Page 1

g

GE Consumer Service Training

TECHNICAL SERVICE GUIDE

COMMERCIAL DRYERS

Commerical Dryer

PERMAMENT PRESSPERMAMENT PRESS

SYNTHETIC KNITSSYNTHETIC KNITS

ASH

T W

HEA

COTTONS

T WITHT WITH

HIGH HEAHIGH HEA

COOL DOWN CYCLECOOL DOWN CYCLE

T

LOW HEALOW HEA

RESUME HEARESUME HEA

ART

PRESS TO STPRESS TO ST

TINGTING

OPERA

Add coins for extra dry time.Add coins for extra dry time.

1.

If dryer door is opened duringIf dryer door is opened during

2.

ART

cycle, push PRESS TO STcycle, push PRESS TO ST

button again to resume cycle.button again to resume cycle.

T

MODEL SERIES:

DCB330EY (Electric)

DCD330EY

DCB330GY (Gas)

DCD330GY

PUB # 31-9041 12/99

Page 2

Table of Contents

Model Series Features

Countdown (DCD Models)

Dimensions/Rating Plate

Installation Highlights

Top Panel/Front Panel

Lower Drum Seal

Drum Removal

Drum Shaft and Bearing

Dryer Controls

Timer/Accumulator

Door Switch

2

3-4

5

6-7

8

9

10

10

11

11

12

Control/Bias Thermostat

High Limit/Thermal Limit

Belt Switch

Motor

Motor Removal

Motor Harness/Wiring

Wiring Diagrams

Troubleshooting Flowcharts

Exploded Views/Parts List

12

13

14

15

16

16

17-18

19-21

22-41

1

Page 3

2

Page 4

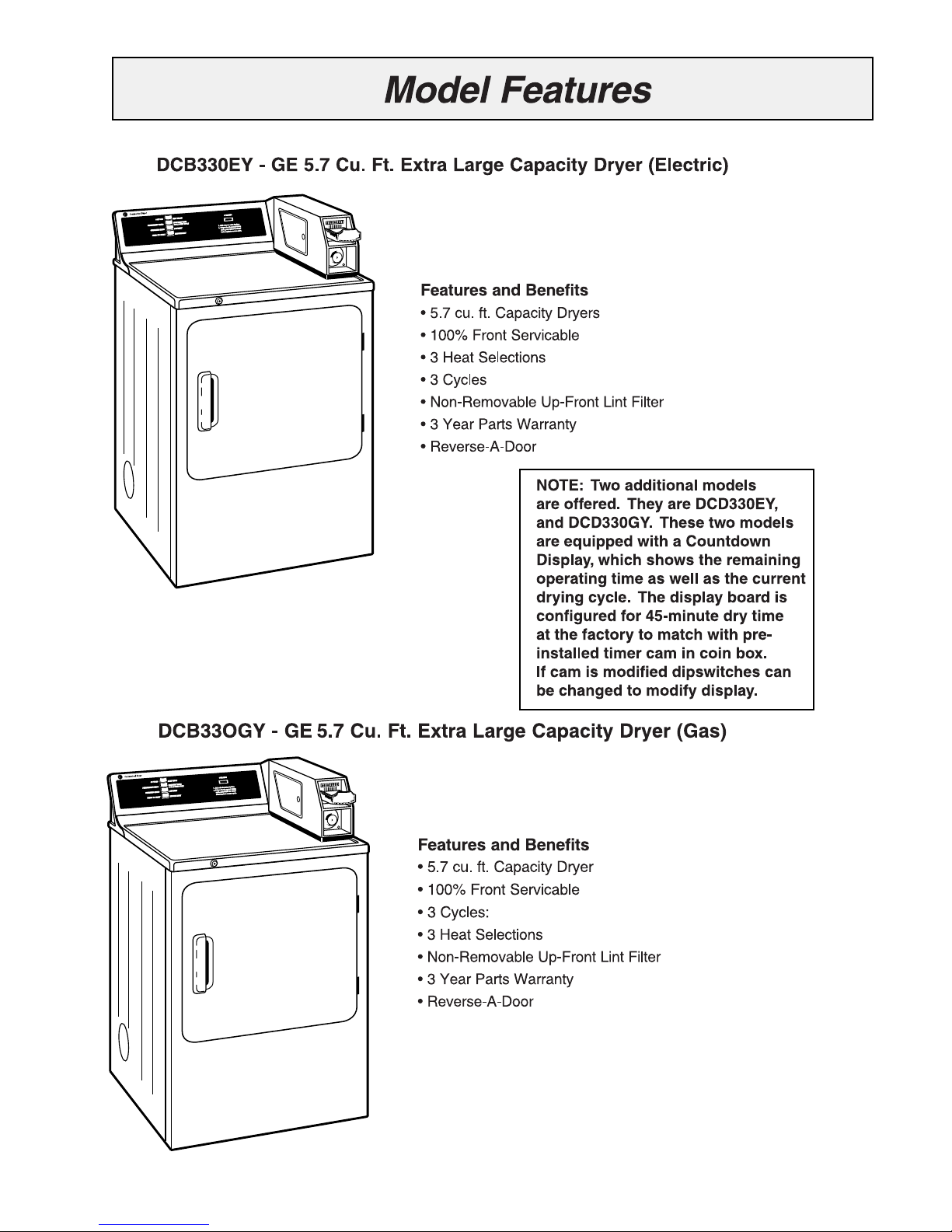

3

Page 5

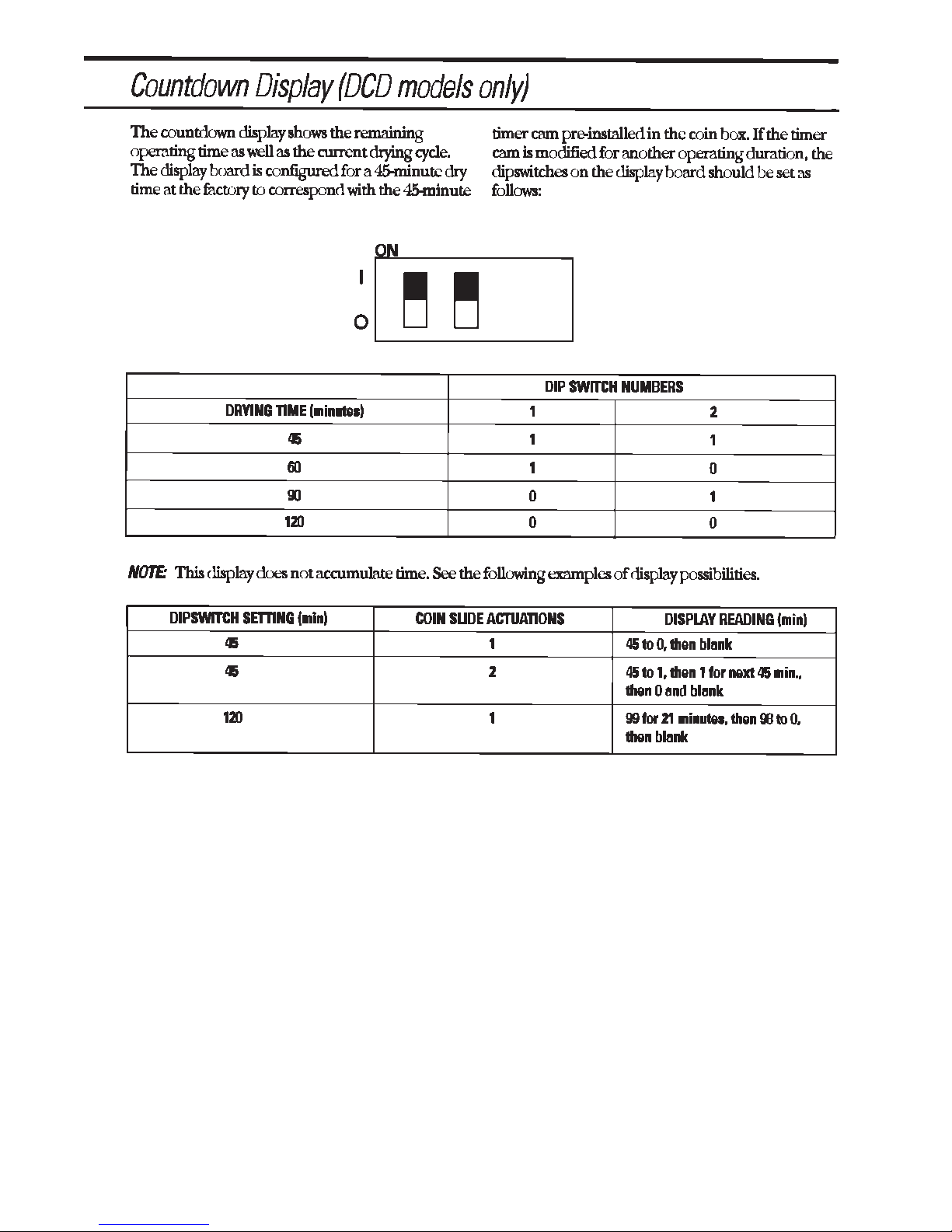

COUNTDOWN DISPLAY DIAGNOSTICS

To verify correct operation of Countdown

Display Board:

1. Make sure power is ON to dryer.

2. Advance coin box timer one cycle.

3. The display should read “88” for two to

three seconds, then default to the dip s witch

settings. (factory setting is “45”).

4. At the same time the “88” displa y is shown

the four indicator LED’s should light for 2-3

