Page 1

GE

Lighting

™

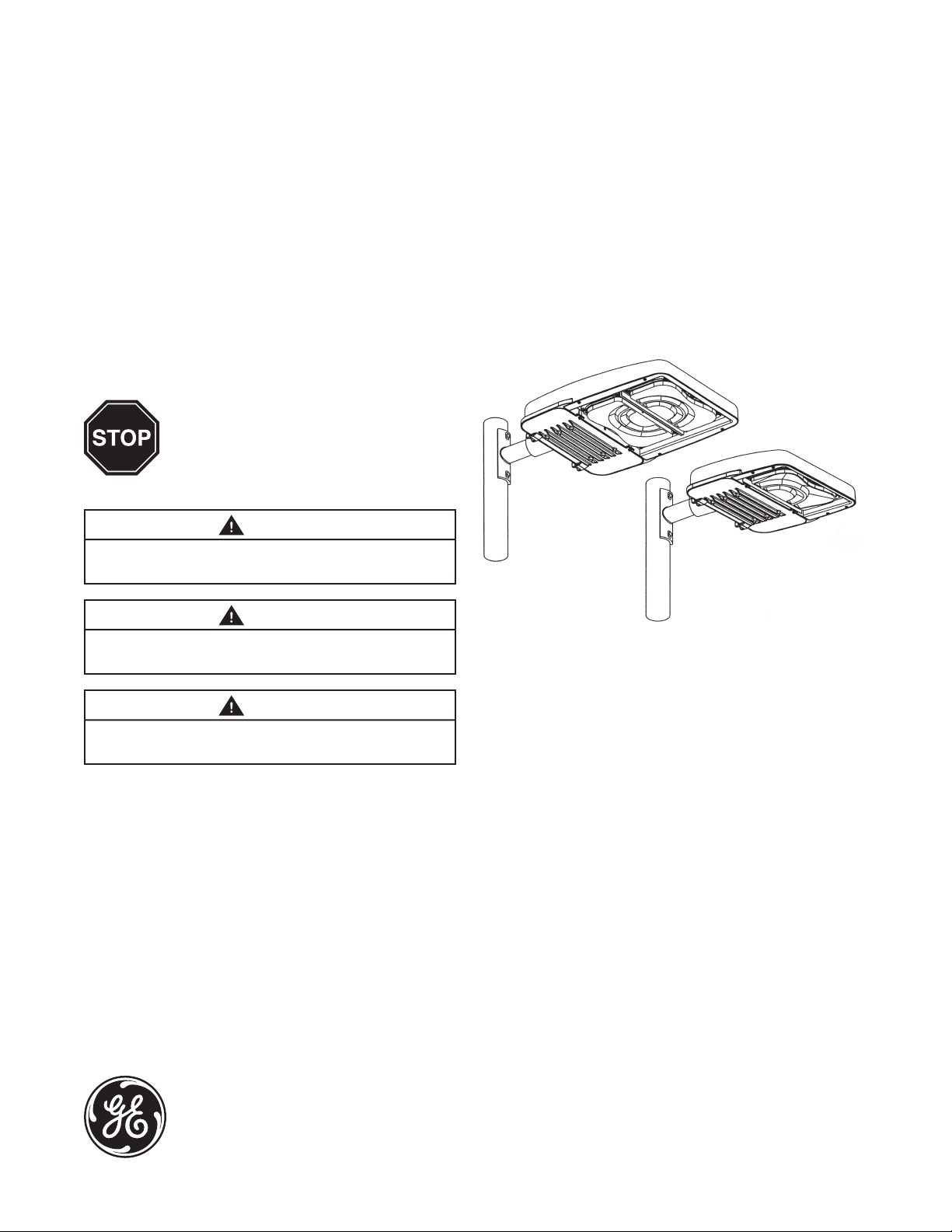

Evolve

Modular Fixtures - Small & Medium (EASM & EAMM)

BEFORE YOU BEGIN

Read these instructions completely and carefully.

Save these instructions for future use.

LED Area Light

WARNING

Installation Guide

GEH-6006A

Risk of electrical shock. Disconnect power before servicing

or installing product.

WARNING

Risk of injury or damage. Unit will fall if not installed

properly. Follow installation instructions.

CAUTION

Risk of injury. Wear safety glasses and gloves during

installation and servicing.

This device complies with Part 15 of the FCC Rules. Operation is

subject to the following two conditions: (1) This device may not cause

harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

This Class [A] RFLD complies with the Canadian standard ICES-003.

Ce DEFR de la classe [ A ] est conforme à la NMB-003 du Canada.

Note: This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area

is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

• This luminaire is designed for outdoor lighting service,

and should not be used in areas of limited ventilation,

or in high ambient temperatures.

• Best results will be obtained if installed and maintained

according to the following recommendations.

• Luminaire is designed to operate in ambient

temperatures ranging from -40°C to 50°C and to be

mounted horizontally to a vertical pole with LEDs

facing down, as shown.

SPECIFICATIONS

• Weight: Maximum weight <50 lbs (22.68 kg)

• EPA: 1.35 sq ft max (0.13 sq M) (Calculated using

1.30 Cd X Total Area of 1.04 ft2)

• IP Rating: Optical 65, Standard Electrical Enclosure:

UL 1598 Wet Location Rated

imagination at work

Page 2

UNPACKING

1

• This luminaire has been properly packed so that no

parts should have been damaged during transit.

• Inspect to conrm.

HANDLING

2

• Damage may occur if luminaire is improperly handled

outside of pack.

• Do not impact or stack luminaire after removal from

packaging.

MOUNTING

3

WARNING

Risk of injury or damage. Unit will fall if not installed

properly. Follow installation instructions.

