Page 1

Applications

The DigitalFlow GS868 steam ultrasonic fl owmeter

is a complete ultrasonic fl ow metering system that

measures saturated or superheated steam for:

• Heating, ventilating and air conditioning (HVAC)

• Pneumatic power systems

• Food and beverage industry

• Water purifi cation and distillation

• Chemical and petrochemical industries

• Electric power generation

• Steel industry

• Public works

• Manufacturing

Features

• Bidirectional

• No moving parts

• No pressure drop

• Wide rangeability with 1500 to 1 turndown ratio

• Non-obstructive fl ow measurement

• Tolerance to dirty streams

• Low maintenance

• Suitable for high temperatures

• Two-path measurement available for maximum

accuracy

GE

Sensing & Inspection Technologies

DigitalFlow

™

GS868

Panametrics Ultrasonic Steam

Mass Flowmeter

GE imagination at work

Page 2

Panametrics Ultrasonic Steam Mass

Flowmeter

The DigitalFlow GS868 steam ultrasonic fl owmeter is

designed to measure the mass fl ow rate of saturated or

superheated steam. It off ers a unique combination of

no pressure drop, wide rangeability, ease of installation,

low maintenance and high accuracy in a full-feature

fl owmeter package.

The DigitalFlow GS868 Flowmeter

Uses the Correlation Transit-Time

™

Technique

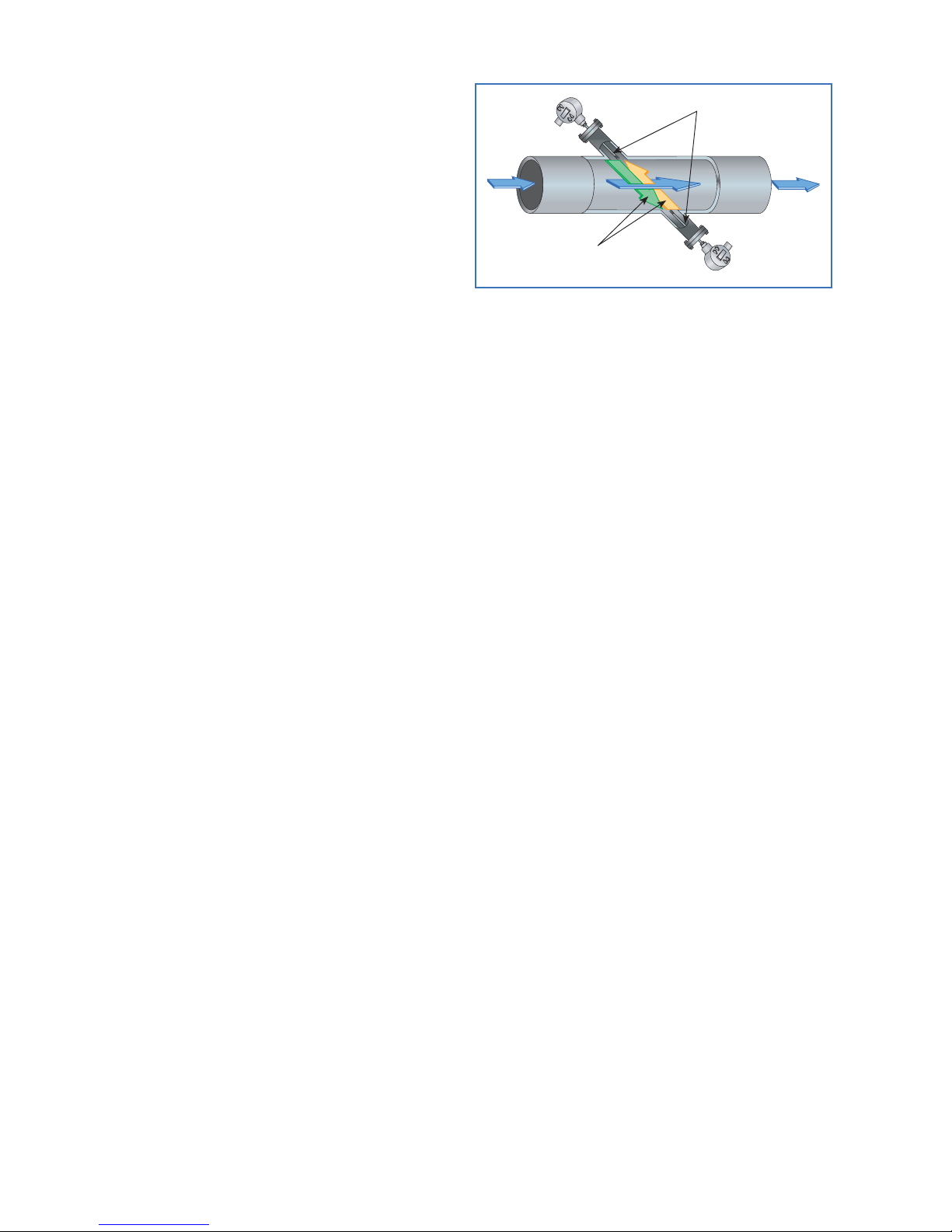

Compact ultrasonic transducers are installed in the pipe

or duct, one upstream of the other. The transducers send

and receive ultrasonic pulses through the steam. The

meter measures the diff erence between the upstream

and downstream transit times, and uses digital signal

processing, advanced signal processing and correlation

detection to calculate velocity and volumetric fl ow rate.

Mass fl ow is calculated from the input of temperature

and pressure and the built-in steam tables.

No Pressure Drop, Low Maintenance

In addition to the standard single-channel model,

an optional two-channel model provides enhanced

accuracy when measuring two paths on a single pipe. It

can also be used to measure a single path on two pipes.

Low Operational Costs

Conventional steam fl owmeters cause a permanent

pressure drop and have limited rangeability, wasting time

and money. Since the DigitalFlow GS868’s transducers

do not obstruct the fl ow, they generally do not cause any

pressure drop. The DigitalFlow GS868 has no parts that

foul or collect debris, and no moving parts to wear out.

As a result, it requires no lubrication, cleaning or other

routine maintenance.

Digital and Analog Output Options

The DigitalFlow GS868 fl owmeter makes it easy to send