seconds. Next the “Press Start” LED will b link

and other indicator lights will go off. (if dryer

door is NOT open)

5. Replace the board if LED’s and Display

do not function as described in #3 and #4

above.

NOTE: The boar d does not control any cyc le

time duration of the dryer. The dryer will

function normally if there is a complete

failure of the board. It is the owners’

discretion whether or not the board should

be replaced.

To replace Countback Display PC Board:

WARNING! THE STEP DOWN CAPACITOR

ON PC BOARD IS 120 VOLTS, AND POWER

MUST BE REMOVED PRIOR TO SERVICING.

THE TRACES ON THE BOARD R UNNING TO

THE CAPACITOR ARE HOT!

1. Remove the four screws in the top of

the control panel.

2. Disconnect harness connector to PC

board.

3. Pull 6 tabs as shown in illustration, one

at a time, starting at connector end,

while applying slight upward pressure,

until all tabs are released. Remove

PCboard.

4. With PCboard cover exposed, lift up on

either end of cover and release the

four tabs, one at a time until the cover

is release and remove.

5. To reinstall, align the PC board cover,

and press carefully. The tabs are

beveled to make installation easy.

6. Align PC board, by inserting the

counter end under the tab in plastic

pcboard cover at the counter opening,

and moving towards the connector

end, carefully press into place, so that

each tab snaps into place. Reconnect

harness connector, and reinstall.

control panel and four screws.

4

Page 6

PERMAMENT PRESS

HIGH HEA

T WITH

COOL DOWN CYCLE

LOW HEA

RESUME HEA

1.

2.

Add coins for extra dry time.

If dryer door is opened during

cycle, push PRESS TO ST

ART

button again to resume cycle.

