Page 1

OPERATIONS AND MAINTENANCE MA

NUAL

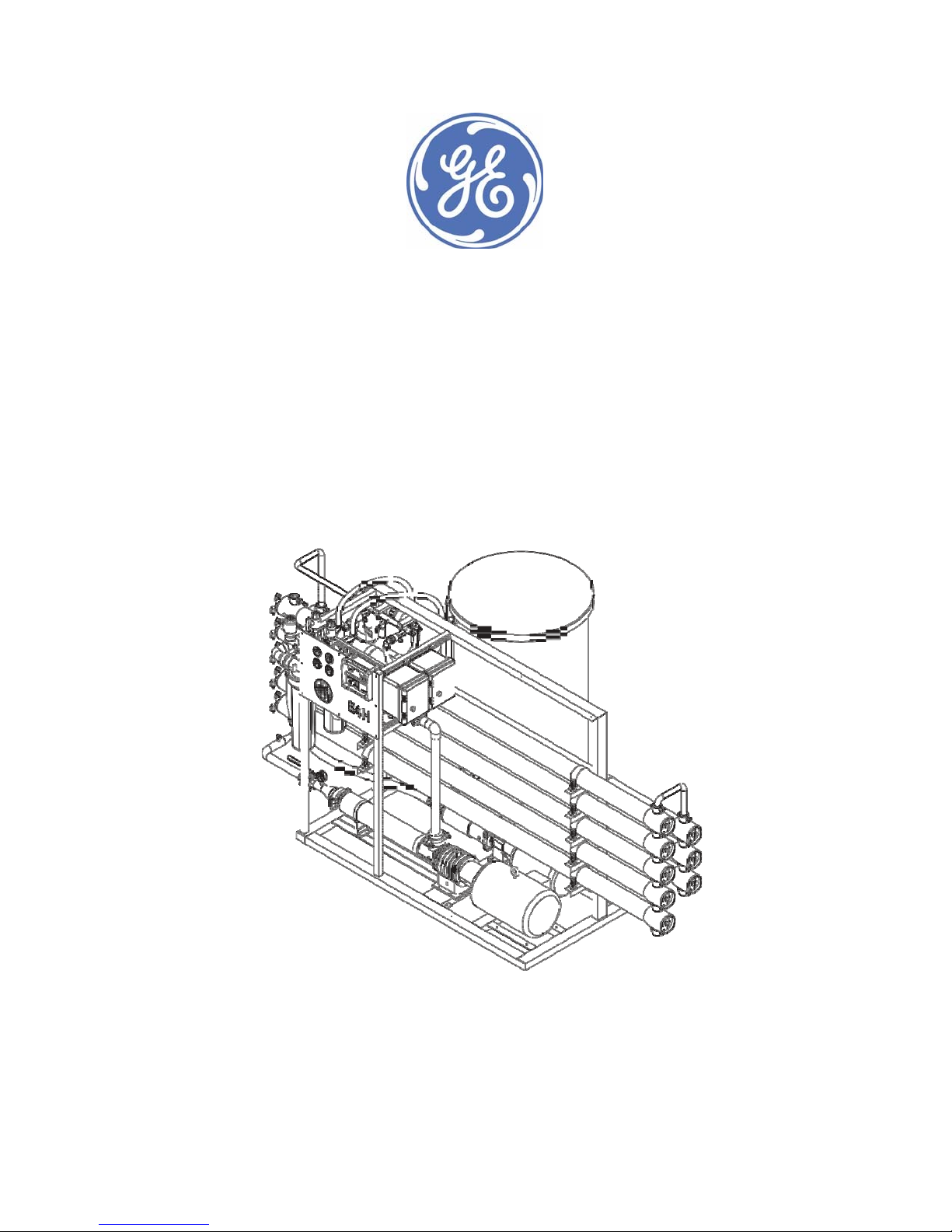

E4H Series Water Purification Machines

16,000 GPD to 43,200 GPD

60.6 m3/day to 163.5

m3/day

The enclosed materials are considered proprietary property of GE Water & Process Technologies. No assignments, either implied or expressed, of

intellectual property rights, data, know-how, trade secrets or licenses of use thereof are given. All information is provided exclusively for the addressee for

the purposes of evaluation and is not to be reproduced or divulged to other parties, nor used for manufacture or other means, or to authorize any of the

above, without the express written consent of GE Water & Process Technologies. The acceptance of this document will be construed as an acceptance of

the foregoing conditions. * Trademark of General Electric Company; may be registered in one or more countries.

NOTICE

Page 2

Operations and Maintenance Manual

E4H Series Water Purification Machines

Table of Contents

1. DESCRIPTION ...................................................................................................................................................................... 5

1.1 Definitions .......................................................................................................................................................................... 5

1.1.1 Permeate Rate (Product Water Rate) [Qp] ...................................................................................................... 5

1.1.2 Concentrate Rate (Reject Rate) [Qc] .................................................................................................................. 5

1.1.3 Feed Rate [Qf ] .............................................................................................................................................................. 5

1.1.4 Reverse Osmosis (RO) ............................................................................................................................................... 5

1.1.5 Membrane Elements ................................................................................................................................................ 6

1.1.6 CIP ...................................................................................................................................................................................... 8

1.1.7 Average Pressure [PAVG] ....................................................................................................................................... 8

1.1.8 Concentration ............................................................................................................................................................... 8

1.1.9 Salt (Ionic) Passage .................................................................................................................................................... 8

1.1.10 Recovery ....................................................................................................................................................................... 8

1.1.11 Salt (Ionic) Rejection ................................................................................................................................................ 8

1.2 Flow Description .......................................................................................................................................................... 10

1.3 Machine Nomenclature ............................................................................................................................................ 10

1.4 Economy (ECN) Model and Deluxe (DLX) Model Options .......................................................................... 11

1.4.1 ECN Model ................................................................................................................................................................... 11

1.4.2 DLX Model .................................................................................................................................................................. 12

1.5 Specifications for E-Series Machines ................................................................................................................. 13

1.5.1 Feed Water Specifications .................................................................................................................................. 13

1.5.2 Permeate Flow Rate ............................................................................................................................................... 14

1.5.3 Concentrate Flow Rate ......................................................................................................................................... 14

1.5.4 Operating Final Pressure ...................................................................................................................................... 14

2

Page 3

Operations and Maintenance Manual

E4H Series Water Purification Machines

1.5.5 Pump .............................................................................................................................................................................. 14

1.5.6 RO Membrane Rejection ....................................................................................................................................... 14

2. INSTALLATION ................................................................................................................................................................ 16

2.1 Mounting .......................................................................................................................................................................... 16

2.2 Piping ................................................................................................................................................................................. 17

2.3 Electrical........................................................................................................................................................................... 17

2.3.1 ECN Electrical System ............................................................................................................................................ 17

2.3.2 DLX Electrical System ............................................................................................................................................ 18

3. PREPARATION AND START-UP................................................................................................................................ 19

3.1 Pretreatment for Water Purification .................................................................................................................. 19

3.2 Start-Up ............................................................................................................................................................................ 20

4. OPERATION AND MAINTENANCE .................................................................................................................................... 26

4.1 Daily Log Sheets ..................................................................................................................................................................... 26

4.2 Pre-Filter ..................................................................................................................................................................................... 26

4.3 Flushing ...................................................................................................................................................................................... 27

4.4 Cleaning ..................................................................................................................................................................................... 28

4.4.1 CLEANING PROCEDURE FOR DLX AND ECN

4.5 Draining Machine for

4.6 Membrane

4.7 Membrane

5. OPTIONAL

5.1 Standard

I

nstallation ............................................................................................................................................... 30

Replacement

A

CCESSORIES

Options ........................................................................................................................................................... 33

Storage/Shipment

........................................................................................................................................... 32

................................................................................................................................................... 33

......................................................................................................... 30

MODELS:

...................................................................... 28

5.2 External

5.3 Filters and Water

5.4 Storage

Controls ........................................................................................................................................................... 34

Softeners .................................................................................................................................... 34

Tanks .................................................................................................................................................................. 34

3

Page 4

Operations and Maintenance Manual

E4H Series Water Purification Machines

6. TROUBLESHOOTING

7. SPARE PARTS

8. RETURN GOODS AUTHORIZATION (RGA)

9.

