GE CGP650SET2SS, CGP650SET3SS, CGP650SET4SS, PGP976DET2BB, PGP976DET2WW Installation Guide

...Page 1

I stollotio

36" SealedGasCooktop

I structio s

j r_l Questions? call 800.GE.CARES (800.432.2737) or Visit our Website at: GEAppliances.com

IN THE COMMONWEALTH OF

MASSACH USETTS:

, This product must be installed by a licensed

plumber or gas fitter.

, When using ball-type gas shut-off valves, they

shall be the T-handle type.

, A flexible gas connector, when used, must not

exceed 3 feet.

BEFORE YOU BEGIN

Read these instructions completely

and carefully.

.IMPORTANT - Savetheseinstructions

for local inspector's use.

, IMPORTANT - ObserveaUgoverning

codes and ordinances.

, Note to Installer- Be sure to leave these

instructions with the Consumer.

Note to Consumer - Keep these instructions for

future reference.

, Product failure due to improper installation is not

covered under the Warranty.

,AWARNING - This appliancemust be

properly grounded.

In Canada, call 1.800.561.3344 or Visit our Website at: www.geappliances.ca

PGP976, PGP986, CGP650

FOR YOUR SAFETY:

_I,WARNING - iftheinformationinthis

manual is not followed exactly, mfire, explosion

or gas leak may result causing property damage,

personal injury or death.

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance!

Do not install this product with an air curtain

hood or other range hood that operates by

blowing air down on the cooktop. This airflow

may interfere with operation of the gas burners

resulting in fire or explosion hazard.

WHAT TO DO IF YOU SMELL

GAS:

, Do not try to light any appliance. Do not touch

any electrical switch; do not use any phone in

your building.

immediately coil your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

, If you cannot reach your gas supplier, coil the

fire deportment.

installation and service must be performed by

a qualified installer, service agency or the gas

supplier.

i

. IMPORTANT - Leak testingofthe

applianceshallbe conducted accordingto the

manufacturer's instructions.

, Proper installation is the responsibility of the

installer and product failure due to improper

installation is NOT covered under warranty.

WARN ING - Disconnectallelectrical

power at the main circuit breaker

or fuse box before installing.

31-i0955 ii-13 GE i

This cooktop has been certified by UL. You'll find

safety precautions in your Owner's Manual. Read

them carefully.

Installation of this cooktop must conform with

local codes or in the absence of local codes with

the National Fuel Gas Code, ANSI Z223.Z/NFPA

54-Latest edition.

Be sure your cooktop is installed properly by a

qualified installer or service technician.

To eliminate reaching over surface burners,

cabinet storage above burner should be avoided.

Do not install the unit near an outside door or

where a draft may affect its use.

Page 2

Installation Instructions

IMPORTANT SAFETY INSTRUCTIONS

ELECTRICAL REQUIREMENTS

This appliance must be supplied with the proper

voltage and frequency and connected to an

individual, properly grounded branch circuit,

protected by a circuit breaker or fuse having

amperage as noted on the rating plate.

We recommend you have the electrical wiring and

hookup of your cooktop connected by a qualified

electrician. After installation, have the electrician

show you where your main cooktop disconnect is

located.

Check with your local utilities for electrical codes

which apply in your area. Failure to wire your

cooktop according to governing codes could result

in a hazardous condition.

If there are no codes, your cooktop must be wired

and fused to meet the requirements

of the National Electrical Code, ANSI/NFPA No. 70--

Latest edition. You can get a copy

by writing:

National Fire Protection Association

Batterymarch Park

Quincy, P1A 02269

PARTS INCLUDED

2Screws Regulator

MATERIALS YOU MAY NEED

Joint Sealant Pipe Fittings

CSA-Approved Flexible Gas Line

3/8" Min. ID, 1/2" NPTConnection,

3-foot Maximum Length (Massachusetts Only)

2 Hold

Down Brackets

Shut-Off Valve

In Canada your cooktop must be wired and fused

to meet the requirements of the Canadian Electrical

Code.

Be sure the installation of this product in a mobile

home conforms with the Manufactured Home

Construction and Safety Standard, Title 24 CFR,

Part 3280. If this standard does not apply, you

must follow the standard for Manufactured Home

Installations, ANSI/NCSBS A225.1 or with local

codes where applicable.

You can get a copy of the Federal Standard by

Writing:

Office of Mobile Home Standards

HUD Building

451 7th Street, S.W.

Washington, D.C. 24010

TOOLS YOU WILL NEED

FOR INSTALLATION

Pencil

Saber Saw

Phillips-Head

Screwdriver

Pipe Wrench

Ruler or Straightedge

!/8" Drill Bit & Electric or

Hand Drill

Safety Glasses

Page 3

Installation Instructions

PRE-INSTALLATION CHECKLIST

When preparing cooktop opening, make

[Z]

sure the inside of the cabinet and the

cooktop do not interfere with each other.

(See section on preparing the opening.)

Remove packaging materials, grote boxes,

@

regulator with literature, and literature

package from the cooktop before beginning

installation.

i/

/i/

Foam

Pac_,_,_///_,_r,_/,_ _ _ _ _

Cooktop J

Package

Grate boxes

Remove Installation Instructions from

E1

literature pack and read them carefully

before you begin.

Be sure to place all literature (Owners Manual,

Installation Instructions, etc.)in a safe place

for future reference.

Make sure you have all the tools and

El

materials you need before starting the

installation of the cooktop.

Your home must provide the adequate

El

electrical service needed to safely and

properly use your cooktop. (Refer to section

on electrical requirements.)

When installing your cooktop in your home,

FF1

make sure all local codes and ordinances

are followed exactly as stated.

Make sure the wall coverings, countertop

[]

and cabinets around the cooktop can

withstand heat (up to 200°F) generated by

the cooktop.

Page 4

Installation Instructions

PREPARING THE OPENING

MAINTAIN THE FOLLOWING

MINIMUM CLEARANCE DIMENSIONS

23" MAX. De R - IVllN. clearance

of unprotected from cutout to right

overhead side wall

cabinets

I

]0" MIN. clearance from

countertop to unprotected

overhead surface

C- MIN. I

clearance from I

cutout to rear

wall

L - MIN. clearance

from cooktop to left

side wall ]0" or wider

2-1/2" MIN from cutout to

front of countertop

ALL HORIZONTAL

CLEARANCES MUST

BE MAINTAINED FOR PGP976

A MINIMUM OF 18" PGP986

ABOVETHECOOKING CGP650

SURFACE,

NOTE: Allow 7/16" minimum

vertical clearance from s 11/16 €

the cooktop bottom (or 3_

3-11/16" minimum depth

from the countertop) to any

combustible surfaces, such as

a cabinet drawer.

cabinetbase

L

3-3/a,"

12"

12"

_ ,-2"

6" 3-3/8"

12" 3-3/8"

12" 3-3/8"

DRAWERI_

18" MIN. height

countertop

to nearest

cabinet on either

side of unit

R C

7/16"

RECOMMENDED GAS SUPPLY

LOCATION FROM BACKWALL

1" Min. From Backwall

Recommended

gas supply

location

From Cutout

Center Line

r_ MAKE SUREWALL COVERINGS,

COUNTERTOP AND CABINETS

AROUND COOKTOP CAN WITHSTAND

HEAT (UPTO 200°FI GENERATED BY

COOKTOP

countertop must l

withstand heat I

For island installation, maintain

2-1/2 in. minimum from cutout to

front and back edge of countertop. Maintain 3 in.

minimum from cutout to side edges of countertop.

E_ OVERALL COOKTOP DIMENSIONS

3-1/4"

18-7/8" _

F_ CUTOUT DIMENSIONS OF COUNTERTOP

To ensure accuracy, it is best to make a template

when cutting the opening in the counter,

19-1/8" width cut

[]_] FOR AMERICANS WITH DISABILITIES

ACT (ADA} FORWARD APPROACH

INSTALLATION ON LY:

Allow 5" minimum I

depth between the I

countertop and an I

enclosure. _

NOTE: The enclosure must be made of wood

material. Also, an access panel is required for the

electrical outlet, pressure regulator, shut-off valve,

hold-down brackets, and service.

I

I

I

I

U

Page 5

Installation Instructions

iNSTALLiNG THE COOKTOP UNiT

LOCATE ELECTRICAL OUTLET AND

rT]

GAS SHUT-OFF VALVE BENEATH

CABINET

NEVER REUSE OLD

CONNECTORS WHEN

INSTALLING THIS

UNIT.

ShutOff _,H IF''

_Valve --_ j ElectricalOutlet 12"

I_ 7f

_1 LJ

II

i

Below

Countertop

ATTACH BRACKETS TO COOKTOP

Remove the screw from the side of the cooktop

and screw the hold-down bracket to the side of the

cooktop unit. Repeat for opposite side of cooktop.

Pre-drilled

Bottom of hole

Cooktop

\

Install a manual shut-off valve in the gas line in an

easily accessible location outside the cooktop. Be

sure you know how and where to shut off the gas

supply to the cooktop. Install the electrical outlet

12" below the countertop.

[_] PROTECT SURFACE OF COOKTOP

Place a towel or tablecloth onto the countertop.

Lay the cooktop upside down onto the protected

surface.

Bottom of cooktop j

Cloth under Cooktop

r_ LOCATE MOUNTING PARTS

Remove the hold down brackets from the literature

package.

Cookto

Surface

r_ INSERT COOKTOP INTO CUTOUT

Insert the cooktop centered into the cutout opening.

Hake sure the front edge of the countertop is

parallel to the cooktop. Hake final check that all

required clearances are met.

Once the unit is in place, screw the

hold- down bracket into the cabinet sides

to secure the unit into place.

Page 6

Installation Instructions

INSTALLATION--GAS CONNECTIONS

r_ PROVIDE ADEQUATE

GAS SUPPLY

This cooktop is designed to operate on natural

gas at 5" of water column manifold pressure and

7" of water column (W.C.)supply pressure. It is

shipped from the factory set for natural gas. The

convertible pressure regulator supplied with the

unit must be connected in series with the manifold

of the cooktop and must remain in series with the

supply line regardless of whether natural or L.P.

gas is being used. FOR PROPEROPERATION, THE

MAXIMUM INLET PRESSURETO THE REGULATOR

MUST BE NO MORE THAN 14" OF WATER COLUMN

PRESSURE.For checking the regulator, the inlet

pressure must be at least 1" W.C.. (or 3.4 KPA)

greater than the regulator output setting. If

the regulator is set for 5" W.C. of water column

pressure, the inlet pressure must be at least 6" W.C.

If the regulator is set for 10" W.C., the inlet pressure

must be at least 11" W.C.. The gas supply line to

the cooktop should be 1/2" or 3/4" pipe.

