Page 1

GEAppliances.com

Safety Instructions ........................ 2–4

Operating Instructions

Controls ........................................................... 5–7

Cycle Options ............................................... 8, 9

Using the Dryer ..............................................10

Installation Instructions

Before You Begin ..................................11, 12

Connecting an

Electric Dryer ..........................................14–16

Exhausting the Dryer ........................ 17–23

Final Setup ........................................................24

Location of your Dryer ......................12, 13

Reversing the Door Swing ............. 25–27

Stacking the Washer

and Dryer ..................................................28–30

Troubleshooting Tips ............. 32–34

Consumer Support

Consumer Support ................ Back Cover

Warranty (Canada) .................................... 36

Warranty (U.S.) .............................................. 35

Owner’s Manual &

Installation Instructions

DCVH480EK

DCVH485EK

PCVH480EK

PCVH485EK

Sécheuses

Manuel d’utilisation

et d’installation

La section française commence à la page 37

Secadoras

Manual del propietario

e instalación

La sección en español empieza en la página 73

Dryers

SAVE THESE INSTRUCTIONS

Write the model and serial

numbers here:

Model # ______________

Serial # _______________

They are on the label on the front

of the dryer behind the door.

175D1807P634 49-90370-1 05-14 GE

Page 2

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

WARNING!

For your safety, the information in this manual must be followed to minimize the risk

of fire or explosion, electric shock, or to prevent property damage, personal injury,

or death.

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

PROPER INSTALLATION

This dryer must be properly installed and located in accordance with the Installation Instructions

before it is used. Installation Instructions are included in the back of this manual.

Properly ground dryer to conform with all

governing codes and ordinances. Follow details

in Installation Instructions.

Install or store where it will not be exposed to

temperatures below freezing or exposed to

Operating Instructions Safety InstructionsConsumer Support Troubleshooting Tips

water or weather, which could cause permanent

damage and invalidate the warranty.

Connect to a properly rated, protected and sized

power supply circuit to avoid electrical overload.

Remove all sharp packing items and dispose of

all shipping materials properly.

Installation and service must be

performed by a qualified installer

or service agency.

Exhaust/Ducting

1

Dryers MUST be exhausted to the outside to

prevent large amounts of moisture and lint from

being blown into the room.

2

Use only rigid metal 4” diameter ductwork inside

the dryer cabinet. Use only rigid metal or flexible

metal 4-in diameter ductwork for exhausting to

the outdoors. Never use plastic or other

combustible, easy-to-puncture ductwork.

For complete details, follow the Installation

Instructions.

2

Page 3

GEAppliances.com

WARNING!

YOUR LAUNDRY AREA

Keep the area underneath and around your

appliances free of combustible materials,

(lint, paper, rags, etc.), gasoline, chemicals

and other flammable vapors and liquids.

Keep the floor around your appliances clean

and dry to reduce the possibility of slipping.

Close supervision is necessary if this appliance is

used by or near children. Do not allow children to

play on, with or inside this or any other appliance.

WHEN USING YOUR DRYER

Never reach into the dryer while the drum is

moving. Before loading, unloading or adding

clothes, wait until the drum has completely

stopped.

Keep the area around the exhaust opening

and adjacent surrounding areas free from the

accumulation of lint, dust and dirt.

Keep all laundry aids (such as detergents,

bleaches, etc.) out of the reach of children,

preferably in a locked cabinet. Observe all

warnings on container labels to avoid injury.

Never climb on or stand on the dryer top.

The laundry process can reduce the flame

retardancy of fabrics. To avoid such a result,

carefully follow the garment manufacturer’s

care instructions.

Clean the lint filter before each load to prevent lint

accumulation inside the dryer or in the room. DO

NOT OPERATE THE DRYER WITHOUT THE LINT

FILTER IN PLACE.

Do not wash or dry articles that have been

cleaned in, washed in, soaked in or spotted

with combustible or explosive substances (such as

wax, oil, paint, gasoline, degreasers, dry-cleaning

solvents, kerosene, etc.). These substances give

off vapors that may ignite or explode. Do not add

these substances to the wash water. Do not use

or place these substances around your washer

or dryer during operation.

Do not place items exposed to cooking oils in

your dryer. Items contaminated with cooking oils

may contribute to a chemical reaction that could

cause a clothes load to catch fire.

Any article on which you have used a cleaning

solvent or that contains flammable materials

(such as cleaning cloths, mops, towels used in

beauty salons, restaurants or barber shops, etc.)

must not be placed in or near the dryer until

solvents or flammable materials have been

removed. There are many highly flammable items

used in homes such as acetone, denatured alcohol,

gasoline, kerosene, some household cleaners,

some spot removers, turpentines, waxes, wax

removers and products containing petroleum

distillates.

Do not dry articles containing rubber, plastic

or similar materials such as padded bras, tennis

shoes, galoshes, bath mats, rugs, bibs, baby pants,

plastic bags or pillows that may melt or burn.

Some rubber materials, when heated, can under

certain circumstances produce fire by spontaneous

combustion.

Do not store plastic, paper or clothing that may

burn or melt on top of the dryer during operation.

Garments labeled Dry Away from Heat or Do Not

Tumble Dry (such as life jackets containing Kapok)

must not be put in your dryer.

Do not dry fiberglass articles in your dryer.

Skin irritation could result from the remaining

particles that may be picked up by clothing

during subsequent dryer uses.

To minimize the possibility of electric shock, unplug

this appliance from the power supply or disconnect

the dryer at the household distribution panel by

removing the fuse or switching off the circuit

breaker before attempting any maintenance or

cleaning (except the removal and cleaning of the

lint filter). NOTE: Pressing START/PAUSE or POWER

does NOT disconnect the appliance from the

power supply.

Consumer SupportTroubleshooting TipsOperating InstructionsSafety Instructions

3

Page 4

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

WARNING!

WHEN USING YOUR DRYER (cont.)

Never attempt to operate this appliance if it is

damaged, malfunctioning, partially disassembled,

or has missing or broken parts, including a

damaged cord or plug.

The interior of the machine and the exhaust duct

connection inside the dryer should be cleaned at

least once a year by a qualified technician. See

the Sorting and Loading Hints section on page 10.

You may wish to soften your laundered fabrics

or reduce the static electricity in them by using

a dryer-applied fabric softener or an antistatic

conditioner. We recommend you use either a

fabric softener in the wash cycle, according to

the manufacturer’s instructions for those products,

or try a dryer-added product for which the

manufacturer gives written assurance on the

package that their product can be safely used

in your dryer. Service or performance problems

caused by use of these products are the

responsibility of the manufacturers of those

products and are not covered under the

warranty of this appliance.

WHEN NOT USING YOUR DRYER

Grasp the plug firmly when disconnecting this

Operating Instructions Safety InstructionsConsumer Support Troubleshooting Tips

appliance to avoid damage to the cord while

pulling. Place the cord away from traffic areas

so it will not be stepped on, tripped over or

subjected to damage.

Do not attempt to repair or replace any part of

this appliance or attempt any servicing unless

specifically recommended in this Owner’s Manual

or in published user-repair instructions that you

understand and have the skills to carry out.

READ AND FOLLOW THIS SAFETY INFORMATION CAREFULLY.

SAVE THESE INSTRUCTIONS

Before discarding a dryer, or removing it from

service, remove the dryer door to prevent children

from hiding inside.

Do not tamper with controls.

4

Page 5

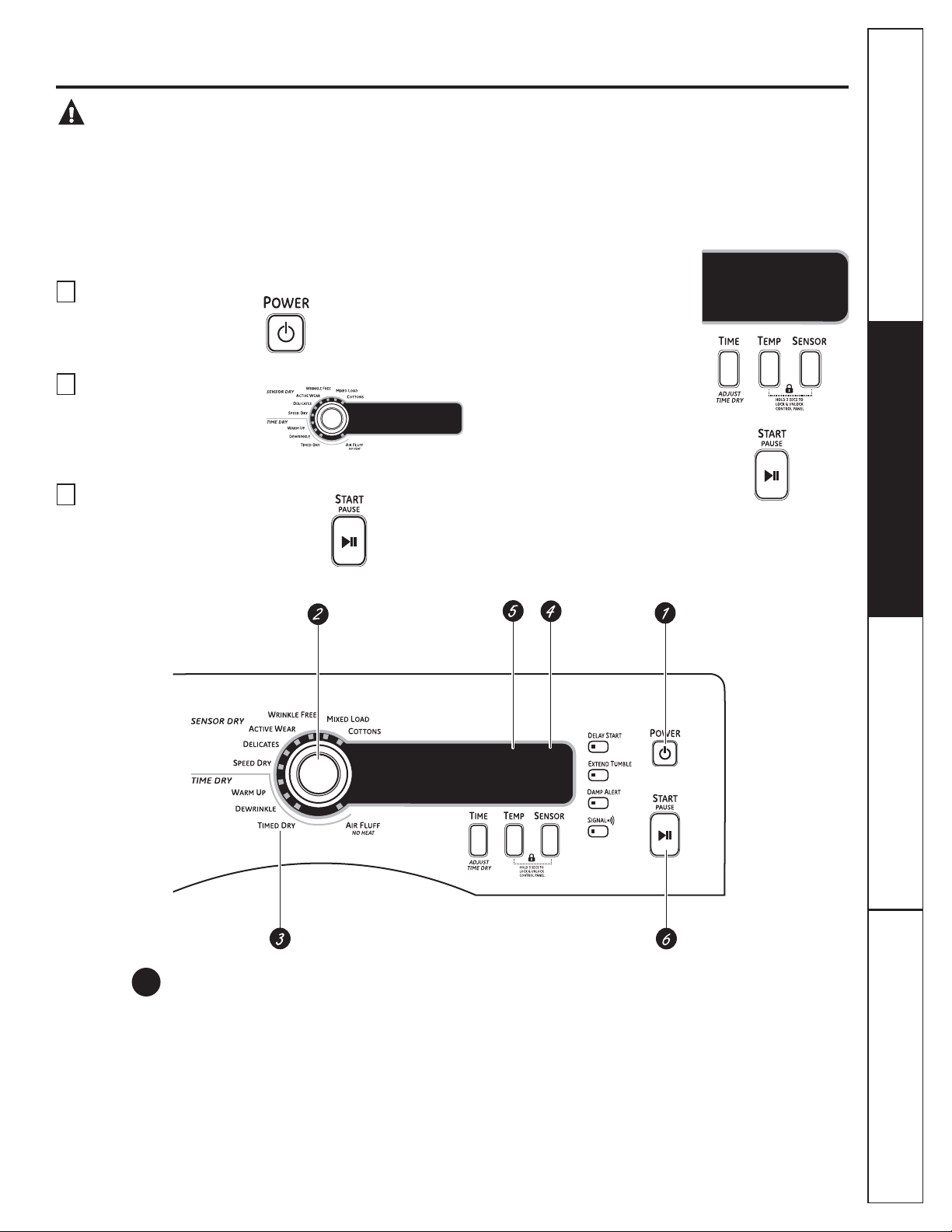

About the dryer control panel.

GEAppliances.com

WARNING! To reduce the risk of fire, electric shock, or injury to persons, read the IMPORTANT

SAFETY INSTRUCTIONS before operating this appliance.

Throughout this manual, features and appearance may vary from your model.

Quick Start

If the screen is dark, press the POWER button to “wake up”

the display.

1

Press the

2

Select a cycle by turning the

Cycle Knob.

3

If you selected a SENSOR DRYF\FOH³

just press the START/PAUSE button.

POWER

button.

If you selected a TIME DRY

F\FOH³VHOHFW\RXUKHDWVHWWLQJ

and the amount of time you

want your items to dry by

pressing the TIME button until

the desired time appears in

the display. Then press the START/

PAUSE button.

Power

1

Press to “wake up” the display. If the display is active, press to turn the dryer off.

NOTE: Pressing POWER does not disconnect the appliance from the power supply.

Consumer SupportTroubleshooting TipsOperating InstructionsSafety Instructions

5

Page 6

About the dryer control panel.

Dry Cycles

2

The dry cycle controls the cycle time for the drying process. The chart below will help you match

the dry setting with the loads.

Sensor Cycles

COTTONS For cottons and most linens.

MIXED LOAD For loads consisting of cottons and poly blends.

WRINKLE FREE For wrinkle-free/easy care and permanent press items.

ACTIVE WEAR Clothing worn for active sports exercise and some casual wear. Fabrics include new

technology finishes and stretch fibers such as spandex.

DELICATES For lingerie and special-care fabrics.

SPEED DRY For small loads that are needed in a hurry, such as sports or school uniforms. Can also be

used if the previous cycle left some items damp, such as collars or waistbands.

Time Dry Cycles

WARM UP Provides 10 minutes of warming time to warm up clothes.

DEWRINKLE For removing wrinkles from items that are dry or slightly damp. This cycle is not

recommended for delicate fabrics.

AIR FLUFF Use this feature to tumble items without heat.

Timed Dry

3

Operating Instructions Safety InstructionsConsumer Support Troubleshooting Tips

Use to set your own dry time. TIMED DRY is also recommended for small loads.

To use TIMED DRY:

1. Turn dry cycle dial to TIMED DRY.

2. Select the drying time by pressing the TIME button. You can increase the time in 10-minute

increments up to 1 hour and 20 minutes.

3. Select the DRY TEMP.

4. Close the door.

5. Press START/PAUSE.

Sensor Dry Level

4

The sensor continuously monitors the amount of moisture in the load. When the moisture in your

clothes reaches your selected dry level, the dryer will stop.

EXTRA DRY Use for heavy-duty fabrics or items that should be very dry, such as towels.

MORE DRY Use for heavy or mixed type of fabrics.

DRY Use for normal dryness level suitable for most loads. This is the preferred cycle

for energy saving.

LESS DRY Use for lighter fabric (ideal for ironing).

DAMP For leaving items partially damp.

NOTE: The Sensor Dry Levels can only be selected in a Sensory Dry Cycle.

6

Page 7

Dry Temp

5

You can change the temperature of your dry cycle.

ANTI-BACTERIAL This option may only be used with COTTONS or MIXED LOAD cycles. This option reduces

certain types of bacteria. The anti-bacterial process occurs when high heat is used

during a portion of this drying cycle.

NOTE: Do not use this cycle on delicate fabrics.

HIGH For regular to heavy cottons.

MEDIUM For synthetics, blends and items labeled permanent press.

LOW For delicates, synthetics and items labeled Tumble Dry Low.

EXTRA LOW For lingerie and special-care fabrics.

START/PAUSE

6

Press to start a dry cycle. If the dryer is running, press it once and it will pause the dryer.

Press it again to restart the dry cycle.

GEAppliances.com

“CLEAN LINT FILTER” (message)

This message stays on until the START button is pressed. This message is only a reminder.

Consumer SupportTroubleshooting TipsOperating InstructionsSafety Instructions

7

Page 8

About cycle options.

NOTE: Not all features are available on all dryer models.

Extend Tumble

Operating Instructions Safety InstructionsConsumer Support Troubleshooting Tips

Minimizes wrinkles by adding

approximately 20 minutes of constant

no-heat tumbling followed by 70 minutes

of intermittent no-heat tumbling after

clothes are dry. The dryer is in EXTENDED

TUMBLE when the ESTIMATED CYCLE TIME

display is illuminated in a circular pattern.

Damp Alert

This option causes the dryer to beep when

clothes have dried to a damp level. Remove

items that you wish to hang dry. The

DAMP ALERT will only beep when this option

is selected (dry cycle keeps running).

Removing clothes and hanging them when

they are damp can reduce the need to iron

some items.

Delay Start

Use to delay the start of your dryer.

1. Choose your dry cycle and any options.

2. Press the DELAY START button. You

can change the delay time in 1-hour

increments (up to 18 hours) each time

you press the DELAY START button. Stop

pressing the button when your desired

time is displayed.

3. Press the START/PAUSE button to start

the countdown.

The countdown time will be shown in the

ESTIMATED TIME REMAINING display.

The light in the button will light up when

EXTEND TUMBLE is on.

NOTE: It is normal for the drum to pause

for short periods of time during EXTEND

TUMBLE.

The light in the button will light up when

DAMP ALERT is on.

NOTE: Only for DRY, MORE DRY and EXTRA

DRY sensor dry selections.

NOTES:

If the door is opened while the dryer is in

DELAY, the countdown time will continue

to count down the delay time. If the door

is not closed and the countdown time

expires, the cycle will not start until the

door is closed and the START/PAUSE

button is pressed.

You can delay the start of a dryer cycle

up to 18 hours.

The light in the button will light up when

DELAY START is on.

8

Page 9

GEAppliances.com

Lock

You can lock the controls to prevent any

selections from being made. Or you can

lock or unlock the controls after you have

started a cycle.

Children cannot accidentally start

the dryer by touching pads with

this option selected.

To lock the dryer, press and hold

the TEMP and SENSOR buttons together

for 3 seconds.

