Page 1

E4, E4LE, EZ4 Series

Water Purification Machines

Operation and Maintenance Manual

2,200 GPD to 13,200 GPD

8.3 m

3

/day to 50 m3/day

July 4, 2014

Document PN 1161875, Rev G

http://www.gewater.com

1

Page 2

TABLE OF CONTENTS

1. DESCRIPTION .......................................................................................................................................... 4

1.1. Definitions ................................................................................................................................................. 4

1.1.1. Permeate Rate (Product Water Rate) [Qp] ........................................................................ 4

1.1.2. Concentrate Rate (Reject Rate) [Qc] .................................................................................... 4

1.1.3. Feed Rate [Qf] ................................................................................................................................ 4

1.1.4. Reverse Osmosis (RO) ................................................................................................................ 4

1.1.5. Membrane Elements .................................................................................................................. 5

1.1.6. CIP ...................................................................................................................................................... 6

1.1.7. Average Pressure [P

1.1.8. Concentration ............................................................................................................................... 6

1.1.9. Salt (Ionic) Passage ..................................................................................................................... 6

1.1.10.Recovery .......................................................................................................................................... 6

1.1.11.Salt (Ionic) Rejection ................................................................................................................... 6

1.2. Machine Nomenclature ...................................................................................................................... 7

1.3. Specifications for E-Series Machines ........................................................................................... 8

2. INSTALLATION ........................................................................................................................................ 8

2.1. Mounting the Unit ................................................................................................................................. 8

2.2. Plumbing ................................................................................................................................................... 8

2.3. Installing Clean-In-Place Valves ..................................................................................................... 9

2.4. Concentrate Outlet Connections .................................................................................................... 9

2.5. Feed Water Requirements .............................................................................................................. 10

2.6. Transporting Pure Water (Permeate) to Point-of-Use ........................................................ 10

2.7. Pressure Correction Factors ........................................................................................................... 10

2.8. Electrical .................................................................................................................................................. 11

2.8.1. Single-Phase Electrical ............................................................................................................ 11

2.8.2. Three-Phase Electrical ............................................................................................................ 11

2.9. Machine Control................................................................................................................................... 12

2.9.1. Economy Model ......................................................................................................................... 12

2.9.2. Deluxe Model ............................................................................................................................... 12

3. PREPARATION AND STARTUP ........................................................................................................12

3.1. Pretreatment for Water Purification ........................................................................................... 12

3.2. Machine Start-Up Preparation ...................................................................................................... 13

3.3. Machine Start-Up ................................................................................................................................ 13

3.4. Temperature Correction Factor .................................................................................................... 14

3.5. Autoflush Timer .................................................................................................................................... 15

3.5.1. Programming the Autoflush Timer .................................................................................... 15

3.6. Calibrating the Conductivity Probe ............................................................................................. 15

4. OPERATION AND MAINTENANCE .................................................................................................16

Daily Flushing for the Economy Model ............................................................................ 16

4.1.1.

4.1.2. Daily Flushing for the Deluxe Model ................................................................................. 17

4.2. Pre-filter Cartridge .............................................................................................................................. 17

] ............................................................................................................ 6

AVG

2

Page 3

4.3. Membrane Element Cleaning ........................................................................................................ 17

4.3.1. Step Wise Cleaning ................................................................................................................... 17

4.3.2. Procedure to Clean with a CIP Pump ............................................................................... 18

4.4. Suction Cleaning .................................................................................................................................. 19

4.5. Changing Out Membrane Elements ........................................................................................... 20

5. TROUBLESHOOTING ..........................................................................................................................22

6. SPARE PARTS LIST ...............................................................................................................................26

7. RETURN GOODS AUTHORIZATION (RGA) PROCEDURE .......................................................26

8. WARRANTY/GUARANTEE .................................................................................................................26

9. START-UP DATA ...................................................................................................................................26

10. DAILY LOG DATA FOR GE WATER AND PROCESS TECHNOLOGIES MEMBRANE

MACHINES ........................................................................................................................................................26

List of Tables

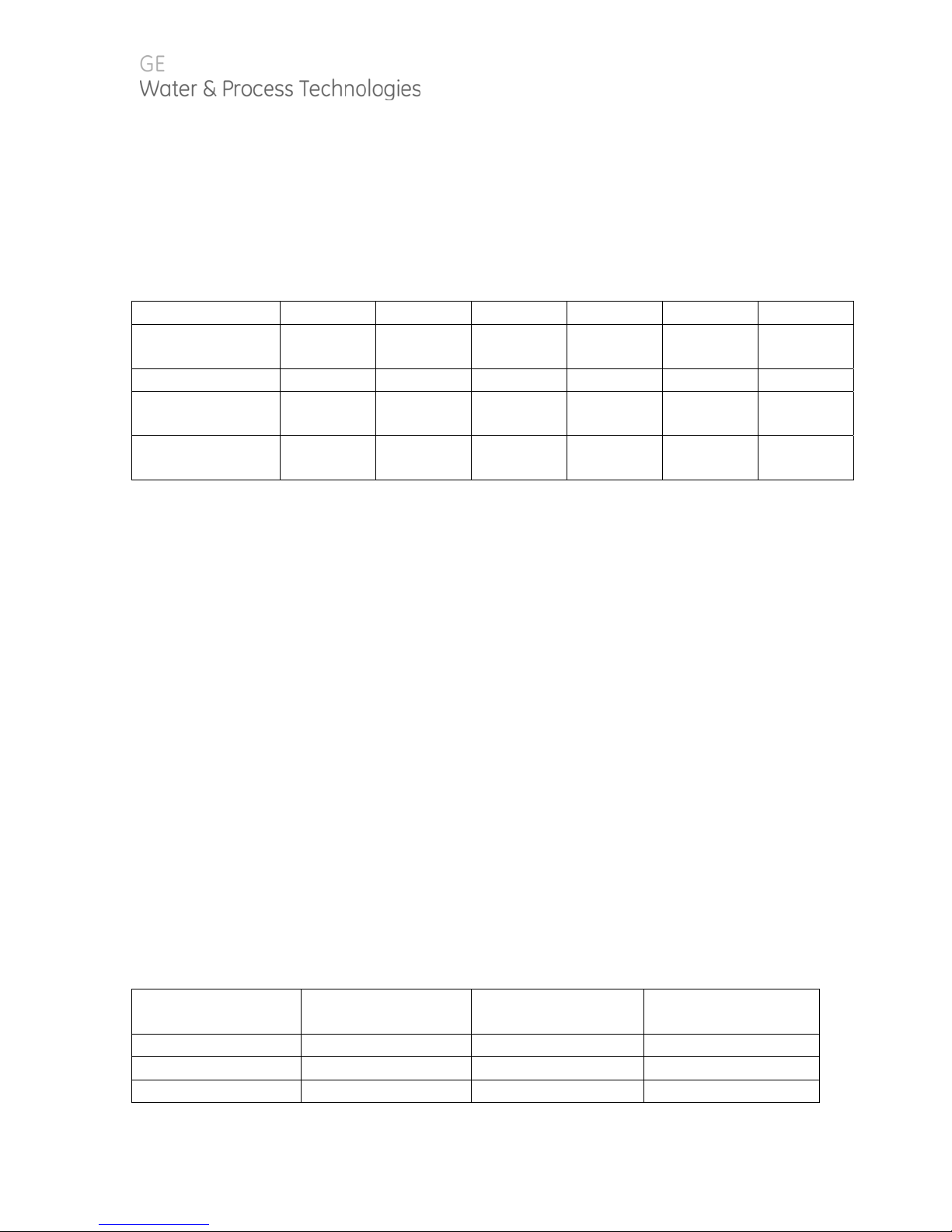

Table 1. Flow Specifications for E4 Machines, 50-75% Recovery ................................................ 8

