Page 1

INSTRUCTIONS

GEK-26423D

TYPE

GROUND

CEYG51A

DISTANCE

RELAY

Protection

GE

205

Great

Maivern,

and

Valley

19355-1337

PA

Control

Parkway

Page 2

iNTRODUCTION

APPLICATION

RATINGS

Contacts

OPERATINO

PRINCIPLES

CHARACTERISTICS

Pickup

Operating

Time

Burden

CALCULATION

OF

CONSTRUCTION

RECEIVING,

ACCEPTANCE

Visual

HANDLING

TESTS

Inspection

Mechanical

Electrical

iNSTALLATION

Relay

PROCEDURE

Settings

Mechanical

Electrical

EQUIPMENT

PORTABLE

TEST

SERVICING

Restraint

Circuit

Directional

Maximum

Torque

Pickup

Clutch

RENEWAL

Adjustment

PARTS

SETTINGS

AND

Inspection

Tests

Checks

Checks

Characteristic

Angle

STORAGE

Angle

Adjustment

GEK-26423

NTS

E

CONT

PAGE

3

3

4

4

5

5

6

6

6

7

9

9

10

10

10

10

11

11

11

11

11

14

15

15

15

15

15

16

MINIMUM

Zero

No

With

MAXIMUM

No

Zero

MAXIMUM

With

PERMISSIBLE

Sequence

Sequence

Zero

PERMISSIBLE

Sequence

PERMISSIBLE

Sequence

Zero

REACH

Current

Current

REACH

Current

REACH

Current

SETTING

Compensation

Compensation

SETTING

Compensation

SETTING

Compensation

FOR

FOR

FUR

THE

THE

THE

APPENDIX

CEYG51A

APPENDIX

CEYGS1A

APPENDIX

CEYGS1A

I

17

17

18

II

18

18

III

20

20

2

Page 3

GEK-26423

The

consists

target

reach

a

and

characteristic

first-zone

comparison

The

missive

tion.

The

faults.

be

will

ground

also

will

faults

any

The

tion.

sequence

zero

phase

to

unit

niho

minimum

In

terminal.

against

trip

and

sequence

the

on

coordinate

must

should

carrier

In

minal.

protected

The

length

required

reach

the

proper

ditions

mho

unit

minimizes

pedance

CEYGS1IX

three

of

seal-in

relay.

and

CEYG51A

overreaching

ground

this

To

high

quite

faults.

respond

not

ground

A

tapped

current

ground

reach

permissible

directional

These

single

all

internal

for

current

carrier

set

be

as

signal

permissive

acts

It

line

choice

system

and

coverage.

on

or

reach

its

present

three

a

is

single-phase

unit

of

The

transferred

ground

transferred

units

rnho

they

end

and

this

For

to

involving

units

mho

auxiliary

faults

considerably

is

reach

comparison

relays

phase

compensation

starting

will

sensitively

block

will

overreaching

a

as

section.

whether

of

conditions.

be

may

swings.

power

setting

response

from

phase,

provides

the

CEYG51A

relay

tripping

relay

mho

the

of

are

relay

the

reason,

phase

three

ground

provided

are

current

compensation

on

as

settings

operate

ground

to

faults

while

units.

operating

be

as

tripping.

combined

or

2

about

then

This

approximately

to

load

to

parallel

a

high

units

indication

relay

specifically

waS

schemes.

applied

is

tripping

CEYG5IA

supplied

will

these

faults.

simply

transformer

is

phase

three

foreshortened

under

schemes,

conjunction

in

faults

the

used

is

This

on

possible.

transferred

transferred

to

not

When

3

to

tends

use

The

or

power

line.

speed,

in

with

have

by

with

used,

on

will

the

use

zero

times

to

of

GROUND

one

has

schemes,

relay

units

If

adding

faults.

both

two

in

other

the

facilitate

same

trip

sequence

sequence

the

make

zero

1.25

swings.

DISTANCE

CEYG51A

INTRODUCTION

single

L2—D

case

of

operation

been

not

designed

Figure

APPL

the

primary

as

employing

specifically

are

quadrature

operating

high

a

not

are

is

this

non—directional

a

separate

used

is

the

ground

If

single

on

conditions.

CEYG51A

relays

with

protected

the

initiates

carrier

torque

will

This

tripping

initiating

current

current

positive

ground

the

sequence

the

times

This

RELAY

RELAY

mho

zone,

with

facilities

for

limited

for

3

shows

CAT

ION

I

ground

voltage

provided

objectionable,

current

obtain

to

unit

iiho

sequence

zero

phase

connected

a

carrier

line

carrier

stopping

the

unit

level,

to

tend

schemes,

and

compensation

compensation

sequence

mho

current

positive

true

is

type,

three

all

to

the

use

as

the

internal

relay

separate

designed

polarization.

torque

with

circuits

the

has

ground

to

channel

section.

blocking

tripping

and

settings

any

in

increase

CEYG51A

one

permissive

a

impedance

more

unit

compensation

sequence

provided

directional

for

testing

distance

point

an

overreaching

connections.

directional

in

primary

detect

to

level

even

memory

zero

the

for

proper

action.

relay

sequence

zero

ratio

essentially

compensation

faults.

back—to-back

provide

to

One

external

on

units,

insure

and

event,

the

security

relay

relay

depends

NOT

is

of

sensitive

impedance

there

units.

where

and

Thus,

on

can

sequence

relay

carrier

since

is

upon

used,

the

reduces

is

distance

one

is

it

device

separate

single

the

very

These

made

be

fault

compensation.

of

same

the

NOT

is

Appendix

See

required

are

high

acts

faults.

should

it

that

the

required

ground

for

the

the

line

operation

to

the

of

little

ground

unit

atatime.

The

suitable

in

comparison

backup

phase

polarizing

close

ground

unresponsive

detector.

current

reach

used,

speed

to

both

starting

presence

at

protected

ground

order

in

necessary

the

line

no

or

relay.

transient

for

directional

to

line

in

niho

compensa

on

ground

the

for

I

each

at

protection

carrier

Stop

zero

if

be

also

units

unit

each

faults

mho

to

on

and,

mutual

use

and

protec

ground

voltage

to

units

When

single

the

used

that

a

of

ter

in

line

unit

provide

load

ground

thus,

im

It

One

over

as

per

to

the

con

eeerc

furtn-r

tn

These

poss:ble

information

purchaser’s

To

he

:ot

sucn

nstroctions

contanJencj

purposes,

extent

-scranc.

be

,eau:red

do

desired

s

not

to

the

;iven

the

purport

be

or

matter

met

should

products

with

to

in

should

respect

cover

connection

particular

be

descrrhed

to

all

referred

local

details

with

problems

herein

installation,

to

codes

the

meet

or

arise

and

variations

which

General

applicable

ordinances

in

operation

are

Electric

?.ESI,

equipment

not

because

or

maintenance.

covorci

Ccmpant.

