Page 1

GE

LISTED

Grid Solutions

F650 Digital Bay Controller

User Guide

Firmware version: 7.5x

EnerVista F650 Setup version: 7.5x

GE publication code: GEK-113000-AF

*GEK-113000AF*

Page 2

© 2017 GE Multilin Inc. All rights reserved.

GE Multilin F650 Feeder Protection System instruction manual for revision AF.

F650 Feeder Protection System, EnerVista, and EnerVista 650 family

Setup are registered trademarks of GE Multilin Inc.

The contents of this manual are the property of GE Multilin Inc.

This documentation is furnished on license and may not be reproduced in

whole or in part without the permissi

this manual is for informational use only and is subject to change without notice.

Part number: GEK-113000-AF (June 2017)

on of GE Multilin. The content of

Page 3

GE

Grid Solutions

F650 Digital Bay Controller

Table of Contents

1 GETTING STARTED 1.1 Important procedures ..................................................................................... 1-1

1.1.1 Cautions and warnings ....................................................................................................... 1-1

1.1.1.1 General cautions and warnings.................................................................................................1-2

1.1.1.2 Communication board withdrawal/insertion...................................................................... 1-3

1.1.1.3 Magnetic module terminals.........................................................................................................1-4

1.1.2 Inspection checklist............................................................................................................... 1-5

1.1.3 Safety instructions................................................................................................................. 1-7

1.1.3.1 General safety instructions.......................................................................................................... 1-8

1.1.3.2 Warning symbols..............................................................................................................................1-9

1.2 Overview .......................................................................................................... 1-10

1.2.1 Introduction to the 650 family of relays....................................................................1-10

1.2.2 Hardware architecture ......................................................................................................1-10

1.2.2.1 F650 basic design.......................................................................................................................... 1-10

1.2.2.2 F650 signal type............................................................................................................................. 1-11

1.2.3 Communications architecture .......................................................................................1-11

1.3 EnerVista 650 Setup software......................................................................1-14

1.3.1 System requirements.........................................................................................................1-14

1.3.2 Installation...............................................................................................................................1-14

1.3.3 Connecting EnerVista 650 Setup to the F650 .........................................................1-18

1.3.3.1 Configuring an Ethernet connection .................................................................................... 1-18

1.3.3.2 Configuring the RS232 connection....................................................................................... 1-18

1.4 650 hardware .................................................................................................. 1-19

1.4.1 Mounting & wiring................................................................................................................1-19

1.4.2 650 communications..........................................................................................................1-19

1.4.3 Faceplate display .................................................................................................................1-20

1.4.4 Maintenance...........................................................................................................................1-21

1.4.4.1 General maintenance.................................................................................................................. 1-21

1.4.4.2 In-service maintenance.............................................................................................................. 1-21

1.4.4.3 Out-of-service maintenance .................................................................................................... 1-21

1.4.4.4 Unscheduled maintenance....................................................................................................... 1-21

1.4.5 Storage......................................................................................................................................1-21

1.4.6 Repairs.......................................................................................................................................1-22

1.4.7 Disposal.....................................................................................................................................1-22

2PRODUCT

DESCRIPTION

GEK-113000-AF F650 DIGITAL BAY CONTROLLER 1-1

2.1 F650 Overview................................................................................................... 2-1

2.2 ANSI device numbers and functions ............................................................. 2-3

Page 4

CHAPTER 1:

2.3 Other device functions .................................................................................... 2-4

2.4 Order codes ....................................................................................................... 2-5

2.4.1 CIO Modules ..............................................................................................................................2-7

2.5 Technical specifications.................................................................................. 2-8

2.5.1 Protection ...................................................................................................................................2-8

2.5.2 Control....................................................................................................................................... 2-16

2.5.3 Monitoring...............................................................................................................................2-19

2.5.4 User-programmable ..........................................................................................................2-21

2.5.5 Metering ................................................................................................................................... 2-22

2.5.6 Inputs......................................................................................................................................... 2-22

2.5.7 Real time clock......................................................................................................................2-24

2.5.8 Outputs.....................................................................................................................................2-24

2.5.9 Control power supply ........................................................................................................ 2-24

2.5.10 Communications..................................................................................................................2-25

2.5.11 Optical....................................................................................................................................... 2-27

2.5.12 Environmental.......................................................................................................................2-28

2.5.13 Packaging and weight....................................................................................................... 2-28

2.5.14 Type tests................................................................................................................................2-28

2.5.15 Approvals.................................................................................................................................2-29

2.6 External connections .....................................................................................2-30

3INTERFACES,

SETTINGS & ACTUAL

VALUES

3.1 EnerVista 650 Setup software ........................................................................ 3-1

3.1.1 Introduction...............................................................................................................................3-1

3.1.1.1 Using settings files ........................................................................................................................... 3-2

3.1.1.2 Viewing actual values..................................................................................................................... 3-2

3.1.1.3 Viewing triggered events .............................................................................................................. 3-2

3.1.1.4 Firmware upgrades......................................................................................................................... 3-2

3.1.1.5 One line diagrams............................................................................................................................ 3-2

3.1.2 Main screen ...............................................................................................................................3-3

3.1.3 Connect to the relay..............................................................................................................3-4

3.1.3.1 Computer Settings: .......................................................................................................................... 3-5

3.1.3.2 Communication Control: ............................................................................................................... 3-5

3.1.3.3 Communication Optimization:.................................................................................................... 3-5

3.1.4 File management menu ......................................................................................................3-6

3.1.4.1 Offline mode........................................................................................................................................ 3-6

3.1.4.2 Online mode........................................................................................................................................ 3-8

3.1.5 EnerVista 650 Setup menu.............................................................................................. 3-10

3.1.6 File menu .................................................................................................................................3-11

3.1.6.1 New, Open, Save, Save as, and Close ..................................................................................3-12

3.1.6.2 Configuration file converter.......................................................................................................3-13

3.1.6.3 Properties ...........................................................................................................................................3-15

3.1.6.4 Print options......................................................................................................................................3-15

3.1.6.5 Compare to settings file ..............................................................................................................3-16

3.1.6.6 PLC checksum calculation .........................................................................................................3-16

3.1.6.7 Setting checksum calculation ..................................................................................................3-17

3.1.7 Setpoint menu.......................................................................................................................3-17

3.1.7.1 Product setup menu......................................................................................................................3-18

3.1.7.2 Communication settings menu ...............................................................................................3-18

3.1.7.3 System setup menu ......................................................................................................................3-19

3.1.7.4 Breaker menu...................................................................................................................................3-19

3.1.7.5 Protection elements menu.........................................................................................................3-19

3.1.7.6 Control elements menu...............................................................................................................3-22

3.1.7.7 Inputs/Outputs menu ...................................................................................................................3-23

3.1.7.8 Quick settings menu .....................................................................................................................3-24

3.1.7.9 Relay configuration menu..........................................................................................................3-24

3.1.7.10 Logic Configuration menu..........................................................................................................3-26

3.1.7.11 IEC 103 Configuration menu ....................................................................................................3-27

1-2 F650 DIGITAL BAY CONTROLLER GEK-113000-AF

Page 5

CHAPTER 1:

3.1.7.12 Clock menu ....................................................................................................................................... 3-27

3.1.8 Actual values menu.............................................................................................................3-28

3.1.8.1 Front panel........................................................................................................................................ 3-28

3.1.8.2 Status................................................................................................................................................... 3-28

3.1.8.3 Metering ............................................................................................................................................. 3-30

3.1.8.4 Inputs/Outputs menu................................................................................................................... 3-31

3.1.8.5 Records menu ................................................................................................................................. 3-31

3.1.9 Operations menu..................................................................................................................3-32

3.1.10 Communications menu.....................................................................................................3-32

3.1.11 Security menu........................................................................................................................3-34

3.1.12 View menu...............................................................................................................................3-35

3.1.13 Help menu ...............................................................................................................................3-35

3.2 Human-machine interface (HMI) ................................................................ 3-36

3.2.1 Display.......................................................................................................................................3-37

3.2.2 LED indicators ........................................................................................................................3-38

3.2.3 Pushbuttons............................................................................................................................3-38

3.2.3.1 Keypad and shuttle key.............................................................................................................. 3-38

3.2.3.2 Command push button............................................................................................................... 3-40

3.2.4 Front port and cover sealing system..........................................................................3-40

3.2.5 Screen contrast.....................................................................................................................3-41

3.2.6 Text menus..............................................................................................................................3-41

3.2.6.1 Navigation......................................................................................................................................... 3-41

3.2.6.2 Text menu hierarchy.................................................................................................................... 3-42

3.2.6.3 Actual Values ................................................................................................................................... 3-42

3.2.6.4 Snapshot events............................................................................................................................. 3-44

3.2.6.5 Fault report ....................................................................................................................................... 3-45

3.2.6.6 View settings menu....................................................................................................................... 3-47

3.2.6.7 Change Settings ............................................................................................................................. 3-51

