Page 1

DVSe

Page 2

Copyright Copyright © 2006, GE Security, Inc. All rights reserved.

This document may not be copied in whole or in part, or otherwise reproduced except as

specifically permitted under US copyright law, without the prior written consent from GE.

Document number/0150-0178H. (February 2006)

Disclaimer THE INFORMATION IN THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. GE

ASSUMES NO RESPONSIBILITY FOR INACCURACIES OR OMISSIONS AND SPECIFICALLY

DISCLAIMS ANY LIABILITIES, LOSSES, OR RISKS, PERSONAL OR OTHERWISE, INCURRED AS A

CONSEQUENCE, DIRECTLY OR INDIRECTLY, OF THE USE OR APPLICATION OF ANY OF THE

CONTENTS OF THIS DOCUMENT. FOR THE LATEST DOCUMENTATION, CONTACT YOUR

LOCAL SUPPLIER OR VISIT US ONLINE AT

WWW.GESECURITY.COM.

This publication may contain examples of screen captures and reports used in daily

operations. Examples may include fictitious names of individuals and companies. Any

similarity to names and addresses of actual businesses or persons is entirely

coincidental.

Access to the interior of the DVSe is intended for trained service personnel only!

Trademarks

and patents

GE and the GE monogram are registered trademarks of General Electric.

The DVSe product and logo are registered trademarks of GE Security.

Other trade names used in this document may be trademarks or registered trademarks

of the manufacturers or vendors of the respective products.

Software

license

agreement

GE software supplied with GE products is proprietary and furnished under license and

can be used or copied only in accordance with the license terms.

THE ENCLOSED PROGRAM IS FURNISHED SUBJECT TO THE TERMS AND CONDITIONS OF

THIS AGREEMENT. RETENTION OF THE PROGRAM FOR MORE THAN 30 DAYS, OPENING OF

THE SEALED WRAPPER, IF ANY, SURROUNDING THE PROGRAM, OR USE OF THE PROGRAM

IN ANY MANNER WILL BE CONSIDERED ACCEPTANCE OF THE AGREEMENT TERMS. IF

THESE TERMS ARE NOT ACCEPTABLE, RETURN THE UNUSED PROGRAM AND ANY

ACCOMPANYING DOCUMENTATION TO GE FOR A FULL REFUND OF THE LICENSE FEE PAID.

(FOR INFORMATION REGARDING THE RETURN OF PROGRAMS ENCODED OR

INCORPORATED WITHIN EQUIPMENT, CONTACT THE NEAREST GE SALES OFFICE.)

Intended use Use this product only for the purpose it was designed for; refer to the data sheet and user

documentation. For the latest product information, contact your local supplier or visit us

online at

www.gesecurity.com.

FCC compliance This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications.

You are cautioned that any changes or modifications not expressly approved by the

party responsible for compliance could void the user's authority to operate the

equipment.

Regulatory

Operation of this equipment in a residential area may cause interference, in which case

the user is required to take all measures that are necessary, at the user's expense, to

correct the interference

Regulatory

UL

"Underwriters Laboratories Inc. has not tested the performance or reliability of the

security or signaling aspects of this product. UL has only tested for fire, shock and

casualty hazards as outlined in UL's Standard for Safety UL 60950-1. UL Certification does

not cover the performance or reliability of the security or signaling aspects of this

product. UL MAKES NO REPRESENTATIONS, WARRANTIES OR CERTIFICATIONS

WHATSOEVER REGARDING THE PERFORMANCE OR RELIABILITY OF ANY SECURITY OR

SIGNALING RELATED FUNCTIONS OF THIS PRODUCT."

DVSe 2 0150-0178H

Page 3

Table of Contents

1

Introduction....................................................................4

1.1 Product Description..............................................................................4

1.2 Unpacking ............................................................................................4

1.3 Installation Environment.......................................................................4

1.4 The Back Panel....................................................................................6

1.5 Connections .........................................................................................6

1.6 Front Panel Indicators ..........................................................................8

2 Hard Drive Installation.................................................10

2.1 Opening The DVSe ............................................................................10

2.2 Identifying The Components...............................................................10

2.3 Compatible Hard Drives .....................................................................11

2.4 Configuring the Hard Drives ............................................................... 12

2.5 Mounting The Hard Drives..................................................................12

2.6 Connecting the Hard Drives ...............................................................12

2.7 Jumper Settings..................................................................................14

3 DVSe Setup...................................................................15

3.1 Connecting by SCSI or 1394..............................................................15

3.2 Power-Up ...........................................................................................16

3.3 Setup Menu........................................................................................16

3.4 Supervisor Menus............................................................................... 18

3.5 Hard Disk Test .................................................................................... 19

3.6 Upgrading the DVSe........................................................................... 20

4 Warranty and Service...................................................23

4.1 Factory Service...................................................................................23

4.2 Factory Address ................................................................................. 23

4.3 Warranty............................................................................................. 23

0150-0178H 3 DVSe

Page 4

1 Introduction

1.1 Product Description

The DVSe is a rack mountable ethernet-ready high capacity digital video storage

system. From 2 to 8 hard drives can be installed in each DVSe chassis. The

unit may be purchased with or without hard drives installed. All hard drives must

be installed in pairs and all drives must be of the same type, speed, and capacity.

