Page 1

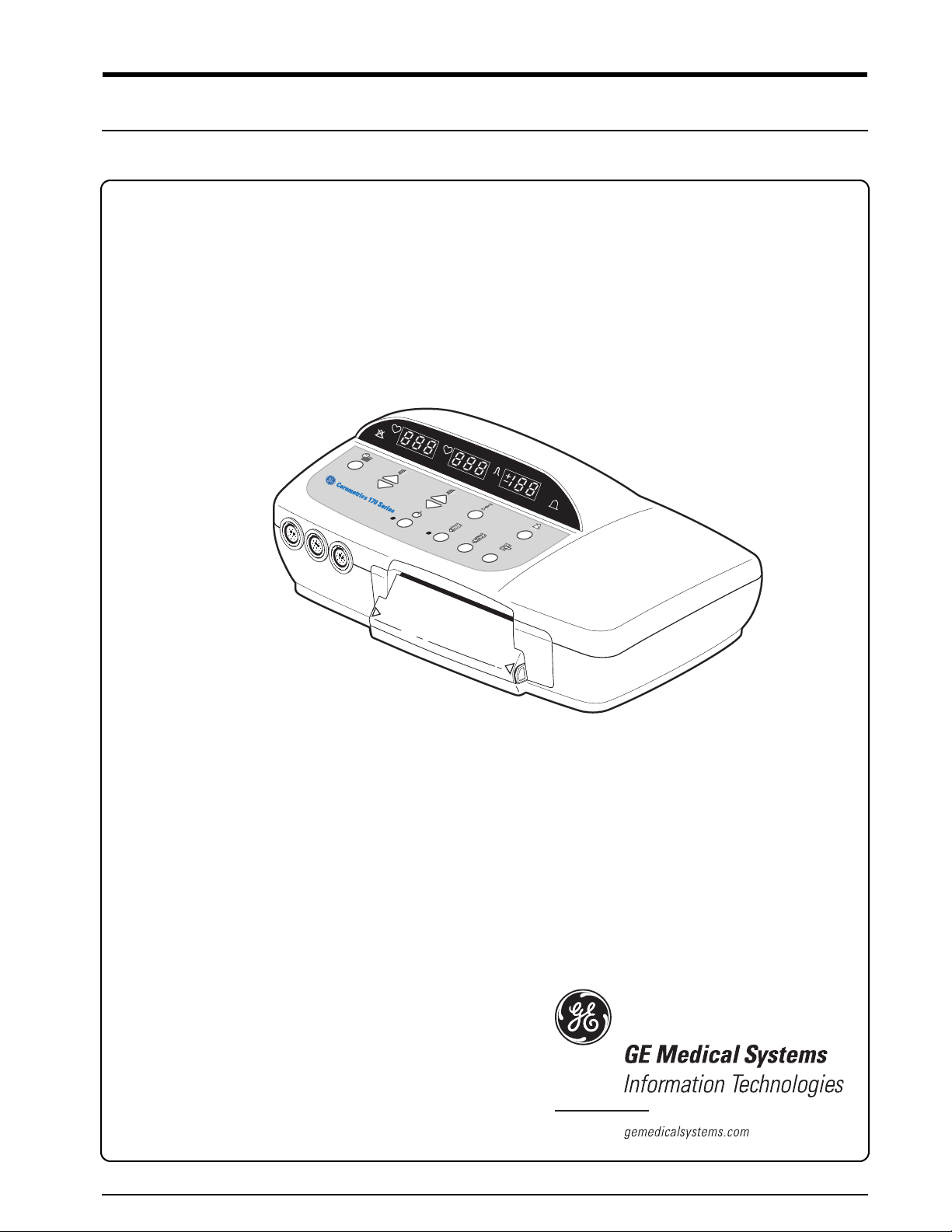

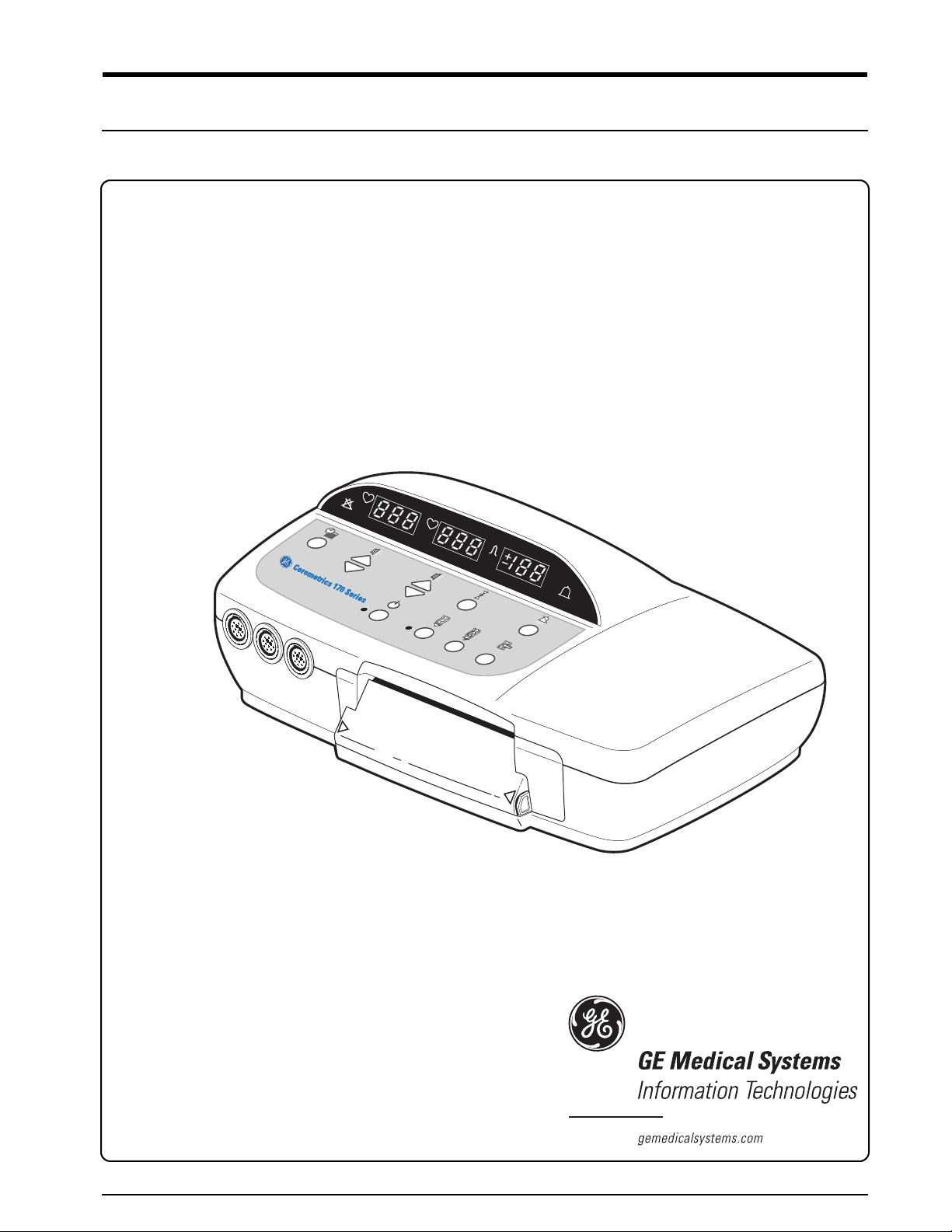

Corometrics®170 Series

SERVICE MANUAL MANUAL P/N 2000947-004 REV. C

Page 2

Page 3

Corometrics® 170 Series

SERVICE MANUAL MANUAL P/N 2000947-004 REV. C

Page 4

GUARANTEE

All equipment sold by GE Medical Systems Information Technologies, is fully guaranteed as to

materials and workmanship for a period of 1 year. Information Technologies reserves the right to

perform guarantee service operations in its own factory, at an authorized repair station, or in the

customer’s installation.

Our obligation under this guarantee is limited to repairing, or, at our option, replacing any

defective parts of our equipment, except fuses or batteries, without charge, if such defects occur in

normal service.

Claims for damage in shipment should be filed promptly with the transportation company. All

correspondence covering the instrument should specify the model and serial numbers.

GE Medical Systems Information Technologies

A GE Medical Systems Company

GE Medical Systems Information Technologies will make available on request such circuit

diagrams, component diagrams, component parts lists, descriptions, calibration instructions, or

other information which will assist the users or appropriately qualified technical personnel to

repair those parts of the equipment which are classified by GE Medical Systems Information

Technologies as repairable. Refer to the service manual for further information.

!

CAUTION: In the United States of America, Federal Law restricts this device to sale by or

on the order of a physician.

Corometrics and Marquette are registered trademarks of GE Medical Systems Information Technologies. GE is a registered

trademark of General Electric Company. All other product and brand names are trademarks or registered trademarks of their

respective companies. ©2002-2004 GE Medical Systems Information Technologies. All rights reserved. No part of this

manual may be reproduced without the permission of GE Medical Systems Information Technologies.

Page 5

Contents

1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Definitions of Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Monitor Contraindications, Warnings, and Precautions . . . . . . . . . . . . . . . . . . . . 1-4

Equipment Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

2 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Indications for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Monitoring Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

About Your Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

3 Controls, Indicators, and Connectors . . . . . . . . . . . . . . . 3-1

Front Panel Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Front Panel Displays and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Front Panel Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Strip Chart Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Rear Panel Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

4 Setup Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Loading Strip Chart Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Turning the Monitor On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Revision C Corometrics 170 Series 5

2000947-004

Page 6

Monitor Self-Test Routines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Customizing the Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Quick Reference Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Flasher Software Utility Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

5 Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Functional Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Main Board Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

FECG/IUP Board Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

6 Functional Checkout Procedure . . . . . . . . . . . . . . . . . . . 6-1

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Monitor Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Front Panel Pushbutton Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Connecting the Simulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

FECG Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Legplate Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Ultrasound Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Fetal Movement Detection Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Ultrasound Transducer Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Uterine Activity Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Tocotransducer Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Strain Gauge Transducer Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Pattern Memory Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

Dual Heart Rate Test (Non-Pattern) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

6 Corometrics 170 Series Revision C

2000947-004

Page 7

Alarm Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

7 Serviceable Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

General Anti-Static Handling Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Transducer Plug Replacement Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Nautilus Transducer Cable Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

Removing the Monitor Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Tocotransducer Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

Nautilus Ultrasound Transducer Top Cover Replacement . . . . . . . . . . . . . . . . . 7-30

Nautilus Transducer Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-32

Testing a Repaired Transducer (TOCO or US) . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-34

Replacing the Main Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-35

Replacing the FECG/IUP Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-36

Replacing the Membrane Switch Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-37

Replacing a Front Panel Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-40

Servicing the Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-41

Boot ROM Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-49

8 Peripheral Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Remote Marks Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Telemetry Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

RS-232 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

9 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Preventative Maintenance Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Revision C Corometrics 170 Series 7

2000947-004

Page 8

10 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

General Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Strip Chart Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

11 Parts Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

2000268-188, Model 171 Final Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

2000268-189, Model 172 Final Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-5

2001972-037, Model 173 Final Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-8

2001972-038, Model 174 Final Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-11

2264AAX, Button-Style Nautilus Tocotranducer Assembly Parts List . . . . . . . 11-14

5700GAX, Button-Style Nautilus Ultrasound Transducer Assembly Parts List 11-15

5700KAX, Loop-Style Nautilus Ultrasound Transducer Assembly Parts List . 11-16

2264DAX, Loop-Style Nautilus Tocotransducer Assembly Parts List (5-ft cord) 11-17

1509AAO/BAO, Qwik Connect Plus Legplate Assembly Parts List . . . . . . . . . 11-18

Block Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-19

8 Corometrics 170 Series Revision C

2000947-004

Page 9

Chapter 1

!

Safety 1

The information presented in this section is important for the safety of both the

patient and operator and also serves to enhance equipment reliability. This chapter

describes how the terms Danger, Warning, Caution, Important, and Note are used

throughout the manual. In addition, standard equipment symbols are defined.

This section includes the following important information:

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Definitions of Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Monitor Contraindications, Warnings, and Precautions . . . . . . . . . . 1-4

Equipment Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Revision C 170 Series Monitor 1-1

2000947-004

Page 10

Safety: General Information

General Information

General Use

If the monitor is cold to the touch or below ambient temperature, allow it to stabilize

before use.

To ensure patient safety, use only parts and accessories manufactured or

recommended by GE Medical Systems Information Technologies. Parts and

accessories used shall meet the requirements of EN60601.1.1.

Disposable devices are intended for single use only. They should not be reused.

Periodically, and whenever the integrity of the monitor is in doubt, test all functions.

Refer to the “Maternal/Fetal Monitoring Operator’s Manual” for information

concerning the limitations of internal and external fetal heart rate monitoring

techniques.

