Page 1

SAFETY

STABILITY DEVICE

WARNING- if the information in

this manual is not followed exacUy,

e fire or explosion may result caus-

ing property damage, personal in-

jury or death.

m Do not store, or use gasoline or other

flammable vapors and liquid in the vicinity

of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier from

a neighbor's phone. Follow the gas

supplier's Instructions.

• If you cannot reach your gas supplier,

call the fire department.

InstallaUon and service must be performad

by a qualified installer, service agency or

the gas supplier.

TOOL LIST

1.1/2", 1 3/16" and 1 3/8" open end or adjustable

wrenches

2. Pipe wrench

3. 1/8" and 1/4" flat blade screwdriver

4. Phillips screwdriver

5. Pliers

6. 1/4" socket or nut driver.

ADDITIONAL MATERIALS

Gas supply line shut-off valve

Pipe joint sealant

Flexible appliance connector (5 ft. In length) with two

flare union adaptors forconnection to supply line and

to 1/2" NPT pressure regulator.

WARNING

• ALL RANGES

CAN TiP

,INJURY TO PERSONS

COULD RESULT

• INSTALL ANTI.TIP

DEVICES PACKED

WITH RANGE

• SEE INSTALLATION

INSTRUCTIONS

REMOVE ALL PARTS FROM THE PLASTIC BAG AT-

TACHED TO THE BACK OF THE RANGE AND SAVE

PACKAGING TAPE.

INSTALLATION

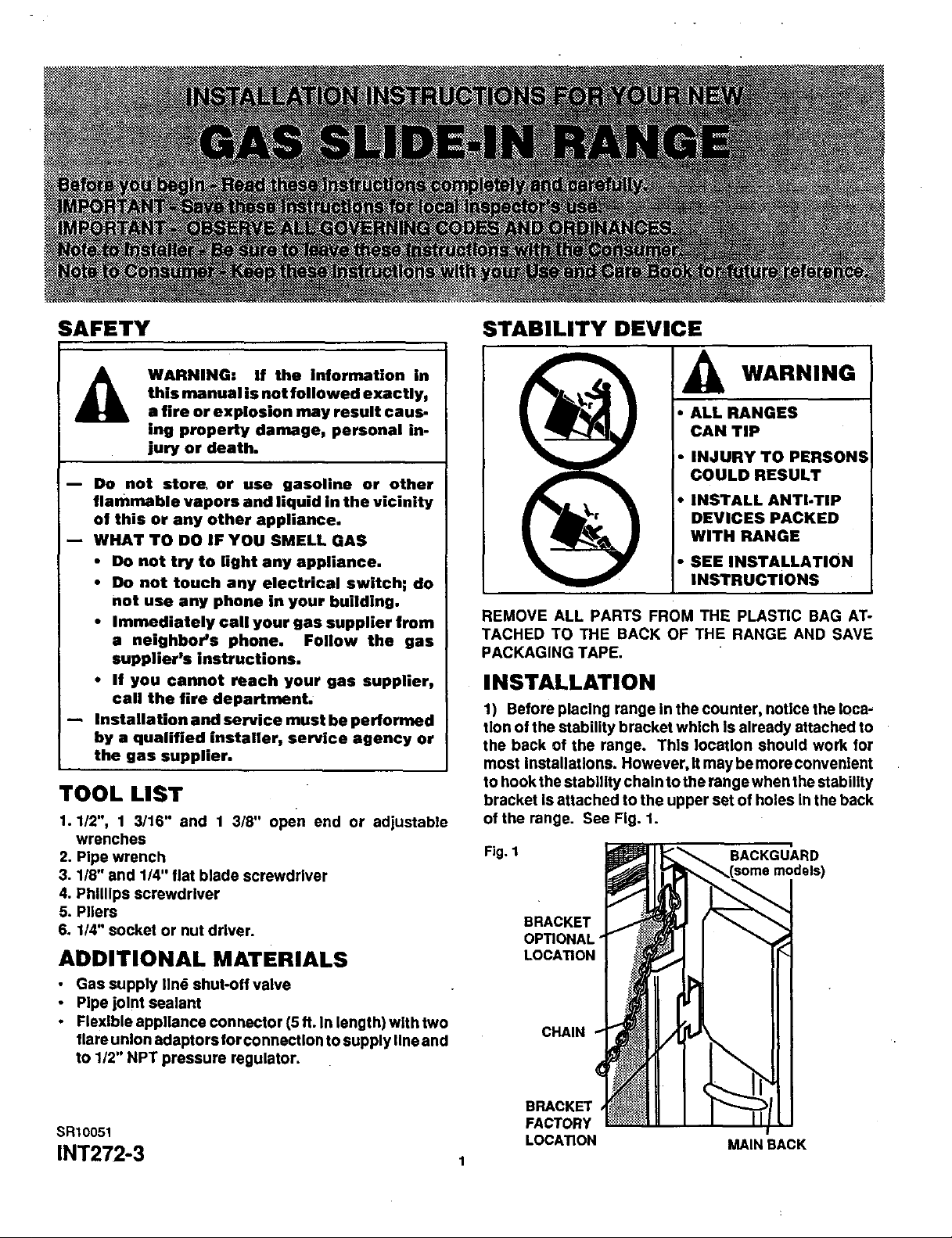

1) Beforeplaclng range ln the counter, noUcatheloca-

tion of the stability bracket which Is already attached to

the back of the range. This location should work for

most Installations. However, It may be more convenient

to hook the stability chain to the range when the stability

bracket Is attached to the upper set of holes In the back

of the range. See Fig. 1.