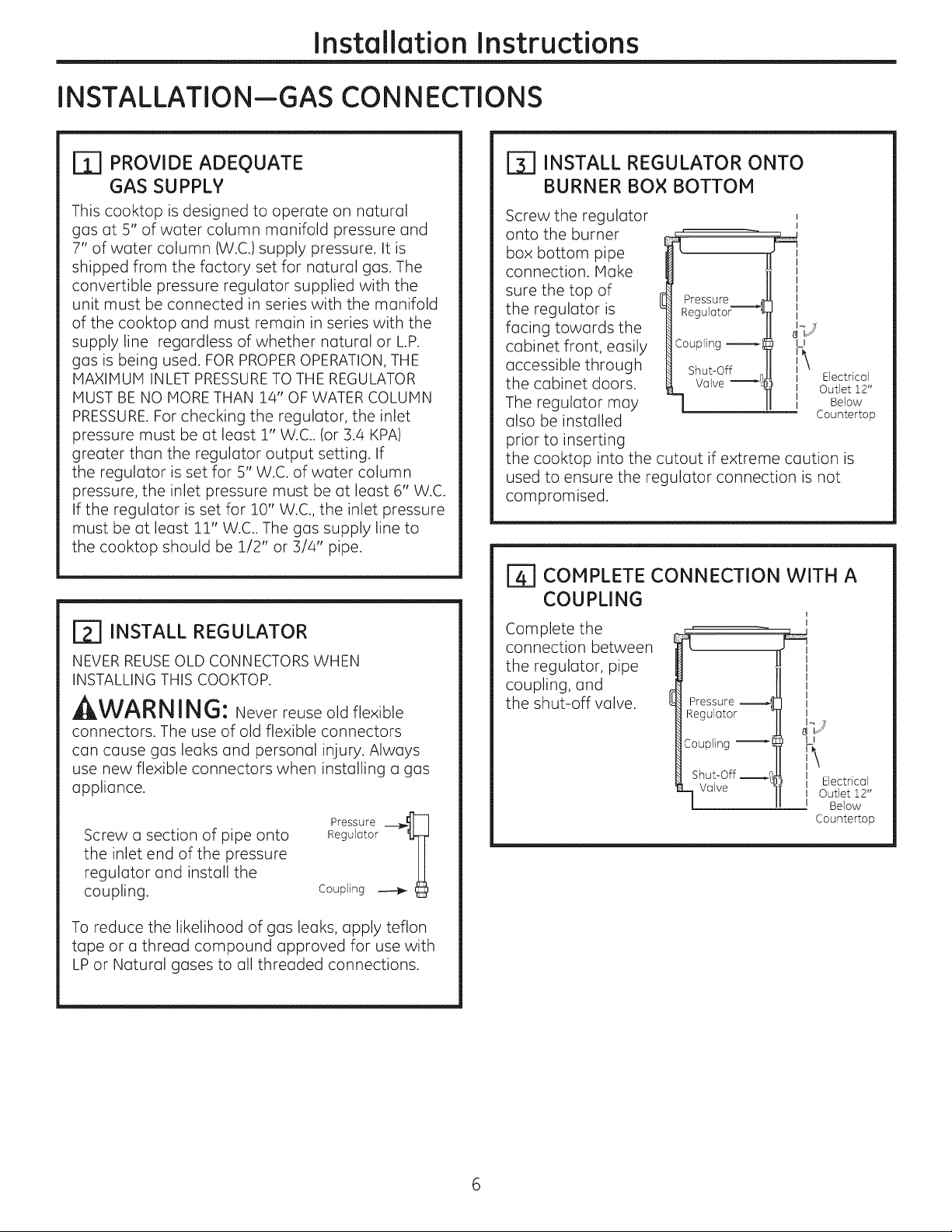

_] INSTALL REGULATOR

NEVER REUSEOLD CONNECTORS WHEN

INSTALLING THIS COOKTOP.

, WARNING: Never reuse old flexible

connectors.The use of oldflexibleconnectors

can cause gas leaksand personalinjury.Always

use new flexibleconnectorswhen installinga gas

appliance.

Screw a section of pipe onto

the inlet end of the pressure

regulator and install the

coupling.

Pressure __-]

Regulator 'U]]J

Coupling _

r_ INSTALL REGULATOR ONTO

BURNER BOX BOTTOM

Screw the regulator

onto the burner

box bottom pipe

connection. Make

sure the top of

the regulator is

Pressure 41

Regulotor-----_l

facing towards the

cabinet front, easily

accessible through

the cabinet doors.

The regulator may

also be installed

Coupling l

LI

', Electrical

II Outlet 12"

I Below

Countertop

prior to inserting

the cooktop into the cutout if extreme caution is

used to ensure the regulator connection is not

compromised.

COMPLETE CONNECTION WITH A

COUPLING

Complete the

connection between

the regulator, pipe

coupling, and

the shut-off valve.

Pressure

Regulator

Coupling

Shut-Off _1

Valve

I

II

II Electrical

I Outlet 12"

I Below

Countertop

To reduce the likelihood of gas leaks, apply teflon

tape or a thread compound approved for use with

LP or Natural gases to all threaded connections.

Page 7

Installation Instructions

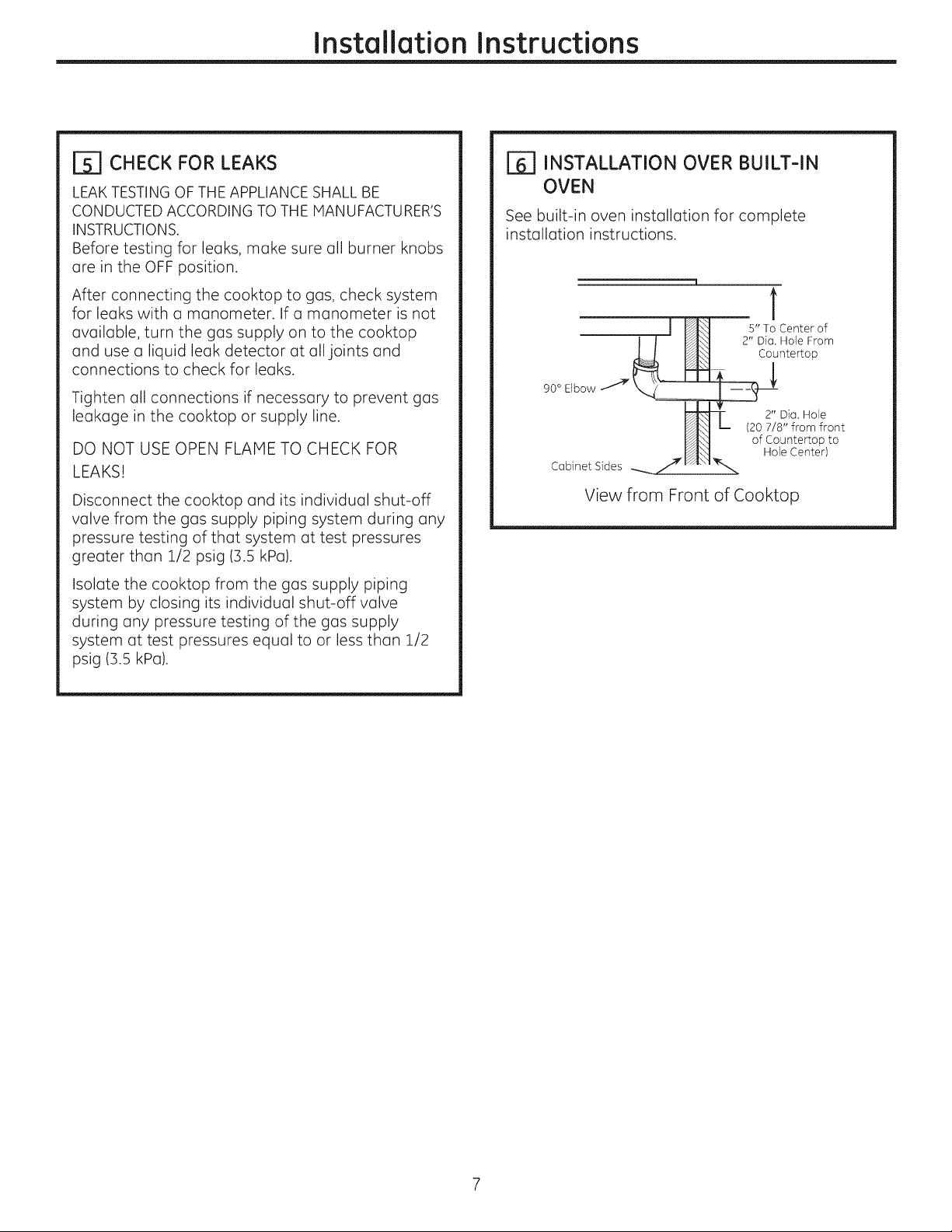

CHECK FOR LEAKS

LEAKTESTING OF THE APPLIANCE SHALL BE

CONDUCTED ACCORDING TO THE MANUFACTURER'S

INSTRUCTIONS.

Before testing for leaks, make sure all burner knobs

are in the OFF position.

After connecting the cooktop to gas, check system

for leaks with a manometer. If a manometer is not

available, turn the gas supply on to the cooktop

and use a liquid leak detector at all joints and

connections to check for leaks.

Tighten all connections if necessary to prevent gas

leakage in the cooktop or supply line.

DO NOT USE OPEN FLAME TO CHECK FOR

LEAKS!

Disconnect the cooktop and its individual shut-off

valve from the gas supply piping system during any

pressure testing of that system at test pressures

greater than 1/2 psig (3.5 kPa).

Isolate the cooktop from the gas supply piping

system by closing its individual shut-off valve

during any pressure testing of the gas supply

system at test pressures equal to or less than 1/2

psig (3.5 kPa).

[_] INSTALLATION OVER BUILT-IN

OVEN

See built-in oven installation for complete

installation instructions.

1

5" To Center of

2" Dia. Hole From

Countertop

90 ° Elbow

2" Dia. Hole

(20 7/8" from front

of Countertop to

Hole Center)

Cabinet Sides __ .J_"

View from Front of Cooktop

Page 8

Instelletion Instructions

INSTALLATION--ELECTRICAL CONNECTIONS

, WARNING - Disconnect all electrical

power at the main circuit breaker or fuse box

before installing.

ELECTRICAL SUPPLY AND OUTLET

An adequate electrical supply and outlet must

be used to operate the electrical parts of your

cooktop.

[]

The power cord of this appliance is equipped

with a 3-prong (grounding) plug which must

be used with a properly grounded 3-hole

outlet with a standard 120 Volt, 60 cycle AC

household current.

D

If you do not have a 3-hole grounded outlet,

have a qualified electrician change your old

one. DO NOT, UNDER ANY CIRCUMSTANCES,

CUT OR REMOVE THE THIRD (GROUND) PRONG

FROM THE POWER CORD. DO NOT USE AN

ADAPTER. DO NOT USE AN EXTENSION CORD.

Insure proper

L ground and

firm connection

before use

Page 9

Installation Instructions

COOKTOP BURNERS

ASSEMBLING THE COOKTOP BURNERS

The electrode of the igniter is exposed. Be careful not to turn on any cooktop controls

while the top of the burner is removed. Do not remove the top or touch the electrode

of any burner while another burner is turned on. Electrical shock might result.

