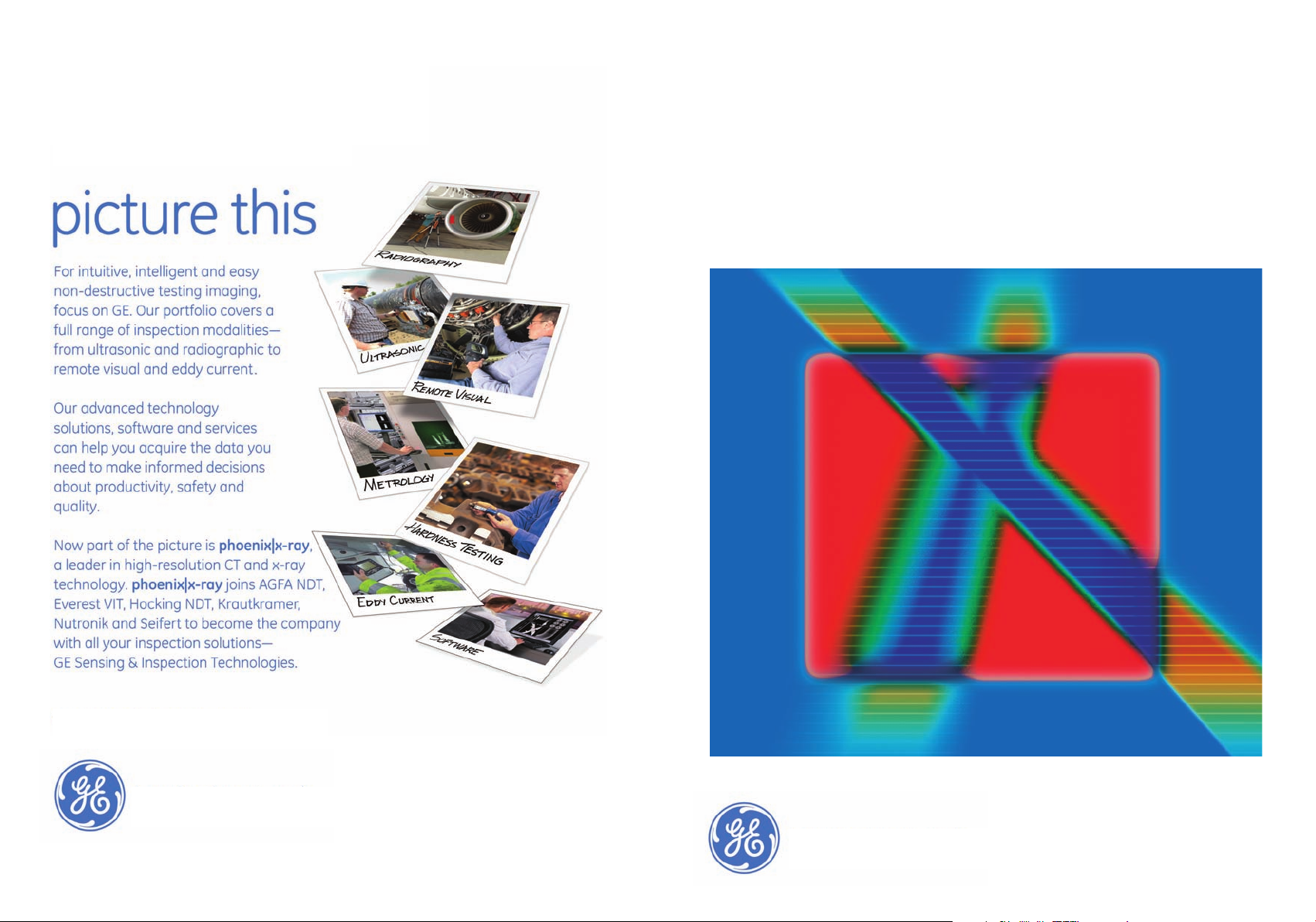

Page 1

Industrial Radiography

Image forming techniques

Issued by GE Inspection Technologies

©

2006 General Electric Company. All Rights Reserved. We reserve the right to technical modifications without prior notice. GEIT-30158EN (06/08)

GE

Inspection Technologies

GE imagination at work

GE imagination at work

Inspection Technologies

GE

Inspection Technologies

www.geinspectiontechnologies.com/en

Page 2

Industrial Radiography

Image forming techniques

1

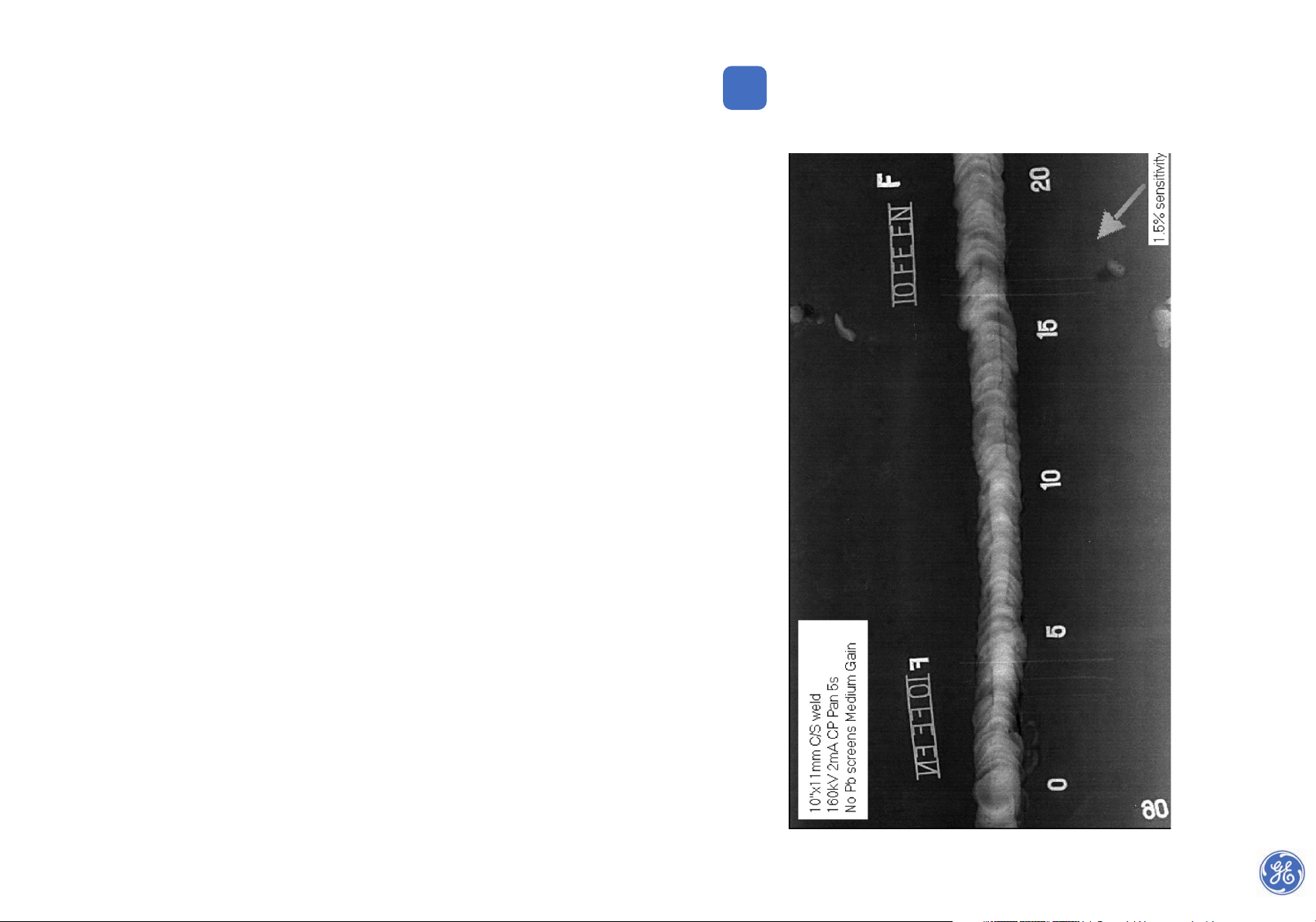

Digital radiography CR-image of a weld

see acknowledgements*

Page 3

The first issue of “Industrial Radiography” was published by Agfa in the sixties, for

educational and promotional purposes. Some improved editions have been released since,

providing information on the latest image forming radiographic techniques.

The booklet has been published in a number of languages and has been very much in demand.

The latest edition was compiled in the seventies but is now obsolete, because of the large

number of computer-aided NDT techniques which have entered the market in recent years.

In 2007 a new edition in the English language was published by GE Inspection Technologies.

That edition was compiled by Mr. J.A. de Raad, NDT-expert and consultant, who has a

considerable number of publications on the subject of Non-Destructive Testing to his name.

Mr. A. Kuiper, an experienced specialist and tutor on industrial radiography, assisted him.

Both had been involved in Non-Destructive Testing during their professional careers at

Applus RTD NDT & Inspection headquartered in Rotterdam, the Netherlands.

Apart from the developments in conventional radiography, primarily regarding X-ray

equipment and films, the 2007 issue describes the now mature methods of digital radiography

using radiation-sensitive plate- and panel detectors, including digitisation of traditional film.

Several other computer-assisted methods such as the CT technique are also included as well

as a separate chapter describing a variety of applications.

In this latest 2008 edition we considerably extended the chapters on digital radiography and

special techniques, such as microfocus and X-ray microscopy. In addition, the impact and

(non) existence of norms, codes and standards on new NDT-technologies and their applications

are addressed.

We trust that this new issue of “Industrial Radiography” will fulfil a need once again.

GE Inspection Technologies, 2008

The author expresses his appreciation to all employed by GE Inspection Technologies and

Applus RTD NDT & Inspection who cooperated and provided ample information to update

this new edition.

3

Introduction to the overview of

“Industrial Radiography”

Image forming techniques

2

Page 4

Introduction to the overview of “Industrial Radiography”

Image forming techniques

Preface 13

1. Introduction to industrial radiography 15

2. Basic properties of ionising radiation 19

2.1 Wavelengths of electromagnetic radiation 19

2.2 X-rays 20

2.3 Gamma-rays (γ-rays) 21

2.4 Main properties of X-rays and γ-rays 22

2.5 Radiation energy-hardness 22

2.6 Absorption and scattering 23

Photoelectric effect

Compton effect

Pair production

Total absorption/attenuation

2.7 Penetrating power 25

2.8 Filtering (hardening) 26

2.9 Half-value thickness 26

3. Units and definitions 29

3.1 Units 29

3.2 Definitions 30

Radioactivity

Ionisation dose rate

Ionisation dose

Absorbed energy dose

Equivalent dose (man dose)

4. Radiation sources 33

4.1 X-ray tube 33

4.2 The anode 33

Cooling the anode

The focal spot

Effective focal spot size

4.3 Tube voltage and tube current 35

4.4 Radioactive sources (isotopes) 36

Natural radioactive sources

4

Contents

Artificial radioactive sources

4.5 Advantages and disadvantages of artificial radioactive sources 36

4.6 Properties of radioactive sources 37

Activity (source strength)

Specific activity

Specific gamma-ray emission (k-factor)

Half-life of a radioactive source

5. NDT equipment 39

5.1 X-ray equipment 39

Types of X-ray tubes

Bipolar X-ray tubes

Unipolar X-ray tubes

Special types of X-ray tubes

5.2 High voltage generators 41

5.3 Megavolt equipment 42

The Bètatron

The linear accelerator (linac)

5.4 Radioactive sources 45

Average energy level (nominal value)

5.5 Source holders (capsules) 46

5.6 Transport- and exposure containers 46

5.7 Checking for container leakage 49

6. Radiation images, filters and intensifying screens 51

6.1 Radiation images 51

6.2 Radiation filters 53

6.3 Intensifying screens 53

Lead screens

Steel and copper screens

Fluorescent screens

Fluorescent salt screens

Fluorometallic screens

7. The X-ray film and its properties 59

7.1 Structure of the X-ray film 59

7.2 Radiographic image 59

Latent image

Developing the latent image

7.3 Characteristics of the X-ray film 60

Density (optical)

Contrast

7.4 Characteristic curve (density curve) 61

5

Page 5

7

Stopbath

Fixing

Final wash

Drying in the drying cabinet

Roller dryers

10.3 Recommendations for the darkroom 90

10.4 Silver recovery 90

10.5 Automatic film processing 91

NDT-U (universal) film processor

NDT-E (economy) film processor

10.6 Checking the developing process and film archiving properties 93

PMC-strips to check the developing process

Thiosulphate-test to check the film archival properties

10.7 Storage of exposed films 95

11. Defect discernibility and image quality 97

11.1 Unsharpness 97

Geometric unsharpness

Inherent (film) unsharpness

Total unsharpness

11.2 Selection source-to-film distance 101

11.3 Other considerations with regard to the source-to-film distance 102

Inverse square law

Selection of radiation energy (kV)

Selection of gamma source

11.4 Radiation hardness and film contrast 104

11.5 Summary of factors that influence the image quality 105

12. Defect orientation, image distortion and useful film length 107

12.1 Defect detectability and image distortion 107

12.2 Useful film length 108

13. Image quality 111

13.1 Factors influencing image quality 111

13.2 Image quality indicators (IQI) 112

Wire type IQI according to EN 462-1

13.3 List of common IQI’s 114

ASTM IQI’s

AFNOR IQI’s

Duplex IQI’s

13.4 Position of the IQI 117

13.5 IQI sensitivity values 117

14. Film exposure and handling errors 119

6

Gradient of the density curve

Average gradient

Effect of developing conditions on the density curve

7.5 Film speed (sensitivity) 65

7.6 Graininess 65

8. Film types and storage of films 67

8.1 The Agfa assortment of film types 67

8.2 Film type selection 70

8.3 Film sizes 70

8.4 Handling and storage of unexposed films 70

9. Exposure chart 73

9.1 Exposure chart parameters 73

Type of X-ray equipment

The radioactive source

Source-to-film distance

Intensifying screens

Type of film

Density

Developing process

9.2 Densitometer 75

9.3 Producing an exposure chart for X-rays 75

9.4 The exposure chart 78

9.5 Use of the exposure chart 78

9.6 Relative exposure factors 80

9.7 Absolute exposure times 80

9.8 Use of the characteristic (density) curve with an exposure chart 81

10. Processing and storage of X-ray films 85

10.1 The darkroom 85

Entrance and colour

Darkroom lighting

Darkroom layout

Tanks

10.2 Chemicals and film-development 86

Making-up processing solutions

Developer

Fixer

Developing time and bath temperatures

Film agitation

Replenishing

Page 6

9

16.7 Resolution number of bits 163

Bit depth

Lateral resolution

16.8 Comparison of film, CR- and DR methods 164

16.9 Impact and status of CR- and DR standards 165

Development of standards

Status of CR standards

Status of DR standards

Impact of standards

Standards for weld inspection

Data exchange and tamper proof standard

16.10 Selection of CR- and DR methods 167

16.11 Applications for CR- and DR methods 168

Corrosion detection

Weld inspection

Dose reduction and controlled area

Automated/mechanised inspection

Girth weld inspection

Useful life of plate and panel

16.12 Work station 171

Hardware and software

Versatility of the software

Archiving and reliability of images

Exchange of data

17. Special radiographic techniques 17 7

17.1 Image magnification techniques 177

17.1.1 Common image magnification technique 177

17.1.2 High resolution X-ray microscopy 178

Magnification factors

Microfocus and nanofocus X-ray tubes

Tube heads

System set-up

Effect of focal dimensions

Imaging systems for high resolution radiography

17.2 Fluoroscopy, real-time image intensifiers 182

Stationary real-time installations

Portable real-time equipment

17.3 Computer Tomography (CT) 185

Unique features

Computing capacity and scanning time

Reverse engineering

CT metrology

High resolution and defect sizing

8

15. Film interpretation and reference radiographs 123

15.1 Film interpretation 123

15.2 The film-interpreter 124

15.3 Reference radiographs 124

Weld inspection

Casting radiography

Examination of assembled objects

16. Digital Radiography (DR) 14 5

16.1 Introduction to DR 145

16.2 Digital image formation 146

16.3 Digitisation of traditional radiographs 146

16.4 Computed Radiography (CR) 148

Two-step digital radiography

The CR imaging plate

Image development

Scanners-Readers

CR cassettes

Dynamic range-Exposure latitude

Exposure time and noise

Fading

Optimisation

Improvements

16.5 Genuine Digital Radiography (DR) 153

One-step digital radiography

16.5.1 Detector types 153

Direct versus indirect detection

Linear detectors

2D detectors

16.5.2 Fill Factor 155

16.5.3 Flat panel and flat bed detector systems 156

Amorphous silicon flat panels

CMOS detectors and flat bed scanners

Limitations

16.6 Image quality and exposure energy 158

16.6.1 Exposure energy 158

16.6.2 Determination of image quality 159

16.6.3 Indicators of image quality- MTF and DQE 160

Factors influencing image quality

Image quality definitions

Exposure parameters

MTF (Modulation Transfer Function)

DQE (Defective Quantum Efficiency)

Noise, image averaging and DQE

Page 7

11

20.

Standards, literature / references, acknowledgements and appendices

215

European norms (EN-standards)

Literature and references

Acknowledgements

Appendices: tables and graphs.

10

17.4 CT for defect detection and sizing 187

Effect of defect orientation

3D CT for sizing of defects in (welded) components

17.5 Neutron radiography (neutrography) 190

17.6 Compton backscatter technique 190

18. Special radiographic applications 193

18.1 Measuring the effective focal spot 193

18.2 Radiographs of objects of varying wall thickness 194

18.3 Radiography of welds in small diameter pipes 195

Elliptical technique

Perpendicular technique

18.4 Determining the depth position of a defect 197

18.5 Determining the depth position and diameter of

reinforcement steel in concrete 198

18.6 On-stream inspection - profiling technique 198

Projection technique

Tangential technique

Selection of source, screens and filters

Exposure time

18.7 Flash radiography 201

18.8 Radiography of welds in large diameter pipes 202

19. Radiation hazards, measuring- and recording instruments 207

19.1 The effects of radiation on the human body 179 207

19.2 Responsibilities 207

The client

The radiographer

19.3 The effects of exposure to radiation 208

19.4 Protection against radiation 208

19.5 Permissible cumulative dose of radiation 209

19.6 Radiation measurement and recording instruments 210

Radiation measuring instruments

Dose rate meters

Scintillation counter

Personal protection equipment

Pendosismeter (PDM)

Thermoluminescent dose meter (TLD-badge)

Film dose meter (film-badge)

19.7 Dose registration 212

19.8 Radiation shielding 212

Distance

Absorbing barrier and distance

Page 8

Preface

13

To verify the quality of a product, samples are taken for examination or a non-destructive

test (NDT) is carried out. In particular with fabricated (welded) assemblies, where a high

degree of constructional skill is needed, it is necessary that non-destructive testing is

carried out.