WARR

ANTY/GUAR

9.1 Machine

Warranty/Guarantee .............................................................................................................................. 46

9.2 Desal* Membrane Element Workmanship

10. OPERATING

LOGS

10.1 START-UP

............................................................................................................................................................. 35

LIST .................................................................................................................................................................. 42

PROCEDURE ...................................................................................... 44

ANTEE ................................................................................................................................................... 46

Warranty

............................................................................... 47

................................................................................................................................................................ 50

DATA

............................................................................................................................................................. 50

10.2 DAILY LOG FOR GE WATER & PROCESS TECHNOLOGIES MEMBRANE

List of Tables

Table 1. 1: Flow Specifications for E4H Machines, 50-75% Recovery

.................................................................. 13

MACHINES .................... 51

Table 1. 2: Feed Water Requirements

Table 1. 3: Membrane Element Specifications –

..................................................................................................................................... 13

AG4040F

......................................................................................... 15

*

Table 2. 1: Connection Schedule ................................................................................................................................................. 17

Table 6. 1: Troubleshooting Guide .................................................................................................................................................. 35

List of Figures

Figure1. 1: Normal vs. Crossflow Filtration ............................................................................................................................... 6

Figure1. 2: Membrane Element with Interconnectors ............................................................................. ............................ 7

Figure1. 3: Cross-Sectional View of Membrane Element ................................................................................................... 7

Figure1. 4: Principle of Operation .................................................................................................................................................. 9

4

Page 5

Operations and Maintenance Manual

E4H Series Water Purification Machines

1. DESCRIPTION

Your E-Series reverse osmosis (RO) machine is a durable piece of equipment which, with proper

care, will last for many years. These instructions give operation and maintenance details vital

to the sustained performance of the machine. Please read this manual completely before

operating your machine.

1.1 Definitions

The operating definitions provided below will help you further understand yo

this manual.

1.1.1 Permeate Rate (Product Water Rate) [Qp]

The flow rate of

membrane

meters/hour (m

(25°C). Permeate rate will vary with temperature.

purif

ied water, which has passed through the membrane and out of the

element

, expressed in gal/min (gpm) or gal/hr (gph) or liter/min (lpm) or cubic

3

/h). Specified permeate rates are based on a feed water temperature of 77 °F

1.1.2 Concentrate Rate (Reject Rate) [Qc]

The flow rate of water containing rejected solids to drain in gpm or gph (lpm or m3/h).

1.1.3 Feed Rate [Qf ]

The flow rate of incoming water in gpm or gph (lpm or m3/h). Feed water rate equals permeate

rate plus concentrate rate.

ur

machine and

1.1.4 Reverse Osmosis (RO)

Reverse osmosis is the separation of one component of a solution from another component by

means of pressure exerted on a semipermeable membrane. In other words, reversing the

natural passage of a liquid from a concentrated solution to a more dilute solution by using

external pressure. Removal of ionic, organic, and suspended /dissolved impurities occurs

during the RO process. Unlike a filter, which separates by “normal” filtration, the membrane

element separates using a process called cross flow filtration. Feed water solution is

separated in to two streams, permeate and concentrate, and collected from both sides of the

membrane. A semipermeable RO membrane, under sufficient pressure, allows passage of

purified

water while rejecting and concentrating dissolved and suspended solids.

5

Page 6

Operations and Maintenance Manual

E4H Series Water Purification Machine

Figure1. 1: Normal vs. Crossflow Filtration

1.1.5 Membrane Elements

Membrane elements are the key to reverse osmosis. Interleaved layers of semipermeable

membrane, spacer and permeate carrier spiraled around a central permeate tube make up

element

the

the permeate carrier carries the purified water out of the membrane

Process Technologies manufactures a patented spiral wound membrane element with a

turbulent flow design. This membrane module collects the purified water within the central

tube, the permeate tube.

elements.

. The spacer allows for movement of the concentrate past the membrane, and

element

. GE Water &

The E4H RO machine utilizes between 9 and 24 membrane

6

Page 7

Operations and Maintenance Manual

E4H Series Water Purification Machine

Figure1. 2: Membrane Element with Interconnectors

Figure1. 3: Cross-Sectional View of Membrane Element

7

Page 8

Operations and Maintenance Manual

E4H Series Water Purification Machine

1.1.6 CIP

The abbreviation for clean-in-place.

1.1.7 Average Pressure [PAVG]

(

P

Primary

+ P

Final

)

2

1.1.8 Concentration

Concentration equals the Total Dissolved Solids (TDS) concentration of a solution expressed

as parts per million (ppm) or conductivity (microSiemens/cm).

= Feed Concentration

C

f

= Permeate Concentration

C

p

C

= Concentrate Concentration

c

C

= Average Concentration in Machine

avg

1.1.9 Salt (Ionic) Passage

The percent of dissolved salts passed through the membrane or 100% minus rejection.

1.1.10 Recovery

Permeate rate divided by feed rate, expressed as a percentage. For example, 33% recovery

means that for a given feed rate, 33% is produced as purified water (permeate).

1.1.11 Salt (Ionic) Rejection

The percent of dissolved salt rejected by the membrane, calculated from an average

concentration over the membrane.

8

Page 9

Operations and Maintenance Manual

E4H Series Water Purification Machine

An example of how to calculate salt rejection and recovery is given below.

Figure1. 4: Principle of Operation

Given the system case in the figure above:

CC

Average Concentration,

CC

Rejection

Passage

Recovery

C

C

Avg

Q

Q

C

Avg

p

237.5mg/L

p

100

f

pAvg

8.3mg/L

C

Avg

100

18gpm

24gpm

cf

2

237.5mg/L

375mg/L100mg/L

TDS 237.5mg/L

2

8.3mg/L237.5mg/L

%5.96100

%5.3100

%75100

9

Page 10

Operations and Maintenance Manual

E4H Series Water Purification Machine

1.2 Flow Description

The feed water passes through a replaceable 5-micron cartridge filter, which removes bulk

suspended solids. Filtered water then flows to the inlet control valve.

This solenoid-controlled diaphragm valve is wired to the on/off switch and opens when the

machine is turned on, allowing water to flow to the pump

off, the valve closes, preventing non-turbulent flow through the membrane elements, which

would lead to shortened membrane life.

The pump feeds water to the membrane housings arranged in parallel and serial

combinations. A throttling valve is included on the pump discharge for manual adjustment

of the pump pressure. The direction of water flow is indicated by an arrow on each housing.

Water is separated by the membrane within the membranes and leaves the housings in two

streams: permeate and concentrate.

Permeate from each membrane housing is collected in a common manifold. The permeate

then flows through a flow meter and to the outlet point of the machine.

inlet.

When the machine is turned

The concentrate leaves the last membrane housing and flows to the flow control center

(recycle/concentrate manifold). At this point, the recycle valve channels a predetermined

amount of concentrate into the pump inlet. Recycle increases recovery while maintaining

adequate cross-flow through the membranes. The other two ports of the flow control center

lead to the concentrate valve and final pressure gauge. The concentrate valve has three

functions: It controls the amount of concentrate flowing to the drain; it controls the pressure

within the machine; and it helps control the system recovery. A feed flush solenoid is added

to the flow control center with an additional tee. The concentrate then flows through a flow

meter and to the outlet point of the machine.

1.3 Machine Nomenclature

E-Series water purification machines are numbered in such a way as to indicate the

permeate flow you can expect from the machine and other specifications.

10

Page 11

Operations and Maintenance Manual

E4H Series Water Purification Machine

Example: RO,E4H-21K-DLX, 460, 6, 50-75

• RO indicates the machine is a reverse osmosis machine.

