 3. DO NOT

INSTALL ON HOT WATER.

Read the other limits (pH, water hardness, etc.), page

3, and be sure the water supply conforms.

Do not use the system on microbiologically unsafe

water, or water of unknown quality.

9-10

11–14

15

16-17

9

WARRANTY INFORMATION

2

Page 3

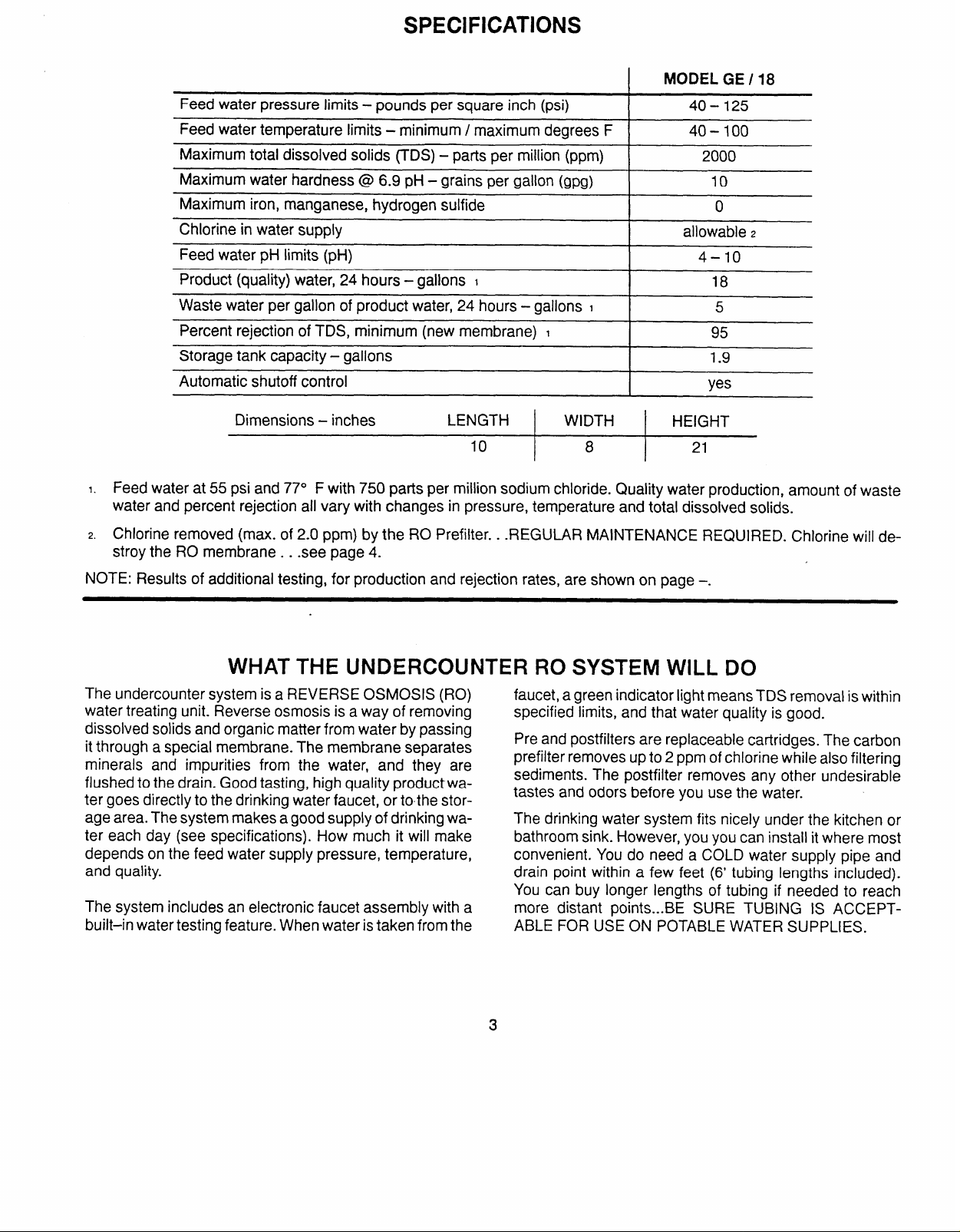

SPECIFICATIONS

[ MODEL GE / 18

Feed water pressure limits - pounds per square inch (psi)

Feed water temperature limits

- minimum / maximum degrees F

I

I

40–125

40–100

Maximum total dissolved solids (TDS) – parts per million (ppm) 2000

Maximum water hardness @ 6.9 pH - grains per gabn (gpg) 10

Maximum iron, manganese, hydrogen sulfide

Chlorine in water supply

Feed water pH limits (pH)

I

I

o

allowable z

4–lo

Product (quality) water, 24 hours - gallons I 18

Waste water per gallon of product water, 24 hours – gallons

I

I

5

Percent rejection of TDS, minimum (new membrane) 1 95

Storage tank capacity - gallons

Automatic shutoff control

Dimensions - inches

LENGTH

10

I

WIDTH

8 21

1.9

yes

HEIGHT

I. Feed water at 55 psi and 77o F with 750 parts per million sodium chloride. Quality water production, amount of waste

water and percent rejection all vary with changes in pressure, temperature and total dissolved solids.

z. Chlorine removed (max. of 2.0 ppm) by the RO Prefilter. .

.REGULAR MAINTENANCE REQUIRED. Chlorine will de-

stroy the RO membrane. . see page 4.

NOTE: Results of additional testing, for production and rejection rates, are shown on page –.

WHAT THE UNDERCOUNTER RO SYSTEM WILL DO

The undercounter system is a REVERSE OSMOSIS (RO)

water treating unit. Reverse osmosis is a way of removing

dissolved solids and organic matter from water by passing

it through a special membrane. The membrane separates

minerals and impurities from the water, and they are

flushed to the drain. Good tasting, high quality productwater goes directly to the drinking water faucet, or tothe storage area. The system makes a good supply of drinking water each day (see specifications). How much it will make

depends on the feed water supply pressure, temperature,

and quality.

