GE Compact Pods, Large Pods, Flameproof Induction Motors, HV Wound Rotor Induction Motors, High Speed Motors Brochure

...Page 1

GE

Power Conversion

Motors

Medium / High Voltage

and High Speed

190 to 100,000 kW

250 to 134,000 HP

Page 2

GE has been setting

the standard in

manufacturing motors

for over 125 years.

2

GE I Power Conversion

Page 3

MV/HV TEFC Motors

MV/HV Synchronous Motors

MV/HV Induction Motors

LV Motors*

kW 0.75 190 375 750 3,750 30,000 75,000 100,000

HP 1.0 250 500 1,000 5,000 40,000 100,000 134,000

*Covered in LV motor brochure.

GE manufactured motors for some

of the first commercial and industrial

electrical applications. We continue to

deliver innovative mechanical power

solutions to the world.

We continue to innovate with

product quality

Motors are designed and manufactured

to operate efficiently and reliably in

Testing

Every machine is tested in our global

state-of-the-art facilities to your exacting requirements. GE has one of the

largest capacities for full load testing.

Applications

Fans, pumps, compressors, grinding

mills, metal rolling, mine hoists,

refiners, propulsion and many others.

High Speed Motors

challenging applications and severe

environments where reliability and

ease of maintenance is critical.

Industries

~ Oil & Gas ~ Mining

~ Power & Energy ~ Cement

Standards & Certifications

We work with all global standards such

as ABS, API, ATEX, CSA, GOST, IEC, IEEE,

and NEMA. GE machines are available

for use in Division I or II and Zone 1, 2,

~ Metals ~ Marine

~ Pulp & Paper

~ Water & Wastewater

~ Other Process Industries

or 22. GE manufacturing facilities are

ISO 9001 certified.