3.2.6.8 Date & time....................................................................................................................................... 3-52

3.2.6.9 Commands........................................................................................................................................ 3-53

3.2.6.10 Passwords ......................................................................................................................................... 3-54

3.2.6.11 Select main screen........................................................................................................................ 3-56

3.2.6.12 Select language ..............................................................................................................................3-56

3.2.7 Graphic display .....................................................................................................................3-57

3.2.7.1 One-line diagram........................................................................................................................... 3-57

3.2.7.2 Metering screen.............................................................................................................................. 3-58

3.2.7.3 All events screen ............................................................................................................................ 3-59

3.2.7.4 New events screen........................................................................................................................ 3-61

3.2.7.5 Alarms panel .................................................................................................................................... 3-62

3.2.7.6 Input/output monitoring screen ............................................................................................. 3-63

3.3 Web server...................................................................................................... 3-66

3.3.1 Home..........................................................................................................................................3-66

3.3.2 Snapshot events ...................................................................................................................3-67

3.3.3 Control events........................................................................................................................3-68

3.3.4 Alarms........................................................................................................................................3-69

3.3.5 Oscillography .........................................................................................................................3-70

3.3.6 Fault report..............................................................................................................................3-71

3.3.7 Data logger .............................................................................................................................3-72

4 SECURITY 4.1 Adding users...................................................................................................... 4-1

4.1.1 User rights ................................................................................................................................. 4-1

4.2 Changing passwords ....................................................................................... 4-2

4.3 Enabling security.............................................................................................. 4-3

4.4 Logging into EnerVista 650 Setup ................................................................. 4-4

GEK-113000-AF F650 DIGITAL BAY CONTROLLER 1-3

Page 6

CHAPTER 1:

5 BOOTCODE AND

FIRMWARE

UPGRADE

5.1 Firmware upgrade versions below 7.00. ...................................................... 5-1

5.1.1 Communication parameters .............................................................................................5-3

5.1.2 Bootware version upgrade.................................................................................................5-4

5.1.2.1 Bootware upgrade........................................................................................................................... 5-4

5.1.3 Firmware version upgrade..............................................................................................5-12

5.1.3.1 Introduction.......................................................................................................................................5-12

5.1.3.2 Firmware upgrade .........................................................................................................................5-12

5.1.4 Summary of main steps ................................................................................................... 5-20

5.1.4.1 Boot code upgrade (*) ..................................................................................................................5-20

5.1.4.2 Firmware upgrade(*).....................................................................................................................5-21

5.2 Firmware upgrade version 7.00 or above.................................................. 5-22

5.2.1 Communication parameters ..........................................................................................5-22

5.2.2 Firmware version upgrade..............................................................................................5-23

5.2.2.1 Introduction.......................................................................................................................................5-23

5.2.2.2 Firmware upgrade .........................................................................................................................5-23

5.2.2.3 Order code upgrade process....................................................................................................5-26

5.2.3 Summary of main firmware upgrade steps............................................................ 5-28

6 COMMISSIONING 6.1 Visual inspection............................................................................................... 6-1

6.2 Out of service setting....................................................................................... 6-2

6.3 General considerations, power supply network......................................... 6-3

6.4 Isolation tests.................................................................................................... 6-4

6.5 Indicators........................................................................................................... 6-5

6.6 Power supply testing ....................................................................................... 6-5

6.7 Communications............................................................................................... 6-5

6.8 Verification of measurement ......................................................................... 6-6

6.8.1 Voltages.......................................................................................................................................6-6

6.8.2 Phase currents .........................................................................................................................6-6

6.8.3 Active, reactive power, and COSJ metering ...............................................................6-7

6.8.4 Frequency ..................................................................................................................................6-8

6.9 Inputs and outputs........................................................................................... 6-9

6.9.1 Digital inputs .............................................................................................................................6-9

6.9.2 Contact outputs....................................................................................................................6-10

6.9.3 Circuit continuity supervision inputs .......................................................................... 6-10

6.9.4 Latching circuits ...................................................................................................................6-10

6.10 Connections for testing protection elements ..........................................6-11

6.11 Instantaneous overcurrent (50PH, 50PL, 50N, 50G, 50SG) .....................6-12

6.12 Time overcurrent (51PH, 51PL, 51N, 51G, 46) ...........................................6-13

6.13 Directional elements (67P, 67N, 67G, 67SG).............................................. 6-14

6.13.1 67P element............................................................................................................................6-14

6.13.2 67N element...........................................................................................................................6-14

6.13.3 67G element........................................................................................................................... 6-15

6.13.4 67SG element ........................................................................................................................6-15

6.14 Undervoltage elements (27P, 27X)..............................................................6-17

6.14.1 27P element............................................................................................................................6-17

6.14.2 27X element ........................................................................................................................... 6-17

6.15 Overvoltage elements (59P, 59X, 59NH, 59NL, 47)...................................6-18

6.15.1 59P element............................................................................................................................6-18

6.15.2 59X element ........................................................................................................................... 6-18

6.15.3 59NH and 59NL elements................................................................................................ 6-19

6.15.4 47 element - Neg Seq OV................................................................................................. 6-19

6.16 Frequency elements (81O/81U)................................................................... 6-21

6.17 Recloser (79)....................................................................................................6-22

6.17.1 Reclosing cycle .....................................................................................................................6-22

1-4 F650 DIGITAL BAY CONTROLLER GEK-113000-AF

Page 7

CHAPTER 1:

6.17.2 Recloser status......................................................................................................................6-23

6.17.3 External reclose initiation.................................................................................................6-23

6.18 Thermal image element (49)........................................................................6-24

7FREQUENTLY ASKED

QUESTIONS

7.1 Communications .............................................................................................. 7-1

7.2 Protection .......................................................................................................... 7-3

7.3 Control & HMI .................................................................................................... 7-4

7.4 Relay configuration.......................................................................................... 7-5

8 F650

8.1 Symptoms and recommended actions......................................................... 8-1

TROUBLESHOOTING

GUIDE

A LOGIC OPERANDS A.1 Operands - F650 - model FX - GX .................................................................. A-1

BREDUNDANCY

PROTOCOL

B.1 PRP and HSR Ethernet protocols .................................................................. B-1

B.1.1 PRP ............................................................................................................................................... B-4

B.1.2 HSR ............................................................................................................................................... B-5

B.2 RSTP (IEEE 802.1D-2004) and daisy chain ...................................................B-6

B.2.1 RSTP description .................................................................................................................... B-6

B.2.2 RSTP concepts ........................................................................................................................B-6

B.2.3 Use in meshed networks ................................................................................................... B-7

B.2.4 Daisy chain .............................................................................................................................. B-7

B.3 Link loss alert (LLA) ..........................................................................................B-8

B.3.1 LLA ................................................................................................................................................ B-8

B.3.2 LLA priority ...............................................................................................................................B-8

B.3.3 LLA timeout .............................................................................................................................. B-8

C FACTORY DEFAULT

LOGIC

D FACTORY DEFAULT

CONFIGURATION

D.1 Factory default settings ................................................................................D-1

D.2 Factory default configuration .................................................................... D-28

E MISCELLANEOUS E.1 GE Multilin warranty ....................................................................................... E-1

GEK-113000-AF F650 DIGITAL BAY CONTROLLER 1-5

Page 8

CHAPTER 1:

1-6 F650 DIGITAL BAY CONTROLLER GEK-113000-AF

Page 9

GE

DANGER

WARNING

CAUTION

NOTICE

Grid Solutions

F650 Digital Bay Controller

Chapter 1: Getting Started

GETTING STARTED

1.1 Important procedures

Use this chapter for initial setup of your new F650 Digital Bay Controller.

1.1.1 Cautions and warnings

To help ensure years of trouble free operation, please read through the following chapter for information to help guide you

through the initial installation procedures of your new relay.

Before attempting to install or use the relay, it is imperative that all warnings and cautions in this manual are reviewed to

help prevent personal injury, equipment damage, and/or downtime.

The following safety and equipment symbols are used in this document.

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

Indicates practices not related to personal injury.

GEK-113000-AF F650 DIGITAL BAY CONTROLLER 1-1

Page 10

1.1 IMPORTANT PROCEDURES CHAPTER 1: GETTING STARTED

WARNING

WARNING

NOTICE

1.1.1.1 General cautions and warnings

The following general safety precautions and warnings apply.

Ensure that all connections to the product are correct so as to avoid accidental risk of shock

and/or fire, for example such as can arise from high voltage connected to low voltage terminals.

Follow the requirements of this manual, including adequate wiring size and type, terminal torque settings, voltage,

current magnitudes applied, and adequate isolation/clearance in external wiring from high to low voltage circuits.

Use the device only for its intended purpose and application.

Ensure that all ground paths are uncompromised for safety purposes during device operation and service.

Ensure that the control power applied to the device, the AC current, and voltage input match the ratings specified on

the relay nameplate. Do not apply current or voltage in excess of the specified limits.