Table 2. Connections ........................................................................................................................................ 8

Table 3. Feed Water Requirements ......................................................................................................... 10

Table 4. Pressure Correction Factors ...................................................................................................... 10

Table 5. Troubleshooting Guide ................................................................................................................ 22

List of Figures

Figure 1. Normal vs. Crossflow Filtration .................................................................................................. 5

Figure 2. Membrane Element with Interconnectors ............................................................................ 5

Figure 3. Cross-Sectional View of Membrane Element ...................................................................... 6

Figure 4. Principle of Operation ..................................................................................................................... 7

Figure 5. Three-Phase Allen Bradley Motor Starter ............................................................................ 12

Figure 6. Conductivity Probe Display ........................................................................................................ 16

Figure 7. Clean-In-Place Pump and Tank Hook-Up ........................................................................... 18

3

Page 4

1. DESCRIPTION

Your E-Series reverse osmosis (RO) machine is a durable piece of equipment which,

with proper care, will last for many years. These instructions give operation and

maintenance details vital to the sustained performance of the machine. Please read

this manual completely before operating your machine.

1.1. Definitions

The operating definitions provided below will help you further understand your

machine and this manual.

1.1.1. Permeate Rate (Product Water Rate) [Q

The flow rate of purified water, which has passed through the membrane and out of

the membrane element, expressed in gal/min (gpm) or gal/hr (gph) or liter/min (lpm)

or cubic meters/hour (m3/h). Specified permeate rates are based on a feed water

temperature of 77 F (25C). Permeate rate will vary with temperature.

1.1.2. Concentrate Rate (Reject Rate) [Q

The flow rate of water containing rejected solids to drain in gpm or gph (lpm or m3/h).

1.1.3. Feed Rate [Q

The flow rate of incoming water in gpm or gph (lpm or m3/h). Feed water rate equals

permeate rate plus concentrate rate.

]

f

]

c

]

p

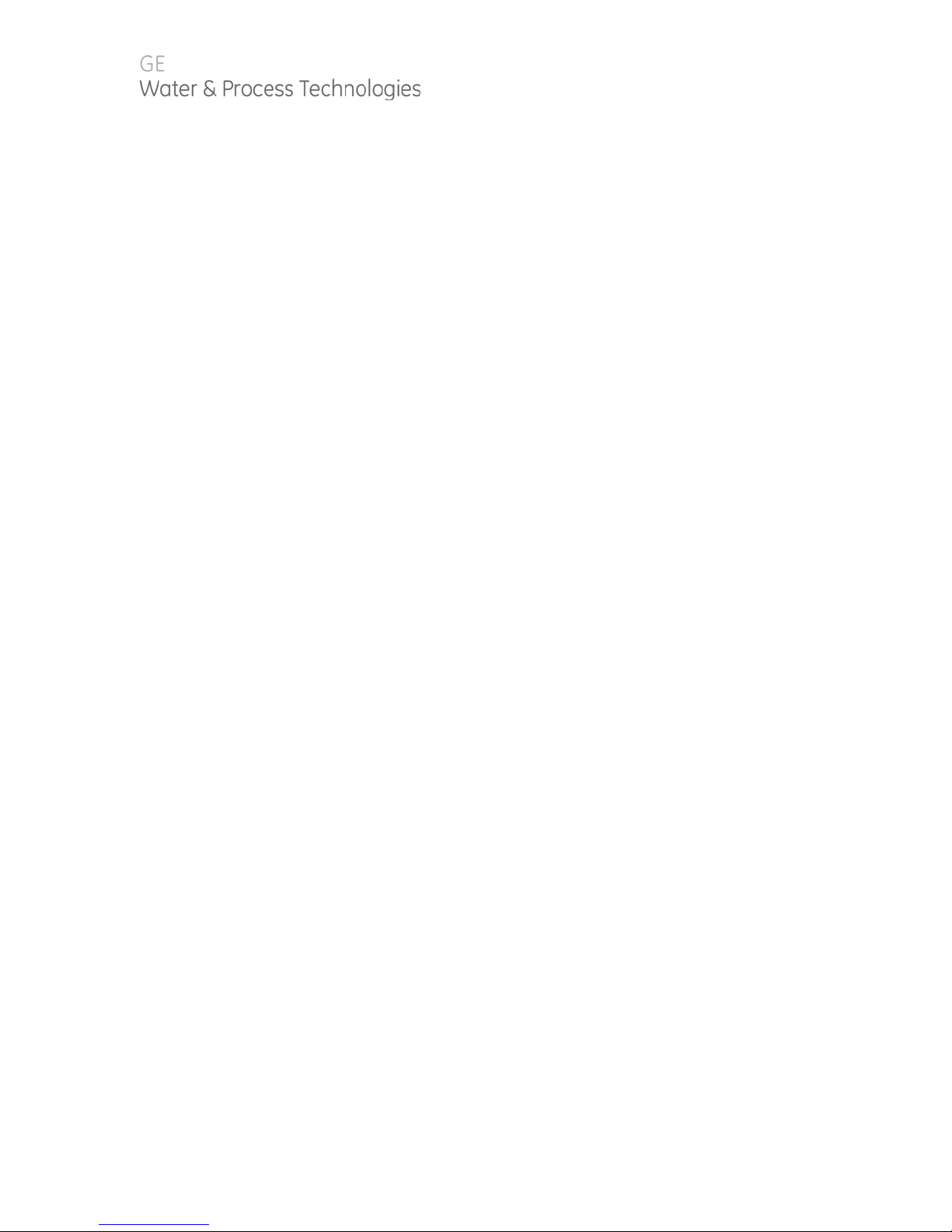

1.1.4. Reverse Osmosis (RO)

The separation of one component of a solution from another component by means of

pressure exerted on a semipermeable membrane. In other words, reversing the

natural passage of a liquid from a concentrated solution to a more dilute solution by

using external pressure. Removal of ionic, organic, and suspended /dissolved

impurities occurs during the RO process. Unlike a filter, which separates by “normal”

filtration, the membrane element separates using a process called crossflow

filtration. Feed water solution is separated in to two streams, permeate and

concentrate, and collected from both sides of the membrane. A semipermeable RO

membrane, under sufficient pressure, allows passage of purified water while rejecting

and concentrating dissolved and suspended solids.