3GE I Power Conversion

Page 4

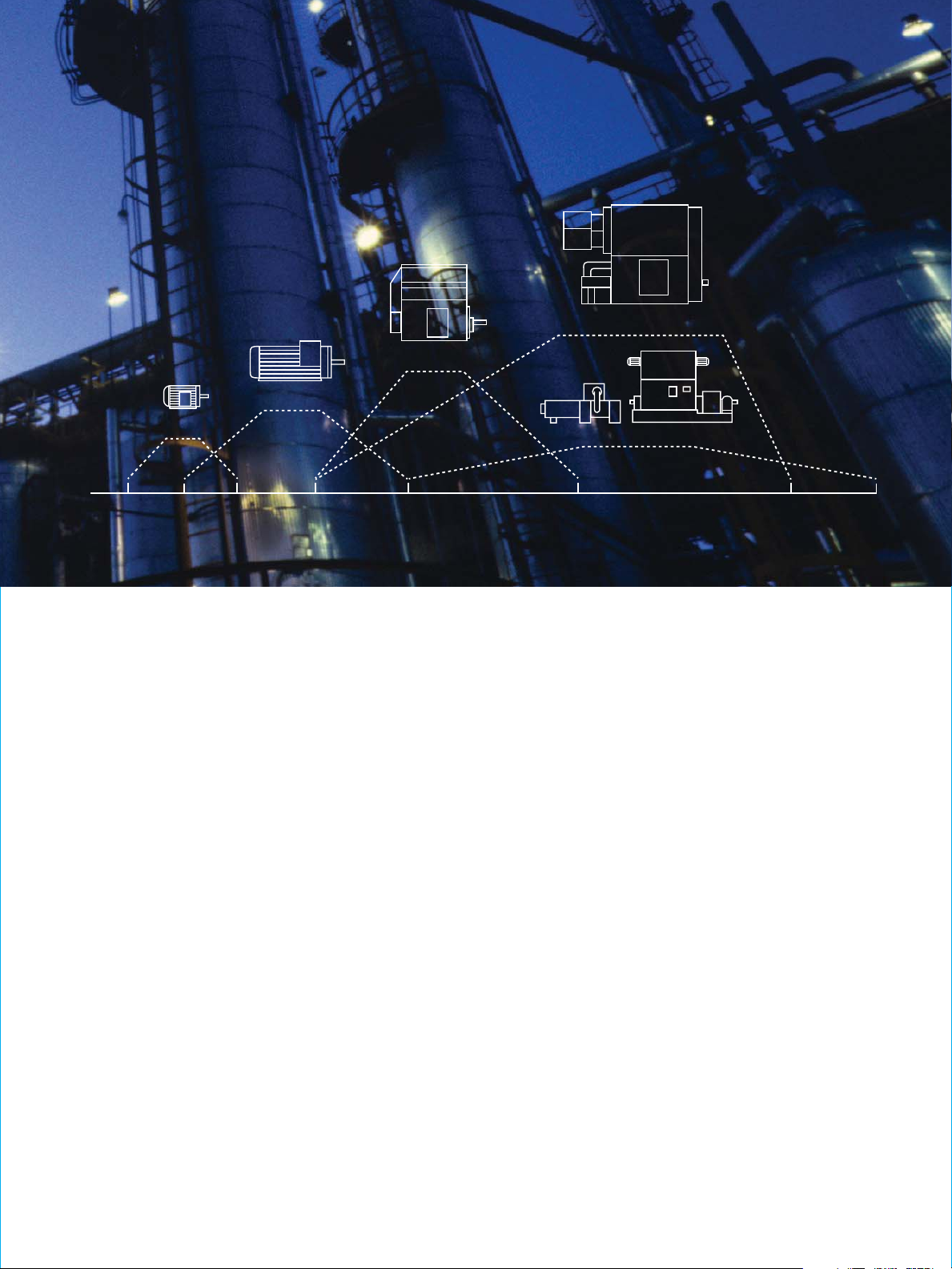

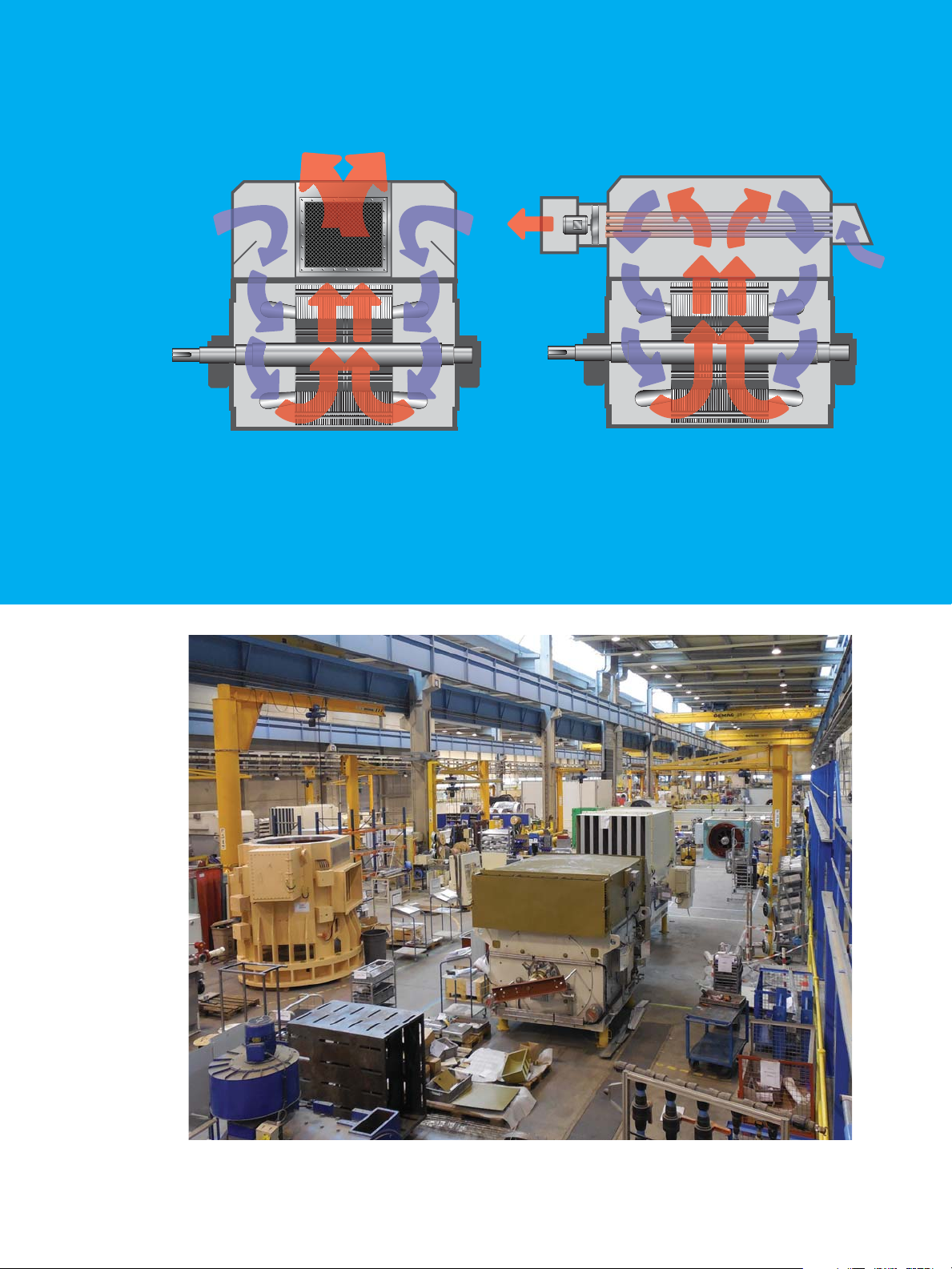

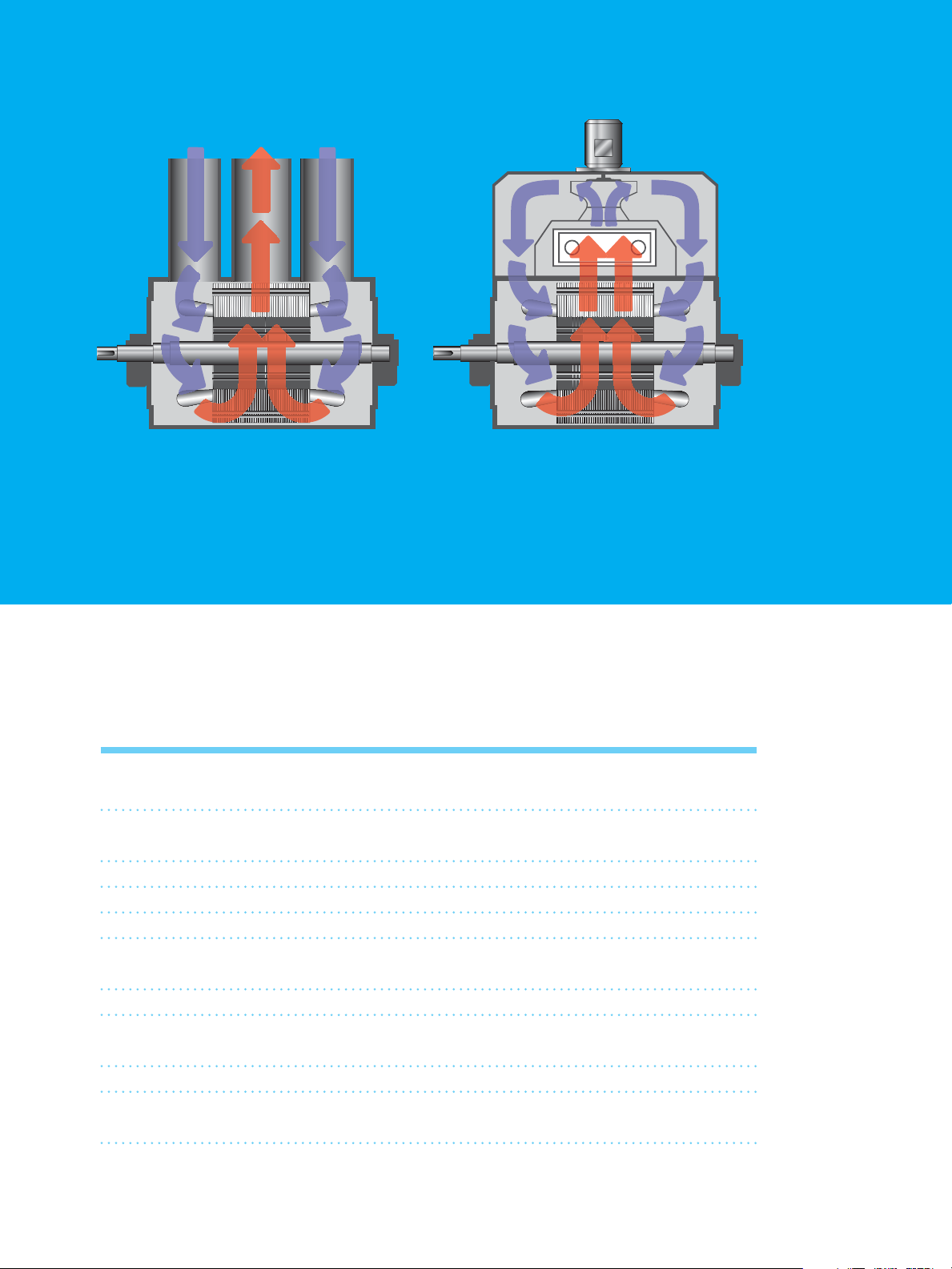

Weather Protected Totally Enclosed Air to Air Cooled

WPII, IC0A1 TEAAC/CACA, IC6A1A6

4 GE I Power Conversion

Page 5

Pipe Ventilated, Forced Ventilated Totally Enclosed Water to Air Cooled

Ducted - IC3A7 TEWAC/CACW, IC8A6W7

Enclosures Designed for Performance

Global Enclosure Designations for Heat Exchange Designs

IEC and NEMA Enclosure Codes IP IC

Open, Drip proof and/or weather protected

(ODP, WPI, WPII) IP00 - IP44 IC0A1

Open, externally ventilated

(machine mounted blower) (ODP) IP00 - IP44 IC0A6

Duct ventilated (separate blower) (TEPV) IP22 - IP44 IC3A7

Totally enclosed non-ventilated (TENV) IP54 - IP56 IC4A1A0

Totally enclosed fan cooled (TEFC) IP54 - IP56 IC4A1A1

Totally enclosed fan cooled

(machine mounted blower) (TEFC) IP54 - IP56 IC4A1A6

Totally enclosed air-to-air cooled (TEAAC, CACA) IP54 - IP56 IC6A1A1

Totally enclosed air-to-air cooled

(machine mounted blower) (TEAAC, CACA) IP54 - IP56 IC6A1A6