1.2 Unpacking

Check the package and contents for visible damage. If any components are

damaged or missing, do not attempt to use the unit. Contact the supplier

immediately. If the unit must be returned, it must be shipped in the original

packaging.

Package Contents

• The DVSe.

• US & EU Power Cables.

• The GE Security DVSe Installation and Users Manual.

• The GE Security DVSe Release Note.

• The Archiving Addendum Manual.

• WaveReader Software and Manual.

• WaveWatch Software and Manual.

• IDE Hard Drive Power Connectors x 2. (If shipped without drives installed)

• IDE Hard Drive Connection Ribbon x 4. (If shipped without drives installed)

• Hard Drive Fastening Screws x 24. (If shipped without drives installed)

• SCSI Cable, 50 HD to 50 HD.

• IEEE 1394 Firewire Cable.

1.3 Installation Environment

Power: Ensure that the site’s AC power is stable and within the rated voltage of

the external power supply. Ensure that a reliable Earthing path is maintained.

This unit is designed to be connected to earth ground. If the site’s AC power is

likely to have spikes or dips, use power line conditioning or an Uninterruptable

Power Supply. Do not overload the circuit. Ensure that the Power Supply is set

to the correct voltage (110/220v) for your area.

Ventilation: Ensure that the location is well ventilated. Do not obstruct the

cooling vents or fans.

Temperature: Observe the unit’s ambient temperature specifications when

choosing a location for the unit. Extremes of heat or cold beyond the specified

operating temperature limits may cause the unit to fail. Do not install this unit on

top of other hot equipment.

DVSe 4 0150-0178H

Page 5

Moisture: Do not expose the unit to rain or moisture. Moisture can damage

internal components. Do not install this unit near sources of water.

Rack Mounting: Carefully load the rack so that it remains stable and unlikely to

tip over. The unit is also suitable for desktop installation. When rack mounting

the DVSe adhere to the following guidelines:

• Elevated Operating Ambient - If installed in a closed or multi-unit rack

assembly, the operating ambient temperature of the rack environment

may be greater than room ambient. Therefore, consideration should be

given to installing the equipment in an environment compatible with the

maximum ambient temperature.

• Reduced Air Flow - Installation of the equipment in a rack should be such

that the amount of air flow required for safe operation of the equipment is

not compromised.

• Mechanical Loading - Mounting of the equipment in the rack should be

such that a hazardous condition is not achieved due to uneven

mechanical loading.

• Circuit Overloading - Consideration should be given to the connection of

the equipment to the supply circuit and the effect that overloading of the

circuits might have on overcurrent protection and supply wiring.

Appropriate consideration of equipment nameplate ratings should be

used when addressing this concern.

• Reliable Earthing - Reliable earthing of rack-mounted equipment should

be maintained. Particular attention should be given to supply connections

other than direct connections to the branch circuit (e.g. use of power

strips)."

