Page 1

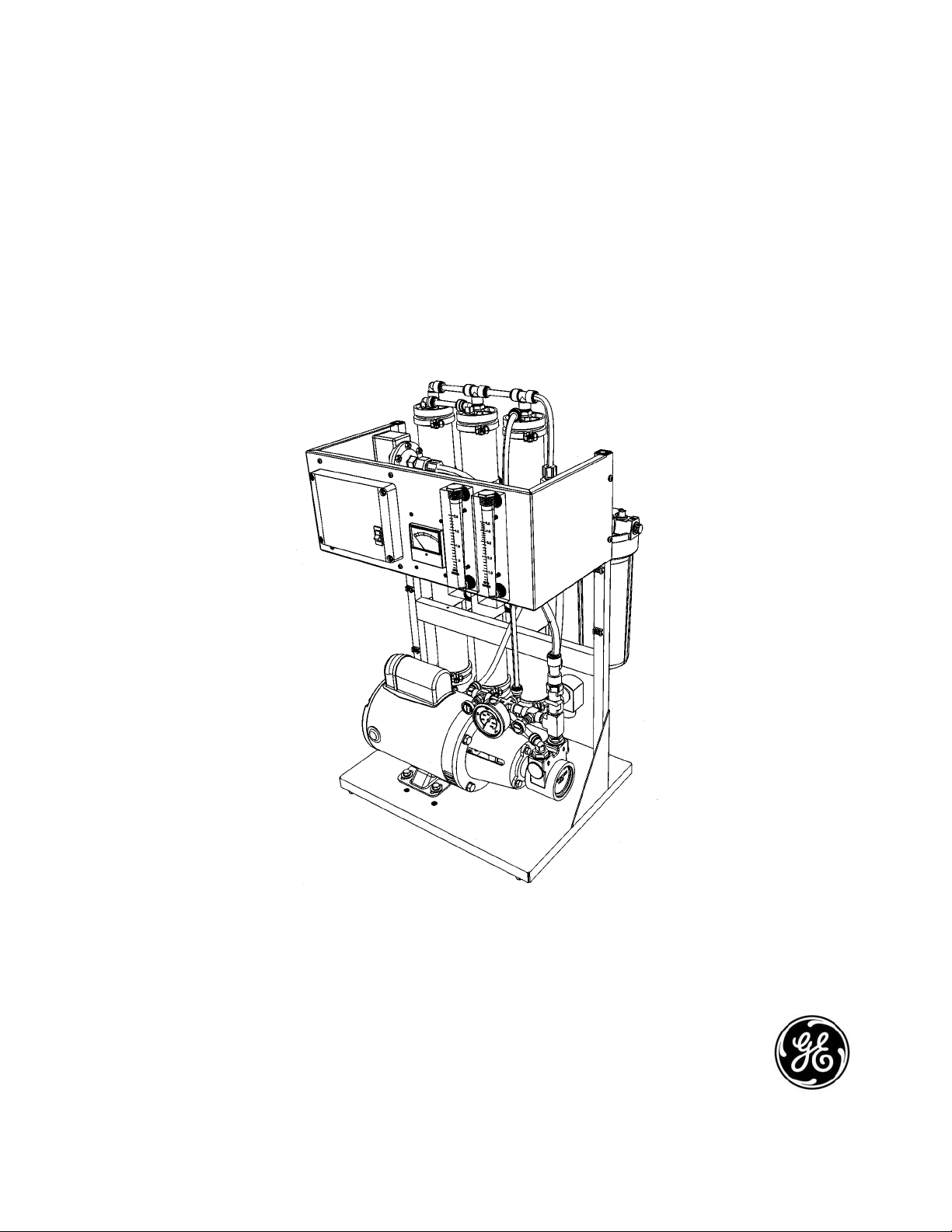

OSMONICS

E2/EZ2 SERIES

TM

WATER PURIFICATION

MACHINES

INSTALLATION, OPERATION,

AND MAINTENANCE

MANUAL

GE Infrastructure

Water & Process Technologies

Page 2

Distributor

Information

Distributor:

Contact:

Phone:

Fax:

Email:

Machine Information

Installation Date:

Model Number:

Serial Number:

Service

Assistance

Consult the Troubleshooting Section of this manual

(Section 2.19). If the problem cannot be identified and corrected, contact your distributor. Prior to making the call, have the

following information available:

Model Number Daily Log Sheets

Serial Number Operating Parameters

Installation Date Description of Problem

Spar

e Parts

Contact your distributor to order spare parts. Refer to the

Spare Parts List (Technote 109).

