Page 1

GE Healthcare

System Service Manual

SYSTEM COMPAX 40E, CE Marked with MPH 50/65/80

(including XT, RS 85 and Tomo−Link

Direction 2154260−100, Revision 9

Copyright 1999 By General Electric Co.

All Rights Reserved

Page 2

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

THIS PAGE INTENTIONALLY LEFT BLANK.

ii

Page 3

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

− THIS SERVICE MANUAL IS AVAILABLE IN ENGLISH ONLY.

WARNING

AVERTISSEMENT

− IF A CUSTOMER’S SERVICE PROVIDER REQUIRES A LANGUAGE OTHER THAN

ENGLISH, IT IS THE CUSTOMER’S RESPONSIBILITY TO PROVIDE

TRANSLATION SERVICES.

− DO NOT ATTEMPT TO SERVICE THE EQUIPMENT UNLESS THIS SERVICE

MANUAL HAS BEEN CONSULTED AND IS UNDERSTOOD.

− FAILURE TO HEED THIS WARNING MAY RESULT IN INJURY TO THE SERVICE

PROVIDER, OPERATOR OR PATIENT FROM ELECTRIC SHOCK, MECHANICAL

OR OTHER HAZARDS.

− CE MANUEL DE MAINTENANCE N’EST DISPONIBLE QU’EN ANGLAIS.

− SI LE TECHNICIEN DU CLIENT A BESOIN DE CE MANUEL DANS UNE AUTRE

LANGUE QUE L’ANGLAIS, C’EST AU CLIENT QU’IL INCOMBE DE LE FAIRE

TRADUIRE.

− NE PAS TENTER D’INTERVENTION SUR LES ÉQUIPEMENTS TANT QUE LE

MANUEL SERVICE N’A PAS ÉTÉ CONSULTÉ ET COMPRIS.

− LE NON-RESPECT DE CET AVERTISSEMENT PEUT ENTRAÎNER CHEZ LE

TECHNICIEN, L’OPÉRATEUR OU LE PATIENT DES BLESSURES DUES À DES

DANGERS ÉLECTRIQUES, MÉCANIQUES OU AUTRES.

WARNUNG

AVISO

− DIESES KUNDENDIENST−HANDBUCH EXISTIERT NUR IN ENGLISCHER

SPRACHE.

− FALLS EIN FREMDER KUNDENDIENST EINE ANDERE SPRACHE BENÖTIGT,

IST ES AUFGABE DES KUNDEN FÜR EINE ENTSPRECHENDE ÜBERSETZUNG

ZU SORGEN.

− VERSUCHEN SIE NICHT, DAS GERÄT ZU REPARIEREN, BEVOR DIESES

KUNDENDIENST−HANDBUCH ZU RATE GEZOGEN UND VERSTANDEN WURDE.

− WIRD DIESE WARNUNG NICHT BEACHTET, SO KANN ES ZU VERLETZUNGEN

DES KUNDENDIENSTTECHNIKERS, DES BEDIENERS ODER DES PATIENTEN

DURCH ELEKTRISCHE SCHLÄGE, MECHANISCHE ODER SONSTIGE

GEFAHREN KOMMEN.

− ESTE MANUAL DE SERVICIO SÓLO EXISTE EN INGLÉS.

− SI ALGÚN PROVEEDOR DE SERVICIOS AJENO A GEMS SOLICITA UN IDIOMA

QUE NO SEA EL INGLÉS, ES RESPONSABILIDAD DEL CLIENTE OFRECER UN

SERVICIO DE TRADUCCIÓN.

− NO SE DEBERÁ DAR SERVICIO TÉCNICO AL EQUIPO, SIN HABER

CONSULTADO Y COMPRENDIDO ESTE MANUAL DE SERVICIO.

− LA NO OBSERVANCIA DEL PRESENTE AVISO PUEDE DAR LUGAR A QUE EL

PROVEEDOR DE SERVICIOS, EL OPERADOR O EL PACIENTE SUFRAN

LESIONES PROVOCADAS POR CAUSAS ELÉCTRICAS, MECÁNICAS O DE

OTRA NATURALEZA.

iii

Page 4

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

− ESTE MANUAL DE ASSISTÊNCIA TÉCNICA SÓ SE ENCONTRA DISPONÍVEL

ATENÇÃO

AVVERTENZA

EM INGLÊS.

− SE QUALQUER OUTRO SERVIÇO DE ASSISTÊNCIA TÉCNICA, QUE NÃO A

GEMS, SOLICITAR ESTES MANUAIS NOUTRO IDIOMA, É DA

RESPONSABILIDADE DO CLIENTE FORNECER OS SERVIÇOS DE TRADUÇÃO.

− NÃO TENTE REPARAR O EQUIPAMENTO SEM TER CONSULTADO E

COMPREENDIDO ESTE MANUAL DE ASSISTÊNCIA TÉCNICA.

− O NÃO CUMPRIMENTO DESTE AVISO PODE POR EM PERIGO A SEGURANÇA

DO TÉCNICO, OPERADOR OU PACIENTE DEVIDO A‘ CHOQUES ELÉTRICOS,

MECÂNICOS OU OUTROS.

− IL PRESENTE MANUALE DI MANUTENZIONE È DISPONIBILE SOLTANTO IN

INGLESE.

− SE UN ADDETTO ALLA MANUTENZIONE ESTERNO ALLA GEMS RICHIEDE IL

MANUALE IN UNA LINGUA DIVERSA, IL CLIENTE È TENUTO A PROVVEDERE

DIRETTAMENTE ALLA TRADUZIONE.

− SI PROCEDA ALLA MANUTENZIONE DELL’APPARECCHIATURA SOLO DOPO

AVER CONSULTATO IL PRESENTE MANUALE ED AVERNE COMPRESO IL

CONTENUTO.

− NON TENERE CONTO DELLA PRESENTE AVVERTENZA POTREBBE FAR

COMPIERE OPERAZIONI DA CUI DERIVINO LESIONI ALL’ADDETTO ALLA

MANUTENZIONE, ALL’UTILIZZATORE ED AL PAZIENTE PER FOLGORAZIONE

ELETTRICA, PER URTI MECCANICI OD ALTRI RISCHI.

iv

Page 5

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

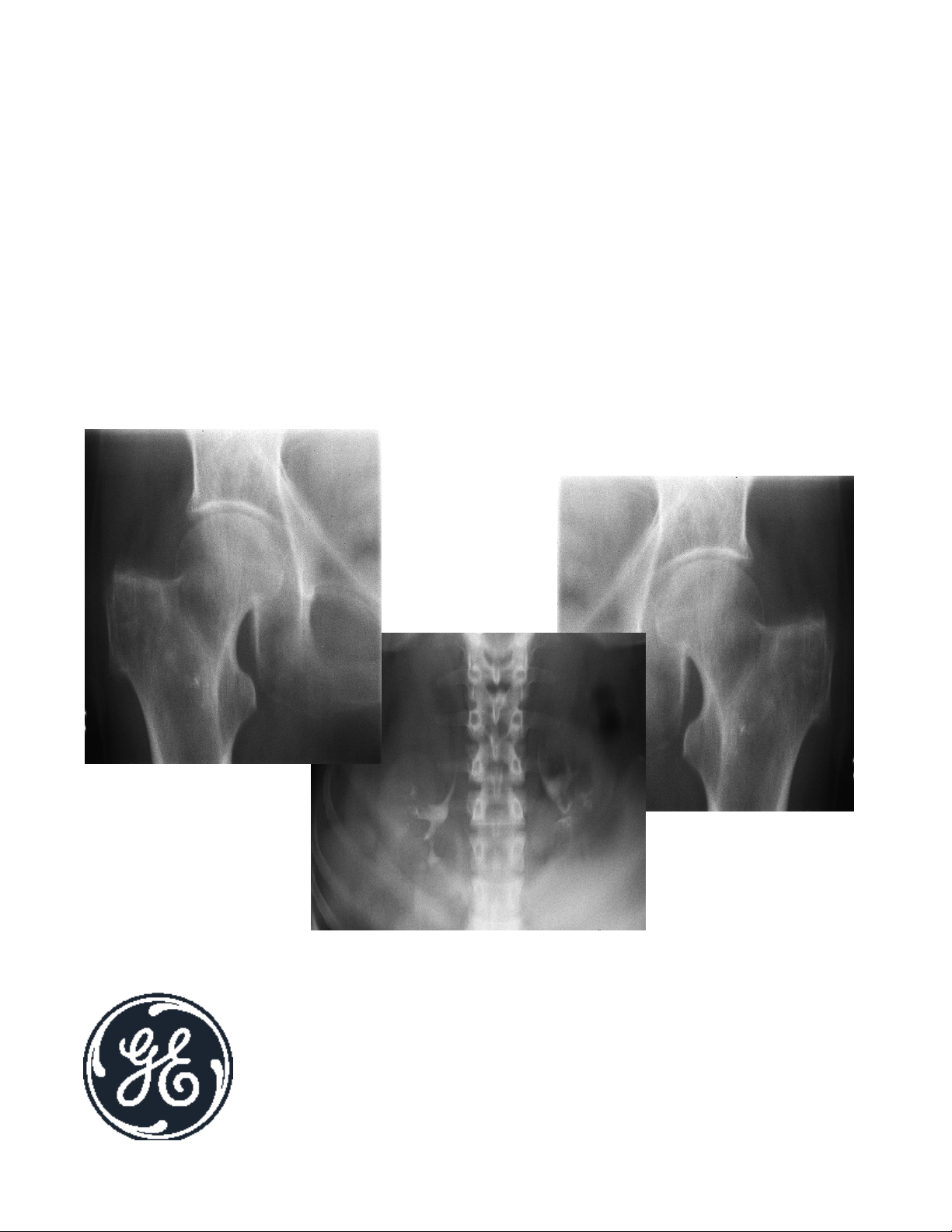

IMPORTANT! . . . X-RAY PROTECTION

X-ray equipment if not properly used may cause injury. Accordingly, the instructions herein contained

should be thoroughly read and understood by everyone who will use the equipment before you attempt to

place this equipment in operation. The General Electric Company, Medical Systems Group, will be glad to

assist and cooperate in placing this equipment in use.

Although this apparatus incorporates a high degree of protection against x-radiation other than the useful beam, no

practical design of equipment can provide complete protection. Nor can any practical design compel the operator to

take adequate precautions to prevent the possibility of any persons carelessly exposing themselves or others to

radiation.

It is important that everyone having anything to do with x-radiation be properly trained and fully acquainted with the

recommendations of the National Council on Radiation Protection and Measurements as published in NCRP Reports

available from NCRP Publications, 7910 Woodmont Avenue, Room 1016, Bethesda, Maryland 20814, and of the

International Commission on Radiation Protection, and take adequate steps to protect against injury.

The equipment is sold with the understanding that the General Electric Company, Medical Systems Group, its agents,

and representatives have no responsibility for injury or damage which may result from improper use of the equipment.

Various protective material and devices are available. It is urged that such materials or devices be used.

CAUTION: United States Federal law restricts this device to use by or on the order of a physician.

CERTIFIED ELECTRICAL CONTRACTOR STATEMENT

All electrical installations that are preliminary to positioning of the equipment at the site prepared for the equipment shall be

performed by licensed electrical contractors. In addition, electrical feeds into the Power Distribution Unit shall be performed

by licensed electrical contractors. Other connections between pieces of electrical equipment, calibrations, and testing shall

be performed by qualified GE Medical personnel. The products involved (and the accompanying electrical installations) are

highly sophisticated, and special engineering competence is required. In performing all electrical work on these products,

GE will use its own specially trained field engineers. All of GE’s electrical work on these products will comply with the

requirements of the applicable electrical codes.

The purchaser of GE equipment shall only utilize qualified personnel (i.e., GE’s field engineers, personnel of third-party

service companies with equivalent training, or licensed electricians) to perform electrical servicing on the equipment.

DAMAGE IN TRANSPORTATION

All packages should be closely examined at time of delivery. If damage is apparent, have notation “damage in

shipment” written on all copies of the freight or express bill before delivery is accepted or “signed for” by a General

Electric representative or a hospital receiving agent. Whether noted or concealed, damage MUST be reported to the

carrier immediately upon discovery, or in any event, within 14 days after receipt, and the contents and containers held

for inspection by the carrier. A transportation company will not pay a claim for damage if an inspection is not requested

within this 14 day period.

Call Traffic and Transportation, Milwaukee, WI (414) 827−3468 / 8*285−3468 immediately after damage is found. At

this time be ready to supply name of carrier, delivery date, consignee name, freight or express bill number, item

damaged and extent of damage.

Complete instructions regarding claim procedure are found in Section “S” of the Policy & Procedure Bulletins.

6/17/94

v

Page 6

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

THIS PAGE INTENTIONALLY LEFT BLANK.

vi

Page 7

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

REVISION HISTORY

REV DATE REASON FOR CHANGE

0 May. 10, 1996 Initial release.

1 Oct. 16, 1996 To add job Card IST 002

2 Feb. 26, 1997 To add RS 85 Tube Stand and Tomo−Link configurations

3 August 7, 1997 MIS Map, MIS Chart Update

4 December 7, 1997 Updated (BUCge 14603, 29344, 29457, 31763)

5 October, 1998 Updated with 115/24OV setting when used with MPH (Chapter 2)

6 November, 1998 New reference number for OM Compax 40E, SG60 and SG100

Medys Bucky instead Liebel Bucky

7 June 1999 Illustrations 7−2, 7−5 and 7−8 updated (ground plug layout)

8 July 2003 Added note about installing local language rating plate over English version.

9 November 2006 To resolve PSR 13077161: added a “Warning” in Card IST 001 to use Loctite

Threadlocker, strength 242 or 243 when installing collimators to help prevent

the screws from backing out over time.

