Page 1

INSTRUCTION

S

GEK—45495

U

MHO

DISTANCE

TYPE

RELAY

CEY52B

GENERALS

ELECTRIC

Page 2

LsURJPTION

APF’L

(Al

I

I

ON

RATINGS

OPERATING

PRINCIPLES

CHARACT[RISEILS

BURDENS

LALCULA1

UONSTRUCT

RECEIVING,

ACLEPTANCE

ASTALLATION

iON

OF

ION

HANDLING

TESTS

PROCEDURE

INSPECTION

PLRIODIC

CHECKS

SERVICING

RENEWAL

PARTS

SETTINGS

AND

AND

ROUTINE

STORAGE

MAINTENANCE

GE

K-A

5495

CONTENTS

PAGE

3

3

2

4

5

7

7

N

8

9

11

14

14

15

17

‘S.)

to

C-)

CD

to

to

“S

Page 3

GE

K-4

54

95

The

designed

is

relay

testing.

dimensions

is

relay

not

been

The

itself,

relays

may

they

protection.

distance

When

that

tap

highest

Since

fault,

a

voltage

protection

The

CEYS2B

section

the

than

less

The

cycles

t

desired

the

back

A-B

as

adjust-nd

means

by

evuuj

u’ctfte’L

the

pu’tcha.ea’-

hIlt

,‘to

CEY52B

specifically

constructed

The

not

limited

C[Y52B

but

may

be

scheme

applying

will

possible

the

at

section

in

type

rating.

will

basic

of

determine

in

of

Thnie

sA6e

po

-ui1jo’tnri..tLon

Io

the

ucJi

relay

interndl

shown

are

intended

in

relay

rather

used

be

as

used

Figure

with

acconinodate

level

memory

the

relay

relay.

the

this

for

under

typical

a

entitled

percent.

25

CEY52

The

noted

be

minimum

relay

the

the

percent

one

autotransformer

utcton

con.tA,nqenc.y

pwtpoe,

oxteiit

asu.’utnce

three-phase,

is

a

use

for

three

of

connections

Figure

in

for

use

respect.

this

BASIC

TAPS

0.5

1.0

is

a

is

designed

a

step-distance

in

of

part

illustrates

4

CEX2OB

the

relay

this

the

of

torque.

action

should

not

The

contingency

CALCULATION

application.

TAPPED

covered

relay

minimum

basic

that

reach

(see

basic

steps

do

bi

de’u’,d

.‘LequL’ted

guJen

..a

MHO

TYPE

DESCRIPTION

speed,

high

the

with

single—phase

for

Typical

16.

first

a

as

MINIMUM

CEY52R

OF

-

1.0

—

-

2.0

-

three—phase,

to

be

high-speed

a

typical

CEX2OA

the

REACH

1.5

3.0

used

scheme

or

units

relay

external

function,

zone

single

with

to

pilot-relaying

external

relay.

the

the

relied

is

protection

reach

CLY52B

should

required.

SETTINGS

OF

Once

the

on

setting.

will

provide

to

be

settings

for

desired

of

be

protection

AUTO—TRANSFORMERS.

instructions

these

three

setting

Fig.

minimum

over

tap

pu.’tpo-’t-t

no.t

be

to

o.’

rnattc’t

the

the

w-tk

by

reach

basic

for

2).

setting

a

leads

met

I-touLd

p’wduc.ta

The

4/1

UL

hou.fd

‘tc.apee.t

and

minimum

each

position

range

the

on

eovciz.

-to

connec,tcon

pa.’ct

dci.eailied

adjustment

unit

of

the

tap

be

to

DiSTANCE

CEY52B

single-zone

CEX2OB

mounted

shown

are

connections

TABLE

ICATION

APPL

mho

zone

CEX2OA

a

provide

connections

given

a

of

This

be

only

supplemented

provides

have

Under

RATINGS

settings

reach

made

is

the

of

mho

any

for

blocks

detaiJs

aU

wLth

pitobfms

cithvi.

e1eived

eke4n

eode4

tocitf

RELAY

reactance

one

in

in

the

thus

I

distance

CEX208

or

zones

two

scheme

circuit,

will

effective

time-delay

worked

a

been

conditions,

no

available

is

ranges

by

two

units.

of

the

the

at

n-taitiou,

thc

to

rnec’-t

azid

directional

type

L2—D

Figure

to

transient,

SELECT

relay

in

to

insure

protection

other

by

example

calculated,

the

of

are

means

sets

The

basic

right

0L

aJLe

(cvtc’uct

appcaIit’e

icknanet’

relay.

case

10,

the

CEX

CEX2OA

CEX2OR

that

reactance

protection

of

addition

relay

the

select

that

several

for

devices

should

for

inho

listed

of

links

links,

of

ohmic

minimum

side

ope’Litu)e

wh{cJ!

with

while

relay

overreach

SHOWN

for

the

120

units

for

reach

of

aiz.C

distance

mho

See

provisions

outline

are

BELOW

is

not

type

providing

to

when

the

the

cycles

for

to

determining

taps

the

volts,

are

the

a

on

(for

of

reach

the

c2u.prnnnt

n

not

etsc

ANSI,

b1

cauc

Table

shown

characteristics

meant

relay.

against

is

it

highest

relay

after

fault

any

detect

are

restraint

5

given

mho

terminal

each

the

settings

relay.

miLtefltliIrc.

o’

cOvQYted

Conipanu.

1H

tlzoe

relay.

I.

for

panel

and

in

Figure

to

The

phase

step-distance

used

basic

operate

will

that

this

the

set

taps

amperes,

in

units.

board

unit),

inho

units

—--..____

no

IMA

a,id

oa-i

it

CEY52B

The

sirjle

drilling

used

be

combination

faults,

step-

a

in

minimum

inception

the

provides

condition

settings

described

as

ever

60

Table

Selection

located

each

can

listed

to

p4ovd

Lt?etif

ttz;

L’att’1.

WaS

phase

4.

The

have

by

or

at

be

50

or

II.

identified

be

Table

in

St(!Led

reach

the

zero

if

of

in

set

of

at

oi

OL

of

of

the

the

II

3

Page 4

BASIL

**MaxiIiluIli

CONTACTS

The

the

circuit

the

relay

REACH

-

1,0

0.5

1-2-3

*Adjustment

increase

contacts

breaker

contacts

TAPS

-

1.5

taps

torque

to

approximately

of

the

trip

have

are

angle

CEY52

circuit

no

interrupting

set

can

relay

BASIC

(ØN

using

be

120

must

MTN

OHMS)*

0.5

1.0

1.5

1

2

middle

adjusted

percent

will

be

rating.

REACH

close

opened

tap

up

of

and

by

GE

K-4

TABLE

r

at

the

to

75

its

carry

an

auxiliary

5495

II

RANGE

(0-N

OHMS)

0.5

-

1.0

-

1.5

-

1—4

2-8

3-

factory.

degrees.

reach

momentarily

at

2.0

4.0

6.0

The

the

switch

60

reach

degree

30

contact

ANGLE

MAX

TORQUE

600

600

60°

600

600

of

amperes

OF

**

**

**

**

**

the

setting.

direct

or

other

iriho

units

current.

suitable

ONE

RATING

150

150

150

150

150

will

SECOND

However,

means

since

TARGET

The

The

‘o:roduced

operating

The

se—tc-jhuse

Dr

entaq

tcr

we.

zhse-

to-phase

The

SEAL-IN

target

inum

nihc

units

ty

quantities.

sc[.emlii:

f

Th

Cl

torque

UNIT

Carry

Carry

Carry

0-C

60

the

c’

the

ux

ot

seal-in

Continuously

30

10

Resistance

Cycle

of

interaction

connections

tage,

5éiPi

in

the

taqe,

the

unit

TARGET

Operating

amps

amps

Impedance

the

CEY52

prodoce

priase

rear

interacts

balance

in

used

the

SEAL-IN

-

CEY52

UNIT

for

for

+lOt

relay

are

of

betweenapolarizing

of

-to-phasa

pole,

point

the

the

with

rho

gel

vo1tiçc

which

o

jr

arzinc

1.

the

the

relay

TABLE

0.2

AMP

0.2

amp

0.4

amp

0.03_=

0.25

7.0

ohms

52

ohms

OPERATING

the

four

flux

are

shown

t

iu

ntr

•nero1z:

nolan

wit

cc

car

has

ratings

III

TAP

sec.

