Page 1

www.GEAppliances.com

Safety Information .......... 2-5

Proper Installation ............. 3

When Using the Dryer .......... 4

Operating lnstructions

Control Panels ................. 6

Control Settings ................ 7

Loading and Using the Dryer . .8, 9

Installation Instructions

Electrical Requirements ....... 11

Exhausing the Dryer ........... 12

Installing the Dryer ........ 13-19

Preparing to Install the Dryer ... 10

Troubleshooting Tips ..... 20, 21

Consumer Support

Consumer Support .... Back (;over

Warranty ..................... 23

DBL333

DCL333

DVL223

NLL113

NVL333

Write the model and serial

numbers here:

Model #

Serial #

You can find them on the label

on the front of the left side of

the door opening.

134047400 175D1807P265 49-9996-1 04-01 JR

Page 2

IMPORTANTSAFETYINFORMATION.

READALLINSTRUCTIONSBEFOREUSING.

A WARNING!

For your safety, the information in this manual must be followed to minimize the risk of fire

or explosion, electric shock, or to prevent property damage, personal injury, or death.

• Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

• Installation and service must be performed

by a qualified installer, service agency or

the gas supplier.

WHATTODOIF YOUSMELLGAS:

_-_ Do not try to light a match, or cigarette, or

turn on any gas or electrical appliance.

[] Do not touch any electrical switch;

do not use any phone in your building.

[] Clear the room, building or area of all

occupants.

Cafifomia Safe Drinking Water and Toxic Enforcement Act

This act requires the governor of California to publish a list of substances hloxm to the state to cause cancer,

birth defects or other reproductive haml and requires businesses to warn customers of potential exposure

to such substances.

(;as appliances can cause minor exposure to fbur of these substances, namely benzene, carbon monoxide,

fbrmaldehyde and soot, caused primarily by the incomplete combustion of natural gas or LP fimls.

Properly adjusted dryers _4ll minimize incomplete combustion. Exposure to these substances can be

minimized further by properly venting the duer to the outdoors.

F_ lmmediately call your gas supplier from a,

neighbors phone. Follow the gas suppliers

instructions carefully,

[] ff you cannotreach yourgas supplier,

call the fire department.

2

Page 3

www.GEAppliances.com

WARNING!

PROPERINSTALLATION

This dryer must be properly installed and located in accordance with the Installation Instructions

before it is used.

• Properly ground &Ter to conform with all

governing codes and ordinances. Follow

details in the Installation Instructions section.

• Install or store where it _411not be exposed

to temperatures below fi'eezing or exposed

to the weather.

• Connect to a properly- rated, protected and

sized power supply circuit to avoid electrical

overload.

• Remove all sharp packing items and dispose

of all shipping materials properly.

YOURLAUNDRYAREA

Keep the area underneath and around your

appliances fl'ee of combustible materials, such

as lint, paper, rags, chemicals, gasoline and

other flammable vapors and liquids.

Keep the floor around your appliances clean

and d,y to reduce the possibility of slipping.

Keep area around the exhaust opening and

surrounding areas fl'ee fl'om the accunmlation

of lint, dust and dirt.

Exhaust/Ducting:

E_] This &Ter MUSTbe exhausted to the outside.

[2-_Use only rigid metal or flexible metal 4"

diameter d'uctwork inside the &yer cabinet or

for exhausting to the outside. USE OFPLASTIC

OROTHERCOMBUSTIBLEDUCTWORKCAN

CAUSEA FIRE.PUNCTUREDDUCTWORKCAN

CAUSEA FIREIFIT COLLAPSESORBECOMES

OTHERWISERESTRICTEDIN USEORDURING

INSTALLATION.

Follow details in the Installation Instructions section.

• Close supex_Tision is necessa D,if this appliance

is used by or near children. Do not allow

children to play on, with, or inside this or

aW other appliance.

• Keep all laundry aids (such as detergents,

bleaches, etc.) out of the reach of children,

preferably in a locked cabinet. Obsm_:e all

warnings on container labels to avoid injm y.

• Never climb on or stand on the dxTer top.

Do not obstruct the flow of ventilating air.

Do not stack or place laundx T or throw rugs

against the fl'ont or back of the dD,er.

• Do not install or store this appliance where

it will be exposed to the weather.

3

Page 4

IMPORTANTSAFETYINFORMATION.

READALLINSTRUCTIONSBEFOREUSING.

WARNING'!

WHENUSINGYOURDRYER

• Never reach into the dryer while the drum is

moving. Beibre loading, unloading or adding

clothes, wait until the drum has completely

stopped.

• Cleanthelint filter beforeeach loadto prevent

lint accumulation inside the dryer or in the

room. DONOTOPERATETHEDRYERWITHOUT

THELINTFILTERIN PLACE,UNLESSTHEDRYING

RACKISIN USE.

• Do not wash or dry articles that have been

cleaned in, washed in, soaked in, or spotted

with combustible or explosive substances

(such as wax, oil, paint, gasoline, degreasers, •

dry-cleaning solvents, kerosene, etc.) which

may ignite or explode. Do not add these

substances to the wash water. Do not use or

place these substances around your washer •

or dryer during operation.

• Any article on which you have used a cleaning

solvent or that contains flammable materials

(such as cleaning cloths, mops, towels used in

beauty salons, restaurants, or barber shops,

etc.) must not be placed in or near the dryer

until solvents or flammable materials have

been removed. There are many highly

flammable items used in homes such as

acetone, denatured alcohol, gasoline,

kerosene, some household cleaners, some spot

removers, turpentines, waxes, wax removers •

and products containing petroleum distillates.

The laundry process can reduce the flame

retardancy ofi_tbrics. To avoid such a resuh,

carefully ibllow the garment manufacturer's

care instructions.

Do not dry articles containing rubber, plastic,

or similar materials such as padded bras, tennis

shoes, galoshes, bath mats, rugs, bibs, baby

pants, plastic bags, pillows, etc. that may meh

or burn. Some rubber materials, when heated,

can under certain circumstances produce fire

by spontaneous combustion.

Do not store plastic, paper or clothing that

may burn or meh on top of the dryer during

operation.

Garments labeled Dry Away from Heat or Do

Not rumble Dry (such as life jackets containing

Kapok) must not be put in your dryer.

Do not dry fiberglass articles in your dryer.

Skin irritation could result from the remaining

particles that may be picked up by clothing

during subsequent dryer uses.

4

To minimize the possibility of electric shock,

unplug this appliance fl'om the power supply

or disconnect the &Ter at the household

distribution panel by removing the fllse or

switching off the circuit breaker before

attempting any maintenance or cleaning

(except the removal and cleaning of the lint

filter). NOTE:Turning the Cycle Selector knob

to an OFFposition does NOTdisconnect the

appliance fi'om the power supply.

Do not spray any type of aerosol into, on or

near dtTer at any time.

Do not place items exposed to cooking oils in

your dryer. Items contaminated with cooking

oils may contribute to a chemical reaction that

could cause a load to catch fire.

Never attempt to operate this appliance if

it is damaged, malflmctioning, partially

disassembled, or has missing or broken parts,

including a damaged cord or plug.

The interior of the machine and the exhaust

duct connection inside the dryer should be

cleaned at least once a year by a qualified

technician. See the Loading and Using the Dryer

section. Do not use any type of spray cleaner

when cleaning dryer interior. Hazardous imnes

or electrical shock could occur.

If yours is a gas &Ter, it is equipped with an

automatic elecu'ic ignition and does not have

a pilot light. DONOTATTEMPTTOLIGHTWITH

A MATCH.Burns may resuh fi'om having your

hand in the vicinity of the burner when the

automauc zgnltzon turns on.

You may wish to soften your laundered fabrics

or reduce the static electricity in them by using

a drye>applied fabric softener or an anti-static

conditioner. We recommend you use either a

fabric softener in the wash cycle, according to

the manufacturer's instructions for those

products, or try a dryer-added product for

which the manufacturer gives written

assurance on the package that their product

can be safely used in your dryer. Set_'ice or

performance problems caused by use of

these products are the responsibility of the

znanufacmrers of those products and are not

covered under the warrant), to this appliance.