Fig. 1 BACKGUARD

BRACKET

OP_ONAL"

LOCA_ON

CHAIN

BRACKET

FACTORY

SR10051 LOCATION MAINBACK

INT272-3 1

Page 2

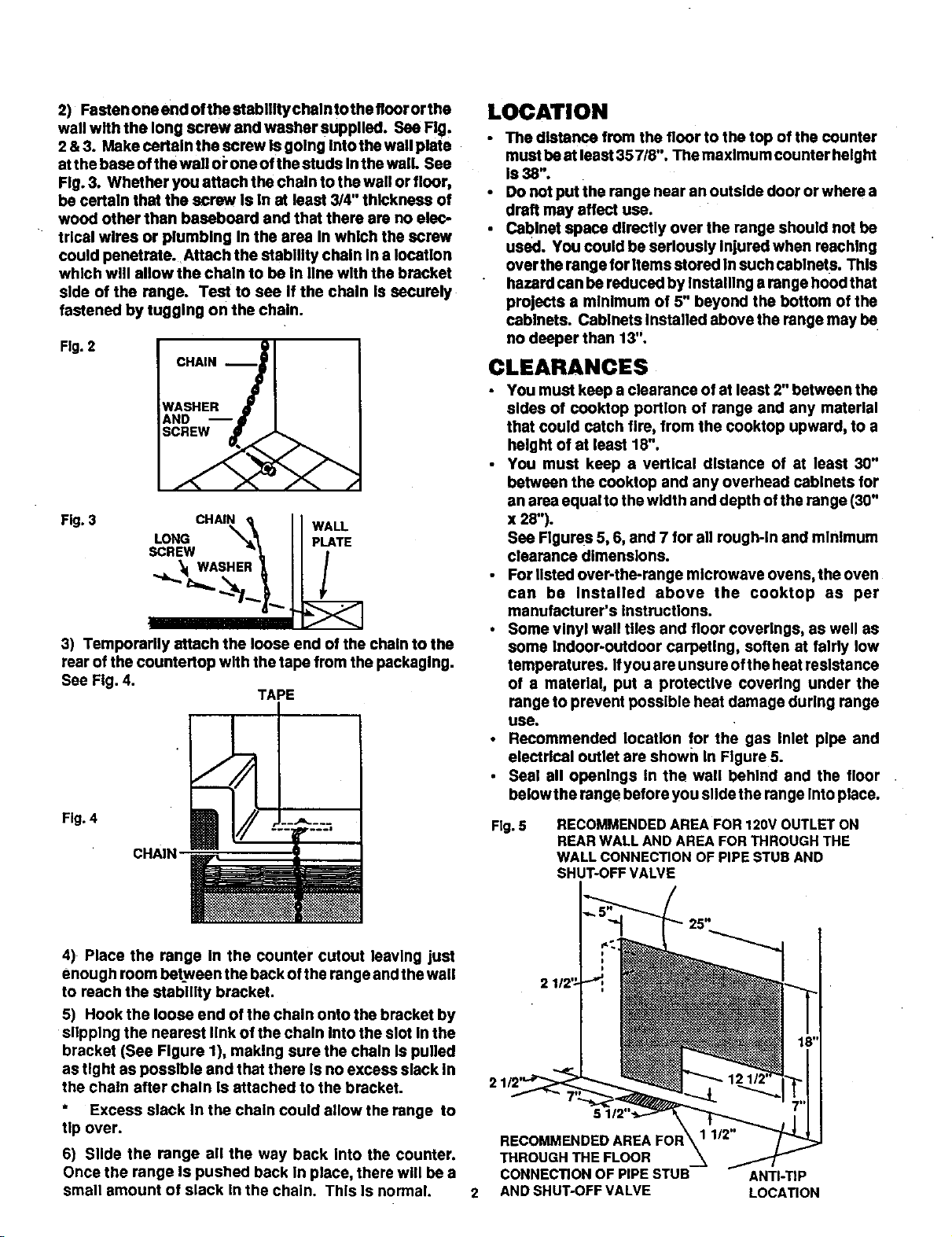

2) Fasten ono end ofthe stabllltychalntothe flnor orthe

wall with the long screw and washer supplied. See Fig,

2 & 3. Make certain the screw Is going Into the wall plate

atthe base of the wall oi"oneof the studs Inthe wall. See

Fig. 3. Whether you attach the chain to the wall or floor,

be certain that the screw Is In at least 3/4" thlcknese of

wood other than baseboard and that there are no elec-

trical wires or plumbing In the area In which the screw

could penetrate. Attach the stablllty chain In a location

which will allow the chain to be In line wlth the bracket

side of the range. Test to see If the chain Is securely

fastened by tugging on the chain.