Most NDT systems are designed to reveal defects, after which a decision is made as to

whether the defect is significant from the point of view of operational safety and/or

reliability. Acceptance criteria for weld defects in new constructions have been specified

in standards.

However, NDT is also used for purposes such as the checking of assembled parts, the

development of manufacturing processes, the detection of corrosion or other forms of

deterioration during maintenance inspections of process installations and in research.

There are many methods of NDT, but only a few of these allow the full examination of a

component. Most only reveal surface-breaking defects.

One of the longest established and widely used NDT methods for volumetric examination

is radiography: the use of X-rays or gamma-rays to produce a radiographic image of an

object showing differences in thickness, defects (internal and surface), changes in

structure, assembly details etc. Presently, a wide range of industrial radiographic equipment, image forming techniques and examination methods are available. Skill and experience are needed to select the most appropriate method for a particular application.

The ultimate choice will be based on various factors such as the location of the object to

be examined, the size and manoeuvrability of the NDT equipment, the existance of

standards and procedures, the image quality required, the time available for inspection

and last but not least financial considerations.

This book gives an overview to conventional industrial radiography, as well as digital

(computer-aided) techniques and indicates the factors which need to be considered for

selection of the most suitable system and procedures to be followed.

At the end of the book a chapter is added describing aspects of radiation safety.

12

Page 9

1514

1

Introduction to industrial radiography

Image forming techniques

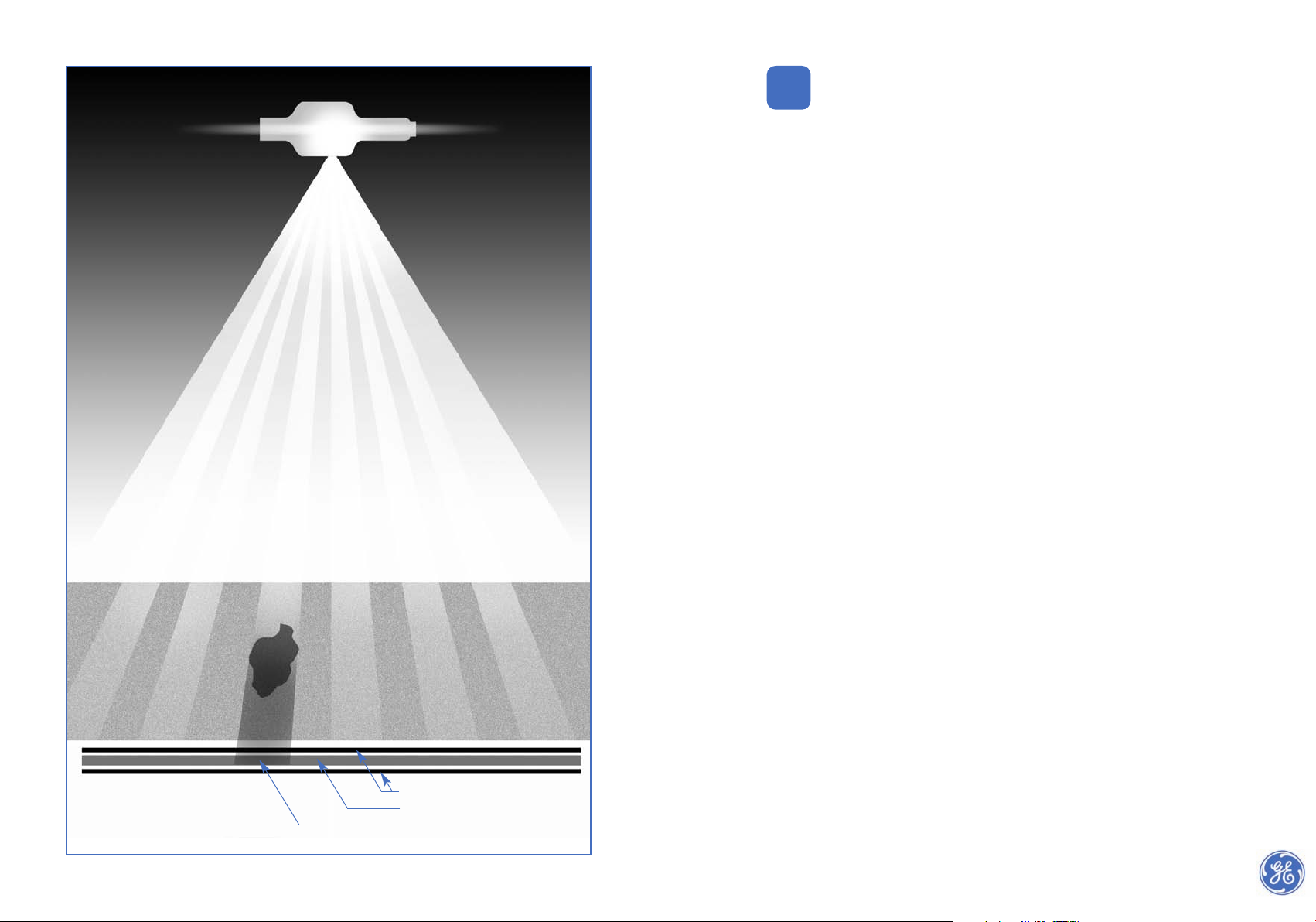

In industrial radiography, the usual procedure for producing a radiograph is to have a

source of penetrating (ionising) radiation (X-rays or gamma-rays) on one side of the

object to be examined and a detector of the radiation (the film) on the other side as shown

in figure 1-1. The energy level of the radiation must be well chosen so that sufficient radiation is transmitted through the object onto the detector.

The detector is usually a sheet of photographic film, held in a light-tight envelope or cassette having a very thin front surface that allows the X-rays to pass through easily.

Chemicals are needed to develop the image on film, which is why this process is called the

classic or “ wet” process.

Nowadays, different kinds of radiation-sensitive films and detectors not requiring the use

of chemicals to produce images, the so-called “dry” process, are used increasingly. These

techniques make use of computers, hence the expressions; digital or computer aided

radiography (CR) or genuine (true) digital radiography (DR), see chapter 16.

A DR related technique that has been available for many decades is the one in which images are formed directly with the aid of (once computerless) radiation detectors in combination with monitor screens (visual display units: VDU’s), see chapter 17. This is in fact is

an early version of DR.

These through transmission scanning techniques (known as fluoroscopy) the storage of

images and image enhancement are continually improved by the gradual implementation

of computer technology. Nowadays, there is no longer a clear division between conventional fluoroscopy with the aid of computers and the entirely computer-aided DR. In time

DR will, to some extent, replace conventional fluoroscopy.

Summarising, the image of radiation intensities transmitted through the component can

be recorded on:

The conventional X-ray film with chemical development, the “ wet” process, or one of

the following “dry” processes:

• A film with memory phosphors and a work station for digital radiography, called

computer-assisted radiography or CR.

• Flat panel and flat bed detectors and a computer work station for direct

radiography, called DR.

• A phosphorescent or fluorescent screen (or similar radiation sensitive medium)

and a closed-circuit television (CCTV) camera as in conventional fluoroscopy,

an early version of direct radiography.

Fig. 1-1. Basic set-up for film radiography

screens

X-ray film

projection of defect on film

cavity

object

homogeneous

radiation

source

Page 10

1716

• By means of radiation detectors, e.g.: crystals, photodiodes or semiconductors in a

linear array by which in a series of measurements an image is built up of a moving

object. This method is applied in systems for luggage checks on airports.

The source of radiation should be physically small (a few millimetres in diameter), and as

X-rays travel in straight lines from the source through the specimen to the film, a sharp

“image” is formed of the specimen and discontinuities. This geometric image formation is

identical to the shadow image with a visible light source. The sharpness of the image

depends, in the same way, on the radiation source diameter and its distance away from

the surface on which the image is formed.

The “classic” film in its light-tight cassette (plastic or paper) is usually placed close behind

the specimen and the X-rays are switched on for an appropriate time (the exposure time)

after which the film is taken away and processed photographically, i.e. developed, fixed,

washed and dried. In direct radiography (DR), a coherent image is formed directly by

means of an computerised developing station.

The two methods have a negative image in common. Areas where less material (less

absorption) allows more X-rays to be transmitted to the film or detector will cause increased density. Although there is a difference how the images are formed, the interpretation of the images can be done in exactly the same way. As a result, the DR- technique is

readily accepted.

The “classic” film can be viewed after photochemical treatment (wet process) on a film

viewing screen. Defects or irregularities in the object cause variations in film density

(brightness or transparency). The parts of the films which have received more radiation

during exposure – the regions under cavities, for example – appear darker, that is, the film

density is higher. Digital radiography gives the same shades of black and white images,

but viewing and interpretation is done on a computer screen (VDU).

The quality of the image on the film can be assessed by three factors, namely :

1. Contrast

2. Sharpness

3. Graininess

As an example, consider a specimen having a series of grooves of different depths machined in the surface. The density difference between the image of a groove and the background density on the radiograph is called the image contrast. A certain minimum image

contrast is required for the groove to become discernible.

With increased contrast:

a. the image of a groove becomes more easily visible

b. the image of shallower grooves will gradually also become discernible

Assuming the grooves have sharp-machined edges, the images of the grooves could

still be either sharp or blurred; this is the second factor: image blurring, called image

unsharpness.

At the limits of image detection it can be shown that contrast and unsharpness are interrelated and detectability depends on both factors.

As an image on a photographic film is made up of grains of silver, it has a grainy appearance, dependent on the size and distribution of these silver particles. This granular appearance of the image, called film graininess, can also mask fine details in the image.

Similarly, in all other image forming systems these three factors are fundamental parameters. In electronic image formation, e.g. digital radiography or scanning systems with

CCTV and screens, the factors contrast, sharpness and noise are a measure for the image

quality; pixel size and noise being the (electronic) equivalent of graininess .

The three factors: contrast, sharpness and graininess or noise are the fundamental parameters that determine the radiographic image quality. Much of the technique in making

a satisfactory radiograph is related to them and they have an effect on the detectability of

defects in a specimen.

The ability of a radiograph to show detail in the image is called “radiographic sensitivity”.

If very small defects can be shown, the radiographic image is said to have a high (good)

sensitivity. Usually this sensitivity is measured with artificial “defects” such as wires or

drilled holes. These image quality indicators (IQIs) are described in chapter 13.

Page 11

2

Basic properties

of ionising radiation

19

In 1895 the physicist Wilhelm Conrad Röntgen discovered a new kind of radiation, which

he called X-rays. The rays were generated when high energy electrons were suddenly

stopped by striking a metal target inside a vacuum tube – the X-ray tube.

It was subsequently shown that X-rays are an electromagnetic radiation, just like light,

heat and radiowaves.

2.1 Wavelengths of electromagnetic radiation

The wavelength lambda (λ) of electromagnetic radiation is expressed in m, cm, mm,

micrometer (μm), nanometer (nm) and Ångstrom (1 Å = 0.1 nm).

18

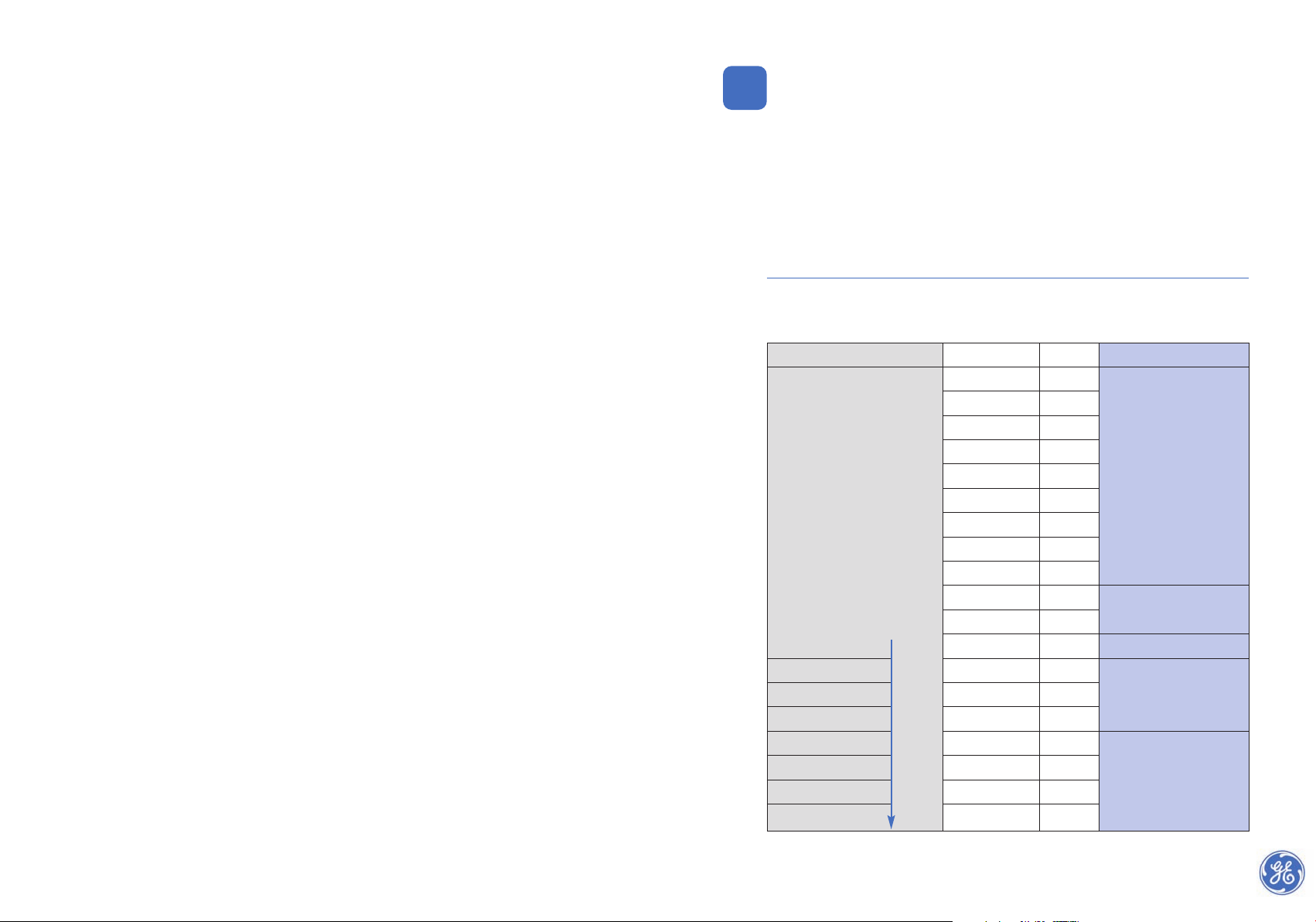

Electromagnetic radiation Wavelength λ m Type

10 km 10

4

1 km 10

3

100 m 10

2

10 m 10

1

1 m 1

10 cm 10

-1

1 cm 10

-2

1 mm 10

-3

100 μm 10

-4

10 μm 10

-5

1 μm 10

-6

100 nm 10

-7

10 nm 10

-8

1 nm 10

-9

0.1 nm 10

-10

0.01 nm 10

-11

1 pm 10

-12

0.1 pm 10

-13

0.01 pm 10

-14

X-ray energy

100 eV

1 keV

10 keV

100 keV

1 MeV

10 MeV

100 MeV

Visible light and Ultraviolet (UV)

X-rays and Gamma-rays

(Radiography)

Heat-rays, Infra-red rays,

microwaves

Table 1-2. Overview of wavelength, energy and type of electromagnetic radiation

Page 12

2.2 X-rays

The radiation which is emitted by an X-ray

tube is heterogeneous, that is, it contains

X-rays of a number of wavelengths, in the

form of a continuous spectrum with some

superimposed spectrum lines.

See fig. 1-2.

The shortest wavelength of the spectrum is

given by the Duane-Hunt formula:

In which :

λ = wavelength in nanometers (10

-9

m)

kV = voltage in kilovolts

The average shape of the X-ray spectrum is generally the same however not truely identical

for different X-ray sets; it depends chiefly on the energy range of the electrons striking the

X-ray tube target and, therefore, on the voltage waveform of the high-voltage generator.

A constant potential (CP) X-ray set will not have the same spectrum as a self-rectified set

operating at the same nominal kV and current. The spectrum shape also depends on the

inherent filtration in the X-ray tube window (glass, aluminium, steel or beryllium).

The energy imparted to an electron having a charge e, accelerated by an electrical potential V is (eV) so the energy of the electrons can be quoted in eV, keV, MeV. These same

units are used to denote the energy of an X-ray spectrum line.

The energy of a single wavelength is :

In which:

E = the energy in electronVolt (eV)

h = Planck’s constant

v = frequency

c = the velocity of electromagnetic radiation, such as light (300,000 km/s)

The heterogeneous X-rays emitted by an X-ray tube do not however have a single

wavelength, but a spectrum, so it would be misleading to describe the X-rays as (say)

120 keV X-rays. By convention therefore, the ‘e’- in keV- is omitted and the X-rays

described as 120 kV, which is the peak value of the spectrum.

