Page 1

GE

LISTED

52TL

IND.CONT. EQ.

E83849

IISO 9001

G

N

E

I

L

M

I

U

T

L

T

E

S

I

R

G

E

E

D

R

Grid Solutions

B90

Low Impedance Bus Differential

System

Instruction Manual

Product version: 7.6x

GE publication code: 1601-0115-AF1 (GEK-130992)

1601-0115-AF1

Page 2

Copyright © 2017 GE Multilin Inc. All rights reserved.

B90 Low Impedance Bus Differential System Instruction Manual for version 7.6x.

B90, FlexLogic, FlexElement, FlexCurve, FlexAnalog, FlexInteger, FlexState, EnerVista,

CyberSentry, HardFiber, Multilin, and GE Multilin are trademarks or registered trademarks

of GE Multilin Inc.

The contents of this manual are the property of GE Multilin Inc. This documentation is

furnished on license and may not be reproduced in whole or in part without the permission

of GE Multilin. The content of this manual is for informational use only and is subject to

change without notice.

Part number: 1601-0115-AF1 (June 2017)

Page 3

B90 Low Impedance Bus Differential System

Table of contents

1INTRODUCTION 1.1 Safety symbols and definitions ........................................................................... 1-1

1.1.1 General cautions and warnings.................................................................................... 1-1

1.2 For further assistance........................................................................................... 1-2

2PRODUCT

DESCRIPTION

2.1 Product description ............................................................................................... 2-1

2.2 Security .................................................................................................................... 2-4

2.3 Order codes............................................................................................................. 2-7

2.3.1 Replacement modules.....................................................................................................2-12

2.4 Signal processing.................................................................................................2-13

2.4.1 UR signal processing ........................................................................................................2-13

2.5 Specifications........................................................................................................ 2-15

2.5.1 Protection elements..........................................................................................................2-16

2.5.2 User-programmable elements ....................................................................................2-17

2.5.3 Monitoring..............................................................................................................................2-18

2.5.4 Metering..................................................................................................................................2-19

2.5.5 Inputs.......................................................................................................................................2-19

2.5.6 Power supply........................................................................................................................2-20

2.5.7 Outputs....................................................................................................................................2-21

2.5.8 Communications ................................................................................................................2-23

2.5.9 Inter-relay communications..........................................................................................2-24

2.5.10 CyberSentry security.........................................................................................................2-25

2.5.11 Graphical front panel........................................................................................................2-25

2.5.12 Environmental......................................................................................................................2-26

2.5.13 Type tests...............................................................................................................................2-27

2.5.14 Production tests..................................................................................................................2-27

2.5.15 Approvals ...............................................................................................................................2-28

2.5.16 Maintenance.........................................................................................................................2-28

3 INSTALLATION 3.1 Unpack and inspect ............................................................................................... 3-1

3.2 Panel cutouts.......................................................................................................... 3-2

3.2.1 Rear terminal layout ........................................................................................................... 3-5

3.3 Wiring.......................................................................................................................3-7

3.3.1 Typical wiring ......................................................................................................................... 3-7

3.3.2 Dielectric strength..............................................................................................................3-13

B90 LOW IMPEDANCE BUS DIFFERENTIAL SYSTEM – INSTRUCTION MANUAL iii

Page 4

TABLE OF CONTENTS

3.3.3 Control power......................................................................................................................3-13

3.3.4 CT and VT modules............................................................................................................3-14

3.3.5 Contact inputs and outputs.......................................................................................... 3-15

3.3.6 RS232 port.............................................................................................................................3-26

3.3.7 CPU communication ports ............................................................................................3-27

3.3.8 IRIG-B.......................................................................................................................................3-29

3.4 Direct input and output communications .......................................................3-30

3.4.1 Description............................................................................................................................3-30

3.4.2 Fiber: LED and ELED transmitters............................................................................... 3-33

3.4.3 Fiber laser transmitters...................................................................................................3-33

3.4.4 G.703 interface....................................................................................................................3-34

3.4.5 RS422 interface................................................................................................................... 3-38

3.4.6 RS422 and fiber interface ..............................................................................................3-40

3.4.7 G.703 and fiber interface................................................................................................3-41

3.4.8 IEEE C37.94 interface.......................................................................................................3-41

3.4.9 C37.94SM interface...........................................................................................................3-44

3.5 Activate relay ........................................................................................................3-47

3.6 Install software.....................................................................................................3-48

3.6.1 EnerVista communication overview......................................................................... 3-48

3.6.2 System requirements....................................................................................................... 3-49