[] Place the burner head onto the burner base. Hake sure to place the correct

burner head on the correct burner base and that the burner head sits level on

the burner base. The burner heads are not interchangeable. Ensure the slot in

the burner head is positioned over the electrode and that the burner head is

fully inserted inside the burner base. A small gap between the base and head is

normal.

Place the burner caps on the burner heads, making sure to place the correct

[]

burner cap on the correct burner head. The burner caps are not

interchangeable. Each cap has three to four pins. Hake sure that the burner

caps are properly seated on the burner heads and that none of the pins sit in the stability chamber.

OR

chamber -_

Burner

base base

Electrode

{\ '7 Burner

Burner cap properly seated

Burner cap not properly seated

J

[_ CHECK IGNITERS

Operation of the electric igniters should be checked after the cooktop and supply line have been carefully

checked for leaks and the cooktop has been connected to the electrical power.

On models so equipped, check to be sure the cooktop is in the UNLOCKED position.

r_ Push and turn a burner valve to the LITE position. All spark igniters will make a series of sparks (ticking

sounds), but only the burner turned to LITE will light.

. The burner should light when gas is available to the burner.

. Once the burner lights, it should be turned out of the LITE position.

r_ Try each valve separately until all burners have been checked.

Page 10

Installation Instructions

T

COOKTOP BURNERS ICONT.}

ITI BURNER IGNITION

Cooktop Spark Ignition-When you turn

the cooktop knob to LITE,the spark igniter makes a

series of electric sparks (ticking sounds) which light

the burner. During a power failure, the burners will

not light automatically. In an emergency, a cooktop

burner may be lit with a match by following the

steps below.

On models so equipped, check to be sure the

cooktop is in the UNLOCKED position.

r_ Light a match and hold the flame near the

burner you want to light. Wooden matches

work best.

r_ Push in and turn the control knob slowly. Be

sure you are turning the correct knob for the

burner you are lighting.

NOTE: If the burner does not light within five seconds,

turn the knob off and wait one minute before trying

again.

[_] BURNER GRATES

The three cooktop grates are designed for specific

positions. For maximum stability, these grates

should only be used in their proper position with

the edges positioned on top of the black bumpers

as shown

/

/

/

/

Grote

//

/'

//'

/'

/

/

//

/

/

Block Grote

Bumpers

[_ THE BURNER FLAMES

Turn each burner on. Flames should be blue in color

with no trace of yellow. The burner flames should

not flutter or blow away from the burner. The flame

should be no less than 1/4" on the lowest setting

and no greater than 1-1/2" on highest setting.

_CAUTION: Ifyouattempt to measure the

flame, please use caution. Burns could result.

i/4" to

i-i/2"

Burners should be checked frequently

Cooktop Burner

10

Page 11

Installation Instructions

OPERATION CHECKLIST

rA1 Make sure all controls are left in the OFF r_

position. Check to be sure the cooktop is in the

UNLOCKED position (on models so equipped).

Make sure the flow of air to and from the

cooktop is unobstructed.

The serial plate for your cooktop is located on

the bottom of the burner box. In addition to the

model and serial numbers, it tells you the ratings

of the burners and the type of fuel and pressure

the cooktop was adjusted for when it left the

factory.

B]

When ordering parts, always include the serial

number, model number and a code letter to

ensure proper replacement parts.

Recheck Steps:

Double check to make sure everything in this

guide has been completed. Rechecking steps

will ensure safe use of the cooktop.

11

Page 12

Installation Instructions

MAKING THE LP CONVERSION

rT1 SAFETY INFORMATION YOU

SHOULD KNOW

The pressure regulator and burner orifices are set

for natural gas. To use LP gas, the regulator and

burner orifices must be converted. The LP orifice

spuds for the cooktop burners are attached to

the regulator along with separate LP conversion

instructions.

JI&L.,/'_LI/IUi_: The cooktop, as shipped from

the factory, is set for use with natural gas. If you

wish to use your cooktop with LPgas, you must

first replace the orifices and convert the pressure

regulator.

_I_W/_KI_I I i_1_: This conversion must be

performed by a qualified installer or gas supplier in

accordance with the manufacturer's instructions

and all codes and requirements of the authority

having jurisdiction. Failure to follow instructions

could result in serious injury or property damage.

The qualified agency performing this work assumes

responsibility for the conversion.

JlLL,,/'_L,!/IU|'_I: The following adjustments

must be made before turning on the burner. Failure

to do so could result in serious injury. Be sure

pressure regulator has been converted as

described in Step 2.

TOOLS YOU WILL NEED

FOR LP CONVERSION

7mm Nutdriver

Safety Glosses

Small Flat-Head

Screwdriver (4mm or

5/]2" tip size,60mm

or 2-]/8" long)

ADJUST YOUR COOKTOP FOR USE

[2]

WITH LP GAS

Disconnect allelectrical power, at the main

circuit breaker or fuse box.

B]

Shut off the gas supply to the cooktop

by closing the manual shut-off valve.

Adjust the pressure regulator, by the following

Fa

instructions:

* Unscrew the cap.

* Carefully look at the spring retainer to locate

the NAT or LP position.

12

Cap Gasket_

N_

NAT.

Position

Pressure Regulator

. Turn the spring retainer over by rotating it

90 deg., pull it from the cap, turn the spring

retainer over so that LP is showing, insert it

back into the cap, and then rotate it 90 deg.

into position.

. Screw the cap back onto the regulator and

tighten.

LP L.P./Propone

Position

Page 13

Installation Instructions

MAKING THE LP CONVERSION (CONT.}

[_ CHANGE COOKTOP BURNER

ORIFICES

FA1 Remove the grates, burner caps, and burner

heads.

[] Using a 7mm nut driver, remove the burner

orifices. These may be accessed through the

burner holes in the cooktop.

Inner j_,(_

burner cap

Burner ,S_ Outer

base -"-__' _ burner

Electrode

Orifice spuds located _l/

through these openings

Tri-Ring Burner

cap

Burner

NOTE: On all burners, the

orifices have a spring-loaded

Retainer

Ring

retaining ring around the hex

head to hold the orifice in the

nut driver during installation

and removal. A slight amount

of force is required to push the

nut driver down over the ring.

OR

BurNer

base

Orifice spud located Electrode

through this opening

Burner

Burner

head

cap

r_ CHANGE COOKTOP BURNER

ORIFICES (CONT.)

PGP976

CGP650 &

PGP986 Simmer: 5! L

Main:58L(x])

Fcl Locate the LPorifices attached to the regulator

along with separate LPconversion instructions.

They will have a digit for size and a letter for type

of gas, on the top or side. (Important: Save the

orifices removed from the appliance for future

use.)

Each orifice will show a series of engraved

marks, (I,II, III, IV or V), located on the top.

These marks denote the location of each orifice to the

cooktop burner.

For PGP976 Models

For PGP986 & CGP650Models

(Shorter)

CENTER BURNER

17,000 BTU/hr Extra Large Burner (PGP976 Models)

Cap

Burner

Set Screw

I

ql_ Choke

I

Extended spud for center

extra large burner

I

Burner

Head

Spud

Extended

Base

Orifice spud located

through this opening

13

Page 14

Installation Instructions

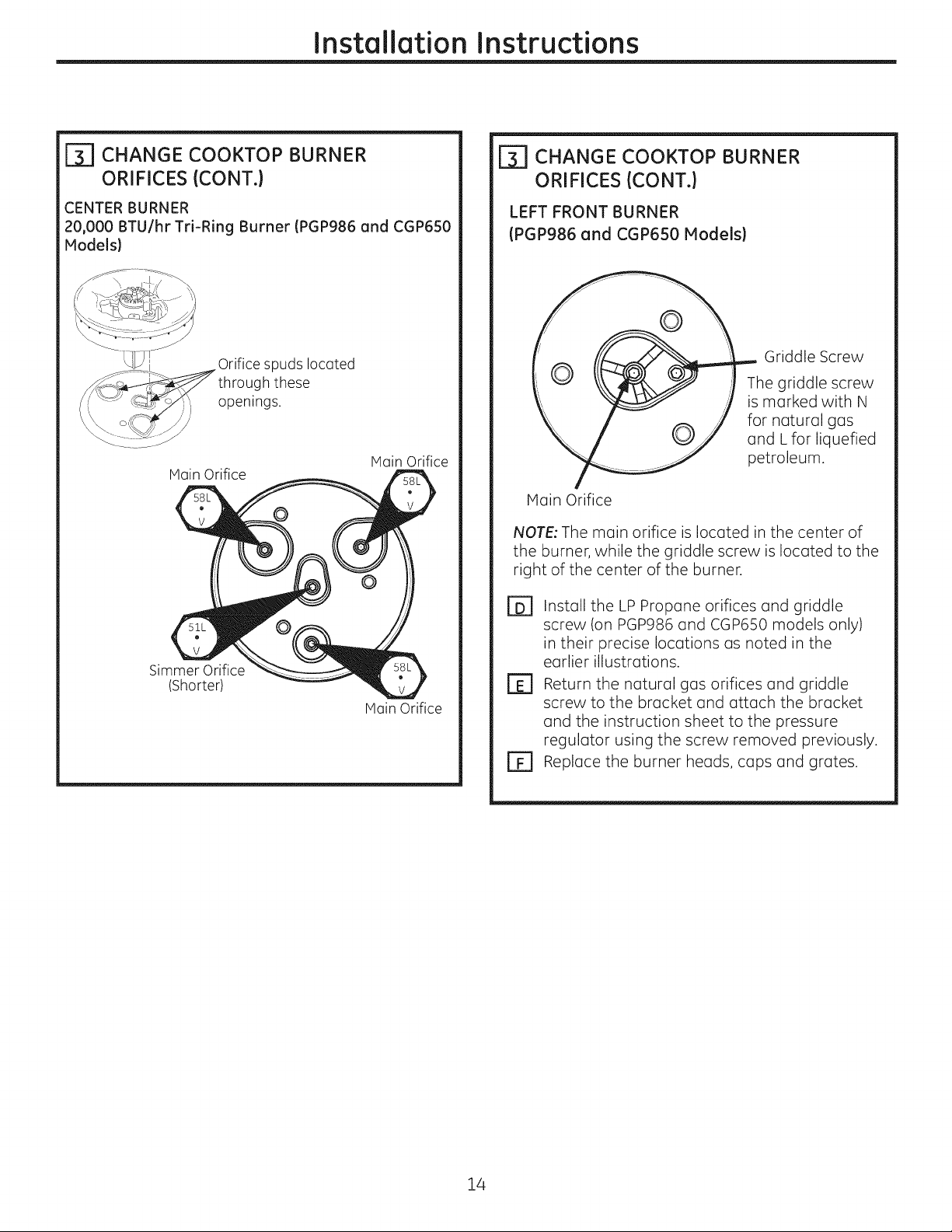

[T_ CHANGE COOKTOP BURNER

ORIFICES (CONT.)