4

Page 5

Figure 1. Normal vs. Crossflow Filtration

1.1.5. Membrane Elements

Membrane elements are the key to reverse osmosis. Interleaved layers of

semipermeable membrane, spacer and permeate carrier spiraled around a central

permeate tube make up the element. The spacer allows for movement of the

concentrate past the membrane, and the permeate carrier carries the purified water

out of the membrane element. GE Water & Process Technologies manufactures a

patented spiral wound membrane element with a turbulent flow design. This

membrane module collects the purified water within the central tube, the permeate

tube. The E8 RO machine utilizes between 8 and 20 membrane elements.

Figure 2. Membrane Element with Interconnectors

5

Page 6

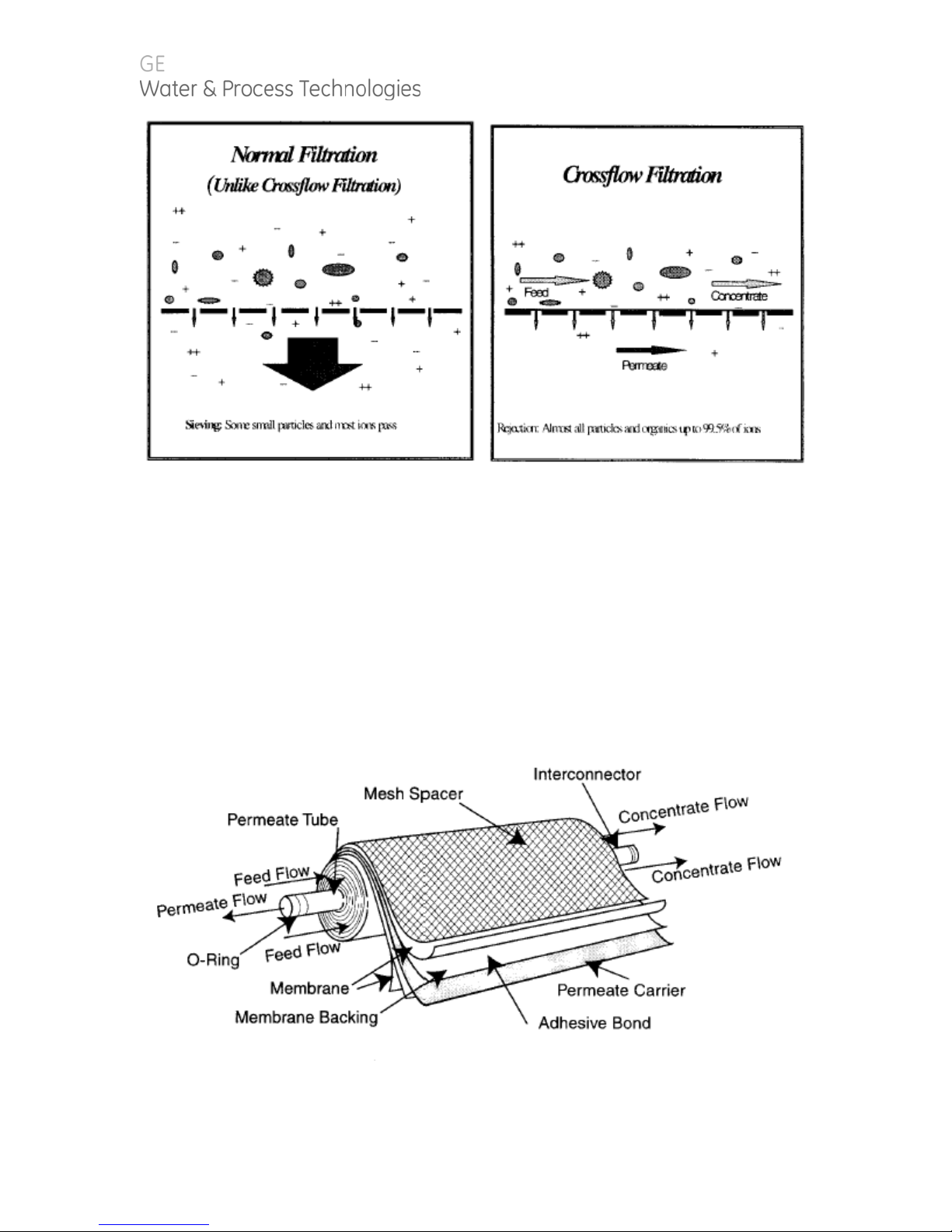

Figure 3. Cross-Sectional View of Membrane Element

1.1.6. CIP

The abbreviation for clean-in-place.

1.1.7. Average Pressure [P

PP

FinalPrimary

AVG

]

2

1.1.8. Concentration

Concentration equals the Total Dissolved Solids (TDS) concentration of a solution

expressed as parts per million (ppm) or conductivity (microSiemens/cm).

Cf = Feed Concentration

Cp = Permeate Concentration

Cc = Concentrate Concentration

C

= Average Concentration in Machine

avg

1.1.9. Salt (Ionic) Passage

The percent of dissolved salts passed through the membrane or 100% minus

rejection.

1.1.10. Recovery

Permeate rate divided by feed rate, expressed as a percentage. For example, 33%

recovery means that out of a given feed rate, 33% is produced as purified water

(permeate).

1.1.11. Salt (Ionic) Rejection

The percent of dissolved salt rejected by the membrane, calculated from an average

concentration over the membrane.

6

Page 7

An example of how to calculate salt rejection and recovery is given below.