Totally enclosed water-air cooled (TEWAC, CACW) IP54 - IP56 IC8A1W7

Totally enclosed water-air cooled

(machine mounted blower) (TEWAC, CACW) IP54 - IP56 IC8A6W7

5GE I Power Conversion

Page 6

Superior Construction

Stator Frame

and Magnetic Core

~ Low Loss Core Design

~ Easy Access for Routine

Maintenance

~ Low Vibration – Long Life

Our stator frame has been optimized

utilizing advanced finite element

analysis tools. Over the decades, these

structures have been proven to comply

with the most demanding industry

standards and requirements.

The stator core is made up of low

loss, high grade electrical sheet steel

insulated with an inorganic coating. By

combining high performance materials,

well-proven design techniques and

modern manufacturing tools, we are

able to offer some of the most compact

and efficient designs in the industry.

6 GE I Power Conversion

Page 7

Insulation System

Ground Wall

Insulation

The reliability of our insulation systems

are validated through a combination

of rigorous qualification testing and

service life experience.

Our insulation system ensures long life

and reliability by meeting the stringent

mechanical and thermal requirements

of a wide range of challenging

specifications.

Our system is comprised of specially

engineered materials selected for

thermal capability, high dielectric

strength, electrical reliability and

chemical resistance. The system

then undergoes a Vacuum Pressure

Impregnation (VPI) process for added

protection and rigidity.

Turn

Insulation

Strand

Insulation

Copper

Conductor

Acceptance Testing

Tests are made during the

manufacture of the windings to

assure that each machine meets

critical material and manufacturing

quality standards. Additional tests are

available to assure the machines meet

unique functional, environmental or

even regional requirements for every

application.

7GE I Power Conversion

Page 8

Rotors to Fit Your Applications

Cage Induction Rotors

~ High Performance

~ Rugged Reliability

~ Small Footprint

This well proven industry work horse

is available in a number of different

designs from low voltage fractional

horse power up to 300 ton machines.