0150-0178H 5 DVSe

Page 6

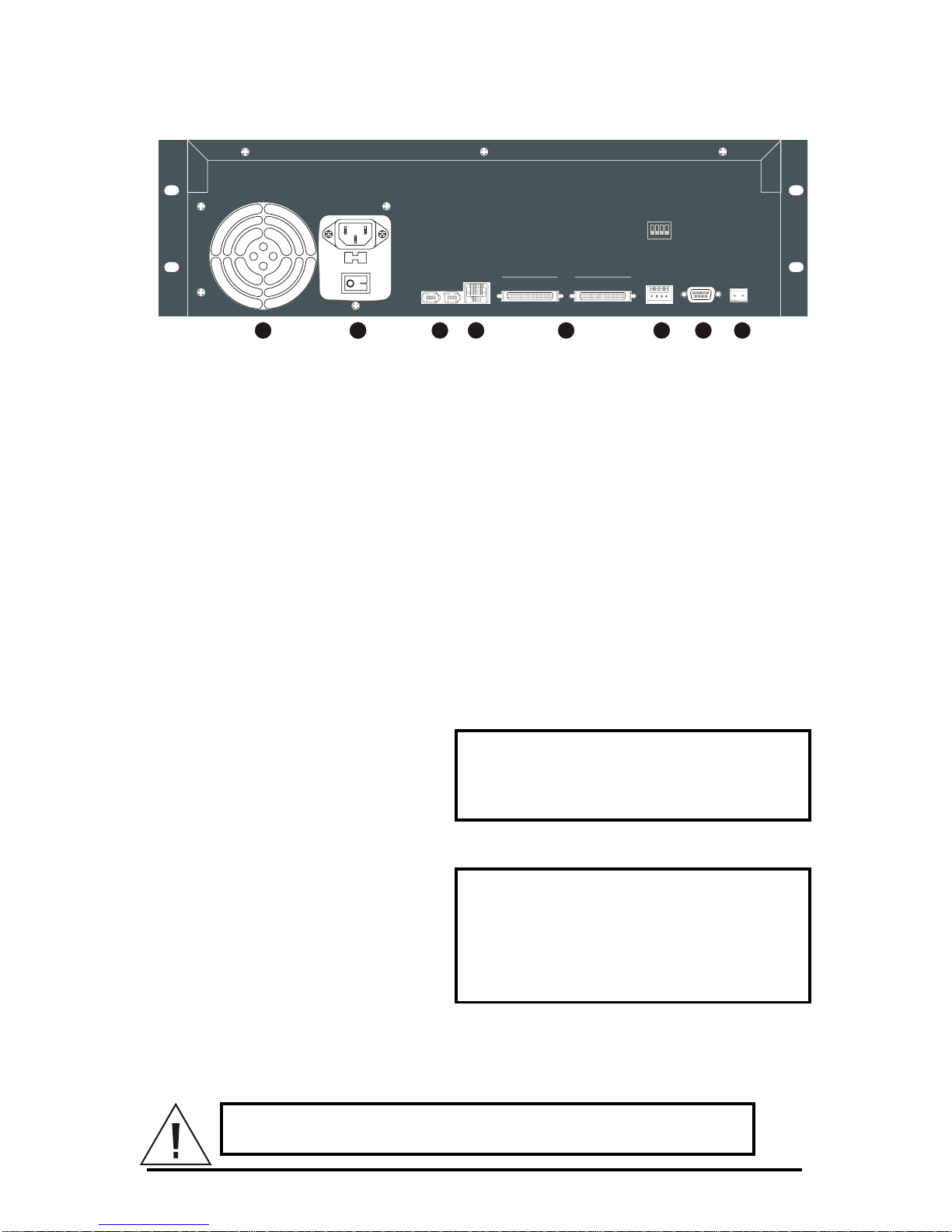

1.4 The Back Panel

ETHERNET

10/100

RELAY

SCSIIEEE-1394 RS-232SW 1

PORT 1PORT 1

OFF

OFF

1234

ON

ON

PORT 2 PORT 2

1: SCSI TERMINATION

2: SCSI POWER

3: BUZZER

4: AUX

1 222 3 4 5 6 7 8

Back Panel Components

1. Cooling Fan: Do not obstruct.

2. Power Connector, Voltage Selector and On/Off Switch.

3. IEEE-1394 Firewire Ports 1 and 2.

4. 10/100 Ethernet Port.

5. SCSI Ports 1 and 2.

6. Dip Switches (SW1).

7. RS-232 Port.

8. Alarm Out Relay Connection (Future feature).

1.5 Connections

10/100 Ethernet Port

The Ethernet port is used to connect

the DVSe into a network

environment.

Wire Type: Cat 5.

Connector Type: RJ-45.

Cable Required: Ethernet.

SCSI Ports 1 and 2

Connect a SCSI device to one of the

two SCSI ports. Set the dip switches

(SW1) on the back panel. Set SCSI

Termination and SCSI Power to On

and use the Bus Select menu option

to enable this feature.

Connector: 50 pin, high density SCSI-2.

Gender (on unit): Female.

SCSI ID: 0.

The unit does not currently support multiple SCSI device connections.

Caution! Ensure the power to DVSe is OFF BEFORE

connectin

g

any SCSI or 1394 devices. Do not attempt to use

DVSe 6 0150-0178H

Page 7

the SCSI and 1394 ports simultaneously.

1394 Firewire Ports 1 and 2

Connect a 1394 Firewire device to

one of the two 1394 ports. Use the

Bus Select menu option to enable

this feature.

Cable: 6 position IEEE 1394.

Connectors: 6 position DIP.

