Page 1

GE Healthcare

eBike III basic

eBike III comfort

with and without NIBP

Service Manual

2018111-336 Revision B

Page 2

Page 3

Manual InforMatIon

• GE Medical Systems Information Technologies GmbH considers itself responsible for the eects on safety,reliability, and

performance of the equipment, only if:

- assembly operations, extensions, readjustments, modications, or repairs are carried out by ergoline GmbH or by

persons authorized by GE Medical Systems Information Technologies GmbH,

- the electrical installation of the relevant room complies with the applicable national and local requirements,

- and the instrument is used in accordance with the intended use and the instructions for use.

• This manual contains service information; operating instructions are provided in the operator’s manual of the

instrument.

• This manual is in conformity with the instrument at printing date.

• The Service Manual eBike III is valid for the following devices:

2017911-301 EBIKE III BASIC

2017911-303 EBIKE III BASIC WITH NIBP

2017911-305 EBIKE III COMFORT

2017911-307 EBIKE III COMFORT WITH NIBP

Software Version GF 1.x and optional with Module “NIBP“ and Supply and Service Items.

Manufacturer: Distributor:

ergoline GmbH GE Medical Systems Information Technologies, Inc

Lindenstraße 5 8200 West Tower Avenue

D-72475 Bitz Milwaukee, WI 53223 USA

Germany Tel. +1 414 355 5000 1 800 437 1171 (US only)

Tel.: +49 (0) 7431 98 94 - 0 1 800 668 0732 (Canada only)

Fax: +49 (0) 7431 98 94 - 128 Fax +1 414 355 3790

e-mail: info@ergoline.com

internet: http://www.ergoline.com

©Copyright 2016 General Electric Company. All rights reserved.

2018111-336 Rev. B eBike III basic / comfort - 3 -

Page 4

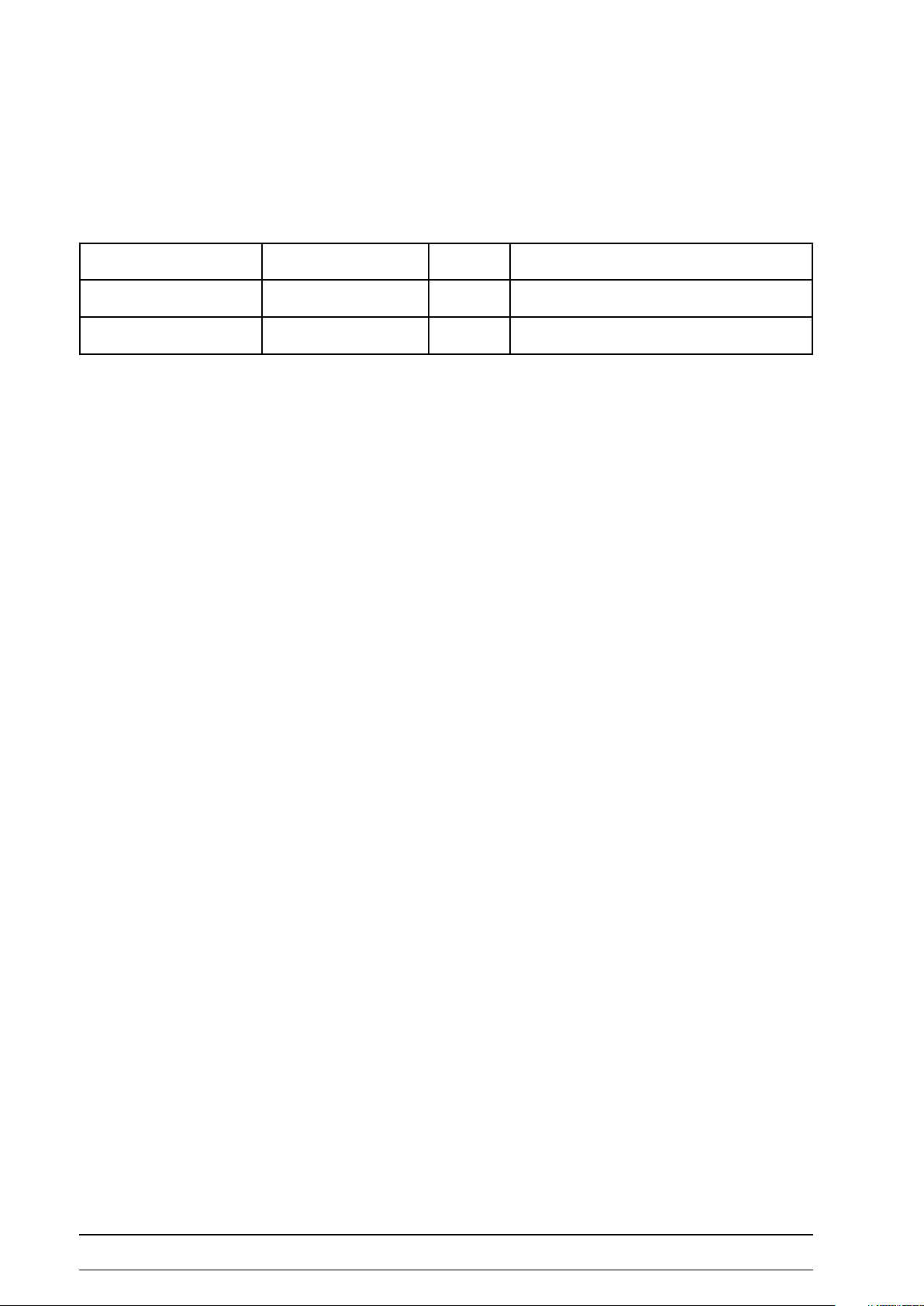

revIsIon HIstory

This manual is subject to the GE Medical Systems Information Technologies change order service.

The revision code, a letter that follows the document part number, changes with every update of the manual.

The initial version of the manual has the letter B.

Part No. Revision Code Date Comment

2018111-336 Rev A 2016-03 Engineering Release

2018111-336 Rev B 2016-04 Initial Release

- 4 - eBike III basic / comfort 2018111-336 Rev. B

Page 5

Contents

Manual Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electrical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Leakage currents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Technical Safety Inspections and Inspections of the Measuring Systems . . . . . . . . . . . . . .7

eBike III basic / comfort . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Very important service note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Final checkout procedure / Functional test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Electrical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Checkout procedure after repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Test procedure “RPM / Load“ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Test procedure “Blood pressure (NIBP)“ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Electronic modules / Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Description of electronics and cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

abbreviations (Electronic modules / PCBs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Electronic carrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Dismounting of the electronic assembly group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Block diagrams bike ergometer electronics eBike III . . . . . . . . . . . . . . . . . . . . . . . 21

Wiring diagrams bike ergometer eBike III . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Control units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

DTU - Control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

DTU - Patient display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

DTU - Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Load regulation and interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

LIU - Load regulation and interface board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

NIBP blood pressure unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Placement of pressure tubes (schematic) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Block diagram of cabling of the bloodpressure unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

BPU - Blood pressure board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Miscellaneous modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

SMU - saddle height motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Mechanical assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Mounting the Handlebar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Handlebar - Adjust xture (inclination) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Handlebar - Dismounting / mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Remove Ergometer Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Plastic screw seals (caps) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Dismounting the Handlebar pole housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Dismount pedal cranks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Remove housing of the eBike III basic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Remove housing of the eBike III comfort . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

2018111-336 Rev. B eBike III basic / comfort - 5 -

Page 6

Saddle pillar exchange (eBike III basic) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Saddle motor (eBike III comfort) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Strain gauge module exchange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

RPM module exchange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Load unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Load unit replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Power switch replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Power supply unit replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Remove Control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Software Control terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Turning the System On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Settings Control Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Service menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

ECG Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

NIBP Beep . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

NIBP mmHg / kPa . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Dynamic Load Cal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Software Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Baudrate 8N2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Saddle Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Manual Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

System Cong. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Error log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

NIBP Test / NIBP Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Analog Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Alignment / Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Dynamic Load Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Calibration of Blood pressure unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

NIBP Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

NIBP Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Software update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Connectivity and installation eBike III to GE ECG devices . . . . . . . . . . . . . 81

eBike III to CASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

eBike III to CARDIOSOFT / CS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

USB interface / driver installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

eBike III to MAC 2000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

eBike III to MAC 5500 (MAC 5000 ST) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Installation of ther COM - Interface extension. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Addendum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Errorcodes Software eBike III . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Error code bits DTU (Control terminal PCB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Error code bits LIU (Load regulation and interface PCB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Error code bits SMU (Saddle-Motor PCB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Error code bits BPU (Blood pressure module) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Error code bits COM (External Analog interface module) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

Technical Specications eBike III basic / comfort . . . . . . . . . . . . . . . . . . . . . . . 121

Technical Specications eBike III Blood pressure module . . . . . . . . . . . . . . . . . . . 123

- 6 - eBike III basic / comfort 2018111-336 Rev. B

Page 7

eleCtrICal safety

leakage Currents

MeasurIng equIpMent

The measuring equipment used for the electrical safety

tests must be inspected and calibrated at regular intervals

(refer to manufacturer of measuring equipment).

The measurement results must be documented.

eBIke III BasIC / CoMfort

The eBike III basic/comfort ergometers are protection

class II equipment (no connection to protective ground).

The necessary electrical safety tests for these devices

together with the limit values are listed in the

chapter titled “eBike III basic/comfort - Preventive

maintenance“.

teCHnICal safety InspeCtIons and

nspeCtIons of tHe MeasurIng systeMs

I

The load unit is recommended to be inspected to the

approved regional standards at intervals of 2 years by a

GE Medical Systems Information Technologies authorized

service technician, and calibrated or repaired if necessary.

Calibration instructions for the NIBP module can be found

in this Service manual. Follow these instructions to display

the BP values with the test setup according to

EN 1060-1 and EN1060-3 or appropriate regional standard.

Warning

• Equipment Damage •

• The regulations about handling ESD sensitive components

must be observed.

Warning

• Patient Hazard, Equipment Damage

• EN 62353 and/or IEC 60601-1 requirements must be

satised during repair, modications and inspections of

medical electrical equipment.

• To ensure that equipment functions faultlessly and

without presenting any hazard after service interventions,

it must be subjected to the test procedures stipulated for

the dierent device categories.

• A device is considered to be unsafe, when:

- it cannot be repaired

- the user does not wish to have the device repaired.

In this case, the operator must be informed in

writing of the hazard presented by the device.

The same remark must be annotated on the

service report and on the service invoice..

The measurement results must be documented.

Warning

• Patient Hazard, Equipment Damage

• Use original spare parts only.

• For information about product changes, refer to the

manufacturer’s original documentation only.

• Observe the fuses’ original ratings, characteristics and

Ampere interrupting capacity.

• Parts of the device that ensure its safe operation must be

neither damaged nor obviously unsuitable. This applies to

insulation and insulating components in particular.

• Power cords must be visually inspected for signs of

damage before connecting them to the power line.