Page 3

INSTALLATION, OPERATION,

AND MAINTENANCE MANUAL

E2/EZ2-SERIES

WATER PURIFICATION MACHINES

T

ABLE OF

CONTENTS

Page

2.0 INSTALLATION 1

2.1 Mounting the Unit 1

2.2 Plumbing 1

2.3 Plumbing Connections 1

2.4 Feed Water Requirements 2

2.5 Transporting Pure Water (Permeate) to Point-of-Use 2

2.6 Machine Control 3

2.6.1 Economy Model 3

2.6.2 Deluxe Model 3

2.7 Single-Phase Electrical 3

2.8 Machine Start-Up Preparations 3

2.8.1 Pretreatment for Water Purification 3

2.8.2 Machine Start-Up Preparation 4

2.9 Machine Start-Up 4

2.10 Recovery 7

2.11 Permeate Back Pressure Correction Factors 8

2.12 Operation and Maintenance 9

2.13 Pre-Filter Cartridge 9

2.14 Daily Flushing 9

2.15 Membrane Element Cleaning 10

2.16 Membrane Element Removal 12

2.17 Membrane Element Replacement 12

2.18 Troubleshooting 15

Page 4

LIST OF FIGURES

Page

Figure Description

2.1 Flow Control Center 6

2.2 Closed Loop Membrane Element Cleaning 11

2.3 Membrane Element Installation 13

2.4 Membrane Element Direction for Installation 14

LIST

OF

TABLES

Table Description

2.1 E2/EZ2-Series Machine Piping Connections 1

2.2 E2/EZ2-Series Feed Water Requirements 2

2.3 E2/EZ2-Series Primary Pressure Range 5

2.4 Flow Specifications for E2/EZ2-Series Machines 7

2.5 Permeate Back Pressure Correction Factors 8

NOTE

: This manual, along with all GE Infrastructure manuals, is available at

www.ge.water.com.

Page 5

1

2.0 INSTALLATION

2.1 Mounting the Unit

When installing your new GE Osmonics reverse osmosis (RO) machine, allow at least

45-inches (114.3 cm) above the machine for membrane element removal and loading. If

space is not available, the entire membrane element housing can be removed for

membrane element change-outs. If the membrane element housings are to be removed to

change-out the membrane elements, at least 25-inches (65.3 cm) is required at one end of

each membrane element housing and 6-inches (15.2 cm) behind the machine.

2.2 Plumbing

The feed water source must be able to provide water quantity and pressures to maintain an

operating feed water pressure of 30 - 60 psi (2.1 - 4.1 bar). If the feed water pressure with

the machine is in excess of 60 psi (4.1 bar) or fluctuates by more than 5 psi

(0.34 bar) a pressure regulator should be installed upstream of the machine inlet. If proper water pressure cannot be maintained to the RO, a booster pump may need to be installed

in front of the pretreatment to provide the proper water quantity and pressure for the operation of the machine.

2.3 Plumbing Connections

Connect proper size drain line to the concentrate outlet (Table 2.1, E2/EZ2-Series

Machine Piping Connections) and run to an open drain. The drain capacity needs to be

large enough to properly drain the feed water flow of the RO.