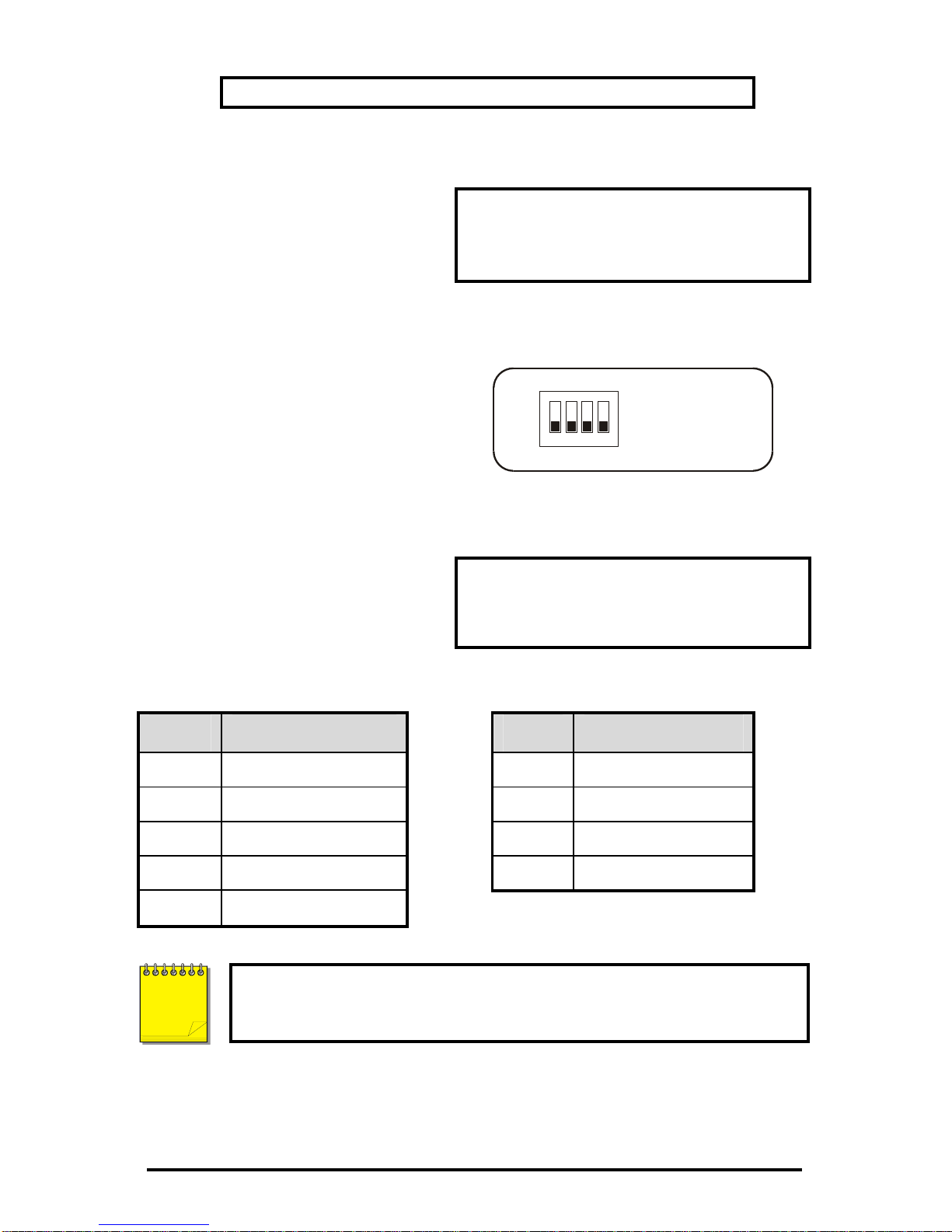

Dip Switches (SW1)

Set the Dip Switches to enable or

disable the features listed on the

illustration to the right. Switch

position up to turn off (disable), down

to turn on (enable).

OFF

1234

ON

1: SCSI TERMINATION

2: SCSI POWER

3: BUZZER

4: AUX

RS-232 Port

The RS-232 port can be used for

Serial Debugging.

Connector Type: DB-9.

Gender (on unit): Male.

Cable Required: Null Modem.

DB-9 Pin Configuration For RS-232 Port

Pin Use Pin Use

1 DCD 6 Not Connected

2 RX 7 RTS

3 TX 8 CTS

4 Not Connected 9 Not Connected

5 Ground

To receive serial debug data from the DVSe’s RS-232 port, set up the

receiving serial port at 57600 bps, No Parity, 8 data bits, and 1 stop

bit.