2018111-336 Rev. B eBike III basic / comfort - 7 -

Page 8

eBIke III BasIC / CoMfort

very IMportant servICe note

Warning

• Hazard, Equipment Damage

• When work at the bottom of the eBike III is required (e.g. access to electronic moduls, exchange

of load unit or installation of COM module) the eBike III should be carefully placed on one side

by grabbing it at the handlebar and the saddle.

• DO NOT tilt the eBike III forward to stand on the handlebar - this is an unsecure and instable

position!

preventIve MaIntenanCe

Note

• eBike III basic / comfort is a protection class II device (no connection to protective ground).

• Preventive maintenance is recommended to be performed every 2 years.

fInal CHeCkout proCedure / funCtIonal test

1. Check the setup for stability, adjust with leveling device if required.

Expected result: No instability Pass/Fail

2. Visually inspect the device:

- inspect cables / power cord

Expected result: No damage or wear detected Pass/Fail

- 8 - eBike III basic / comfort 2018111-336 Rev. B

Page 9

3. Check cranks and pedals:

- pedals have no signs for damage / wear

- pedals securely xed on cranks

- crank screws securely xed (torque 40 Nm ± 2 Nm) on axis

Expected result: Cranks and pedals OK Pass/Fail

eBike III basic

- Check bellow on saddle for damage / wear / cracks

- Check handlebar adjustment (angle)

- Check saddle height adjustment

- Check that the clamping levers (saddle [height] and handlebar [angle] adjustment) are tight.

Grease the thread of the saddle clamping lever.

(Use of an universal high-performance lubricant such as OKS 470 is recommended.)

eBike III comfort

- Check handlebar adjustment (angle)

- Check that the clamping lever is tight.

- Check electrical saddle adjustment: adjust minimum and maximum saddle height;

then return saddle to mid-level

- Check correct indication of saddle height display

- Check that the clamping lever for handlebar adjustment (angle) is tight

Expected result: Adjustments work and levers are tight, thread properly greased Pass/Fail

4. Using the power cord, connect the device to the mains power line and place the power switch in the ON position

Wait for self test to end:

- check LCD for error messages (refer to „Turning the System On“ on page 60)

- check the software version in the service menu for correct version GF 1.x

(refer to „Software update“ on page 78)

- check the “error log le“ in service menu (refer to „Error log“ on page 67)

Expected result: Device powers on without errors, FW is correct version, no errors logged Pass/Fail

5. Check speed indication (rpm) is displayed on LCD and the additional speed indication on the patient display.

Check noise level of idling drive unit (for example, for grinding noises or noise from the bearing)

Expected result: Speed displayed on both displays and no noticeable noise Pass/Fail

6. Units with NIBP module:

- Check cu tubing and tubing connections, microphone connectors

- Check blood pressure measurement on test subject at rest (refer to the „eBike III operators manual“)

- Check blood pressure readings are displayed on LCD

Expected result: BP values are displayed and in proper range Pass/Fail

7. Set manual load (see „Manual Load“ on page 66), change load (for example, 50 W, 100 W)

- Check load level and load indication

Expected result: Load is set and changes as expected Pass/Fail

8. If ergometer is remote controlled from ECG recorder or PC-ECG system:

- Check connecting cable

- Check load control via ECG recorder or PC ECG system

- Check remote start if applicable

Expected result: Ergometer can be controlled by external unit Pass/Fail

2018111-336 Rev. B eBike III basic / comfort - 9 -

Page 10

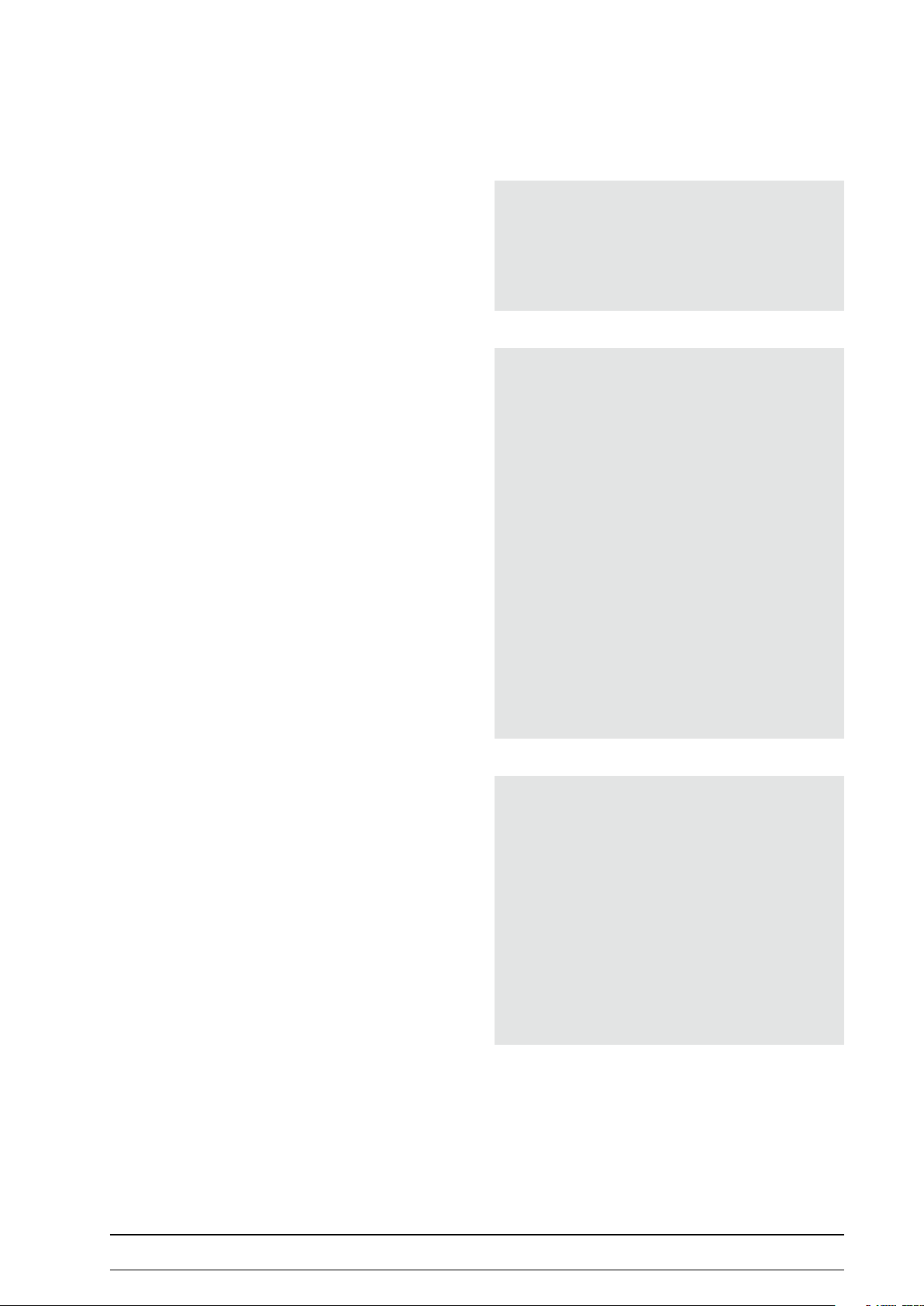

eleCtrICal safety

Perform electrical safety checks when indicated - current leakage test results meet requirements.

All indicated electrical safety checks require a pass/fail indication for steps performed.

Record the measurement values in your debrief.

Step Condition

(1)

UUT - ON

(2)

Result Leakage

Current limits

Earth Leakage Current

1. Forward Polarity N/A

2. Neutral open, Forward Polarity N/A

3. Neutral open, Reverse Polarity N/A

4. Reverse Polarity N/A

Enclosure Leakage Current

1. Forward Polarity NC __________ μA Pass/Fail 100 μA

2. Neutral open, Forward Polarity SFC __________ μA Pass/Fail 500 μA

3. Ground open, Forward Polarity N/A

4. Ground open, Reverse Polarity N/A

5. Neutral open, Reverse Polarity SFC __________ μA Pass/Fail 500 μA

6. Reverse Polarity NC __________ μA Pass/Fail 100 μA

Patient Leakage Current to Ground (3)

1. Forward Polarity NC __________ μA Pass/Fail 100 μA

2. Neutral open, Forward Polarity SFC __________ μA Pass/Fail 5000 μA

3. Ground open, Forward Polarity N/A

4. Ground open, Reverse Polarity N/A

5. Neutral open, Reverse Polarity SFC __________ μA Pass/Fail 5000 μA

6. Reverse Polarity NC __________ μA Pass/Fail 100 μA

Ground Continuity Resistance

1. AC mains power cord ground prong to

exposed metal surface (ground lug)

(1) NC = Normal Condition

SFC = Single Fault Condition

N/A = Not Applicable

(2) UUT = Unit Under Test

(3) Test applies for eBike III with blood pressure unit only - measuring point is the microphone connector

N/A

- 10 - eBike III basic / comfort 2018111-336 Rev. B

Page 11

CHeCkout proCedure after repaIr

After replacing a FRU or performing certain tasks, it is necessary to also inspect the unit and perform a series of checks to

ensure the unit is functioning properly. The following tables identify the inspections and checkout procedures to perform.

To use the tables, locate the relevant FRU or task in the rst column and note the required checkout procedure(s) for the

item(s). Then locate the corresponding instructions in the sections following the tables.