Responsibility of the Manufacturer

GE is responsible for the effects on safety, reliability, and performance if:

assembly operations, extensions, readjustments, modifications, or repairs are

carried out by persons authorized by GE;

the electrical installation of the relevant room complies with the requirements of

appropriate regulations; and

the monitor is used in accordance with the instructions of use.

Responsibility of the User

This device is intended for use by clinical professionals who are expected to know

the medical procedures, practices, and terminology required to monitor obstetrical

patients. This manual documents all possible parameters available in the 170 Series

of monitors. It is the responsibility of each hospital to ensure that the Labor and

Delivery staff is trained in all aspects of the selected model.

The 170 Series Monitor is designed to assist the perinatal staff by providing

information regarding the clinical status of the fetus during labor. The monitor does

not replace observation and evaluation of the mother and fetus at regular intervals,

by a qualified care provider, who will make diagnoses and decide on treatments or

interventions. Visual assessment of the monitor display and strip chart must be

combined with knowledge of patient history and risk factors to properly care for the

mother and fetus.

1-2 170 Series Monitor Revision C

2000947-004

Page 11

Safety: Definitions of Terminology

Definitions of Terminology

Six types of special notices are used throughout this manual. They are: Danger,

Warning, Caution, Contraindication, Important, and Note. The warnings and

cautions in this Safety section relate to the equipment in general and apply to all

aspects of the monitor. Be sure to read the other chapters because there are

additional warnings and cautions which relate to specific features of the monitor.

When grouped, warnings and cautions are listed alphabetically and do not imply any

order of importance.

Danger

Warning

Table 1-1. Definitions of Terminology

A DANGER notice indicates an imminently

hazardous situation which, if not avoided, will result

in death or serious injury.

A WARNING indicates a potentially hazardous

situation which, if not avoided, could result in death

or serious injury.

Caution

Contraindication

Important

Note

A CAUTION indicates a potentially hazardous

situation which, if not avoided, may result in minor

or moderate injury. Cautions are also used to

avoid damage to equipment.

A CONTRAINDICATION describes any special

symptom or circumstance that renders the use of a

remedy or the carrying out of a procedure

inadvisable, usually because of a risk.

An IMPORTANT notice indicates an emphasized

note. It is something you should be particularly

aware of; something not readily apparent.

A NOTE indicates a particular point of information;

something on which to focus your attention.

Revision C 170 Series Monitor 1-3

2000947-004

Page 12

Safety: Monitor Contraindications, Warnings, and Precautions

Monitor Contraindications, Warnings, and Precautions

Warnings

WARNINGS

ACCIDENTAL SPILLS—In the event that fluids are accidentally

spilled on the monitor, take the monitor out of operation and

inspect for damage.

APPLICATION—This monitor is not designed for direct cardiac

connection.

CONDUCTIVE CONNECTIONS—Avoid making any

conductive connections to applied parts (patient connection)

which are likely to degrade safety.

CONDUCTIVE PARTS—Ensure that the conductive parts of the

lead electrodes and associated connectors do not contact other

conductive parts including earth.

DEFIBRILLATION—During defibrillation, all personnel must

avoid contact with the patient and monitor to avoid a dangerous

shock hazard. In addition, proper placement of the paddles in

relation to the electrodes is required to minimize harm to the

patient.

ELECTRICAL SHOCK—To reduce the risk of electrical shock,

do not remove monitor cover. Refer servicing to qualified

personnel.

ELECTROMAGNETIC INTERFERENCE—Be aware that

strong electromagnetic fields may interfere with monitor

operation. Interference prevents the clear reception of signals by

the monitor. If the hospital is close to a strong transmitter such as

TV, AM or FM radio, police or fire stations, a HAM radio

operator, an airport, or cellular phone, their signals could be

picked up as signals by the monitor. If you feel interference is

affecting the monitor, contact your Service Representative to

check the monitor in your environment. Refer to page 1-8 for

additional information.

1-4 170 Series Monitor Revision C

2000947-004

Page 13

Safety: Monitor Contraindications, Warnings, and Precautions

WARNINGS

ELECTROSURGERY—The monitor is not designed for use with

high-frequency surgical devices. In addition, measurements may

be affected in the presence of strong electromagnetic sources such

as electrosurgery equipment.

EXPLOSION HAZARD—Do not use this equipment in the

presence of flammable anesthetics or inside an oxygen tent.

GROUNDING—Do not defeat the three-wire grounding feature

of the power cord by means of adaptors, plug modifications, or

other methods. A dangerous shock hazard to both patient and

operator may result.

INSTRUCTIONS—For continued and safe use of this equipment,

it is necessary to follow all listed instructions. However, the

instructions provided in this manual in no way supersede

established medical procedures concerning patient care. The

monitor does not replace observation and evaluation of the

patient, at regular intervals, by a qualified care provider who will

make diagnoses and decide on treatments and interventions.

INTERFACING OTHER EQUIPMENT—Monitoring equipment

must be interfaced with other types of medical equipment by

qualified biomedical engineering personnel. Be certain to consult

manufacturers’ specifications to maintain safe operation.

LEAKAGE CURRENT TEST—The interconnection of auxiliary

equipment with this device may increase the total leakage current.

When interfacing with other equipment, a test for leakage current

must be performed by qualified biomedical engineering personnel

before using with patients. Serious injury or death could result if

the leakage current exceeds applicable standards. The use of

accessory equipment not complying with the equivalent safety

requirements of this equipment may lead to a reduced level of

safety of the resulting system. Consideration relating to the

choice shall include: use of the accessory in the patient vicinity;

and evidence that the safety certification of the accessory has been

performed in accordance with the appropriate EN60601.1 and/or

EN60601.1.1 harmonized national standard.

Revision C 170 Series Monitor 1-5

2000947-004

Page 14

Safety: Monitor Contraindications, Warnings, and Precautions

WARNINGS

LINE ISOLATION MONITOR TRANSIENTS—Line isolation

monitor transients may resemble actual cardiac waveforms, and

thus cause incorrect heart rate determinations and alarm activation

(or inhibition).

STRANGULATION—Make sure all patient cables, leadwires,

and tubing are positioned away from the patient’s head to

minimize the risk of accidental strangulation.

WATER BIRTHS—Do not use the monitor to directly monitor

patients during water births, in whirlpool or submersion water

baths, during showers, or in any other situation where the mother

is immersed in water. Doing so may result in electrical shock

hazard.

1-6 170 Series Monitor Revision C

2000947-004

Page 15

Cautions

Safety: Monitor Contraindications, Warnings, and Precautions

CAUTIONS

ANNUAL SERVICING—For continued safety and performance

of the monitor, it is recommended that the calibration, accuracy,

and electrical safety of the monitor be verified on an annual basis

by an GE Service Representative.

DAILY TESTING—It is essential that the monitor and

accessories be inspected every day. It is recommended practice to

initiate the monitor’s self-test feature at the beginning of each

monitoring session; follow the instructions in “Chapter 4, Setup

Procedures”.

ENVIRONMENT—The performance of the monitor has not been

tested in certain areas, such as x-ray and imaging suites. The

monitor is not recommended for use in these environments.

PERFORMANCE—Report all problems experienced with the

monitor. If the monitor is not working properly, contact your

Service Representative for service. The monitor should not be

used if it is not working properly.

PINCHING—Keep fingers clear of the paper roller because the

roller could pinch your fingers.

TRAPPING—Keep hands, hair, jewelry, and loose clothing away

from the paper roller because the roller could trap these items.

TRIPPING—Arrange monitoring equipment so that cords and

cables do not present a tripping hazard.

Revision C 170 Series Monitor 1-7

2000947-004

Page 16

Safety: Monitor Contraindications, Warnings, and Precautions

Electromagnetic Interference

This device has been tested and found to comply with the limits for medical devices

to the IEC 601-1-2:1993, EN60601-1-2:1994, Medical Device Directive 93/42/EEC.

These limits are designed to provide reasonable protection against harmful

interference in a typical medical installation.

However, because of the proliferation of radio-frequency transmitting equipment

and other sources of electrical noise in the health-care and home environments (for

example, cellular phones, mobile two-way radios, electrical appliances), it is

possible that high levels of such interference due to close proximity or strength of a

source, may result in disruption of performance of this device.

This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with these instructions, may cause harmful

interference with other devices in the vicinity. Disruption or interference may be

evidenced by erratic readings, cessation of operation, or incorrect functioning. If this

occurs, the site of use should be surveyed to determine the source of this disruption,

and actions taken to eliminate the source.

The user is encouraged to try to correct the interference by one or more of the

following measures:

Turn equipment in the vicinity off and on to isolate the offending equipment.

Reorient or relocate the other receiving device.

Increase the separation between the interfering equipment and this equipment.

If assistance is required, contact your GE Service Representative.

1-8 170 Series Monitor Revision C

2000947-004

Page 17

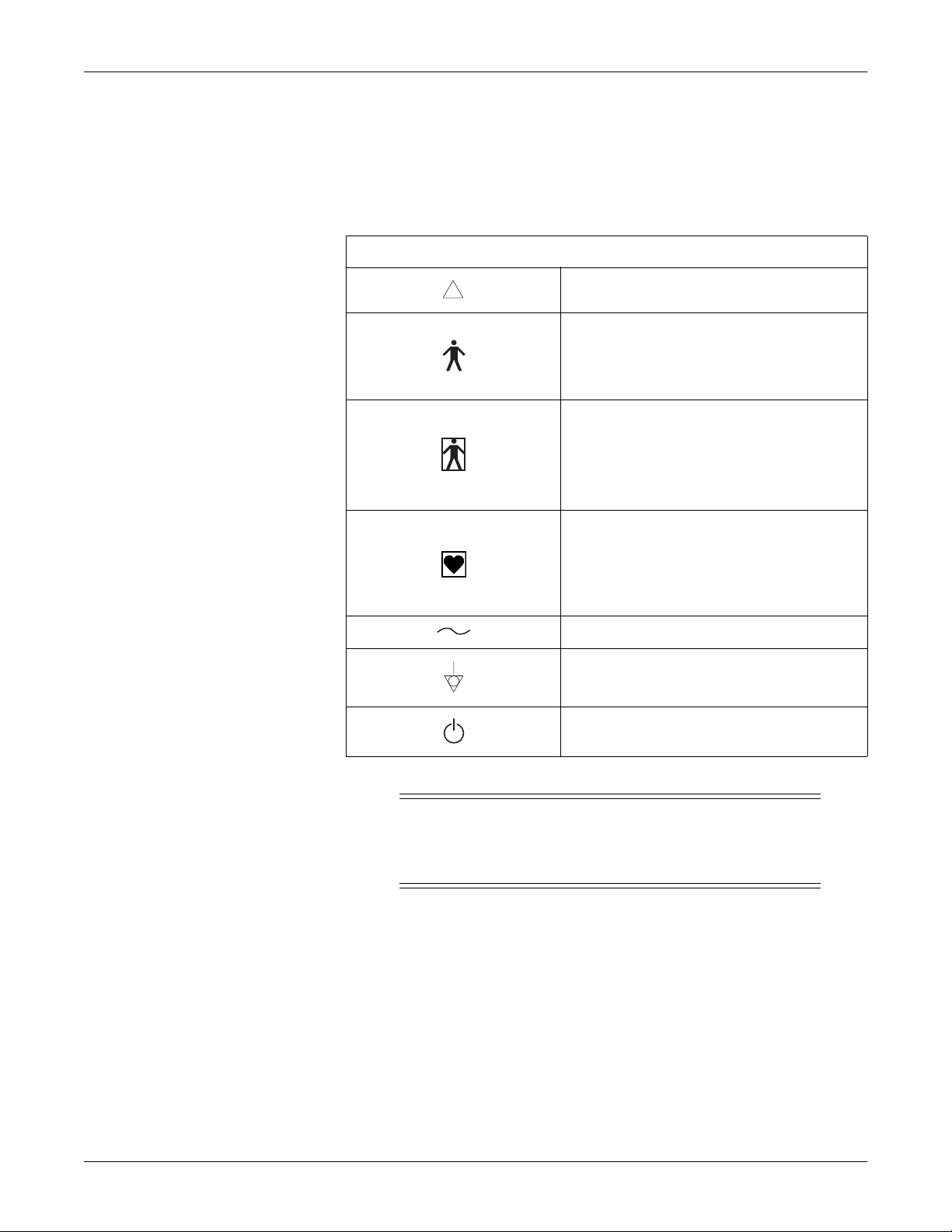

Equipment Symbols

The following is a list of symbols used on products manufactured by GE. Some

symbols may not appear on your unit.

Safety: Equipment Symbols

Table 1-2. Equipment Symbols

!

ATTENTION: Consult accompanying documents.

TYPE B EQUIPMENT. Type B equipment is

suitable for intentional external and internal

application to the patient, excluding direct cardiac

application.