21

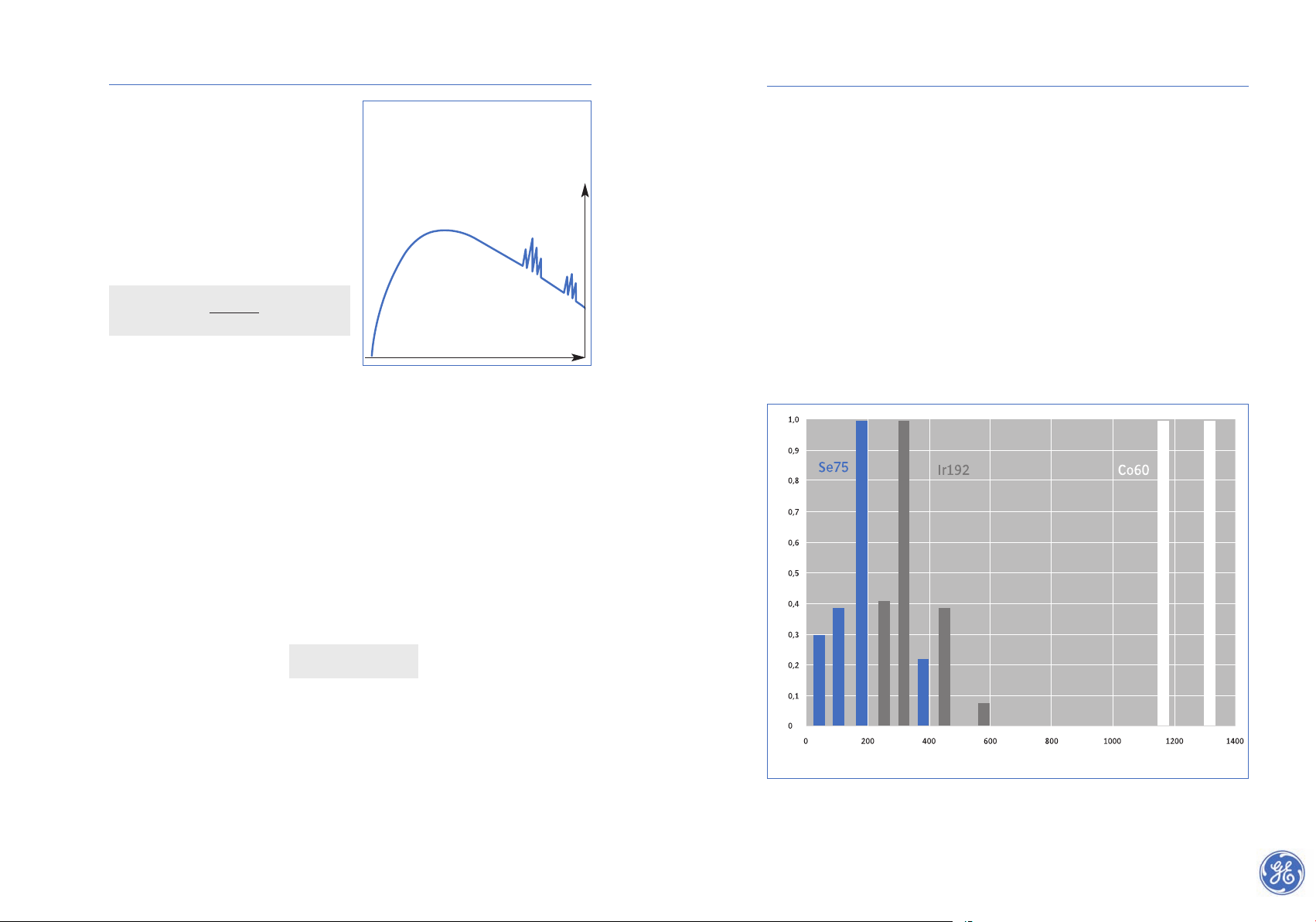

2.3 Gamma-rays (γ-rays)

Radioactivity is the characteristic of certain elements to emit alpha (α), beta (β) or

gamma (γ) rays or a combination thereof. Alpha and beta rays consist of electrically charged particles, whereas gamma rays are of an electromagnetic nature.

Gamma rays arise from the disintegration of atomic nuclei within some radioactive substances, also known as isotopes. The energy of gamma-radiation cannot be controlled; it

depends upon the nature of the radioactive substance. Nor is it possible to control its

intensity, since it is impossible to alter the rate of disintegration of a radioactive substance.

Unlike X-rays, generated to a continuous spectrum, Gamma-rays are emitted in an isolated line spectrum, i.e. with one or more discrete energies of different intensities.

Figure 2-2 shows the energy spectrum lines for Selenium75, Cobalt60 and Iridium192.

In practical NDT applications, sources (radio active isotopes) are allocated an average

nominal energy value for calculation purposes, see section 5.4. Spectrum components

with the highest energy levels (keV values) influence radiographic quality the most.

20

λ

min

=

1.234

Ε=h.v λ.v=c

kV

Fig. 1-2. X-ray spectrum – intensity/wavelength

distribution

The small peaks are the characteristic radiation of the

target material

wavelength

intensity

relative intensity

energy (keV)

Fig. 2-2. Energy spectrum (lines) for Se75, Ir192 and Co60

Page 13

2.4 Main properties of X-rays and γ-rays

X-rays and γ-rays have the following properties in common:

1. invisibility; they cannot be perceived by the senses

2. they travel in straight lines and at the speed of light

3. they cannot be deflected by means of a lens or prism, although their path can be bent

(diffracted) by a crystalline grid

4. they can pass through matter and are partly absorbed in transmission

5. they are ionising, that is, they liberate electrons in matter

6. they can impair or destroy living cells

2.5 Radiation energy-hardness

Radiation hardness (beam quality) depends on wavelength. Radiation is called hard

when its wavelength is small and soft when its wavelength is long. In industry the quality

of the X-ray tube ranges from very soft to ultra hard. The beam quality is related to a tube

voltage (kV) range, or keV for isotopes.

The first two columns of table 2-2 below indicate the relationship hardness/tube voltage

range applied in NDT. The third column gives the related qualification of the radiation

effect, i.e. half-value thickness (HVT), described in detail in section 2.9.

Table 2-2. Comparative values of radiation quality (hardness) against tube voltage.

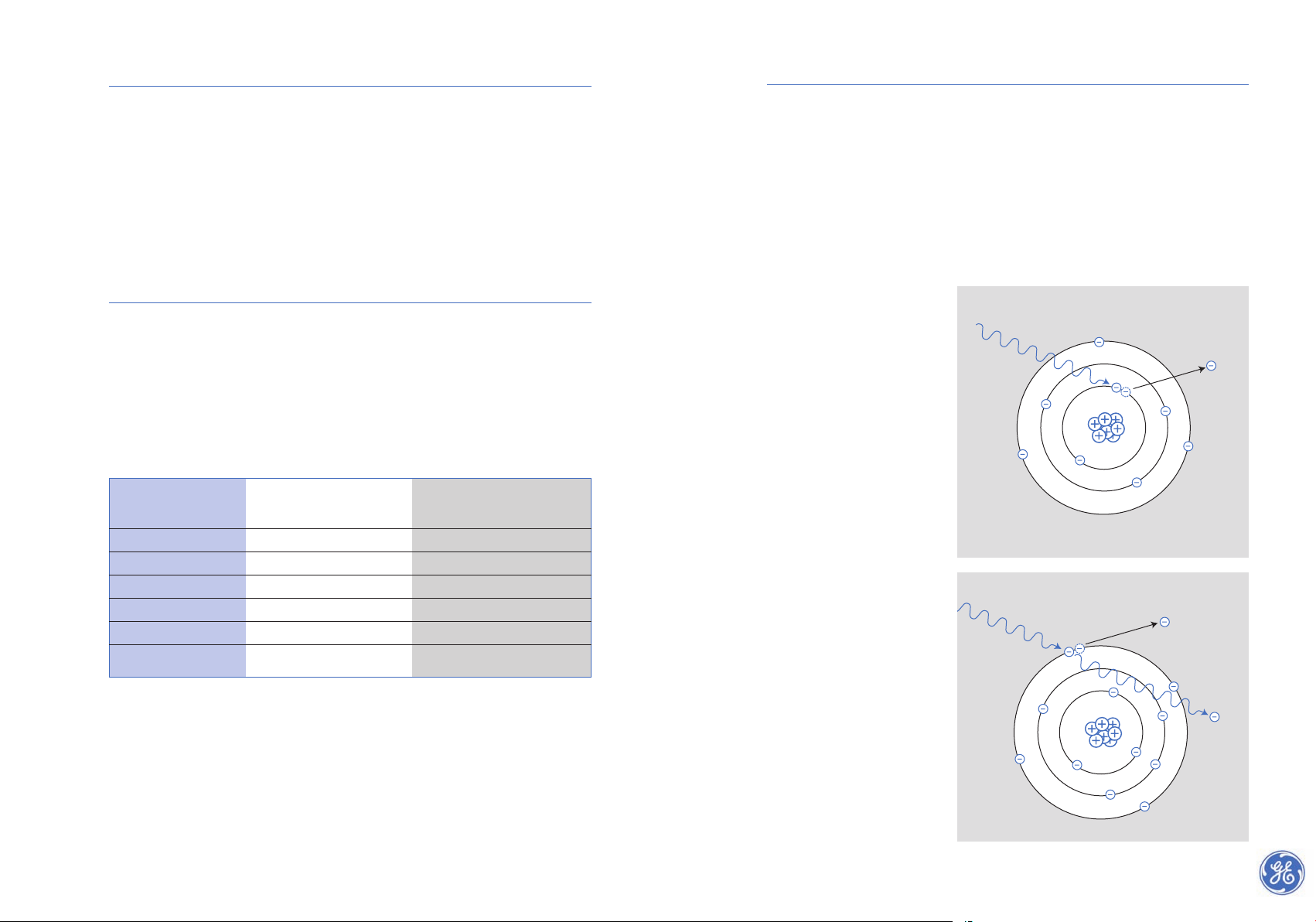

2.6 Absorption and scattering

The reduction in radiation intensity on penetrating a material is determined by the

following reactions :

1. Photoelectric effect

2. Compton effect

3. Pair production

Which of these reactions will predominate depends on the energy of the incident

radiation and the material irradiated.

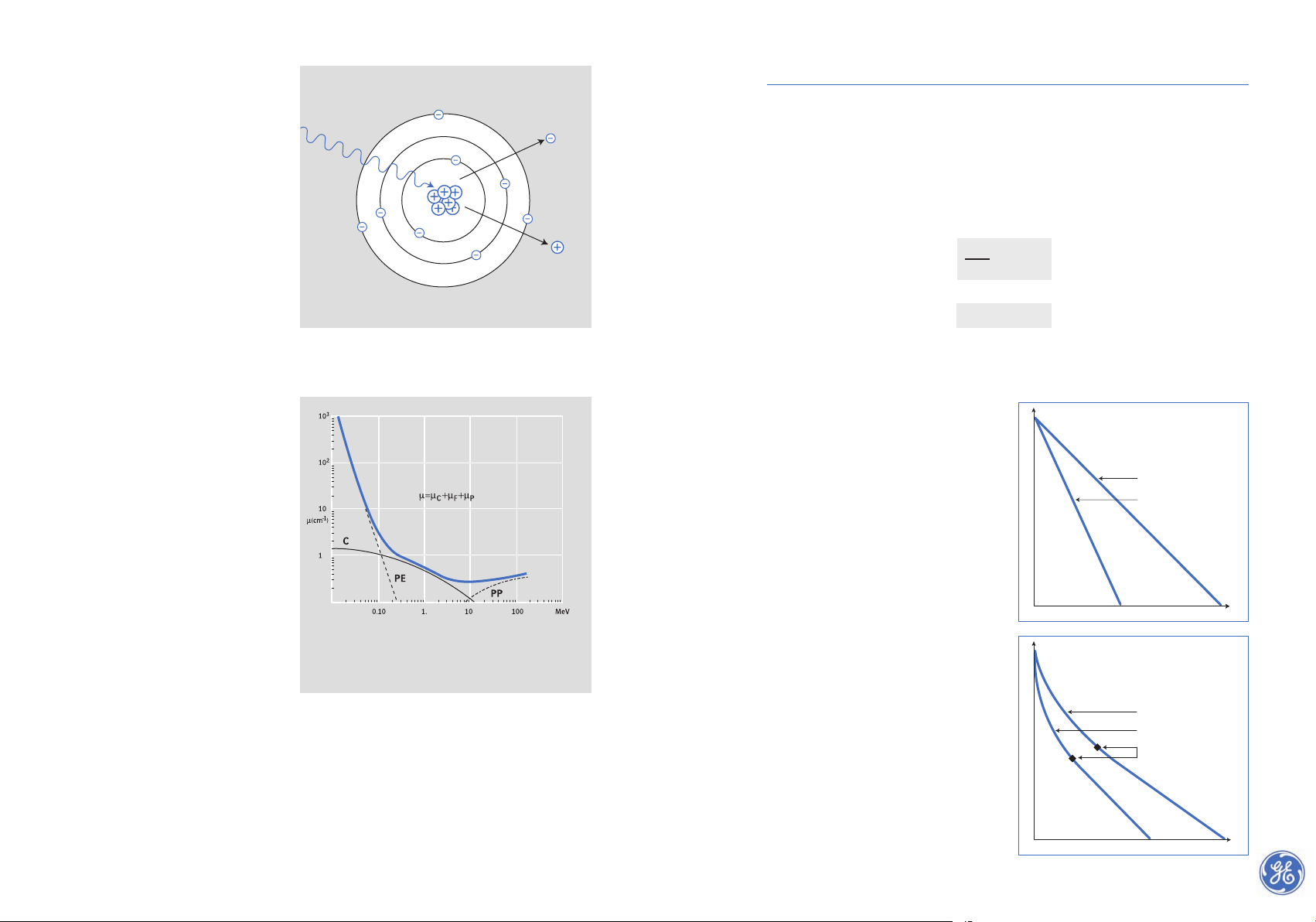

Photoelectric effect

When X-rays of relatively low

energy pass through a material

and a photon collides with an

atom of this material, the total

energy of this photon can be

used to eject an electron from the

inner shells of the atom, as figure

3-2 illustrates. This phenomenon

is called the photoelectric effect

and occurs in the object, in the

film and in any filters used.

Compton effect

With higher X-ray energies (100

keV to 10 MeV), the interaction

of photons with free or weakly

bonded electrons of the outer

atom layers causes part of the

energy to be transferred to these

electrons which are then

ejected,

as illustrated in figure 4-2.

At the

same time the photons will be

deflected from the initial angle

of incidence and emerge from

the collision as radiation of reduced energy, scattered in all directions including backward, known

as “backscatter”, see section 17.6.

In this energy band, the absorption of radiation is mainly due to

the Compton effect and less so to

the photoelectric effect.

22

Radiation quality Tube voltage Global half-value

Hardness thickness for steel (mm)

Very soft Less than 20 kV

Soft 20 – 60 kV

Fairly soft 60 – 150 kV 0.5-2

Hard 150 – 300 kV 2-7

Very hard 300 – 3000 kV 7-20

Ultra hard more than 3000 kV > 20

incident

X-ray s

ejected

electron

Fig. 3-2. Photoelectric effect

X-ray

100keV - 10 MeV

ejected

electron

scattered

radiation

Fig. 4-2. Compton effect

23

Page 14

2.7 Penetrating power

The penetrating power of X-radiation increases with the energy (hardness).

The relationship of energy and penetrating power is complex as a result of the various

mechanisms that cause radiation absorption. When monochromatic ( homogeneous single wave length) radiation with an intensity I

o

passes through matter, the relative

intensity reduction ΔI/I

o

is proportional to the thickness Δt. The total linear absorption

coefficient (μ) consisting of the three components described in section 2.6 is defined by

the following formula:

Expressed differently:

In which:

Io= intensity at material entry t = thickness

I = intensity at material exit e = logarithm: 2.718

μ = total absorption coefficient

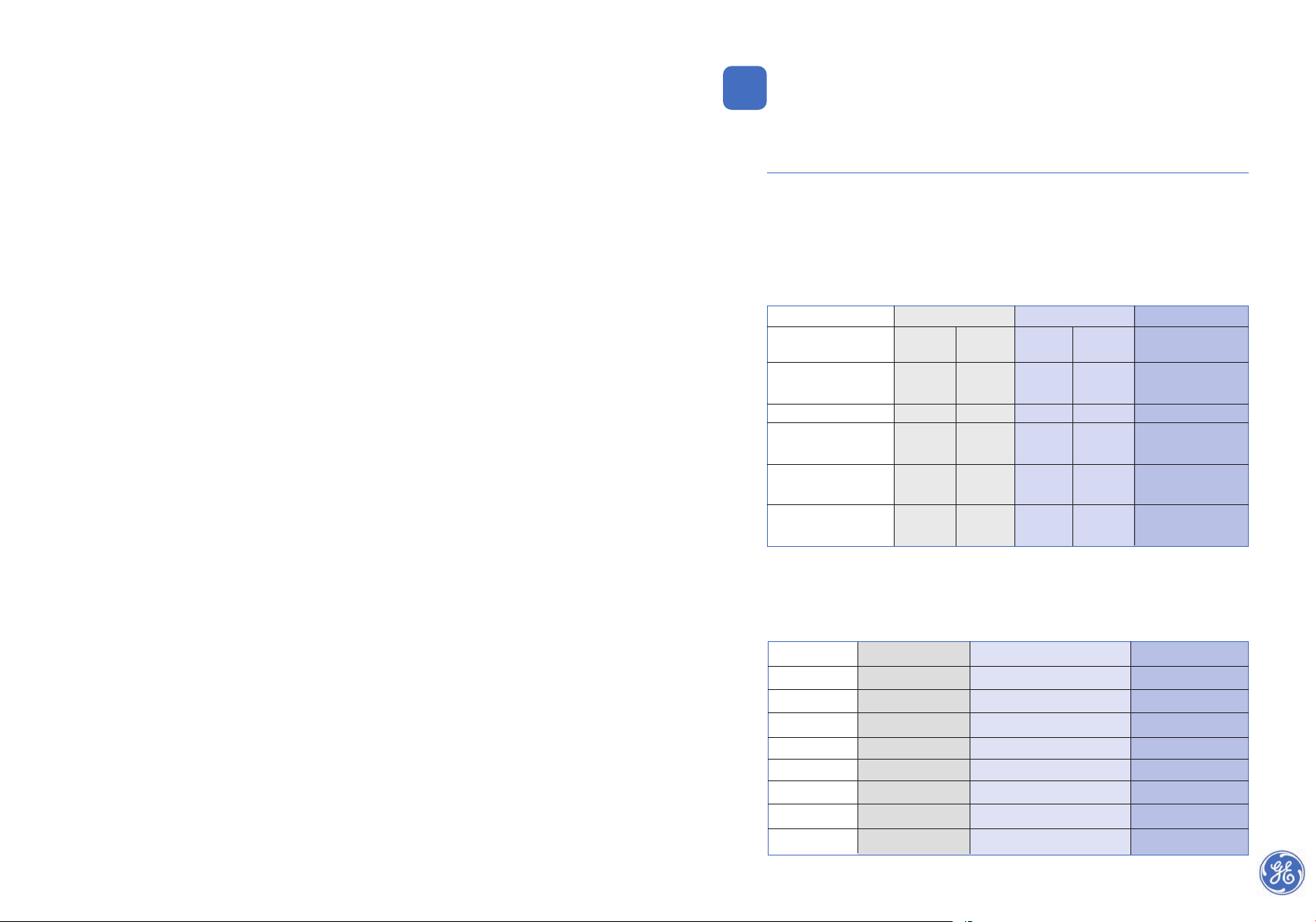

Figure 7-2 shows the resulting radiation

intensity (logarithmic) as a function of

increased material thickness, for soft and

hard homogeneous radiation.

