Page 1

Eagle 1000 Patient Monitor

Servicing Instructions

227 468 01 SA(e) Revision G

Page 2

Caution:

During repairs/service interventions, observe the protective measures against damage due

to ESD.

· GE Medical Systems Information Technologies (GEMS IT) considers itself

responsible for the effects on safety, reliability, and performance of the equipment, only

if:

- assembly operations, extensions, readjustments, modifications, or

repairs are carried out by

GE Medical Systems Information Technologies (GEMS IT) or by persons

authorized by GE Medical Systems Information Technologies,

- the electrical installation of the relevant room complies with the applicable

national and local requirements, and

- the instrument is used in accordance with the instructions for use.

• This manual contains service information; operating instructions are provided in the

operators manual of the instrument.

• This manual is in conformity with the instrument at printing date.

• All rights are reserved for instruments, circuits, techniques, and names appearing in the

manual.

© Copyright 1997 - 2003, GE Medical Systems Information Technologies GmbH.

All rights reserved.

Printed in Germany

Page 3

GE Medical Systems EAGLE 1000 Page 3

Information Technologies Servicing Instructions 227 468 01 Rev. G

Contents

1. General overview of EAGLE 1000 ........................................................................................................ 7

1.1 Documentation and nomenclature of Marquette Hellige instrument part numbers .......................... 7

1.1.1 Configuration of instrument part number ............................................................................... 7

1.1.2 Configuration of the PCB par numbers .................................................................................. 7

1.2 Eagle 2000 system overview ............................................................................................................ 9

1.3 System overview............................................................................................................................. 10

1.3.1 Hooking up EAGLE 1000 monitors to PC Central Station SynOpsis 1000 ......................... 10

1.3.2 Patient data transfer from EAGLE 1000 via HELAN to SMU using QuickLink .................... 12

1.3.2.1 Introduction .......................................................................................................... 12

1.3.2.2 Data transfer between Eagle and Gateway ........................................................ 13

1.3.2.3 Connection to the LAN ........................................................................................ 13

1.3.2.4 EAGLE 1000 - QuickLink - HELAN - Examples of the link to networks .............. 15

1.3.2.4.1 Functional structure overview .......................................................... 15

1.3.2.4.2 Main components for the installation of QuickLink: .......................... 15

1.3.2.4.3 EAGLE 1000 - QuickLink ................................................................. 16

1.3.2.4.4 Network link - HELAN Concentrator ................................................ 17

1.3.2.4.5 Network link - HELAN Twisted Pair.................................................. 18

2. System overview .................................................................................................................................. 19

2.1 Technical specifications .................................................................................................................. 19

2.1.1 System interfaces ................................................................................................................ 19

2.1.2 Display ................................................................................................................................. 19

2.1.3 Monitor functions ................................................................................................................. 19

2.1.4 Power supply ....................................................................................................................... 20

2.1.5 Operation and storage ......................................................................................................... 21

2.1.6 ECG and heart rate ............................................................................................................. 21

2.1.7 Oxygen saturation Sp02 ...................................................................................................... 23

2.1.8 Non-invasive blood pressure ............................................................................................... 24

2.1.9 Invasive blood pressure ....................................................................................................... 25

2.1.10 Temperature......................................................................................................................... 27

2.1.11 Trend.................................................................................................................................... 28

2.2 Functional description of PCBs and subassemblies ...................................................................... 28

2.2.1 Eagle 1000 configuration and functional groups ................................................................. 28

2.2.2 PCB ECG Monitor................................................................................................................ 29

2.2.3 System power supply .......................................................................................................... 30

2.2.4 Floating system power supply and signal flow .................................................................... 31

2.2.5 Signal exchange with the processor.................................................................................... 31

2.2.6 Display ................................................................................................................................. 32

2.2.7 Block diagrams .................................................................................................................... 33

2.2.7.1 Functional groups ................................................................................................ 33

2.2.7.2 Floating system supply and signal flow ............................................................... 34

2.2.7.3 System power supply .......................................................................................... 35

2.2.7.4 PROCESSOR block diagram .............................................................................. 36

2.2.7.5 DISPLAY block diagram ...................................................................................... 37

2.2.8 ECG signal preprocessing ...................................................................................................38

2.2.8.1 Functional descriptiony ........................................................................................ 38

2.2.8.2 ECG/Pace Preprocessing ................................................................................... 40

2.2.9 PCB MP 204 Oximeter 930 117 26 ...................................................................................... 41

2.2.9.1 Function ............................................................................................................... 41

2.2.9.2 Figure of pcb MP204 Oximeter ........................................................................... 41

2.2.9.3 Pin assignment .................................................................................................... 42

2.2.10 Non-invasive blood pressure module .................................................................................. 43

2.2.10.1 Function ............................................................................................................... 43

2.2.10.2 Figure of PCB NBP Module NB11: 930 117 15 ................................................... 44

2.2.10.3 Figure of PCB NBP 2000 Module 930 117 93 or 388 032 60 ............................. 45

2.2.10.4 Pin assignment .................................................................................................... 46

2.2.11 PCB Press-Temp 388 031 75/PCB Temp 388 032 04......................................................... 47

Page 4

GE Medical Systems EAGLE 1000 Page 4

Information Technologies Servicing Instructions 227 468 01 Rev.G

2.2.11.1 PRESS module .................................................................................................... 47

2.2.11.2 Temp module ....................................................................................................... 48

2.2.11.3 Internal interfaces ................................................................................................ 49

2.2.11.4 Interfaces to peripherals ...................................................................................... 50

2.2.11.5 TEMPERATURE BLOCK DIAGRAM ................................................................... 51

2.2.11.6 PRESS BLOCK DIAGRAM ................................................................................. 52

2.2.12 Recorder 50 Part No. 218 111 12 ........................................................................................ 53

2.2.12.1 Function ............................................................................................................... 53

2.2.12.2 Recorder block diagram ...................................................................................... 54

2.2.12.3 Internal interfaces ................................................................................................ 55

2.2.12.4 Interfaces to peripherals ...................................................................................... 56

2.2.13 PCB Power Supply 930 117 41 ........................................................................................... 57

2.2.13.1 Function and pin assignment .............................................................................. 57

2.2.13.2 Figure of PCB Power Supply 930 117 41 ............................................................ 58

2.2.14 Membrane keypad ............................................................................................................... 59

2.2.14.1 Pin assignment ........................................................................................................................ 59

2.2.14.2 Membrane keypad 390 001 30 and 390 001 64, circuit diagram ........................ 60

2.3 Pin configuration of panel connectors ............................................................................................ 61

2.3.1 Socket ECG 303 444 28 ......................................................................................................61

2.3.2 Socket SpO2 303 444 29.....................................................................................................62

2.3.3 Socket PRESS 303 444 30 ................................................................................................. 63

2.3.4 Socket Temperature (TEMP) 303 444 31 ............................................................................ 64

2.3.5 Socket on the rear panel of the Eagle 1000 ........................................................................ 65

2.3.6 2-Port Press Adapter 220 102 01 ........................................................................................ 66

2.4 Complete circuit diagram and mechanical diagrams ...................................................................... 67

2.4.1 Systems without a recorder 101 123 .. ................................................................................ 67

2.4.2 Systems with a recorder 101 124 .. ..................................................................................... 67

2.4.3 Complete wiring circuit (S-Plan) .................................................... Please refer to the appendix

2.5 Master Record Index (MRI) ................................................................... Please refer to the appendix

3. Maintenance and technical inspection .............................................................................................. 69

3.1 Visual check .................................................................................................................................... 69

3.2 Checkout Procedures ..................................................................................................................... 70

3.2.1 Recommended testing/calibration equipment and accessories: ......................................... 70

3.2.2 Test preliminaries ................................................................................................................. 71

3.2.3 Operating control and indicator performance checks.......................................................... 71

3.2.4 ECG performance check ..................................................................................................... 72

3.2.4.1 Patient cable identification ................................................................................... 72

3.2.4.2 ECG Simulator settings ....................................................................................... 72

3.2.4.3 Analysis of the ECG signal, HR value and QRS beep ........................................ 72

3.2.4.4 Testing alarm limits, recorder start, audible alarm activation .............................. 73

3.2.4.5 Testing the input amplifier offset .......................................................................... 73

3.2.4.6 Testing pacing detection ...................................................................................... 73

3.2.4.7 Testing the lead fail detection .............................................................................. 74

3.2.5 NI blood pressure performance check ................................................................................ 74

3.2.5.1 Leakage test ........................................................................................................ 74

3.2.5.2 Testing display errors .......................................................................................... 74

3.2.5.3 Testing the deflation pressure threshold ............................................................. 76

3.2.5.4 Dynamic blood pressure measurement .............................................................. 76

3.2.6 SpO2 performance check .................................................................................................... 76

3.2.6.1 Simulator setting .................................................................................................. 76

3.2.6.2 Monitor settings ................................................................................................... 76

3.2.6.3 Displaying waveforms and parameter readings .................................................. 76

3.2.6.4 Testing display accuracy of SpO2 and pulse rate ............................................... 77

3.2.7 Invasive blood pressure performance check (Vers. 2.0 and higher) ................................... 77

3.2.8 Temperature performance check (Vers. 2.0 or higher) ........................................................ 78

3.2.9 RS232 performance check (Vers. 2.0 or higher) ................................................................. 78

3.2.10 Nurse call output performance check .................................................................................. 79

3.2.11 Testing condition of battery .................................................................................................. 79

Page 5

GE Medical Systems EAGLE 1000 Page 5

Information Technologies Servicing Instructions 227 468 01 Rev. G

3.2.12 Backup battery for the clock ................................................................................................ 79

3.3 Calibration check of the measuring system....................................................................................80

3.3.1 Technical Inspections of the Measuring System ................................................................. 80

3.4 Safety Analysis Test ........................................................................................................................ 81

3.4.1 General introduction ............................................................................................................ 81

3.4.2 Recommended Test Equipment .......................................................................................... 81

3.4.3 Protective Earth Resistance Test......................................................................................... 83

3.4.4 Leakage Current Measurement........................................................................................... 83

3.4.4.1 Enclosure Leakage Current Test ......................................................................... 83

3.4.4.2 Patient Leakage Current Test .............................................................................. 84

3.4.4.3 Enclosure Leakage Current Test (System) ......................................................... 85

4. Instrument service ............................................................................................................................... 86

4.1 Service mode tests ......................................................................................................................... 86

4.2 Instrument performance .................................................................................................................. 87

4.2.1 Start-up performance ........................................................................................................... 87

4.2.2 Operating performance ........................................................................................................ 87