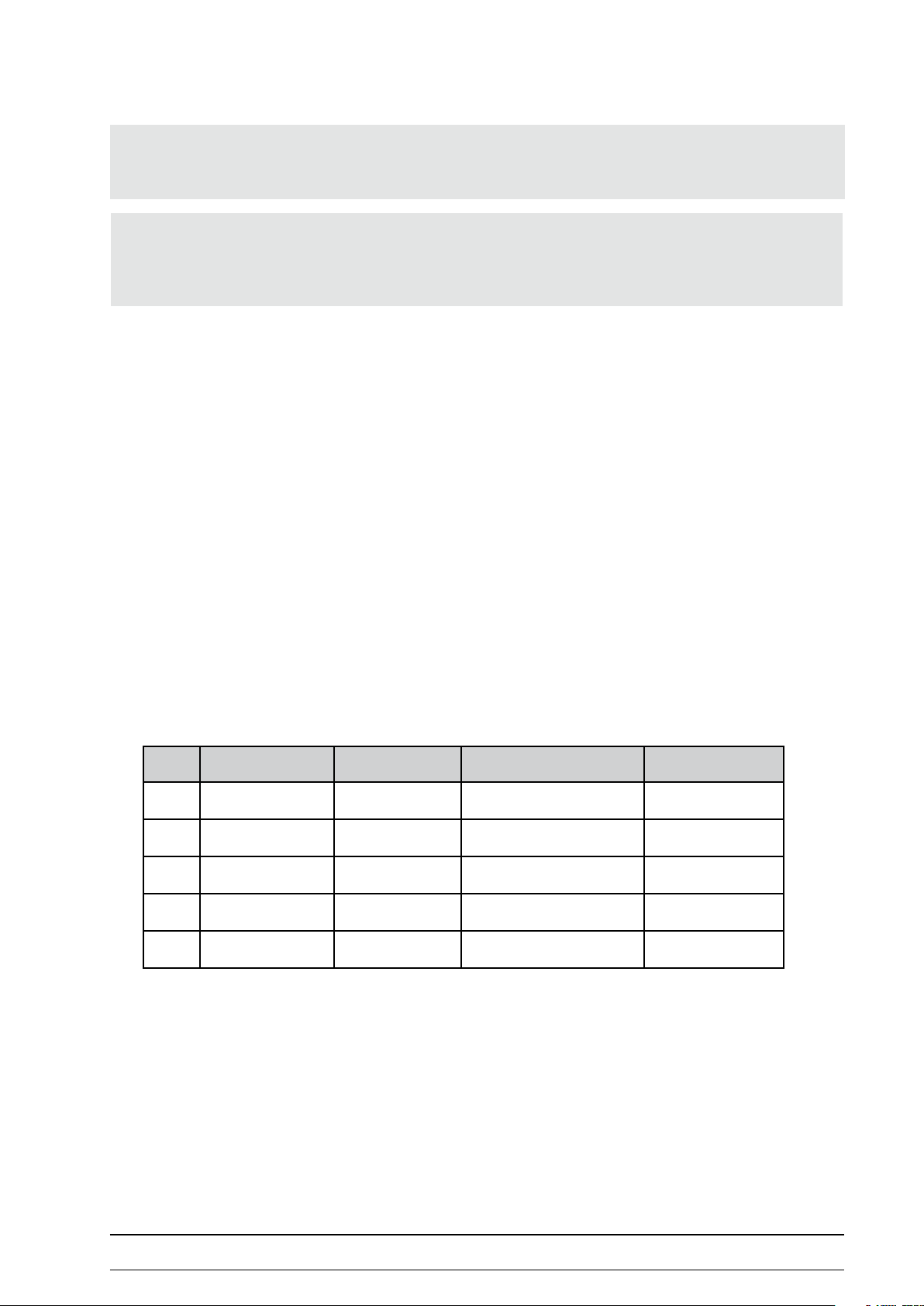

fru repaIrs (exCHange)

FRU P/N Functional Checkout Procedure

Plastic cover parts 2018111-300

Details

1,2,3,5,6,24 42

Electrical

safety checks

2018111-303

2018111-304

2018111-326

2018111-327

2018111-328

Saddle 2018111-022 1,11,12,15,16

Saddle clamp lever 2018111-148 1,11,12,15,16

Saddle tube 2018111-144

1,2,3,5,6,11,12,1718,19,20 42

2018111-310

Saddle guidance tube 2018111-332 1,2,3,5,6,12,17,18,19,20,24,40 42

Saddle motor 2018111-337 1,2,3,5,6,8,10,12,1718,19,20,24,40 42

Leg leveler(s) 2018111-021 1,23,24

Wheel set(s) 2018111-311 1,7,23,24

Pedal(s) / crank(s) 2018111-301

1,28,41

2018111-302

Handle bar 2018111-324 1,13,14

Handle bar clamp lever 2018111-322 1,13,14

Drive unit 2018111-306

1,2,3,8,9,10,21,22, 24,27,28,29,41 42

2018111-307

Strain gauge module 2018111-308 1,2,3,8,9,10,21,22, 24,27,28,29,39,41 42

RPM sensor 2018111-309 1,2,3,8,9,10,21,22, 24,27,28,29,39,41 42

Power supply 2018111-152 1,2,3,5,6,8,10,22, 24,27,28,29 42

2018111-336 Rev. B eBike III basic / comfort - 11 -

Page 12

FRU P/N Functional Checkout Procedure

Details

Electrical

safety checks

Power switch 2018111-305

1,2,3,5,6,8,10, 24,27,28,29 42

2018111-339

LIU (PCB) 2018111-312 1,2,3,8,9,10,21,22,

24,25,26,27,28,29,35,39

SMU (PCB) 2018111-314 1,2,3,8,9,10,21,22,

24,25,26,27,28,29,35,40

Blood pressure

components

2018111-313

2018111-315

1,2,3,8,9,10,21,22, 24,26,30,31,32,33,

34,35,36,37,38

42

42

42

2018111-316

2018111-317

2018111-318

Terminal cuff connector 2018111-323 1,2,3,4,8,10, 24,26,32,33,34,36,37,38 42

Control terminal w/o NIBP 2018111-321 1,4,8,21,22, 24,25,26,27,29,35 42

Control terminal with NIBP 2018111-320 1,4,8,21,22, 24,25,26,27,29,30,31,32,

33,34,35,36,37,38

42

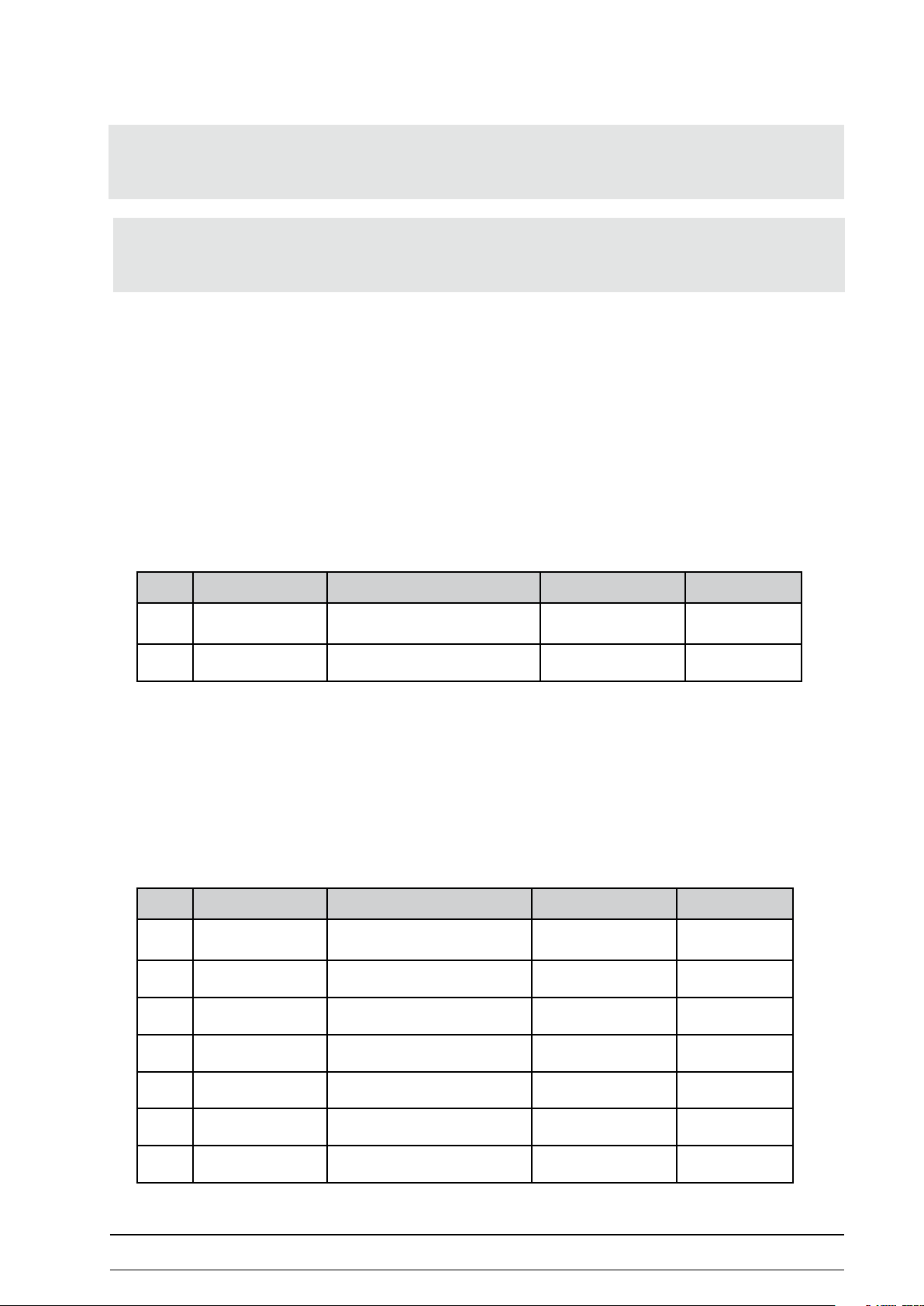

non fru repaIrs

Repair Functional Checkout Procedure

Details

Software update 4,21,22, 24,26,27,30,32,33,34

Load calibration (recommended every 2 years) 1,2,3,21,22, 24,26,27,39

Electrical safety checkout (recommended every 2 years) 1,2,3,4,5,6,21,22,24,26 42

Electrical

safety checks

- 12 - eBike III basic / comfort 2018111-336 Rev. B

Page 13

funCtIonal CHeCkout proCedure detaIls

Visual / functional checks

1. External surfaces passed inspection? pass/fail

2. Plastic cover screws complete and xed? pass/fail

3. Plastic caps on housing screws complete? pass/fail

4. Terminal foil, LCD and LED passed inspection? pass/fail

5. AC Power cord passed inspection? pass/fail

6. AC power cord strain relief mounted and cable secured pass/fail

7. Casters passed inspection? pass/fail

8. All board connectors and cable connectors connected and secured? pass/fail

9. All PCBs xed with screws on electronic carrier? pass/fail

10. All harnesses‘ and internal wiring has been secured? pass/fail

11. Bellow on saddle passed inspection? pass/fail

12. Saddle xture on saddle tube passed inspection? pass/fail

13. Handlebar adjustment (angle) passed inspection?

(refer to „Handlebar - Adjust xture (inclination)“ on page 37) pass/fail

14. Clamping lever handlebar angle adjustment passed inspection? pass/fail

15. eBike III basic only: Mechanical saddle height adjustment passed inspection? pass/fail

16. eBike III basic only:Clamping lever saddle height passed inspection

(tight; thread of lever is greased)? pass/fail

17. eBike III comfort only: Saddle motor keys at terminal functional? pass/fail

18. eBike III comfort only: Electrical saddle adjustment passed inspection? pass/fail

19. eBike III comfort only: Check correct indication of saddle height display pass/fail

20. eBike III comfort only: Check if saddle tube moves tightly and without any mechanical wobble

in saddle tube guidance. pass/fail

21. Check software (rmware) is at correct version GF 1.x

(refer to „Software update“ on page 78) pass/fail

22. Check and clear the “error log le“ in service menu

(refer to „Error log“ on page 67) pass/fail

23. Check stable position on oor, check leveler adjustment pass/fail

Operational Checks

24. Power-up self-test passed (no error messages on LCD)? pass/fail

25. LCD contrast ok?

(refer to „Contrast“ on page 62) pass/fail

26. eBike successfully communicates with ECG device?