When radiation is heterogeneous the

graphs are not straight, see figure 7-2, but

slightly curved as in figure 8-2.

The slope of the curves becomes gradually

shallower (because of selective absorption

of the softer radiation) until it reaches the

so-called “point-of-homogeneity”.

After passing this point the coefficient of

absorption remains virtually unchanged, as

if the radiation had become homogeneous.

The position of the point of homogeneity

varies with the nature of the material irradiated. The graph shows that with increasing

material thickness, softer radiation is filtered out, more than hard radiation.

This effect is called “hardening”.

2524

Pair production

The formation of ion pairs, see

figure 5-2, only occurs at very

high energy levels (above 1 MeV).

High-energy photons can cause

an interaction with the nucleus

of the atom involved in the collision. The energy of the photon is

here converted tot an electron(e-)

and a positron (e+).

Total absorption/attenuation

The total linear absorption or

attenuation of X-rays is a combination of the three absorption

processes described above, in

which the primary X-ray energy

changes to a lower form of energy. Secondary X-ray energy arrises of a different wavelength and

a different direction of travel.

Some of this secondary (scattered) radiation does not contribute to radiographic image forming

and may cause loss of image

quality through blurring or fog.

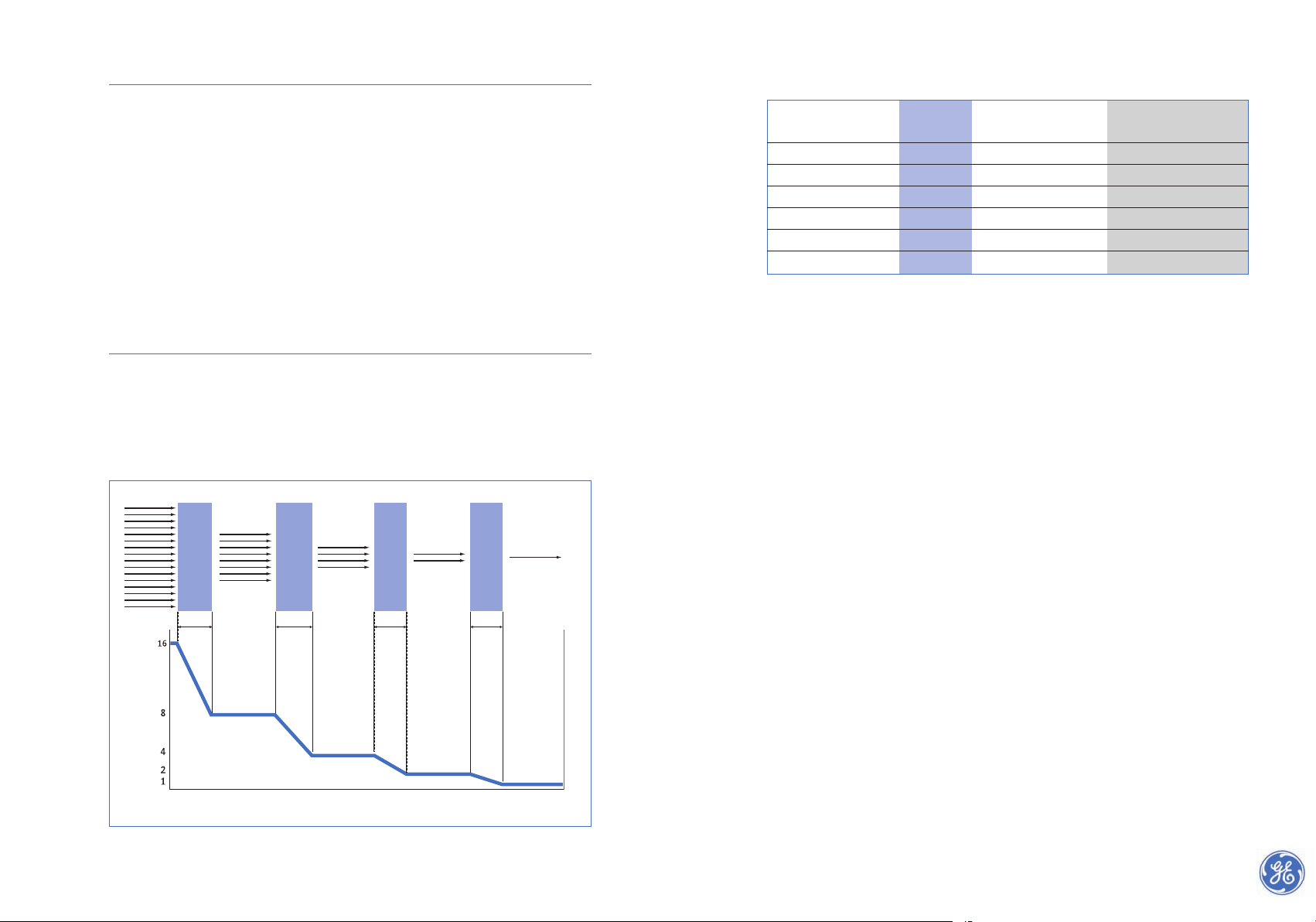

The contribution of the various

causes of X-ray absorption to the

total linear absorption coefficient (μ) for steel plotted against

radiation energy, are shown in

figure 6-2.

X-ray

> 1 MeV

ejected

electron

ejected

positron

Fig. 5-2. Pair production

Fig. 6-2 Absorption coefficient for steel plotted against radiation energy

PE = Photoelectric effect

C = Compton effect

PP = Pair production

= μ.Δt

I = I

o

.

e

-μt

ΔI

I

o

hard radiation,

high tube voltage

hard radiation

soft radiation

points of homogeneity

soft radiation,

low tube voltage

penetrated material thickness

intensityintesity

penetrated material thickness

Fig. 7-2. Intensity of homogeneous

radiation as function of increasing

thickness

Fig. 8-2. Intensity of heterogeneous

radiation as function of increasing

thickness hard radiation

Page 15

Table 2-2 shows the average HVT-values for steel, table 3-2 shows the values for lead.

For a heterogeneous beam the HVT is not constant; the second HVT is slightly larger

than the first. In general, in industry where relatively hard radiation is used, a fixed

“average” HVT is applied.

2726

2.8 Filtering (hardening)

All materials, for example a metal layer between the radiation source and the film, cause

absorption and filtering. The position of the metal layer plays an important role in the

effect it has. A metal layer in front of the object will “harden” the radiation because it filters out the soft radiation. The degree of hardening depends on the type and the thickness

of the material. This phenomenon is used to reduce excessive contrast (variation in density) when examining objects of which the thickness varies greatly.

A metal layer between the object and the film filters the soft scattered radiation that

occurs in the object, thereby increasing the contrast and consequently the image quality.

This method of filtering is for example applied in the use of Cobalt60 in combination with

exposure time reducing intensifying screens, which are sensitive to scattered radiation.

Lead, copper and steel are suitable filtering materials.

2.9 Half-value thickness

A convenient practical notion (number) of the linear absorption coefficient is the introduction of the half-value thickness (HVT). It quantifies the penetrating power of radiation for a particular type of material and is defined as the thickness of a particular material necessary to reduce the intensity of a monochromatic beam of radiation by half, as

shown in figure 9-2. This HVT-value depends on the hardness of radiation.

Table 3-2. Half-value thickness for lead

Fig. 9-2. Illustration of half-value thickness

thickness

HVT HVT HVT HVT

intensity

Element/Isotope Symbol Average energy level Half-value thickness

in MeV in mm lead

Ceasium137 Cs137 0.66 8.4

Cobalt60 Co60 1.25 13

Iridium192 Ir192 0.45 2.8

Selenium75 Se75 0.32 2

Ytterbium169 Yb169 0.2 1

Thulium170 Tm170 0.072 0.6

Page 16

3.1

Units

Until 1978 the “International Commission of Radiation Units and Measurements” (ICRU)

used the conventional radiation units of roentgen (R), rad (rd), and curie (Ci). Since 1978

the ICRU has recommended the use of the international system units (SI) with special

new units for radiation quantities; the Becquerel, Gray and Sievert.

Table 1-3 shows the relationships of these new units to the older units.

In radiography and radiation safety, units are preceded by prefixes.

Table 2-3 shows the ones mostly used.

3

Units

and definitions

2928

Table 1-3. Overview of new and old units

* disintegrations per second C = Coulomb = A.s J = Joule

** RBE = Relative Biological Effect A = Ampère

Table 2-3. Prefixes

SI –units Formerly used Conversion

Designation of quantity Name Unit Name Unit Old to SI

Designation Designation

Activity (A) Becquerel 1/s* Curie Ci 1 Ci = 37 GBq

(Bq)

Ionisation dose Coulomb (C) C/kg Röntgen R 1 R=2.58 x 10

-4

C/kg

Ionisation dose rate Coulomb (C) C/kg.s R/s

Ampère (A) or A/kg

Absorbed energy Gray J/kg Rad Rad 1 Rad = 0.01 Gy

dose (D) (Gy)

Equivalent dose (H) Sievert J/kg Rem Rem 1 Rem = 0.01 Sv

H=D x RBE** (Sv)

Prefix Meaning Value Notation

p pico 0.000000000001 10

-12

n nano 0.000000001 10

-9

μ micro 0.000001 10

-6

m milli 0.001 10

-3

- 11 1

k kilo 1000 10

3

M Mega 1000000 10

6

G Giga 1000000000 10

9

Page 17

3130

3.2 Definitions

Radioactivity

The activity of a radioactive source of radiation (isotope) is equal to the number of disintegrations per second. The SI-unit is the Becquerel (Bq) and is equal to 1 disintegration per

second. The Becquerel is too small a unit to be used in industrial radiography. Source

strengths are, therefore, quoted in Giga Becquerel (GBq).

1 Curie = 37 GBq, see table 2-3.

Ionisation dose rate

The output of an X-ray set or isotope per unit of time is generally quoted at one metre

distance from the source, and designated in C/kg, see table 1-3.

Ionisation dose

The ionising effect of radiation in one kilogram of dry air is used to define the ionisation

dose. The dose of radiation delivered is equal to the ionisation dose rate multiplied by the

amount of time during which radiation takes place.

The designation used is C/kg.sec.

The output of an X-ray set, however, is quoted in Sievert per hour, measured at 1 metre

distance.

Absorbed energy dose

The radiation energy that is absorbed is expressed in Joules per kilogram (J/kg).

The SI-unit is called Gray (Gy) whereby 1 J/kg = 1 Gy.

Equivalent dose (man dose)

The Sievert (Sv) is the SI-unit for the biological effect of ionising radiation upon man. It

corresponds with the product of the absorbed energy dose gray (Gy) with a factor that has

been experimentally determined and that indicates the relative biological effect (RBE) of

the ionising radiation. For X- and

γ-radiation this factor is equal to one, so that the Sievert

is equal to the Gray.

Page 18

4

Radiation sources

33

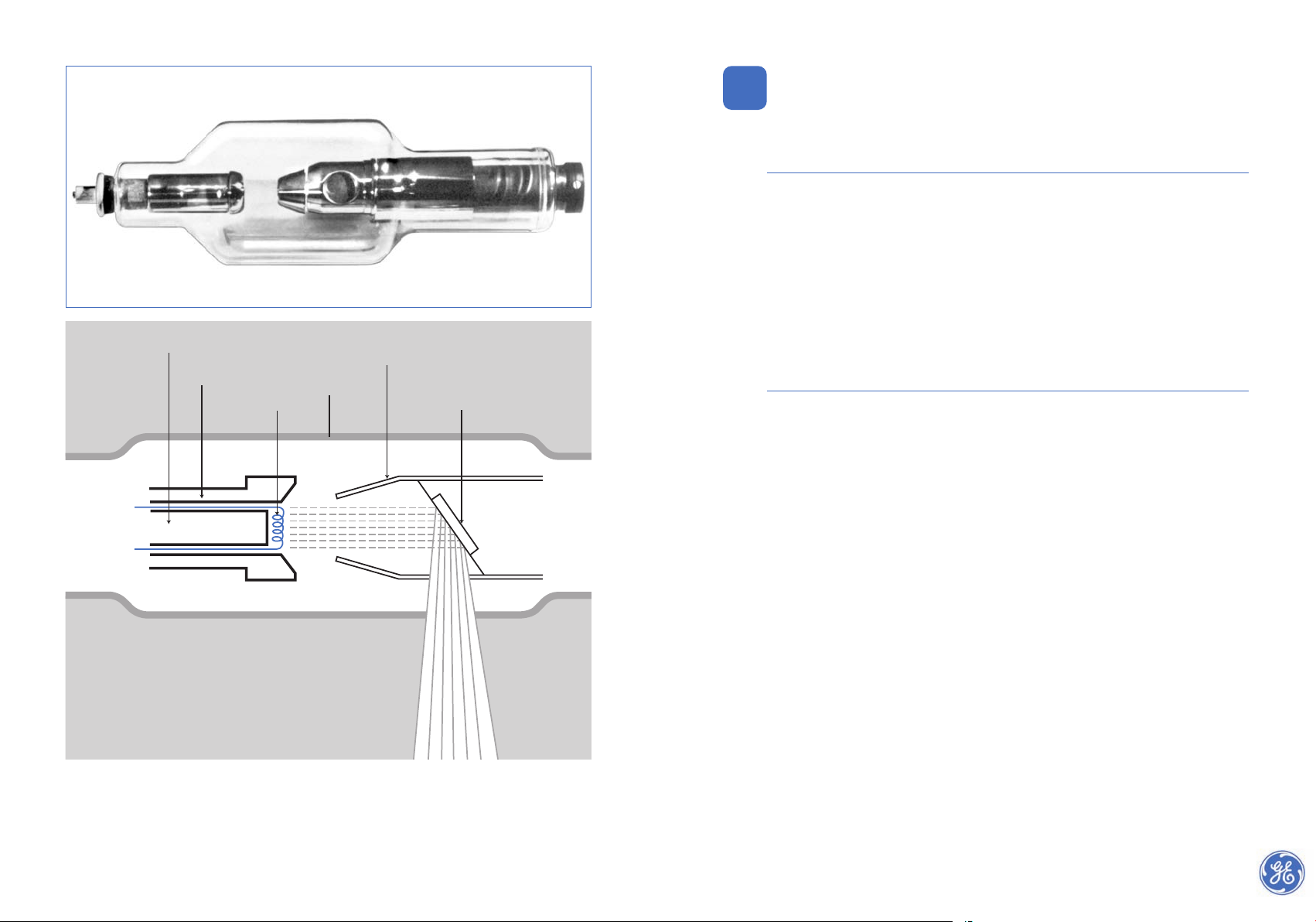

4.1 X-Ray tube

The X-ray tube, see figure 1-4, consists of a glass (or ceramic) envelope containing a positive

electrode (the anode) and a negative electrode (the cathode) evacuated to an ultra high

vacuum [10

- 9

hPa (hectoPascal)].

The cathode comprises a filament that generates electrons. Under the effect of the electrical tension set up between the anode and the cathode (the tube voltage) the electrons from

the cathode are attracted to the anode, which accelerates their speed.

This stream of electrons is concentrated into a beam by a “cylinder” or “focusing cup”.

When the accelerated electrons collide with a target on the anode, part of their energy is

converted to X-radiation, know as X-rays.

4.2 The anode

The target is generally made of tungsten. Not only because it has a high atomic number, but

also because of its high melting point (approx. 3400˚C). It is essential to use a material with

a high melting point because of the substantial amount of heat dissipated as the electron“bombardment” is concentrated (focused) on a very small surface. Only a part (approx. 0.1

% at 30 keV; 1 % at 200 keV; 40 % at 30 to 40 MeV) of the kinetic energy of the electrons

is converted into X-radiation; the remainder is transformed into heat.

Cooling the anode

The heat which accompanies the production of X-radiation is quite considerable, so that

the anode has to be cooled. This can be done in a variety of ways :

1. by natural radiation

2. by convection

3. by forced circulation of liquid or gas

4. by conduction

The focal spot

The area of the target which is struck by the electrons, see figure 2-4, is called the focal spot

or “the focus”. It is essential that this area is sufficiently large to avoid local overheating,

which might damage the anode.

From the radiographic point of view, however, the focus has to be as small as possible in

order to achieve maximum sharpness in the radiographic image. This “focal loading” is

expressed in Joule/mm

2

. A tungsten target can take a maximum loading of 200 Joule/mm2.

A higher loading might damage the anode.

