Page 1

GE Fanuc Automation

Computer Numerical Control Products

Series 0 / 00 / 0-Mate

for Lathe

Parameter Manual

GFZ-61400E/03 November 1996

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages, currents,

temperatures, or other conditions that could cause personal injury exist in this equipment or

may be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a

Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL-001

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein

which are not present in all hardware and software systems. GE Fanuc Automation assumes

no obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

©Copyright 1996 GE Fanuc Automation North America, Inc.

All Rights Reserved.

Page 3

Preface

The models covered by this manual, and their abbreviations are:

.

Product Name

Abbreviations

FANUC Series 0-TC

FANUC Series 0-TF 0-TF

FANUC Series O-TX O-IX

FANUC Series 0-GCC

FANUC Series 00-TC 00-TC

FANUC Series OO-GCC OO-GCC

FANUC Series O-Mate TC

The table below lists manuals related to the Series O/00/0-Mate. In the table, this manual is marked with an asterisk (*).

Table 1 Manuals Related to the FANUC Series 0/00/O-Mate

FANUC Series O/00/0-Mate DESCRIPTIONS

FANUC Series O/OO/&Mate CONNECTION MANUAL

FANUC Series 0/00/O-Mate For Lathe OPERATOR’S MANUAL

FANUC Series O/OO/O-Mate For Machining Center OPERATOR’S MANUAL

FANUC Series O/00/0-Mate MAINTENANCE MANUAL

0-TC

I

0-GCC

O-Mate TC

Manual name

Series. 0

Series 00

Series O-Mate

Specification

Number

B-61 392E

B-61393E

&I 394E

B61404E

B-61 395E

FANUC Series O/00/0-Mate OPERATION AND MAINTENANCE HANDBOOK

FAN& Series O/OO/O-Mate For Lathe PARAMETER MANUAL

FANUC Series O/OO/O-Mate For Machining Center PARAMETER MANUAL

GRAPHIC CONVERSATION A FOR LATHE (Series 0-TF, Series 0-TC) OPERATOR’S MANUAL

GRAPHIC CONVERSATION B/C FOR LATHE (Series 0-TF, Series 0-TC) OPERATOR’S MANUAL

GRAPHICS CONVERSATION FOR MACHINING CENTER

(Series O-MC, Series O-MF, Series O-Mate MF) OPERATOR’S MANUAL

FANUC PMC-MODEL K/L/M/P PROGRAMMING MANUAL (LADDER LANGUAGE) ,

FANUC Series O/O-Mate PROGRAMMING MANUAL (Macro Compiler/Macro Executer)

B-61 397E

Bal400E *

B-61 41 OE

B-61 424E

B--61424E-1

B-61 434E

B-551 93E

B-61 393E-I

Page 4

CONTENTS

LIST OF PARAMETERS FOR EACH FUNCTION

1.