Page 5

WHENNOTUSINGYOURDRYER

www.GEAppliances.com

Grasp the plug firmly when disconnecting this

appliance to avoid damage to the cord while

pulling. Place the cord aw W fl'om traffic areas

so it will not be stepped on, u'ipped over or

subjected to damage.

Do not attempt to repair or replace any part

of this appliance or attempt any sex_,icing

unless specifically recommended in this

Owner's Manual or in published use>repair

insuuctions that you understand and have the

skills to car Wout.

• Befbre discarding a duer, or removing it

fl'om se,_,ice, remove the d,Ter door to

prevent children fl'om hiding inside.

• Do not tamper with controls.

READAND FOLLOWTHISSAFETYINFORMATIONCAREFULLY

SAVETHESEINSTRUCTIONS

5

Page 6

Aboutthe dryercontrolpanel

You can locate your model number on the label on the front of the left side of the door opening.

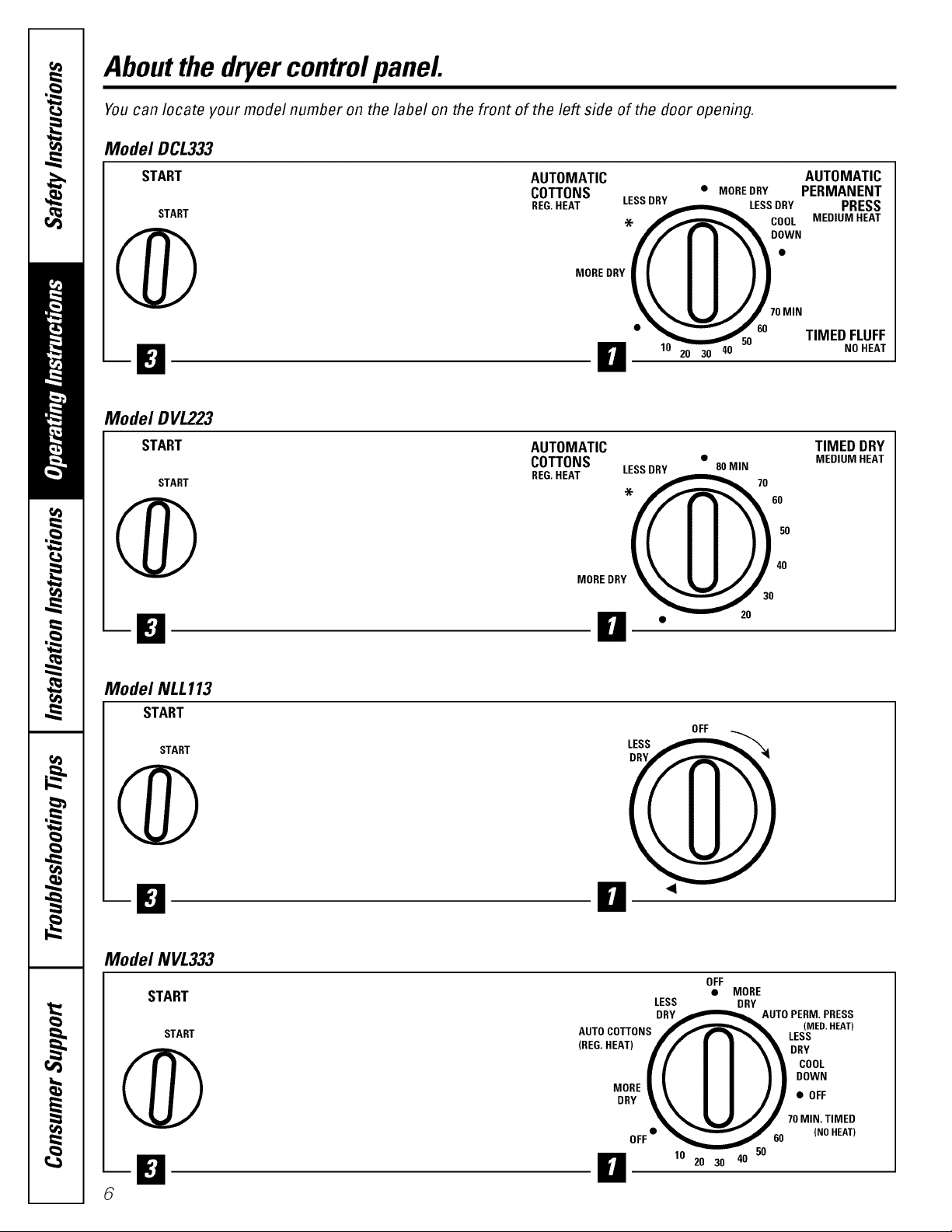

Model DCL333

START

START

AUTOMATIC AUTOMATIC

COTTONS • MOREDRY PERMANENT

REG.HEAT _LESS DRY PRESS

LESS DRY

,'X..,_"-_"_L COOL

f/! I_'V:=

MEDIUM HEAT

@

Model DVL223

START

START

@

Model NLL113

START

START

oo...._[_,II ))

%_._ZJJ/ 70MIN

• _-""'"_j 60

-- lO_ 50 TIMED FLUFF

H 20 30 40 NOHEAT

AUTOMATIC TIMED DRY

COTTONS • 80 MIN MEDIUM HEAT

REG.HEAT 70_0

LESS DRY

'-X" 6O

5O

40

MOREDRY

• 20

OFF

LESS

@

-El

Model NVL333

START

START

@

8

ii

OFF

LESS DRY

DRY _,= AUTO PERM, PRESS

AUTOCOTTONS f_"_ LES(_ED'HEAT)

• MORE

=EO,HEAT_// I I \\ DR,,

I I I I \ t COOL

I I I I I | DOWN

,_o_\II 21.o,,

% _ %,,l_J" J 70MIN,TIMED

• _ 60 (NOHEAT)