(refer to „Connectivity and installation eBike III to GE ECG devices“ on page 81) pass/fail

27. Check load level and load indication on LCD pass/fail

28. Set manual load (see „Manual Load“ on page 66),

change load (for example, 50 W, 100 W)

Check noise level of idling drive unit (for example, for grinding noises or noise from the bearing) pass/fail

29. Check speed indication (rpm) displayed on LCD and the additional speed indication

on the patient display. pass/fail

30. Blood pressure measurement successfully initiated by ECG device? pass/fail

31. Blood pressure values successfully communicated to ECG device pass/fail

32. Check cu tubing and tubing connections, microphone connectors pass/fail

33. Check blood pressure measurement on test subject at rest pass/fail

34. Check blood pressure readings on LCD pass/fail

Tests and Calibration Checks

35. System conguration and settings correct?

(refer to „System Cong.“ on page 66) pass/fail

36. NIBP test successfully passed?

(refer to „NIBP Test“ on page 76) pass/fail

37. NIBP calibration successfully performed?

(refer to „NIBP Calibration“ on page 77) pass/fail

2018111-336 Rev. B eBike III basic / comfort - 13 -

Page 14

38. Check and clear the “NIBP error log le“ in service menu

(refer to „Error log“ on page 67) pass/fail

39. Dynamic load calibration with test bench successfully performed?

(refer to „Dynamic Load Calibration“ on page 72) pass/fail

40. Electrical saddle adjustment: adjust minimum and maximum saddle height

(refer to „Saddle Calibration“ on page 64) pass/fail

41. Check torque values for screws pass/fail

Electrical Safety Checks

42. Current leakage and ground continuity test results meet requirements?

Perform electrical safety checks when indicated (refer to „Electrical Safety“ on page 10).

All indicated electrical safetychecks require a pass/fail indication for steps performed.

Record the measurement values. pass/fail

- 14 - eBike III basic / comfort 2018111-336 Rev. B

Page 15

test proCedure “rpM / load“

Note

• Unless regulatory requirements of the country dene a dierent test procedure or test intervall, it is recommended to perform the

test “RPM / load“ at least every 2 years.

Note

• An external calibration device for dynamic load testing is needed to perfom the following test procedures

(“ergoline ergotest 550“ - order direct from Ergoline P/N 705890) or equivalent device.

• Please refer to the operator manual of the used calibration device.

test preparatIon

1. Dismount BOTH (!) pedal cranks of the eBike III - see “Dismount pedal cranks“ under section „Dismount pedal cranks“

on page 41.

2. Follow the operator manual from the manufacture of calibration device being used to connect the calibration device

with the axis of the eBike III.

3. If supported by the calibration device, connect the eBike III interface (RS-232 or USB) with the calibration device.

4. Connect the calibration device to the PC / notebook setup containing the software and conguration to work with the

device.“

5. Start the test software of the calibration device.

rpM test protoCol

1. Apply a load of 100 W to the eBike III

(-either by command of the test software or manually on the eBike III (see „Manual Load“ on page 66).

2. Perform the following RPM tests step by step. Note the results in the table or use the printed protocol of the

calibration device to document the test.

Step Target RPM Actual RPM Deviation max. Pass / Fail

#1 30 ± 1 rpm

#2 40 ± 1 rpm

#3 50 ± 1 rpm

#4 100 ± 1 rpm

#5 120 ± 1 rpm

2018111-336 Rev. B eBike III basic / comfort - 15 -

Page 16

load test protoCol

1. Perform the load test (RPM is set by the calibration device / load of the eBike III is set either by command of the test

software or manually on the eBike III -see „Manual Load“ on page 66) step by step.

2. The actual load is measured and displayed by the calibration device software. Note the results in the table or use the

printed protocol of the calibration device to document the test.

Step RPM set Target Load Actual Load Deviation max. Pass / Fail

#1 40 25 ± 3 Watt

#2 40 50 ± 3 Watt

#3 40 100 ± 5 Watt

#4 70 200 ± 10 Watt

#5 90 300 ± 15 Watt

#6 100 500 ± 25 Watt

- 16 - eBike III basic / comfort 2018111-336 Rev. B

Page 17

test proCedure “Blood pressure (nIBp)“

Note

• Unless regulatory requirements of the country dene a dierent test procedure or test interval, it is recommended to perform the

test “Blood pressure (NIBP)“ at least every 2 years.

Note

• A calibrated NIBP measure instrument set is needed to perfom the following test procedures.

• Please refer to the operator manual of the used device.

test preparatIon

1. Power eBike III on and enter service menu / NIBP test (-see „Calibration of Blood pressure unit“ on page 75).

2. Connect the calibration equipment with the eBike III cu connector.

leak-tIgHtness test

1. Use the connected test equipment to apply the target pressure (see table below) to the eBike III cu connector, wait

until the pressure in the system has stabilized (approx. 5 sec).

2. After 1 min check the actual pressure and note the pressure drop in the table

Step Target Pressure Actual pressure drop Pressure drop max. Pass / Fail

#1 50 mmHg mmHg / min < 6 mmHg / min

#2 300 mmHg mmHg / min < 6 mmHg / min

aCCuraCy test

1. Use the connected test equipment to apply the target pressure (see table below) to the eBike III cu connector, wait

until the pressure in the system has stabilized (approx. 5 sec).

2. Check the actual pressure displayed on the eBike III display and note the value in the table.

Step Target pressure Displayed pressure (eBike III) Deviation max. Pass / Fail

#1 0 ± 3 mmHg

#2 50 ± 3 mmHg

#3 100 ± 3 mmHg

#4 150 ± 3 mmHg

#5 200 ± 3 mmHg

#6 250 ± 3 mmHg

#7 300 ± 3 mmHg

2018111-336 Rev. B eBike III basic / comfort - 17 -

Page 18

tools

The following tools (metric) are recommended to disassemble the eBike III devices:

Flat bladed screwdrivers: Allan keys:

1 pc. 1.0 x 0.18 mm 1 pc. 2.5 mm straight and elbow

1 pc. 4.5 x 0.8 mm 1 pc. 3 mm straight and elbow

1 pc. 4 mm straight and elbow

Philips screwdrivers: 1 pc. 5 mm straight and elbow

1 pc. PH 2

1 pc. PH 3 1 pc. 8 mm straight and elbow

1 pc. extension for Allen key 8 mm (drive unit exchange)

1 pc. 6 mm straight and elbow

Fork wrenches: Socket wrenches:

1 pc. 10 mm 1 pc. 10 mm

1 pc. 13 mm 1 pc. 13 mm

1 pc. 14 mm 1 pc. 14 mm

1 pc. 17 mm 1 pc TORX T30

1 pc. 19 mm

Pliers

1 pc. side cutter

1 pc. flat nose pliers

Special tools

1 pc. crank extractor (P/N 2005737-001)

1 pc. round pin, max. 3 mm, minimum length 15 mm

1 pc torque wrench (10 - 100 Nm)

1 pc. calibrated NIBP measurement instrument set

1 pc. external calibration device for dynamic load testing

(“ergoline ergotest 550“ - order direct from Ergoline P/N 705890) or equivalent device

- 18 - eBike III basic / comfort 2018111-336 Rev. B

Page 19

eleCtronIC Modules / asseMBly

overvIew

desCrIptIon of eleCtronICs and CaBlIng

The electronics of the eBike III are based on a modular

concept.

Each module has its own processor with appropriate

software.

To communicate between dierent modules, the CAN bus

is used, which is a stable and standardized protocol that is

used in the automotive industry.

The connection between dierent modules is made by

direct adaptation of the dierent PCBs or by use of

standard shielded CAT-5 patch cables.

The direct connectors and cables carry the power lines

(24 volt) and the CAN bus signal lines.

pcb direct connector SyStem

aBBrevIatIons (eleCtronIC Modules / pCBs)

DTU Display terminal unit

LIU Load regulation and interface unit

BPU Bloodpressure unit

SMU Saddle motor unit

(also used as handlebar motor unit))

DMS Torque sensor

LCD Display Standard connecting cablel (cat-5 patch cable, Shielded)

2018111-336 Rev. B eBike III basic / comfort - 19 -

Page 20

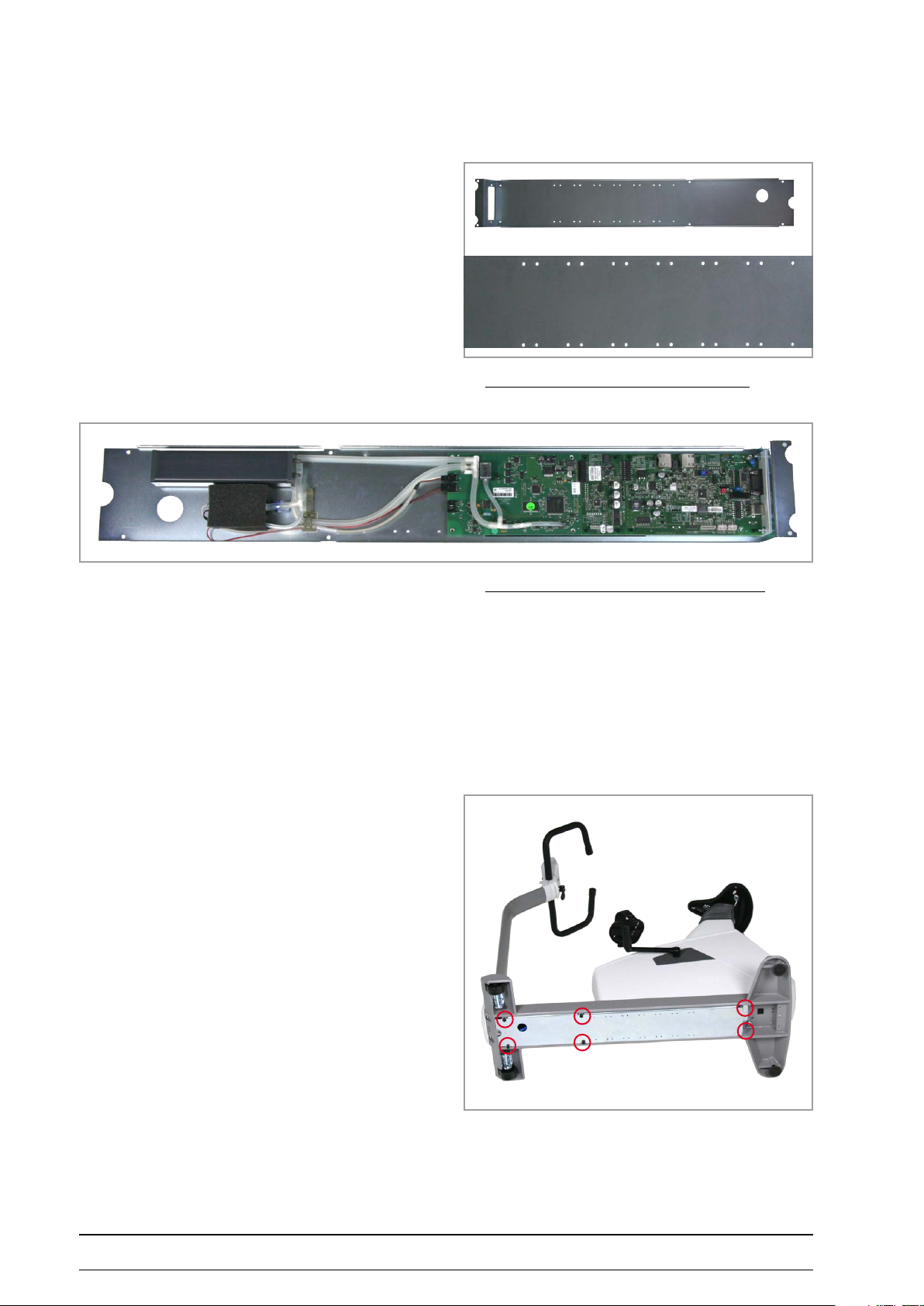

eleCtronIC CarrIer

desCrIptIon

All electronic boards are mounted on a special metal sheet

integrated in the bottom plate of the eBike III ergometers.