Parameters related to setting

2. Parameters related to the reader/punch interface/remote buffers

3. Parameters related to controlled axes/increment systems

4. Parameters related to coordinate systems

5. Parameters related to stroke limits

6. Parameters related to the feedrate

7. Parameters related to acceleration/deceleration control

8. Parameters related to the servo system

9. Parameters related to Dl/DO

10. Parameters related to CRT/MDI, display, and editing

11. Parameters related to programs

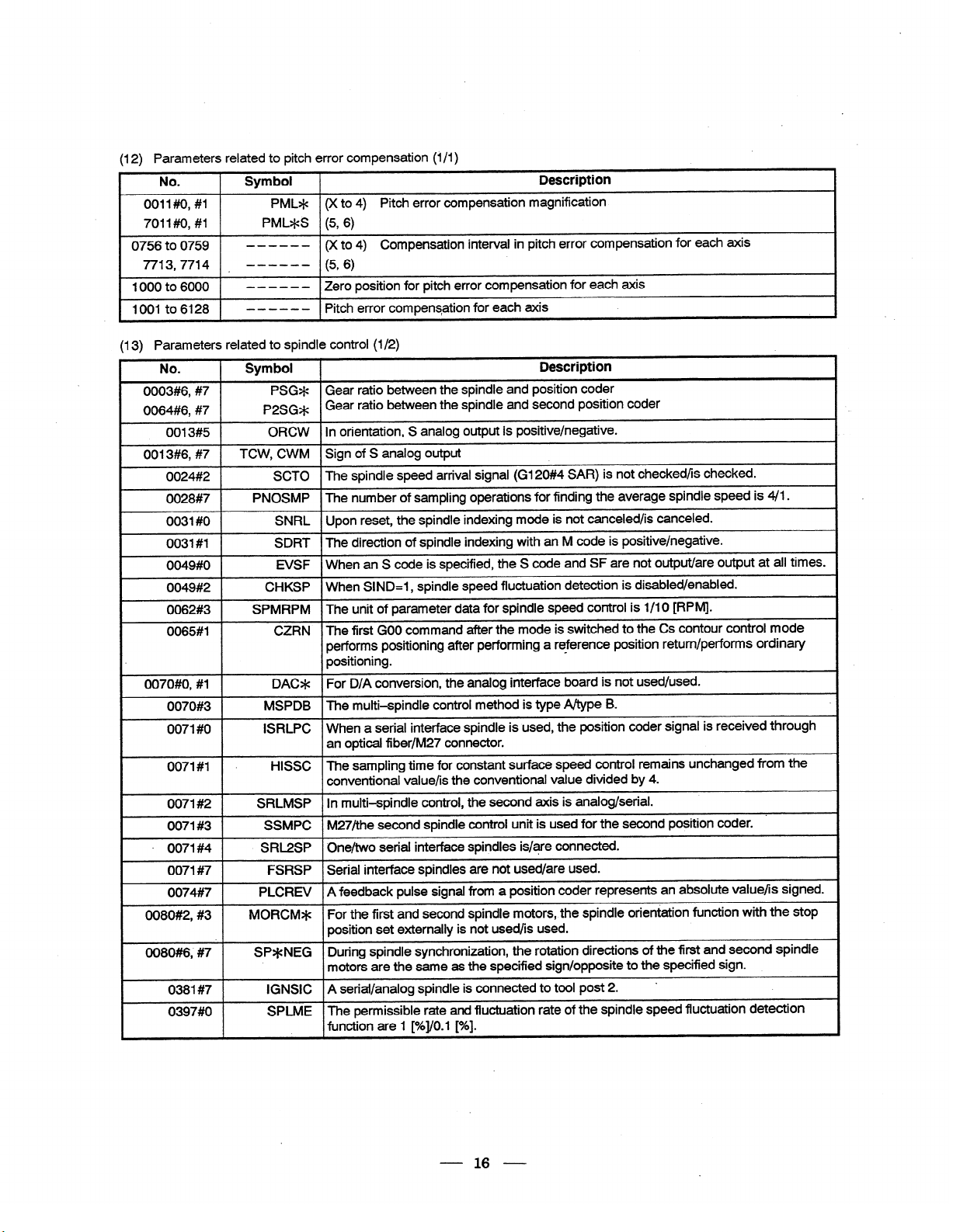

12. Parameters related to pitch error compensation

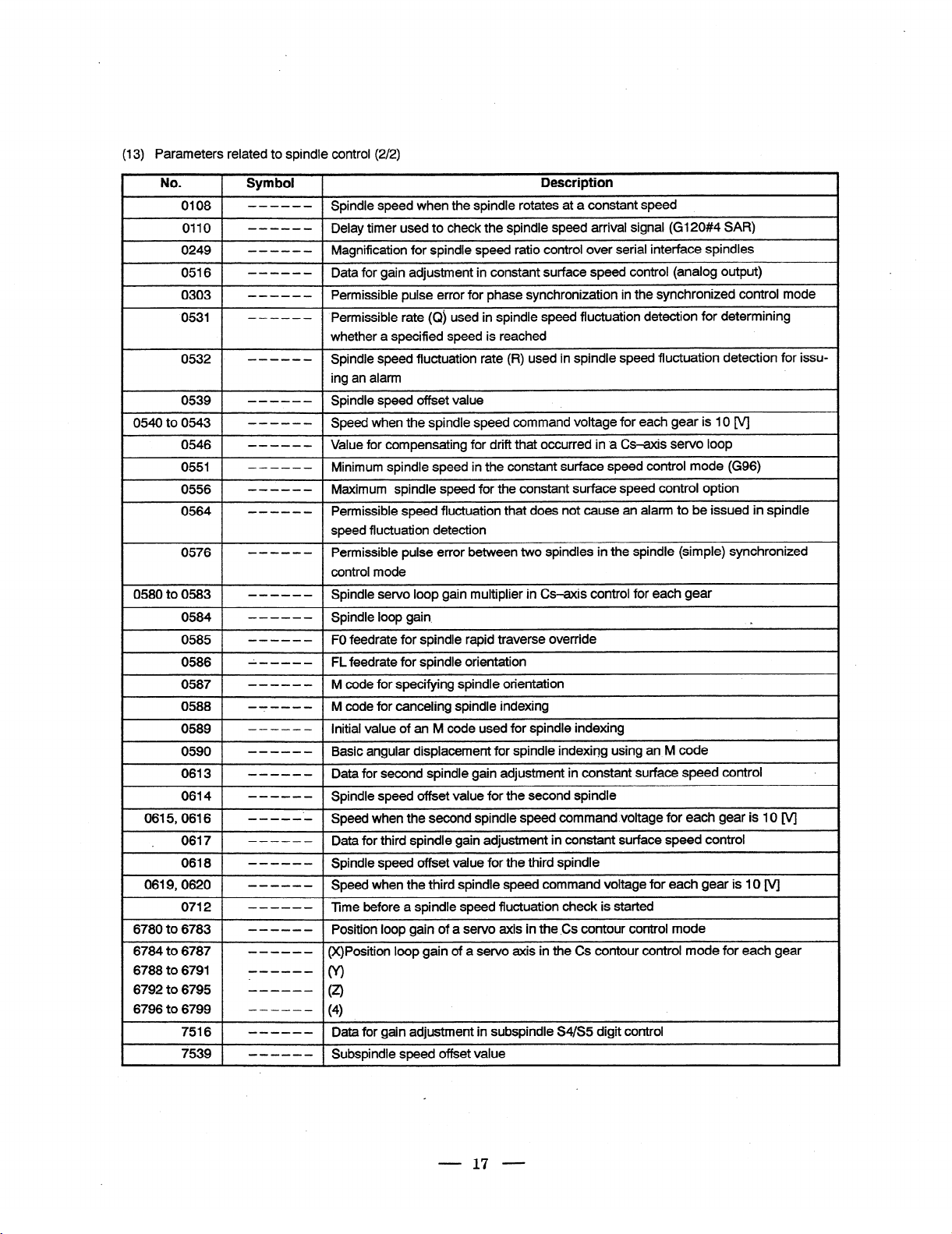

13. Parameters related to spindle control

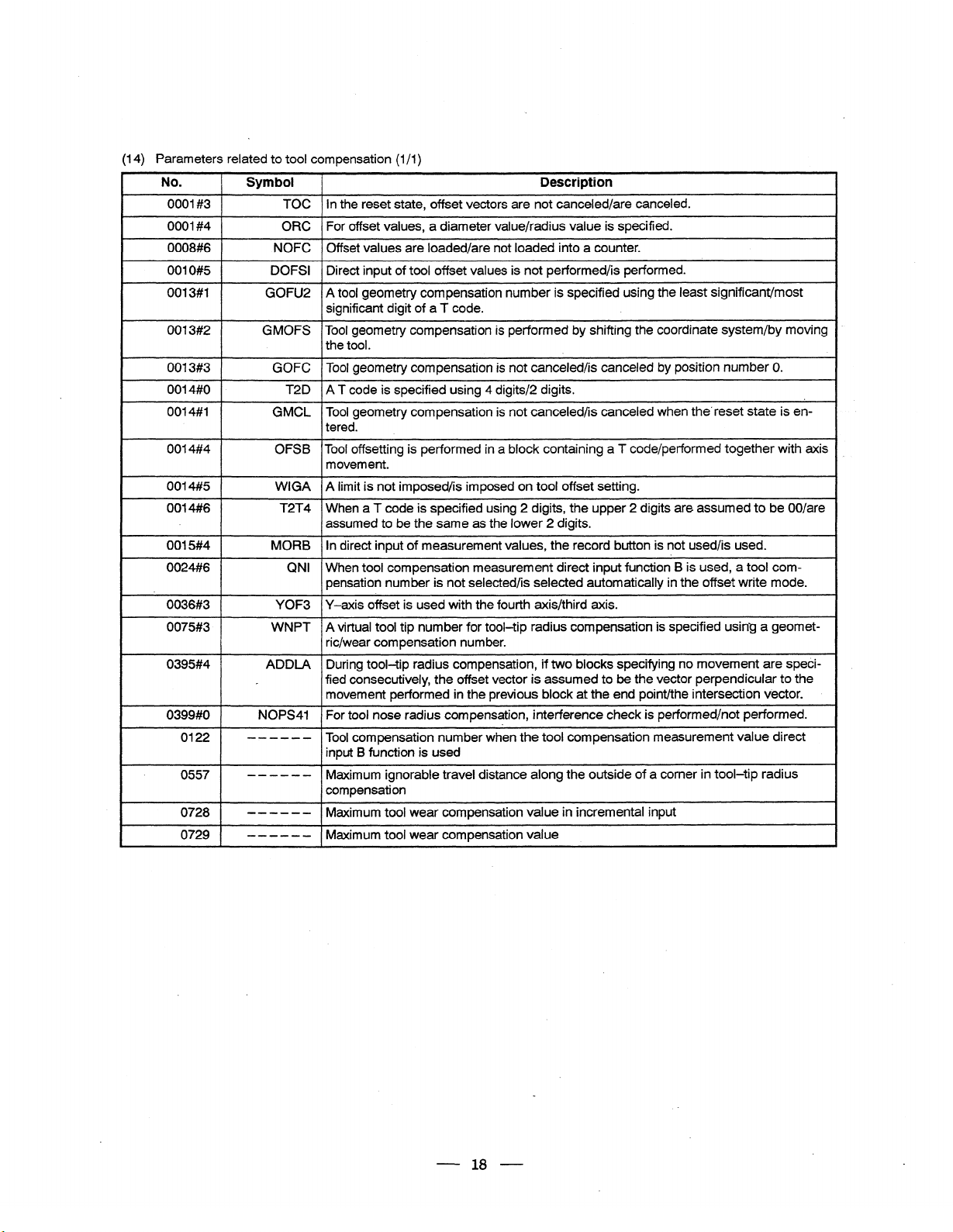

14. Parameters related to tool compensation

15. Parameters related to canned cycles

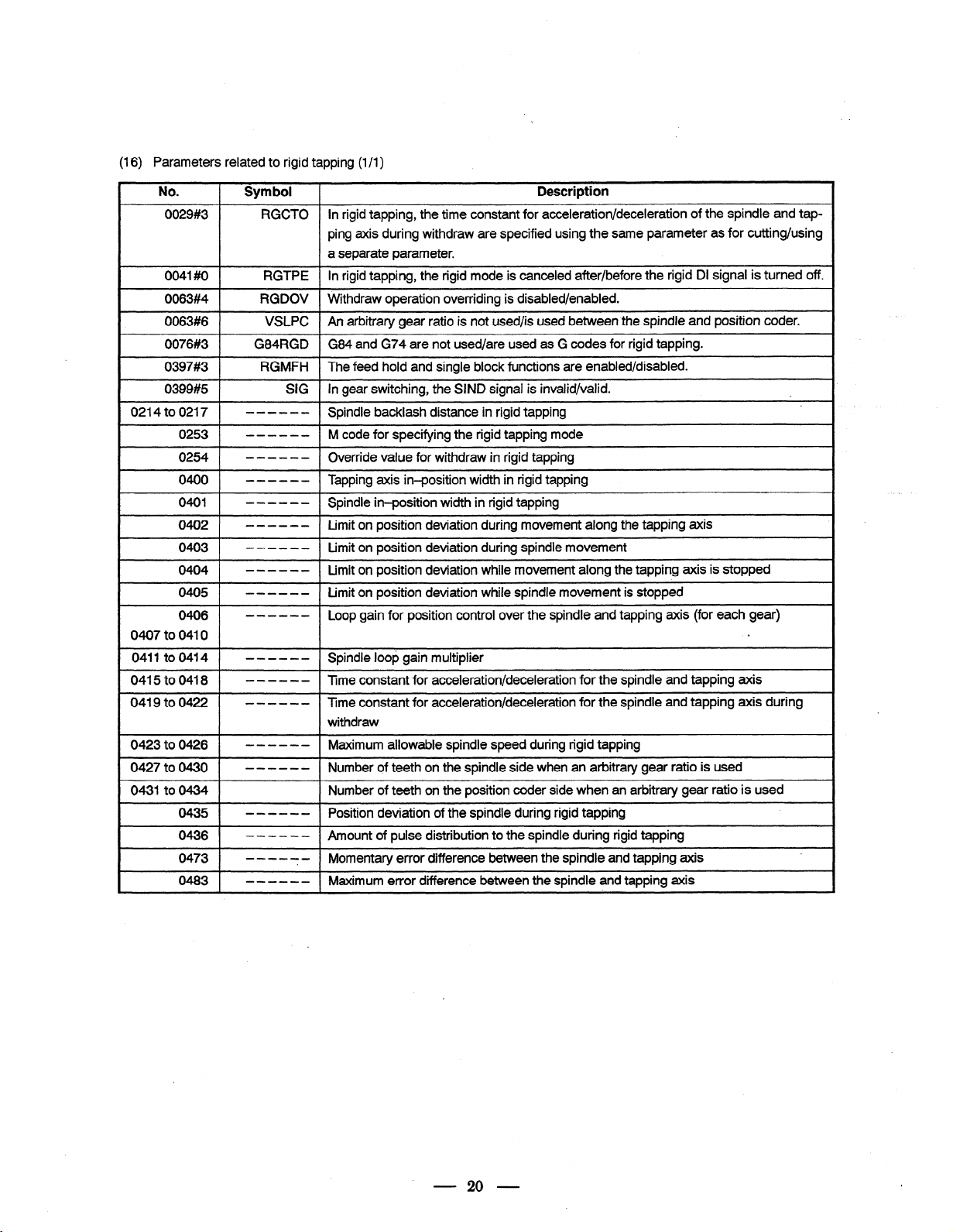

16. Parameters related to rigid tapping

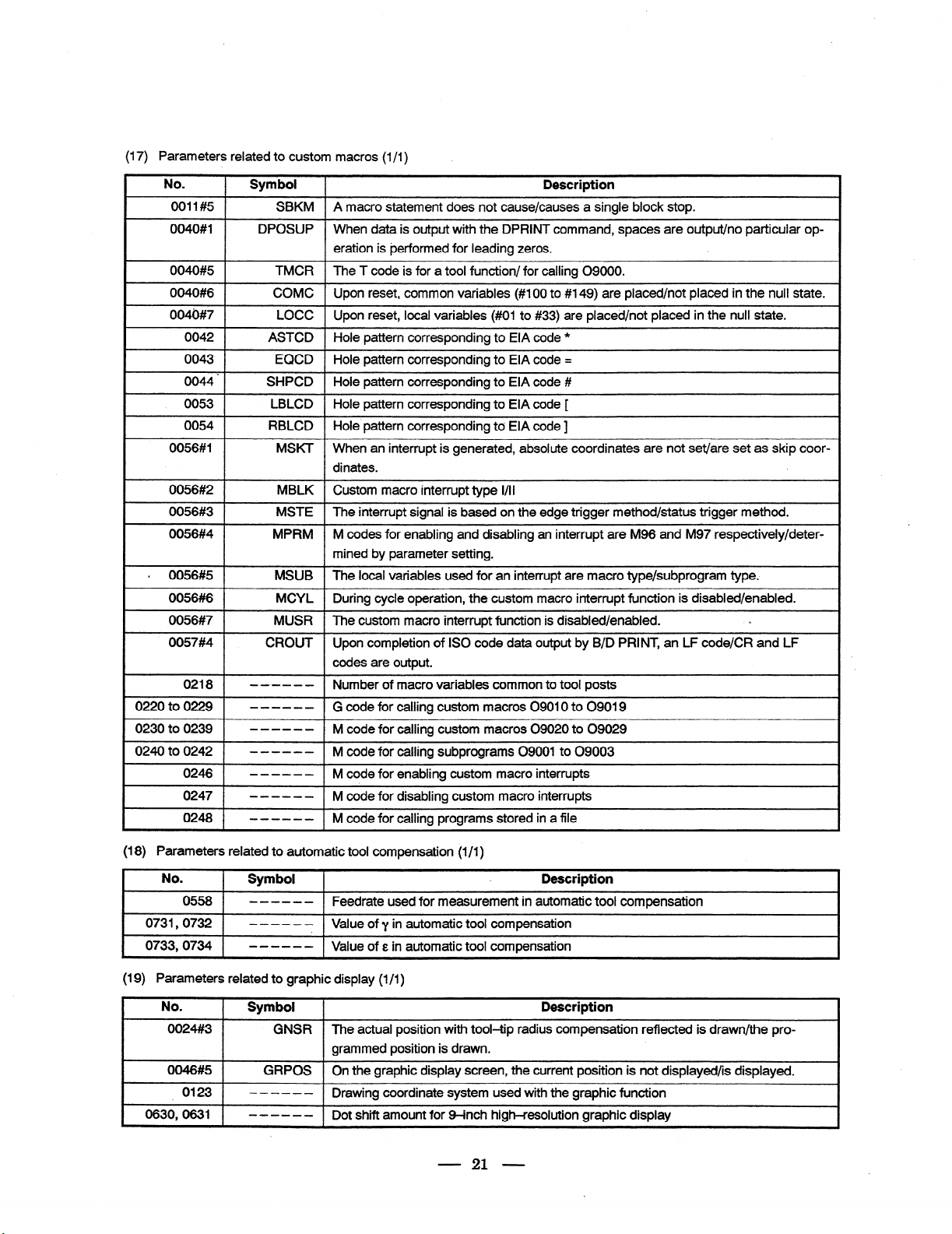

17. Parameters related to custom macros

18. Parameters related to automatic tool compensation

;i 9. Parameters related to graphic display

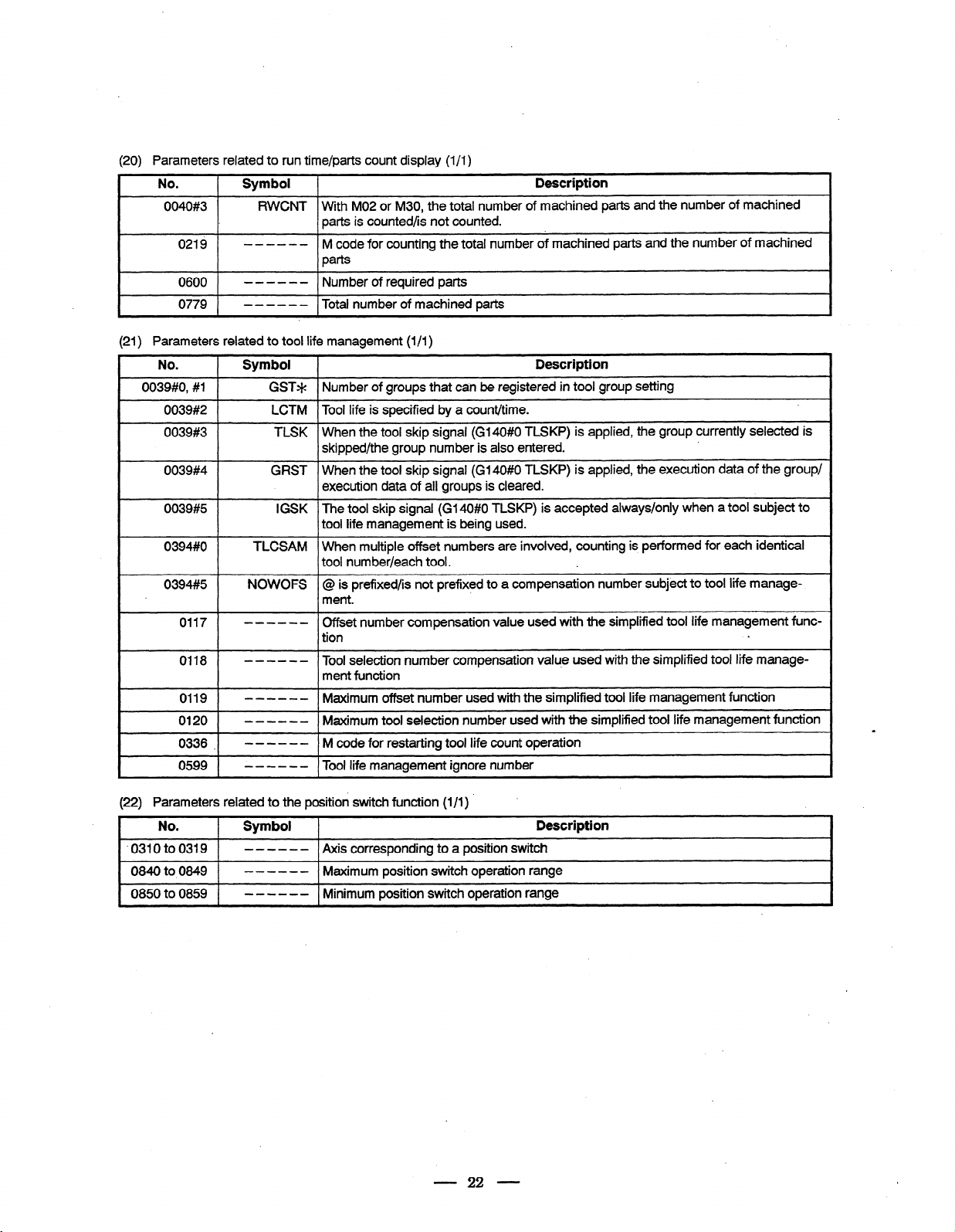

20. Parameters related to run time/parts count display

21. Parameters related to tool life management

22. Parameters related to the position switch function

23 . . Parameters related to manual handle feed/manual handle interrupt

24. Parameters related to the software operator’s panel

25. Parameters related to restarting programs

26. Parameters related to high-speed cycle machining/high-speed remote buffers

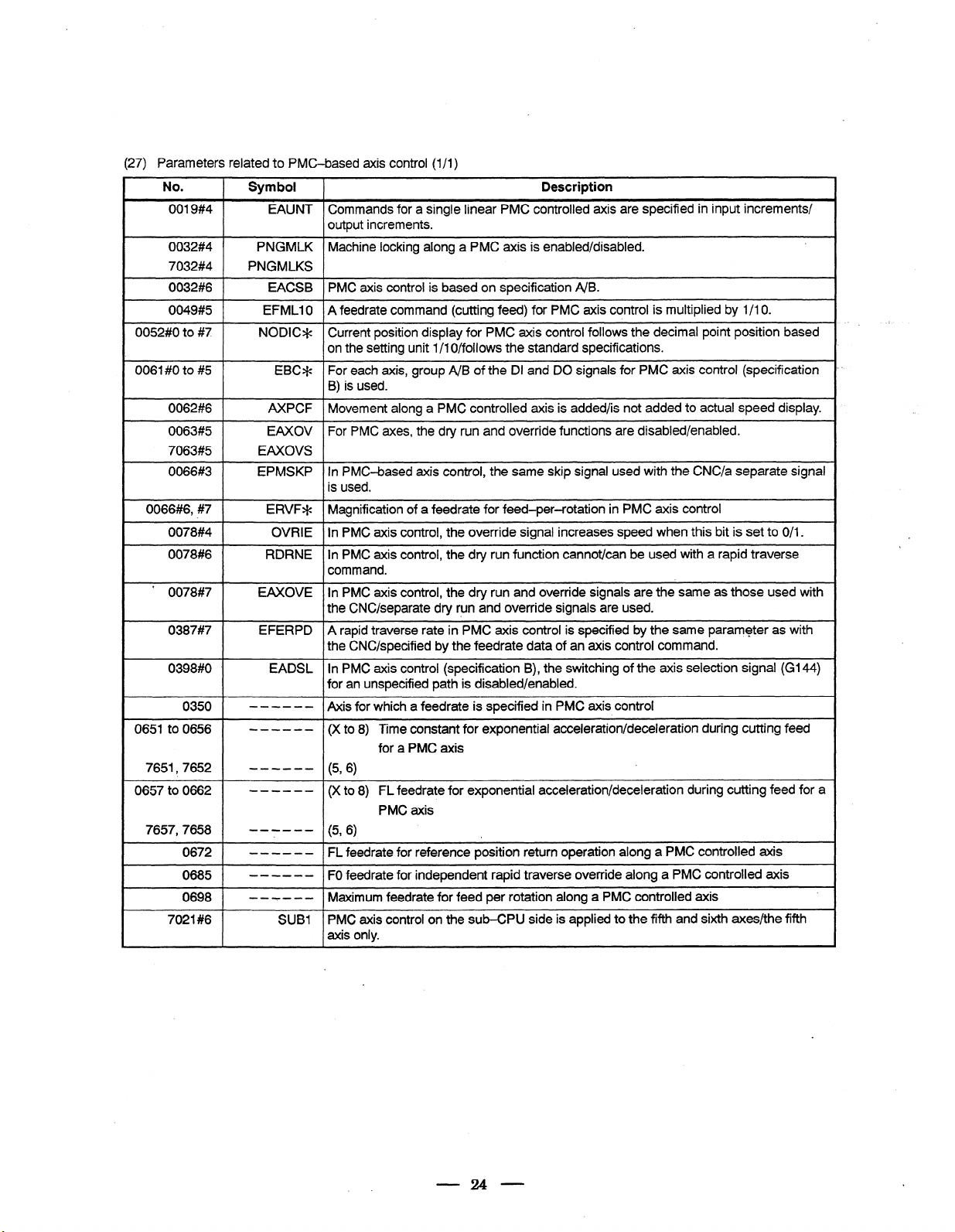

27. Parameters related to PMGbased axis control

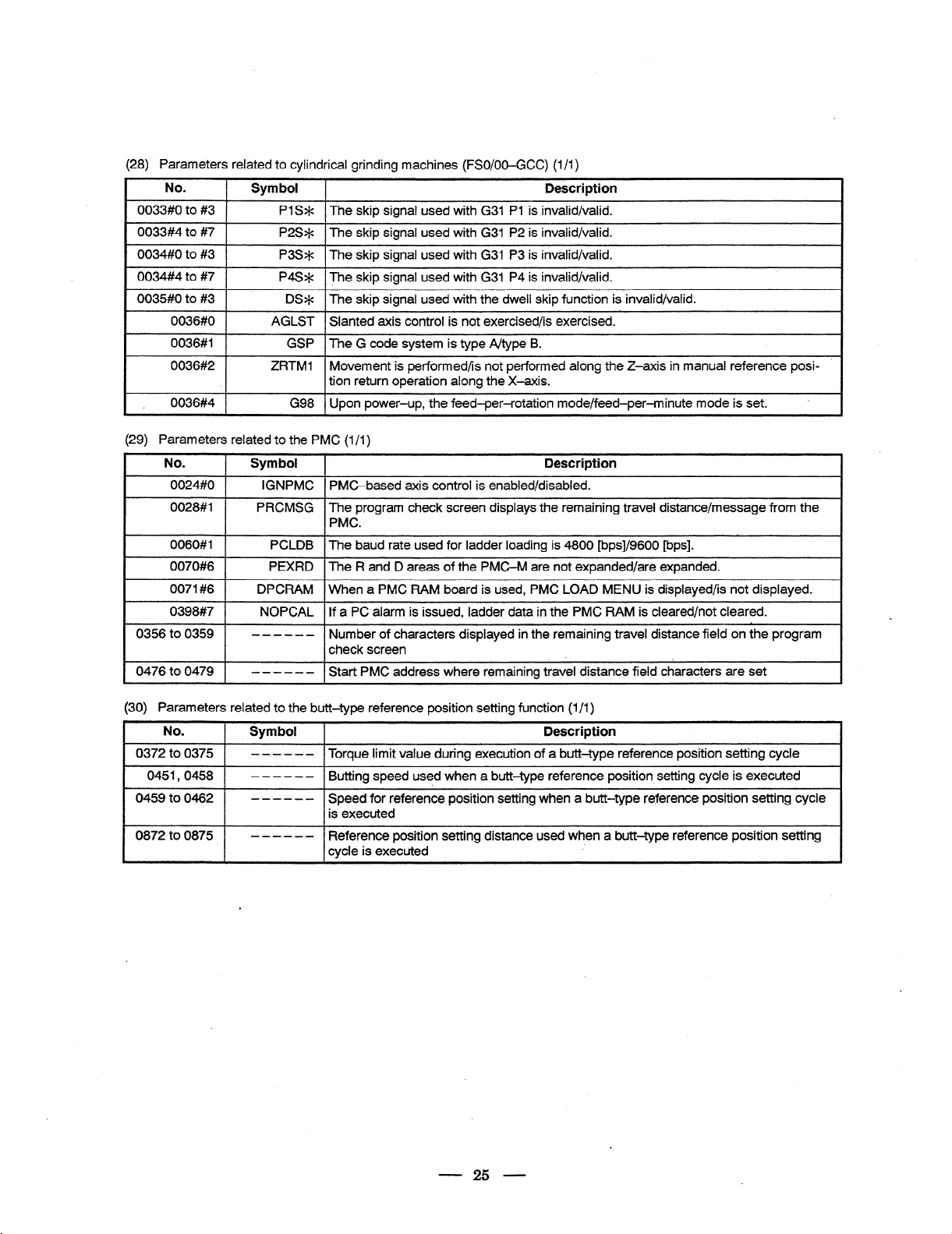

28. Parameters related to cylindrical grinding machines (FS O/OO-GCC)

29. Parameters related to the PMC

30. Parameters related to the butt-type reference position setting function

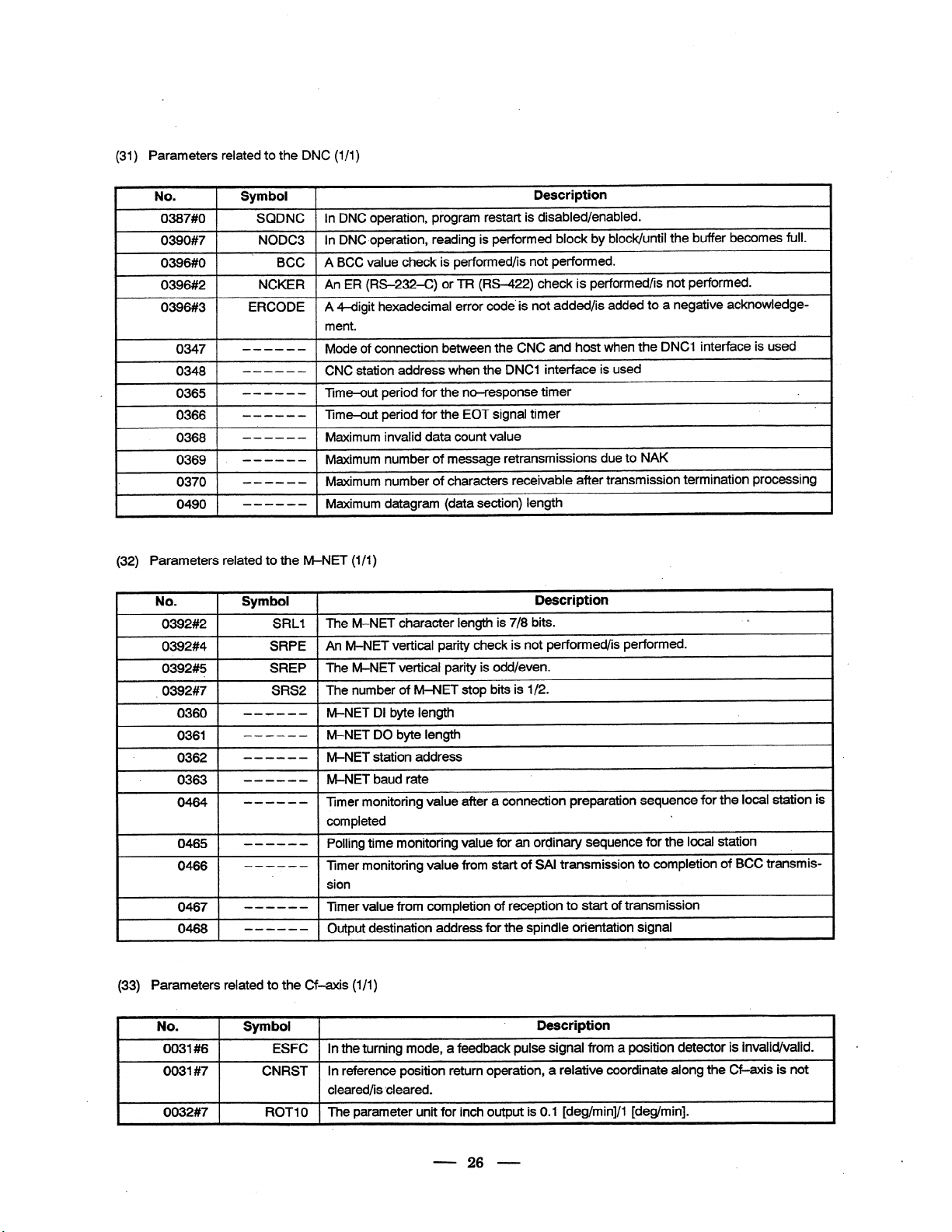

31. Parameters related to the DNC

32. Parameters related to the M-NET

33. Parameters related to theCf-axis

34. Parameters related to 2-path lathes (TT)

35. Parameters related to polygon turning

36. Parameters related to synchronized control/axis recomposition

........................................................................ 2

.................................................................... 6

...............................................................

............................................................... 9

........................................................................ 11

.....................................................................

................................................................ I6

................................................................. 19

..................................................................

................................................................

................................................................ 21

.....................................................................

......................................................................

...................................................................

.................................................................... 26 .

................................................................

...................................................

.......................................... 3

................................................ 4

............................................................. 5

.................................................. 8

................................................

.......................................................

.............................................................

....................................................

....................................................... 22

...........................................................

.........................................

......................................

...................................................