OFF

O 10 20 30 40 50

Page 7

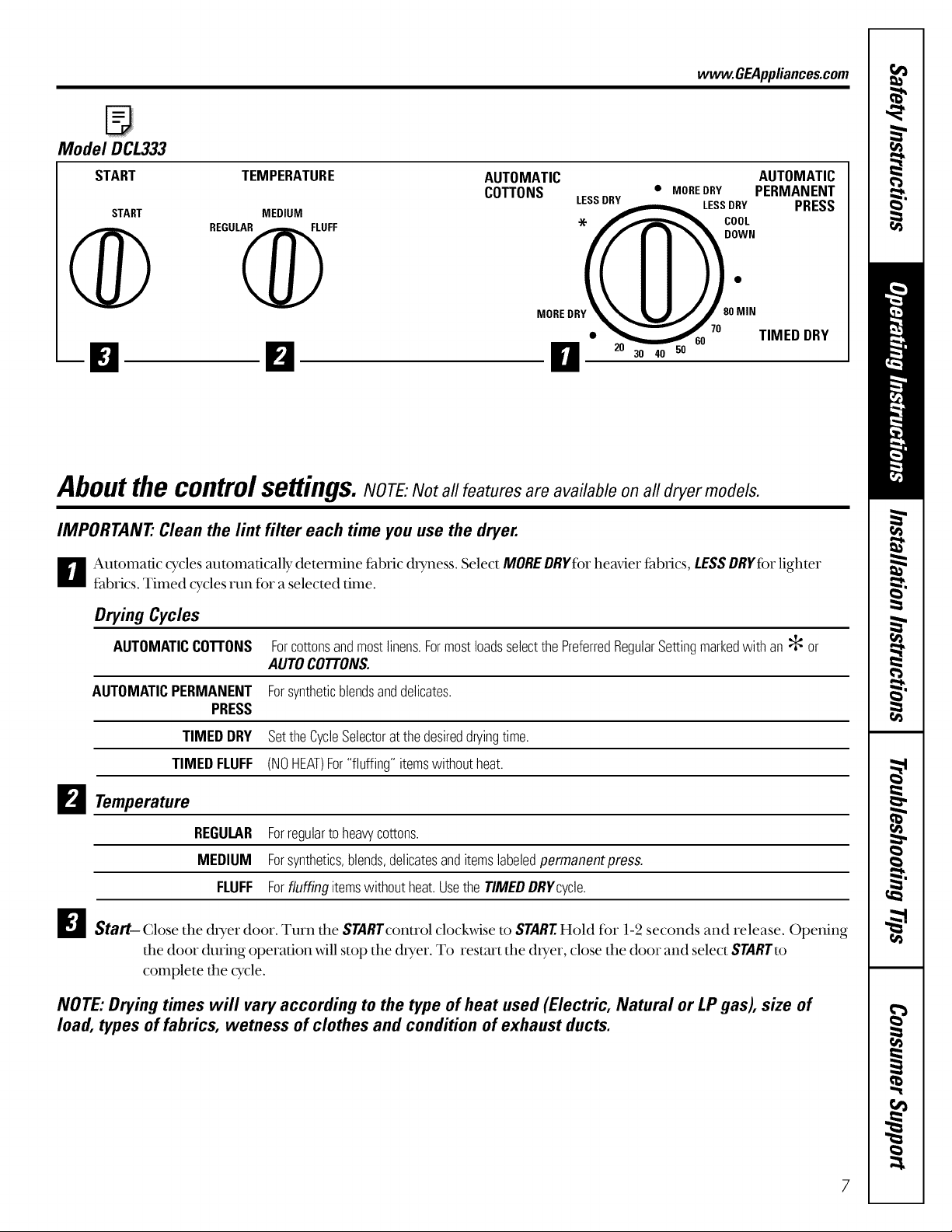

Model DCL333

START TEMPERATURE

www.GEAppliances.com

AUTOMATIC AUTOMATIC

COTTONS • MOREDRY PERMANENT

LESS DRY LESSDRY

DOWN

PRESS

START MEDIUM '-X._

REGUL_UFF COOL

MOREDRY / 00MIN

TIMED DRY

_1_ 20 30 40 50

Aboutthe control

IMPORTANT" Clean the lint filter each time you use the dryer.

_r_ Automatic cycles automatically determine fabric chyness. Select MOREDRYfor heavier fabrics, LESSDRYfbrlighter

fabrics. Timed cycles run fbr a selected time.

Drying Cycles

AUTOMATICCOTTONS Forcottonsandmostlinens.FormostloadsselectthePreferredRegularSettingmarkedwithan :_ or

AUTOMATICPERMANENT Forsyntheticblendsanddelicates.

PRESS

aLlL m_ __

serungs.NOTE: Not all features are available on all dryer models.

AUTOCOTTONS.

TIMEDDRY SettheCycleSelectorat thedesireddryingtime.

TIMEDFLUFF (NOHEAT)For"fluffing"itemswithoutheat.

B Temperature

REGULAR Forregulartoheavycottons.

MEDIUM Forsynthetics,blends,delicatesanditemslabeledpermanentpress.

FLUFF Forfluffingitemswithoutheat.Usethe TIMEDDRYcycle.

_iStart- Close the &yer door. Turn the STARTconu'ol clock_4se to STARTHold tbr 1-2 seconds and release. Opening

the door during operation will stop the &yet. To restm't the &yet, close the door and select STARTto

complete the cycle.

NOTE: Drying times will vary according to the type of heat used (Electric, Natural or LP gas), size of

load, types of fabrics, wetness of clothes and condition of exhaust ducts.

7

Page 8

Loadingand usingthe dryer.Always follow the fabric manufacturer's care label when laundering.

SortingandLoadingHints

As a general rule, if clothes are sorted properly for the washer, they are sorted properly for the dryer.

Donotaddfabricsoftenersheetsoncetheloadhasbecomewarm.Theymaycausefabricsoftenerstains.Bounce_ Fabric

ConditionerDryerSheetshavebeenapprovedfor usein a//GEDryerswhenusedinaccordancewith themanufacturer's

instructions.

Do notoverload.Thiswastesenergyandcauseswrinkling.

Do notdrythe following items:fiberglassitems,woolens,rubber-coateditems,plastics,itemswith plastictrimand

foam-filleditems.

\1/.-_.,

CareandCleaningof theDryer

TheExterior:Wipe or dust any spills or washing

compounds with a damp cloth. D_Ter control

panel and finishes may be damaged by some

laun& T pretreatment soil and stain remover

products. Apply these products away from the

duer. The fabric may then be washed and dried

normally. Damage to your dlTer caused by these

products is not covered by your warranty.

The LintFilter: Clean the lint filter beibre each

use. Remove by pulling straight up. Run your

fingers across the filter. A waxy build-up may form

on the lint filter from using due>added fabric

softener sheets. To remove this buil&up, wash the

lint screen in warm, soapy water. DU thoroughly

and replace. Do not operate the dtTer without the

lint filter in place.

Have a qualified technician vacuum the lint

fi'om the dtTer once a year.

TheExhaustDuct:Inspect and clean the exhaust

ducting at least once a year to prevent clogging.

A partially clogged exhaust can lengthen the

dtTing time.

Follow these steps:

Z] Turn off electrical supply by disconnecting

the plug fl'om the wall socket.

[2--]Disconnect the duct from the d_Ter.

[-_ Vacuum the duct with the hose attachment

and reconnect the duct.

TheExhaustHood:Check with a mirror that the

inside flaps of the hood move freely when

operating. Make sure that there is not wildlife

(birds, insects, etc.) nesting inside the duct or

hood.

8

Page 9

FabricCareLabels

WASH LABELS

www.GEAppliances.com

Machine ___

wash

cycle Normal

Water

temperature

BLEACHLABELS

Bleach

symbols

DRY LABELS

Any bleach

(when needed)

U

Permanent Press/

wrinkle resistant

000

Hot

(50°C/120°F)

Only non-chlorine bleach

(when needed)

_U

Gentle!

delicate

O0

Warm

(40°C/105°F)

A

Hand wash Do not wash Do not wring

0

Cold/cool

(30°C/85°F)

Do not bleach

Tumble

dry

Heat_GGO

setting

Special

instructions

Fq

Dry

High Medium Low

Normal Permanent Press/ Gentle/ Do not tumble dry (used with

wrinkle resistant delicate do not wash)

D

Line dry! Drip dry

hang to dry

No heat!air

Dry flat

Do not dry

Pq

Inthe shade

9

Page 10

Prepartingto installyourdryer.

Read these instructions completely and carefully.

WARNING

This dryer must be exhausted to the outdoors

using only rigid metal or flexible metal 4"

diameter ductwork tar inside the dryer cabinet

or exhausting.

• Never useplastic or othercombustibleductwork.

See Exhaustingsection.

• This appliance must be properly grounded

and installed as described in these Installation

Instructions.

• Do not install or store appliance in an area

where it _ill be exposed to water/weather.

See Location of YourOryorsection.

• The National Fuel Gas code resu'icts installations

of gasappliancesin garages. They must be 18"

(45.7 cm) off the ground and protected fl'om

vehicles by a barrier. See Location of Your Dolor

section.

• The electrical serviceto the dryer must conform

with local codes and ordinances and the latest

edition of the National Electrical Code,

ANSI/NFPA 70.

• The gasserviceto the dryer nmst confbrm with

local codes and ordinances or the latest edition

of the National Fuel (;as Code ANSI Z223.1.

The gas dryer is designed under ANSI Z 21.5.1

fbr homeuse only.This d_Ter is not

recommended for commercial applications

such as restaurants or beauty salons, etc.

ToolsandMaterialsRequiredforDryerInstallation

• Phillips head screwdriver

• Channel-lock adjustable pliers

• Carpenter's level

• Flat or su'aight blade screwdriver

• Duct tape

• Rigid or flexible metal 4" (10.2cm) duct

• Vent hood

• Pipe thread sealer (GAS DRYER)

• Plastic knife

• 1/2" open-end wrench

10

UnpackingtheDryer

_] Using the tour shipping carton corner posts

(two on each side), careflflly lay the dryer on

its letY side and remove foam shipping pad.