Only qualified personnel are to operate the device. Such personnel must be thoroughly familiar with all safety

cautions and warnings in this manual and with applicable country, regional, utility, and plant safety regulations.

Hazardous voltages can exist in the power supply and at the device connection to current transformers, voltage

transformers, control, and test circuit terminals. Make sure all sources of such voltages are isolated prior to

attempting work on the device.

Hazardous voltages can exist when opening the secondary circuits of live current transformers. Make sure that

current transformer secondary circuits are shorted out before making or removing any connection to the current

transformer (CT) input terminals of the device.

For tests with secondary test equipment, ensure that no other sources of voltages or currents are connected to such

equipment and that trip and close commands to the circuit breakers or other switching apparatus are isolated,

unless this is required by the test procedure and is specified by appropriate utility/plant procedure.

When the device is used to control primary equipment, such as circuit breakers, isolators, and other switching

apparatus, all control circuits from the device to the primary equipment must be isolated while personnel are working

on or around this primary equipment to prevent any inadvertent command from this device.

Uses an external disconnect to isolate the mains voltage supply.

LED transmitters are classified as IEC 60825-1 Accessible Emission Limit (AEL) Class 1M. Class 1M

devices are considered safe to the unaided eye. Do not view directly with optical instruments.

This product is rated to Class A emissions levels and is to be used in Utility, Substation Industrial

environments. Not to be used near electronic devices rated for Class B levels.

Figure 1-1: Front view of F650 unit

1-2 F650 DIGITAL BAY CONTROLLER GEK-113000-AF

Page 11

CHAPTER 1: GETTING STARTED 1.1 IMPORTANT PROCEDURES

WARNING

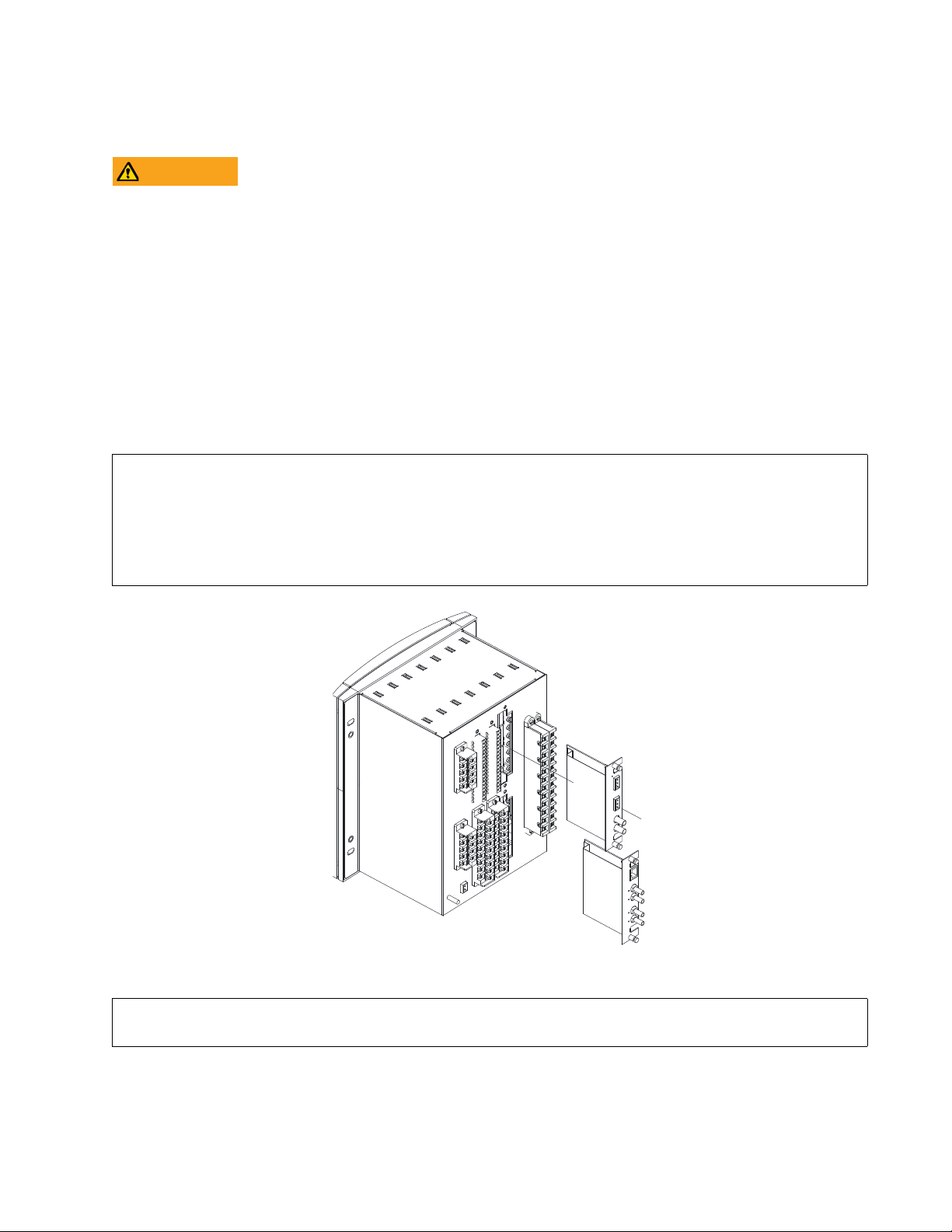

1.1.1.2 Communication board withdrawal/insertion

MODULE WITHDRAWAL AND INSERTION SHALL ONLY BE PERFORMED BY DULY QUALIFIED

SERVICE PERSONNEL. FOR PERSONAL SECURITY PURPOSES, BEFORE ACCOMPLISHING ANY

WITHDRAWAL OR INSERTION OPERATION, THE RELAY MUST BE POWERED OFF AND ALL THE REAR

TERMINALS MUST BE POTENTIAL FREE. THE RELAY MUST BE GROUNDED USING THE REAR

GROUNDING SCREW.

The modular design of the relay allows for the withdrawal and insertion of the communication module.

Figure 1-1: Module withdrawal/insertion shows the location of communication modules on the rear part of the relay.

Qualified personnel must carry out the insertion or extraction of the communication boards only after disconnecting the

relay auxiliary voltage and ensuring that all the rear terminals are potential free.

Communication boards are installed on the rear of the unit, with upper port reserved for the asynchronous

communications board and CAN bus, and the lower port for the ETHERNET board. (The Ethernet module can be withdrawn

or inserted only in models with Rear Ethernet Communication Board 2: "B", "C", "D" or "E". For the remaining options,

Ethernet communications are included in the main CPU).

Before performing any of these actions, control power must be removed from the relay and all the rear terminals must

be potential free. A grounded antistatic wristband must be used when manipulating the module in order to avoid

electrostatic discharges that may cause damage to the electronic components.

WITHDRAWAL: Loosen the small screws that keep the faceplate in place and extract the module.

INSERTION: Insert the module and press it firmly in the case, until it is completely fixed. After this, bolt the faceplate

screws and replace the control power. Check that the relay is fully operative.

GEK-113000-AF F650 DIGITAL BAY CONTROLLER 1-3

Figure 1-1: Module withdrawal/insertion

GE Multilin will not be responsible for any damage to the relay, connected equipment or personnel whenever these

safety rules are not followed.

Page 12

1.1 IMPORTANT PROCEDURES CHAPTER 1: GETTING STARTED

1.1.1.3 Magnetic module terminals

The transformer module for the VTs and CTs is already connected to a female connector screwed to the case. The current

inputs incorporate shorting bars, so that the module can be extracted without the need to short-circuit the currents

externally. It is very important, for safety reasons, not to change or switch the terminals for CTs and VTs.

Figure 1-1: Rear view of F650 unit

GE Multilin will not be responsible for any damage of the relay, connected equipment or personnel whenever

these safety rules are not followed.

1-4 F650 DIGITAL BAY CONTROLLER GEK-113000-AF

Page 13

CHAPTER 1: GETTING STARTED 1.1 IMPORTANT PROCEDURES

1.1.2 Inspection checklist

1. Unwrap the relay and inspect the relay for physical damage.

2. View the nameplate and verify that the correct model has been or

top.

dered and delivered. The model number is at the

Figure 1-2: Identification label (A4454P6)

Please ensure that you received the following items with your relay:

• Mounting screws for fixing the relay to a cabinet

• GE EnerVista™ DVD (includes the EnerVista 650 Setup

• Wiring diagram.