TYPE BF EQUIPMENT.

suitable for intentional external and internal

application to the patient, excluding direct cardiac

application. Type BF equipment has an F-type

applied part.

TYPE CF EQUIPMENT. Type CF equipment is

suitable for intentional external and internal

application to the patient, including direct cardiac

application. Type CF equipment has an F-type

applied part.

ALTERNATING CURRENT (AC).

EQUIPOTENTIALITY.

ON/STANDBY: button toggles between full power

and standby.

Type BF equipment is

CAUTION

AC MAINS—The On/Standby switch does not disconnect the

monitor from AC mains power. To completely remove power, you

must disconnect the power cord from the AC wall outlet.

Revision C 170 Series Monitor 1-9

2000947-004

Page 18

For your notes

Safety: Equipment Symbols

1-10 170 Series Monitor Revision C

2000947-004

Page 19

Chapter 2

Introduction 2

This section lists the indications for use for monitors in the 170 Series as well as

provides an explanation of the different patient monitoring modalities.

This section summarizes the clinical applications of monitors in the 170 Series:

Indications for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Monitoring Methods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

About Your Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Revision C 170 Series Monitor 2-1

2000947-004

Page 20

Indications for Use

Models 171 and 172

Models 171 and 172 Fetal Monitors are indicated for use in the monitoring of the

fetus during the antepartum period as well as throughout labor and delivery. Each

monitor also has an optional monitoring mode to detect fetal body movements.

Models 173 and 174

Models 173 and 174 Fetal Monitors are indicated for use in the monitoring of the

fetus throughout labor and delivery. Each monitor also has an optional monitoring

mode to detect fetal body movements.

Introduction: Indications for Use

2-2 170 Series Monitor Revision C

2000947-004

Page 21

Introduction: Monitoring Methods

Monitoring Methods

The following is a summary of all the clinical monitoring methods found in the 170

Series.

Fetal Heart Rate

External Method, Pulsed Doppler Ultrasound

Ultrasound monitoring is available on all 170 Series Monitors. Models 171 and 173

provide a single ultrasound channel, while Models 172 and 174 provide two

ultrasound channels.

Fetal heart rate can be measured externally using pulsed Doppler Ultrasound. A

transducer placed on the mother’s abdomen is used to direct an ultrasonic beam

toward the fetal heart and to sense Doppler shifted echoes created by moving cardiac

structures. A patented autocorrelation process is used to determine the timing of

successive cardiac cycles. The resulting fetal heart rate (FHR) pattern is recorded on

the strip chart paper and the FHR appears on the digital display.

Internal Method, Direct Fetal Electrocardiogram (FECG)

FECG is available on Models 173 and 174 only. The Model 173 provides a

dedicated FECG connector. The Model 174 provides a combi-connector which can

be used for either FECG or US.

FECG signals are obtained via a spiral electrode attached to the fetal presenting part.

FHR is computed on a beat-to-beat basis using the R-to-R time interval of the QRS

complexes. The instantaneous FHR pattern is printed on the strip chart paper and

the FHR appears on the digital display.

Maternal Uterine Activity

External Method, Tocotransducer (TOCO)

Maternal uterine activity is measured externally using a tocotransducer (toco).

Relative pressure within the uterus is measured using a tocotransducer attached to

the mother’s abdomen in the area of the uterine fundus. The readings are plotted on

the strip chart paper in a relative scale from 0 to 100 as well as shown on the digital

display. All 170 Series Monitors provide external uterine activity monitoring.

Internal Method, Intrauterine Pressure Catheter and Strain Gauge (IUP)

IUP is available on Models 173 and 174 only.

Intrauterine pressure is measured using a transcervical catheter. The pressure trend

is plotted over the range of 0 to 100 mmHg and the readings appear on the digital

display.

Revision C 170 Series Monitor 2-3

2000947-004

Page 22

Features

Introduction: Features

The 170 Series is a family of fetal monitors offering various combinations of

modalities to suit your institution’s needs. Each monitor boasts the following

qualities:

The strip chart recorder is a quiet, easy-to-load, high resolution thermal array

printer. The recorder prints continuous trends and alphanumeric data on one

strip chart.

Automatic mode selection is provided simply by inserting the appropriate

transducer plug into the front panel receptacle.

Wide beam ultrasound transducer provides an advanced level of system

performance.

Transducer connectors are easy-to-use, color-coded, and durable.

Frequently-used functions are controlled by front panel buttons—including

audio volume, uterine activity reference, alarm silence, event mark, paper

advance, and user setup controls.

The ultrasound mode provides clean accurate traces with few “dropouts”

because of a patented autocorrelation processing.

Fetal heart rate alarm limits are user-defined, with pre-set defaults.

Alarm silencing is controlled by a front panel pushbutton—colored for easy

recognition.

Fetal heart rate alarm conditions have both audible and visual indications. The

audible indicator can be silenced on an alarm-by-alarm basis.

Two RS-232C ports provide interfacing to external devices.

2-4 170 Series Monitor Revision C

2000947-004

Page 23

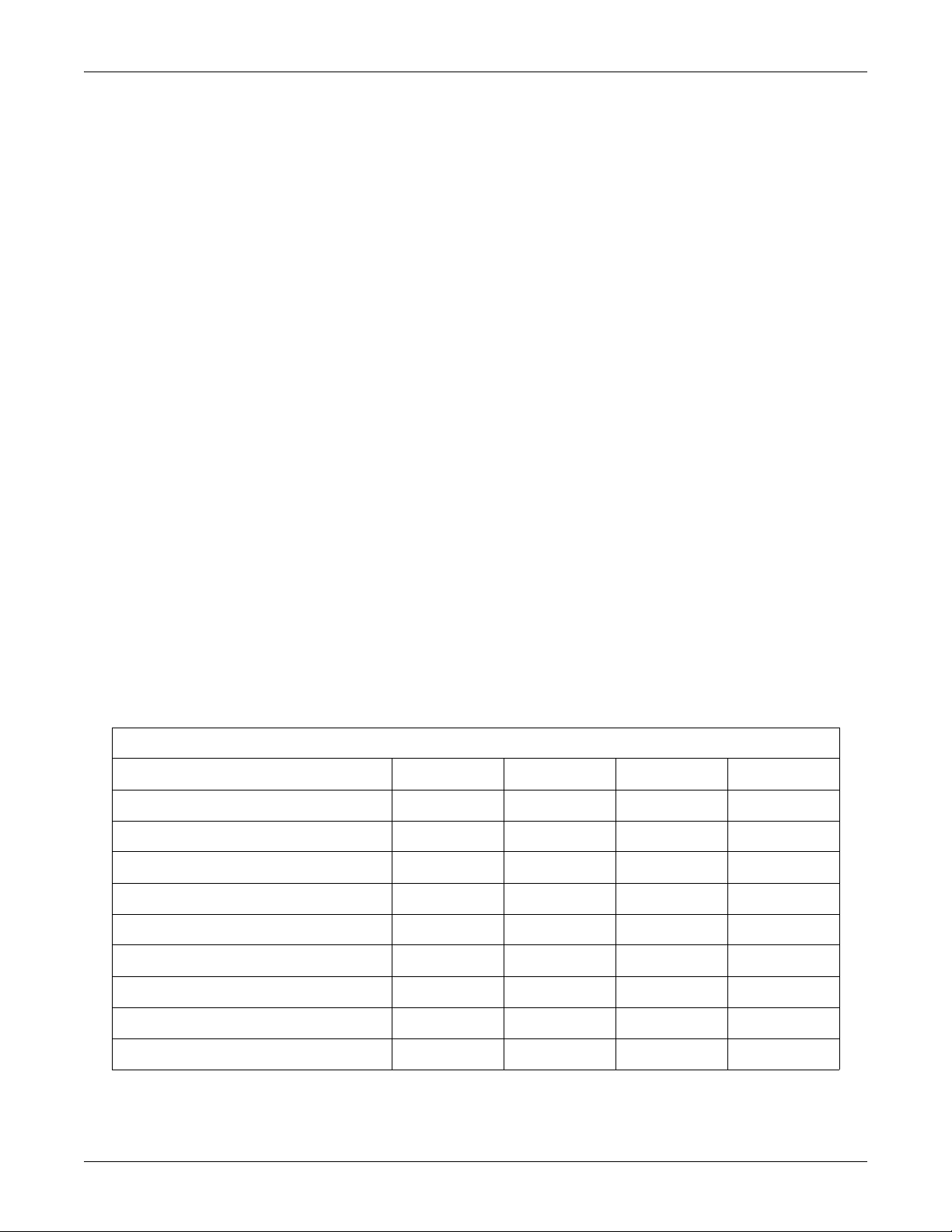

About Your Monitor

This manual describes all monitors in the 170 Series; therefore some sections may

not apply to your model monitor. Refer to Table 2-1.

Model 171

The Model 171 Antepartum Fetal Monitor provides singleton ultrasound and

external uterine activity monitoring.

Model 172

The Model 172 Antepartum Fetal Monitor provides dual ultrasound and external

uterine activity monitoring.

Model 173

The Model 173 Intrapartum Monitor provides dual heart rate monitoring using

FECG and ultrasound. The monitor also provides external uterine activity

monitoring using a tocotransducer or internal monitoring using an intrauterine

pressure catheter (IUPC).

Introduction: About Your Monitor

Model 174

The Model 174 Intrapartum Monitor provides dual heart rate monitoring using

FECG/ultrasound or dual ultrasound. The monitor also provides external uterine

activity monitoring using a tocotransducer or internal monitoring using an IUPC.

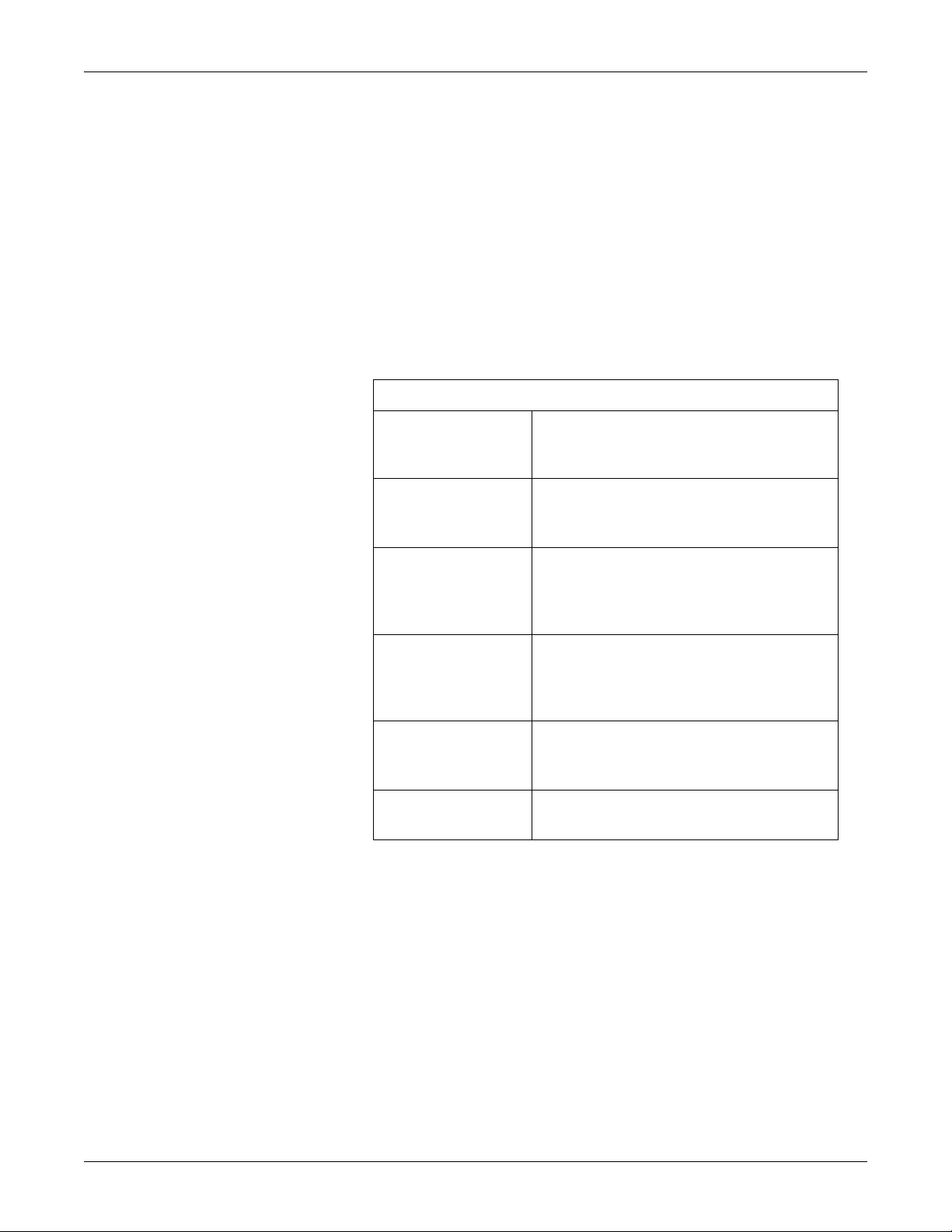

Table 2-1. Summary of Features

Feature 171 172 173 174

External uterine activity (TOCO) 9999

Internal uterine activity (IUPC) 99

Ultrasound

Dual ultrasound 99

FECG

Fetal heart rate alarms 9999

Fetal movement detection (optional) 9999

Heartbeat coincidence 999

Fetal heart rate offset 999

a

a

a

The Model 174 has a combi-connector for the primary FHR that can be used for either US or FECG.