Follow the appropriate installation instructions based on

your selected mounting method:

a. Sliptter Mounting

b. Round Pole Architectural Arm Mounting

c. Square Pole Architectural Arm Mounting

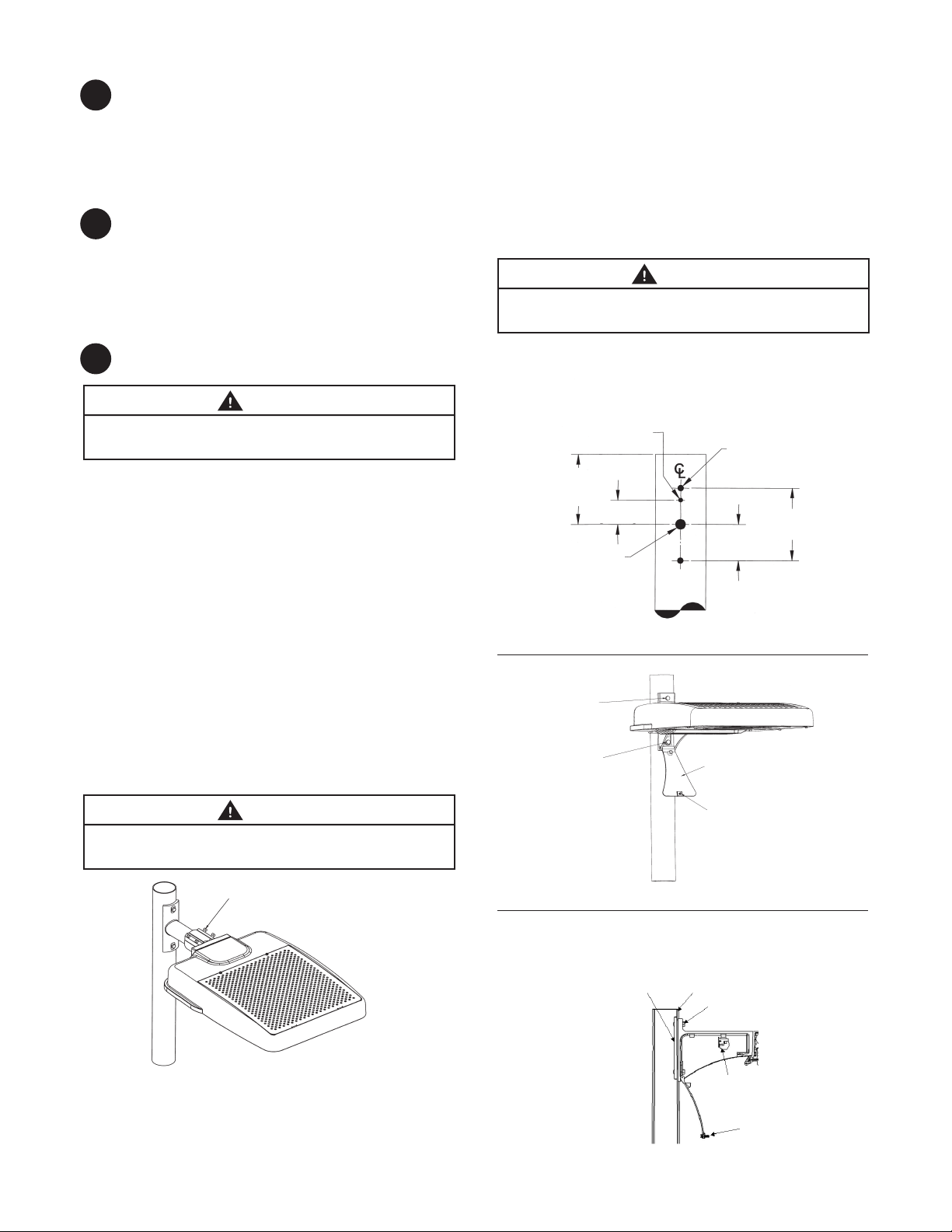

3a Sliptter Mounting

This luminaire has been congured specically to mount to a

2-inch pipe brackets (2-3/8” OD).

• Place xture against pole

• Install 3/8 bolt, lock washer and washer in top as

shown and tighten into nut plate

• Open arm door and install 3/8 bolt, lock washer and

washer inside arm as shown and tighten into nut

plate. (See Figure 3 and 4)

• Torque top and bottom bolts to 25 - 32 ft-lbs (34-43 N-m).

• Inspect installation to ensure xture is secure.

WARNING

Under no conditions should architectural arm mounting bolts

be torqued to greater than 32 ft-lbs.

DRILLING TEMPLATE

ROUND POLE MOUNTING

3.5 to 4.5 inch (89 to 114mm) OD

round pole mounting arm.

.312 in. DIA.

(8 mm DIA.)

5.250 in.

(133 mm)

(MIN.)

1.812 in.

(46 mm)

.750 in. DIA.

(19 mm DIA.)

(HOLE)

FIGURE 2

(43 N-m)

.438 in. DIA.

(11 mm DIA.)

(2 PLACES)

2.719 in.

(69 mm)

5.438 in.

(138 mm)

• Hold luminaire approximately level with pipe. Pull

wires through arm and place slip tter over 2-inch

(51mm) pipe (2 3/8-inch (60mm) OD).

• Tighten the (4) sliptter 3/8 bolts to 10-14 ft-lbs

(14-19 N-m). Tighten jam nuts after bolts have been

tightened. (See Figure 1)

• Inspect installation to ensure xture is secure.

WARNING

Under no conditions should sliptter bolts be torqued to a

level greater than 14 foot pounds (19 N-m).

Sliptter 3/8 Bolts and Jam Nuts

FIGURE 1

3b Round Pole Architectural Arm Mounting

This luminaire has been congured specically to mount

to round pole 3.5-4.5 inches (89-114mm) in diameter. Hole

pattern on round pole shall be in accordance with Figure 2.

Torque Top Bolt

to 25-32 ft-lbs.

(34-43N-m)

Torque Bottom Bolt

to 25-32 ft-lbs.

(34-43N-m)