CENTER BURNER

20,000 BTU/hr Tri-Ring Burner (PGP986 and CGP6SO

Models)

spuds located

through these

openings.

Main Orifice

Main Orifice

Simmer Orifice

(Shorter)

Main Orifice

_] CHANGE COOKTOP BURNER

ORIFICES (CONT.)

LEFT FRONT BURNER

(PGP986 and CGP650 Models)

Griddle Screw

The griddle screw

is marked with N

for natural gas

and Lfor liquefied

petroleum.

Main Orifice

NOTE: The main orifice is located in the center of

the burner, while the griddle screw is located to the

right of the center of the burner.

r6] Install the LPPropane orifices and griddle

screw (on PGP986and CGP6S0models only)

in their precise locations as noted in the

earlier illustrations.

r_ Return the natural gas orifices and griddle

screw to the bracket and attach the bracket

and the instruction sheet to the pressure

regulator using the screw removed previously.

r_ Replace the burner heads, caps and grates.

14

Page 15

Installation Instructions

MAKING THE LP CONVERSION (CONT.}

ADJUST BURNER FLAMES

Turn all burners full on and check the flames.

They should be blue in color with some yellow

tipping at the ends of the flame. Foreign

particles in the gas line may cause an orange

flame at first, but this will soon disappear.

r_ Turn the cooktop burner knob to the lowest

setting while observing the flame.

Adjust the low flame setting using the valve bypass

screw as follows:

Low-setting adjustments must be made with two

other burners in operation on a medium setting.

This prevents the low flame from being set too low,

resulting in the flame being extinguished when

other burners are turned on.

E1 To adjust the flame,

remove the knobs. Use

screwdriver to remove

valve stem plugs as

shown.

Insert a screwdriver

through the access hole

in valve switch. Engage

adjustment screw in

valve. Refer to the

illustration below that

matches the adjustment

screw location for

your model. The

griddle burner (PGP986

and CGP650) has 2

adjustment screws,

one for the left rear

burner and one for the

left front burner during

griddle control. Griddle

control must be turned

to LO when making this

adjustment.

, If the flames were too

small or fluttered, open

the valve more than the original setting.

Left of stem

For left front griddle

burner and tri-ring

burner simmer

adjustment screw

Inside ste m_'_._¢_

For all burners

except tri-ring

r_ Testing Flame Stability:

Test 1 - Temporarily replace knobs. Turn the

knob from "HI" to the lowest setting

quickly. If the flame goes out at the

lowest setting, increase the flame size

and test again.

Test 2 -

El Flame Recheck:

After the adjustment is made, turn all burners off.

Ignite each burner individually. Observe the flame

at the "HI" position. Rotate the valve to the lowest

setting and be sure that the flame size decreases

as the valve is rotated counterclockwise.

TO CONVERT THE COOKTOP BACK TO NATURAL

GAS, REVERSETHE STEPS UNDER HAKING THE LP

CONVERSION.

Once the conversion is complete and checked ok,

replace valve stem plugs and knobs, and fill out

the LP sticker. Include your name, organization and

date conversion was made. Apply the sticker near

the cooktop gas inlet opening to alert others in

the future that this appliance has been converted

to LP gas. If converting back to natural gas from

LP, please remove the sticker so others know the

appliance is set to use natural gas.

With the burner on the lowest setting,

open and close the cabinet door

under the cooktop. If the flame is

extinguished by the air currents

created by the door movement,

increase the flame height and test

again.

, If the flames blew away from the burner,

close the valve more than the original

setting.

B] Hake the adjustment by slowly turning the

screw until flame appearance is correct.

15

Page 16

Notes.

16

Page 17

I structio s

Ta lede cuisson scell

d'i stallati

Web 8 I'adresse : www.electromenagersge.ca

au gaz de 91.4 cm (36")

AVANT DE COMMENCER

Avant de commencer, lisez attentivement la totalit#

de ces instructions.

.IMPORTANT - Conservezces

instructions pour votre inspecteur local.

, IMPORTANT - Respectez toutesles

ordonnances et les codes Iocaux.

, Note 6 I'installateur - Assurez-vous de laissez ces

instructions au consommateur.

, Note au consommateur - Conservez ces

instructions pour r6f6rence future.

, La garantie ne couvre aucune panne due

a une mauvaise installation.

AAVERTISSEMENT -

Cet appareil doit @trebien mis 6 la terre.

PGP976, PGP986, CGP650

POUR VOTRE SI_CURITI_

A AVERTISSEMENT -

Si vous ne suivez pas exactement les instructions

de ce manuel, vous risquez d'occasionner un

incendie, une explosion ou une fuite de gaz, qui

peuvent provoquer des dommages mat#riels, des

blessures corporelles ou la mort.

Ne conservez pas ou n'utilisezjamais d'essence

ou d'autres liquides ou vapeurs inflammables 6

proximit# de cet appareil ou de tout autre appareil

m#naged

Ne pas installer ce produit si I'on utiJise une hotte

6 rideau d'air ou une hotte de cuisini_re soufflant

I'air au-dessus de la surface de cuisson. Le d_bit

d'air peut nuire au fonctionnement des br@leurs

6 gaz et repr_sente un risque d'incendie ou

d'explosion.

.IMPORTANT - vousdevez

v#rifierque cetappareiln'oitpas de fuite

conform#ment aux instructionsdu fabricant.

, L'installateur est responsable d'une bonne

installation et la garantie ne couvre aucune

panne due 6 une mauvaise installation.

A AVERTISSEMENT - D6brancheztout

courant #lectrique au niveau du disjoncteur de la

maison ou de la boTte 6 fusibles avant d'installer.

CI QUE VOUS DEVEZ FAIRE Sl

VOUS SENTEZ LE GAZ"

, N'essayezjamais d'allumer un appareil

#lectrom6nager. Netouchez 6 aucun

commutateur d'61ectricit6, n'utilisez jamais un

t616phonedans votre batiment.

, Appelez imm6diatement votre fournisseur de

gaz 6 I'aide du t616phoned'un voisin. Suivezles

instructions de votre fournisseur de gaz.

, Sivous ne pouvez pas entrer en contact avec

votre fournisseur de gaz, appelez les pompiers.

L'installation et le service de votre table de cuisson

doivent _tre faits par un installateur qualifi6, un

technicien de service ou votre fournisseur de gaz.

31-i0955 ii-13 GE i

Page 18

Instructions d'installation

INSTRUCTIONS IMPORTANTES DE SI CURITI

Cette table de cuisson a 6t6 homologu6e UL. Vous

trouverez des pr6cautions 6 prendre en mati6re de

s6curit6 dans votre Guide d'utilisation et de soins.

Lisez-les attentivement.

. L'installation de votre table de cuisson

dolt se conformer aux codes Iocaux ou, en

I'absence de codes Iocaux, au National Fuel Gas

Code, ANSI Z223.1/NFPA 54 Derni6re 6dition.

. Assurez-vous que votre table de cuisson soit

bien install6e par un installateur qualifi6 ou un

technicien de service.

, Pour 61iminer tout mouvement corporel

au dessus des brOleurs de votre table de cuisson,

6vitez de placer des armoires de cuisine au

dessus des br01eurs.

. N'installezjamais votre appareil pr6s d'une porte

d'entr6e ou dans un emplacement oO un courant

d'air peut g6ner son usage.

s s

BESOINS D'ELECTRICITE

PII_CES COMPRISES

2vis R_gulateur 2 Supports de fixation

MATI'RIAUX DONT VOUS POUVEZ

AVOIR BESOIN

Agent de scellement

de tuyau

Raccord flexible de gaz approuv6 par I'ACNOR

Raccords de tuyau×

DI min 3/8", Jonction NPT1/2

Robinet d'alimentation

de gaz

Cet appareil m6nager dolt 6tre Iivr6 avec le bon

voltage et la bonne fr6quence et branch6 6 son

propre circuit de d6rivation bien mis 6 la terre,

prot6g6 par un disjoncteur ou un fusible qui ont

I'amp6rage not6 sur la plaque min6ralogique de

votre appareil.

Nous vous recommandons de faire brancher le

cSblage 61ectrique et la fiche de votre cuisini6re

par un 61ectricien qualifi6. Apr6s I'installation,

demandez 6 1'61ectricien de vous montrer

I'emplacement de votre coupe-circuit principal.

Demandez 6 votre entreprise de services publics les

codes 61ectriques en vigueur dons votre r6gion. En

ne c_blant pas votre cuisini6re conform6ment aux

codes en vigueur, vous provoquez une situation

dangereuse. En I'absence de codes, vous devez

c_bler et isoler votre cuisini6re conform6ment aux

exigences du Canadian Electrical Code.

OUTILS DONT VOUS AUREZ BESOINS

Crayon

Scie sauteuse

Tournevis Phillips

R_gle ordinaire ou de

v@ification

Lunettes de s_curit_

CI66 tuyau

Perceuse 6 main ou _lectrique

et foret de !/8po

Page 19

Instructions d'installation

LISTE DE VITRIFICATION AVANT INSTALLATION

Pour pr6parer I'ouverture de la surface de

[]

cuisson, vous devez vous assurer que

I'int6rieur de I'armoire ne touche pas la table

de cuisson {consultez la section sur la

pr6paration de I'ouverture).

Enlevez les mat6riau× d'emballage, les

@

boTtes de grille, le r6gulateur avec sa

documentation et la documentation de

votre table de cuisson avant de commencer

6 I'installer.

Documentotion

Bottes de

grille

/

Enlevez les instructions d'installation de la

D

trousse de documentation et lisez-les

soigneusement avant de commencer.

Assurez-vous de bien ranger toute la

documentation,(Hanuel du propri6taire,

Instructions d'installation, etc.) dans un

endroit sOr pour r6f6rence future.

Assurez-vous d'avoir tousles outils et tous

r67

les mat6rau× n6cessaires avant de

commencer 6 installer votre table de

cuisson.

rE7 Votre maison dolt @tre aliment6e en courant

61ectrique ad6quat pour vous permettre de

bien utiliser en toute s6curit6 votre table de

cuisson. (Consultez la section sur les besoins

d'61ectricit6.)

cuisson

r_ pour installer votre table de cuisson dans

votre maison, assurez-vous de vous

conformer scrupuleusement 6 tous les

codes et 6 toutes les ordonnances locales.

Assurez-vous que les rev6tements de mur, le

[]

comptoir et les armoires autour de la table

de cuisson puissent supporter la chaleur

[pouvant atteindre 93°C {200°F)] produite

par la table de cuisson.

Page 20

Instructions d'installation

PREPARATION DE L'OUVERTURE

r_ vous DEVEZ RESPECTERLES

DEGAGEMENTS MINIMAU× SUIVANT

Profondeur max de 55 R- MIN.

cm (15") des armoires

en surplomb D6gagement

I droit

D#gagement min. de 76 cm

(30") du comptoir 6 la surface Hauteur min

en non surplomb non prot6g#es 45 cm (18")

C - MIN. du comptoir

D6gagement 6 I'armoire la

entre I'ouverture plus proche

et ]emur arri_re de chaque

L - MIN. D#gagement

entre la d6coupe et le

mur lot@a] gauche

2-1/2" MIN. Entre I'ouverture

et le devant du eomptoir

L

PGP976 9,5 cm(3-5/4")

PGP986

CGP650

TOUS LES D#GAGEMENTS HORIZONTAUX DOIVENT

S'APPLIQUER SUR UNE DISTANCE MINiMALE DE 45,7 CM

(18") AU-DESSUS DE LA SURFACE DE CUISSON.