4.2.3 Performance in the event of a malfunction .......................................................................... 87

4.3 Battery management ...................................................................................................................... 88

4.4 Safety information ........................................................................................................................... 89

4.4.1 Insulating foil ........................................................................................................................ 89

4.4.2 High voltage ......................................................................................................................... 89

4.4.3 ESD protection..................................................................................................................... 89

4.5 Eagle 1000 servicing information ................................................................................................... 90

4.5.1 Service repair kit .................................................................................................................. 90

4.5.2 Opening the instrument ....................................................................................................... 90

4.5.3 Removing and reinstalling assemblies ................................................................................ 91

4.5.4 Adjustment procedures ........................................................................................................ 95

4.5.4.1 Location of the adjustment devices on PCB ECG Monitor Index G to I .............. 97

4.5.5 Recorder service ................................................................................................................. 99

4.5.6 PCB Press-Temp 388 031 75, PCB Temp (partly equipped PCB Press-Temp) ................ 101

4.6 Troubleshooting tips...................................................................................................................... 101

4.7 QuickLink test ............................................................................................................................... 105

4.7.1 Technical inspections ......................................................................................................... 105

4.7.2 Tools required .................................................................................................................... 105

4.7.3 Testing QuickLink adapter leading to QuickLink Station and HELAN ............................... 105

4.7.4 Testing QuickLink adapter leading to Eagle 1000 ............................................................. 107

4.7.5 QuickLink test: RS-232 connections ................................................................................. 108

4.7.6 Maintenance and checkout procedures ............................................................................ 109

5 PCB R-Plan, P-Plan .............................................................................................................................111

5.1 PCB ECG Monitor 388 031 19 (V2.0) ........................................................................................... 111

5.2 PCB ECG Monitor 388 031 19 I (V2.01) ........................................................................................111

5.3 PCB Recorder 50: 388 031 70 ...................................................................................................... 111

5.4 PCB Press/Temp 388 031 75 ........................................................................................................ 111

5.5 PCB Temp 388 032 04................................................................................................................... 111

5.6 PCB Press Distributer 388 032 12 ................................................................................................. 111

5.7 Isolation relay Eagle 1000: 388 032 14 ......................................................................................... 111

6. Sparparts List ..................................................................................................................................... 113

7. Miscellaneous, Notes ........................................................................................................................ 117

Appendix............................................................................................................................................. 119

Circuit diagrams, mechanical diagrams ................................................................. Apprendix

Master Record Index (MRI) .................................................................................... Apprendix

Page 6

GE Medical Systems EAGLE 1000 Page 6

Information Technologies Servicing Instructions 227 468 01 Rev.G

Revision History

This manual is subject to the GE Medical Systems Information Technologies change order service. The

revision code, a letter that follows the document part number, changes with every update of the manual.

The initial version of the manual has the letter A.

Part No. Revision Code Date Comment

227 468 01 A 1997-05 Initial Release

227 468 01 B 1997-06 Updates

227 468 01 C 1997-08 Updates

227 468 01 D 1997-12 Updates

227 468 01 E 1998-02 ECO 063757

227 468 01 F 2001-02 ECO 065760

227 468 01 G 2003-02 ECO 068791

Page 7

GE Medical Systems EAGLE 1000 Page 7

Information Technologies Servicing Instructions 227 468 01 Rev. G

1.1 Documentation and nomenclature of Marquette Hellige

instrument part numbers

1.1.1 Configuration of instrument part number

The instrument part number comprises 8 digits, the first 6 digits determining the instrument

type, the last 2 digits the instrument version. The language is determined by configuration,

thus having no influence on the part No.

E.g. Instrument Type Version

EAGLE 1000

without recorder 101 123..

with recorder 101 124..

07 complete system

02 ECG only

1.1.2 Configuration of the PCB par numbers

388 xxx yy Spare part numbers for the operative PCBs.

The instrument documentation, e.g., reference diagrams, circuit diagrams and parts lists

are listed under these part numbers.

The 388 number is located on the barcode label.

Configuration of the barcode labels:

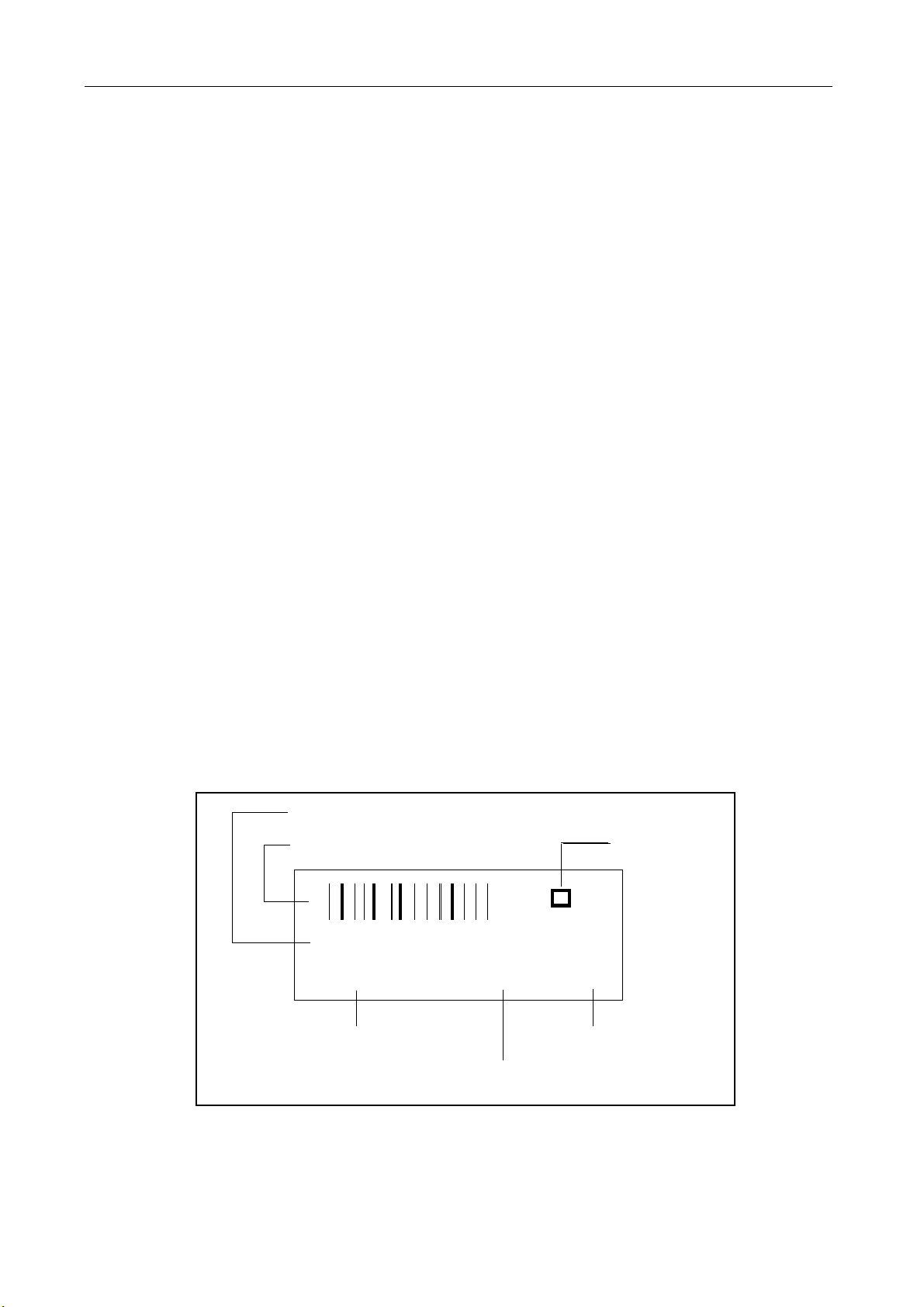

Consecutive number

Consecutive number barcode Test mark

0000000219

388 011 51 3131 C3

Part No. Parts list index

Test number (batch)

Page 8

GE Medical Systems EAGLE 1000 Page 8

Information Technologies Servicing Instructions 227 468 01 Rev.G

303 xxx yy Spare part numbers for PCBs tested especially thoroughly

303 numbers are only given to PCBs where the level of testing applied to 388 PCBs is

inadequate for implementation when servicing in the field, or where only a complete set of

PCBs can be replaced in the field.

In addition to a barcode label (388 number) 303 part numbers also have an additional

label with a 303 number and are to be found in the spare parts list under this number.

Exchange for defective PCBs

Where servicing is required exchange PCBs are available for the replacement of some

PCBs. When using a exchange PCB, the defective PCB is to be returned to the Freiburg

factory. Replacement PCB part numbers are included in the spare parts list.

1.1.3 Instrument status documentation (nominal status)

Due to the hardware and software combination unambiguous documentation of the instrument assembly status is necessary, also in the event of repairs.

This documentation comprises the following documents and measures:

Master Record Index (MRI)

This document is a component of this instrument documentation.

This document states the combination of permissible hardware and software for a particular instrument version. The permissible PCB Index is given in the Index column with each

update delivered. Further permissible PCB Indexes are given in the compatible column.

The PCB Index can be found in the PCB barcode label.

Product Status Index

This document is created during manufacture. The Product Status Index documents the

hardware/software product status.

Page 9

GE Medical Systems EAGLE 1000 Page 9

Information Technologies Servicing Instructions 227 468 01 Rev. G

1.2 Eagle 2000 system overview

These servicing instructions describe the instrument versions with Hellige circular connectors.

Compact, multi-parameter patient monitor, 12 different models

101 123 02 EAGLE 1002 ECG

101 124 02 EAGLE 1003 ECG Alarm recorder

101 123 03 EAGLE 1004 ECG SPO

101 124 03 EAGLE 1005 ECG SPO

101 123 04 EAGLE 1006 ECG NBP

101 124 04 EAGLE 1007 ECG NBP Alarm recorder

101 123 05 EAGLE 1008 ECG SPO

101 124 05 EAGLE 1009 ECG SPO

101 123 06 EAGLE 1010 ECG SPO

101 124 06 EAGLE 1011 ECG SPO

101 123 07 EAGLE 1014 ECG SPO

101 124 07 EAGLE 1015 ECG SPO

2

2

2

2

2

2

2

2

Alarm recorder

NBP

NBP Alarm recorder

NBP TEMP

NBP TEMP Alarm recorder

NBP TEMP 2 x IBP

NBP TEMP 2 x IBP Alarm recorder

Table of EAGLE 1000 models (NBP = non-invasive blood pressure, IBP = invasive blood

pressure.