............................................................ 23

........................................................ 24

..................................... 25

............................................................. 27

.......................................... 28

.... 7

1

..

i

12

15

16

18

20

21

21

22

..........

.:

22

23

23

............................ 23

25

................................... 25

26

26

28

1

PARAMETER DESCRIPTION

I. Setting method

2. Terminology

3. Cautions..

...................................................................................

.......................................................................................

.......................................................................................

SE-l-l-ING PARAMETER

................................................................... 29

........................................................................ 31

SPECIFICATIONS OF ADDITIONAL PARAMtERS

29

29

30

............................................. 101

Page 5

List of Parameters for each Function

The Parameters for each function is the following.

Parameters related to setting

Parameters related to the reader/punch interface/remote buffers

Parameters related to controlled axes/increment systems

Parameters related to coordinate systems

Parameters related to stroke limits

Parameters related to the feedrate

Parameters related to acceleration/deceleration control

Parameters related to the servo system

Parameters related to Dl/DO

Parameters related to CRT/MDI, display, and editing

Parameters related to programs

Parameters related to pitch error compensation

Parameters related to spindle control

Parameters related to tool compensation

Parameters related to canned cycles

Parameters related to rigid tapping

Parameters related to custom macros

Parameters related to automatic tool compensation

Parameters related to graphic display

Parameters related to run time/parts count display

Parameters related to tool life management

Parameters related to the position switch function

Parameters related to manual handle feed/manual handle interrupt

Parameters related to the software operator’s panel

Parameters related to restarting programs

Parameters related to high-speed cycle machining/high+peed remote buffers

Parameters related to PMC-based axis control

Parameters related to cylindrical grinding machines (FSO/O&GCC)

Parameters related to the PMC

Parameters related to the butt-type reference position setting function

Parameters related to the DNC

Parameters related to the M-NW

Parameters related to the Cf-axis

Parameters related to 2-path lathes (IT)

Parameters related to polygon turning

Parameters related to synchronized control/axis recomposition

For details, see “Parameter Explanation”.

In the explanation of each bit parameter, the left-hand side of a slash (I) indicates the state when the bit is set

to 0, and the right-hand side of a slash indicates the state when the bit is set to 1.

Example: The current setting is O/l.

.

1

Page 6

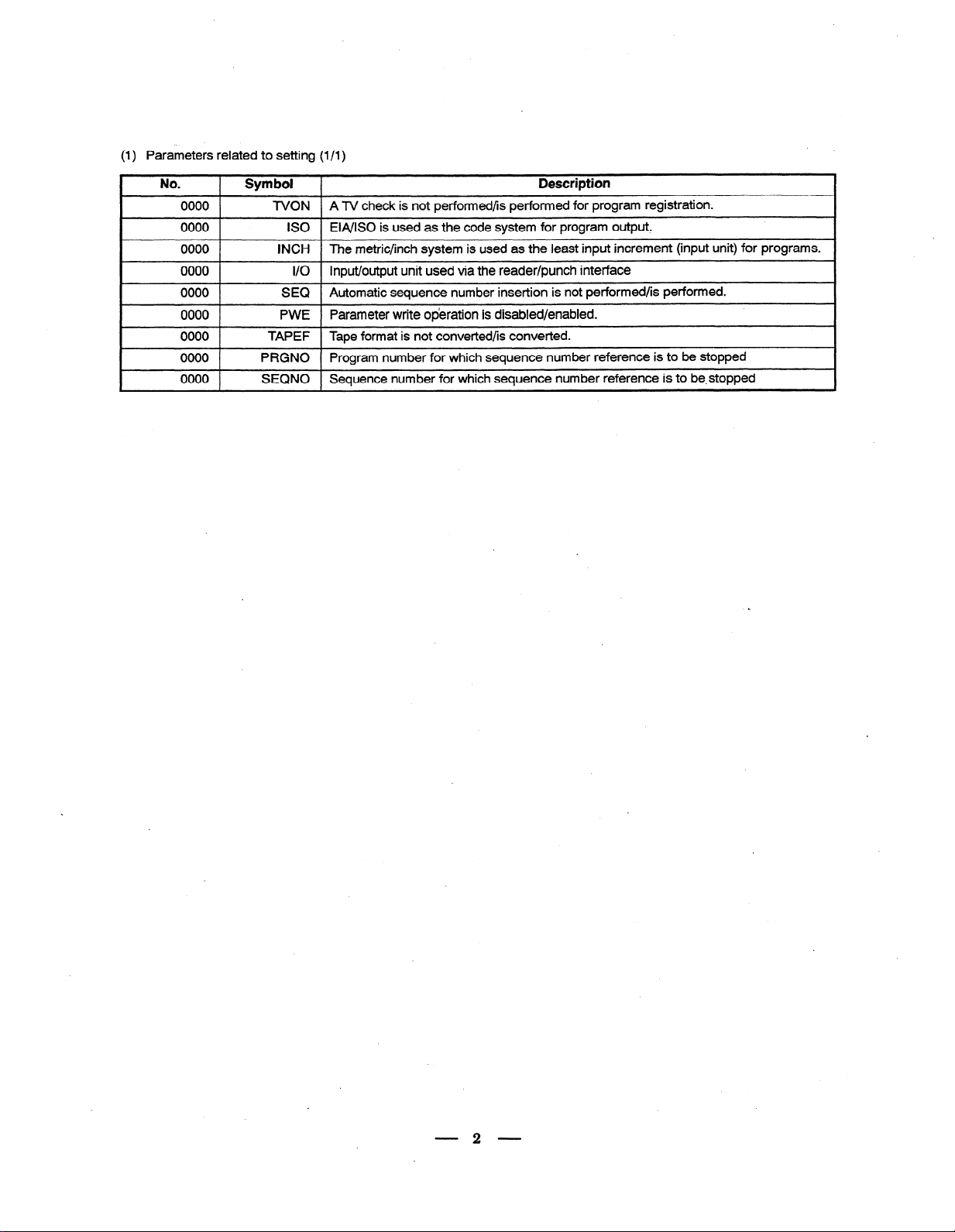

(1) Parameters related to setting (l/l )

I

I

I

r

I

No.

1 Symbol 1 Description

0000 1

0000

0000 INCH The metric/inch system is used as the least input increment (input unit) for programs.

0000 1

0000 1

0000 1 PWE 1 Parameter write operation is disabled/enabled.

0000 1 TAPEF I Tape format is not converted/is converted.

TVON 1 A TV check is not performed/is performed for program registration-.

IS0 EIA/ISO is used as the code system for program output,

I/O 1 Input/output unit used via the reader/punch interface

SEQ 1 Automatic sequence number insertion is not performed/is performed.

00001 PRGNOlogram number for which sequence number reference is to be stopped

0000 1 SEQNOI Sequence number for which sequence number reference is to be. stopped

2

Page 7

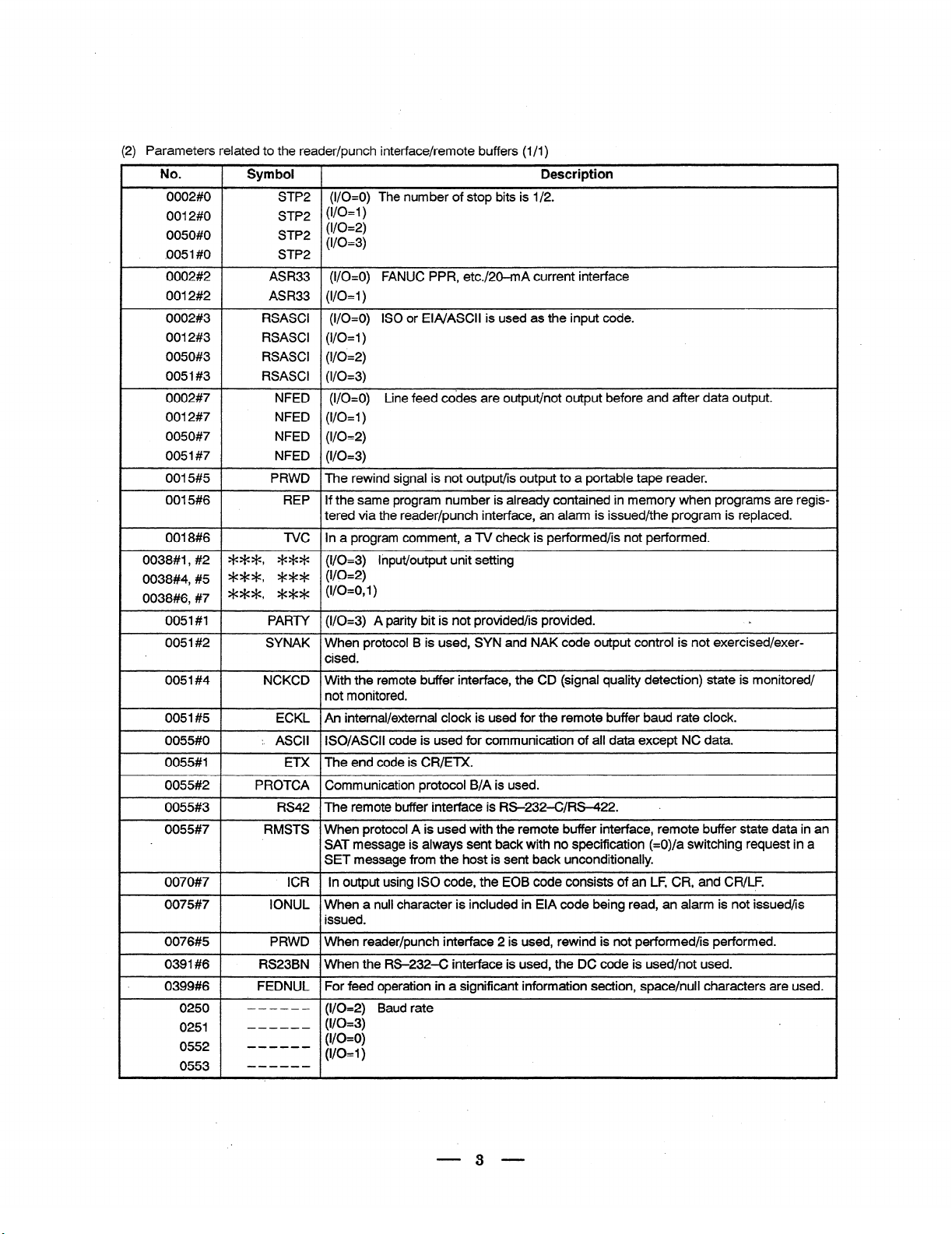

(2) Parameters related to the reader/punch interface/remote buffers (l/l)

No.