PRINCIPLES

pole

induction

and

n

The

flu

s

iith

by

the

t

triereforo

i

fluxes

Fia

in

the

two

produce

.ne

as

0.6

0.6

1.5

0.5

4.0

0.6

6.0

.a.

the

polorizing

I

rxpr’.sed

shown

in

AMP

TAP

amp

amp

sec.

sec.

ohms

ohms

cylinder

proportional

Tue

two

front

currents

inc

operating

Table

—

construction

to

side

p010,

flux

associated

torque.

by

the

III.

0

2.0

3.5

4.0

30.0

0.13

0.53

the

poles,

which

produce

to

following

AMP

TAP

amp

amp

sec.

sec.

ohms

ohms

in

restraining

oneraized

is

energized

restrain

with

equation:

which

the

torque

or

by

by

seme

a

where:

Torque

=

0

E

phase-to—phase

I

=

delta

0

=

angle

=

power

0

K

=

design

El

of

factor

4

cos

current

maximum

constant

(0-9)

angle

-

voltage

1

torque

KE

2

(E12)

-

12)

of

the

unit

of

fault

impedance

Page 5

equation

GE

K—4

54

95

to

prove

that

the

reduces

equation

to:

defines

a

mho

characteristic

divide

both

sides

by

[2

and

transpo.e.

The

angle

MHO

UNIT

1.

setting

the

autotransformer

unit

through

unit

as

The

resulting

Ths

is

.

irec

Thus,

of

maximum

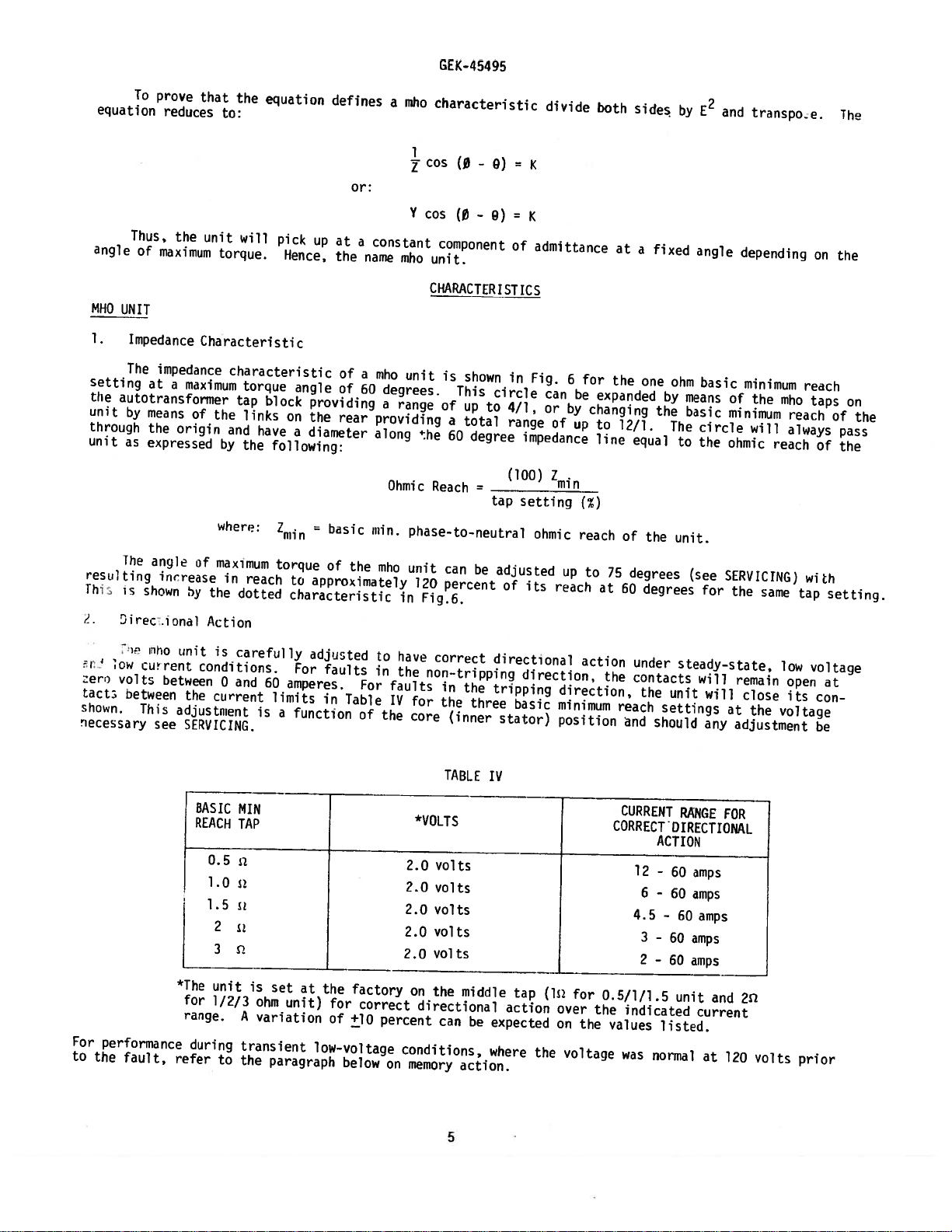

Impedance

The

impedance

at

by

means

the

expressed

angle

increase

shown

.iunal

the

Characteristic

maximum

a

of

origin

of

iy

unit

torque.

characteristic

the

and

by

where:

maximum

in

the

Action

will

torque

tap

links

the

reach

dotted

pick

Hence,

block

have

following:

2

njin

torque

up

at

the

of

angle

of

providing

on

the

rear

a

diameter

=

basic

of

to

approximately

characteristic

or:

a

a

60

the

constant

name

mho

degrees.

a

providing

along

Ohmic

mm.

mho

cos

(

Y

cos

(

component

mho

unit.

CHARACTER

unit

is

This

range

of

a

he

60

Reach

phase-to-neutral

unit

can

120

percent

in

Fig.6.

-

-

shown

up

total

degree

be

0)

B)

ISTICS

circle

to

tap

adjusted

of

K

K

of

admittance

in

Fig.

4/1

,

range

impedance

(lo0

setting

ohmic

its

can

or

of

z

reach

6

by

up

up

for

be

expanded

changing

to

line

()

reach

to

at

a

fixed

angle

depending

the

one

ohm

basic

by

means

the

12/1.

equal

of

75

degrees

at

60

The

the

degrees

basic

to

unit.

(see

of

minimum

circle

the

ohmic

SERVICING)

for

the

minimum

the

will

same

mho

reach

always

reach

reach

with

tap

on

taps

of

the

on

of

pass

the

setting.

the

:eri

tact:

shown.

‘tecessary

For

performance

to

the

low

volts

between

fault,

TihO

current

between

This

see

unit

is

conditions.

0

current

the

adjustment

SERVICING.