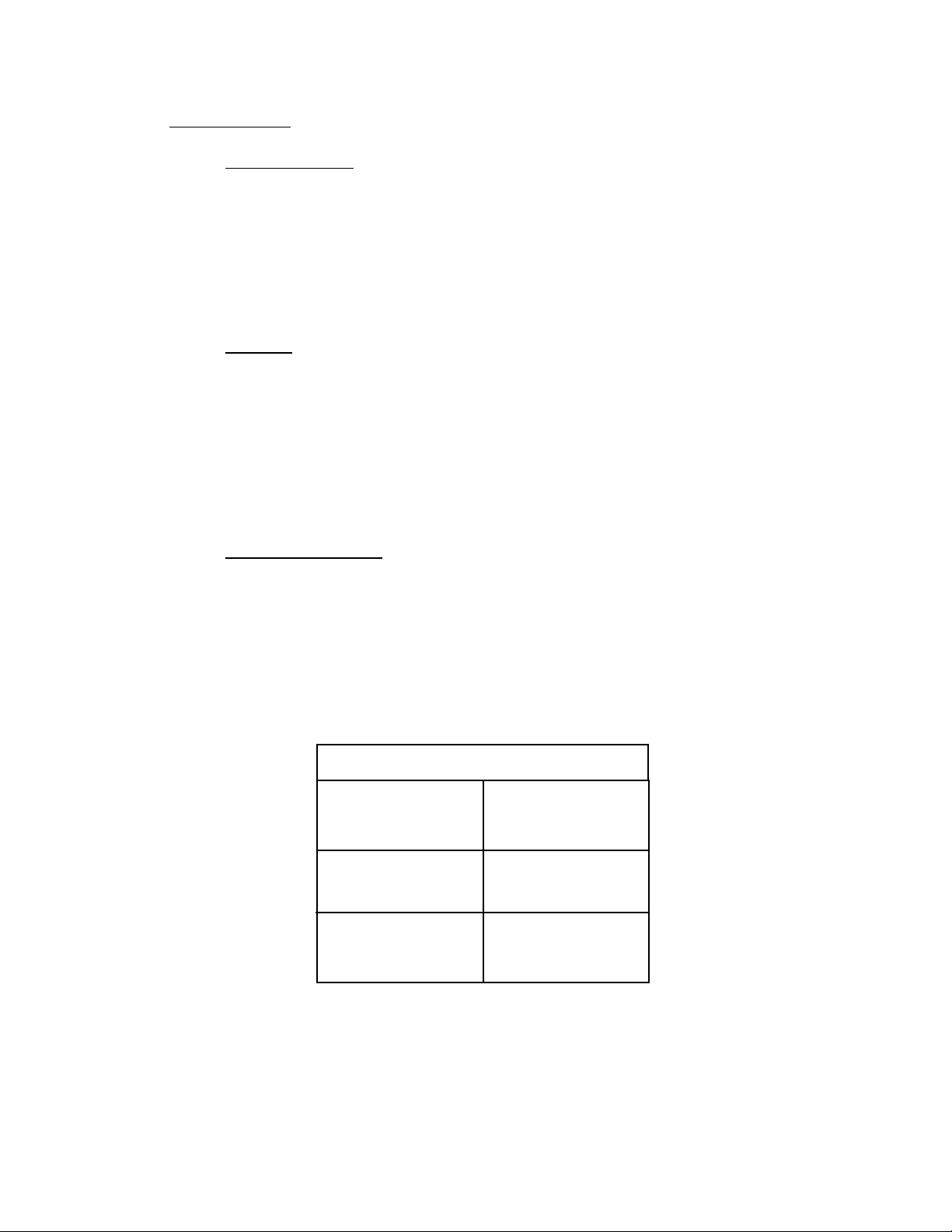

Table 2.1

E2/EZ2- Series Machine

Piping Connections

CONNECTIONS

Inlet

inch (cm)

Permeate

inch (cm)

Concentrate

inch (cm)

0.38 (0.96)

0.38 (0.96)

0.38 (0.96)

Page 6

2.4 Feed Water Requirements

The following feed water requirements must be met before installing your E2/EZ2-Series

machine to ensure quality permeate and extended membrane element life. Refer to

Table 2.2 (

E2/EZ2-Series Feed Water Requirements) for feed water information.

Table 2.2

E2/EZ2-Series Feed

Water Requirements

* American Standard for Testing Materials

2.5 T

ransporting Pure Water (Permeate) to Point-of-Use

Pure water, or permeate, is in an aggressive state and should only be transported from the

machine to the point-of-use in food grade flexible nylon, stainless steel (SS) tubing, or

polyvinyl chloride (PVC) material for the inlet, permeate, and concentrate piping sizes.

Refer to Connections (Table 2.1, E2/EZ2-Series Machine Plumbing Connections) for

inlet, permeate, and concentrate piping sizes.

W

ARNING

: MACHINE DAMAGE MAY OCCUR IF PERMEATE BACK PRES-

SURE EXCEEDS 60 PSI (4.1 BAR) DURING OPERATION.

2

Temperature

Inlet Pressure

Chlorine

(continuous feed)

Operating pH

Silt Density Index

(SDI)

Typical: 50° - 85°F (10° - 29°C)

Limits: 33° - 104°F (0.60° - 40°C)

Minimum: 30 psig (2.1 barg)

Maximum: 60 psig (4.1 barg)

0 parts per million (ppm)

5.5 - 8.5

Less than or equal to 5 to minimize

membrane element fouling and

extend cleaning intervals. Refer to

ASTM* Standard D4189.

Page 7

2.6 Machine Control

2.6.1 Economy Model

To remotely control the Economy Model (ECN) with float switches and/or pretreatment lockout, remove the jumper between terminals 4 and 5 and wire in the

float switches or pretreatment components in series. After all field wiring is complete and complies with local and national electrical codes, move onto

Section 2.7 (Single-Phase Electrical).

NOTE

: External control contacts are normally closed, dry contacts.

2.6.2 Deluxe Model

To remotely control the Deluxe Model (DLX), with float switches and/or pretreatment lockout, remove the jumper between terminals 2 and 3 and wire in the

float switches and pretreatment in series. After all field wiring is complete and

complies with local and national electrical codes, move onto Section 2.10

(Pretreatment for Water Purification).

NOTE

: External control contacts are normally closed, dry contacts.

2.7 Single-Phase Electrical

Always check voltage tag on the machine to ensure the correct voltage and amperage is

available.

The E2/EZ2-Series machines are shipped as either 120 Volt 60 Hertz or 220 Volt

50 Hertz from the factory. Machines should always be connected to a 15 Amp singlephase dedicated circuit. The circuit provided should be a separately fused disconnect with

the proper protection for the Hp and Amp draws of the machine. Reverse osmosis (RO)

machines with 115 Volt circuit include an 8-foot (2.4 m) electrical cord which plugs into

a single-phase outlet. All machines shipped with a 220 VAC single-phase power requirement are shipped with an 8-foot (2.4 m) electrical cord, but customers must provide

electrical plug. All field wiring must comply with applicable local and national electrical

codes.