Page 10

GE Medical Systems EAGLE 1000 Page 10

Information Technologies Servicing Instructions 227 468 01 Rev.G

1.3 System overview

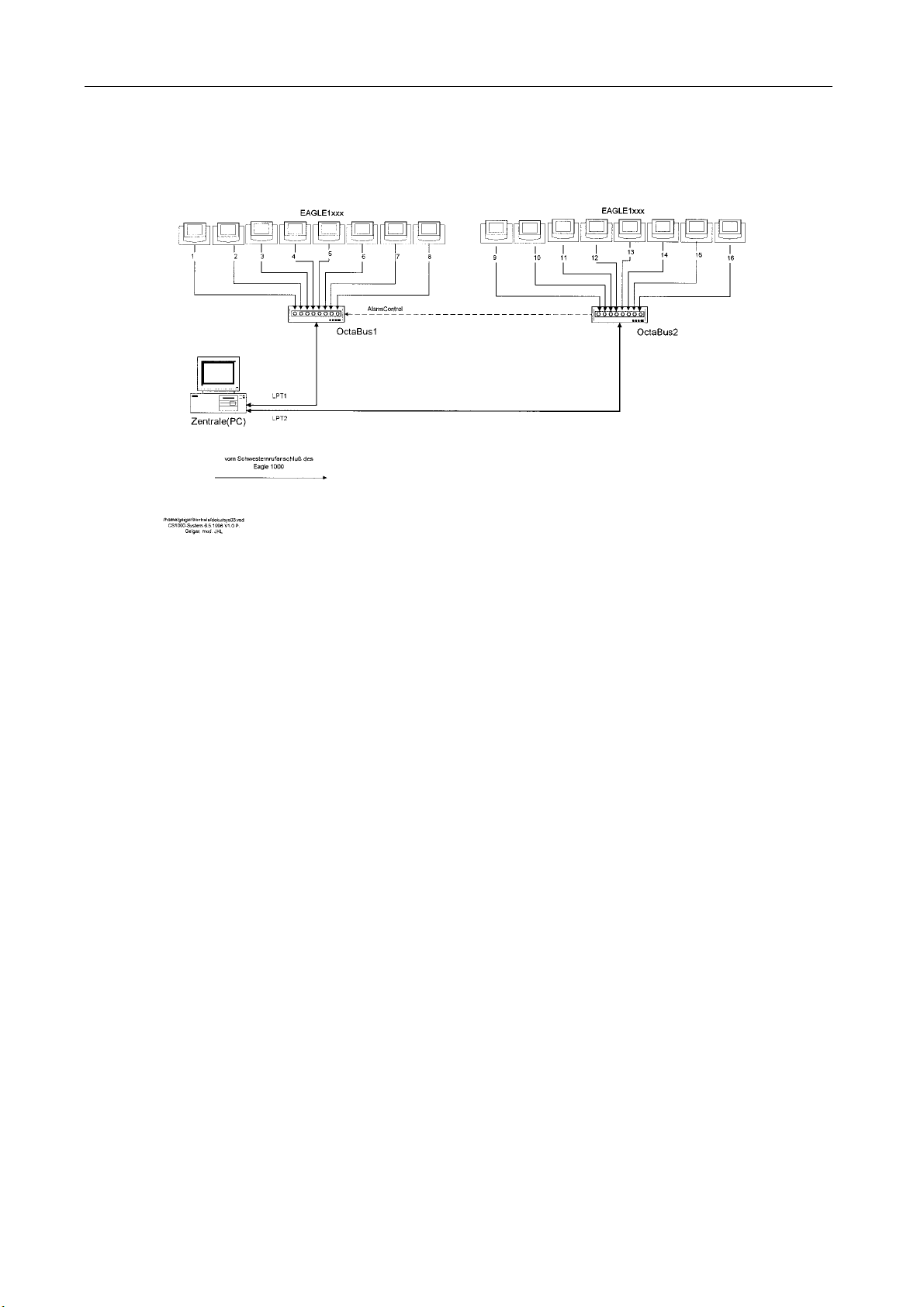

1.3.1 Hooking up EAGLE 1000 monitors to PC Central Station SynOpsis 1000

Eagle 1000 monitors version V2.1 and higher can be connected up to the PC Central

Station SynOpsis 1000. This involves the hooking up of up to eight monitors via a serial

cable with an OctaBus 1000. Up to two OctaBus 1000s can be connected up to the

Central Station. Each OctaBus is connected to the Central Station PC using a printer port.

Alarm release ensues from one of the two OctaBus devices, these being connected appropriately. The OctaBus devices and the Central Station PC monitor controll each others

performance and give an alarm when a malfunction is detected. For configuration see

figure below.

Nurse Call

EAGLE wall outlet

Figure 1. Connection of EAGLE 1000 with current loop output to Nurse Call/ Central Station

socket

Connection

The Nurse Call socket of Eagle 1000 V2.1 or higher is used for hooking up to the Central

Station via the OctaBus. A current loop permits connections over distances of up to 200 m.

Connection to the OctaBus is via an 8-lead cable either from a wall outlet or directly. Refer

to the Installation Instructions for more details.

Page 11

GE Medical Systems EAGLE 1000 Page 11

Information Technologies Servicing Instructions 227 468 01 Rev. G

Central Station PC

Figure 2. Connection of EAGLE 1000 monitors to a PC Central Station SynOpsis 1000 using

2 OctaBus hardware interfaces.

Page 12

GE Medical Systems EAGLE 1000 Page 12

Information Technologies Servicing Instructions 227 468 01 Rev.G

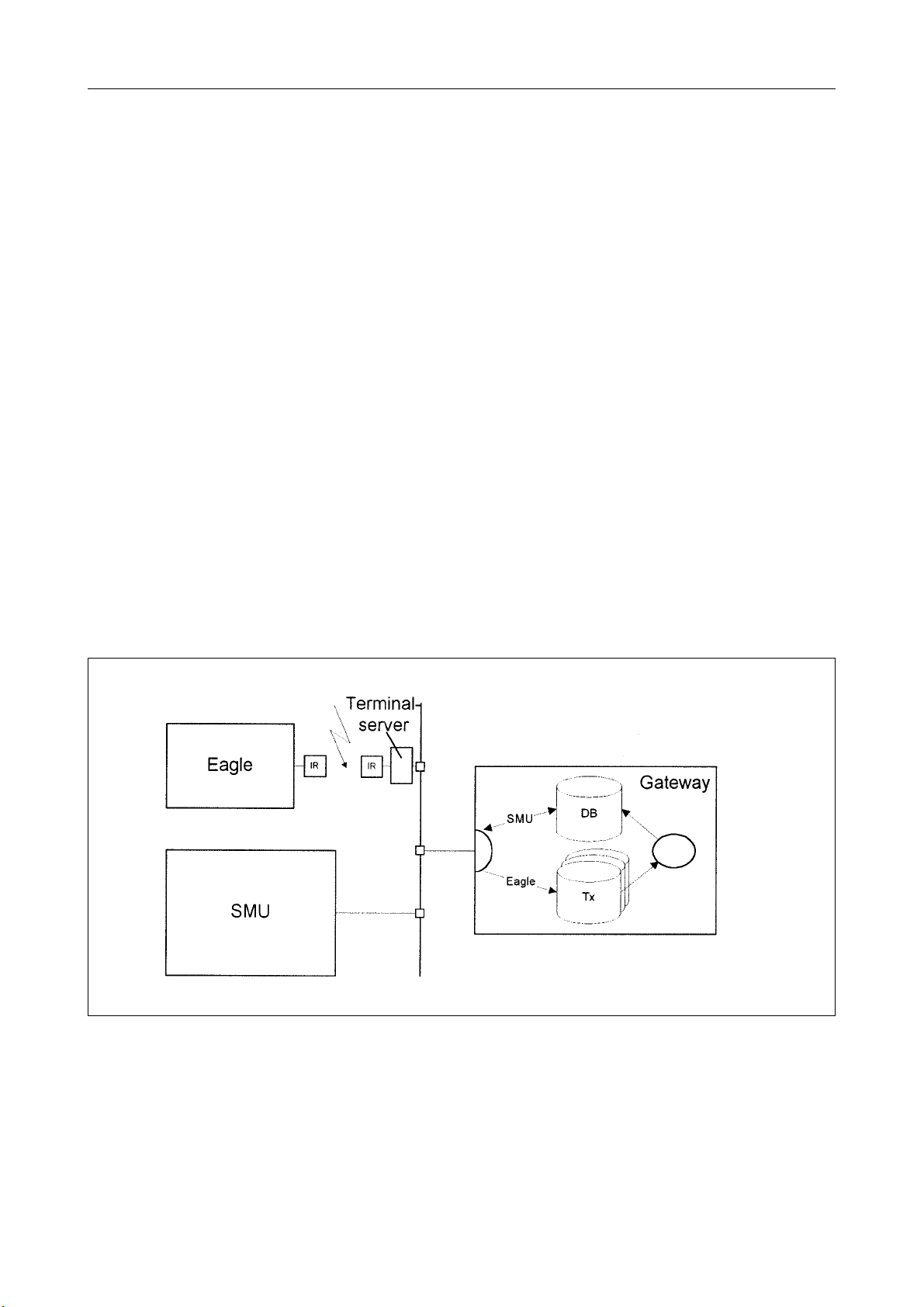

1.3.2 Patient data transfer from EAGLE 1000 via HELAN to SMU using

QuickLink

1.3.2.1 Introduction

To ensure continuous monitoring it is also necessary to be able to record patients vital

signals during relocation and transportation. However, since during patient transfer there is

no connection to the LAN, the trend data are collected and then transferred later as a

block.

After taking over patient monitoring on the transport monitor recording of the data begins.

No connection is being established with the Gateway. The patient remains anonymous,

i.e., his name is not entered into the transport monitor.

Upon arrival at his new destination the patient is hooked up to the destination monitor and

the transfer of the trend data initiated by the transport monitor operator. The transport

monitor establishes a connection over an IR beam and a terminal server (QuickLink) with

the LAN and transfers the data to the Gateway.

In the Gateway the data are stored in a file bearing a file name indicating the ID of the

transport monitor used. Assignment of patient data is carried out using the operating routines of the destination monitor. The operator selects the transport monitor ID, to which the

transferred patient belonged to. It is now the task of the Gateway to enter the trend data

into the database correctly.

Figure 3 shows the principle of data transfer. The terminal server comprises QuickLink, the

Gateway comprises VICOM TR server or VICOMport + VICOMserver.

Page 13

GE Medical Systems EAGLE 1000 Page 13

Information Technologies Servicing Instructions 227 468 01 Rev. G

1.3.2.2 Data transfer between Eagle and Gateway

Eagle and Gateway will communicate while transferring trend data. Transfer is initiated by

the user request function.