CAUTION:To prevent damage, do not use

the control panel as a means to pick up or

move the dryer.

[2-_Return the dtTer to an upright position.

I-j] Adjust the leveling legs to match the washer

height. The dxTer must be level and rest firmly

on all four leveling legs.

Page 11

Electrical requirements.

Read these instructions completely and carefully.

ElectricalConnectionInformationforElectricDryers

WARNING--To reduce the risk of fire,

elecu'ic shock, or personal injm7:

• DONOT USEAN EXTENSIONCORDWITH THIS

APPLIANCE.

• THISAPPLIANCEMUSTBE PROPERLYGROUNDED.

Thisdryermustbe electrically groundedin

accordance with local codesandordinances,or in

the absenceof local codes,inaccordancewith the

NATIONALELECTRICALCODE,ANSI/NFPANO.70.

Electrical Requirements

• This dxyer must be connected to an individual

branch circuit, protected by the required time-

delay fllses or circuit breakers. 208V or 240V

installation 30 amps.

• Use copper conductors only.

• If the electric supply does not meet the above

specifications, call a licensed electrician.

NOTE:A wiring diagram is located inside the

control panel.

ElectricalConnectionInformationfor GasDryers

WARNING--To reduce tile risk of fire,

electric shock, or personal injmy:

• DONOT USEAN EXTENSIONCORDORAN

ADAPTERPLUGWITH THISAPPLIANCE.

• DONOT UNDERANYCIRCUMSTANCES,CUTOR

REMOVETHETHIRDGROUNDINGPRONGFROM

THEPOWERCORD.

Thisdryermustbe electrically groundedin

accordance with local codesandordinances,or in

theabsenceof localcodes, in accordancewith the

NATIONALELECTRICALCODE,ANSI/NFPANO.70.

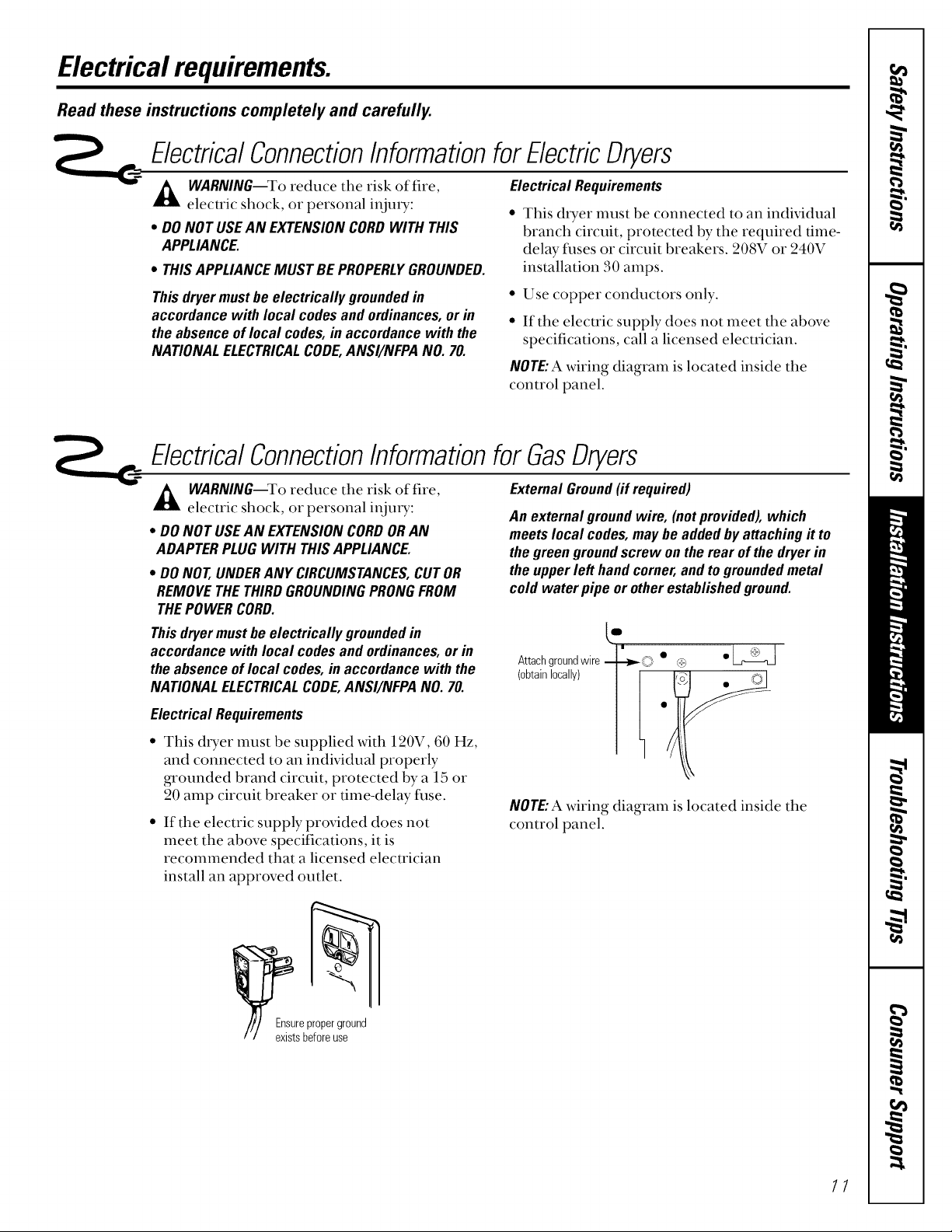

ExternalGround(ifrequired)

An externalgroundwire, (notprovided),which

meetslocal codes,maybe addedby attachingit to

thegreen groundscrew onthe rear of thedryer in

theupperleft handcorner,and togroundedmetal

cold water pipe or otherestablished ground.

Attachgroundwire ,v _+)

........................

Electrical Requirements

This dUeT must be supplied with 120V, 60 Hz,

and connected to an individual properly

grounded brand circuit, protected by a 15 or

20 amp circuit breaker or time-delay fuse.

If the electric supply provided does not

meet the above specifications, it is

recommended that a licensed elecu'ician

install an approved outlet.

Io to, oc l]

NOTE:A wiring diagram is located inside the

control panel.

11

Page 12

Exhausingthedryer.

Read these instructions completely and carefully.

ExhaustSystemRequirements

Useonly4" (10.2cm)diameter(minimum)rigidmetal A

ductforbestperformance,orflexiblemetalduct.Use

approved vent 11oo(!which has swing-out dampers

that open when the dryer is in operation. _qmn the

dryer stops, the dampers automatically close to

prevent drafLs and the entrance of insects and

rodents. To avoid restricting the outlet, maintain a A

mininmm of 12" (. 0.a cm) clearance between the

vent hood and the ,ground or any other obsmmtion.

If all rigid metal duct cannot be used, then flexible

all-metal venting can be used, but it _411reduce the

maximum recommended duct length. See Additional

InstallationInstructionsfollowing.

Do_ Don't

3 -

Correct

Incorrect

ThedryerexhaustsystemMUSTBEEXHAUSTED

AHt

TOTHEOUTSIDEofthedwelling.

DONOTallow combustible materials (for example:

clothing, draperies/curtains, paper) to come in

contact Mth exhaust system.

ThedryerMUSTNOTbeexhaustedintoagasvent,

chimney,a wall, a ceiling,acommonductwith a

kitchenexhaustoranyconcealedspaceofa

buildingwhichcanaccumulatelint,resultingin

a firehazard.

DONOTexceed die lengdl of duct pipe or

A

number of elbows allowed in the MaximumLength

charts. Lint can accumulate in the exhaust

system, plugging the system and creating a fire

hazard, aswell as increasing &)4ng times.

DONOTscreen the exhaust ends of the vent

A

sysmm, nor use aW screws or rivets to assemble

the exhaust system. Lint can become caught in

the screen, on the screws or rivets, clogging the

duct work and creating a fire hazard aswell as

increasing chTing tilnes. Use an approved vent

hood to terminate the duct outdoors, and seal

alljoints with duct tape. All male duct pipe

fittings MUSTbe installed do_lsu'emn with

the flow of air.