To unlock the dryer controls, press

and hold the TEMP and SENSOR buttons

together for 3 seconds. A sound will

indicate the lock/unlock status.

The control lock icon on the display will

light up when it is on.

NOTE: The POWER button can still be used

when the machine is locked.

Signal

When the light is “on,” the dryer will beep

at the end of the cycle and every time

you press a button on the control panel.

To turn the signal off, press the SIGNAL

button and the light will go off.

Consumer SupportTroubleshooting TipsOperating InstructionsSafety Instructions

9

Page 10

Using the dryer.

Always follow fabric manufacturer’s care label when laundering.

Operating Instructions Safety InstructionsConsumer Support Troubleshooting Tips

Sorting and Loading Hints

As a general rule, if clothes are sorted

properly for the washer, they are sorted

properly for the dryer. Try also to sort items

according to size. For example, do not dry

a sheet with socks or other small items.

Do not add fabric softener sheets once

the load has become warm. They may

cause fabric softener stains. Bounce®

Fabric Conditioner Dryer Sheets have

Fabric Care Labels

Below are fabric care label “symbols” that

affect the clothing you will be laundering.

Dry Labels

Tumble

dry

Dry

Normal

Permanent Press/

wrinkle resistant

Heat

setting

High

Medium

been approved for use in this dryer when

used in accordance with the manufacturer’s

instructions.

See below for lint filter cleaning instructions.

Do not overload. This wastes energy and

causes wrinkling.

Do not dry the following items: fiberglass

items, woolens, rubber-coated items, plastics,

items with plastic trim and foam-filled items.

Do not dry

(used with

do not wash)

Low

Gentle/

delicate

No heat/air

Do not tumble dry

10

Special

instructions

Line dry/

hang to dry

Drip dry

Care and Cleaning of the Dryer

Dryer Interior and Duct: The interior of

the appliance and exhaust duct should be

cleaned once a year by qualified service

personnel.

The Exterior: Wipe or dust any spills or

washing compounds with a damp cloth.

Dryer control panel and finishes may be

damaged by some laundry pretreatment

soil and stain remover products. Apply

these products away from the dryer. The

fabric may then be washed and dried

normally. Damage to your dryer caused

by these products is not covered by your

warranty.

Do not touch the surface or the display

with sharp objects.

The Lint Filter: Clean the lint filter before

each use. Remove by pulling straight up.

Open the filter and run your fingers across

the filter. A waxy buildup may form on the

lint filter from using dryer-added fabric

softener sheets. To remove this buildup,

wash the lint screen in warm, soapy

Dry flat

In the shade

water. Dry thoroughly and replace. Do not

operate the dryer without the lint filter

in place.

Vacuum the lint from the dryer lint

filter if you notice a change in dryer

performance.

Stainless Steel: To clean stainless steel

surfaces, use a damp cloth with a mild,

nonabrasive cleaner suitable for stainless

steel surfaces. Remove the cleaner

residue, and then dry with a clean cloth.

The stainless steel used to make

the dryer drum provides the highest

reliability available in a GE dryer. If

the dryer drum should be scratched or

dented during normal use, the drum

will not rust or corrode. These surface

blemishes will not affect the function

or durability of the drum.

The Exhaust Hood: Check with a mirror

that the inside flaps of the hood move

freely when operating. Make sure that

there is no wildlife (birds, insects, etc.)

nesting inside the duct or hood.

Page 11

Installation Dryer

Instructions

Questions? Call 800.GE.CARES (800.432.2737) or visit our Website at: GEAppliances.com

In Canada, call 1.800.561.3344 or visit www.GEAppliances.ca

DCVH480EK, DCVH485EK, PCVH480EK, PCVH485EK

If you are planning to stack the washer and dryer,

order Stacking Kit number GE24STACK to be used

for this dryer. Kit sold separately.

BEFORE YOU BEGIN

Read these instructions completely and carefully.

•

IMPORTANT – Save these instructions for local

electrical inspector’s use.

IMPORTANT – Observe all governing codes and

•

ordinances.

•

Install the clothes dryer according to the manufacturer’s

instructions and local codes.

•

Note to Installer – Be sure to leave these instructions

with the Consumer.

•

Note to Consumer – Keep these instructions for future

reference.

•

Clothes dryer installation must be performed by a

qualified installer.

•

This dryer must be exhausted to the outdoors.

•

Before the old dryer is removed from service or

discarded, remove the dryer door.

•

Service information and the wiring diagram are located

in the control console.

•

Do not allow children on or in the appliance. Close

supervision of children is necessary when the appliance

is used near children.

•

Proper installation is the responsibility of the installer.

•

Product failure due to improper installation is not

covered under the Warranty

• Install the dryer where the temperature is above 50°F

for satisfactory operation of the dryer control system.

• Remove and discard existing plastic or metal foil duct

and replace with UL-listed duct.

.

FOR YOUR SAFETY:

WARNING –

• To reduce the risk of severe injury or death, follow

all installation instructions.

• Clothes dryer installation must be performed by a

qualified installer.

• Install the clothes dryer according to these

instructions and in accordance with local codes.

• This dryer must be exhausted to the outdoors.

• Use only 4” rigid metal ducting for exhausting the

clothes dryer to the outdoors.

• DO NOT install a clothes dryer with flexible plastic

ducting materials. If flexible metal (semi-rigid or

foil-type) duct is installed, it must be UL-listed and

installed in accordance with the instructions found

in “Connecting the Dryer to House Vent” on page 18

of this manual. Flexible ducting materials are known

to collapse, be easily crushed and trap lint. These

conditions will obstruct dryer airflow and increase

the risk of fire.

• Do not install or store this appliance in any location

where it could be exposed to water and/or weather.

• The National Fuel Gas Code restricts installations of

gas appliances in garages. They must be 18 inches

off the ground and protected by a barrier from

vehicles.

• Save these instructions. (Installers: Be sure to leave

these instructions with the customer.)

Risk of Fire

11

Page 12

Installation Instructions

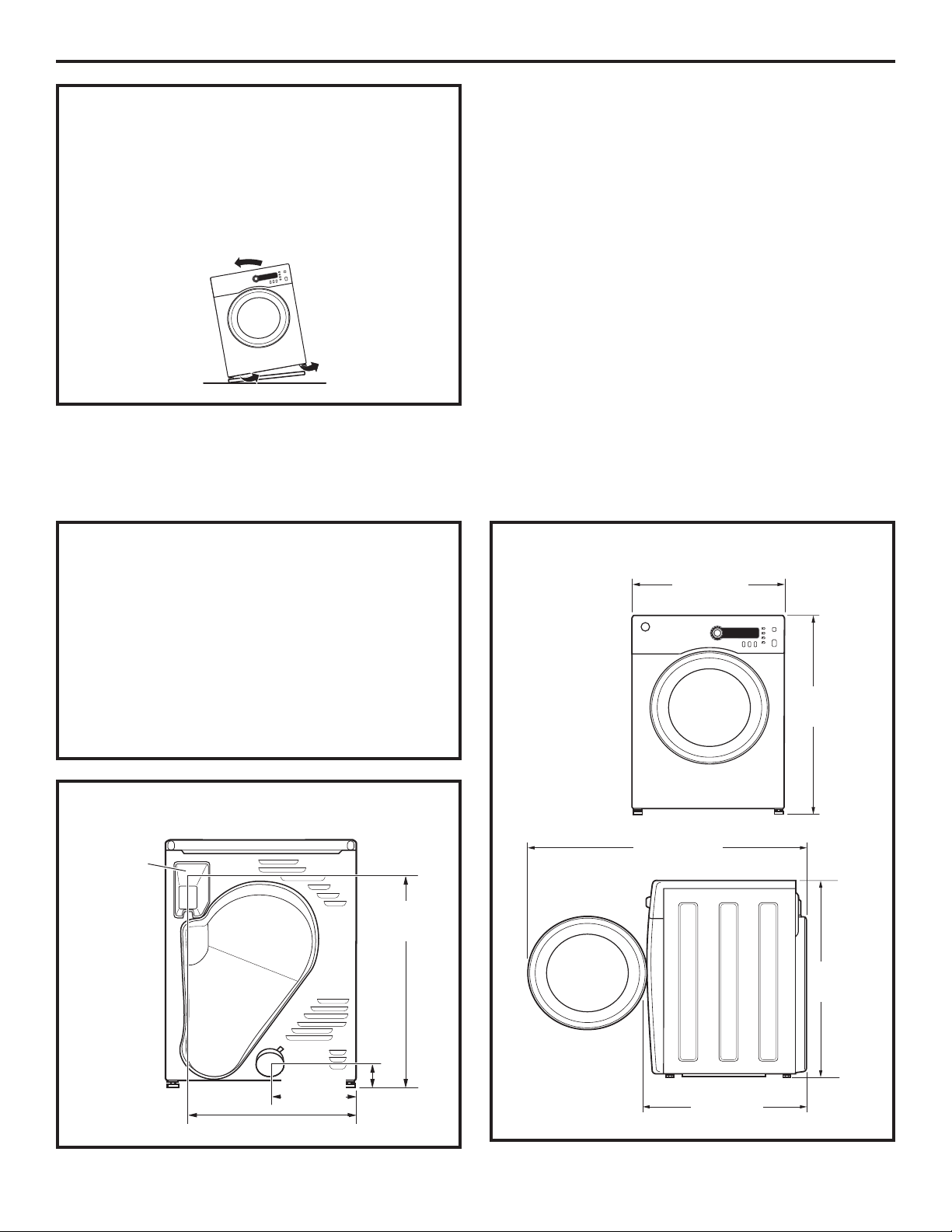

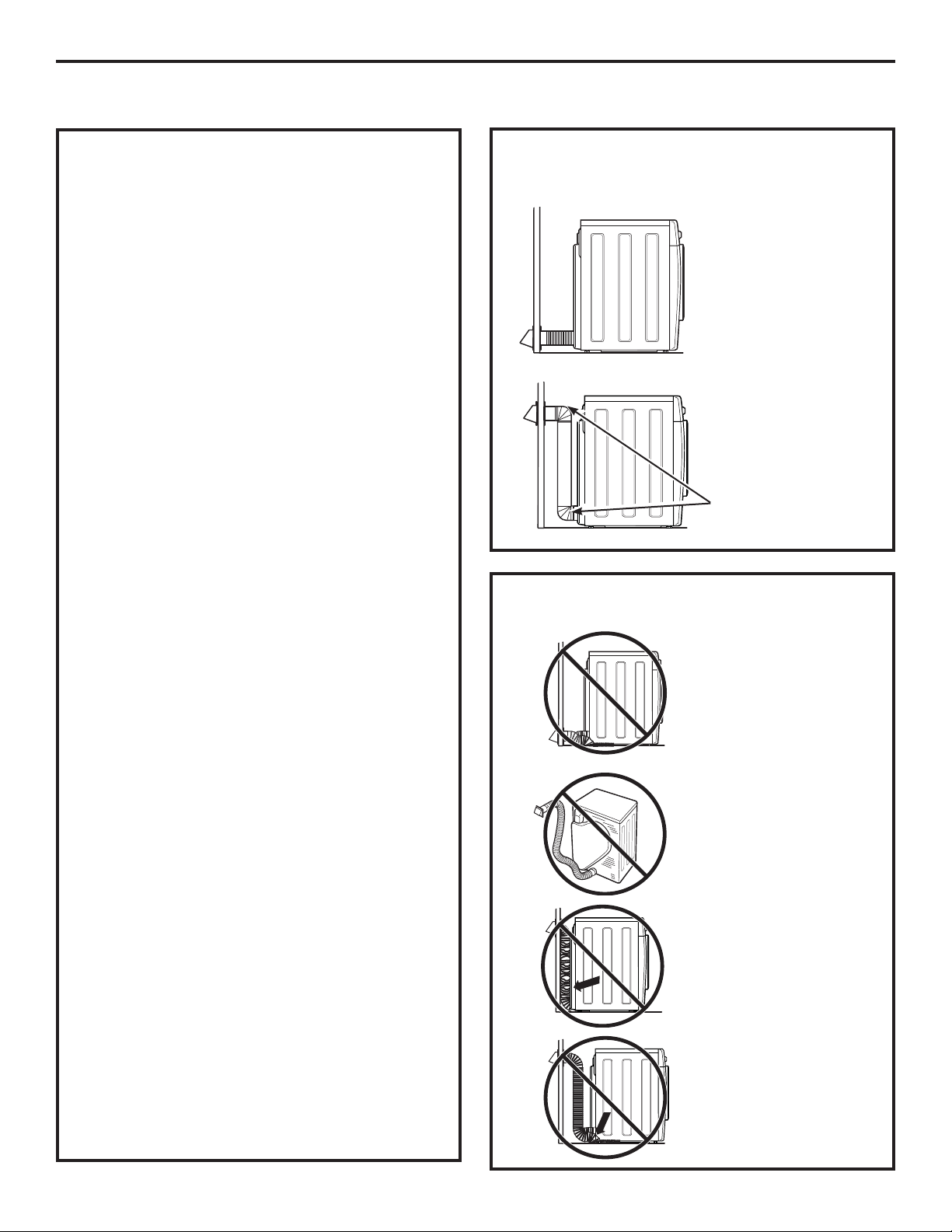

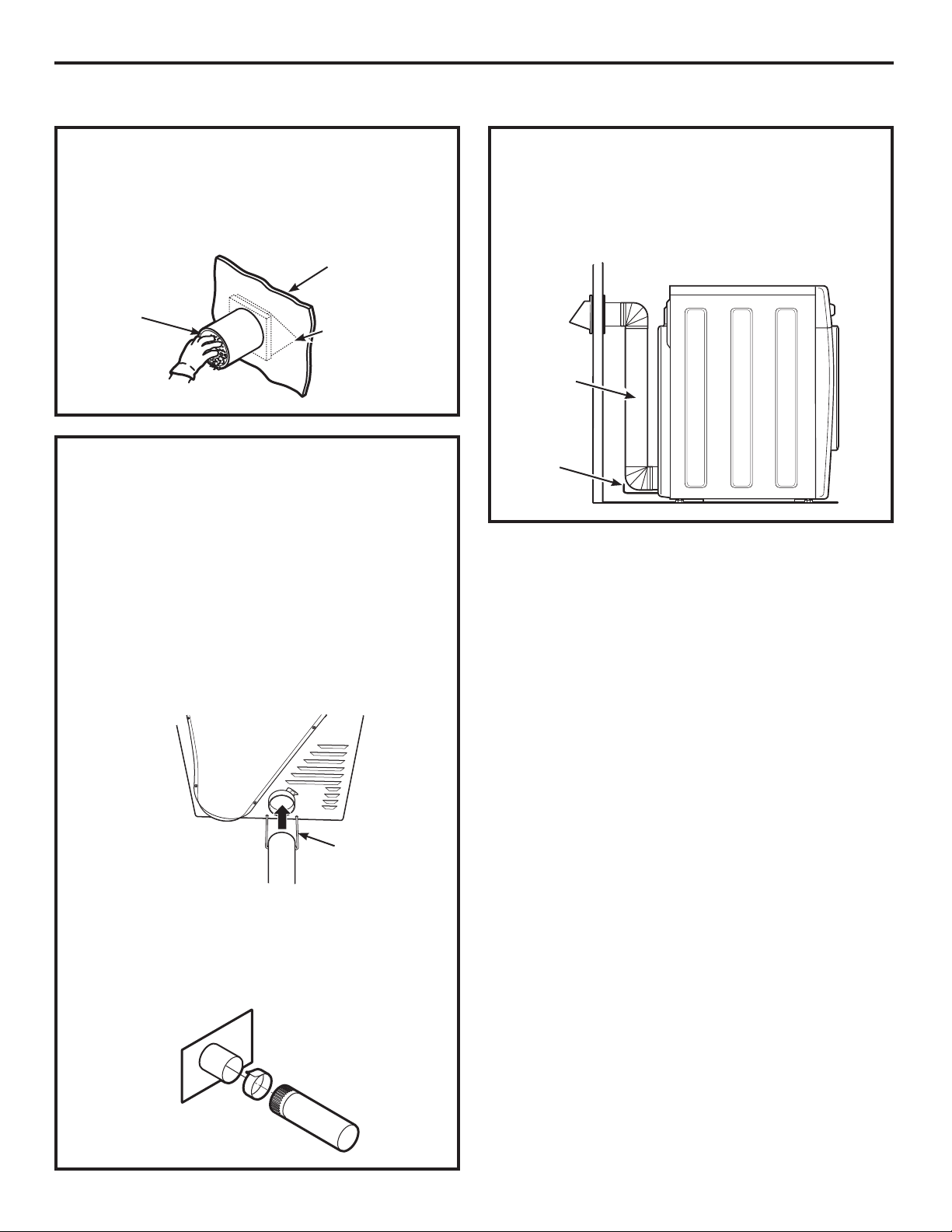

UNPACKING YOUR DRYER

Tilt the dryer sideways and remove the foam

shipping pads by pulling at the sides and breaking

them away from the dryer legs. Be sure to remove

all of the foam pieces around the legs.