2.8 Machine S

tart-Up Preparations

2.8.1 Pretreatment for Water Purification

A water analysis of your feed water should have been performed, as part of the

planning and engineering that went into developing your RO system.

The water analysis will provide information on what type of pretreatment may be

required and what recovery the machine can be run at on the feed water provided. If the machine is moved to a different water source, a new water analysis

should be taken before operating the machine.

3

Page 8

Your RO is designed to operate on softened tap feed water with an SDI of 5 or

less. The pH should be in a range of 5.5 - 8.5. Exposure to any levels of chlorine may cause irreversible damage to the Thin-layer composite (TLC) polyamide

(PA) membrane elements in your machine. Daily water checks are recommended to ensure the integrity of your pretreatment and RO system. Refer to

Table 2.2 (E2/EZ2-Series Feed Water Requirements).

2.8.2 Machine Start-Up Preparation

Check the function and integrity of your pretreatment equipment. Ensure that

your water softener and activated carbon filters have been leaked checked and

properly flushed, before starting up your RO machine.

W

ARNING: IMPROPERLY FLUSHED PRETREATMENT MAY

CAUSE SERIOUS RO MACHINES PROBLEMS AT

START-UP.

W

ARNING: NEVER OPERATE THE MACHINE WITH THE CON-

CENTRATE OR PERMEATE LINES BLOCKED.

SEVERE DAMAGE TO THE UNIT MAY RESULT.

2.9 Machine S

tart-Up

STEPS

1. Turn the feed water supply to the machine ON, while checking for leaks in the

pretreatment and inlet feed water lines.

2. Check to ensure power to the motor is de-energized and the ON/OFF button, on

the machine, is in the ON position.

3. Plug in the factory-supplied power cord.

NOTE

: Fifty (50) Hertz models require customer supplied plug compatible

with existing outlet.

4. For initial start-up, redirect the permeate and concentrate lines to the drain for

start-up flush.

5. Open the concentrate and recycle flow control valves two (2) complete turns.

These valves are positioned on the flow control plumbing (Figure 2.1, Flow

Control Center).

W

ARNING

: ONCE MACHINE IS OPERATING, FLUSH CONCEN-

TRATE AND PERMEATE TO THE DRAIN FOR

20 - 30 MINUTES. FLUSHING ENSURES ALL BIOCIDES

AND CONTAMINATES ARE REMOVED FROM THE

MEMBRANE ELEMENTS.

4

Page 9

6. Turn the ON/OFF button on the machine ON.

7. As the pump starts to build pressure, begin to adjust the valves in the following

manner: start by slowly closing the concentrate valves while slowly opening the

recycle valve (Figure 2.1, Flow Control Center).

CAUTION

: Monitor machine to ensure inlet pressure of 30 - 60 psi

(2.1 - 4.1 bar) is maintained during operation.

8. After 20 - 30 minutes of flushing permeate to the drain, ensure all chemical

residue has been removed before hooking up to point of use.

While operating, the pressure range should never operate outside of the pressure

ranges displayed in Table 2.3 (E2/EZ2-Series Primary Pressure Range).

Table 2.3

E2/EZ2-Series

Primary Pressure Range*

* Primary pressure temperature for normal operation is 77°F (25°C).

CAUTION

: The E2/EZ2-Series must not operate outside the ranges listed

above.

NOTE: Optimum recovery will vary according to feed water quality.

The concentrate valve is drilled, and when completely closed the machine is running at the correct concentrate flow for a 75% recovery (Table 2.4, Flow

Specifications for E2/EZ2-Series Machines).

If the temperature of the inlet feed water is not 77°F (25°C) use the Temperature

Correction Factor Table (Technote 113). The proper adjustment of the recycle and

concentrate valves are critical to the correct operation of the machine.

5

Operating

Pressure

Operating

Range

220 psi

(15.2 bar)

165 - 250 psi

(114. - 17.2 bar)

E2/EZ2-Series

Page 10

9. Complete the Start-Up Data Sheet (Technote 101). The Start-Up Data Sheet and

the Daily Log Sheet (Technote 106) are invaluable in diagnosing the performance

of the equipment, and must be be kept for reference. If you have questions concerning the operation of your machine or the method of data recording, contact

your distributor or the manufacturer.

Figure 2.1

Flow Control Center

CAUTION: Once the machine is running, with orifices, adjust pressures and

flows to the correct measure, flush machine to drain for

30 - 45 minutes.

CAUTION

: The E2/EZ2-Series machines are designed to run at 50% recov-

ery. To confirm flows are correct, check Table 2.4 (Flow

Specifications for E2/EZ2-Series Machines). To correct any

temperature variations, check Table 2.4. If your E2/EZ2-Series

machine is operating under permeate back pressure to point of

use, refer to Table 2.5 (E2/EZ2-Series Permeate Back Pressure

Correction Factors).