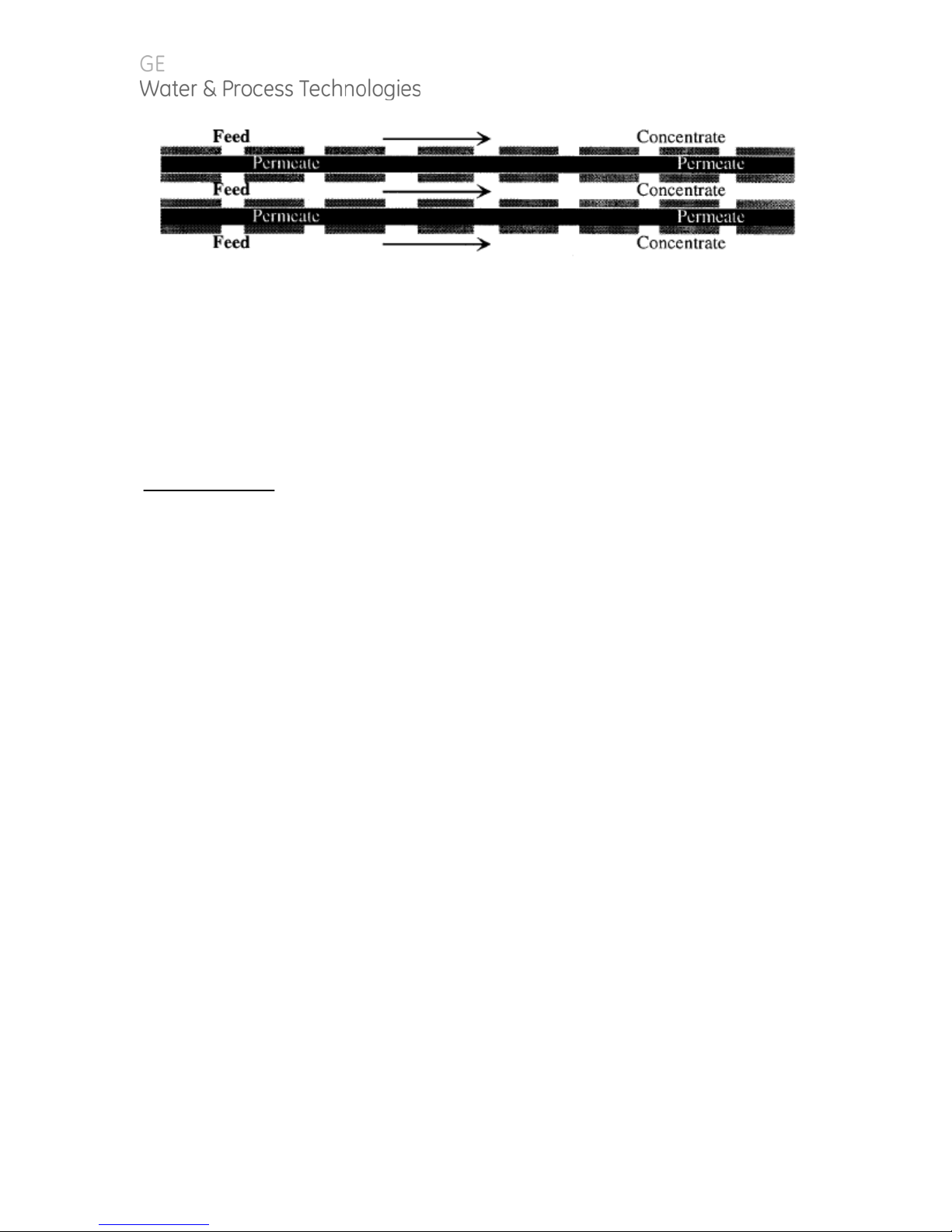

Figure 4. Principle of Operation

Given the system case in the figure above:

Average Concentration,

CC

pAvg

Rejection

Passage

C

Avg

C

p

C

Avg

100

8.3mg/L

237.5mg/L

CC

C

Avg

cf

2

8.3mg/L237.5mg/L

237.5mg/L

%5.3100

375mg/L100mg/L

2

%5.96100

Recovery

Q

p

100

Q

f

18gpm

24gpm

%75100

TDS 237.5mg/L

1.2. Machine Nomenclature

E-Series water purification machines are numbered in such a way as to indicate the

permeate flow you can expect from the machine and other specifications.

Example: RO,E4-4400-DLX,460,6,HR(PA)

RO indicates the machine is a reverse osmosis machine.

E4 indicates the machine series (E) and 4-inch housings/membrane elements

4400 indicates the rated permeate flow in thousands of gallons per day at 77F

(25C), i.e. 4400 = 4400 gallons per day

DLX indicates the deluxe model and ECN indicates the economy model

460 indicates 460 VAC, 3-phase voltage to starter. Standard models offer 460

VAC, 60 Hz, 3-phase and 380 VAC, 50 Hz, 3-phase.

6 indicates 60 Hz operation, (50 Hz operation is also available and is indicated by

a 5 in place of the 6.

7

Page 8

HR(PA) indicates that the machine includes high rejection (HR) polyamide (PA)

membranes. Low energy membranes are also available and are indicated by

LE(PA).

1.3. Specifications for E-Series Machines

The machine flow specifications listed in Table 1 below are based on 77°F (25°C) and

2,000 ppm NaCl.

Table 1. Flow Specifications for E4 Machines, 50-75% Recovery

Model E4-2200 E4-4400 E4-6600 E4-8800 E4-11000 E4-13200

Units

Permeate Rate

Concentrate

Rate

Feed Rate

gpm

(m3/h)

1.5 (0.3) 3 (0.7) 4.5 (2.0) 6 (1.4) 7.5 (1.7) 9 (2.1)

1.5-0.5

(0.3-0.1)

3.0-2.0

(0.6-0.4)

gpm

(m3/h)

3.0-1.0

(0.7-0.2)

6.0-4.0

(1.4-0.9)

gpm

(m3/h)

4.5-1.5

(1.0-0.3)

9.0-6.0

(3.0-2.3)

gpm

(m3/h)

6.0-2.0

(1.4-0.5)

12.0-8.0

(2.8-1.9)

gpm

(m3/h)

7.5-2.5

(1.7-0.9)

15-10

(3.4-2.6)

gpm

(m3/h)

9.0-3.0

(2.1-0.7)

18-12

(4.2-2.8)

2. INSTALLATION

2.1. Mounting the Unit

When installing your new GE Water & Process Technologies reverse osmosis (RO)

machine, allow at least 45-inches (114 cm) above the machine for membrane

element removal and loading. If space is not available, the entire membrane element

housing can be removed for membrane element change outs. If the membrane

element housings are to be removed to change out the membrane elements, at least

6-inches (15.2 cm) is required at the end of each membrane element housing and 24inches (61 cm) behind the machine.

2.2. Plumbing

The feed water source must be able to provide water quantity and pressures to

maintain an operating feed water pressure of 30 - 60 psig (2.1 - 4.1 barg). If the feed

water pressure with the machine is in excess of 60 psig (4.1 barg) or fluctuates by

more than 5 psig (0.34 barg) a pressure regulator should be installed up stream of the

machine Inlet. If proper water pressure cannot be maintained to the RO, a booster

pump may need to be installed in front of the pretreatment to provide the proper

water quantity and pressure for the operation of the machine.

Table 2. Connections

Model

E4-2200

E4-4400

E4-6600

Inlet

inches (cm)

0.75 (1.9) 0.5 (1.27) 0.5 (1.27)

0.75 (1.9) 0.5 (1.27) 0.5 (1.27)

0.75 (1.9) 0.5 (1.27) 0.5 (1.27)

Permeate

inches (cm)

Concentrate

inches (cm)

8

Page 9

E4-8800

E4-11000

E4-13200

0.75 (1.9) 0.75 (1.9) 0.75 (1.9)

0.75 (1.9) 0.75 (1.9) 0.75 (1.9)

0.75 (1.9) 0.75 (1.9) 0.75 (1.9)

2.3. Installing Clean-In-Place Valves

NOTE: Clean-In-Place (CIP) valves are not included with the machine. The CIP valves

must be purchased and installed by the customer.