• E4H indicates the machine series (E) and 4-inch housings/membrane elements

• H indicates horizontal membrane element housing configuration

• 21K indicates the rated permeate flow in thousands of gallons per day at 77°F (25°C),

i.e. 21K = 21,000 gallons per da

y

• DLX indicates the deluxe model and ECN indicates the economy model

• 460 indicates 460 VAC, 3-phase voltage to starter. Standard models offer 460 VAC, 60

Hz, 3-phase, 230 VAC, 60 Hz, 3-phase, and 380 VAC, 50 Hz, 3-phase.

• 6 indicates 60 Hz operation, (50 Hz operation is also available and is indicated b

place of the 6.

• 50-75 indicates a recovery range of 50 to 75%.

1.4 Economy (ECN) Model and Deluxe (DLX) Model Options

1.4.1 ECN Model

E-Series ECN model water purification machines have all the features necessary for safe,

continuous production of high purity water. This assumes good quality feed water, adequate

pretreatment and regular operator maintenance, each shift or dai

sy

stem.

• 50% to 75% recover

• Multi-stage centrifugal pump, SS construction (stainless steel castings with Noryl*

Stages)

• Base model electrical package includes NEMA-1 enclosure with a 110 VAC, 60 Hz or

220 VAC, 50 Hz single-phase control circuit; applies to all ECN models

y

y

a 5 in

ly

, to the operation of the

• Automatic inlet shutoff valve

11

Page 12

Operations and Maintenance Manual

E4H Series Water Purification Machine

• Pre-filter housing and 5-micron cartridge filter

• Pre-filter, post-filter, primary and final pressure gauges

• Concentrate and permeate flow rotameters

• Pump throttling valve

• Digital conductivity monitor, panel-mounted, for permeate quality monitoring

• Feed flush System - programmable, automated high-velocity membrane flushing for

the longest membrane life; set at the factory and adjustable in the field

• Gauges, valves and rigid piping of stainless steel or plastic

• Fiberglass reinforced plastic (FRP) membrane housing, with Noryl end caps

• Stainless steel concentrate and recycle valves

• All components in contact with the purified water (permeate) are either FDAacceptable plastic (nylon, Noryl, polypropylene, PVC) or stainless steel materials.

• All high pressure fittings are 304 stainless steel.

• Alarms included: low inlet pressure and motor fault

1.4.2 DLX Model

The DLX package contains all of the above ECN standard features along with an AccuTrak®

RO solid state controller.

• Electrical package includes AccuTrak® RO controller

• Chemical dosing system for antiscalant or pH adjustment

• Clean-In-Place (CIP)

• Digital flow meter and conductivity sensor

• Analog pH sensor on inlet

sy

stem

• Alarms included: low inlet pressure, high permeate pressure, high/low inlet pH, high

temperature, high permeate conductivity, f ill-time exceeded, and motor fault

12

Page 13

Operations and Maintenance Manual

E4H Series Water Purification Machine

1.5 Specifications for E-Series Machines

The machine flow specifications listed in Table 1.1 below are based on 77°F (25°C) and 2,000 ppm

NaCl.

Table 1. 1: Flow Specifications for E4H Machines, 50-75% Recovery

Mode

l

U

nit

s

Permeate Rate

C

oncentrat

Rat

e

Feed Rate

E4H-16K

gpm (m3/h) gpm (m3/h) gpm (m3/h) gpm (m3/h) gpm (m3/h)

11.2 (2.56) 15 (3.4)

11.2-3.7

e

(2.5-0.8)

22.4-14.9

(5.1-3.4)

1.5.1 Feed Water Specifications

The feed water requirements stated in the following table must be met to ensure quality

permeate and extended membrane element life.

Temperatur

Inlet Pre

e

ssure

E4H-21K

15-5

(3.4-1.1)

30-20

(6.8-4.5)

E4H-27K

18.8 (4.3)

18.8-6.3

(4.3-1.4)

37.6-25.1

(8.5-5.7)

Table 1. 2: Feed Water Requirements

Typical: 50-85°F (10-29°C)

Maximum: 32-104°F (0-40°C)

Minimum 30 psig (2.1 bar)

Maximum 60 psig (4.1 bar)

E4H-38K

26.2 (5.9) 30 (6.8)

26.2-8.7

(5.9-2.0)

52.4-34.9

(11.9-7.9)

E4H-43K

30-10

(6.8-2.3)

60-40

(13.6-9.1)

Chlorine (continuous feed)

Operating

p

H

Silt Density Index (SDI

0 ppm

For soft water (less than 1 grain per gallon (gpg) or 17 mg/L hardness),

acceptable pH is 4.0-11.0.

For unsoftened water contact factory with water analysis, acceptable pH

is 5.5-6.0.

For short term (cleaning) a pH range of 2-12 is acceptable.

)

Less than or equal to 3 to minimize membrane fouling and extend cleaning

intervals. Refer to ASTM standard D4189.

13

Page 14

Operations and Maintenance Manual

E4H Series Water Purification Machine

1.5.2 Permeate Flow Rate

Stated in Table 1.1 above and on the machine serial number label (assumes no permeate

backpressure, 2000mg/L TDS maximum feed concentration, and rated temperature).

To estimate permeate output with backpressure, use the formula below:

Maximum permeate backpressure is 80 psig (5.5 bar).

re)Backpressu (Permeate-Pressure) (Operating

Label) on Flow (Permeate

Pressure) (Operating

1.5.3 Concentrate Flow Rate

Stated in Table 1.1 and factory set as stated on serial number label.

1.5.4 Operating Final Pressure

Minimum - 200 psig (13.8 bar)

Maximum - 235 psig (16.2 bar)

1.5.5 Pump

Multi-stage centrifugal; approximate primary operating pressure of 190 psig (13.1

bar) excluding line pressure.

1.5.6 RO Membrane Rejection

E4H reverse osmosis machines use GE fiberglass reinforced plastic (FRP) covered

AG4040F membrane elements. For ordering information refer to the attached Spare

Parts List. See Table 1.3 below for details.

14

Page 15

Operations and Maintenance Manual

E4H Series Water Purification Machine

Table 1. 3: Membrane Element Specifications –

Outer Cover Materia

l

FRP

AG4040F

*

Typical Ionic Rejection (TDS)*

Nominal Permeate Flow Rate at 225 ps

i

Typical Feed Water Temperature Range

Maximum Temperature

pH Range

Chlorine Tolerance

Active Membrane Are

a

99.0 – 99.5%

2,200 gpd (8.

50 – 85°F (10-29.4C)

122°F (50C)

4.0 – 11.0

< 0.01 ppm

85 ft2 (7.9 m2)

3m3/day)

*Specification is based on a 2,000 mg/L NaCl solution at 225 psi (1,551 kPa) operating pressure, 77°F

(25°C), pH 7.5 and 15% recovery. Individual flux may vary +25%/-15%. Average salt rejection after a

minimum of 24 hours of continuous operation.

15

Page 16

Operations and Maintenance Manual

E4H Series Water Purification Machine

2. INSTALLATION

2.1 Mounting

E4H Series machines are equipped with a stand-alone frame, which supports the machine. At

least 45 inches (114 cm) of space should be allowed on each end of the membrane element

housings for removal and loading of membrane elements. If 45 inches (114 cm) are not

available, the entire membrane element housing may need to be removed for membrane

element replacement.

WARNING!!

A vacuum breaker must be installed at the highest point along the

concentrateline.Failuretodosomaycauseavacuumtoformwithinthis

line after shutdown. This may in turn cause numerous problems,

including biological fouling, water hammer, leaks from RO housing side‐

ports,andthe

siphoningoftreatmentchemicals.

WARNING:

Connect the concentrate line to the RO machine’s concentrate outlet. A vacuum breaker must

be installed at the highest point along the concentrate line. This provides an atmospheric

break upstream from where the flow enters the drainage system. For systems which include

multiple RO machines, install check valves along each machine’s concentrate line prior to

connecting the lines to a common manifold.