CAUTION

: Machine performance is based on a feed water temperature of

77°F (25°C). If feed water temperature is other than

77°F (25°C), reference Table 2.4 (Temperature Correction

Factors) to confirm machine’s performance

6

Pressure Gauge

Feed Water

Inlet

Concentrate Valve

Recycle Valve

Page 11

2.10 Recovery

The machine flow specifications listed below are based on 77°F (25°C).

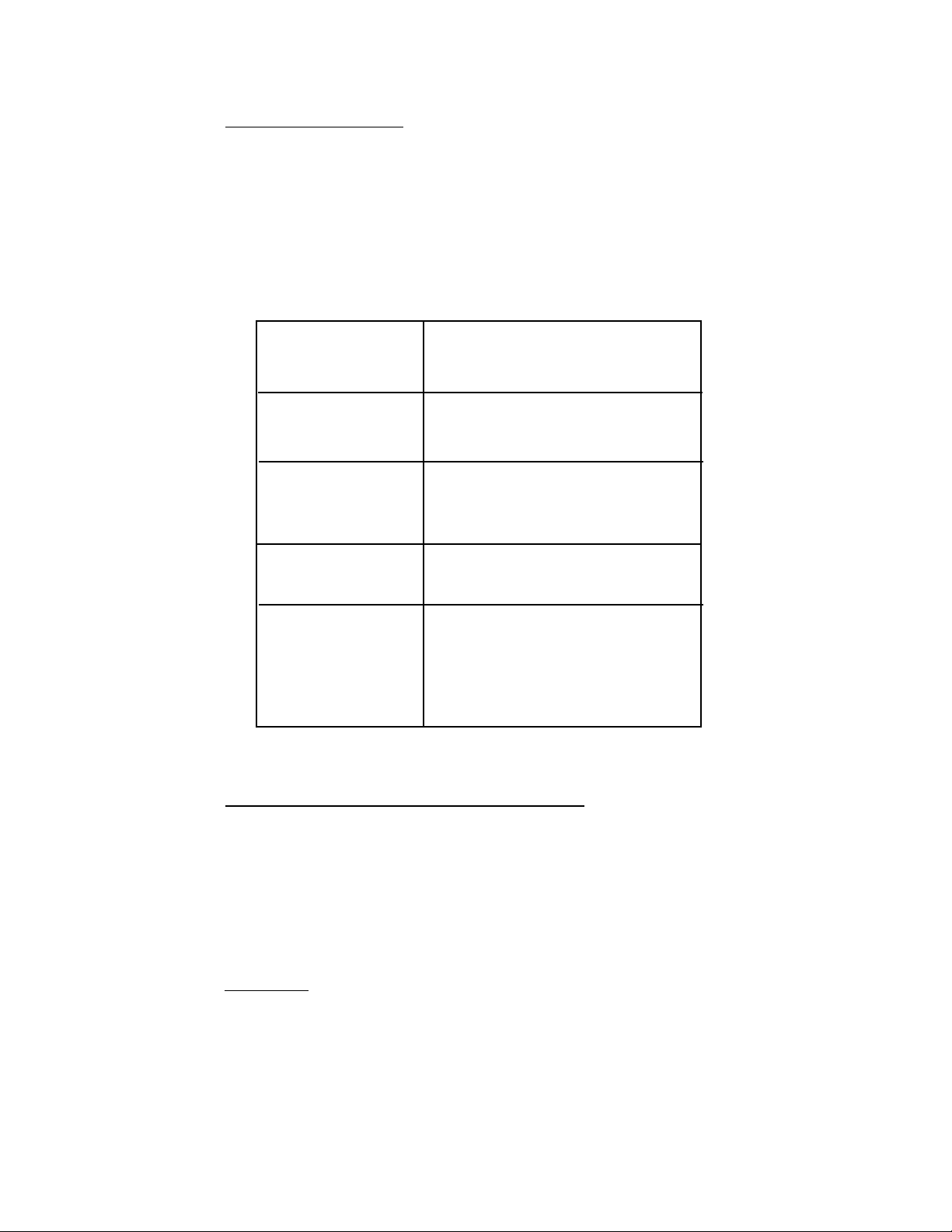

Table 2.4

E2/EZ2 - Series

Flow Specifications for

Machines

7

2100/

2535

33 - 50%

95 - 98%

1.8 (0.40)

1.8 - 1.2

(0.41 - 0.82)

1400/

1690

33 - 50%

95 - 98%

1.2 (0.27)

1.2 - 0.8

(0.27 - 0.54)

1125

33 - 50%

95 - 98%

0.9 (0.20)

0.9 -0.6

(0.20 - 0.13)

620/

750

33 - 50%

95 - 98%

0.5 (0.11)

0.5 - 0.3

(0.11 - 0.07)

0375

33 - 50%

95 - 98%

0.3 (0.07)

0.3 - 0.2

(0.07 -0.14)

E2/EZ2-Series

Units

Recovery Range

Rejection Rate

Permeate Rate

gpm (m

3

/h)

Concentrate Rate

gpm (m

3

/h)

Page 12

2.11 Permeate Back Pressure Correction Factors

It is often necessary to operate RO machines with permeate back pressure. Permeate back

pressure will decrease permeate production. See Table 2.5 (Permeate Back Pressure

Correction Factors) to calculate loss of permeate.