FIGURE 3

FIGURE 4

Door

Arm Door Screw

Section view: Round Pole Mounting

Architectural Arm with Door

Nut Plate

Pole

Bolt, Lock Washer,

Flat Washer

Terminal Board

Arm Door Screw

Page 3

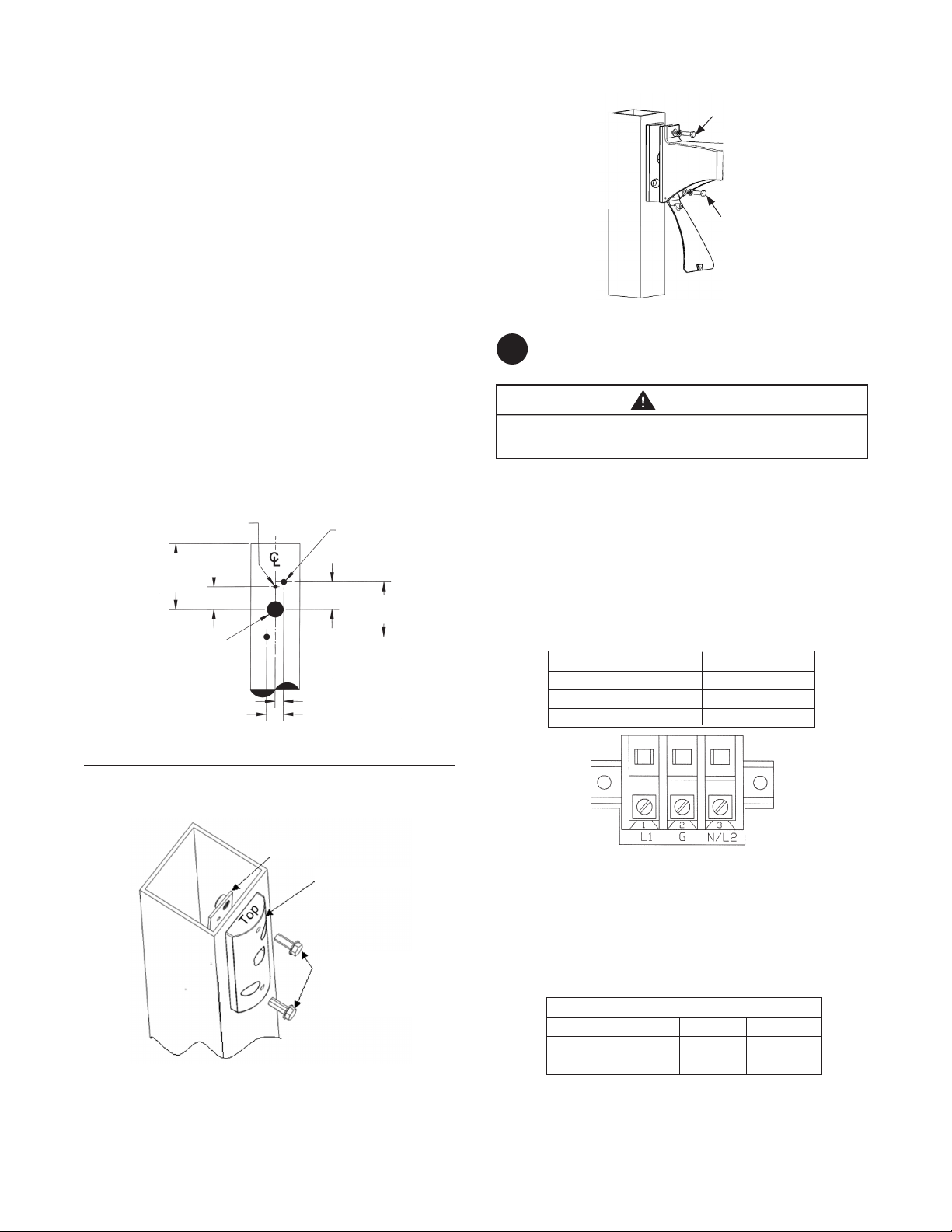

3c Square Pole Architectural Arm Mounting

This luminaire has been congured the same as 3b

and an adapter plate has been included to mount to

a square pole. Hole pattern on square pole shall be in

accordance with Figure 5.

• Orient adapter block so that the end marked top is in

the up position.

• With adapter block end oriented properly, mount

adapter block to pole with the nut plate and 3/8-16

bolts and washer supplied as shown. Torque 3/8-16

bolts to 25 - 32ft-lbs (34-43 N-m). (See Figure 6)

• Place xture against adapter block.

• In top location install 3/8-16 bolt through lock

washer, washer and mounting arm as shown.

(See Figure 7)

• Open arm door and Install 3/8 bolt into tapped hole

of adapter block. (See Figure 7)

• Torque top and bottom bolts to 25 - 32 ft-lbs (34-43 N-m).

• Inspect installation to ensure xture is secure.

FIXTURE ARM TO ARM ADAPTER

Torque Top Bolt

to 25 - 32 ft-lbs.

(34-43 N-m)

Torque Bottom Bolt

to 25 - 32 ft-lbs.

(34-43 N-m)

FIGURE 7

WIRING

4

CAUTION

Risk of Damage or Injury: Door should be closed with

screw until xture in nal location.

FIGURE 5

SQUARE POLE MOUNTING

.312 in. DIA.

(8 mm DIA.)

5.250 in.

(133 mm)

(MIN.)

1.812 in.

(46 mm)

1.250 in. DIA.

(32 mm DIA.)

(HOLE)

ADAPTER PLATE FOR

DRILLING TEMPLATE

2.196 in.

(56 mm)

.656 in. (17 mm)

1.312 in. (33 mm)

SQUARE POLE

Nut Plate

Adapter Block

.438 in. DIA.

(11 mm DIA.)

(2 PLACES)

4.392 in.

(112 mm)

• NOTE: Make all electrical connections in accordance

with the National Electrical Code and any applicable

local code requirements.

• Strain relief for incoming power must be provided in

the pole top by the customer.

• Supply Wire Type and Size, for Customer Connection

to Terminal Board: 16 AWG (1.5mm2) to 6 AWG

(10mm2) Solid or Stranded.

Terminal Board Connections:

Terminal Board Position Supply Type

L1 High Line

G Ground

N/L2 Low Line/Neutral

• NOTE: Verify that supply voltage is correct by

comparing it to nameplate inside door or on carton.

FIGURE 6

3/8-16 Washer and Bolts

Torque Bolts to 25 - 32ft-lbs.

(34-43 N-m)

External Dimming Control (If Applicable):

• Gray Lead = 0VDC (-)

• Violet Lead = Up To 10VDC (+)

Dimming Input/Output

Control Voltage1 Low (0V) High(7.5-10V)

Nominal Input Wattage2

Nominal Lumen Output

• 1 Linear Transition between Low and High

• 2 Component and system tolerance may aect the

end point levels and linearity of transition

20% of Max 100%

2

Page 4

PE

Dimming Control (If Applicable):

• No external connections for Dimming are required

when the GE Dimming PE Control and GE Dimming PE

Receptacle is used.

• All dimming control connections will be made

between the Dimming PE and Luminaire through the

included PE Receptacle.

• Refer to instructions included with GE Dimming PE

Control regarding appropriate settings for dimming

control.

PHOTOELECTRIC CONTROL:

• (If option present)—Photoelectric control receptacle

should be oriented before control is installed.