Designs are offered with copper or

copper alloy, or for smaller machines,

both copper and fabricated aluminum.

Each machine is optimized to suit

specific needs by modifying the stator

and stator winding as well as the rotor

cage bar profiles and materials. In this

way a design can be optimized to give

the right starting torque capability,

ensuring high efficiency and an

optimized power factor.

With our ability to optimize motor

designs for use with variable frequency

drives, cage motors are now being

supplied for applications never

previously considered. GE has supplied

very high speed cage induction motors

that eliminate the need for gearboxes

(some of which operate at 20,000 rpm!)

Our mine hoist technology supplies

shaft-less induction motors in excess of

100 tons.

Aluminum Cage Construction

> Low mass bars and end-rings reduce

centrifugal force.

8 GE I Power Conversion

Copper Cage Construction

> This design provides greater capability

for starting high inertia loads.

> High efficiency helping to reduce

CO

emissions.

2

Page 9

Synchronous Rotors

~ Highest Available Efficiency

~ Brushless Excitation for Minimum

Maintenance and Maximum Reliability

Wound Rotors

~ Versatile

~ Long Track Record of Success

~ Soft Starts

Synchronous motors are utilized for a

number of applications across a broad

range of industries. Because of the

high efficiency and controllable power

factor of the design, utility costs (and

CO

emissions) are minimal. Starting

2

characteristics and normal operating

performance can be optimized

separately and independently giving

you the benefits of both. A number of

different design options are available for

your application. Included are laminated

and solid pole designs – both cylindrical

and salient pole. GE also offers a unique

forged integral pole tip design well

suited to high load inertia applications.

Field windings are optimized to suit

individual applications utilizing either

wire wound or strip wound options.

By eliminating the need for a rotormounted synchronizing module, GE has

further improved motor reliability. Fixed

speed applications

benefit from the use of our ESP1

excitation control. This not only gives

reliable starting but also ensures the

best protection for your investment.

With the ability to provide a ‘soft-start’

when used in conjunction with a liquid

resistor as well as some speed control,

the wound rotor motor has long been

utilized in mining and other process

industries with great success.

By employing modern design

techniques and updated materials,

we have revitalized this technology.

Through our variable speed drive

expertise, we are now able to offer slip

energy recovery systems making this

an efficient option.

9GE I Power Conversion

Page 10

Bearings and Lubrication

Plain white metal or rolling element endshield-mounted

bearings are available appropriate to the motor speed

and application. All bearings are of the highest quality

produced to the standards of internationally recognized

manufacturers. This ensures replacement bearings will be

readily available.

10

GE I Power Conversion

Page 11

Endshield & Pedestal

Sleeve Bearings

These bearing designs incorporate

specially developed multiple labyrinth

floating oil and air-seals. This ensures

dynamic pressure changes inside

the motor will not adversely affect

the lubrication system and allow for

IP56 degree protection. Center flange

bearings are used on larger machines

improving rotor dynamic performance

and overall efficiency. Self-contained

or flood lubricated options are

available along with suitable provisions

for emergency run-down.

Rolling Element /

Anti-Friction Bearings

Ball or roller type bearings on horizontal

machines are regreaseable and operate

smoothly providing long life with low

running noise. They are assembled with

grease in a sealed housing to avoid

contamination and allow for IP56 degree

protection. The lubrication system includes

a suitable pressure relief plug to purge

excess or old grease during lubrication.

Thrust Bearings

Angular contact ball, spherical roller and

sleeve tilting pad (hydrodynamic plate)

thrust bearings are designed to meet

specific project requirements. Depending

upon application, bearings can be selfcontained grease or oil lubricated, water

cooled or flood lubricated.

Endshield & Pedestal

Sleeve Bearings

Rolling Element /

Anti-Friction Bearings

Thrust Bearings

Vibration

All motors are capable of complying

with the requirements of API 541, 547

or 546 (as applicable). The rotors are

dynamically balanced in two or more

planes. The vibration level is then

checked in the factory before and

after over-speed tests. This check is

designed to prove the stability required

to achieve quiet operation and long

bearing life.