0002#0 STP2 (I/0=0) The number of stop bits is l/2.

0012#0

0050#0

.0051 #O STP2

0002#2 ASR33 (I/0=0) FANUC PPR, etcJ2O-mA current interface

0012#2 ASR33 (I/0=1)

0002#3 RSASCI (I/0=0) IS0 or EIA/ASCII is used as the input code.

0012#3 RSASCI (l/0=1)

0050#3

0051#3

0002#7

0012#7 NFED (I/0=1)

0050#7 NFED (l/0=2)

0051#7

0015#5 PRWD The rewind signal is not output/is output to a portable tape reader.

0015#6 REP If the same program number is already contained in memory when programs are regis-

0018#6 TVC In a program comment, a TV check is performed/is not performed.

0038#1, #2 *Wk, *W (l/0=3) Input/output unit setting

OO38#4, #5 ‘k’k*, *** (l/0=2)

0038#6, #7

0051#1

0051#2

0051#4

0051#5

0055#0

0055#1 ETX The end code is CR/ETX.

0055#2

0055#3

0055#7

0070#7

0075#7 IONUL When a null character is included in EIA code being read, an alarm is not issued/is

0076#5

0391#6 RS23BN When the RS-232-C interface is used, the DC code is used/not used.

0399#6 FEDNUL For feed operation in a significant information section, space/null characters are used.

0250

0251

0552

0553

Symbol

STP2 (l/0=1 )

STP2 (l/o=2)

RSASCI (l/0=2)

RSASCI (l/0=3)

NFED (I/0=0) Line feed codes are output/not output before and after data output.

NFED (l/0=3)

***, *** WO=o,l)

PARTY (l/0=3) A parity bit is not provided/is provided.

SYNAK When protocol B is used, SYN and NAK code output control is not exercised/exer-

NCKCD With the remote buffer interface, the CD (signal quality detection) state is monitored/

ECKL An internal/external clock is used for the remote buffer baud rate clock.

(l/0=3)

tered via the reader/punch interface, an alarm is issued/the program is replaced.

cised.

not monitored.

:. ASCII ISO/ASCII code is used for communication of all data except NC data.

PROTCA Communication protocol B/A is used.

RS42 The remote buffer interface is RS-232-C/RS-422.

RMSTS When protocol A is used with the remote buffer interface, remote buffer state data in an

PRWD When reader/punch interface 2 is used, rewind is not performed/is performed.

- - - - - - (l/0=2) Baud rate

------

------ (I/0=1)

------

SAT message is always sent back with no specification (=0)/a switching request in a

SET message from the host is sent back unconditionally.

ICR In output using IS0 code, the EOB code consists of an LF, CR, and CR/LF.

issued.

(l/0=3)

(l/0=0)

Description

.

L

3

Page 8

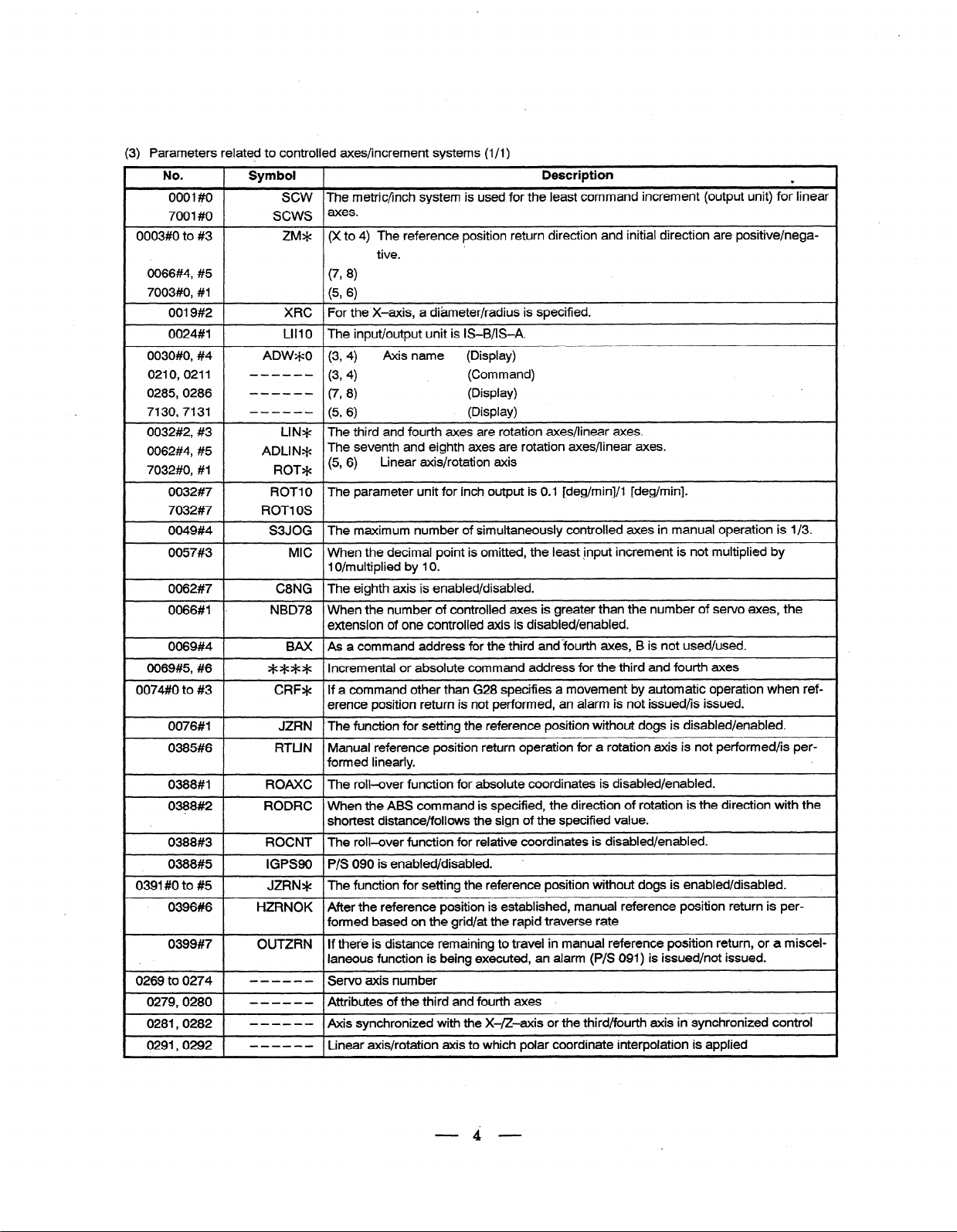

(3) Parameters related to controlled axes/increment systems (l/l)

No.

Symbol

Description

0001 #O SCW The metric/inch system is used for the least command increment (output unit) fo;linear

7001 #O sews axeS*

0003#0 to #3 ZM* (X to 4) The reference position return direction and initial direction are positive/nega-

tive.

0066#4, #5

7003#0, #l

(7, 8)

(596)

0019#2 XRC For the X-axis, a dikmeter/radius is specified.

0024#1

0030#0, #4

0210,0211

0285,0286

7130,7131

LIIlO The input/output unit is IS-B/IS-A.

ADW*O (3, 4)

Axis name (Display)

------ (3,4) (Command)

------ (7, 8) (Display)

------ (5, 6)

(Display)

0032#2, #3 LIN* The third and fourth axes are rotation axes/linear axes.

0062#4, #5

7032#0, #I ROT* (5’ 6,

0032#7

7032#7

ADLlN.+ The seventh and eighth axes are rotation axes/linear axes.

Linear axis/rotation axis

ROT1 0 The parameter unit for inch output is 0.1 [deg/min]/l [deg/min].

ROT1 OS

0049#4 SSJOG The maximum number of simultaneously controlled axes in manual operation is l/3.

0057#3

MIC When the decimal point is omitted, the least @put increment is not multiplied by

1 O/multiplied by 10.

0062#7 C8NG The eighth axis is enabled/disabled.

0066#1 NBD78 When the number of controlled axes is greater than the number of servo axes, the

extension of one controlled axis is disabled/enabled.

0069#4 BAX As a command address for the third and fourth axes, B is not used/used.

0069#5, #6 **** Incremental or absolute command address for the third and fourth axes

0074#0 to #3 CRF* If a command other than G28 specifies a movement by automatic operation when ref-

erence position return is not performed, an alarm is not issued/is issued.

0076#1 JZRN ‘The function for setting the reference position without dogs is disabled/enabled.

0385#6 RTUN Manual reference position return operation for a rotation axis is not performed/is per-

formed linearly.

0388#1 ROAXC The roll-over function for absolute coordinates is disabled/enabled.

0388#2 RODRC When the ABS command is specified, the direction of rotation is the direction with the

shortest distance/follows the sign of the specified value.

0388#3

ROCNT The roll-over function for relative coordinates is disabled/enabled.

0388#5 IGPS90 P/S 090 is enabled/disabled. .

0391 #O to #5 JZRN* The function for setting the reference position without dogs is enabled/disabled.

0396#6 HZRNOK After the reference position is established, manual reference position return is per-

formed based on the grid/at the rapid traverse rate

0399#7

OUTZRN If thet’e is distance remaining to travel in manual reference position return, or a miscel-

laneous function is being executed, an alarm (P/S 091) is issued/not issued.

3269 to 0274 ------ Servo axis number

0279,028O - - - - - - Attributes of the third and fourth axes

0281,0282 - - - - - - Axis synchronized with the X-/Z-axis or the third/fourth axis in synchronized control

9291,0292 - - - - - - Linear axis/rotation axis to which polar coordinate interpolation is applied

Page 9

(4) Parameters related to coordinate systems (l/l)

No.

0002#1 PPD Relative coordinates are not preset/are preset by coordinate system setting.

0010#6

0010#7 APRS Automatic coordinate system setting is not performed/is performed in manual refer-

7010#7

0028#5

0075#6 CLCL The local coordinate system is not canceled/is canceled in manual reference position

0388#6 WKZRST In workpiece coordinate system setting, the workpiece coordinate system is not re-

0388#7 WKZSFT The workpiece shift and offset from the external workpiece reference point are not.

0708 to 0711 - - - - - - (X to 4) Reference position coordinates in automatic coordinate system setting

0815 to 0820 ------ (Xto8)

0825,0826 ------ (7, 8)

7708,7709 ------ (5, 6)

0735 to 0738

0866,0867 ------ (7, 8)

0780 to 0783

0868,0869

0784 to 0787

0870,087l

0788 - - - - - - Travel distance per rotation of a rotation axis

0940 to 0943

0944 to 0947 - - - - - - Cffset from the first workpiece reference point for each axis (G54)

0948 to 0951 - - - - - - Cffset from the second workpiece reference point for each axis (G55)

0952 to 0955 - - - - - - Offset from the third workpiece reference point for each axis (G56)

0956 to 0959 - - - - - - Offset from the fourth workpiece reference po.int for each axis (G57)

0960 to 0963 - - - - - - Cffset from the fifth workpiece reference point for each axis (G58)

0964 to 0967 - - - - - - Cffset from the sixth workpiece reference point for each axis (G59)

7717 - - - - - - Machine coordinate system when the fifth/sixth axis is a rotation axis

Symbol

WSFT Workpiece coordinate system shift operation is not performed/is performed.

APRSS ence position return operation.

RSFT In direct input of a workpiece coordinate system shift amount, a diameter value/radius

value is entered for the value of MX.

return.

turned/is returned to G54 by an NC reset.

stored/are stored in the same memory location.

- - - - - - (X to 4) Distance of the second reference position from the first reference position

- - - - - - (X to 4) Distance of the third reference position from the first reference position

------ (7, 8)

- - - - - - (X to 4) Distance of the fourth reference position from the first reference position

------ (7, 8)

.- - - - - - Offset from the external workpiece reference point for each axis

I

Description

L.

-5-

Page 10

(5) Parameters related to stroke limits (1 /I )

No.

0015#2

0020#4

0024#4

0065#3

0076#7

0079#7

0700 to 0703

0821,0822

7700,770l

0704 to 0707

0823,0824

7704,7705

0747 to 0748

.0751 to 0752

0760 to 0761

0764 to 0765

0770 to 0773

0774 to 0777

0988 to 0993

7721,7722

0994 to 0999

7723,7724

Symbol Description

COT2 The hardware overtravel signals (XOl8#5 *+Lz, XO40#6 *-lZS) are valid/invalid.

LM2 The switching signal for the second stored stroke limit is invalid/valid.

INOUT The out-of-range area of the third stored stroke limit is the inside/outside.

PSOT A stored stroke limit check is performed/is not performed until reference position return

I

operation is performed.

OTRFOM An alarm is issued after/before a stroke limit is exceeded.

MTCHK Upon power-on, shift of the machine position is not checked/is checked.

------

’

------

------ (5, 6)

- - - - - - (X to 4) First stored stroke limit in the negative direction for each axis

------ (7, 8)

------ (5, 6)

- - - - - - Third stored stroke limit in the positive direction for each axis

- - - - - - Third stored stroke limit in the negative direction for each axis

- - - - - - Fourth stored stroke iimit in the positive direction for each axis

- - - - - - Fourth stored stroke limit in the negative direction for each axis

- - - - - - Second stored stroke limit in the positive direction for each axis

- - - - - - Second stored stroke limit in the negative direction for each axis

- - - - - - (1 to 4, 7,8) Maximum allowable machine position shift for each axis

------ (1 to 4, 7, 8) Machine position prior to power-off for each axis

(X to 4)

(798)

(596)

(596)

First stored stroke limit in the positive direction for each axis

*

\ -(j--

Page 11

(6) Parameters related to the feedrate (l/l)

No.

0001#6

7001#6

0008#4

0008#5

001 O#O

0015#3

0041#2

0049#6

0049#7

0059#0, #I

0058#3, #4

0065#5

0077#5

0393#5

0394#1

0397#2

0399#2

0518 to 0521

0643,0644

7518,7519

0527

0528

0530

7530

0533

7533

0534

7534

0548

0559 to 0562

0605 to 0608

0628

0636

0657 to 0662

7657,7658

Symbol

RDRN

RDRNS

MFPR

ROVE

SKPF

ZRNJF

NPRV

FMLI 0

EDP*

EDM*

G92zAX

MICRF

.

STOVO

TFHOVR

OVR255

PLAUT

---c-m

------

------

--B-B-

-----_--___

------

------

------

-,-A--

------

-----c----c-----

------

------

------

-----a

For a rapid traverse command, dry run is disabled/enabled.

Manual synchronized feed (feed by spindle rotation) is disabled/enabled.

The rapid traverse override signal (G117#7 ROV2) is valid/invalid.

ISOT

When no reference position is established, manual rapid traverse is disabled/enabled.

When G31 is specified, dry run, override, and automatic acceleration/deceleration are

disabled/enabled.

Manual reference position return is not performed/performed at the jog feedrate.

When no position coder is used, the command for feed per rotation is disabled/en-

abled.

The units of the parameters for setting the rapid traverse rate and cutting feedrate are

not multiplied/are multiplied by 10.

For a plus-direction command for each axis, external deceleration is enabled only for

rapid traverse/external deceleration is enabled for rapid traverse and cutting feed.

For negative-direction commands for each axis, external deceleration is enabled only

for rapid traverse/external deceleration is enabled for rapid traverse and cutting feed.

The parameters for a Z-axis time constant in threading and for an FL feedrate for ac-

celeration/deceleration are common to all axes/Nos. 0627 and 0628.

The unit of the feedrate specified in F is 1 [mm/min]/O.OOl [mm/min].

In rapid traverse, the tool is not stopped/stopped when a cutting feedrate override of

0% is specified.

The rapid traverse override for threading cycle retraction is the parameter-specified

value/l 00 p?].

The I %-step feedrate override signal is invalid/valid.

During polar coordinate interpolation, if the specified rotation axis feedrate exceeds the

maximum cutting feedrate, the command is output as is/the command is split.