• Certificate of Compliance

For product information, instruction manual updates, and the latest software updates, please visit the GE Multilin Home

Page: http://www.gegridsolutions.com/multilin

GEK-113000-AF F650 DIGITAL BAY CONTROLLER 1-5

software and manuals in PDF format)

Page 14

1.1 IMPORTANT PROCEDURES CHAPTER 1: GETTING STARTED

CAUTION

Note: If there is any physical damage detected on the relay, or any of the contents listed are missing, please contact

GE Grid Solutions, Multilin immediately:

EUROPE, MIDDLE EAST AND AFRICA:

GE Grid Solutions

Av. Pinoa, 10

48170 Zamudio, Vizcaya (SPAIN)

Tel.: (34) 94-485 88 54

Fax: (34) 94-485 88 38

E-mail: multilin.tech.euro@ge.com

AMERICA, ASIA AND AUSTRALIA:

GE Grid Solutions

650 Markland Street

Markham, Ontario

Canada L6C 0M1

North America toll-free: +1 800 547 8629

Tel.: +1 905 927 7070

Fax: +1 905 927 5098

E-mail: multilin.tech@ge.com

The information provided herein is not intended to cover all the details of the variations of the

equipment, nor does it take into account the circumstances that may be present in your

installation, operating or maintenance activities.

Should you wish to receive additional information, or for any particular problem that cannot be solved by referring to the

information contained herein, please contact General Electric, Grid Solutions.

1-6 F650 DIGITAL BAY CONTROLLER GEK-113000-AF

Page 15

CHAPTER 1: GETTING STARTED 1.1 IMPORTANT PROCEDURES

1.1.3 Safety instructions

The F650 ground screw shown in Figure 1-3: Location of grounding screw must be correctly grounded.

Figure 1-3: Location of grounding screw

Before communicating with the F650 through the front USB port, ensure that the computer's power supply is grounded.

When using a laptop, it is recommended that the power supply be disconnected. In many cases the laptop may not be

correctly grounded either due to the power supply or to the connector cables used.

GE Multilin will not be responsible for any damage to the relay or connected equipment when this basic safety rule

is not followed.

GEK-113000-AF F650 DIGITAL BAY CONTROLLER 1-7

Page 16

1.1 IMPORTANT PROCEDURES CHAPTER 1: GETTING STARTED

CAUTION

1.1.3.1 General safety instructions

• Failure to practice safe working procedures is likely to damage the equipment, cause severe injury and/or death.

• The use of appropriate safety gloves, safety glasses and pr

installation, maintenance and service of the equipment.

• All procedures must be strictly adhered to.

• Failure to observe and follow the instructi

damage to the equipment and could lead to property damage, personal injury and/or death.

• Before attempting to use the equipment, it is important that all danger and caution indicators are reviewed.

• If the equipment is used in a manner not specified by t

caution. Otherwise, the protection provided by the equipment may be impaired and can result in Impaired

operation and injury.

• Beware of potential hazards, wear personal protective e

and objects that may have been left inside the equipment.

• Caution: Hazardous voltages can caus

• Test/Installation/Service personnel must be familiar with general device t

follow standard ESD precautions to avoid personal injury or equipment damage.

• Before performing visual inspections, tests, or periodic m

or disconnect all hazardous live circuits and sources of electric power.

• Failure to shut equipment power off prior to removing the pow

voltages causing injury or death.

• All recommended equipment that should be grounded must hav

for safety purposes, protection against electromagnetic interference and proper device operation.

• Equipment grounds should be bonded together and connect

power.

• Keep all ground leads as short as possible.

• At all times, equipment ground terminal must b

• While the equipment manual may suggest several safety and

conjunction with the safety codes in force at your location.

• LED transmitters are classified as IEC 60825-1 Accessible Emission Li

considered safe to the unaided eye. Do not view directly with optical instruments.

• It is the responsibility of the user to check the equipment r

commissioning, service.

• Use a lift system with side rails/bucket to reduce a fall hazar

servicing.

• In addition to the safety precautions mentioned all ele

jurisdiction electrical code.

• Before working on CTs, they must be short circuited.

• Do not remove the voltage terminal blocks

live. The voltage inputs must be de-energized prior to any servicing.

ons provided in the equipment manual(s) could cause irreversible

e shock, burns or death.

e grounded during device operation.

or disconnect the voltage input wires when the voltage phases are

otective clothing are recommended during equipment

he manufacturer or functions abnormally, proceed with

quipment and carefully inspect the work area for tools

est practices, safety precautions and

aintenance on this device or associated circuits, isolate

er connections could expose you to dangerous

e a reliable and un-compromised grounding path

ed to the facility's main ground system for primary

reliability steps, safety precautions must be used in

mit (AEL) Class 1M. Class 1M devices are

atings and installation instructions prior to

d as opposed to other means when installing or

ctrical connections made must respect the applicable local

1-8 F650 DIGITAL BAY CONTROLLER GEK-113000-AF

Page 17

CHAPTER 1: GETTING STARTED 1.1 IMPORTANT PROCEDURES

!

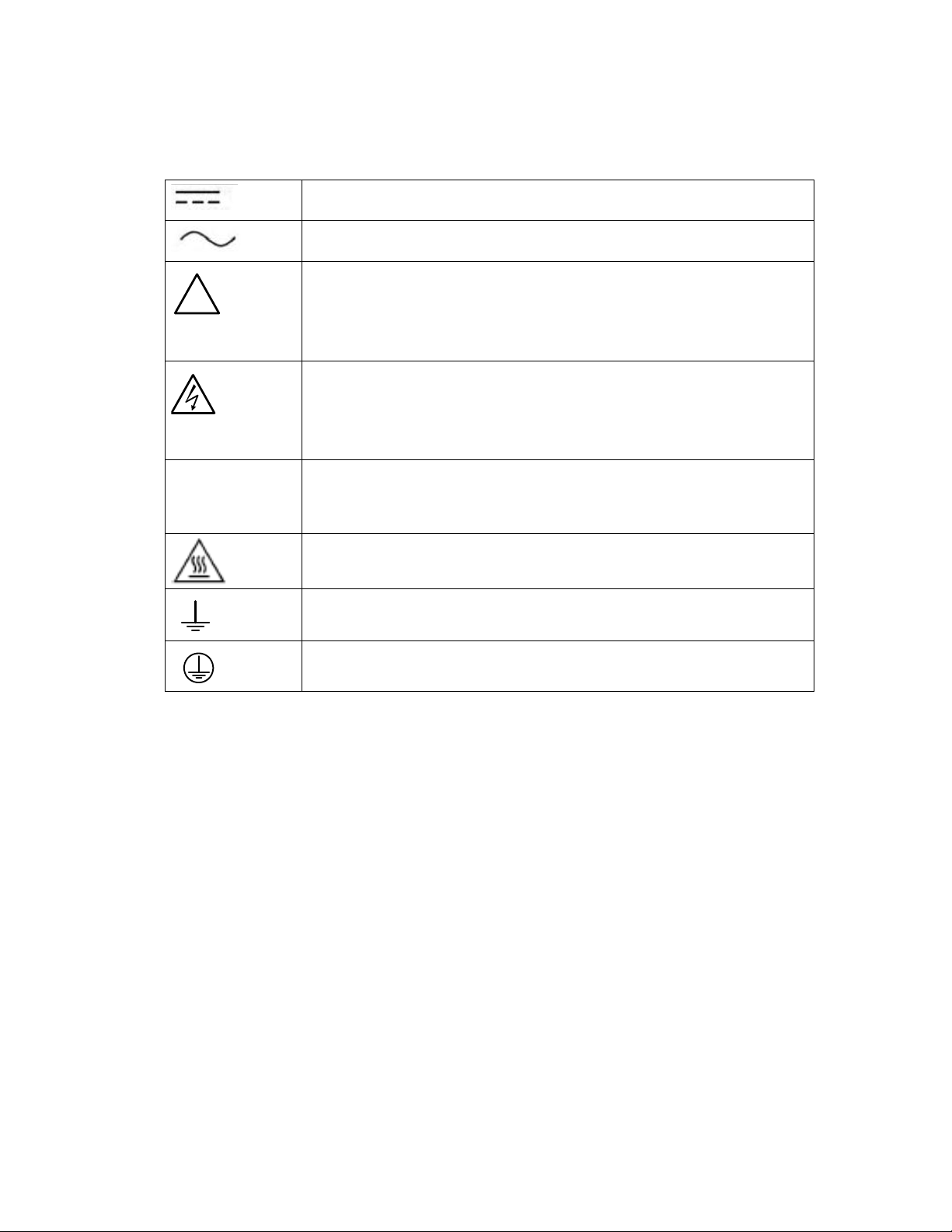

1.1.3.2 Warning symbols

The following table explains the meaning of warning symbols that may appear on the device or in this manual.

The relevant circuit is direct current .

Le circuit principal est à courant continu.

The relevant circuit is alternating current.

Le circuit principal est à courant alternatif.

CAUTION: Refer t

instructions. Failure to take or avoid a specified action can result in loss of data or

physical damage.

AVERTISSEMENT:

L'absence ou èviter de prender des mesures spècifiques peut entraîner des pertes

de données ou même causer des dommages physiques.

WARNI NG!

within the unit. Failure to take or avoid a specified action can result in physical

harm to the user.