When installing the CIP valves, a three-way valve should be installed in the inlet feed

stream of the machine. The tees on the permeate and concentrate lines should be

installed with two-way valves. All valves should be installed in a manner that will

allow circulation of the cleaning chemicals through the machine and back to the CIP

container during cleaning.

CAUTION: If CIP valves are not installed when machine is installed, provisions must be

made to bypass permeate and concentrate to drain for flushing at start-up.

WARNING: NEVER OPERATE THE MACHINE WITH THE CONCENTRATE OR PERMEATE

LINES BLOCKED. SEVERE DAMAGE TO THE UNIT MAY RESULT.

2.4. Concentrate Outlet Connections

Connect proper size drain line to the concentrate outlet (Table 2) and run to an open

drain. The drain capacity needs to be large enough to properly drain the feed water

flow of the RO. The maximum concentrate back pressure is 60 psig (4.1 barg) for the

RO machine.

CAUTION: Operation above 60 psig (4.1 barg) concentrate back pressure may

damage the machine.

CAUTION: A vacuum breaker must be installed at the highest point along the

concentrate line. Failure to do so may cause a vacuum to form within this line after

shutdown. This may in turn cause numerous problems, including biological fouling,

water hammer, leaks from RO housing side-ports, and the siphoning of treatment

chemicals.

1. Connect the concentrate line to the RO machine’s concentrate outlet. A

vacuum breaker must be installed at the highest point along the concentrate

line. This provides an atmospheric break upstream from where the flow enters

the drainage system. For systems which include multiple RO machines, install

check valves along each machine’s concentrate line prior to connecting the

lines to a common manifold.

9

Page 10

2.5. Feed Water Requirements

The following feed water requirements must be met before installing your new E4

machine to ensure quality permeate and extended membrane element life. Refer to

Table 3 for feed water information.

Table 3. Feed Water Requirements

Temperature

Inlet Pressure

Chlorine (continuous feed)

Operating pH

Silt Density Index (SDI)

*American Standard for Testing Materials

Typical: 50-85F (10-29C)

Maximum: 32-104F (0-40C)

Minimum 30 psig (2.1 bar)

Maximum 60 psig (4.1 bar)

0 ppm

For soft water (less than 1 grain per gallon (gpg) or 17

mg/L hardness), acceptable pH is 4.0-11.0.

For unsoftened water (contact factory with water

analysis, acceptable pH is 5.5-6.0.

For short term (cleaning) a pH range of 2-12 is

acceptable.

Less than or equal to 3 to minimize membrane fouling

and extend cleaning intervals. Refer to ASTM standard

D4189.

2.6. Transporting Pure Water (Permeate) to Point-of-Use

The pure water, or permeate, is in an aggressive state and should only be transported

from the machine to the point-of-use in food grade flexible nylon, stainless steel (SS)

tubing, or polyvinyl chloride (PVC) material for the inlet, permeate, and concentrate

piping sizes. Refer to Connections (Table 2) for inlet, permeate, and concentrate piping

sizes.

WARNING: MACHINE DAMAGE MAY OCCUR IF PERMEATE BACK PRESSURE EXCEEDS

60 PSIG (4.1 BARG) DURING OPERATION.

2.7. Pressure Correction Factors

It is often necessary to operate RO machines with permeate back pressure. Permeate

back pressure will decrease permeate production. See Table 2.3 (Pressure Correction

Factors) to calculate loss of permeate.

Table 4. Pressure Correction Factors

Back Pressure

10 psig (0.7 barg) 5% 10% 0.95 0.90

20 psig (1.4 barg) 10% 20% 0.90 0.80

30 psig (2.0 barg) 15% 30% 0.80 0.70

% Loss of Permeate Flow

E4/EZ4 E4LE

Pressure Correction Factor

E4/EZ4

E4LE

10

Page 11

40 psig (2.7 barg) 20% 40% 0.70 0.60

50 psig (3.4 barg) 25% 50% 0.60 0.50

60 psig (4.1 barg) 30% 60% 0.50 0.40

WARNING: IF PERMEATE BACK PRESSURE EXCEEDS 60 PSIG (4.1 BARG) MACHINE

DAMAGE MAY OCCUR.

WARNING: INSTALLING A CHECK VALVE WILL PREVENT REVERSE FLOW THROUGH

THE MEMBRANE ELEMENT WHEN THE MACHINE IS NOT IN OPERATION. REVERSE

FLOW, WHEN THE MACHINE IS NOT IN OPERATION, CAN SEVERELY DAMAGE THE

MEMBRANE ELEMENTS.

2.8. Electrical

This RO machine requires two supply voltages; the control voltage and the pump

motor voltage.

2.8.1. Single-Phase Electrical

The control voltage can be connected to either a 115 VAC, 60 Hertz or 220 VAC, 50

Hertz single-phase power supply. The RO control circuit should always be installed on

at least a 15 Amp, single-phase dedicated circuit. Reverse osmosis machines with

115 VAC, single-phase control voltage include an eight-foot (2.4 m) cord which plugs

into a three-prong grounded receptacle. All machines shipped with a 220 VAC, singlephase control circuit are shipped with an eight-foot electrical cord, but customers

must provide electrical plug.

2.8.2. Three-Phase Electrical

The three-phase pump motor requires a 15 AMP dedicated circuit. Always verify

correct voltage and Amp rating by checking voltage tag on the starter box or by

checking electrical specifications on the pump. The motor is wired for 460 Volts, 60

Hertz, three-phase voltage from the factory (Figure 5, Three-Phase Allen Bradley

Motor Starter). The pump motor can be rewired to 208 or 230 Volts. If this is done, a

wiring change must be made internally in the pump motor and a higher amperage

relay and starter may need to be installed. All field wiring must comply with

applicable local and national electrical codes.

After checking the voltage tag on the motor starter to ensure the available voltage

and amperage are correct, connect the provided three-phase power to the motor

starter (Figure 5). This can be done by connecting the three phase power to the top of

the starter relay terminals: L1, L2, and L3. A separate, fused disconnect for the motor

wiring with proper protection for the Horsepower and Amp draw of the motor is

recommended. All field wiring must comply with applicable local and national

electrical codes. See Figure 5 for three phase Allen Bradley Starter Hook-Up.

11

Page 12

Figure 5. Three-Phase Allen Bradley Motor Starter

2.9. Machine Control

2.9.1. Economy Model

To remotely control the Economy Model (ECN) with float switches and/or

pretreatment lockout, remove the jumper noted on the electrical drawing and wire in

the float switches or pretreatment components in series. After all field wiring is

complete and complies with local and national electrical codes, move onto Section

3.1 (Pretreatment for Water Purification).