30,5 cm (12") 30,5 cm (12") 8,6cm(3-3/8")

30,5 cm (12") 30,5 cm (12") 8,6cm(3-3/8")

Base d'armoire

de 76,2 cm (30")

ou sup@ieur

R C

15,2 cm (6") 8,6cm(3-3/8")

REMARQUE :Laissez un 9,4cm ]

d6gagement vertical minimum (3-11/1B")(

de 1,1cm (7/16 po) entre le

dessus de la table de cuisson

(ou une profondeur minimum

de 9,4 cm (3 11/16 po) et route

surface combustible, par

exemple un tiroir d'armoire.

Pour une installation en Tlot, maintenir

une distance minimum de 6,3 cm (2 !4 po)

entre le bord et le dos du comptoir. Garder un espace de

7,6 cm (3 po) minimum sur Ins c6t@sdu comptoir,

entre I'ouverture

et ]e mur Iot@al

:6t6 de

I'appareil

1,1 cm (7/16")

[_ EMPLACEMENT RECOMMANDE DE

L'ALIMENTATION DE G.AZ

PARTIR DU MUR ARRIERE

2.5 cm (i")min. du mur artiste

Emplacement

recommand6 de

I'aJimentation

de gaz

[_] ASSUREZ-VOUS QUE LES

REVETEMENTS MUR, LE COMPTOIR

ET LES ARMOIRES AUTOUR DE LA

TABLE DE CUISSON PUISSENT

SUPPORTER LA CHALEUR

(POUVANT ATTEINDRE 93°C [200°F])

pouvoir supporter

une chaleru pouvant

atteindre 95°C (200°F)

[_] DIMENSIONS DU DI_COUPAGE DE

LA TABLE DE CUISSON

76 cm (30") _-'" 53 cm (21")

_4 -1/4 cm

o--_ --.._ _i- 72 cm (28-1/4")

49 cm 119-3/8"1 _

(3-1/4"1

r_ DIMENSIONS TOTALES DE LA TABLE

DE CUISSON

Pour assurer lajustesse du d_coupage, ilvaut mieux faire

un gabarit pour couper I'ouverture dans le comptoir.

72,4 cm 128-i/2"1 cm 119-S/8"1

longueur

du

d#coupag_.__<_ 36,2 cm

Largeur du d#coupage

(14-i/4")

[]_ INSTALLATI.ON POUR PERSONNE.

HANDICAPEE SEULEMENT (E.-U. •

DISABILITIES ACT FORWARD

APPROACH) •

<12,7,5")

Laissez une profondeur

minimum de 12,7 cm

(5 po) entre la table de

cuisson et une enceinte.

REMARQUE : L'enceinte

dolt #tre construite en bois.

Aussi, un panneau d'acc#s

est n#cessaire pour la prise

#lectrique, le r#gulateur de

pression, le robinet de sectionnement, les supports

de retenue et I'entretien ou les r#parations.

2

r

Page 21

Instructions d'installation

INSTALLATION LA

PLACEZ LA PRISE

[i]

UNITE DE LA TABLE DE CUISSON

D'ALIMENTATION

I_LECTRIQUE ET LE ROBINET

D'ALIMENTATION DE GAZ

AU-DESSOUS DE L'ARMOIRE

N'UTILISEZ JAMAIS DES

RACCORDS USAGES

POUR INSTALLER CET

APPAREIL

Plontez le robinet d'alimentation manuel sur le

tuyau de gaz 6 un emplacement facile 6 atteindre

en dehors de la table de cuisson. Assurez-vous de

savoir oQet comment couper I'alimentation de gaz

6 la table de cuisson. Montez la prise 61ectrique 30

cm (12") au-dessous du comptoir.

W Roblnet " [\

N d'alimentation II I

w _f!_ I Prise61ectrique

[ ]J_ sous Jecomptoir

. II

_ ',SOcm(12't

[_] PROTE_GEZLA SURFACE DE LA

TABLE DE CUISSON

Placez une serviette ou un torchon sur le comptoir.

Posez la table de cuisson 6 I'envers sur la surface

prot@g@e.

Envers de la table de cuisson

J

_7 FIXEZ LES SUPPORTS DE FIXATION

A LA TABLE DE CUISSON

Enlevez la vis d'un c6t6 de la table de cuisson,

vissez un support de fixation 6 un c6t6 de la table

de cuisson. R6p@ez la m_me op@ation de I'autre

c6t6 de la table de cuisson.

Support de

fixation \ _t/

Bas de la table de \ _/

Verre de la

de cussion

r_ INSEREZ LA TABLE DE CUISSON

DANS L'OUVERTURE DECOUPEE

Ins6rez la table de cuisson centr6e dans I'ouverture

d6coup6e. Assurez-vous que I'arr@te de devant

du comptoir soit bien parall61e 6 I'extr6mit6 de la

surface de cuisson. Faites une v@rification finale

pour vous assurer de bien respecter tous les

d6gagements.

Linge sous la table de cuisson

r_ TROUVEZ LES PIECES DE

MONTAGE

Retirez les supports de fixation de la trousse de

documentation.

Une fois la table de cuisson en place,

vissez les supports de fixation aux c6t6s de

I'armoire pour tenir la table de cuisson bien en

place.

Page 22

Instructions d'installation

INSTALLATION--BRANCHEMENT DU GAZ

rT] FOURNISSEZ UN BON

APPROVISIONNEMENT EN GAZ

Cette table de cuisson est conque pour fonctionner au

gaz naturel 6 une pression de tubulure d'admission

de 4 po. de colonne d'eau et 6 une pression

d'approvisionnement de 5 po. de colonne d'eau. Elle

est exp6di6e de I'usine r6gl6e pour le gaz naturel.

Le r6gulateur de pression convertible fourni avec

I'appareil dolt @re branch6 en s@ie 6 la tubulure

d'admission de la table de cuisson et dolt rester

branch6 sur la ligne d'approvisionnement qu'il

s'agisse de gaz naturel ou de gaz propane (LP).POUR

OBTENIR UN BON FONCTIONNEMENT, LA PRESSION

MAXIMALE D'ENTREEAU REGULATEURNEDOlT PAS

ETRESUPERIEURE/_14 po. DECOLONNE D'EAU.Pour

v@ifier le r6gulateur, la pression d'entr6e dolt @re

au moins de i po. de colonne d'eau (ou 3,4 KPA)plus

grande que celle de r6glage de sortie du r6gulateur.

Si le r6gulateur est r6g16 6 une pression de 5 po. de

colonne d'eau, la pression d'entr6e dolt @re au moins

6gale 6 6 po.. Si le r6gulateur est r6g166 une pression

de 10 po., la pression d'entr6e dolt @re au moins

6gale 6 11 po. La ligne d'approvisionnement de gaz 6

la table de cuisson dolt @re un tuyau de 1/2 po.

ou de 3/4 po.

r_ INSTALLEZ LE RI_GULATEUR EN

BAS DE LA BO/TE DE BRULEURS

Vissez le r6gulateur dans

le raccord du bas de

I

la boTte de brOleurs.

Assurez-vous que le

haut du r6gulateur

soit face 6 I'avant

de I'armoire, et

soit facilement

accessible 6

partir des portes

de I'armoire. Le

r6gulateur peut

aussi _tre install6

R6gulateur

de pression _

Raccord

Robinet _f

d'arr_t "

l]J

U

IPfise @lectrique

I 12 po.

Iou-dessous du

comptoir

avant I'insertion de

la table de cuisson dans I'ouverture 6 condition

d'user d'une grande prudence afin de ne pas g@ner

la connexion du r6gulateur.

_-I TERMINEZ LE RACCORDEMENT

AVEC UN RACCORD

ITI INSTALLEZ LE RE_GULATEUR

N'utilisezjamais de vieux raccords quand vous

installez votre table de cuisson..

A AVERTISSEMENT :

N'utilisezjamais des raccords flexibles usag6s.

L'utilisation de raccords flexibles usag6s peut

occasionner des fuites de gaz et des blessures

corporelles. Utilisez toujours des raccords flexibles

neufs quand vous installez un appareil 6 gaz.

Pour r6duire la possibilit6 de fuites de gaz, posez un

Vissez une section du tuyau dans R6gulateur de__._- 1

I'extr_mit6 d'entr6e du r6gulateur presslon

de pression et installez le

raccord. Raccord

ruban de t6flon ou mettez de la graisse pour filetage

approuv6e pour le gaz naturel ou butane sur tousles

raccords filet6s.

Compl6tez la connexion entre le r6gulateur, le

raccord et le robinet

I

I

d'arr@t.

R6gulateur

de pression

Raccord

m4

Iv

LI

i\

Robinet _I

d'arr_t

IiPrise61ectrique

I 12 po.

lau-dessous du

comptoir

Page 23

Instructions d'installation

VI_RIFIEZ QU'IL N'Y A PAS DE

FUITE

LA VERIFICATION DEFUITES SUR L'APPAREIL DOlT

ETREEFFECTUEEEN CONFORMITE AVEC LES

INSTRUCTIONSDU FABRICANT.

Avant de v@ifier qu'il n'y a pas de fuite, assurez-

vous que tousles boutons de brOleurs soient en

position OFF (arr_t).

Apr_s avoir branch6 la table de cuisson au gaz,

v@ifiez qu'il n'y a pas de fuite dans le syst_me

6 I'aide d'un manom_tre. Si vous n'avez pas de

manom_tre, ouvrez I'approvisionnement de gaz 6

la table de cuisson et utilisez un d@ecteur de fuite

liquide 6 tousles raccords etjoints pour trouver les

fuites.

Resserrez tousles raccords le cas 6ch6ant pour

arr_ter les fuites de gaz de la table de cuisson ou

de la ligne d'approvisionnement.

N'UTILISEZ JAMAIS DE FLAMME POUR

VI_RIFIER LES FUITES!

D6branchez la table de cuisson et son robinet

d'arr_t du syst_me de tuyau d'alimentation en gaz

avant de proc6der 6 un essai de pression de ce

syst_me 6 des pressions de test sup@ieures 6 1/2

psig (3,5 kPa).

[_] INSTALLATION SUR UN FOUR

ENCASTRt_

Consultez I'installation du four encastr6 pour y

trouver les instructions d'installation.

!

T

_J _ 5 po. depuis le comptoir

| _ _ jusqu'au centre du trou

_j. _ de2po.

de 90 °

C6t6s de

I'armoire .... 7"

_,_ jusqu'au centre du trou)

Trou de 2 po. (20 7/8 po.