SYNTHETIC KNITS

PRESS TO ST

ART

OPERA

TING

COTTONS

HEA

T W

ASH

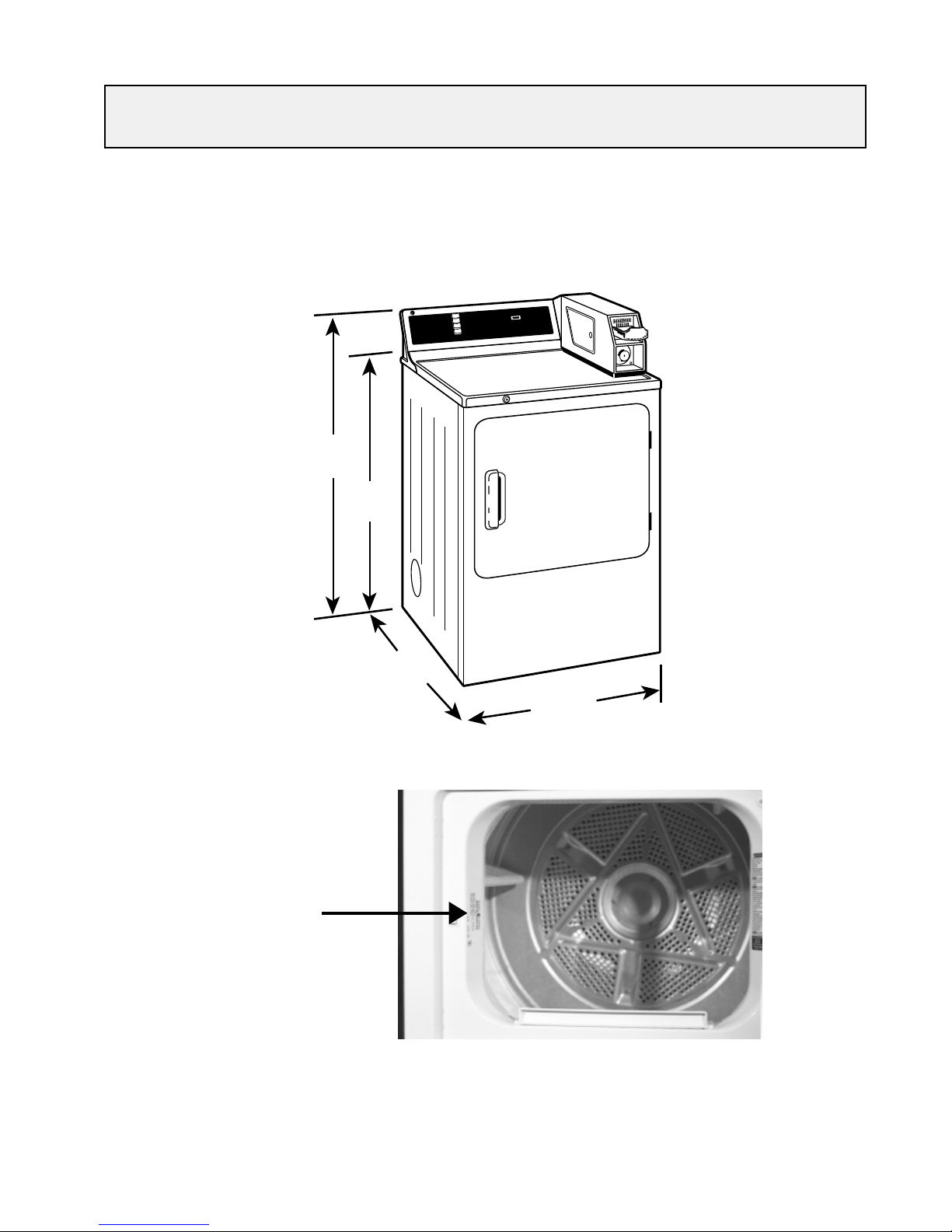

CABINET DIMENSIONS

DRYER CABINET DIMENSIONS

42"

36"

25-1/2"

Commerical Dryer

N

W

O

D

L

S

O

S

O

E

C

R

P

T

N

E

M

A

M

R

E

P

T

A

E

H

W

O

L

S

IT

N

K

C

I

T

E

H

T

N

Y

S

T

A

E

H

E

M

U

S

E

R

T

R

A

T

S

O

T

S

S

E

R

P

e.

xtra dry tim

d coins for e

Ad

.

1

ed during

pen

or is o

r do

rye

If d

.

2

T

R

A

T

O S

T

SS

RE

sh P

, pu

ycle

c

.

ycle

e c

sum

re

to

ain

ag

utton

b

¨

27"

G

TIN

ERA

P

O

H

S

A

W

T

A

E

H

S

N

O

T

T

O

C

H

IT

W

T

A

E

H

H

G

I

H

E

L

C

Y

C

Rating Plate with

Model/Serial Number

5

Page 7

6

Page 8

NOTE: When exhausting from the side or bottom, a vent kit is available as publication

#14-A018. The vent kit replaces the existing duct inside the dryer to allow a 90° elbow

to vent the dryer out the side or bottom. The kit consists of a 6 1/2” long, 4” diameter

metal duct with attached mounted bracket and instructions. A 90° elbow is not supplied

and must be provided by the installer.

7

Page 9

DRYER OPERATION

PERMAMENT PRESS

HIGH HEA

T WITH

COOL DOWN CYCLE

LOW HEA

RESUME HEA

1.

2.

Add coins for extra dry time.

If dryer door is opened during

cycle, push PRESS TO ST

ART

button again to resume cycle.

SYNTHETIC KNITS

PRESS TO ST

ART

OPERA

TING

COTTONS

HEA

T W

ASH

The dryer drum rotates clockwise at 48 – 54 rpm

as viewed from front. On electric models, air is

drawn into the heater housing and across the

open coils of the electric heater. On gas models,

air is drawn into the combustion chamber and over

the burner flame. The air is then pulled through

the tumbling clothes, picking up moisture and lint.

Lint is filtered out as air passes from the drum,

across the filter screen and into the blower duct,

where it is discharged out the vent. The bias

control thermostat, according to the setting of the

fabric selector switch, controls the air temperature.

The length of the drying cycle is controlled by the

number of minutes selected on the timer or automatically controlled by the timer, in conjunction

with the thermostat, for the type of fabric selected

(automatic dry cycles).