AVERTISSEMENT! T

sont presents dans l'equipement. L'absence ou èviter de prender des mesures

spècifiques peut causer des dommages physiques à l'utilisateur.

CAUTION: Cla

DO NOT VIEW DIRECTLY WITH OPTICAL INSTRUMENTS.

AVERTISSEMENT: La

DIRECTEMENT LE DISPOSITIF QUI ÉMET LE LASER OPTIQUE.

CAUTION: Hot sur

AVERTISSEMENT: Su

o the documentation for important operating and maintenance

Se réferer à la documentation pour l'entretien et l'utilisation.

Dangerous voltage constituting a risk of electric shock is present

ensions dangereuses comportant un risque de choc électrique

ss 1M Laser (IEC 60825-1 Safety of laser products)

ser de classe 1M (IEC60825-1) ÉVITER DE REGARDER

face.

rface chaude.

Earth (Ground) Terminal.

Terminal de terre (masse).

Protective Earth Terminal.

Terminal de terre de protection.

Note: Read all instructions included in package before using your product. Additional safety information

Product Safety Supplement document available at; http://www.gegridsolutions.com/ProductSafety/

GEK-113000-AF F650 DIGITAL BAY CONTROLLER 1-9

Page 18

1.2 OVERVIEW CHAPTER 1: GETTING STARTED

1.2 Overview

1.2.1 Introduction to the 650 family of relays

The GE 650 family relay is a new generation of digital and multifunction equipment that is easily incorporated into

automation systems, at both the station and enterprise levels.

1.2.2 Hardware architecture

1.2.2.1 F650 basic design

The 650 is a digital-based device containing a central processing unit (CPU) that handles multiple types of input and output

signals. The 650 family can communicate over a local area network (LAN) with an operator interface, a programming

device, or another 650 device.

The CPU module contains firmware that provides protection elements in the form of logic algorithms, as well as

programming logic gates, timers, and latches for control features.

Input Elements accept a variety of analog or digital signals from the field. The 650 isolates and converts these signals into

logic signals used by the relay.

Output Elements convert and isolate the logic signals generated by the relay into digital signals that can be used to

control field devices.

Figure 1-1: 650 concept block diagram

1-10 F650 DIGITAL BAY CONTROLLER GEK-113000-AF

Page 19

CHAPTER 1: GETTING STARTED 1.2 OVERVIEW

1.2.2.2 F650 signal type

Contact Inputs/Outputs: Digital signals.

CT and VT inputs: Signals coming from the inputs of current and voltage transformers, used for monitoring the power

system signals.

Remote CAN Bus Inputs/Outputs: Signals associated with physical input/output contacts from a Remote Digital Input/

Output Module (CIO) connected to the 650 unit via the CAN Bus existing in options X, Y, Z, C and M for rear serial

communication board 1.

PLC: Programmable Logic Controller. Control module that enables the unit configuration (assignment of inputs/outputs)

and the implementation of logic circuits.

Protection Elements: Relay protection elements, for example: Overcurrent, overvoltage, etc.

Remote inputs and outputs: Provide a means of sharing digital point state information between remote devices using IEC

61850 GSSE and GOOSE messages.

Analog Inputs: Signals associated with transducers.

1.2.3 Communications architecture

A dedicated serial port is used for communication between the main processor and the human-machine interface. The

serial connection provides immunity against electromagnetic disturbances, thus increasing system safety.

All 650 units incorporate one RS232 (USB or DB9)serial port on the front of the relay. They can also incorporate up to two

additional communication modules on the rear.

One of the modules provides asynchronous serial communications, using different physical media (RS485 + cable remote

CAN bus I/O, plastic or glass fiber optic) depending on the selected model. The module incorporates two identical ports,

COM1 and COM2. The COM2 port is multiplexed with the front port. Additionally, this module may incorporate a port for

CAN bus communications, used for the connection to the remote CAN Bus I/O module. This feature increases the I/O

capability by up to 100% if the maximum number of I/Os available inside the relay is not enough for a specific application.

Available options are:

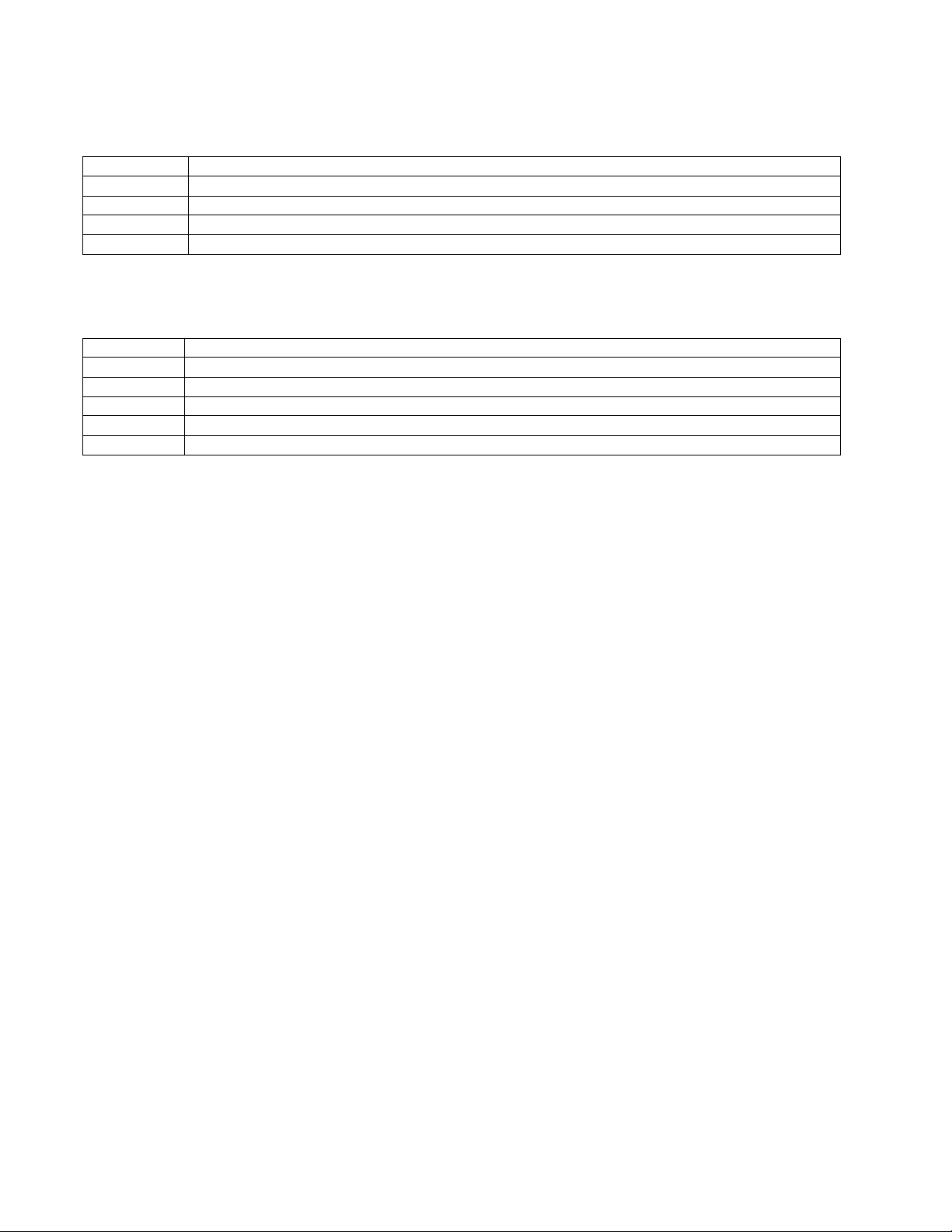

Table 1-1: Rear serial communications board 1

Board Code Functionality

F Without additional communication ports

A Two RS485 ports

P Two Plastic F.O. ports

G Two Glass F.O. ports

X Two RS485 ports and a CAN port for remote CAN bus Inputs/Outputs

Y Two Plastic F.O. ports and a CAN port for remote CAN bus Inputs/Outputs (fiber)

Z Two Glass F.O. ports and a CAN port for remote CAN bus Inputs/Outputs (fiber)

C CAN port for remote CAN Bus I/O (cable)

M RS485 + RS485 port and a CAN port for remote CAN Bus I/O (cable)

The other module provides Ethernet communications (ETH Port), using 10/100BaseTX (self-negotiable speed) or 100BaseFX

connectors, depending on the selected model. The most complete models include a double redundant 100BaseFX fiber

optic port. Redundancy is provided at the physical level, for options D and E; the unit incorporates internally duplicated

and independent controllers for extended system reliability and accessibility.

GEK-113000-AF F650 DIGITAL BAY CONTROLLER 1-11

Page 20

1.2 OVERVIEW CHAPTER 1: GETTING STARTED

Available Options are:

Table 1-2: REAR ETHERNET COMMUNICATIONS BOARD 2

Board Code Functionality

B One 10/100BaseTX port (self-negotiable speed)

C One 10/100BaseTX port and one 100BaseFX port.