12

WARNING:Thefollowingarespecificrequirements

forproperandsafeoperationofyour dryer.Failure

to followtheseinstructionscancreateexcessive

dryingtimes andfirehazards.

DONOTuseplastic flexible duct toexhaust the

dryer.Excessivelintcanbuildupinsideexhaust

systemandcreateafirehazardandrestrictair

flow.Restrictedairflow will increasedryingtimes.

ffFourpresentsystemismadeupofplasticductor

metalfoilduct,replaceitwith rigidorflexible

metalduct.Ensurethepresentductisfreeofany

lintpriortoinstallingdryerduct.

Additional Installation Instructions

If all rigid metal duct cannot be used, then flexible

all-metal venting can be used, but it will reduce the

m>Lximum recommended duct length. In special

installations when it is impossible to make a

connection with the above recommendations, then

UL-listedclothes dryertransitionductmay be used as

mmsition venting between the &yer and wall

connection only. The use of this ducting will affect

&Ting time.

Ifflexibletransitionductisnecessary,onlyUL-listedduct

identifiedforusewith clothesdryersisapproved.

EXPLOSIONHAZARD.Do not install the dtTer

A

where gasoline or odmr flammables are kept

or stored. If the dryer is installed in a garage,

it must be a minimum of 18" (45.7 cm) above

the floor. Failure to do so can result in death,

explosion, fire or bums.

_ rovide an access for inspection and cleaning of

the exhaust system, especially at turns. Inspect

and clean at least once per year.

Do not obsu'uct incoming or exhausted air.

Thefollowingdirectionsmustbe followed.

• Use the shortest length possible.

• Su'etch the duct to its maximum length.

• Do not crash or collapse.

• Never use u'ansition duct inside the wall, flooring,

ceiling or inside the dryer.

• Avoid resting the duct on sharp objects.

• Venting must conibmi to local building codes.

Page 13

Installingthedryer.

Exhaust Ducting Length

The exhaust system should be inspected and cleaned

at least once a year _dth nomml usage. The more the

dUeT is used, the more often you should check the

exhaust system and vent hood for proper operation.

Kroofvents or louvered plenums are used, they must

be equivalent to a 4" dampered wall cap in regard to

resistance to aid]ow, prevention of back drafts and

maintenance required to prevent clogging.

MAXIMUM LENGTH of 4" 110.2cm)Dia. RIGIDMETALDUCT

PREFERREDVENTHOODTYPE

4" 110.2cm) Louvered

• DONOTassemble the duct work with fksteners that

extend into the duct. They will serve as collection

points for lint.

• Ductworkwhich rims through an unheated area or

is near an air conditioning duct should be insulated

to reduce condensation and lint build-up.

MAXIMUM LENGTHof4" 110.2cm)Dia.FLEXIBLEMETALDUCT

PREFERREDVENTHOODTYPE

4" (102 cm) Louvered

Number of

90°turns

0 60' !10.28m)

1 52' (15.04m)

2 44' (13.41m) (9.75m)

3 32' (9.75m) (7.31m)

4 20' (0.53m) (4.87 m)

48' (14.63m)

40' (12.19m)

32'

24'

16'

INSTALL MALE FITTINGSIN

CORRECTDIRECTION

ExhaustDirection

All dryers shipped fi'om fl_efactory are set up for

rear exhausting. However, on ELECTRICDRYERS,

exhausting can be on the right or left side of the

cabinet or the bottom of the dryer. On GAS DRYERS,

exhausting can be on the right side of the cabinet or

the bottom of the dUeT. Directional exhausting can

be accomplished by installing Exhaust Kit, Pub.

No. 14-A018, available through your parts distributor.

Follow the instructions supplied _4th the kit.

Use only rigid metal ducting inside the dryer cabinet.

0

1

2

3 notrecommended

/ Same as EXHAUST DUCT LOCATING

| It" other side DIMENSIONS

(I,_ 5-7/8"

L (15cm) 4-3/8"

3-3/4"(9.5cm)t

30"!9.14m)

22' !6.71m)

14' (4.27m)

_/' 3-I/2" cm)

(34cm)

10' (5.49 m)

14' t4.27m)

10' (3.05m)

gas SupplyRequirements

A Replace brass connecting pipe that is not

plastic-coated. Stainless steel or plastic-coated

brass MUSTbeused.

WARNING:Never reuse old flexible connectors.

The use of old flexible connectors can cm_segas

leaks and personal injury. Alwa}_use NEWflexible

connectors when installing a gas appliance.

Installation MUSTconibrm _dth local codes, or

in the absence of local codes, with the National

Fuel Gas Code, ANSI Z223.1 (latest edition).

The gas supply line should be of 1/2" 11.27 cm)

rigid pipe.

If codes allow, flexible metal tubing may be used

to connectyour dryer to the gas supply line. The

tubing MUSTbeconsu'ucted of stainless steel or

pla_stic-coated brass.

V_]The gas supply line MUSThave an indMdual

shut_ffvalve.

[_-]A 1/8" (0.32 cm) NPT minimum plugged

tapping, accessible for test gauge con_'lection,

MUSTbe installed immediately upstream of the

ga_ssuppb_ connection to the dryer.

V6-]The dryer and its indMdual shutoffvah;e MUST

be disconnected fi'om the gas supply piping

system during aW pressure testing of the gas

supply piping system at test pressures in excess

of 1/2 psig (3.45 kPa).

V_The dryer MUSTbe isolated from the gas supply

piping system by closing its indMdual manual

shutoffvalve during any pressure testing of the

gas supply piping system at test pressures

equal to or less than 1/2 psig (3.45 kPa). 13

Page 14

Installingthedryer.

Read these instructions completely and carefully.

Locationof YourDryer

Do Not Install the Dryer:

p] Donot installthe dryerin an area exposed to

dripping water or outside weather conditions.

]Do not install the &yorin an area where it _s411

come in contact _s4thcurtains, drapes, or

anything that will obstruct the flow of

combustion and ventilation air.

Installation in Recess or Closet

[] ThisdryerMUSTbeexhaustedoutdoors.

f_ No other fuel burning appliance shall be

installed in the same closet as the GAS DRYER.

_] Your dryer needs the space around it for proper

ventilation. DONOTINSTALLYOURDRYERINA

CLOSETWITHASOLIDDOOR

f-_A minimum of 120 square inches (774.2 square

cm) of opening, equally dMded at the top and

bottom of the door, is required. Air openings are

required to be unobstructed when a door is

installed. A louvered door with equivalent air

openings for the fifll length of the door is

acceptable.

[] Do not install the dryer on cmpet.

Floor MUSTbe solid with a maximum slope

of 1" (_2.54cm).

Allow the followingclearancesfor easeofinstallation:

FRONT SIDES REAR TOP

Alcove O(Ocm) O(Ocm) O(Ocm) 15"(38.1cm)

Closet 1"(2.54cm) 0 (0cm) 0(0cm) 15"(38.1cm)

Closet door ventilation required: 2 louvered

openings each 60 square inches (387.1 square cm)

-3" (7.6 cm) fl'om bottom and mp of door.

0

!

|

|

Closetdoor

I

J

!

60 sq. in.

(387.1sq.cm)

sq. in.

(387.1sq.cm)

15"

(38.1cm)

1

0"(0cm)

14

Page 15

Mobile Home Installation

Fff]D1Ter MUSTbe exhausted outside (outdoors, not

beneath the mobile home) using metal ducting

that _411not support combustion. Metal ducting

nmst be 4" (10.16 cm) in dimneter xdth no

obsu'uctions. Rigid metal duct is preferred.

_-_ Ifdxyer is exhausted through the floor, the

exhaust system MUSTNOT'terminate beneath the

mobile home. Termination MUSTbe securely

fastened to the mobile home su'ucture.

f-_ %t_en installing a dxyer into a mobile home,

a provision mt_st be made tbr outside make-up

air. Provide an opening _4th a flee area of at least

25 square inches for inu'oduction of outside air

into the dxyer room.