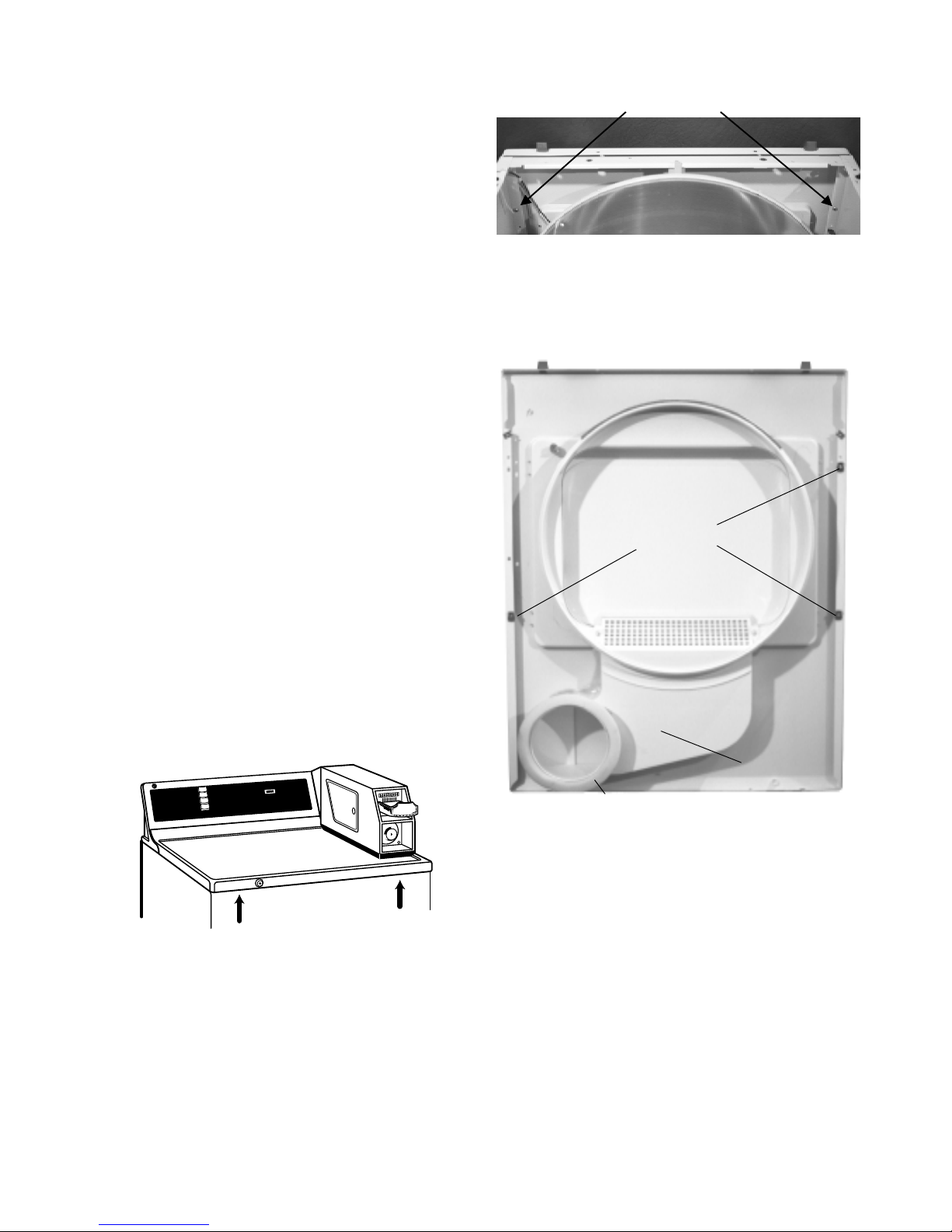

ACCESSING THE DRYER COMPONENTS

Top Panel Removal

The top panel is held in place by two spring clips

located at the front of the dryer and two tabs located

at the back. To release the clips, use a stiff putty

knife inserted between the top and front panel at

the locations shown at right. Holding the putty knif e

in a horizontal position, push in on one spring clip to

release that edge of the top. Repeat with the other

clip, lift the top at the front and disengage it from the

tabs at the rear.

2 Phillips screws

Starting at the top edge, pull the front panel forward.

3 guide clips align the front panel to the sides. Once

the clips are released, lift the front panel to remove.

Guide Clips

Commerical Dryer

H

S

A

W

T

A

E

H

S

N

O

T

T

O

C

H

IT

W

T

A

E

H

H

IG

H

E

L

C

Y

C

N

W

O

D

L

S

O

S

O

E

C

R

P

T

N

E

M

A

M

R

E

P

T

A

E

H

W

O

L

S

IT

N

K

IC

T

E

H

T

N

Y

S

T

A

E

H

E

M

U

S

E

R

T

R

A

T

S

O

T

S

S

E

R

P

G

N

I

T

A

R

E

P

O

.

e

m

i

t

y

r

d

a

r

t

x

e

r

o

f

s

n

i

o

c

d

d

A

.

1

g

n

i

r

u

d

d

e

n

e

p

o

s

i

r

o

o

d

r

e

y

r

d

f

I

.

2

T

R

A

T

S

O

T

S

S

E

R

P

h

s

u

p

,

e

l

c

y

c

.

e

l

c

y

c

e

m

u

s

e

r

o

t

n

i

a

g

a

n

o

t

t

u

b

Front Panel Removal

The remove the front panel, disconnect power and

remove the top panel. Once the top panel is off,

remove the two Phillips screws, one on each side,

located on the top inside edge of the front panel.

Disconnect the two wires from the door switch.

Air Duct

Air Duct Seal

Front Panel Air Duct

The front panel air duct is glued to the front panel.

Should the air duct need to be replaced, an air duct

seal will also be required. The foam air duct seal is

gluded to the air duct and seals between the duct

and the opening for the blo wer wheel on the blo wer

housing. To replace the air duct or install a replacement front panel, remove the front panel, remove

the lint filter, remove the 2 Phillips screws from the

lint trap cover and remov e the lint tr ap cov er . Using

a sharp knife, cut the adhesive between the air duct

and the front panel. If reinstalling the or iginal front

panel, use a putty knife to remove as much of the

old adhesive as possible. Apply adhesive along the

edge of the air duct and position it on the front panel.

8

Page 10

Apply a bead of WH60X20 adhesive on the air duct

seal and position it on the air duct. Reinstall the lint

trap cover and filter, front and top panel.

Door Gasket

The door gasket is secured to the door panel by

tabs. To replace the gasket, pull the old gasket off

the inner door panel, align the new gasket tabs with

the slots in the door and press the gasket into place.

Door Handle

The door handle is secured to the outer door panel

by tabs. To replace the door handle, remove the

door from the front panel and remove the screws

from the sides and bottom of the door. Separate

the inner and outer door panels. Release the tabs

that secure the door handle to the front panel.

Rear Access Panel

The rear access panel allows access to view the

motor, centrifugal s witch, idler pulley assembly, belt

and belt switch. The panel is secured to the back b y

two Phillips screws.

Mini Manual

Heat Deflector Shield

Drum Glide and Upper Seal

The drum glide is glued to the top outer edge of the

door opening and is a part of the felt upper drum

seal. To replace the drum glide/upper seal assembly ,

raise the top panel, remove the two Phillips screws

on the front panel and pull the front panel towards

you. Remove the old seal assembly and glue the

new seal in place using WH60X20 adhesive.

Reinstall the front and the top panels.

Drum Glide and Upper Seal

Rear Access Panel

NOTE: Located on the rear of the dryer is a heat

deflector shield. The purpose of the shield is to

prevent someone from coming in contact with the

hot part of the cabinet near the heater. If y ou remove

the shield for any reason, make cer tain to reinstall

the shield upon dryer reassembly.