The system includes an electronic faucet assembly with a

built–in water testing feature. When water is taken from the

faucet, a green indicator light means TDS removal is within

specified limits, and that water quality is good.

Pre and postfilters are replaceable cartridges. The carbon

prefilter removes up to 2 ppm of chlorine while also filtering

sediments. The postfilter removes any other undesirable

tastes and odors before you use the water.

The drinking water system fits nicely under the kitchen or

bathroom sink. However, you you can install it where most

convenient. You do need a COLD water supply pipe and

drain point within a few feet (6’ tubing lengths included).

You can buy longer lengths of tubing if needed to reach

more distant points...BE SURE TUBING IS ACCEPTABLE FOR USE ON POTABLE WATER SUPPLIES.

Page 4

COMPONENTS OF THE SYSTEM

The factory assembled RO system is shippedinI carton.

A parts bag includes the RO product water faucet and tubing adaptor fittings. All tubing (6 ft lengths), required for

installation, is attached to the RO system. An additional 27

in. length is provided to connect between the faucet and

the drain point. This electronic model also includes a package of special faucet base parts.

THINGS TO CHECK BEFORE YOU START TO INSTALL

●

FEED WATER - The water supply to the undercounter RO system must have the qualities listed in the

specifications. If not, it will not make product water as

it should and life of the RO membrane is shortened.

City water most often will have these qualities. Well

water may need conditioning. Have the water tested

by a water analysis Iabatory, and get their recommendations for treatment. Observe plumbing codes when

providing a water supply to the RO. A self–piercing

saddle valve is included for tapping into a cold water

pipe (check local codes). Refer to pages 5 and 17.

CAUTIONS:

MODEL GE/ 18- Feed water must have all chlorine

removed (prefilter removes up to 2.0 ppm). Chlorine

will destroy the R

to service the prefilter at suggested intervals, page 11.

O membrane cartridge. Be sure

INSTALLER PROVIDES: The water supply valve and

drain fitting (pages 5 and 6) are included for use in areas

where codes permit. Both items nwst comply with

state and/ or /oca/ codes. If not, the installer must provide, (1)fittings to tap the cold water pipe for a feed water

source to the RO...must adapt to 1/4” OD tubing; and (2)

a drain point for RO discharge water...must adapt to 3/8’

OD tubing.

●

DRAIN POINT - A suitable drain point (check your

local codes) is needed for reject water from the RO

membrane cartridge. We suggest using the SINK P–

TRAP drain pipe. A drain clamp (drilling required) is

included to use where codes permit. Refer to pages

6 and 17.

●

RO FAUCET - The RO product water faucet installs

on the sink, or on the countertop next to the sink.

Often, it’s installed in an existing sink spray attachment hole. Space is required underneath for tubing to

and from the faucet, and for securing it in place. All

electronic faucet connections and installation procedures are done on or above the sink or countertop.

Refer to page 7 or 8.

..

4

Page 5

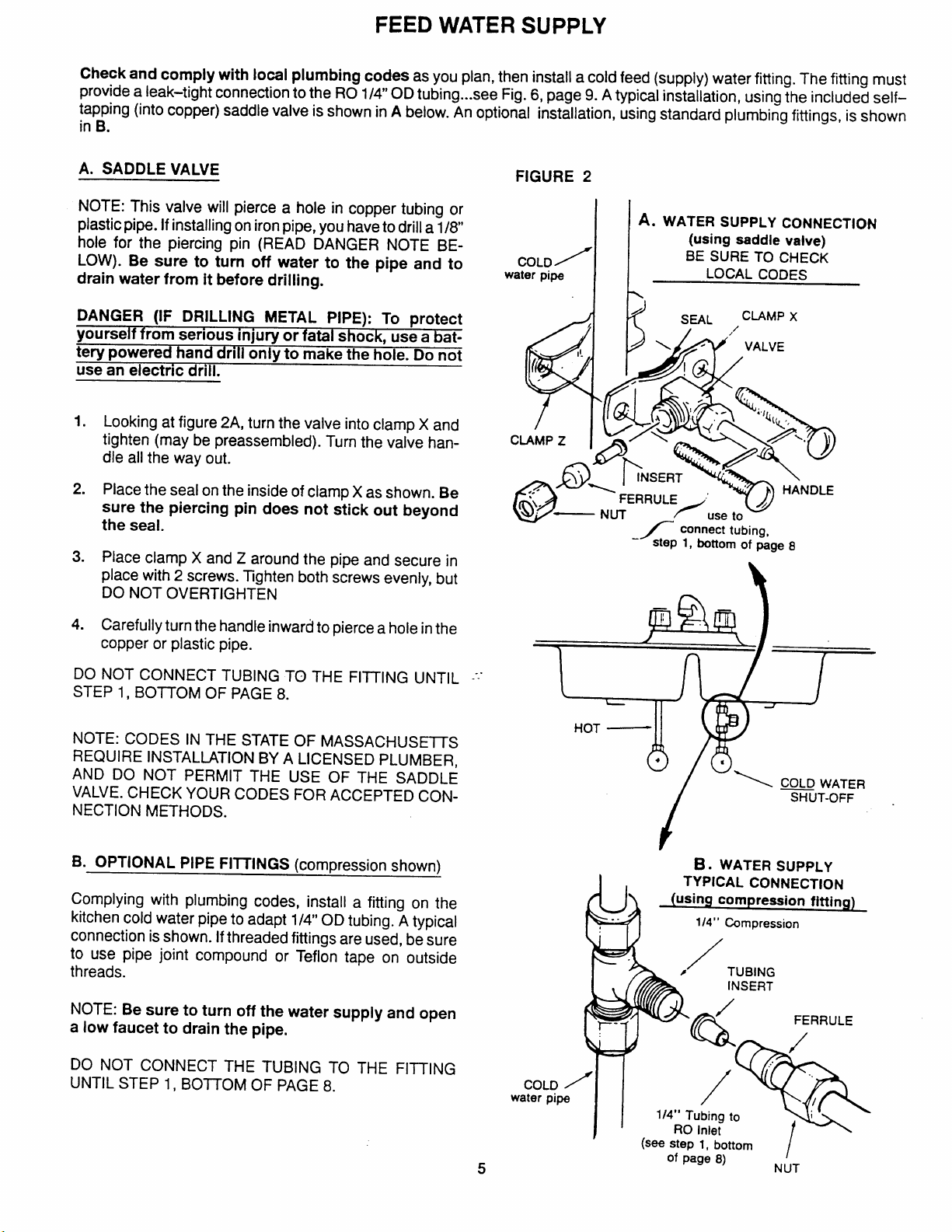

FEED WATER SUPPLY

Check and comply with local plumbing codes as you plan, then install a cold feed (supply) water fitting. The fitting must