16

Page 17

Operations and Maintenance Manual

E4H Series Water Purification Machine

2.2 Piping

The E4H comes with threaded NPT fittings. A CIP system is supplied with the DLX Model E4H.

Table2.1:

Connection Schedule

Mode

Inle

t

Permeat

Concentrat

CIP Drain (DLX only)

2.3 Electrical

The DLX and ECN E-Series models are supplied with a single-phase, 110 VAC 60 Hz or 220 VAC

50 Hz control circuit. Refer to your machine electrical single-line drawing for dedicated circuit

requirements.

The electrical system control circuit is separate from the motor voltage. Therefore, two supply

voltages are required for electrical wiring in the field, the control circuit voltage and a separate

three-phase motor voltage. All field wiring must comply with applicable local and national

electric codes.

l

e

e

E4H-16K

1.5-inch 1.5-inch 1.5-inch 1.5-inch 1.5-inch

1.0-inch 1.0-inch 1.0-inch 1.0-inch 1.0-inch

1.0-inch 1.0-inch 1.0-inch 1.0-inch 1.0-inch

1.5-inch 1.5-inch 1.5-inch 1.5-inch 1.5-inch

E4H-21K

E4H-27K

E4H-38K

E4H-43K

2.3.1 ECN Electrical System

• A panel mounted power on/off switch is provided on the electrical enclosure.

• Connect the control circuit power cord to 110 VAC, 60 Hz, or 220 VAC, 50 Hz, single

phase power.

• Connect the three-phase power in to the motor starter 3-pole contacts (230/460 VAC

or 380 VAC as appropriate). Ensure that the power supplied matches the motor voltage and

phase requirements. Check the tag (located on the motor starter) that indicates the factory

wiring. A separate, fused disconnect for the motor wiring is required with proper protection for

the HP and amp draw of the RO and CIP motors (provided by others). Please refer to singleline drawing for further detail.

17

Page 18

Operations and Maintenance Manual

E4H Series Water Purification Machine

2.3.2 DLX Electrical System

• The DLX series E4H’s include the AccuTrak® RO solid state controller. The AccuTrak

includes a menu screen for selecting the operation mode of the RO. The RO must be in either

“Auto” or “Hand” position for the high pressure pump to start.

• Connect the control circuit power to 110 VAC, 60 Hz, or 220 VAC, 50 Hz, single phase

power.

• Connect the three-phase power in to the motor starter 3-pole contacts (230/460 VAC

or 380 VAC as appropriate). Ensure that the power supplied matches the motor voltage and

phase requirements. Check the tag (located on the motor starter) that indicates the factory

wiring. A separate, fused disconnect for the motor wiring is required with proper protection for

the HP and amp draw of the RO and CIP motors (provided by others). Please refer to singleline drawing for further detail.

18

Page 19

Operations and Maintenance Manual

E4H Series Water Purification Machine

3. PREPARATION AND START-UP

3.1 Pretreatment for Water Purification

All systems will operate most efficiently on filtered water with a pH of less than 6.5 and a Silt

Density Index (SDI) of 3 or below. If the machine is operated on higher pH water, other forms of

pretreatment may be necessary. A water analysis prior to start-up of the machine is required.

To minimize the chances of calcium carbonate, calcium sulfate, or other salt precipitation on

the membrane, GE Water & Process Technologies strongly suggests that each application and

water condition be evaluated so that specific recommendations can be made to ensure

continuity of the membrane warranty. Data from the water analysis is processed with a

computer program analysis to determine if potential problems exist. If the machine is to be run

at a different location than was originally intended, a new water analysis is required for

warranty consideration and should be sent to GE Water & Process Technologies for review and

recommendations for operation of the machine.

Before entering the machine, the feed water must be filtered to 5-microns.

TFC membrane feed water must not contain the following chemicals or permanent loss of

rejection and/or permeate flow may result:

• Free chlorine

• Formalin (until after a membrane has been run for 24 hours; thereafter, 0.5%formaldehyde may be used as a biocide)

• Iodine compounds

• Quaternary germicides

• Cationic surfactants

• Detergents containing non-ionic surfactants

Cleaners not approved by GE Water & Process Technologies

A water softener should not regenerate while the machine

running unless safeguards are used to be sure the machine

operated on softened water during regeneration

is

is

.

Caution!

19

Page 20

Operations and Maintenance Manual

E4H Series Water Purification Machine

3.2 Start-Up

NOTE

1. Re-check the function and integrity of your pretreatment equipment. Ensure that

your water softener, activated carbon filters and iron filters (where applicable) have

been leak-checked, backwashed, and thoroughly rinsed for service before starting

up your RO unit.

If your machine is provided with the membranes installed in

the housings, proceed to step 1. If your machine is provided

with the membranes in shipping boxes, you must load the

membranes in the housings prior to starting the machine.

For

membrane loading

completion of membrane

to continue your start-up procedure.

instructions,

installation,

skip to Section 4.6. Upon

return to section 3.2

2. Attach the feed water pipe to the inlet of the machine.

3. Check for leaks at all connection points.

4. Turn on the feed water gradually and check for leaks in the inlet piping. No flow

should go through the machine while the power is off and the inlet solenoid is in the

closed position.

When the machine is off, there should never be flow through the

machine. Flow through the machine when it is off can damage the

membranes, and the inlet solenoid m u s t b e

repaired

NOTE

5. Attach tubing from permeate and concentrate outlet points, and run the tubing to

drain.

6. Ensure that you have made provisions for both voltages required to operate

machine. The machine requires two power sources: (1) the high voltage for the motor

operation, and (2) the control circuit power supply. The motor electrical service must be

field-wired directly into the motor starter on the machine. Bring your motor service

wiring to the 3-pole contacts on the motor starter. Check the voltage label to ensure

that you have brought the correct voltage to the starter.

y

our

7. Be sure the power to the motor starter is de-energized.

20

Page 21

Operations and Maintenance Manual

E4H Series Water Purification Machine

8. With the machine in the OFF position, connect the 110 VAC (or 220 VAC 50 Hz) wiring.

9. Open your concentrate and recycle flow control valves two complete turns. These

valves are positioned on the flow control center of the machine. This piping is located

on the left section of the machine, near the membrane housings. The flow control

center features a concentrate flow control valve, a recycle flow control valve, and a

pressure gauge sensor tubed into the panel-mounted pressure gauge.

The feed flush valve is positioned in this flow control center.

NO

TE

The proper adjustment of these valves is critical to the operation of the RO machine.

The concentrate valve determines the amount of rejected water leaving the machine,

and creates the operating pressure shown on the pressure gauge. The recycle valve

returns reject flow back into the inlet stream to the RO pump. It is important to

balance the operating pressure and the respective flows of these valves to ensure

that your machine is operating correctly. It is also important to understand the

relationship of these two valves, the pressure gauge, and your RO pump. The pump

has a fixed amount of flow produced, and the valves are the control devices to

distribute this fixed flow amount. The pressure gauge is an indicator of applied

membrane pressure, at the flows set by the valves.

10. For ECN machines (skip to step 14 for DLX) - Turn the panel switch to the ON

position. Water will begin to flow through the machine at this point, but the pump will

not start. Allow the machine to operate in this manner for 10 minutes, to purge the

air out of the machine.

NOTE

11. As your machine is filling check for leaks and repair as needed.

The high-pressure pump should not be operating at this time.

21

Page 22

Operations and Maintenance Manual

E4H Series Water Purification Machine

12. Turn the panel switch to the OFF position.

13. Energize the power source to the motor starter. The pump should not operate at this

point. Skip to step 18 to continue with startup procedures.

14. For DLX machines – Energize the power source to the motor starter. The pump should

not operate at this point.

15. Select Fill mode on the AccuTrak® RO controller. Water will begin to flow through the

machine at this point but the pump will not start. Allow the machine to operate in this

manner for 10 minutes, to purge the air out of the machine. Verify alarm set points in

the AccuTrak® RO controller.