(X to 4) Rapid traverse rate for each axis

(718)

(516)

Maximum allowable cutting feedrate

FL feedrate for acceleration/deceleration along the X-axis in threading (G92)

(X to 4) FL feedrate for exponential acceleration/deceleration in cutting feed

(596)

(X to 4) FO feedrate for rapid traverse override

(596) -

(X to 4) FL feedrate for reference position return

(5#6)

FL feedrate for exponential acceleration/deceleration in manual feed

Jog rapid traverse rate for each axis

FL feedrate for exponential acceleration/deceleration in manual feed for each axis

FL feedrate for acceleration/deceleration along the Z-axis in threading (G92)

Feedrate for external deceleration

(X to 4) FL feedrate for exponential acceleration/deceleration in cutting feed for PMC

Description

,

.

L

.

axes

Page 12

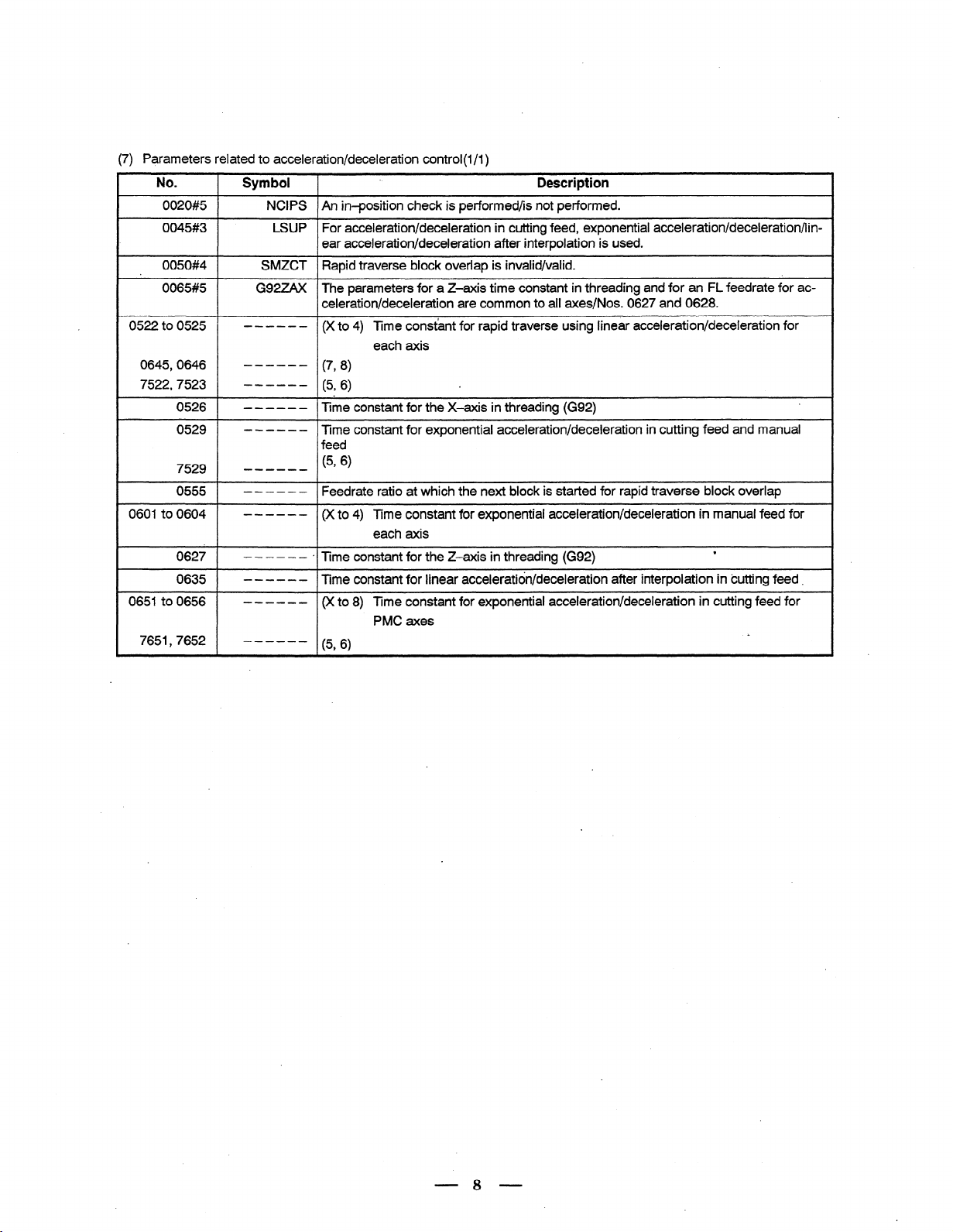

(7) Parameters related to acceleration/deceleration control(lj1)

No.

0522 to 0525 ------

0645,0646 -----7522,7523 ------

0601 to 0604

0651 to 0656

7651,7652

0526

0529

7529

0555 1

0627 1

0635 1

1 Symbol

NCIPS

-----W--.--W

-W-W--

-----a

------

----we ’

-a----

----a-

------

An in-position check is performed/is not performed.

For acceleration/deceleration in cutting feed, exponential acceleration/deceleration/lin-

ear acceleration/deceleration after interpolation is used.

Rapid traverse block overlap is invalid/valid.

The parameters for a Z-axis time constant in threading and for an FL feedrate for acceleration/deceleration are common to all axes/Nos. 0627 and 0628.

(X to 4) Time constant for rapid traverse using linear acceleration/deceleration for

each axis

(7,8)

(596)

Time constant for the X-axis in threading (G92)

Time constant for exponential acceleration/deceleration in cutting feed and manual

feed

(596)

Feedrate ratio at which the next block is started for rapid traverse block overlap

(X to 4) Time constant for exponential acceleration/deceleration in manual feed for

each axis

Time constant for the Z-axis in threading (G92)

Time constant for linear acceleration/deceleration after interpolation in cutting feed.

(X to 8) Time constant for exponential acceleration/deceleration in cutting feed for

PMC axes

66)

Description

.

8

Page 13

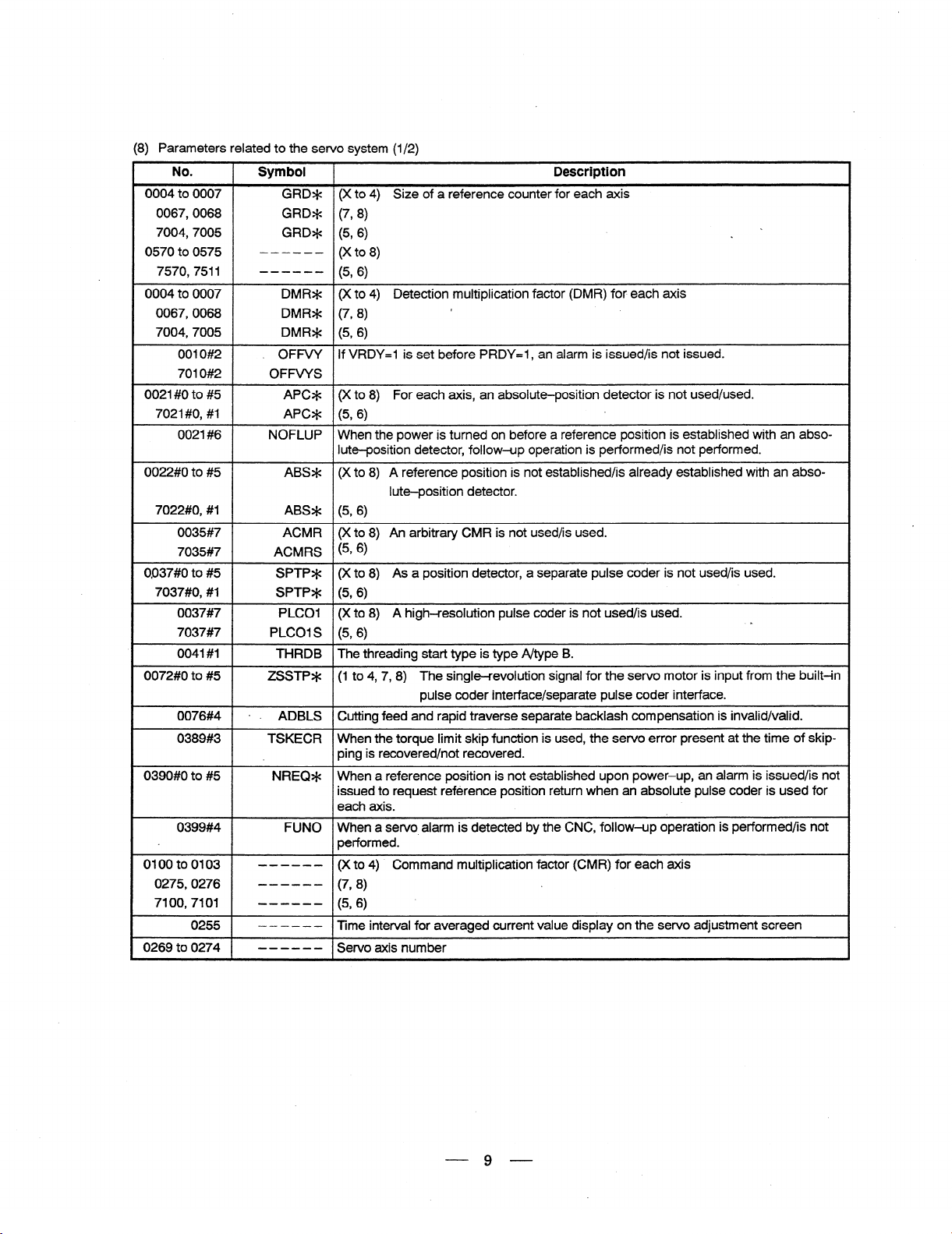

(8) Parameters related to the servo system (l/2)

No. Symbol Description

0004 to 0007

0067,0068

7004,7005

0570 to 0575 ------ (X to 8)

7570,7511

0004 to 0007 DMR* (X to 4) Detection multiplication factor (DMR) for each axis

0067,0068

7004,7005

0010#2 . OFFW If VRDY=l is set before PRDY=l, an alarm is issued/is not issued.

7010#2

0021 #O to #5

7021#0, #I

0021#6 NOFLUP When the power is turned on before a reference position is established with an abso-

0022#0 to #5

7022#0, #I

0035#7 ACMR (X to 8) An arbitrary CMR is not used/is used.

7035#7 ACMRS (5, 6,

0,037#0 to #5 SPTP* (X to 8) As a position detector, a separate pulse coder is not used/is used.

7037#0, #I

0037#7

7037#7

0041 #I THRDB The threading start type is type A/type 8.

0072#0 to #5 ZSSTP* (1 to 4, 7,8) The single-revolution signal for the servo motor is input from the built-in

0076#4 . . ADBLS Cutting feed and rapid traverse separate backlash compensation is invalid/valid.

0389#3 TSKECR When the torque limit skip function is used, the servo error present at the time of skip-

0390#0 to #5 NREQ* When a reference position is not established upon power-up, an alarm is issued/is not

0399#4 FUN0 When a sewo alarm is detected by the CNC, follow-up operation is performed/is not

0100 to 0103

0275,0276 ------ (7,8)

7100,7101

0255 - - - - - - Time interval for averaged current value display on the servo adjustment screen

0269 to 0274 ------ Servo axis number

GRD* (X to 4) Size of a reference counter for each axis

GRD* (7,8)

GRD* (5, 6)

------ (5, 6)

DMR* (798)

DMR* (5,6)

OFFVYS

APC* (X to 8) For each axis, an absolute-position detector is not used/used.

APC* (5,6)

lute-position detector, follow-up operation is performed/is not performed.

ABS* (X to 8) A reference position is not established/is already established with an abso-

lute-position detector.

ABS* (5, 6)

SPTP* (5, 6)

PLCOI (X to 8) A high-resolution pulse coder is not used/is used.

PLCOIS (5,6)

ping is recovered/not recovered.

issued to request reference position return when an absolute pulse coder is used for

each axis.

performed.

- - - - - - (X to 4) Command multiplication factor (CMR) for each axis

------ (5, 6)

,

pulse coder interface/separate pulse coder interface.

.

.

L

9

Page 14

(8) Parameters related to the servo system (2/2)

No.

0452 to 0457

0739 to 0742

0827,0828

7580,758l

7739,774o

0463

0500 to 0503

0637,0638

7500,750l

0504 to 0507

0639,064O

7504,7505

0508 to 0511

0641,0642

7508,7509

051 2 to 0515

0517

0632,0633

7517

0535 to 0538

0647,0648

7535,7536

0593 to 0596

0649,065O

7593,7594 ------ (5, 6)

0673 to 0678

Symbol

------ (Xto83RDWORD)

------

------

------ (5,6 LOWER2 WORD)

------

- - - - - - Maximum position deviation for which manual reference position return is assumed to

- - - - - - (X to 4) in-position width for each axis

------

------

- - - - - - (X to 4) Limit of position deviation during movement along each axis

------ (7, 8)

------ (5, 6)

- - - - - - (X to 4) Grid shift for each axis

------

------

- - - - - - (X to 4) Position control loop gain for each axis

- - - - - - (X to 8) Position control loop gain common to all axes

- - - - - - (7, 8) Position control loop gain for each axis

------ (5, 6)

- - - - - - (X to 4) Backlash compensation for each axis

------

------

- - - - - - (X to 4) Limit of position deviation in the stop state for eadh axis

------ (7, 8)

- - - - - - (X to 4) Rapid traverse backlash compensation value for each axis

(X to 4 LOWER 2 WORD)

(7,8 LOWER 2 WORD)

(5, 6 3RD WORD)

be possible

(7, 8)

(5T6)

(7, 8)

(5, ‘6)

(7, 8)

(5S6)

.

Description

Counter value at the APC reference position

,

c

.

- 10 -

Page 15

(9) Parameters related to DI/DO (I/I )

NO.

0001#2

0001#5

7001#5

0003#4

7003#4

0008#7

0009#0 to #3

7009#0 to #3

0009#4 to #7

7009#4 to #7

0024##7

0031#5

0038#0

0041#3

0045#2

0045#7

0070#4

0394#6

0113,0114

0252

0713,0714

0743 to 0746

Symbol

Description

DCS The signal from the START button on the MDI panel is routed/not routed via the ma-

chine.

DECI (X to 4) The deceleration signal for reference position return starts deceleration when

this bit is set to O/I.

DECIS (5, 6)

OVRI (X to 4) The override signal and rapid traverse ove.rride signal increase speed when

this bit is set to.O/I .

OVRIS (5, 6)

EILK The start lock signal is common to all axes/defined for each axis.

TFIN (X to 4) Acceptance time width for the M, S, or T function completion signal (GI2Q#3

FIN)

TFIN (5, 6)

TMF (X to 4) 7Ime before the M, S, or T function code read signal is sent

TMF (5, 6)

EDILK The interlock signal for each axis direction is invalid/valid.

ADDCF The PMC address for the GRl , GR2, and DRN signals is GO11 8/G0123.

DEC34 The PMC addresses for the *DEC3 and *DEC4 signals are GXI 9#7 and

XI 9#5/GI 6#7 and GI 7#7.

.

ROVC The rapid traverse override signals are ROV and ROV2/ROVl D, ROV2D, and

ROV3D.

RWDOUT The rewind in-progress signal’ (F164##6 RWD) is output only while the tape reader is

being rewound/while programs in memory are being rewound.

I-lSIF M, S, T, and B code processing is performed using an ordinary/high-speed interface.

DSTBGE When output is started in background editing, the manual data input start signal

(F150#5 DST) is output/is not output.

POSILK The start lock signal is invalid/valid for manual feed.

- - - - - - Position signal output grid pumber for each axis

- - - - - -

Reset signal extension time

- - - - - - Position signal output grid width for each axis

- - - - - -

Distance to a contact surface for each axis

- 11 -

Page 16

(10) Parameters related to CRT/MDl, display, and editing (i/3)

No. Symbol

0001 #I

0002#1 PPD Relative coordinates are not preset/are preset by coordinate system setting.

7002#1 PPDS

0008#3 LCD The display unit is a CRT/LCD.

001 O#l EBCL When programs stored in memory are displayed, the EOB code is displayed using ;I’*.

0011#7 MCI NP Programs are not stored/are stored in memory with G117#0 MINP.

0013#4 . INHMN Menu display is performed/not performed.