9999

99

Revision C 170 Series Monitor 2-5

2000947-004

Page 24

For your notes

2-6 170 Series Monitor Revision C

2000947-004

Page 25

Chapter 3

Controls, Indicators, and Connectors

This section describes all possible controls, indicators, and connectors in the 170

Series.

This section contains the following information:

Front Panel Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Front Panel Displays and Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Front Panel Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Strip Chart Recorder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Rear Panel Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3

Revision C 170 Series Monitor 3-1

2000947-004

Page 26

Controls, Indicators, and Connectors: Front Panel Controls

Front Panel Controls

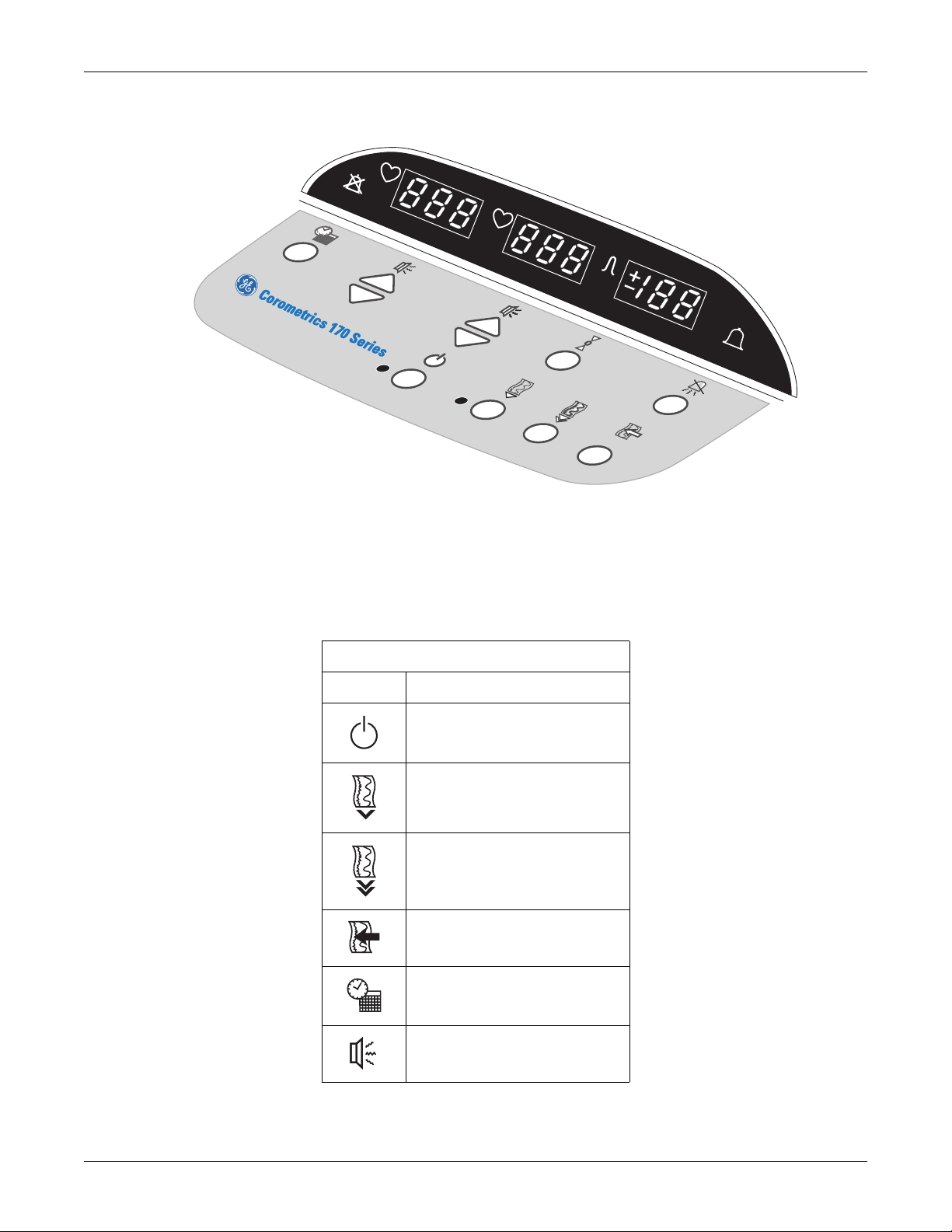

Figure 3-1. Front Panel Controls (Model 172 shown)

Table 3-1. Front Panel Controls

Symbol Name

Power

Record

Paper Advance

Mark/Offset

Setup

Volume

3-2 170 Series Monitor Revision C

2000947-004

Page 27

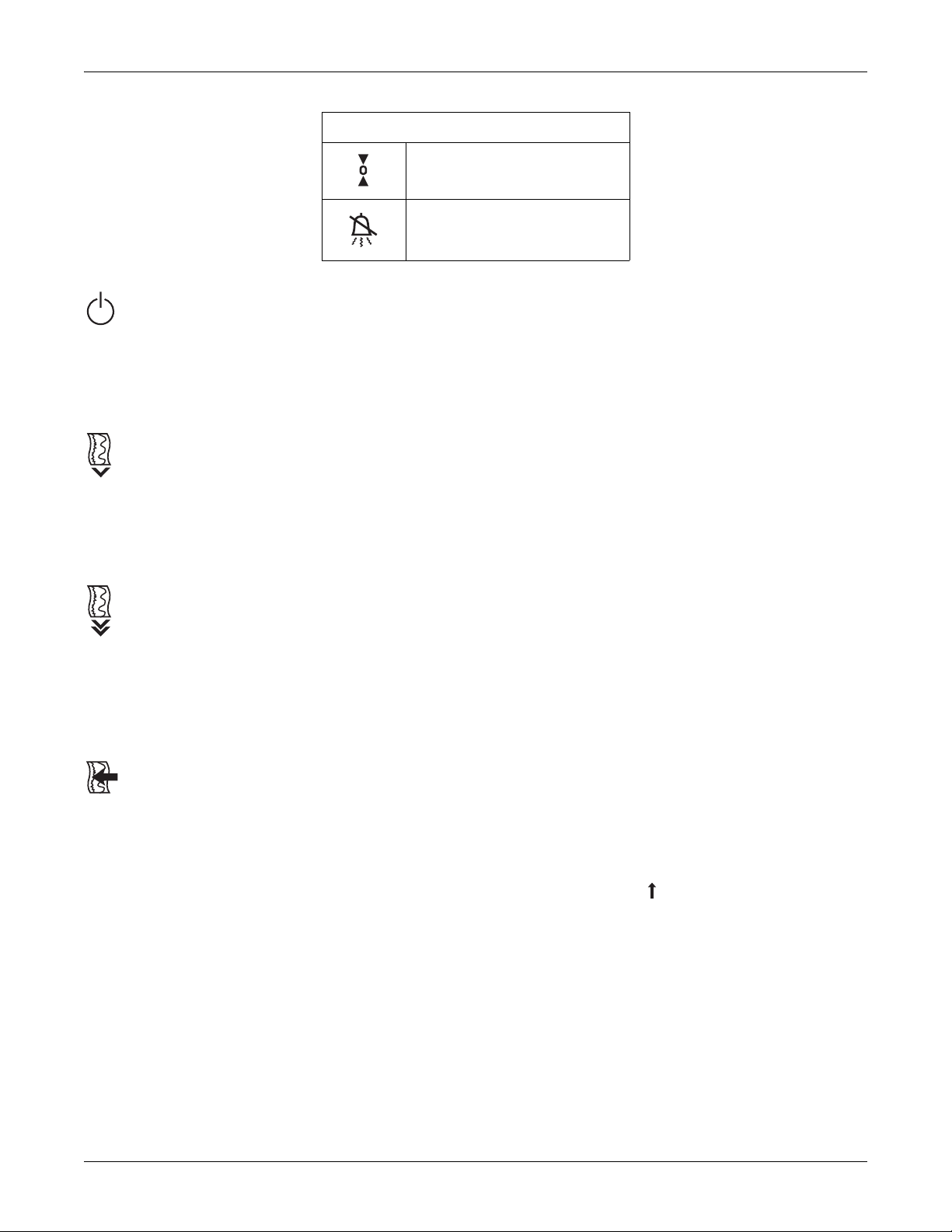

Controls, Indicators, and Connectors: Front Panel Controls

Table 3-1. Front Panel Controls

Power Button and Indicator

Pressing the blue Power button turns the monitor on and illuminates the green

indicator to the left of the button. Pressing the button again puts the monitor in

standby and extinguishes the indicator.

Record Button and Indicator

Pressing the Record pushbutton activates the recorder, provided paper is installed;

the amber indicator illuminates to the left of the button. Pressing the button again

turns the recorder off and extinguishes the indicator.

UA Reference

Alarm Silence

Paper Advance Button

Pressing the Paper Advance button causes the recorder to advance chart paper at a

rate of 40 cm/min for as long as the button is pressed. If the recorder is on, twenty

seconds after the button is released, the recorder prints the time, date, active trends

legends, and chart speed.

Mark/Offset Button

The Mark/Offset button is a multifunction button:

Mark

Briefly pressing the button prints an event mark on the bottom two lines of the

heart rate grid.

Offset (Models 172, 173, and 174 Only)

When the heart rate offset mode is enabled, pressing and holding the Mark/Offset

button for at least two seconds shifts the secondary FHR trend +20 BPM for

visibility purposes. You will hear a “beep” for confirmation. Refer to the “170

Series Operator’s Manual” for more information.

Revision C 170 Series Monitor 3-3

2000947-004

Page 28

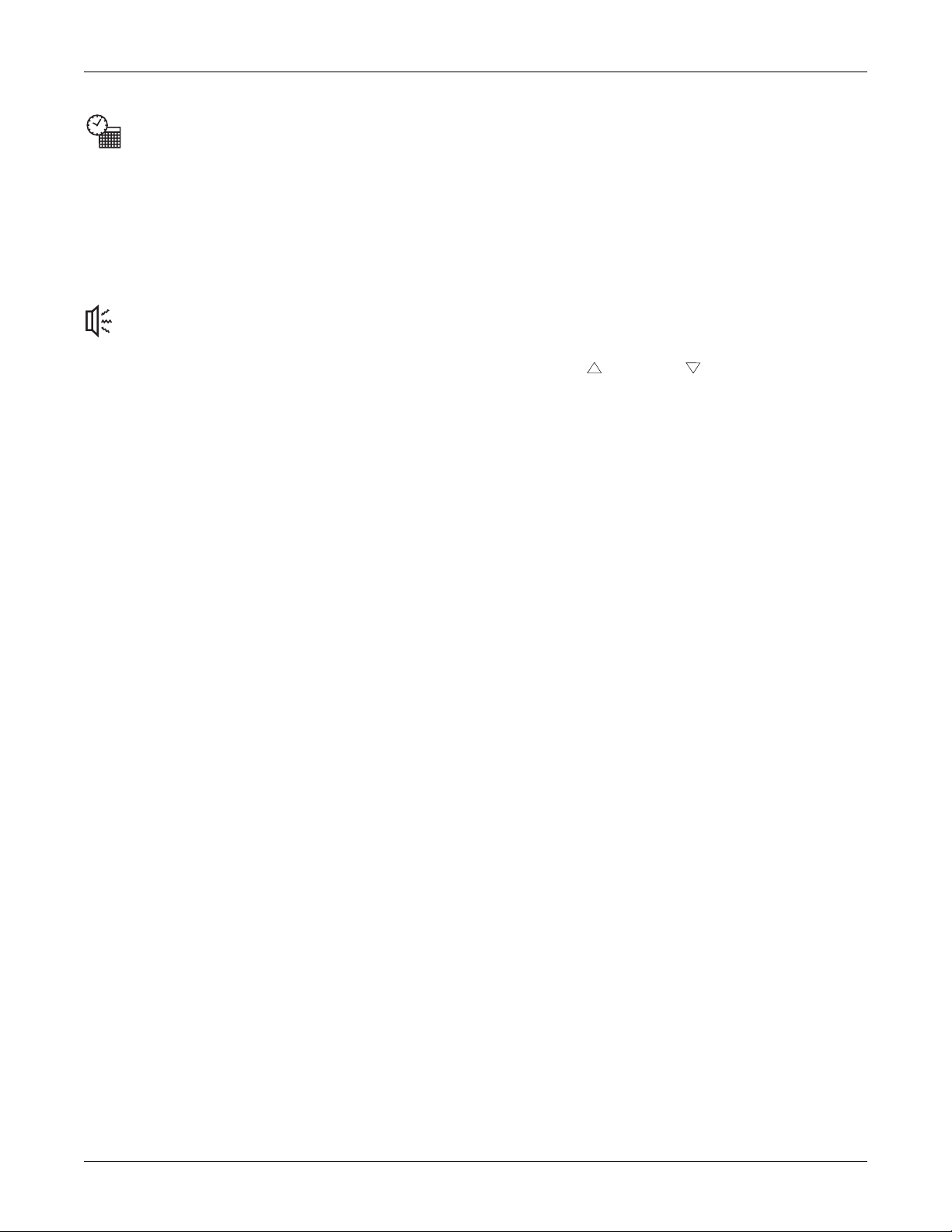

Controls, Indicators, and Connectors: Front Panel Controls

Setup Button

Volume Buttons

Model 171

Models 172, 173, and 174

Pressing and holding this button while the monitor is on enters a user setup mode for

configuring the monitor.