the data where it needs to go, through the standard

digital output, standard or optional analog outputs, or

optional alarms. All outputs are conveniently set up and

calibrated from the keypad or from a computer using

PanaView

™

PC-interface software.

Wide Range of Pipe Sizes and Flow

Conditions

With its broad range of measurement velocities and its

ability to measure fl ow in any pipe from small to very

large, one DigitalFlow GS868 meter does the job of

several conventional meters. It handles pipes from 2 in

to 48 in (50 mm to 1200 mm) in diameter and velocities

from 0.1 to 150 ft/s (0.03 to 46 m/s)―in either direction―in

saturated or superheated steam.

For maximum accuracy, use a two-channel meter to

measure along two diff erent paths at the same location.

A two-channel meter can also measure the fl ow in two

separate pipes for additional cost savings.

Convenient Installation

Straightforward installation is another advantage of the

DigitalFlow GS868. The fl owmeter system consists of

one or two pairs of transducers, preamplifi ers and an

electronics console. The transducers can be installed as

part of a fl owcell, or installed directly into the existing

pipeline. The electronics console can be up to 500 ft (150

m) from the transducers. Local and remote programming

and output options allow the DigitalFlow GS868 to fi t in

any process.

Steam Flow Data and Diagnostics

In addition to velocity, volumetric and mass fl ow data, the

DigitalFlow GS868 also provides diagnostic parameters

such as transit times and sound speed, to aid in setup and troubleshooting. Any of this data can be easily

printed, logged, sent to an analog or digital output, or

read in numeric or graphic format on the dual window

display.

Transit-time fl ow measurement technique

Wetted transducers

Fluid

fl ow

Ultrasonic signal path

Page 3

GS868 Specifi cations

Operation and Performance

Fluid Types

Saturated and superheated steam

Pipe Sizes

2 in to 48 in NB (50 mm to 1200 mm DN)

Pipe Materials

All metals. Consult GE for other materials.

Flow Accuracy (Velocity)

±1% to 2% of reading typical

Accuracy depends on pipe size and whether measurement

is one-path or two-path. Accuracy to ±0.5% of reading

may be achievable with process calibration.

Repeatability

±0.2% to 0.5% of reading

Range (Bidirectional)

–150 to 150 ft/s (–46 to 46 m/s)

Rangeability (Overall)

1500:1

Specifi cations assume a fully developed fl ow profi le

(typically 20 diameters upstream and 10 diameters

downstream of straight pipe run) and fl ow velocity greater

than 3 ft/s (1 m/s).