Fig. 2

CHAIN_-_

WASHER 4r I

AND -- i I

Fig. 3 CHAIN _ WALL

WAS

3) Temporarily attach the loose end of the chain to the

rear of the countertop with the tape from the peckaglng.

See Fig. 4.

Fig. 4

TAPE

LOCATION

The distance from the floor to the top of the counter

must be at least 35718". The maximum counter height

IS38".

DOnot put the range near an outside door or where a

draft may affect use.

Cabinet space directly over the range should not be

used. You could be seriously Injured when reaching

over the range for items stored in such cablnets. This

hazard can be reduced by Installing a range hoodthat

projects a minimum o1 5" beyond the bottom of the

cabinets. Cabinets Installed above the range may be

no deeper than 13".

CLEARANCES

• You must keep a clearance of at least 2" between the

sides of cooktop portion of range and any matarlal

that could catch fire, from the cooktop upward, to a

height of at least 18".

You must keep a vertlcal distance of at least 30"

between the cooktop and any overhead cabinets for

an area equal to the width and depth of the range (30"

x 28").

See Figures 5, 6, and 7 for all rough-in and minimum

clearance dimensions.

• For listed over-the-range microwave ovens, the oven

can be Installed above the cooktop as per

manufacturer's Instructions.

• Some vinyl wall tiles and floor coverings, as well as

some Indoor-outdoor carpeting, soften at fairly low

temperatures. Ifyou are unsure ofthe heatresistance

of a materia!, put a protective covering under the

range to prevent possible heat damage during range

use.

• Recommended location for the gas Inlet plpe and

electrlcal outlet are shown In Figure 5.

• Seal all openings In the wall behind and the floor

belowthe range before you slide the range Into place.

Fig.5

RECOMMENDED AREA FOR 120V OUTLET ON

REAR WALL AND AREA FOR THROUGH THE

WALL CONNECTION OF PIPE STUB AND

SHUT-OFF VALVE

4) Place the range In the counter cutout leaving just

enough room between the back of the range and the wall

to reach the stability bracket.

5) Hook the loose end of the chain onto the bracket by

slipping the nearest link of the chain Into the slot In the

bracket (See Figure 1), making sure the chain Is pulled

as tight as possible and that there Is no excess slack In

the chain after chain is attached to the bracket.

* Excess slack In the chain could allow the range to

tip over.

6) Slide the range all the way back Into the counter.

Once the range Is pushed back In place, there will be a

small amount of slack In the chain. This Is normal.