Pressing and holding this button during power up enters a service setup mode.

Refer to “Chapter 4, Setup Procedures” for instructions.

The Volume buttons are used to raise ( ) and lower ( ) the volume of the audio

signals emitted by the speaker. The volume buttons are also used during setup.

This monitor has two volume buttons used to control the ultrasound audio.

These monitors have four volume buttons. The left pair controls the audio signals

for the mode shown in the primary FHR display; likewise, the right pair of buttons

controls the audio for the mode shown in the secondary FHR display.

Setup Mode

When the monitor is in setup mode (user or service), the volume buttons change: the

setting or value shown in the FHR display; or the monitor feature code shown in the

UA display. (For Models 172, 173, and 174, only the leftmost volume controls are

active during setup mode.)

3-4 170 Series Monitor Revision C

2000947-004

Page 29

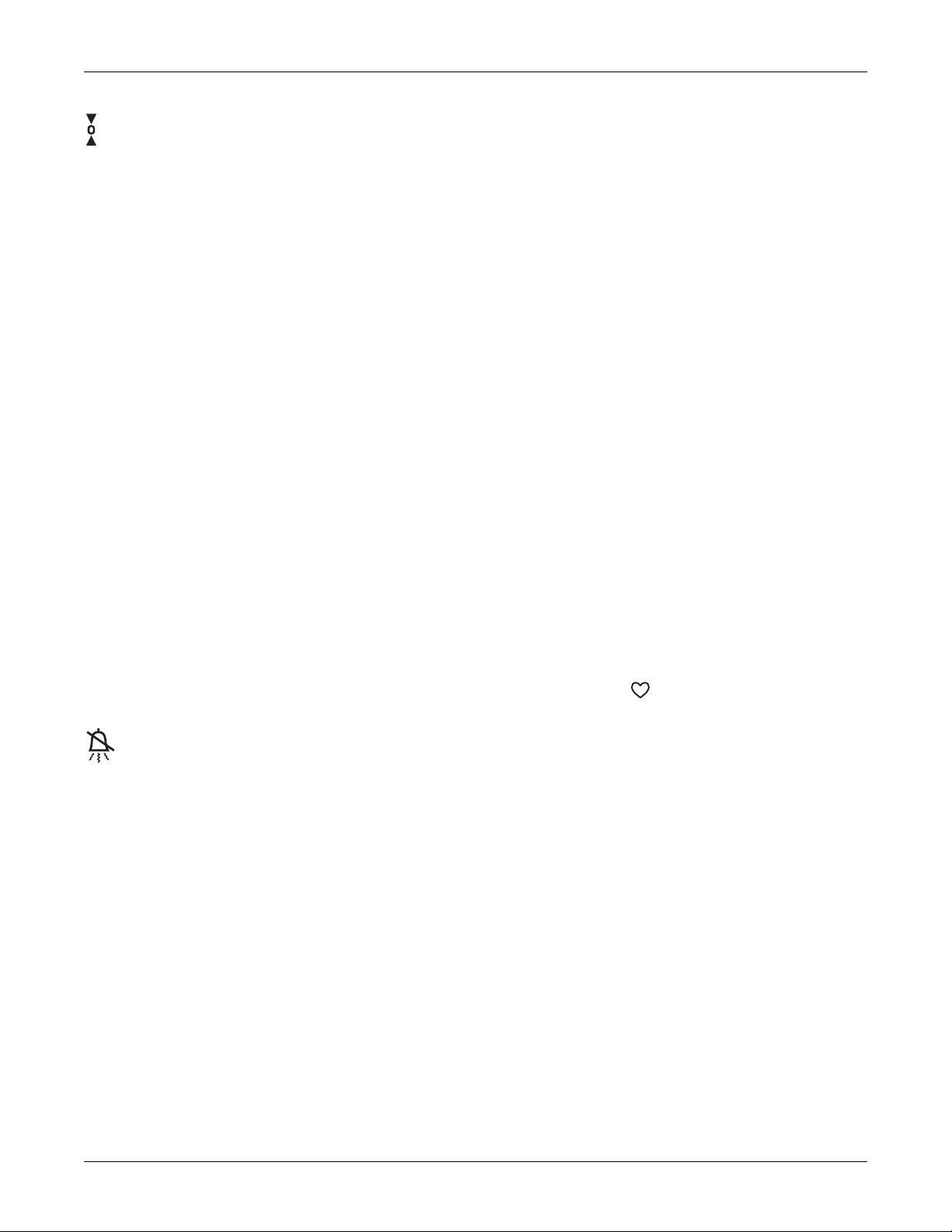

Controls, Indicators, and Connectors: Front Panel Controls

UA Reference Button

The UA Reference button is used to set the uterine activity pressure reference. This

button is also used during setup.

Setting a Baseline for External Monitoring (Tocotransducer)

Briefly pressing the UA Reference button sets the pressure baseline at a preset

default. The monitor is shipped from the factory with a default setting of 10 relative

units. Qualified service personnel can access a service screen to set the default to 5,

10, 15, 20, or 25 relative units.

Pressing this button for more than two seconds causes the uterine activity reference

value to override the default setting and cycle through all available selections: 5, 10,

15, 20, or 25 relative units, starting at the default setting—until the button is

released. While the button is held down, the strip chart tracing remains unchanged.

Once the button is released, the recorder trace takes on this new value. This value is

stored as the new baseline for the currently measured uterine activity signal.

Setting a Baseline for Internal Monitoring (IUPC)

Pressing the UA Reference button sets the pressure baseline at 0 mmHg.

Setup Mode

Alarm Silence Button

NOTE: IUPC monitoring is only available on Models 173 and 174.

When the monitor is in setup mode, the UA Reference button selects the active

display. Pressing the button alternates between the UA display (which shows a

monitor feature code) and the FHR display (which shows the setting or value for the

selected feature code). When the UA display is active, the ± sign lights. When the

FHR display is active, the heartbeat indicator lights.

This button is yellow for easy recognition. Pressing the Alarm Silence button

removes the audible indication of an individual fetal heart rate alarm.

NOTE: Silencing an alarm does not affect the visual indications.

Revision C 170 Series Monitor 3-5

2000947-004

Page 30

Controls, Indicators, and Connectors: Front Panel Displays and Indicators

Front Panel Displays and Indicators

Fetal Heart Rate Display(s) and Indicator(s)

FHR Display

A three-digit yellow numeric display indicates the fetal heart rate in beats per

minute. The value flashes during an alarm condition.

Heartbeat Indicator

A yellow heart shaped indicator flashes with each detected valid heartbeat for the

fetal heart.

Primary Versus Secondary (Models 172, 173, and 174 only)

Refer to Table 3-2 for a summary of display positions relative to connectors.

Uterine Activity Display

This green three-digit display indicates the uterine activity values.

Tocotransducer

If uterine activity is measured using a tocotransducer, the uterine activity value

displays in relative units. A plus sign flashes when the uterine activity value

exceeds the strip chart range of 100 relative units.

IUP (Models 173 and 174 Only)

If uterine activity is measured using an intrauterine pressure catheter or a strain

gauge pressure transducer, the uterine activity value displays in mmHg.

.

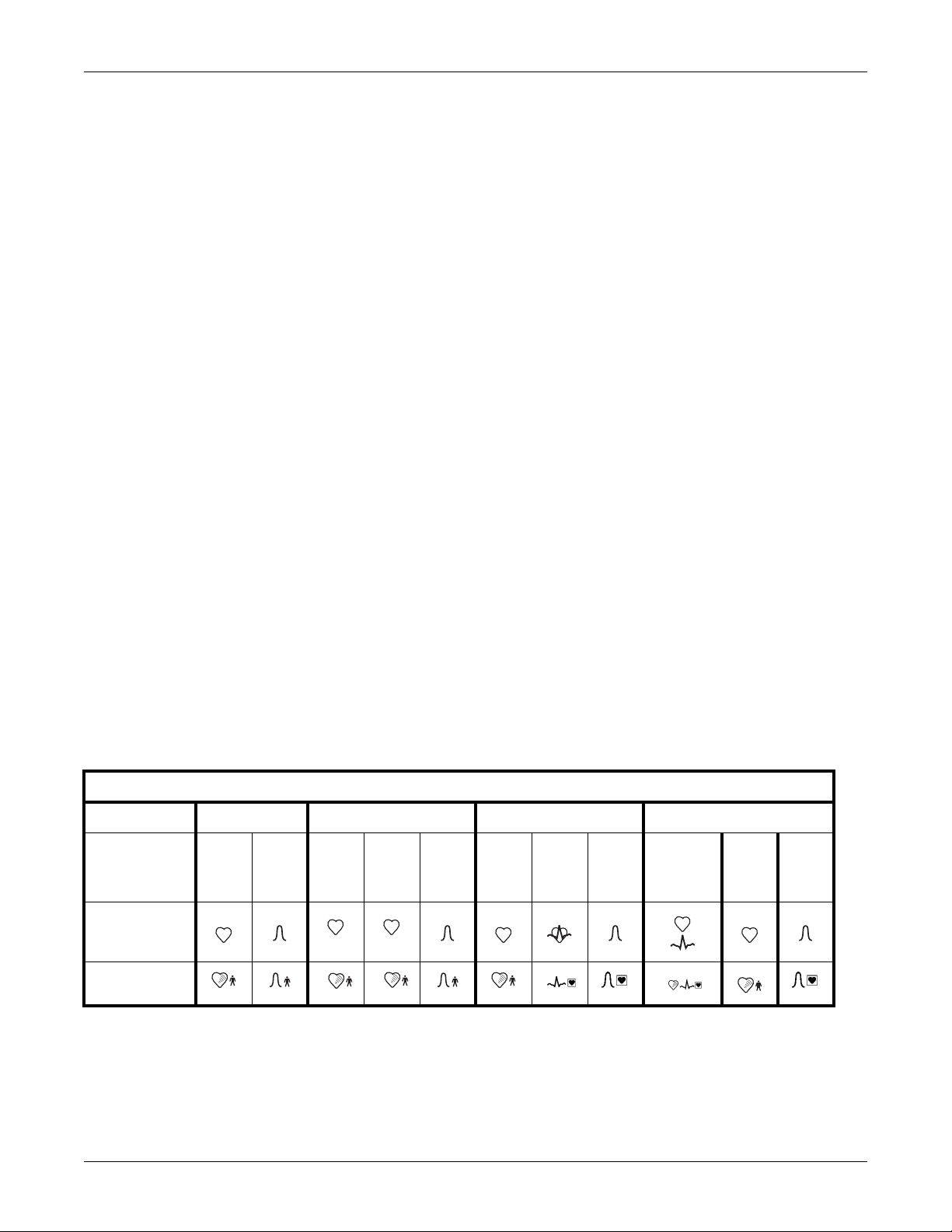

Table 3-2. Display/Connector Summary

Monitor Model 171 Model 172 Model 173 Model 174

Mode US TOCO US1 US2 TOCO US FECG

Display

1 2

TOCO

or

IUP

US1

or

FECG

US2

TOCO

or

IUP

Connector

3-6 170 Series Monitor Revision C

1

2

2000947-004

Page 31

Controls, Indicators, and Connectors: Front Panel Displays and Indicators

Alarms Disabled Indicator

Audio Alarm Indicator

Active Patient Alarms

Resolved Patient Alarms

Signal Quality Alarms

This yellow indicator illuminates when all alarms have been disabled. The indicator

is unlit when alarms are enabled. Refer to “Chapter 4, Setup Procedures” for

information on enabling/disabling alarms.