3.6.3 Install software....................................................................................................................3-50

3.7 Add device to software........................................................................................3-51

3.7.1 Set IP address in UR.......................................................................................................... 3-51

3.7.2 Configure serial connection..........................................................................................3-56

3.7.3 Configure Ethernet connection................................................................................... 3-57

3.7.4 Configure modem connection.....................................................................................3-59

3.7.5 Automatic discovery of UR devices...........................................................................3-59

3.8 Connect to the B90...............................................................................................3-60

3.8.1 Connect to the B90 in EnerVista .................................................................................3-60

3.8.2 Use Quick Connect via the front panel RS232 port............................................ 3-61

3.8.3 Use Quick Connect via a rear Ethernet port..........................................................3-62

3.9 Set up CyberSentry and change default password........................................3-63

3.10 Import settings .....................................................................................................3-63

3.11 Connect to D400 gateway...................................................................................3-64

3.11.1 Oscillography files.............................................................................................................. 3-64

3.11.2 Event records.......................................................................................................................3-64

3.11.3 Log files...................................................................................................................................3-64

3.11.4 Setting files............................................................................................................................3-65

4INTERFACES 4.1 EnerVista software interface................................................................................4-1

4.1.1 Introduction.............................................................................................................................4-1

4.1.2 Settings files ............................................................................................................................4-1

4.1.3 Event viewing..........................................................................................................................4-2

4.1.4 File support..............................................................................................................................4-3

4.1.5 EnerVista main window.....................................................................................................4-3

4.1.6 Protection summary window..........................................................................................4-4

4.1.7 Settings templates................................................................................................................4-5

4.1.8 Secure and lock FlexLogic equations..........................................................................4-9

4.1.9 Settings file traceability...................................................................................................4-12

4.2 Front panel interface ...........................................................................................4-14

4.2.1 Front panel............................................................................................................................4-14

4.2.2 Front panel display............................................................................................................ 4-16

4.2.3 Front panel navigation keys .........................................................................................4-37

4.2.4 LED indicators......................................................................................................................4-39

4.2.5 Front panel labelling.........................................................................................................4-43

iv B90 LOW IMPEDANCE BUS DIFFERENTIAL SYSTEM – INSTRUCTION MANUAL

Page 5

TABLE OF CONTENTS

4.2.6 Menu navigation.................................................................................................................4-50

4.2.7 Change settings..................................................................................................................4-52

4.2.8 View actual values.............................................................................................................4-57

4.2.9 Change passwords............................................................................................................4-58

4.2.10 Invalid password entry ....................................................................................................4-60

4.3 Logic diagrams.....................................................................................................4-60

4.4 FlexLogic design using Engineer .......................................................................4-61

4.4.1 Design logic...........................................................................................................................4-63

4.4.2 Send file to and from device .........................................................................................4-73

4.4.3 Monitor logic .........................................................................................................................4-74

4.4.4 View front panel and print labels................................................................................4-75

4.4.5 Generate connectivity report........................................................................................4-76

4.4.6 Preferences...........................................................................................................................4-76

4.4.7 Toolbars..................................................................................................................................4-80

5 SETTINGS 5.1 Settings menu......................................................................................................... 5-1

5.2 Overview.................................................................................................................. 5-3

5.2.1 Introduction to elements .................................................................................................. 5-3

5.3 Product setup.......................................................................................................... 5-5

5.3.1 B90 function............................................................................................................................ 5-5

5.3.2 Security ..................................................................................................................................... 5-5

5.3.3 Display properties..............................................................................................................5-23

5.3.4 Graphical front panel........................................................................................................5-24

5.3.5 Clear relay records.............................................................................................................5-36

5.3.6 Communications ................................................................................................................5-37

5.3.7 Modbus user map..............................................................................................................5-99

5.3.8 Real-time clock....................................................................................................................5-99

5.3.9 User-programmable fault report.............................................................................5-104

5.3.10 Oscillography..................................................................................................................... 5-105

5.3.11 User-programmable LEDs ..........................................................................................5-107

5.3.12 User-programmable self-tests .................................................................................5-111

5.3.13 Control pushbuttons......................................................................................................5-112

5.3.14 User-programmable pushbuttons..........................................................................5-113

5.3.15 Flex state parameters ...................................................................................................5-119

5.3.16 User-definable displays................................................................................................ 5-120

5.3.17 Direct inputs and outputs............................................................................................5-122

5.3.18 Installation.......................................................................................................................... 5-128