Lower Drum Seal

The lower drum seal is glued in place around the

outer lower edge of the door opening on the front

panel. To replace the lower seal, remove the top

panel and the front panel. Remo ve the old seal and

glue a new seal in place. Reinstall the front and top

panels.

9

Page 11

Dryer Drum Removal

Drum Bearing

To remove the dryer drum, disconnect power and

remove the top and front panels. Next, remove the

yellow spacer/bumper attached to the top cross

brace by a Phillips screw.

Drum Spacer/Bumper

Remove the drive belt from the motor drive pulley

by reaching under the drum from the front or through

the rear access opening. Once the belt is loose , the

drum must be lifted

straight up to disengage

the drum shaft from the

drum bearing. Once the

shaft ball is above the

drum bearing cup, pull the

drum forward through the

cabinet opening.

The drum bearing mounts to the inside rear of the

dryer cabinet by means of a sheet metal bracket

secured by two 5/16” screws. To replace, remove

the two screws holding the bearing to the back of

the dryer. Note: A small steel ball is used to provide

a grounding path. Make certain the steel ball is

installed during reassembly. Thoroughly lubricate

the new bearing with lithium grease and reassemble.

Drum Shaft

The drum shaft is attached to the drum by three

Torx screws. To replace the dr um shaft, align the

mounting holes and use a piece of tape to hold the

shaft in place while installing the Torx screws from

inside the drum. Thoroughly lubricate the shaft ball

with Lubriplate or a high quality lithium grease.

Drum V anes

All three dryer drum vanes are replaceable. Each

vane is attached to the drum by two Phillips screws.

NOTE: If necessary , the drum shaft and bearing are

available as a kit under the part# WE25X10001. The

kit contains the drum shaft, shaft bearing, mounting

brackets , a steel ball, screws and a tube of Lubriplate,

a high quality lithium grease.

10

Page 12

Dryer Controls

PERMAMENT PRESS

HIGH HEA

T WITH

COOL DOWN CYCLE

LOW HEA

RESUME HEA

1.

2.

Add coins for extra dry time.

If dryer door is opened during

cycle, push PRESS TO ST

ART

button again to resume cycle.

SYNTHETIC KNITS

PRESS TO ST

ART

OPERA

TING

COTTONS

HEA

T W

ASH

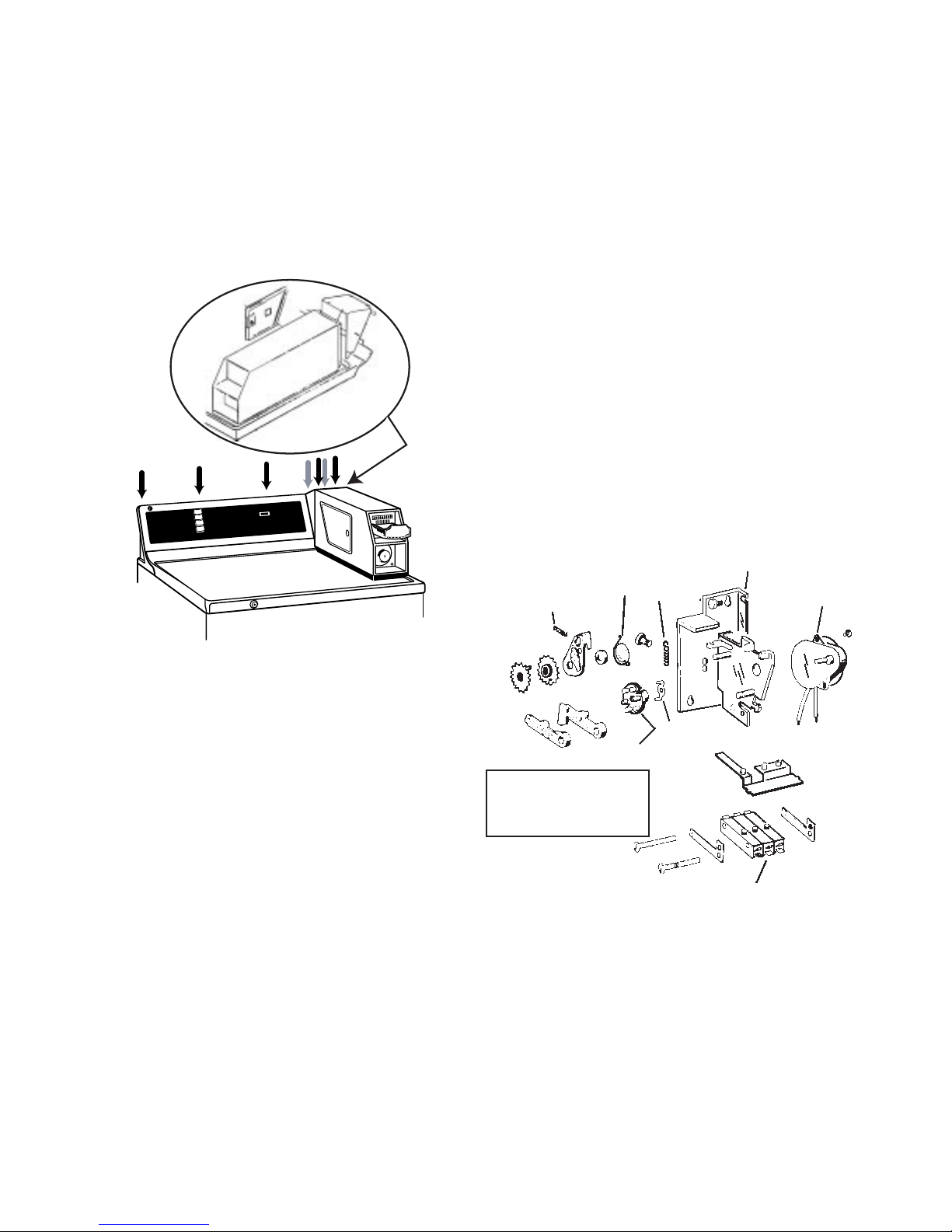

To access the dryer controls, disconnect power and

remove the four Phillips screws at the top of the

switch trim, remove the screws and the switch trim

adapter (shown in illustration below). Grasp the trim

at the top and pull forward. Three tabs at the bottom

fit into slots on the top panel.