The data are first stored in a file and, when data transfer is complete, arranged in proper

order. The transport monitor waits for the results of this processing procedure.

If an error occurs in the database during this procedure, all the data in the Gateway are

deleted and the entire data must be transferred once more.

When the data transfer is initiated, the time will be sent by the transport monitor real-time

clock. From this the Gateway can identify any possible time misalignment of the internal

clock of the transport monitor and account for this when the trend data are entered.

Sporadic trend data, e.g., non-invasive blood pressure values, are only transferred for the

period of time in which continuous trend data, e.g., ECG, are also available. Earlier or later

parameter readings will be ignored.

1.3.2.3 Connection to the LAN

The QuickLink Station is connected to a Multiport or an SMX using twisted-pair wiring.

The Multiport can lead to the LAN using BNC or AUI wiring.

The SMX 008 leads to the LAN using AUI wiring, the SMX 009 to the LAN using BNC

wiring.

Page 14

GE Medical Systems EAGLE 1000 Page 14

Information Technologies Servicing Instructions 227 468 01 Rev.G

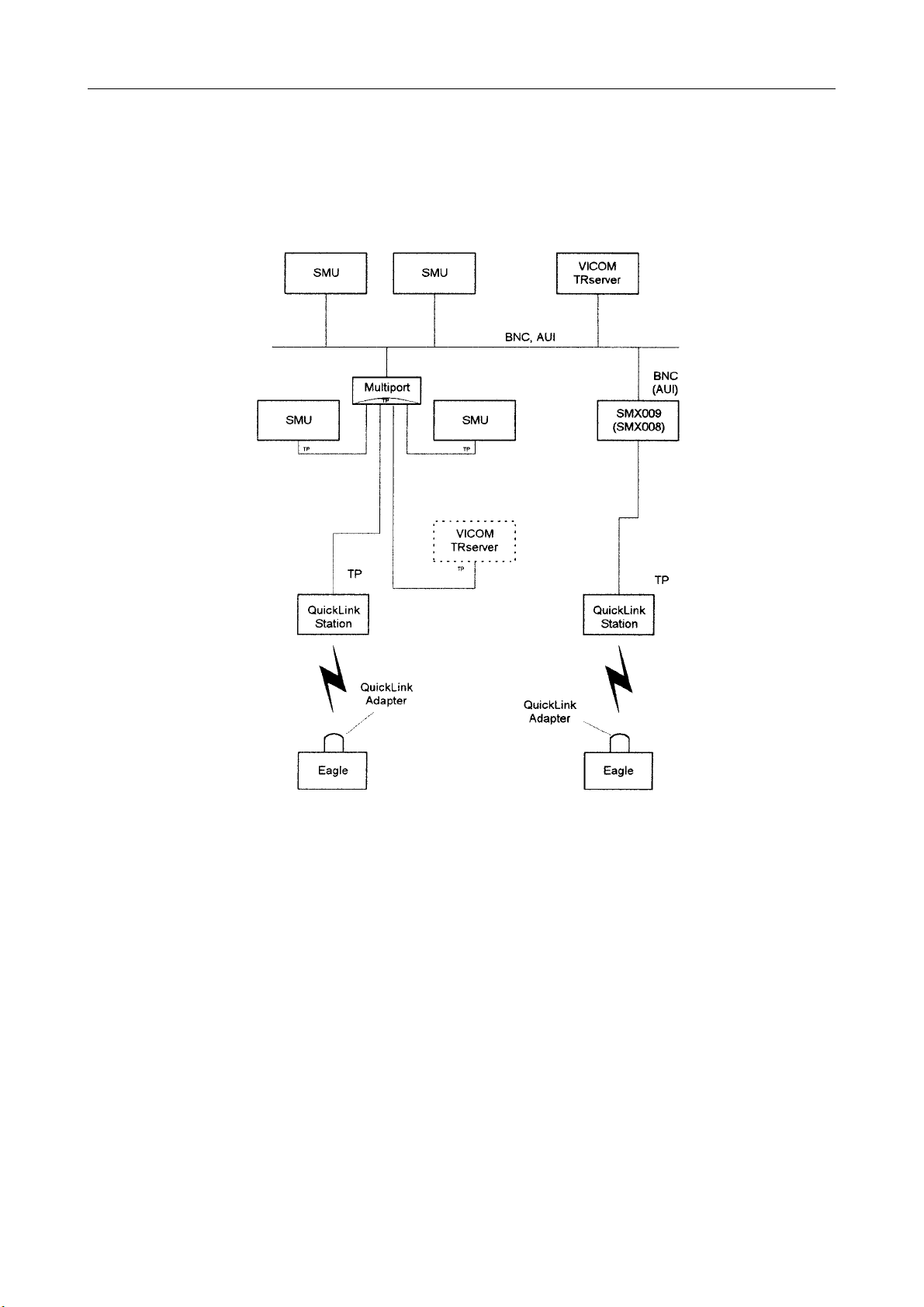

Configuration with BNC, AUI or twisted pair (TP)

Figure 4. QuickLink - LAN connection

twisted pair

installation option

Page 15

GE Medical Systems EAGLE 1000 Page 15

Information Technologies Servicing Instructions 227 468 01 Rev. G

1.3.2.4 EAGLE 1000 - QuickLink - HELAN - Examples of the link to networks

1.3.2.4.1 Functional structure overview

The link of Eagle 1000 to the networks via QuickLink enables the transfer of patient data

acquired during patient relocation and transportation for continuous and uninterrupted

analysis.

A QuickLink adapter connected to the RS 232 interface of the Eagle 1000 sends the transportation data using IR to a QuickLink Station. The QuickLink Station acts as a terminal

server and is the communication partner to the HELAN network.

The data transferred onto the HELAN are stored on a server which acts as a Gateway

(VICOM TRserver or VICOMport in connection with VICOMserver).

This is where the patient data and the measured values recorded during transportation are

made available for complete documentation on any patient monitor or on a clinical information system.

1.3.2.4.2 Main components for the installation of QuickLink:

Part Number Device Description

216 135 01 QuickLink Adapter IR-Interface, connectable to Eagle 1000

216 134 01 QuickLink Station Station to receive IR signal from QuickLink

adapter incl. RJ45 connection (Twisted

Pair)

216 107 01 SMX 001 Transceiver for AUI

216 133 01 SMX 005 Transceiver for RJ45 (Twisted Pair)

930 117 40 SMX 006 Multiport Repeater (12 x RJ45)

930 117 39 SMX 007 Multiport Repeater (24 x RJ45)

930 117 76 SMX 008 Repeater RJ45 to AUI

930 117 77 SMX 009 Repeater RJ45 to BNC (CheaperNet)