_ deI'avant ducomptoir

Ilsolez la table de cuisson du syst_me de tuyau

d'alimentation en gaz avant de proc6der 6 un essai

de pression du syst_me d'alimentation en gaz 6

des pressions de test 6gales ou inf6rieures 6 1/2

psig (3,5 kPa).

Page 24

Instructions d'installation

J

INSTALLATION--RACCORDS ELECTRIQUES

AVERTISSEMENT - D6brancheztout

courant 61ectrique au niveau du disjoncteur de la

maison ou de la boTte 6 fusibles avant d'installer.

ALIMENTATION I_LECTRIOUE ET PRISE

Vous devez utiliser une bonne alimentation

61ectrique et une bonne prise pour faire fonctionner

les 616ments 61ectriques de

votre table de cuisson.

D

Le cordon d'alimentation de votre appareil est

muni d'une fiche 6 trois broches (avec mise 6

la terre) qui doit @tre utilis6e dans une prise

61ectrique bien mise 6 la terre, qui alimente

en courant m6nager CA normal de

120 volts, 60 cycles.

B]

Si vous n'avez pas de prise triphas6e,

demandez 6 un 61ectricien qualifi6 de changer

votre ancienne prise. EN AUCUN CAS, VOUS

NE DEVEZ COUPER NI ENLEVERLA TROISIEME

BROCHE (TERRE)DU CORDON

D'ALIMENTATION. N'UTILISEZ PAS UN

ADAPTATEUR. N'UTILISEZ PAS UNE RALLONGE.

Assurez une bonne

L mise 6 la terre et un

bon contact avant

I'usage

Page 25

Instructions d'installation

BRULEURS DE LA TABLE DE CUISSON

ITI ASSEMBLEZ LES BRULEURS DE LA TABLE DE CUISSON

L'61ectrode de I'allumeur est expos6e. Veillez 6 n'allumer aucun contr61e de la table

de cuisson Iorsque le dessus ctu br01eur est enlev6. N'enlevez jamais le haut ct'un

br01eur ou son 61ectrode quancl un autre br01eur est allure6. Cela risque de procluire

une secousse 61ectrique.

Placez la t6te de brOleur sur Io base de brOleur. Assurez-vous de bien mettre

B3

la bonne t_te de br01eur sur la bonne base de br01eur et de bien mettre

horizontalement la t_te de br01eur sur sa base. Les t_tes de br01eur ne sont

pas interchangeables. Assurez-vous que la fente de la t_te de br01eur est

plac6e au-dessus de 1'61ectrode et que la t_te est ins6r6e 6 fond dans la base.

Un petit espace entre la base et la t_te est normal.

B]

Placez les capuchons de brOleur sur les t@tes de brOleur, en vous assurant de

mettre le ban capuchon de brOleur sur la bonne t@te de brOleur. Les pasbienplac6

capuchons de br01eur ne sont pas interchangeables. Chaque capuchon est

muni de trois 6 quatres chevilles. Assurez-vous que les capuchons de br01eur tiennent bien sur les t_tes de

br01eur Chaque capuchon est muni de trois 6 quatres chevilles.

Capuchon de brOleurbien plac6

Capuchon de brOleur

Capuchon

OU

stabilit6 i Electrode

Base de \ de

brOleur brQleur

T_te de

br0leur

[_] VI_RIFIEZ LES ALLUMEURS

Vous devez v@ifier le fonctionnement des allumeurs 61ectriques apr@svous @tresoigneusement assur6 que la

table de cuisson et la ligne d'approvisionnement n'ont pas de fuite et que la table de cuisson est bien branch6e au

courant 61ectrique.

Sur les modules qui sont ainsi 6quip6s, assurez-vous que la table de cuisson soit en position UNLOCKED

(d6verrouill6e).

rA1 Appuyez sur un robinet de brQleur et tournez-le en position LITE(allumage). Tousles allumeurs feront une

s6rie d'@incelles (cr6pitement) mais, seul, le brQleur en position LITE(allumage) s'allumera.

, Le brOleur doit s'allumer quand du gaz lui parvient.

, ©uand le brOleur s'allume, vous devez I'enlever de sa position LITE(allumage).

r_ Essayeztous les robinets pour v6rifier le fonctionnement detous les brOleurs.

Page 26

Instructions d'installation

F_l ALLUMAGE DES BRULEURS

Allumage de la table de cuisson -©uand vous

mettez le bouton de la table de cuisson en position

LITE(ollumoge), I'°llumeur foit une s6rie d'6tincelles

(cr6pitement) pour ollumer le brOleur. Pendont

une panne de couront, les brOleurs ne s'ollument

pos outomotiquement. En cos d'urgence, °llumez

un brOleur de I° table de cuisson 6 I'oide d'une

allumette en suivant les 6tapes suivantes :

Sur les mod61es ainsi 6quip6s, v6rifiez que la

table de cuisson soit en position UNLOCKED

(d6verrouill6e).

r_ Allumez une allumette et approchez la flamme

du brOleur que vous voulez allumer. IIvaut

mieux utiliser une °llumette en bois.

Poussez et tournez doucement le bouton de

B]

contr61e. Assurez-vous de tourner le bouton

de contr61e qui correspond au brOleur que

vous voulez allumer.

NOTE: ISile br01eur ne s'allume pas en cinq secondes,

tournez le bouton en position OFF (arr_t) et °ttendez

une minute avant d'essayer

6 nouveou.

LES FLAMMES DU BRULEUR

Allumez chaque brOleur. Les flammes doivent 6tre

bleu sons trace de joune. Les flommes du brOleur

ne doivent pas scintiller ou s'6corter du brOleur. Lo

flomme ne peut pos 6tre plus petite que 1/4 po. en

r6glage le plus bas et ne dolt pas 6tre plus grande

que 1-1/2" po. en r6glage le plus hout.

BrOleur de table

de cuisson

Vous devez v_rifier fr_quemment les brOleurs

A ATTENTION : sivousessoyezde

mesurer lu flumme, fuites bien attention. Vous

pouvez vous brOler.

GRILLES DE BRULEUR

Les trois grilles de lu table de cuisson sont pr6vues

pour des positions pr6cises. Pour assurer un

maximum de stobilit6, ces grilles doivent se trouver

6 Io position oppropri6e ovec leurs bords reposont

sur le dessus des butoirs noirs, tel qu'illustr6.

/'

/

/

/'

//

Grille

/

/'

//

/

/

/

/' /'

/' / _,

iS"_ Butoirs de

...................... _....................... grille noirs

/

10

Page 27

Instructions d'installation

LISTE DE VITRIFICATION DE FONCTIONNEMENT

r_ Assurez-vous que tousles contr61es restent en r_

position OFF (arr6t). V6rifiez que la table

de cuisson soit en position UNLOCKED

(d6verroui%e) (sur les modules ainsi 6quip6s).

Assurez-vous que la circulation d'air autour de la

table de cuisson ne soit pas g6n6e.

La plaque min6ralogique de votre table de

cuisson est situ6e en bas de la boTte de br01eurs.

En plus des num6ros de mod61e et de s6rie, elle

indique la cote des brOleurs, et la cat6gorie de

carburant et la pression de votre table de

cuisson au d6part de la fabrique.

B]

q)uand vous commandez des pi_ces, indiquez

toujours le num6ro de s6rie, le num@o de

mod61e et les lettres de code pour obtenir les

bonnes pi6ces de rechange.

Re-v@ification :

V6rifiez 6 nouveau pour vous assurer d'avoir

bien suivi toutes les instructions de ce guide.

Cela assure une bonne utilisation s6curitaire de

la table de cuisson.

11

Page 28

Instructions d'installation

CONVERSION AU GAZ PROPANE (LP)

RENSEIGNEMENTS RELATIFS A LA

SI_CURITI_ QUE VOUS DEVEZ

CONNA/TRE

Lesdiaphragmes du rGgulateur de pression et du

brQleur sont rGglGspour le gaz naturel. Pour utiliser du

gaz propane (LP),vous devez convertir les diaphragmes

du r#gulateur de pression et du brOleur. Lesorifices

des 616ments de gaz PLdes brOleurs de la surface de

cuisson sont rattachGs aux rGgulateur de pression et

accompagnGs des instructions de conversion du gaz PL.

A ATTENTION :Latabledecuisson,ou

d@partde l'usine,estr@gl@epourlegoznoturel.Si

vousd@sirezutiliservotretoblede cuissonovecdu

goz en bouteille(LP),vousdevezd'obordremplocerles

diaphrogmes,puisconvertirlerGguloteurde pression.

A AVERTISSEMENT :Cetteconversion

doit 6tre effectuGe par un installateur qualifi6 ou un

fournisseur de gaz conformGment aux instructions du

fobricant et 6 tous les codes et exigences de I'autorit6

comp@ente. Sivous ne suivez pos ces instructions, vous

risquez d'occosionner des blessures corporelles et des

dommoges mot@iels importonts. L'ogence quolifiGe qui

fait ce travail assume la responsabilit6 de la conversion.

A ATTENTION : Lesojustements suivonts

doivent _tre effectu#s ovont d'allumer lebrOleur. Si

vous ne les foites pos, vous risquez d'occosionner des

blessures s@ieuses. Assurez-vous que le r#gulateur de

pression soit bien converti conform#ment 6 I'#tope 2.

OUTILS NECESSAIRES A LA

CONVERSION AU GAZ LP

Tourne-#crou

de 7 mm

Lunettes de s#curit#

[2]

AJUSTEZ VOTRE PLAQUE DE

CUISSON #, UN USAGE AU GAZ LP

[]

DGbranchez tout le courant #lectrique, au

niveau du disjoncteur principal ou de la boTte

6 fusibles.

Coupez I'approvisionnement de gaz 6 la table

de cuisson en fermant 6 la main le robinet

d'arrGt.

[] Ajustez le r#gulateur de pression en suivant

les instructions suivantes "

, D#vissez le capuchon.

, Trouvez, sur 1'6trierde ressorts, les positions

NAT (gaz naturel) et LP(gaz propane).

p_int

__,_ Etrier de

_T

Position

NAT

R_gulateurde pression

. Tournez I'@rier de ressorts de 90 degr#s,

retirez-le du capuchon, tournez I'@rier

de ressortsjusqu'6 ce que LP apparaisse,

r#ins#rez-le dans le capuchon, puis

tournez-le de 90 degr#s en position.

. Revissez le capuchon sur le r#gulateur et

serrez.

.,,T ressorts

III

LP Position LP/

Propone

Petit tournevis 6 t#te

plate (t_te de 4 mm

ou 5/32 po., 60 mm.

ou (2 3/8 po de long))

12

Page 29

Instructions d'installation

CONVERSION AU GAZ PROPANE (LP)(SUITE)

r_ CHANGEZ LES DIAPHRAGMES DES

BRULEURSDE LA TABLE DE CUISSON

FA1 Enlevez les grilles, les capuchons de br01eur et

les t6tes de brOleur.