provide a leak-tight connection to the RO 1/4” OD tubing...see Fig. 6, page 9. A typical installation, using the included self-

tapping (into copper) saddle valve is shown in A below. An optional installation, using standard plumbing fittings, is shown

in B.

A. SADDLE VALVE

NOTE: This valve will pierce a hole in copper tubing or

plastic pipe. If installing on iron pipe, you have to drill a 1/8

hole for the piercing pin (READ DANGER NOTE BELOW). Be sure to turn off water to the pipe and to

drain water from it before drilling.

DANGER (IF DRILLING METAL PIPE): To protect

YOWSe!f from serious iniurv or fatal

~erv Dowered hand

-.

drill &nlj to make the h

..* .—--.7..-

shock, Use a bat-

--—.—---

..._..ole. Do not

use an electric drill.

1.

Looking at figure 2A, turn the valve into clamp X and

tighten (may be preassembled). Turn the valve handle all the way out.

2.

Place the seal on the inside of clamp X as shown. Be

sure the piercing pin does not stick out beyond

the seal.

3.

Place clamp X and Z around the pipe and secure in

place with 2 screws. Tghten both screws evenly, but

DO NOT OVERTIGHTEN

FIGURE 2

A. WATER SUPPLY CONNECTION

H

(using saddle valve)

/’

COLD

water pipe LOCAL CODES

BE SURE TO CHECK

c

~= I INSERT

.. “

‘k

$3

‘NUT _

o

FERRULE :

_/ connect tubing

step 1, bottom of p& 8

m

/

use to

1-

IANDLE

1

/

4.

Carefully turn the handle inward to pierce a hole in the

copper or plastic pipe.

DO NOT CONNECT TUBING TO THE FllTING UNTiL ---”

STEP 1, BOl_JOM OF PAGE 8.

NOTE: CODES IN THE STATE OF MASSACFIUSHTS

REQUIRE INSTALLATION BY A LICENSED PLUMBER,

AND DO NOT PERMIT THE USE OF THE SADDLE

VALVE. CHECK YOUR CODES FOR ACCEPTED CON-

NECTION METHODS.

B. OPTIONAL PIPE FIITINGS (compression shown)

Complying with plumbing codes, install a fitting on the

kitchen cold water pipe to adapt 1/4” OD tubing. A typical

connection is shown. If threaded fittings are used, be sure

to use pipe joint compound or Teflon tape on outside

threads.

NOTE: Be sure to turn off the water supply and open

a low faucet to drain the pipe.

DO NOT CONNECT THE TUBING TO THE FllTING

UNTIL STEP 1, BOJTOM OF PAGE 8.

5

COLD ~

water pipe

HOT —

&(

~-

%

F

I

using compre~ion fitting)

.-

1/4” Tubing to

RO Inlet

(see step 1, bottom

of page 8)

\

SHUT-OFF .

B . WATER SUPPLY

TYPICAL CONNECTION

Compression

1/4”

/

#

TUBING

INSERT

/

Q

/

,..

NUT

FERRULE

/

-.

/

t’