THROUGH THE FLOOR

CONNECTION OF PIPE STUB ANTI-TIP

AND SHUT-OFF VALVE LOCATION

2

Page 3

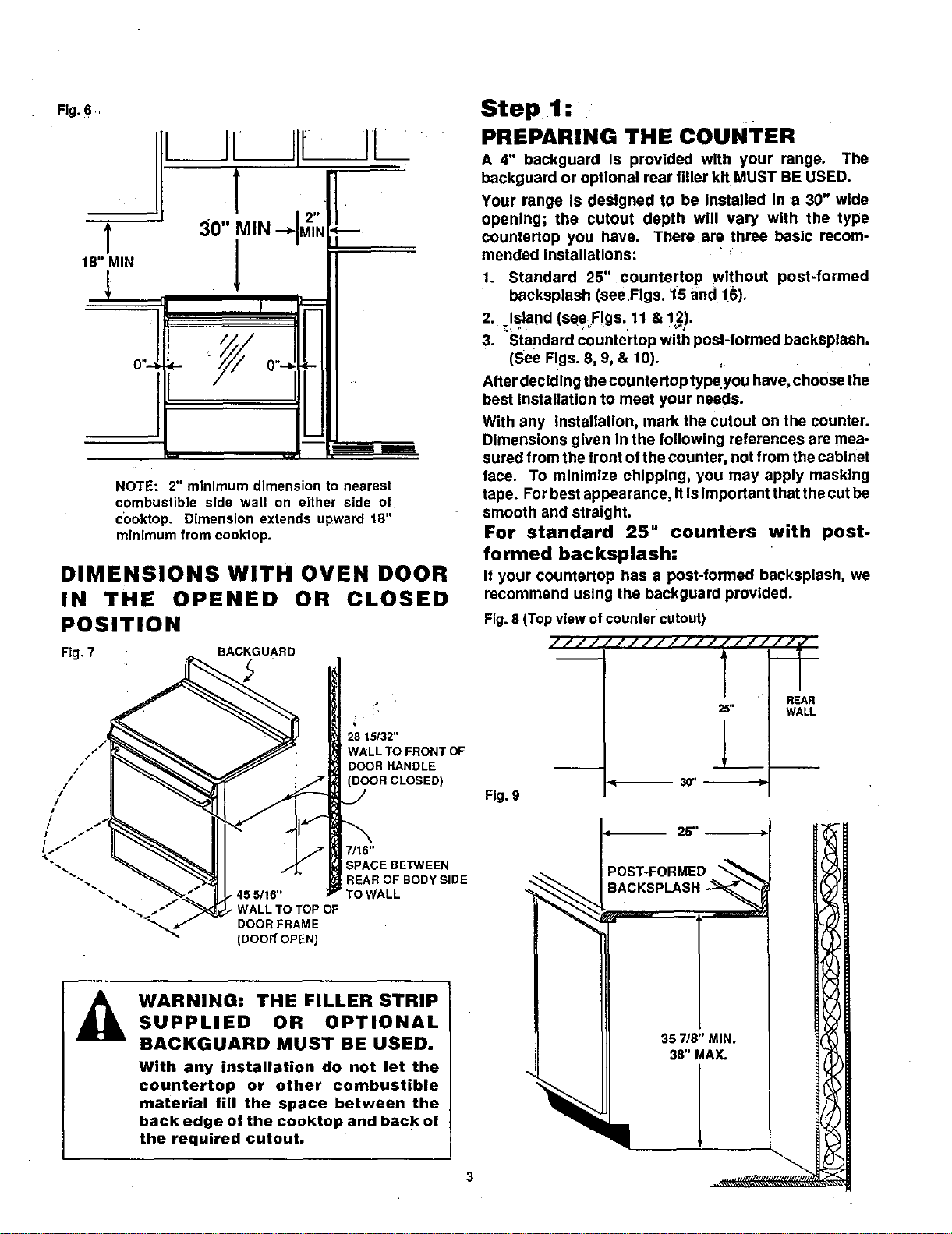

Fig.6

L

T

18" MIN

l

I

NOTE: 2" minimum dimension to nearest

combustible side wall on either side of.

c0oktop. Dimension extends upward 18"

minimum from cooktop.

DIMENSIONS WITH OVEN DOOR

IN THE OPENED OR CLOSED

POSITION

Fig. 7 BACKGUARD

Step 1:

PREPARING THE COUNTER

A 4" backguard Is provided with your range. The

backguard or optional rear lifter kit MUST BE USED.

Your range Is designed to be Installed In a 30" wide

opening; the cutout depth will vary with the type

countertop you have. There are three basic recom-

mended Installations: =_

1. Standard 25" countertop without post-formed

backsplash (see Figs. 15 and !6).

2. Island (seeFIgs. 11 & 12).

3. Standard countertop with post-formed backsplash.

(See Figs. 8, 9, & 10).

After decldln g the cou ntertop type you have, choose the

best installation to meet your needs.

With any Installation, mark the cutout on the counter.

Dimensions given In the following references are mea,

sured from the front of the counter, not from the cabinet

face. To minimize chipping, you may apply masking

tape. For best appearance, it Is important that the cut be

smooth and straight.

For standard 25" counters with post.

formed backsplash:

It your countertop has a post-formed backsplash, we

recommend using the backguard provided.

Fig. 8 (Top view of counter cutout)

//////////f/////,

J

//,/

//

/

/

, II1-

$

7

",. , 45 5/16"

_- , WALL TO TOP OF

_ WARNING: THE FILLER STRIP

SUPPLIED OR OPTIONAL

BACKGUARD MUST BE USED.

With any installation do not let the

countertop or other combustible

material fill the space between the

back edge of the cooktop and back of

the required cutout.

DOOR FRAME

(DOON OPEN)

.J

28 15/32"

WALL TO FRONT OF

DOOR HANDLE

(DOOR CLOSED)

7/16"

SPACE BETWEEN

REAR OF BODY SIDE

TO WALL

Fig. 9

-- 30' I --

25 °l __

_OST-FORMED__

BACKSPLASH--_

357/8"MIN.

38" MAX.