101 130 01 VICOM TRServer R.2.0 Patient data transfer within HELAN

101 131 01 VICOMport R.2.0 Link of HELAN to VICOM Server

101 132 01 VICOMserver R.2.0 Database for HELAN and interface to other

networks

Page 16

GE Medical Systems EAGLE 1000 Page 16

Information Technologies Servicing Instructions 227 468 01 Rev.G

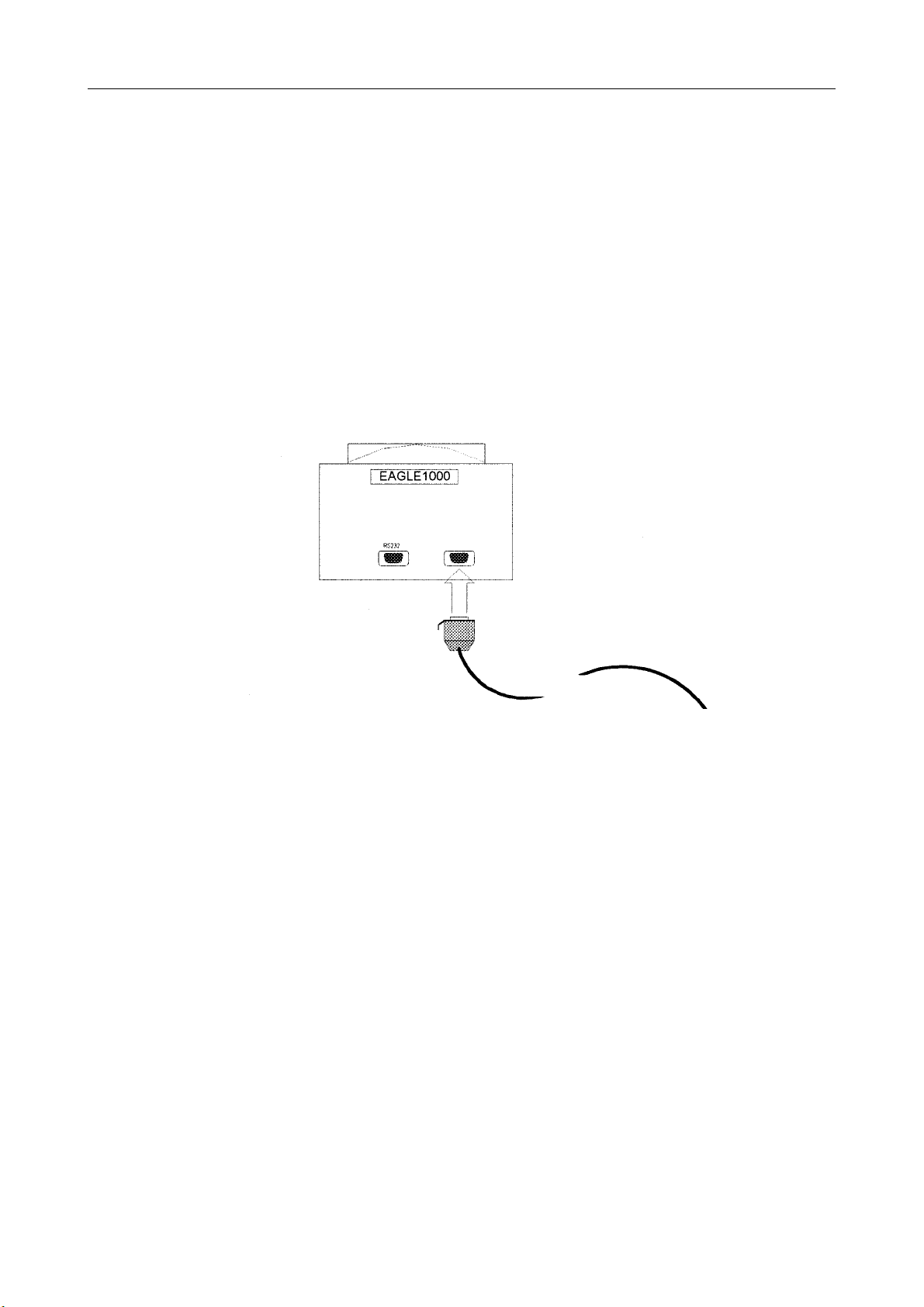

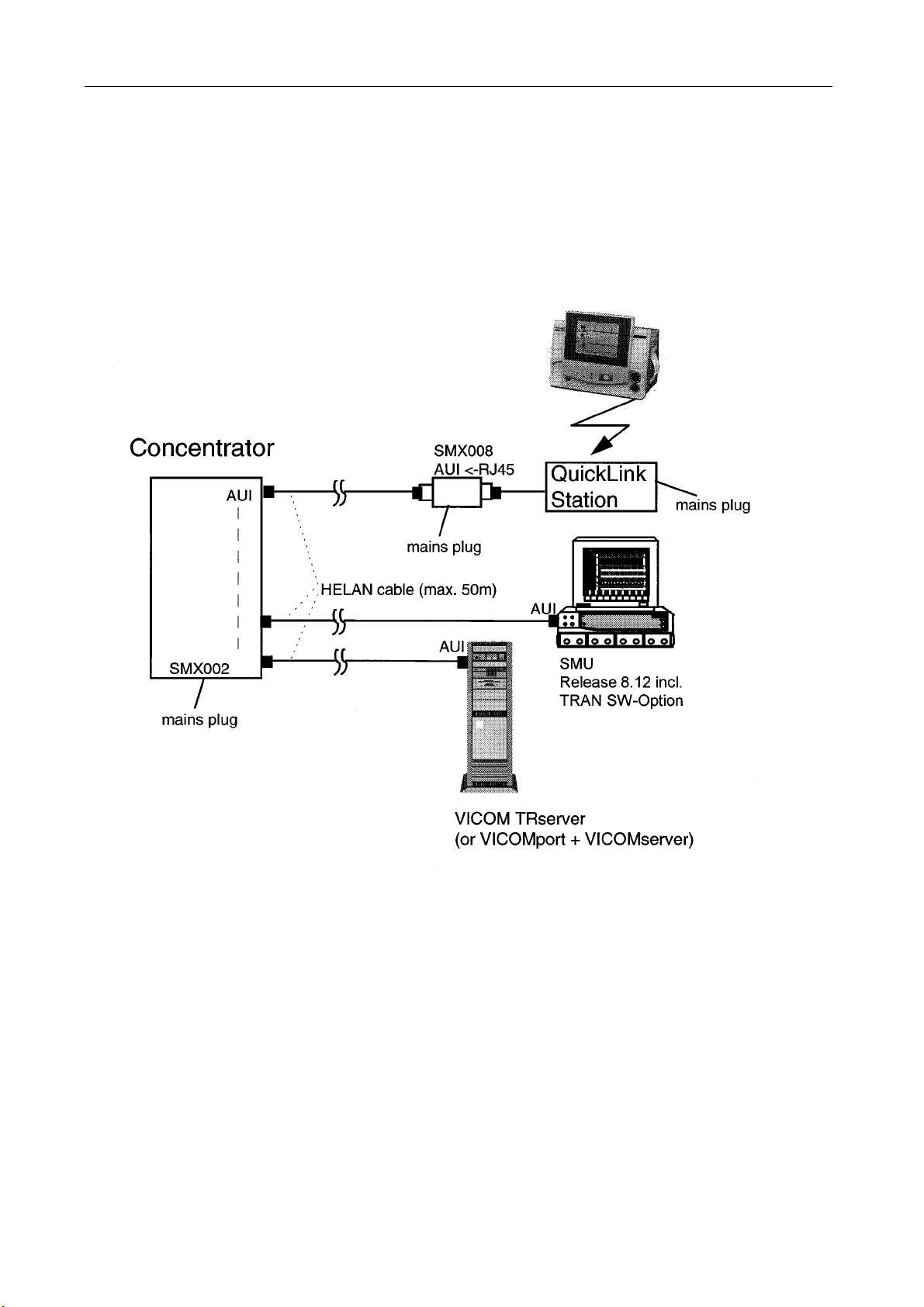

1.3.2.4.3 EAGLE 1000 - QuickLink

Network link - HELAN CheaperNet

SMX 008 + SMX 001 can be used in place of SMX 009 + BNC T-Plug.

Page 17

GE Medical Systems EAGLE 1000 Page 17

Information Technologies Servicing Instructions 227 468 01 Rev. G

1.3.2.4.4 Network link - HELAN Concentrator

Page 18

GE Medical Systems EAGLE 1000 Page 18

Information Technologies Servicing Instructions 227 468 01 Rev.G

1.3.2.4.5 Network link - HELAN Twisted Pair

Page 19

GE Medical Systems EAGLE 1000 Page 19

Information Technologies Servicing Instructions 227 468 01 Rev. G

2.1 Technical specifications

2.1.1 System interfaces

Interface for Nurse Call and Central Station

* output for control signal in the case of alarm or warnings for connection of an Isolation

Relay 303 444 77, short-circuit-proof

* trigger output (digital impulse, width 1 ms, 0 V to 9.5 to 14.5 V)

* 20 mA current loop output to connect OctaBus to PC Central Station SynOpsis with

V2.1 or higher version

RS 232 interface

* RS 232/V24 interface for connection of QuickLink to HELAN, available from V 2.0 or

higher

2.1.2 Display

* size: 6-inch diagonal (14 cm)

* type: monochrome liquid-crystal display

* resolution: 320 by 240 pixels

Waveform display

* 3 channels

* sweep speed of 25 mm/s

* erase-bar mode

2.1.3 Monitor functions

Operating modes

* test, monitoring enabled/disabled, service mode, data transfer (download)

Alarm system

* text on display, alarm LED, Alarms OFF LED, audible alarm signal (can be disabled

via softkey or from the defaults menu)

Data storage in case of line failure or empty battery

* at least 5 minutes

Page 20

GE Medical Systems EAGLE 1000 Page 20

Information Technologies Servicing Instructions 227 468 01 Rev.G

2.1.4 Power supply

* from the power line, monitor design in IEC protection class I

Potential equalization

* potential equalization connection according to DIN 42 801(measurement in or at the

heart) or connection for function ground (interference elimination during general cardio-

logical examinations)

Rated voltage range from 95 to 240 V AC

* operating voltage range from 85 to 264 V, 49 to 65 Hz

* rated current from 0.15 to 0.3 A

Internal power supply (rechargeable battery)

* automatic toggling from line to battery operation and vice versa

* integrated charge circuit with automatic adaption of charge characteristics

* fast battery charging to 80% of its capacity within 3.5 hours, afterwards

* normal charging to 100% of its capacity within 8 hours, afterwards

* continuous trickle charging by means of charge pulses to prevent the memory effect

Charge balance

measurement of the charge and load current

compensation for battery self-discharge

graphic indication of battery capacity

Alarms

warning when battery provides power for only 5 minutes of operation (without

recorder)

automatic switch-off at 10.0 V to prevent overdischarging

Capacity of the rechargeable battery

2000 mAh, 12 volts

Charging indicator

LED

Operating time

approx. 3 hours (typical operating time with fully charged battery at 23 °C, at a

battery temperature of 60 °C the capacity may be reduced to 70%)

(min. 2 hours at 25 °C ambient temperature and new, fully charged battery)

Page 21

GE Medical Systems EAGLE 1000 Page 21

Information Technologies Servicing Instructions 227 468 01 Rev. G

2.1.5 Operation and storage

Operational readiness

after approximately 5 seconds

Operating position

vertical (free circulation of air under the unit and ventilation openings must not be ob-

structed)

Environmental conditions

Operation

* ambient temperature between +10 °C and +40 °C

* battery charging temperature between +10 °C and +40 °C

* relative humidity between 30% and 75%, no condensation

* atmospheric pressure between 700 and 1060 hPa

Storage

* ambient temperature between -30 °C and +60 °C

* relative humidity between 10 and 100%, no condensation

* atmospheric pressure between 500 and 1060 hPa

Dimensions

width 262 mm

height 215 mm

depth 160 mm

weight 2 kg to 4.4 kg (depending on monitor model)

2.1.6 ECG and heart rate

ECG signal inputs

Electrode connection for simultaneous transfer of 2 ECG signals: ECG 1 and ECG 2 via

lead selector (7 standard lead configurations each).

Signal inputs for 3-lead and 5-lead patient cables with connections for electrode leads;

buffer amplifier with protective circuit and HF filter; floating input circuit (isolated patient

connection of the CF type, IEC); overvoltage protection for all inputs, detection of pacing

pulses, monitoring of electrode-to-skin contact impedance (specifications without leads):

differential input impedance for DC > 65 MOhms, for f<=100 Hz > 6 MOhms

common-mode input impedance referred to RL

for DC > 10 GOhms, for f<=100 Hz > 50 MOhms

Page 22

GE Medical Systems EAGLE 1000 Page 22

Information Technologies Servicing Instructions 227 468 01 Rev.G

overrange limit (e.g. for polarization voltages) for differential signals >0.6 V, for signals

referred to RL > 1.0 V

common-mode rejection referred to RL for f<= 50 Hz approx. 80 dB RL referred to

chassis >110 dB

patient leakage current (rms values): under normal conditions <0.005 mA, in fault condi

tion (e.g. patient in contact with mains voltage) <0.020 mA

quiescent input current <40 nA

non-destructive load for electrode connections referred to RL ± 50 V, referred to chas-

sis ± 1000 V

pulse-voltage resistance of all electrode connections and of the RL-connection referred

to chassis (either polarity, e.g. defibrillation, electrocautery) 5000 V

Signal processing

The signal in channel 1 is processed. All specifications refer to a signal free of inter

ference.