/

Page 6

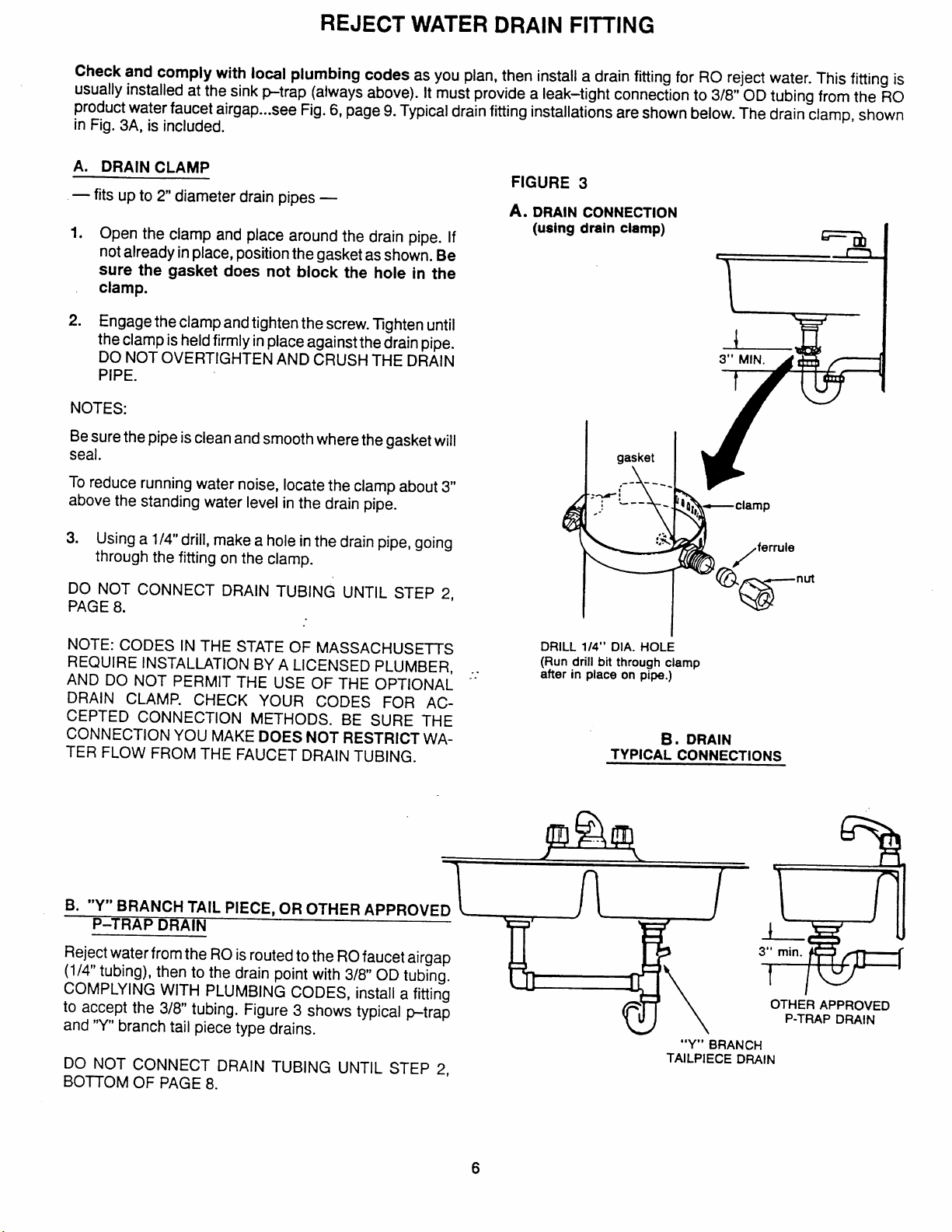

REJECT WATER DRAIN FITTING

Check and comply with local plumbing codes as you plan, then install a drain fitting for RO reject water. This fitting is

usually installed at the sink p-trap (always above). it must provide a leak-tight connection to 3/8 OD tubing from the RO

product water faucet airgap...see Fig. 6, page 9. Typical drain fitting installations are shown below. The drain clamp, shown

in Fig. 3A, is included.

A. DRAIN CLAMP

— fits up to 2 diameter drain pipes —

1. Open the clamp and place around the drain pipe. If

not already in place, position the gasket as shown. Be

sure the gasket does not block the hole in the

clamp.

2. Engage the clamp and tighten the screw. llghten until

the clamp is held firmly in place against the drainpipe.

DO NOT OVERTIGHTEN AND CRUSH THE DRAIN

PIPE.

NOTES:

Be sure the pipe is clean and smooth where the gasket will

seal.

To reduce running water noise, locate the clamp about 3“

above the standing water level in the drain pipe.

FIGURE 3

DRAIN CONNECTION

A.

(using drain clamp)

gasket

,---- ~.

A

3. Using a 1/4” drill, make a hole in the drain pipe, going

through the fitting on the clamp.

DO NOT CONNECT DRAIN TUBING UNTIL STEP 2,

PAGE 8.

NOTE: CODES IN THE STATE OF MASSACHUSETTS

REQUIRE INSTALLATION BY A LICENSED PLUMBER,

AND DO NOT PERMIT THE USE OF THE OPTIONAL ‘:

DRAIN CLAMP. CHECK YOUR CODES FOR AC-

CEPTED CONNECTION METHODS. BE SURE THE

CONNECTiON YOU MAKE DOES NOT RESTRICT WATER FLOW FROM THE FAUCET DRAIN TUBING.

B. “Y” BRANCH TAIL PIECE, OR OTHER APPROVE

P-TRAP DRAIN

Reject water from the RO is routed to the RO faucet airgap

(1/4” tubing), then to the drain point with 3/8 OD tubing.

COMPLYING WITH PLUMBING CODES, install a fitting

to accept the 3/8” tubing. Figure 3 shows typical ~trap

and “Y” branch tail piece type drains.

DO NOT CONNECT DRAIN TUBING UNTIL STEP 2,

BOITOM OF PAGE 8.

DRILL 1/4” DIA. HOLE

(Run drill bit through clamp

after in place on pipe.)

B. DRAIN

TYPICAL CONNECTIONS

u\

“Y” BRANCH

TAILPIECE DRAIN

OTHER APPROVED

P-TRAP DRAIN

6

Page 7

INSTALL ELECTRONIC FAUCET

li!ii

Select one of the following places to install the faucet. Be

sure there’s room underneath so you can make the needed connections.

NOTE: Looking at Fig. 4D, be sure the faucet base will fit

~lat against the surface, at the selected Iocatlon, so the

gasket will seal.

—

In an existing sink spray attachment hole.

—

Drill a hole in the sink top.

—

Drill a hole in the countertop, next to the sink.

1.

If drilling is needed, make a 1-1/4” dia. hole (mini-

mum). Be sure to use proper procedures for dri/-

iing porcelain or stainless steel.

2.

Place plumbers putty around the drilled hole.

3.

Looking at Fig. 4A, insert a screw into the NON–

SLOITED base mounting hole. Turn a special nut a

few turns onto the screw.

4.

Position the base gasket over the mounting hole. Set

the base on the gasket, routing the leadwire through

the mounting hole. Holding the special nut under the

sink with 1 finger, tighten the screw until just snug.

Turn the remaining special nut a few turns onto the

5.

other screw. Position the screw in the slotted base

mounting hole, and tighten until. snug. Carefully

tighten both screws until the base is held firmly in

place. Do not overtighten and break the base.

NOTE: If the faucet is unassembled, slide the lever over

the small cylindrical nut. Then, push or turn the spout into

the faucet body.

Assemble the top gasket, top faucet base, and hex

6.

nut onto the faucet stud...Fig. 4C. Tighten the nut until

snug. Other included faucet parts are

7.

Using the washer, Fig. 4D, turn the tubing adaptor

onto the faucet stud and tighten securely.

Take the 27” length of 3/8 tubing and push 1 end onto

8.

the 3/8” faucet barb fitting...Fig. 4D.

not used

FIGURE 4

lever ‘

?’il

a

\.=., H base

h

..