, I

l

REAR

WALL

3

Page 4

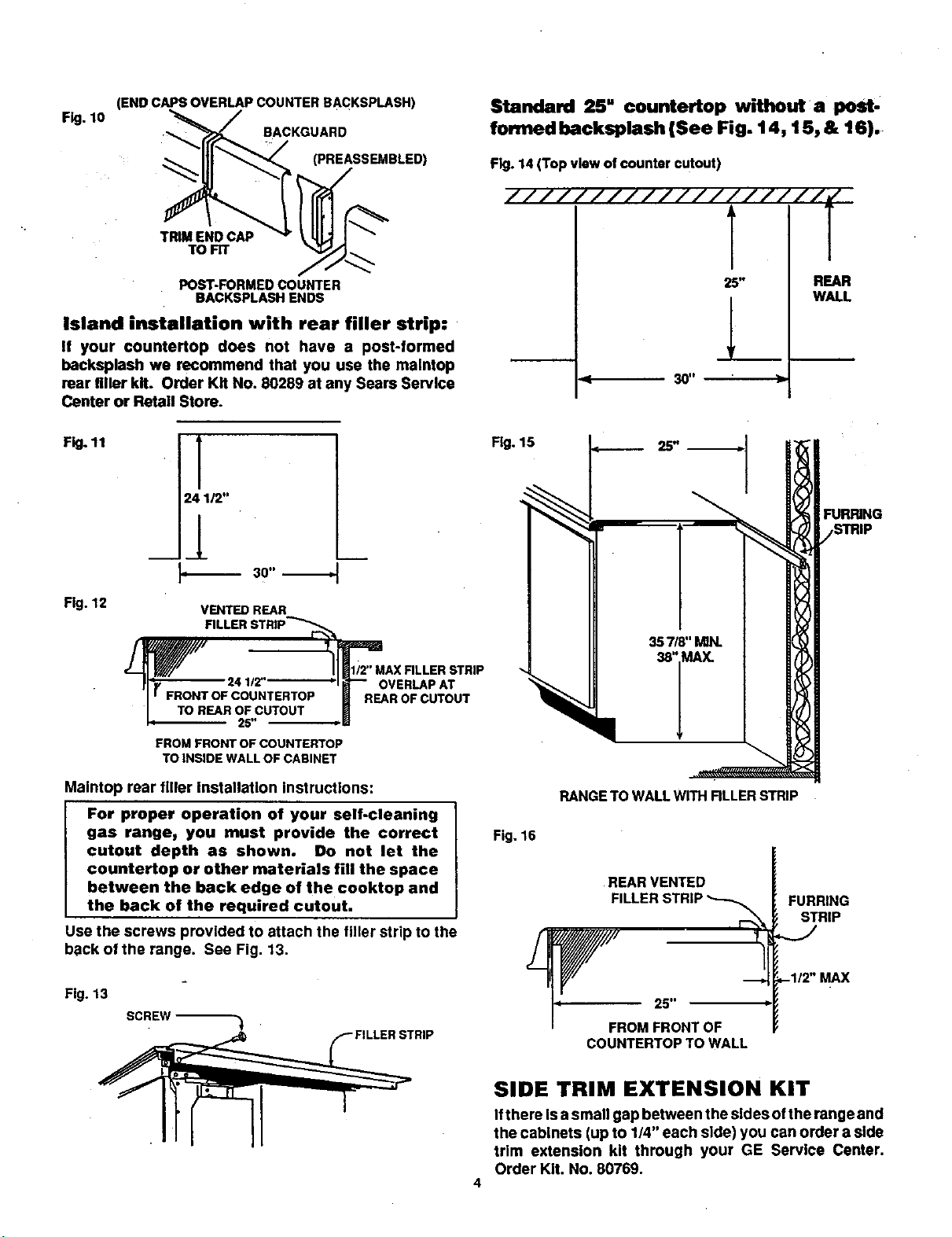

(END CAPS OVERLAP COUNTER BACKSPLASH)

F_g.10 formed backsplash (See Fig. 14, 15, & 16).

•_ BACKGUARD

Standard 25" countertop without a post,

(PREASSEMBLED)

TRIM END CAP

TOFIT

POST-FORMED COUNTER

BACKSPLASH ENDS

Island installation with rear filler strip:

If your countertop does not have a post-formed

backsplash we recommend that you use the maintop

rear filler kit. Order Kit No. 80289 at any Sears Service

Center or Retail Store.

Fig. 11

[

24 1/2"

30 °l

Fig. 12

VENTED REAR

FILLER STRIP'_

Fig. 14 (Top view of counter cutout)

////////I//////////J

T l

25" REAR

W,M.L

FUR_NG

r_ 24ll_'--------I _--- OVER_PAT

I I FRONTOFCOUNTERTOP m REAR OF CUTOUT

I TO REAR OF CUTOUT

I,I- 25" -Pl_

FROM FRONT OF COUNTERTOR

TO INSIDE WALL OF CABINET

Maintop rear filler Installation instructions:

For proper operation of your self.cleaning

gas range_ you must provide the correct

cutout depth as shown. Do not let the

countertop or other materials fill the space

between the back edge of the cooktop and

the back of the required cutout.

Use the screws provided to attach the filler strip to the

b;_ckof the range. See Fig. 13.

Fig. 13

SCREW ,_

RANGE TO WALL WITH RLLER STRIP

Fig. 16

REAR VENTED

FURRING

FILLER STRIP "_

25"

FROMFRONTOF

COUNTERTOPTO WALL

STRIP

,-1/2" MAX

SIDE TRIM EXTENSION KIT

Ifthere Is a small gap between the sides of the range and

the cabinets (up to 1/4" each side) you can order a side

trim extension kit through your GE Service Center.

Order Kit. No. 80769.

4

Page 5

Step 2:

ELECTRICAL CONNECTIONS

See Fig. 5 for compatible electrical locations.