To add “Collimator PM” and “Collimator Installation” procedures to Chapter 6.

vii

Page 8

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

THIS PAGE INTENTIONALLY LEFT BLANK.

viii

Page 9

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

CHAPTER 2 − INSTALLATION 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1

OVERVIEW 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1 FOREWORD 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 UNPACKING 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-1 Receipt of Equipment 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-2 Inventory 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2-3 Unpacking 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 INSTALLATION STEERING GUIDE 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 CABLE CONNECTIONS 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-1 Preliminaries 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-2 Mis Chart 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-3 Mis Chart 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4-4 Mis Chart 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Job Card IST 001 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X−Ray Tube & Collimator

Installation ON XT SUSPENSION 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Job Card IST 001 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X−Ray Tube & Collimator

Installation ON XT SUSPENSION 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Job Card IST 001 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X−Ray Tube & Collimator

Installation ON XT SUSPENSION 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Job Card IST 001 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X−Ray Tube & Collimator

Installation ON XT SUSPENSION 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Job Card IST 001 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X−Ray Tube & Collimator

Installation ON XT SUSPENSION 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Job Card IST 001 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X−Ray Tube & Collimator

Installation ON XT SUSPENSION 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Job Card IST 001 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X−Ray Tube & Collimator

Installation ON XT SUSPENSION 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Job Card IST 001 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X−Ray Tube & Collimator

Installation ON XT SUSPENSION 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Job Card IST 001 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X−Ray Tube & Collimator

Installation ON XT SUSPENSION 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Job Card IST 001 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X−Ray Tube & Collimator

Installation ON XT SUSPENSION 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Job Card IST 001 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X−Ray Tube & Collimator

Installation ON XT SUSPENSION 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Job Card IST 001 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X−Ray Tube & Collimator

Installation ON XT SUSPENSION 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Job Card IST 001 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ix

Page 10

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

X−Ray Tube & Collimator

Installation ON XT SUSPENSION 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Job Card IST 001 72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X−Ray Tube & Collimator

Installation ON XT SUSPENSION 72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Job Card IST 001 73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X−Ray Tube & Collimator

Installation ON XT SUSPENSION 73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Job Card IST 001 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X−Ray Tube & Collimator

Installation ON XT SUSPENSION 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Job Card IST 001 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X−Ray Tube & Collimator

Installation ON XT SUSPENSION 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Job Card IST 001 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X−Ray Tube & Collimator

Installation ON XT SUSPENSION 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Job Card IST 001 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X−Ray Tube & Collimator

Installation ON XT SUSPENSION 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Job Card IST 001 78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X−Ray Tube & Collimator

Installation ON XT SUSPENSION 78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Job Card IST 001 79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X−Ray Tube & Collimator

Installation ON XT SUSPENSION 79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Job Card IST 001 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X−Ray Tube & Collimator

Installation ON XT SUSPENSION 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 3 − DISASSEMBLY/REASSEMBLY 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Job Card IST 001 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X−Ray Tube & Collimator

Installation ON XT SUSPENSION 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Job Card IST 001 84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X−Ray Tube & Collimator

Installation ON XT SUSPENSION 84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 4 − FUNCTIONAL CHECKS 85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1

PRELIMINARIES 85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2

OPERATIONAL TESTS 85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1 TABLE OPERATIONAL TESTS 85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 TECHNIQUE TESTS 85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 SG 60 OPERATIONAL TESTS 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 SG 100 OPERATIONAL TESTS 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5 XT SUSPENSION OPERATIONAL TESTS 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6 RS 85 TUBESTAND 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7 ULTRANET SM COLLIMATOR 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

x

Page 11

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

2-8 ULTRANET SA COLLIMATOR 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3

PERFORMANCE TESTS 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 5 − SYSTEM CABINET SPARE PARTS 89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 6 − PREVENTIVE MAINTENANCE 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1

PERIODICITY 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1 TABLE 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 MPH GENERATOR 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 XT 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 RS 85 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5 SG60 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-6 SG100 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-7 TOMO−LINK 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8 COLLIMATOR 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2

OPERATIONS 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1 TABLE 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 MPH GENERATOR 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 XT 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 RS 85 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5 SG60 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6 SG100 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7 TOMO−LINK 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8 COLLIMATOR 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8-1 Equipment Required for Collimator PM 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8-2 Removing the Covers from the Collimator 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8-3 Lubrication 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8-4 Collimator General Inspection 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8-5 Check Tightness of Collimator Mounting Ring (every 12 months) 97. . . . . . . . . . . . . . . . . . . .

2-8-6 If the collimator has no play: 98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8-7 Checking Electrical Cables and Connections, and Cable Connection Points 98. . . . . . . . . . .

2-8-8 Reassembling the Parts 98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3

COLLIMATOR INSTALLATION VERIFICATION 99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4

ULTRANET COLLIMATOR INSTALLATION CHECK LIST 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 7 − SCHEMATICS 103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1

1-1 SCHEMATICS 105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 CABLES IDENTIFICATION ACCORDING TO THE MIS MAP AND MIS CHART 114. . . . . . . . . . . . .

xi

103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 12

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

CHAPTER 1 − PRELIMINARIES

SECTION 1

INTRODUCTION

1-1 Safety

ALL SERVICE OR SPARES REPLACEMENT ON THIS SYSTEM MUST BE

CARRIED OUT BY QUALIFIED TECHNICIANS ONLY. FOLLOW THE

DIRECTIONS IN THIS MANUAL CAREFULLY.

PREVENTION OF IONIZING RADIATION

− It is mandatory to wear a film badge.

− Remain as little time as possible in or near of an X−ray field.

− When working near X−rays, it is mandatory to wear a lead (Pb) apron.

− The kV and mA setting values must be as low as possible.

− The X−ray field setting must be as low as possible (a beam limiter must be used).

− The operator must stand as far away as possible from the X−ray beam.

PREVENTION OF ELECTRICAL HAZARDS

− Do not open electrical cabinets if power supply is on.

− Do not disconnect a ground wire.

− Before disconnecting HV cables, discharge them with a voltage divider.

− Be careful of capacitors which may be charged (specially those HV units).

PREVENTION OF ACCIDENTS CAUSED BY MOVING PARTS

When adjusting mechanical sub−assemblies, be careful of:

− movements starting up.

− transmission parts (chain, gears, ....).

EQUIPMENT PROTECTION

To avoid accidental damage to the equipment, it is mandatory to cut the electric power supply before:

− connecting or disconnecting a printed board or a connector.

− connecting or disconnecting a test probe.

1

Page 13

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

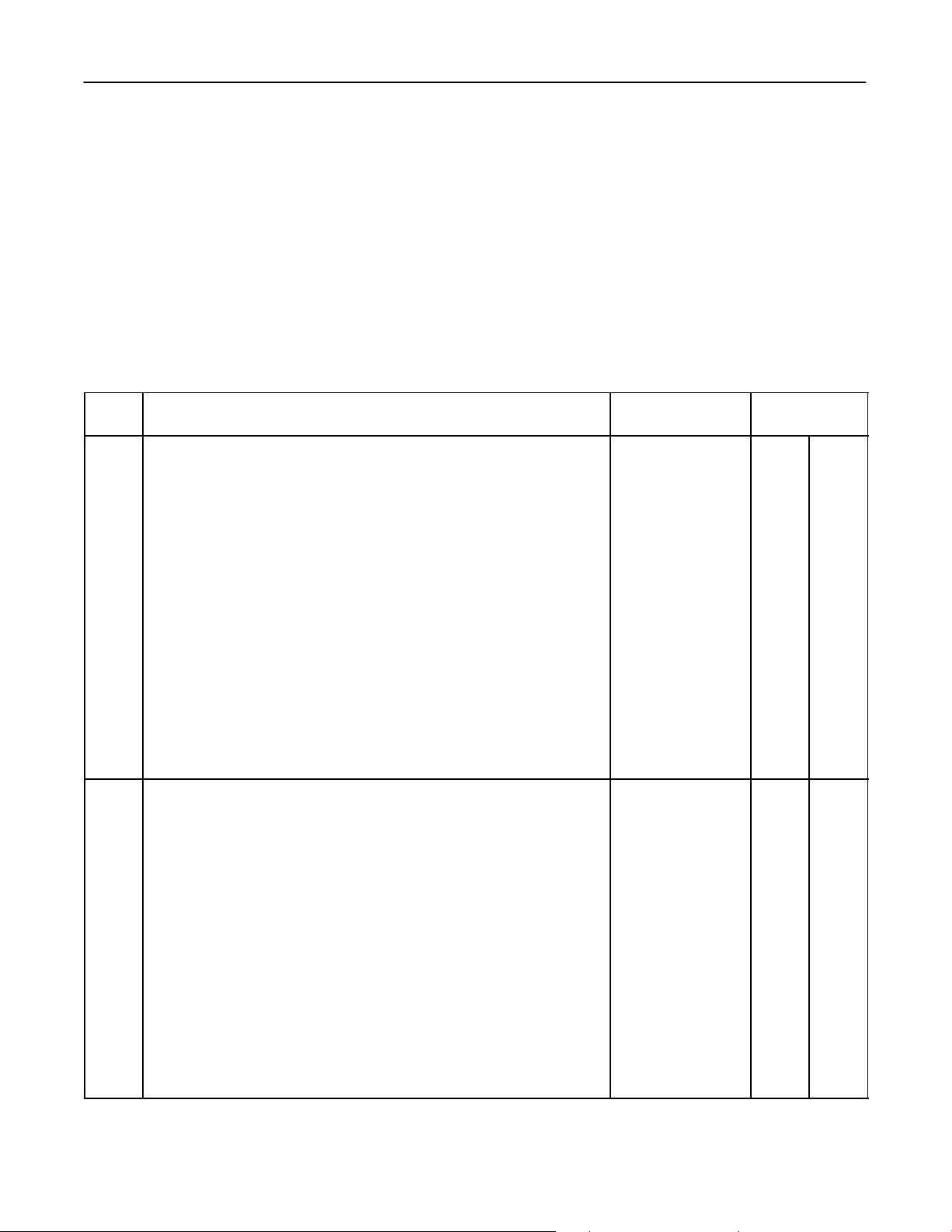

1-2 Available Documentation

System COMPAX 40E with MPH GENERATOR, SG 60 or SG100, XT Suspension, RS 85 Tube Stand or

Tomo−Link

Type

DESCRIPTION

Ref. nr. or Direction Language Furnished Available

SYSTEM

ssm System COMPAX 40E 2154260−100 Eng X

TABLE

OM OPERATING MANUAL

COMPAX 40E CE TABLE

SM SERVICE MANUAL

COMPAX 40E CE TABLE

SCH COMPAX 40E TABLE SCHEMATICS Direction 2150299−100 Eng X

pim Pre−Installation Manual

COMPAX 40E CE TABLE

Direction 2226656−148 Eng/Fre/Spa

Ger/Ita/Por

Direction 2150299−100 Eng X

Direction 2150306−100 Eng X

GENERATOR

SM MPH 50/65/80 GENERATOR

SERVICE MANUAL

SCH MPH 50/65/80 GENERATOR

SCHEMATICS

ASM ADVANCED SERVICE MANUAL

MPH 50/65/80 GENERATOR

pim Pre−Installation Manual

MPH 50/65/80 GENERATOR

Direction 2137354−100 Eng X

Direction 2137357−100 Eng X

Direction 2137631−100 Eng X

Direction 2133000−100 Eng X

X

OM OPERATING MANUAL

MPH 50/65/80 GENERATOR

Direction 2137352−100

Direction 2137352−101

Direction 2137352−106

Direction 2137352−108

Direction 2137352−111

Direction 2137352−127

Eng

Fre

Spa

Ger

Ita

Por

ION CHAMBER

SM Ion Chamber ( UL − 3 Fields ) 826 921 P285 Eng X

PROGRAM−X Option

OM OPERATING MANUAL

PROGRAM−X

Direction 2103514−100

Direction 2103514−101

Direction 2103514−106

Direction 2103514−108

Direction 2103514−111

Direction 2103514−127

Eng

Fre

Spa

Ger

Ita

Por

X

X

2

Page 14

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

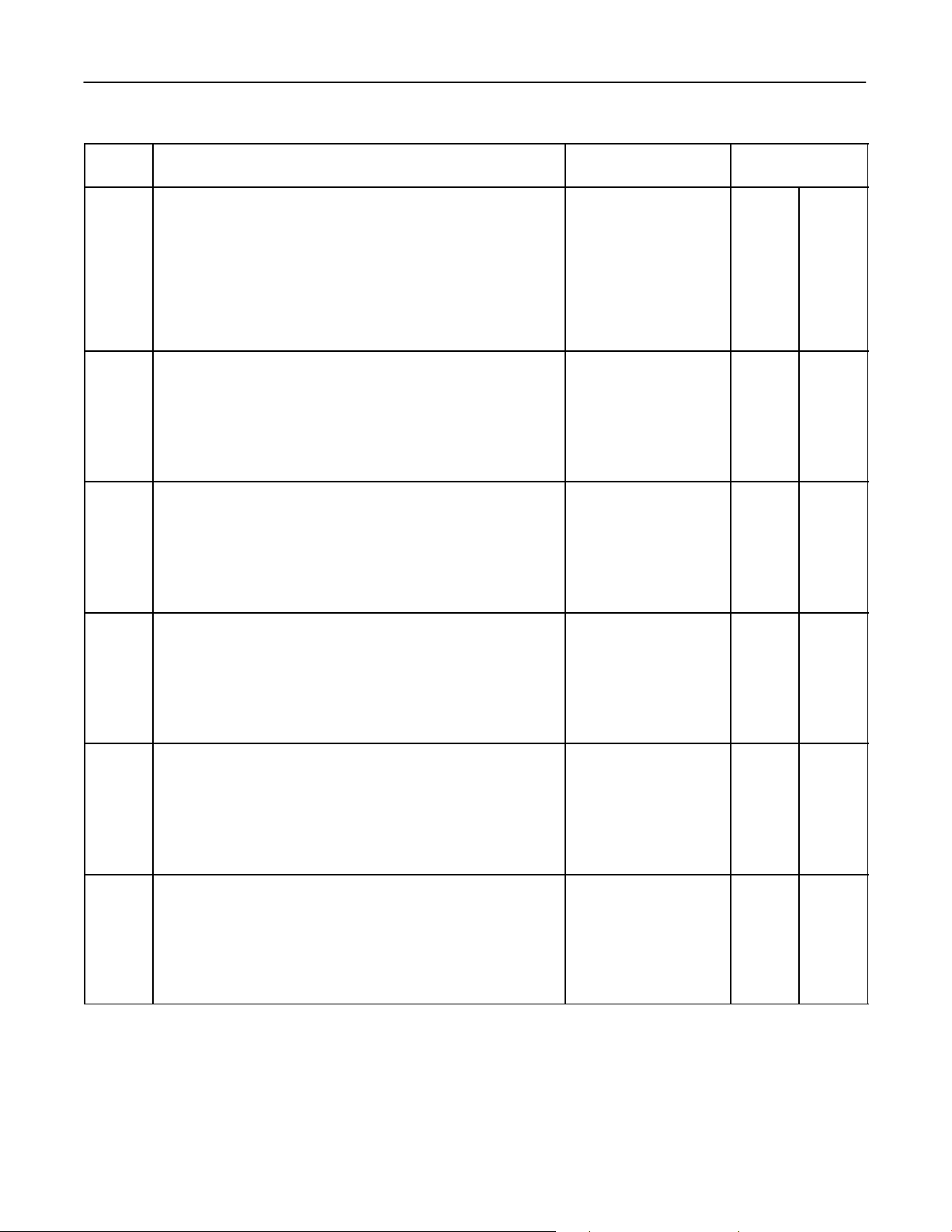

Type

DESCRIPTION

Ref. nr. or Direction Language Furnished Available

PRINT−X Option

OM OPERATING MANUAL

PRINT−X

Direction 2107167−100

Direction 2107167−101

Direction 2107167−106

Direction 2107167−108

Direction 2107167−111

Direction 2107167−127

Eng

Fre

Spa

Ger

Ita

Por

RAFL−S

SM ULTRANET SA & RAFL−S (Collimator Con-

trol)