D One 10/100BaseTX port and redundant 100BaseFX ports

E Redundant 10/100BaseTX ports

For options C and D you must select the active physical media, by means of an internal selector inside the module. The

factory configuration for this selection is the 10/100BaseTX port. For firmware versions 7.00 and above, the following

options are available:

G 1588, 10/100 Base TX* + 100 Base TX

H 1588, 10/100 Base TX* + 100 Base FX

J PRP, 1588, 10/100 Base TX* + Redundant 100 Base FX

K PRP, HSR, RSTP, 1588, 10/100 Base TX* + Redundant 100 Base FX

L PRP, 1588, 10/100 Base TX + Redundant 100 Base TX

M PRP, HSR, RSTP, 1588, 10/100 Base TX + Redundant 100 Base TX

Finally, internal communication with input and output modules is performed via an internal CAN Bus, independent of the

one used for remote CAN Bus I/Os. This provides increased communication speed, and acknowledgement of modules,

abnormalities, etc. As this is a serial port supporting a communications protocol, it provides immunity against external or

internal disturbances.

1-12 F650 DIGITAL BAY CONTROLLER GEK-113000-AF

Page 21

CHAPTER 1: GETTING STARTED 1.2 OVERVIEW

DSP

MEASUREMENT

PROCESSO R

ANALOG

INP UT S

CURENT AC

AND

VOLTAGE AC

I/O I/O

DIGITAL SUPERVISION

ETH1

ETH2 ETH3

Redundancy

(Optional)

CAN COM1 COM2

CAN

REMOTE

I/O

CAN I/O

INTE RNAL

SERIAL

COM 1

SERIAL

COM 2

SERIAL

COM H

COM2

SERIAL

COM H

HMI

HUMAN MACHINE IN TERFACE

FRONT

SERIAL

PORT

MULTIPLEXED

ETHERNET COMMUNICATIONS

MAIN PROCESSOR

COMMUNICATION

CONTROL

PROTEC TION

Figure 1-1: Communications architecture (B6816F2)

GEK-113000-AF F650 DIGITAL BAY CONTROLLER 1-13

Page 22

1.3 ENERVISTA 650 SETUP SOFTWARE CHAPTER 1: GETTING STARTED

1.3 EnerVista 650 Setup software

1.3.1 System requirements

The relay front panel or the EnerVista 650 Setup software can be used to communicate with the relay. The software

interface is the preferred method to edit settings and view actual values because the computer monitor can display more

information.

The minimum system requirements for the EnerVista 650 Setup software are as follows:

• Pentium® 4 (Core Duo recommended).

• Windows® XP with Service Pack 2 (Service Pack 3

• 1 GB of RAM (2 GB recommended).

• 500 MB free hard drive space (1 GB recommended).

• 1024 x 768 display (1280 x 800 recommended).

• RS232 and USB serial and/or Ethernet por

t for communications with the relay.

1.3.2 Installation

After ensuring the minimum requirements for using EnerVista 650 Setup are met (see previous section), obtain the

software from the GE EnerVista DVD, or download from: http://www.gegridsolutions.com/multilin/ as follows:

1. Insert the GE EnerVista DVD into the DVD drive of your computer.

2. Click In

3. When installation is complete, start the EnerVista Launchpad application.

4. Click IED

stall Now and follow the installation instructions to install the complimentary EnerVista software.

Setup in the Launch Pad window.

recommended), Windows 7, or Windows 8

Figure 1-2: Launchpad window

1-14 F650 DIGITAL BAY CONTROLLER GEK-113000-AF

Page 23

CHAPTER 1: GETTING STARTED 1.3 ENERVISTA 650 SETUP SOFTWARE

5. Click Add Product and select the “F650 Bay Controller” relay from the Install Software window as shown below. Select

the “Web” option to ensure the most recent software release, or select “CD” if you do not have a web connection, then

click Add Now to list software items for the F650.

Figure 1-3: Add Product window

6. EnerVista Launchpad obtains the installation program from the

Web or CD. Once the download is complete, double-

click the installation program to install the EnerVista 650 Setup software.

7. Follow the on-screen instructions to install the EnerVista 650 Setup software. When the Welc

click Next to continue with the installation.

Figure 1-4: EnerVista 650 Setup installation

ome window appears,

GEK-113000-AF F650 DIGITAL BAY CONTROLLER 1-15

Page 24

1.3 ENERVISTA 650 SETUP SOFTWARE CHAPTER 1: GETTING STARTED

8. When the Choose Destination Location window is displayed, change the installation directory id needed by clicking

Change… and typing in the complete path name including the new directory name. Click Next to continue with the

installation.

Figure 1-5: EnerVista 650 Setup installation cont.

9. The default program group containing the application is added to as shown in the Se

lected Program Folder window.

Click Next to begin the installation process, and all the necessary program files are copied into the selected directory.

Figure 1-6: Select program folder

1-16 F650 DIGITAL BAY CONTROLLER GEK-113000-AF

Page 25

CHAPTER 1: GETTING STARTED 1.3 ENERVISTA 650 SETUP SOFTWARE

10. To complete the installation, select the desired language for startup.

Figure 1-7: Language window

11. Click Fin

ish to end the installation. The F650 device has been added to the list of installed IEDs in the EnerVista

Launchpad window, as shown below.

Figure 1-8: EnerVista Launchpad

GEK-113000-AF F650 DIGITAL BAY CONTROLLER 1-17

Page 26

1.3 ENERVISTA 650 SETUP SOFTWARE CHAPTER 1: GETTING STARTED

1.3.3 Connecting EnerVista 650 Setup to the F650

This section is intended as a quick start guide to using the EnerVista 650 Setup software. Refer to section 4.1 in this manual

for more information about the EnerVista 650 Setup software interface.

1.3.3.1 Configuring an Ethernet connection

Before starting, verify that the Ethernet network cable is properly connected to the Ethernet port on the back of the relay.

1. Install and start the latest version of the EnerVista 650 Setup software (available from the GE EnerVista DVD or online

from http://www.gegridsolutions.com/multilin (see previous section for installation instructions).

2. Go to Co

3. Select Con

parameters that must be entered for proper Ethernet communications.

4. Enter the relay IP address (from Setpoint >

IP Address field in MODBUS TCP/IP SETUP.

5. Enter the relay ModBus address (from Setpoin

ModBus Address COM1/COM2 setting) in the Unit Identifier (Slave Address) field.

6. Enter the ModBus port address (from Setpoint > Pr

ModBus Port Number setting) in the ModBus Port field.

7. The Device has now been configured for Ethernet communications. Click ON

mmunication > Computer.

trol Type as MODBUS TCP/IP from the drop-down list. This option displays a number of interface

Product Setup > Communication Settings > Network > IP Address) in the

t > Product Setup > Communication Settings > ModBus Protocol >

oduct Setup > Communication Settings > ModBus Protocol >

to begin communicating.

1.3.3.2 Configuring the RS232 connection

Before starting, verify that the RS232 serial cable, or the USB Cable, is properly connected to the RS232port or the USB port

on the front panel of the relay.

1. Install and start the latest version of the EnerVista 650 Setup software (available from the GE EnerVista DVD or online

from http://www.gegridsolutio

2. Go to Co

3. Under Contr

4. Enter the relay Slave Address (Se

Address field. The default value is 254.

5. Enter the physical communications parameters (Baud rate and parity settings) from the Set

Communication Settings > Serial Ports menu. Default values are 19200 for baud rate and none for parity.

6. The unit has now been configured for RS232 communications. Click ON

mmunication > Computer and enter the following data referred to communications:

ol Type select No Control Type from the drop-down list.

ns.com/index.htm (see previous section for installation instructions).

tpoint > Product Setup > Communication Settings > ModBus Protocol) in the Slave

point > Product Setup >

to begin communicating.

1-18 F650 DIGITAL BAY CONTROLLER GEK-113000-AF

Page 27

CHAPTER 1: GETTING STARTED 1.4 650 HARDWARE

1.4 650 hardware

1.4.1 Mounting & wiring

Refer to Chapter 3. Hardware for detailed mounting and wiring instructions.