Table 2.5

E2/EZ2-Series

Permeate Back

Pressure Correction

Factors

W

ARNING: IF PERMEATE BACK PRESSURE EXCEEDS 60 PSI (4.1 BAR)

MACHINE DAMAGE MAY OCCUR.

W

ARNING: INSTALLING A CHECK VALVE WILL PREVENT REVERSE

FLOW THROUGH THE MEMBRANE ELEMENT WHEN THE

MACHINE IS NOT IN OPERATION. REVERSE FLOW, WHEN

THE MACHINE IS NOT IN OPERATION, CAN SEVERELY

DAMAGE THE MEMBRANE ELEMENTS.

8

BACK

PRESSURE

10 psig (0.7 barg)

20 psig (1.4 barg)

30 psig (2.0 barg)

40 psig (2.7 barg)

50 psig (3.4 barg)

60 psig (4.1 barg)

PRESSURE

CORRECTION

FACTOR (PCF)

0.95

0.90

0.80

0.70

0.60

0.50

% LOSS OF

PERMEATE

FLOW

5%

10%

15%

20%

25%

30%

Page 13

2.12 Operation and Maintenance

The operation and maintenance of an E2/EZ2-Series RO machine requires regular data

recording and routine preventative maintenance. It cannot be emphasized enough the

importance of filling out the Daily Log Sheet (Technote 106) during each operating shift.

A Start-Up Data Sheet (Technote 101) should have been completed at start-up. The StartUp Data Sheet contains pertinent facts on the operation of your machine. These two

records are invaluable in diagnosing the performance of the equipment, and must be kept

for reference. If you have questions concerning the operation of your machine or the

method of data recording, contact the manufacturer.

Three preventative maintenance procedures, which must be done on a regular basis, are

as follows:

1. Change the pre-filter cartridges as needed.

2. The machine needs to run and flush for at least 10 minutes every 72 hours, clock

time.

3. Clean the RO membrane elements with approved cleaners at least quarterly,

depending on feed water quality.

2.13 Pre-filter Cartridge

A 1 micron pre-filter cartridge is factory installed to protect the membrane elements and

valves from particles, which may be in the feed water. To order replacements, see the

Spare Parts List (Technote 109).

A pressure drop across the filter of 8 psi (0.55 bar) or more during operation indicates that

the pre-filter cartridge(s) need changeing. Use only GE approved filters rated at 2 microns

or less. Refer to Technote 109 (Spare Parts List) for pre-filter cartridge replacements. Do

not attempt to clean used pre-filter cartridges.

NOTE

: Failure to perform normal preventative maintenance procedures will void

machine warranty.

2.14 Daily Flushing

A manually flush of the E2/EZ2-Series must be done machine daily.

To flush the machine:

NOTE

: During flushing procedure, the machine must be running.

STEPS

1. With the machine running, open the concentrate valve 1/2 -3/4 of a turn

(Figure 2.1, Flow Control Center).

9

Page 14

2. Allow the machine to operate with the concentrate valve open 1/2 - 3/4- of a turn

(Step 1) for 10 - 15 minutes.

3. After 10 - 15 minutes, return the concentrate valve to its previous setting, and

return to normal operation.

CAUTION

: When opening the concentrate valve, never allow the machine’s

primary pressure to drop more than 10% below normal operating

pressure (Table 2.3, E2/EZ2-Series Primary Pressure Range).

2.15 Membrane Element Cleaning

Periodic cleaning of the machine with appropriate membrane element cleaners will prolong the life of the membrane elements. Local conditions will determine the frequency of

cleaning. Cleaning may be required when:

1. The permeate quality begins to decline.

2. The reading on the final pressure gauge begins to change noticeably.

GE recommends that you clean your E2/EZ2-Series RO machine every quarter. You may

have to clean the RO machine more frequently, depending on the quality of your feed

water. Cleaning of the membrane elements is vital because contanimants can build-up on

the membrane element surfaces, reducing the permeate flow rate and affecting the quality of the permeate.

To clean the membrane elements:

NOTE

: It is always best to start with the acid or inorganic cleaner.

STEPS

1. Remove and replace the pre-filter cartridge (Section 2.14, Pre-filter Cartridge).

NOTE

: For best results, GE recommend pre-filters be replaced before and after

cleaning.

2. In a clean container, collect approximately five (5) gallons (19 Liters) of RO

permeate water.

3. Turn machine and water supply OFF.

10

Page 15

Figure 2.2

E2/EZ2-Series

Closed Loop Membrane

Element Cleaning

NOTE

: This clean container will be referred to as the Clean-In-Place (CIP)

container.