-.

x ‘W”l c

faucet

,

top gasket

top faucet

1/4” barb

fitting

318” tubing,

27” {ong

1-1/4” hole

B.

-4iiF

gasket

LOCATE BASE OVER

HOLE AS SHOWN

FAUCET

.

4$

ASSEMBLED

D.

?(J)

.&;

i- *

%

‘3$; - “

r-

I

.—

--

.-

1

Y-l

-.

.

r)

3/8” bacb

fitting

Move the ro system into position, under the sink.

9.

Route the 1/4” tubing (marked “1/4 BARB ON FAUCET’), and the 3/8” tubing (marked “FAUCET”), from

the bottom, up through the mounting hole and faucet

base. Connect to the faucet as follows...see Fig. 4D:

a. Push 1 end of the 1/4” tubing onto the 1/4” barb on

the faucet.

b. Using the tubing adaptor nut, fasten the 3/8” tubing

to the tubing adaptor, and tighten the nut.

10.

Lower the faucet assembly and lock into place on the

faucet base.

1/4” tubing ‘

(1/4” BARB)

NOTE: FOR EASE OF SERVICE AND

MAINTENANCE, KEEP TUBING

LENGTHS LONG ENOUGH SO REMOVAL OF THE RO SYSTEM FROM

UNDER THE SINK IS POSSIBLE.

///’./////7

faucet base

Ieadwire

Page 8

CONNECT WATER SUPPLY AND FAUCET DRAIN TUBING,

ELECTRONIC FAUCET LEADWIRES

1. Run the 1/4” tubing ( marked “WATER SUPPLY”) from

the RO system, to the feed water supply fitting, installed

on page 5. Connect the tubing as applies (Fig. 2A or 2B)

and tighten the nut securely. Also refer to Fig. 6, page 9.

2. Run the 3/8” tubing from the 3/8” faucet barb, to the

drain fitting installed on page 6. Keep this tubing run as

straight as possible, without loops, dips or low-spots.

Cut the tubing as needed and fasten to the drain fitting

TYPICAL FINISHED

FIGURE 6

2

(Fig. 3A or 3B), securing as required,

3. Remove the electronic box back cover and, looking at

Fig. 6, fasten the battery connector to the battery pack (be

sure batteries are installed correctly). Put the battery pack

in the electronic box and replace the back cover.

Fasten the electronic box leadwire to the faucet base leadwire...Fig. 6.

INSTALLATION

I_

Electronic Faucet

RO MODEL

GE/18

..

) //

8

Page 9

PRESSURE TESTING

DO THE SANITIZING PROCEDURES, ON PAGE 15, BEFORE CONTINUING BELOW.

1. Doubl~heck all tubing connections to be sure they

are tightened. system. At that time, carefully check all fittings and

2. Turn on the water supply to the RO system, and open

the tank shutoff valve...Fig. 6.

4. IMPORTANT PURGING INSTRUCTIONS: The RO cartridge contains a food grade presewative that you should

clean from it before using the system. The preservative will give product water an unpleasant taste and odor. After

the bladder has filled (takes about 4 hours), open the system faucet until the bladder is empty. Allow the bladder to

fill again for 4 hours, then open the faucet and empty. After 4 purgings, the system is ready to make product water

.for your use.

3. In about 4 hours, pressure will start to build in the RO

tubing connections for any water leaks. Correct leaks

if any are found.

HOW THE UNDEI?COUNTER RO SYSTEM WORKS (FIG. 7)

PREFILTER

Water from the cold supply pipe enters the RO assembly

and is directed to the prefilter cartridge.

NOTE: Before going to the prefilter, supply water first

passes through the electronic box to measure total dissolved solids (TDS).

The prefilter is a replaceable sediment cartridge with acti-

vated carbon in its composition. The cartridge (5 micron)

removes sand, silt, dirt, other sediments, and up to 2.0

ppm of chlorine from the feed water., CHLORINE DESTROYS THE ERO 392 MEMBRANE. Filtered, clean,

chlorim+free water flows from the prefilter, to the RO

membrane cartridge. IMPORTANR See prefilter main-

tenance, page 11.

REVERSE OSMOSIS (RO} CARTRIDGE

The cartridge, inside the RO housing, includes a tightly

wound, special membrane. Water is forced through the

cartridge where the membrane removes the dissolved

solids and organic matter. High quality product water exits

the RO housing and goes to the storage area. Reject water, with the dissolved solids and organic matter, leaves

the housing and is discharged to the drain through 1/4”

tubing.

NOTE: On electronic models, product water passes

through the electronic box before going to the faucet, to

measure total dissolved solids (TDS).

continued

FIGURE 7

~ shutoff

4*

G

supply water

—

iJ-J

● “

tank

..

shutoff -—.

..

product water”:

to postfilter

and faucet

H

,

)

automatic

assembly

4

to drain

PRODUCT WATER STORAGE

The storage area holds up to 1.7 gallons of product water.

The flexible bladder keeps water pressurized for fast flow

to the faucet when drinking water is needed.

POSTFILTER

After leaving the storage area, but before going to the faucet, product water goes to the postillter. The postfilter is

also the activated carbon type sediment filter. Any remain-

ing tastes, odors, or sediments are removed from product

water. Tast&free, odor–free, clean, high quality drinking

water flows through the tubing and to the faucet.

check

valve

product

water

RO housing

.

- bladder

Page 10

HOW THE UNDERCOUNTER RO SYSTEM WORKS (FIG. 7)

FAUCET AND ELECTRONICS

The sink or countertop faucet vends the drinking water

when opened. it has a hand operated, spring loaded

closed lever to prevent waste. You can also keep the faucet open by pushing upward on the lever and locking it

against the faucet spout.

To comply with plumbing codes, an air-gap is built into the

faucet drain water connection.

The electronic faucet provides a built–in water quality tester. As water is taken from the faucet, the indicator lights

show how the RO system is operating to provide high

quality drinking water.