IEEE

he;

and

nor

sufficientlq

.S1IMA

varo

to

provide

standards;

rcatly.

For

Should

for

Page 4

GEK-26423

Whether

correct

line

the

avoid

to

sequence

setting

The

II

fault

zero

will

in

and

behind

If

sequence

permit

Figure

Ill

the

Since

performance

sired

setting

The

operation

to-phase.

ohmic

The

by

steps

will

It

desired

the

The

positions

reach

ohmic

or

operation

impedance

this

current

zero

when

system

are

,

the

reach

tripping

4.

the

will

CEYG5IA

Type

wye-wye

on

Current

BASIC

OHMIC

(0-N

1/2/3

0.5/1.0/1.5

reach

means

be

basic

setting

MINIMUM

zero

not

on

and

tripping.

false

compensation

sequence

conch

tions

rather

relay

the

of

directional

CEYG51A

obtained

be

used.

is

coil

MIN.

REACH

OHMS)

at

is

of

a

noted

minimum

the

of

sequence

ground

system

unusual

is

unfaulted

only

an

is

relays

connected

ratings

the

tapped

that

sets

two

follows:

as

OHMIC

current

faults

immediately

conditions.

Appendix

NOT

is

requ

They

.

than

compensation

current

which

larger

phase

overcurrent

fault

the

when

extended

the

if

covered

potential

and

RANGE

OHMIC

(0-N

of

angle

autotransformer.

basic

three

is

reach

REACH

links,

of

SETTING

compensation

II

used

the

cc

occur

the

units

relay

is

range

highest

these

by

transformers

ohmic

REACH

OHMS)

-

1

-

0.5

maximum

minimum

by

made

(for

(OHM

is

the

used.

is

tdtion

the

sequence

the

forward

with

minimum

the

limiatations

ill

of

zero

non-trip

nay

three

behind

nayhenecessary

It

gives

Appendix

im

1

when

positive

ii

(CFPG16A)

the

in

relay

basic

RATINGS

instructions

which

as

ranges

are

30

15

of

of

N

60

settings

links

unit),

torque

reach

means

each

PHASE-TO-NEUTRAL)

used,

relay

gives

uho

the

sequence

current

direction

used

be

direction.

basic

reach

available

are

supply

tabulated

CONTIN.

CURRENT

AMPERES

degrees

are

terminal

on

each

the

ground

terminals.

1

mit

to

of

the

limitdtions

unit

current

to

minimum

tap

secondary

below:

RATING

5

5

lag,

listed

identified

A

+

mho

This

mho

the

mho

the

reach,

contribution

contribution.

an

is

supervise

external

The

reach

setting

that

with

can

and

for

boards

as

B

units

will

unit

unit

reach

the

of

as

described

application

the

settings,

will

potential

voltage

—

adjusted

be

mho

the

located

A-B

may

be

dependent

be

reach

setting

inho

over

CEYG51

connections

accommodate

circuits

of

120

SEC.

ONE

RATING

CUR.

AMPERES

225

225

units.

rear

on

determine

subject

setting

unit

reach

by

Appendices

the

limitation,

operation.

best

the

volts

percent

5

in

Selection

of

the

to

upon

in

when

line

shown

are

overall

the

rated

phase-

the

minimum

in

order

zero

to

a

This

de

for

of

relay.

a

CONTACTS

main

The

tripping

always

by

amperes,

current

The

shown

as

circuit-closing

at

duty

opened

tripping

a

Table

in

I—C

Carry

Carry

Carry

control

an

by

relay

carrying

I

Resistance

Continuously

Amps

30

Amps

10

voltages

auxiliary

should

rating

for

for

contacts

switch

be

of

of

used.

the

——

of

250V

main

the

DC

other

or

contacts

TARGET

2.0

Amp

0.13

3.5

re1a

or

Tap

4

less.

suitable

TABLE

AND

Ohms

Amps

Secs.

will

The

is

I

SEAL-IN

4

and

close

circuit

means.

determined

UNIT

0.6

A;np

0.6

1.0

0.5

carry

breaker

the

If

by

Tap

Ohms

Amps

Secs.

the

amperes

30

trip

tripping

tap

—

coil

setting

DC

momentarily

should,

current

of

0.2

Amp

7

0.35

0.2

Tap

Ohms

Amps

Secs.

exceeds

the

for

however,

30

seal—in

coil

Page 5

0.3

normally

The

amperes

closed

in

non—inductive

contacts

circuits

between

up

terminals

250V

to

GEK-26423

and

19

DC.

20

will

close,

carry

continuously,

or

interrupt

inhu

The

Fig.

with

6)

phase-to-phase

polarizing

tdye

vol

in

izing

the

The

of

rear

flux

torque

following

where:

type

schematic

flux.

the

pole,

produce

to

equation:

Ebc’

units

voltage

flux

The

protected

which

operating

balance

the

at

Torque

design

K

Phase—A-to-neutral

=

Phase

=

Phase

=

‘a

Angle

=

B

Restraint

=

T

Angle

=

CEYGS1A

the

in

connections

in

quadrature

in

phase,

energized

is

0

=

constant

to

B

current,

A

by

by

relay

shown

as

with

front

the

interacts

by

torque.

point

for

KIaEbc

=

PhaseCvoltage

at

Ea

setting

‘a

leads

which

tap

which

OPERATING

are

in

Fig.

the

phase-to—neutral

which

pole,

the

the

the

with

line

phaseAstarting

((

COS

voltage

relay

the

Ebc’

leads

Ebc

PRINCIPLES

of

the

3.

is

polarizing

current

-30)

the

at

(Eb

location

(900

four-pole

The

energized

—

TEEb’

relay

E)