Amplification, QRS detection, digitization, display

HR measuring range 15 to 300 bpm, error ± 1 BPM (EC 13)

ECG cut-off frequency >=100 Hz

differential signal range ± 4.5 mV

ECG resolution 0.005 mV

sampling rate 1000/1200 Hz

noise below 0.04 mV

time constant for ECG transfer 0.3 s (0.5 Hz)

HR averaging for displayed value: weighted average from the most recent RR intervals

display update interval: 2 seconds

trigger sensitivity 0.25 mV to 0.30 mV for pulse width of 40 ms

max. rate stabilization of 6 seconds for RR interval change of 95%

alarm delay 4 seconds

asystole alarm 4 seconds

3 signal sizes for monitor display in freeze mode or else on the recorder trace: 5 10

20 mm/mV

1-mV calibration signal on waveform and recorder trace

detection of pacing pulses (these specifications refer to an ECG signal free of inter-

ference)

pulse duration dp>approx. 0.2 ms, <40 ms

pace marker independent of polarity

pulse amplitude ap±10 to ±700 mV

over/undershoot ao±1 mV

time constant to 25 to 100 ms

Page 23

GE Medical Systems EAGLE 1000 Page 23

Information Technologies Servicing Instructions 227 468 01 Rev. G

alarm limits adjustment range: 20 to 250 BPM

trigger output on Nurse Call connection nominally 12 V 1 ms, delay max. 25 ms, tole-

rance 9.5 V to 15.5 V

rate measurement

derivation of trigger pulses from the ECG signal or from the pressure waveform or from

the Sp02 signal with automatic adaption of the trigger threshold or blanking of pacing

pulses; calculation of the mean rate; 3-digit display on the monitor screen

2.1.7 Oxygen saturation Sp0

2

Signal input

Connection for one Sp02 probe, isolated from ground, floating input circuit (isolated patient

connection of the CF type, IEC).

Used in conjunction with the approved probes, the module is protected from voltages

generated by defibrillation discharges and electrocautery.

Signal processing

dual-wavelength pulse oximeter

Sp0

measuring range 1 to 100%

2

PR measuring range 20 to 250 BPM

resolution 1% Sp0

2

deviations from actual value (% Sp02 = 1st standard deviation) in combination with:

standard finger probe (DS 100A)

between 70 and 100%: ±3 digits

disposable probe for adults (D25)

between 70 and 100%: ±2 digits

disposable probe for children (OXI D20)

between 70 and 100%: ±2 digits

disposable probe for babies (J-20)

between 70 and 95%: ±2 digits

disposable probe for neonates (N-25)

between 70 and 95%: ±2 digits

unspecified between 0 and 69% Sp0

Plethysmogram

accuracy of the pulse rate measurement

±3 pulses/min between 20 and 150 pulses/min

±2% between 150 and 250 pulses/min

2

Page 24

GE Medical Systems EAGLE 1000 Page 24

Information Technologies Servicing Instructions 227 468 01 Rev.G

2.1.8 Non-invasive blood pressure

Signal input

Single-lumen tubing system, type CF signal input (IEC 601-1), patient is electrically not

connected to the system, thus the system is protected from defibrillation discharges and

electrosurgery voltages).

Signal processing

Oscillometric method:

stepwise pressure decrease, zero pressure reference prior to each measurement

Two measuring modes: adult

neonate

mmHg

adult systolic 25 to 255

diastolic 10 to 220

mean 18 to 255

neonate systolic 20 to 155

diastolic 5 to 110

mean 10 to 130

The specifications are met for pulse rates between 40 and 240 BPM (adult/neonate).

Safety circuits

Redundant monitoring of the cuff pressure by means of a second independent pressure

sensor; cuff deflation immediately on exceeding max. cuff pressure, on detection of faults

during a measurement and on power loss.

Max. cuff pressure

adult 300 mmHg

neonate 160 mmHg

Special features

When the cuff is properly applied the module recognizes in the adult mode whether the

cuff matches the selected range. If the wrong cuff is applied, the measurement is interrupted.

Page 25

GE Medical Systems EAGLE 1000 Page 25

Information Technologies Servicing Instructions 227 468 01 Rev. G

Cuff inflation pressure

adult 160 mmHg

neonate 100 mmHg

Adaptive cuff inflation pressure

After a measurement the inflation pressure of the subsequent measurement depends on

the previous measuring result: it is either 1.8 times the previous mean pressure or 15%

above the previous inflation pressure (whichever is less).

Measurement cycles

Selectable intervals for automatic measurement cycles:

2, 5, 10, 15, 30, 60 minutes

Measuring accuracy

P

sys/Pdia

<= 8 mmHg, 1st standard deviation

error limits for cuff pressure via the pressure transducer ±3 mmHg

Measurement duration

adult: 90 seconds max.

neonate: 70 seconds max.

typical duration for undisturbed measurement: 30 seconds

Technical inspection, calibration

Technical inspection must be carried out once a year, calibrations every two years (refer to

section 3 Maintenance and technical inspection).

2.1.9 Invasive blood pressure

Signal inputs

2 connections which are both isolated from ground (type CF according to IEC 601-1) for

pressure transducers with ohmic strain-gauge bridge, diagonal resistance of 200 Ohms to

10 kOhms with a sensitivity of 0.005 mV/mmHg per V of supply voltage:

supply voltage for transducer:

5 volts DC

At 50 and 60 Hz:

differential input impedance > 100 kOhms, real component 500 kOhms

common-mode input impedance > 100 kOhms

common-mode rejection > 60 dB up to 60 Hz

Page 26

GE Medical Systems EAGLE 1000 Page 26

Information Technologies Servicing Instructions 227 468 01 Rev.G

Connections

direct connection for measurement of one pressure

connection via adapter for measurement of two pressures

Display

pressure waveform with 25 mm/s sweep for both channels

pressure waveform for the following pressure sites: arterial (ART1, ART2), pulmonary

artery (PA), venous (VEN), left-atrial (LAP), intracranial (ICP) for ART, PA and LAP the

systolic, diastolic and mean values can be displayed

display update interval: 2 seconds

Signal processing

Pressure

measuring range -30 to +300 mmHg

resolution 0.25 mmHg, internal

cut-off frequency 12 Hz

accuracy ±2 mmHg ±1% of actual value

zero drift < ±0.1 mmHg/°C

5 minutes to warm up for full accuracy

Zero balancing

automatic compensation of the transducer value for a zero pressure in both channels,

every channel to be zeroed is checked for absence of pulse signals

balancing initiated after key press > 2 seconds

balancing range ±100 mmHg

storage of the balancing value for 5 minutes after power failure or when monitor is

switched off

deviation < ±1 mmHg

initiation only when signal modulation < ±1 mmHg

Page 27

GE Medical Systems EAGLE 1000 Page 27

Information Technologies Servicing Instructions 227 468 01 Rev. G

2.1.10 Temperature

Signal input

Input isolated from ground (type CF according to IEC 601-1) for connection of a temperature probe from the Marquette HELLIGE accessory range (these probes conform to the

YSI 400 or Exacon 4000 series; as these probes have jack plug contacts which are accessible when not connected, they were additionally tested with 1500 V

cal saline according to IEC 601-1)

Signal processing

Together with two test readings and a correction value the temperature reading is processed for regular self-tests and for fine-balancing by multiplexing in a common amplification

circuit:

measuring range 0 to 44 °C

error limits for module without probe: between 0 and 25 °C ±0.2 °C, between 25 and

44 °C ±0.1 °C

display update interval: 2 seconds

5 minutes to warm up for full accuracy

50 Hz in physiologi-

rms

Functional safety

Continuous self-tests prevent display of values outside the calibration error limits; when

service screen is called up the test values of 38.8 °C ±0.1 °C and 4.0 °C ±0.2 °C are displayed.

Technical inspection, calibration

Calibration tests must be carried out on the monitor every two years (refer to section 3

Maintenance and technical inspection), technical inspection once a year.

Page 28

GE Medical Systems EAGLE 1000 Page 28

Information Technologies Servicing Instructions 227 468 01 Rev.G

2.1.11 Trend

* storage of parameter values

* tabular trend, NBP table depending on NBP intervals

* graphic trend for each parameter

* storage of trend values every 20 seconds or after NBP measurement

* display of trends via softkeys

* automatic display of a time scale and of reference lines (labelled)

* zoom function for selection of other trend periods (graphic: 45 minutes, 3 hours,

24 hours; tabular: 1 minute, 5 minutes, 15 minutes)

* trend memory can be cleared with a softkey, or the memory is cleared automatically

when the monitor is switched off for more than 5 minutes

2.2 Functional description of PCBs and subassemblies

2.2.1 Eagle 1000 configuration and functional groups

see diagram Functional groups

The basic Eagle 1000 patient monitor version comprises the large PCB ECG Monitor

installed in the system on the front side of an L-shaped metal plate. In addition to the ECG

input circuit, the instrument control system is also located on this PCB.

The keypad, display screen, battery and the PCB Power Supply are connected to it. Also

connected are the ECG input socket and the two rear panel outputs RS-232 and Nurse

Call.

The keypad and CRT have conductor foil connections and care must be taken when connecting them up and sharply bending them avoided.

The battery is installed in the bottom side of the L-shaped metal plate.

The power supply is located inside the rear panel of the system next to the power supply

socket.

The recorder, if there is one, is mounted on the base plate and connected to the PCB

ECG Monitor.

Page 29

GE Medical Systems EAGLE 1000 Page 29

Information Technologies Servicing Instructions 227 468 01 Rev. G

In the models with additional features the PCB ECG Monitor also acts as a motherboard. The PCB Oximeter, the PCB for non-invasive blood pressure and the PCB for

temperature or for temperature and 2 invasive blood pressures can be added to this

board.

In conformity with Cardiac floating there is a high-impedance isolating transformer referred separately to the ECG input module, the PCB Oximeter, the PCB module for temperature and the PCB module for 2 invasive blood pressures. Both pressure measuring components are electrically connected. These PCBs are insulated from the non-floating components of the system and each other by spacing and insulating foil.

Warning: It is thus important that when disconnecting or replacing PCBs in the

system to ensure PCBs and circuits are correctly installed and the insulating foil positioned accordingly.

2.2.2 PCB ECG Monitor

The PCB ECG monitor appears as a block diagram in the PCB circuit diagrams. The

circuits are arranged so that (viewing Eagle 1000 from the rear) the floating ECG Processing is located in the left-hand third, in the remainder all the other functions:

Floating Non-Floating

x Display Controller

x ECG Controller

x Interface Output

x ECG Filter x Controller

x Power Supply (instrument, battery, floating)

x ECG Input x Interface Input

This means that ECG Processing and the Central System signal processing and system

controller are implemented on this PCB. The description of each is given below, indicating

the connected modules and their functions.

The PCB plugs and sockets are shown in the S-Plan of the system plans and are allocated as listed below. This allocation is useful in finding the pin configuration in the P circuit

diagrams of the PCB ECG Monitor.