11GE I Power Conversion

Page 12

MW

High Speed Motors

100

80

60

40

Synchronous

Range

20

Induction

Ranges

0

0 5,000 10,000 15,000

With over 120 machines in our

reference list, GE is the leading supplier

of high speed motors. We have 20

years of experience with this design

and are constantly improving it to

ensure reliable performance for this

demanding application.

12 GE I Power Conversion

20,000

rpm

Our third generation MGV induction

range is based on a reliable ‘stiff-shaft’

design. Available with a Class H

insulation system, sleeve, tiling pad

or active magnetic bearings, we offer

a flexible design suitable for a broad

range of applications.

Page 13

GE I Power Conversion

13

Page 14

Parts

& Services

Superior Product Quality

~ OEM parts designed using the

latest materials and manufacturing

processes.

~ A full complement of spare parts are

available for the entire range of GE

motors.

Exact Fit and Specification

~ Experience less replacement time

and more efficiency using genuine

GE parts.

Spare Parts Program

~ Save time with a GE spare parts

inventory plan.

World Class Service

~ Our technology and manufacturing

teams have dedicated parts people

to help you.

Remote Monitoring,

Diagnostics and Prognostics

~ Commissioning Benefits

> GE experts observe in real-time

to guide engineers onsite

> Quicker and smoother

commissioning process

~ Operations Benefits

> Optimize your system with

full visibility

> Full lifecycle coverage

~ Warranty Benefits

> More proactive, less downtime

> Your teams can solve minor

issues quicker based on

remote diagnosis

> Field service engineers can arrive

fully equipped with solutions

Machine Section Parts

Coils

Ammortisseurs, Synchronous Poles, Equalizers

Commutators/Collectors Replacement Commutators and Slip Ring Assemblies

Brush Assembly Brushes, Springs and Brushholders

Bearings Sleeve Bearings and Oil Rings

Exciters Rotors and Stators

Accessories Molded Equalizer Trays, Air Filters, Thyristors, Speed Limit Switches, Heaters

Thermostats, Converter Assemblies, Oil Gauges, Fans

Blower Assemblies or Wheel

14 GE I Power Conversion

Armature, Field, and Stator coils

Page 15

Global Expertise

Proven

Experience

The GE

Advantage

Complete

Product

Offering

Rotating Machine Factories

Converter Factories

Business Centers

Few manufacturers can claim the depth and

breadth of experience that GE has in building

and delivering electrical and mechanical

solutions for customers.

GE offers a complete portfolio

of rotating machines.

5).),-!,)'.)%

.)

5 ( ,.),-/*.)A

5)1(' $/'0)&."

0,$& !, +/ (3,$0 -

Innovative

Technology

World-Class

Service

GE has the global resources and capabilities

to maximize the performance and reliability

of your machines.

5#$"#&3 2* ,$ ( . ')!**&$.$)(

(-& - ("$( ,s

5("$( ,$("-/**),.)*.$'$4

!),3)/,**&$.$)n

GE is constantly innovating product

technologies to meet and exceed

customer expectations.

GE I Power Conversion

15

Page 16

MAIN OFFICES

Australia, Botany

Tel: +61 (0) 2 8313 9980

Brazil, São Paulo

Tel: +55 11 3614 1930

Canada, Mississauga

Tel: + 1 905 858 5100

Chile, Santiago

Tel: + 56 2 652 6500

China, Shanghai

Tel: +86 21 6498 2600

France, Massy

Tel: +33 1 77 31 20 00

Germany, Berlin

Tel: +49 30 7622 0

Japan, Tokyo

Tel: +81 3 5544 3852

Russia, Moscow

Tel: +7 495 981 13 13

Singapore

Tel: +65 6332 0940

South Africa, Midrand

Tel: +2711237 0000

South Korea, Busan

Tel: +82 51 710 9015

UAE, Dubai

Tel: +971 44296161

UK, Rugby

Tel: +44 1788 563 563

India, Chennai

Tel: +91 44 4968 0000

USA, Fort Wayne

Tel: +1 800 541 7191

www.gepowerconversion.com

© 2014 General Electric Company and/or its affiliates. All rights reserved.

GEA30775A Motors (01/2014)

Loading...

Loading...