For active patient alarms, this yellow indicator flashes; it continues to flash even if

the alarm is silenced.

For resolved patient alarms, the indicator continues to flash until you silence the

alarm. This ensures that the alarm is acknowledged by a clinician.

For signal quality alarms, the indicator flashes during an active alarm and turns off

as soon as the condition is resolved. The indicator is unaffected by silencing the

audio alarm.

Revision C 170 Series Monitor 3-7

2000947-004

Page 32

Controls, Indicators, and Connectors: Front Panel Connectors

Front Panel Connectors

Model 171 Connectors

Ultrasound Connector

The ultrasound connector1 is a blue, round receptacle mechanically keyed to accept

only a Corometrics ultrasound transducer plug. The fetal heart rate derived from

this transducer shows in the fetal heart rate display.

Figure 3-2. Model 171 Connectors

Uterine Activity Connector

The uterine activity connector is a white, round receptacle mechanically keyed to

accept a Corometrics tocotransducer. The uterine activity value obtained from this

transducer shows in the uterine activity display.

1

If the Model 171 is interfaced to a clinical information system (CIS), be aware that the CIS may be

designed to alarm when there is no fetal heart rate signal. Therefore it is recommended that you

unplug the ultrasound transducer from the monitor, when not in use, to eliminate false alarms.

3-8 170 Series Monitor Revision C

2000947-004

Page 33

Controls, Indicators, and Connectors: Front Panel Connectors

Model 172 Connectors

1

2

Primary Ultrasound Connector

Secondary Ultrasound Connector

Uterine Activity Connector

1

Figure 3-3. Model 172 Connectors

The primary ultrasound connector1 is a blue, round receptacle mechanically keyed

to accept only a Corometrics ultrasound transducer plug. The fetal heart rate derived

from this transducer shows in the primary fetal heart rate display.

The secondary ultrasound connector1 is a blue, round receptacle identical to the

primary ultrasound connector described above. The fetal heart rate derived from

this connector displays in the secondary fetal heart rate display.

The uterine activity connector is a white, round receptacle mechanically keyed to

accept a Corometrics tocotransducer. The uterine activity value obtained from this

transducer shows in the uterine activity display.

2

1

If the Model 172 is interfaced to a clinical information system (CIS), be aware that the CIS may be

designed to alarm when there is no fetal heart rate signal. Therefore it is recommended that you

unplug the ultrasound transducer(s) from the monitor, when not in use, to eliminate false alarms.

Revision C 170 Series Monitor 3-9

2000947-004

Page 34

Controls, Indicators, and Connectors: Front Panel Connectors

Model 173 Connectors

Ultrasound Connector

Figure 3-4. Model 173 Connectors

The ultrasound connector1 is a blue, round receptacle mechanically keyed to accept

only a Corometrics ultrasound transducer plug. The fetal heart rate derived from

this transducer shows in the primary fetal heart display.

FECG Connector

The FECG connector1 is a dark grey, round receptacle mechanically keyed to

accept a Corometrics FECG cable/legplate plug. The fetal heart rate derived from

the spiral electrode displays in the secondary fetal heart rate display.

Uterine Activity Connector

The uterine activity connector is a white, round receptacle mechanically keyed to

accept a Corometrics tocotransducer, a Corometrics strain gauge transducer plug, or

any intrauterine pressure catheter with compatible cable plug. The uterine activity

value obtained from this transducer shows in the uterine activity display.

1

If the Model 173 is interfaced to a clinical information system (CIS), be aware that the CIS may be

designed to alarm when there is no fetal heart rate signal. Therefore it is recommended that you

unplug the ultrasound and/or FECG transducers from the monitor, when not in use, to eliminate false

alarms.

3-10 170 Series Monitor Revision C

2000947-004

Page 35

Controls, Indicators, and Connectors: Front Panel Connectors

Model 174 Connectors

Combi-Connector (Primary Ultrasound or FECG)

Figure 3-5. Model 174 Connectors

The combi-connector is a blue connector1 with a dark grey inner center. This round

receptacle is mechanically keyed to accept only a Corometrics ultrasound transducer

plug or a Corometrics FECG cable/legplate plug. The fetal heart rate derived from

this transducer or cable/legplate shows in the primary fetal heart display.

IMPORTANT

COMBI-CONNECTOR—The combi-connector can be used for

monitoring ultrasound or FECG depending on what you plug in

(US transducer or FECG cable/legplate). When used in

conjunction with the secondary ultrasound connector, you have

the option of monitoring twins using dual US or FECG/US.

Secondary Ultrasound Connector

The secondary ultrasound connector1 is a blue, round receptacle mechanically

keyed to accept only a Corometrics ultrasound transducer plug. The fetal heart rate

derived from this connector shows in the secondary fetal heart rate display.

Uterine Activity Connector

The uterine activity connector is a white, round receptacle mechanically keyed to

accept a Corometrics tocotransducer, a Corometrics strain gauge transducer plug, or

any intrauterine pressure catheter with compatible cable plug. The uterine activity

value obtained from this transducer shows in the uterine activity display.

1

If the Model 174 is interfaced to a clinical information system (CIS), be aware that the CIS may be

designed to alarm when there is no fetal heart rate signal. Therefore it is recommended that you

unplug the ultrasound and/or FECG transducers from the monitor, when not in use, to eliminate false

alarms.

Revision C 170 Series Monitor 3-11

2000947-004

Page 36

Controls, Indicators, and Connectors: Strip Chart Recorder

Strip Chart Recorder

4305AAO

bpm

150

180

210

240

FHR

30

60

90

120

8

12

10

Figure 3-6. Strip Chart Recorder

UA

kPa

0

426

Heart Rate Grid

The strip chart recorder is located on the right side of the front panel. Latches on

each side of the recorder open the paper drawer.

Two styles of paper are available: 30-240 BPM scale and 50-210 BPM scale.

Refer to “Chapter 4, Setup Procedures” for instructions on loading strip chart paper

into the recorder.

One or two fetal heart rate trends print in the top (or left) grid of the strip chart

paper—depending on your model monitor and the active modalities.

If only one fetal heart rate is being monitored, the FHR trend is printed in black. If

twins are being monitored, the primary trend is printed in plain black while the

secondary trend is bolded.

Refer to the “170 Series Operator’s Manual” for additional information about fetal

heart rate trends and annotations.

3-12 170 Series Monitor Revision C

2000947-004

Page 37

Controls, Indicators, and Connectors: Strip Chart Recorder

Uterine Activity Grid

Annotation Area

The uterine activity trend prints in black on the bottom (or right) grid of the strip

chart paper.

Refer to the “170 Series Operator’s Manual” for more information about uterine

activity trends and annotations.

An annotation area is provided between the fetal heart rate and uterine activity grids.

Revision C 170 Series Monitor 3-13

2000947-004

Page 38

Controls, Indicators, and Connectors: Rear Panel Connectors

Rear Panel Connectors

CONNECT TO:

GE MEDICAL SYSTEMS

REF 7714AAT ONLY

Figure 3-7. Rear Panel Connectors

RS232 RS232

12

Power Supply Connector

This is the receptacle for the AC adapter, P/N 7714AAT only. A line cord connects

from the other end of the adapter to an AC wall outlet. The connector is labeled

CONNECT TO GE MEDICAL SYSTEMS REF 7714AAT ONLY. The power supply is a

universal AC-to-DC converter which can accept an AC input in the range 100–230

VAC. The converter supplies a regulated 12 Vdc to the monitor.

Remote Mark Connector

This connector is provided for attaching an optional Corometrics Model 146 Fetal

Acoustic Stimulator (FAST). The annotation

the Model 146 is used.

Remote Mark Connector

This connector is provided for attaching an optional Corometrics Remote Event

Marker. This accessory annotates the strip chart recorder paper with a marker which

can be configured as one of the following:

The monitor is factory set to use the annotation. Refer to the “Chapter 4, Setup

Procedures” for information about selecting the annotation.

prints on the strip chart each time

: This annotation is commonly used to record an “event.”

FM

: This annotation is commonly used as an indication that the mother has

perceived fetal movement.

FM

3-14 170 Series Monitor Revision C

2000947-004

Page 39

Controls, Indicators, and Connectors: Rear Panel Connectors

Nurse Call Interface

RS-232C Connectors

This connector is intended for future interfacing to a standard Nurse Call System.

Two RS-232C connectors are provided for interfacing to peripheral equipment such

as:

a maternal non-invasive blood pressure monitor

a central information system that uses Hewlett-Packard’s Digital Series

Interface Protocol

Contact your Service Representative for more information.

CAUTION

NON-DESTRUCTIVE VOLTAGE—The maximum nondestructive voltage that may be applied to the rear panel

connectors is 0 V. Do not attempt to connect cables to these

connectors without contacting your Biomedical Engineering

Department or Service Representative. This is to ensure the

connectors comply with leakage-current requirements of one of

the following applicable standards: Underwriters Laboratories

UL-2601.1, Canadian Standards Associations CSA 22.2 No. 125,

or International Electrotechnical Commission EN60601.1.

Telemetry Connector

This high-density 15-pin connector is intended for future interfacing to the receiver

of a Corometrics telemetry system. Contact your Service Representative for more

information.

IMPORTANT

TELEMETRY—For proper operation when using a telemetry

system, disconnect all transducers from the front panel of the 170

Series Monitor. Refer to the operator’s manual for your telemetry

system for more information.

Revision C 170 Series Monitor 3-15

2000947-004

Page 40

For your notes

3-16 170 Series Monitor Revision C

2000947-004

Page 41

Chapter 4

Setup Procedures 4

This section contains information about configuring a 170 Series Monitor to meet

the individual needs of your clinic or hospital. Use of the monitor will vary

according to the accessories attached to it, the clinical applications in which it is

used, and the personal preferences of the users.

This chapter lists all available user setup options in the monitor and provides stepby-step instructions for making selections:

Loading Strip Chart Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Turning the Monitor On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Recorder Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Customizing the Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Printing a Summary of Configuration Settings . . . . . . . . . . . . . . . . 4-17

Quick Reference Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Flasher Software Utility Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Revision C 170 Series Monitor 4-1

2000947-004

Page 42

Setup Procedures: Loading Strip Chart Paper

Loading Strip Chart Paper

The required paper for use with the 170 Series Monitor is:

catalog number (REF) 4305AAO/CAO

(HR scale of 30–240 BPM); or

catalog number (REF) 4305BAO/DAO

(HR scale of 50–210 BPM).

CAUTIONS

LOADING PAPER—The instructions for loading paper into a

120 or 170 Series Monitor are different than the instructions for

loading paper into other Corometrics monitors with which you

may be familiar. Improper loading can cause paper jams. Follow

the instructions carefully.

PAPER TYPE—Do not use non-Corometrics paper or paper

designed for use with other Corometrics monitors. Using paper

other than catalog number (REF) 4305AAO/BAO/CAO/DAO:

may produce inferior print quality; could result in permanent

damage to the recorder’s print head; and may void your warranty.

STORAGE/TRANSPORT—Paper should be installed in the

monitor’s strip chart recorder at all times. This reduces particle

build up on the printhead and facilitates opening the recorder door.

To protect against paper jams, the 170 Series recorder contains a paper-loading

sensor which detects if the paper has been incorrectly loaded. When the recorder

detects a paper-load–error condition:

the recorder will not print;

the Record indicator flashes on and off every second; and

three short beeps (low tones) sound every three seconds at a fixed volume.

The most likely cause of a paper-load–error condition is that you loaded the paper

with the black squares facing up. The correct method is to load the paper with the

black squares down, as explained later in this section.

4-2 170 Series Monitor Revision C

2000947-004

Page 43

Setup Procedures: Loading Strip Chart Paper

To install Corometrics catalog number (REF) 4305AAO/BAO/CAO/DAO chart

paper in the 170 Series Monitor, follow these steps:

CAUTION

LOADING PAPER—Paper loading instructions for a 170 or 120

Series Monitor are different than other Corometrics monitors with

which you may be familiar.

1. Press on each side of the paper drawer to release the drawer latches.

Figure 4-1. Releasing the Drawer Latches

2. Slide the paper drawer out toward you.

Figure 4-2. Opening the Paper Drawer

3. Remove the plastic wrapper from the paper and discard.

Revision C 170 Series Monitor 4-3

2000947-004

Page 44

Setup Procedures: Loading Strip Chart Paper

4. Fan the pack of Z-fold paper on all sides to loosen any folds and to ensure

proper feed of the paper throughout the recorder.

Figure 4-3. Fanning the Paper

5. Hold the package of paper so that:

the black squares are on the bottom of the pack; and

the Information Technologies name and page numbers are on the left side

of the pack.

NOTE: The black squares indicate the end of the recorder paper. When the black

squares appear, the strip chart recorder has approximately 20 minutes of

paper remaining, when running at a speed of 3 cm/min.