Page 30

GE Medical Systems EAGLE 1000 Page 30

Information Technologies Servicing Instructions 227 468 01 Rev.G

Name Connection Denotation Page P-Plan Subtitle

AA Conductor Foil Display 9 Display

AB For Optrex LCD only 9 Display

AC Cable Battery 6 Power

AD Cable PCB Power Supply 6 Power

AE Cable LCD Backlight 9 Display

AF Flat cable Recorder 8 Interface_Out

AG Flat cable PCB Non-Invasive Blood 5 Interface_In

Pressure

AH Flat cable PCB Oximeter (Sp02) 5 Interface_In

AI Debugging Connector only 7 Control

AJ Stackable Connector PCB Press/Temp 5 Interface_In

AK Flat cable ECG Input 2 ECG_Input

AM Conductor Foil Membrane Keypad 5 Interface_In

AN Flat cable RS 232 External Port 8 Interface_Out

AO Flat cable Nurse Call Adapter 8 Interface_Out

2.2.3 System power supply

see diagram System Power Supply

The power supply is in protection class I with a protective ground terminal. A primaryregulated wide-range power supply unit, delivering 15.5 V DC, precludes the necessity of a

power toggle switch. This unit also acts as a charger for the 12-V system battery. All control functions are regulated on the PCB ECG Monitor. A charge controller measures the

battery current across a resistance referred to zero, activates the front panel charge indicator and communicates with the processor. Should the output voltage of the power unit

fail to reach 15.5 V, the battery will not be charged to full capacity.

The battery meets the temporary high current demand of the recorder and the PCB NonInvasive Blood Pressure as well as current peaks and is also essential for retaining data.

As the battery continuously is discharged, this is indicated by an 11.5V comparator, which

triggers the warning display Battery blinking and the audible alarm signal sounding.

When the charge drops below 10 V after storing the data the 10V comparator switches off

the system to protect the battery.

Page 31

GE Medical Systems EAGLE 1000 Page 31

Information Technologies Servicing Instructions 227 468 01 Rev. G

Otherwise, the system is switched on and off with the appropriate button on the front panel, which, just like the 10V comparator, exerts an effect via the processor on the ON/OFF

interface with its FET switch.

A 5V analog voltage +5VREF is generated with a linear controller from the battery voltage

supplied when it is switched on. A switching controller generates the 5V digital voltage

from the battery voltage supplied when it is switched on. Apart from this the battery voltage

supply is used directly and unregulated for oscillators and other components requiring a

power supply.

2.2.4 Floating system power supply and signal flow

Power supply

see diagram Floating system supply and signal flow

The floating system is supplied from a central 100-kHz oscillator on the PCB ECG Moni

tor. This delivers the supply voltage stabilized on a HF transformer, i.e., individual power

fluctuations on some PCBs are not fully compensated. The individual floating components

receive power via the primary HF transformers connected in parallel. Isolation is effected

in these floating transformers. These each generate ±7.5V ±5%. In turn, in each case a

linear +5V ±2% analog/digital voltage is obtained from these voltages.

Signal flow

see diagram Floating system supply and signal flow.

Apart from the non-invasive blood pressure all patient input circuits are high-impedancefloating circuits. In terms of signals, these are isolated in both directions via optoelectronic couplers. All other circuit components are not isolated and referred to circuit zero.

Furthermore, there is a separate ground contact to enable potential equalization.

The non-invasive blood pressure input is isolated by means of a non-electronic patient

input.

2.2.5 Signal exchange with the processor

see Processor block diagram

The processor on the PCB ECG Monitor comprises a controller with a separate 32kHz

quartz crystal, watch dog, RAM and EPROM. The controller is in communication with all of

the following units.

Page 32

GE Medical Systems EAGLE 1000 Page 32

Information Technologies Servicing Instructions 227 468 01 Rev.G

The keypad is used to enter data, the beeper to give alarms and acknowledgment sig

nals. The recorder interface leads to the integrated recorder and the CPU interface to the

liquid-crystal screen.

The RS 232 interface acts as a system output, it is mainly used for sending signals to the

QuickLink to output data to the HELAN after patient relocation and transportation.

The Nurse Call interface leads to the nurse call adapter. A nurse call system can be

connected by means of the nurse call relay for the Eagle 1000. From Version 2.1 and

higher, a 20 mA current loop is available to connect the Eagle to an OctaBus of a SynOpsis Central Station.

The patient data inputs are entered via three serial interfaces:

The QSPI interface allows the transfer of ECG, temperature and the two invasive blood

pressures via the 16 Qued Processor Interface signals. One chip select signal each is

generated for each of the three signal groups. A clock signal synchronizes the transfer of

the two Master In - Slave Out and Master Out - Slave In signals.

The PCBs Oximeter and Non-Invasive Blood Pressure are each connected separately via

an asynchronous interface. This has both an Rx and a Tx cable as well as a reset cable.

Another EC.Syn signal is provided for the oximeter (Sp02), another RESETB signal for the

non-invasive blood pressure (NBP).

2.2.6 Display

see Display block diagram

All of the elements shown apart from the block display are located on the PCB ECG

Monitor.

The LCD display is controlled by an LCD controller. This works together with an external

3.6MHz oscillator and external display RAM. The control of the LCD controller is effected

via the CPU interface.

The LCD display is controlled by a -23V power supply. This voltage is acquired from the

battery voltage supply. The contrast on the PCB ECG Monitor must be adjusted.

The display has a reverse video feature which is supplied with 300 V AC at 30 to 40 Hz

from a CCFT supply. In open-circuit operation this is approx 565 V.

Warning: Avoid contact with this voltage where it is exposed on the PCB ECG

Monitor.

Page 33

GE Medical Systems EAGLE 1000 Page 33

Information Technologies Servicing Instructions 227 468 01 Rev. G

2.2.7 Block diagrams

2.2.7.1 Functional groups

Keypad

Tastenfeld

NBP

Press-Temp

Display

Bildschirm

AC AD

Schw.Ruf

Nuse Call

Power Supply

Stromversorgung

RS 232

AD

230 V~

115 V AC

AC

Recorder

Registriergerät

EKG / ECG

Oxymeter ECG-Monitor

Batterie/Battery

Page 34

GE Medical Systems EAGLE 1000 Page 34

Information Technologies Servicing Instructions 227 468 01 Rev.G

2.2.7.2 Floating system supply and signal flow

2

CALL

BEEPER RS 232 NURSE DISPLAY

KEYPAD

PROCESSOR

QSPI

RECORDER

NIBP

Asyn

Asyn

SPO

Float.

15 V

Supply

100 kHz

ISOLATION

±7.5 V

FLOATING NON-FLOATING

SENSORS

+5 V

each

PRESS1

PRESS2

TEMP

ECG

Page 35

GE Medical Systems EAGLE 1000 Page 35

Information Technologies Servicing Instructions 227 468 01 Rev. G

2.2.7.3 System power supply

Processor

SW

<11.5 V Lo. Bat. Warn.

OFF

<10 V

9.5...15.5 V

+12 V

ON-

+5 V REF

+5 V

+5 VSWGenerator

ON/OFF

OFF

+12 V

Front

Charge Control

Charge Battery

+15.5 V

Mains

99 V AC

264 V AC

Page 36

GE Medical Systems EAGLE 1000 Page 36

Information Technologies Servicing Instructions 227 468 01 Rev.G

2.2.7.4 PROCESSOR block diagram

Display

TIME OF

RECORDER IF

CPU-IF

RS 232-IF

Nurse-Call-IF

DAY CLOCK

BEEPER / KEYPAD

Watch

Dog

CONTROLLER

MEMORY

32 kHz

QSPI-IF

-Asyn-IF

2

SPO

NIBP-Asyn-IF

ECG

Temp.

BPress.

Page 37

GE Medical Systems EAGLE 1000 Page 37

Information Technologies Servicing Instructions 227 468 01 Rev. G

2.2.7.5 DISPLAY block diagram

LCD

DISPLAY

Hinterleuchtung

back lighting

EE

U

565 V/300 V

30...40 kHz

CCFT

SUPPLY

-23 V

+5V

+12 V

LCD-CONTROL

CPU IF

RAM

CONTRAST

~

3,6 MHz

Page 38

GE Medical Systems EAGLE 1000 Page 38

Information Technologies Servicing Instructions 227 468 01 Rev.G

2.2.8 ECG signal preprocessing

2.2.8.1 Functional description

The block diagram ECG/Pace Preprocessing shows the functional setup.

ECG input

In the Eagle 1000 ECG signal acquirement and processing takes place in one of the

remaining functional groups electrically separated from the others on the motherboard.

The functions of this component comprise analog processing of the ECG signals and a

QRS detector to monitor the cardiac rhythm.

All control functions are monitored by a processor, which exchanges data and commands

with the ECG circuit via the optoelectronic coupler.

Before it becomes operative the ECG circuit must be initialized. This is effected by the

processor in accordance with the selected accessories. The processor receives ID signals

called LET1, LET2 and LET3, identifying the nature of the connected accessories and,

hence, determines which ECG leads are available and which connections need to made

to the patient.

For this reason, the lead selector is preset to identify the patient cables used and to test

whether all the electrode leads are connected correctly. Every disconnected (electrode)

lead produces an error signal which is evaluated by the processor so that such electrodes

are not used for ECG monitoring.

ECG signal transfer

If fully operational electrodes are correctly connected to the EAGLE 1000, the ECG signal

is first amplified to 1.1 V per 1 mV as an analog signal, then transferred as a digital signal

via the optoelectronic coupler.

During analog signal amplification signal transfer is interrupted in the event of pacemaker

pulses and the arithmetic mean value is transferred as a baseline in place of the ECG

signal. The digital data are generated 1000 times a second from each of the transferred

amplitude values.

ECGs up to max. ±4.5 mV are digitized completely.

Three-lead patient cables provide only one ECG lead (lead I, II or III) on channel 1, connecting a five-lead cable enables EAGLE 100X to provide one lead each on two channels.

The options are leads I, II, III, AVR, AVL, AVF, V.

Page 39

GE Medical Systems EAGLE 1000 Page 39

Information Technologies Servicing Instructions 227 468 01 Rev. G

Heart rate monitoring

A QRS detector in the ECG circuit detects the beats. This detector filters and triggers the

signal components typical of QRS from the channel 1 ECG signals when their amplitude is

greater than a threshold value arising in the prior amplitudes.

The processor receives a signal for every beat detected by the ECG circuit, calculates the

heart rate from these and triggers an alarm when the heart rate is outside the programmed

limits.

Pacing detection

Signal segments with a steep rising or falling edge are suppressed as long as their amplitude exceeds a value of 6 mV. This suppression is limited to a time period of about 50 ms.

During this period the baseline is recorded and a pacing-pulse message is passed on to

the processor, which puts a marker for this event on the display.

Page 40

GE Medical Systems EAGLE 1000 Page 40

Information Technologies Servicing Instructions 227 468 01 Rev.G

2.2.8.2 ECG/Pace Preprocessing

SR

+12 V

Processor

SR_ON

SW. Regulator

Status

Reg.