SERVICE MANUAL

DIR. Y00W20L.04 Eng X

BUCKY

SI BUCKY SERVICE INSTRUCTIONS DIR. 248950 Eng X

COLLIMATOR

OM ULTRANET SM CE marking

Operating Manual

SM ULTRANET SM DIR Y00W21L.04 Eng X

Direction 2144901−100

Direction 2144901−101

Direction 2144901−106

Direction 2144901−108

Direction 2144901−111

Direction 2144901−127

Eng

Fre

Spa

Ger

Ita

Por

X

X

OM ULTRANET SA CE marking

Operating Manual

SM ULTRANET SA DIR Y00W23L.04 Eng X

Direction 2144903−100

Direction 2144903−101

Direction 2144903−106

Direction 2144903−108

Direction 2144903−111

Direction 2144903−127

Eng

Fre

Spa

Ger

Ita

Por

WALL BUCKY

OM SG 60 VERTICAL BUCKY STAND CE

Operating Manual

pim SG 60 VERTICAL BUCKY STAND CE

Pre−Installation Manual

SM SG 60 VERTICAL BUCKY STAND CE

Service Manual

OM SG 100 VERTICAL BUCKY STAND CE

Operating Manual

Direction 2224051−148 Eng/Fre/Spa

Ger/Ita/Por

Direction 2150301−100 Eng X

Direction 2150293−100 Eng X

Direction 2226754−148 Eng/Fre/Spa

Ger/Ita/Por

X

X

X

3

Page 15

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

Type

pim SG 100 VERTICAL BUCKY STAND CE

Pre−Installation Manual

SM SG 100 VERTICAL BUCKY STAND CE

Service Manual

DESCRIPTION

X−RAY TUBE

TP Maxiray 100 X−RAY TUBE

Technical Publications

TP Maxiray 100 X−RAY TUBE

Technical Publications

XT SUSPENSION

OM X−RAY TUBE SUSPENSION

OPERATING MANUAL

SM X−RAY TUBE SUSPENSION

SERVICE MANUAL

pim X−RAY TUBE SUSPENSION

Pre−Installation MANUAL

RS 85 TUBE STAND

OM RS 85 CE Marked

Operating Manual

Ref. nr. or Direction Language Furnished Available

Direction 2150305−100 Eng X

Direction 2150297−100 Eng X

Direction 46−014427 Eng X

Direction 46−013804 Eng X

DIR 2116790−100 Eng X

DIR 2118733−100 Eng X

DIR 46019618 Eng X

Ongoing Eng X

IS Mounting Instructions RS 85 Tube Stand CE Direction 0327 7223 Eng X

SM RS 85 Interface Package for Compax 40E CE

Marked Systems

Service Manual

PIM RS 85 Tube Stand

Pre−Installation Manual

OI Operating Instructions RS 85 Tube Stand CE Direction 0327 7324

Direction 2165897−100 Eng X

Direction 2172805−100 Eng X

Direction 0327 7341

Direction 0327 7361

Direction 0327 7303

Direction 0327 7351

Direction 0327 7371

Eng

Fre

Spa

Ger

Ita

Por

TOMO−LINK

OM Tomo−Link

Operating Manual

SM Tomo−Link

Service Manual

Direction 2122884−100

Direction 2122884−101

Direction 2122884−106

Direction 2122884−108

Direction 2122884−111

Direction 2122884−127

Direction 2133821−100 Eng X

Eng

Fre

Spa

Ger

Ita

Por

X

X

X

X

X

X

X

4

Page 16

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

Type

SM Tomo−Link Schematics Direction 2132473−100 Eng X

SM Tomo−Link Upgrade Assembly for CE Marked

Compax 40E Tables

Installation Guide

DESCRIPTION

Ref. nr. or Direction Language Furnished Available

Direction 2182386−100 Eng X

5

Page 17

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

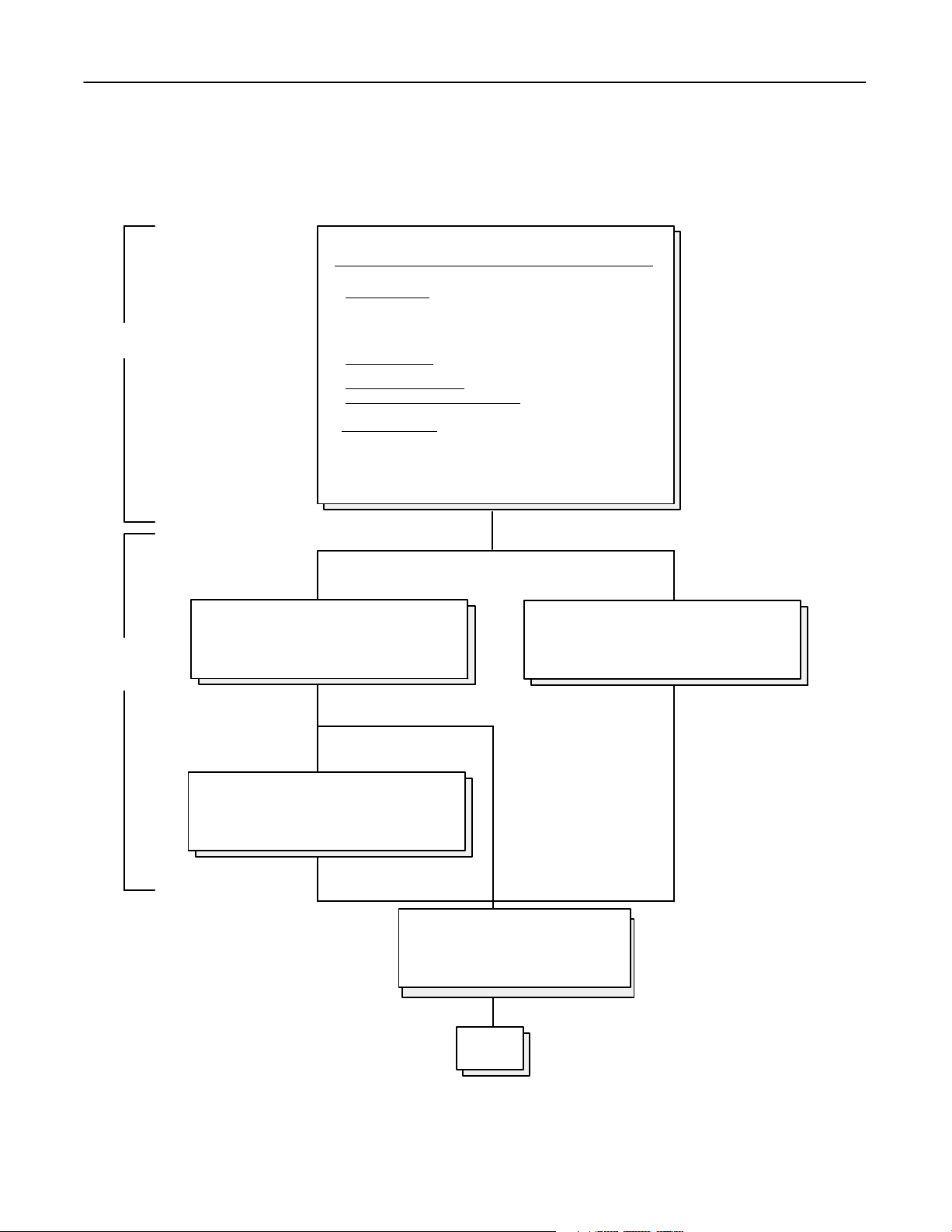

1-3 Manual System Composition

SYSTEM COMPAX 40E (Manual) with MPH 50/65/80

− COMPAX 40E

CLASSICAL RAD TABLE with Anticollision Kit

Core

− MPH 50/65/80

− High Speed Starter

− High Impedance Adaptation

Table Bucky with Grid & Ion Chamber

with AEC

To change mode

Optional

Features

− Power Supply:

XT SUSPENSION Inboard or Outboard with:

− HV cables + Stator and Collimator cables

− Manual Ultranet SM Collimator

− Maxiray 100 Tube

Tomo−Link

− Adapting kit for 40E

380Vac....480Vac (+/− 10%)

RST+GND

50/60 Hz

RS 85 TUBE STAND: with:

− Manual Collimator Ultranet SM

− Maxiray 100 Tube

SG 60/100 Vertical Bucky Stand

Right or Left hand

Grid & Ion Chamber

END

6

Page 18

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

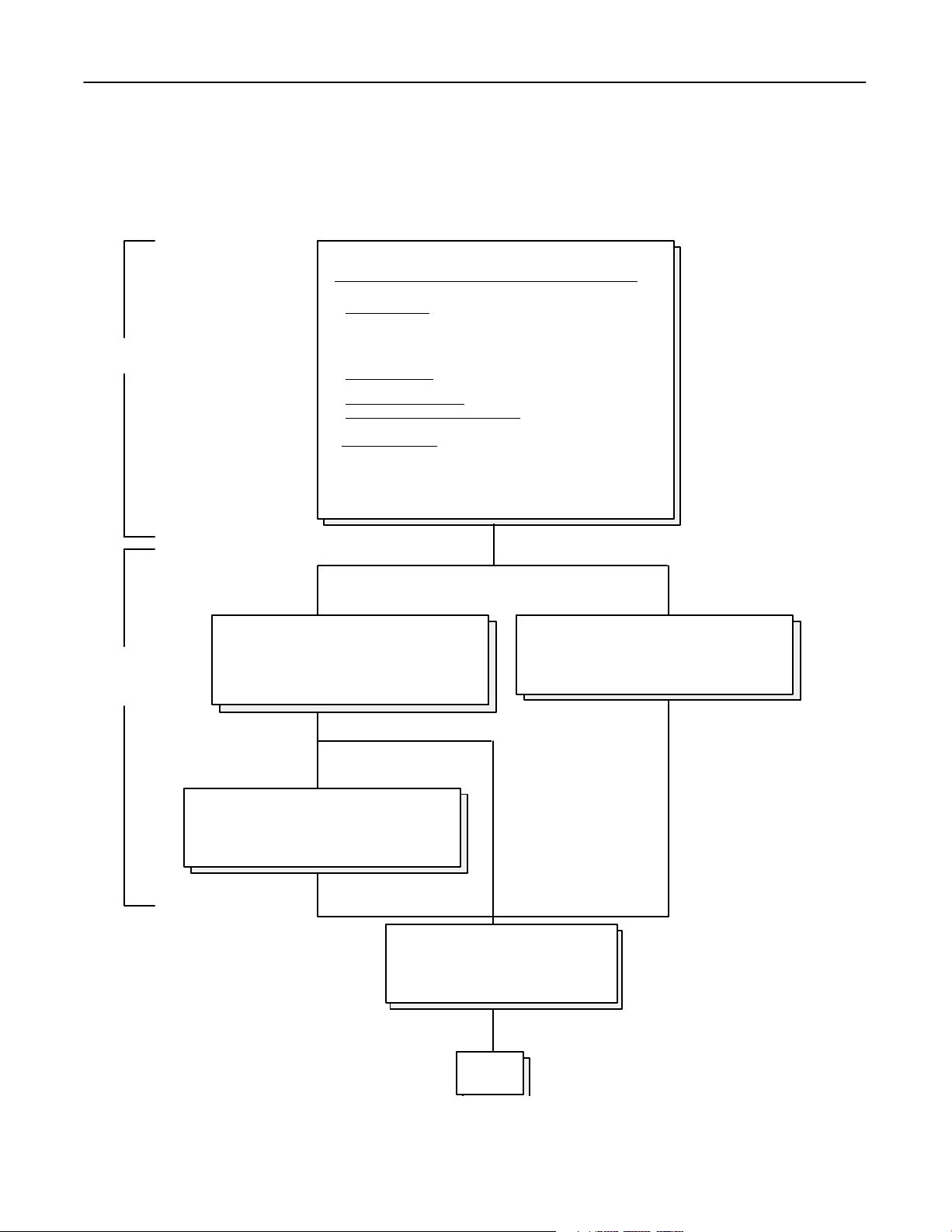

1-4 Automatic System Composition

SYSTEM COMPAX 40E (Auto) with MPH 50/65/80

− COMPAX 40E

CLASSICAL RAD TABLE with Anticollision Kit

Core

− MPH 50/65/80

− High Speed Starter

− High Impedance Adaptation

Table Bucky with Grid & Ion Chamber

with AEC

To change mode

Optional

Features

− Power Supply:

XT SUSPENSION Inboard or Outboard with:

− HV cables + Stator and Collimator cables

− Auto Ultranet SA Collimator

− Maxiray 100 Tube

− RAFL−S Collimator Control

Tomo−Link

− Adapting kit for 40E

380Vac....480Vac (+/− 10%)

RST+GND

50/60 Hz

RS 85 TUBE STAND: with:

− Auto Collimator Ultranet SA

− Maxiray 100 Tube

− RAFL−S Collimator Control

SG 60/100 Vertical Bucky Stand

Right or Left hand

Grid & Ion Chamber

END

7

Page 19

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

THIS PAGE INTENTIONALLY LEFT BLANK.