-

for

of

balanced

induction-cylinder

two

side

voltage

by

flux

the

protected

can,

unit

sin

location

at

the

poles,

percentage

a

to

produce

B

relay

3-phase

which

the

of

phase,

therefore,

are

protected

of

restraint

interacts

be

(1)

condition)

construction

energized

phase,

the

phase-to-neutral

torque.

with

expressed

(see

the

by

produce

The

the

the

by

the

flux

polar

The

impedance

rather

The

diameter

current

line

there

maximum

this

voltage

The

which

compensated

not

special

positive

the

selecting

The

applied

tap

the

operating

specific

inho

passing

essentially

is

by

diameter

would

case

ohmic

to

block.

diagram

as

fault

characteristics

has

unit

through

for

(Ia

torque

600,

which

of

be

is

it

single-phase—to-ground

of

basic

the

sequence

reach

a

setting.

reach

restraint

the

Ohmic

shown

conditions

circular

a

example)

phase

no

angle

is

the

not

impedance

the

of

Fig.

in

origin

the

leads

shift

(i.e.

condition

the

impedance

minimum

accurate

an

mho

circuit,

ReQch

of

the

7.

described

characteristic

defines

the

in

maximum

circle

reach

distance

the

to

can

unit

that

2

=

Tap

E

CHARACTER

mho

units

should

It

below:

the

quadrature

the

line—to—neutral

reach

represented

would

with

the

faults

fault.

extended

be

by

is

setting

(Zi)

Setting

in

be

which

angle

polarizing

angle)

in

nomally

tap

E

measuring

where

Instructions

100

()

1ST

the

noted

passes

of

occurs

Fig.

be

leads

zero-sequence

the

reducing

by

the

1

CS

CEYG51A

that

through

maximum

voltage

voltage

when

8.

considered

on

until

are

tap

E

2

(5)

represented

be

may

relay

these

steady-state

torque

the

origin

of

(Ebc

the

for

of

unit,

example)

forasingle-phase-to-ground

current

line

the

ohmic

the

100

except

given

the

leads

as

percent.

on

impedance

in

percentage

on

However,

3-phase

Appendices

of

lower

a

to

characteristics

R-X

the

which

by

the

lags

reach

if

faults,

fault

the

and

II

fault

the

percentaoe

R—X

the

on

are

diagram.

occurs

30°.

when

Since

fault,

phase—to-neutral

unit,

the

of

niho

for

unit

the

equal

is

for

the

or

III

voltage

position

for

The

is

to

on

5

Page 6

The

(600).

equation

from

PICKUP

The

ufficient

for

mum

percent

On

result

percent

current

ohmic

reduced

The

operating

magnitude

fault

voltage

by

(5)

currents

with

reach

cos

torque

to

which

currents

obtained

reach

MINIMUM

REACH

(0-N

0.5

1.5

single-phase-to-ground

will

relay

the

that

restraint

for

the

voltage

3-ohm

minimum

from

line

at

(60-0)

will

overcome

lag

OHMIC

SETTING

OHMS)

1

2

3

operate

and

close

as

faults

120

reach

equation

angles

where

the

restraint

the

unity

the

tabulated

at

volts

setting.

(5)

other

is

the

0

contacts

power

below:

quadrature

the

considerably

polarizing

GE

K—2

assumes

than

line

when

torque.

factor

CURRENT

64

23

that

600

can

angle.

the

The

position

polarizing

current

less

unit

the

line

be

fault

operating

RANGE

will

angle

obtained

current

by

FOR

36

18-60

12

9

6

potential

than

operate

maximum

and

multiplying

by

is

torque

degrees

60

RELIABLE

60

-

60

—

60

-

60

-

will

tabulated.

with

certiri

in

a

3-phase

on

and

OPERATION

remain

less

torque

is

For

than

angle

reach

the

direction

faults

reliable

quite

example,

ampere

1

high

are

obtained

is

down

with

with

equal

of

and

maxi

a

one

to

the

one

a

operating

OPERATING

typical

For

BURDEN

burden

The

percent

100

at

Basic

Ohms

1

0.5

1

the

I-f

equation:

where

TIME

30

-

15

-

30

-

restraint

Watts

VARS

T

operating

imposed

as

is

Rated

Freq

Restraint

Restraint

=

Tap

given

60

60

50

tap

VA

on

in

time

the

below:

reduced,

is

Watts

=

circuit

circuit

percent.

characteristics

potential

Polarizing

V

120

120

120

Watts

10.1

10.1

8.41

the

*(2

watts

Vars

see

transformers

Circuit

Vars

burden

+

.

table

from

table

from

Figure

by

8.88

8.88

7.38

of

the

VARS(i”)

above.

above.

13A

type

the

VA

13.5

13.5

11.2

restraint

and

CEYG51A

circuit

138.

Volts

70

70

70

relay

Restraint

Watts

2.7

0.9

1.7

given

is

with

the

Circuit

by

Vars

4.0

1.6

3.0

the

restraint

following

VA

4.8

1.8

3.4

tap

set

6

Page 7

The

burdens

imposed

on

the

current

transformers

GEK-26423

the

by

current

circuits

are

given

below:

quently

be

followed

Basic

Ohms

1-3D

0.5

1

NOTE:

applying

In

do

Determimimme

1.

the

line

Determine

2.

relay

a.

b.

c.

following

The

Consider

-

15

-

30

Above

for

materialize.

not

determine

to

necessary

power

terminal.

When

further

When

further

no

neither

If

determine

lay,

the

Rated

Freq.

data

the

the

relay

if

zero

loadings

if

there

zero

evaluation

zero

Type

calculations

protected

60

60

50

is

lower

to

what

sequence

unit

rnho

and

is

sequence

sequence

evaluation

nor

a

if

it

CFPH16A.

line

3-4,

I

5

5

5

for

the

reach

particular

a

Therefore,

final

tap

power

limitation

a

current

need

current

above

b

is

necessary

are

to

5-6,

0.070

0.007

0.058

mho

settings

tap

calculations

current

settings

swings.

compensation

made.

be

compensation

be

need

is

made

between

be

7-8

or

Circuit

X

0.040

0.005 0.008

0.033

units set

on

will

CALCULATION

line

and

system,

recommended

it

is

maybenecessary

compensation

and

the

Appendix

See

application

the

in

Appendix

See

made. See

applicable,

use

an

the zero

example

to

as

breakers

their

be

less

SETTINGS

OF

is

relation

is

t.{Qi

is

used:

Appendix

evaluate

of

A

2

0.080

0.067

maximum

than

the

limitations

the

that

required.

the

of

equations

I,

for

used:

equations

II,

if

III,

the

sequence

determining

and

B

on

1

5

5

5

ohmic

the

initial

and

This

resulting

incorrect

if

Co

(3K

equations

equations

directional

the

0.210

0.021

0.175

tabulated

how

‘b

is

ha,

+

1)

actual

the

portion

Circuit

9-10

R

reach

taps.

burdens.

outlined

calculations

the

relay

will

depend

mho

and

I.

operation

equal

hib

equal to

Co

is

lIla,

of

either

overcurrent

tap

of

X

0.120

0.013

0.100

The

under

of

may

be

upon

characteristic

on

or

less

to

tIc.

and

and

hlIb

Appendix

settings

system

a

Z

0.240

0.024

0.200

burden

APPLICATION

and

2

1

applied.

evaluation

on

with

than

less

behind

C,

than

faults

or

Ihic.

II

or

supervising

be

to

in

shown

fre

below

no

III

used.

Fig.

of

the

the

C,

to

re

5.

Assume

Checking

breaker

the

Z

1

CT

Ratio

PT

Ratio

Secondary

=

21

Z0’

=

Zom

Appendix

detect

A

to

following

=

24.0

=

72.0

14.4

600/5

1200/1

Ohms

2.4

/79°

/75°

7.2

/75°

1.4

a

characteristics:

/790

/750

/75°

=

CT

PT

=

0.47

=

1.9

=

0.36+jI.35

first

I

single

primary

primary

primary

Ratio

Ratio

to

phase

ohms

ohms

Primary

x

+

j2.36

+

j6.95

establish

to

ohms

secondary

secondary

secondary

ground

Ohms

the

fault

ohms

ohms

ohms

maximum

(F2)

7

tap

at

setting

the

remote

that

bus,

would

Equation

still

permit

should

lb

the

CEYG5IA

used.

be

at

Page 8

GEK-26423

Assume

Substituting

obtain:

we

The

should

restraint

Consider

calculate

double

or

constants:

value

be

for

C

0

C

10’

used.

tap

the

phase

this

=

=

=

=

=

=

9

these

T

=

of

T

For

T

should

T

=

a

now

maximum

to

fault

0.17

0.20

13.7

4.1

-0.88

negative

from

790

0.204K

could

the

0.204K

ground

safe

ground

at

secondary

secondary

secondary

sign

that

values

F

obtained

be

three

no

be

=

fault

reach

faults

F2

in

and

+

larger

61

that

amperes

amperes

amperes

because

which

the

(7.2

(0.4

ohm

percent

at

setting

at

system

a

I

I

flows

values

K

-2.4)(0.17)

0.17)

÷

all

for

basic

than:

immediately

Fl

this

study

based

based

flows

of

Cos

three

reach

to

eliminate

location.

yields

600/5

on

the

on

in

the

in

impedance

(60-79)

(1.4)(-0.88)

+

basic

settings

behind

CTs

protected

opposite

the

protected

13.7

K

the

Assume

following

the

assumed

minimum

300.

relay.

the

possibility

that

line

direction

line

above

reach

Thus,

system

a

quantities.

CT

ratio

(A

to

into

settings.

for

Appendix

an

of

study

in

B).

equation

this

incorrect

of

the

H

yields

600/5.

parallel

However,

basic

indicates

Note

of

Tb

the

setting

tap

operation

following

the

the

line

Appendix

highest

approach

the

on

(0

to

I,

the

single

system

C)

one

to

TIc

Using

of

C

C

0

Z

1

the

Appendix

0.27

0.11

=

tap

ohms

ohms

settings

ha)

JIb)

lIc)

established

values

above

setting

tap

of

tabulated

are

T

evaluating

and

equations

below.

ha,

and

JIb

VALUE

0.875

1.05

/82°

/780

1.2

0.11

0.27

100

123°

82°

Percent

-10.5

Percent

-18

Percent

-14.5

0.875

=

1.05

=

1.2

=

basic

ohm

3

the

II,

secondary

/780

minimum

minimum

secondary

permissible

QUANTITY

ZI

Z

0

Z0/Z

1

Co

C

K

A

8

(Equation

T

(Equation

T

(Equation

T

8

Page 9

GEK-26423

Since

tap

the

Since

setting

remote

These

the

If

tings

be

at

carrier

the

terminal

set

be

setting.

reach

Thus,

setting

should

terminal.

application

of

least

as

In

any

setting

If

zero

we

all

the

61

the

same

carrier

the

1.25

starting

and

they

sensitively

case,

Thus,

as

sequence

obtain.

values

for

this

percent

used.

be

Thus,

calculations

for

is

starting

times

relay

will,

as

ALWAYS

carrier

the

tripping

the

current

of

T

application.

setting

is

It

50

for

T

=

Set

should

directional

the

setting

at

therefore,

possible.

the

set

start

K

the

in

above

will

desirable

percent

61

41

40

on

tap

be

CEYG51A

of

rear

the

coordinate

relays

CEYG51A

CEYG51A

compensation

-

6.95

=

3(2.36)

table

Thus,

insure

the

that

to

set

additional

percent

percent

repeated

comparison

relays

the

at

tripping

terminal

must

that

relay

at

relay

used,

is

2.36

= =

are

relays

the

the

reach

the

for

carrier,

both

relay

will

properly.

coordinate

terminal

at

terminal

equation

4.59

7.08

negative,

maybeset

relay

relay

the

relays

terminals.

outreach

A.

0.65

to

it

at

In

these

will

reach

restraint

at

will

the

remote

the

any

event

with

should

B

should

Ic

per

in

reach

at

the

also

The

carrier

each

unit

equations

range

the

only

least

setting

tap

remote

necessary

be

carrier

terminal.

tripping

carrier

the

other

set

be

be

used

impose

of

the

to

25to50

should

of

end

start

This

starting

the

on

the

with

instead

no

restrictions

10to61

remote

percent

be:

line

the

determine

to

settings

relay

will

at

relay

basic

same

same

equation

of

percent.

bus,

at

insure

the

units

basic

a

lower

beyond

terminal

the

remote

should

minimum

minimum

on

the

B.

set

should

that

tap

lb.