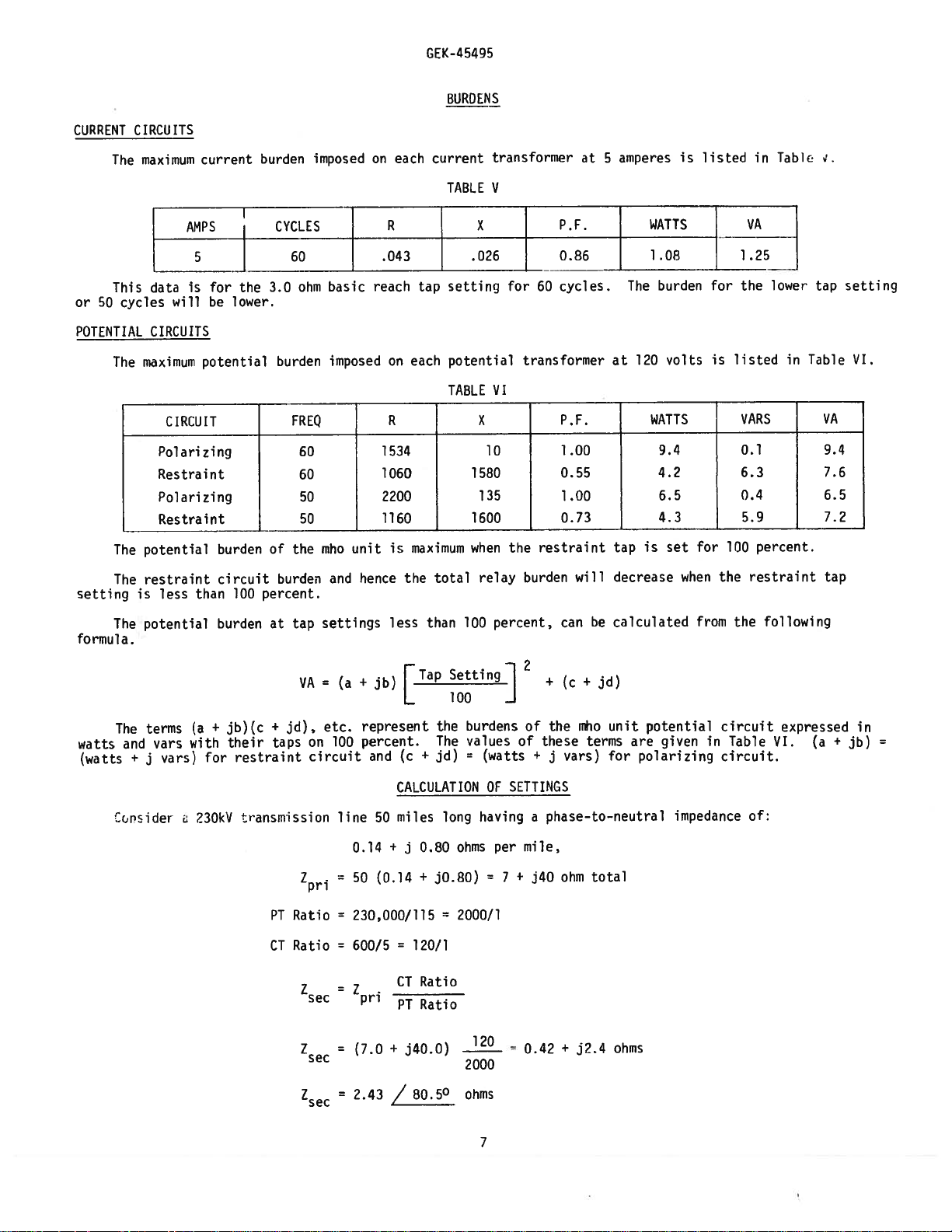

BASIC

REACH

1.0

1.5

2

*The

unit

for

1/2/3

range.

during

refer

to

carefully

and

60

is

MIN

TAP

i

is

ohm

A

variation

transient

the

adjusted

For

amperes.

limits

a

function

set

at

unit)

paragraph

faults

For

in

Table

of

the

factory

for

correct

of

+10

low-voltage

below

to

in

faults

IV

the

percent

on

have

correct

the

non-tripping

for

core

*VOLTS

2.0

vol

2.0

volts

2.0

volts

2.0

volts

volts

2.0

on

the

directional

can

conditions,

memory

in

the

the

(inner

TABLE

ts

middle

be

action.

three

IV

expected

where

directional

direction,

tripping

basic

stator)

tap

action

the

direction,

minimum

position

j_

(lii

over

on

voltage

action

under

the

contacts

the

reach

and

CURRENT

steady—state,

unit

settings

should

RANGE

CORRECTOIRECTIONAL

ACTION

12

-

60

6

-

60

4.5

-

60

3

—

60

2

-

60

for

the

0.5/1/1.5

the

indicated

values

was

unit

listed.

normal

will

will

any

amps

amps

amps

amps

amps

and

current

at

remain

close

at

the

adjustment

FOR

2

120

volts

low

open

its

voltage

prior

voltage

at

con

be

5

Page 6

3,

linderreach

t

LJICulat(d

miiInuI1

oi

,L:ing.

of

rig.

‘pHed.

hr

laul

4.

Memory

[he

polorizing

effective

be

nost

ri

ht

at

percent

zero

percent

the

memory

percent

The

cannot

is

delayed

application

depending

reduced

reach

liree

wirer

3

The

mis

t

dynamic

at

forcefully

time

of

action

tap

memory

be

relied

by

on

value.

settings.

dynamic

applied.

Action

flux

low

relay

its

of

setting

the

to

memory

voltaqe

This

ohmic

The

determined

curves

for

a

voltage

illustrated

bus

setting.

the

relay

is

will

action

on

if

zone

operate

action.

the

pullback

The

reach

itho

unit

curves

of

few

levels

and

Fig.

effective,

operate

will

the

2

setting

for

ohmic

unit

tap

will

by

tests

were

Fig.

cycles

therefore,

3

setting

close

tripping

nearby

value

or

reach

settings.

Operate

performed

obtained

illustrate

3

following

where

for

a

shows

regardless

Fig.

if

the

of

faults

reduction

it

zero

to

that

3

I3

contact

is

the

at

which

in

percent

Note

for

with

the

enables

voltage

protect

the

shows

is

greater

delayed.

type

and

all

with

the

who

of

that

for

RPM

there

GEK-45495

the

in

reach

of

that

points

no

full

effect

inception

the

fault

for

unit,

the

mho

than

only

When

relay,

will

niho

the

voltage

rated

who

this

tap

unit

the

unit

is

setting

fault

to

of

of

unit

by

under

setting.

1.6

a

short

the

be

shown

the

supplied

voltage

memory

the

referring

fault,

with

amperes.

relay

static

sufficient

will

is

plotted

current

right

fault.

to

operate

it

static

a

period

is

action

However,

three-ohm

operate

in

Fig.

against

scale

of

the

to

the

of

120

in

This

for

to

Fig.

is

imperative

conditions,

of

time

used,

as

characteristic

voltage

may

for

3

changes

volts

the

memory

low

3.

under

basic

a

be

curve.

relay

supplied

who

A

and

second

to

somewhat

the

1,

the

with

before

unit

action

fault

zero

that

will

dynamic

minimum

therefore,

should

give

lower

and

2

three—phase

the

The

steady-state

the

the

to

which

is

currents.

voltage

the

relay

not

see

conditions

reach

zone

relay

be

used.

tripping

than

3

ohm

fault

basic

fault

relay

maintains

particularly

This

fault

reach

fault

a

and

memory

and

without

the

basic

r,iniiuuw

curves

W.i

before

must

when

100

action

tripping

For

this

cur

the

can

be

zero

at

5.

Operating

The

setting

relay

fault.

rnho

TAPPED

operating

of

voltage

Time

taps

were

AUTO-TRANSOFRMERS

The

ohmic

auto-transformer

The

other

winding

The

necting

desired

the

subtracted

The

ale

tap

impedance

1:

neutral

:Xj

TAP

the

prior

curves

in

two

from

setting

SETTING

Time

time

unit,

the

reach

has

is

tap

windings

the

expressed

of

fault

to

the

are

given

100

of

the

two

windings.

tapped

setting

of

15-95

required

DESIRED

the

current

fault.

percent

(See

mho

at

the

percent

in

who

unit

magnitude,

The

for

four

position

Fig.

7)

units

may

One

percent,

0

is

made

by

auto-transformer.

winding.

to

protect

secondary

Tap

Setting

where:

=

91

is

curves

ratios

winding

the

a

terms,

0

9

determined

ratio

in

of

and

the

be

adjusted

1

percent,

proper

zone

(100)

=———

Power

Angle

Fig.

fault

angle

is

tapped

location

Note

Z

ohms

is

determined

(Mm.

factor

of

maximum

by

of

fault

8

impedance

by

percent

3

long,

a

are

of

means

in

that

Ohms

angle

number

impedance

for

the

maximum

of

10

percent

and

of

the

the

0—5

where

by

the

Setting)

of

fault

torque

of

to

torque

taps

5

leads

Z

of

factors

to

condition

relay

on

steps

percent.

marked

percent

is

positive

following

Cos

impedance

the

unit

relay

reach

was

the

winding

(—@)

such

as

reach,

of

rated

setting.

set

at

two

auto-transformers.

from

15

No.

1

may

phase

equation:

the

and

volts

60

degrees

percent

and

sequence

basic

magnitude

In

the

be

added

minimum

prior

all

lag.

to

jumper

phase-to-

to

cases,

95

or

reach

of

the

the

Each

percent.

con

cite

:xample

m,Nate

Set

Set

the

the

2:

one

4

TAP

one

4

end

percent

SETTING

end

percent

of

of

jumper

setting

DESIRED

jumper

setting

lead

of

lead

of

the

the

to

89

to

95

0—5

85

0-5

percent.

percent

percent.

percent

Set

winding

Set

winding

the

the

6

other

subtracts

other

adds

end

to

percent.