0014#2 STDP The actual speed of the spindle, S codes, and T codes are not displayed/are dis-

PROD Tool length compensation data is included/is not included in relative coordinate display.

Description

played.

0015#0

0015#1 NWCH When tool wear compensation values are displayed, the character W is displayed/is

0015#6 REP If the same program number is already contained in memory when programs are regis-

0018#7 EDITB The type of editing using the standard keyboard is edit operation A/B.

0019#6 NEOP When a program is registered, M02, M30, or M99 ends/does not end registration.

0019#7 DBCD When the diagnostic screen is displayed, timer and counter data are displayed in

0023#0 to #6 **** Display language setting

0028#0 PRCPOS On the program check screen, relative/absolute coordinates are displayed.

0028#2 . DACTF Actual speed is not displayed/is displayed.

0028#3 MMDL In MDI operation B, the modal state is not displayed/is displayed.

0029#0, #1 DSP* The current position of the third/fourth axis is not displayed/is displayed.

0029#6 DSPSUB The fifth/sixth axis is not displayed/is displayed on the absolute/relative position dis-

0038#3 FLKY The keyboard of the CRT unit or MDI panel employs the standard keys/full keypad.

0040#0

0040#4 SORT The program directory is displayed in the order of program registration/in the ascend-

0045#0

0045#1

0048#7 SFFDSP Soft keys are displayed and controlled according to the additional option function

0050#1 NOFMK In sequence number search, a format check is performed/is not performed.

0056#0 NOCND When the part program storage length is 120 m/320 m, or when the background edit

0057#0 PWNNC The MMC/CNC screen is displayed when the power is turned on.

0057#1 ALMNC When an alarm is issued on the CNC during MMC screen display, the MMC/CNC

CBLNK The cursor blinks/does not blink.

not displayed.

tered via the reader/punch interface, an alarm is issued/the program is replaced.

binary/decimal.

play screen.

NAMPR Program names are not displayed/are displayed in the program directory.

ing order of program numbers.

RDL During external control of input/output units, read operation follows the specification of

No. 0015#6 REP/registration is performed after deletion of all programs.

RAL In reading via the reader/punch interface, all programs are registered/only the first pro-

gram is registered.

specification/regardless of the additional option function specification.

function is provided, automatic memory compression is performed/is not performed.

screen is displayed.

h

- 12 -

Page 17

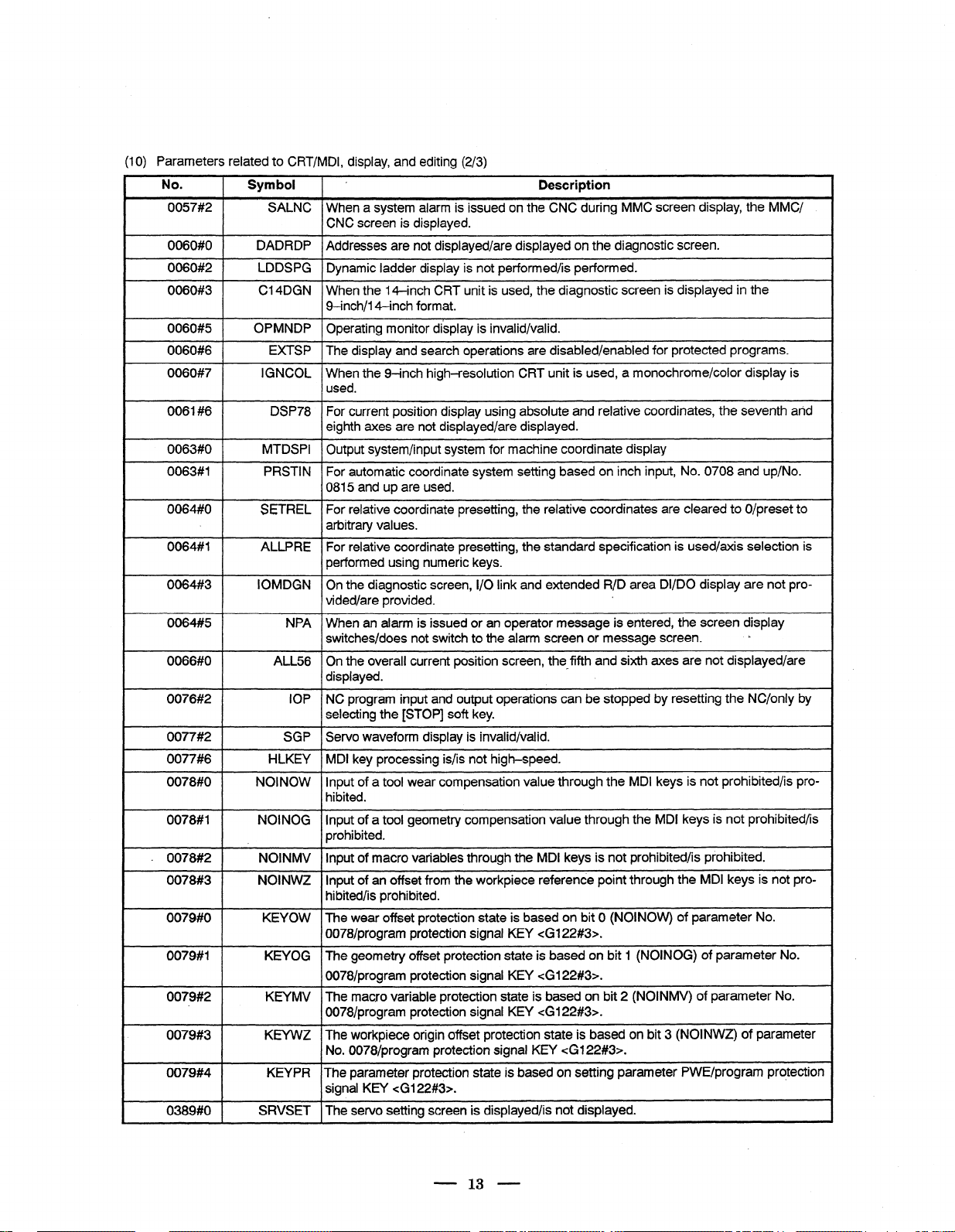

(10) Parameters related to CRT/MD& display, and editing (2/3)

No.

0057#2

0060#0 1 DADRDP 1 Addresses are not displayed/are displayed on the diagnostic screen.

I

0060#2 1

I

0060#3 Cl 4DGN When the 14-inch CRT unit is used, the diagnostic screen is displayed in the

0060#5

0060#6 1

I

0060#7

Symbol *

SALNC When a system alarm is issued on the CNC during MMC screen display, the MMCl

CNC screen is displayed.

LDDSPG 1 Dynamic ladder display is not performed/is performed.

Q-inch/l 4-inch format.

OPMNDP Operating monitor display is invalid/valid.

EXTSP 1 The display and search operations are disabled/enabled for protected programs.

When the g-inch high-resolution CRT unit is used, a monochrome/color display is

~~ ~~

Description

I

0061#6

0063#0 1

0063#1

0064#0

0064##1 ALLPRE For relative coordinate presetting, the standard specification is used/axis selection is

0064#3

0064#5 NPA When an alarm is issued or an operator message is entered, the screen display

0066#0 ALL56 On the overall current position screen, the fifth and sixth axes are not displayed/are

0076#2

0077#2

0077#6

0078#0

0078#1

- 0078#2 ]

0078#3

0079#0

0079#1 KEYOG The geometry offset protection state is based on bit 1 (NOINOG) of parameter No.

0079#4 KEYPR The parameter protection state is based on setting parameter PWE/program protection

0389#0 1

DSP78 For current position display using absolute and relative coordinates, the seventh arid

MTDSPI 1 Output system/input system for machine coordinate display

PRSTIN For automatic coordinate system setting based on inch input, No. 0708 and up/No.

SETREL For relative coordinate presetting, the relative coordinates are cleared to O/preset to

IOMDGN On the diagnostic screen, I/O link and extended R/D area DI/DO display are not pro-

HLKEY MDI key processing is/is not high-speed.

NOINOW Input of a tool wear compensation value through the MDI keys is not prohibited/is pro-

NOINOG Input of a tool geometry compensation value through the MDI keys is not prohibited/is

NOINMV 1 Input of macro variables through the MDI keys is not prohibited/is prohibited.

NOINWZ input of an offset from the workpiece referende point through the MDI keys is not pro-

KEYOW The wear offset protection state is based on bit 0 (NOINOW) of parameter No.

KEYMV The macro variable protection state is based on bit 2 (NOINMV) of parameter No.

KEYWZ The workpiece origin offset protection state is based on bit 3 (NOINWZ) of parameter

SRVSET 1 The servo setting screen is displayed/is not displayed.

eighth axes are not displayed/are displayed.

0815 and up are used.

arbitrary values.

performed using numeric keys.

vided/are provided.

switches/does not switch to the alarm screen or message screen.

displayed.

IOP NC program input and output operations can be stopped by resetting the NC/only by

selecting the [STOP] soft key.

SGP Servo waveform display is invalid/valid.

hibited.

prohibited.

hibited/is prohibited.

0078/program protection signal KEY cG122#3>.

0078lprogram protection signal KEY <G122#3>.

0078/program protection signal KEY cG122#3>.

No. 0078/program protection signal KEY <Gl22#3>.

signal KEY <G122#3>.

c

L.

I

I

I

I

I

I

I

I

I

I

13

Page 18

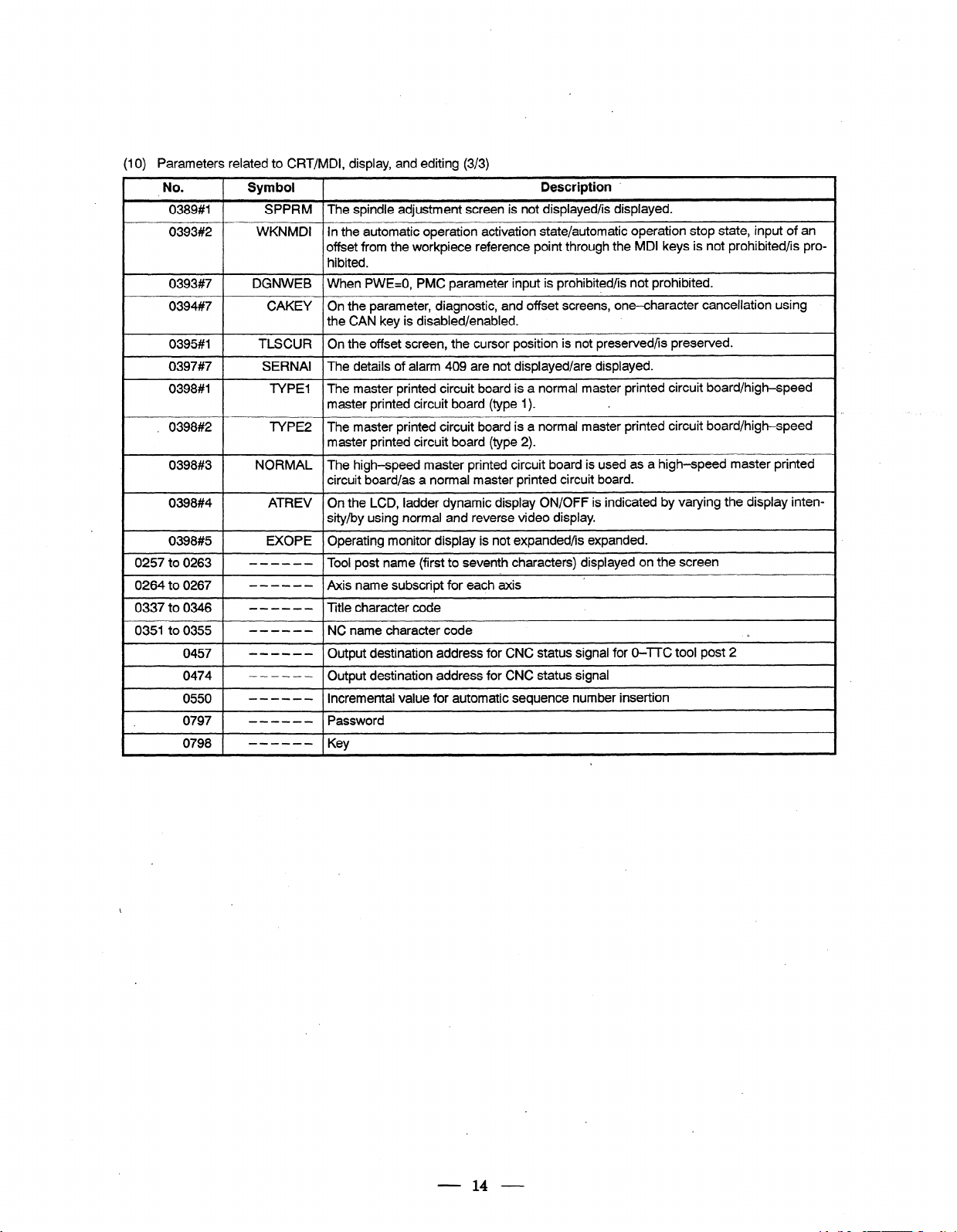

110) Parameters related to CRT/MDl, display, and editing (3/3)

No. ( Symbol 1 Description ’

0389#1 SPPRM

0393#2

WKNMDI In the automatic operation activation state/automatic operation stop state, input of an

The spindle adjustment screen is not displayed/is displayed.

offset from the workpiece reference point through the MDI keys is not prohibited/is pro-

1

1 hibited.

- 0393#7 1 DGNWEB-1 When PWE=O, PMC parameter input is prohibited/is not prohibited.

0394#7

0395#1 1

0397#7

0398#1

. 0398#2

0398#3 NORMAL

TLSCUR 1 On the offset screen, the cursor position is not preserved/is preserved.

SERNAI

TYPE1

TYPE2 The master printed circuit board is a normal master printed circuit board/high-speed

0398#4 ATREV On the LCD, ladder dynamic display ON/OFF is indicated by varying the display inten-

0398#5 1 EXOPE

0257 to 0263 1

0264 to 0267 1

0337 to 0346

0351 to 0355

0457

0474

0550

0797

0798 1

- - - - - -

- - - - - - f Axis name subscript for each axis

- - - - - -

- - - - - -

- - - - - -

- - - - - - Output destination address for CNC status signal

- - - - - - Incremental value for automatic sequence number insertion

- - - - - - Password

_-_-_- ,Key

On the parameter,-diagnostic, and offset screens, one-character cancellation using

the CAN key is disabled/enabled.

The details of alarm 409 are not displayed/are displayed.

The master printed circuit board is a normal master printed circuit board/high-speed

master printed circuit board (type 1).

master printed circuit board (type 2).

The high-speed master printed circuit board is used as a high-speed master printed

circuit board/as a normal master printed circuit board.

sity/by using normal and reverse video display.

1 Operating monitor display is not expanded/is expanded.

1 Tool post name (first to seventh characters) displayed on the screen

Title character code

NC name character code

Output destination address for CNC status signal for O-TX tool post 2

a.