4. Disconnect and route the inlet, permeate, concentrate lines from their service

locations to the CIP container (Figure 2.2 E2/EZ2-Series Closed Loop Membrane

Element Cleaning.

5. Connect the CIP feed line to the E2/EZ2-Series machine inlet feed water port

(Figure 2.2, E2/EZ2-Series Closed Loop Membrane Element Cleaning).

6. Mix the appropriate cleaning compound in the 5 gallons of permeate water, in the

CIP container, according to the cleaning label instructions.

7. Turn machine ON and allow machine to recirculate the cleaning solution for

10 - 15 minutes.

NOTE

: The incoming feed pressure should be 30 psi (2.1 bar).

As machine starts up it will achieve prime and begin to draw solution into the

machine and circulate the solution back into the CIP container.

If the machine makes noise or primary pressure does not climb to normal operating pressure (Table 2.3, E2/EZ2-Series Primary Pressure Range) turn machine

OFF. Refer to Troubleshooting (Section 1.18). Once pressure range is corrected,

continue start-up procedure.

As the machine runs normally check CIP tank to ensure that the CIP inlet line to

the machine is submerged in the cleaning solution, so the pump prime will not be

lost.

11

Page 16

8. After circulaiting the macine for 10 - 15 minutes or solution has reached

95°F (35°C), shut machine OFF.

9. Dump solution. Repeat Setps 6 - 8.

10. With machine OFF (Step 8), let cleaning solution dwell in machine for

15 - 30 minutes.

11. After 15 - 30 minutes, reconnect feed to RO unit and connect concentrate and permeate to drain. Turn machine ON and flush permeate water to the drain for

10 - 15 minutes.

This ensures that all cleaning agents have been removed for the machine.

12. If cleaning with an organic cleaner, return to Step 1 and repeat Steps 1 -11.

13. After completing cleaning (normal and organic) and flushing to the drain reconnect permeate to the point of use, concentrate to the drain, and reconnect feed to

the RO unit.

W

ARNING: LOSS OF PRIME DURING SUCTION CLEANING MAY

RESULT IN SERIOUS DAMAGE TO THE PUMP.

NOTE

: As previously mentioned, the manufacturer recommends use of a CIP

or booster pump to circulate the cleaning solution during membrane

element cleaning.

2.16 Membrane Element Replacement

CAUTION: Replacement membrane elements are shipped from the factory in a plas-

tic bag with a small amount of bactericide solution to prevent biological

growth. When installing the membrane elements, always provide adequate ventilation and wear gloves while handling the membrane elements

as recommended. The membrane elements must be kept moist at all

times to prevent possible damage to the membrane element material.

STEPS

1. Remove the top end caps and clamps from the membrane element housings

(Figure 2.4, Membrane Element Installation). Lubricate all O-rings and brine

seals, and the polyvinyl chloride (PVC) membrane element stems (stingers) with

a non-petroleum based lubricate (i.e., glycerin or poly water).

2. Load the down flow membrane elements first, by inserting the membrane element

into the membrane element housing with the brine seal end of the membrane element up. Slowly turn the membrane element as you lower it into the membrane

12

Page 17

element housing. As you reach the bottom of the housing slowly guide the PVC

stem or stinger on the end of the membrane element into the head of the end cap.

As the membrane element slides into the housing the brine seal will be on the top

(Figure 2.4, Direction of Membrane Element Installation).

Figure 2.3

Membrane Element

Installation

3. Next, load the up flow membrane elements, by lubricating all brine seals, O-rings,

and the membrane element stingers. With the up flow membrane element and the

brine seal will be on the bottom of the membrane element. Turn the membrane

element slowly as you lower it down into the housing. As with the down flow

membrane element, one must slowly guide the PVC stinger on the end of the

membrane element into the end cap.

4. Reinstall the end caps by using non-petroleum based lubricant to lubricate the Oring inside the end cap. Reinstall the end cap on the membrane element by first,

aligning the stinger into the hole in the end cap and then turn the end cap slowly

clockwise, as you push it down into the membrane element housing.

5. Reattach the housing clamp and tighten.

6. Reattach the feed line and flush permeate and concentrate lines to the drain for

25 - 30 minutes.

7. Take appropriate tests to insure biocide has been flushed from the machine.

8. Reconnect permeate line to point-of-use.

9. The machine is now ready for operation.

13

Page 18

Figure 2.4

Membrane Element

Direction for

Installation

14

Page 19

2.17 Troubleshooting

This troubleshooting guide can assist you in identifying common operating problems you may

experience with your machine. The operator can easily correct may of these problems, however,

for those that persist or are not understood you should contact the GE Customer Support Center.

Have the following information available when calling the Customer Support Center:

1. Machine installation date

2. Model number

3. Serial number

4. Detailed description of problem.

15

REMEDIES

Open feed water valve. Check

feed water valve for restrictions

in feed plumbing.

Replace pre-filter cartridge.

Flush and/or clean machine.

Verify valve receiving power

when machine is ON. Clean or

replace solenoid valve.