For

maximum

the

The

associated

restraint

details

tion

The

cradle

the

plug

is

case

can

attaches

the

vent

Outline

These

protect

transit.

transportation

the

Reasonable

immediately,

metallic

and

is

cover

ground

the

safe

CEYG51A

Type

tapped

circuits

of

components

locked

block

and

inserted

be

the

to

from

cover

and

relays,

against

them

injury

If

care

they

chips.

removed

fault

setting

reach

relay

autotransformer

adjustment

for

relay.

the

mounted

are

case

the

in

cradle

place

in

from

case

being

drilling

panel

not

when

damage.

damage

or

company

should

should

Foreign

cause

and

=

T

immediately

F2

consists

Internal

by

block

the

replaced

included

and

be

stored

be

matter

trouble

0.33K

using

when

of

for

of

angle

connections

a

cradle

on

means

completed

are

connection

the

of

front

and

until

dimensions

RECEIVING,

as

Immediately

resulting

promptly

exercised

in

collected

in

0.33

=

behind

zero

three

controlling

and

assembly

latches

of

includes

the

are

part

a

upon

from

notify

unpacking

in

original

their

operation

the

300=99

x

the

sequence

percent

relay,

current

CONSTRUCTION

reach

of

4—pole

and

minimum

relay

the

inho—type,

basic

which

the

at

through

plig

the

connection

shown

a

to

target

in

top

removable

permit

plug

Figure

HANDLING

control

a

of

receipt

rough

the

of

handling

nearest

the

cartons

outside

the

on

the

of

use

adjustable

can

and

reset

AND

panel,

a

General

relay.

relay.

equation

the

compensation.

induction

ohmic

shown

are

easily

be

bottom.

connection

testing

mechanism

been

has

15.

STORAGE

will

relay,

evident,

is

If

a

place

in

of

the

resistors

reach.

the

inserted.

be

examine

Electric

the

case

of

cylinder

Figures

Figure

in

removed

electrical

The

plug.

relay

and

shipped

it

a

file

Apparatus

relays

that

find

may

Appendix

units.

in

3.

from

in

an

in

any

for

damage

are

is

free

its

III

Each

polarizing

the

and2show

1

relay

the

connections

separate

A

case.

its

interlock

cartons

damage

claim

Sales

not

to

from

way

calculate

to

unit

case.

testing

The

armtopre

designed

ststained

once

at

Office.

installed

be

moisture,

inside

has

and

construc

between

cover

with

dust,

when

an

The

to

in

the

9

Page 10

GEK-26423

Immediately

damage

no

ViSUAL

has

INSPECTION

Check

received

agree

Remove

molded

parts

MECHANICAL

is

It

There

1.

so

tact

There

the

There

check

contacts

2.

lower

shaft

3.

.012

4.

that

5.

assembly

6.

should

armature

should

that

7.

There

The

inch

The

it

The

The

Check

closed

The

the

to

connection

blocks,

gram.

Note

high

the

and

Figure

that

enough

main

improper

circuited.

upon

been

nameplate

the

with

relay

the

other

or

INSPECTION

recommended

should

should

should

screw

jewel

locked

by

contact

clearance

spring

touches

just

clutch

at

armature

a

be

hand

by

at

be

target

the

the

diagram

that

11

is

there

that

so

brush.

adjustment

receipt

sustained

the

from

signs

that

be

be

bearing

its

gap

windup

of

moving

the

and

screw

and

least

location

for

long

the

shows

an

when

This

of

stamping

requisition.

its

of

the

noticeable

no

closed

be

end

an

set

each

on

between

should

the

unit

each

contacts

only

in

check

1/32

resets

the

and

sectional

a

auxiliary

the

especially

is

the

the

of

shipment

in

to

case

physical

following

play

of

screw.

unit

the

solid

contact.

that

wipe

positively

the

of

relay.

short

connecting

auxiliary

relay

insure

and

when

each

stationary

be

stop

should

of

one

contact

brush

and

check

damage,

friction

the

from

of

unit

should

sufficient

when

slip

the

the

of

the

the

on

sure

Be

brushes

view

in

important

brush

ACCEPTANCE

inspection

an

that

that

by

mechanical

in

relay

.005

should

approximately

be

contact

the

when

target

tap

target

seal—in

the

when

brushes

that

on

the

of

position

each

is

plug

could

the

model

the

visual

that

and

adjustments

the

in

is

to

be

cause

to

unit

force

a

and

positions

latches

contacts.

reset

on

the

cradle

the

case

inserted

current

in

result

TESTS

and

relay

number,

inspection

all

rotating

the

inches

.015

screwed

rod

the

dc—energized.

is

of

seal-in

in

button

the

shorting

cradle

and

on

in

acceptance

calibrations

screws

structure

upright

firmly

.045

the

and

normally

45

unit

the

on

exposed

its

With

at

cradle

bars

block

the

engages

it

other

and

CT

a

rating,

that

be

position.

on

to

solid

to

should

right

the

and

agree

blocks

case

secondary

test

there

are

checked:

the

in

.065

closed

grams

65

stationary

position

the

5ottom

case

are

with

with

block.

the

circuits

have

and

tight.

of

shafts

place,

inches.

backstop

move

cover

blocks

the

in

auxiliary

should

not

ohmic

are

each

of

and

stationary

applied

is

freely

fastened

of

proper

the

the

This

with

circuit

made

be

been

range

broken

no

unit.

rotating

the

the

There

when

when

contact

before

cover

the

against

locations

internal

connection

brush

brush

shorting

being

to

disturbed.

of

or

The

pivot

should

contact

the

contact

the

to

operated

strip.

contacts

the

securely

is

the

connection

plug

should

before

momentarily

insure

the

cracked

normally

structures.

the

at

to

moving

operated.

internal

on

be

bars

relay

top

.004

be

is

deflect

by

Operate

place,

in

the

place.

in

formed

striking

since

that

of

open.

con

hand.

close.

case

dia

an

open

ELECTRICAL

is

It

Polarity

1.

polarizing

connections

test

the

the

CaUSe

unit

that

Directional

2.

characteristics.

phase

the

contacts

on

closed

100

remain

be

TESTS

recommended

Check

restraint

and

contacts

should

develop

shifter

of

the

as

unit

each

percent

of

Use

so

for

that

-

in

that

Check

the

that

should

current

these

the

The

circuits

Figure

a

-

test

the

following

unit

strong

The

current

close

is

tests.

following

each

of

With

9.

close.

to

contact

following

connections

at

increased

electrical

check

all

leads

some

will

unit

tap

With

opening

checks

shown

the

value

the

to

insure

correct,

is

leads

the

torque.

are

in

voltage

less

maximum

checks

removed

tap

E

2

to

Figure

than

10

made

be

that

Each

of

determine

10.