• Loosen the two holding screws and rotate receptacle

until “North” is directed as near as possible to true

North.

• Tighten holding screws and install control.

CAUTION

Ensure the PE socket base gasket is properly seated in the

die casting hole before tightening the holding screws.

SLIPFITTER MOUNTING:

• Connect Luminaire wire leads to supply wire.

• Connections are to be made in interior of pole.

• Replace pole cap. A wiring diagram is provided on a

label inside luminaire for reference.

• For sliptter units without leads, connections may be

made to terminal board inside xture.

• Note that care should be exercised not to pinch leads

between door and housing when closing the door.

MAINTENANCE / CLEANING

5

WARNING

Risk of electric shock. Make certain power is o before

attempting any maintenance.

• To maintain high optical eciency, occasional

cleaning of the outer lens surface may be needed,

with frequency dependent on local conditions.

• Use a mild soap or detergent, which is essentially

neutral pH (pH approximately 6 to 8), nonabrasive,

and which contains no chlorinated or aromatic

hydrocarbons.

• Wash thoroughly, using a soft cloth.

• Rinse with clean, cold water and wipe dry.

STORAGE

6

• Prior to installation, units should NOT be stored

outside in corrugated boxes (cardboard boxes) alone.

• Until installation, all units should be placed in a

covered dry storage area. The storage area should

not exceed -40°C (-40°F) to 50°C (122°F).

- This can be preferably in a roofed area or with a

tarp that is secured in such a way to keep water

o of the corrugated boxes (cardboard boxes).

ARM MOUNTINGS:

• Terminal Board is in the Architectural Mounting Arm.

• Open mounting arm door to gain access to terminal

board.

• Wire supply leads to terminal board in accordance

with labeling.

• Close door when wiring is complete.

These instructions do not purport to cover all details or variations in equipment nor to provide for every possible contingency to be met in

connection with installation, operation or maintenance. Should further information be desired or should particular problems arise which are not

covered suciently for the purchaser’s purposes, the matter should be referred to GE Lighting.

GE Lighting • 1-888-MY-GE-LED (1 - 888 - 69 - 43 - 533) • www.gelighting.com

GE Lighting is a subsidiary of the General Electric Company. Evolve and the GE brand and logo are trademarks of the General Electric Company.

© 2013 GE Lighting. Information provided is subject to change without notice. All values are design or typical values when measured under laboratory conditions.

g

35-201578-198 (Rev 09/17/13)

English

Page 5

GE

Lighting

Lampadaire à DEL Evolve

Systèmes d’installation Modulaires – Petit et Moyen

(EASM & EAMM)

Guide d’Installation

GEH-6006A

™

ARRÊT

AVANT DE COMMENCER

Lisez attentivement toutes ces instructions.

Conservez ces instructions pour référence future.

AVERTISSEMENT

Risque de choc électrique. Déconnectez l’alimentation

électrique avant d’installer ou réparer ce produit.

AVERTISSEMENT

Danger de blessure et de dommage matériel. L’appareil

tombera au sol s’il est mal installé. Suivez les instructions

d’installation.

ATTENTION

Danger de blessure. Lors de l’installation et de la réparation

de cet appareil, porter des lunettes et des gants de sécurité.

Cet appareil est conforme aux exigences de la partie 15 des règles

de la FCC. Son utilisation est sujette aux conditions suivantes : (1) cet

appareil ne doit pas causer d’interférences nuisibles; (2) cet appareil

doit accepter toutes les interférences reçues, y compris celles pouvant

causer un fonctionnement indésirable. Ce DEFR de la classe [ A ] est

conforme à la NMB-003 du Canada.

Remarque : Cet appareil a été testé et reconnu conforme aux

limites établies pour les appareils numériques de classe A, selon

la partie 15 des règles de la FCC. Ces limites sont conçues pour

assurer une protection raisonnable contre les interférences nuisibles

dans un environnement commercial. Cet appareil génère, utilise

et émet de l’énergie sous forme de radiofréquences, de sorte que

si son installation et son utilisation ne sont pas conformes à la

notice d’utilisation, il peut être la cause de parasites nuisibles aux

communications radio. L’utilisation de cet équipement dans une zone

résidentielle risque fort de causer des interférences nuisibles, auquel

cas l’utilisateur devra corriger le problème à ses propres frais.

• Ce lampadaire est conçu pour l’éclairage extérieur et ne

doit pas être utilisé dans des lieux à faible ventilation ou à

températures ambiantes élevées.

•

Les meilleurs résultats seront obtenus si l’installation et

l’entretien sont conformes aux recommandations suivantes.

•

Le lampadaire est conçu pour fonctionner à des tempéra tures allant de -40°C à 50°C et doit être installé horizontale ment à un poteau vertical avec les LED orientées vers le bas,

comme indiqué sur l’illustration.

SPÉCIFICATIONS

• Poids: Maximum <50 lbs (22.68 kg)

• EPA: 1.35 sq ft max (0.13 sq M2) (Calculé en utilisant 1.30 Cd

X Surface Totale de 1.04 pi2)

• Classication IP: Optique 65, Enceinte Électrique Standard:

UL 1598 Classication pour emplacements mouillés

imagination at work

Page 6

DÉBALLAGE

1

• Ce lampadaire et été emballé pour qu’aucune pièce ne soit

endommagée lors du transport.

• Inspecter pour conrmer.

MANIPULATION

2

• Des dégâts peuvent se produire si le lampadaire est

incorrectement manipulé au dehors de l’emballage.

• Ne pas iniger de choc au lampadaire et ne pas superposer

les lampadaires après déballage.

• Placer le gabarit contre le poteau

• Installer la vis de 3/8, la rondelle anti-retour et la rondelle

supérieure comme indiqué et serrer contre la plaque de l’écrou.

• Ouvrir la trappe d’accès du support et installer la vis de 3/8,

la rondelle anti-retour et la rondelle à l’intérieur du support

comme indiqué et serrer la plaque de l’écrou. (Voir Figure 3 et 4)

• Serrer les vis supérieures et inférieures à 25 -32 ft-lbs

(34-43 N-m).

• Inspecter pour s’assurer que l’installation est sûre.

AVERTISSEMENT

Les vis du bras de support ne doivent en aucune circonstance

être serrées au-delà de 32 ft-lbs. (43 N-m)

MOUNTING

3

AVERTISSEMENT

Risque de blessure ou de dégât. L’unité risque de tomber

si l’installation n’est pas eectuée correctement. Suivre les

instructions d’installation.