[] A I'aide d'un tourne _crou de 7 mm., enlevez les

diaphragmes du br01eur,Vous pouvez lesatteindre en

passant par letrou de la table de cuisson.

Capuchon _O

int@ieur de_

brOleur

T6te_ ext6rieur

br01eur_ de br01eur

Electrode,.. _._1 Base de

dons ces ouvertures

_ Bague NOTE : Sur tousles brQleurs, les

['_ _i_Capuchon

Basede br01eur

// brOleur

BrOleur 6 trois anneau×

de

r@ention diaphragmes ant une bague de

r@ention 6 ressort autour de

brOleur

Injecteur 6 orifice situ6 Electrode

dons cette ouverture

la t_te hexagonale pour retenir

le diaphragme dons le tourne-

#crou pendant I'installation et I'enl_vement. IIfaut

exercer un peu de force pour pousser le tourne-6crou

vers le bas de la bague.

Capuchon de

br01eur

T_te de

[_] CHANGEZ LESDIAPHRAGMES DES

BRULEURSDE LA TABLE DE CUISSON

(SUITE)

PGP976

CGP650 & Principal 58 LIxS]

PGP986 MijotageSl L

r-c-] Rep@ez les orifices PLfix@sou r@guloteur de

pression et accompagn@s des instructions de

conversion du gaz PL La taille est indiqu@epar

un chiffre et le type de gaz par une lettre, sur le

dessus ou le c6t@.(important : Conservez les

diaphragmes que vous avez enlev#s de votre

appareil pour une utilisation future.)

Chaque diaphragme indique une s@ie de

signes grav#s (I, II, III, IV, V ou rien) en haut.

Ces signes indiquent I'emplacement pr6cis de chaque

diaphragme sur le br01eur de la table de cuisson.

Pour les modules PGP976

Pour les modules PGP986 et CGP650

(Plus court)

BRULEUR CENTRAL

Br01eur grand format de 17 000 Btu/h (ModUles PGP976}

Capuchon

de br0leur

Visde r#glage

I

_I_ Etranglement

I

Injecteur allong6 pour brOleur

central grand format

allong6

Injecteur

br01eur

T_te de

Basede

r0leur

13

©

Injecteur 6 orifice situ6

dons cette ouverture

Page 30

Instructions d'installation

ITI CHANGEZ LES DIAPHRAGMES DES

BRULEURS DE LA TABLE DE

CUISSON {SUITE}

BRULEUR CENTRAL

Br6leur 6 trois anneaux de 20 000 Btu/h (ModUles

PGP986 et CGP650}

_cteurs6orifice situ#s

dans ces ouvertures

Orifice principal

Orifice principal

[_] CHANGEZ LES DIAPHRAGMES DES

BRULEURS DE LA TABLE DE

CUISSON {SUITE}

BRULEUR AVANT GAUCHE

(ModUles PGP986 et CGP650)

vis de plaque

Sur la vis de plaque

figure un N pour

gaz naturel et un L

pour gaz de p6trole

liqu6fi6.

Orifice principal

NOTA : L'orifice principal est situ6 au centre du

brOleur, tandis que la vis de plaque est situ6e 6 la

droite du centre du brOleur.

Orifice de mijotag,

(Plus court)

Orifice principal

D

Installez les orifices de gaz LP(propane) et la

vis de plaque (sur les modules PGP986 et

CGP650 seulement) 6 leur emplacement

pr6cis tel qu'indiqu6 dans les illustrations

pr6c6dentes.

[E]

Remettez les diaphragmes pour gaz naturel

sur le support et fixez 6 nouveau le support et

la feuille d'instructions au r6gulateur de

pression 6 I'aide de la vis enlev6e

pr6c6demment.

r_l Remettez en place les t@tes, les capuchons de

brOleur et les grilles.

14

Page 31

Instructions d'installation

CONVERSION AU GAZ PROPANE (LP)(SUITE)

AJUSTEZ LES FLAMMES DES

BRULEURS

Allumez tousles brOleurs au maximum et

[]

v6rifiez les flammes. Elles doivent 6tre bleu

avec un peu de jaune 6 leur extr6mit6. Des

particules @rang_res dans lu ligne de gaz

peuvent occasionner une flamme orange au

d6but, mais cette couleur dolt disparaitre

rapidement.

Tournez le bouton du br01eur de la table de

[]

cuisson 6 son r6glage le plus bas tout en

observant la flamme.

Ajustez le r6glage de flamme basse 8 I'aide de la vis

de d@ivation de robinet comme suit:

Vous devez ajuster le r6glage de flamme basse

avec deux autres brOleurs en fonctionnement

en r6glage moyen. Cela vous emp_che de r6gler

trap bas la flamme basse, et qui risque d'@eindre

la flamme quand d'autres br01eurs sont en

fonctionnement.

[] Pour ajuster la flamme, _ _"_

enlevez les boutons.

Utilisez le tournevis

pour retirer les

bouchons de tige de

soupape tel qu'illustr&

Faites entrer la vis de J

r6glage dans le

robinet. Consultez Agauche de

I'illustration la ti

ci-dessous qui

correspond 6

I'emplacement de la

vis de r6glage pour Pourlavisder@glagedu

votre mod@le. Le br01eurde plaque avant

br01eur de plaque gauche et le mode mUotage

avant gauche

(PGP986 et CGP650) /_I'int@ieur_"_

est dot6 de deux de__

(2) vis de r6glage,

une pour le brOleur

arri@re gauche et

une pour le brOleur Pour tousles br01eurs

avant gauche saul 6 trois anneaux

Iors du contr61e

de plaque. Le contr61e de plaque dolt _tre

positionn6 8 LO Iors de ce r6glage.

du brOleur 6 trois anneaux.

, Si les flammes sont trop petites ou si elles

clignotent, ouvrez le robinet davantage que

dans le r6glage original.

, ISi les flammes s'61oignent du brQleur,

fermez le robinet davantage que dans le

r6glage original.

rD] Continuez 6 ajuster en tournant lentement la

visjusqu'a ce que les flammes soient normales.

Essai de stabilit6 de la flamme :

Essai 1 - Tournez rapidement le bouton de

HI (temp@ature 61ev6e)jusqu'au

r6glage le plus bas. Si la flamme

s'@eint au r6glage le plus bas,

augmentez la taille de la flamme et

essayez 6 nouveau.

Essai 2- Mettez le br01eur 6 son r6glage le

plus bas, ouvrez et fermez la porte

de I'armoire situ6e au-dessous de

la table de cuisson. Si la fiamme

s'6teint 6 cause du courant d'air

cr66 par le mouvement de la porte,

augmentez la taille de la flamme et

essayez 6 nouveau.

r_ Nouvelle v@ification des flammes:

Apr_s avoir ajust6, @eignez tous les br01eurs.

Allumez chaque br01eur s6par6ment. Observez les

flammes en position HI (temp@ature 61ev6e). Faites

tourner le robinetjusqu'6 son r6glage le plus bas

et assurez-vous que la taille de la flamme diminue

quand vous tournez le robinet en sens inverse 6

celui des aiguilles d'une montre.

POUR RECONVERTIR LA TABLE DE CUISSON AU

GAZ NATUREL, FAITES _, L'ENVERS TOUTES LES

I_TAPES DE CONVERSION AU GAZ LP.

q)uandvousavez termin# la conversion et avez v@ifi#

que tout va bien,remplissez I'@iquetteLP et inscrivez

votre nom, le nom de votre organisme et la date

de conversion. CollezI'@iquette pros de I'ouverture

d'entr@ de gaz de la table de cuisson pour signaler

aux autres que cet appareil a 6t6 converti au gaz LP.

Sivous reconvertissezvotre appareil au gaz naturel,

enlevezI'@iquette pour signaleraux autres que cet

appareil fonctionne au gaz naturel.

15

Page 32

Notes.

16

Page 33

I struccio es

Estufa a GasSellada de 36"

del stal ci"

j r_l_Preguntas? Llame a 800.GE.CARES (800.432.2737) o visite nuestro sitio web en: GEApplionces.com

EN EL COMMONWEALTH DE

MASSACH USETTS:

, Este producto debe ser instalado par un plomero

licenciado o un mecdnico gasista.

, AI usar v&lvulas de cierre de gas tipo bal6n,

deberdn ser del tipo de manija T.

, Cuando se use un conector de gas flexible, #ste

no deber6 exceder los 3 pies.

ANTES DE COMENZAR

Lea estas instrucciones en su totalidad y

atentamente.

, IMPORTANTE - Conserveestas

instrucciones para usa del inspector local.

En Canadd, Ilame al 1.800.561.3344 o visite nuestro sit:io web en: www.geappliances.ca

PGP976, PGP986, CGP650

PARA SU SEGURIDAD:

,_ADVERTENCIA - silainformaci6n

de este manual no se sigue exactamente, se

podr6 producir un incendio, e×plosi6n o p_rdida

de gas, ocasionando dafios sabre la propiedad,

lesiones o la muerte.

No guarde ni use gasolina u otros vapores

inflamablesy liquidos cerca de _ste ni de otros

electrodom_sticos.

No instale este producto con una campana con

cortina de aire u otra campana de cocina que

lleve aire a la placa de cocci6n. El flujo de aire

podr(_ interferir en el funcionamiento de los

quemadores de gas, produciendo riesgos de

incendio o explosi6n.

QUI_ DEBE HACER SI HUELE

GAS:

• IMPORTANTE - Cumplacontodoslos

c6digos y ordenanzas gubernamentales.

, Nota para el Instalador- AsegOrese de que el

Comprador conserve estas instrucciones

, Nota para el Comprador - Conserve estas

instrucciones para referencia futura.

, Si se producen fallas en el producto debido a una

instalaci6n inadecuada, la Garantia no cubrir6

las mismas.

_ADVERTENCIA - Este

electrodom#stico deber6 estar conectado a tierra

de forma adecuada.

.IMPORTANTE - Laprueba de goteras

del electrodom#stico se deberd realizar de

acuerdo con las instrucciones del fabricante.

, La instalaci6n correcta es responsabilidad del

instalador y cualquier falla del producto debido a

una instalaci6n inadecuada NO estarc_ cubierta

por lagarantia.

, No intente iluminar ningSn electrodom_stico.

No toque ningSn interruptor el_ctrico; no use

tel_fonos en su edificio.

, De inmediato llame a su proveedor de gas

desde el tel_fono de un vecino. Siga las

instrucciones del proveedor de gas.

, Si no se puede comunicar con su proveedor de

gas, llame al departamento de bomberos.

La instalaci6n y las reparaciones deber6n ser

realizadas por un instalador calificado, agenda

de servicios o el proveedor de gas.

Esta estufa estc_certificada par UL. En el Manual

del Propietario, encontrar(] precauciones de

seguridad. Lea las mismas detenidamente.

, Esta estufa se deber(_ instalar de acuerdo con

los c6digos locales, o en la ausencia de c6digos

locales, con el C6digo de Gas Combustible

Nacional, ANSIZ223.1/NFPA.54, 01tima edici6n.