This metal sheet contains a grid of holes to mount all

possible combinations of electronic boards (e.g. LIU, SMU,

BPU).

metal Sheet carrier with mounting holeS (grid)

pcb direct connector SyStem

dIsMountIng of tHe eleCtronIC asseMBly group

1. Grab the eBike at handlebar and saddle and carefully

lay it sideways on one side.

2. Remove six screws (see picture) and ip the carrier

plate carefully aside.

3. Remove the connecting cables from the corresponding

boards.

4. The PCBs are mounted on spacers, screwed from

outside of the metal sheet carrier.

5. After removing these screws, the PCBs can be

removed.

metal Sheet carrier, aSSembled (bpu, Smu, liu)

6. After replacing a board, installation is performed by

following the steps in reverse order.

- 20 - eBike III basic / comfort 2018111-336 Rev. B

Page 21

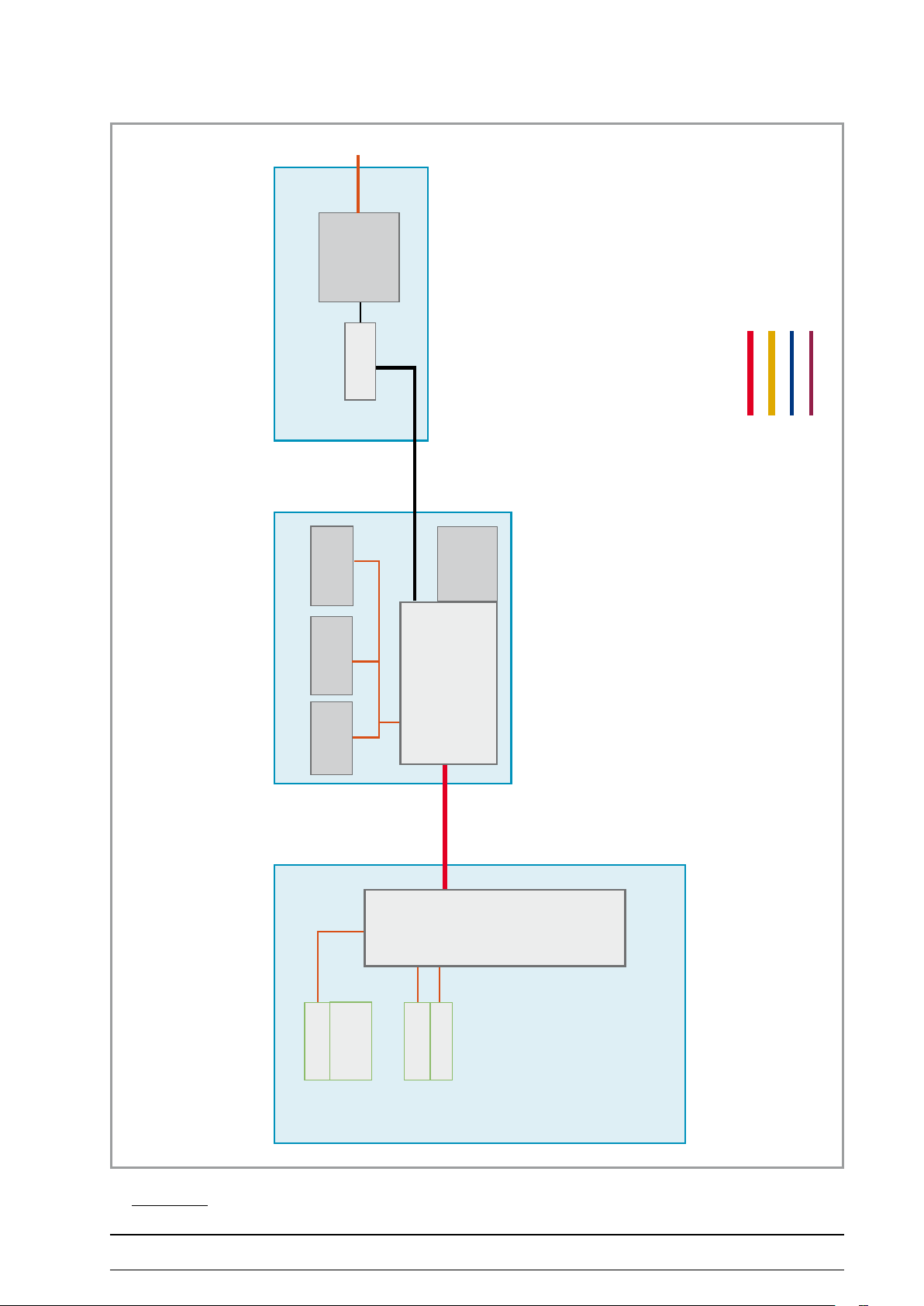

BloCk dIagraMs BIke ergoMeter eleCtronICs eBIke III

power cable

power

supply unit

Power supply

switch

24 V

RJ-45 Patchcable

PCB connector (direct)

Microfone cable

Connecting tube (cu)

rpm sensor

module

strain gauge

Brake unit + interface

brake

eddy current

Control unit

USB

RS-232

LIU

DTU

LCD

NIBP key

ebike iii baSic

keys for

saddlemotor,

service menu

patient rpm

2018111-336 Rev. B eBike III basic / comfort - 21 -

Page 22

cu connector

pressure

microphone

connector

patient rpm

service menu

NIBP key

LCD

saddlemotor,

keys for

Control unit

DTU

eddy current

brake

BPU

valves etc.

PCB connector (direct)

Microfone cable

Connecting tube (cu)

Bloodpressure module

pump

RJ-45 Patchcable

USB

LIU

RS-232

24 V

supply unit

module

switch

power

Brake unit + interface

strain gauge

rpm sensor

Power supply

power cable

ebike iii baSic with bloodpreSSure unit

- 22 - eBike III basic / comfort 2018111-336 Rev. B

Page 23

Power supply

power cable

power

supply unit

switch

24 V

RJ-45 Patchcable

PCB connector (direct)

Microfone cable

Connecting tube (cu)

rpm sensor

module

strain gauge

Brake unit + interface

brake

eddy current

Control unit

USB

RS-232

LIU

motor

Motor saddle height

sensor

position

saddle height

SMU

DTU

LCD

NIBP key

ebike iii comfort

keys for

saddlemotor,

service menu

patient rpm

2018111-336 Rev. B eBike III basic / comfort - 23 -

Page 24

cu connector

pressure

microphone

connector

patient rpm

service menu

NIBP key

LCD

saddlemotor,

keys for

Control unit

DTU

eddy current

brake

BPU

valves etc.

Microfone cable

Connecting tube (cu)

Bloodpressure module

pump

RJ-45 Patchcable

PCB connector (direct)