Commerical Dryer

H

AS

T W

HEA

S

TTON

CO

ITH

T W

EA

H H

HIG

YCLE

N C

OL DOW

CO

RESS

T P

EN

AM

PERM

T

HEA

LOW

ITS

THETIC KN

SYN

T

E HEA

UM

RES

ART

TO ST

RESS

P

TING

PERA

O

.

dry time

oins for extra

dd c

A

.

1

r door is opened during

If drye

.

2

ART

T

S

S TO

ES

cycle, push PR

le.

e cyc

gain to resum

button a

Timer

The timer is an electromechanical control with a 115v

drive motor. On a timed cycle, the timer motor

receives 115 volts continuously for the number of

minutes selected for the cycle. The timer/

accumulator assembly consist of a mounting brac ket,

timing motor, snap s witch, timing cam, drive (timing

cams) coil spring(pawl), torsion spring (rachet asm),

amd coil spring (index lever). The timing motor is

115V-60HZ, and runs at 1/180 R.P.M. It is shipped

from the factory with a 45 minute cycle time. This

can be changed by ordering a different motor.

(specify voltage, frequency, and speed.) from

Greenwald Industries. See sample par ts catalog

pages for timer section for full address.

Timer/Accumulator

Torsion Spring

(Ratchet Asm)

Coil Spring

(pawl)

Coil

Spring

(IndexLever)

Mounting

Bracket

Timing Motor

Temperature Selector Switch

The temperature selector switch, allows the

customer to select different temperature settings f or

drying. The switch contains a 3K ohm resistor on

the electric model and a 2.4K ohm resistor on the

gas model. On the “Medium” setting, the selector

switch activates a control thermostat bias heater,

which is in series with the resistor on the switch. To

check the switch, disconnect power, remove the

wires from the switch and check f or continuity. With

the switch set on

“Regular” setting, there

should be continuity

only between terminals

1 and 2. On the

“Medium” setting, there

should be continuity

only between terminals

3 and 4. On a “Fluff ”

setting, there should be no continuity between either

set of terminals.

Timing Cam

Greenwald Industries, Inc.

1340 Metropolitan AVe.,

Brooklyn, N.Y 11237

Phone 1-800-221-0982

Drive

(Timing Cams)

Enclosed Snap

Switch

11

Page 13

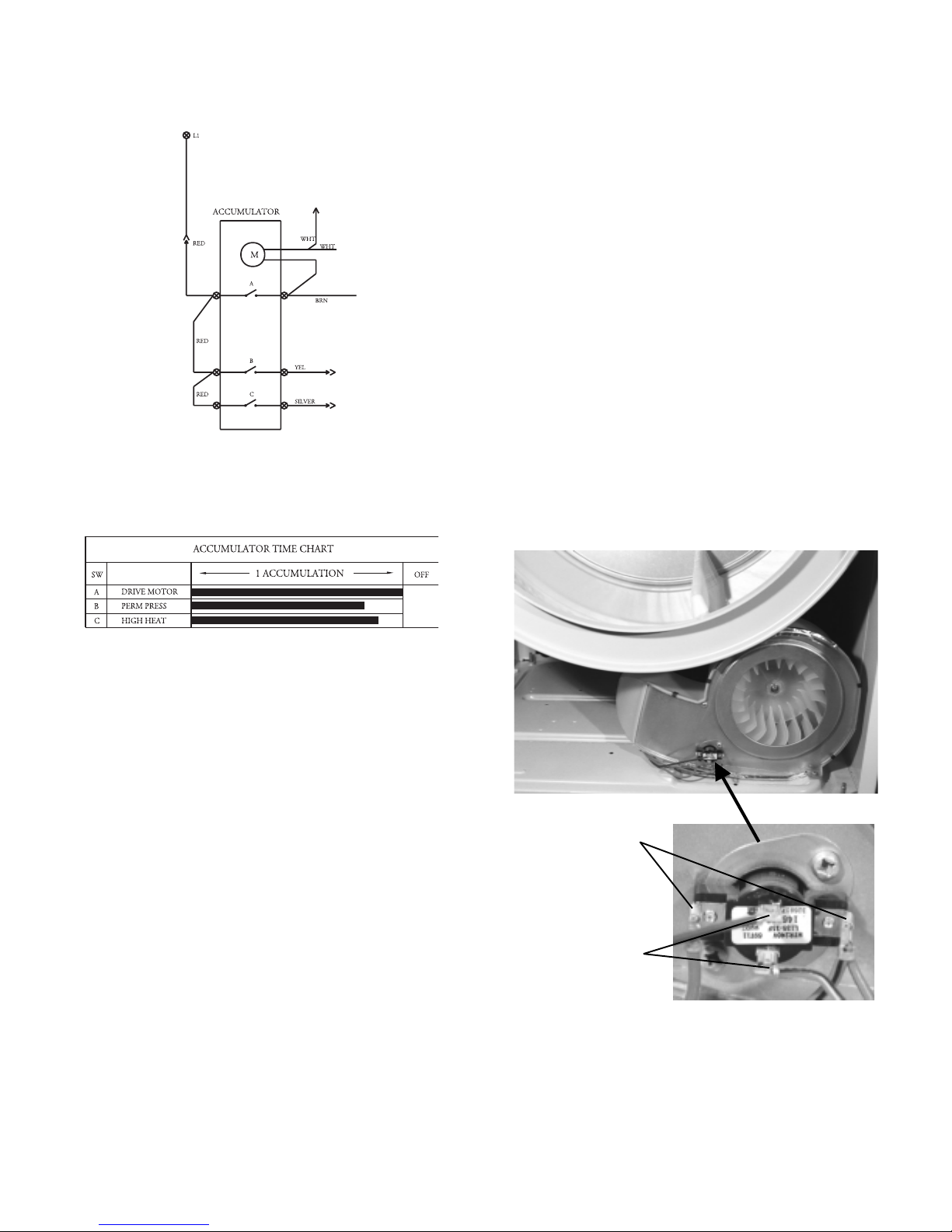

Schematic Detail of Timer/Accumulator

Door Switch

The door switch is a normally open switch wired in

series with the drive motor. When the door is closed

and the motor running, a circuit is completed through

the motor’s run winding. To test the switch, remove

the top panel and wires from the switch. When the

door is closed, the switch should read continuity.

When the door is open, the switch should read open.

To replace the switch, squeeze the retaining clips

together and pull the switch from the front of the

dryer.