Call your Electric Company and ask which codes apply

In your area. If there are no codes, you must follow the

NATIONAL ELECTRICAL CODE, ANSI/NFPA NO. 70-

Latest Edition. You can get a copy by writing:

National Fire Protection Association

Batterymarch Park

Quincy, MA 02269

The range cord has a three prong plug and must be

plugged Into a properly grounded three hole outlet. The

outlet must be In a standard 120 Volt, 60 Hertz AC

household circuit.

cut or remove the grounding prong

from the range cord. Failure to

J _, DO not under any circumstances J

Improper grounding can affect spark Ignition on models

so equipped.

If you do not have a grounded three hole outlet, have an

electrician change your old outlet or install a new one.

To temporarily use a properly polarized and grounded

two hole outlet until a grounded three hole outlet can be

Installed, a grounding adapter plug may be used. Have

an electrlclen test the outlet to be sure it meets require-

ments.

provide proper polarization may

cause shock and fire hazard.

Step 3:

GAS CONNECTIONS:

See Fig. 5 for compatible gas locations.

WARNING:

The conversion kit must be installed

by a qualified service technician in

accordance with the manufacturer's

instructions and all codes and

requirements of the authority having

jurisdiction.

Failure to follow instructions could

result in serious injury or property

damage. The qualified agency

performing the work assumes

responsibility for the conversion.

Call your gas supplier and ask which codes apply In

your area. If there are no codes, you must follow the

NATIONAL FUEL GAS CODE, ANSI/Z223.t-Latest Edi-

tion. You can get a copy by writing:

American Gas Assoclstlon

1515 Wilson Boulevard

Arlington (Rosslyn), VA 22209

Install a manual shut-off valve In the gas supply line In

an easily eccesslble location. Know how and where to

shut off the gas supply to the range.

Shut off gas supply before removing an old range.

Leave it off unUl hookup of new range Is finished.

Because solid pipe restricts moving the range, we rec-

ommend use of an A.G.A. certified metal appliance

connector. Never reuse an old connector when

installing a new range.

Before making gas connections, make sure that the

oven shut-off lever (visible at back of range) is in the

open position. See Figure 17.

F_.17 GAS SUPPLY

TO OVEN

The range, as shipped from the fac-

tory, can only be operated with natu-

ral gas. Do not try to operate it with

L.P. (bottled) gas. High flames and

toxic fumes could cause serious in-

jury. If you wish to use your range with

L.P. gas, you must purchase an L.P.

Conversion Kit and have it installed by

a qualified installer.

L.P. CONVERSION KIT

Your range is shipped from the factory set to operate

only with Natural Gas.

If you wish to use your range with Liquefied Petroleum

Gas, you can have your salesperson order Kit 80075 for

Model 36725 or Kit 80079 for Model 36729.

HOMEOWNER:

Do not attempt this conversion yourself!