Verify proper voltage is present.

Check fuses and circuit

breakers.

Contact your distributor for

replacement or repair of pump

or motor.

POSSIBLE CAUSES

Insufficient feed water pressure

or flow

Clogged pre-filter cartridge

Dirty or fouled membrane

elements

Inlet solenoid valve not

opening

Insufficient electrical power

Pump or motor not operating

correctly

PROBLEM

Low operating pressure

TROUBLESHOOTING GUIDE

Page 20

16

REMEDIES

Refer to Section 2.9 for proper-

ly setting concentrate and

recycle valves

See above.

Check the water temperature.

If needed, install a hot/cold

tempering valve. Permeate

production rate is dependent on

77°F (25°C). Refer to Section

2.5 (Temperature Correction

Factor).

Refer to Section 2.18 for cor-

rect membrane element

installation procedure.

Membrane elements with

damaged brine seals may be

returned for repair. For low

permeate production, it is

wise to test the permeate pro-

duction of each membrane

element.

Refer to Section 2.18 for cor-

rect membrane element

installation.

Flush and/or clean the

machine.

Reduce permeate line backpressure. Check for restric-

tions in permeate plumbing.

POSSIBLE CAUSES

Concentrate or recycle valve to

far open

Low operating pressure

Machine operating on cold

water

Membrane elements installed

incorrectly

Brine seal has “rolled” or been

damaged

Dirty or fouled membrane

elements

Backpressure on the permeate

line

PROBLEM

Low operating pressure

(continued)

Low permeate production

.

TROUBLESHOOTING GUIDE

Page 21

17

REMEDIES

Install new membrane ele-

ment(s). See Spare Parts List

(Section 2.20).

Check the flow rate manually

with a stop watch and a cali-

brated container.

Flush and/or clean machine.

Replace the O-rings, check

the sealing surfaces on the

O-ring groove and end caps.

Replace damaged parts.

Replace with new membrane

elements. See Spare Parts

List (Section 2.20).

Calibrate the meter with a DS

standard solution or check the

readings with another conductivity meter. Replace or clean

the probe. Check the connec-

tions between the probe and

monitor. Refer to Section

2.16.2 (Deluxe Model).

Ensure machine is

plugged in.

POSSIBLE CAUSES

Useful life of membrane

element(s) expired

Inaccurate permeate flow meter

(DLX only)

Dirty or fouled membrane

element (s)

O-rings on membrane ele-

ment(s) unseated or

damaged parts

Useful life of membrane ele-

ment(s) expired

Change in incoming

water quality

No power to machine

PROBLEM

Low permeate production

(continued)

Low concentrate flow with

normal or high operating

pressure

Declining rejection

(high permeate

conductivity)

ON/OFF switch ON:

machine not running

TROUBLESHOOTING GUIDE

Page 22

18

REMEDIES

The storage tank may be full.

The switch control may

require adjustment.

Allow the machine to cool.

Check the Amp draw to the

machine.

Check the fuses or circuit

breakers; measure the volt-

age. Contact your distributor

for service.

Disconnect and clean the

concentrate valve.

Check for blockage of the

concentrate flow at the inlets

and outlets of membrane

element housings.

Ensure that the anti-telescop-

ing device (ATD) is intact.

Flush and/or clean the

machine.

POSSIBLE CAUSES

Pressurized storage switch or

storage tank float switch cut

power to machine

Thermal overload of motor

Pump motor failure

Dirty concentrate valve

Restricted flow after pump

outlet

Telescoped membrane element

covering membrane element

housing

Fouled or dirty membrane

elements

PROBLEM

ON/OFF switch ON:

machine not running

(continued)

Pressure does not drop when

concentrate valve opened

Excessive pressure drop

acrosse membrane

element(s)

[over 50 psi (3.5 bar)]

TROUBLESHOOTING GUIDE

Page 23

19

REMEDIES

Ensure valve is not getting any

power when machine is OFF.

Replace inlet solenoid valve.

POSSIBLE CAUSES

Inlet solenoid valve not fully

closed

PROBLEM

Flow through machine while

power is OFF

TROUBLESHOOTING GUIDE

Page 24

Page 25

For more information call 952-933-2277 or 800-848-1750 in the U.S., or visit www.gewater.com.

© 2004, General Electric Company. All rights reserved.

P/N 1227273 Rev.C

North American Sales Euro/Africa Sales Asia/Pacific Sales

5951 Clearwater Drive 230 rue Robert Schurman 1044/8 SOI 44/2

Minnetonka, MN ZA des Uselles Sukhumvit Road Parkanog

55343-8995 77350 Le Mée sur Seine Bangkok 10110

USA FRANCE THAILAND

(952) 933-2277 Phone +33 1 64 10 2000 Phone +66 2 38 14213 Phone

(952) 933-0141 Fax +33 1 64 10 3747 Fax +66 2 39 18183 Fax

GE Infrastructure

Water & Process Technologies

Loading...

Loading...