5

from

the

95

end

to

percent.

the

85

1

percent

to

percent

Set

setting.)

Set

No.

setting)

No.

1

to

1

percent.

1

to5percent.

Page 7

GEK-45495

BURDENS

CURRENT

CIRCUITS

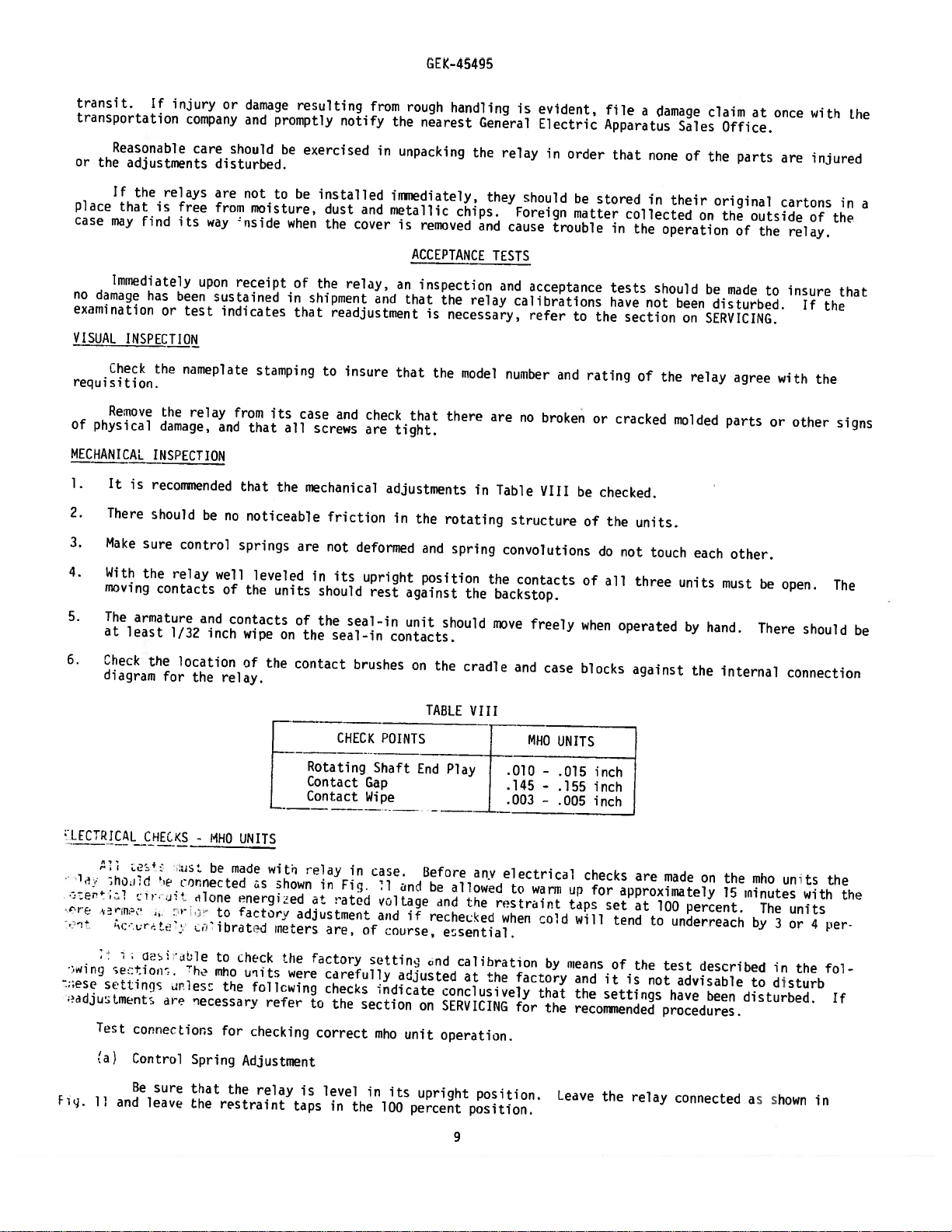

The

This

or

50

cycles

POTENTIAL

The

The

The

setting

maximum

data

will

CIRCUITS

maximum

CIRCUIT

Polarizing

Restraint

Polarizing

Restraint

potential

restraint

is

less

current

AMPS

5

is

for

be

potential

than

the

lower.

burden

circuit

100

burden

CYCLES

3.0

burden

of

burden

percent.

imposed

ohm

FREQ

60

60

50

50

the

basic

imposed

niho

and

unit

hence

on

R

.043

reach

on

R

1534

1060

2200

1160

each

each

is

maximum

the

current

tap

TABLE

setting

potential

TABLE

total

transformer

V

X

.026

VI

X

10

1580

35

1

1600

when

relay

for

60

transformer

restraint

the

burden

at

P.F.

0.86

cycles.

P.F.

1

.00

0.55

1.00

0.73

will

amperes

5

The

at

tap

decrease

WATTS

1.08

120

WATTS

is

is

burden

volts

9.4

4.2

6.5

4.3

set

when

listed

for

for

is

100

the

in

VA

1.25

the

lower

listed

VARS_—

0.1

6.3

0.4

5.9

percent.

restraint

Tah1€

in

.

tap

Table

VA

9.4

7.6

6.5

7.2

tap

setting

VI.

formula.

watts

(wattc

The

The

and

+

Tcride

potential

terms

vars

vars)

j

(a

with

230kv

burden

+

for

jb)(c

their

at

+

jd),

taps

restraint

transmission

PT

CT

tap

VA

Zpri

Ratio

Ratio

sec

z

settings

=

etc.

on

100

circuit

ec

+

jb)

(a

represent

percent.

and

line

50

0.14

=

50

(0.14

=

230,000/115

=

600/5

=

pri

=

than

less

rTap

L

(c

÷

Setting]

100

the

The

jd)

100

burdens

values

=

CALCULATION

long

miles

ohms

0.80

+

j

jO.80)

+

=

2000/1

=

120/1

CT

Ratio

PT

Ratio

+

j40.Q)

2000

(watts

OF

having

=

120

percent,

2

of

of

+

SETTINGS

a

nile,

per

7

+

j40

=

0.42

be

+

mho

terms

calculated

unit

are

for

+

the

these

j

can

(c

vars)

phase—to—neutral

ohm

total

j?.a

+

ohms

potential

given

polarizing

impedance

from

in

the

circuit

Table

circuit.

following

VI.

of:

expressed

(a

in

=

+

jb)

Zsec

=

2.43

80.5°

/

ohms

7

Page 8

GE

K-45495

Assume

is

it

this

For

given

The

both

at

case

the

connection

external

overlap

(see

brush

locking

leads

bottom

connections

cover,

mechanism

thick

insure

to

panel

the

drawn

‘abo1s

nagram

ito

a’

2.

minmJm

most

orotect

that

application

section

the

type

in

studs

plug

connections

circuit

the

when

contact

circuits.

relay

by

between

is

a

is

relay

appropriate

that

either

and

1

aid

tc

usea

in

Fip.

ralav

after

CEYS2

are

which

connections

mechanism

a

part

case

proper

replaced

icaludes

uesired,

*i

ends

Every

internal

make

The

terminated

and

which

The

and

separate

A

out

Pies.

The

wittrrisforrners

The

R23

The

he

hese

rio

ssed

reach

tap

removed

relays,

them

sub-a;seIHbly

in

car

blockS

against

CEY52

the

considering

the

under

relays

rear

the

made

and

in

connecting

as

at

the

guide

the

drawn

of

is

testing

from

2

show

identify

10.

settinq

oe

for

from

when

is

to

three-ohm

CHARACTERISTICS-

Percent

750

80.5°

are

external

for

inner

the

drawout

plug

Fig.

in

mounted

is

inner

the

at

respective

case

the

cover

can

plug

own

another

relay

the

=

Percent

Percent

assembled

block.

will

source

z

=

=

9

=

through

completes

the

indicated

pin

to

the

suitable

hardware

hardware

its

by

nircuit

similar

th’en

and

tap

includes

angle

tie

adjusted

from

changirg

to

case

its

included

not

damage.