- 14 -

Page 19

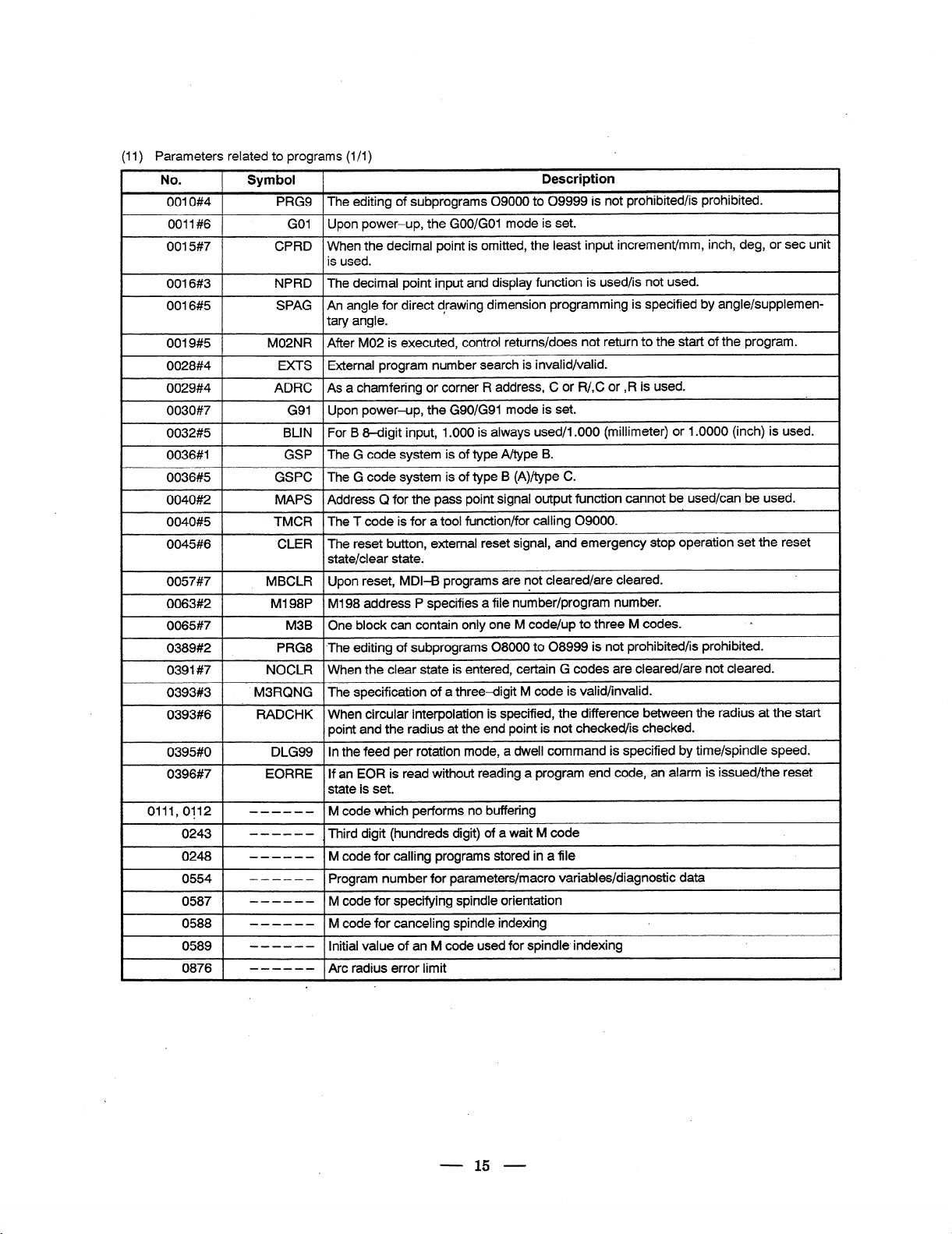

(11) Parameters related to programs (l/l)

No.

0010#4

0011#6

0015#7

0016#3

0016#5

0019#5 M02NR

0028#4

0029#4

0030#7

0032#5 (

0036#1

0036#5 1 GSPC 1 The G code system is of type B (A)/type C.

0040#2

0040#5

0045#6

0057#7 1

I

0063#2

0065#7

0389#2

0391#7

0393#3

Symbol

PRG9

GO1 Upon power-up, the GOO/GOl mode is set.

CPRD When the decimal point is omitted, the least input increment/mm, inch, deg, or set unit

NPRD The decimal point input and display function is used/is not used.

SPAG An angle for direct drawing dimension programmin,g is specified by angle/supplemen-

EXTS

ADRC

G91 Upon power-up, the G90/G91 mode is set.

BLIN 1 For B 8-digit input, 1 .OOO is always used/l .OOO (millimeter) or 1 .OOOO (inch) is used.

GSP The G code system is of type A/type B.

MAPS Address Q for the pass point signal output function cannot be used/can be used.

TMCR The T code is for a tool function/for calling 09000.

CLER The reset button, external reset signal, and emergency stop operation set the reset

MBCLR f Upon reset, MDI-E! programs are not cleared/are cleared.

Ml 98P

M3B One block can contain only one M code/up to three M codes.

PRG8 *The editing of subprograms 08000 to 08999 is not prohibited/is prohibited.

NOCLR

M3RQNG

0393#6 RADCHK

. I

0395#0

0396#7

0111,0112 1

0243

0248 - - - - - - M code for calling programs stored in a file

0554 1 - - - - - -

0587 1

0588 1 - - - - - - 1 M code for canceling spindle indexing

0589 1 - - - - - - 1 Initial value of an M code used for spindle. indexing

0876 1 - - - - - - 1 Arc radius error limit

DLG99 In the feed per rotation mode, a dwell command is specified by time/spindle speed.

EORRE

- - - - - - . 1 M code which performs no buffering

- - - - - - , Third digit (hundreds digit) of a wait M code

- - - - - - 1 M code for specifying spindle orientation

Description

The editing of subprograms 09000 to 09999 is not prohibited/is prohibited.

is used.

tary angle.

After MO2 is executed, control returns/does not return to the start of the program.

External program number search is invalid/valid.

As a chamfering or corner R address, C or R/,C or ,R is used.

state/clear state.

Ml 98 address P specifies a file number/program number.

When the clear state is entered, certain G codes are cleared/are not cleared.

The specification of a three-digit M code is valid/invalid.

When circular interpolation is specified, the difference between the radius at the start

point and the radius at the end point is not checked/is checked.

If an EOR is read without reading a program end code, an’alarm is issued/the reset

state is set.

,

L

1 Program number for parameters/macro variables/diagnostic data

1

4

I

I

m

I

15

Page 20

112)

Parameters related to pitch error compensation (i/l)

No.

0011 #O, #I PML* (X to 4) Pitch error compensation magnification

7011##0, #I PML*S (5, 6)

0756 to 0759 - - - - - -

7713,7714 . ------ (5, 6)

1000 to 6000 1

1001 to 6128 1

(13)

Parameters related to spindle control (l/2)

No. Symbol

0003#6, #7

0064#6, #7 P2SG*

0013#5 ORCW In orientation, S analog output is positive/negative.

0013#6, #7 TCW, CWM

0024#2 SCTO The spindle speed arrival signal (G120##4 SAR) is not checked/is checked.

0028#7 PNOSMP

0031 #O

0031 #l SDRT The direction of spindle indexing with an M code is positive/negative.

0049#0

0049#2

0062#3 SPMRPM

I

0065#1

0070#0, #I

0070#3 MSPDB The multi-spindle control method is type A/type B.

0071 #O

0071#1 . HISSC The sampling time for constant surface speed control remains unchanged from the

0071#2 SRLMSP In multi-spindle control, the second axis is analog/serial.

0071#3

. 0071#4

0071#7

0074#7 PLCREV A feedback pulse signal from a position coder represents an absolute value/is signed.

0080#2, #3

0080#6,’ #7 SP*NEG During spindle synchronization, the rotation directions of the first and second spindle

0381#7 IGNSIC A serial/analog spindle is connected to tool post 2.

0397#0 SPLME The permissible rate and fluctuation rate of the spindle speed fluctuation detection

I

1 Symbol 1

- - - - - -

(X to 4)

1 Zero position for pitch error compensation for each axis

Compensation interval in pitch error compensation for each axis

- - - - - - 1 Pitch error compensation for each axis

PSG* Gear ratio between the spindle and position coder

SNRL Upon reset, the spindle indexing mode is not canceled/is canceled.

EVSF When an S code is specified, the S code and SF are not output/are output at all times.

CHKSP When SIND=l, spindle speed fluctuation detection is disabled/enabled.

CZRN The first GO0 command after the mode is switched to the Cs contour control mode

DAC*

ISRLPC When a serial interface spindle is used, the position coder signal is received through

SSMPC M27/the second spindle control unit is used for the second position coder.

SRL2SP ‘One/two serial interface spindles is/are connected.

FSRSP

MORCM* For the first and second spindle motors, the spindle orientation function with the stop

Gear ratio between the spindle and second position coder

Sign of S analog output

The number of sampling operations for finding the average spindle speed is 4/l.

The unit of parameter data for spindle speed control is l/l 0 [RPM].

performs positioning after performing a reference position return/performs ordinary

positioning.

For D/A conversion, the analog interface board is not used/used.

an optical fiber/M27 connector.

conventional value/is the conventional value divided by 4.

Serial interface spindles are not used/are used.

position set externally is not usedhs used.

motors are the same as the specified sign/opposite to the specified sign.

function are 1 p%JO.l [%].

Description

Description

*

.

- 16 -

Page 21

(13) Parameters related to spindle control (2/2)

No.

0108

0110

0249

0516

0303

0531

0532

0539

0540 to 0543

0546

0551

0556

0564

0576

0580 to 0583

0584 ------ Spindle loop gain.

0585 - - - - - - FO feedrate for spindle rapid traverse override

0586 A - - - - - FL feedrate for spindle orientation

0587

0588 - - - - - - M code for canceling spindle indexing

0589 - - - - - - Initial value of an M code used for spindle indexing

0590 -- --- - Basic angular displacement for spindle indexing using an M code

0613

0614

0615,0616 -----.- Speed when the second spindle speed commandvoltage for each gear is 10 M

Symbol

- - - - - - Spindle speed when the spindle rotates at a constant speed

- - - - - - Delay timer used to check the spindle speed arrival signal (G120#4 SAR)

- - - - - - Magnification for spindle speed ratio control over serial interface spindles

- - - - - - Data for gain adjustment in constant surface speed control (analog output)

------

------

- - - - - - Spindle speed fluctuation rate (R) used in spindle speed fluctuation detection for issu-

- - - - - - Spindle speed offset value

- - - - - - Speed when the spindle speed command voltage for each gear is 10 M

- - - - - - Value for compensating for drift that occurred in a Cs-axis servo loop

- - - - - - Minimum spindle speed in the constant surface speed control mode (G96)

- - - - - - Maximum spindle speed for the constant surface speed control option

------

------

- - - - - - Spindle servo loop gain multiplier in Cs-axis control for each gear

------

------

- - - - - - Spindle speed offset value for the second spindle

Permissible pulse error for phase synchronization in the synchronized control mode

Permissible rate (Q) used in spindle speed fluctuation detection for determining

whether a specified speed is reached

ing an alarm

Permissible speed fluctuation that does not cause an alarm to be issued in spindle

speed fluctuation detection

Permissible pulse error between two spindles in the spindle (simple) synchronized

control mode

M code for specifying spindle orientation

Data for second spindle gain adjustment in constant surface speed control

Description

c

_ 0617 - - - - - - Data for third spindle gain adjustment in constant surface speed control

0618

0619,062O - - - - - - Speed when the third spindle speed command voltage for each gear is 10 M

0712 - - - - - - Time before a spindle speed fluctuation check is started

6780 to 6783

6784 to 6787

6788 to 6791

6792 to 6795 L----- (2)

6796 to 6799

7516 - - - - - - Data for gain adjustment in subspindle S4/S5 digit control

7539

- - - - - - Spindle speed offset value for the third spindle

- - - - - - Position loop gain of a servo axis in the .Cs contour control mode

- - - - - - (X)Position loop gain of a sewo axis in the Cs contour control mode for each gear

------

------

- - - - - - Subspindle speed offset value

03

(4) .

.

- 17 -

Page 22

(14) Parameters related to tool compensation (1 /I)

No.

0001#3

0001#4

0008#6

0010#5

0013#1

0013#2

0013#3

0014#0

0014#1

0014#4

0014#5

0014#6

0015#4

0024#6

0036#3

0075#3

0395#4

0399#0

0122

0557

0728

0729 - - - - - - Maximum tool wear compensation value

Symbol

TOC In the reset state, offset vectors are not canceled/are canceled.

ORC For offset values, a diameter value/radius value is specified.

NOFC Offset values are loaded/are not loaded into a counter.

DOFSI Direct input of tool offset values is not performed/is performed.

GOFU2 A tool geometry compensation number is specified using the least significant/most

significant digit of a T code.

GMOFS Tool geometry compensation is performed by shifting the coordinate system/by moving

GOFC Tool geometry compensation is not canceled/is canceled by position number 0.

GMCL Tool geometry compensation is not canceled/is canceled when the’reset state is en-

OFSB Tool offsetting is performed in a block containing a T code/performed together with axis

WIGA A iimit is not imposed/is imposed on tool offset setting.

MORB In direct input of measurement values, the record button is not used/is used.

YOF3 Y-axis offset is used with the fourth axis/third axis.

WNPT A virtual tool tip number for tool-tip radius compensation is specified using a geomet-

ADDLA During tool-tip radius compensation, if two blocks specifying no movement are speci-

e

NOPS4l For tool nose radius compensation, interference check is performed/not performed.

- - - - - - Tool compensation number when the tool compensation measurement value direct

- - - - - - Maximum ignorabte travel distance along the outside of a corner in tool-tip radius

- - - - - - Maximum tool wear compensation value in incremental input

the tool.

T2D A T code is specified using 4 digits/2 digits.

tered.

movement.

T2T4 When a T code is specified using 2 digits, the upper 2 digits are assumed to be OO/are

assumed to be the same as the lower 2 digits.

QNI When tool compensation measurement direct input function B is used, a tool com-

pensation number is not selected/is selected automatically in the offset write mode.

ric/wear compensation number.

fied consecutively, the offset vector is assumed to be the vector perpendicular to the

movement performed in the previous block at the end point/the intersection vector.

input B function is used

compensation

Description

- 18 -

Page 23

(15) Parameters related to canned cycles (1 /I )

No. 1 Symbol 1 Description

I

0031#2

0031#3

0031#4 RTCT The peck drilling cycle is type A/B.

0393#1

0393#4

0109

0204

1 0212,0213 1

0591

0592 1 lL=- - -Retract dimension (d) used for peck drilling in a drilling cycle

0717,0718 1 -------I phfut/t

0719,072O 1 - - - - - -

0721 1 - - - - - - 1 Number of divisions in the multiple repetitive canned cycle (G73)

0722 1

0723 1

0724 1 - - - - - - I Tool angle in the multiple repetitive canned cycle (G76)

0725

0726

TAPM

MCQSCH In a multiple repetitive canned cycle for lathes, a sequence number check with Q spe-

CHKMRC In a multiple repetitive canned cycle for lathes, specification of a pocket figure is valid/

- - - - - - Cut width in threading cycle G92/G76

- - - - - - M code for C-axis clamping in a drilling canned cycle

-a----

- - - - - - Dwell time used when C-axis unclamping is specified in a drilling cycle

In a tapping cycle, MO3 or M04/M05 is output in the case of forward or reverse rota-

tion.

ILVL In a drilling cycle, the initial point is not updated/is updated when a reset occurs.

cified is not performed/is performed.

invalid.

I M code for forward spindle rotation/reverse spindle rotation in a drilling canned cycle 1

De t o c re ract dimension in the multiple repetitive canned cycles (G71, G72)

1 Retract dimension for each axis in the multiple repetitive canned cycle (G73)

- - - - - - 1 Return distance in the multiple repetitive canned cycles (G74, G75)

---m-e

- - - - - - Minimum depth of cut in the multiple repetitive canned cycle (G76)

- - - - - - Finishing allowance in the multiple repetitive canned cycle (G76)

1 Number of times finishing is performed in the multiple repetitive canned cycle (G76)

I

I

h

I

1

I

I

I

1

.

I

L

- 19 -

Page 24

:I 6) Parameters related to rigid tapping (l/l)

No. 1 Symbol 1

0029#3 RGCTO In rigid tapping, the time constant for acceleration/deceleration of the spindle and tap-

ping axis during withdraw are specified using the same parameter as for cutting/using

a separate parameter.

0041#0 1

0063#4 1 RGDOV 1 Withdraw operation overriding is disabled/enabled.

0063#6 1

0076#3 [

0397#3 1 RGMFH 1 The feed hold and single block functions are enabled/disabled.

0399#5 1 SIG 1 In gear switching, the SIND signal is invalid/valid.

0214 to 0217 1 -- - - - - 1 Spindle backlash distance in rigid tapping

0253 1

0254 1

0400 1

0401 I - - - - - - I Spindle in-position width in rigid tapping

0402 - __----_

0403 - - - - - - Limit on position deviation during spindle movement

0404

0405 - - - - - - Limit on position deviation whife spindle movement is stopped

0406 - - - - - - Loop gain for position control over the spindle and tapping axis (for each gear)

0407 to 0410

0411 to 0414

0415 to 0418 - - - - - - Time constant for acceleration/deceleration for the spindle and tapping axis

0419 to 0422 - - - - - - Time constant for acceleration/deceleration for the spindle and tapping axis during

0423 to 0426 - - - - - - Maximum allowable spindle speed during rigid tapping

0427 to 0430 - - - - - - Number cf teeth on the spindle side when an arbitrary gear ratio is used

0431 to 0434 Number of teeth on the position coder side when an arbitrary gear ratio is used

0435

0436 - - - - - - Amount of pulse distribution to the spindle during rigid tapping

0473 - - - - 7 - Momentary error difference between the spindle and tapping axis

0483

RGTPE 1 In rigid tapping, the rigid mode is canceled after/before the rigid DI signal is turned off.