32

Fig 1-4. Glass envelope X-ray tube

cathode

focusing

cylinder

or cup

filament

electron beam

X-ray beam

anode

glass

target

Page 19

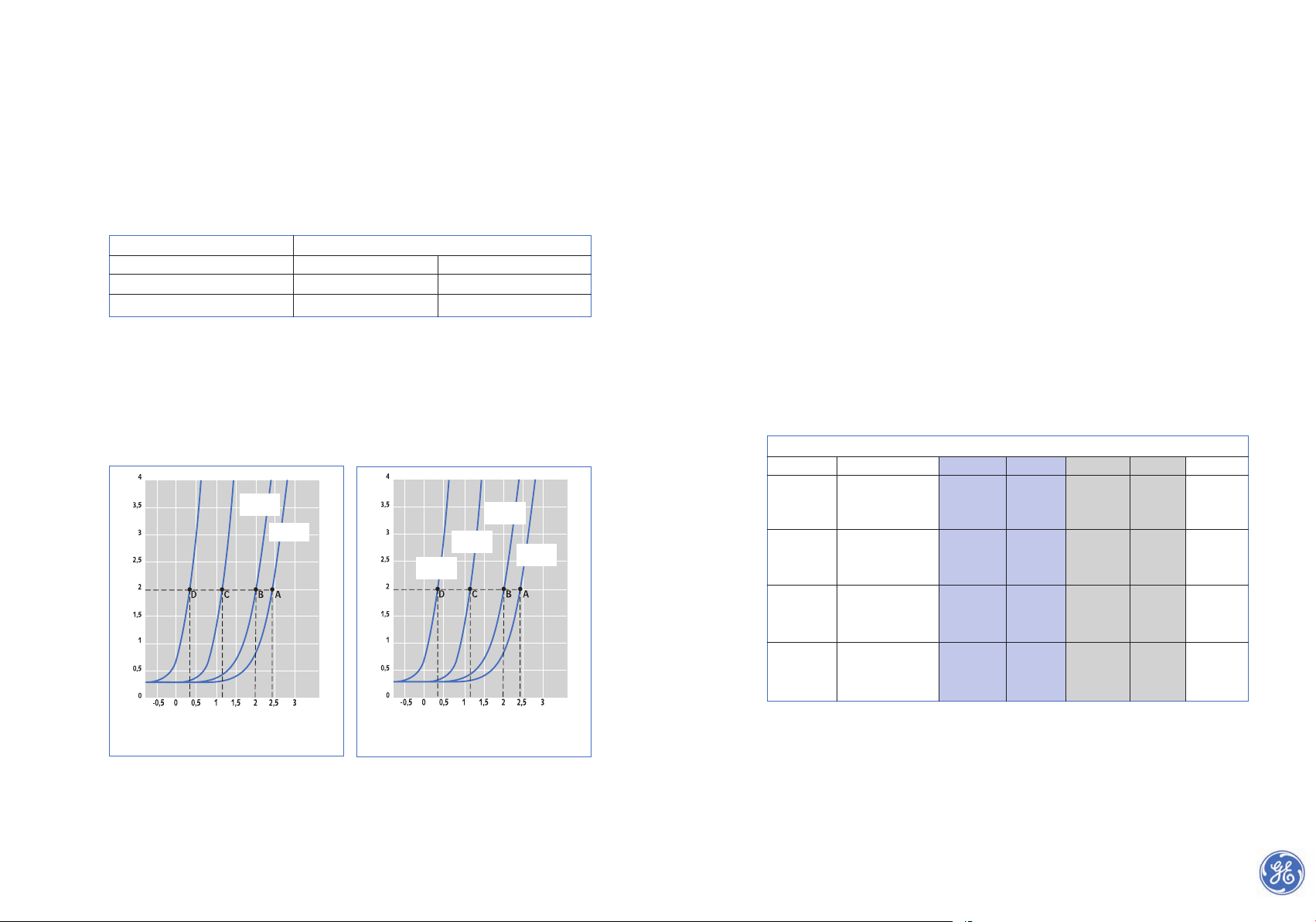

4.3 Tube voltage and tube current

The voltage across the X-ray tube determines the energy spectrum and so the hardness of the

radiation, see figure 3-4. The intensity is proportional to the tube current, see figure 4-4.

This graph shows that, contrary to a change in tube voltage, a change in tube current does

not shift the spectrum (in other words: the hardness does not change).

The energy spectrum is also influenced by the characteristics of the high voltage applied to

the tube. When the spectrum of one X-ray tube on constant voltage is compared with that

of another with a current of pulsating voltage, of the same kV value, both spectra will be

slightly different. With a current of pulsating voltage there are, during each cycle, moments

of relatively low voltage, during which there will be a greater proportion of “soft” X- rays,

with their side-effects. This means that a set working on a constant voltage will provide a

higher intensity of hard radiation than one on a pulsating voltage; although both working

at the same nominal kV value.

However, even identical X-ray tubes may also show differences in generated energy. The

energy generated by one 200 kV X-ray tube will not be true identical to the energy generated by another X-ray tube with the same applied voltage, not even if they are the same type

of tube. This behaviour impedes individual calibration in kV of X-ray sets. Another reason

why it is hard to calibrate an X-ray tube within a small tolerance band is, that the absolute

level and wave characteristics of the supplied high voltage are difficult to measure.

It follows that it is difficult to standardise and calibrate X-ray equipment as far as spectra

and kV-settings is concerned, which precludes the exchange of exposure charts, see section 9.1. Each X-ray set therefore requires its own specific exposure chart. Even the exchange of a similar control panel or another (length) of cable between control panel and X-ray

tube can influence the level of energy and its spectrum. Usually after exchange of parts or

repair the exposure chart for that particular type of X-ray set is normalised (curve-fitting)

for the new combination of components. In practice adjusting the zero point of the exposure graph is sufficient.

3534

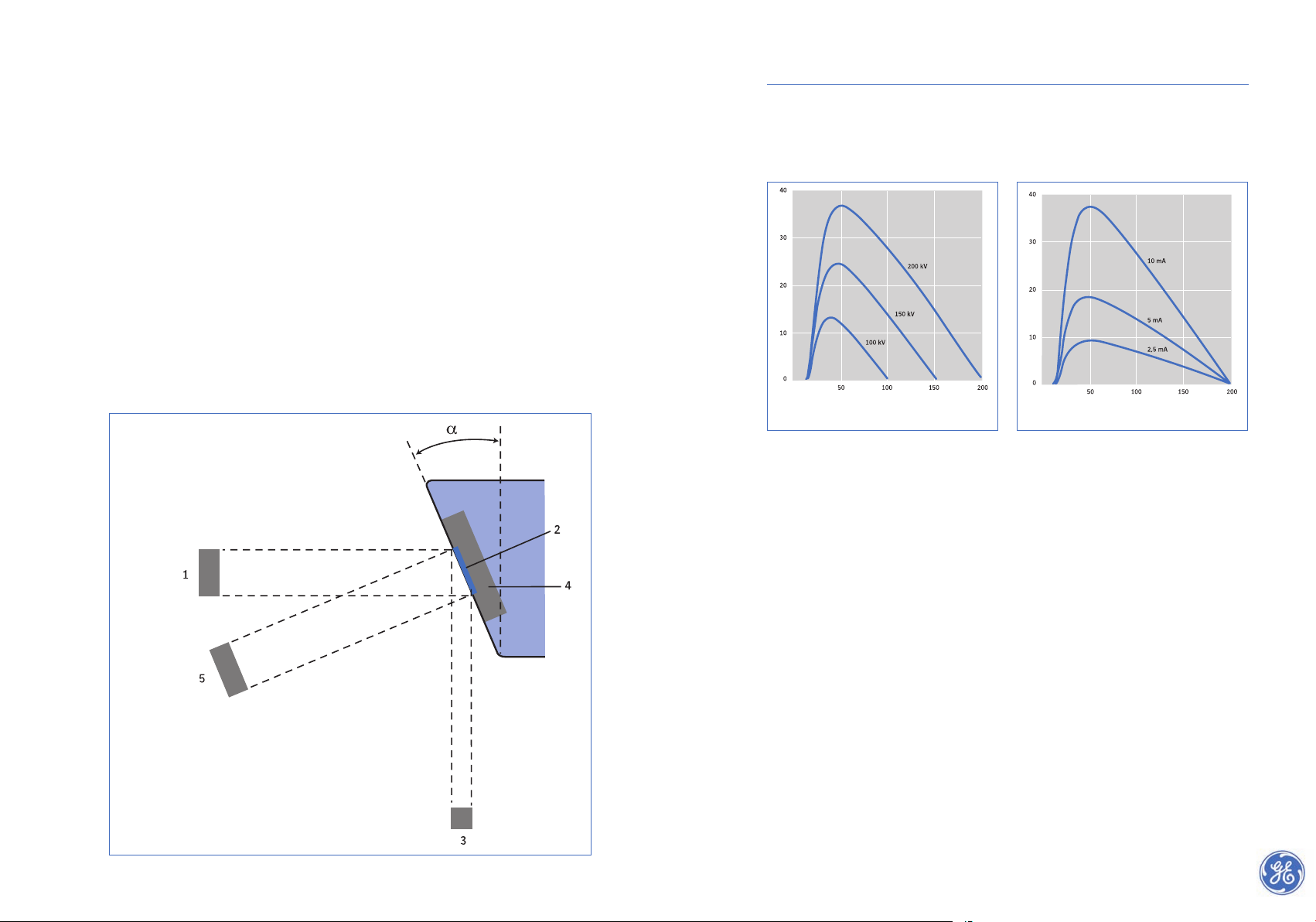

Effective focal spot size

The projections of the focal spot on a surface perpendicular to the axis of the beam of

X-rays is termed the “ effective focal spot size” or “ focus size”, see figure 2-4. The effective

focus size is one of the parameters in radiography, see section 11-1. The effective focus size,

principally determining the sharpness in the radiographic image, has to be as small as possible in order to achieve maximum sharpness. The dimensions of the focus are governed by:

1. The size of the focal spot, and

2. The value of angle α, see figure 2-4.

It should be noted that when in radiography we speak of the “size of the focus” without specifying this more exactly, it is normally the effective focal spot size which is meant.

Conventional X-ray tubes have effective focal spot sizes in the range 4 x 4 mm to 1 x 1 mm.

There are fine-focus tubes with focal spots from 0.5 x 0.5 mm ad microfocus tubes down to

50 μm diameter or even much less, known as nanofocus tubes.

The effective focal spot size can be determined in accordance with the procedures described in EN 12543 replacing the old IEC 336 which however is still in use. For more information on focal spot measurement see section 18.1.

1. Dimension of the electron beam

2. Focal spot

3. Effective focal spot size

4. Anode target

5. True focus size

Fig 3-4. Energy spectra at varying tube voltages and constant tube current (here 10mA)

Fig. 4-4. Energy spectra at varying values for tube current

and constant high voltage (here 200 kV)

Fig. 2-4. Effective focal spot size

KeV

KeV

relative intensity

relative intensity

Page 20

4.6 Properties of radioactive sources

Activity (source strength)

The activity of a radioactive substance is given by the number of atoms of the substance

which disintegrate per second.

This is measured in Becquerels (Bq), 1 Becquerel corresponds to 1 disintegration per

second(1 Bq = 1/s).

Specific activity

The specific activity of a radioactive source is the activity of this substance per weight unit,

expressed in Bq/g.

Specific gamma-ray emission factor (k-factor)

The k-factor is the generally used unit for radiation output of a source and is defined

as the activity measured at a fixed distance. It indicates the specific gamma-emission

(gamma constant) measured at 1 metre distance.

The higher the k-factor, the smaller the source can be for a particular source strength.

A source of small dimensions will improve the sharpness of a radiograph.

Table 1-4 shows the various k-factors and half-life values.

Half-life of a radioactive source

Of an Iridium192 source with an activity of 40 GBq for example 10 GBq will remain after

two half-lives (148 days), 5 GBq after three half-lives (222 days) etc.

3736

4.4 Radioactive sources (isotopes)

Natural radioactive sources

The elements from this group which have been used for the purposes of industrial radiography are radium and mesothorium. These give a very hard radiation, making them particularly suitable for examining very thick objects.

A disadvantage of natural sources, next to their high cost, is that it is not possible to make

them in dimensions small enough for good quality images and still give sufficient activity.

Artificial radioactive sources

Artificial radioactive sources for NDT are obtained by irradiation in a nuclear reactor. Since

1947, it has been possible to produce radioactive isotopes this way in relatively large quantities and in a reasonably pure state and particularly of sufficiently high concentration; the

latter being extremely important in NDT because the size of the source has to be as small

as possible. Among the many factors deciding a source suitability for non-destructive

testing are the wavelength and intensity of its radiation, its half-life and its specific radiation. In fact, only a few of the many artificial radio-isotopes available have been found to

be suitable for industrial radiography.

4.5 Advantages and disadvantages

of artificial radioactive sources

Advantages

1. require no electric power supply; easy to use in the field

2. can be obtained in a range of source diameters, so that if necessary a very short

source-to-film distance with a small diameter source can be used, for example,

for pipes of small diameter

3. a wide variety of radiation hardnesses

4. higher radiation hardness (more penetration power) than those of conventional

X-ray equipment can be selected

Disadvantages

1. cannot be switched off

2. the energy level (radiation hardness) cannot be adjusted

3. the intensity cannot be adjusted

4. limited service life due to source deterioration (half-life)

5. less contrast than X-ray equipment

Isotope Half-life Specific gamma constant

or k-factor

Ytterbium169 31 days 0.05

Iridium192 74 days 0.13

Selenium75 120 days 0.054

Cobalt60 5.3 years 0.35

Caesium137 30 years 0.09

Table 1-4 Various k-factors and half-life values

Page 21

5

NDT equipment

39

5.1 X-ray equipment

X-ray sets are generally divided in three voltage categories, namely:

1. Up to 320 kV, mainly for use on intermittent, ambulatory work. Tubes are generally of

the unipolar alternating current type. Higher voltages are hardly possible with this

type of equipment because of insulation problems.

2. Up to 450 kV, mainly for use on continuous, stationary or semi-ambulatory work,

because of their dimensions, limited manageability and weight.

Tubes are of the bipolar direct current type.

3. Up to 16 MeV, so called Megavolt equipment.

Virtually exclusively applied to stationary work.

The first two categories are suitable for radiography on most common objects. Objects of

extreme thickness, however, require an energy even higher than 450 kV. In this case

Megavolt equipment is used, if alternative sources such as Cobalt60 prove unsuitable.

It will normally involve stationary installations of large dimensions and high weight. Lately,

portable versions have become available meant for ambulatory use.

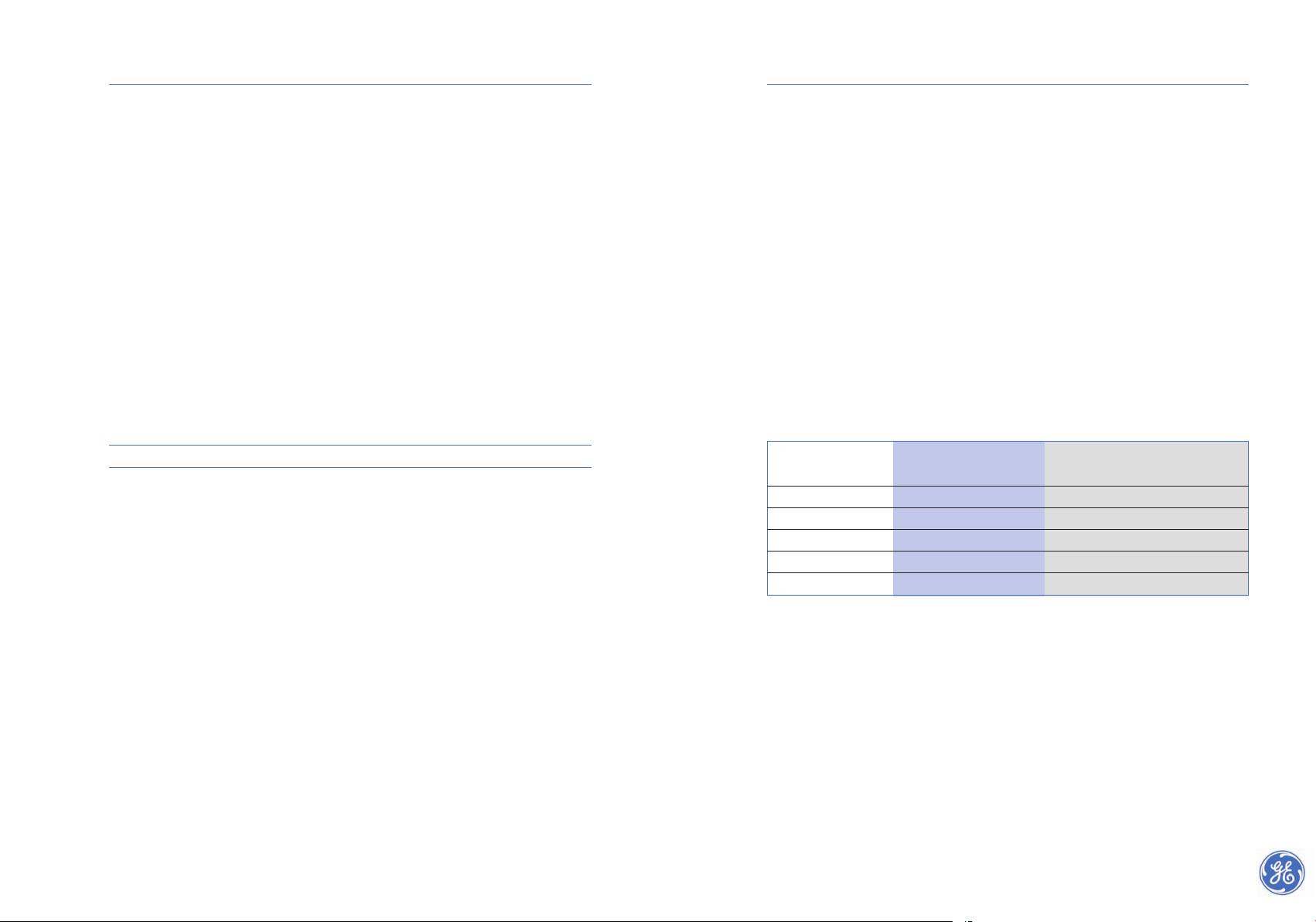

Types of X-ray tubes

Depending on the shape of the anode, X-ray tubes produce :

a. a beam of radiation in one direction (directional tube)

b. an annular beam (panoramic tube)

X-ray tubes are either unipolar or bipolar.

Bipolar tubes

Figure 1a-5 shows a bipolar tube. The bipolar tube has the advantage that the potential difference with respect to earth on both the anode and the cathode is equal to one-half of the

tube voltage, which is a great help from the point-of-view of insulation. The exit window

is necessarily situated in the middle of the tube. Bipolar tubes usually operate on direct current and are generally air, oil or water cooled. They are designed to operate at voltages of

100 to 450 kV and a tube current of up to 20 mA.