8

Page 20

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

CHAPTER 2 − INSTALLATION

SECTION 1

OVERVIEW

1-1 Foreword

teHLA (High Level Assembly) Program: There are two different versions of equipment shipped to the

customer, a non HLA or an HLA version.

COMPAX 40E SYSTEMS are fully assembled and calibrated at the factory (*) before shipment. Only

Tables purchased as add−ons to existing tables are non−HLA.

The aim of this factory integration, or High Level Assembly Program, is to improve the general quality of

the installation procedure on site while decreasing the installation time.

Program results:

− Increased customer satisfaction by reducing the equipment installation time and an increased

reliability and performance from its first use.

− Facilitate the technician’s work:

> by relieving him of time−consuming, tricky and repetitive jobs.

> by involving technicians in this new global process which consists of reducing installation time

and the global quality improvement of our equipment.

This reduces work load and warranty cost.

The Installation Steering Guide which follows is conceived to take maximum advantage of this High

Level Assembly program.

To avoid any duplication of information given in other documents, this manual makes a number of cross

references to Service or Installation Manuals specific to the various components that make up the system.

Any remarks improving the contents of this document would be appreciated.

(*) COMPAX 40E Systems for the US are factory checked with a XT “tool” since the suspension

is purchased locally.

9

Page 21

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

1-2 Unpacking

1-2-1 Receipt of Equipment

HANDLING PACKED SUB−ASSEMBLIES

Prior to installation, store the equipment in its original packing, and handle it with care.

Do not drop, throw or stamp packages containing equipment or parts of it.

1-2-2 Inventory

Depending on the equipment ordered, check the number of packages delivered to the installation site.

The lists of packages hereafter do not include the optional components.

Crate Contents Dimensions Gross Weight

kg lb

N° 1

Compax 40E CE Table base including:

230x130x31 350 770

− Medys Bucky

− BVM Ion Chamber

− Telescopic Covers

− Compax 40E Documentation

− System Inspection Report

− System Cables

− Packing List

N° 2

Compax 40E CE Table Top

− Sensing Size Tray

150x94x103 75 165

10

Page 22

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

Crate Contents Dimensions

N° 3

MPH Cabinet including:

215x100x47 280 616

− I/F Room

− RAD Option

− HV Tank

− RAFL−S Collimator Control (optional)

− System cables

− C40E/MPH/XT/RS 85/SG SSM

(System Service Manual)

− Inspection Report

N° 4

MPH Console including:

72x120x62 50 110

− Program−X

− Hand Switch

− MPH Generator Documentation

− Packing List

N° 5

X−Ray Tube (Maxiray 100)

50x84x60 46 100

− X−ray Tube Unit

− Documentation

Gross Weight

kg lb

N° 6

N° 7

N° 8

GEMS−AM

delivered

systems

only

Ultranet SA Collimator or Ultranet SM Collimator

− Collimator Head

− Documentation

− Tools

SG60 or SG100 Vertical Bucky Stand including:

− Medys Bucky

− BVM Ion Chamber

− Size Sensing Tray

− SG60 or SG100 Documentation

− Packing List

− System cables

Tomo−Link

NOTE: In GEMS−AM delivered systems, the XT suspension

is shipped separately

47x39x56 30 66

230x87x86 288 633

109x82x88 98 216

11

Page 23

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

Crate Contents Dimensions

N° 8

GEMS−E

and

GEMS−A

delivered

systems

only

N° 9

GEMS−E

and

GEMS−A

delivered

systems

only

N° 10

GEMS−E

and

GEMS−A

delivered

systems

only

XT Suspension including:

− Covers and Accessories

− Documentation

NOTE: In GEMS−AM delivered systems, the XT suspension

is shipped separately

XT Suspension Bridge

NOTE: In GEMS−AM delivered systems, the XT suspension

is shipped separately

Inboard Concealment 60’ Cables for MPH Generator

including: TBC

− HV Cables

− Stator Cable

− Suspension Cables

NOTE: In GEMS−AM delivered systems, the XT suspension

106x90x152 276 607

318x82x48 140 308

214x30x61 109 240

is shipped separately

N° 11

GEMS−E

and

GEMS−A

delivered

systems

only

Stationary Rails

NOTE: In GEMS−AM delivered systems, the XT suspension

is shipped separately

476x18x12 48 100

Gross Weight

kg lb

N° 12

GEMS−E

and

GEMS−A

delivered

systems

only

Tomo−Link

NOTE: In GEMS−AM delivered systems, the XT suspension

is shipped separately

109x82x88 98 216

12

Page 24

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

Crates N° 1 thru N° 7 are the same for both XT suspension and RS 85 Tube Stand Systems

Crate Contents Dimensions

N° 8

RS 85 Tube Stand including:

320x66x56 190 396

Gross Weight

kg lb

− Documentation

RS 85 Interface Package for Compax 40E System including:

− Set of System cables

− Documentation

N° 9

Accessories 47x39x56 30 63

Nº 10 Print−X (Option)

− Pedestal box

− Documentation

380 x 820 x 350 20 51

13

Page 25

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

1-2-3 Unpacking

Damage Due to Transport

On delivery of the equipment, all packages must be checked to make sure that they have not been

damaged during transport.

If damage is observed, notify the transport service and the factory transport insurance service

immediately.

The above also applies for non apparent damage due to transport discovered when unpacking the

material or during installation, WITHIN 14 DAYS MAXIMUM AFTER DELIVERY.

Generally, a transport service will not pay a bill for non−apparent damage unless an expert’s report has

been requested within 14 days of delivery.

If damage is discovered, contact the concerned services immediately, specifying the type of apparatus,

the serial number and the order number if possible, as well as a description of the damage.

Unpacking and Inspection

Tools required for unpacking:

− a tool for removing nails, i.e. claw−hammer.

− a crowbar (minimum length 600 mm).

− a dolly for lifting and transporting the table base and SFD−fork, etc...

The components are wrapped in protective material and immobilized in the transport boxes. Each box is

numbered.

When unpacking, first find the packing list and check that all items are present. Check also that there is

no damage to the components received.

In case of missing parts, file a claim immediately mentioning the serial number of the unit as well as all

the shipping data.

Do not discard packing materials, such as envelopes or boxes, until all parts are accounted for.

− Do not place equipment cabinets in areas that are damp, poorly ventilated, too far from the console,

or on another floor.

− Avoid poor floor anchoring.

− Ensure that the screws and washers of each cover are inside plastic bags stuck on the inside of the

cover.

14

Page 26

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

1-3 Installation Steering Guide

Note: Read the following paragraphs carefully before continuing with this Steering Guide.

• Pre−installation: Pre−installation work is required to prepare the room for installing the

equipment. Check that this work is complete, if not, complete

pre−installation work now.

• Inspection Report: Some of the Steering Guide steps are factory performed. Refer to Inspection

Report Dir. 2167647 TDR, 2172166 TDR or 2179651 TDR(supplied with the

system) to know exactly which steps have already been performed.

• Steering Guide: Some steps of the Steering Guide refer to other Service Manual chapters.

When each task is performed, return to the Steering Guide and proceed with

the next step.

• Clamping: Do not forget to clamp the system cables for EMC compliance. Refer

to Job Card IST 005.

• Pinning: To facilitate critical realignment on−site, several sub−assemblies are

pre−drilled and pinned or marked during factory integration. Refer to Job

Cards IST001, IST002, IST003 and IST 004 for installation procedures

The Undertable configuration comes with several system cables

pre−installed in the Table Rolling frame. The remaining system cables are

pre−installed in the Tubestand assy. Take care not to damage these cables.

Step

A1

A2

Data Base Backup: Performed by Manufacturing on Xamine Calibration Diskette.

Mark each box when task is done

Description Done

Supporting Documents

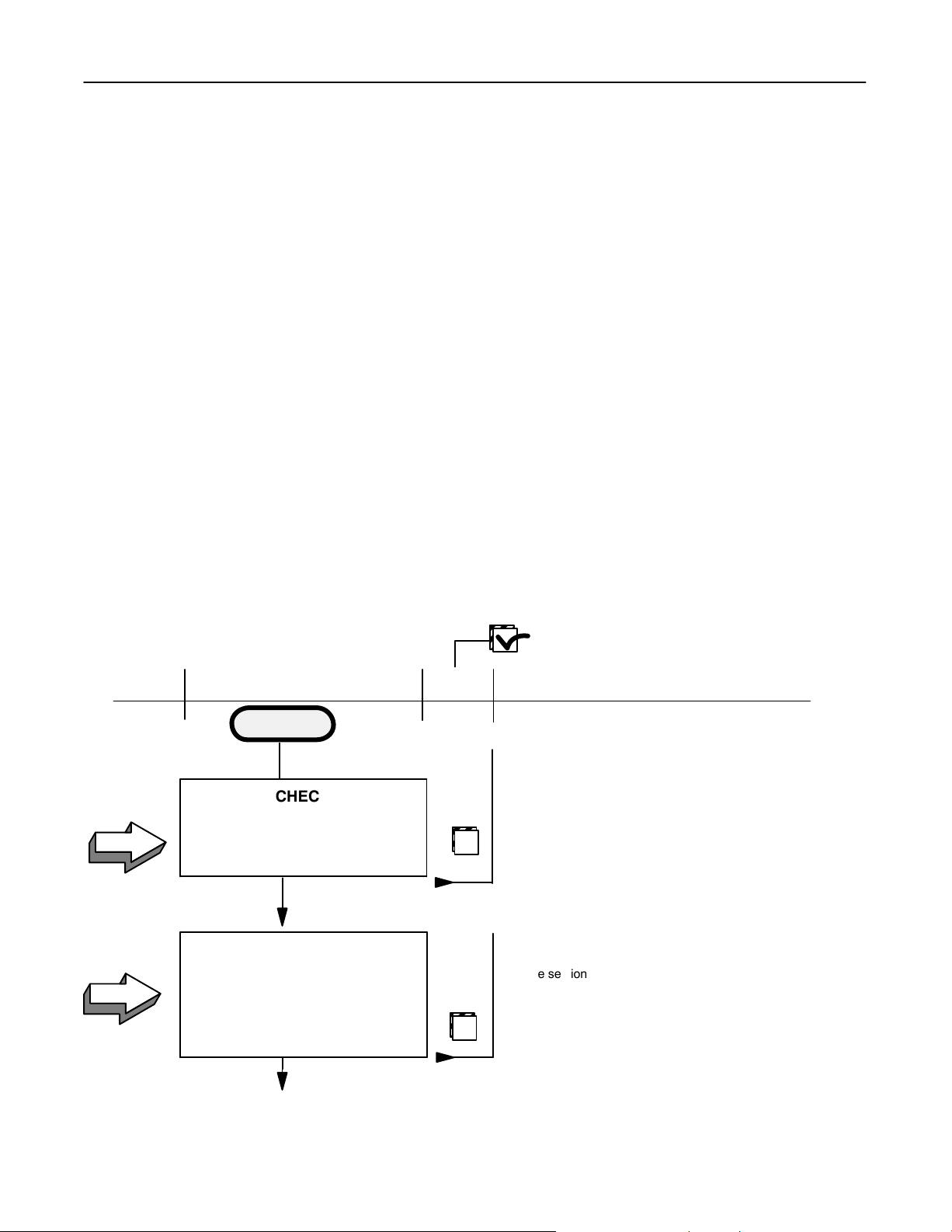

START

See PRE−INSTALLATION MANUALS

and LOCAL LAYOUT DATA Compax 40E CE, PIM

CHECK

Pre−installation Requirements

are met

1 person

1 Hour

Dir. 2150306−100

Vertical Bucky Stand CE, PIM Dir 2150305−100 (SG100),

Dir 2150301−100 (SG60)

MPH50/65/80, PIM Dir 2133000−100

XT CE, PIM Dir 46−019618

RS 85 CE, PIM Dir 2172805−100

UNPACKING

Collect the Product Locator cards

in sequential order

Localize Installation Flowchart

See section 1-2-3 of this manual.