The factory alarm set points are as follows: (consult the AccuTrak® RO Multifunction

Water Treatment Controller Manual for operating instructions and additional

information).

Low Inlet Pressure 12 psig

High Permeate Pressure 80 psig

Permeate Conductivity 200 µS (microSiemen)

Low pH 4.0

High pH 8.0

pH Control 5.6-6.2

High Temperature 104°F (40°C)

16. As your machine is filling check for leaks and repair as needed.

17. Turn the AccuTrak® RO controller to the OFF position.

18. Check the rotation of the high pressure pump by briefly turning the RO S

Selector switch to the MANUAL position. Watch the motor, or coupling shaft, for

direction of rotation. The motor should rotate clockwise as one looks at the motor end

of the high pressure pump. If the motor is not rotating clockwise, change an

three leads (for three-phase) in the motor starter and recheck rotation. Always

y

two of the

turn the

power off to change any wiring.

y

stem

22

Page 23

Operations and Maintenance Manual

E4H Series Water Purification Machine

Operation of the pump backwards for even a short time can cause

damage to the pump.

Caution!

Turn the RO System Selector to the MANUAL position. The high-pressure pump will

operate and the machine will begin to build pressure. As you are operating, be sure to

watch the pressure gauge on the instrument panel. The machine is designed

at 220 psi (15.2 bar).

to operate

Do not allow the pressure to exceed 250 psi (17.3 bar). If the pressure

exceeds 250 psi (17.3 bar), open the concentrate flow control valve until

NO

TE

the pressure gauge shows 250 psi (17.3 bar) or less.

As the machine purges the air and fills with water, the pressure will gradually increase.

You should see water flowing through the permeate and concentrate flow meters. If you

do not see flow, turn the machine off and return to step 1.

NEVER ALLOW THE MACHINE TO OPERATE WITHOUT ADEQUATE WATER PRESSURE. THIS

CAN CAUSE SEVERE DAMAGE TO THE HIGH-PRESSURE PUMP.

19. Gradually close the concentrate flow control valve. As you close the valve, watch the

pressure gauge and your concentrate flow meter. Close the valve until

concentrate flow meter displays your design flow, and you do not exceed 250 psi

(17.3 bar). If you reach 250 psi (17.3 bar) before the valve is completely closed, open

the recycle flow control valve one full turn, then continue to close the concentrate

flow control valve. Continue to close the concentrate flow control valve until it is

completely closed and your pressure is below 250 psi (17.3 bar).

y

our

23

Page 24

Operations and Maintenance Manual

E4H Series Water Purification Machine

The concentrate flow control valve has a drilled orifice to ensure a predetermined

amount of flow and pressure in the closed position. This orifice is sized to operate the

y

machine at 75% recover

.

20. With the concentrate flow control valve fully closed and the pressure below 250 psi

(17.3 bar), gradually close the recycle flow control valve until the pressure reaches

250 psi (17.3 bar).

Your machine is now operating at the design pressure and flow rates in a 75%

recovery configuration. Your specific needs or conditions may dictate the need to

operate the machine at a lower recovery. If you wish to operate in a recover

y

configuration lower than 75%, step 19 will explain the necessary steps.

21. Your machine is equipped with flow meters and a pressure gauge that will assist you

in setting alternate flow rates for variable recoveries. If you wish to operate at a

recovery lower than 75% you must ensure that the flow rates for the permeate and

concentrate are at desired levels. Some minor adjustments in the concentrate and

y

recycle flow control valves may be necessar

.

y

See Table 1 for specified flow rates for various machine recoveries. When

ou have

selected your desired flow rate, gradually adjust the concentrate flow control valve

to achieve desired flow and use the recycle valve to bring the operating pressure up

to 250 psi (17.3 bar).

Once the desired flow rate is achieved [250 psi (17.3 bar) operating pressure] no

further valve adjustment is needed.

NO

TE

Permeate flow rates are dependent upon temperature

conditions at your site. Contact your dealer if you have an

questio

n

and

y

22. The system is now operational.

23. Before putting the machine into final operation, continue to run the permeate and

concentrate streams to drain for at least 30 minutes. This is done to ensure that all

of the bactericide has been removed from the membranes.

24

Page 25

Operations and Maintenance Manual

E4H Series Water Purification Machine

24. Connect the permeate line to the point of use of the permeate. Check for leaks and

ensure that you have no kinks in hoses, or blockage of any piping on the permeate

and concentrate outlet lines.

25. Make any necessary final adjustments to flows and pressure according to step 17.

26. NOTE: The membrane(s) in your machine are rated for certain flow rates at 77ºF

(25ºC). Maximum flow rates are achieved when the membranes have been

completely rinsed and on-line for at least 24 hours.

27. Record all operating parameters at initial startup on a log sheet. A start up data log

sheet is included in section 9.3 of this manual.

28. A daily log sheet, which includes general operating conditions (pressures, flows,

concentrations, pH, and pretreatment conditions), and routine or special

maintenance (flushing or cleaning as needed) must be kept . This log sheet will be

required by GE Water & Process Technologies if a warranty question arises.

25

Page 26

Operations and Maintenance Manual

E4H Series Water Purification Machine

4. OPERATION AND MAINTENANCE

The operation and maintenance of your GE Water & Process Technologies E4H Machine is

relatively simple but requires regular data recording and routine preventative maintenance.

We cannot emphasize too strongly the importance of filling out the daily log sheet during

each operating shift. A data sheet should have been filled out upon start-up containing

pertinent facts on the operation of

diagnosing the performance of the equipment and must be kept for reference.

If you have questions concerning the operation of your machine or the method of data

recording, contact the GE Water & Process Technologies Technical Support Team. The three

preventative maintenance procedures, which must be done on a regular basis are as follows:

1. Change the pre-filter cartridge.

y

our machine. These two records are invaluable in

2. Flush the machine da

3. Clean the machine with approved GE Water & Process Technologies cleaners.

See the following sections for specific maintenance procedures.

4.1 Daily Log Sheets

A daily log sheet, which includes general operating conditions (pressures, flows and

concentrations) and routine or special maintenance (pre-filter changes, flushing, cleaning,

etc.) must be kept. Copies of the log can be made from the template. A copy of this log sheet

will be required by GE Water & Process Technologies if a warranty question arises.

4.2 Pre-Filter

A 5-micron pre-filter is factory-installed to protect the membranes and valves from particles,

which may be in the feed water. The pre-filter uses two 20-inch (50.8-cm) diameters, 2micron nominal rated cartridges. To order replacements, see the standard parts list.

The filter cartridges must be replaced, at a minimum, once per week or after ever

hours of operation, whichever comes first. A pressure drop of 8 psig (0.6 bar) across the filter

or more during operation indicates one or more cartridges need changing. Use only GE

Water & Process Technologies approved filters rated for 5 microns or less. Do not attempt to

clean used filters - install new replacements.

ily

.

y 100

26

Page 27

Operations and Maintenance Manual

E4H Series Water Purification Machine

Failure to change the

!

requir

ements

filter

according to these

will void the warranty.

IMPORTANT!

4.3 Flushing

The machine should be flushed periodically to remove sediment from membrane surfaces.

NO

To flush the unit:

1. Open the concentrate valve until the pressure gauge indicates the minimum pressure

The feed flush system automatically flushes the machine at shutdown

when the RO System Selector is set to AUTO mode in the deluxe version

and when the ON/OFF switch is set to ON in the economy version. This

eliminates the need for frequent manual flushing.

TE

designated on the nameplate. This increases the flushing action on the membrane.

If pressure will not decrease to designated pressure, or if

t

he

concentrate rate does not increase when the valve is opened

,

the valve may be plugged.

NO

2.

Operate the machine at the designated minimum pressure for 10 to 20 minutes.

TE

27

Page 28

Operations and Maintenance Manual

E4H Series Water Purification Machine

Caution!