Unipolar tubes

In these (shorter) tubes, as shown in figure 1b-5, the anode is held at earth potential and

the cathode only has a potential difference to earth. This makes anode cooling a simpler

operation. It also means that for low/medium kilo-voltage sets, up to approx. 300 kV as often

used in ambulant applications, a single simpler high voltage supply source will suffice.

The radiation window is placed asymmetric which can be advantageous in practice.

38

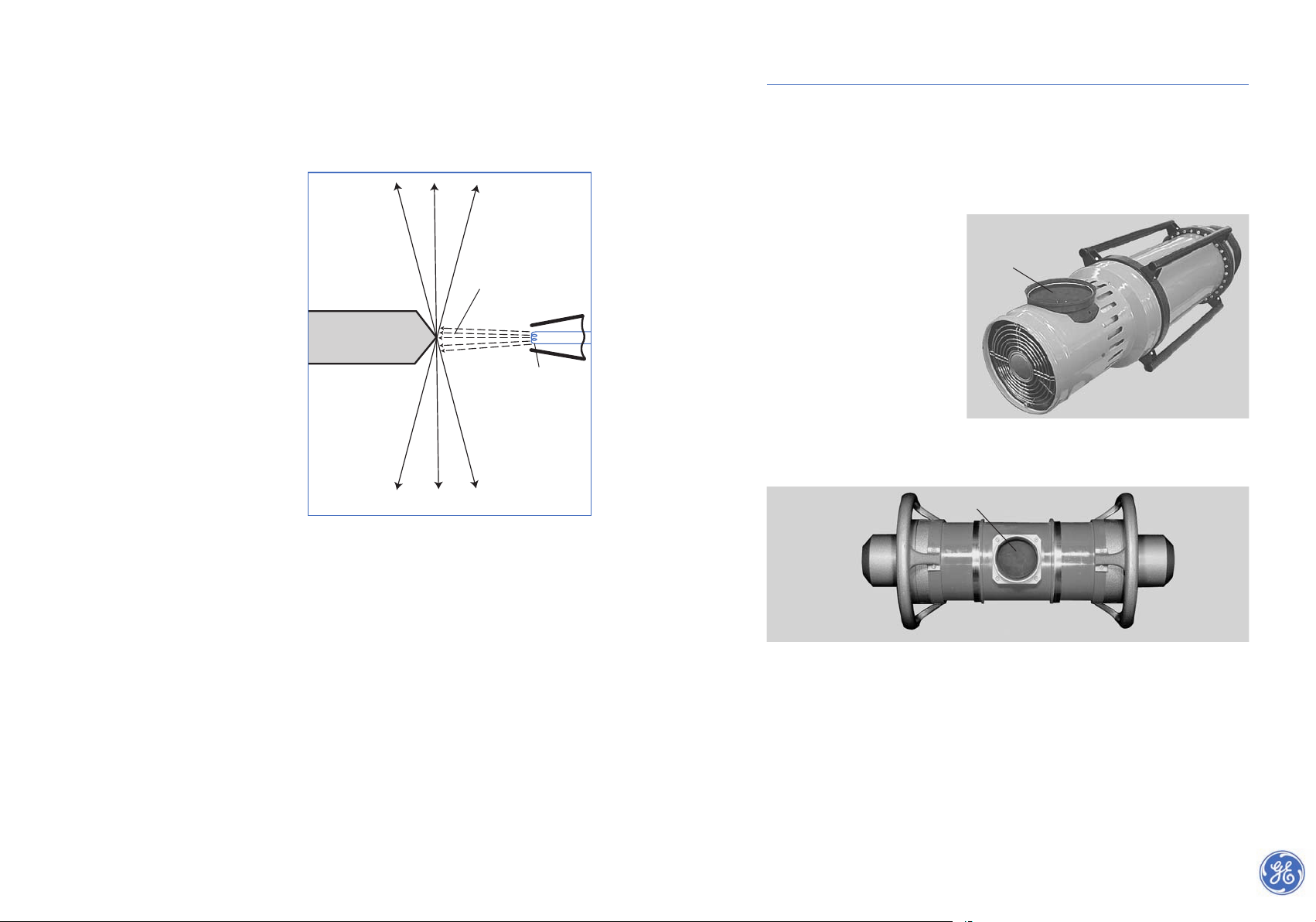

Fig. 1-5. – X-ray tubes

A = position of target

Panoramic

X-ray beam

Directional

X-ray beam

1a-5 Bipolar tube

1b-5 Unipolar tube

Directional

X-ray beam

Directional

X-ray beam

1c-5 Hollow anode tube giving annular (panoramic) beam

Focus

Focus

Page 22

41

5.2 High voltage generators

Conventional (trans)portable X-ray equipment for use up to approximately 300 kV are provided with step-up HT transformers, rectifiers and smoothing capacitors. The X-ray tube

and the circuitry of this equipment are usually placed in an insulated tank. In most cases

these tank type sets use oil for insulation and cooling and weigh approximately 60 kg.

Gas is used when weight is important; the set than weighs approximately 30 kg.

Figure 3-5 shows an integrated

(all-in-one) tank set for 300 kV

with an asymmetric window. At

voltages over 300 kV housing everything in one tank becomes very

difficult because the high voltage

insulation would be inadequate.

Figure 4-5 shows a direct current

X-ray tube with a symmetric window.

Equipment up to 450 kV operating

on direct current is connected to a

separate high tension (HT) supply

unit by means of HT leads. As a result this equipment is bigger and heavier than “all-in-one”

tank sets and mostly meant for stationary or semi-ambulant use.

The 300 kV “all-in-one” tank set and the 450 kV direct current X-ray tube only are of

roughly the same dimensions.

Most tank sets are connected to a mains power supply with a frequency of 50 or 60 Hz. At

this frequency the supply voltage can be transformed upward.

This is followed by rectifying, which occurs in various forms. With some sets the X-ray tube

itself functions as rectifier, so called single-phase rectifying. If there is no smoothing

applied, considerable changes in voltage per cycle of alternating current will occur.

This periodic and greatly varying high voltage affects the intensity and spectrum of the

radiation generated, see section 4.3.

40

Special types of X-ray tubes

Unipolar X-ray tubes with a long hollow anode, as shown in fig. 1c-5, are generally known

as “rod anode tube” and can be inserted into pipes or vessels. These tubes produce an

annular (panoramic) beam over 360º, so allowing a complete circumferential weld to be

radiographed in one exposure.

Figure 2-5 shows the conical anode

of a (360º) panoramic tube, which

allows a circumferential weld to be

radiographed centrally, hence uniformly, from within. With this

anode the axis of the electron

beam must strike the top of the

cone in such a way that the centre

of the generated X-ray beam is

perpendicular to the longitudinal

axis of the tube.

Note: Anodes shaped so that the centre of the generated X-ray beam is

not perpendicular (oblique) to the

centre line of the tube (which was

acceptable in the past), are no longer

allowed when work is to be performed to official standards.Tubes that

produce a real perpendicular beam

are known as "true panoramics"

There are also panoramic tubes in which the electron beam is focused over an extended

length by means of a magnetic lens or an electrostatic lens (Wehnelt-cylinder) to produce

a very small focal spot size. These sets are called microfocus rod anode tubes with which a

very small focal spot size, of less than 10 micrometers, can be achieved. Since the anode

can be damaged relatively easy through overheating the anode is usually interchangeable.

This requires a separate vacuum unit in order to restore the vacuum after replacement. The

advantage of this construction is that with different types of anodes, different radiation

patterns can be obtained for special applications. The maximum energy level is usually

below 150 kV.

However, there are 150 kV microfocus tubes with a fixed anode for enlarging or scanning

purposes, see section 17.1. With these tubes the tube current has to be kept low, because of

heat dissipation limitations of the non-interchangeable anode.

Some X-ray tubes used in the radiography of plastics and aluminium are equipped with a

beryllium window to allow the softer radiation generated at the lower tube voltages of

5 to 45 kV, to pass.

Fig. 2-5. Anode configuration for an annular panoramic tube

Fig. 4-5. Direct current X-ray tube for 450 kV with a symmetric window

X-ray

electron beam

cathode

X-ray

anode

filament

Window

Window

Fig. 3-5. “All-in-one“ 300 kV tank set with an asymmetric window

Page 23

43

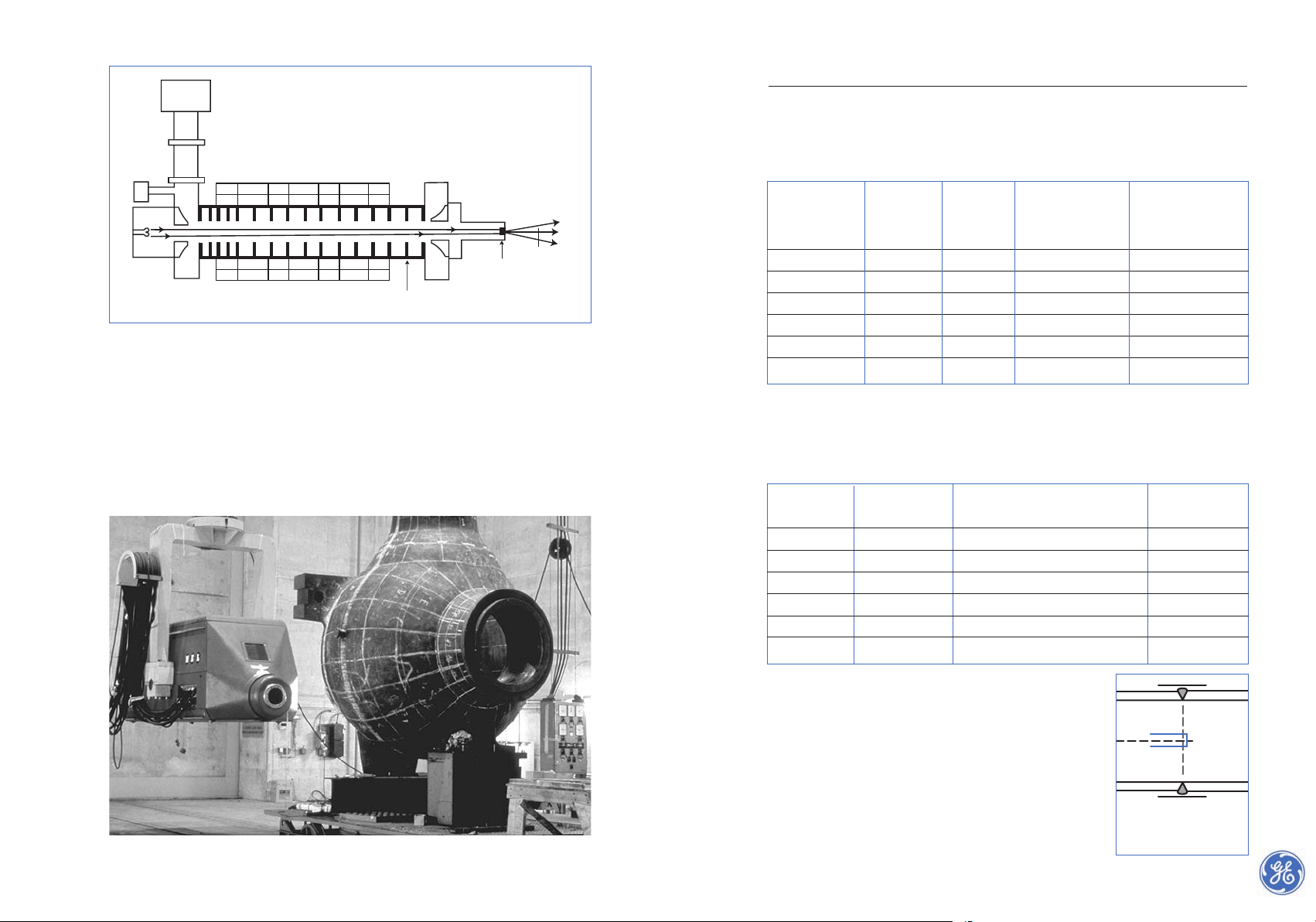

The linear accelerator (linac)

The energy levels mostly used for linacs (linear accelerators) are 4 MeV and 8 MeV. Linear

accelerators can be constructed for one or two energy levels.

In the travelling-wave linac, the acceleration of electrons from a heated filament to very

high energies results from the electrons “riding” a high-frequency (3-10 MHz) electromagnetic wave travelling in a straight line down an acceleration tube (the hollow guide).

The electrons are bunched into pulses at a frequency of a few hundred pulses per second.

The target, which the electrons strike to generate X-radiation, is at the opposite end of the

main wave guide of the filament assembly. This is a transmission type target from which

the radiation beam passes in a straight line.

The X-ray output from a linear accelerator is many times higher than from a Bètatron of the

same energy. An 8 MeV linac with a 2 mm diameter focal spot can deliver a radiation dose

rate of 30 Sv/minute at 1 metre distance from the focus. Small light-weight portable linacs

of 3 MeV capacity can have outputs of 1.5 Sv/minute at 1 metre distance.

42

The intensity of radiation is increased by double-phased rectifying and varying degrees of

smoothing. At very low voltage ripple these sets are considered constant potential (CP)

equipment.

In the latest types of tank sets the mains frequency is first converted to a high frequency

alternating current and only then transformed upward, which makes it easier still to

smooth the ripple. At very high frequencies, up to 50 kHz, smoothing is hardly necessary

anymore and such X-ray sets can be called CP systems. Additional features may be built in,

for example an automatic warm-up facility, see note below. This type of circuitry with

advanced electronics leads to a higher degree of reliability and significant space and weight

reduction compared with earlier power supply systems. As a result of the various improvements that have gradually been implemented, present day (high frequency) AC X-ray sets

perform as well as true CP sets.

Note: Because of the high vacuum prevailing inside the X-ray tube, it carefully has to be warmed-up

after a period of rest. During rest the vacuum deteriorates. This warm-up procedure has to be done

in accordance with the supplier’s instructions, to prevent high voltage short-circuiting which might

damage the tube or render it useless.

5.3 Megavolt equipment

The equipment described in sections 5.1 and 5.2 is used to generate X-radiation up to

approximately 450 kV. However, sometimes higher energy levels are needed.

Several types of equipment have been built to operate in the 1 MeV to 16 MeV range. In

industrial radiography almost exclusively Bètatrons or linear accelerators (linacs) are used.

Operating high-energy X-ray installations requires (costly) safety precautions.

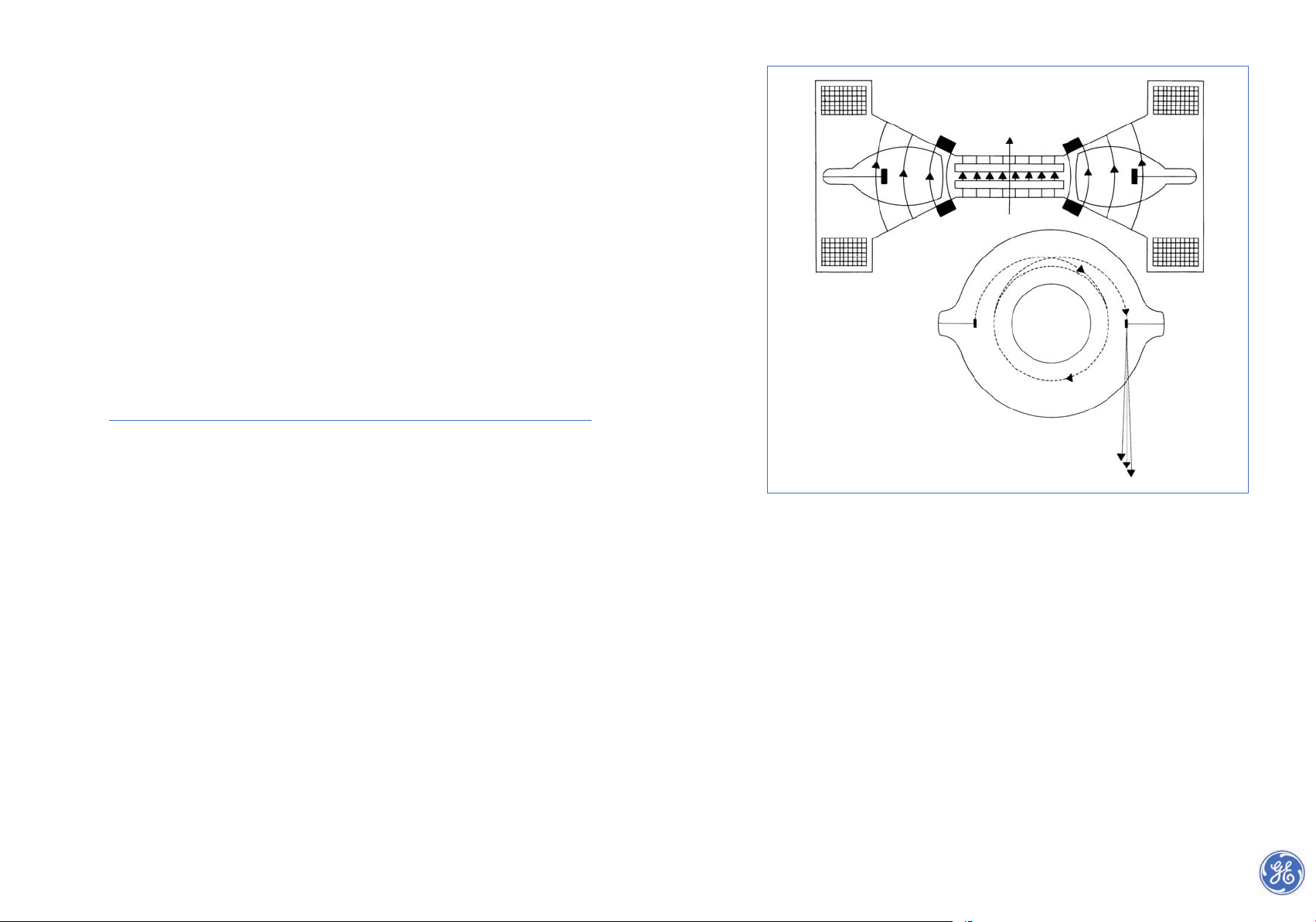

The Bètatron

The Bètatron is an electron accelerator, which can produce X-radiation in the 2-30 MeV

energy range. The electrons are emitted into a round-sectioned donut shaped glass

vacuum tube, as shown in figure 5-5. After several millions of revolutions the electrons

reach maximum energy and are deflected towards the target. On the target, part of the

electron energy is converted into a tangentially directed beam of X-radiation.