NOTE: External control contacts are normally closed, dry contacts.

2.9.2. Deluxe Model

To remotely control the Deluxe Model (DLX), with float switches and/or pretreatment

lockout, remove the jumper noted on the electrical drawing and wire in the float

switches and pretreatment components in series. After all field wiring is complete and

complies with local and national electrical codes, move onto Section 3.1

(Pretreatment for Water Purification).

NOTE: External control contacts are normally closed, dry contacts.

3. PREPARATION AND STARTUP

3.1. Pretreatment for Water Purification

A water analysis of your feed water should have been performed, as part of the

planning and engineering that went into developing your RO system.

12

Page 13

The water analysis will provide information on what type of pretreatment may be

required and what recovery the machine can be run at on the feed water provided. If

the machine is moved to a different water source, a new water analysis should be

taken before operating the machine.

Your RO is designed to operate on tap feed water with an SDI of 5 or less. The pH

should be in a range of 5.5 - 8.5. Exposure to any levels of chlorine may cause

irreversible damage to the thin-layer composite (TLC) polyamide (PA) membrane

elements in your machine. Daily water checks are recommended to ensure the

integrity of your pretreatment and RO system.

3.2. Machine Start-Up Preparation

Check the function and integrity of your pretreatment equipment. Ensure that your

water softener and activated carbon filters have been leaked checked and properly

flushed, before starting up your RO machine.

CAUTION: Improperly flushed pretreatment may cause serious RO machine problems

at start-up.

3.3. Machine Start-Up

Turn the feed water supply ON, while checking for leaks in the pretreatment and inlet

feed water lines.

Check to ensure power to the motor is de-energized and the ON/OFF button on the

machine is in the OFF position.

Plug in the factory-supplied power for the control voltage.

For initial start-up, redirect the permeate and concentrate lines to the drain.

Open the concentrate and recycle flow control valves two complete turns. These

valves are positioned on the flow control plumbing in the top right rear section of the

machine.

Turn the ON/OFF button on the machine ON. System will open allowing water to flow

through the machine to the drain through the permeate and concentrate CIP valves.

Let the machine run to drain for 5 - 10 minutes. This provides a wet start-up of the

pump and removes any air in the system.

Turn the ON/OFF button on the machine to the OFF position.

Re-energize the pump power and trigger the ON/OFF button on the machine to check

rotation of the pump motor. Observing from the back of the pump motor, pump

rotation should be clockwise. If rotation is wrong, de-energize the pump voltage from

the source and switch any two of the three-phase wires coming in on top of the

13

Page 14

three-phase starter. Re-energize the pump voltage and re-check, to ensure correct

rotation for the start-up and operation of your machine.

WARNING: IF THE RO PUMP IS STARTED WITH INCORRECT ROTATION (i.e.,

BACKWARDS), A NOTICEABLE DROP IN FLOWS AND PRESSURES WILL RESULT. IF

PUMP MOTOR OPERATES BACKWARDS FOR ANY LENGTH OF TIME, PUMP DAMAGE

MAY RESULT.

After correct rotation has been verified, you are now ready to start the machine and

set the flows and pressures.

With the recycle and concentrate orifices still two (2) turns open and adequate feed

water available, start the machine by turning the ON/OFF button to the ON position.

As the pump starts to build pressure, begin to adjust the orifices in the following

manner: start by slowly closing the concentrate orifice while slowly opening the

recycle valve.

Primary Pressure for Normal Operation at 77°F (25°C):

E4-Series: 220 psi (15.2 bar) at 77°F (25°C)

EZ4/E4LE-Series: 115 psi (7.9 bar) at 77°F (25°C)

While you are doing these valve adjustments, to obtain correct flows and pressures,

observe the primary or pump pressure. The pump pressure, while adjusting the

orifices, should never operate outside of these ranges:

E4-Series Range: 190 - 275 psi (13.1 - 19.0 bar)

EZ4/E4LE-Series Range: 100 - 140 psi (6.9 - 9.6 bar)

The concentrate valve is drilled, and when completely closed the machine is running

at the correct concentrate flow for a 75% recovery (Table 1, Flow Specifications for

E4-Series Machines).

If the temperature of the inlet feed water is not 77°F (25°C) use the Temperature

Correction Factor Table (Technote 113). The proper adjustment of the recycle and

concentrate valves are critical to the correct operation of the machine.

CAUTION: Optimum recovery will vary according to water quality.

3.4. Temperature Correction Factor

If the temperature of the inlet feed water is not 77°F (25°C), refer to Technote 113 for

Temperature Correction Factors.

14

Page 15

NOTE: Optimum recovery will vary according to water quality.

3.5. Autoflush Timer

3.5.1. Programming the Autoflush Timer

The Autoflush timer clock operates and displays in real time, but the Autoflush feature

will only work when the RO machine is operating. When the machine is operating in

the Autoflush Mode, the total flow through the machine is increased. This provides

extra cross flow, which flushes the loose foulants from the surface of the membrane

elements. When the machine is operating in the Autoflush Mode a slight drop in

permeate production, as well as a decrease in the primary and final pressures may

be observed. An ideal way to set the timer is to program ten Autoflush sequences,

with a 10 to 15 minute duration, per 24 hours. To do this, follow the procedure in the

Technote 126 containing the programming manual for the Autoflush Timer.

3.6. Calibrating the Conductivity Probe

1. Make sure the calibration meter is in Measure Mode (with the MEAS LED light

ON).

2. Immerse the Conductivity Probe in a HI 7033 prepared calibration solution

(84.00 microSiemens (mS)).

3. Immerse and agitate Conductivity Probe, and wait for the reading to stabilize.

4. Calibrate the meter by adjusting the CAL adjustment screw until the Liquid

Crystal Display (LCD) display reads 84 mS of the solution.

The meter is now calibrated.

NOTE: The alarm and dosing pump selector switch function on the conductivity meter

is not used on E4/EZ4/E4LE Series machines and should be switched to OFF.

15

Page 16

Figure 6. Conductivity Probe Display

4. OPERATION AND MAINTENANCE

The operation and maintenance of an E-Series RO machine requires regular data

recording and routine preventative maintenance. It cannot be emphasized enough

the importance of filling out the Daily Log Sheet (Technote 106) during each operating

shift. A Start-Up Data Sheet (Technote 105) should have been completed at startup

containing pertinent facts on the operation of your machine. These two records are

invaluable in diagnosing the performance of the equipment, and must be kept for

reference. If you have questions concerning the operation of your machine or the

method of data recording, contact the manufacturer.

Three preventative maintenance procedures, which must be done on a regular basis,

are as follows:

1. Change the pre-filter cartridges as needed. Pressure drop across the pre-

filters should not exceed 8 psi (0.6 bar).