30

by

the

value

relative

the

unit

connections

the

each

Set

degrees

minimum

given

immediately

can

set

unit

each

that

voltages

the

with

amperes

Table

in

polarity

checked

be

in

unit

the

upon

shown

80

the

has

to

connections

given

III.

receipt

operating,

of

individually

each

for

percent

correct

volts

two

Tble

in

EL

The

the

of

unit

position,

directional

and

shown.

III

taps

relay.

using

should

set

The

and

should

Page 11

GE

K-

TABLE

26423

III

Set

should

unit

3.

connections

amperes,

for

5

With

unit

the

of

contact

bisector

the

at

the

unit

The

operating

4.

percent

+14

set

and

at

with

100

voltage

Table

in

phase

the

phase

the

remain

Maximum

shown

the

phase

will

just

to

left

maximum

current

Pickup

of

percent

relay

the

30

by

IV.

angle

shifter

Torque

in

with

be

open.

of

contact

torque

leads

Check

the

degrees,

Resistor

of

OHMIC

SETTING

TAP

0.5

1.0

1.5

2.0

3.0

from

open

Angle

Figure

polarizing

shifter

closed.

These

the

angle

just

angle

the

-

The

minimum

and

the

connected

check

R11-R12-R

13

restraint

the

REACH

that

so

zero

-

10,

set

Next

are

between

opens

(110

of

polarizing

following

reach

voltage

as

that

the

to

The

but

voltage

that

so

find

the

at

310)

+

the

as

shown

the

circuit

current

amperes.

60

maximum

with

at

operating

the

zero

the

1100

210°,

=

units

voltage

check

given

adjusted

in

current

should

torque

the

120

angles

torque

two

and

should

is

on

for

Figure

not

the

leads

tap

E

volts.

zero

3100.

ie

for

to

the

the

10.

required

be

same

MINIMUM

AMPERES

32

16

12

8

6

the

angle

disconnected.

current

either

on

angles

torque

The

3Q0

lead

300

be

at

particular

a

determine

nameplate.

value

Set

to

used

to

the

as

voltage

the

of

leads

the

of

lines.

angle

lead,

that

shown

the

close

adjust

phase

by

mho—type

polarizing

side

unit.

of

unit.

the

These

in

phase

the

pickup.

angle

degrees.

210

operating

The

the

of

The

example,

For

maximum

This

+3°.

ohmic

checks

Table

shifter

contacts

of

units

voltage

300

position

maximum

torque

reach

should

IV

so

The

the

MAXIMUM

AMPERES

60

60

60

60

60

The

can

be

current

by

torque

assume

will

the

is

angle

each

of

be

for

the

current

that

within

falls

resistors

polarizing

contacts

checked

30°,

which

that

be:

unit

made

specific

are

circuit.

using

should

the

cause

position

for

which

by

is

with

ohmic

leads

the

used

each

of

be

left

the

particular

a

witin

the

range

to

the

set

contact

will

the

E

range

shown

make

left

be

taps

UNIT

-N

0.5

2.0

3.0

Compensating

5.

compensating

connect

but

With

the

close

1.0

1.5

windings

the

voltage,

left

current

UNiT

E

2

contact

REACH

LINK

SETTING

Winding

between

Ml

M2

M3

tap,

0.5

1.0

1.5

2.0

3.0

circuits

of

and

edch

Check

terminals

as

phase

unit.

RESTRAINT

APPLIED

VOLTAGE

20V

25

35

35

70

-

The

9-10,

tabulated

I

•

SUD

angle

The

following

is

in

TO

3

5

7

as

set

current

TABLE

check

correct.

the

the

in

should

11

IV

POLAR.

APPLIED

VOLTAGE

120V

120

120

120

120

is

Use

following:

pickup

be

to

2

STUD

10

10

10

one

confirm

basic

the

TO

check

half

PICKUP

CURRENT

34.4

21.6

20.0

15.0-20.0

20.0

that

test

measure

(4),

the

values

45.6

—

-

28.5

-

26.6

26.6

-

relative

the

connections

listed

JUMPER

STUDS

4-9

6

8-9

the

polarity

-

9

current

in

PHASE

ANGLE

°LEAD

30°

30°

300

30°

30°

Figure

of

Table

of

required

IV.

the

10,

to

Page 12

taps.

held

Refer

steps

6.

closed,

to

to

Target

Use

the

change

a

Seal-in

source

DC

can

section

the

be

Unit

with

gradually

Target

on

setting.

tap

With

—

the

increased

Seal-in

the

circuit

target

arranged

the

to

Unit

in

pickup

Settings

GEK-26423

down’

the

that

so

point.

under

unexposed

or

current

test

Pickup

INSTALLATION

position,

through

current

PROCEDURE

studs

should

check

1-11,

be

for

pickup

with

rating

tap

recommended

the

Ml

on

both

contact

less.

or

after

If

recommended

The

before

relay

vibration.

repeated

excessive

connections

SETTINGS

RELAY

Mho

1.

to

Refer

determining

reach

The

the

taps

blocks.

proper

of

MECHANICAL

Check

1.

left

the

When

reclose

and

Examine

2.

cleaned

be

surface.

use

not

Do

Operate

3.

and

make,

when

the

reset

ACCEPTANCE

the

the

that

installation.

should

shown

are

Units

section

the

mho

the

the

of

the

on

The

CHECKS

the

contact

normally

the

the

a

with

Burnishing

knives,

the

the

that

button

visual

mounted

be

The

in

unit

mho

blocks.

tap

green

movable

is

contact

burnishing

tools

files,

target

contacts

is

the

TESTS

mechanical

and

on

outline

Fig.

on

tap

units

and

and

3

CALCULATIONS

block

can

The

should

leads

contact

closed

closed

structures

by

contact

surfaces

tool,

designed

abrasive

or

seal-in

at

have

operated.