Remove the bag containing the literature.

LOCATION OF YOUR DRYER

MINIMUM CLEARANCE OTHER THAN

ALCOVE OR CLOSET INSTALLATION

Minimum clearance to combustible surfaces and

for air openings are:

•

0 inch clearance both sides

•

3 inches front and rear

Consideration must be given to provide adequate

clearance for proper operation and service.

ELECTRICAL CONNECTION

Electrical

Connection

27.65”

Back View

(702 mm)

DRYER DIMENSIONS

23.5”

(598 mm)

Front View

33.4”

(848 mm)

42.9”

(1090 mm)

33.4”

(848 mm)

10.0”

(254 mm)

20.75” (527 mm)

4.0”

(101 mm)

Side View

25.7”

(653 mm)

12

Page 13

Installation Instructions

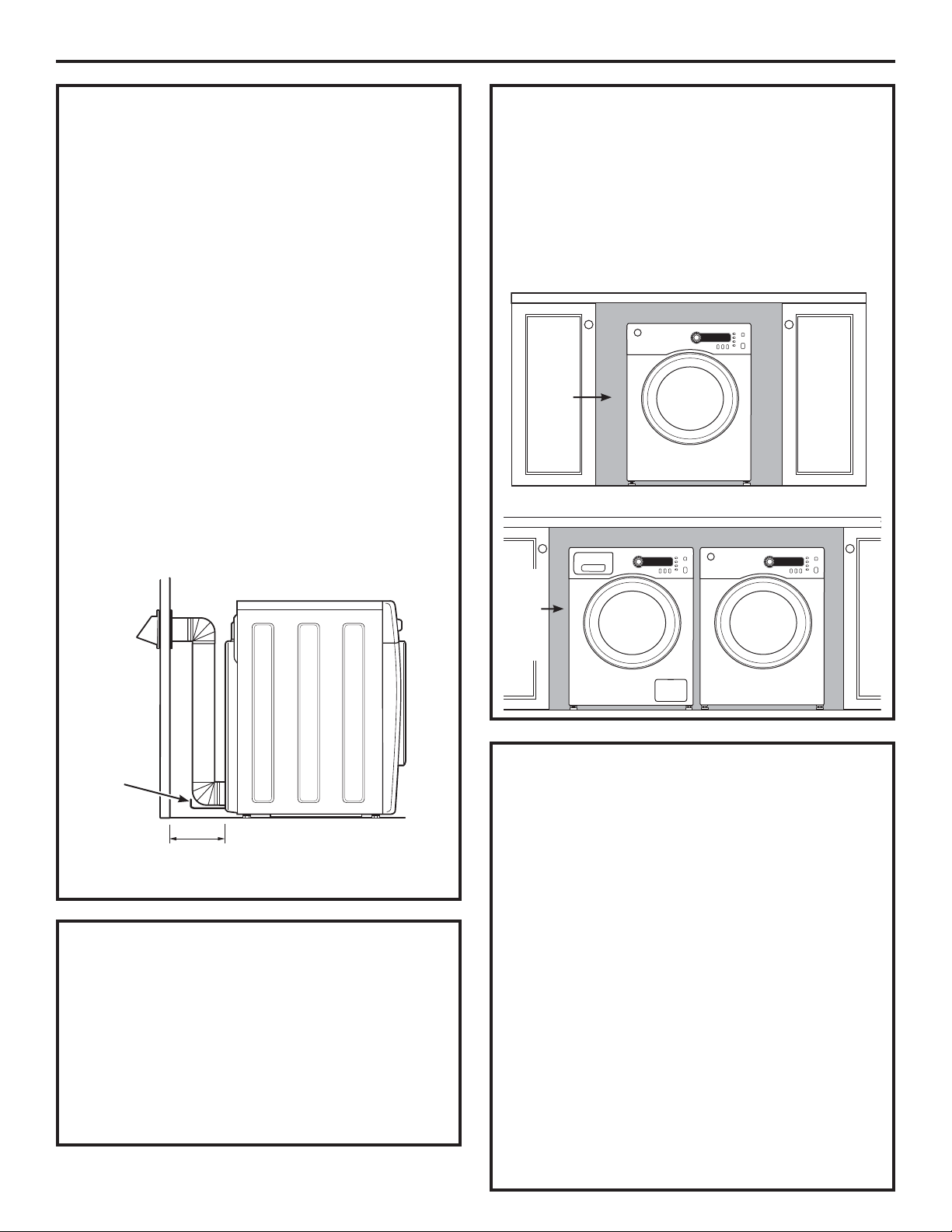

REQUIREMENTS FOR ALCOVE OR

CLOSET INSTALLATION

• Your dryer is approved for installation in

an alcove or closet, as stated on a label on

the dryer back.

The dryer MUST be vented to the outdoors. See

•

the EXHAUSTING THE DRYER section.

Minimum clearance between dryer cabinet and

•

adjacent walls or other surfaces is:

0” either side

3” front and rear

Minimum vertical space from floor to overhead

•

shelves, cabinets, ceilings, etc., is 52”.

Closet doors must be louvered or otherwise

•

ventilated and have at least 60 square inches

of open area equally distributed. If the closet

contains both a washer and a dryer, doors must

contain a minimum of 120 square inches of open

area equally distributed.

NOTE: WHEN THE EXHAUST DUCT IS LOCATED AT

THE REAR OF THE DRYER, MINIMUM CLEARANCE

FROM THE WALL IS 5.5 INCHES.

UNDERCOUNTER INSTALLATION

If an undercounter installation is desired:

•

No special dryer installation kit is required.

If the dryer is installed alone, a minimum of

•

60 square inches of open area is required.

If a washer and dryer are installed together,

a minimum of 120 square inches of open area

is required.

60

square

inches

min.

open

area

Dryer installed alone

Countertop and side cabinets

Washer and Dryer installed together

Countertop and side cabinets

Wire

frame

spacer

5.5”

(140 mm)

BATHROOM OR BEDROOM

INSTALLATION

• The dryer MUST be vented to the outdoors. See

EXHAUSTING THE DRYER.

The installation must conform with local codes or,

•

in the absence of local codes, with the NATIONAL

ELECTRICAL CODE, ANSI/NFPA NO. 70 (for electric

dryers) or NATIONAL FUEL GAS CODE, ANSI Z223

(for gas dryers).

120

square

inches

min.

open

area

MOBILE OR MANUFACTURED HOME

INSTALLATION

• The installation must conform to the

MANUFACTURED HOME CONSTRUCTION & SAFETY

STANDARD, TITLE 24, PART 32–80 or, when such

standard is not applicable, with AMERICAN

NATIONAL STANDARD FOR MOBILE HOME,

NO. 501B.

The dryer MUST be vented to the outdoors with

•

the termination securely fastened to the mobile

home structure. (See EXHAUSTING THE DRYER.)

The vent MUST NOT be terminated beneath a

•

mobile or manufactured home.

The vent duct material MUST BE METAL.

•

Do not use sheet metal screws or other

•

refastening devices which extend into the interior

of the exhaust vent.

Provide an opening with a free area of at least

•

25 sq. in. for introduction of outside air into the

dryer room.

13

Page 14

Installation Instructions

CONNECTING AN ELECTRIC DRYER

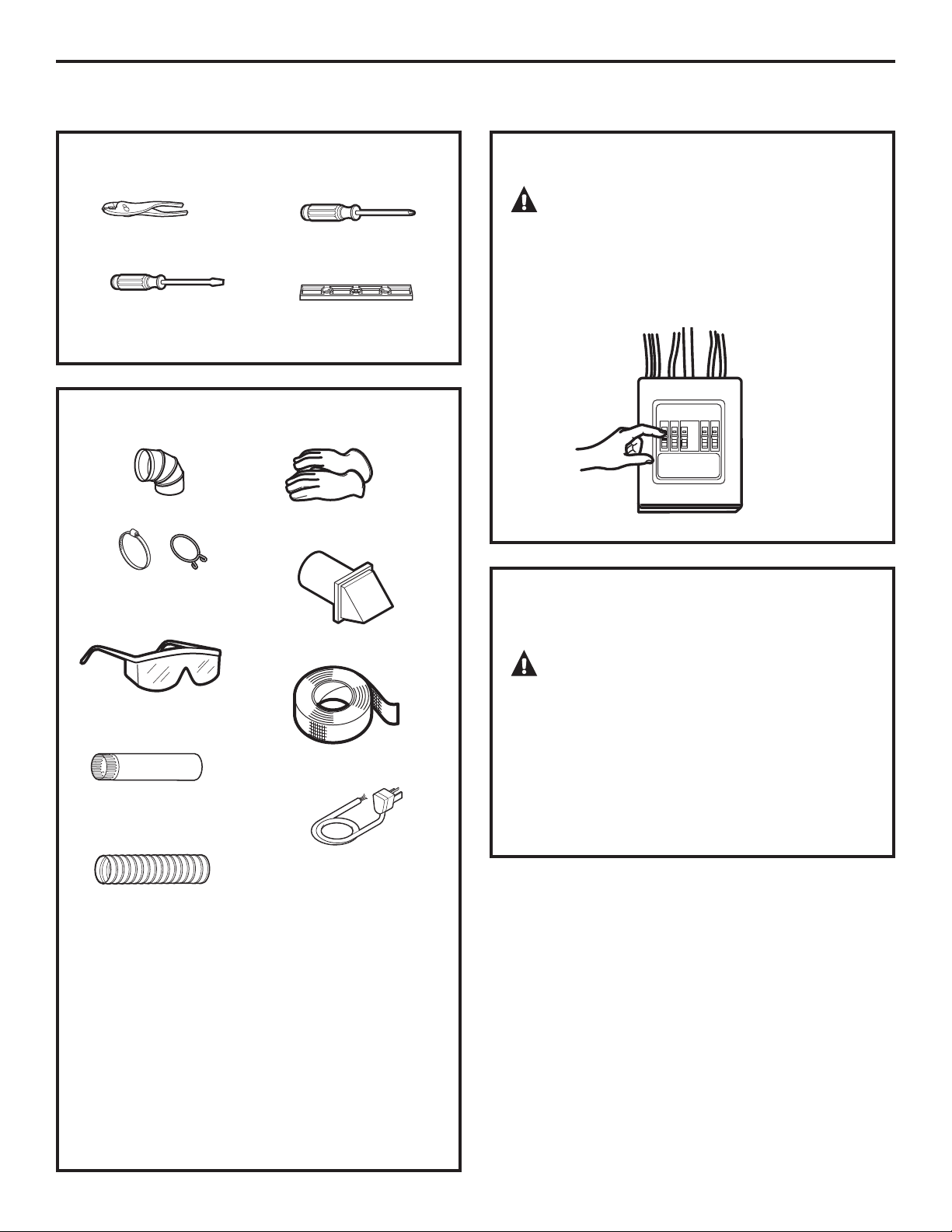

TOOLS YOU WILL NEED

Slip joint pliers

Flat-blade

screwdriver

Phillips screwdriver

Level

MATERIALS YOU WILL NEED

4” dia. metal elbow

4” duct clamps (2) or

4” spring clamps (2)

Gloves

FOR YOUR SAFETY:

WARNING

Before making the electrical connection, turn off

the circuit breaker(s) or remove the dryer’s circuit

fuse(s) at the electrical box. Be sure the dryer cord

is unplugged from the wall. NEVER LEAVE THE

ACCESS COVER OFF THE TERMINAL BLOCK.

ELECTRICAL CONNECTION

INFORMATION FOR ELECTRIC DRYERS

Safety glasses

4”-dia. metal duct

(recommended)

4”-dia., UL-listed

flexible metal duct (if

needed)

Exhaust hood

Duct tape

Dryer power cord kit

6 ft. long (not

provided with dryer)

UL-rated 120/240V,

30A with 3 or 4 prongs.

Identify the plug type as

per the house receptacle

before purchasing line

cord. (4-prong cord set

is included and installed

on Canadian models

PCVH480 and PCVH485.)

Stacking installations

may require a power

cord up to 6 feet in

length.

WARNING – To reduce the risk of

fire, electrical shock and personal injury:

•

Do not use an extension cord or an adapter

plug with this appliance.

The dryer must be electrically grounded in

•

accordance with local codes and ordinances

or, in the absence of local codes, in accordance

with the NATIONAL ELECTRICAL CODE,

ANSI/NFPA NO. 70.

14

Page 15

Installation Instructions

ELECTRICAL REQUIREMENTS

FOR ELECTRIC DRYERS

This dryer must be connected to an individual

branch circuit, protected by the required time-delay

fuses or circuit breakers. A three- or four-wire,

single-phase, 120/240V or 120/208V, 60Hz, 30-amp

circuit is required.

If the electric supply does not meet the above

specifications, then call a licensed electrician.

NOTE: For Canadian consumers with models

PCVH480 and PCVH485, cord set installation is not

required. Please skip to the next section, Exhausting

the Dryer.

GROUNDING INSTRUCTIONS

This dryer must be connected to a grounded

metal, permanent wiring system, or an equipmentgrounding conductor must be run with the circuit

conductors and connected to the equipmentgrounding terminal on the appliance.

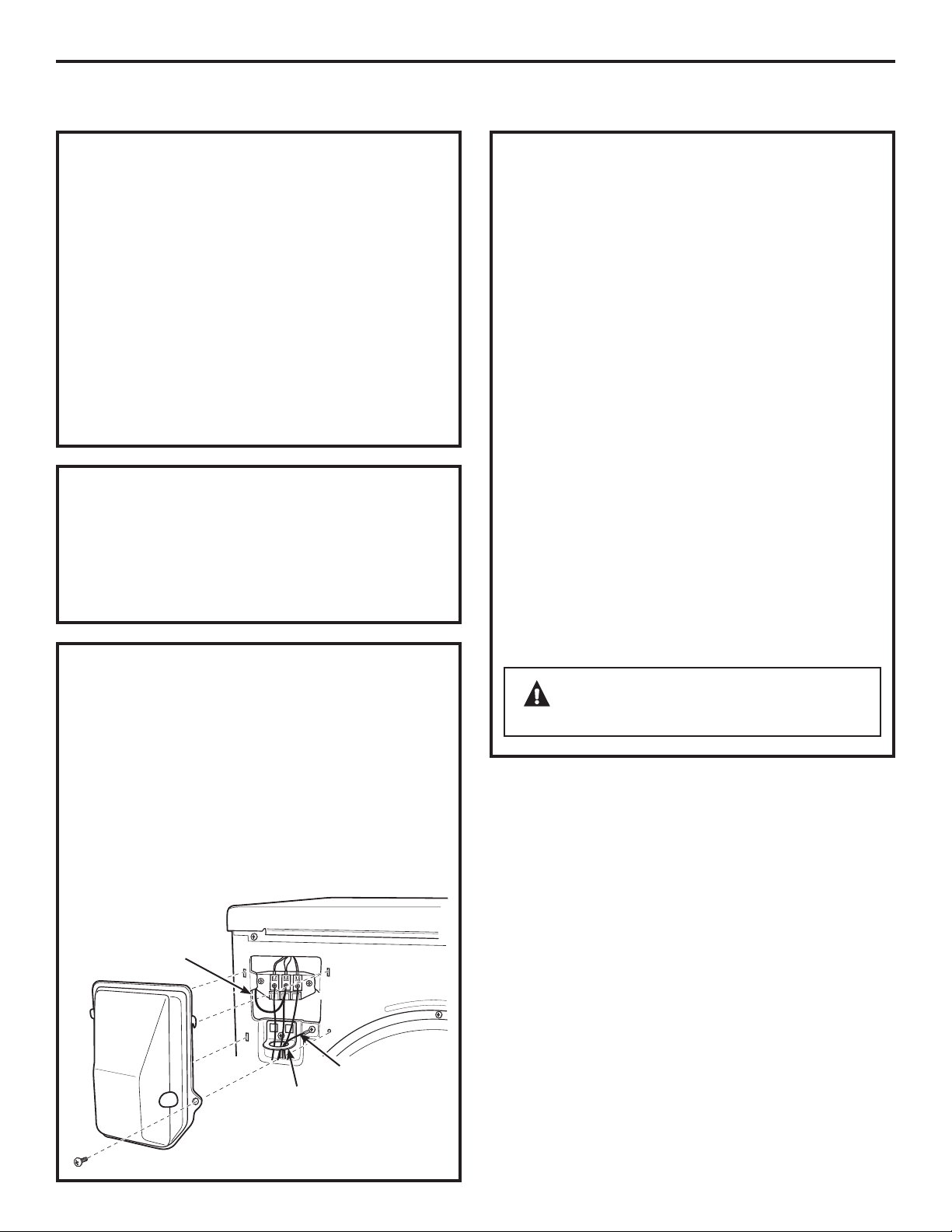

CONNECTING DRYER USING 4-WIRE

CONNECTION (MUST BE USED FOR

MOBILE HOME INSTALLATION) (cont.)