[-_Gas duets MUSTbe fastened to the floor

using Mobile Home Installation Kit

Pub. No. 14-D346-33.

f_See the ExhaustSystemRequirementssection for

other important venting information.

_-] Installation MUSTconfbrm to current

Manufactured Home Construction & Safeb"

Standard (which is a Federal Regulation Title

24 CFR--Part 32-80) or, when such standard is

not applicable, with American National Standard

fbr Mobile Homes, ANSI/NFPA No. 50lB.

Correct

Incorrect

Don't

Thedryer isdesignedunderANSIZ21.5.1for HOME

USEonly.

flough-lnDimensions

_-_ 267/8" --_,

-- (68.3cm)

471/2"

1

[_ Dooropen

[3-- Electricalconnection

29/16'1_,.

(6.5 cm) I

131/2" -_1

(34.4cm)/

! ©

n-

"_ L._.. 3/8"(O.96cm) Dia.

3 3/4" gaspipe

(9.5cm)

REARVIEW SIDEVIEW

Servicing - Considerationmustbegiven to provide adequate clearances for installation and servicing.

435/8"

(110.7cm)

36"

(91.5cm)

L !

f

1" (2.54cm)

90°

l°

43/8"

(11.1cm)""_!

Optional------_ "

ventknockout .

27" ,_

(68.6cm)

1

m

1

33/4"

(9.5 cm)

CAUTION:Label all wires prior to disconnection when se_icin_ conu'ols. _ iring errors can cause

improper and dangerous operation (verify proper operation after self,icing/installation).

15

Page 16

Installingthedryer.

Read these instructions completely and carefully.

ElectricalInstallationforElectricDryers

A WARNING:Tile fbllo_4ng are specific A WARNING:AUL-approved su'ain relief must be

requirements far proper and safe electrical

installation of your dtTer. Failure to follow

these instructions can create electrical shock

and/or a fire hazard.

A

WARNING: This appliance MUSTbe properly

grounded. Electrical shock can resuh if the

dlyer is not properly grounded. Follow tile

instructions in this manual for proper

grounding.

A

WARNING:DONOTuse an extension cord _dth

this dpyer. Some extension cords are not

designed to _dthstand tile amounts of

electrical current this &yet" utilizes and carl

meh, creating elecuical shock and/or fire

hazard. Locate the duer within reach of the

wall outlet, taking into account the length

of power cord to be purchased and allowing

some slack in the cord. Refer to Electrical

Requirements in this manual for the proper

power cord to be purchased.

installed onto power cord. If the strain relief is

not attached, tile cord can be pulled out of the

dpyer and can be cut by any movement of the

cord, resulting in electrical shock.

A WARNIN& Usecopperreceptaclesonly.

NOTE:Dlyers operating on 208-voh power supply will

have longer d*ying times than those operating on

240-voh power supply.

A wiring diagram is located inside fire conu'ol panel.

Grounding Requirements

A DANGER:Improperconnectionofthe

equipment-_'ounding conductor can result in a risk

of electric shock. Check with a licensed elecu'ician if

you are in doubt a_sto whether the appliance is

properly grounded.

Grounding must be in accordance with local codes

and ordinances, or in the absence of local codes, in

accordance _4th the National Elecuical Code

ANSI/NFPA No. 70.

Foragrounded,cord-connectedelectricdryer:

I-]]Tile &yer MUSTbe grounded. In the event of

a malfimction or breakdown, _'ounding will

reduce the risk of electrical shock by creating

a path of least resistance fbr electrical current.

[_ If your duer is equipped with a power supply

cord having an equipment-_'ounding conductor

and a grounding plug, tile plug MUSTbe plugged

into an appropriate, copper-wired receptacle that

is properly installed and grounded in accordance

with all local codes and ordinances. Ifin doubt, call

a licensedelectrician.

Forapermanently-connectedelectricdryer:

• The &Ter MUSTbe connected to a grounded

metal, permanent wMng system; or an equipment-

grounding conductor must be run _4th the circuit

conductors and connected to the equipment-

grounding terminal or lead on the appliance.

Foracord-connectedgasdryer:

• This &Ter is equipped with a three-prong

(grounding) plug for your protection against

shock hazard and should be plugged directly into

a properly grounded three-prong receptacle.

Do not cut or remove the grounding prong fl'om

this plug.

16

Page 17

3-Wire System for Electric Dryers-DO NOT use for Mobile Home Installations

_] Remove the screws securing the temfinal block

access cover and the strain relief mounting

bracket located on the back of the duer

upper corner.

[2-_Install a UL-approved su'ain relief into the power

cord entry"hole of the mounting bracket. Use

a su'ain relief which attaches to the mounting

bracket with a nut. Finger-tighten the nut only

at this time.

Vj] Thread a UL-approved 30A, 240V, 3 #10 AWG

minimum copper conductor power cord through

the strain relief.

Green gl

Green neutral

gr°undwire _//__ _/"(\Nu_

Use copper Strain elief Po_wercord

Silverterminal

_/'/"'%lighten nut to

thesethreads

conductorsonly. mountingbracket

V_ Attach the power cord neuu'al (center _4re)

conductor to the silver-colored center terminal

on the terminal block. Tighten the screw

securely.

_] Attach the remaining two power cord outer

conductors to the ol{ter brass-colored temnnals

on the terminal block. Tighten both screws

securely.

WARIVING:Donot make a sharp bend or crimp

wiring/conductor at connections.

_-] Reattach the su'ain relief mounting bracket to

the back of the dryer _4th two screws" Tighten

screws securely.

[--_Tighten the f_steners securing the cord restraint

firl'nly against the power cor&

[_ Tighten the strain relief nut securely so that the

strain relief does not turn.

V_ Reinstall the temnnal block access cover.

4-Wire System for Electric Dryers--MUST be used for Mobile Home Installations

[7] emove the screws securing the temfinal block

access cover and the strain relief mounting

bracket located on the back of tim dtTer

upper corner.

[_-]Install a UL-approved smtin relief in the enuy

hole of the mounting bracket. Use a strain relief

which attaches to the mounting bracket with a

nut. Finger-tighten the nut only at this time.

V_]Remove the green neutral _'ound _4re from

the _een _ound screw located at)ove the

temfinal block.

Typical4

conductor| | | ]

receptacle_J

Typical

4conductorcord_

Black240V

,_- Whiteneutral

_,_ Red240V

" Greenground

V_ Thread a UL-approved 30A, 240V, 4 #10 AWG

minimum copper conductor power cord fllrough

the strain relief.

_ ttach the _een power cord ground wire to the

cabinet with the _'een _'ound screw.

_-] Attach the white (neuu'al) power cord conductor

fi'om the power cord and the green ground _4re

V-_ Attach the red and black power cord conductors

to the outer bra_ss-colored terminals on the

temfinal block.

Greenground _ /

screw Silverterminal

Greenneutral _ __'_,

groundwire mJ_,_)'S/_i_ --'_'_ Black

Red!,,,,,,____['/_White / Nut lighten nutto

Powercord/ _ [nounting[_)_ "_

Green power cord ground wire

_'__'_J_ _._Terminal block

_!_ _, _i¢'_ these threads

//..,. ,J/// Strain_._

'/'_" _ relief T .Y"/_&

bracket

WARNING:Donot make a sharp bend or crimp

wiring/conductor at the connections.

_-] Tighten the fasteners securing the cord

restraint firmly against the p[)wer cord.

_-_ Tighten the strain relief nut securely so the strain

relief does not tuna.

-0]Reinstall the terminal block access cover.

fi'om the dryer harness to the silver-colored

center terminal on the terminal block. Tighten

the screw securely.

17

Page 18

Installingthedryer.

Read these instructions completely and carefully.

GasConnectionforGasDryers

[-_ Rentove the shipping cap from gas pipe at tile

rear of tile dtTer.

NOTE:DONOTconnect tile dryer m LP gas setx_ce

without converting tile gas valve. An LP conversion

kit (Pub. No. 14-A038) MUSTbe installed bya

qualified gas technician.