5.4 System setup.......................................................................................................5-129

5.4.1 AC inputs .............................................................................................................................5-129

5.4.2 Power system.................................................................................................................... 5-129

5.4.3 FlexCurves...........................................................................................................................5-130

5.4.4 Bus..........................................................................................................................................5-137

5.5 FlexLogic ..............................................................................................................5-139

5.5.1 FlexLogic operands ........................................................................................................ 5-139

5.5.2 FlexLogic rules..................................................................................................................5-147

5.5.3 FlexLogic evaluation......................................................................................................5-147

5.5.4 FlexLogic example ..........................................................................................................5-148

5.5.5 FlexLogic equation editor............................................................................................ 5-153

5.5.6 FlexLogic timers...............................................................................................................5-153

5.5.7 Non-volatile latches.......................................................................................................5-153

5.6 Grouped elements..............................................................................................5-154

5.6.1 Overview..............................................................................................................................5-154

5.6.2 Setting group 1.................................................................................................................5-154

5.6.3 Bus differential..................................................................................................................5-155

5.6.4 Breaker failure (ANSI 50BF).........................................................................................5-160

B90 LOW IMPEDANCE BUS DIFFERENTIAL SYSTEM – INSTRUCTION MANUAL v

Page 6

TABLE OF CONTENTS

5.6.5 Voltage elements............................................................................................................ 5-168

5.6.6 Current elements ............................................................................................................ 5-169

5.6.7 End fault protection.......................................................................................................5-176

5.7 Control elements ............................................................................................... 5-179

5.7.1 Overview ............................................................................................................................. 5-179

5.7.2 Trip bus ................................................................................................................................5-179

5.7.3 Setting groups.................................................................................................................. 5-181

5.7.4 Digital elements...............................................................................................................5-182

5.7.5 Monitoring elements ..................................................................................................... 5-185

5.8 Inputs/outputs ................................................................................................... 5-190

5.8.1 Contact inputs.................................................................................................................. 5-190

5.8.2 Virtual inputs..................................................................................................................... 5-192

5.8.3 Contact outputs...............................................................................................................5-193

5.8.4 Virtual outputs.................................................................................................................. 5-196

5.8.5 Resetting............................................................................................................................. 5-196

5.8.6 Direct inputs and outputs........................................................................................... 5-197

5.9 Testing................................................................................................................. 5-201

5.9.1 Test mode function........................................................................................................ 5-201

5.9.2 Test mode forcing........................................................................................................... 5-202

5.9.3 Force contact inputs ..................................................................................................... 5-202

5.9.4 Force contact outputs.................................................................................................. 5-203

6 ACTUAL VALUES 6.1 Actual Values menu ...............................................................................................6-1

6.2 Front panel...............................................................................................................6-2

6.3 Status........................................................................................................................6-3

6.3.1 Contact inputs........................................................................................................................6-3

6.3.2 Virtual inputs...........................................................................................................................6-3

6.3.3 RxGOOSE boolean inputs..................................................................................................6-4

6.3.4 RxGOOSE DPS inputs ...........................................................................................................6-4

6.3.5 Contact outputs.....................................................................................................................6-4

6.3.6 Virtual outputs........................................................................................................................6-4

6.3.7 RxGOOSE status.....................................................................................................................6-5

6.3.8 RxGOOSE statistics...............................................................................................................6-5

6.3.9 Flex States................................................................................................................................6-6

6.3.10 Ethernet.....................................................................................................................................6-6

6.3.11 Real time clock synchronizing.........................................................................................6-6

6.3.12 Direct inputs ............................................................................................................................6-7

6.3.13 Direct devices status...........................................................................................................6-7

6.3.14 Remaining connection status .........................................................................................6-8

6.3.15 Parallel Redundancy Protocol (PRP) .............................................................................6-8

6.3.16 TxGOOSE status.....................................................................................................................6-9

6.4 Metering...................................................................................................................6-9

6.4.1 Metering conventions.........................................................................................................6-9

6.4.2 Bus zone.................................................................................................................................6-10

6.4.3 Currents ..................................................................................................................................6-10

6.4.4 Voltages..................................................................................................................................6-11

6.4.5 Frequency.............................................................................................................................. 6-11

6.4.6 RxGOOSE analogs.............................................................................................................. 6-11

6.5 Records...................................................................................................................6-11

6.5.1 User-programmable fault reports ............................................................................. 6-11

6.5.2 Event records.......................................................................................................................6-12

6.5.3 Oscillography....................................................................................................................... 6-13