position

sensor

SMU

saddle height

motor

Motor saddle height

USB

LIU

RS-232

24 V

supply unit

module

switch

power

Brake unit + interface

strain gauge

rpm sensor

Power supply

power cable

ebike iii comfort with bloodpreSSure unit

- 24 - eBike III basic / comfort 2018111-336 Rev. B

Page 25

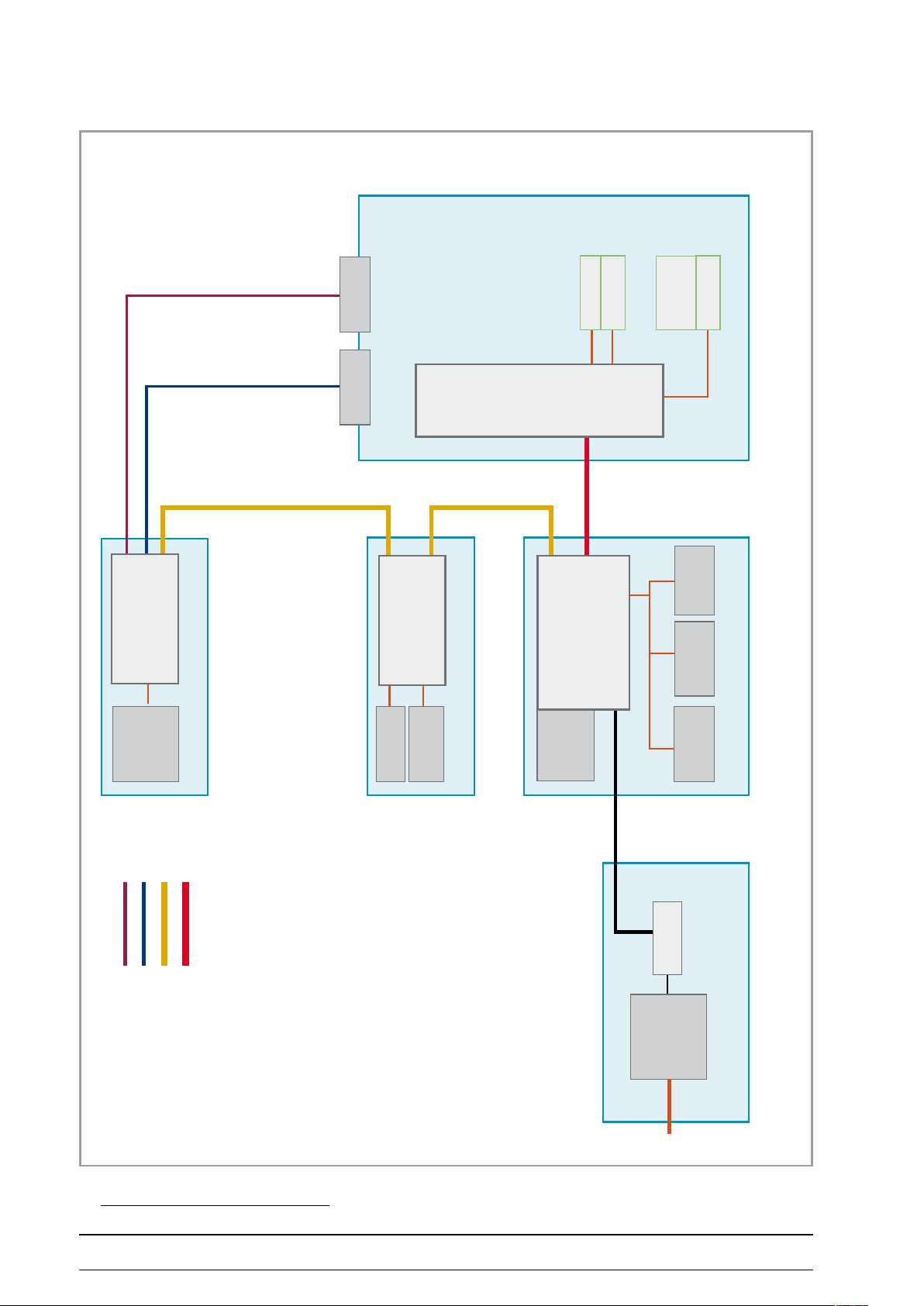

wIrIng dIagraMs BIke ergoMeter eBIke III

Power supply

white

black

Main switch

white

brown

rpm module

X 2

RS 232

USB

Torque module

Eddy current brake

Brake unit

X 19 X 11X 14 X 13

red

blue

LIU PCB

Load regulation / interface

X 8

Patch cable

RJ-45

Control unit

ebike iii baSic

2018111-336 Rev. B eBike III basic / comfort - 25 -

Page 26

Microphone cable

Control unit

RJ-45

Patch cable

pump + valve

J4 to pump

J6 to valve

J 9

Bloodpressure module

X 8

Load regulation / interface

Brake unit

Eddy current brake

BPU PCB

LIU PCB

Direct PCB connector

blue

red

Torque module

X 19 X 11X 14 X 13

USB

RS 232

rpm module

X 2

white

brown

Main switch

white

black

Power supply

ebike iii baSic with bloodpreSSure unit

- 26 - eBike III basic / comfort 2018111-336 Rev. B

Page 27

Power supply

Main switch

rpm module

Torque module

white

white

black

brown

X 19 X 11X 14 X 13

X 2

RS 232

USB

Eddy current brake

Brake unit

Control unit

red

blue

RJ-45

LIU PCB

Load regulation / interface

X 8

Patch cable

Direct PCB connector

SMU PCB

Saddle motor

X 5 (2 pol) to motor

X10 (3 pol) to sensor

ebike iii comfort

2018111-336 Rev. B eBike III basic / comfort - 27 -

Page 28

Microphone cable

J 9

Control unit

pump + valve

J4 to pump

J6 to valve

X 5 (2 pol) to motor

X10 (3 pol) to sensor

Bloodpressure module

BPU PCB

Direct PCB connector

Saddle motor

SMU PCB

Direct PCB connector

Patch cable

Patch cable

X 8

RJ-45

Load regulation / interface

LIU PCB

blue

red

X 19 X 11X 14 X 13

Brake unit

Eddy current brake

Torque module

USB

RS 232

rpm module

X 2

white

brown

Main switch

white

black

Power supply

ebike iii comfort with bloodpreSSure unit

- 28 - eBike III basic / comfort 2018111-336 Rev. B

Page 29

Control unIts

dtu - Control unIt

The DTU board of the control unit is the “mainboard“ of

the eBike III electronics.

The DTU together with the LCD is mounted inside the

housing of the control unit.

Note

• The housing of the control unit CANNOT be opened!

• For repairs / upgrades the complete control unit has to be

replaced.

control unit

dtu board (top view) with patient rpm diSplay

dtu with lcd

2018111-336 Rev. B eBike III basic / comfort - 29 -

Page 30

dtu - patIent dIsplay

The patient display for rpm and the push buttons for

service menu control are internally connected by a at

cable and screwed into the housing.

dtu - ConneCtors

1 2 3

dtu patient diSplay / buttonS for Saddle height

1 LED for rpm zones

2 Display for rpm

3 Push buttons for saddle height (eBike III comfort) and

service menu control

1

dtu

1 RJ-45 connector (patch cable to LIU)

- 30 - eBike III basic / comfort 2018111-336 Rev. B

Page 31

load regulatIon and InterfaCe

lIu - load regulatIon and InterfaCe Board

The electronics of the LIU-PCB stabilizes the actual load of

the eddy current brake with given accuracy.

The signal of the rpm sensor (non-contact hall sensor)

and the feedback signal of the strain gauge module are

analyzed and the actual brake force adjusted.

In addition, the processor of the LIU board generates the

interface signals (RS-232 and USB) to external devices (e.g.

PC-ECG or ECG recorders).

Both signals (RS-232 and USB) are galvanically isolated

(opto couplers).

The LIU board is mounted directly on the electronic carrier

plate in the bottom of the ergometer.

The power supply (24 Volt) is connected to the LIU and fed

into the bus system.

The connection between DTU (control unit M) and LIU is

made by a patch cable (RJ-45 jacks); the other boards are

connected to the LIU by direct connectors.

2 3 4

1

liu board

1 direct connector for internal BUS system

2 connector to eddy current brake

3 RJ-45 connector for internal BUS system (DTU)

4 jumper for connecting the external COM module

5 RS-232 interface connector (galv. isolated)

6 USB interface connector (galv. isolated)

7 connector rpm sensor

8 connector DMS module (torque sensor)

9 connector power supply 24 V (from main switch)

5

6

789

2018111-336 Rev. B eBike III basic / comfort - 31 -

Page 32

nIBp Blood pressure unIt

asseMBly

The NIBP module consists of several components.

The complete measurement electronics, the deating valve

and the power drivers for the pump are placed on the

BPU board (see picture).

bpu meaSuring electronic board

1

The pump and the measuring valve are placed on a

separate sound and vibration absorbing foam carrier.

2

3

bpu meaSuring electronic board

1 microphone connector (J 9)

2 measuring valve connector (J 6)

3 pump connector (J 4)

1

2

3

foam carrier for meaSuring valve (1) and pump (2)

(with compenSating container 3)

When replacing the measuring valve, the silicon tube has

to be connected with the upper hose nipple of the valve

and the cable bended to a loop. The carefully slip the valve

back into the foam carrier.

replacing the valve

- 32 - eBike III basic / comfort 2018111-336 Rev. B

Page 33

plaCeMent of pressure tuBes (sCHeMatIC)

foam carrier

measuring valve

lter

BPU electronic board

pressure-

sensor 1

pressure-

sensor 2

deating

valve

check valve

pump

compensating container

sound

absorber

cu

connector

(in control unit)

BloCk dIagraM of CaBlIng of tHe Bloodpressure unIt

microphone

connector

(in control unit)

J 9

BPU electronic board

deating valve

J 6 J 4

2

measuring

valve

2

pump

2018111-336 Rev. B eBike III basic / comfort - 33 -

Page 34

Bpu - Blood pressure Board

The BPU electronics is responsible for analyzing the

microphone signals, controlling the valves and the pump.

The input of the microphone (1) is galvanically isolated, see

upper left in picture.

A redundant surveillance system (with two pressure

sensors (2) ) continously monitors the actual cu pressure

and the pump time.

The BPU board is connected to other PCBs by use of the

direct bus connector (3).

The measuring valve is connected to J6 (4) and the pump

to J4 (5).

1

4 5

2

2

bde- blood preSSure meaSuring board

3

pump

measuring valve

Note

• The BPU is ALWAYS the last module last module placed

in the “PCB chain“ on the electronic carrier.

• The SMU board is mounted between BPU and LIU.

ergometer blood preSSure unit, complete

- 34 - eBike III basic / comfort 2018111-336 Rev. B

Page 35

MIsCellaneous Modules

sMu - saddle HeIgHt Motor

The control of the saddle motor is performed by the SMU

board.

The SMU has one connector for the motor (1) and another

coded connector (2) for the position sensor (actual motor

position).

Motor and sensor are connected with special cables.

The SMU board is connected directly to the LIU (3) or BPU.

1 2

33

Smu board (top view)

2018111-336 Rev. B eBike III basic / comfort - 35 -

Page 36

MeCHanICal asseMBly

Controls and IndICators

1 Control unit

2 Speed readout for patient

2

1

3

3 Connectors (for blood pressure cu)

4 Adjustment of handlebar angle

5 Castors

6 Baseplate (small)

7 Leveling feet to adjust the ergometer to uneven oors

8 Sockets for power cord and connection cables

(underside of ergometer)

9 Power switch (toggle switch [I / 0]

10 Saddle adjustment with clamping lever

1 Control unit

2 Speed readout for patient

keys for saddle height motor adjustment

3 Connectors (for blood pressure cu)

4

10

9

8

7

6

5

ebike iii baSic

2

1

3

4

4 Adjustment of handlebar angle

5 Castors

9

6 Baseplate (large)

7 Leveling feet to adjust the ergometer to uneven oors

8

8 Sockets for power cord and connection cables

(underside of ergometer)

7

9 Power switch (toggle switch [I / 0] )

6

5

ebike iii comfort

- 36 - eBike III basic / comfort 2018111-336 Rev. B

Page 37

MountIng tHe HandleBar

HandleBar - adjust fIxture (InClInatIon)

1. Use an allen key to adjust the 2 screws.

2. Open the handlebar lever.

3. Start with a quarter turn clockwise for both screws.

4. Close the lever and check if the handlebar is secure.

5. The force of the lever can be adjusted by turning the

screw inside the lever.

6. Open the handlebar lever.

7. Turn the screw clockwise (a quarter turn) using a at

screwdriver.

8. Close the lever and check if the handlebar is secure.

HandleBar - dIsMountIng / MountIng

1. Open the handlebar lever and turn the handlebar

downwards.

2. Remove the allen screw from the lever.

2018111-336 Rev. B eBike III basic / comfort - 37 -

Page 38

3. Using a at screwdriver, loosen the screw

inside the handlebar lever by turning the screw

counterclockwise.

4. Unscrew the lever out of the terminal adapter by

turning the lever counterclockwise.

5. Remove the washer.

6. Remove the two allen screws and remove the rear part

of the terminal adapter.

7. The handlebar can be changed.

8. Follow the steps in reverse order to secure the

handlebar.

- 38 - eBike III basic / comfort 2018111-336 Rev. B

Page 39

reMove ergoMeter HousIng

plastIC sCrew seals (Caps)

The screws xing the plastic housing parts of the eBike

III basic and eBike III comfort are covered by small plastic

caps.

Due to the dierent screw sizes there are 5 dierent caps

used. The dierent caps are marked with small slots from

cap type 0 (no slot) up to cap type 4 (4 slots) - see picture.

plaStic cap with marking SlotS (type 4)

cap type 0

handlebar housing

The caps can only be removed by destroying them.

Before removing plastic parts of the housing, be sure to

have spare plastic caps available (PN 2018111-335).

cap type 1

eBike III basic

eBike III comfort

cap type 2

eBike III comfort

cap type 3

eBike III comfort

cap type 4

eBike III basic

2018111-336 Rev. B eBike III basic / comfort - 39 -

Page 40

dIsMountIng tHe HandleBar pole HousIng

1. Remove the two plastic caps (type 0) on both sides of

the handlebar pole housing

2. Using a small screwdriver, cut into the plastic caps

covering the screws and remove the caps

(the caps will later be replaced by spare ones;

P/N 2018111-335).

ebike iii

3. Remove the screws with an allen key tool.

4. The two parts of the handlebar pole housing can be

carefully removed.

5. Follow the steps in reverse order to reassemble the

handlebar pole housing.