Choisir les instructions adaptées à la méthode d’installation :

a. Installation par encastrement

b. Installation par support sur poteau à section circulaire

c. Installation par support sur poteau à section carrée.

3a Installation par encastrement

Ce lampadaire a été conguré spécialement pour être installé sur

des supports de conduits de 2 inch de diamètre (2-3/8” de diamètre

extérieur).

• Maintenir le lampadaire à niveau avec le conduit. Tirer les

ls au travers du bras et placer la bague d’encastrement sur

le conduit de 2-inch (51 mm) (2 3/8-inch (60 mm) diamètre

extérieur).

• Serrer les (4) vis de 3/8 en utilisant un couple de serrage de

10-14 ft-lbs (14-19 N-m). Serrer les contre-écrous après le

serrage des vis (voir Figure 1)

• Inspecter pour s’assurer que l’installation est sûre.

AVERTISSEMENT

Les vis du bras de support ne doivent en aucunes

circonstances être serrées au-delà de 14 ft-lbs. (19 N-m)

Bras de support pour poteau à section circulaire de

3,5 à 4,5 inch (89 à 114 mm) de diamètre extérieur

5.250 in.

(133 mm)

(MIN.)

.750 in. DIA.

(19 mm DIA.)

(PERÇAGE)

FIGURE 2

Serrer les vis du

haut à 25-32 ftlbs.

(34-43 N-m)

Serrer les vis du bas

à 25-32 ft-lbs. (34-43

N-m)

SCHÉMA DE PERÇAGE

INSTALLATION SUR POTEAU À

SECTION CIRCULAIRE

.312 in. DIA.

(8 mm DIA.)

1.812 in.

(46 mm)

.438 in. DIA.

(11 mm DIA.)

(2 PLACES)

2.719 in.

(69 mm)

Trappe

Vis de la trappe

5.438 in.

(138 mm)

Vis d’encastrement de 3/8 et contre-écrous

FIGURE 1

3b Installation par support sur poteau à section

circulaire

Ce lampadaire a été spécialement conguré pour être installé sur

un poteau à section circulaire de 3,5-4,5 inches (89-114 mm) de

diamètre. L’arrangement des trous de xation doit être conforme

à la Figure 2.

FIGURE 3

FIGURE 4

Section: Poteau à section circulaire

avec bras architectural et trappe

Plaque de serrage

des écrous

Poteau

Vis, rondelle anti-retour,

Rondelle plate

Borne Électrique

Vis de la trappe

Page 7

3c Installation par support sur poteau à section

carrée

Ce lampadaire a été conguré de la même manière que 3b

et une plaque intermédiaire a été incluse pour installation sur

poteau à section carrée. L’arrangement des trous de xation

sur poteau à section carrée doit être conforme à la Figure 5.

• Orienter le bloc intermédiaire tel que l’extrémité identiée par

l’inscription ‘haut’ est en position haute.

• Avec le bloc intermédiaire orienté de manière correcte,

installer le bloc intermédiaire sur le poteau à l’aide de la

plaque de serrage des écrous et les vis de 3/8-16 et la ron delle fournie comme indiqué. Serrer les vis de 3/8-16 à 25

- 32 ft-lbs (34-43 N-m). (Voir la Figure 6)

• Placer le gabarit contre le bloc intermédiaire.

• A l’emplacement supérieur, installer une vis 3/8-16 au travers

de la rondelle anti-retour, la rondelle et le bras de xation

comme indiqué (voir Figure 7)

• Ouvrir la trappe d’accès du support et installer une vis 3/8

dans le letage du bloc intermédiaire. (Voir Figure 7)

• Serrer les vis supérieures et inférieures à 25 -32 ft-lbs

(34-43 N-m).

• Inspecter pour s’assurer que le gabarit est bien installé.

GABARIT ET SUPPORT INTERMÉDIAIRE

Serrer la vis du haut à

25 - 32 ft-lbs. (34-43 N-m)

Serrer la vis du bas

à 25 - 32 ft-lbs. (3443 N-m)

FIGURE 7

CABLAGE

4

MISE EN GARDE

Risque de dégât ou de blessure : La trappe doit être

fermée à l’aide d’une vis tant que le gabarit n’est pas en

position dénitive.

FIGURE 5

FIGURE 6

SCHÉMA DE PERCAGE INSTALLATION

SUR POTEAU À SECTION CARRÉE

.312 in. DIA.

(8 mm DIA.)

5.250 in.

(133 mm)

(MIN.)

1.812 in.

(46 mm)

1.250 in. DIA.

(32 mm DIA.)

(PERÇAGE)

PLAQUE INTERMÉDIAIRE POUR

POTEAU À SECTION CARRÉE

Plaque de serrage des écrous

2.196 in.

(56 mm)

.656 in. (17 mm)

1.312 in. (33 mm)

Bloc intermédiaire

Rondelle et vis 3/8-16

Serrer les vis a 25-32ft-lbs.

(34-43 N-m)

.438 in. DIA.

(11 mm DIA.)

(2 PLACES)

4.392 in.

(112 mm)

• REMARQUE: Eectuer toutes les connections électriques

en accord avec le National Electrical Code et les exigences

locale applicables.

• Le client doit fournir le réducteur de tension pour

l’alimentation électrique, placé en haut du poteau.

• Fournir au client le type de câble et la taille pour connexion

à la borne électrique : de 16 AWG (1.5 mm2) à 6 AWG

(10mm2) Fil unique ou multiple.

Connexions de la borne électrique:

Position au bornier Câblage

L1 Secteur

G Terre

N/L2 Neutre

• REMARQUE: Vérier que la tension d’alimentation est

correcte en la comparant à la plaque signalétique placée à

l’intérieur de la trappe ou sur le carton.

GRADATEUR EXTERNE (SI APPLICABLE) :

• Fil gris = 0 V c.c. (-)

• Fil violet = Jusqu’à 10 V c.c. (+)

Gradation, entrée/sortie

Tension de commande1 Basse (0 V) Élevée (7,5-10 V)

Puissance nominale d’entrée

Sortie nominale en lumens

2

20% of Max 100%

2

• 1 Transition linéaire entre basse et élevée

• 2 La tolérance des composants et du système peuvent

aecter les niveaux de point nal et la linéarité de

la transition

Page 8

GRADATEUR PHOTOÉLECTRIQUE (SI APPLICABLE) :

• Aucune connexion externe de gradation n’est

nécessaire lorsque la commande de gradateur PE

et le réceptacle de gradateur PE de GE sont utilisés.