1. Turn off the circuit breaker(s) (30 amp) or remove

the dryer’s circuit fuse at the electrical box.

Be sure the dryer cord is unplugged from the wall

2.

receptacle.

Remove the power cord cover located at the

3.

upper back.

Remove the green ground screw and attach

4.

the ground strap to the center terminal along

with the (white) neutral line described below.

Keep the green ground screw for Step 7.

Bring the power cord through the bracket.

5.

Connect power cord as follows:

6.

A. Connect the 2 hot lines to the outer screws

of the terminal block (marked L1 and L2).

B. Connect the neutral (white) line to the center

of the terminal block (marked N).

Attach ground wire of power cord with the green

7.

ground screw (hole above strain relief bracket).

Tighten all terminal block screws (3) completely.

Reinstall the cover.

8.

CONNECTING DRYER USING 4-WIRE

CONNECTION (MUST BE USED FOR

MOBILE HOME INSTALLATION)

NOTE: Since January 1, 1996, the National

Electrical Code requires that new constructions

utilize a 4-wire connection to an electric dryer.

A 4-wire cord must also be used where local codes

do not permit grounding through the neutral.

3-wire connection is NOT for use on new

construction.

Ground strap

Green wire from

Bracket

power cord

WARNING – NEVER LEAVE THE

COVER OFF OF THE TERMINAL BLOCK.

15

Page 16

Installation Instructions

CONNECTING AN ELECTRIC DRYER (cont.)

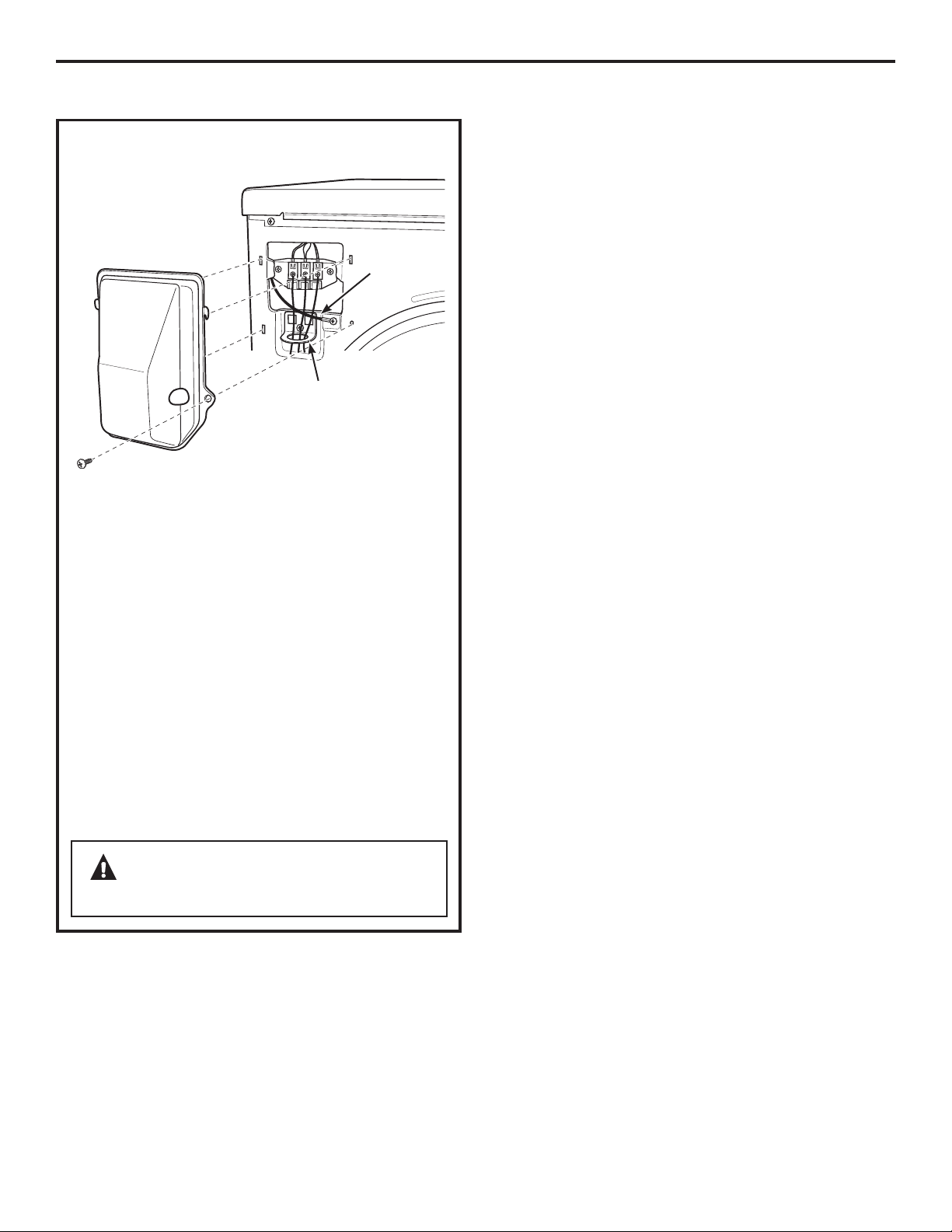

CONNECTING DRYER USING 3-WIRE

CONNECTION

Ground

strap

Bracket

1. Turn off the circuit breaker(s) (30 amp) or remove

the dryer’s circuit fuse at the electrical box.

Be sure the dryer cord is unplugged from the

2.

wall receptacle.

Remove the power cord cover located at the

3.

upper back.

Bring the power cord through the bracket.

4.

Connect power cord as follows:

5.

A. Connect the 2 hot lines to the outer screws

of the terminal block (marked L1 and L2).

B. Connect the neutral (white) line to the center

of the terminal block (marked N).

Be sure ground strap is connected to green

6.

ground screw on cabinet rear. Tighten all

terminal block screws (3) completely.

Reinstall the cover.

7.

WARNING – NEVER LEAVE THE

COVER OFF OF THE TERMINAL BLOCK.

16

Page 17

Installation Instructions

EXHAUSTING THE DRYER

WARNING – To reduce the

risk of fire or personal injury:

This clothes dryer must be exhausted to the outdoors.

•

”

• Use only 4

duct.

• Use only 4

(semi-rigid or foil-type) duct to connect the dryer

to the home exhaust duct. It must be installed in

accordance with the instructions found in “Connecting

the Dryer to House Vent” on page 18 of this manual.

• Do not terminate exhaust in a chimney, a wall, a

ceiling, gas vent, crawl space, attic, under an enclosed

floor, or in any other concealed space of a building.

• Never terminate the exhaust into a common duct with

a kitchen exhaust system. A combination of grease

and lint create a potential fire hazard.

• Do not use duct longer than specified in the exhaust

length table. Longer ducts can accumulate lint,

creating a potential fire hazard.

• Never install a screen in or over the exhaust duct. This

will cause lint to accumulate, creating a potential fire

hazard.

• Do not assemble ductwork with any fasteners that

extend into the duct. These fasteners can accumulate

lint, creating a potential fire hazard.

• Do not obstruct incoming or exhausted air.

• Provide an access for inspection and cleaning of the

exhaust system, especially at turns and joints. Exhaust

system shall be inspected and cleaned at least once

a year.

This dryer comes ready for rear exhausting. If space

•

is limited, use the instructions on pages 21–23 to

exhaust directly from the sides or bottom of the

cabinet.

rigid metal ducting for the home exhaust

”

rigid metal or UL-listed flexible metal

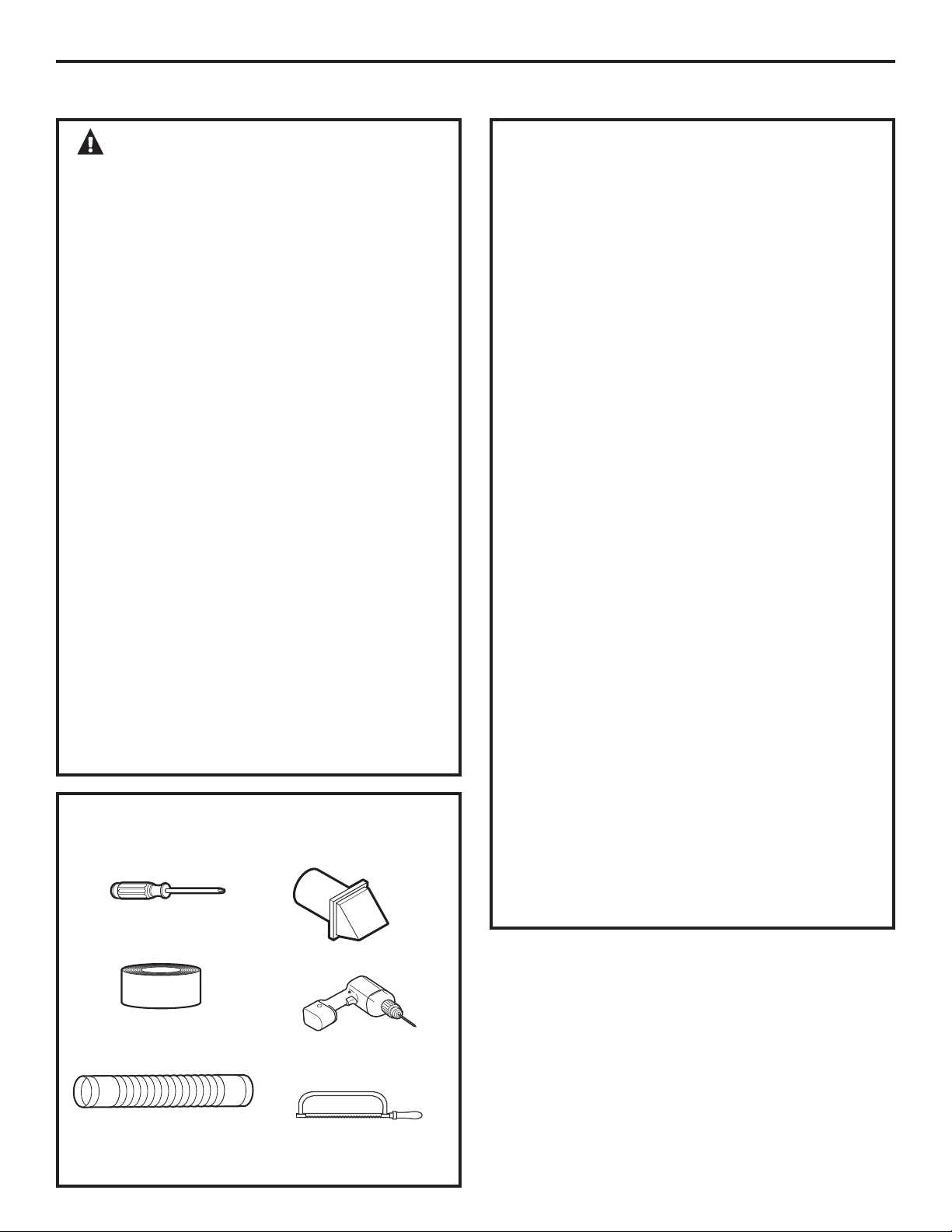

TOOLS AND MATERIALS YOU WILL

NEED TO INSTALL EXHAUST DUCT

Phillips-head

screwdriver

Vent hood

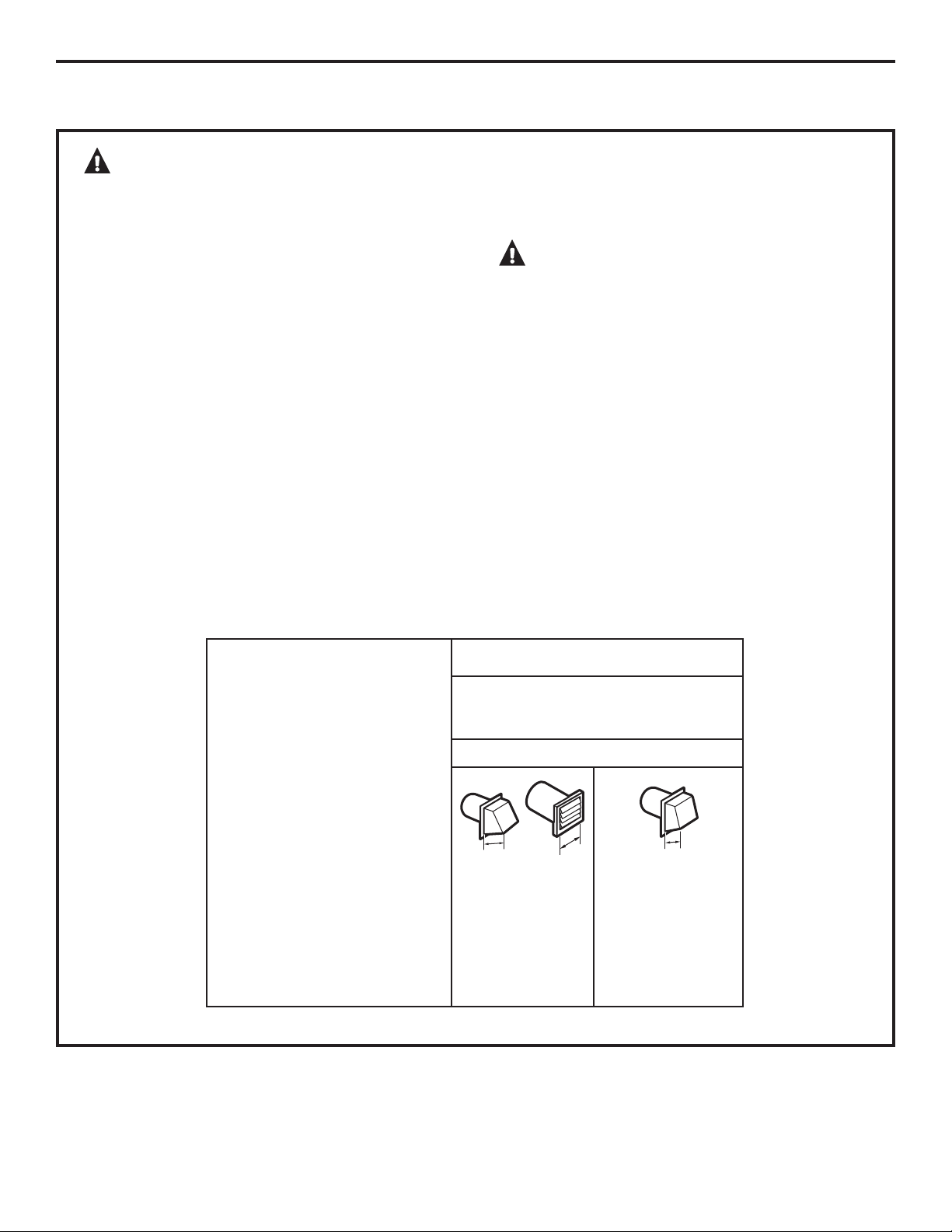

EXHAUST SYSTEM CHECKLIST

HOOD OR WALL CAP

•

Terminate in a manner to prevent back drafts

or entry of birds or other wildlife.

Termination should present minimal resistance

•

to the exhaust airflow and should require little

or no maintenance to prevent clogging.

Never install a screen in or over the exhaust

•

duct.

Wall caps must be installed at least 12” above

•

ground level or any other obstruction with the

opening pointed down.

SEPARATION OF TURNS

• For best performance, separate all turns by

at least 4 ft. of straight duct, including distance

between last turn and dampened wall cap.

For turns less than 4 ft. apart, see the Ducting

Component Equivalency Chart.

SEALING OF JOINTS

All joints should be tight to avoid leaks. The male

•

end of each section of duct must point away

from the dryer.

Do not assemble the ductwork with fasteners

•

that extend into the duct. They will serve as

a collection point for lint.

Duct joints should be made air- and

•

moisture-tight by wrapping the overlapped

joints with duct tape or aluminum tape.

Horizontal runs should slope down towards

•

outdoors 1/4” per foot.

INSULATION

•

Ductwork that runs through an unheated area

or is near air conditioning should be insulated

to reduce condensation and lint buildup.

Duct tape or duct

clamp

Rigid or UL-listed

flexible metal 4” (10.2

cm) duct

Drill with 1/8” drill bit

(for bottom venting)

Hacksaw

17

Page 18

Installation Instructions

EXHAUSTING THE DRYER (cont.)

CONNECTING THE DRYER TO

HOUSE VENT

RIGID METAL TRANSITION DUCT

For best drying performance, a rigid metal

•

transition duct is recommended.

Rigid metal transition ducts reduce the risk of

•

crushing and kinking.

UL-LISTED FLEXIBLE METAL (SEMI-RIGID)

TRANSITION DUCT

If rigid metal duct cannot be used, then UL-listed

•

flexible metal (semi-rigid) ducting can be used

(Kit WX08X10077).