- 40 - eBike III basic / comfort 2018111-336 Rev. B

Page 41

dIsMount pedal Cranks

1. Carefully lift the protective cover o the crank, using a

small at screw driver.

2. Plug the crank extractor onto the screw of the crank.

3. Loosen the screw with a wrench (17 mm).

4. Remove the screw and the lock washer.

(When mounting the cranks after repair use a torque

wrench to tighten the screw with a torque of

40 Nm.)

5. Turn the crank extractor and securely tighten the

screw completely (!!) into the winding of the crank

screw.

6. Use a wrench (17 mm) to remove the crank by

screwing the bolt onto the axis.

2018111-336 Rev. B eBike III basic / comfort - 41 -

Page 42

reMove HousIng of tHe eBIke III BasIC

reMove top Cover

1. Remove the saddle.

(When mounting the saddle after repair use a torque

wrench to tighten the screw with a torque of

25 Nm.)

2. Remove the lever for saddle height by turning it

counterclockwise.

3. Remove the two plastic caps (cap type 4) on both

sides.

4. Using a small screwdriver, cut into the plastic caps

covering the screws and remove the caps

(the caps will later be replaced by spare ones;

P/N 2018111-335).

5. Remove the two allen screws underneath the plastic

caps.

6. Remove the allen screw at the rear side of the top

cover.

- 42 - eBike III basic / comfort 2018111-336 Rev. B

Page 43

7. The top cover can be lifted and carefully removed.

reMove Inlays

1. Using a small at screwdriver, lift the inlay panel, and

carefully release the panel.

Note

• Avoid scratching the main plastic housing!

2. Continue to carefully loosen the remaining tabs until

the panel can be removed completely.

2018111-336 Rev. B eBike III basic / comfort - 43 -

Page 44

reMove sIdes of tHe HousIng

1. Using a small screwdriver, cut into the plastic caps

(cap type 1) covering the screws and remove the six

caps (3 on each side); the caps will later be replaced by

spare ones (P/N 2018111-335)

(see picture: items “A“).

2. Remove the three allen screws in the main side parts

(see picture: items “A“) and the two allen screws under

the removed inlays (picture: items “B“) on both sides.

A

B

B

AA

A

3. Unlock the metal bracket connecting both sides covers

of the housing by lifting it with a at screwdriver.

B

B

- 44 - eBike III basic / comfort 2018111-336 Rev. B

Page 45

4. The side covers of the housing can be removed by

lifting up the panels from the aluminum bottom plate

(see detail).

5. The drive unit, saddle mechanics, and power supply

are accessible.

6. Follow the steps in reverse order to assemble

the eBike III basic housing.

2018111-336 Rev. B eBike III basic / comfort - 45 -

Page 46

reMove HousIng of tHe eBIke III CoMfort

reMove top Cover

1. Remove the allen screw from the front part of the top

cover.

Using a small screwdriver, cut into the plastic cap

(cap type 3) covering the screw and remove the cap

on both sides; the caps will later be replaced by spare

ones (P/N 2018111-335).

2. Using two allen keys, remove the long screw securing

the top cover to the housing brackets.

- 46 - eBike III basic / comfort 2018111-336 Rev. B

Page 47

3. The top cover can be easily removed.

reMove HousIng BraCkets

1. Using a small screwdriver, cut into the two plastic

caps (top: cap type 2, bottom: cap type 1) covering the

screws and remove the caps on both sides.

The caps will later be replaced by spare ones

(P/N 2018111-335).

Note

• The top plastic cap (cap type 2) is not symmetric - when

reassembling the bracket housing, the indication mark of

this cap (two notches) has to be positioned at the top!

2018111-336 Rev. B eBike III basic / comfort - 47 -

Page 48

2. Insert a small screwdriver or a round 3 mm pin into

the small holes (front and rear of bracket top) to

unlock the housing.

3. Remove the two metal brackets connecting the two

sides of the housing brackets.

4. Starting at the bottom, release the housing panels

from the brackets in the side housing covers and

remove.

- 48 - eBike III basic / comfort 2018111-336 Rev. B

Page 49

reMove HousIng sIde panels

1. Remove the four screws securing the housing panels

to the metal chassis.

2. Lift the housing covers to release the covers from the

brackets in the aluminium base and remove.

3. The drive unit, saddle mechanics, and power supply

are accessible.

4. Follow the steps in reverse order to assemble the

eBike III comfort housing side panels.

2018111-336 Rev. B eBike III basic / comfort - 49 -

Page 50

saddle pIllar exCHange (eBIke III BasIC)

1. Follow the steps in “Remove housing of the eBike III

basic“ on page 42

2. Loosen the limiting screw for the saddle pillar with an

Allen key.

3. Remove the lever.

4. Loosen the Philips screw.

5. Remove the clamping plate and the threaded plate.

6. The saddle pillar can be pulled out.

7. Follow the steps in reverse order to assemble the

saddle pillar.

- 50 - eBike III basic / comfort 2018111-336 Rev. B

Page 51

saddle Motor (eBIke III CoMfort)

1. Follow the steps in “Remove housing of the eBike III

comfort“ on page 46.

2. Disconnect the two connection cables of the saddle

motor from PCB Interface SMU.

3. Remove the saddle.

4. Loosen and remove the bottom xation of the saddle

motor; screw and nut are accessible via a hole at the

bottom.. Use a socket wrench and an Allen key from

the counter side to dismount the screw.

Note

Try to position the saddle at mid-level setting before removing

the saddle motor.

5. Unscrew the four screws of the saddle guide tube with

a fork wrench (13mm):

Start by removing screws (1) to (3) (see picture).

Loosen screw (4) and move the guide backwards until

the screw releases and can be removed.

1

3

2

4

2018111-336 Rev. B eBike III basic / comfort - 51 -

Page 52

6. Remove the complete saddle motor unit from the

ergometer.

7. Loose both TORX screws at the top

8. Push the saddle motor inside the saddle tube to allow

the cylindrical pin to be removed from the saddle

shaft.

9. Pull the saddle motor out of the saddle guide tube.

10. Follow the steps in reverse order to install the new

motor.

- 52 - eBike III basic / comfort 2018111-336 Rev. B

Page 53

straIn gauge Module exCHange

1. Follow the steps in

“Remove housing of the eBike III basic“ on page 42

or

“Remove housing of the eBike III comfort“ on page

46.

2. Disconnect the cable of the strain gauge module from

the LIU electronics (the electronic housing is located

underneath the bottom plate).

Remove the toroid ferrite o the cable.

3. Remove the two allen screws securing the strain

gauge module.

4. Remove the strain gauge module (1) and the heat sink

(2) and carefully pull the cable through the hole in the

bottom plate.

5. When installing the new module carefully allign the

module and the heat sink in parallel to the eddy

current brake.

6. When securing the module in place, carefully tighten

the two screws; excessive force may damage the

module.

2

1

7. Lead the connecting cable through the hole in the

bottom plate.

Lead the cable through the toroid ferrite and

reconnect it to the LIU electronic board.

2018111-336 Rev. B eBike III basic / comfort - 53 -

Page 54

rpM Module exCHange

1. Follow the steps in

“Remove housing of the eBike III basic“ on page 42

or

“Remove housing of the eBike III comfort“ on page

46.

2. Disconnect the cable of the RPM module from the

LIU electronics (the electronic housing is located

underneath the bottom plate).

3. Use a long, exible, magnetic Allen key to remove the

two Allen screws securing the RPM module from the

bottom plate.

4. Carefully remove the RPM module through the hole in

the bottom plate.

5. Insert the new RPM module carefully through the hole

in the bottom plate into the load unit.

6. From the top of the load unit carefully tighten the two

Allen screws..

7. Connect the cable to the appropriate connector on the

LIU board (marked as “RPM brake“).

- 54 - eBike III basic / comfort 2018111-336 Rev. B

Page 55

load unIt

asseMBly

The eBike III ergometers are equipped with an identical

load unit (brake unit) with an eddy current brake of

1000 Watt.

load unIt replaCeMent

aSSembly of the load unit

1 Galvanized steel housing

2 Precision bearings

3 Calibrated strain gauge module

4 Eddy current brake (1000 W)

5 Special drive belt

1. Grab the eBike at handlebar and saddle and carefully

lay it sideways on one side.

2. Disconnect all cables from the electronic boards.

3. The load unit is secured with six Allen key screws on

the ergometer chassis.

Brace the load unit from falling over and then using a

socket wrench, loosen the screws.

Use a torque wrench to tighten the screws of the new load

unit with a torque of 25 Nm.

2018111-336 Rev. B eBike III basic / comfort - 55 -

Page 56

power swItCH replaCeMent

1. The power switch is mounted between the two rear

parts of the ergometer housing.

2. Follow the steps in

“Remove housing of the eBike III basic“ on page 42

or

“Remove housing of the eBike III comfort“ on page

46.

3. Remove the cables from the defect power switch and

place them on the appropriate contacts of the new

switch.

If the cable between switch and LIU board has to be

replaced, open the electronic carrier (underneath the

eBike), disconnect the power cable from the LIU board

and replace it with the spare cable included in the

package..

4. Secure the cables with a cable strap

power connector (from main Switch) on liu board

When reassembling the housing:

5. Slide the plastic cover of the power switch in the

appropriate slot in one side part of the housing.

6. During assembly of the side parts take care, that

the plastic cover of the main switch ts into the

corresponding slot of the other side part.

- 56 - eBike III basic / comfort 2018111-336 Rev. B

Page 57

power supply unIt replaCeMent

1. The power supply is mounted in the rear of the

ergometer.

2. Remove the mounting bracket (2 screws).

3. Replace the power supply unit and secure the

mounting bracket again.

4. Remove the power supply cable from the main switch

and connect the cable of the new power supply

accordingly

5. Secure the cables with a cable strap

When reassembling the housing:

6. Slide the plastic cover of the power switch in the

appropriate slot in one side part of the housing.

7. During assembly of the side parts take care, that

the plastic cover of the main switch ts into the

corresponding slot of the other side part.

2018111-336 Rev. B eBike III basic / comfort - 57 -

Page 58

reMove Control unIt

1. To remove the control unit, loosen both Phillips-head

screws on the side of the control terminal.

2. Remove the control terminal from the support.

3. Disconnect the patch cable (1) from the DTU board.

1

eBike III with blood pressure measurement

• Disconnect microphone cable (2) and cu hose (3)

(see following instructions and pictures)

Note

• The housing of the control unit CANNOT be opened!

• For repairs / upgrades the complete control unit has to be

replaced.

2

3

- 58 - eBike III basic / comfort 2018111-336 Rev. B

Page 59

4. Disconnect the microphone cable at the 3 pole

connector (see picture):

Press the small clip downwards (1),

and pull out the connector carefully (2) with clip

pressed downwards.

1

2

5. Disconnect the blue hose at the hose connector

(see picture).

Warning

Do not pull at the microphone cable to disconnect the

microphone connector - the cable will be damaged..

2018111-336 Rev. B eBike III basic / comfort - 59 -

Page 60

software Control terMInal

turnIng tHe systeM on

The ergometer is powered on by pressing the power switch

to the ON position.