Control Thermostat and Bias Heater

The control thermostat regulates the temperature

inside the dryer drum. It is a single pole, single throw

switch wired in series with the high limit (or safety)

thermostat and the heat source. It is mounted on

the front of the blower housing. The control

thermostat also contains a bias heater. The purpose

of the bias heater is to apply a small amount of heat

to the control thermostat when the fabric selector

switch is set to the medium temperature setting. This

small amount of heat causes the thermostat to open

sooner to maintain a lower drum temperature.

Timer/Accumulator Bar Chart

T o diagnose the timer/accumulator , use the bar chart

located on the mini manual behind the switch trim.

Rotate the timer to a point in the particular cycle

you want to check. Find the appropriate location

the timer pointer is set in the cycles across the first

column. Read ver tically down the chart from that

point. At each point you cross a shaded row, the

contacts listed at the left on the same row should

have continuity. Note the shaded areas are

proportional to the total time, so take several

continuity measurements at different points within

the cycle before determining the timer motor needs

replacement. As you can see from the e xample of a

gas dryer above, the contacts are made most of the

cycle.

THERMOSTAT

TERMINALS

BIAS HEA TER

TERMINALS

NOTE:

The control thermostats are not interchangeable

between an electric and a gas dryer. The resistance

of the bias heater is 28K ohms on the electric dryer

and 7K ohms on the gas dryer.

12

Page 14

To check the control thermostat, remove the wiring

from the terminals. At room temperature, the

thermostat should have continuity between the

control thermostat terminals. To check the bias

heater, remove the wiring from the bias heater

terminals. Check the resistance between the bias

heater terminals. On an electric dryer, the resistance

should be 28K ohms. On a gas dryer, the resistance

should be 7K ohms.

To check for correct dryer temperatures, make

certain all panels are in place on the dryer and

remove the e xhaust venting from the rear of the dryer.

Place a thermometer capable of reading at least

300°F in the end of the dryer duct. Set the timer

and allow the dryer to operate for 10 minutes with

an empty drum. Check the temper ature immediately

after the thermostat has cycled off and the dryer

has reached its highest temperature. Depending

upon the cycle selected, the temperatures should

be between 165°F-195°F on a “High” setting and

between 150°F-180°F for a “Medium” setting. If the

complaint is long drying times and the temperatures

are correct, check for a restricted vent, too long a

vent run, or an excessiv e number of turns in the vent.

High Limit (Safety) Thermostat

The high limit (safety) thermostat is a single pole,

single throw switch wired in series with the control

thermostat. It is mounted towards the top of the

heater pan shield at the rear of the drum. If the

control thermostat should fail closed or an air

blockage occurs, raising the temperature in the

heater pan, the high limit thermostat opens the circuit

to the heat source.

THERMAL

LIMITER

HIGH LIMIT

SAFETY

THERMOSTAT

Thermal Limiter

The thermal limiter is wired in series with the drive

motor on all electric dryers. The purpose of the

thermal limiter is to shut down the dryer should the

control thermostat and the high limit thermostat fail

to open. Once the ther mal limiter has opened, it

must be replaced. In addition, the condition that

caused it to open must be corrected. The most lik ely

cause would be a restriction in the dryer vent, an

excessively long v ent or a vent with excessiv e turns.

This is especially true if vinyl or plastic venting was

used.

Heat System (Electric Dryers)

The heater assembly is located behind the dryer

drum. Holes in the back of the drum allow heated

air to be drawn into the drum. The heating element

is an open coil heater, attached to a metal shroud

HIGH LIMIT

SAFETY

THERMOSTAT

HEATER

TERMINALS

13

Page 15

by removing the drum and visually inspecting the

element for breaks. Remove the leads from the

heater terminals and check for 12 ohms across the

terminals, then check each terminal to ground. If

the element is open or grounded, replace the heating

assembly. To replace the heater assembly, remove

the four Phillips screws holding the assemb ly to the

cabinet back. Transfer the high limit (safety)

thermostat from the old heater shroud to the new

shroud and install the new assembly.

Heat System (Gas models)

Belt Switch

The belt switch is a normally closed switch and is

mounted on the motor bracket ne xt to the idler arm.

If the drive belt breaks or jumps off the idler pulley,

the idler arm will contact the belt switch, causing the

switch contacts to open, and thereby opening the

circuit to the motor. T o access the belt switch, remo ve

the access panel on the rear of the dryer. Remove

the leads from the switch and connect an ohmmeter

across the switch terminals. The ohmmeter should

read continuity when the belt is on.

The heating system for a gas dryer is comprised of

three main components, the ignitor, the flame sensor

switch, and the gas control valve.

The ignitor is a silicon carbide thermistor mounted

at an angle with the tip extending into the flame area.

Depending on room temperature, the resistance of

the ignitor should be between 50 to 400 ohms. The

ignitor is fragile and susceptible to contamination

from skin oils. Use only the ignitor’s insulated support

when handling to prevent damage . Electrically, the

ignitor is in parallel with the booster coil. The parallel

circuit of the ignitor and booster coil is in series with

the secondary coil on the gas valve. The series –

parallel circuit of the ignitor, booster coil, and

secondary coil is in tur n in parallel with the holding

coil on the gas valve. Note: During the auto dry

cycle, you will be able to read some voltage at the

ignitor whenever the dryer is operating.

The flame sensor switch mounts on the side of the

burner duct and is single pole, single throw switch.

When the ignitor reaches approximately 1800°, the

flame sensor switch detects this high radiant heat

and opens. This energizes the secondary solenoid

gas valve coil, allowing gas to flow through the gas

valve . Gas flowing into the b urner duct is ignited by

the still hot ignitor. The flame within the b urner duct

heats the air being drawn into the back of the drum.

IGNITOR

BURNER ASSEMBLY

CENTRIFUGAL SWITCH

BELT

SWITCH

Motor

The drive motor is a single speed, dual shaft, ¼ hp,

1725 rpm motor with an automatic reset overload

protector. The overload protector in an internal

component of the motor and cannot be replaced

separately. The motor shaft is threaded on one end

for the blo wer wheel, with the belt pulley on the other.

The pulley is not available separately and comes

pressed on the shaft of a new motor.