[] Connect a 1/2" (1.27 cm) I.D. semi-rigid

or approved pipe from gas supply line to

the 3/8" (0.96 cm) pipe located on the back

of the dryer. Use a 1/2" to 3/8" (1.27 cmm

0.96 cm) reducer for a connection. Apply an

approved thread sealer that is resistant m the

CO1TOSiveaction of liquefied gases on all pipe

connections.

BeforeOperatingtheDryer

Connect the exhaust duct to outside exhaust

system. Use duct tape to seal all joints.

[2-_With the dryer in its final position, adjust one or

more of the legs until tim dryer is resting solidly

on all fbur legs. Place a level on top of the dryer.

THEDRYERMUSTBELEVELANDRESTING

SOLIDLYONALLFOURLEGS.Turn tile lock nuts

on each of the fbur legs up toward tile base of the

dryer and snug with a 1/2" open-end _u'ench.

I-j] Plug the power cord into a grounded oudet.

NOTE:Cl{eck to ensure the })ower is offat circuit

breaker/fuse box befbre plugging the power

cord into tile outlet.

[_ Turn on the at the circuit breaker/

fuse box.

power

I-j] Open the shutoffvalve in the gas supply line.

[-_ Test all connections by brushing on a soapy water

solution.

CAUTION:NEVERTESTFORGASLEAKSWITH

AN OPENFLAME.

NOTE:On gas dryers, before the burner will light,

it is necessary fbr the gas line to be bled of air. If

the burner does not light within 45 seconds the first

time the dryer is turned on, the safety switch will

shut the burner off. If this happens, mm the timer

m OFFandwait 5 minutes before making another

attempt m light.

CAUTION:Before operating tim dryer, make

sure the dryer area is clear and flee front

combustible materials, gasoline, and other

flmmnable vapors. Also see that nothing

(such as boxes, clothing, etc.) obstructs the

flow of combustion and ventilation air.

_-]Run the dryer through a cycle check for proper

operation.

[-6-]If your dryer does not operate, please review the

TroubleshootingTips section in this manual befbre

calling fbr set-dce.

_-] Place these instructions in a location near the

dryer for future reference.

18

Page 19

ReplacementParts

If replacement par_s are needed for your dryer,

contact the source where you purchased your duer.

CAUTION:Label all _dres prior to disconnection

A

when servicing conu'ols. Wiring errors can

cause improper and dangerous operation.

Veriff proper operation after set_"icing.

WARNING:Destroy the carton and plastic bags

A

after the dryer isunpacked. Children might use

them/or pl W. Cartons covered _"ith rags,

bedspreads or plastic sheets can become

airtight chambers causing suffocation. Place all

materials in a garbage container or make

materials inaccessible to children.

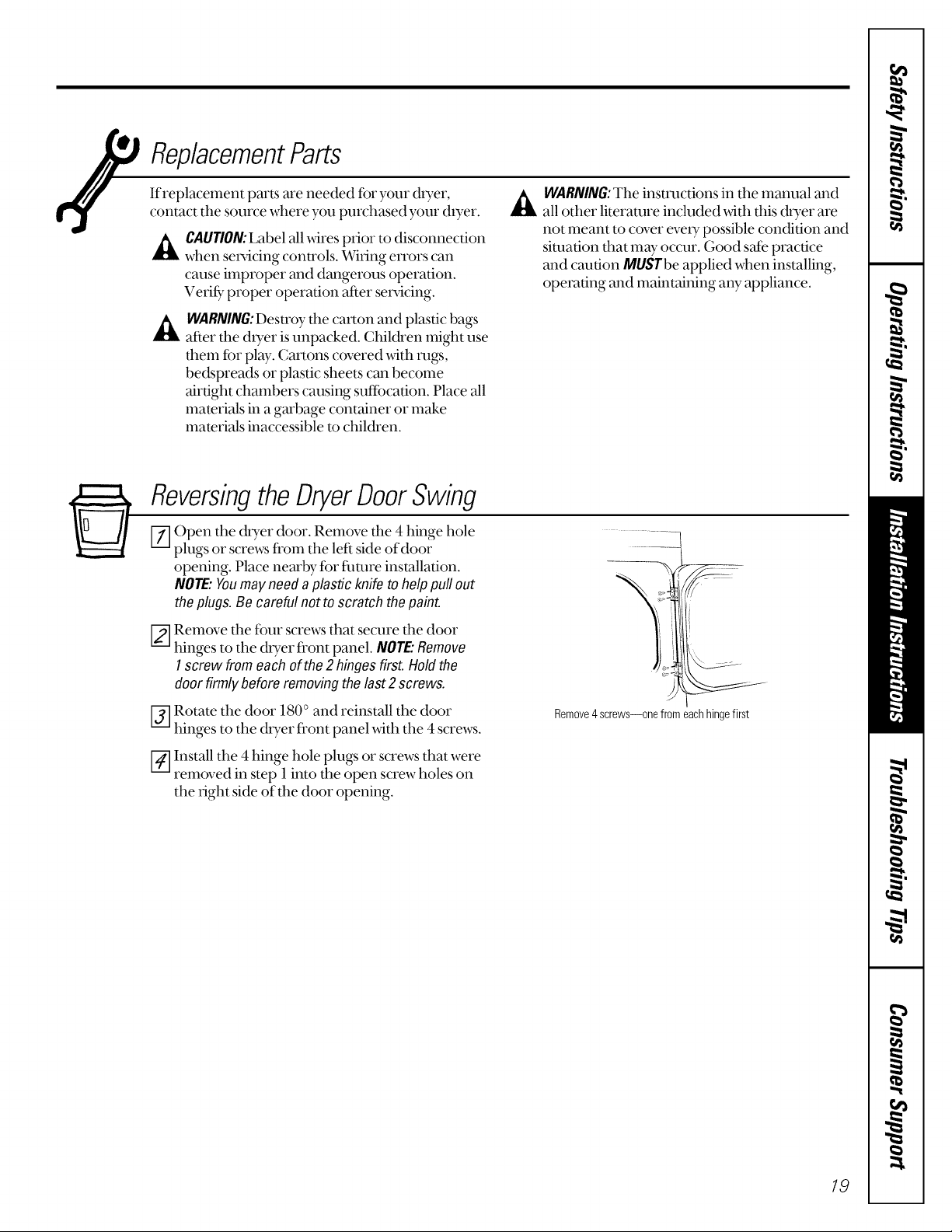

ReversingtheDryerDoorSwing

F_] Open the dryer door. Remove the 4 hinge hole

plugs or screws fl'om the left side of door

opening. Place nearby tbr filmre installation.

NOTE:Youmayneedaplastic knife to helppullout

theplugs.Be careful notto scratch the paint.

F2-]Remove the ibm" screws that secure the door

hinges to the dryer front panel. NOTE."Remove

I screw fromeach of the2 hinges first.Holdthe

door firmlybeforeremovingthelast2 screws.

,_WARNING: The instructions in the manual and

all other literature included _dth this duet are

not meant to cover eve U possible condition and

situation that may occur. Good s_e practice

and caution MUSTbe applied when installing,

operating and maintaining any appliance.

_] Rotate the door 180° and reinstall the door

hinges to the dryer front panel with the 4 screws.

[-_ Install the 4 hinge hole plugs or screws that were

removed in step 1 into the open screw holes on

the right side of the door opening.

Remove4screws--onefromeachhingefirst

19

Page 20

Beforeyoucall forservice...

Troubleshooting tips

Save time and money! Review the charts on the following

pages first and you may not need to call for service.

Problem Possible Causes What ToDo

Drier doesn'tstatt Dryer is unplugged * Make sure the chyer plug is pushed completely into

Fuse is blown/circuit breaker * Check the household Disu'ibution Panel iilse/circuit

is tripped breaker box in your home, and replace fuse or reset

Thermal limiter tripped * Call authorized service person for replacement.