, AsegOreseque su cocina sea instalada de forma

adecuada par un instalador calificado o t6cnico

del servicio.

AADVERTENCIA - Desconectetodas

lasfuentesel#ctricasdeldisyuntorprincipalo de la

caja de fusibles antes de realizar la instalaci6n.

, Para que no se alcancen los quemadores de

la superficie, se deberc_evitar la colocaci6n de

gabinetes sabre los quemadores.

, No instale la unidad cerca de la puerta exterior o

donde una corriente pueda afectar su usa.

i

31-i0955 ii-13 GE i

Page 34

Instruccionesde Instalaci6n

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

REQUISITOS ELI_CTRICOS

Este electrodom6stico deber6 ser suministrado

con la frecuencia y el voltaje adecuados, y ser

conectado a un circuito derivado individual

correctamente conectado a tierra, protegido por un

disyuntor o fusible con el amperaje que figura en la

etiqueta de caracteristicas t6cnicas.

Le recomendamos que el cable el6ctrico y el

gancho de su estufa sean conectados por un

electricista calificado. Luego de la instalaci6n, pida

al electricista que le muestre d6nde se encuentra la

desconexi6n principal de su estufa.

Consulte a los servicios locales sobre qu6 c6digos

el6ctricos se aplican en su 6rea. Si el cable de su

estufa no es adecuado de acuerdo con los c6digos

del gobierno, se podr6 producir una condici6n

riesgosa. En caso de no haber c6digos, el cable

y el fusible de su estufa deber6n cumplir con los

requisitos del C6digo Nacional de Electricidad,

ANSI/NFPA No. 70--Oltima edici6n. Puede solicitar

una copia escribiendo a:

National Fire Protection Association

Batterymarch Park

Quincy, HA 02269

En Canad6, el cable y el fusible de su estufa

deber6n cumplir con los requisitos del C6digo de

Electricidad de Canad6.

AsegOrese de que la instalaci6n de este producto

en una casa m6vil cumpla con el Est6ndar

de Construcci6n y Seguridad de una Casa

Manufacturada, T[tulo 24 CFR, Parte 3280. Si

este est6ndar no se aplica, deber6 cumplir

con el est6ndar de Instalaciones de Casas

Manufacturadas, ANSI/VCSBS A225.1, o con los

c6digos locales donde se apliquen. Puede solicitar

una copia del Est6ndar Federal escribiendo a:

Office of Mobile Home Standards

HUD Building

4517th Street, S.W.

Washington, D.C. 24010

PARTES INCLUIDAS

2 Tornillos Regulador

2 Soportes

MATERIALES QUE PUEDE NECESITAR

Sellador de Juntas Uniones de Tuber[as V61vulade Cierre

L[nea de Gas Flexible Aprobada por CSA

Diam. Int. Min. 3/8", Conexi6n NPTde 1/2",

Longitud M6xima de 3 pies ($61oen Massachusetts)

HERRAMIENTAS OUE NECESITARI_ PARA

LA INSTALACI6N

L6piz

Sierra de Vaiv@n

Destornillador con

Cabeza Phillips

Regla o Regla

de Borde Recto

Gafas de Seguridad

Llave para Tuberias

Broca y Taladro El@ctricoo

Manual de 1/8"

Page 35

Instruccionesde Instalaci6n

J

LISTA DE CONTROL DE PRE-INSTALACION

AI preparar la abertura de la estufa,

r_

asegOrese de que el interior del gabinete y

de la estufa no interfieran uno con otto.

(Consulte la secci6n sabre preparaci6n de la

abertura).

Retire los materiales de embalaje, cajas de

@

parrillas, regulador con instrucciones, y el

paquete de instrucciones de la estufa antes

de realizar la instalaci6n.

rcl Retire las instrucciones de instalaci6n del

paquete de instrucciones y lea las mismas

de forma detenida antes de comenzar.

AsegOrese de colocar las instrucciones

(Manual del Propietario, Instrucciones de

Instalaci6n, etc.) en un lugar seguro para

referencia futura.

_-------_ Paquete de Instrucciones

/_/

Cajas con las

/

//

AsegQrese de contar con todas las

r61

herramientas y materiales necesarios antes

de comenzar con la instalaci6n de la estufa.

Su hogar deber6 brindar el servicio el#ctrico

B]

necesario para un usa seguro y apropiado

de su estufa. (Consulte la secci6n sabre

requisitos el#ctricos).

AI instalar la estufa en su hogar, asegOrese

D

de que todos los c6digos y ordenanzas

locales se sigan exactamente coma se

indica.

AsegQrese de que los cobertores de pared,

[]

mesada y gabinetes alrededor de la estufa

puedan resistir el color (basra 200 ° F)

generado par la estufa.

Page 36

Instruccionesde Instalaci6n

J

PREPARACION DE LA ABERTURA

| MANTENGA LAS SIGUIENTES

DIMENSIONES MINIMAS DE DESPEJE

13" de F

me×ima debajo R - Despeje minimo

de gabinetes desde la apertura

desprotegidos hasta la pared del

30" de despeje

mfnimo desde

C- Despeje

mfnimo desde

la apertura

basra la pared

trasera

L - Despeje mfnimo _"_

desde la abertura

basra la pared del

lado izquierdo

SE DEBER/_N MANTENER A

TODOS LOS DESPEJES PGP976 3-3/4"

HORIZONTALES POR PGP986 12"

UN PIINIMO DE 18"

SOBRE LA SUPERFICIE CGP650 12"

DE COCa6N.

la mesada hasta I 18" de altura

una superficie i la

supenor . mesada hasta

desprotegida el gabinete m6s

Base de

_binete de 30"

Mfnimo de 2 1/2" desde

la apertura basra el

frente de la mesada

o m6s ancha

NOTA °Dejeun espacioverticals n ZBj_

de por Io menos 7/16" desde la - / ":_

parte inferior de la placa de cocci6n TI

(o una profundidad de pot Io menos

3-11/16" desde la mesada) hasta

cualquier superficie combustible, tal

como elcaj6n de un gabinete

Para la instalaci6n de la isla, deje

un espacio minimo de 2-1,6" entre

la abertura y el extremo frontal y trasero de la

mesada. Deje un minimo de 3" entre la abertura y los

extremos laterales de la mesada.

lado derecho

cercano sabre

los lados de la

unidad.

B C

6" 3-3/8"

12" 3-3/8"

12" 3-3/8"

|

_tnn

CAJON f_l I

@era de

7/16"

[4=-1UBICACI6N DEL SUMINISTRO DE GAS

RECOMENDADA DESDELA PARED

TRASERA r' como minima,

Ubicaci6n del 7'_

suministro

de gas

recomendada / la Lhea

desde JaPared Trasera

Central de

Corte

ITI ASEGURESEDE QUE LOSCOBERTORES

DEPARED,MESADAY GABINETES

ALREDEDORDE LA ESTUFAPUEDAN

RESISTIRELCALOR (HASTA200° F)

GENERADOPORLA ESTUFA.

mesada deben

resistir un caJor i _

[TI DIMENSIONESTOTALESDE LA ESTUFA

3-1/4,,

18-7/8" q_..._,_-

r3] DIMENSIONES DE ENCASTRE DE LA

MESADA

Para asegurar la precisi6n, es mejor realizar una

plantilla al cortar la abertura de la mesada.

Longitud _'_'_-de 19-1/8"

de carte -__-._J

A _ torte deancho

F6] INSTALACI6N POR DELANTE

s

UNICAMENTE DE ACUERDO CON

LA LEY DE ESTADOUNIDENSES

CON INCAPACIDADES IADAi

Deje una profundidad

de por Io menos 5"

entre la mesada y la

cubierta.

NOTA: The enclosure

must be made of wood

material. Ademds, un panel

de acceso es necesario

para la toma de corriente,

regulador de presi6n,

vdlvula de cierre, los soportes de los

costados, y el servicio t6cnico.

4

Page 37

Instruccionesde Instalaci6n

J

INSTALACION DE LA UNIDAD DE LA ESTUFA

m

UB!QUE EL TOMACORRIENTE

ELECTRICO V LA VALVULA DE CIERRE

DE GAS DEBAgO DEL GABINETE

NUNCA VUELVA A _ _x

USAR CONECTORES i,

ANTIGUOS AL V61vula _ ,r_

INSTALAR ESTA Cierre_ I •

UNIDAD. Debajodela

Instale una v61vula de cierre manual en

la tuberia de gas en una ubicaci6n de f6cil acceso

fuera de la estufa. Aseg0rese de saber c6mo y

d6nde cerrar el suministro de gas de la estufa.

Instale el tomacorriente el6ctrico de 12" debajo de

la mesada.

i i

Ii_ie ]j_ i Tomacomente

I_ 7f

EI6ctricode 12"

Mesada

l_] PROTEJA LA SUPERFICIE DE LA

ESTUFA

Coloque una toallao mantel sobre lamesada.

Apoye la estufa al rev6s sobre la superficie

protegida.

Parte inferior de la estufa

ADHIERA LOS SOPORTES A LA

ESTUFA

Retire el tornillo del costado de la estufa y atornille

el soporte al costado de la unidad de la estufa.

Repita en el lado opuesto de la estufa.

Marca pora

Realizar

Parte Inferior Agujero \

SuF

Io Estufo

de la Estufa

-1

\

INSERTE LA ESTUFA EN EL

ENCASTRE

Inserte la estufa centrada sobre la abertura del

encastre. Aseg0rese de que el extremo frontal de

la mesada est6 paralelo a la estufa. Haga el control

final para verificar que todos los despejes necesarios

hayan sido realizados.

Telodebojode Ioestufo

UBIQUE LAS PARTES DE MONTAJE

Retire los soportes del paquete de instrucciones.

Una vez colocada la unidad, atornille el soporte

sobre los costados del gabinete para asegurar la

unidad en su ubicaci6n.

Page 38

Instruccionesde Instalaci6n

J

INSTALACION -CONEXIONES DE GAS

rT] BRINDE EL SUMINISTRO DE GAS

ADECUADO

Esta estufa fue diseBada para funcionar con gas

natural con una presi6n de actmisi6n de columna

de agua de 5" y una presi6n de suministro de

columna de agua de 7". Se envia con el equipo

de f6brica para gas natural. El regulador de

presi6n convertible suministrado con la unictad

debe set conectado en serie con la admisi6n de

la estufa y deber6 permanecer en serie con la

linea de suministro, sin importar si se est6 usando

gas natural o LP. PARA UN FUNCIONAMIENTO

CORRECTO, LA MAXIMA PRESION DE ENTRADA AL

REGULADOR NO DEBERA SER SUPERIORA 14" DE

PRESION DE LA COLUMNA DE AGUA. Para controlar

el regulador, la presi6n de entrada deber6 set

por Io menos de una columna de agua de 1". (o

3.4 KPA) superior que la configuraci6n de salida

del regulador. Si el regulador est6 configurado

para una presi6n de columna de agua de 5", la

presi6n de entrada deber6 ser por Io menos de

una columna de agua de 6". Si el regulaclor est6