SHUT-OFF LEVER

SHOWN IN

OPEN POSITION

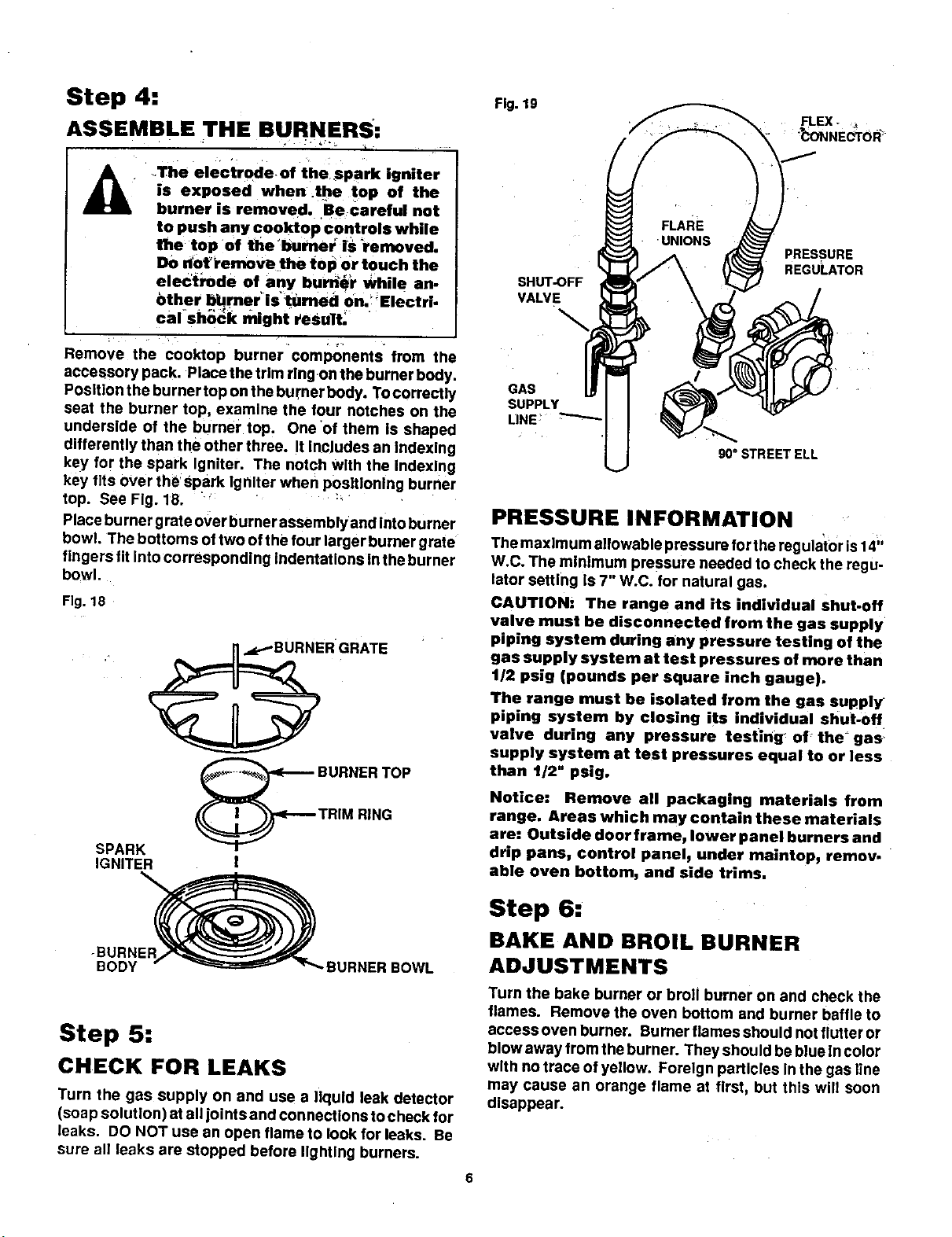

Install 1/2" flare union adaptor to the 1/2" NPT elbow on

pressure regulstor. Connect flexible appllence connec-

tor to flareunlon. Move range intoapproximate position

and connect flexible connector to gas supply line with

proper flare union adaptor. See Fig. 19.

To prevent gas leaks, put a pipe joint sealant on all male

threads.

When you are finished making connections, be surethat

all range knobs are turned to OFF before you open the

main gas supply valve.

5

GAS SUPPLY

TO TOP

BURNERS

PRESSURE

REGULATOR AS

SEEN FROM

FRONTOF RANGE

Page 6

Step 4:

ASSEMBLE THE BURNERS:

Fig. 19

_ The electrode of thespark igniter

accessory pack. Placethe trim rlng on the burner body.

Position the burner top on the burner body. To correctly

seat the burner top, examine the four notches on the

underside of the burner top. One of them Is shaped

differently than the other three. It IncJudes an indexing

key for the spark Igniter. The notch with the Indexing

key flts over th__spark Igniter when positioning burner

top. See Fig. 18. :'

Place burner grate over burner assemblyand intoburner

bowl. The bottoms of two of the four larger burner grate

fingers fit into corresponding indentations inthe burner

bowl.

Fig. 18

SPARK

IGNITER

is exposed when _the top of the

burner is removed. Becareful not

to push any cooktop controls while

tlhe top of the bumel: iS renlmved.

Do dot_Vemov_ the top Or touch the

electrode of any burn_'r While an_

bther bbrner_is't'umed onJ Eiectri

cal sh_k ndght reSult.

burner components theRemove the cooktoP _ from

ER'GRATE

BURNERTOP

TRIMRiNG

!

PRESSURE

REGULATOR

SHUT-OFF

VALVE

GAS

SUPPLY

LINE:

90° STREET ELL

PRESSURE INFORMATION

The maximum allowable pressure forthe regulator is14"

W.C. The minimum pressure needed to check the regu-

lator setting Is 7" W.C. for natural gas.

CAUTION: The range and its individual shut.off

valve must be disconnected from the gas supply

piping system during any pressure testing of the

gas supply system at test pressures of more than

1/2 psig (pounds per square inch gauge).

The range must be isolated from the gas supply

piping system by closing its individual shut-off

valve during any pressure testing _of' the _gas,

supply system at test pressures equal to or less

than t/2" psig.

Notice: Remove all packaging materials from

range. Areas which may contain these materials

are: Outside door frame, lower panel burners and

drip pans, control panelj under maintopj remov.

able oven bottom, and side trims.

-BURNER

BODY .BURNER BOWL

Step 5:

CHECK FOR LEAKS

Turn the gas supply on and use a liquid leak detector

(sospsolution) at all joints and connections to check for

leaks. DO NOT use an open flame to look for leaks. Be

sure all leaks are stopped before lighting burners.

Step 6:

BAKE AND BROIL BURNER

ADJUSTMENTS

Turn the bake burner or broil burner on and check the

flames. Remove the oven bottom and burner baffle to

access oven burner. Burner flames should not flutter or

blow away from the burner. They should be blue In color

with no trace of yellow. Foreign particles In the gas llne

may cause an orange flame at first, but this will soon

disappear.