Drier doesn't heat Fuse is blown/circuit breaker * Check the fuse/circuit breaker box in yore" home, and

is tripped, the dryer may replace iilse or reset breaker.

tumble but not heat

Gas service is off * Make sure gas shutoffat &yer and main shutoffare

There are 2 fuses in the • Replace ihse.

household Distribution Panel

for the dryer circuit. If 1 of the

2 fuses in the household

Distribution Panel is blown,

the drum may turn but the heat

will not operate

the outlet.

breaker. NOTE:Most elecu'ic dryers require your home

to use 2 fuses or a breaker.

fiflly open.

Gas supply valve is not open * Check to make sure supply valve is open.

(gas models) See InstallationInstructionsibr procedure.

Dryer does not have enough air • See Installation Instructions

supply to support the burner

flame (gas models)

LP gas supply tank is empty * Refill or replace tank. D_yer should heat when utility

or there has been a utility service is restored.

interruption of natural gas

(gas models)

Drier shakes or Some shaking/noise is normal. * Move &yer to an even floor space, or adjust leveling legs

makes noise Dryer may be sitting unevenly as necessmy until even.

Greasy spots on clothes Improper use of labile softener * Follow directions on fabric softener package.

Drying dirty items with • Use your duer to dU only clean items. Dirty"items can

clean ones stain clean items and the duet.

Clothes were not * Sometimes stains which cannot be seen when the clothes

completely clean are wet appear after duing. Use proper washing

procedures before drying.

Linton clothes Lint filter is full • Clean lint screen before each load.

Improper sorting * Sort lint producers (like chenille) from lint collectors

(like corduroy).

Static electricity can attract lint • See suggestions in this section under STATIC.

Overloading • Sepatvtte large loads into smaller ones.

Paper, tissue, etc. left in pockets * Empty all pockets before laundering clothes.

2O

Page 21

www.GEAppliances.com

Problem Possible Causes

Static occurs No fabric softener was used

Overdrying • T_y a iabfic soi_ener.

Synthetics, permanent press • T*y a ihbfic soi_ener.

and blends can cause static

Inconsistent Type of heat • Automatic dD_ng times will valy according to the t3qoe

drying times of heat used (elecu'ic, natural or LP ga_s), size of load,

Clothes take Improper sorting • Separate heax T items fl'om lightweight items (generally,

too long to dry a well-sorted washer load is a welbsorted &yet load).

Large loads of heavy fabrics • Large, heax T fabrics contain more moisture and take

(like beach towels) longer to dU. Separate large, heax T fabrics into smaller

Controls improperly set • Match conu'ol settings to the load you are duing.

Lint Filter is full • Clean lint filter befbre eve U load.

Improper or obstructed dueling • Check installation insu'uctions fbr proper

What ToDo

* Try a fabric softener.

• Bounce ®Fabric Conditioner Dlyer Sheets have been

approved fbr use in all GE Duers when used in

accordance _th the manufacturer's insu'uctions.

• Adjust controls for less &ying.

t}_es of fabrics, wemess of clothes and condition of

exhaust ducts.

loads to speed dly_ng time.

ducting/venting.

• Make sure ducting is clean, ii'ee of kinks and

unobstructed.

• Check to see if outside wall damper operates easily.

• Check the Installation Insu'uctions m make sure the

d*yer venting is correct.

Blown fuses or tripped • Replace filses or reset circuit breakers. Since most duets

circuit breaker use 2 ruses/breakers, make sure both are operating.

Overloading/combining loads • Do not put more than one washer load in the duer

at a time.

Underloading • If you are drying only one or two items, add a iew items

to ensure proper rambling.

Clothes are wrinkled Overdrying • Select a shorter &ying time.

• Remove items while they- still hold a slight amount of

moisture.

Letting items sit in dryer • Remove items when ©'cle ends and fold or hang

after cycle ends immediately.

Clothes shrink Some fabrics will nattwally shrink • To avoid shrinkage, itllow gammnt care labels exactly.

when washed. Others can be • Some items may be pressed back into shape after drying.

safelywashed, but will shrink

in the dryer • If you are concerned about shrinkage in a particular

item, do not machine wa_shor ramble d_yit.

27

Page 22

m

__ Notes.

m

m

w

m

m

m

1=

w

m

w

_ L

22

Page 23

GEDryer Warranty.

All warranty service provided by our Factory Service Centers,

or an authorized Customer Care®technician. Toschedule service,

on-line, 24 hours aday, vis# us at www.GEAppliances.com,

or call 800.GECARES(800.432.2737).

For The Period Of: GE Will Replace:

One}'ear

Fromthedateof the

originalpurchase

What GE Will Not Cover:

• Service trips to your home to teach you how to use the

product.

• Improper installation.

• Failure of the product if it is abused, misused, or used for

other than the intended purpose or used commercially.

This warranty is extended to the original purchaser and any succeeding owner for products purchased for home

use within the USA. In Alaska, the warranty excludes the cost of shipping or service calls to your home.

Anypartof the chyer which fails due to a defect in materials or worlananship. During this

full one-year warranty, GE will also provide, free ofcharge, all labor and in-home setx_iceto

replace the defective parc

• Replacement of house ['uses or resetting of circuit

breakers.

• Damage to the product caused by accident, fire, floods or

acts of God.

• Incidental or consequential damage caused by possible

defects with this appliance.

Staple your receipt here.

Proof of the original purchase

date is needed to obtain service

under the warranty.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state. To know what your

legal rights are, consult your local or state consumer affairs office or your state's Attorney General

Warrantor: General Electric Company.Louisville, KY 40225

23

Page 24

ConsumerSupport.

GEAppliancesWebsite wvvvv.GEAppliances.com

Have a question or need assistance with your appliance? T_y the GE Appliances Website 24 hours a day,

aW day of the year! For ,greater convenience and faster sewice, you can now download Owner's Manuals,

order parts, catalogs, or even schedule selMce on-line. You can also "Ask Our Team of Experts rv''

your questions, and so much more...

ScheduleService

Expert GE repair service is only one step mvayfrom your door. Get on-line and schedule your sewice at

your convenience 24 hours any day of the year! Or call 800.GE.CARES (800.432.2737) during normal

business hours.

RealLifeDesignStudio

GE supports the Universal Design concept-products, services and environments that can be used by

N

people of all ages, sizes and capabilities. We recognize the need to desi_l tot a wide range of physical and

mental abilities and impairments. For details of (;E's Universal Desi_l applications, including kitchen

design ideas tot people with disabilities, check out our Website today. For the hearing impaired, please call

800.TDD.GEAC (800.833.4322).

ExtendedWarranties

Purchase a GE extended warranty and learn about special discounts that are mTailablewhile your wan'an_ _

is still in effect. You can purchase it on-line anytime, or call 800.626.2224 during normal business hours.

GE Consumer Home Smvices will still be there after your wan'anty expires.

PartsandAccessories

wvvvv.GEAppliances.com

wvvvv.GEAppliances.com

wvvvv.GEAppliances.com

wvvvv.GEAppliances.com

IndMduals qualified to sets,ice their own appliances can have parts or accessories sent directly to their homes

(VISA, MasterCard and Discover cards are accepted). Order on-line today, 24 hours every day or by phone at

800.626.2002 during nomml business hours.

Instructionscontainedinthismanualcoverprocedurestobe performedbyanyuser.Otherservicing generally

shouldbe referredto qualifiedservicepersonnelCautionmustbeexercised,sinceimproperservicingmaycause

unsafeoperation.

ContactUs

Ifyou are not satisfied _4th the service you receive front GE, contact us on our Website with all the details

including your phone number, or write to: General Manager, Customer Relations

GE Appliances, Appliance Park

Louisville, KY 40225

vvvvvv.GEAppliances.com

RegisterYourApplbnce wvvvv.GEAppliances.com

Register your new appliance on-line--at your convenience! Timely product registration will allow for

enhanced communication and prompt set_4ce under the temps of your wan'anty, should the need arise.

You may also mail in the pre-printed regisu'ation card included in the packing material, or detach and

use the torm in this ()_mr's Manual.

Printed in the United States

Loading...

Loading...