2. Clean the RO membrane elements with approved cleaners at least quarterly,

depending on feed water quality.

3. Flush the RO machine daily.

4.1.1. Daily Flushing for the Economy Model

If your E4-Series machine is an ECN Model it needs to be manually flushed daily. The

DLX E4-Series machine is equipped with an Autoflush Timer (Section 3.5, Autoflush

Timer). A daily manual flush must be performed. To flush the machine:

1. With the machine running, open the concentrate valve 1/2 - 3/4 turn.

16

Page 17

NOTE: During flushing procedure, the machine must be running.

2. Allow the machine to operate with the concentrate valve open (Step 1) for 10 -

15 minutes.

3. After 10 - 15 minutes, return the concentrate valve to its previous setting, and

return to normal operation.

CAUTION: When opening the concentrate valve, never allow the machine’s

primary pressure to drop more than 10% below normal operating pressure.

4.1.2. Daily Flushing for the Deluxe Model

The DLX Model machine includes an Autoflush Timer Option. The Autoflush Timer

Option automatically flushes the machine at preset intervals.

4.2. Pre-filter Cartridge

A 1-micron pre-filter cartridge is factory installed to protect the membrane elements

and valves from particles, which may be in the feed water. To order replacements,

see the Spare Parts List.

A pressure drop across the filter of 8 psi (0.55 bar) or more during operation indicates

that the pre-filters cartridge(s) need changing. Use only GE approved filters rated for 5

microns or less. Do not attempt to clean used filters.

IMPORTANT NOTE: Failure to change the pre-filter cartridge according to these

requirements will void machine warranty.

4.3. Membrane Element Cleaning

GE recommends that you clean your RO every quarter, depending on the quality of

your feed water. Cleaning of the membrane elements is vital because contaminants

can build up on the membrane element surfaces, reducing the permeate flow rate

and affecting the quality of the permeate.

4.3.1. Step Wise Cleaning

This RO machine and many others have a centrifugal pump on them. Centrifugal

pumps are not designed to draw water. They are designed to operate with flooded

suction only. The manufacturer recommends using a Clean-In-Place (CIP), or booster

pump, to provide water pressure and flow to the RO machine pump from the CIP

container.

17

Page 18

4.3.2. Procedure to Clean with a CIP Pump

1. With the machine running, open the CIP permeate valve, close the permeate

service valve and fill the CIP tank with permeate water. When the container is

filled to desired level, turn machine OFF.

2. Add and mix up the cleaners in the CIP container. Please use only PA

membrane element compatible cleaners.

3. Close the inlet feed water supply valve to the machine and open the CIP inlet

feed water to the CIP container.

4. Close the permeate valve to point of use and also the concentrate valve drain.

5. Open the CIP valves, allowing permeate and concentrate to return to the CIP

container. When set properly, the RO machine, the CIP pump, and the CIP

container should be assembled in a loop configuration to recirculate the water

through the machine and back to the container during cleaning. The size of

the CIP container should be a minimum of three times the permeate rate.

CAUTION: GE recommends the use of a CIP or booster pump to provide the proper

feed water pressure and quantity to the RO machine during cleaning.

Figure 7. Clean-In-Place Pump and Tank Hook-Up

With the machine set-up in the CIP configuration and the cleaning solution mixed in

the container, you are now ready to start the CIP process. Follow the Steps below.

1. Check to ensure that the feed, permeate, and concentrate valves and line are

open and unrestricted in the tank loop.

18

Page 19

2. Start the CIP and RO machine pumps together. As they start up, observe all RO

machine pressures and flows.

3. Recycle the cleaning solution for about 15 minutes. Damage may result to

membrane elements if the temperature of the CIP solution exceeds 105°F

(40°C). If the water temperature exceeds 100°F (38°C), place bags of ice into

the CIP container to absorb the extra heat.

4. After recirculating the cleaner for 15 minutes, shut down the RO and the CIP

pump.

5. Let the CIP solution dwell in the machine for 20 minutes.

6. After the 20-minute dwell time, start the CIP recirculation process again for 10

minutes.

7. After the 10-minute recirculation time is complete, de-energize the machine.

Then, open the inlet water line and route the concentrate and permeate lines

to the drain.

8. Start the RO machine and flush to drain for 20 minutes. Verify the permeate

quality is good before returning to normal operation.

9. After permeate quality is verified as good, route the permeate to point of use

and concentrate to drain. You are now ready for normal operation.

4.4. Suction Cleaning

GE does not recommend the suction cleaning method to clean the E4-Series RO

machine. If using suction cleaning, reference cleaning with a CIP pump above

(Section 4.3.2, Procedure to Clean with a CIP Pump).

1. Arrange the RO and the CIP container in a closed loop situation with the

cleaning solution, reference Section 4.3 (Membrane Element Cleaning).

2. Move the L1 and L2 wires on the pressure switch across to the motor

terminals (Figure 5, Three Phase Allan Bradley Motor Starter). The wires can

also be temporally jumped.

3. Open the inlet feed valve.

4. Start the RO machine

5. As the machine starts up on inlet feed water, slowly close the inlet feed water

valve while slowing opening the feed water valve to the CIP tank.

You will begin to hear the RO pump draw the CIP solution into the machine

and circulate it back into the CIP tank. After achieving prime, observe the RO

19

Page 20

closely to ensure that you do not loose pump prime, which may result in pump

damage.

6. Refer to the CIP cleaning procedure (Section 4.3.1) for cleaning steps.

WARNING: LOSS OF PRIME DURING SUCTION CLEANING MAY RESULT IN SERIOUS

DAMAGE TO THE PUMP.

NOTE: As previously mentioned, the manufacturer recommends use of a CIP or

booster pump to circulate the cleaning solution during membrane element cleaning.

7. After suction cleaning cycle is complete, reopen inlet water and flush machine

to drain for twenty minutes.

8. After permeate quality is verified as good, return machine to normal operation

mode.

4.5. Changing Out Membrane Elements

CAUTION: Replacement membrane elements are shipped from the factory in a

plastic bag with a small amount of bactericide solution to prevent biological growth.

When installing the membrane elements, always provide adequate ventilation and

wear gloves while handling the membrane elements as recommended. The

membrane elements must be kept moist at all times in to prevent possible damage to

the membrane element material.

1. Remove the top end caps and clamps from the membrane element housings.

Lubricate all O-rings and brine seals, and the PVC membrane element stems

(stingers) with a non-petroleum based lubricate (i.e., glycerin or poly water).

2. Load the down flow membrane elements first, by inserting the membrane

element into the membrane element housing with the brine seal end of the

membrane element up. Slowly turn the membrane element as you lower it

into the membrane element housing. As you reach the bottom of the housing

slowly guide the PVC stem or stinger on the end of the membrane element

into the head of the end cap. As the membrane element slides into the

housing the brine seal will be on the top.