1.4.2 650 communications

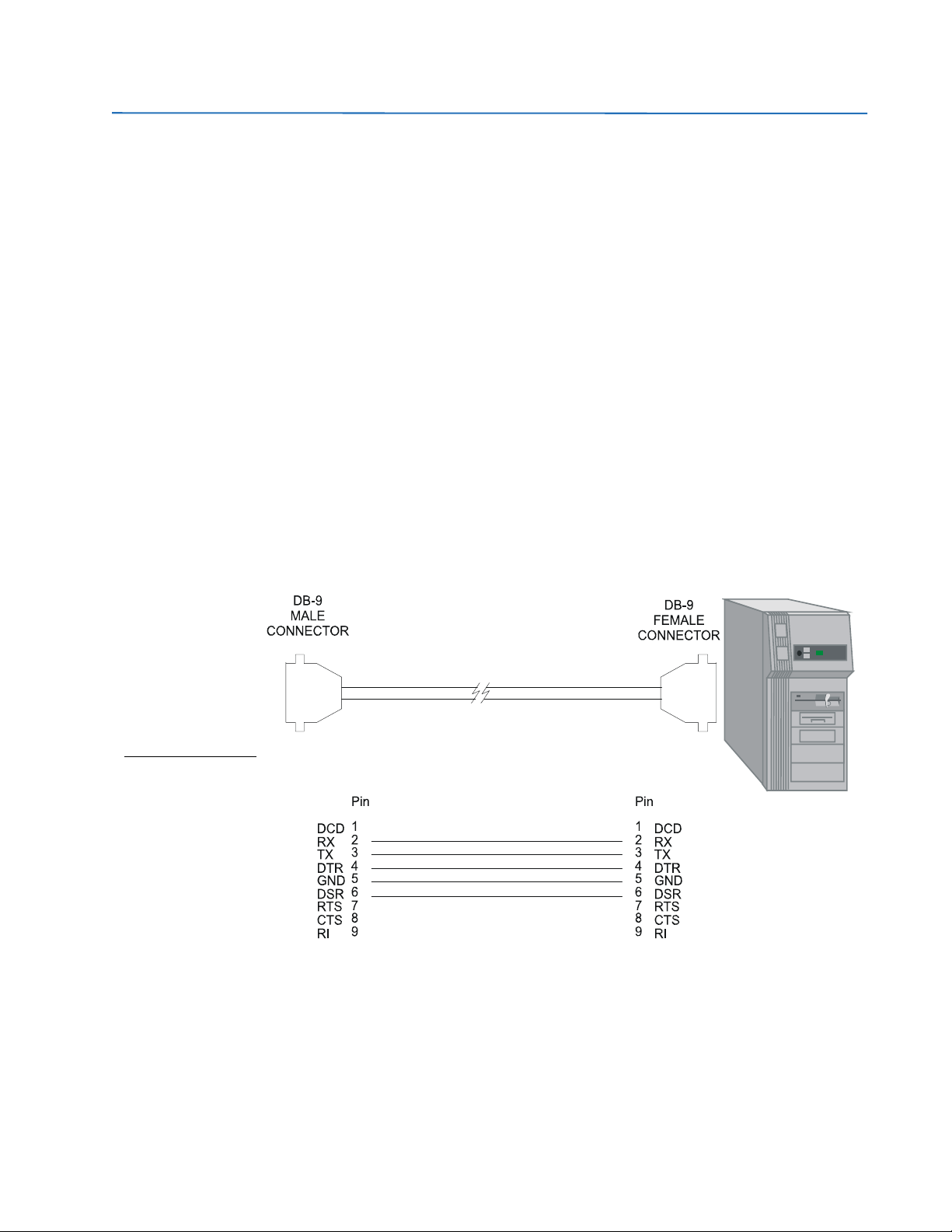

The Enervista 650 Setup software communicates with the relay via the faceplate USB port in hardware 04 (E in order code)

or RS232 port or the rear RS485/Ethernet ports. To communicate via the faceplate RS232 port, a standard “straightthrough” serial cable is used. The DB-9 male end is connected to the relay and the DB-9 or DB-25 female end is connected

to the PC COM1 or COM2 port as described in Figure 1-1: Relay- PC connection for RS232 front port. To communicate via

USB port a male A / male B USB shielded wire is needed

To communicate via the F650 rear RS485 port from a PC RS232 port, the GE Multilin RS232/RS485 converter box is

required. This device (catalog number F485) connects to the computer using a “straight-through” serial cable. A shielded

twisted-pair (20, 22 or 24 AWG according to American standards; 0.25, 0.34 or 0.5 mm2 according to European standards)

connects the F485 converter to the F650 rear communication port.

To minimize communication errors that can be caused by external noise, a shielded twisted pair is recommended. In order

to avoid loops where external currents can flow, the cable shield must be grounded at one end only.

The converter box (-, +, GND) terminals are connected to the relay (SDA, SDB, GND) terminals respectively. For long

communications cables (longer than 1 km), the RS485 circuit must be terminated in an RC network (i.e. 120 ohm, 1 nF). This

circuit is shown in Figure 1-2: RS485 connection for 650 units, associated with the text Zt(*).

Figure 1-1: Relay- PC connection for RS232 front port

To minimize errors from noise, the use of shielded twisted pair wire is recommended. For correct operation, polarity must

be respected, although a different polarity will not damage the unit. For instance, the relays must be connected with all

RS485 SDA terminals connected together, and all SDB terminals connected together. This may result in confusion, as the

RS485 standard refers to terminals “A” and “B”, although many devices use terminals labeled “+” and “-“.

GEK-113000-AF F650 DIGITAL BAY CONTROLLER 1-19

Page 28

1.4 650 HARDWARE CHAPTER 1: GETTING STARTED

As a general rule, terminals labeled “A” should be connected to terminals “-“, and terminals “B” to “+”. The GND terminal

should be connected to the common wire inside the shield, when provided. Otherwise, it should be connected to the shield.

Each relay should also be daisy chained to the next relay in the system. A maximum of 32 relays can be connected in this

manner without exceeding driver capability; for larger systems, additional serial channels must be added. It is also

possible to use commercially available repeaters to increase the number of relays on a single channel. Do not use other

connection configurations.

Lightening strikes and ground surge currents can cause large momentary voltage differences between remote ends of the

communication link. For this reason, surge protection devices are provided internally. To ensure maximum reliability, all

equipment should have similar transient protection devices installed.

Figure 1-2: RS485 connection for 650 units

To communicate through the F650 rear Ethernet port from a PC, a crossover cable is required. If the connection is

performed through a hub or a switch, a direct Ethernet cable is required.

1.4.3 Faceplate display

All messages are displayed on a 20x4 character LCD display. An optional graphic display is also available. Messages are

displayed in different languages depending on the model and configuration settings.

1-20 F650 DIGITAL BAY CONTROLLER GEK-113000-AF

Page 29

CHAPTER 1: GETTING STARTED 1.4 650 HARDWARE

NOTICE

NOTICE

1.4.4 Maintenance

1.4.4.1 General maintenance

The F650 requires minimum maintenance once it is commissioned into service. F650 is a microprocessor based relay and

its characteristics do not change over time; as such no further functional tests are required. While the F650 performs

continual self-tests, it is recommended that maintenance be scheduled with other system maintenance. This maintenance

can involve in-service, out-of-service, or unscheduled maintenance.

If it is concluded that the relay or one of its modules is of concern, contact GE Multilin or one of its representative for

prompt service.

1.4.4.2 In-service maintenance

1. Visual verification of the analog value integrity such as voltage and current (in comparison to other devices in the

system).

2. Visual verification of active alarms, relay display messages and LED indications.

3. Visual inspection for any damage, corrosion, dust or loose wires.

4. Event recorder file download with further event analysis.

1.4.4.3 Out-of-service maintenance

1. Check wiring connections for firmness.

2. Analog value (current, voltages, analog inputs) injection test and metering accuracy verification. Calibrated test

uipment is required.

eq

3. Protection element setpoint verification (analog values injec

relay settings).

4. Contact inputs and outputs verification. This test can be conducted by direct change of state forcing or as part of the

syst

em functional testing.

5. Visual inspection for any damage, corrosion or dust.

6. Event recorder file download with further events analysis.

To avoid deterioration of electrolytic capacitors, power up units that are stored in a de-energized

state once per year, for one hour continuously.

tion or visual verification of setting file entries against

1.4.4.4 Unscheduled maintenance

Unscheduled maintenance such as during a disturbance causing system interruption:

• View the event recorder and oscillography or fault report for correct operation of inputs,outputs and elements.

1.4.5 Storage

Store the unit indoors in a cool, dry place. If possible, store in the original packaging. Follow the storage temperature range

outlined in the Specifications.

To avoid deterioration of electrolytic capacitors, power up units that are stored in a de-energized

state once per year, for one hour continuously.

GEK-113000-AF F650 DIGITAL BAY CONTROLLER 1-21

Page 30

1.4 650 HARDWARE CHAPTER 1: GETTING STARTED

1.4.6 Repairs

The firmware and software can be upgraded without return of the device to the factory.

For issues not solved by troubleshooting, the process to return the device to the factory for repair is as follows:

• Contact a GE Grid Solutions Technical Support Center. Contact information is found in the first chapter.

• Obtain a Return Materials Authorization (RMA) number from the Technical Support Center.

• Verify that the RMA and Commercial Invoice received have the correct information.

• Tightly pack the unit in a box with bubble wrap, foam material, or styrofoam inserts or packaging peanuts to cushion

em(s). You may also use double boxing whereby you place the box in a larger box that contains at least 5 cm of

the it

cushioning material.