Refer to Installation Flowchart for typical

main task durations

2 people

Continues on next page

4 Hours

15

Page 27

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

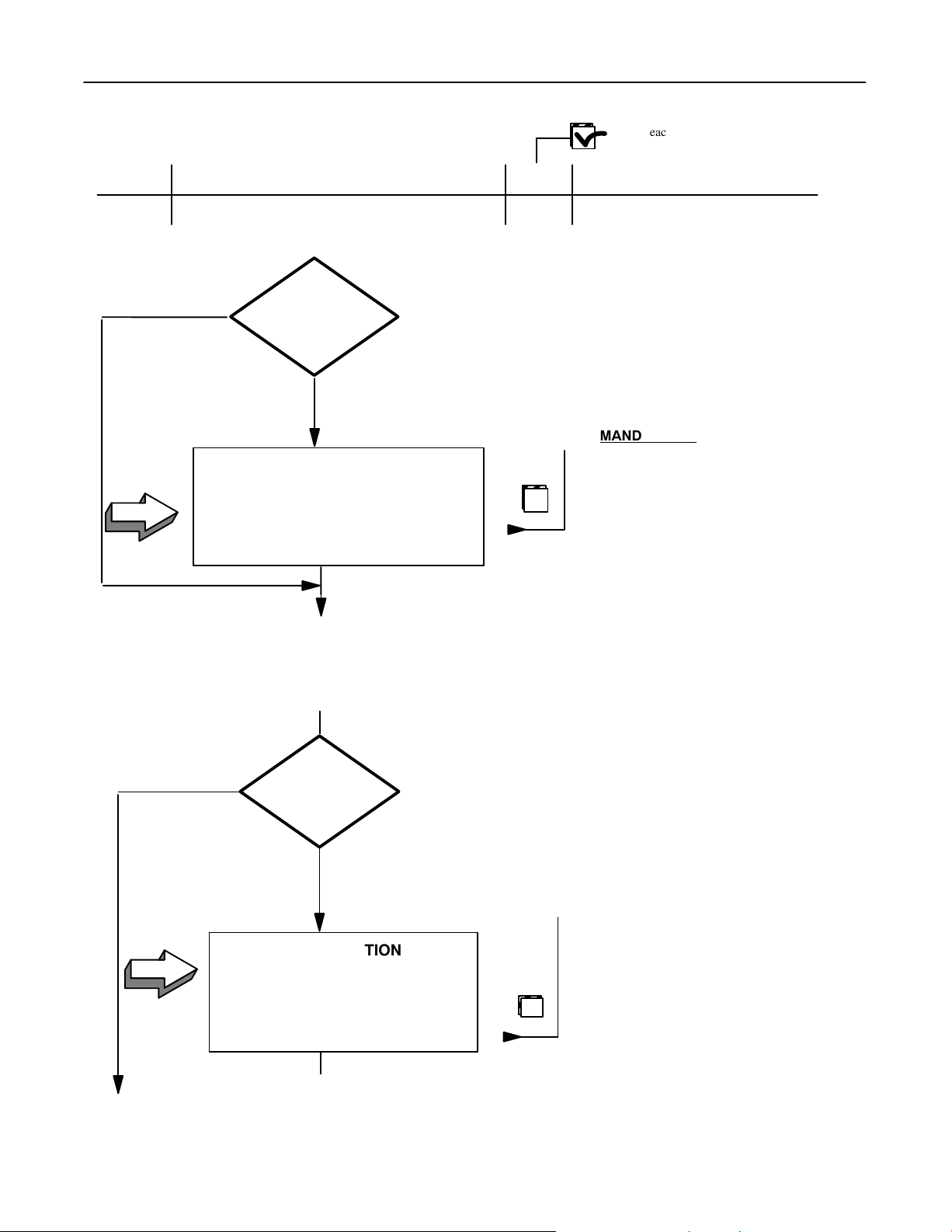

Mark each box when done

Step Description Done

From previous page

No

Pilot

System

Yes/No

Yes

FEEDBACK FORMS

A3

PGS 017 (Appendix 2)

1 Person

1 Hour

Supporting Documents

MANDATORY: Fill out this Pilot

Feedback Form in English

throughout the System installation

process.

This General Service Procedure PG017 is

available for GEMSE at local GE offices

PHYSICAL INSTALLATION OF SYSTEM COMPONENTS

XT INSTALLATION

Without XT

A4

XT Ceiling Suspension

Horizontal SID Sensors

2 people

Continues on next page

XT

with/without

With XT

INSTALLATION

If present, the ceiling suspension must be

installed first: carefully follow instructions

given in XT SM, Dir 2118733−100;

Chapter 3 or 4 (Do not install covers now)

16

Page 28

System Service Manual − SYSTEM COMPAX 40E, CE Marked

Í

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

Mark each box when done

Step Description Done

From previous page

INSTALLATION

A5

X−Ray Tube

Collimator Head (SA/SM)

2 people

A4 − A5=16 Hours

Without

Tomo−Link

Supporting Documents

Refer to Inspection Report 2179651 TDR

or 2167647 TDR, sections 2.1 and 3.1

CAUTION: X−Ray Tube and Collimator

are factory aligned and assembled during

HLA.

The mounting ring should be not be

adjusted during installation .

See Job Card IST001 of this manual for

X−Ray Tube and Collimator installation

and levelling.

A6

with/without

With

INSTALLATION

Drive Unit

Yoke

Fulcrum Arm Support (Wall)

Operator Control Console

2 People 8 Hrs

Continues on next page

Refer to Inspection Report 2179651 TDR,

section 5.1

Refer to Tomo−Link SM 2133821−100

sections 1,2,5

17

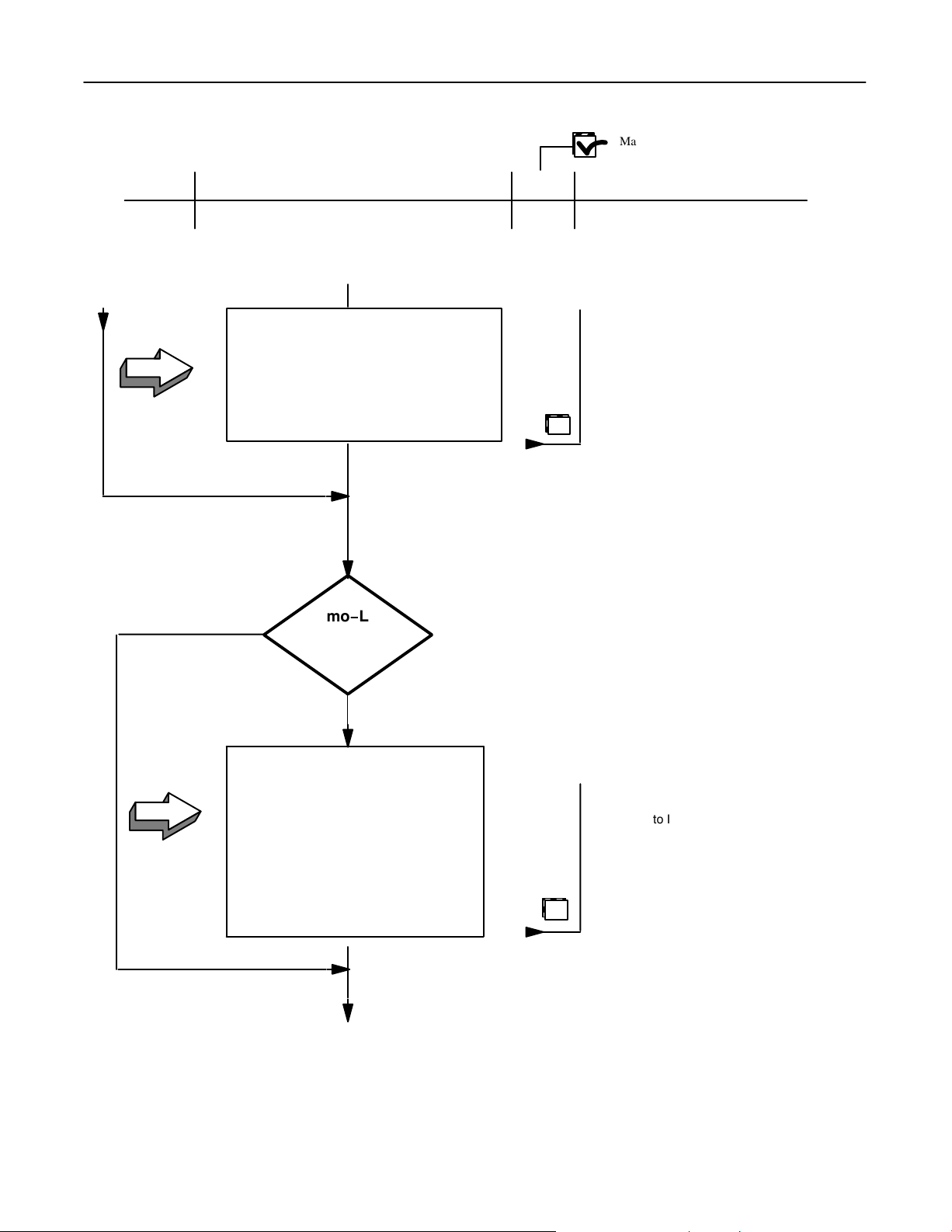

Page 29

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

Step

Description Done

From previous page

RS 85 INSTALLATION

without

RS 85

with/without

with

INSTALLATION

A7

Column Cables Wall Box

Tube Stand Rail

Column With Carriage

Tube Support Arm

Counterweights

Supporting Documents

If present, RS 85 Tube Stand must be

installed first. Follow instructions given in

RS 85 PIM, Dir 2172805−100, Chapter 2.4

Refer to Inspection Report 2172166 TDR,

sections 1.1 and 1.2

See SM− RS 85 Dir. 0327 7223

Mounting Instructions Chapter 1 Section

1.6.1 (Overall dimensions) and:

Chapter 2, Section 2.3 (Adjust floor rails)

Chapter 2, Section 2.4

Chapter 2 sections 2.5 thru2.6

A8

2 People

INSTALLATION

X−ray Tube with Adapter

Collimator Assembly

HV Cable Routing

H

2 People

Continues on next page

XXHrs

Refer to Inspection Report 2172166 TDR,

sections 3.1 and 2.1

See SM− RS 85 Dir. 0327 7223

Installation & Service Instructions

CAUTION: X−Ray Tube and Collimator are

factory aligned and assembled during HLA.

The mounting ring should be not be

adjusted during installation .

See Job Card IST003 of this manual

HANDLE with CARE (by the support only).

18

Page 30

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

Mark each box when done

Step

A9

A 10

Description Done

From previous page

INSTALLATION

Counterbalancing & Leveling

1 Person

CONNECTIONS

Collimator cable

Lock Cable

Column Cable concealment

1 Person

A7 − A10= 8 Hours

Supporting Documents

See RS 85 Mounting Instructions, SM Dir.

0327 7223. Chapter 1, Section 1.7, Chapter

2 section 2.9 and Chapter 3 sections 3.1

thru 3.3 and 3.5.

REMARK: Most of these cables are already

factory connected.

See RS 85 Interface Kit for Compax 40E CE;

SM Dir.2165897−100, Chapter 1 Installation,

Chapter 2 MIS MAP and Chapter 3 MIS

CHART

See Job Card IST 005 for cable clamping

See MIS MAPS, Chapter 5 of this manual, and

MIS CHART in section 1-4-3 this chapter.

MIS No. 27304

See Job Card IST003 for Cable concealment

A 11

A12

COMPAX 40E TABLE INSTALLATION

INSTALLATION

Table Base Installation and leveling

Tabletop Installation

2 People

ALIGNMENT

Table Base Longitudinal Axis Alignment with:

XT Longitudinal Rails

(or) RS 85 Longitudinal Rails

2 People

Continues on next page

A11 − A12 = 4 Hours

Refer to Inspection Report 2179651 TDR

or 2167647 TDR sections 4.1 and 4.3

or

Inspection Report 2172166 TDR

sections 4.1 and 4.8

See SM COMPAX 40E CE, Dir. 2150299−100,

Chapter 1, Section 3.

NOTE: Precise alignment is extremely

important for Tomographic Performance.

See SM COMPAX 40E CE, Dir. 2150299−100,

Chapter 1, Section 3.2

19

Page 31

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

Mark each box when done

Step Description Done

From previous page

WALL BUCKY INSTALLATION

A17

without

without

WALL

BUCKY

with/without

with

WALL

MOUNTING

KIT

with

Supporting Documents

See SM Vertical Bucky Stand SG 100 CE −

Dir 2150297−100, Chapter 1 or SM Vertical

Bucky Stand SG60, Dir 2150293−100

Chapter 1.

REMARK: Use of the Wall Mounting Kit is optional

but strongly recommended with certain kinds of

Hospital wall construction (Unistrut wall). Refer to

SG60 PIM 2150301−100 or SG100 PIM 2150305−100

.

A16

A17

INSTALLATION

Mounting Hardware Kit

1 Person

2 Hours

INSTALLATION

SG60/SG100 Installation

Vertical Leveling

Route System Cables from SG to MPH

Cabinet location

Lateral alignment across the wall to Table

Longitudinal Axis

2 People

2 Hours

Continues on next page

See SG60 SM 2150293−100, Job Card IST001

or SG100 SM 2150297−100, Job Card IST001

Refer to Inspection Report 2179651 TDR

or 2172166 TDR sections 6.1, 6.2 and 6.3

or

Inspection Report 2167647 TDR,

sections 5.1, 5.2 and 5.3

REMARK: Most of these cables are already factory

connected. See MIS MAP / MIS CHART of this

Manual (section 1−4)

.

Connections to be done during Installation:

SG60: MIS 5.1

SG100: MIS 5.1−9

20

Page 32

System Service Manual − SYSTEM COMPAX 40E, CE Marked

Í

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

Mark each box when done

Step Description Done

From previous page

MPH SYSTEM CABINET INSTALLATION

INSTALLATION

Cabinet Positioning

A18

A19

Cabinet Securing

2 People

CONFIGURATION

Generator Power Connection

Line Voltage and Frequency:

Dependent Settings

AC Voltage Supply for Buckies

*,

XT

RS85 Power Supply*

1 Person

2 Hours

*

1 Hour

Supporting Documents

See Pre−installation Manual (Layout).

See SM MPH 50/65/80 dir. 2137354−100,

Chapter 1 Installation ; section 2,

Job Card IST002. Use Securing Kit (Part

2175309 provided with Upper Cabinet

REMARK:Verify PCB have not moved

during transportation, particularly the

Power PCB in RAFL−S rack.

If the Wall Attachment Kit* is available, follow

instructions supplied with the Kit *(Part #

Refer to Inspection Report 2179651 TDR or

2167647 TDR, section 1.2 and 3.3

or

Inspection Report 2172166 TDR, section 1.2

and 3.4

See SM MPH Dir 2137354−100, Chapter 1,

Installation: section 2, Job Card IST002

WARNING

1. Refer to Inspection Report and/or to orange

2. With MPH the XT is ALWAYS powered with

3. XT is shipped separately for the US.

2164271, S16201EB)

MAINLY FOR USE IN THE USA:

labels fixed to the buckies

230VAC.

Default setting is 110V.

Refer to XT Service Manual Dir

2118733−100 for 220V setting.

A20

INSTALLATION

Console Generator

PRINT−X Console (option)

PROGRAM−X (option)

1 Person

Continues on next page

Refer to Inspection Report 2179651 TDR or

2172166TDR or 2167647 TDR, section 1.1

See Pre−Installation manual (layout).

See SM MPH 50/65/80 dir. 2137354−100, Chapter 1

Installation; section 2, Job Card IST002.