Irnediately

used

be

effects

the

basic

3.54

stationary

circuits.

the

blocks

case

withdrawn

is

10)

Fig.

in

inasteel

back

blocks

by

assembly.

either

for

available.

is

be

which

removed

components

blocks

the

the

the

make

conjunction

in

of

minimum

TAPPED

Setting

Tap

Minimum

Setting

Tap

Setting

Tap

in

a

connections.

molded

have

an

has

on

and

with

9

cradle

This

of

the

of

thumbscrews,

semi—flush

included.

be

inserted

current

of

has

been

ro

are

suhassembi:

rho

mounted

i—pole

fOL

f

ma.’inlui

front

r;inioum

basic

the

settings.

RECEIVIND,

i

part

as

upon

with

infeed,

reach

CONSTRUCTION

deep

The

the

auxiliary

or

those

adequate

framework

case.

the

However,

in

place

and

its

the

to

setting

AUTO-TRANSFORMERS

(100)

=

Ohms

(100)

=

=

size,

large

electrical

The

and

inner

inserted.

is

cradle

holds

outer

terminals

circuits,

held

The

or

panel

blocks

brush,

pressure

called

connecting

and

the

surface

of

voltage,

tested

in

drawout

arie

Cienents

‘bc

or

back

or

the

inS

relay.

torce

of

reach

a

AND

control

of

HANDLING

of

receipt

a

set

(Mm.

3.0

(3.6)

outer

Some

firmly

case,

connecting

the

the

case

those

as

-‘

rrnostats

of

ne

STORAGE

panel,

relay,

a

CEX2OA

relay

the

should

ohms)

7

at

60

Cos

3.64

double-end

blocks

attached

for

the

shown

as

circuits

is

it

to

the

in

also

mounting

thickness

connecting

from

or

laboratory.

wth

which

mojntcd

the

ossoc

units

provide

to

to

used.

be

is

used.

Cos

deg.,

(80.5

connections

internal

in

especially

prevent

cradle

case

the

plug,

locks

plugs

must

plug

other

all

appear

on

cradle.

i

ated

,

811

are

will

examine

reach

(0—9)

3.6

75)

—

(L2D)

between

the

to

Fig.

are

the

and

besides

on

be

sources;

major

the

See

circuit

R2,

mounted

shipped

be

it

second

3.64

ohmic

The

75

at

drawout

between

which

case

connections.

to

9,

equipped

important

opening

isacomplete

latch

a

with

making

latch

the

in

place.

panels

all

indicated

test

to

components

the

an

front

Rj

05

cunipcnents.

used

813

on

in

any

for

/80.50

dog.

have

provide

the

or

of

the

zone

reach

case

the

nests

the

with

that

of

at

the

in

place.

The

up

on

relay

the

interncl

the

and

jr

back.

cartons

4

mage

protection

secondary

having

relay

a

studs

adequate

shorting

the

important

unit

both

electrical

target

two

to

the

relay

ider.ti

cradle

2

heostt.

settinj

sustained

equation,

units

removable

auxiliary

with

top

The

reset

inches

relay

in

place

ca

fiec

connection

ann

the

The

designed

studs

for

bars

inter

be

-

relay

and

ohms.

and

th’

all

and

order

on

a

basic

to

in

Page 9

GE

K-4

5495

transit.

transportation

Reasonable

or

the

adjustments

If

place

case

the

that

may

Immediately

no

damage

exwiination

ViSUAL

INSPECTION

Check

requisition.

Remove

of

physical

MECHANICAL

It

1.

2.

3.

4.

is

There

Make

With

moving

5.

The

armature

at

least

6.

Check

diagram

If

injury

company

care

relays

is

free

find

its

has

been

or

test

the

nameplate

the

relay

damage,

INSPECTION

recomended

should

sure

control

the

relay

contacts

1/32

the

location

for

the

or

disturbed.

are

from

way

upon

sustained

indicates

and

be

no

well

of

and

inch

relay.

damage

and

should

not

moisture,

nside

receipt

stamping

from

that

that

noticeable

springs

leveled

the

contacts

wipe

of

promptly

be

to

when

of

in

that

its

all

the

units

on

the

resulting

exercised

be

installed

dust

the

the

shipment

readjustment

to

case

screws

mechanical

friction

are

not

in

should

of

the

the

seal—in

contact

notify

relay,

insure

and

its

seal-in

from

in

and

cover

and

check

are

adjustments

deformed

upright

rest

brushes

rough

the

nearest

unpacking

ininediately,

metallic

is

removed

ACCEPTANCE

an

inspection

that

the

is

that

the

that

tight.

in

the

and

position

against

unit

should

contacts.

on

the

handling

General

the

chips.

and

relay

necessary,

model

there

in

rotating

spring

the

cradle

is

relay

they

should

Foreign

cause

TESTS

and

calibrations

number

are

no

Table

structure

convolutions

the

contacts

backstop.

move

and

evident,

Electric

in

order

be

matter

trouble

acceptance

refer

to

and

broken

VIII

freely

case

rating

or

be

of

of

when

blocks

file

Apparatus

that

stored

collected

in

tests

have

the

section

cracked

checked.

the

do

not

all

operated

a

damage

none

in

the

should

not

of

units.

touch

three

against

Sales

of

their

operation

been

on

the

relay

molded

each

units

by

the

claim

at

Office.

the

parts

original

on

the

outside

of

be

made

disturbed.

SERVICING.

agree

parts

other.

must

hand.

internal

once

the

to

or

be

There

with

are

injured

cartons

of

relay.

insure

If

with

the

other

open.

should

connection

the

in

the

that

signs

The

the

a

be

L[CRJCAL

1

a.•

s:er

1

•

r.r

rTJ-:’

wit-c

;ese

•idjtrnentc

Test

(a)

Fig.

11

sho

;etion-.

setiini

and

CHECKS

e:-

cernected

s’r

jt

.,.

r

ur

t.