3. Return the concentrate valve to its previous position

4.4 Cleaning

Cleaning the E-Series machine on a regular basis is vital. Over time, contaminants build up to

form a layer on membrane surfaces, reducing the permeate flow and quality. If this buildup is

not removed from the membrane, it may cause permanent chemical damage and reduce

membrane life. A decrease in permeate flow and/or rejection of salts, or an increased pressure

drop across the machine will indicate when cleaning is required. Cleaning may be required as

often as once every week or as infrequently as every three months, depending upon the local

water supp

once a quarter to assure good membrane element performance and long membrane element

life.

Do not operate the machine below the designated pressure without

approval from GE Water & Process Technologies. Operation below the

stated pressure may be detrimental to the pump.

ly

conditions. GE Water & Process Technologies recommends cleaning at least

4.4.1 CLEANING PROCEDURE FOR DLX AND ECN MODELS:

1. With the RO machine running, open the CIP permeate valve. After this valve has been

opened, close the permeate service valve. Permeate water will flow into the CIP tank. Allow the

water to run through the CIP tank and the CIP tank drain valve for a few minutes to ensure the

ly

tank is rinsed thorough

After a minute or so, close the CIP tank drain valve. The CIP tank should begin to fill with RO

permeate. When the CIP tank has filled to the indicated full line, turn the RO System Selector

on the AccuTrak® RO controller (DLX model) or the ON/OFF two position power switch (ECN

model) to the OFF position.

2. While the machine is OFF, open the CIP inlet valve. Divert the permeate and concentrate

streams to the CIP tank for recirculation. Ensure that the pre-filter is clean. A CIP pump

(supplied with DLX models only) is recommended to suppl

3. For DLX models only - ECN models go to step 4: Highlight CIP Pump on the AccuTrak® RO

controller and select AUTO mode. Next, highlight RO system and select CIP mode and

recirculate the cleaning solution through the machine. It is best to clean at temperatures of

100°F to 110°F (38°C to 43°C), but lower temperatures will suffice. The cleaning solution should

.

y

feed pressure into the machine

28

Page 29

Operations and Maintenance Manual

E4H Series Water Purification Machine

be recirculated for approximately 15 minutes or until the solution temperature reaches a

minimum of 85°F (29°C). Do not allow the cleaning temperature to exceed 110°F (43°C).

Highlight the CIP and RO System Selectors and select the OFF mode and allow the membranes

to soak in the solution for approximately 10 minutes. If heat rise occurs too quickly, larger

volumes of cleaning solution or the use of a heat exchanger will slow the temperature rise.

Turn the CIP off and allow it to soak for 10 minutes.

Caution!

For ECN model only:

4. The ECN model does not include a CIP pump. You will need to install a CIP pump, a CIP

pump motor starter with a manual start/stop switch, plumb a CIP recirculation line back to the

CIP tank, a CIP recirculation hand valve, and a CIP recirculation pressure gage located after the

CIP pump but before the CIP recirculation hand valve in order to have the necessary

equipment to perform the cleaning process.

Do not operate the machine below the designated pressure without

approval from GE Water & Process Technologies. Operation below the

stated pressure may be detrimental to the pump.

Connect the CIP pump discharge plumbing to the Victaulic fitting on the CIP inlet just upstream

of the RO pre filter. Connect CIP concentrate and permeate hoses from the RO to the CIP tank

(supplied by others). Open the CIP recirculation valve so as to create 15 psig back pressure to

the CIP pump. Turn on the CIP pump and recirculate the cleaning solution in the CIP tank for 5

minutes.

Open the CIP hand valve to the RO inlet line. Turn the panel two-position power switch to on

and recirculate the cleaning solution for 15 minutes or until the solution temperature reaches

100°F (38°C). Do not exceed 110°F (43°C). The membrane elements can only handle

temperatures in excess of 85°F (29°C) for short periods of time. If the cleaning solution

temperature rises too quickly then use a heat exchanger to control high temperature swings.

Turn off the RO high pressure pump by turning the panel two-position power switch to OFF

and turn off the CIP pump. Allow the RO to soak for 10 minutes.

5. To flush the detergent from the machine, close the CIP inlet valve and divert the permeate

and concentrate to drain by opening the CIP drain valve. Highlight to RO system and select

MANUAL mode on the AccuTrak® (DLX model) or turn the panel two-position power switch to

ON and flush the RO machine for one hour. The detergent is sufficiently flushed when the

permeate conductivity is restored to nearly its previous level.

29

Page 30

Operations and Maintenance Manual

E4H Series Water Purification Machine

6. To return the RO to service, open the permeate, concentrate valves so that flow is routed as

intended in the service mode. Close the CIP permeate, CIP concentrate valves. The RO is now

ready for operation.

4.5 Draining Machine for Storage/Shipment

Prior to shipping or outside storage of a GE Water & Process Technologies E4H Machine, the

system should be cleaned with the appropriate cleaner, flushed with water, and protected

from biological attack with the appropriate solution for TFC membrane. The membrane

housings and piping lines of the machine must be completely drained. Any water remaining in

the piping of a machine may freeze, causing damage to the piping, pump, membranes, etc.

The party shipping or storing the machine is responsible for any damage resulting from

freezing.

1. Disconnect the inlet, concentrate and permeate outlets.

2. Drain all water from the cartridge filter housing.

3. Remove the tubing connections on the inlets and outlets of the membrane housings.

4. Open the concentrate valve.

5. Remove the drain plugs from all PVC manifolds.

6. Be sure the flow meters are drained by disconnecting the bottom fitting of each meter.

7. Allow the machine to drain for a minimum of eight hours or until the opened ports quit

dripping.

8. After draining is complete, reconnect all of the piping.

4.6 Membrane Installation

For machines with membranes not loaded at the factory, the following steps are to be used for

installation.

The membrane is packaged in a small amount of

bactericide solution to prevent biological growth; provide

adequate

mu st be kept moist at all times in order to prevent

possible damage to

CAUTION!

ventilation when h a ndl i n g. The m embra n e

t

he

membrane material.

30

Page 31

Operations and Maintenance Manual

E4H Series Water Purification Machine

1. Remove the membrane bag containing the membrane from the shipping tube.

2. Cut the bag open as close as possible to the seal at the end of the bag, so that the bag

y

may be re-used if necessar

.

3. Remove the membrane from the bag and remove the foam protectors from each end of

the membrane.

4. Remove the parts from the parts container (if included) and inspect. Make sure that all

parts are clean and free from dirt. Examine the O-rings, brine seal, and permeate tube for

nicks or cuts. Replace the O-rings or brine seal if damaged. Set the membrane aside in a

clean space and continue on to step 5.

5. Remove the end caps from both ends of all membrane housings on

done by loosening the clamp bolts at each end cap closure assembl

y

our machine. This is

y

.

6. Determine the direction of fluid flow in the membrane housing. (Be certain to look at the

“Direction of Flow” arrow for each membrane housing. Direction of flow may vary within a

given machine.)

7. Inspect the membrane housing and clean as necessary to remove an

y

contaminants,

obstructions, etc.

8. Apply a small amount of O-ring lubricant to all O-rings on the end caps, and the brine

seal on the membrane.

9. Insert the downstream end of the membrane in the upstream end of the membrane

housing (i.e., load in the direction of flow; the brine seal is on the end of the membrane that

goes in last. For membrane housings with the flow arrow pointing up refer to step 11).

10. Insert the membrane in the membrane housing with a smooth and constant motion.

When you reach the point where the brine seal is about to enter the housing, gently turn the

membrane to ensure the brine seal enters the housing without coming out of the brine seal

groove.

11. When all of your membranes are installed, you must close the membrane housing

package by re-installing the end caps and clamps. It is preferred to install the bottom end

cap first, and tighten the clamp completely, before installing the top end cap.