● FLASHING GREEN LIGHT - The RO system is giv-

ing you high quality drinking water.

NOTE: The green light may stop flashing when the supply

of RO water is nearly gone, and flow from the RO faucet

decreases. This is a normal condition.

● FLASHING RED “FILT” LIGHT - The prefilter car-

tridge and postfilter need replacing. This occurs after

6 months, or 900 gallons of product water use. Also

replace the control box batteries... see page 12.

● FLASHING AMBER “RO” LIGHT - The RO car-

tridge no longer removes at least 75% of the TDS from

supply water and needs replacement.

NOTE: Disregard initial or short periods of the flashing

“ROY’ light.

SHUTOFF ASSEMBLY

To conserve water, the drinking water system has an automatic shutoff assembly. When the storage tank has filled

to capacity, and the drinking water faucet is closed, pres-

sure closes the shutoff. Water flow to the RO housing is

shut off until drinking water is used again, and pressure

drops in the RO system.

CHECK VALVE

A check valve (Fig. 7) is buiit into the bottom end of the RO

housing. The check valve prevents a backward flow of

product water from the storage area. A backward flow

could cause TDS to bleed into the product water, and

could rupture the RO membrane.

FLOW CONTROL

The flow control (see Fig. 8) regulates flow, through the

RO cartridge, to the required rate to get the desired quality

of product water. The control is located in the drain tubing,

at the RO cap fitting. A small, corwshaped screen fits

over the front end of the flow control to help prevent plugging with drain water sediments.

10

Page 11

MAINTENANCE

(

AlSO see Filter-cartridge Replacement Guide, page 14 )

To keep the undercounter RO system operating and mak-

ing high quality drinking water, the prefilter cartridge, RO

cartridge, and postillter need replacement at certain intervals. Use the following information to keep the RO system

properly sewiced and maintained.

——— —6——— ——— —,

r

I

BEFORE SERVICING THE RO SYSTEM, DO THE FOL-

LOWING TO RELIEVE PRESSURE AND ALLOW AIR

I

TO ENTER THE RO TANK.

ID

1‘Tu~off~e ~e~p~to~e ~.

2. Open the product water faucet and allow water to run

until it stops.

3. Using a 2 gal (minimum) container to catch the water,

disconnect the postfilter. Allow the storage bladder to

empty.

4. Looking at Fig. 8, remove the protective cap and depress the vacuum relief valve stem, allowing air to en-

ter the tank. Release the valve stem after flow from

the tank shutoff slows to a slight drip. Replace the protective cap.

CAUTION: This valve is for vacuum relief only. DO NOT

attempt to pressurize the tank.

CAUTION:

———

FIGURE 8

cone screen

..

1

1

I

J

R~ Cap /“~ ‘ ‘

91

o-ring

UP

4

arrow

protective

cap

M“ Kg:’s

vacuum

‘.

.

i

UP

K

@

i

.

RO

flow control

“=

membrane

cartridge

1/11—

‘h ~

-= retainer (2)

5. Reconnect the postfilter.

PREFILTER CARTRIDGE AND POSTFILTER RE-

PLACEMENT

You must replace the prefilter cartridge often to protect the RO membrane from being destroyed by chlorine, and/or from plugging with sediments in the water

supply. Ifthe water suppl y contains both chlorine and sediments, replace the prefilter cartridge at least every-6

months, or more often if it begins to plug with sediments.

If the water has sedhnents on/~ with no chlorine, you may

begin to notice a slower making of product water. When

this happens, a new sediment cartridge is needed. Also

replace the postfilter.

To signal correct replacement interval, the red “FllT” indicator light, on the electronic faucet base, will beginto flash

after6 months, or 900 gallons of product water use, which-

occurs first.

ever

At the same time, replace the batteries in the control box.

Replacing the batteries resets the 6 month or 900 gallon

period, and assures proper operation of the RO indicator

Iight...see page 12.

postfi!ter

-

-.

.—,

\

\

Shutoff assembly

not shown. See

Pages 9,13 and 16.

%-H

Maintenance continued, page 12

11

Page 12

MAINTENANCE

● sT~ps To REpLAcE T~EposTF\LTERo

IMPORTANT Read the caution on page 11 and do

steps 1-4, to relieve pressure in the RO, before continu-

ing below.

1. Disconnect tubing at both ends... see Fig. 8.

2. Pull the filter from the holder and remove fittings from

both ends

NOTE: Both ends of the postfilter may be externally

threaded to accept the tubing nuts directly without the t7t-

Just be sure the flow arrow points downward.

tings.

If needed, turn the fittings (use Teflon tape) into both

3.

ends of the postfilter, observing the flow arrow.

4. Replace filter into the holder and reconnect the tubing

at both ends.

● STEPS TO REPLACE THE PREFILTER CARTRIDGE ●

IMPORTANT Read the caution on page 11 and do

steps 1-4, to relieve pressure in the RO before continu-

ing below.

1.

Referring to Fig. 8, remove the clamp retainers and

clamp sections.

2. Separate the cap from the RO housing (no need to

disconnect tubing) and set aside.

NOTE: If the cap o+ing seal remained in the RO housing, replace it on the cap.

It’stime to replace the RO cartridge when product water

quality and/or rate of production drop (first replace the prefilter cartridge and postfilter). Product water may begin to

taste different or even bad, indicating solids and organics

getting through the cartridge.

are

NOTE: When replacing the RO cartridge, also install a

new flow control and screen. The prefilter cartridge and

postfilter should also be replaced.

ELECTRONIC MODELS — it’s time to replace the RO

cartridge when the amber “RO” light, on the faucet base,

flashes continually while RO water is taken from the fau-

cet...see page 10.

c STEPS TO REPLACE THE RO CARTRIDGE ●

1. Do all steps under “To Replace The Prefilter Car-

tridge”, also on this page.

2. Remove and replace the flow control and

screen... see below.

3. Turn on the water supply and PURGE THE RO CAR-

TRIDGE...SEE PAGE 9.