PRINT−X

1 Hour

CAUTION: Ensure proper tightening of wire

connections and setting of connectors

21

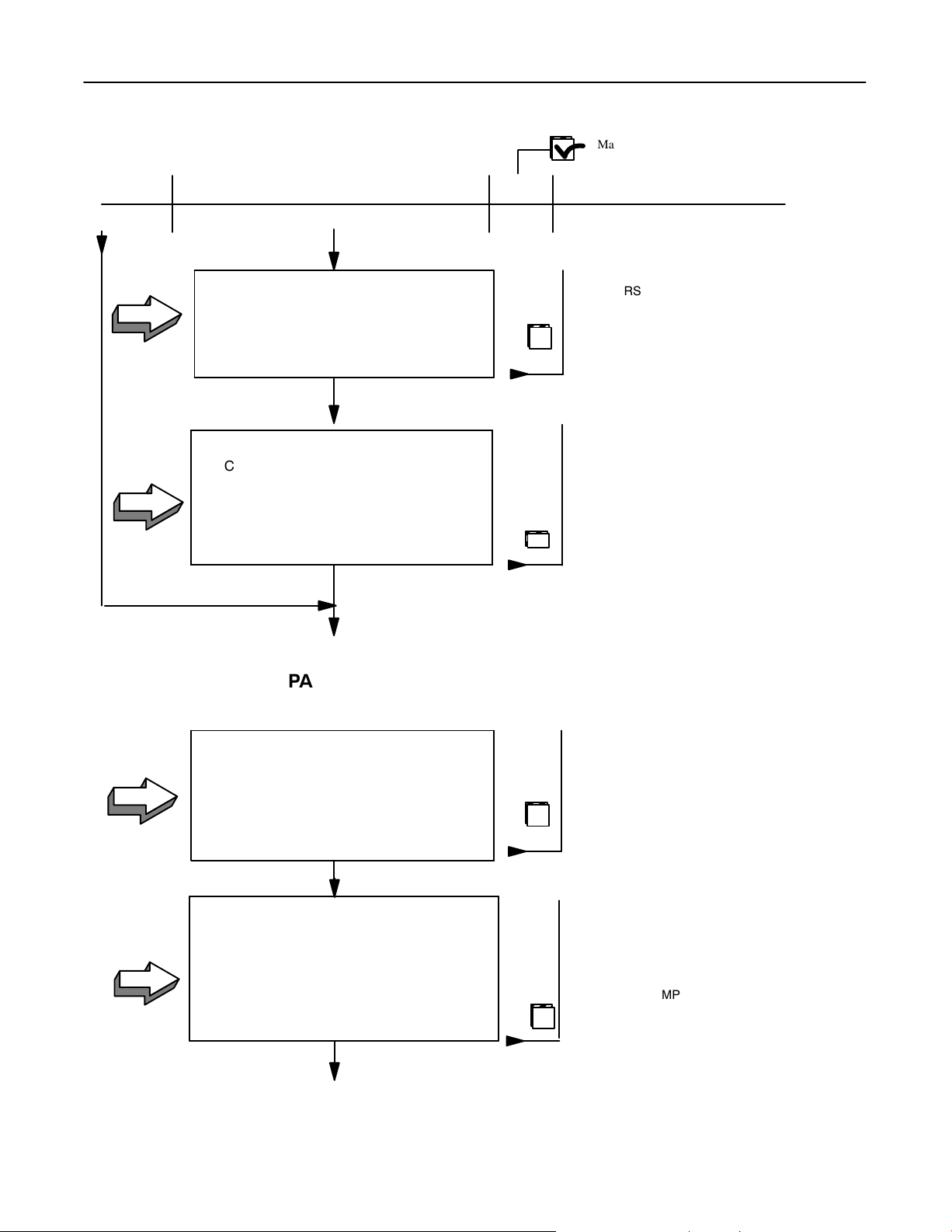

Page 33

System Service Manual − SYSTEM COMPAX 40E, CE Marked

Í

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

Mark each box when done

Step Description Done

From previous page

SYSTEM CONNECTIONS

POWER AND GROUND

CABLE CONNECTIONS

POWER WIRING CONNECTIONS

A21

Route Power and Ground cables

Connect cables onto MPH

2 People

Supporting Documents

Refer to Inspection Report 2179651 TDR or

2172166 TDR or 2167647 TDR, section 1.2

REMARK: Most of these cables are already factory

connected. See MIS MAP / MIS CHART of this

Manual (section 1−4)

.

Connections to be done during Installation:

MIS 3, 4, 6, 9, 11

MIS 1−1, 21, 3−1, 4−1, 5−1, 6−1, 7.1

See SM MPH: Dir 2137354−100

Chapter 1, Job Card IST002

A22

SYSTEM CABLES CONNECTION

SYSTEM WIRING CONNECTION

Route remaining System cables

2 People

Continues on next page

A21 − A22 = 4 Hours

22

REMARK: Most of these cables are already factory

connected. See MIS MAP / MIS CHART of this

Manual (section 1−4)

.

Connections to be done during Installation:

MIS 1, 2, 6, 7, 8, 10, 12 to 23

NOTE: For connection of DOOR OPEN switch

and EXPOSURE ON signal lamp refer to Jov

Card IST004 of this manual

See Job Card IST 005 for cable clamping

Page 34

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

Mark each box when done

Step Description Done

Supporting Documents

From previous page

WARNING

MAINLY FOR USE IN THE USA:

*

• For Bucky: refer to Inspection Report 2179651

TDR, section, 4.2 for 40E, section 6.3 for SG

or to Inspection Report 2167647 TDR or

2172166 TDR, section 4.2 for 40E; section

5.3 for SG

Refer also to orange label fixed to the Bucky

See IST 004

A23

CONFIGURATION CHECK

Bucky Voltage Settings:

110 or 220AC for SG60−100 Bucky

110 or 220AC for Compax 40E Bucky

220V for XT Suspension, RS85, C40E,

TLK, SG

• For components: refer to Inspection Report

1 Person

VERY IMPORTANT: Read Inspection Report (IR) ( Dir. 21722166TDR for Compax 40E/MPH/SG/RS 85; Dir.

2167647TDR for Compax 40E/MPH SG/XT; Dir. 2179651TDR for Compax 40E/MPH/SG/Tomo−Link) through

carefully before eventually proceeding with the MPH software configuration, Step A24 of this Steering Guide.

2179651 TDR or 2167647 TDR or 2172166

TDR

POWER ON AUTHORIZED

CALIBRATION OF SYSTEM COMPONENTS

IR

meets

expectations?

Yes

No

Continues on next page

If more reconfiguration is necessary, proceed to step A24

Reconfiguration is complete.

23

Page 35

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

Mark each box when done

Step

A24

Description Done

From previous page

MPH CONFIGURATION CHECKS

CONFIGURATION

Re−do MPH necessary Configuration

1 Person

CONFIGURATION

Supporting Documents

Refer to Inspection Report 2179651 TDR or to

Inspection Report 2167647 TDR, or 2172166 TDR

section 1.3

See MPH SM 2137354−100, Job Cards

LG001, RG001 and RG002

NOTE: Connect Service Terminal as described

Refer to Inspection Report 2167647 TDR, or 2172166 TDR

section 4.3 for C40E; section 5.3 for SG; section 6.2 for

RAFL−S

or

Refer to Inspection Report 2179651 TDR, section

4.3 for 40E; 6.3 for SG; 7.2 for RAFL−S

in Job Card LG 001

A25

A26

D Re−do necessary Sub−System

Components Configuration

1 Person

RUN−IN & STABILITY CHECK

Rotating anode Tube

1 Person

Continues on next page

See C40E SM 2150259−100 (Chapter 2)

SG60 SM 2150258−100 (Chapter 2), SG100 SM

2150257−100 (Chapter 2), XT SM 46−019803 or

2118910−100 (section 12), RS 85 SM Mounting

Instructions 0327 7223 (section 3)

Refer to Inspection Report 2179651 TDR or Inspection

Report 2167647 TDR, or 2172166 TDR section 2.2

REMARK: The Run−in & Stability check is

performed at the factory. See Technical

Publications, Dir. 46−013804

1 Hour

To redo on site ONLY if necessary (refer to

System Inspection Report Completion date).

Use procedure for MVP generators.

24

Page 36

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

Mark each box when done

Step Description Done

From previous page

MPH CALIBRATION

Yes

kV, mA, mAs

Calibration Checks

A27

1 Person

OK

1 Hour

No

Supporting Documents

REMARK: The MPH calibration is

performed at the factory but it is necessary

to re−check it.

Refer to Inspection Report 2167647 TDR or

2179651 TDR or 2172166 TDR.section 2.3

and proceed with required calibration

checks marked in grey:

Make several exposures at different kV, mA

and mAs stations. Read Post Display on

MPH Console and if out of range, proceed

to step A28 otherwise, skip to step A29

NOTE: kV must be measured using a

Keithley 3508 kV pic meter.

A28

CALIBRATION

Run necessary MPH Calibrations

1 Person

Continues on next page

XX Hrs

Refer to Inspection Report 2167647 TDR, or

2172166 TDR, section 2.2−2.3

Connect Service Terminal. Refer to the MPH

SM Dir. 2137354−100 Chapter 1 section 3

and proceed with calibrations in that section.

25

Page 37

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

Mark each box when done

Step Description Done

From previous page

COMPAX 40E, XT, RS−85 CALIBRATION

(Factory Calibrated)

CALIBRATION

Perform necessary calibrations on:

A29

Compax 40E Table

XT Suspension

RS 85

1 Person

Supporting Documents

Refer to Inspection Report 2179651 TDR or

2167647 TDR, section 4.9 for 40E

and XT

Refer to Inspection Report 2172166 TDR,

section 4.10 for RS 85 and 40E

See SM COMPAX 40E− Dir. 2150299−100,

Chapter 3 − Calibration,

See SM. XT Radiographic Suspension Dir

2118733−100, Chapter 5 Service

Adjustments.

See RS 85 SM Mounting Instructions 0327

7223, section 3

A30

X−RAY BEAM ALIGNMENT/SID ADJUSTMENT

PERPENDICULAR ADJUSTMENT

Perpendicularity of X−Ray beam with

Table

Bucky Stand.

1 Person 1/2 Hour

Continues on next page

26

See C40E SM; Dir. 2150299−100

Chapter 3, section 3 (use RMI 161 B

tool)

Page 38

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

Step Description Done

From previous page

CENTERING ADJUSTMENT

A31

X−ray beam and Light beam alignment check

Center X−Ray beam on Table

Center X−Ray beam on Bucky Stand

1 Person 1 1/2 Hours

SID DETENT ADJUSTMENT

(FINAL POSITIONING)

Horizontal SID Detent

Horizontal SID Detent

A32

Horizontal SID Indicators

1 Person

1/2 Hour

Supporting Documents

See Ultranet SA + RAFL−S sm

Dir. Y00W20L.04 or Ultranet SM sm

Dir. Y00W1L.04 Chapter 4.

See C40E SM: Dir 2150295−100,

Chapter 3, section

See XT SM Dir 46−019803, section 8

or Dir 2118910−100, section 12

or RS−85 SM Mounting Instructions

Dir. 2172805−100 Chapter 2.

and RS 85 Interface SM 2165897−100,

Chapter 1, section 5.

A33

COLLIMATOR CALIBRATION

VERIFICATION

(SA or SM) Collimator lamp voltage

1 Person

Continues on next page

1/2 Hour

Refer to Inspection Report 2179651 TDR or

2167647 TDR, section 3.3

or

Inspection Report 2172166 TDR section 4.7

−For XT see Job Card IST002

of this manual

−For RS 85 see Job Card IST003 of this

manual

27

Page 39

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

Step Description Done

From previous page

Manual (SM)

Ultranet

Collimator

Auto/Manual

Auto (SA)

CALIBRATION

Ultranet SA Collimator + RAFL−S

A34

C40E

SG60/SG100

1 Person

2 Hours

Supporting Documents

Refer to Inspection Report 2179651 TDR,

section 7.3, or 2167647 TDR or 2172166 TDR,

section 6.3

Proceed with required calibrations labelled:

See ULTRANET SA + RAFL−S SM

Dir. Y00W20L.04, Chaps 3, 4 and 6.

(Use extension cable/support provided to

connect RAFL keyboard and fix it on front

of cabinet − Must be removed after the

CALIBRATION is completed).

See Job Card IST005 to open the

RAFL−S rack

A35

TOMO−LINK CALIBRATION

CALIBRATION

Perform C1, C2, C3, C4, C5 ,C7

Calibration Procedures

Drive Power amp adjustment

1 Person

Continues on next page

1 Hour

Refer to Inspection Report 2179651 TDR

section 5.2

See SM Tomo−Link Dir. 2133821−100,

Section 16 and 20.

28

Page 40

System Service Manual − SYSTEM COMPAX 40E, CE Marked

Í

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

Step Description Done

From previous page

AEC CALIBRATION

FILM PROCESSING

Processor ready and operational

A36

Film/Screen characteristics defined

Film Image Quality available

CALIBRATION

Supporting Documents

NOTE: Film processor must be

fully operational at this stage to

proceed with AEC calibration.

Image quality tools (sensitometer,

etc.) must also be available.

A37

A38

AEC for Table Bucky Technique

AEC for Wall Bucky Technique

AEC for Tomo Technique

2 People

6 Hours

SID SCALES

POSITIONING

XT Suspension

RS 85 Tubestand

SG60/SG100

1 Person 1 Hour

See SM MPH 50/65/80, X−ray unit, Dir.

2137354−100, Chapter 1, Installation, Job

Card RG005.

XT: Refer to SM 2118733−100 Dir

46−019803, section 8.6

or Dir 2118910−100, section 12.6

RS−85: Refer to Interface SM

2165897−100 (Chapter 1, section 4 and 5)

SG60: Refer to SM 2150293−100

SG100: Refer to SM 2150297−100

Chapter 1, section 9

Continues on next page

29

Page 41

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

Step Description

From previous page

FUNCTIONAL CHECKS

SYSTEM CHECKS

SYSTEM COMPONENT

FUNCTIONAL CHECKS

SG60/SG100

A39

Collimator SA/SM

Compax 40E

XT/RS 85

MPH 50−65−80

Tomo−Link

Program−X

2 People

4 Hours

Done

Supporting Documents

Refer to Inspection Report 2167647 TDR,

sections 1.2 & 1.5 (MPH), 4.11 (40E), 3.4

(XT/Collimator), 5.4 (SG60/100), 7 (general system

functional check)

or

Refer to Inspection Report 2179651 TDR,

sections 1.2 & 1.5 (MPH), 4.11 (40E), 3.4

(XT/collimator), 5.3 (Tomolink), 6.4 (SG60/100),

8 (general system functional check)

or

Inspection Report 2172166 TDR, sections 3.3

(RS 85/collimator), 4.12 (40E), 1.2 & 1.5 (MPH),

5.4 (SG60/100)

SG60/SG100 Dir 2150297−100

ULTRANET Collimator SM Dir.Y00W1L.04;

SM COMPAX 40E CE, Dir. 2150299−100,

Chapter 4, Section 3−4.;

XT sm Dir. 2118733−100;

RS 85 sm Mounting Instructions 03277223;

MPH SM Dir.2137354−100

SM ULTRANET SA & RAFL−S, Dir. Y00W20L.04,

Chapter 4;

SM Tomo−Link 2133821−100 (section 18)

A40

IMAGE QUALITY

CHECKS

SG60−100 Film Resolution

Tomo−Link Image Quality

40E Film Resolution

2 People 4 Hours

Continues on next page

Refer to SG60 SM Dir 2150293−100, Job Card

VF001,

SG100 SM Dir 2150257−100, Job Card VF001,

Tomo−Link SM Dir 2133821−100 section 18−10

Refer to 40E Service Manual 2150299−100,

Jobcard VF001.