Figure 4-4. Orienting the Paper

4-4 170 Series Monitor Revision C

2000947-004

Page 45

Setup Procedures: Loading Strip Chart Paper

6. Unfold two sheets from the top of the pack so that they extend toward you.

Figure 4-5. Creating a Paper Leader

7. Place the pack in the drawer so that the pack is laying flat in the bottom of the

paper tray.

Figure 4-6. Inserting the Paper

Revision C 170 Series Monitor 4-5

2000947-004

Page 46

Pull paper

leader taut

Remaining paper

lays flat in drawer

Setup Procedures: Loading Strip Chart Paper

8. Pull the paper leader taut at an angle between remaining pack and the paper

guides. The balance of the paper pack should stay flat in the drawer as shown in

Figure 4-7. (The paper guides are shown in Figure 4-8.)

Figure 4-7. Paper Drawer Side Cutaway View

9. Slide the drawer closed by exerting even pressure on both sides of the drawer.

Avoid skewing the drawer in its tracks. (The pre-printed vertical lines on the

paper should be parallel to the printhead.) You will hear a click when the

drawer is locked in place.

Paper Guide

90

60

30

Printhead

12

10

8

6

4

2

A

U

a

kP

0

Paper Guide

bpm

240

210

180

R

H

F

150

O

A

5A

430

120

Figure 4-8. Closing the Paper Drawer

IMPORTANT

PAPER—Paper should always be installed in the monitor. The

monitor runs a self-test routine each time it is powered on; part of

this routine includes a recorder test.

4-6 170 Series Monitor Revision C

2000947-004

Page 47

Setup Procedures: Turning the Monitor On

Turning the Monitor On

The 170 Series uses a universal AC-to-DC converter which accepts an AC input in

the range 100–230 VAC. The converter supplies a regulated 12 Vdc to the 170

Series Monitor.

1. Connect the AC adapter into the power supply connector labeled:

GE MEDICAL SYSTEMS REF 7714AAT ONLY

Figure 4-9. Connecting the AC Adapter

2. Connect one end of the detachable line cord to the AC adapter; connect the

other end into a hospital grade grounded wall outlet.

.

CONNECT TO

3. Press the monitor’s

illuminates. A self-test routine automatically runs. Read "Monitor Self-Test

Routines" on the next page.

Power button . The green indicator next to the button

Figure 4-10. Turning the Monitor On

Revision C 170 Series Monitor 4-7

2000947-004

Page 48

Setup Procedures: Monitor Self-Test Routines

Monitor Self-Test Routines

NOTE: Ensure paper is installed in the recorder in order to verify a successful

recorder test.

Each 170 Series Monitor contains a self-test routine which checks the internal

circuitry of the monitor, the displays and indicators, and the strip chart recorder.

The self-test routine is automatically initiated each time you turn on the monitor.

CAUTION

SELF-TEST FAILURE—If there is any problem with the self-test

routine, turn off the monitor and remove it from operation. Notify

your Biomedical Engineering Department or Service

Representative.

After completion of a successful self-test routine, the monitor is ready for use.

NOTE: If the recorder was off at the time the monitor was turned off, the test

routine will turn the recorder on, then turn it off after the tests are complete.

If the recorder was on at the time the monitor was turned off, the tests will

be performed and the recorder will remain on.

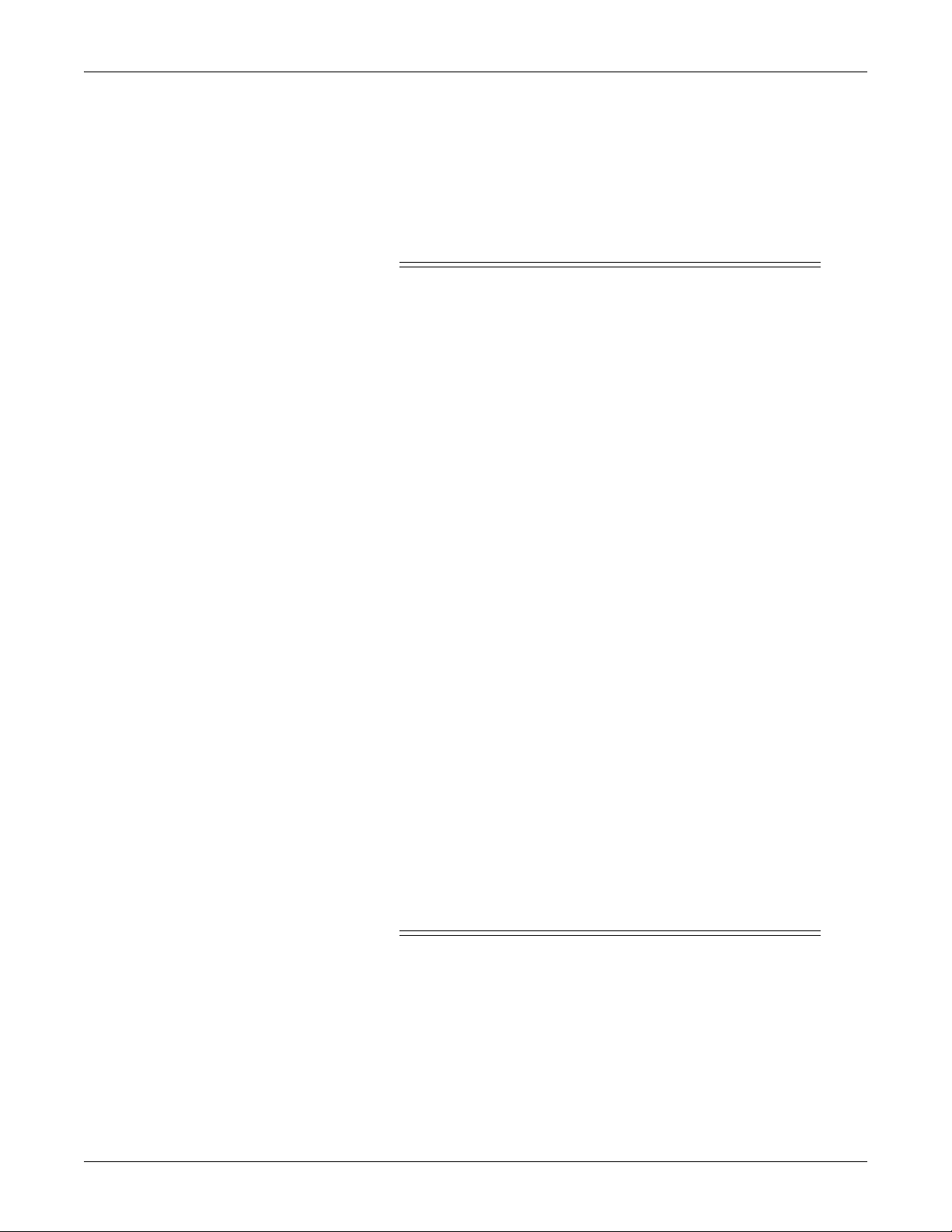

Table 4-1. Summary of Self-Test Routines

Test Description What to Verify

Display/Indicator Test: All displays and indicators

illuminate.

Internal Test: The internal circuitry of the monitor is

verified.

Recorder Test: The following message prints on the

strip chart paper: TEST: ARE ALL DOTS PRINTED?

Three continuous lines are drawn across the strip chart

recorder paper, testing the integrity of the printhead.

See Figure 4-11.

Ensure all indicators and each segment of the displays

illuminate throughout the entire self-test routine.

Make sure the monitor performs the recorder test. If

there is a problem with the internal circuitry, the recorder

test will not be performed.

Ensure that the lines are printed in the correct positions

on the paper. Verify that the lines are continuous and no

gaps appear on the traces.

4-8 170 Series Monitor Revision C

2000947-004

Page 49

Setup Procedures: Monitor Self-Test Routines

HR Scale

4305CAO

GE MEDICAL SYSTEMS

PAGES

REMAING

30-240

TEST: ARE

ALL DOTS

PRINTED?

12

10

8

6

FHR

240

210

180

150

120

90

60

30

bpm

41153

100

75

50

4

2

kPa

0

Figure 4-11. Recorder Test

25

0

UA mm Hg

Revision C 170 Series Monitor 4-9

2000947-004

Page 50

Setup Procedures: Customizing the Monitor

Customizing the Monitor

User Setup Mode

The monitor includes a user setup mode where you can:

enable/disable alarm functionality

set the high alarm limit for the fetal heart rate

set the low alarm limit for the fetal heart rate

set the alarm volume

set the time and date

Service Setup Mode

The monitor includes a service setup mode where you can access all user setup

modes as well as the following:

enable/disable fetal movement detection

(if purchased and installed)

select the language for printing on the strip chart paper

set the chart speed

select the paper scale

choose a communication mode for each rear panel communications port

set the baud rate for each communications port

select the remote mark annotation style

enable/disable fetal heart rate offset

(Models 172, 173, and 174 only)

enable/disable ECG artifact elimination

(Models 173 and 174 only)

enable/disable heartbeat coincidence

(Models 172, 173, and 174 only)

set the default UA reference value

perform a recorder alignment test

print the software version number along with a summary of all current

configuration settings

4-10 170 Series Monitor Revision C

2000947-004

Page 51

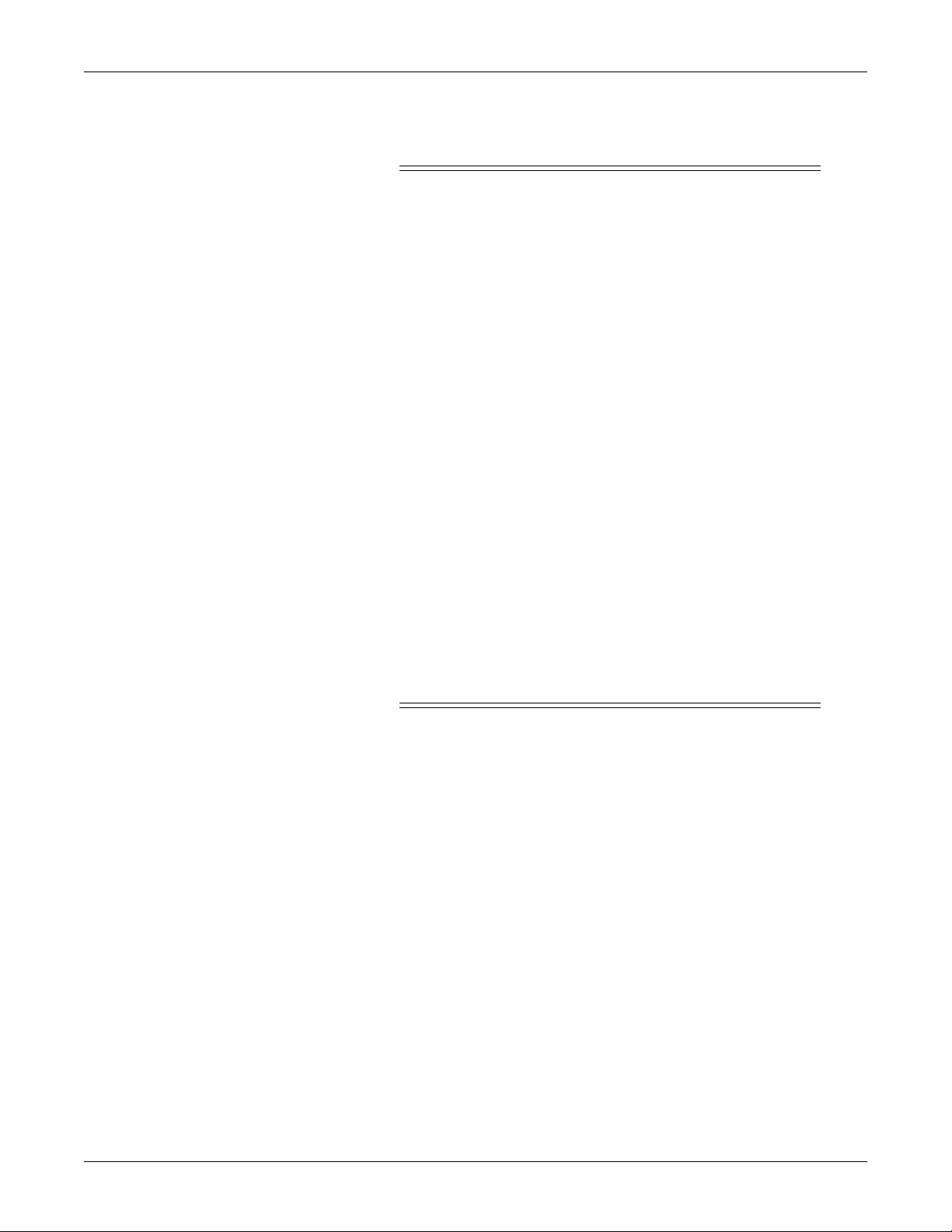

EXAMPLE

Setup Procedures: Customizing the Monitor

Setting or value for

selected feature (e.g.