FLAME SENSOR

GAS V AL VE

14

Page 16

The motor contains a centrifugal switch which serves

three purposes: It disengages the motor start

winding, engages the motor run winding and closes

the circuit for the heat source. When the motor is

off, the switch completes a circuit from M5 through

the motor start winding to M4. The contact M1 to

M2 is open. Immediately as the motor is started,

centrifugal force pulls the switch activating collar in

on the motor. This opens the circuit through the

start winding and completes the circuit M6 through

the run winding to M4. The contacts M1 to M2 close

to activate the heat source.

MOTOR OFF

tape, two Phillips screws and the six clips holding

the cover in place. Note the retaining clips under

the aluminum tape at the bottom edge of the cover.

When reassembling, make certain the cover is

sealed to the housing with aluminum tape. If the

original tape cannot be reused, use aluminum tape

WD49X27 to seal the cover.

Unscrew the blower wheel in a clockwise direction

from the motor shaft using a 7/8” sock et on the blower

wheel and holding the motor shaft by the pulley. The

clockwise direction is marked on the center of the

wheel.

MOTOR RUNNING

T o chec k the switch, disconnect the dryer from power

and remove the drum. If the motor starts to run and

stops when the start switch is released, place an

ohm meter across terminals M5 and M6 and

manually pull in on the collar to activate the switch.

You should read continuity. If the motor runs and

there is no heat, activate the switch and check

between M1 and M2. You should read continuity.

Motor Removal

T o replace the motor , disconnect power , remov e the

top and front panels, belt and dryer drum. Remov e

the fan cover by carefully removing the aluminum

Direction

of removal

marked on

the blower

wheel

7/8”

hex nut

Once the blower wheel is unscrewed, remove the

motor mounting clip and unplug the wiring harness

from the motor.

MOTOR

MOUNTING

CLIP

WIRING HARNESS

F AN COVER

15

Page 17

Next, remove the fan housing lock from the rear of

the blower housing.

FAN

HOUSING

LOCK

To remove the lock, insert a flat bade screwdriver

as shown below . Pry the lock away from the housing

far enough to clear the retaining tab and lift the lock

out of the channel.

MOTOR AND HARNESS WIRING

(Motor remove for clarity in illustrations)

FAN

HOUSING

LOCK

RETAINING

TAB

Once the lock is removed, the motor can be pulled

from the blower housing.

16

Page 18

Ω

Ω

17

Page 19

18

Page 20

Dryer Will Not Run

Service fuse,

breaker, outlet

problem

Repair terminal

block connection.

Replace door

switch

Replace start

switch

Electric Dryer

N

N

N

N

Adequate voltage

to dryer?

Y

Connections at

terminal block

OK?

Y

Door switch

contacts closed?

Y

Start switch

contacts closed?

Y

Service fuse,

breaker, outlet

problem

Replace door

switch

Replace start

switch

Replace timer

in coinbox

(Greenwald)

Gas Dryer

N

N

N

N

Adequate voltage

to dryer?

Y

Door switch

contacts closed?

Y

Start switch

contacts closing?

Y

Timer contacts

B & C closed?

Y

Replace timer

Replace thermal

limiter and

correct failure

fault

Replace belt

switch

Replace motor

N

N

N

N

Timer contacts

B & C closed?

Y

Contacts on

thermal limiter

closed?

Y

Belt switch

contacts closed?

Y

Check motor

centrifugal switch

reading between

contacts 4 & 5:

Or

Using a properly

grounded test

cord connected to

terminals 4 & 5

does the motor

run?

Y

Replace belt

switch

Replace motor

N

N

Belt switch

contacts closed?

Y

Check motor

centrifugal switch

reading between

contacts 4 & 5:

Or

Using a properly

grounded test

cord connected to

terminals 4 & 5

does the motor

run?

Y

Open wiring

between

components.

Locate and repair.

components.

Locate and repair

Open wiring

between

19

Page 21

No Heat - Drum Turns

Electric Dryer

Service fuse,

breaker, wall

outlet problem

Replace power

cord

Replace timer

Greenwald

Replace

temperature

selector switch

Replace control

thermostat

N

N

N

N

N

Adequate voltage

to dryer at outlet?

Y

Correct voltage at

dryer terminal

block?

Y

Turn timer on

Contacts A & B

closed on the

timer?

Y

Contacts 1 & 2

closed on the

temperature

selector switch?

Y

Contacts on the

control thermostat

closed?

Not applicable

on all models

Replace hi limit

thermostat

Replace heater

Replace

motor

N

N

N

Open wiring

between

components.

Locate and repair

Y

Contacts on high

limit thermostat

closed?

Y

Heater resistance

OK?

Y

Continuity

between contacts

1 & 2 on

centrifugal

switch? Manually

move the switch

to run position to

check these

contacts

Y

20

Page 22

No Heat - Drum Turns

Gas Dryer

Ignitor glowing?

N Y

Replace flame

sensor

Replace timer N

Greenwald

Replace

temperature

selector switch

Replace control

thermostat

Replace high limit

thermostat

N

contacts closed?

Contacts A & B

Contacts 1 & 2

N

selector switch?

Contacts on the

N

control thermostat

Contacts on the

N

Flame sensor

Y

closed on the

timer?

Y

closed on the

temperature

Y

closed?

Y

high limit

thermostat

closed?

Fix supply

problem

Ignitor between

50 and 400 ohms

at room

temperature?

Y

Flame sensor

contacts open

after ignitor has

been on 15 to 90

seconds max.?

Y

Gas valve

solenoids check

OK?

Y

120 volts to gas

valve solenoids?

N

Y

N

N

N

N

Gas supply OK

to dryer?

Replace ignitor

Replace flame

sensor

Replace gas

valve assembly

Open wiring in

gas valve circuit,

locate and repair

Replace

motor

Open wiring to

one of the

components.

Locate and repair.

N

Continuity

between contact

1 and 2 on the

centrifugal

switch?

Manuall move the

switch to the run

position to check

the contacts.

Y

Y

Y

Replace gas

valve assembly

Not applicable

on all models

21

Page 23

For complete Illustrated

Parts Catalog information

consult your GE Parts

Catalog, or Microfiche.

These examples are for

illustration purposes only.

22

Page 24

23

Page 25

24

Page 26

25

Page 27

26

Page 28

27

Page 29

28

Page 30

29

Page 31

30

Page 32

31

Page 33

32

Page 34

33

Page 35

34

Page 36

35

Page 37

36

Page 38

37

Page 39

38

Page 40

39

Page 41

40

Page 42

41

Loading...

Loading...