NOTE

0150-0178H 7 DVSe

Page 8

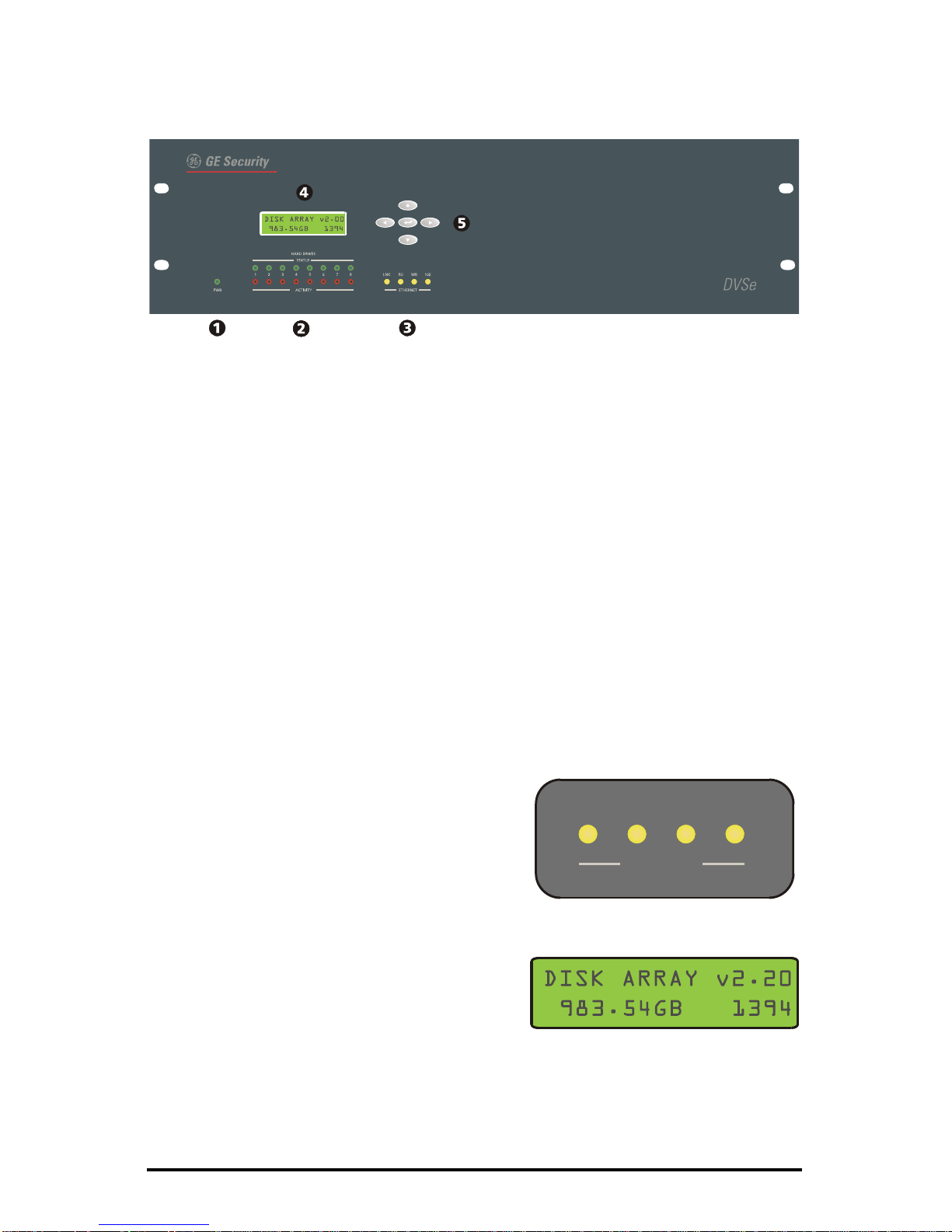

1.6 Front Panel Indicators

1. Power LED.

2. Hard Drive Status Indicators.

3. Ethernet Indicators.

4. LCD Display.

5. Key Pad buttons.

Hard Drive Status Indicators (Green LEDs)

LED On: Drive present and operating normally.

LED Off: No drive present, drive not detected, drive disabled due to error.

Hard Drive Activity Indicators (Red LEDs)

The LED blinks when the drive is being accessed (read or write).

Ethernet Indicators

The ethernet LEDs light to indicate the following:

• Link: A detected ethernet connection.

• RD: Receiving Data.

• WR: Transmitting Data.

• 100: 100 Mbps bandwidth

LNK RD WR 100

ETHERNET

LCD Display

Once power-up is complete, the LCD

displays the total disk storage capacity of the

unit. The LCD display also provides visual

feedback for the menu settings. See DVSe

Menu Setup for details.

DVSe 8 0150-0178H

Page 9

Key Pad

The Key Pad buttons provide access and control of the Setup Menu.

• Up Arrow: Change field data (ascending).

• Left Arrow: Move field selection to left.

• Enter Button: Press to access setup

menu. Toggles through menu screens.

• Right Arrow: Move field selection to right.

• Down Arrow: Change field data

(descending).

0150-0178H 9 DVSe

Page 10

2 Hard Drive Installation

This section contains important information on adding or replacing the internal

Disk Drives. Please read the entire section before performing any work.

Caution: Do not allow any metal object to contact the

motherboard. Do not allow loose screws to become lost inside

the DVSe chassis. Wear an Electro Static Discharge protection

device any time work is being performed inside the unit.

2.1 Opening The DVSe

Before removing the cover, turn off the unit and unplug it. Using a Phillips-head

screwdriver, carefully remove the twelve screws fastening the lid to the chassis.

Save the screws and use them to refasten the lid when finished.