• Toutes les connexions de commande de gradation

seront réalisées entre le gradateur PE et le luminaire

via le réceptacle PE inclus.

• Lire les instructions incluses avec la commande de

gradateur PE de GE concernant les réglages

appropriés de la commande de gradateur.

COMMANDE PHOTOÉLECTRIQUE :

• (Si l’option est choisie) Le réceptacle de la commande

peut être orienté avant d’installer la commande.

• Desserrez les deux vis de retenue et faites tourner

le réceptacle jusqu’à ce que l’inscription « North »

soit orientée le plus près possible du nord véritable.

• Serrez les vis de retenue et installez la commande.

ATTENTION

Assurez-vous que le joint de la base de douille est

correctement enfoncé dans le trou du réceptacle moulé

avant de serrer les vis de retenue.

MONTAGE SUR JOINT COULISSANT :

• Connectez les ls conducteurs du luminaire au câble

d’alimentation.

• Les connexions doivent être faites à l’intérieur du

poteau.

• Réinstallez le capuchon du poteau. Un schéma de

câblage gure sur une étiquette à l’intérieur du

luminaire pour référence.

• Si vous utilisez un joint coulissant sans ls

conducteurs, les connexions peuvent être faites sur la

plaque de connexions à l’intérieur du luminaire.

• Faites attention de ne pas pincer les ls entre le volet

et le boîtier lorsque vous fermez le volet.

ENTRETIEN / NETTOYAGE

5

AVERTISSEMENT

Risque de choc électrique. Avant de commencer toute

opération d’entretien, assurez-vous que l’alimentation électrique est coupée.

• Pour conserver l’ecacité du module optique,

nettoyez périodiquement la surface extérieure de la

lentille (la fréquence des nettoyages dépendra des

conditions locales).

• Utilisez un savon doux ou un détergent essentielle

ment neutre (ayant un pH d’environ 6 à 8), sans

abrasif et sans hydrocarbure chloré ou aromatique.

• Lavez à fond avec la solution de nettoyage en

utilisant un chion doux.

• Rincez avec de l’eau froide et propre, puis essuyez.

STOCKAGE

6

• Avant l’installation, les unités ne doivent PAS être stockées à

l’extérieur dans des emballages de carton.

• Jusqu’à l’installation, toutes les unités doivent être placées

dans un local couvert et sec. L’espace de stockage ne doit

pas excéder -40 °C (-40 °F) à 50 °C (122 °F).

– Ceci peut être dans un local couvert ou sous une bâche

attachée de manière à protéger les emballages de la

pluie/l’eau.

MONTAGE SUR BRAS :

• La plaque de connexions est située dans le bras

architectural.

• Ouvrez le volet du bras de montage an de pouvoir

accéder à la plaque de connexions.

• Faites passer les ls conducteurs sur la plaque de

connexions, conformément à l’étiquette.

• Lorsque le câblage est terminé, fermez le volet.

Ces instructions n’ont pas pour but de couvrir tous les détails et toutes les variantes de l’équipement, ni de répondre à tous les impondérables

possibles en relation avec l’installation, le fonctionnement et l’entretien. Si vous désirez plus d’informations ou si des problèmes particuliers

surviennent qui ne sont pas couverts susamment pour les besoins de l’acheteur, le sujet doit être soumis à GE Lighting.

GE Lighting • 1-888-MY-GE-LED (1 - 888 - 69 - 43 - 533) • www.gelighting.com

GE Lighting est une liale de la General Electric Company. Evolve ainsi que la marque et le logo GE sont des marques commerciales déposées de la General Electric Company.

© 2013 GE Lighting. Les informations fournies ici sont susceptibles de changer sans préavis. Toutes les données sont des valeurs de conception ou caractéristiques lors de leur

g

mesure en conditions de laboratoire.

35-201578-198 (Rev 09/17/13)

French

Page 9

GE

Guía de instalación

GEH-6006A

Lighting

Lámpara de LEDs para áreas Evolve

Lámparas modulares - pequeñas y medianas (EASM y EAMM)

ANTES DE COMENZAR

Lea estas instrucciones completamente y cuidadosamente.

Guarde estas instrucciones para uso futuro.

ADVERTENCIA

™

Riesgo de descarga eléctrica. Desconecte la energía antes de

suministrar servicio de mantenimiento o instalar el producto.

ADVERTENCIA

Riesgo de lesiones o daño. La unidad fallará si no se instala apro-

piadamente. Siga las instrucciones de instalación.

PRECAUCIÓN

Riesgo de lesiones. Utilice gafas de seguridad y guantes durante la

instalación y mantenimiento.

Este dispositivo cumple con la Parte 15 de las Reglas de la FCC.

La operación está sujeta a las dos condiciones siguientes: (1) este

dispositivo no puede causar interferencia perjudicial, y (2) este

dispositivo debe aceptar cualquier interferencia recibida, incluida

la interferencia que pueda causar una operación no deseada. Este

Dispositivo de iluminación de radiofrecuencia (RFLD) de Clase [A]

cumple con la norma canadiense ICES-003.

Nota: este equipo ha sido probado y se ha determinado que cumple

con los límites de un dispositivo digital Clase A, de conformidad con

la Parte 15 de las Reglas de la FCC. Estos límites están diseñados

para proporcionar una protección razonable contra la interferencia

perjudicial cuando el equipo se opera en un entorno comercial. Este

equipo genera, usa y puede irradiar energía de radiofrecuencia y, si

no se instala y usa de acuerdo con el manual de instrucciones, puede

causar interferencia perjudicial a las radiocomunicaciones.

La operación de este equipo en un área residencial puede causar

interferencia perjudicial, en cuyo caso el usuario deberá corregir la

interferencia a su propia costa.

• Esta lámpara está diseñada para servicio de iluminación

en exteriores, y no debe utilizarse en áreas con ventilación

limitada, o en temperaturas ambiente altas.

• Se obtendrán los mejores resultados si se instala y recibe

mantenimiento según las siguientes recomendaciones.

• La lámpara está diseñada para funcionar a temperaturas

ambiente que varían desde -40°C a 50°C y para montarse

horizontalmente en un poste vertical con las bombillas LEDs

dirigidas hacia abajo, según se muestra.