Never install flexible metal duct in walls, ceilings,

•

floors or other enclosed spaces.

Total length of flexible metal duct should not

•

exceed 8 feet (2.4 m).

For many applications, installing elbows at both

•

the dryer and the wall is highly recommended (see

illustrations at right). Elbows allow the dryer to sit

close to the wall without kinking and/or crushing

the transition duct, maximizing drying performance.

Avoid resting the duct on sharp objects.

•

UL-LISTED FLEXIBLE METAL (FOIL-TYPE)

TRANSITION DUCT

In special installations, it may be necessary to

•

connect the dryer to the house vent using a flexible

metal (foil-type) duct. A UL-listed flexible metal

(foil-type) duct may be used ONLY in installations

where rigid metal or flexible metal (semi-rigid)

ducting cannot be used AND where a 4” diameter

can be maintained throughout the entire length

of the transition duct.

In Canada and the United States, only the flexible

•

metal (foil-type) ducts that comply with the “Outline

for Clothes Dryer Transition Duct, Subject 2158A”

shall be used.

Never install flexible metal duct in walls, ceilings,

•

floors or other enclosed spaces.

Total length of flexible metal duct should not

•

exceed 8 feet (2.4 m).

Avoid resting the duct on sharp objects.

•

For best drying performance:

•

1. Slide one end of the duct over the clothes

dryer outlet pipe.

2. Secure the duct with a clamp.

3. With the dryer in its permanent position,

extend the duct to its full length. Allow 2

duct to overlap the exhaust pipe. Cut off and

remove excess duct. Keep the duct as straight

as possible for maximum airflow.

4. Secure the duct to the exhaust pipe with the

other clamp.

”

of

FOR TRANSITION VENTING

(DRYER TO WALL), DO:

• DO cut duct

as short as

possible and

install straight

into wall.

DO use elbows

•

when turns are

necessary.

Elbows

DO NOT:

• DO NOT bend or

collapse ducting.

Use elbows

if turns are

necessary.

DO NOT use

•

excessive

exhaust length.

Cut duct as short

as possible.

• DO NOT crush

duct against

the wall.

DO NOT set

•

dryer on duct.

18

Page 19

Installation Instructions

WARNING

USE ONLY METAL DUCT 4” DIAMETER (102 mm

FOR CANADA). DO NOT USE DUCT LONGER THAN

SPECIFIED IN THE EXHAUST LENGTH TABLE.

'U\HU([KDXVWLQJ,QIRUPDWLRQ³0HWDO'XFW2QO\

Ducting Materials: For best performance, this dryer

should be vented with 4” diameter all-rigid metal

exhaust duct.

Exhaust Length Calculation:

1. Determine the number of 90º turns needed for

your installation.

2. The maximum length of 4’ rigid (aluminum or

galvanized) duct which can be tolerated is shown

in the table.

A turn of 45º or less may be ignored. Two 45º

turns within the duct length should be treated

as a 90º elbow.

A turn over 45º should be treated as a 90º elbow.

Best Performance

Maximum Length

of a 4” Dia.

Rigid Metal Duct

CAUTION:

terminate exhaust into a chimney, under any

enclosed house floor (crawl space), or into an attic,

since the accumulated lint could create a fire hazard

or moisture could cause damage. Never terminate

the exhaust into a common duct or plenum with a

kitchen exhaust, since the combination of lint and

grease could create a fire hazard.

Exhaust ducts should be terminated in a dampered

wall cap to prevent back drafts, bird nesting, etc.

The wall cap must also be located at least 12” above

the ground or any other obstruction with

the opening pointed down.

Other terminations, such as louvered wall boxes,

are acceptable provided they are equivalent to

a 4” opening dampered wall cap.

For more information on venting kits and

accessories, please call 1.800.GE.CARES.

For personal safety, do not

Exhaust Hood Type

Number of A B

90º Turns 4” Opening 2-1/2” Opening

Front-Loading Dryers 0 90 ft. 60 ft.

1 60 ft. 45 ft.

2 45 ft. 35 ft.

3 35 ft. 25 ft.

4”

4”

2-1/2”

19

Page 20

Installation Instructions

EXHAUSTING THE DRYER (cont.)

BEFORE YOU BEGIN

• Remove and discard existing plastic or metal

duct and replace with UL-listed duct.

• Remove any lint from the wall exhaust opening.

Wall

Internal

duct

opening

Check that exhaust

hood damper

opens and closes

freely.

STANDARD REAR EXHAUST

We recommend that you install your dryer before

installing your washer. This will permit direct

access for easier exhaust connection.

Pull out the wire spacer and swing upward to its full

extension. Let the wire spacer lay flat and extended

on the floor. This will prevent the dryer from being

pushed too close to a wall or object, causing the

ducting to come loose from the dryer.

RECOMMENDED CONFIGURATION

TO MINIMIZE EXHAUST BLOCKAGE

Using duct elbows will prevent duct kinking and

collapsing.

Transition

ducting

Wire

frame

spacer

Slide the end of the exhaust duct on the back

of the dryer and secure with duct tape or a

hose clamp.

Wire frame

spacer

Duct

NOTE: We strongly recommend using rigid metal

exhaust duct.

•

For straight-line installation, connect the dryer

exhaust to the wall, using duct tape.

Wall side

Dryer

side

20

Page 21

Installation Instructions

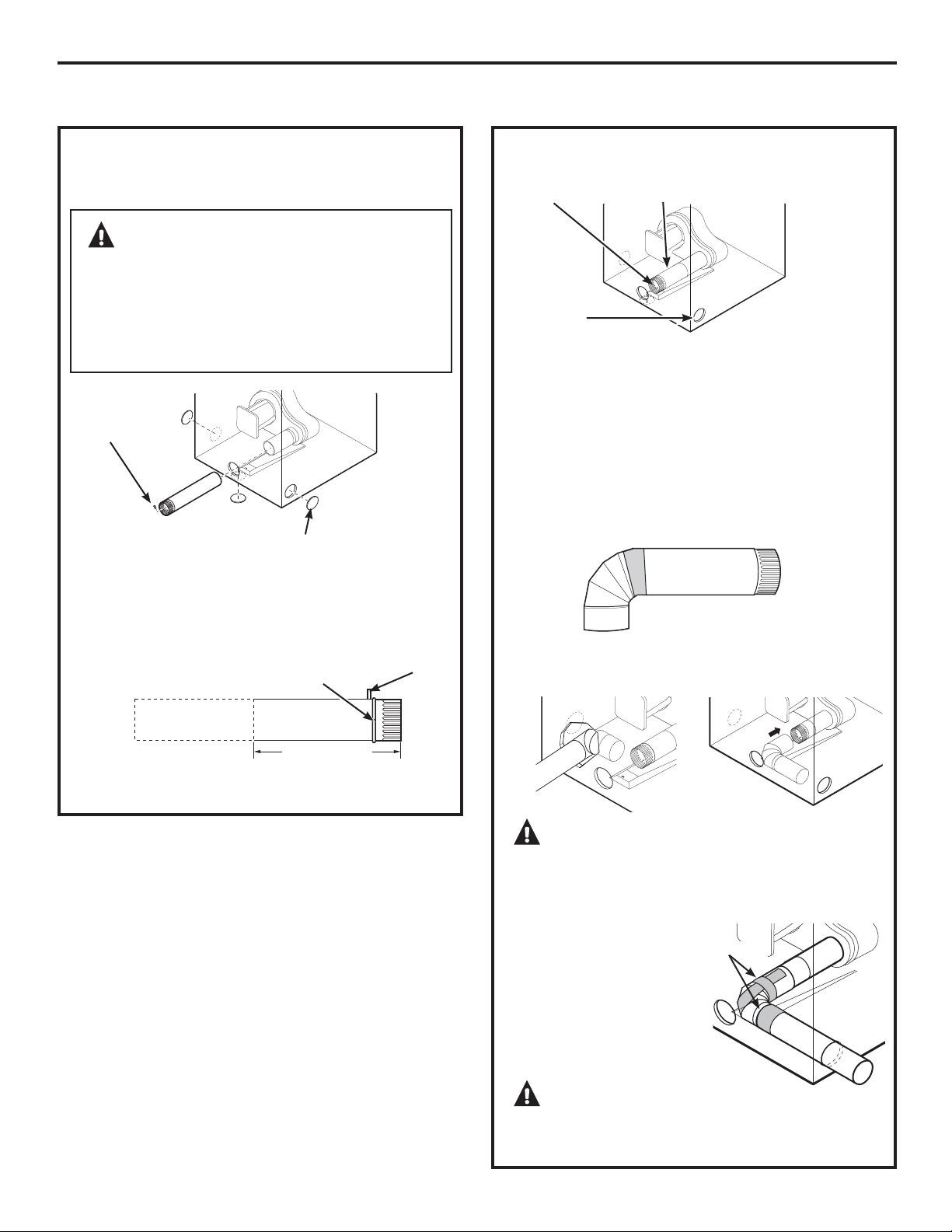

SIDE VENTING:

Dryer Exhaust to side of cabinet

WARNING – BEFORE

PERFORMING THIS EXHAUST INSTALLATION, BE

SURE TO DISCONNECT THE DRYER FROM ITS

ELECTRICAL SUPPLY. PROTECT YOUR HANDS

AND ARMS FROM SHARP EDGES WHEN

WORKING INSIDE THE CABINET. BE SURE TO

WEAR GLOVES.

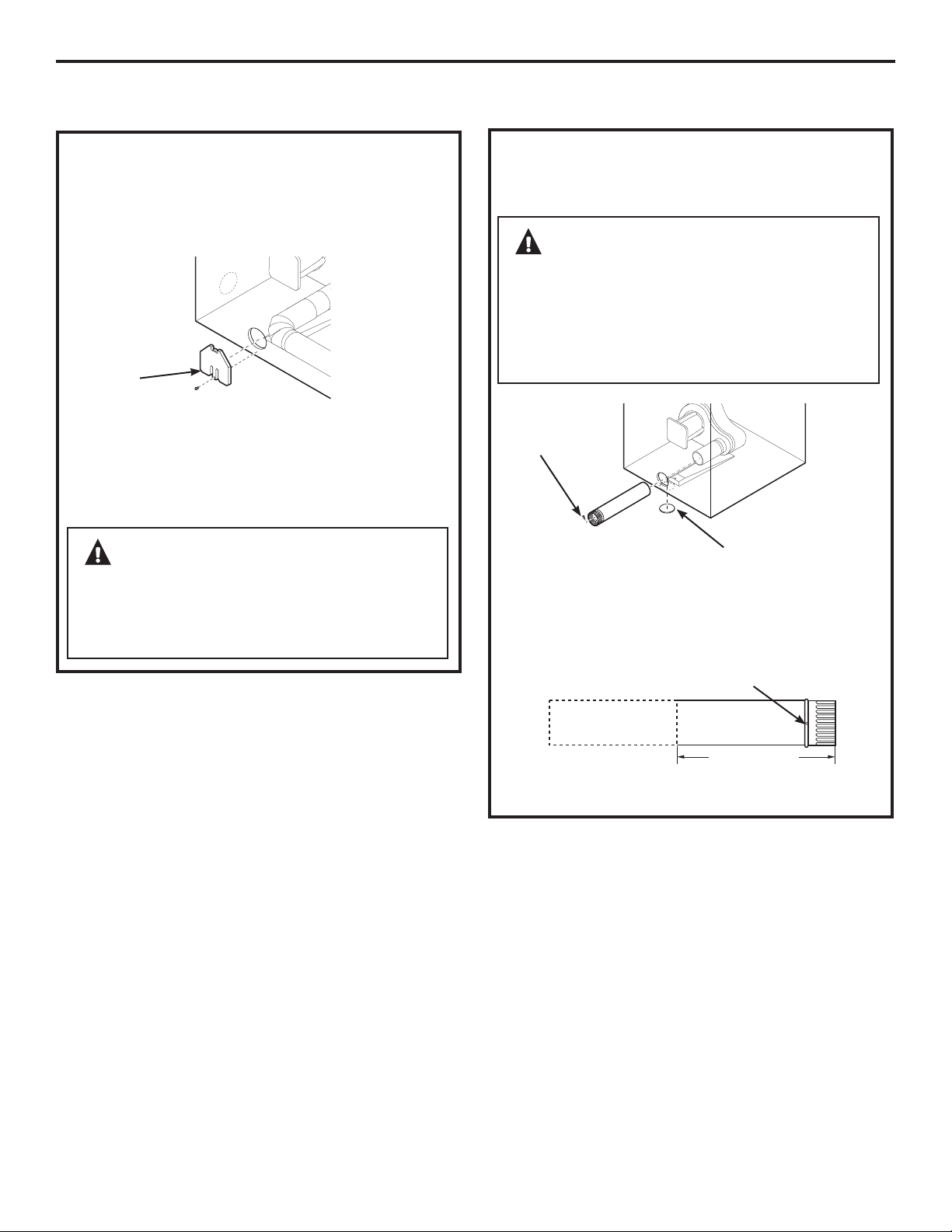

Remove

screw and

save

Detach and remove the bottom, right or left side

knockout as desired. Remove the screw from the

rear of the casing and save. Pull the duct out of

the dryer.

Right

Bottom

Remove desired

knockout (one only)

Fixing hole

Left

Tab

ADDING A NEW DUCT

Fixing hole

Left side

exhaust

Reconnect the cut portion (A) of the duct to the

blower housing. Make sure that the screw holes

in the duct and ramp base are aligned. Use the

screw saved previously to secure the duct in place

through the ramp on the appliance base.

Portion “A”

ADDING ELBOW AND DUCT FOR EXHAUST

TO LEFT OR RIGHT SIDE OF CABINET

• Tape the connection between the duct and elbow.

•

Insert the duct with elbow through the rear

opening and connect to the internal duct.

A

4.9” (125 mm)

Cut the duct as shown and keep portion A.

CAUTION: Be sure not to pull or

damage the electrical wires inside the dryer when

inserting the duct. A slight interference may

occur between the exhaust and the wire

components.

• Apply duct tape as

shown on the joint

between the dryer

internal duct and

the elbow, and also

the joint between the

elbow and the side duct.

Duct tape

CAUTION: Internal duct joints must be

secured with tape; otherwise, they may separate

and cause a safety hazard.

21

Page 22

Installation Instructions

EXHAUSTING THE DRYER (cont.)

SIDE VENTING (cont.)

ADDING COVER PLATE TO REAR OF CABINET

(SIDE EXHAUST)

Cover Plate

Connect standard metal elbows and ducts to

complete the exhaust system. Cover back opening

with a cover plate (Cover Plate – WE1M454)

available from your local service provider. Place

dryer in final location.

WARNING – NEVER LEAVE

THE BACK OPENING WITHOUT THE PLATE.

COVER BACK OPENING WITH A COVER PLATE

(COVER PLATE – WE1M454) AVAILABLE FROM

YOUR LOCAL SERVICE PROVIDER.

BOTTOM VENTING:

Dryer Exhaust to the bottom of cabinet

WARNING – BEFORE

PERFORMING THIS EXHAUST INSTALLATION, BE

SURE TO DISCONNECT THE DRYER FROM ITS

ELECTRICAL SUPPLY. PROTECT YOUR HANDS

AND ARMS FROM SHARP EDGES WHEN

WORKING INSIDE THE CABINET. BE SURE TO

WEAR GLOVES.

Remove

screw

and save

Bottom

Remove desired

knockout (one only)

Remove the screw inside the dryer exhaust duct

and save. Pull the duct out of the dryer. Detach

and remove the bottom knockout.

Fixing hole

A

4.9” (125 mm)

Cut the duct as shown and keep portion A.

22

Page 23

Installation Instructions

BOTTOM VENTING (cont.)