HR

TRIG.

Dir.

Pace

Pace

ECG1

PACE

DETECT

+BLOCK

QSPI

Gain

Offset

ECG 2

ADC

OPTO ISOL.

3.6 MHz

~

Gain

Offset

Reg

Control

-7.5 V

+5 V

+7.5 V

Lead Fault

Detection

Pat. Cable

coding

Codes

ECG 1

Electrode Ampl.

ECG 2

Lead Selector

Protective circuit

3/5 Electrodes

Page 41

GE Medical Systems EAGLE 1000 Page 41

Information Technologies Servicing Instructions 227 468 01 Rev. G

2.2.9 PCB MP 204 Oximeter 930 117 26

2.2.9.1 Function

The PCB Oximeter acquires and automatically processes the Sp02 signal. Via an inter

nal asynchronous connection it passes the data on oxygen saturation and pulse rate on

to the PCB ECG Monitor. The entire PCB Oximeter is floating (CF). The floating separation for power supply and communication is located on the PCB ECG Monitor.

2.2.9.2 Figure of pcb MP204 Oximeter

V

JP1

JP5

AH

388 031 19

Lpl MP204-Oxymeter Board

930 117 26

Page 42

GE Medical Systems EAGLE 1000 Page 42

Information Technologies Servicing Instructions 227 468 01 Rev.G

2.2.9.3 Pin assignment

Sensor interface connector pin assignment (JP1)

Pin 1: Anodes (detector)

Pin 2: no connection

Pin 3: no connection

Pin 4: Cathode (detector shield) shield

Pin 5: ground (RCAL return)

Pin 6: RCAL

Pin 7: -LED

Pin 8: no connection

Pin 9: +LED

Pin 10: ground

Host interface pin assignment (JP5)

Pin 1: VCC (+5V)

Pin 2: ground

Pin 3: ground

Pin 4: +7.5V

Pin 5: ground

Pin 6: -7.5V

Pin 7: unused

Pin 8: TX Transmit data (output from module)

Pin 9: RX Receive data (input to module)

Pin 10: CTS_ Clear to send (input to module, active low)

Pin 11: RESET_ (Reset input, active low)

Pin 12: ground

Pin 13: ECG sync input, active high

Pin 14: ground

Page 43

GE Medical Systems EAGLE 1000 Page 43

Information Technologies Servicing Instructions 227 468 01 Rev. G

2.2.10 Non-invasive blood pressure module

2.2.10.1 Function

The PCB NBP acquires and automatically processes the non-invasive blood pressure

signal. Via an internal asynchronous connection it passes the non-invasive blood pressure data on to the PCB ECG Monitor. From here it receives a reset signal as well as a

separately controlled pump power supply for safety reasons. The PCB is not electrically

isolated as isolation is effected by the pneumatic signal input.

Warning: For safety requirements, when replacing the PCB it is important to use

the flat strip cable of correct length to match the version used.

Page 44

GE Medical Systems EAGLE 1000 Page 44

Information Technologies Servicing Instructions 227 468 01 Rev.G

2.2.10.2 Figure of PCB NBP Module NB11: 930 117 15

Use wire set 383 273 30

PCP NBP Module NB11

Page 45

GE Medical Systems EAGLE 1000 Page 45

Information Technologies Servicing Instructions 227 468 01 Rev. G

2.2.10.3 Figure of PCB NBP 2000 Module 930 117 93 or 388 032 60

Use wire set 383 273 65

Page 46

GE Medical Systems EAGLE 1000 Page 46

Information Technologies Servicing Instructions 227 468 01 Rev.G

2.2.10.4 Pin assignment

NBP pin connections to PCB ECG Monitor

Plug-in connector 2 rows of 5 pins

1 +7 V

2 +7 V

p

p

Pump power supply, host-controlled

Pump power supply, host-controlled

3 + 7V Power supply for PCB NBP

4 GND

5 GND

6 GND

7 KEY Plug coding

8 RESET Reset, host-controlled

9 Rx Receive

10 Tx Transmit

Page 47

GE Medical Systems EAGLE 1000 Page 47

Information Technologies Servicing Instructions 227 468 01 Rev. G

2.2.11 PCB Press-Temp 388 031 75/PCB Temp 388 032 04

General information

The PCB PRESS-TEMP enables measurement of the two electrically isolated parameters

temperature (one temperature) and invasive blood pressure (two pressures,both isolated

together). These parameters are connected along with the ECG to the processor by means of a QSPI interface. The signals are isolated by optoelectronic couplers.

The power supply is fed in via one HF transformer each for PRESS and TEMP from a

common oscillator, which also supplies power to the ECG circuit and the SpO2 module.

See block diagram Floating system supply and signal flow.

The PCB is equipped with precision components (and an adjustment program in the case

of TEMP) so that a potentiometer adjustment is not required.

The individual floating measurement circuits are shielded on both sides of the PCB by a

metal cover. For PCBs which do not have an insulating cover over the two floating parts

the PCB is underlayed with a sheet of insulating foil. These insulation precautions are

important for safety reasons!

2.2.11.1 PRESS module

The circuit is described in the block diagram Press block diagram.

Power supply

The floating power supply for PRESS uses an HF transformer connected in parallel with

the other floating transformers. The corresponding oscillator delivers a closed-loop controlled transformer output voltage, which may vary somewhat depending on the load, from the

unregulated battery voltage. This supplies the amplifier and the connection detector with

±7.5 V.

The ADC and digital circuit are supplied by a voltage controller with a stabilized 5 V, in the

form of an analog and a decoupled digital power supply. When the 5V power supply drops

below 4.75 V an error signal interrupts the chip select to ADC so that no incorrect parameter readings can be transferred.

Probe detection

Each PRESS channel is assigned an ID by means of a resistor coding system which, even

in operation via an adapter, informs the system which channel the probe is connected to or

whether two probes are connected up. This is transmitted to the pro

cessor by a probe ID amplifier as an analog signal via the ADC.

If no probe is connected, this is detected by the probe connection comparator and dis

ables the 5V power supply to save power. The processor is informed of this by the MISO

signal being reset to zero (optoelectronic coupler under continuous current).

Page 48

GE Medical Systems EAGLE 1000 Page 48

Information Technologies Servicing Instructions 227 468 01 Rev.G

ADC operation

The ADC receives all the information and transfers the parameter readings via a

bidirectional serial interface. Although this provides a clock to operate the interface

functions, it does not provide the clock for conversion. This is obtained as a local asyn

chronous signal from a 4MHz oscillator, whose output is divided into two times 2 MHz.

PRESS amplifier

An integrated precision instrument amplifier acts as an amplifier for the pressure signaling

each channel, which amplifies the signal by a factor of approx. 200 and has an earthed

neutral over ¼ of the ADC range. A signal feedback to the input capacitors maintains the

common mode rejection.

12 Hz filter

Downline from the amplifier there is one 12V low-pass filter each. This filter is a Bessel

low-pass Grade II filter so that jumps in pressure are transferred exactly as registered.

2.2.11.2 Temp module

The circuit is shown in the block circuit diagram Temperature block diagram.

Power supply

The floating power supply for TEMP uses an HF transformer connected in parallel with

the other floating transformers, from the unregulated battery voltage. The corresponding

oscillator delivers a closed-loop controlled transformer output voltage, which may vary

somewhat depending on the load. This supplies the amplifier and the connection detector

with ±7.5 V.

The ADC and digital circuit are supplied by a voltage controller with a stabilized 5 V, in the

form of an analog and a decoupled digital power supply. When the 5V power supply drops

below 4.75 V an error signal interrupts the chip select to ADC so that no incorrect parameter readings can be transferred.

Probe detection

If no probe is connected, this is detected by the probe connection comparator with 3

threshold values, which differ between Hellige and Marquette front panel connectors,and

disables the 5V power supply to save power. The processor is informed of this by the

MISO signal being reset to zero (continuous current to optoelectronic coupler).

Page 49

GE Medical Systems EAGLE 1000 Page 49

Information Technologies Servicing Instructions 227 468 01 Rev. G

ADC operation

The ADC receives all the information and transfers the parameter readings via a

bidirectional serial interface. Although this provides a clock to operate the interface functions, it does not provide the clock for conversion. This is obtained as a local asynchronous signal from a 4MHz oscillator, whose output is divided into two times 2 MHz.

TEMP amplifier

An integrated precision instrument amplifier acts as an amplifier for the temperature signal, which alternately receives the measurement signal from the temperature halfbridge, two control values and a reference value for offset correction from the precision

resistor network via a multiplexer. The multiplexer is controlled along with the ADC of the

serial interface by a PAL.

2.2.11.3 Internal interfaces

Mechanical interfaces

The PCB PRESS-TEMP is plugged into the PCB ECG Monitor mechanically. The floating

power supply, i.e., the oscillator connections and the QSPI signal paths to the processor

are via this plug-through connector. This is located at the middle of the floating section of

the PCB.

Electronic interfaces

Internal communication is mediated by a QSPI interface.

JJ/1 SCLK Serial clock

JJ/2 MOSI Master Out Slave In signal

JJ/3 PCS2_ Chip select PRESS

JJ/4 PCS3_ Chip select TEMP

JJ/5 MISO Master In Slave Out signal

JJ/6 JJ/7 +5 V

JJ/8 GND

JJ/9 +12 VH Transformer power supply

JJ/10 SR_VSW Transformer power switch

Page 50

GE Medical Systems EAGLE 1000 Page 50

Information Technologies Servicing Instructions 227 468 01 Rev.G

2.2.11.4 Interfaces to peripherals

Mechanical interfaces

There is an interface for the patient connections of the three connectable probes (2 x

PRESS, 1 x TEMP).

PRESS:

The measurement input to the two pressure amplifiers is connected floating to the front

panel via the elbow plug-in connector P1 top right along the shortest path via ferrite toroidal cores.

The single pressure input of the system with HELLIGE connectors only permits one pressure transducer to be connected directly to PRESS1. Two invasive pressures can be

measured by inserting an adapter bearing two transducer interfaces to this system input.

This can be affixed to the system using a Velcro strip.

TEMP:

The measurement input to the temperature amplifier is connected floating to the front

panel on the other opposite side via the coded left-hand plug-in connector and ferrite

toroidal cores.

Electronic interfaces

PRESS:

The PRESS channels are identified by resistor coding, even when an adapter is interposed in systems with a Marquette Hellige connector. Data transfer is on channel 1 of the

ADC.

TEMP:

In model versions with Marquette Hellige round connectors the jack plug socket is scanned for the position of the normally closed contact to detect the presence of the probe