ESPECIFICACIONES

• Peso: Peso máximo <50 lbs (22.68 kg)

• Área Proyectada Efectiva: 1.35 pie2 máx (0.13 m2) (calculada

utilizando 1.30 Bujías X área total de 1.04 pie2)

• Clasicación IP (Ingress Protected): Óptico 65, Carcasa están-

dar para componentes eléctricos:

• Clasicada para lugares mojados según UL 1598

imagination at work

Page 10

DESEMPAQUE

1

• Esta lámpara ha sido empacada apropiadamente de modo

que las piezas no deberían sufrir daño durante el transporte.

• Inspeccione para conrmar.

MANIPULACIÓN

2

• Podría ocurrir daño si la lámpara se manipula inapropiadamente fuera del paquete.

• No golpee ni apile la lámpara después de sacarla del embalaje/paquete.

MONTAJE

3

ADVERTENCIA

Riesgo de lesiones o daño. La unidad fallará si no se instala apro-

piadamente. Siga las instrucciones de instalación.

Siga las instrucciones de instalación apropiadas según su método de

montaje seleccionado:

a. Montaje con ajustador deslizante

b. Montaje con brazo arquitectónico en poste redondo

c. Montaje con brazo arquitectónico en poste cuadrado

3a Montaje con ajustador deslizante

Esta lámpara ha sido congurada especícamente para montaje en

abrazaderas para tubo de 2 pulgadas (2-3/8” de Diámetro Exterior).

• Coloque la lámpara contra el poste

• Instale el perno de 3/8, la arandela de seguridad y la arandela

encima según se muestra, y apriete en la tuerca tipo placa

• Abra la puerta del brazo e instale el perno de 3/8, la arandela

de seguridad y la arandela en el interior del brazo según se

muestra, y apriete en la tuerca tipo placa (Vea la Figura 3 y 4).

• Apriete los pernos superior e inferior hasta 25 a 32 lbs-pie

(34 a 43 N-m)

• Inspeccione la instalación para garantizar que la lámpara

está segura.

ADVERTENCIA

Bajo ninguna circunstancia, los pernos de montaje del brazo

arquitectónico deben apretarse hasta un valor superior a 32

libras-pie. (43 N-m)

PLANTILLA DE TALADRADO

MONTAJE EN POSTE REDONDO

Brazo de montaje en poste redondo de 3,5 a

4,5 pulgadas (89 a 114mm) de Diámetro Exterior.

FIGURA 2

0,312 pulg. DIÁM.

(8 mm DIÁM.)

5,250 pulg.

(133 mm)

(MÍN)

1,812 pulg.

(46 mm)

0,750 pulg. DIÁM.

(19 mm DIÁM.)

(ORIFICIO)

0,438 pulg. DIÁM.

(11 mm DIÁM.)

(2 LUGARES)

2,719 pulg.

(69 mm)

5,438 pulg.

(138 mm)

• Sostenga la lámpara aproximadamente a nivel con el tubo.

Hale los alambres a través del brazo y coloque el ajustador

deslizante sobre el tubo de 2 pulgadas (51mm) [2-3/8 pulgadas (60mm) de Diámetro Exterior].

• Apriete los (4) pernos de 3/8 del ajustador deslizante hasta 10

a 14 lbs-pie (14 a 19 N-m). Apriete las contratuercas después

de haber apretado los pernos. (Vea la Figura 1)

• Inspeccione la instalación para garantizar que la lámpara

está segura.

ADVERTENCIA

Bajo ninguna circunstancia, los pernos del ajustador deslizante

deben apretarse hasta un valor superior a 14 libras-pie (19 N-m)

Pernos de 3/8 del ajustador deslizante

y contratuercas

FIGURA 1

3b Montaje con brazo arquitectónico en poste

redondo

Esta lámpara ha sido congurada especícamente para montarse

en poste redondo de 3.5 a 4.5 pulgadas (89 a 114mm) de diámetro.

El patrón de oricios en el poste redondo deberá estar de acuerdo

con la Figura 2.

Apriete el perno

superior hasta 25

a 32 lbs-pie.

(34 a 43N-m)

Apriete el perno

inferior hasta 25 a 32

FIGURA 3

FIGURA 4

lbs-pie.

(34 a 43N-m)

Tuerca tipo placa

Puerta

Tornillo de la

puerta del brazo

Vista en sección: Brazo arquitectónico (con

puerta) de montaje en poste redondo

Poste

Perno, arandela de seguridad,

arandela plana

Placa de terminales

Tornillo de la puerta

del brazo

Page 11

3c Montaje con brazo arquitectónico en poste

cuadrado

Esta lámpara tiene la misma conguración del montaje 3b y se

incluye una placa adaptadora para montaje en poste cuadrado.

El patrón de oricios en el poste cuadrado deberá estar de acuerdo con la Figura 5.

• Oriente la placa adaptadora de modo que la parte superior

marcada como extremo (“end”) esté en la posición arriba.

• Con el extremo de la placa adaptadora orientada apropia-

damente, monte la placa adaptadora al poste con la tuerca

tipo placa y los pernos de 3/8-16 y la arandela suministrados,

según se muestra. Apriete los pernos de 3/8-16 hasta 25 a

32 lbs-pie (34 a 43 N-m) (Vea la Figura 6)

• Coloque la lámpara contra la placa adaptadora.

• En la ubicación superior, instale el perno de 3/8-16 a través de

la arandela de seguridad, la arandela y el brazo de montaje,

según se muestra. (Vea la Figura 7)

• Abra la puerta del brazo e instale el perno de 3/8 dentro del

roscado de la placa adaptada. (Vea la Figura 7)

• Apriete los pernos superior e inferior hasta 25 a 32 lbs-pie

(34 a 43 N-m)

• Inspeccione la instalación para garantizar que la lámpara está

segura.

PLANTILLA DE TALADRADO

MONTAJE EN POSTE CUADRADO

FIGURA 5

0,312 pulg. DIÁM.

(8 mm DIÁM.)

5,250 pulg.

(133 mm)

(MÍN)

1,812 pulg.

(46 mm)

1,250 pulg. DIÁM.

(32 mm DIÁM.)

(ORIFICIO)

0,438 pulg. DIÁM.

(11 mm DIÁM.)

(2 LUGARES)

2,196 pulg.