r1ecs

re

connections

Control

Re

sure

leave

-

WHO

be

i1ane

or

to

ibratd

to

T

he

mho

necessarY

Spring

that

the

restraint

UNiTS

adde

energed

factory

check

uitc

the

follewing

for

checking

Adjustment

the

ss

relay

with

shown

meters

refer

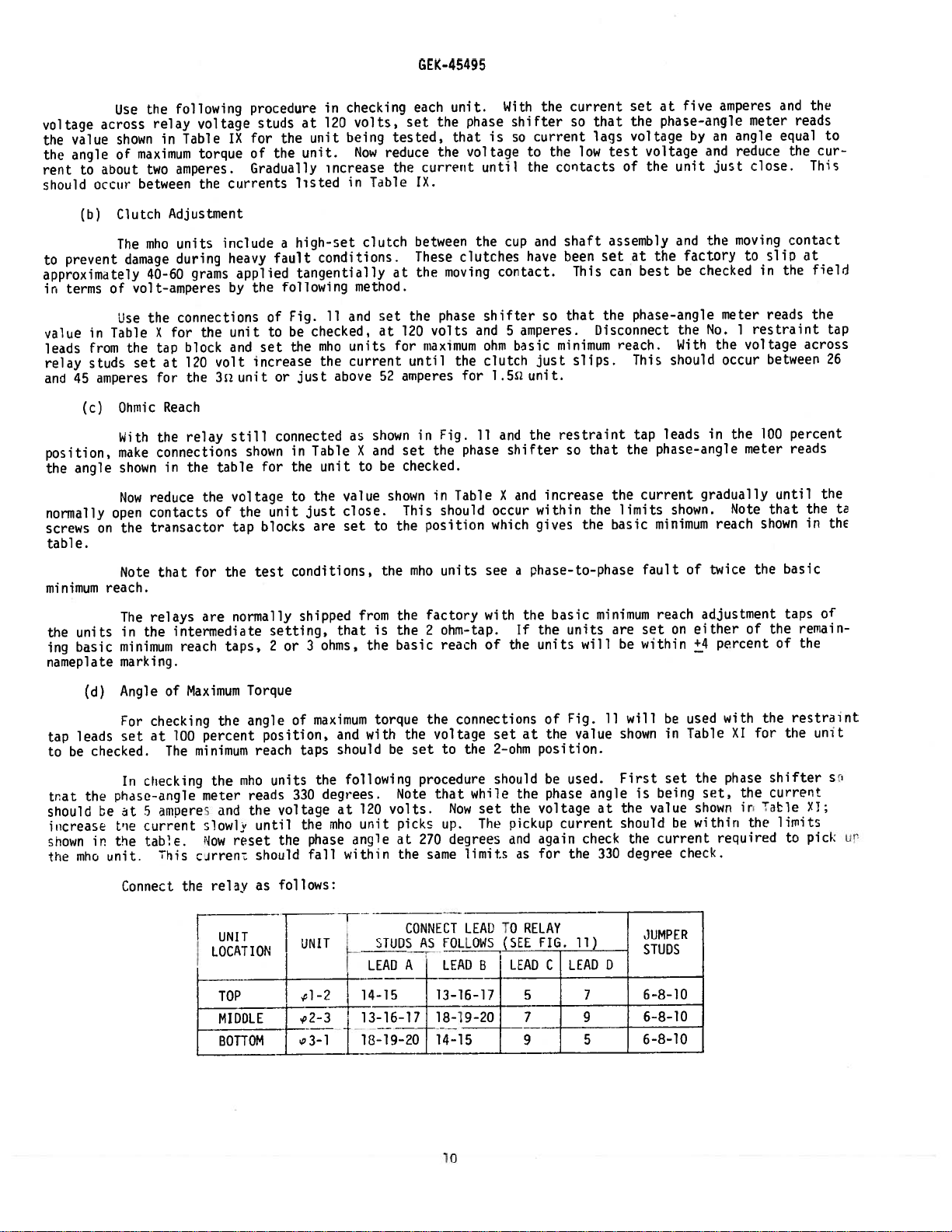

Rotating

Contact

Contact

adjustment

the

were

to

is

taps

e1a

in

at

are,

fctory

carafully

checks

the

correct

level

in

CHECK

in

Fig.

rateu

of

section

the

POINTS

Shaft

Gap

Wipe

case.

l

vcltiqe

and

:ovrse,

sOttinU

indicate

mho

in

its

100

TABLE

End

Before

an•

be

if

rechecied

Lnd

adjusted

on

unit

upright

percent

VIII

Play

f

I

____

any

allowed

and

the

esential

calibration

at

the

conclusively

SERVICING

operation.

position.

position.

9

MHO

.010

.145

.003

electrical

to

restraint

when

factory

for

-

-

-

warm

col

by

that

the

UNITS

.015

inch

.155

inch

.005

inch

checks

op

for

taps

a

will

means

and

the

settings

recommended

Leave

the

are

approximately

set

at

tend

to

of

the

it

is

not

relay

made

on

100

percent.

underreach

test

described

advisable

have

procedures.

connected

been

the

15

disturbed.

mho

minutes

The

by

in

to

disturb

as

shown

3

units

units

or

the

with

4

the

the

per

fol

If

in

Page 10

voltage

the

angle

the

rent

should

value

to

across

dbout

occur

Use

shown

of

following

the

relay

in

Table

maximum

amperes.

two

between

voltage

torque

the

procedure

studs

for

IX

of

Gradually

currents

the

the

at

unit

unit.

listed

checking

in

120

volts,

being

Now

increase

in

reduce

Table

GEK-45495

each

set

tested,

current:

the

IX.

the

the

unit.

that

phase

vol

until

is

taqe

With

shifter

so

the

current

to

the

current

so

the

contacts

low

that

lags

test

set

the

voltage

voltage

of

the

amperes

five

at

phase—angle

by

an

and

just

unit

meter

angle

reduce

close.

and

reads

equal

the

the

to

cur

This

(b)

prevent

to

approximately

of

terms

ii

in

45

Table

from

studs

amperes

value

leads

relay

and

(c)

position,

angle

the

normally

screws

open

on

table.

minimum

the

ing

reach.

units

basic

nameplate

Clutch

mho

Toe

damage

40-60

volt-amperes

ise

the

X

tap

the

set

for

Ohmic

the

With

connections

make

shown

reduce

Now

contacts

transactor

the

that

Note

relays

The

in

the

minimum

marking.

Adjustment

units

during

grads

connections

the

for

block

120

at

the

Reach

relay

the

in

the

for

are

intermediate

reach

include

heavy

applied

by

unit

and

volt

unit

3c

still

table

voltage

of

the

tap

the

normally

taps,

the

of

to

set

increase

shown

for

unit

blocks

test

setting,

2

high-set

a

conditions.

fault

tangentially

following

Fig.

be

checked,

the

just

or

connected

Table

in

the

the

to

just

are

conditions,

shipped

3

or

11

mho

the

above

unit

that

ohms,

clutch

method.

and

units

current

as

X

to

value

close.

set

from

set

at

52

shown

and

be

to

the

is

the

at

the

120

for

until

amperes

set

checked.

shown

This

the

mho

the

the

basic

between

These

the

moving

phase

volts

maximum

Fig.

in

the

in

should

position

units

factory

ohm-tap.

2

reach

the

clutches

and

ohm

the

for

11

phase

Table

cup

contact.

shifter

5

clutch

1

.5s2

and

shifter

X

occur

which

see

with

of

the

shaft

and

have

been

that

so

amperes.

minimum

basic

just

unit.

restraint

the

so

increase

and

within

gives

a

phase-to-phase

basic

the

units

the

If

units

set

This

Disconnect

slips.

that

the

the

minimum

will

assembly

at

can

phase—angle

the

reach.

This

tap

the

the

limits

basic

are

be

and

the

be

best

the

With

should

leads

phase-angle

current

shown.

minimum

fault

reach

on

set

within

the

factory

checked

No.

the

in the

gradually

reach

twice

of

adjustment

either

+4

percent

moving

meter

1

occur

Note

slip

to

in

reads

restraint

voltage

between

100

meter

that

shown

the

the

of

contact

the

percent

reads

until

basic

taps

of

at

field

the

across

the

the

in

of

remain

the

tap

26

tc

the

tap

be

to

tat

should

1’crease

cnown

the

(d)

leads

checked.

the

in

mhci

Angle

For

set

In

phase-angle

he

t

‘ie

the

unit

Connect

of

checking

100

at

The

ciecking

mDeres

5

current

table.

Tii

Maximum

the

percent

minimum

the

meter

and

s1owly

:10w

carren:

relay

the

UNIT

LOCATION

TOP

MIDDLE

bTTl

Torque

angle

mho

rcset

position,

reach

reads

the

until

should

as

of

units

330

voltage

the

follows:

F-

maximum

taps

the

degrees.

nho

the

phase

fall

3T

l-2

and

with

should

following

120

at

unit

angle

within

LEAD

14-15

13-16-17

1L-19-20

torque

the

be

Note

volts.

picks

at

the

CONNECT

TUDSA

A

the

voltage

set

to

procedure

that

Now

up.

degrees

270

same

.

LEAD

13—16-17

18-19-20

l4-15

connections

set

at

position.

2—ohm

the

should

while

the

the

pickup

and

as

LEAD

voltage

again

for

set

The

limits

LEAUTORELAY

.

B

7

9

of

the

be

phase

current

C

Fig.

value

used.

check

the

11)

LEAD

7

9

5

will

11

showninTable

First

is

angle

the

at

should

the

degree

330

JUMPER

STUDS

D

6-8-10

6-8-10

6-8-10

be

set

being

value

current

used

be

check.

the

set,

shown

within

with

XI

phase

the

ir

required

the

the

for

Table

restraint

the

shifter

currert

1

imits

to

unit

Yl;