FHR Alarms On or 180

BPM High Alarm Limit).

Monitor Feature Code

(e.g. FHR Alarms or

High Alarm Limit).

Press to enter the

1

user setup mode.

Use

2

3

4

( ) to select

feature code 2FHR

High Alarm Limit.

See Table 4-2.

Press

to switch

displays. The

heartbeat indicator

lights.

Use ( ) to change

the value to 185

BPM. See Table

4-2.

21

21

Press

between displays.

21

Use ( or ) to

change the number.

21

( or ) to

Use

change the number.

to switch

Press to switch between displays.

Repeat steps to change other settings.

Press

5

to switch

displays again. The

± sign lights. (Repeat

steps 2 to 5 .)

21

NOTE: For Models 172, 173, and 174, use the leftmost set of volume controls.

Figure 4-12. Setup Mode Summary (Model 172 shown)

Revision C 170 Series Monitor 4-11

2000947-004

Page 52

Setup Procedures: Customizing the Monitor

You can enter the user setup mode during an active monitoring session. The fetal

heart rate and uterine activity trends print without interruption and the FHR tones

remain audible; however you will be unable to see the heart rate and uterine activity

values on the display while in the user setup mode.

You can only enter the service setup mode from a power off state.

NOTE: If an alarm occurs while in user setup mode, the heart rate display will not

flash; however, the alarm indicator flashes and the audio alarm sounds.

As soon as you exit the setup mode, the affected display flashes to indicate

the alarm condition.

1. Enter the appropriate mode, user or service, as follows:

User: To enter the user mode:

Press the monitor’s Power button to turn on the monitor. Wait until

the monitor completes the self-test routine and enters the normal operating

mode.

Press and hold the Setup button , for three seconds, to enter the user

setup mode.

Service: To enter the service mode:

Press and hold the Setup button

Press and hold the blue Power button .

Release both buttons. The service mode is now activated.

2. Use the

UA Reference button to toggle between the setup code (shown in

the UA display) and the setting or value (shown in the primary FHR display).

The UA display is active when the

active when the heartbeat indicator

3. Use the

Volume buttons to increase ( ) or decrease ( ) the code,

± qualifier illuminates; the FHR display is

() illuminates.

value, or setting shown in the active display. Refer to Table 4-2 (user codes) or

Table 4-3 (service codes). (For Models 172, 173, and 174, use the leftmost set

of volume controls.)

4. Repeat steps 2 and 3 until all settings are configured.

5. Press the

Setup button to exit the setup mode. Exiting the user setup

mode returns to the monitoring mode; exiting the service setup mode turns the

monitor to standby.

4-12 170 Series Monitor Revision C

2000947-004

Page 53

Setup Procedures: Customizing the Monitor

NOTE: If you press the

Power button to exit the setup mode (user or service)

any changes you made will not be stored in memory.

NOTE: You must exit by pressing the

Setup button in order for changes to

take effect.

NOTE: If an alarm is in progress when you exit the user setup mode, any changes

to an alarm setting do not take effect until the alarm condition is resolved.

Table 4-2 lists the available settings for the user setup mode. Table 4-3 lists the

available settings for the service setup mode. Table 4-4 provides a summary of the

factory default settings for both the user and service setup options.

Revision C 170 Series Monitor 4-13

2000947-004

Page 54

Setup Procedures: Customizing the Monitor

Table 4-2. Summary of User Setup Codes

Code

(UA Display)

Code Description

Setting or Value

(Primary FHR Display)

1

FHR Alarms

0 = off (disabled)

1 = on (enabled)

2 FHR High Alarm Limit 140–210 (BPM, in increments of 5 BPM)

3 FHR Low Alarm Limit 50–140 (BPM, in increments of 5 BPM)

4 FHR Alarm Volume 2–10

10 Minutes (time setting) 0–59 (minutes)

11 Hours (time setting) 0–23 (hours)

12 Day of Month (date setting) 1–31 (day)

13 Month (date setting) 1–12 (month)

14 Year (date setting) 00–99 (year)

4-14 170 Series Monitor Revision C

2000947-004

Page 55

Setup Procedures: Customizing the Monitor

Table 4-3. Summary of Service Setup Codes

Code (UA Display)

Code # Code Description

Setting Or Value

(Primary FHR Display)

20 ECG artifact elimination (173, 174 only) 0 = off; 1 = on

21 heartbeat coincidence (172, 173, 174 only) 0 = off; 1 = on

22 fetal movement enable/disable

1 = on (if option installed)

0 = off

0 = English; 1 = Spanish; 2 = German;

23 language

3 = French; 4 = Japanese; 5 = Italian;

6 = Swedish; 7 = Dutch; 8 = Portuguese;

9 = Chinese

24 chart speed 1= 1; 2 = 2; 3 = 3 (cm/min)

25 paper scale 0 = 30–240; 1 = 50–210 (BPM)

0 = HP; 1 = HP w/notes;

30, 40 communications mode (port 1, 2)

2 = ext BP; 3 = factory test; 4 = ext. FSpO

5 = 115 update; 6 = 115 transmit/receive

3

31, 41 baud rate (port 1, 2)

00; 600; 1200; 2400;

48

00; 9600; 19200; 38400

50 remote mark annotation style 0 = FM; 1 = arrow

2;

51 future use (Japanese units only) 0 = off; 1 = on

52 fetal heart rate offset enable/disable 0 = off; 1 = 10 minute auto-revert; 2 = on

53 UA reference default 5, 10, 15, 20, 25 (relative units)

100 recorder alignment 0–255

Revision C 170 Series Monitor 4-15

2000947-004

Page 56

Setup Procedures: Customizing the Monitor

Table 4-4. Summary of Factory Defaults

Setup Option Factory Default Hospital/Clinic Setting

FHR Alarms on

FHR High Alarm Limit 160 BPM

FHR Low Alarm Limit 120 BPM

FHR Alarm Volume 5

Eastern Standard Time or Daylight-

Time/Date

Saving Time—whichever is

applicable

*ECG Artifact Elimination

(Models 173 and 174 only)

*Heartbeat Coincidence

(Models 172, 173, and 174 only)

*Fetal Movement Detection

(if purchased and installed)

*Language

*Recorder Speed

*Paper Scale

*RS-232 Port 1

Communications Mode

*RS-232 Port 1

Baud Rate

*RS-232 Port 2

Communications Mode

*RS-232 Port 2

Baud Rate

off

off

on

set according to shipping

destination

United States: 3 cm/min

International: 1 cm/min

United States: 30–240 BPM

International: 50–210 BPM

HP

1200

ext. BP

600

*Remote Mark Annotation

*HR Offset

(Models 172, 173, and 174 only)

on with 10-minute auto-revert

FM

on ( )

*UA Reference 10 relative units

* = service setup mode

4-16 170 Series Monitor Revision C

2000947-004

Page 57

Setup Procedures: Customizing the Monitor

Printing a Summary of Configuration Settings

To print the software version number and a summary of configuration settings on

the strip chart paper:

NOTE: You can only enter the service setup mode from a power off state.

1. Enter the service mode:

Press and hold the Setup button

Press and hold the blue Power button .

Release both buttons. The service mode is now activated.

2. Press the

Record button . Figure 4-13 shows a sample printout.

Figure 4-13. Configuration Summary Printout

Revision C 170 Series Monitor 4-17

2000947-004

Page 58

Setup Procedures: Quick Reference Card

Quick Reference Card

Your monitor was shipped with a Quick Reference Card in the appropriate language.

The front side lists the user setup codes while the reverse lists the service setup

codes. The card is laminated and comes with hook and loop adhesives to attach to

your monitor.

A copy of this card is included on the following page if you wish to make additional

copies for training. Additional Quick Reference Cards can be purchased by calling

one of the numbers listed in the front of this manual. Table 4-5 provides a summary

of the Quick Reference Card re-order numbers:

Table 4-5. 170 Series Quick Reference Card

Language Document Part Number

English 2003024-001

Chinese 2003024-002

Dutch 2003024-003

French 2003024-004

German 2003024-005

Italian 2003024-006

Japanese 2003024-007

Portuguese 2003024-008

Spanish 2003024-009

Swedish 2003024-010

Polish 2003024-011

Greek 2003024-013

Russian 2003024-014

Czechoslovakian 2003024-015

4-18 170 Series Monitor Revision C

2000947-004

Page 59

Setup Procedures: Quick Reference Card

Revision C 170 Series Monitor 4-19

2000947-004

Page 60

Setup Procedures: Flasher Software Utility Upgrade

Flasher Software Utility Upgrade

The Corometrics Flasher is a software utility program which uses one of the

monitor’s RS-232 serial ports to upgrade to a newer software release; or to install a

purchased option such as fetal movement detection. Each Flasher disk contains the

software upgrade for one-time use only. (In other words, you need an individual

Flasher disk for each monitor being upgraded.) Table 4-6 lists the Flasher kits

available for the 170 Series.

Table 4-6. Flasher Kits

Kit Description Catalog Number

Fetal Movement Detection

Feature Addition

Software Upgrade to Version 3.2x

which includes the following

features:

Heartbeat coincidence

Portuguese/Chinese languages

(1701BAO only)

Communications interface to

external FSpO2 monitors

Communications support of 115

Update and 115 Transmit/

Receive protocols

1700AAO

1701AAO (English language units)

1701BAO (non-English language units)

4-20 170 Series Monitor Revision C

2000947-004

Page 61

Chapter 5

Theory of Operation 5

This section of the manual contains the electronic theory of operation for the 170

Series Monitor. When possible, references are made to the appropriate schematic

contained in “Chapter 11, Parts Lists” of this manual

Throughout this chapter, signal names ending with an asterisk (*) are active low.

This chapter contains the following information:

Functional Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Main Board Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

FECG/IUP Board Theory of Operation . . . . . . . . . . . . . . . . . . . . . . 5-36

Revision C 170 Series Monitor 5-1

2000947-004

Page 62

Theory of Operation: Functional Overview

Functional Overview

For all 170 Series Monitors, the Main Board controls the majority of the 170 Series

functionality including:

antepartum (US, TOCO) front ends and connector(s)

uterine activity front end and connector

seven-segment displays

user-interface buttons

peripheral device communications

processing

For Models 173 and 174, a separate FECG/IUP Board controls:

intrapartum front ends

isolation for analog signals

Figure 5-1 provides an overview of the system architecture. Table 5-1 through

Table 5-17 provide pinouts for each of the external connectors and the internal main

board harness connectors. Figure 5-2 through Figure 5-9 provide illustrations of the

front and rear panel connectors.

Display Board

Membrane

Switch Panel

Speaker

Cable

Display

Speaker

Cable

Cable

Membrane

Cable

Printhead

Cable

Sensor

MAIN BOARD

Figure 5-1. Overview of System Architecture

RECORDER MODULE

Printhead and Sensors

5-2 170 Series Monitor Revision C

2000947-004

Page 63

Theory of Operation: Functional Overview

Table 5-1. Main Power Connector

Pin Number Description

1 +12 Vdc Input

2 Negative Input

3 Shield

1

2

3

Figure 5-2. Main Power Connector

Revision C 170 Series Monitor 5-3

2000947-004

Page 64

Theory of Operation: Functional Overview

Table 5-2. Recorder Printhead Connector

Signal Type

Pin Number Signal Name

(Relative To Recorder

Signal Description

Board)

1 +24V Input +24 Volts for Recorder

2 +24V Input +24 Volts for Recorder

3 +24V Input +24 Volts for Recorder

4 +24V Input +24 Volts for Recorder

5 HGND Input Ground for +24V

6 HGND Input Ground for +24V

7 HGND Input Ground for +24v

8 HGND Input Ground for +24V

9 HGND Input Ground for +24V

10 +5v Input +5V for Logic

11 NC No Connection

12 NC No Connection

13 STB0* Input Head Strobe 0

14 STB1* Input Head Strobe 1

15 STB2* Input Head Strobe 2

16 STB3* Input Head Strobe 3

17 BSCK Input Head Serial Clock (3.07 MHz)

18 LD* Input Head Load Line

19 PDATA Input Head Serial Data

20 NC No Connection

* Active low.

5-4 170 Series Monitor Revision C

2000947-004

Page 65

Theory of Operation: Functional Overview

Table 5-3. Recorder Motor Connector

Signal Type

Pin Number Signal Name

(Relative to

Signal Description

Main board)

1 NC No Connection

2 P3 Output Motor Phase 3

3 P4 Output Motor Phase 4

4 +5VM Output +5 Volts for Motor

5 NC No Connection

6 P2 Output Motor Phase 2

7 P1 Output Motor Phase 1

8 +5VM Output +5 Volts for Motor

Table 5-4. Recorder Sensor Connector

Signal Type

Pin Number Signal Name