BAITERIES IN ELECTRONIC CONTROL BOX

Always replace the 4, “AA” alkaline batteries in the control

box when changing the prefilter cartridge and postfilter.

Good batteries are needed to assure proper indicator light

operation. Weak batteries may give a false indication.

Changing the batteries also resets the 6 month or 900 gallon period.

3. Lift the RO cartridge and prefilter cartridge from the ‘housing. Separate and dispose of the prefilter car-

tridge.

4. Dump water from the RO housing.

5. Slide the RO cartridge INTO THE TOP END of the

new prefilter cartridge, as shown in Fig. 8. Then,

place into the RO housing.

NOTE: Be sure the bottom end of the prefilter is at the

bottom, and the UP arrow on the RO cartridge points

upward.

6. Lubricate the cap o-ring seal (silicone grease). Then,

push the cap into position and install the clamp sections and retainers.

RO CARTRIDGE

The life of the RO cartridge depends mostly on the pH of

properly treated feed water... see pages 3 and 4. The higher the pH, the shorter cartridge life is. For example, if feed

water pH is from 6.8 to 7.7, the cartridge may last for well

over 1 year. However, cartridge life may be as short as 6

months if the pH is as high as 8.0 or 10 (see specifica-

tions). The higher pH weakens the cartridge membrane

and makes pin–hole leaks.

FLOW CONTROL AND SCREEN

The flow control is vital for proper operation of the RO cartridge. The control must keep water flow through the cartridge at the proper rate to obtain the best quality product

water.

When servicing the RO, it’s good practice to check the

flow control (and tubing to it) to make sure the small tube

and surrounding surfaces are clean and unrestricted. A

small, cone-shaped screen (Fig. 8) is located in front of

the flow control to help keep it clean. If the flow control

should plug with foreign particles, the RO cartridge cannot

discharge minerals and impurities to the drain. If this

should happen, it will only take a short time for the cartridge to plug, making it useless.

CAUTIONS:

To install the screen, place the cone end into the RO cap.

Then, carefully push it in using l/4’’ tubing as a tool. Do not

force in farther after you feel resistance. Visually check to

be sure it is properly positioned.

When installing the flow control, tighten the tubing nut by

hand, then another 1/4 to 1/2 turn with a pliers. DO NOT

OVERTIGHTEN AND DISTORT OR CRUSH THE TUB-

ING AND FLOW CONTROL.

12

Page 13

MAINTENANCE

SERVICING THE BLADDER

If the bladder should require inspection and replacement,

use the following guides. Refer to the parts illustration on

page 16.

NOTE: READ THE CAUTION ON PAGE 11 AND DO

STEPS 1-4, TO RELIEVE PRESSURE IN THE RO BE-

FORE CONTINUING BELOW.

1. Remove the vacuum relief valve using a 7/1 6“ socket.

2. Rotate the tank shutoff valve 90° and pull from the RO

housing.

—.-—— ——-—- ———-— ———. — .—

r

1“

I DO NOT USE VINEGAR, OR OTHER ACID I

I BASED CLEANERS ON THIS RO SYSTEM. 1

I THEY WILL DEGRADE SOME RO SYSTEM I

I PARTS. ALWAYS USE SOAP AND WATER. j

L —--— ———— ——-— ——. — ———— —.

-———— —--—— ————— ————— ——

r

I This reverse osmosis system contains a replace- ~

I able treatment component critical for effective re- ,

I

moval of total dissolved solids. The water should be

I tested periodically to verify the system is performing ~

I satisfactorily.

I I

i ———— ———— ———— ———— ———— ——

CAUTION

7

1

J

3. Apply downward pressure on the RO cap while rotating it counterclockwise 90”.

NOTE: If the cap turns in the RO housing, first do steps

1 and 2 under “To Replace The Prefilter Cartridge”, page

12.

4.5.Lift the RO housing out of the liner assembly and

PLACE WHERE CLEAN AND SANITARY.

Remove the bladder.

NOTE: BE SURE THE INNER SURFACE OF THE RE-

PLACEMENT BLADDER, ANI) THE OUTER SURFACE

OF THE RO HOUSING ARE CLEAN. USE DISH SOAP

AND HOT WATER TO CLEAN AND RINSE.

6.

Install the bladder into the liner assembly. Wet the top .

bead of the bladder with water, or apply a light coatirlg

of silicone grease.

Install the RO housing, push downward and rotate

7.

clockwise 90° to lock in place.

Replace the tank shutoff valve and rotate 90° to Io-ck.

8.

FIGURE 9

SHUTOFF

ASSEMBLY

(4)

\

diaphragm

e

Using pipe joint compound, replace the vacuum relief

9.

valve.

10.

DO THE SANITIZING AND PURGING PROCE-

AUTOMATIC SHUTOFF SERVICE

If the shutoff assembly requires service, be sure to reassemble parts exactly as shown in Fig. 9, and to reconnect

tubing as shown on pages 9 and 16.

diaphragm

e

Elbow fitting turns

into OUT port and

connects to RO

13

Page 14

FILTER - CARTRIDGE REPLACEMENT GUIDE

IMPORTANT Before doing maintenance on the ro system, relieve pressure and allow air

to enter the tank, steps 1 – 5, page 11.

MODEL GE/ 18

AT LEAST EVERY 6 MONTHS

– Replace sediment-carbon prefilter cartridge and postfilter...see

important note above. Also see Electronic Indicator, below.

- Make replacements indicated if any of the following occur

before the 6 months, -

CHLORINE TASTE AND/OR ODOR

– Replace prefilter cartridge, postfilter, RO cartridge, flow control

and screen... see important note above.

OTHER TASTE ANDIOR ODOR

- Replace the postfilter...see important note above.

– If taste and odor persists, replace prefilter cartridge, RO cartridge, flow control and screen.

SLOW PRODUCTION RATE

– Replace prefilter cartridge... see important note above.

– If rate does not increase, replace postfilter, RO cartridge, flow

control and screen.

HIGH TDS

– Replace prefilter cartridge, postfilter, RO cartridge, flow control

and screen... see important note above.