12. Re-install the end caps by gently twisting the end cap while pushing it on to the

permeate tube. Ensure that you do not pinch or fatigue any O-rings while pushing the end

cap on. Push the end cap on until the outer diameter of the cap is flush with the outer

31

Page 32

Operations and Maintenance Manual

E4H Series Water Purification Machine

diameter of the membrane housing. Install the clamp halves, and tighten the bolts until the

clamp halves meet.

13. Re-connect any fittings that were removed when disassembling the membrane

housings.

14. Return to step 1 in Section 3.2 in the Start-Up Procedure.

4.7 Membrane Replacement

As time progresses, the efficiency of the membrane will be reduced. In general, the salt

rejection does not change much until two-three years after installation, when operated on

properly pretreated feed water and when routine maintenance is performed. The permeate

flow rate will begin to decline slightly after one year of operation but can be extended with

diligent flushing and cleaning of the machine. High pH feed water and/or precipitation of

hardness can cause premature loss in rejection and even flow rate. The following procedure

is to be followed to replace existing membranes in the machine.

1. Remove the end caps from all of the membrane housings.

2. Remove all of the membranes from the membrane housings in the direction of flow

where possible. If necessary, a membrane can be removed against the direction of flow. A

heavy duty pliers or channel lock pliers may be necessary to pull the old membrane out of

the membrane housing.

3. To re-install replacement membranes, follow Sections 4.6.

Do not operate the machine on water over 85°F (29°C).

NOTE

Do not allow the machine to freeze unless it is totally drained. It

must thaw a minimum of 24 hours before starting.

NOTE

32

Page 33

Operations and Maintenance Manual

E4H Series Water Purification Machine

5. OPTIONAL ACCESSORIES

5.1 Standard Options

The following optional features are available upon request. Selection of these options will not

affect the start up or operating procedures described above.

Optio

n

D

escriptio

1

Cold Water

2

Stainless Steel

4

Low Energy

5

Nanof

6

PLC

Instrumentation

Upgrade (PLC

7

575 VAC 3-phase

Power with CU

electrical (CUL)

n

(CW)

(LE)

iltration (N

and

)

Design temperature

(SS)

FRP membrane

Machine operates at

F)

Reverse Osmosis (RO)

Motor

Standard Design

Feature

at 77F (25C).

element housings.

approximately 220

psi (15 bar).

membrane elements.

Accutrack RO solidstate controller with

blind instruments.

Standard electrical

L

package.

s

Selecting this Option will . .

Produce rated permeate flow at 55F (13C). Replace

standard membrane elements with low energy

elements. The machine will operate at approx. 220 psi

(15 bar).

Replaces Fiberglass Reinforced Plastic (FRP) housings

with stainless steel membrane element housings.

Replaces standard membrane elements with low

energy elements. Replaces standard RO pump with

lower pressure pump.

.

Result is machine will produce rated permeate flow at

77F (25C), but at an operating pressure of approx. 115

psi (8 bar).

Note: Design is already standard on E4-LE Series.

Replaces standard membrane elements with NF

elements. The machine will operate at approx. 115 psi

(8 bar).

Replaces standard controller with modular PLC (GE

Fanuc Micro40) that offers increased I/O and Ethernet

communication capabilities. This option is only a

hardware change and does not add more functional

y

stem

control or display capability to the s

.

Note: Available only on DLX models.

Replaces motors with 575 VAC, 60 Hz models and

removes standard electrical with one that meets

Canadian standards.

33

Page 34

Operations and Maintenance Manual

E4H Series Water Purification Machine

5.2 External Controls

Your E4H RO machine is equipped with External Control capability. External Control is the

on/off control of the RO via a signal from a remote device. The External Control could be

remote on/off, level control, pre-treatment lockout, and/or post-treatment lockout, etc.

Utilization of this feature requires a customer-wired control loop, wired to factory-supplied

terminals. Refer to either the DLX or ECN electrical drawings for proper wiring and/or

electrical connections.

5.3 Filters and Water Softeners

Backwashable filters and softeners should be installed such that unfiltered or unsoftened

water will not be fed to the machine while the RO unit is operating. Failure to do this may

cause fouling or precipitation of calcium carbonate or other materials onto the membranes.

5.4 Storage Tanks

Fiberglass, polyethylene and stainless steel storage tanks are available. All tanks are

available with fittings installed at the factory. These tanks must be installed with even

support along the bottom.

34

Page 35

Operations and Maintenance Manual

E4H Series Water Purification Machine

6. TROUBLESHOOTING

This troubleshooting guide can assist you in identifying common operating problems you

may experience with your machine. The operator can easily correct many of these

problems; however, for those that persist or are not understood, you should contact the GE

Water & Process Technologies technical support team. Have the following information

available when calling the GE Water & Process Technologies technical support team:

• Machine installation date.

• Model number (found on right-hand side of front panel).

• Serial number (found on right-hand side of front panel).

• Daily Log Sheets.

• Detailed description of problem.

Table 6. 1: Troubleshooting Guide

Symptom (Alarm

Low inlet pressure

(low inlet alarm)

Low operating pressure High flow rates Close the concentrate bypass valve,

)

Possible

Ins

uff

icient feed water

pressure

Clogged

Solenoid valve not opening Clean or replace the solenoid valve.

Pump discharge screen

Cau

se

pre-f

ilter Replace the

R

Increase the feed pressure, open the

inlet/feed valve, check for restrictions,

and consider installing a feed water

boost pump.

check the permeate and concentrate

flow rates and adjust if

Excessive permeate flow may indicate

improper interconnector installation.

Inspect and clean.

emedie

s

pre-f

ilters.

necessary.

(low primary pressure)

Dirty or fouled membranes

Clean the membranes.

(low final pressure)

Warm operating conditions Correct temperature.

Pump rotating backwards

(3-phase power only

Pump not operating co

)

Switch any two 3-phase leads to the

motor starter.

rrectl

y

See pump instructions.

35

Page 36

Operations and Maintenance Manual

E4H Series Water Purification Machine

Table 6.1: Troubleshooting Guide

Symptom (Alarm

)

Possible

Cau

se

R

emedies

Low permeate flow rate Low operating pressure

Dirty or fouled membranes Clean the membranes.

Operating on cold water less

than 55 - 60°F (13 - 16°C)

Membranes installed

backwards or damaged

concentrate seal

Flow sensor inaccurate Check the flow rate manually with a

Valve position Check CIP and outlet valve positions for

Low concentrate flow rate,

normal or higher than normal

pressure

Concentrate valve plugged Disassemble and the clean the plumbing

Concentrate outlet line

restricted

See the possible causes for low operating

pressure.

Install a hot/cold feed water tempering

valve if more permeate flow is needed.

Operate with a feed water temperature

of 72 - 77°F (22 - 25°C).

Install

flow. Clean the machine immediately.

membranes

in the direction of fluid

Membranes with damaged concentrate

seals should be cleaned.

stopwatch and calibrated container

(such as CIP tank).

correct orientation.

to the valve.

Examine the concentrate line for

obstructions or a closed valve.

Flow sensor inaccurate Check the flow rate manually with a

stopwatch and calibrated container.

Note: CIP tank can be used for this

recycle

High operating pressure Recycle or concentrate lines

plugged

Inaccurate pressure gauge Replace or calibrate the gauge as

Service and CIP valves closed

at the same time

Restricted or reduced

permeate flow rate

purpose.

Disassemble the plumbing to the

orifice and remove foreign particles.

required.

Verify water path to both is open.

See the possible causes for low permeate

flow rate.

36

Page 37

Operations and Maintenance Manual

E4H Series Water Purification Machine

Table 6.1: Troubleshooting Guide

Symptom (Alarm

Excessive pressure drop

[exceeding max

primary pressure – low

pressure)

Water flowing when machine

is turned off

)

Possible

∆P] (high

f

inal

Cau

se

Restricted flow after pump

outlet

Telescoped membrane

covering membrane housing

outlet port

Severely fouled or

membranes

Inlet control valve not closing

or seating

properly.

dirt

y

R

emedie

Check for blockage of the concentrate

flow at the inlets and outlets of the

membrane

at the pump discharge screen.