ADDING A NEW DUCT

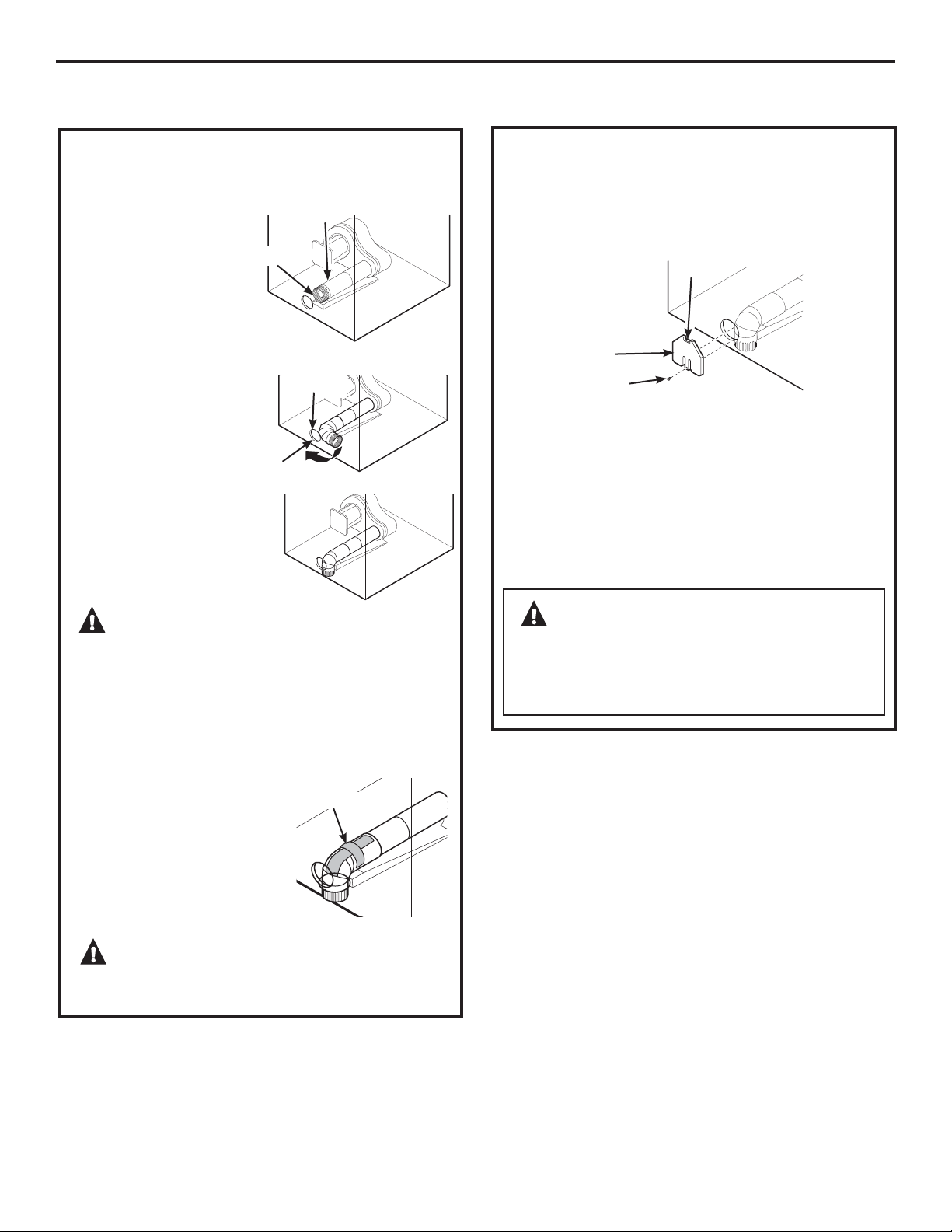

• Reconnect the cut

portion A of the

duct to the blower

housing.

•

Tape the elbow

in a 90-degree

position to

prevent rotation.

•

Insert the elbow

through the rear hole

and connect it to

portion A. Rotate

the elbow through

the bottom opening.

Fixing hole

Portion “A”

Rear hole

Bottom

opening

Dryer Exhaust to the bottom of cabinet.

ADDING COVER PLATE TO REAR OF CABINET

(BOTTOM EXHAUST)

Tab

Cover Plate

Screw

Connect standard metal elbows and ducts to

complete the exhaust system. Cover back opening

with a cover plate (Cover Plate – WE1M454)

available from your local service provider.

Insert the tab at the top of the cover plate into the

opening. Fasten screw at the bottom of the cover

plate.

Place dryer in final location.

CAUTION: Be sure not to pull or

damage the electrical wires inside the dryer

when inserting the duct.

•

While still holding down

the pipe and elbow from

the rear opening, screw

the pipes in place with

the previously saved screw.

•

Apply duct tape

as shown on the joint

between the dryer internal

duct and the elbow.

NOTE: Make sure the tape

covers the screw hole in

portion A where it connects

to the elbow.

Duct tape

CAUTION: Internal duct joints must be

secured with tape; otherwise, they may separate

and cause a safety hazard.

WARNING – NEVER LEAVE

THE BACK OPENING WITHOUT THE PLATE.

COVER BACK OPENING WITH A COVER PLATE

(COVER PLATE – WE1M454) AVAILABLE FROM

YOUR LOCAL SERVICE PROVIDER.

23

Page 24

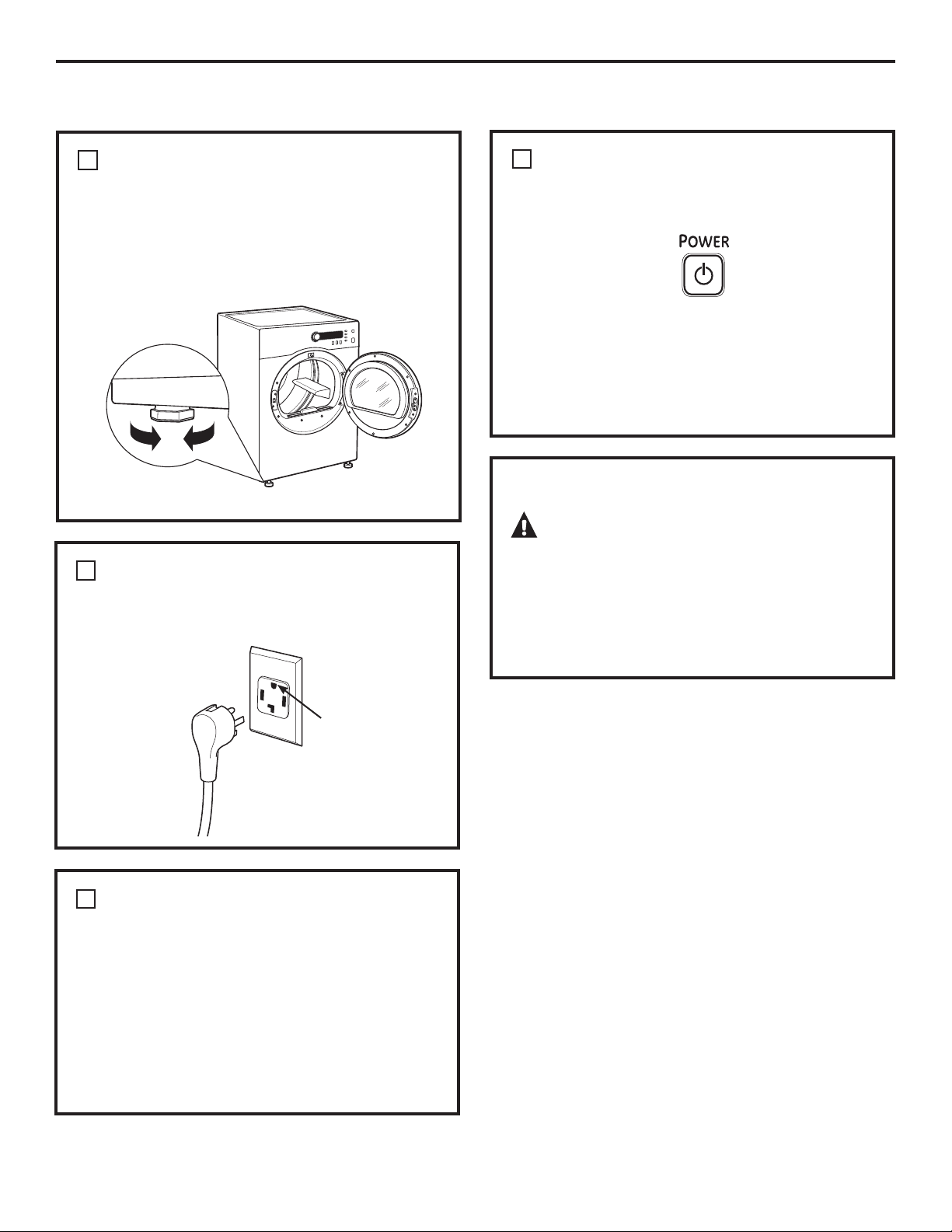

FINAL SETUP

1

LEVEL THE DRYER

Installation Instructions

4

DRYER STARTUP

Stand the dryer upright near the final location

and adjust the four leveling legs at the corners

to ensure that the dryer is level from side to side

and front to rear.

Lower

2

PLUG DRYER IN

NOTE: Stacking installations may require a power

cord up to 6 feet in length.

Raise

Press the POWER button.

NOTE: If the dryer has been exposed to

temperatures below freezing for an extended

period of time, allow it to warm up before pressing

POWER. Otherwise, the display will not come on.

The dryer is now ready for use.

SERVICING

WARNING – Label all wires prior

to disconnection when servicing controls. Wiring

errors can cause improper and dangerous

operation after servicing/installation.

For replacement parts and other information,

refer to the back cover for servicing phone

numbers.

Ensure proper

ground exists

before use.

3

GROUNDING INSTRUCTIONS

This appliance must be grounded. In the event

of malfunction or breakdown, grounding will

reduce the risk of electric shock by providing

a path of least resistance for electric current.

This appliance is equipped with a cord having an

equipment-grounding conductor and a grounding

plug. The plug must be plugged into an appropriate

outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

24

Page 25

Installation Instructions

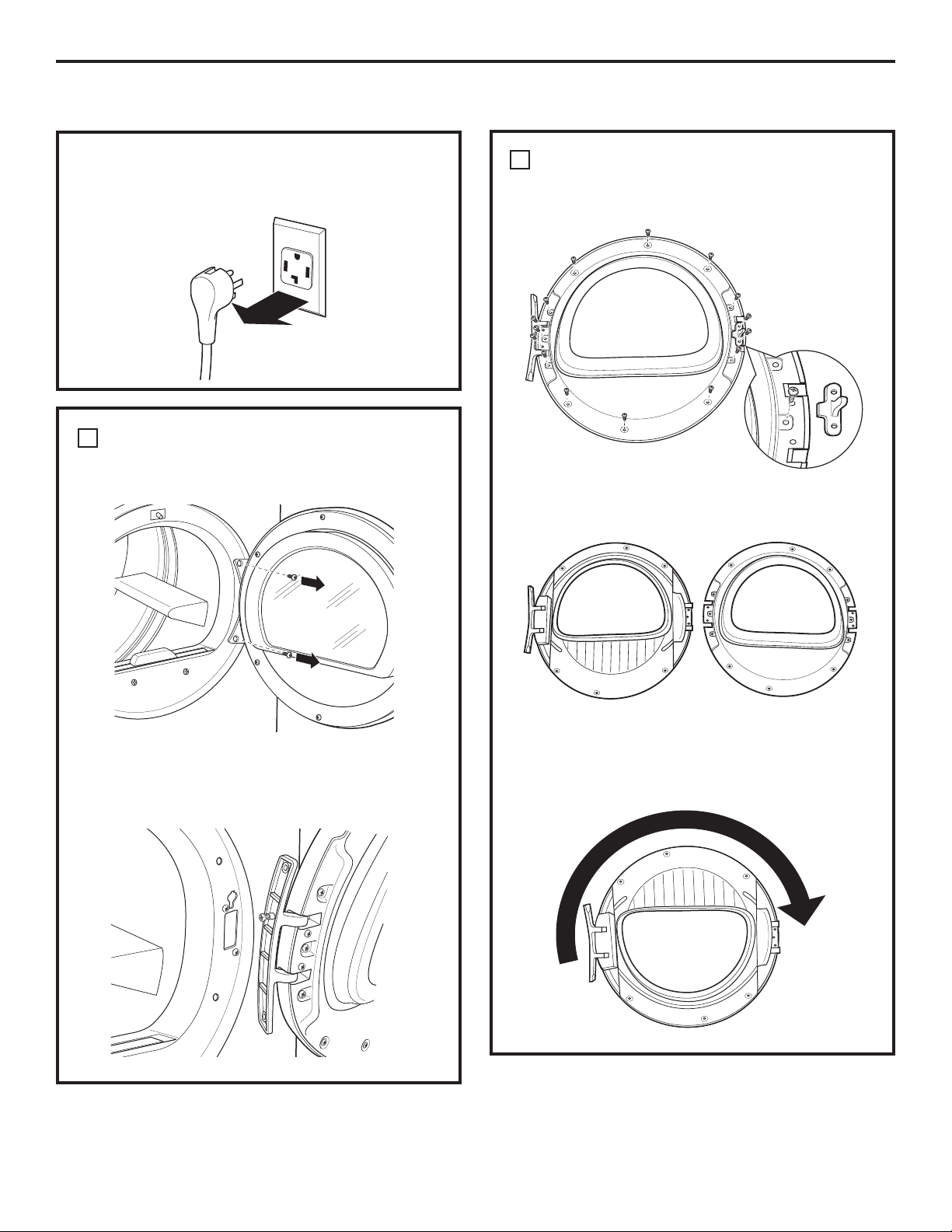

REVERSING THE DOOR SWING (if desired)

IMPORTANT NOTES

• Read the instructions all the way through before

starting.

• Handle parts carefully to avoid scratching paint.

• Provide a nonscratching work surface for

the doors.

• Set screws down by their related parts to avoid

using them in the wrong places.

• All screws must be hand-tightened.

• Normal completion time to reverse the door

swing is 20–30 minutes.

IMPORTANT: Once you begin, do not move the

cabinet until door-swing reversal is completed.

These instructions are for changing the hinges

IURPWKHULJKWVLGHWRWKHOHIWVLGH³LI\RXHYHUZDQW

to switch them back to the right side, follow these

same instructions and reverse all references

to the left and right.

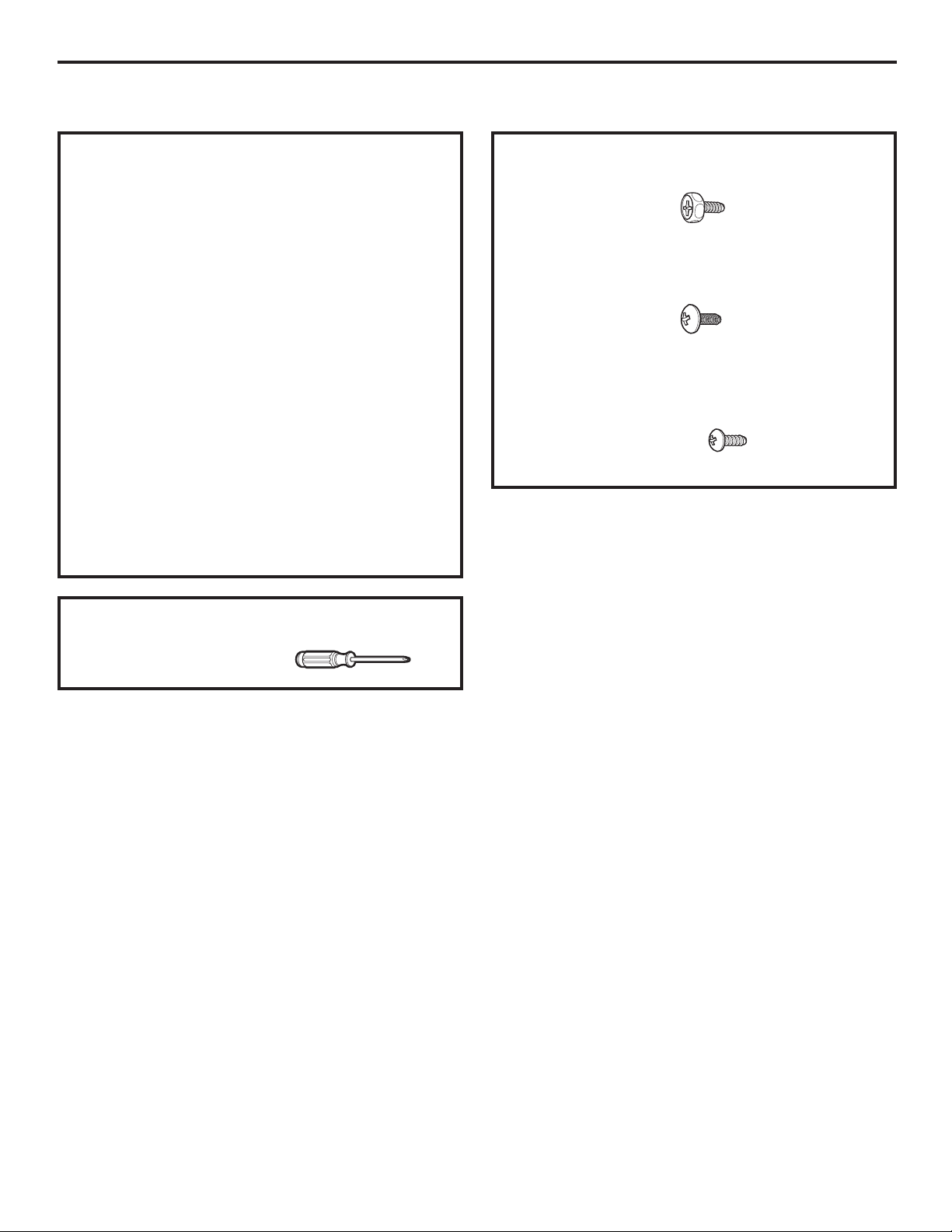

HARDWARE USED

Mounting Screw

Hinge Bracket

Anchoring Screws

Door and Latch Screws

TOOLS YOU WILL NEED

Phillips-head screwdriver

25

Page 26

Installation Instructions

REVERSING THE DOOR SWING (if desired)

2

BEFORE YOU START

DISASSEMBLE THE DOOR ASSEMBLY

Unplug the dryer from its electrical outlet.