SLOW FLOW FROM RO FAUCET

– Relieve pressure and allow-air to enter the tank, steps

page 11.

1-5,

ELECTRONIC INDICATOR

BE SURE TO COMPLY WITH THE IMPORTANT NOTE ABOVE.

AT LEAST EVERY 6 MONTHS OR 900 GALLONS OF RO PRODUCT WA-

USE

ER

postfilter, and batteries in the electronic control box.

WHEN THE AMBER “ROS’ LIGHT FLASHES ...

– Replace the RO

Rt D “FILT” LIGHT FLASHES – Replace the prefilter cartridge,

...

cartridge, flow control and screen.

14

Page 15

SANITIZING THE RO SYSTEM

Sanitizing is recommended upon installation of the RO

system, and after servicing inner par&s of the RO housing

and cap. It is

important for the service person to have

clean hands while handling inner parts of the system.

1. Be sure the water supply to the RO is turned off, and

the RO faucet is open.

2. Remove the clamp retainers and clamp sections, Fig.

8, page 11.

3. Lift the cap from the RO housing (no need to disconnect tubing) and move aside.

NOTE: If the cap o+ing seal remained in the ro hous-

ing, replace it on the cap.

4. Remove the RO cartridge and prefilter cartridge

from the RO housing. If needed, flush housing with

fresh, clean water.

5. Fill the RO housing, with fresh water, to about 1“ from

the top. Add 1.0 oz of chlorine (ordinary 5.25% house-

hold bleach... Hilex, Clorox, etc.) and mix in the water.

DO NOT ADD CHLORINE FIRST. Concentrated, it

WIIIattack plastlcs.

6.

Replace the cap, with o-ring, and install the retaining

clamps.

7.

Connect the RO faucet product water tubing directly

to the tank shutoff valve, isolating the carbon postfilter.

8.

Open the tank shutoff valve, and the water supply to

the RO. Open the RO faucet, locking the lever upward against the spout.

9.

Allow water to circulate through the system until all

bleach odor is gone.

10.

Turn off the water supply to the RO. Close the RO faucet after water flow stops.

11.

Reconnect the postfilter (replace a used filter) to the

RO system, Fig. 6, page 9, and page 12.

12.

a

Do steps 2 and 3.

b

Replace the RO cartridge and prefilter cartridge

(BE SURE YOUR HANDS ARE CLEAN).

Do step 6.

Turn to page 9 and do the pressure testing and

purging steps 1 through 4.

PRETREATMENT OF THE WATER SUPPLY

NEEDED TO PREVENT SCALING

TO USE THE CHART...

...Locate the intersecting point of feed water hardness

and pH.

If this point falls within the shaded area, pretreatment* is

needed.

●Softening of the water is the suggested pretreatment.

..

1=

I

RECNJIREn =

,

1

I

10

FEED WATER HARDNESS (GPG)

20

I

I

30 40

I

I

50 60

15

Page 16

RO REPAIR PARTS ILLUSTRATION

\

/

6’

o

(

‘1..,

@

SADDLE VALVE

41

1

OPTIONAL

\

\

\

I +1 *

I

I

LJ

x TO

FAUCET

AIR GAP

,.

I

I

(ial

a

1

.“

—

?

i

~-

9--

..

46

Page 17

RO REPAIR PARTS LIST

Key

No. No.

1

2

3 7051206

4 71

5 0900713

6 71

7 7114614

8 7115725

9 9003204

10

11 7114509

12 7131349

13 9003203

14 71

15

16 71

17

18 7087477

19

20 7115822

21

22

23 7014979 Plunger

24 9004504 Elbow, 1/8” NPT x 1/4” Tube

Part

Description

7095925

7064144

1260600

9043201 Nut, 3/8 Tubing

7131331

7116763 O–ring, 7/16’ x 5/8” – for shutoff

7128524

7127756

1269800

7126506

7112426

7099296

Faucet

Tubing Adaptor–includes washer &

nut

Washer, Compression

Top Gasket

Top, Faucet Base

Screw, #6- 32x 1-3/8’ (2)

Base, Faucet @

Gasket

Nut (2)

Nut, 1/4” Tube (8)

Insert, 1/4” Tube (7)

Tank Shutoff Valve

valve

Insert, 3/8 Tube (5)

Nut, 3/8” Tube (3) @

Post Carbon Filter

Filter Holder

Electronic Box @

Flow Washer “

Magnet

Spring

Battery Holder Q

Cable Extender, 15 ft. (optional)

Valve Bottom

Diaphragm (2)

Key

No.

25 7167683

26

27 7112434 Valve Center

28 7030721

29 7078127

30 7138676

31 0900044

32 7140869

33 7109910

34 7121954

35 7155018

36 7088033

37 7088041 Clamp Section (2)

38 7115610 O-ring, RO Cap

39 7167706

40 7124986

41 7011272

42

43 7095030

44 7167764 Flow Control

45

46

47 7147748

Part

No.

Connector, 1/8” NPT x114° Tube

7112442

7133838

71227’98

71

71

7063889 Tubing, 1/4” – order length needed

0010251 Tubing, 3/8” - order length needed

Valve Top

Screw, #10- 14x 1-3/4” (4)

Shutoff Assem., Incls.

Connector, 1/4” NPT x 1/4” Tube

Liner Assembly

O-ring, 5/16” x 7/16

Vacuum Relief Valve

Bladder

Ball-Check Kit

RO Housing, incls. key no. 34

Clamp Retainer

RO Cap

Elbow, 1/4” NPT x 1/4” Tube

Supply Saddle Valve @

Drain Clamp @

Cone Screen

Repl. RO Cartridge

Pre (Carbon) Filter

Cover Assembly

Description

(2)

21–23, 26-28

@ Includes key nos. 3,4, 5,7 and 8

@includes key nos. 17,18 and 19-orderbattery holder

if needed

@does not include batteries

@ Not included with RO. Not allowed in all localities.

Check your local codes.

Loading...

Loading...