Page 7

Fig.20

Fig. 22 ORIRCE

RTrlNG

COVER

UAJ,

YELLOW FLAMES

CALL FOR SERVICE

"a"

YELLOW

TIPPING

NORMAL FOR LP GAS

I_Cll

SOFT BLUE FLAMES

NORMALFORNATURALGAS

If burner flames look like "A", call for service. Normal

burner flames should look like =B"or =C", depending on

the type of gas you use.

With LP gas, some yellow tlpplng on outer cones Is

normal.

Foreign partlcles In the gas line may cause an orange

flame at first, but this will soon disappear.

If the flames are yellow or flutter, open the air shutter

more.

If the flames blow away from the burner, close the

shutter more. Burner flames should be checked fre-

quently.

To adjust air shutters:

Bake/broil burners, (see figures below)--use a screw-

driver to loosen the air shutter screw. Adjust airshutter.

Retlghten the air shutter screw.

*The broil burner Is located and accessible In the top

rear of the oven.

Fig. 21

BURNER

AIR

SHUTTER

AIR

SHUTTER

SCREW

AIR

SHUTrER

SCREW

Check the In ner cone of the flame. It should be between

1/2" and 3/4" long for the oven/broiler burners.

Fig. 23

INNER CONE

112"to3/4" J"

11F'L OVE BROiLER

f OF FLAME

AI

I

NOTE: After the air

shutter ad-

justments

have been

made to the

burners, be

sure to rein.

stall the ori.

lice fitting

cover.

Step 7:

COOKTOP BURNERS

Turn each burner full on. Flames should be blue In color

with no trace of yellow. Forelg n parUcles In the gas line

may cause an orange flame at first but this will soon

disappear. The burner flames should not flutter or blow

away from the burner. The Inner cone of the flame

should be between 1/2" and 3/4" long.

Fig. 24

COOKTOP

112"to3/4"

*The bake burner is located and accasslble by removing

the oven bottom, baffle (flame spreader), and the orifice

fitting cover.

NOTE: Removal of the oven door will make this

easier. To remove the door, open to the

stop position. Grasp both sides and lift

straight off the hinges.

NOTE: The cooktop burners are equipped with an

auto-relight feature which will light or

rel|ght the burners with the control knob

in any position except off. Drafts from

fans, open windows, or overhead vents

may disrupt the burner flame, resulting in

sparking of the top burner electrodes af-

ter the bumer has lit. See use and care

manual for additional information.

Page 8

Step 8:

LEVELING

For proper baking results, the range must be leveled.

The height of the range must also be adjusted to the

height of the counter. To do this:

1. Install theoven racks (ssa cleaning and care section

In the manual for Instructions and additional

Information).

2. Usa 1 3/8" open end or adjustable wrench to equatly

back out the tour leg levelers until the flanges (rims)

on the sides of the cooktop are above the top of the

counter.

3. Place range where It will he Installed. Put a spirit

level or a glass measuring cup partially filled with

water on one of the oven racks.

4. Use the wrench to adjust the leg levelers.

Fig.25

SPIRIT

LEVEL

Fig. 26

//

3"MAX. HEIGHT

This gap Isvery Important to the proper venUlstlon of the

range and must be maintained when treating the appear-

ance of the toe space.

The following Is a suggested method of making afiller for

the toe space when the legs are extended as mentlened

before.

After the range Is Installed with the longer legs and Is In

position and level, measure from the bottom of the

bodyslde to the floor. This will be the required belght of

the toe space filler. See Fig. 26. This height may range

from 2 1/16"to 3". Any height lessthan 2 1/16" may not

be visually objectionable and not need the filler.

"o." ]1// //

Step 9:

Double check to make sure anti-tip chain Is connected.

See pages I and 2.

IMPORTANT INSTALLATION IN-

STRUCTIONS FOR RANGES USED

WITH COUNTERTOP HEIGHTS UP

TO 38"

";'heheight of the range must beadjusted to the counter-

top height. For countertop heights greater than 37",

addltlenal measurements may need to be taken as

detailed below.

When the range Is elevated to the maximum height,

there Is a large space between the bottom of the range

and the floor, referred to as the toe space. This may be

visually objectionable. The legs should not be extended

any further than to provide a maximum of 3" toe space.

See Fig. 26.

The range Is deslg ned to provide amlBlmu_

at the bottom of the range. See Fig.27. (Example: When

legs are screwed all the way IntOlhLrb_'_-dT_ _

"MIN. HEIGHT

Build the filler as shown In Fig. 26. Make sure to provide

the 3/4" gap at the top and the 5/16" gap at the bottom.

These gaps will provide the proper ventilation as men-

tioned before.

If you wish to attach the filler to the floor or adjacent

cabinets, use screws or other removable fasteners, so

that the range can be readily removed if necessary.

Fig.28

J

USE 114" TO 1/2"

MATERIAL FINISHED

TO MATCH TOE AREA

OF CABINETS

SR10051

INT272-3 8

Printed in LaFayette, Georgia

Loading...

Loading...