pick

sc

u

in

Page 11

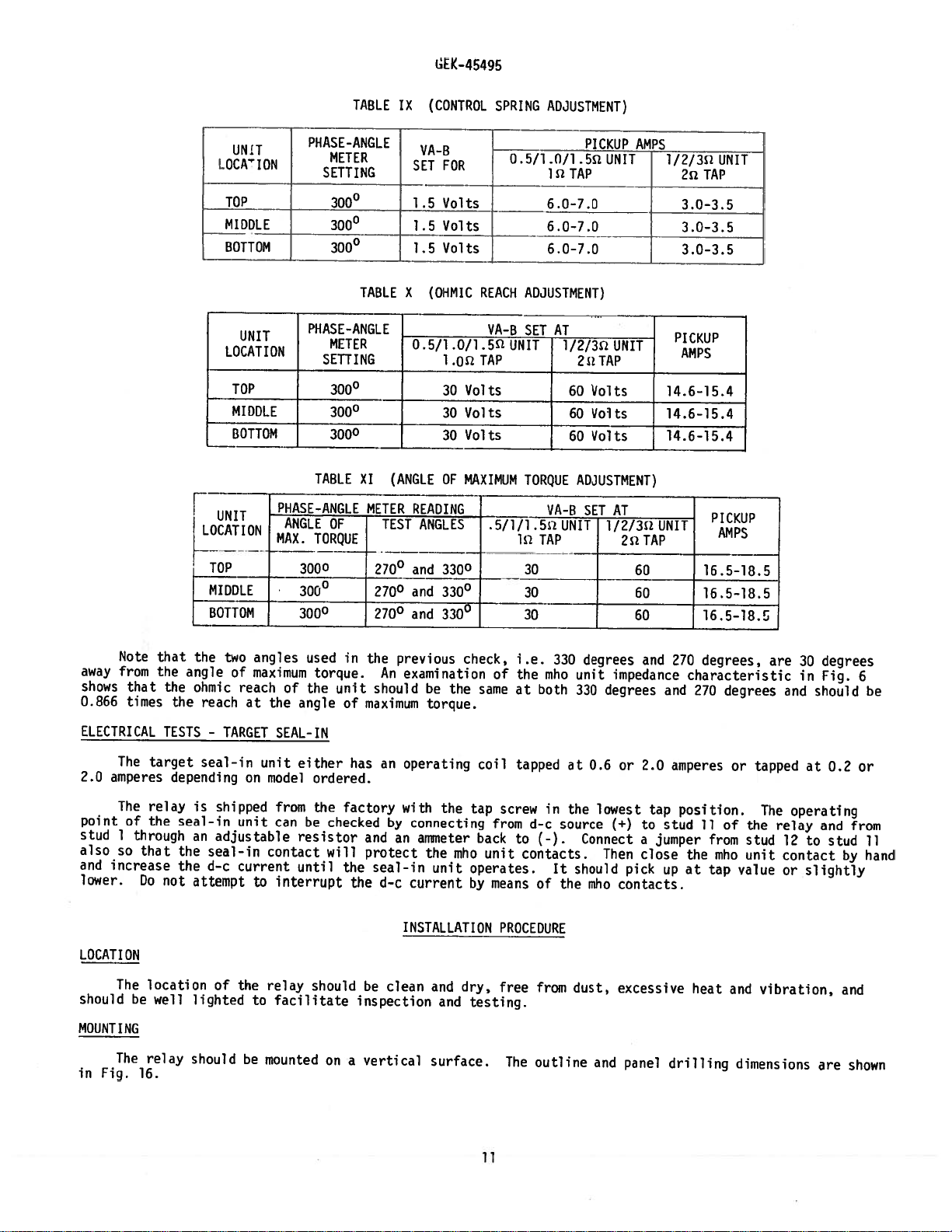

TABLE

IX

tEK-45495

(CONTROL

SPRING

ADJUSTMENT)

LOCAION

TOP

MIDDLE

BOTTOM

LOCATION

TOP

MIDDLE

BOTTOM

UNIT

LO

TION

TOP

MIDDLE

BOTTOM

PHASE-ANGLE

METER

SETTING

3000

3000

300°

PHASE-ANGLE

METER

SETTING_—

300°

300°

3000

TABLE

PHASEANGLE

ANGLE

MAX.

OF

TORQUE

3000

3000

3000

TABLE

(ANGLE

XI

METER

TEST

2700

270°

2700

SOR

1.5

Volts

Volts

1.5

Volts

1.5

(OHMIC

X

O.5/l.O/1.5c1UNIT

.oc

1

—

-

READING

Volts

30

Volts

30

Volts

30

OF

MAXIMUM

ANGLES

3300

and

3300

and

and

330°

-

O,5/l.O/L5c2UNIT

ADJUSTMENT)

REACH

VA-B

SET

TAP

TORQUE

1

.5sz

5/1/1

TAP

l

30

30

30

PICKUP

]iZTAP

6.0-7.0

6.0-7.0

6.0-7.0

AT

l/2/3cUNIT

2i2

TAP

Volts

60

60

Volts

Volts

60

ADJUSTMENT)

VA-H

SET

UNIT

AT

l/2/32

2s

AMPS

—

UNIT

TAP

60

60

60

l/2/3I2UNIT

22TAP

3.0-3.5

3.0-3.5

3.0-3.5

PICKUP

AMPS

14.6-15.4

14.6-15.4

14.6-15.4

AMPS

16.5-18.5

16.5-18.5

16.5-18.5

Note

away

from

shows

0.866

that

times

ELECTRICAL

target

The

2.0

amperes

The

of

1

through

so

that

increase

Do

relay

the

point

stud

also

and

lower.

LOCATION

The

The

location

be

relay

16.

should

MOUNTING

Fig.

in

that

the

the

the

TESTS

depending

seal-in

the

the

not

well

the

angle

ohmic

reach

—

seal-in

is

an

seal—in

d—c

attempt

lighted

should

two

angles

of

maximum

reach

at

TARGET

on

shipped

unit

adjustable

current

to

of

the

to

be

of

the

SEAL-IN

unit

model

from

can

contact

interrupt

relay

facilitate

mounted

used

torque.

the

angle

either

ordered.

the

be

resistor

will

until

should

on

in

unit

of

has

factory

checked

the

the

inspection

a

the

previous

An

examination

should

maximum

operating

an

with

by

connecting

and

an

protect

seal-in

current

d-c

INSTALLATION

be

clean

vertical

be

the

torque.

the

ammeter

the

ruho

unit

and

and

surface.

check,

same

coil

tap

back

unit

operates.

by

dry,

testing.

means

i.e.

the

at

330

mho

both

of

tapped

in

screw

from

d-c

source

to

(-).

contacts.

It

of

the

PROCEDURE

free

from

The

outline

degrees

unit

330

at

the

Connect

should

dust,

degrees

0.6

lowest

Then

reho

and

and

impedance

or

2.0

tap

(+)

to

jumper

a

close

pick

contacts.

excessive

panel

degrees,

270

characteristic

and

270

amperes

position.

stud

11

the

at

up

heat

drilling

degrees

or

of

from

mho

tap

and

are

and

tapped

The

the

relay

stud

12

unit

contact

value

or

vibration,

dimensions

degrees

30

in

Fig.

should

at

0.2

operating

and

stud

to

slightly

are

from

by

and

shown

6

be

or

11

hand

11

Page 12

CONNECTIONS

internal

The

external

connections

connections

shown

is

45495

GEK

typical

Fig.

10.

CEY52B

the

of

Fig.

in

relay

4.

in

shown

are

elementary

An

diagram

of

VISJL

INSPECTION

Remove

screws

all

MECHANiCAL

Recheck

To

from

TEST

eliminate

In

PORTABLE

units

mended.

impedance

fault

the

+

may

jX[

RL

is

enough

Fo

as

user

necessary

convenience

ri

relays.

the

is

This

with

arranged

distaece

well

the

ELECTRLAL

manner

The

OF

SETTINGS

To

of

have

check

purpose

which

portable

according

plugs

connections

matic

Use

is

necessary

normally

.isually

be

especially

suitable

Since

i

desirable

difference

selected

taken

being

Fig.

From

relay

the

tight.

are

INSPECTION

six

the

EQUIPMENT

the

single-phase

a

figure

this

line

the

of

switch

be

and

made

since

so

taps

a

portable

The

and

line

referred

ON

TESTS

in

section.

electrical

the

made

been

the

reactor,

test

to

the

source

of

only

considered

necessary

a

when

be

value

reactance

the

check

to

between

12

be

of

tie

it

is

should

from

adjustments

errors

RS

section

line

appear

to

it

that

field

in

test

box

source

GEI—38977.

to

MHO

THE

which

Examples

for

calibration

Cat.

14.

Fig.

in

shown

iinpedanceR

5

if

the

necessary

in

with

unit

for

used

mho

line

the

test

the

difference

seen

case

its

which

test

a-c

jX

5

+

for

impedance,

to

is

not

combination

the

testing,

box,

provided

is

impedances

UNITS

settings

reach

of

tests

particular

a

of

No.