REMOVE THE DOOR ASSEMBLY

1

Remove hinge bracket anchoring screws.

Remove 16 door screws and male end of latch

from the inner side of the door.

Remove the inner face.

Slide door and hinge assembly upward; then

remove the assembly from the dryer front panel.

Lift and rotate the window assembly 180º and

replace. Also rotate the inner face 180° and

replace.

26

Page 27

Installation Instructions

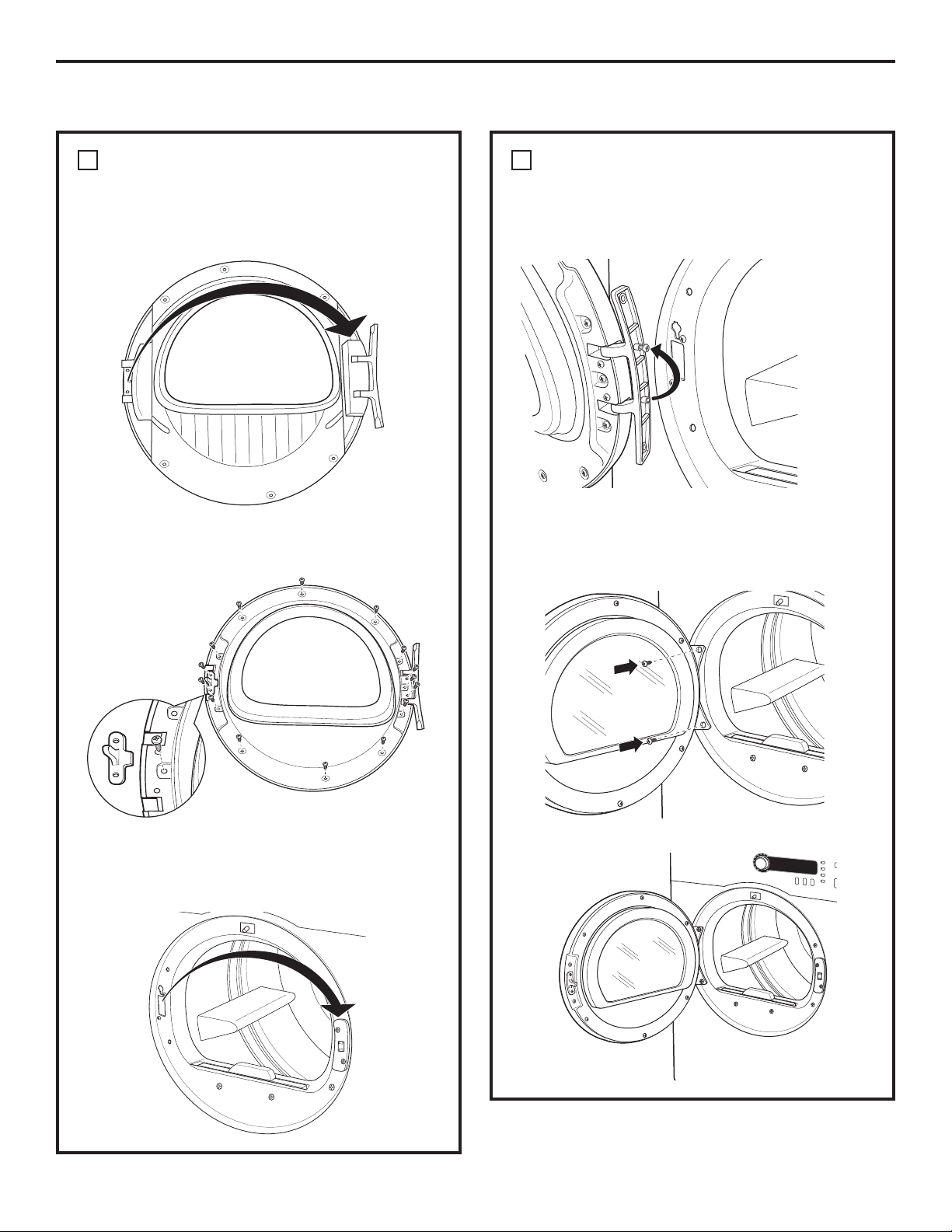

3

REPLACE DOOR ASSEMBLY

Replace a door screw in the center of the side

opposite the hinge. Then put the male end of the

latch into place and fasten with two door screws.

Replace all door screws that were removed.

3

REPLACE DOOR ASSEMBLY (CONT.)

Move the mounting screw to the upper screw hole

position on the hinge so that the door can be set

on the cabinet during final installation.

Fasten the hinge back on at the top and bottom

with the hinge mounting screws.

Remove the female end of the latch from the front

panel of the dryer, rotate 180° and replace on

the opposite side.

27

Page 28

Installation Instructions

STACKING THE WASHER AND DRYER (if desired)

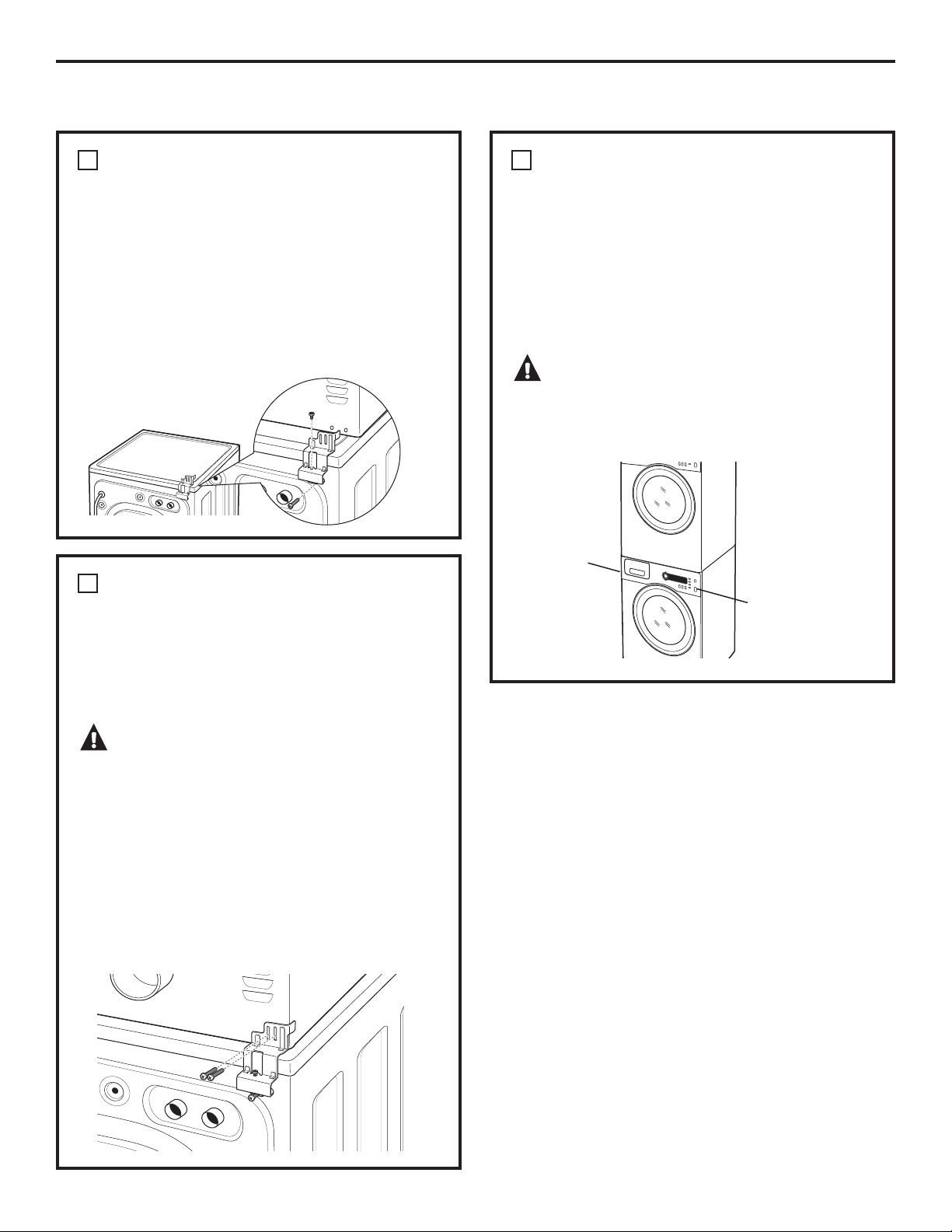

If you are planning to stack the washer and dryer, order Stacking Kit number GE24STACK to be used for this dryer.

Kit sold separately.

BEFORE YOU BEGIN

Read these instructions completely and carefully.

IMPORTANT – Save these instructions

•

for local electrical inspector’s use.

IMPORTANT – Observe all governing

•

codes and ordinances.

•

Note to Installer – Be sure to leave these

instructions with the Consumer.

•

Note to Consumer – Keep these instructions

for future reference.

•

Service must be performed by a qualified

installer.

•

Proper installation is the responsibility of

the installer.

•

Stacking installations may require a power cord

up to 6 feet in length.

FOR YOUR SAFETY:

WARNING –

• Electric Shock Hazard. Disconnect power before

installing. Failure to do so could result in serious

injury or death.

• Potential Personal Injury. More than two people

are recommended to lift the dryer into position

because of its weight and size. Failure to do so

could result in personal injury or death.

MINIMUM CLEARANCE OTHER THAN

ALCOVE OR CLOSET INSTALLATION

Minimum clearance to combustible surfaces

and for air opening are: 0” both sides and 3” front

and rear. Consideration must be given to provide

adequate clearance for installation and service.

REQUIREMENTS FOR ALCOVE OR

CLOSET INSTALLATION

• Your dryer is approved for installation in

an alcove or closet, as stated on a label on

the dryer back.

The dryer MUST be vented to the outdoors. See

•

the EXHAUSTING THE DRYER section.

Minimum clearance between dryer cabinet and

•

adjacent walls or other surfaces is:

0” either side

3” front and rear

Minimum vertical space from floor to overhead

•

shelves, cabinets, ceilings, etc., is 67.7”.

Closet doors must be louvered or otherwise

•

ventilated and have at least 60 square inches

of open area equally distributed. If the closet

contains both a washer and a dryer, doors must

contain a minimum of 120 square inches of open

area equally distributed.

NOTE: WHEN THE EXHAUST DUCT IS LOCATED AT

THE REAR OF THE DRYER, MINIMUM CLEARANCE

FROM THE WALL IS 5.5 INCHES.

• Avoid Tipping and Rupture of Utility Services.

Dryer must be securely attached to the washer.

DO NOT place the washer on top of the dryer.

Failure to do so could result in personal injury/

death or property damage.

28

Page 29

Installation Instructions

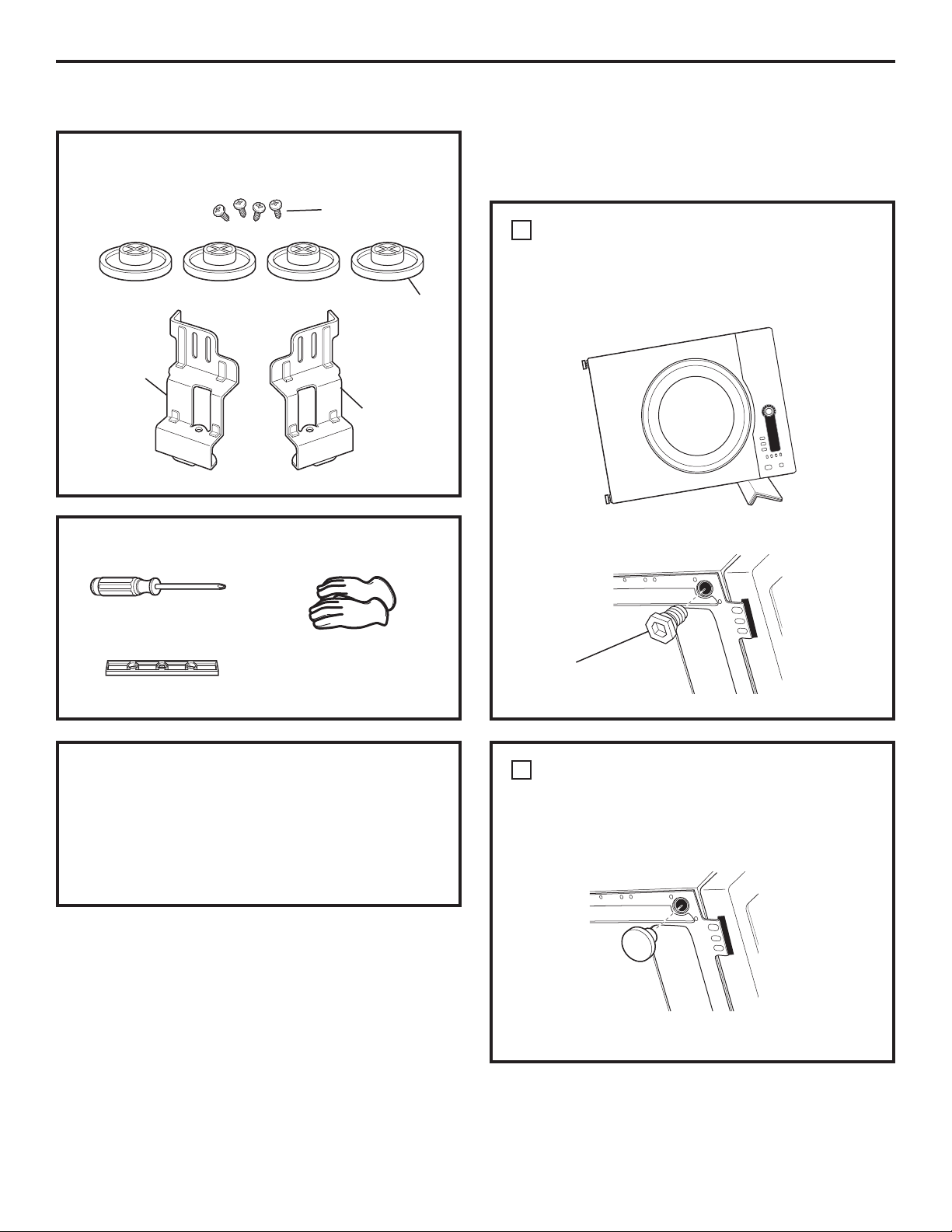

KIT CONTENTS (GE KIT #GE24STACK)

Screws (4)

Rubber

pads (4)

Bracketstack (R)

Bracketstack (L)

TOOLS YOU WILL NEED

INSTALLING THE STACK

BRACKET KIT

1

REMOVE THE DRYER LEVELING LEGS

A. Carefully lay the dryer on its side. Use the

packing material so you don’t scratch the finish

on the dryer.

B. Remove the dryer leveling legs.

Phillips screwdriver

Gloves

Level

INSTALLATION PREPARATION

Remove the packaging.

Flatten the product carton to use as a pad to lay the

dryer down on its side. Continue using the carton to

protect the finished floor in front of

the installation location.

Unscrew and remove

all 4 leveling legs

2

INSTALL RUBBER PADS

TO DRYER BASE

A. Locate the 4 rubber pads in the parts package.

Insert rubber pads into the leveling leg holes.

B. Set the dryer upright.

29

Page 30

Installation Instructions

STACKING THE WASHER AND DRYER (if desired) (cont.)

3

INSTALL BRACKET TO WASHER

A. Remove washer top cap screw from the rear

left. Align left bracket holes with top cap screw

hole on rear left of the unit and replace screw.

NOTE: Leave screws loose so dryer hole

alignment will be easier.

B. Drive next screw through the bracket into

the rear of the washer.

C. Repeat the above steps with the right side.

4

INSTALL DRYER AND BRACKET

ON DRYER

5

FINALIZE THE INSTALLATION

A. Refer to the washer Installation Instructions

to complete the washer installation.

B. Refer to the dryer Installation Instructions

to complete the dryer installation.

C. Carefully slide or walk the stacked washer and

dryer into place. Use felt pads or other sliding

device to assist moving and to protect flooring.

WARNING – Potential Personal

Injury. Do not push on the dryer once installed

to top of the washer. Pushing on the dryer may

result in pinched fingers.

Place

hands

here

Place

hands

here

A. Lift the dryer on top of the washer. Protect the

washer control panel with cardboard or other

protection. Be sure to lift the dryer high enough

to clear the washer control panel.