2.2 Identifying The Components

Complete Internal Overview

Mother

Board

Disk Drives

Power

Supply

Drive Support Bracket

DVSe 10 0150-0178H

Page 11

Motherboard Overview

IDE Power

Connectors

IDE

Connectors

Power

Supply

Load

Resistors

Jumpers

2.3 Compatible Hard Drives

The DVSe is designed to be compatible with Maxtor D540X and MaXLine II

series of hard drives. Hard drives in this series up to 250 GB may be used.

Refer to www.maxtor.com for details.

Hard Drives must be added in pairs and must be of the same type,

speed, and capacity.

GE Security cannot provide technical support for DVSe units using

hard drives other than those described above. Using drives other

than those described above may result in failure or intermitt ent data

errors.

NOTE

Please contact GE Security Technical Support regarding hard disk compatibility.

0150-0178H 11 DVSe

Page 12

2.4 Configuring the Hard Drives

Hard drives are connected in pairs

to each of the four IDE

connectors. Each pair of hard

drives must be configured as a

Master and a Slave. Configure

the Master/Slave settings on each

hard drive individually using the

jumpers provided with the drive.

Use the diagram located on the

hard drive to determine the proper

jumper configuration.

2.5 Mounting The Hard Drives

Remove the Hard Drive Support Bracket. This entails removing the screws at

either end and one screw from each installed hard drive.

Orient the hard drive so that the IDE Power Connector is near the bottom of the

chassis and facing the motherboard. Populate the drive array in order, starting

from the left.

Fasten the drive in place using the supplied screws. Fasten each drive using two

screws through the bottom of the chassis and one screw in the Hard Drive

Support Bracket.

2.6 Connecting the Hard Drives

Power Supply Cables

It is recommended, for ease of installation, that the IDE and power

cables be first connected to the drives before the drive screws are

tightened.

NOTE

DVSe 12 0150-0178H

Page 13

Connect the hard

drives to the power

supply connectors

with power supply

cables.

When connecting a

single drive to a

cable, attach the

drive to the

connector at the end

of the power cable.

Disk 1

Disk 2

Disk 3

Disk 4

Disk 5

Disk 6

Disk 7

Disk 8

Power Supply

Mother Board

NOTE

The diagram above shows a typical connection. The connections

may vary according to the number of drives in the system and the

power cable type.

IDE Data Cables

Use an IDE cable to connect the drives as shown in the diagram in section 2.3.

When attaching the IDE connector, make sure the connectors are oriented

properly.

Connecting To The Motherboard

The red stripe on the connection ribbon

should connect nearest the Pin 1 indicator

on the motherboard.

Pin 1

Indicator

Connecting To The Hard Drive

The red stripe on the connection ribbon

should connect near the jumpers on the hard

drive.

Pin 1 Near

Jumpers

0150-0178H 13 DVSe

Page 14

2.7 Jumper Settings

Jumper Configuration

Configure the jumpers based on the number of hard drives installed in the unit.

Do not throw away unused jumpers.

See section 2.2 to locate this block of jumpers.

2-6 Drives 8 Drives

Load 4

Load 3

Load 2

Load 1

Load 4

Load 3

Load 2

Load 1

After any drives are installed, replaced or removed, the Reset Disk

Failure command must be run from the Supervisor Menu for the

changes to be recognized by the DVSe.

NOTE

DVSe 14 0150-0178H

Page 15

3 DVSe Setup

This section contains important information on setting up the DVSe for

operation. Please read the entire section before performing any work.

3.1 Connecting by SCSI or 1394

Caution! The DVSe does NOT support the simultaneous use

of the SCSI and 1394 ports. Only connect one type of device at

a time.

SCSI

Connect a SCSI device to one of the two SCSI ports using the supplied SCSI

cable. Set the dip switches (SW1) on the back panel. Set SCSI Termination

and SCSI Power to On. Select SCSI as the type of Bus in the Setup Menu

under Bus Select.

Caution! Power must be shut down before connecting SCSI

cables between SCSI devices and the DVSe.

Dip Switches (SW1)

Set the Dip Switches to enable or

disable the features listed on the

illustration to the right. Switch

position up to turn off (disable), down

to turn on (enable).

OFF

1234

ON

1: SCSI TERMINATION

2: SCSI POWER

3: BUZZER

4: AUX

1394 Firewire

Connect a 1394 device to one of the two 1394 ports using the supplied 1394

cable. Set the dip switches (SW1) on the back panel. Set SCSI Termination

and SCSI Power to OFF. Select 1394 as the type of Bus in the Setup Menu

under Bus Select.

Caution! Power must be shut down to all devices before

connecting 1394 cables between the 1394 dev ice and the

DVSe.

0150-0178H 15 DVSe

Page 16

3.2 Power-Up

Select the correct voltage before supplying power to the unit. Use the voltage

selector switch located on the back panel of the unit, between the power

connector and the On/Off Switch.

Caution! Applying incorrect voltage will damage unit.