INSTALLATION

relay

vertical

a

panel

typical

AND

settings

adjusted

be

leads

red

be

and

hand

with

for

which

specially

paper

by

unit

least

is

held

inspection

surface

drilling

external

SETTINGS

for

should

connected

of

then

the

signs

consists

for

or

hand

1/32”

a

in

each

released

relay

of

cloth

and

wipe.

specific

five

tarnishing

of

cleaning

PROCEDURE

in

storage

described

location

in

a

dimensions

connections

a

for

application.

percent

connected

be

of

one

to

by

unit

the

completely

flexible

a

any

of

that

check

With

before

under

are

are

discussion

steps

the

hand.

movable

corrosion.

or

strip

contacts

relay

to

kind

the

cover

the

shipment

section

the

is

which

shown

in

shown

of

suggested

connecting

by

of

one

to

two

tap

5t

There

structure

deenergized.

metal

of

clean

target

replaced

clean

Fig.

Fig.

in

the

positions.

should

Fine

can

relay

latches

the

to

on

10

be

should

silver

with

obtained

be

contacts.

check

and

15.

4.

the

percent

before

site,

job

ACCEPTANCE

and

dry

internal

The

procedures

leads

tap

tap

noticeable

no

reset

to

contacts

etched,

an

from

contacts

the

the

that

it

is

TESTS

from

free

for

to

positions

friction.

the

should

roughened

factory.

the

target

be

the

right

resets

ELECTRICAL

Using

CHECKS

the

ACCEPTANCE

manner

The

titled

section.

up

form

SAMPLE

settings

eliminate

To

in

It

Fig.

impedance,

tested.

being

is

percent

10

nearly

very

sible

tion

to

may

provide

be

connections

test

PICKUP

-

TEST

which

in

CALCULATIONS

the

purpose

have

is

which

errors

the

for

16

is

the

5

F

and

The

percent

1

actual

the

as

the

to

made

CHECK.

reach

FOR

of

made

been

which

units

mho

switch,

fault

autotransformer

steps

line

portable

any

match

in

shown

settings

SETTINGS.

electrical

the

for

result

may

are

and

that

so

which

on

reactor

test

line.

Figure

PORTABLE

made

are

Examples

particular

a

from

recommended.

jX

+

RL

which

TA

line

the

relay

the

XL

check

10

TEST

the

on

of

in

tests

line

instrument

the

is

across

is

impedance

is

the

and

12

the

EQUIPMENT

starting

calculation

the

this

section.

inaccuracies

figure

the

In

impedance

the

RL

used.

be

to

test

relay

section

fault

jXL

+

resistor

reach

units

of

to

R

5

the

switch

may

This

with

is

of

the

+jX

5

setting

briefly

typical

check

line

be

is

enough

as

the

circuit

test

(when

section

line

and

to

made

necessary

described

discussed

settings

starting

used)

for

impedance

appear

since

taps

is

so

are

unit

shown

the

which

to

it

that

in

under

the

given

in

source

is

the

is

the

section

ohmic

schematic

relay

the

tapped

relay

not

combina

in

fea

that

pick

in

Page 13

For

arranged

and

distance

well

as

test

box

B.

T[STING

To

resistor

schematic

in

the

only

for

the

to

these

convenience

in

a

as

the

the

TIlE

check

be

arranged

connections

section

the

fault.

conditions.

in

portable

relays.

line

user

the

and

is

MHO

UNITS

calibration

The

referred

with

of

on

CHARACTERISTICS

special

The

case

tests

field

test

source

Fig.

outlined

box,

box

Type

where

testing,

Cat.

is

provided

impedances

GEI-38977.

to

of

the

XLA

16,

the

who

test

except

the

zero

below

the

No.

mho

fault

102L201,

with

may

unit

plugs

that

unit

sequence

check

GEK-26423

switch

terminals

be

readily

it

is

as

shown

the

XLA

provides

impedance

the

line-to—neutral

and

which

suggested

in

test

an

tapped

is

particularly

to

which

connected.

that

Fig.

18.

plug

accurate

is

equal

autotransforiner

the

relay

For

the

test

These

connections

distance

to

ohms

that

adapted

current

a

complete

box,

connections

are

measurement

the

positive

the

of

for

test

now

unit

Fig.

16

testing

and

potential

description

reactor,

are

similar

included.

on

sequence

would

have

directicnal

and

As

ground

impedance

measure

of

to

been

circuits

the

test

the

noted

faults

under

After

is

RL+jXL

using

the

test

box

The

percent

close

its

where:

The

a

set

as

been

set

impedances

the

in

calibration

the

to

approximate

of

the

fault

portable

identified

at

above

test

the

who

/60°,

test

tap

contacts,

ZMU

ZL

0

the

600

at

equation

reactor

circuit

switch

setting

=

=

=

test

factory

sheet

the

unit

which

is

Ohmic

Test

Angle

by

and

600

at

been

has

exceeds

of

Fig.

to

SF

of

the

given

Tap

%

reach

impedance

of

reactor

a

calibration

n

conjunction

30

angles.

will

be

used,

is

impedance,

the

various

the

by

test

(Cat.

600.

set

the

18

(note

‘ON”

test

equation

Z

=

of

the

in

impedance

If

or

if

then

nominal

TEST

REACTOR

the

for

reach

setting

that

position

box

autotransfornier,

(12).

cos

(60

L

mho

ohms

No.

6054975)

curve

with

of

one

If

a

resistor-reactor

the

test

the

TAP

desired

current

and

-

unit

number

taps

the

reactor

actual

tap

of the

adjust

0)

(See

and

shown

on

60°

value

settings

TABLE

reach,

limiting

(100)

Equation

test

on

the

associated

impedance

used

is

of

are

VI

select

unit

by

impedance

the

selector

which

should

(12)

5

in

resistor

the nameplate.

values

tap

combination

with

should

0

given

value

of

the

a

smallest

test

amount

and

X

5

switches

cause

the

CHARACTERISTICS

(Cat.

No.

6158546)

The

reactor

test

thus

obtained

other

some

other

used

be

in

Table

non-inductive

in

VI.