To obtain a reasonably high radiation intensity, most Bètatrons have been designed to operate in the 10-30 MeV energy range, as these voltages achieve maximum conversion rate of

electron energy into radiation. Even so the output of Bètatrons is usually small compared

to linacs. Transportable low energy Bètatrons (2-6 MeV) have been built, but these generally have a low radiation output, which limits their application.

One advantage of Bètatrons is that they can be built with very small (micromillimeter)

focal spots. A disadvantage is that with these very high energy levels the X-ray beam is usually narrow, and the coverage of larger film sizes is only possible by using increased source-to-film distances. The extended exposure times required can be a practical problem.

Fig. 5-5. Bètatron

X-rays

1. Ring-shaped accelerator tube

2. Anode

3. Cathode filament (emitting electrons)

4.&5 magnetic fields

6. Coils

7. Auxiliary winding

1

2

3

6

5

7

7

4

Page 24

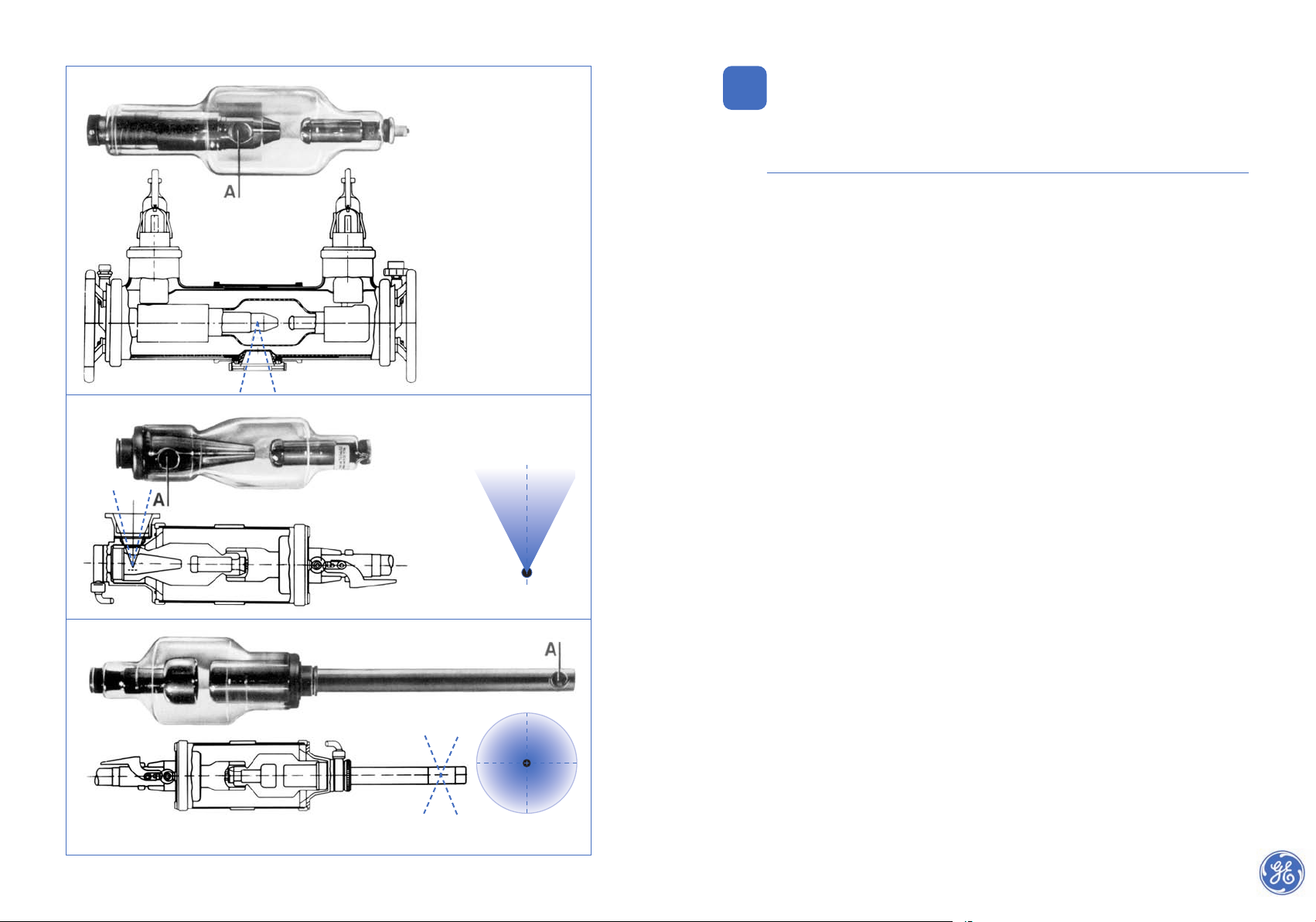

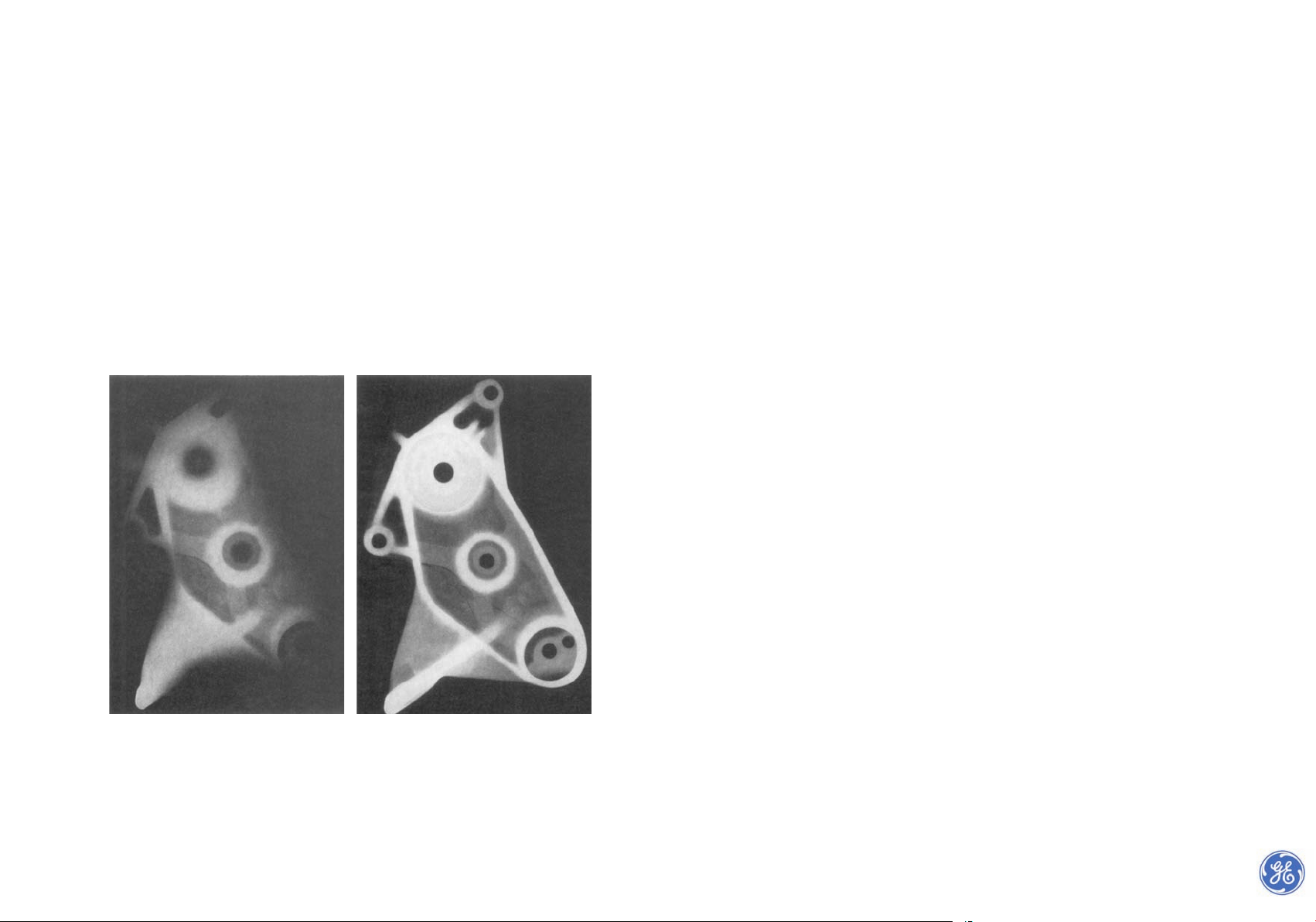

5.4 Radioactive sources

Table 1-5 shows various radioactive sources for industrial NDT. The most commonly used

ones are Cobalt, Iridium and increasingly Selenium. Selenium is very attractive while it

permits lighter containers than Iridium. Due to its average energy level it often is a good

alternative for an X-ray tube, also attractive while no electricity is needed.

Average energy level (nominal value)

The spectrum of a source has one or more energy lines, as shown in figure 2-2. For sources

with multiple energy lines an average energy level is assumed, the so-called nominal value.

On the basis of these spectra data it is clear that Co60, Cs137

and Ir192 sources produce high-energy radiation and are therefore well suited to irradiate thick materials.

Yb169, on the other hand, is a source that produces relatively

soft radiation and is of a very small size (0.5 mm), which makes

it particularly suitable for radiographic examination of circumferential welds in pipes of a small diameter and thin wall thickness, with the source centrally positioned so that the weld can

be exposed uniformly in one exposure, as shown in figure 8-5.

4544

The main properties of a linear accelerator are:

1. very high output of radiation

2. very small focal spot dimensions (<2 mm)

3. considerable weight (approx. 1200 kg for an 8 MeV stationary installation)

Figure 7-5 shows an 8 MeV linac in a radiation bunker examining a pump housing.

Fig.7-5. Linac and pump house in a radiation bunker

Table 1-5. Radioactive sources used in industrial radiography, in sequence of nominal (average) energy level

Table 2-5. Radiation spectra and nominal values

Element Symbol Mass Specific gamma Average energy

Number constant level

k-factor in MeV

Cobalt60 Co 60 0.35 1.25

Caesium137 Cs 137 0.09 0.66

Iridium192 Ir 192 0.13 0.45

Selenium75 Se 75 0.054 0.32

Ytterbium169 Yb 169 0.05 0.2

Thulium170 Tm 170 0.001 0.072

Source Number of Main energy Nominal value

spectrum lines levels in MeV in MeV

Cobalt60 2 1.17 and 1.34 MeV 1.25 MeV.

Caesium137 1 0.66 MeV 0.66 MeV

Iridium192 >10 0.3; 0.31; 0.32; 0.47 en 0.6 MeV 0.45 MeV.

Selenium75 >4 120, 140 and 400 keV 320 keV.

Ytterbium169 >6 0.06 and 0.2 MeV 200 keV.

Thulium170 2 52 and 84 keV 72 keV.

source

film

Fig. 8-5. Ytterbium169 source in

central position for exposure of

circumferential weld

Fig. 6-5. Linear electron accelerator (linac)

X-rays

target

wave guide

electron gun

vacuum pump

magnetron

focus coils

Page 25

Also greatly depleted uranium (with the highest radiation absorption) is used for shielding,

resulting in very compact exposure containers. A disadvantage of this material, however, is

that it has a certain minimal radioactivity, which is reason that in some countries the use of

depleted uranium is not allowed.

Regardless of the shielding material used, all containers have a considerable weight in

common.

There are several solutions to the problem of safely storing a source on the one hand, and

of putting it in a simple but absolutely safe manner in its radiation position on the other

hand. Two regularly used constructions for this purpose are: source S is situated in a rotating cylinder, as shown in figure 11-5, or in an S-channel container as shown in figure 12-5.

The S-channel container is usually provided with a means to move the source out from a

distance (after all, distance is the safest protection from radiation). This may be done by

means of a flexible cable in a hose (Teleflex design) as shown in figures 13-5 and 14-5.

With this construction it is possible to extend the flexible hose in such a way that the source

can safely be moved several metres out of the container to the most favourable exposure

position.

4746

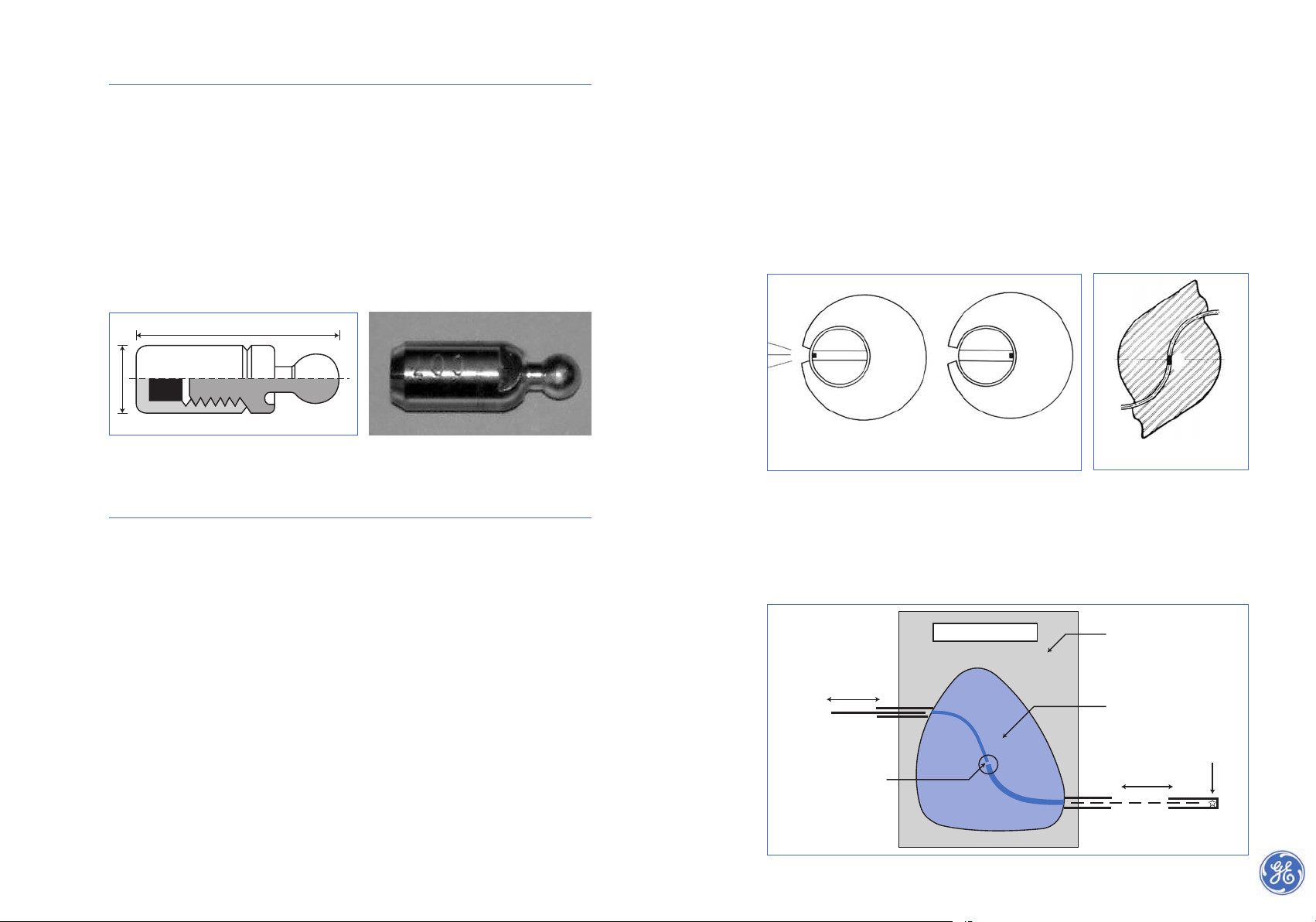

5.5 Source holders (capsules)

All gamma-ray sources for radiography are supplied in hermetically sealed, corrosion

resistant source holders (capsules), made out of monel, vanadium or titanium.

The Atomic Energy Authority in the country of origin encapsulates the radioactive material. The supplier will supply the source with a certificate which indicates the type of source,

its serial number, the activity at a certain date, and a disintegration graph.

The radiation material proper, also called the source or pellet, ranges in size from

1 to 4 mm. The size is dictated by the specific radiation activity of the source material.

The outside dimensions of the cylindrical capsule are approximately 5.5 x 15 mm, as shown

in figure 9-5.

5.6 Transport- and exposure containers

Transportation and handling of sealed sources are subject to strict international safety

regulations, as a source is continuously emitting radiation in all directions, in contrast to an

X-ray tube which can be switched off. During transportation and use the source must be

surrounded by a volume of radiation absorbing material, which in turn is encapsulated in

a container. The level of radioactivity at the outside surface of the container shall not

exceed the legally established maximum limit.

Like the transport container, the exposure container needs to be robust and must function

safely at all times. The exposure container, also called camera, must be fail-safe and waterand dirt proof. It must also not be effected by impact.

Moreover, if the radiation-absorbing material, for example lead, melts (in a fire) the radiation absorbing qualities must not be lost.

This requires a casing made of a material with a high melting point, for example steel.

Besides lead, increasingly a new sintered material with very high tungsten content (97%)

is used as shielding material. This material is easily worked and finished and not prone

to melting.