Ensure that the anti-telescoping device

(ATD) is located properly on the

membrane.

Clean the membranes.

Clean or replace the solenoid valve.

Clean the membranes

Water must not pass through the inlet

when the machine is off.

s

housings. Check for blockage

immediately.

Repair or replace valve components as

necessary.

Declining rejection (high

permeate

conductivit

y)

Dirty or fouled membranes Clean the membranes.

O-ring seal broken or damaged Replace the O-ring, check the sealing

surfaces on the O-ring groove,

interconnectors and end caps. Replace

damaged parts.

NOTE: This typically only happens

immediately after membrane

installation.

Change in incoming water

y

qualit

Inaccurate co

monitor or fouled probe

Low recycle flow Adjust recycle flow (if applicable).

nductivit

y

Open the concentrate valve and flush.

Test the water for pH, hardness, TDS, and

content

iron

sent to GE Water & Process Technologies

for review.

Calibrate the sensor with a co

standard solution or check the readings

with another conductivity meter. Replace

or clean the probe. Check the

connections between the probe and the

controller.

. A water analysis should be

nductivit

y

37

Page 38

Operations and Maintenance Manual

E4H Series Water Purification Machine

Table 6.1: Troubleshooting Guide

Symptom (Alarm

)

Possible

Cau

se

R

emedies

RO System Selector on

AccuTrak® (DLX model) set to

MANUAL or AUTO or the panel

two position power switch is

ON (ECN model), unit not

operating

Electrical machine shutdown

Pressurized storage switch or

float switch has cut power to

the machine

External control or

pretreatment contacts have

shut down the machine.

Thermal overload in motor has

tripped.

No power to machine. Check the fuses or circuit breakers;

Motor and/or pump not

operating

Alarm condition has turned off

machine.

Alarm condition has turned off

machine.

External control or

pretreatment contacts have

shut down the machine.

proper

ly.

Check the permeate backpressure or

position of float in the storage tank.

Check for proper operation of control

contacts. Restart machine manually or

wait for automatic start-up.

Allow the machine to cool; check the feed

water supply and/or amp draw of the

motor.

measure the voltage.

See the pump instructions. Contact GE for

repair of

Check for minimum inlet pressure and

push alarm reset switch.

Restart the machine by pushing the

alarm bypass. Check all possible alarm

conditions; inlet pressure and push alarm

reset switch.

Check for proper operation of control

contacts. Restart machine manually or

wait for automatic start-up.

replacement

.

AccuTrak® RO error:

4-20mA Out X failed:

Short message

Permanent message

Motor starter overloaded,

heater tripped.

Internal communication with

4-20 mA Output X failed more

than 3 times in series OR

more than 20 times in series

(After a successful

communication the internal

error counter is

reset

.)

Turn all selectors to OFF on AccuTrak®

(DLX models) or power switch to OFF

(ECN models); let the heater(s) cool.

Contact your local GE Service. The device

has to be replaced.

38

Page 39

Operations and Maintenance Manual

E4H Series Water Purification Machine

Table 6.1: Troubleshooting Guide

Symptom (Alarm

AccuTrak® RO error:

Battery Failed!

- Permanent message

- Short message

)

Possible

The back-up battery of the

internal real time clock (RTC)

failed.

Year of internal clock is lower

than 2007.

Cau

se

R

emedie

The back-up battery (Type CR 2032, 3V

DC) on the reverse side of the printed

circuit board needs to be replaced by

qualified personnel.

s

Set the clock to current date and time.

- Flashing message in menu 7

(Clock)

AccuTrak® RO error:

Datalog IS NOT ACTIVE

AccuTrak® RO error:

CalibFault 4-20mA In

Data Logging was stopped due

to fault while writing to SD card

or due to removed SD card.

Defect Calibration data for at

least one configured 4-20 mA/

nput

Pt100 I

.

Check, if SD card was removed during

data Logging. Did Error message “No SDCard detected” appear? If not check the

free memory capacity. If the SD card

memory is not full, the SD card has to be

exchanged.

Contact local GE Service.

(Input State: Fc)

AccuTrak® RO error:

CalibFault PT100 In

(Input State: Fc)

AccuTrak® RO error:

CalibFault 4-20mA Out

(Output State: Fc)

AccuTrak® RO error:

False code

Defect Calibration data for at

least one configured 4-20 mA

nput

/ Pt100 I

inputs will be treated as

inputs with input fault.

Defect Calibration data for at

least one configured 4-20 mA

utput

O

outputs will output 0 mA.

Wrong code for current

required code level. Access to

target menu item(s) is denied.

. The concerned

. The concerned

Contact local GE Service.

Contact local GE Service.

Input the right code for the required code

level.

39

Page 40

Operations and Maintenance Manual

E4H Series Water Purification Machine

Table 6.1: Troubleshooting Guide

Symptom (Alarm

)

Possible

Cau

se

R

emedies

Factory Reset All configuration and

parameter data is reset to

default values and the

AccuTrak® RO can operate no

longer as controller.

Sensor Fault

(Input State: FS)

Analog inputs:

4-20 mA: current above

approx. 20.5 mA

Pt100: resistance > input range

The continuation of the operating as

controller is possible after the

conf

downloading of a new

parameterization.

iguration and

Check the wiring from the corresponding

sensor to AccuTrak® RO.

40

Page 41

Operations and Maintenance Manual

E4H Series Water Purification Machine

41

Page 42

Operations and Maintenance Manual

E4H Series Water Purification Machine

7. SPARE PARTS LIST

For detailed spare part lists, please refer to the manual addendum. Contact the GE Water &

Process Technologies Customer Support Center to order parts.

42

Page 43

Operations and Maintenance Manual

E4H Series Water Purification Machine

43

Page 44

Operations and Maintenance Manual

E4H Series Water Purification Machine

8. RETURN GOODS AUTHORIZATION (RGA) PROCEDURE

If you wish to return goods for repair, warranty evaluation and/or credit, please have your

original sales order or invoice available when you call GE Water & Process Technologies. Call

the GE Water & Process Technologies technical support team at (866)-GE WATER. A GE Water &

Process Technologies technical support representative will provide instructions and a return

authorization number, which needs to be clearly written on the outside of the box used to ship

your materials. All equipment must be shipped to GE Water & Process Technologies with the

freight prepaid by the customer. Call our Customer Support Center with any questions or

issues concerning freight claims and a representative will discuss your situation.

Machines must never be shipped with water in them; this

w

ill

!

IMPORTANT!

void the

before shipping a n d avoid freezing before draining. The

machine should be sanitized prior to draining. Refer to

the draining and cleaning

details.

warranty.

Drain the machine completely

instructions

in this manual for

44

Page 45

Operations and Maintenance Manual

E4H Series Water Purification Machine

45

Page 46

Operations and Maintenance Manual

E4H Series Water Purification Machine

9. WARRANTY/GUAR

ANTEE

9.1 Machine Warranty/Guarantee

Seller warrants its products to be free from defects in material or workmanship for a period

of 15 months from receipt or 12 months from start-up/first use of the product , whichever

occurs first , but only when said products are operated at all times in accordance with

Seller ’s written instructions. This warranty does not apply to replaceable parts or

components normally subject to wear and replacement.

Unless stated specifically on a form, official “Performance Warranty Document” signed by

an officer or director level employee of the Seller and an employee of the Buyer who is

authorized to make such representations, there is no performance warranty on products or

warranty on process results.

Seller expressly disclaims liability for incidental and/or consequential damages including,

without limitation, lost profits. This warranty is made expressly in lieu of all other warranties,

express or implied, including all implied warranties of merchantability or fitness for any

particular purpose. Buyer assumes all liabilities for use and misuse by buyer, its agents or

assignees.

Buyer shall give immediate notice in writing to Seller if products or components thereof or

performance (where applicable) appear defective, and shall provide Seller with reasonable

opportunity to make inspections, tests, and repairs using the most efficient and cost