Once the correct voltage has been selected and all connections have been

made, connect the power cable suited to your geographic location. Apply power

to the unit.

3.3 Setup Menu

The Setup menu provides setup options for the following features:

• Ethernet enable/disable.

• Bus Select: SCSI/1394

• Auto Delete Mode.

• IP Address.

• Subnet Mask Address.

• Default Gateway Address.

• Date/Time Setup.

Menus will automatically be exited after 30 seconds of inactivity.

NOTE

Access to menu is only allowed when the DVSe is Offline, i.e. the

DVSe is not presently archiving or connected via ethernet.

NOTE

Press the Enter Button to access the first menu.

Ethernet Enable

Select ethernet enable, yes or no. Default

setting is no.

Bus Select

Select from SCSI or 1394 to enable. Default

setting is 1394.

DVSe 16 0150-0178H

Page 17

Auto Delete Mode

Auto Delete Mode, select yes or no. Default

setting is no. Auto Delete Mode

automatically invalidates data that is over 30

days old.

Obtain the required network parameters from you Network

Administrator.

NOTE

NOTE

The DVSe will automatically reboot if any of the Bus or Network

parameters are changed.

IP Address

Enter the assigned IP address by using the

left/right arrows to select the field and the

up/down arrows to change the values.

Subnet Mask

Enter the assigned Subnet Mask address by

using the left/right arrows to select the field

and the up/down arrows to change the

values.

Default Gateway

Enter the assigned Default Gateway address

by using the left/right arrows to select the

field and the up/down arrows to change the

values.

Date/Time

Enter the current date and time by using the

left/right arrows to select the field and the

up/down arrows to change the values.

Required only when Auto Delete Mode is set

to yes.

0150-0178H 17 DVSe

Page 18

3.4 Supervisor Menus

The Supervisor menus provides advanced options for the following features:

• Disk Status.

• Reset Disk Failure.

• Serial Debug Output.

The Key Pad buttons provides access and control of the Supervisor Menus. To

access the Supervisor menus press the left and right arrows simultaneously.

• Up Arrow: Quits the menu.

• Left Arrow: Move field selection to left.

• Enter Button: Press to access setup

menu. Toggles through menu screens.

• Right Arrow: Move field selection to right.

• Down Arrow: Quits the menu.

Disk Status

This menu indicates the current disk status.

Disk status is viewable only on this display.

• N: Normal

• W: Error writing to Disk

• R: Error Reading Disk

• T: Timeout during disk initialization or disk

absent

• E: Fails Disk Test

The letters on the Disk Status screen represent Disk 1 (left) thru Disk 8 (right).

NOTE

Do not attempt to reset a disk with read/write errors (a R or W

status). This could lead to more disk errors and data loss. Disks

with read/write errors should be replaced.

NOTE

Disks with a T status may be recovered, but the DVSe will

attempt to start recording to this disk. A recovery should not be

attempted until the preceding disk is filled up. Contact Technical

Support for detailed instructions on replacing or recovering

problem hard disks.

DVSe 18 0150-0178H

Page 19

NOTE

Be sure to confirm that the drives are connected according to the

diagram in Section 2.3 before removing or replacing. The disk

status display and LEDs represent the wiring and Master/Slave

configuration, not the physical location of the drives.

Reset Disk Failure

This command allows the DVSe to re-enable

disks with timeout errors and reset the Disk

Status. Changing this setting restart the unit.

Any time that a disk is replaced, added, or

removed this command must be executed.

Serial Debug

Serial Debug output, select yes or no.

Default setting is no. Enabling serial debug

will output debug messages on the RS232

port at 57600 bps. Changing this setting will

cause the unit to restart.

3.5 Hard Disk Test

Two types of Hard Disk Test are accessible via the front panel:

• The Quick Disk Test: This test takes approximately 5 minutes.

• The Burn In Disk Test: This test can run over 8 hours

depending on the size of the Hard Disks.

The Quick Disk Test

The Quick Disk Test is accessible by

simultaneously pressing the UP and Down

Arrow buttons. This test performs random

read and writes on all the disks. See the

flow chart on the following page for detailed

information.

The Burn In Disk Test

The Burn In Disk Test is accessible by

selecting No on the Quick Disk Test Screen

and pressing the Enter button. This test

performs sequential read and writes on all

the disks and is a much more

comprehensive. See the flow chart on the

following page for detailed information.

0150-0178H 19 DVSe

Page 20

Both Tests may be cancelled by depressing the UP Arrow Button

until the test stops.

NOTE

Caution! Do not run any SCSI, Ethernet, or Firewire Operation

while performing either Disk Test. Permanent damage to the

DVSe may occur.

3.6 Upgrading the DVSe

Upgrading the software for the DVSe is accomplished via the ethernet port

and a PC/Laptop equipped with a web browser.