(56 mm)

0,656 pulg. (17 mm)

1,312 pulg. (33 mm)

4,392 pulg.

(112 mm)

BRAZO DE LÁMPARA A PLACA ADAPTADORA

Apriete el perno superior

hasta 25 a 32 lbs-pie.

(34 a 43 N-m)

Apriete el perno inferior

hasta 25 a 32 lbs-pie.

(34 a 43 N-m)

FIGURA 7

CABLEADO

4

PRECAUCIÓN

Riesgo de daño o lesiones: La puerta debe estar cerrada con el

tornillo hasta que la lámpara esté en la ubicación nal.

• NOTA: Realice todas las conexiones eléctricas de acuerdo con

el Código Eléctrico Nacional y cualquier requisito aplicable del

código local.

• Debe suministrarse un elemento de alivio de esfuerzo

mecánico para el cable de energía entrante en la parte superior del poste por parte del cliente.

• Suministre el tipo y tamaño de cable, para la Conexión del

Cliente con la placa de terminales: 16 AWG (1.5mm2) a 6 AWG

(10mm2) macizo o trenzado.

Conexiones de la placa de terminales:

Posición en la placa de terminales Tipo de suministro

L1 Línea de alta

G Conexión a tierra

N/L2 Línea de baja/Neutra

FIGURA 6

PLACA ADAPTADORA PARA

POSTE CUADRADO

Tuerca tipo placa

Placa adaptadora

Arandela y pernos de 3/8-16

Apriete los pernos hasta 25 a

32 lbs-pie.

(34 a 43 N-m)

• NOTA: Verique que el voltaje de suministro es correcto

comparándolo con el voltaje mostrado en la placa de datos

ubicada en el lado interior de la puerta o en la caja de cartón.

Control externo de atenuación (si es aplicable):

• Cable de conexión gris = 0 V CC (-)

• Cable de conexión violeta = hasta 10 V CC (+)

Entrada/salida de atenuación

Tensión de control1 Baja (0 V) Alta(7.5-10 V)

Potencia de entrada nominal (watts)

Potencia luminosa nominal (lumens)

• 1 Transición lineal entre Alta y Baja

• 2 Las tolerancias de los componentes y del sistema

pueden afectar los niveles extremos y la linealidad

de la transición

2

20% de la máx 100%

2

Page 12

Control fotoeléctrico (PE) de atenuación

(si es aplicable):

• Cuando se utiliza el Control de atenuación PE de GE y el

Receptáculo de atenuación PE de GE, no se necesitan

conexiones externas para atenuación.

• Todas las conexiones de control de atenuación se harán

entre el Control PE de atenuación y la luminaria, a través del

Receptáculo de atenuación PE incluido.

• Para ver los ajustes apropiados del control de atenuación,

consulte las instrucciones incluidas con el Control de atenu

ación PE de GE.

CONTROL FOTOELÉCTRICO:

• (Si la opción está presente): el receptáculo de control

fotoeléctrico debe orientarse antes de instalar el control.

• Aoje los dos tornillos de jación y gire el receptáculo hasta

dirigir ‘Norte’ hacia el norte verdadero con la mayor

aproximación posible.

• Apriete los tornillos de jación e instale el control.

PRECAUCIÓN

Asegúrese de que la junta de la base del zócalo PE esté correctamente asentada en el agujero de la pieza fundida antes de

apretar los tornillos de jación.

MONTAJE CON POSICIONADOR DESLIZANTE:

• Conecte los cables de conexión de la luminaria al cable de

alimentación.

• Las conexiones deben hacerse en el interior del poste.

• Vuelva a colocar la tapa del poste. En la etiqueta que está

dentro de la luminaria se proporciona un diagrama de

conexionado como referencia.

• Para unidades con posicionador deslizante sin cables de

conexión, las conexiones pueden hacerse a la tira de

terminales que está dentro del artefacto.

• Tenga cuidado para no pinzar cables de conexión entre la

puerta y el alojamiento cuando cierre la puerta.

MANTENIMIENTO / LIMPIEZA

5

ADVERTENCIA

Riesgo de choque eléctrico. Asegúrese de que la alimentación

eléctrica esté desconectada antes de realizar cualquier tarea de

mantenimiento.

• Para mantener una alta eciencia óptica puede ser

necesaria una limpieza ocasional de la supercie del lente

externo, con una frecuencia que depende de las

condiciones locales.

• Utilice un jabón o detergente suave, con pH esencialmente

neutro (pH comprendido entre 6 y 8 aprox.), no abrasivo, y

que no contenga hidrocarburos clorados ni aromáticos.

• Lave bien a fondo con un paño suave.

• Enjuague con agua fría limpia y seque.

ALMACENAMIENTO

6

• Antes de la instalación, las unidades NO se deben

almacenar en exteriores en cajas de cartón corrugado

únicamente.

• Hasta el momento de la instalación, todas las unidades

deben colocarse en un área de almacenamiento seca y

cubierta. El área de almacenamiento debe tener una

temperatura comprendida entre -40 °C (-40 °F) y

50 °C (122 °F).

- Esto debe tener lugar preferiblemente en un área

techada o con un toldo sujeto de forma tal que evite la

llegada de agua a las cajas de cartón corrugado.

MONTAJES DE BRAZOS:

• La tira de terminales está en el brazo de montaje

arquitectónico.

• Abra la puerta del brazo de montaje para tener acceso

a la tira de terminales.

• Conecte los cables de alimentación eléctrica a la tira

de terminales de acuerdo con la etiqueta.

• Una vez nalizado el cableado, cierre la puerta.

Estas instrucciones no pretenden cubrir todos los detalles o variaciones en los equipos, ni contemplar toda posible contingencia a encontrar en

relación con la instalación, operación o mantenimiento. Si se deseara información adicional o surgiera algún problema especíco que no esté

sucientemente tratado aquí para los propósitos del comprador, debe consultarse a GE Lighting.

GE Lighting • 1-888-MY-GE-LED (1 - 888 - 69 - 43 - 533) • www.gelighting.com

GE Lighting es una lial de General Electric Company. Evolve y la marca y logo GE son marcas registradas de General Electric Company.

© 2013 GE Lighting. La información suministrada está sujeta a cambios sin aviso previo. Todos los valores son valores típicos o de diseño,

g

medidos en condiciones de laboratorio.

35-201578-198 (Rev 09/17/13)

Spanish

Loading...

Loading...