These

Fig.

relay

at

source

the

short

this

the

of

unit

reactance,

reactor

in

twice

that

and

mentioned

may

source,

the

is

which

is

the

feasible

Cat.

calculations

this

in

mho

the

6054975;

connections

except

13

÷

be

to

is

the

connection

reach

purpose

test

pickup

tap

angle

the

check

result

source

the

tapped

relay

may

the

No.

with

may

are

line

jX5,

tested

time

setting

since

reactor

with

XL,

nearest

of

relay

that

under

from

the

relay

very

provide

to

be

fault

lO2L2Ol,

terminals

be

made

section

section.

units,

test

and

that

simulating

installation

of

may

the

and

the

reach

there

Mechanical

instrument

circuit

test

impedance,

being

is

10

percent

in

nearly

made

switch

which

readily

for

typical

for

check

to

is

it

resistor,

the

of

type

the

overreach

for

limit

to

is

to

will

this

be

fault

unit

mho

above

reactor

test

of

are

as

the

match

to

and

is

which

to

connecd.

mho

tae

suggested

test

XLA

the

current

be

tend

very

reactor

angle

twice

the

broken

no

Inspection

inaccuracies

shown

iS

SF

tested.

dnd

actual

the

portable

any

tapped

particularly

the

units

settings

ohmic

the

Cat.

and

box

test

conditions

or

during

or

checked,

to

accurately

alone,

of

the

tap

angle

or

in

in

schematic

fault

the

The

percent

1

line

test

line.

autotransformer

relay

For

a

is

are

pickup

the

that

6158546

No.

other

connections

plug

which

contact

periodic

and

limit

the

fault

it

harmonics

in

determined

due

maximum

unit

mho

impedance

of

the

cracked

section

the

to

and

form

switch,

autotransformer

so

steps

which

on

reactor

adapted

current

XL

for

and

complete

of

discussed

in

the

briefly

given

portable

arranged

be

equipment

would

coordination,

testing.

circuit

suggested

is

in

from

account

being

reach.

phase-to-neutral

the

and

reactor

test

component

on

permit

Fig.

in

and

RL

TA,

that

the

the

and

Fig.

of

testing

potential

description

section.

that

units

mho

box,

test

similar

are

now

are

encountered

be

tests

Some

a

to

that

the

its

taken

line

The

angle

unit

impedance

and

parts

ACCEPTANCE

13

jXL

which

test

13

line

is

have

the

recom

is

the

is

is

impedance

to

resistor

testing

+

the

relay

directional

circuits

the

of

CALCULATION

the

in

It

the

at

No.

Cat.

Type

with

to

included.

in

which

impedance

reasonable

reactor

a

current.

fault

calibration

the

of

reactance,

with

reach

maximum

of

is:

that

TESTS.

mho

across

be

been

test

the

is

settings

102L201;

XLA

the

practice,

are

value,

of

curve,

angular

XL,

account

used.

and

as

box

test

sche

not

will

it

reach.

unit

To

illustrete

that

has

been

by

where:

an

factory

Relay

22

example

adjusted

Z

Mm.

let

200

0=

9=

us

to

Tap

the

mho

basic

=

consider

pickup

Setting

angle

unit

minimum

at

of

angle

the

%

percent

three

12

Cos

the

of

reach

ohms

(0—0)

test

maximum

of

tap

minimum

reactor

mho

required

reach

units

impedance

on

at

and

test

the

maximum

a

autotransformer

box

torque

angle

for

of

Page 13

60

degrees.

reactor

impedance

In

impedance

is:

determining

is

8’)

deos.

2Z

the

relay

reactor

From

=

200X

the

tap

setting

above,

cos

GEK-45495

to

twice

(80-60)

use,

the

it

nay

be

relay

=

5.64

assumed

reach

ohms

that

the

at

angle

the

angle

of

the

of

(0)

test-reactor

th

te’.

Therefore,

should

degrees.

From

fore,

The

the

exact

assume

impedance

From

particular

1-

and

be

recalculated

The

the

calibration

reactance

that

of

this

reactor

0.5-ohm

table

above

the

this

calculation

taps.

use

the

b.

table

curve

of

reactance

tap

tap.

using

ow

the

may

reactor

shows

it

is

2Z

relay

for

6-ohm

is

6.1

be

calculated

-

ZL

-

it

Actually

the

sin

is

6-ohm

the

seen

the

ohms.

XL

seen

actual

=

portable

tap

86

the

tap.

angles

TAP

24

12

6

3

2

0.5

that

200X

at

the

Since

as

-

6.1

.9976

that

difference

angle

the

follows:

the

Twice

of

for

angle

cos

test

current

the

-

6

-

reactance

the

each

(86-60)

reactor

angle

115

need

the

relay

reactor

of

ANGLE

88

87

86

85

83

81

78

of

level

only

the

the

=

should

being

of

and

reach

tap

reactor

impedance

5.4

ohms

again

used.

the

impedance

the

be

taken

at

the

impedance

taps.

COS

0-60

0.883

0.891

0.899

0.906

0.921

0.934

0.951

of

be

impedance

into

angle

the

referred

For

of

account

rather

6-ohm

the

the

may

of

tap

to

purpose

6-ohm

be

assumed

on

test

than

the

in

tap

reactor

the

is

order

of

reactor

86

this

is

the

impedance

assumed

degrees.

to

illustration

86

degrees,

same

3-,

80

There

determine

for

this

2-,

the

closed

istic

angle

brated

in

degrees

30

bra

which

former

where

degree,

case

mately

The

Ficj.

is

If

of

such

‘legree

ed

‘ives

9

of

10

test

is:

13

not

the

the

test

manner

a

and

positions.

test

the

percent

is

the

30-degree

the

previous

amperes

box

autotransforrner

should

off

the

ohmic

pickup

characteristic

resistor

that

30

degrees

resistor

exact

tap

for

angle

or

to

%

be

checked

calculated

of

in

combination

when

used

respectively

The

inho

alone

as

impedance

pickup

%

Tap

of

maximum

zero-degree

tests,

flow

in

=---

the

is

the

the

(100)

to

value

mho

correct.

with

unit

the

and

at

a

torque

impedance

load

fault

tap

setting

=

determine

because

unit

with

12-

will

ohmic

line

impedance.

angle

particular

of

box

circuit

88.5%

checks

The

various

and

be

reach

for

the

value

which

required

(use

that

of

correctly

angle

reactor

6-ohm

available

at

each

angle

unit,

taken

serves

when

the

low

may,

the

The

of

0

the

to

88%

Tap)

test

current.

however,

taps

for

zero-degree

calibrated

the

is

given

is

the

from

as

source

fault

13

close

current

according

taps.

of

the

The

specified

checking

combinations

by:

angle

the

calibrated

impedance

switch

the

used

be

the

position

test

of

mho-unit

is

to

the

very

easily

calibrated

rnho

resistor

available.

the

test

should

is

closed.

high

above,

test

unit

may

resistor

contacts

enough

the

checked

test

reactor,

reach

be

checked

is

supplied

The

impedance

be

with

so

chances

by

resistor

at

test-box

data

adjusted

the

that

the

are

using

taps

impedances

the

60

by

using

with

Z

(ZL),

sheet.

to

allow

fault

character

that

the

are

at

degree

the

a

data

autotrans

is

the

As

in

switch

the

cali

pre-set

60

and

cali

sheet

60-

the

approxi

Page 14

When

becomes

the

at

apparent

checking

relatively

zero-degree

error

in

the

large

position

reach.

mho

unit

with

at

phase-angle

that

a

angles

two

GEK-4

5495

of

more

error.

or

three

This

degree

than

30

is

error

degrees

apparent

in

off

phase

from

the

Fig.

angle

maximum

12

where

will

reach

cause

position,

it

is

considerably

a

seen,

the

for

error

example,

INSPECTION

uni

ts.

cover

MHO

contact

lower

screw.

the

in

the

the

by

sary

value

reach

can

plug.

are

is

into

Before

The

armature

There

The

target

the

on

UNITS

There

should

There

jewel

If

there

bottom

jewel

All

nuts

The

felt

Determine

relay,

reduce

to

found

of

the

A

shorter

be

accomplished

All

Replace

away

from

the

placing

should

relay.

should

should

screw

of

screw.

checks

mho

units

the

station

should

just

is

the

and

gasket

the

the

the

test

should

lower

the

a

and

be

a

be

no

return

be

approximately

bearing

reason

unit

screws

on

impedance

tap

tap

with

unit

which

by

station

bus,

relay

into

contacts

screw

in

reset

promptly

noti

ceable

to

should

believe

to

and

examined.

should

the

cover

and

value

at

setting

the

calculated

low

at

currents.

will

disconnecting

have

strong

plug

and

bus

and

the

resultant

of

only

the