The ergometer runs a self-test. The Self-Test screen is

displayed.

eBike III

settIngs Control terMInal

The control unit is controlled remotely by a host device (for

example, CASE, CardioSoft).

No setup is required by the user.

Selftest running

Self-teSt Screen

Note

• Instruct the patient not to pedal while the ergometer is

powering and during the self-test.

• Apply the blood pressure cu to the patient AFTER the

ergometer has been powered on and the self-test completed.

• If an error message appears displays after the self-test,

please refer to the Addendum / Error Messages section

for instruction.

All conguring is done through the service menu only.

- 60 - eBike III basic / comfort 2018111-336 Rev. B

Page 61

servICe Menu

To activate the service menu, the ergometer has to be

powered o and on again.

As soon as the self test displays on the ergometer LCD,

press the two arrow keys simultaneously:

To prevent settings from being changed in error, the

service menu is “protected“ with a password.

Select “999“ with the arrow keys and conrm by pressing

NIBP.

The service menu with the following parameters displays:

• Contrast

• ECG type

• NIBP mmHg / kPa

• NIBP Beep

• Baudrate 8N2

• Analog Calibration

• Software Update

• Dynamic Load Calibration

• Saddle Calibration

• NIBP Calibration

• NIBP Test

• System Cong.

• Error log

• Manual load

• Reset DMS values

Service Code

paSSword for Service menu

999

Note

• The service menu in the ergometers is available in

english only.

• Depending on the actual ergometer conguration,

not all settings are enabled.

• Leaving the service menu is only possible by powering the

device o.

• The following descriptions are not in the same order as in

the service menu.

Navigate through the menus by using the arrow keys

(saddle height) to position the cursor bar.

Conrm the selection by pressing NIBP (to the right

of the LCD).

Service Menu

Contrast

ECG type

NIBP mmHg / kPa

NIBP Beep

Baudrate 8N2

Analog Calibration

Software update

Select the desired parameter using the arrow keys and

conrm by pressing NIBP.

2018111-336 Rev. B eBike III basic / comfort - 61 -

Selection of parameterS in Service menu

Page 62

Contrast

The contrast of the LCD can be adjusted between

0 to 100 %.

eCg type

The selected ECG Type determines the communication

method with the ECG recorder, PC-based ECG system, etc.

To prevent settings from being changed in error, the menu

is protected with a password.

Using the arrow keys, enter ”003” and conrm the entry by

pressing NIBP.

Contrast

adjuSting the diSplay contraSt

50 %

ECG Type

003

All eBike III ergometers support the following

communication modes:

• Digital (default)

The communication with the ergo meter is entirely

controlled with digital commands.

• Analog / Digital (optional)

An analog voltage controls the load - blood pressure

measurements can be initiated with digital commands.

To use the ”Analog/Digital” communication mode,

the eBike III ergometers have to be equipped with the

optional „COM-Modul (PN 201118-340)“.

Select the communication mode and conrm by pressing

NIBP.

entering the ekg type paSSword

ECG-Type

Digital

Analog / Digital

Selecting the ergometer communication mode

Note

• The ECG Type needs to be selected only when the ergometer is connected to an ECG unit. The selection is part of

the installation procedure.

- 62 - eBike III basic / comfort 2018111-336 Rev. B

Page 63

nIBp Beep

The tone signal for the systolic pulse (during NIBP

measurement) can be set to on or o.

Select the desired setting and conrm by pressing NIBP.

nIBp MMHg / kpa

The units for the NIBP values displayed can be changed.

Select the desired units and conrm by pressing NIBP.

NIBP Beep

On

Off

beep during bp meaSurementS

NIBP mmHg / kPa

mmHg kPa

unit Selection for nibp valueS

2018111-336 Rev. B eBike III basic / comfort - 63 -

Page 64

dynaMIC load Cal.

To perform a dynamic load calibration, a calibrated

dynamic test bench is needed.

The dynamic calibration of the load unit is described in the

session “„Dynamic Load Calibration“ on page 72.

software update

For a description of a software update of the ergometer

(rmware) see the session „Software update“ on page

78.

Baudrate 8n2

The baudrate can be selected between 1200 Baud and

115000 Baud.

Default value for standard ergometers is 4800 Baud.

Select the desired parameter using the arrow keys and

conrm by pressing NIBP.

saddle CalIBratIon

(eBike III comfort only)

This parameter is used to adjust the electrical saddle motor

(display scale 1-40).

Select “SET TOP Position“ and conrm by pressing NIBP.

Baudrate 8N2

1.200

2.400

4.800

9.600

19.200

38.400

76.800

Selection of Serial baudrate

Saddle Calibration

SET TOP Position

SET BOTTOM Position

EXIT

Use the arrow keys to move the saddle to the desired top

position (99 cm ± 0,5 cm above bottom plate; see picture)

and conrm “SET“ by pessing NIBP.

Saddle Calibration

TOP Position

Adjust with

SET Height: 22

calibration of Saddle height top poSition

- 64 - eBike III basic / comfort 2018111-336 Rev. B

Page 65

Select „SET BOTTOM Position“ and conrm by pressing

NIBP.

Saddle Calibration

SET TOP Position

SET BOTTOM Position

EXIT

Use the arrow keys to move the saddle to the desired

bottom position (69 cm ± 0,5 cm above bottom plate; see

picture) and conrm “SET“ by pessing NIBP.

Select “EXIT“ and conrm by pressing NIBP to return to the

service menu

Saddle Calibration

Bottom Position

Adjust with

SET Height: 5

calibration of Saddle height botom poSition

Saddle Calibration

SET TOP Position

SET BOTTOM Position

EXIT

top: 99 CM

BottoM: 69 CM

2018111-336 Rev. B eBike III basic / comfort - 65 -

Page 66

Manual load

A manual load can be set between 1 - 999 Watt.

Use the arrow keys and set the desired value by pressing

NIBP.

Pressing NIBP at 0 Watt (EXIT) returns to the service menu.

systeM ConfIg.

Manual load

75 Watt

Manual load

0 Watt

EXIT

The hardware conguration of the ergometer is dened in

this setup.

Select the module / option and change the setting to I

if the module is integrated in the actual ergometer.

The last selection “EXIT“ returns to the service menu.

System Cong.

Saddle engine 0 I

NIBP-Modul 0 I

Analog Interface 0 I

EXIT

Settting of ergometer configuration

Note

• ”Analog Interface” is set to “I” only if a MAC5500 is

connected to the eBike III.

In conjunction with this setting, a special adapter

(COM module PN 2018111-340) has to be installed to add

an analog interface to the eBike III.

- 66 - eBike III basic / comfort 2018111-336 Rev. B

Page 67

error log

The software of the eBike III ergometers stores internal

error messages in a special memory area (Error Logs) and

also stores statistics for the quality of the blood pressure

measurements (NIBP Logs).

These error messages can be checked and cleared in this

menu.

To display the stored error messages select „Show Error

Logs“ and conrm with by pressing NIBP.

The rst error message is displayed:

Source: The unit generating the error

Err.Code: Corresponding error code of the software

Quantity: Number of occurences of this error

Error log

Err. Log Quantity: 2

Show Error Logs

Show NIBP Logs

Clear Error Logs

Clear NIBP Logs

EXIT

error log memory

Error No.: 1 / 3

Source: SMU

Err.Code: 0100

Quantity: 1

Using the arrow keys, the following error messages can be

displayed.

Press the NIBP (Exit) to close the error log displayed.

To display the bloodpressure statistics, select „Show NIBP

Logs“ and conrm by pressing NIBP.

The statistics are displayed:

NIBP failed: Number of failed measurements

Mic.Level 1...5: Number of measurements with the

shown microphone signal strength

(5 = best signal)

EXIT

diSplaying a Single error

NIBP failed: 2

Mic. level 1: 2

Mic. level 2: 5

Mic. level 3: 3

Mic. level 4: 9

Mic. level 5: 7

EXIT

error log memory nibp

2018111-336 Rev. B eBike III basic / comfort - 67 -

Page 68

nIBp test / nIBp CalIBratIon

This menu is enabled, if the ergometer is equipped with an

automatic NIBP module and this module is activated.

Test and calibration of the NIBP module is described in

session „Calibration of Blood pressure unit“ on page 75..

analog CalIBratIon

This function is used to allign the analog remote signals

(input and output) to the corresponding ECG devices.

The eBike III ergometers have to be equipped with the

optional „COM Module (PN 201118-340)“. This module is

connected with a small cable to the 9-pin DSUB connector

and xed to the chassis with a plastic velcro tape.

In addition, a jummper connector has to be installed on

the LIU board.

The COM module handles one analog input and ve analog

output signals from/to external devices.

Note

• To align the analog load signals, the corresponding ECG

recorder should be connected as a reference voltage

source.

• Disconnect the RS232 or USB cable, if connected.

• The alignment of the analog signals can be controlled

after exiting the service menu (e.g. by starting a remote

controlled stress test).

Signal aSSignment of analog connector (com module)

Pin 1 : INPUT Load

Pin 2:

Pin 3: reserved - do not connect

Pin 4: OUTPUT BP heartrate

Pin 5: OUTPUT Load

Pin 6: OUTPUT Diastole

Pin 7: OUTPUT rpm

Pin 8: OUTPUT Systole

Housing: Signal GND

reserved - do not connect

Select the analog signal to be aligned and conrm

by pressing the NIBP key.

Analog Calibration

Input 1 Load

Output 1 Load

Output 2 Heart.

Output 3 Syst.

Output 4 Diast.

EXIT

alignment of analog input / output SignalS

- 68 - eBike III basic / comfort 2018111-336 Rev. B

Page 69

alIgnMent “Input: analog load Control“

IN-Volt: displays the voltage at the analog input

Set the ECG recorder output to a low load value

(for example 20 Watt).

The corresponding voltage is displayed (IN-Volt).

Wait until the voltage has settled.

Select “OFFSET“ and conrm by pressing NIBP.

Use the arrow keys to set the load value to the ECG

recorder vaue (for example 20 Watt) and conrm by

pressing NIBP.

The setting is stored in the ergometer.

INPUT 1 Load

IN-Volt: 0.10 V

OFFSET 20 Watt

GAIN 300 Watt

EXIT

alignment of analog input „load“

INPUT 1 Load

IN-Volt: 0.10 V

OFFSET 20 Watt

GAIN 300 Watt

EXIT

Set the ECG recorder output to a high load value

(for example300 Watt).

The corresponding voltage is displayed (IN-Volt).

Wait until the voltage has settled.

Select “GAIN“ and conrm by pressing NIBP.

Use the arrow keys set the load value to the ECG recorder

vaue (for example 300 Watt) and conrm by pressing NIBP.

The setting is stored in the ergometer.

offSet alignment of analog input „load“

INPUT 1 Load

IN-Volt: 3.05 V

OFFSET 20 Watt

GAIN 300 Watt

EXIT

alignment of analog input „load“

INPUT 1 Load

IN-Volt: 3.05 V

OFFSET 20 Watt

GAIN 300 Watt

EXIT

Setting range:

OFFSET: range from 20 to 1000 Watt in 10 Watt steps