30

Page 42

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

Step Description Done

From previous page

HHS TEST (If Required)

Step A28

No

1 Person

Test

OK

Yes

4 Hours

Supporting Documents

Note: HHS test or any local, in−house,

regional or governmental acceptance tests.

NOTE: If your country requires the product

rating plate label to be in the language of that

country, follow the instructions on document

#45474336. Paste the appropriate language

label over the English rating plate. The rating

plate labels are: 2379361 (Spanish),

2379361−2 (German), 2379361−3 (French),

2379361−4 (Italian).

A41

COVER INSTALLATION

Compax 40E

SG60−100

Tomo−Link

MPH

XT Suspension

RS−85

2 People

Continues on next page

2 Hours

Refer to Inspection Report 2167647 TDR,

4.12 (40E) and 5.5 (SG60/100)

Refer to Inspection Report 2179651 TDR,

sections 4.12 (40E) and 6.5 (SG60/100)

Refer to Inspection Report 2172166 TDR,

sections 4.13 (40E) and 5.5 (SG60/100)

See SM COMPAX 40E CE, Dir. 2150299−100,

Chapter 1, Installation, Section 7.

See SM SG60 Dir 2150253−100 Chapter 1

See SM SG100 CE Dir 2150297−100 Chapter 1

See SM XT RADIOGRAPHIC SUSPENSION

Dir 2118733−100; Chapter 3 or 4, Installation.

MPH 50/65/80: See SM 2137354−100,

Job Card IST 002

Note: GRN wires must be connected to

metal covers when available.

31

Page 43

System Service Manual − SYSTEM COMPAX 40E, CE Marked

Í

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

Mark each box when done

Step Description Done

From previous page

FINAL SYSTEM CHECKS

MOVEMENTS

A42

Compax 40E, SG60−100, XT, RS 85

X−Ray Tube Rotor noise

1 Person

1 Hour

MISCELLANEOUS

Supporting Documents

COMMENT: Check for any unusual noise

and on vibration during components

movement. Make appropriate corrections

A43

A44

PRODUCT LOCATOR

Please complete and send in cards to

Product Locator Administrator

1 Person

1 Hour

GIF & DOA

Please complete and send in green card

to GIF Administrator

DOA tag must be returned with parts

found Dead On Arrival

Continues on next page

Refer to COM 3.3 or COM 3.4 ISERV (on Profs)

for Administrator Contact

Refer to COM 3.3 or COM 3.4 ISERV (on Profs)

for more details.

32

Page 44

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

Mark each box when done

Step

A45

Description

From previous page

PILOT SYSTEM ONLY

(PGS017 FORM)

Complete and return the PILOT FEEDBACK

FORM to USD/RAD (BUC)

Complete and return the Installation

Flowchart to ISS (BUC)

1 Person XX Hours

Done

Supporting Documents

Refer to PGS017 Form and to COM 3.3 or

COM 3.4 ISERV (on Profs) for USD Contact.

A46

SOFTWARE BACKUP

Record MPH set up parameters on the

calibration diskette

1 Person

END

Refer to MPH SM Dir. 2137354−100,

Job Card IST013

1/2 Hour

33

Page 45

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

1-4 Cable Connections

1-4-1 Preliminaries

1. The following interconnection cable numbers refer to the MIS MAP and GROUNDING

INTERCONNECTING MAP included at the end of this manual.

2. The reference numbers between brackets ( ) refer to internal cables also described in the Service

Manuals.