VSLPC 1 An arbitrary gear ratio is not used/is used betweenthe spindle and position coder.

G84m G84 and G74 are not used/are used as G codes for rigid tapping.

- - - - - - 1 M code for specifying the rigid tapping mode

--B-m- 10~

- - - - - - I Tapping axis in-position width in rigid tapping

---- -- Limit on position deviation while movement along the tapping axis is stopped

- - - - - - Spindle loop gain multiplier

- - - - - - Position deviation of the spindle during rigid tapping

- - - - - - Maximum error d’ifference between the spindle and tapping axis

‘d

em

e value for withdraw in rigid tapping

Limit on position deviation during movement along the tapping axis

withdraw

Description

L

20

Page 25

(17) Parameters related to custom macros (1 /I )

No.

0011#5 1

0040#1 DPOSUP I When data is output with the DPRINT command, spaces are output/no particular op-

0040#5 1 TMCR 1 The T code is for a tool function/ for calling 09000.

0040#6 1 COMC 1 Upon reset, common variables (#IO0 to #149) are placed/not placed in the null state.

0040#7 I LOCC I Upon reset, local variables (##Ol to #33) are placed/not placed in the null state.

0056#1 MSKT When an interrupt is generated, absolute coordinates are not set/are set as skip coor-

0056#2 1 MBLK I Custom macro interrupt type l/II

0056#3 1

0056#4

c 0056#5

0056#6

0056#7

0057#4

0220 to 0229

0230 to 0239

0240 to 0242

1 Symbol 1 Description

SBKM 1 A macro statement does not cause/causes a single block stop.

eration is performed for leading zeros.

0042 1

0043 I EQCD 1 Hole pattern corresponding to EIA code =

0044’ I

0053 I

0054 1

0218

0246

0247

0248

ASTCD 1 Hole pattern corresponding to EIA code *

SHPCD I Hole pattern corresponding to EIA code #

LBLCD I Hole pattern corresponding to EIA code [

RBLCD I Hole pattern corresponding to EIA code ]

dinates.

MSTE I The interrupt signal is based on the edge trigger method/status trigger method.

MPRM M codes for enabling and disabling an interrupt are M96 and M97 respectively/deter-

mined by parameter setting.

MSUB The local variables used for an interrupt are macro type/subprogram type.

MCYL During cycle operation, the custom macro interrupt function is disabled/enabled.

MUSR The custom macro interrupt function is disabled/enabled.

CROUT Upon completion of IS0 code data output by B/D PRINT, an LF code/CR and LF

codes are output.

---- - - Number of macro variables common to tool posts

- - -- - - G code for calling custom macros 09010 to 09019

------

- - - - - - M code for calling subprograms 09001 to 09003

- - - - - - M code for enabling custom macro interrupts

- - - - - - M code for disabling custom macro interrupts

- - - - - - M code for calling programs stored in a file

M code for calling custom macros 09020 to 09029

c

(18) Parameters related to automatic tool compensation (l/l)

.

No.

I

0731,0732 1

0733,0734 I

(19) Parameters related to graphic display (l/l)

No.

0024#3

0046#5 I GRPOS I On the graphic display screen, the current position is not displayed/is displayed.

0630,063l 1

0558 1

1 Symbol

- - - - - - I Feedrate used for measurement in automatic tool compensation

I

- - - - - - I Value of y in automatic tool compensation

- - - - - - I Value of E in automatic tool compensation

I Symbol 1

GNSR The actual position with tool-tip radius compensation reflected is drawn/the pro-

grammed position is drawn.

0123 1 - - - - - - I Drawing coordinate system used with the graphic function

- - - - - - Dot shift amount for 9-inch high-resolution graphic display

Description

Description

21

Page 26

(20) Parameters related to run time/parts count display (l/l)

&

No. Symbol

0040#3

0219

0600 - - - - - - Number of required parts

I

(21) Parameters related to tool life management (l/l)

0779 1 - - - - - - 1 Total number of machined parts

No. Symbol

0039#0, #I GST* Number of groups that can be registered in tool group setting

0039#2 LCTM Tool life is specified by a count/time.

0039#3 TLSK When the tool skip signal (Gl40#0 TLSKP) is applied, the group currently selected is

0039#4 GRST When the tool skip signal (Gl40#0 TLSKP) is applied, the execution data of the group/

0039#5 IGSK The tool skip signal (Gl40#0 TLSKP) is accepted always/only when a tool subject to

0394#0

0394##5

0117

0118

0119 - - - - - - Maximum offset number used with the simplified tool life management function

0120 - - - - - - Maximum tool selection number used with the simplified tool life management function

0336 . - - - - - - M code for restarting tool life count operation

0599

RWCNT With MO2 or M30, the total number of machined parts and the number of machined

parts is counted/is not counted.

------

TLCSAM When multiple offset numbers are involved, counting is performed for each identical

NOWOFS @ is prefixed/is not prefixed to a compensation number subject to tool life manage-

- - - - - - Cffset number compensation value used with the simplified tool life management func-

- - - - - - Tool selection number compensation value used with the simplified tool life manage-

- - - - - - Tool life management ignore number

M code for counting the total number of machined parts and the number of machined

parts

skipped/the group number is also entered.

execution data of all groups is cleared.

tool life management is being used.

tool num her/each tool.

ment.

tion

ment function

Description

Description

.

c

.

(22) Parameters related to the position switch function (l/l)

.

No. Symbol

‘0310 to0319 - - - - - - Axis corresponding to a position switch

0840 to, 0849 - - - - - - Maximum position switch operation range

0850 to 0859 - - - - - - Minimum position switch operation range

I

22

Description

Page 27

123) Parameters related to manual handle feed/manual handle interrupt (l/l)

No.

0002#5

0002#6

0013#0

0075#2

0077#4

0386#0 to #3

0386#4 to #7

0121

0699

(24) Parameters related to the software operator’s panel (l/l)

No.

0017#0 1 OPGI 1 On the software operator’s panel, mode selection is not performed/is performed,

0017#1

0017#2

0017#3

0017#4

0017#5

0017#6

0130 to 0137 1

0140 to 0203 - - - - - - Character codes of the general-purpose switches on the software operator’s panel

Symbol

HSLE When two manual pulse generators are installed, the axis selection signal is invalid/

TJHD In the TEACH IN JOG mode, a manual pulse generator is disabled/enabled.

INHND The unit of manual handle interrupt movement is the output unit with acceleration/de-

HDLPM When the handle of a manual pulse generator is turned quickly, the scale indication

HPNEG* For each axis, the direction of manual handle feed is the same/opposite.

HDPIG* For each axis, the magnification (x 10000) of manual ,handle feed is used/is not used.

- - - - - - Manual handle feed magnification (M)

- - - - - - Manual handle feed magnification

1 Symbol 1

OPG3 On the software operator’s panel, manual pulse generator axis selection and magnifi-

0PG4 On the software operator’s panel, jog feedrate override switching is not performed/is

0PG5 On the software operator’s panel, BDT, SBK, MLK, and DRN switching is not per-

OPG6 On the software operator’s panel, protect switching is not performed/is performed.

0PG7 On the software operator’s panel, feed hold switching is not performed/is performed.

___--- 1 gf d

valid.

JHD In the JOG mode, a manual pulse generator is disabled/enabled.

celeration disabled/is the input unit with the acceleration/deceleration enabled.

and travel distance may not match/the scale indication and travel distance match.

On the software operator’s panel, jog feed axis selection is not performed/is performed.

~~~~

cation switching are not performed/are performed.

performed.

formed/is performed.

Jo ee axes and directions of the keys on the software operator’s panel

Description

Description

L

[25) Parameters related to restarting programs (l/l)

No.

I

0387#0 1 SQDNC 1 In DNC operation, program restarting is disabled/enabled.

I

1 0124to0127 1

(26) Parameters related to high-speed cycle machining/high-speed remote buffers (l/l)

No.

I

1 0055#4 to #6 1 ITPCNT 1 GO5 data interpolation interval

1 Symbol 1

-a,--, l()cj f

1 Symbol 1

r er 0 movement to program restart positions

Description

Description

0597 1 - - - - - - ] Number of high-speed remote buffer controlled axes

23

Page 28

:27) Parameters related to PMC-based axis control (l/l)

No.

0019#4 EAUNT Commands for a single linear PMC controlled axis are specified in input increments/

0032#4 PNGMLK Machine locking along a PMC axis is enabled/disabled.

7032#4 PNGMLKS

0032#6

0049#5

0052#0 to #7

0063 #0 to #5

0062#6 AXPCF Movement along a PMC controlled axis is added/is not added to actual speed display.

0063#5 EAXOV For PMC axes, the dry run and override functions are disabled/enabled.

7063#5

0066#3

0066#6, #7

0078#4

0078#6

’ 0078#7

0387#7

0398#0

0350

0651 to 0656

7651,7652

0657 to 0662

7657,7658

0672

0685

0698

7021#6

Symbol

output increments.

EACSB PMC axis control is based on specification A/B.

EFMLlO A feedrate command (cutting feed) for PMC axis control is multiplied by 1 /I 0.

NODIC* Current position display for PMC axis control follows the decimal point position based

on the setting unit 1 /I O/follows the standard specifications.

EBC* For each axis, group A/B of the DI and DO signals for PMC axis control (specification

8) is used.

EAXOVS

EPMSKP In PMC-based axis control, the same skip signal used with the CNC/a separate signal

is used.

ERVF* Magnification of a feedrate for feed-per-rotation in PMC axis control

OVRIE In PMC axis control, the override signal increases speed when this bit is set to O/l.

RDRNE In PMC axis control, the dry run function cannot/can be used with a rapid traverse

command.

EAXOVE In PMC axis control, the dry run and override signals are the same as those used with

the CNC/separate dry run and override signals are used.

EFERPD A rapid traverse rate in PMC axis control is specified by the same paramgter as with

the CNC/specified by the feedrate data of an axis control command.

EADSL In PMC axis control (specification B), the switching of the axis selection signal (G144)

for an unspecified path is disabled/enabled.

- - - - - - Axis for which a feedrate is specified in PMC axis control

- - - - - - (X to 8) Time constant for exponential acceleration/deceleration during cutting feed

for a PMC axis

------ (5, 6)

- - - - - - (X to 8) FL feedrate for exponential acceleration/deceleration during cutting feed for a

PMC axis

------ (5, 6)

-- -- - - FL feedrate for reference position return operation along a PMC controlled axis

-- -- - - FO feedrate for independent rapid traverse override along a PMC controlled axis

- - - - - - Maximum feedrate for feed per rotation along a PMC controlled axis

SUB1 PMC axis control on the sub-CPU side is applied to the fifth and sixth axes/the fifth

axis only.

Description

24

Page 29

(28) Parameters related to cylindrical grinding machines (FSO/OO-CCC) (1 /I)

No.

I

1 0033#0 to#3 /

1 0033#4to #7 1

1 0034#0 to #3 I

1 0034#4tO #7 I

I 0035#0 to#3 I

0036#0 (

I

0036#1 1

I

0036#2

1 _ 0036#4 1

(29) Parameters related to the PMC (l/l)

No.

0024#0 1 IGNPMC ] PMC-based axis control is enabled/disabled.

I

0028#1

0060#1 1

I

0070#6 ]

0071#6 1

0398#7 1

0356 to 0359

0476 to 0479 1

1 Symbol 1 Description

Pl S* 1 The skip signal used with G31 PI is invalid/valid.

P2S* f The skip signal used with G31 P2 is invalid/valid.

P3S* I The skip signal used with G31 P3 is invalid/valid.

P4S* 1 The skip signal used with G31 P4 is invalid/valid.

DS* I The skip signal used with the dwell skip function is invalid/valid.

AGLST I Slanted axis control is not exercised/is exercised.

GSP 1 The G code system is type A/type B.

ZRTMI Movement is performed/is not performed along the Z-axis in manual reference posi-

] Symbol 1 Description

PRCMSG The program check screen displays the remaining travel distance/message from the

PCLDB 1 The baud rate used for ladder loading is 4800 [bps]/9600 [bps].

PEXRD 1 The R and D areas of the PMC-M are not expanded/are expanded.

DPCRAM 1 When a PMC RAM board is used, PMC LOAD MENU is displayed/is not displayed.

NOPCAL f If a PC alarm is issued, ladder data in the PMC RAM is cleared/not cleared.

- - - - - - Number of characters displayed in the remaining travel distance field on the program

-w-e--

tion return operation along the X-axis.

G98 1 Upon power-up, the feed-per-rotation mode/feed-per-minute mode is set. .

PMC.

check screen

Start PMC address where remaining travel distance field characters are set

130) Parameters related to the butt-type reference position setting function (I/l)

No.

0372 to 0375 1

0451,0458 1

0459 to 0462

0872 to 0875

] Symbol I Description

- - - - - - 1 Torque limit value during execution of a butt-type reference position setting cycle

- - - - - - I Butting speed used when a butt-type reference position setting cycle is executed

- - - - - - Speed for reference position setting when a butt-type reference position setting cycle

is executed

- - - - - - Reference position setting distance used when a butt-type reference position setting

cycle is executed

- 25 -

Page 30

(31) Parameters related to the DNC (l/l)

No. 1 Symbol 1

I

0387#0 1 SQDNC 1 In DNC operation, program restart is disabled/enabled.

I

0390#7 NODC3 In DNC.operation, reading is performed block by block/until the buffer becomes full.

0396#0 1 . BCC 1 A BCC value check is performed/is not performed.

I

0396#2

0396#3

I

I

(32) Parameters related to the M-NET (l/l)

I

I

I

r---

I

I

0347 1

0348 ( - - - - - - 1 CNC station address when the DNCI interface is used

0365 - - - - - - mme-out period for the no-response timer

0366 - - - - - - Time-out period for the EOT signal timer

0368

0369 f

0370 I

0490 - - - - - -

No.

0392#2 1

0392#4

0392#5

_ 0392#7 1 SRS2 f The number of M-NET stop bits is l/2.

0360 1

0361 1

0362

0363

0464

0465

0466

0467 1

0468 1 - - - - - -

NCKER An ER (RS-232-C) or TR (RS-422) check is performed/is not performed.

ERCODE

------

- - - - - - Maximum invalid data count value

I

--e-w-

------

A 4-digit hexadecimal error code’is not added/is added to a negative acknowledge-

ment.

I Mode of connection between the CNC and host when the DNCI interface is used

Maximum number of message retransmissions due to NAK

1 Maximum number of characters receivable after transmission termination processing

Maximum datagram (data section) length

I Symbol I

SRLI 1 The M-NET character length is 7/8 bits.

SRPE An M-NET vertical parity check is not performed/is performed.

SREP The M-NET vertical parity is odd/even.

------ 1 M-NETDI bytelength

------ I M-NETDO byte length

- - - - - -

-- -- - -

------

------

------

- - - - - -

M-NET station address

M-NET baud rate

Timer monitoring value ager a connection preparation sequence for the local station is

completed

Polling time monitoring value for an ordinary sequence for the local station

Timer monitoring value from start of SAI transmission to completion of BCC transmission

I

1 Timer value from completion of reception to start of transmission

1 Output destination address for the spindle orientation signal

Description

~ ~~

Description

*

~~~

,

(33)

Parameters related to the Cf-axis (l/l)

No.

0031#6 1

0031#7

0032#7

I Symbol 1 Description

ESFC 1 In the turning mode, a feedback pulse signal from a position detector is invalid/valid.

CNRST

ROT1 0 The parameter unit for inch output is 0.1 [deg/min]/l [deglmin].

In reference position return operation, a relative coordinate along the Cf-axis is not

cleared/is cleared.

- 26 -

Page 31

(34) Parameters related to 2-path lathes (TT) (1 /I )

No.

0046#0