WARNING – Potential

Personal Injury. More than two people are

recommended to lift the dryer into position

because of its weight and size. Failure to do

so could result in personal injury or death.

B. Align the holes in the bracket with the holes

in the back of the dryer. Using a Phillips

screwdriver, attach the 2 #8 x 1/2” tapping

screws.

C. Tighten the dryer bracket screws; then tighten all

stacking kit screws.

30

Page 31

Notes. GEAppliances.com

31

Consumer SupportTroubleshooting TipsOperating InstructionsSafety Instructions

Page 32

Before you call for service…

Troubleshooting Tips

Save time and money! Review the charts on the following pages,

or visit GEAppliances.com. You may not need to call for service.

PROBLEM Possible Causes What To Do

Dryer shakes or Some shaking/noise is normal. • Move dryer to an even floor space, or adjust leveling legs

makes noise Dryer may be sitting unevenly as necessary until even.

Clothes take too long Improper or obstructed ducting • Check the Installation Instructions to make sure the

to dry dryer venting is correct.

• Make sure ducting is clean, free of kinks and

unobstructed.

• Check to see if outside wall exhaust hood operates

correctly and is clean.

Improper sorting • Separate heavy items from lightweight items (generally,

a well-sorted washer load is a well-sorted dryer load).

Large loads of heavy fabrics • Large, heavy fabrics contain more moisture and take

(like beach towels) longer to dry. Separate large, heavy fabrics into smaller

loads to speed drying time.

Controls improperly set • Match control settings to the load you are drying.

Lint filter is full • Clean lint filter before every load.

Blown fuses or tripped circuit • Replace fuses or reset circuit breakers. Since most

Operating Instructions Safety InstructionsConsumer Support Troubleshooting Tips

breaker dryers use 2 fuses/breakers, make sure both are

operating.

Overloading/combining loads • Do not put more than one washer load in the dryer at

a time.

Underloading • If you are drying only one or two items, add a few items

to ensure proper tumbling.

The DRY dryness level Load consists of a mixture • When combining heavy and light fabrics in a load,

was chosen but load is of heavy and light fabrics choose MORE DRY.

still damp

Exhaust system is blocked • Inspect and clean exhaust system.

Control pads not Controls accidentally put in • Press START/PAUSE.

responding service mode

Controls accidentally put in • Hold the LOCK button for 3 seconds to unlock the dryer.

lock mode

Controls performed an • Reset the in-house breaker.

incorrect operation

Dryer doesn’t start Control panel is “asleep” • This is normal. Press POWER to activate the control panel.

Dryer is unplugged • Make sure the dryer plug is pushed completely into

the outlet.

Fuse is blown/circuit breaker • Check the building’s fuse/circuit breaker box and

is tripped replace fuse or reset breaker. NOTE: Electric dryers

use two fuses or breakers.

Dryer was accidentally paused • If the light on the START/PAUSE button is flashing,

when starting Delay Start the dryer is paused. Press START/PAUSE to restart

the countdown.

32

Page 33

GEAppliances.com

PROBLEM Possible Causes What To Do

No numbers displayed Dryer is continuously • This is normal. When the dryer senses a low level of

during cycle, only lights monitoring the amount of moisture in the load, the dryer will display the dry time

moisture in the clothes remaining.

Time Remaining The estimated time may change • This is normal.

jumped to a when a smaller load than usual

lower number is drying

Cannot make a The DRYNESS LEVEL, TEMP • This is normal.

selection and the or OPTION that you are

dryer beeps twice trying to select is incompatible

with the chosen dry cycle

Dryer is running but The EXTEND TUMBLE • This is normal. During extended tumbling, the time

00 is displayed in option was chosen remaining is not displayed. The extended tumbling

Time Remaining option lasts approximately 20 minutes. It will then

tumble intermittently for approximately 70 minutes.

Clean Lint Filter (message) POWER button was activated • Press START/PAUSE to begin a dry cycle and the message

will disappear.

Dryer doesn’t heat Fuse is blown/circuit breaker • Check the building’s fuse/circuit breaker box and

is tripped; the dryer may tumble replace both fuses or reset both breakers. Your dryer

but not heat may tumble if only one fuse is blown or one breaker

tripped.

Inconsistent drying times Type of heat • Drying time will vary according to the type of heat used.

If you recently changed from an electric to a gas

(natural or LP) dryer, or vice versa, the drying time

could be different.

Type of load and • The load size, types of fabric, wetness of clothes and the

drying conditions length and condition of the exhaust system will affect

drying times.

Glow at the rear Heaters behind the drum • This is normal. Under certain drying conditions and

of the drum room ambient lighting, the glow of the heaters may be

visible at the rear of the drum.

Clothes are still wet The door was opened mid-cycle. • A dry cycle must be reselected each time a new load

and dryer shut off The load was then removed from is put in.

after a short time the dryer and a new load put in

without selecting a new cycle

Small load • When drying 3 items or less, choose SPEED DRY or

TIMED DRY.

Load was already dry except • Choose SPEED DRY or TIMED DRY to dry damp collars

for collars and waistbands and waistbands. In the future, when drying a load with

collars and waistbands, choose MORE DRY.

Dryer is not level • Move dryer to an even floor space or adjust leveling legs

as necessary until even.

Clothes are wrinkled Overdrying • Select a shorter drying time.

• Remove items while they still hold a slight amount of

moisture. Select a LESS DRY or DAMP setting.

Letting items sit in dryer after • Remove items when cycle ends and fold or hang

cycle ends immediately, or use the EXTEND TUMBLE option.

Overloading • Separate large loads into smaller ones.

Consumer SupportTroubleshooting TipsOperating InstructionsSafety Instructions

33

Page 34

Before you call for service…

Troubleshooting Tips.

PROBLEM Possible Causes What To Do

Clothes shrink Some fabrics will naturally shrink • To avoid shrinkage, follow garment care labels exactly.

when washed. Others can be

safely washed, but will shrink

in the dryer

item, do not machine wash or tumble dry it.

Greasy spots on clothes Improper use of fabric softener • Follow directions on fabric softener package.

Drying dirty items • Use your dryer to dry only clean items. Dirty items can

with clean ones stain clean items and the dryer.

Clothes were not • Sometimes stains which cannot be seen when the

completely clean clothes are wet appear after drying. Use proper washing

procedures before drying.

Lint on clothes Lint filter is full • Clean lint screen before each load.

Improper sorting • Sort lint producers (like chenille) from lint collectors

(like corduroy).

Static electricity can attract lint • See suggestions in this section under STATIC.

Operating Instructions Safety InstructionsConsumer Support Troubleshooting Tips

Overloading • Separate large loads into smaller ones.

Paper, tissue, etc., left in pockets • Empty all pockets before laundering clothes.

• Some items may be pressed back into shape after drying.

• If you are concerned about shrinkage in a particular

Static occurs No fabric softener was used • Try a fabric softener.

®

• Bounce

approved for use in all GE Dryers when used in

accordance with the manufacturer’s instructions.

Overdrying • Try a fabric softener.

• Adjust setting to LESS DRY or DAMP.

Synthetics, permanent press • Try a fabric softener.

and blends can cause static

Collars and waistbands The dryness monitor senses • Choose SPEED DRY or TIMED DRY to dry damp collars

still wet at end of cycle that the body of the clothes and waistbands. In the future, when drying a load with

is dry collars and waistbands, choose MORE DRY.

Slight variation This is normal • Due to the metallic properties of paint used for this unique

in metallic color product, slight variations of color may occur due to viewing

angles and lighting conditions.

Fabric Conditioner Dryer Sheets have been

34

Page 35

GE Dryer Warranty. (For customers in the United States)

All warranty service provided by our Factory Service Centers,

®

or an authorized Customer Care

technician. To schedule service

on-line, visit us at GEAppliances.com, or call 800.GE.CARES

(800.432.2737).

Staple your receipt here.

Proof of the original purchase

date is needed to obtain service

under the warranty.

Please have serial number and model number available when

calling for service.

For The Period Of: We Will Replace:

One Year Any part of the dryer which fails due to a defect in materials or workmanship. During this

From the date of the limited one-year warranty, GE will also provide, free of charge, all labor and related service costs

original purchase to replace the defective part.

What Is Not Covered (in the United States):

Service trips to your home to teach you how to use

the product.

Improper installation, delivery or maintenance.

Failure of the product if it is abused, misused or used for

other than the intended purpose or used commercially.

Replacement of the light bulb after its expected

useful life.

Damage to the product caused by accident, fire, floods

or acts of God.

Incidental or consequential damage caused by possible

defects with this appliance.

Damage caused after delivery.

Product not accessible to provide required service.

Replacement of house fuses or resetting of circuit

breakers.

(;&/86,212),03/,(':$55$17,(6³<RXUVROHDQGH[FOXVLYHUHPHG\LVSURGXFWUHSDLUDVSURYLGHGLQ

this Limited Warranty. Any implied warranties, including the implied warranties of merchantability or

fitness for a particular purpose, are limited to one year or the shortest period allowed by law.

This warranty is extended to the original purchaser and any succeeding owner for products purchased

for home use within the USA. If the product is located in an area where service by a GE Authorized Servicer

is not available, you may be responsible for a trip charge or you may be required to bring the product to an

Authorized GE Service location for service. In Alaska, the warranty excludes the cost of shipping or service calls

to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty

gives you specific legal rights, and you may also have other rights which vary from state to state. To know

what your legal rights are, consult your local or state consumer affairs office or your state’s Attorney General.

Warrantor: General Electric Company. Louisville, KY 40225

Consumer SupportTroubleshooting TipsOperating InstructionsSafety Instructions

35

Page 36

GE Dryer Warranty. (For customers in Canada)

All warranty service provided by our Factory Service Centres or an authorized

technician. For service, call 1.800.561.3344.

Please have serial number and model number available when calling for service.

For The Period Of: We Will Replace:

One Year Any part of the dryer which fails due to a defect in materials or workmanship. During this

From the date of the limited one-year warranty, GE will also provide, free of charge, all labor and related service costs

original purchase to replace the defective part.

What Is Not Covered (in Canada):

Service trips to your home to teach you how to use

the product.

Improper installation, delivery or maintenance.

Failure of the product if it is abused, misused or used for

other than the intended purpose or used commercially.

Replacement of the light bulb after its expected

useful life.

Replacement of house fuses or resetting of circuit

breakers.

Damage to the product caused by accident, fire, floods

or acts of God.

Incidental or consequential damage caused by possible

defects with this appliance.

Damage caused after delivery.

Product not accessible to provide required service.

Operating Instructions Safety InstructionsConsumer Support Troubleshooting Tips

(;&/86,212),03/,(':$55$17,(6³<RXUVROHDQGH[FOXVLYHUHPHG\LVSURGXFWUHSDLUDVSURYLGHGLQWKLV/LPLWHG

Warranty. Any implied warranties, including the implied warranties of merchantability or fitness for a particular

purpose, are limited to one year or the shortest period allowed by law.

This warranty is extended to the original purchaser and any succeeding owner for products purchased in

Canada for home use within Canada. In-home warranty service will be provided in areas where it is available

and deemed reasonable by Mabe to provide.

WARRANTOR IS NOT RESPONSIBLE FOR CONSEQUENTIAL DAMAGES.

36

Warrantor: MABE CANADA INC.

Page 37

Mesures de sécurité ................ 38–40

Foncionnement

Options de cycle ....................................44, 45

Panneau de contrôle ........................ 41–43

Utilisation de la sécheuse ......................46

Installation

Avant de commencer ........................47, 48

Emplacement

de votre sécheuse ..............................48, 49

Évacuation de la sécheuse .......... 53–59

Installation finale ...........................................60

Inversion de l’ouverture

de la porte ................................................ 61–63

Raccordement

d’une sécheuse électrique .............50–52

Superposer la laveuse

à la sécheuse ........................................ 64–66

Conseils de dépannage ....... 67–69

Soutien au consommateur

Garantie .......................................................... 70

Soutien au

consommateur ............................................ 72

CONSERVEZ CES DIRECTIVES

Inscrivez ici les numéros

de modèle et de série :

Modèle N° ________________

Série N° __________________

Ces informations figurent

sur l’étiquette située à l’avant

de la sécheuse, derrière la porte.

Soutien au consommateurConseils de dépannageFonctionnementMesures de sécurité

37

Page 38

MESURES DE SÉCURITÉ IMPORTANTES.

LISEZ D’ABORD TOUTES LES DIRECTIVES.

AVERTISSEMENT!

Pour votre sécurité, suivez les directives fournies dans le présent manuel afin

de minimiser les risques d’incendie, d’explosion et de chocs électriques et prévenir

des dégâts matériels et des blessures graves ou mortelles.

N’entreposez pas ou n’utilisez pas

d’essence ou autres vapeurs ou

liquides inflammables à proximité

de cet appareil ou de tout autre

électroménager.

UNE INSTALLATION ADÉQUATE

Avant d’utiliser votre sécheuse, assurez-vous qu’elle a été adéquatement installée, conformément

aux Instructions d’installation. Les consignes d’installation figurent au dos de ce manuel.

Mettez l’appareil à la terre conformément à tous

les codes et règlements en vigueur. Suivez les Directives

Fonctionnement Mesures de sécuritéSoutien au consommateur Conseils de dépannage

d’installation.

Installez ou entreposez l’appareil dans une pièce

où la température est supérieure à 0°C, et où il sera

à l’abri des intempéries,

l’appareil et invalider la garantie.

Branchez l’appareil sur un circuit protégé et de capacité

appropriée afin d’éviter toute surcharge électrique.

Retirez tous les articles d’emballage tranchants et jetez

tous les matériaux de transport.

qui pourraient endommager

L’installation et les réparations doivent

être effectuées par un installateur

qualifié, une entreprise de réparation

ou votre fournisseur de gaz.

Conduit d’évacuation :

1

L’air des sécheuses DOIT être évacué à l’extérieur pour

empêcher que de grandes quantités d’humidité et de

charpie soient envoyées dans la pièce.

2

Utilisez uniquement des conduits métalliques rigides,

d’un diamètre de 4 po, à l’intérieur de la carrosserie de

la sécheuse. Utilisez uniquement un conduit métallique

rigide ou flexible de 4 po de diamètre pour l’évacuation

vers l’extérieur. N’utilisez jamais un conduit en plastique

ou autre matériau combustible facilement perforable.

Pour des détails complets, suivez les Instructions

d’installation.

38

Page 39

www.electromenagersge.ca

AVERTISSEMENT!

AUTOUR DE VOTRE SÉCHEUSE

Conservez la zone sous et autour de vos appareils libre

de tous matériaux combustibles (charpies, papiers,

chiffons, etc.), essence, produits chimiques et autres gaz

et liquides inflammables.

Gardez le sol propre et sec à proximité de vos

électroménagers afin de ne pas glisser.

Il faut exercer une étroite surveillance lorsque

vous faites fonctionner cet appareil en présence

d’enfants. Ne les laissez pas jouer sur, avec ou

dans cet appareil ou dans tout autre appareil.

LORSQUE VOUS UTILISEZ LA SÉCHEUSE

Ne vous penchez jamais dans la sécheuse pendant

que le tambour tourne. Avant de charger ou de

décharger la sécheuse ou d’y ajouter des vêtements,

attendez que le tambour se soit complètement arrêté.

Avant chaque séchage, nettoyez le filtre à charpie afin

de prévenir l’accumulation de charpie à l’intérieur

de la sécheuse ou dans la pièce. NE FAITES PAS

FONCTIONNER LA SÉCHEUSE SANS LE FILTRE

À CHARPIE.

Ne lavez pas ou ne faites pas sécher des articles qui ont

été lavés avec des produits combustibles ou explosifs,

ou qui ont été trempés dans ces produits ou qui en

sont tachés (cire, peinture, huile, essence, dégraissants,

solvants pour le nettoyage à sec, kérosène, etc.). Ces

substances émettent des vapeurs qui peuvent prendre

feu ou exploser. Ne versez pas ces substances dans l’eau

de la laveuse. N’utilisez pas ces substances à proximité

de votre laveuse ou de votre sécheuse pendant qu’elles

fonctionnent.

Ne rangez pas dans votre sécheuse des articles qui

ont été en contact avec des huiles de cuisson; ceux-ci

peuvent provoquer une réaction chimique susceptible

de faire s’enflammer vos vêtements.

Il ne faut pas mettre dans la sécheuse, ou à proximité

de celle-ci, tout article ayant été utilisé avec un solvant

dégraissant ou contenant une substance inflammable

(comme des chiffons de nettoyage, des vadrouilles,

des serviettes utilisées dans les salons de coiffure, etc.),

à moins qu’ils aient été débarrassés de toute trace et

de toute vapeur de substance inflammable. On utilise

à la maison de nombreux produits inflammables :

acétone, alcool dénaturé, essence, kérosène, nettoyants

ménagers, détachants, térébenthine, cire, décapants,

contenant du distillat de pétrole.

La lessive peut atténuer les propriétés ignifugeantes