To properly upgrade the GE Security DVSe the following preconditions mu st

exist:

DVSe 20 0150-0178H

Page 21

1. The Flash upgrade file and path. This file is obtained by calling GE

Security Technical Support at 1-800-469-1676. When calling, pleas e

have the following information available:

T he model number of the product.

T he serial number and revision of the product

T he current firmware version.

The date purchased.

Symptoms of the unit that might require u pgrade.

2. The DVSe unit connected to a PC equipped with Microsoft Internet

Explorer version 5.5 or later via ethernet cable.

3. The IP address of the DVSe.

4. WaveReader software must NOT be connected to the DVSe. Please

exit all non-essential software on the PC.

5. Ensure that the DVSe is not currently recording or archiving.

Follow the steps below to Upgrade the DVSe:

Step 1. Launch the Browser software (Microsoft Internet Explorer 5.5 or

later).

Step 2. Enter the IP address of the DVSe in the address field of the Browser

followed by /upgrade.ssi and press enter. For example if the IP

address is 3.18.173.71 type 3.18.173.71/upgrade.ssi.

Step 3. The Enter Network Password window should appear. Enter the

correct Username and Password in their respective fields. (The

default username is admin and the password is admin. It is

recommended that the defaults be changed ASAP). Click the OK

button. The DVSe upgrade page should appear.

0150-0178H 21 DVSe

Page 22

Step 4. Navigate to the upgrade file using the Browse button or type in the

correct path and filename. Click on the Send File button.

Step 5. Click on the Confirm Button. A progress bar will appear. PLEASE

WAIT FOR THE PROGRESS BAR TO FINISH, THEN WAIT FOR

CONFIRMATION!

Step 6. Click on the Reboot button to restart the unit for changes to take

effect. If unsuccessful, download the flash file again and retry the

steps 1-6.

DVSe 22 0150-0178H

Page 23

4 Warranty and Service

4.1 Factory Service

If the unit requires factory service, contact the dealer who supplied the unit to you

for the correct procedures on returning the unit to the factory or the nearest

factory service center.

If the dealer is not available, contact the manufacturer of the unit as detailed

below and request a Return Material Authorization number (RMA). The unit’s

serial number must be provided before an RMA number can be issued. Units

returned to the factory for service must have freight and insurance prepaid, and

must show the RMA number clearly on all shipping documents. The failure

symptoms must be clearly described by the operator and enclosed with the unit

together with a copy of the original supplier’s invoice. Failure to comply with

these instructions will delay service of the unit, and may result in the unit not

being accepted by the Repair Center.

4.2 Factory Address

GE Security

Attention: Repair Center

3050 Red Hill Ave.

Costa Mesa, CA 92626

United States of America

Telephone: 800-343-3358 (7:00 AM to 4:30 PM, Pacific Time)

In Oregon: 541-754-9133

Fax: 541-754-7162 (24 hours a day)

For warranty information, see the following page.

4.3 Warranty

GE Security warrants all of its equipment for three years from the date of

purchase. This warranty covers any defects in materials and workmanship.

Equipment failures that are due to improper installation, modification, abuse, or

acts of nature will not be covered by this warranty. The repair department will

evaluate all equipment returned for repair to determine warranty coverage. The

Tech Support Manager will resolve any questions that may arise during

evaluation to make a final determination.

Note: The three-year warranty does not apply to the following products:

MobileView

®

and the monitor CRT, which carry a 12-month warranty from the date of

purchase.

The warranty specifically covers any defects in material and workmanship and

does not cover equipment that has been abused, damaged, or modified.

For all warranty repairs, GE Security will cover all costs, including parts, labor,

and shipping. Repaired equipment will be returned via the same method of

0150-0178F 23 DVSe

Page 24

shipment in which it was received. If a customer requests a faster return

shipment, the difference will be charged.

For all non-warranty repairs, the customer will be billed for parts, labor, and

shipping. Labor will be billed in half-hour increments.

Note: Customers requesting an estimate prior to repair will be notified by phone. If they

cannot be reached, they will be notified by fax. If we are unable to reach the contact person

for repair authorization after one phone attempt and two fax attempts, the equipment will be

returned without being repaired. We will hold equipment no longer than two weeks.

Advance Replacement Policy

When an advance replacement is required, we will send the customer

replacement equipment from our stock and receive the returned product in

exchange. The received equipment will be evaluated a nd the repair department

will determine whether it is a warranty replacement. If it is non-warranty, see our

repair policy above for details. The following guidelines will be used for all

advance replacements:

• Fewer than 45 days from purchase, GE Security will replace the product with new

equipment.

• From 45 days to 1 year from purchase, GE Security will replace the product with

refurbished equipment.

• From 1 year to 3 years from purchase, the product must be sent in for repair.

Advance replacements will be sent for a fee of $100.

If you have questions about this policy, please contact GE Security’s RMA

Department at

800-469-1676.

DVSe 24 0150-0178H

Loading...

Loading...