• Ship the unit by courier or freight forwarder, along with the Commercial Invoice and RMA, to the factory.

• Fax a copy of the shipping information to the GE Grid Solutions service department. Customers are responsible for

shipp

ing costs to the factory, regardless of whether the unit is under warranty.

Use the detailed return procedure outlined at

https://www.gegridsolutions.com/multilin/support/ret_proc.htm

The current warranty and return information are outlined at

https://www.gegridsolutions.com/multilin/warranty.htm

1.4.7 Disposal

The F650 is intended to be part of defective large-scale stationary industrial tools and large-scale fixed installations. This

product cannot be disposed of as unsorted municipal waste in the European Union. For proper recycling return this

product to your supplier or a designated collection point. For more information go to www.recyclethis.info.

1-22 F650 DIGITAL BAY CONTROLLER GEK-113000-AF

Page 31

GE

Grid Solutions

F650 Digital Bay Controller

Chapter 2: Product Description

PRODUCT DESCRIPTION

2.1 F650 Overview

F650 is a protection, control, monitoring, metering and registering unit, suitable for many different applications, such as

main protection for distribution feeders and transmission lines, as well as backup protection for transformers, busbars,

capacitor banks, etc.

Overvoltage and undervoltage protection, overfrequency and underfrequency protection, breaker failure protection,

directional current supervision fault diagnostics and programmable logic functions are provided.

This relay also provides phase, neutral, ground and sensitive ground, instantaneous and time overcurrent protection. The

time overcurrent function provides multiple curve shapes or FlexCurves™ for optimum co-ordination. Automatic reclosing,

synchrocheck, and line fault locator features are also provided.

Voltage, current, power, and energy metering is built into the relay as a standard feature. Current parameters are

available as true RMS magnitude, or as RMS magnitude of undamental frequency and angle (phasor).

Diagnostic features include a sequence of records. The internal clock used for time-tagging can be synchronized with an

IRIG-B signal or via SNTP, DNP or Modbus protocol over the Ethernet port. From firmware version 7.00 and above, IEEE

1588 time protocol is also available. Precise time stamping allows the sequence of events to be determined throughout the

system. Oscillography data capture may be set to record the measured parameters before and after the event for viewing

on a personal computer (PC). These tools significantly reduce troubleshooting time and simplify report generation in the

event of a system fault.

A faceplate RS232 or USB port may be used to connect to a PC for programming settings and monitoring actual values.

A variety of communications modules are available. Two rear RS485 ports allow independent access by operating and

engineering personnel. All serial ports use the Modbus® RTU protocol. Optional communications modules include a

100BaseFX Ethernet interface which can be used to provide fast, reliable communications in noisy environments.

GEK-113000-AF F650 DIGITAL BAY CONTROLLER 2-1

Page 32

2.1 F650 OVERVIEW CHAPTER 2: PRODUCT DESCRIPTION

Another option provides two 100BaseFX fiber optic ports for redundancy. The Ethernet port supports IEC 61850, Modbus®/

TCP, DNP 3.0 and TFTP protocols, and allows access to the relay via any standard web browser. The IEC 60870-5-104

protocol is supported on the Ethernet port. The Ethernet port also supports the Parallel Redundancy Protocol (PRP) and

High-availability Seamless Redundancy (HSR) of IEC 62439-3 (clause 4 (PRP) and clause 5 (HSR)) for firmware version 7.00

and so on.

Rear port COM1 can be set to support IEC60870-5-103 protocol

The F650 IEDs use flash memory technology which allows field upgrading as new features are added:

Figure 2-1: FUNCTIONAL BLOCK DIAGRAM

2-2 F650 DIGITAL BAY CONTROLLER GEK-113000-AF

Page 33

CHAPTER 2: PRODUCT DESCRIPTION 2.2 ANSI DEVICE NUMBERS AND FUNCTIONS

2.2 ANSI device numbers and functions

Main features available in the relay are gathered in tables below

DEVICE NUMBER PROTECTION & CONTROL FUNCTIONS

25 Synchronism Check

27/27X Bus/Line Undervoltage

32 Sensitive Directional Power

32FP Forward Power

32N Wattmetric Zero-Sequence Directional

46 Negative Sequence Time Overcurrent

47 Negative Sequence Voltage

48 Locked Rotor

49 Thermal Image - overload protection

50 BF Breaker Failure

50PH/PL Phase Instantaneous Overcurrent (High/Low)

50N Neutral Instantaneous Overcurrent

50G Ground Instantaneous Overcurrent

50SG Ground Instantaneous Overcurrent for sensitive ground systems (measured from 5

50IG Isolated Ground Instantaneous Overcurrent (measured from 5

51N Neutral Time Overcurrent

51G Ground Time Overcurrent

51SG Sensitive Ground Time Overcurrent

51PH/V Voltage Restraint Phase Time Overcurrent

51PL/V Voltage Restraint Phase Time Overcurrent

59/59X Bus/Line Overvoltage

59NH/NL Neutral Overvoltage - High/Low

67P Phase Directional Overcurrent

67N Neutral Directional Overcurrent

67SG Sensitive Ground Directional Overcurrent

79 Autoreclose (Four shot recloser)

81 U/O Under/Over Frequency Broken Conductor Detection

N/A Load Encroachment

N/A Broken Conductor

81df/dt Frequency Rate of Change

VTFF VT Fuse Failure Detection

60CTS Failure Current Transformer Failure **

2nd Harmonic

Inhibit

transformer input)

th current transformer input)

Second Harminic Inhibit **

th current

** These functions are available for firmware version 7.50 or above

GEK-113000-AF F650 DIGITAL BAY CONTROLLER 2-3

Page 34

2.3 OTHER DEVICE FUNCTIONS CHAPTER 2: PRODUCT DESCRIPTION

2.3 Other device functions

INPUTS/OUTPUTS METERING COMMUNICATIONS

9 Analog Inputs:

5 current inputs (3 for phases, 1 for ground, 1

for sensitiv

4 voltage inputs (3 for phases, 1 for busbar or

auxil

Digital Programmable Contact Inputs (up to

64)

Digital Programmable Contact Outputs (up to

16)

32 Latched Virtual Inputs

32 Self-Reset Virtual Inputs

Virtual Outputs (up to 512) Frequency ModBus User Map

Tripping and closing circuit supervision Sequence components of currents and

Remote Inputs/Outputs (GSSE and GOOSE

messag

Analog Inputs (dCmA) Analog Comparators

e ground),

iary voltage)

es)

Metering Current for phases, ground and

ensitive ground inputs

s

Voltages phase to phase and phase to

ound

gr

Real, Reactive and Apparent Power and

wer Factor

Po

Three Phase Energy IEC 870-5-104

oltages

v

Pulse Counters IEC 870-5-103 protocol

*Digital Counters

Front RS232 port, USB port in HMI

option E, Two rear RS485/fibre optic

ports, 10/100 TX and 100 FX Mbps

Ethernet port

ModBus Communications RTU and

over TCP/IP

DNP Multimaster (3.0 Level 2)

IEC 61850 protocol

*This functionality is available from firmware version 7.00

USER INTERFACE RECORDS OTHERS

Alphanumerical display (4x20) Data Logger

Graphic display (16 x 40) Demand Breaker Control

User Programmable LEDs (15) Event Recorder (up to 128 configurable

User Programmable Keys (up to 5) Fault Locator and Fault report (up to 10

Easy menu management Oscillography (up to 20 records) Operations (up to 24)

Configurable One-Line Diagram (Graphic

mod

el only)

Phasor Diagram (available in EnerVista 650

Setup)

ev

ents)

cords)

re

Snapshot Events (up to 1023)** Web Server Application

Breaking Arcing Current (I

IRIG-B synchronization/SNTP/

IEEE 1588

Logic Equations (PLC Editor)

** Maximum number of events can vary depend on firmware version. See details in section 2.5.3.3

2

t)

2-4 F650 DIGITAL BAY CONTROLLER GEK-113000-AF

Page 35

CHAPTER 2: PRODUCT DESCRIPTION 2.4 ORDER CODES

2.4 Order codes

F650 units are supplied as ½ 19” rack, 6 units high, containing the following modules: power supply, CPU, I/O modules,

communication modules. The required information to completely define an F650 model is shown on Table 2–1:

Table 2-1: Order codes

F650 - - - F - G - - - - - DESCRIPTION

B Basic Display (See Note 2)

M Graphic Display with Standard Symbols (See Note 2)

N Graphic Display with IEC symbols (See Note 2)

REAR SERIAL COMMUNICATIONS BOARD 1

F None

A Redundant RS485

P Redundant plastic fiber optic

G Redundant glass fiber optic

X Redundant RS485 + fiber remote CAN bus I/O

Y Redundant plastic fiber optic + fiber remote CAN bus I/O

Z Redundant glass fiber optic + fiber remote CAN bus I/O

C Cable Remote CAN bus I/O