Fig. 9-5. Cross-section of a capsule for a radioactive source

15 m m

5.5 O

/

Fig. 10-5. Sealed capsule

handling / operation side

flexible connection

storage position

of the source

casing/container

exposure position

of the source

shielding

Fig 11-5. Exposure container with source S in a rotating inner cylinder

Fig. 12-5. S-channel container with

source S in storage position

Fig. 13-5. Exposure container

with S-channel and flexible

operating hose ad cable

open

SS

S

closed

Page 26

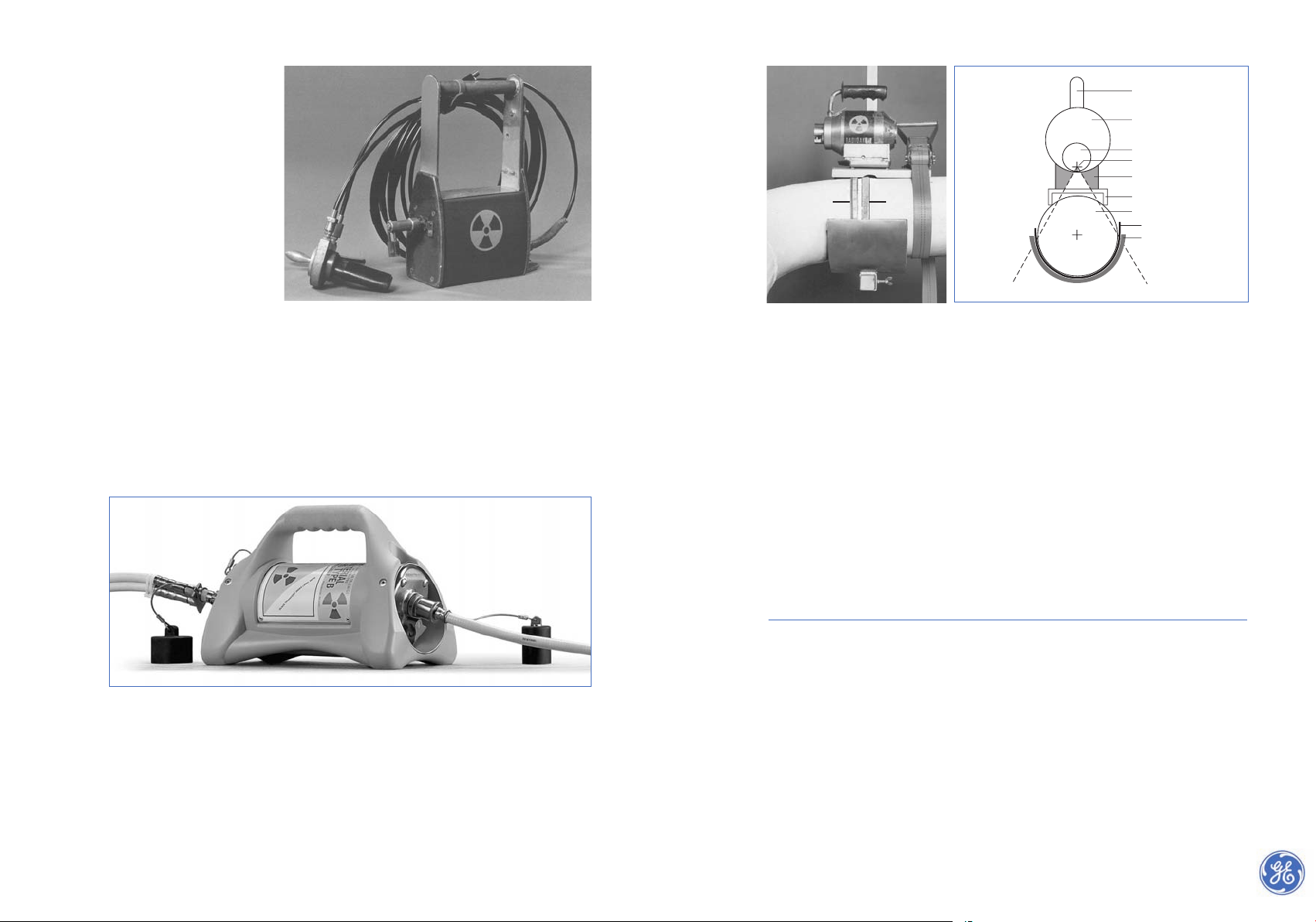

Figure 14-5 shows an S-channel container with a flexible

(metal) hose and cable in rolled up (transport) position.

Figure 15-5 shows a more

recent (2006) S-channel

Selenium75 container with

operation hoses and pigtail.

Selenium75 radio-isotope is

becoming popular since new

production (enrichment)

methods resulted in a much

better k-factor. Thus for a certain activity (source strength)

a much smaller source size (focus) is achieved. This results in a better/sharper image quality than could be achieved with the old Selenium75 production method.

Due to its average energy level of 320 kV, Selenium75 increasingly replaces X-ray

equipment for a thickness range from 5 mm to 30 mm of steel. This eliminates the need for

electric power, very attractive in the field for reasons of electrical safety and more

convenient at remote- or work locations with difficult access (high, deep, offshore,

refineries, etc). Last but not least, a Selenium container is of much lower weigth than

needed for an Iridium192 container with the same source strength.

To enable radiography on work sites with (many) people in the vicinity, for example on

offshore installations or in assembly halls, containers with rotating cylinders

and collimators were developed so that only the beam of radiation required for the

radiograph is emitted.

The remainder of radiation is absorbed by the collimator material which allows people to

work safely at a distance of a few metres while radiography is in progress. Such containers

with collimators are known by the name of “CARE” (Confined Area Radiation Equipment)

or “LORA” (Low Radiation) equipment.

4948

Fig. 14-5. S-channel container with the flexible cable and deployment mechanism.

Fig. 15-5. S-channel container for Selenium75 with pigtail (at right) and operating hoses (at left)

Fig. 16a-5. Gamma container with collimator

on a circumferential weld in a pipe

handle

tungsten container

rotating cylinder

source

Collimator

base

pipe and weld

film

lead shielding

boundaries of the beam of radiation

Fig. 16b-5. Cross-section of CARE/LORA container on the pipe

Without collimating the minimum safety distance is considerably more than 10 metres (in

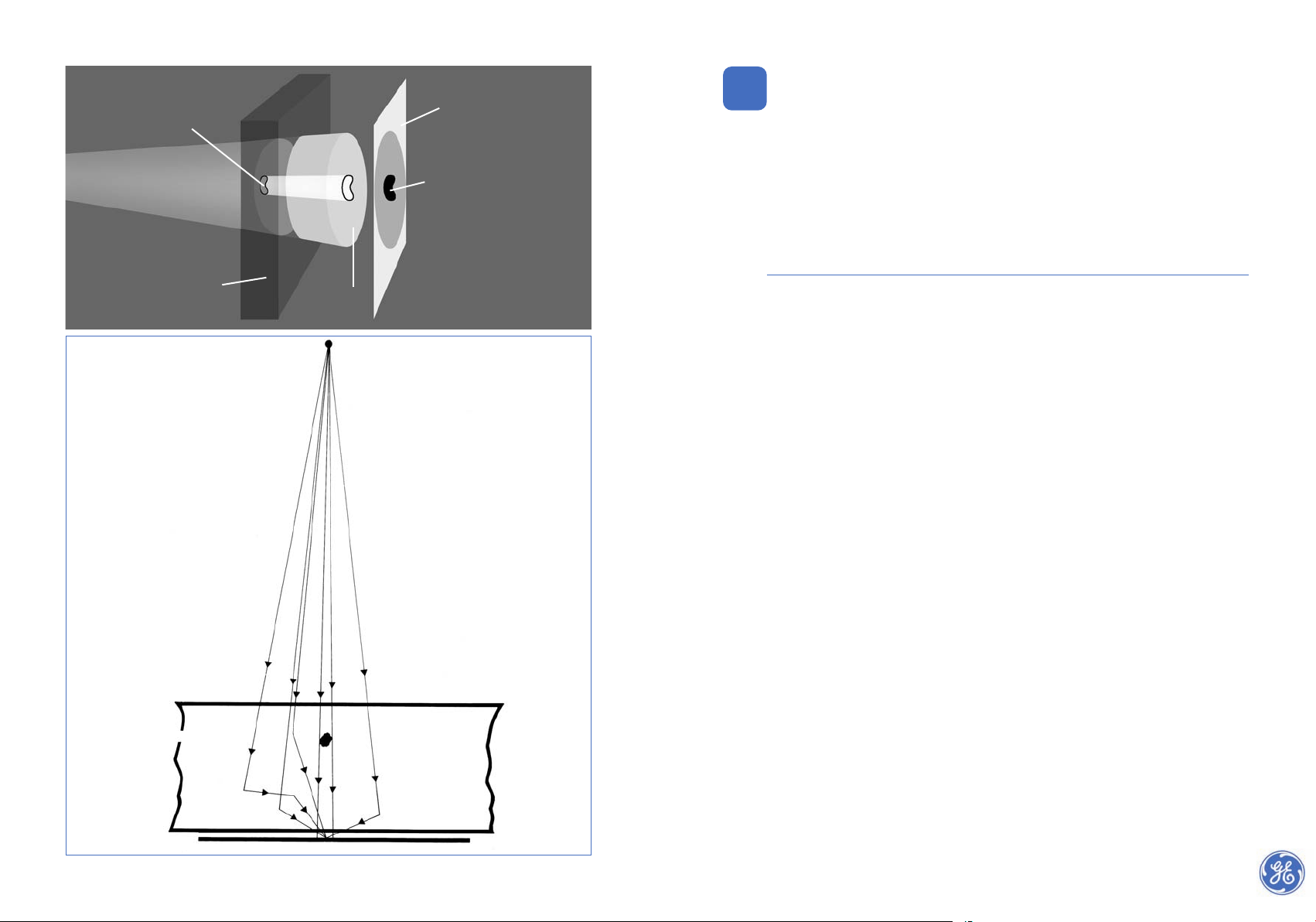

all directions!).

Such containers with collimators are particularly suitable for frequent and

identical repetitive NDT work, for example radiographic testing of welds in pipes of

< 300 mm diameter.

Figure 16a-5 shows such a special container with collimator set up for a double wall

radiograph. The cross-section drawing of figure 16b-5 shows the boundaries of the beam of

radiation. For bigger focus-to-film distances, longer collimators are used to restrict the

beam of radiation.

This type of container is suitable for Iridium sources up to 1000 GBq and weighs “only”

approx. 20 kg. A similar system (Saferad) with a weight of up to 15 kg exists, using

Selenium75, which almost eliminates the usual disruption to construction, maintenance

and process operations in the vicinity of the exposure.

5.7 Checking for container leakage

A sealed radioactive source (capsule) might start to leak and become an open source as a

result of corrosion, mechanical damage, chemical reactions, fire, explosion etc.

Regular mandatory “wipe-tests” by specialists serve to detect leakage at an early stage.

measuring tape

weld

lead

Page 27

51

50

6

Radiation images, filters and

intensifying screens

To influence the effects of radiation on an image, filters and intensifying screens are used to :

• filter / harden the radiation to influence contrast and/or

• to intensify the effect of radiation to improve contrast

6.1 Radiation images

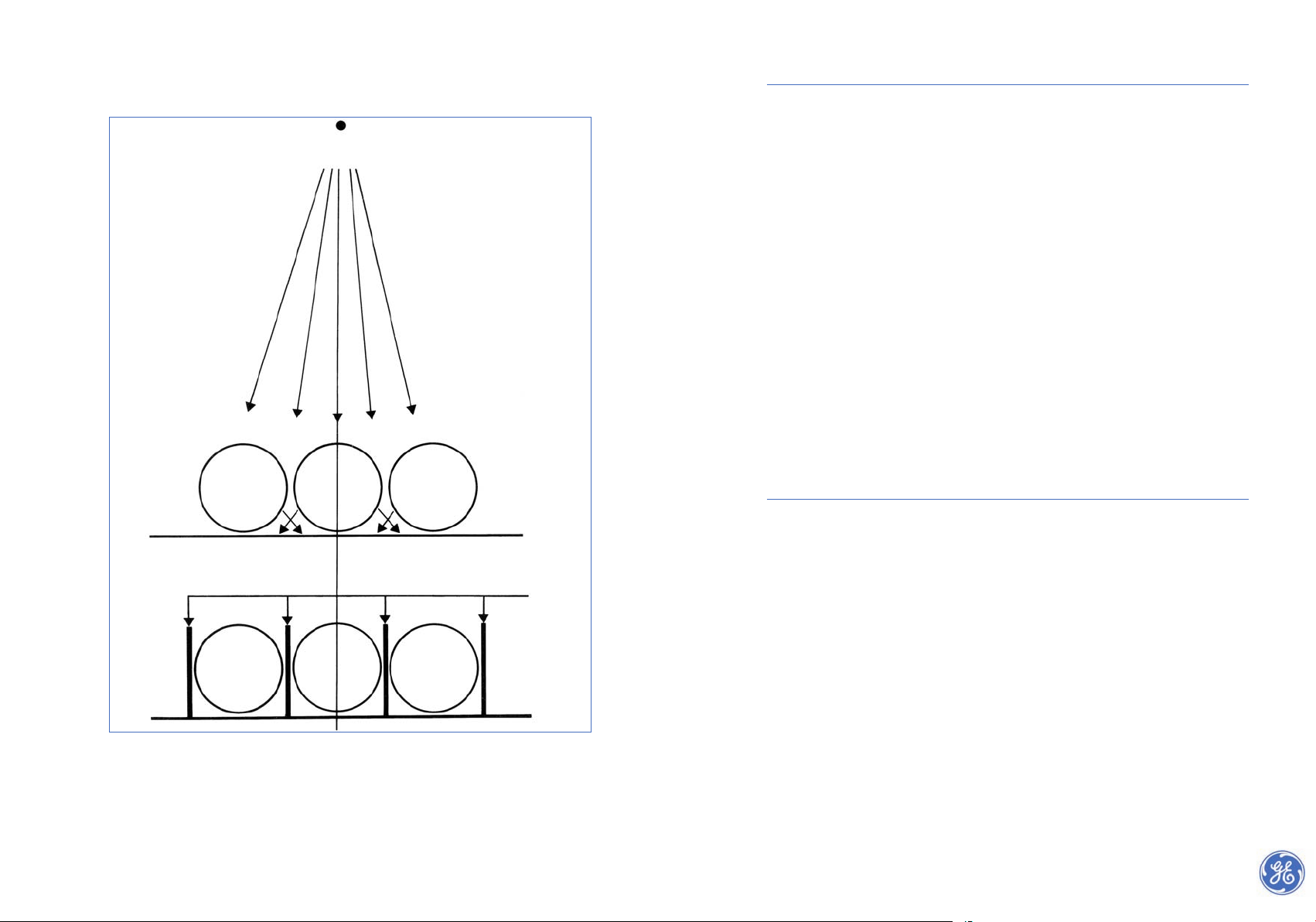

The intensity of a beam of X-rays or gamma-rays undergoes local attenuation as it passes

through an object, due to absorption and scattering of the radiation. On a uniform object

attenuation of the primary beam will also be uniform and the film evenly exposed. If the

object contains defects or is of variable thickness, the surface of the film will be unevenly

exposed resulting in a shadow image of the object and the defects in it. When the film is

processed the variations in radiation intensity show up as varying film densities; higher

radiation intensity producing higher film density resulting in a negative X-ray image as

shown in figure 1-6.

When the primary beam is partly absorbed in the object, some radiation,

as shown in figure 2-6, will be scattered and reach the film as secondary radiation by an

indirect path. The quality of the radiograph is reduced by this scattered radiation, and it is

important to keep its effects to a minimum.

At any point P on the film, therefore, the total radiation reaching that point is made up of

some transmitted primary radiation forming the image of cavity (N), the “image forming”or direct radiation intensity Ip, and some secondary “ non-image forming” , scattered radiation, intensity Is. Hence, the total radiation intensity at P is (I

p

+ Is).

The ratio Is/Ipis called the “scattered radiation factor” and can be as high as 10 for great

wall thicknesses, which means that the scattered radiation is ten times higher than the

image-forming radiation. The ratio (I

p+Is

)/Ip = 1+Is/Ipis called the “build-up factor” and

is of considerable importance for the detectability of defects. It usually has a value between

2 and 20, depending on radiation energy and object thickness.

It must also be appreciated that any object in the neighbourhood of the object being examined (table, walls, ground and so on) which is struck by the gamma- or X-rays will partially reflect these rays in the form of “backscatter” which is liable to fog the film.

Backscatter coming from the object under examination is less hard than the primary radiation that has caused it and can be intercepted by a metal filter between object and film.

Radiation scattered by objects nearby the film can be intercepted by means of a protective

sheet of lead at the rear face of the film cassette.

defect

object

object

film

A

A

C

N

D

E

B

F

P

source (S)

primary radiation

Fig. 1-6. The negative X-ray image

film

negative

(shadow) image

on the film

radiation intensity

after passing

through the object

Fig. 2-6. Image forming and non-image

forming radiation

Only the radiation from source (S) that

reaches the film in straight lines via beam

section DE, produces an image of cavity

N at P. The remainder, not reaching P

directly, is scattered radiation, no defect

image forming thus reducing the image

quality.

Page 28

53

6.2 Radiation filters

When a metal plate, usually lead or copper, is placed between the tube window and the

object, radiation “hardening” occurs leading to a lower image contrast.

This may be counter-balanced by a metal filter placed immediately behind the object (i.e.

between object and film). This filter will cause the (softer) scattered radiation passing

through the object to be absorbed by the filter to a greater extent than the primary (harder) radiation. This also improves the image quality.

If the edges of an object being radiographed are not close to the film (as in the case of a

cylindrical body in figure 3-6) considerable scatter of the primary radiation can occur,

leading to fogging. This scatter can be prevented by positioning sheets of lead foil between

the object and the film as illustrated in this figure.

Reducing the contrast by filtration is also desirable when a radiographic image of an object

of widely varying thicknesses has to be obtained on a single film see section 18.2.

Typical filter thicknesses are :

0.1 – 0.25 mm lead for 300 kV X-rays

0.25 – 1.0 mm lead for 400 kV X-rays

6.3 Intensifying screens

The radiographic image is formed by only approximately 1 % of the amount of radiation

energy exposed at the film. The rest passes through the film and is consequently not used.

To utilise more of the available radiation energy, the film is sandwiched between two intensifying screens. Different types of material are being used for this purpose.

Lead screens

Under the impact of X-rays and gamma-rays, lead screens emit electrons to which the film

is sensitive. In industrial radiography this effect is made use of: the film is placed between

two layers of lead to achieve the intensifying effect and intensity improvement of approximately factor 4 can be realised. This method of intensification is used within the energy

range of 80 keV to 420 keV, and applies equally to X-ray or gamma-radiation, such as produced by Iridium192.

Intensifying screens are made up of two homogeneous sheets of lead foil (stuck on to a thin

base such as a sheet of paper or cardboard) between which the film is placed: the so called

front and back screens.

The thickness of the front screen (source side) must match the hardness of the radiation