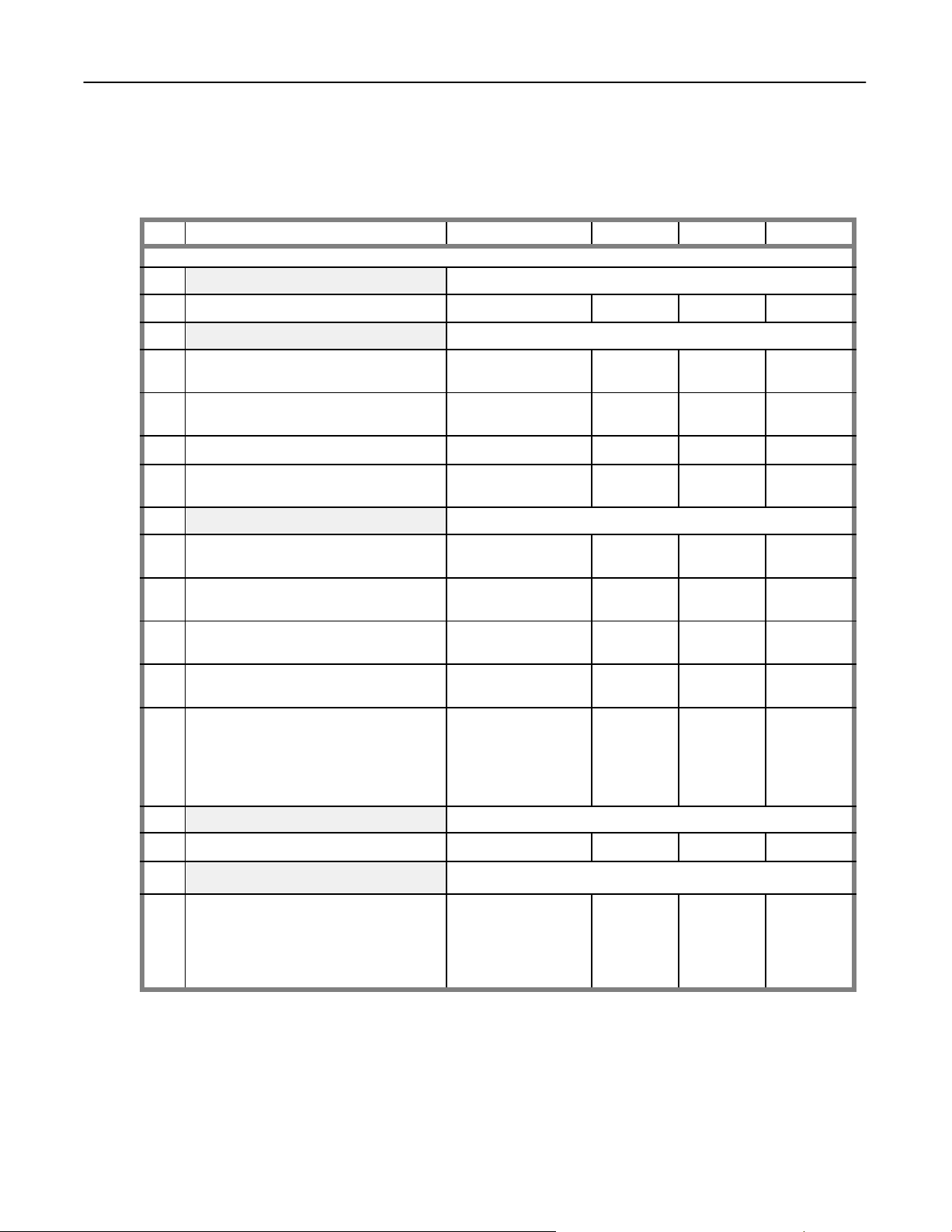

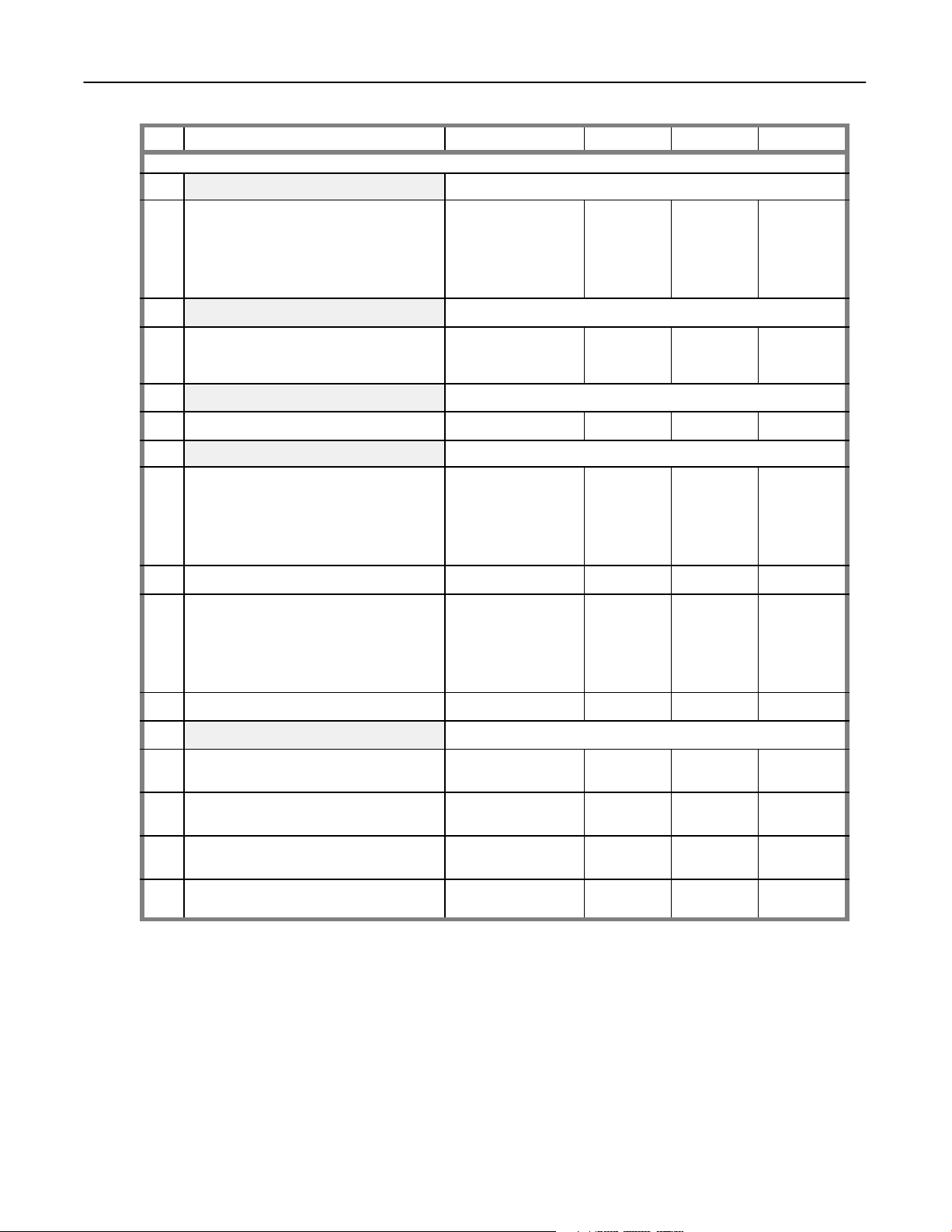

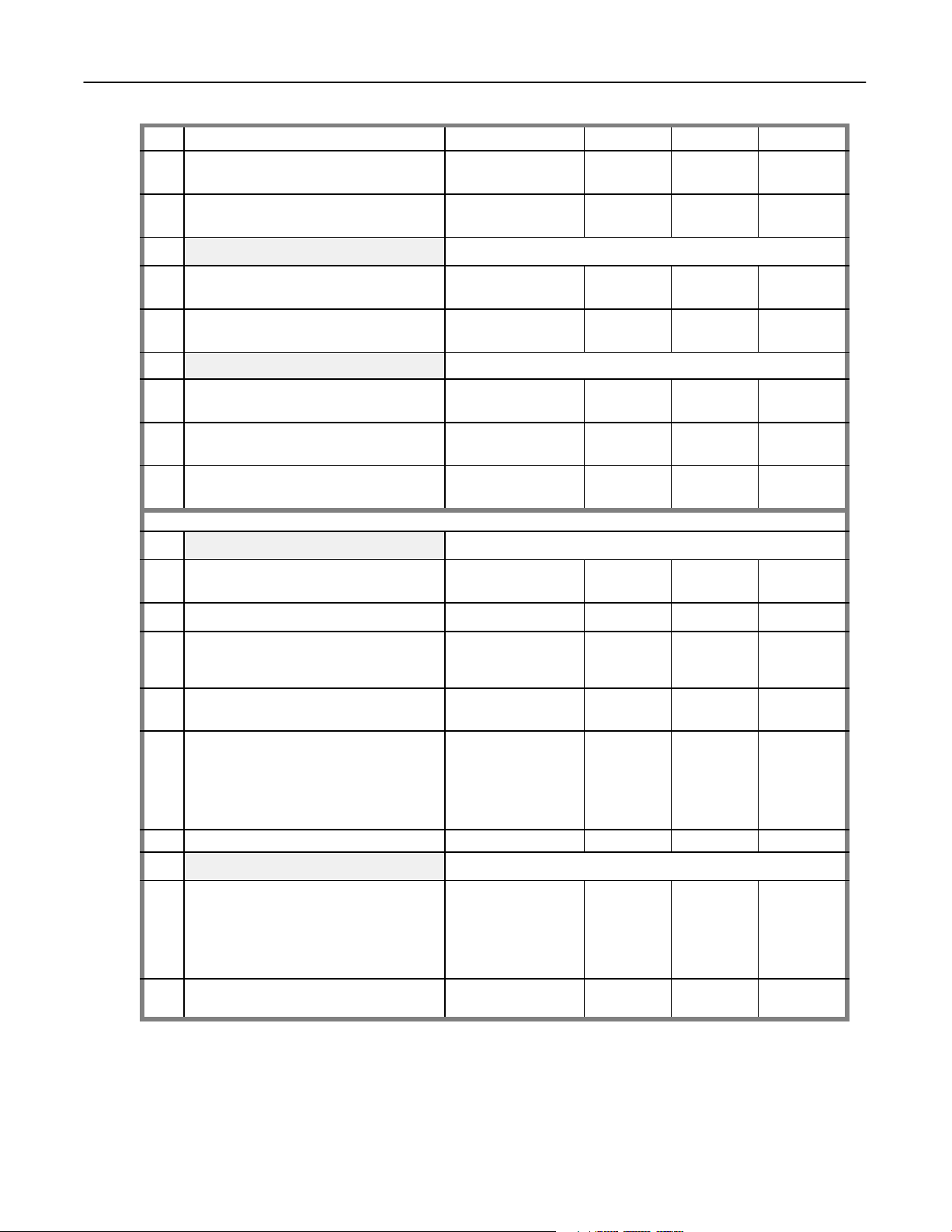

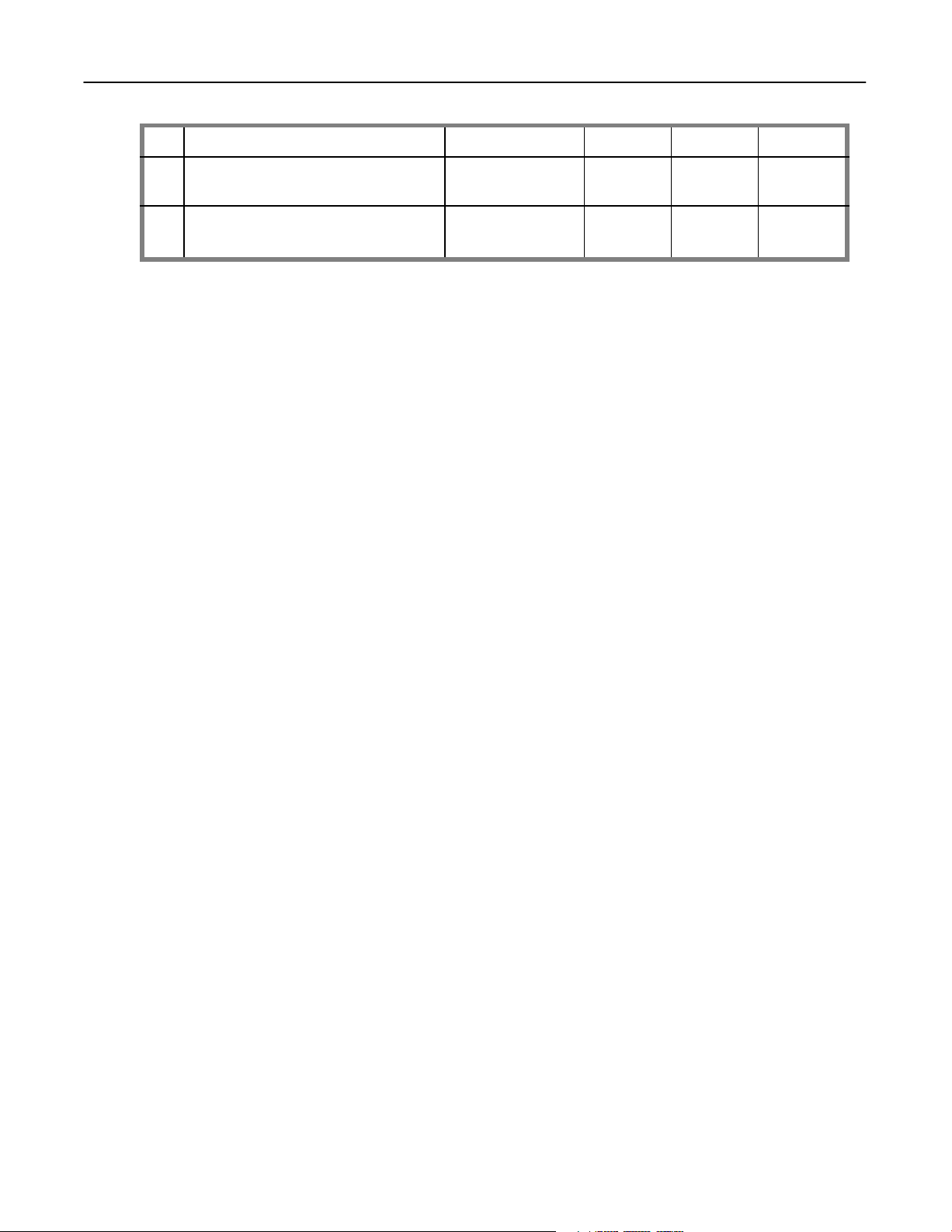

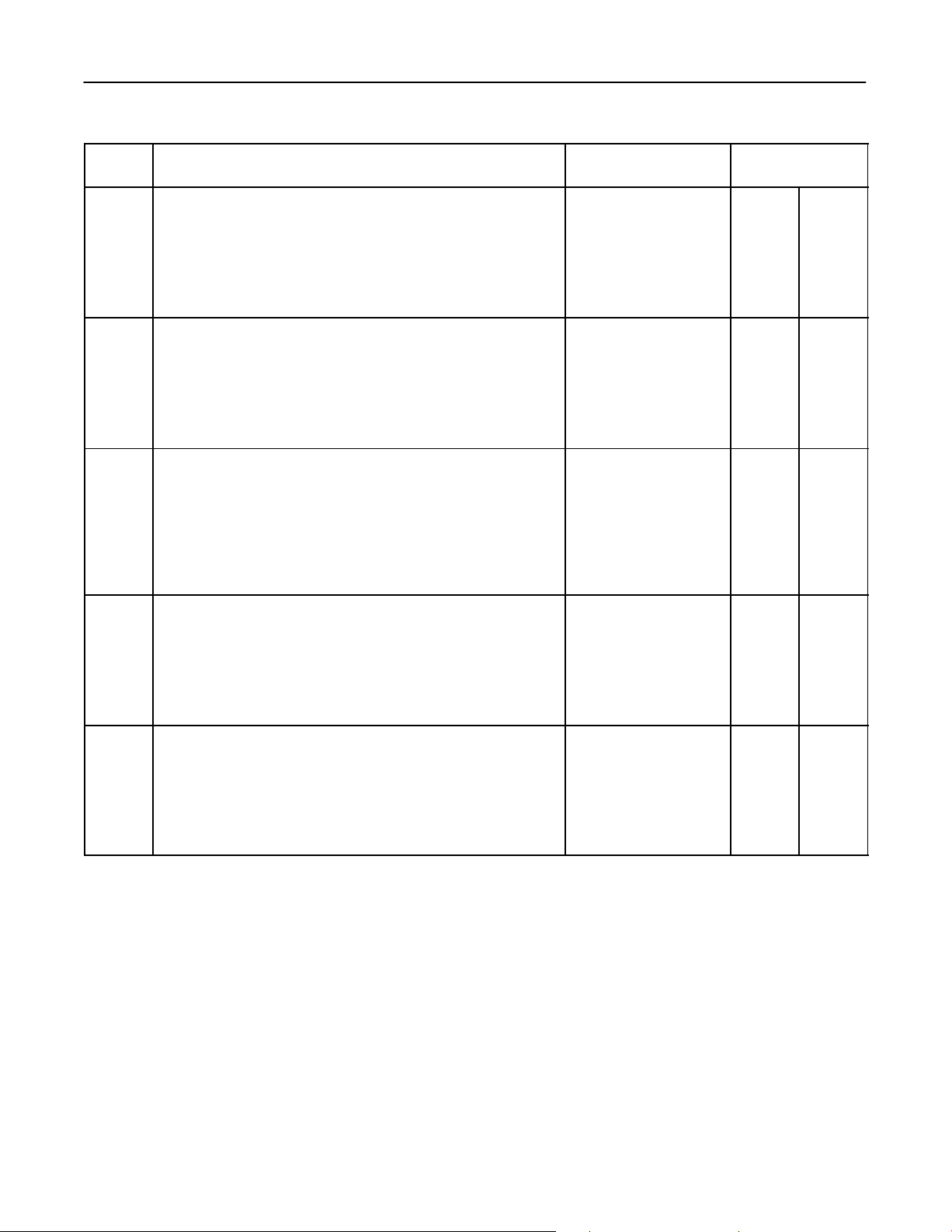

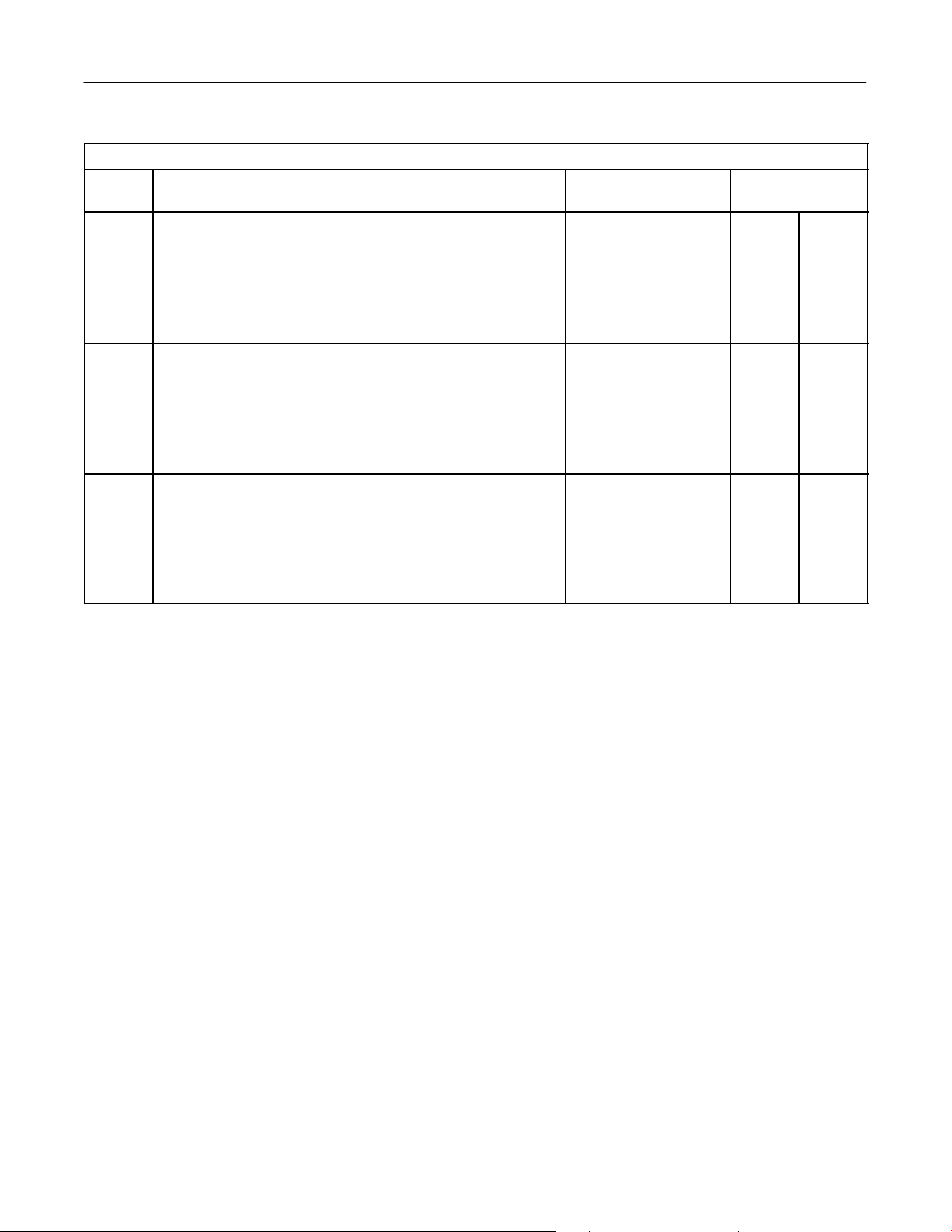

1-4-2 Mis Chart

System MPH 50/65/80 with Compax 40E / SG 60 or SG100 / XT Suspension

Note: Some of the cables, or set cables, are factory connected at one end. In the following MIS Charts:

− Numbers on the left presented in grey squares are HLA numbers (CABLES #).

− The symbol is used to identify those connections which remain to be done during on site

installation.

− The symbol indicates where cable clamping is necessary (refer to Job Card IST006 of this Manual

for EMC rules requirements.

DO NOT FORGET TO CLAMP CABLES ENTERING THE MPH CABINET. IT IS

MANDATORY TO MAINTAIN THE SYSTEM EMC COMPLIANT.

34

Page 46

System Service Manual − SYSTEM COMPAX 40E, CE Marked

GE HEALTHCARE with MPH 50/65/80 (including XT, RS 85 and Tomo−Link)

REV 9 DIRECTION 2154260−100

CABLE #

TERMINALS

1

2

MPH A1 A2 MODULE

(Stator Connector

Panel)

3

MPH A6 A3 MODULE

(Distribution Board)

CAUTION

HV TANK

L

TUBE−I (+)

HV

MPH 50/65/80 CABINET

ANODE

TUBE−I (−)

CATHODE

XJ1A/B−1 TSxx−L

XJ1A/B−2

Ground Plug

ST1−1

ST1−3

ST1−5

ST1−7

ST1−10

ST1−11

ST1−12

Clamped

C

S

M

L

C

S

M

Black

White

Green

Brown

Blue

Orange

Yellow

Shield

120/240Vac

0Vac

Ground

VERIFY THE 240V XT POWER SETTING

MIS 107

46−195120G4

46−195120G4

MIS 10680

2128497

STATOR

CABLE

W34

2104204

PRINTER−X Power Supply

CABLE

X−RAY TUBE

L

C

ANODE

S

M

L

C

CATHODE

S

M

Black

White

Green

Brown

Blue

Orange

Yellow

Shield GND Screw

120/240Vac

0Vac

Ground

TSxx−N

GND STUD