Measurement Parameters

Mass fl ow, standard and actual volumetric fl ow, totalized

fl ow, and fl ow velocity

Electronics

Flow Measurement

Patented Correlation Transit-Time mode

Enclosures

• Standard: Epoxy-coated aluminum weatherproof

Type 4X/IP66, FM/CSA Class I, Division 2, Groups

A,B,C&D

• Optional: Stainless steel, fi berglass, explosion-proof,

fl ameproof, ISSep 03ATEX113

Dimensions

Standard: Weight 11 lb (5 kg),

size (h x w x d) 14.24 in x 11.4 in x 5.12 in

(362 mm x 290 mm x 130 mm)

Channels

• Standard: One channel

• Optional: Two channels (for two pipes or two-paths)

Display

Two independent software-confi gurable 64 x 128 pixel

backlit LCD graphic displays

Keypad

39-key tactile-feedback membrane keypad

Power Supplies

• Standard: 100 to 130 VAC, 50/60 Hz

or 200 to 265 VAC, 50/60 Hz

• Optional: 12 to 28 VDC, ±5%

Power Consumption

20 W maximum

Operating Temperature

–4°F to 131°F (–20°C to 55°C)

Storage Temperature

–67°F to 167°F (–55°C to 75°C)

Standard Inputs/Outputs

Two 0/4 to 20 mA isolated outputs, 550Ω maximum load

Transit-time fl ow measurement technique

Page 4

© 2009 General Electric Company. All Rights Reserved. Specifi cations are subject to change without notice. GE is a registered trademark of General Electric Company. Other company or product

names mentioned in this document may be trademarks or registered trademarks of their respective companies, which are not affi liated with GE.

www.gesensinginspection.com

920-006D

Optional Inputs/Outputs

There are six additional slots available for any

combination of the following I/O boards:

• Analog outputs: each with four isolated 0/4 to 20 mA

outputs, 1 kΩ maximum load

• Analog input board with two isolated 4 to 20 mA inputs

and 24 V loop power

• RTD input board with two isolated, three-wire, RTD

inputs; span –148°F to 662°F (–100°C to 350°C); 100Ω

• Totalizer/frequency outputs:

– Totalizer mode: Pulse per defi ned unit of parameter

– Frequency mode: Pulse frequency proportional to

magnitude of parameter (e.g., 10 Hz = 1 ft

3

/h)

• Alarm relays:

– General purpose

– Hermetically sealed

Permanent pressure loss by fl owmeter type

4 in (100 mm) vortex shedding 8.28 in H2O Saturated steam fl ow

4 in (100 mm) orifi ce plate 14.1 in H2O 100 ft/s, 4 in Sch 40,

Transit-time 0.05 in H2O 40 psig (2.7 bar)

12 in (300 mm) vortex shedding 186 in H2O Saturated steam fl ow

12 in (300 mm) orifi ce plate 318 in H2O 100 ft/s, 12 in Sch 160,

Transit-time 0.0 in H2O 300°F (148°C)

Digital Interfaces

• Standard: RS232

• Optional: RS485 (multiuser)

• Optional: Modbus® RS485 or TCP protocol

• Optional: Ethernet

• Optional: OPC server

• Optional: Foundation fi eldbus

Site Parameter Programming

Menu-driven operator interface using keypad and “soft”

function keys

Data Logging

Memory capacity (linear and/or circular type) to log over

43,000 fl ow data points

Display Functions

• Graphic display shows fl ow in numerical or graphic

format

• Displays logged data and diagnostics

European Compliance

Complies with EMC Directive 89/336/EEC, 73/23/EEC

LVD (Installation Category II, Pollution Degree 2) and PED

97/23/EC for DN<25

Wetted Ultrasonic Flow Transducers

Temperature Ranges

Overall range –190° to 450°C (–310° to 842°F)

Pressure Ranges

• Standard: 0 to 2700 psig (1 to 187 bar)

• Optional: 3480 psig (240 bar) maximum

Transducer Materials

• Standard: Titanium or stainless steel

Transducer Mounting

Flanged port: spool piece or cold tap

Area Classifi cations

• Standard: Weatherproof Type 4/IP65

• Optional: Explosion-proof Class I, Division 1,

Groups C&D

• Optional: Flameproof II 2 G EEx d IIC T6

Additional Options

PanaView PC-Interface Software

The DigitalFlow GS868 communicates with a PC through

a serial interface and Windows® operating systems.

Consult the manual for details on sites, logs and other

operations with a PC.

{

{

Loading...

Loading...