ANGLE

impedance

R

5

is

to

obtain

starting

section).

test

resistor

to provide

is

than

equation

possible.

omitted),

a

unit

are

used

those

12.

at

balance

to

normally

taps

a

range

the

covered

resistance

The

600,

Then

turn

angle

that

the

point.

just

sold

have

of

9

by

angles

As

and

that

10

of

reach

equation

Using

reach

will

and

of

setting

just

an

is

the

5

illustration

has

been

67

percent

starting

in

the

typical

a

is

close

can

of

the

decided

above

to

determined

unit

its

at

CHARACTERISTICS

combination

ohms.

be

The

calculated

14.4

then

Tap

assume

the

set

in

the

600

section.

test

of

percent

6.68c00

24

12

6

3

2

1

0.5

example

angle

as

E

reactor

tap

follows

that

tap

of

of

the

on 45

in

the

maximum

and

the

from

-

600)

13

3

percent.

test

test

ohm

section

torque

resistor,

box

equation

(100)

basic

minimum

This

SAMPLE

will

autotransfornier

(12):

=

46.3

88°

87°

86°

85°

83°

81°

78°

reach

link

setting

setting

falls

within

CALCULATIONSOFSETTINGS.

be

600

6.68

ohms,

impedance

which

at

as

closest

the

then

the

is

to

limits

the

determined

above

who

unit

be

Ohmic

this

contacts

used

from

Page 14

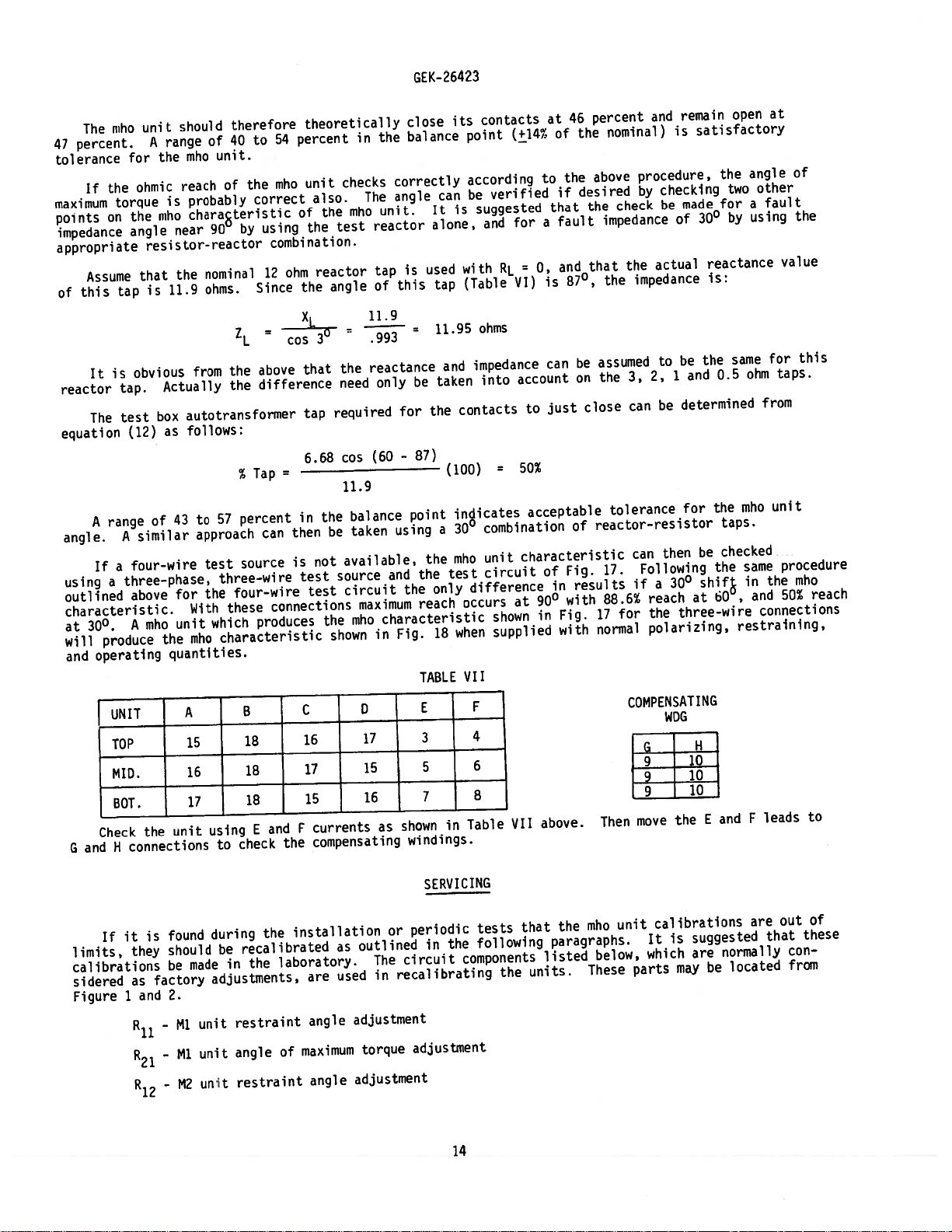

The

percent.

47

tolerance

the

If

maximum

points

on

impedance

appropriate

Assume

this

of

It

reactor

The

equation

A

range

angle.

If

using

outlined

characteristic.

3Q0

at

produce

will

operating

and

Check

and

G

unit

ruho

A

for

ohmic

torque

the

angle

resistor-reactor

that

is

tap

is

obvious

tap.

test

(12)

similar

A

four-wire

a

three-phase,

a

above

mho

A

UNIT

TOP

MID.

BOT.

the

connections

H

should

range

mho

the

reach

probably

is

chara8teristic

iiiho

near

the

11.9

from

Actually

autotransforrner

box

follows:

as

43

of

for

With

unit

mho

the

quantities.

A

15

16

17

unit

therefore

40

of

unit.

of

90

nominal

ohms.

the

the

57

to

approach

test

three-wire

four-wire

the

these

which

characteristic

using

to

to

the

correct

using

by

12

Since

=

above

difference

Tap

%

percent

can

source

produces

B

18

18

18

and

E

check

theoretically

54

percent

unit

rnho

also.

the

of

the

combination.

reactor

ohm

angle

the

X

1

30

cos

that

tap

6.68

=

the

in

be

then

not

is

test

test

connections

the

shown

C

16

17

15

currents

F

compensating

the

in

checks

The

niho

test

11.9

the

need

required

cos

11.9

balance

taken

available,

source

circuit

maximum

mho

D

17

15