3. Next, load the up flow membrane elements, by lubricating all brine seals, O-

rings, and the membrane element stingers. With the up flow membrane

element and the brine seal will be on the bottom of the membrane element.

Turn the membrane element slowly as you lower it down into the housing. As

with the down flow membrane element, one must slowly guide the PVC

stinger on the end of the membrane element into the end cap.

20

Page 21

4. Reinstall the end caps by using non-petroleum based lubricant to lubricate the

O-ring inside the end cap. Reinstall the end cap on the membrane element by

first, aligning the stinger into the hole in the end cap and then turn the end

cap slowly clockwise, as you push it down into the membrane element

housing.

5. Reattach the housing clamp and tighten.

6. Next reconnect the permeate and concentrate lines.

The machine is ready for start-up.

21

Page 22

5. TROUBLESHOOTING

This troubleshooting guide can assist you in identifying common operating problems

you may experience with your machine. Many of these problems can be easily

corrected by the operator, however, for those that persist or are not understood, you

should contact the GE Customer Support Center. Have the following information

available when calling the Customer Support Center:

1. Machine installation date

2. Model number

3. Serial number

4. Weekly log sheets

5. Detailed description of problem

Table 5. Troubleshooting Guide

Symptom (Alarm) Possible Cause

Low inlet pressure

Low operating

pressure

Insufficient feed water

pressure

Clogged pre-filter Replace the pre-filters.

Solenoid valve not

opening

High flow rates Close the orifice bypass valve, check

Pump discharge screen

(low primary pressure)

Dirty or fouled

membranes

(low final pressure)

Warm operating

conditions

Pump rotating

backwards

(3-phase power only)

Pump not operating

correctly

Remedies

Increase the feed pressure, open the

inlet/feed valve, check for

restrictions, and consider installing a

feed water boost pump.

Clean or replace the solenoid valve.

Clean air line for adequate pressure.

Check regulator for correct

operation and setting.

the permeate and concentrate flow

rates and adjust if necessary.

Excessive permeate flow may

indicate improper interconnector

installation.

Inspect and clean.

Clean the membranes.

Correct temperature.

Switch any two 3-phase leads to the

motor starter.

See pump instructions.

22

Page 23

TROUBLESHOOTING GUIDE

Symptom (Alarm) Possible Cause

Low permeate flow

rate

Low operating

pressure

Dirty or fouled

membranes

Operating on cold

water less than 55 60°F (13 - 16°C)

Membranes installed

backwards or

damaged concentrate

seal

Flow meter inaccurate Check the flow rate manually with a

Low concentrate flow

rate, normal or higher

than normal pressure

Concentrate valve

plugged

Concentrate outlet line

restricted

Flow meter inaccurate Check the flow rate manually with a

High operating

pressure

Recycle or concentrate

lines plugged

Inaccurate pressure

gauge

Service and CIP valves

closed at the same

time

Restricted or reduced

permeate flow rate

Remedies

See the possible causes for low

operating pressure.

Clean the membranes.

Install a hot/cold feed water

tempering valve if more permeate

flow is needed. Operate with a feed

water temperature of 72 - 77°F (22 25°C).

Install membranes in the direction of

fluid flow. Clean the machine

immediately.

Membranes with damaged

concentrate seals should be

cleaned.

stopwatch and calibrated container

(such as CIP tank).

Disassemble and the clean the

plumbing to the valve.

Examine the concentrate line for

obstructions or a closed valve.

stopwatch and calibrated container.

Note: CIP tank can be used for this

purpose.

Disassemble the plumbing to the

recycle orifice and remove foreign

particles.

Replace or calibrate the gauge as

required.

Verify water path to both is open.

See the possible causes for low

permeate flow rate.

23

Page 24

TROUBLESHOOTING GUIDE

Symptom (Alarm) Possible Cause

Excessive pressure

drop [exceeding max

Restricted flow after

pump outlet

∆P] (high primary

pressure – low final

pressure)

Telescoped membrane

covering membrane

housing outlet port

Severely fouled or dirty

membranes

Water flowing when

machine is turned off

Inlet control valve not

closing or seating

properly.

Declining rejection

(high permeate

conductivity)

Dirty or fouled

membranes

O-ring seal broken or

damaged

Change in incoming

water quality

Inaccurate

conductivity monitor or

fouled probe

Low recycle flow Adjust recycle flow (if applicable).

Remedies

Check for blockage of the

concentrate flow at the inlets and

outlets of the membrane housings.

Check for blockage at the pump

discharge screen.

Ensure that the anti-telescoping

device (ATD) is located properly on

the membrane.

Clean the membranes.

Clean or replace the solenoid valve.

Clean the membranes immediately.

Water must not pass through the

inlet when the machine is off.

Repair or replace valve components

as necessary.

Clean the membranes.

Replace the O-ring, check the

sealing surfaces on the O-ring

groove, interconnectors and end

caps. Replace damaged parts.

NOTE: This typically only happens

immediately after membrane

installation.

Open the concentrate valve and

flush. Test the water for pH,

hardness, TDS, and iron content. A

water analysis should be sent to GE

Water & Process Technologies for

review.

Calibrate the monitor with a

conductivity standard solution or

check the readings with another

conductivity meter. Replace or clean

the probe. Check the connections

between the probe and monitor.

24

Page 25

TROUBLESHOOTING GUIDE

Symptom (Alarm) Possible Cause

Switch on, unit not

operating

Pressurized storage

switch or float switch

has cut power to the

machine

Thermal overload in

motor has tripped.

No power to machine. Check the fuses or circuit breakers;

Deluxe (DLX) Electrical

machine shutdown

Alarm condition has

turned off machine.

Motor and/or pump

not operating properly.

Timer relay

defective/burned out

Motor starter

overloaded, heater

tripped.

Remedies

Check the permeate backpressure

or position of float in the storage

tank.

Allow the machine to cool; check the

feed water supply and/or amp draw

of the motor.

measure the voltage.

Restart the machine by pushing the

alarm bypass. Check all possible

alarm conditions; inlet pressure and

push alarm reset switch.

See the pump instructions. Contact

GE for repair of replacement.

Replace the relay.

Turn the switch off; let the heater(s)

cool.

25

Page 26

6. SPARE PARTS LIST

For detailed spare part lists, please refer to the manual addendum. Contact the GE

Water & Process Technologies Customer Support Center to order parts.

7. RETURN GOODS AUTHORIZATION (RGA)

PROCEDURE

Refer to addendum Technote 114.

8. WARRANTY/GUARANTEE

Refer to addendum Technote 100 for the machine Warranty/Guarantee document.

9. START-UP DATA

Refer to addendum Technote 101 for the machine startup data sheet document.

10. DAILY LOG DATA FOR GE WATER AND

PROCESS TECHNOLOGIES MEMBRANE MACHINES

Refer to addendum Technote 106 for the daily log data sheet document.

26

Loading...

Loading...