6.6 Product information.............................................................................................6-14

6.6.1 Model information.............................................................................................................6-14

6.6.2 Firmware revisions............................................................................................................6-14

vi B90 LOW IMPEDANCE BUS DIFFERENTIAL SYSTEM – INSTRUCTION MANUAL

Page 7

TABLE OF CONTENTS

7 COMMANDS AND

TARGETS

8 APPLICATION OF

SETTINGS

7.1 Commands menu................................................................................................... 7-1

7.1.1 Virtual inputs........................................................................................................................... 7-2

7.1.2 Clear records.......................................................................................................................... 7-2

7.1.3 Set date and time.................................................................................................................7-2

7.1.4 Relay maintenance.............................................................................................................. 7-3

7.1.5 Security ..................................................................................................................................... 7-4

7.2 Targets menu.......................................................................................................... 7-4

7.2.1 Target messages.................................................................................................................. 7-5

7.2.2 Relay self-tests ......................................................................................................................7-5

8.1 Overview.................................................................................................................. 8-1

8.1.1 Introduction............................................................................................................................. 8-1

8.1.2 Sample busbar and data.................................................................................................. 8-1

8.2 Zoning and dynamic bus replica ......................................................................... 8-3

8.2.1 North bus zone ...................................................................................................................... 8-3

8.2.2 South bus zone...................................................................................................................... 8-4

8.3 Biased characteristic breakpoints...................................................................... 8-5

8.3.1 Description .............................................................................................................................. 8-5

8.3.2 High breakpoint .................................................................................................................... 8-5

8.3.3 Low breakpoint...................................................................................................................... 8-6

8.4 Slopes and high set threshold ............................................................................. 8-6

8.4.1 Description .............................................................................................................................. 8-6

8.4.2 External faults on C-1......................................................................................................... 8-7

8.4.3 External faults on C-2......................................................................................................... 8-9

8.4.4 External faults on C-3......................................................................................................... 8-9

8.4.5 External faults on C-4.......................................................................................................8-10

8.4.6 External faults on C-5.......................................................................................................8-10

8.5 Bus differential settings......................................................................................8-10

8.5.1 Description ............................................................................................................................8-10

8.6 Enhancing relay performance...........................................................................8-11

8.6.1 Using setting groups.........................................................................................................8-11

9 THEORY OF

OPERATION

9.1 Introduction ............................................................................................................ 9-1

9.1.1 Bus differential protection................................................................................................9-1

9.2 Dynamic bus replica.............................................................................................. 9-3

9.2.1 Dynamic bus replica mechanism................................................................................. 9-3

9.2.2 CT ratio matching................................................................................................................. 9-3

9.3 Differential principle.............................................................................................. 9-3

9.3.1 Biased differential characteristic.................................................................................. 9-3

9.3.2 Differential and restraining currents........................................................................... 9-4

9.3.3 Enhanced security ............................................................................................................... 9-5

9.4 Directional principle.............................................................................................. 9-6

9.4.1 Current directional protection........................................................................................ 9-6

9.5 Saturation detector ............................................................................................... 9-7

9.5.1 CT saturation detection..................................................................................................... 9-7

9.6 Output logic and examples .................................................................................. 9-9

9.6.1 Output logic............................................................................................................................. 9-9

9.6.2 Internal and external fault example..........................................................................9-10

10 MAINTENANCE 10.1 Monitoring ............................................................................................................. 10-1

10.1.1 Devices with Site Targets................................................................................................10-1

10.1.2 Data with Modbus Analyzer ..........................................................................................10-1

B90 LOW IMPEDANCE BUS DIFFERENTIAL SYSTEM – INSTRUCTION MANUAL vii

Page 8

TABLE OF CONTENTS

10.2 General maintenance ..........................................................................................10-3

10.2.1 In-service maintenance..................................................................................................10-3

10.2.2 Out-of-service maintenance ........................................................................................10-3

10.2.3 Unscheduled maintenance (system interruption) ..............................................10-3

10.3 Retrieve files ..........................................................................................................10-3

10.3.1 CyberSentry security event files..................................................................................10-4

10.4 Convert device settings.......................................................................................10-5

10.5 Copy settings to other device ............................................................................10-7

10.6 Compare settings .................................................................................................10-7

10.6.1 Compare against defaults .............................................................................................10-7

10.6.2 Compare two devices ...................................................................................................... 10-8

10.7 Back up and restore settings .............................................................................10-8

10.7.1 Back up settings ................................................................................................................. 10-8

10.7.2 Restore settings............................................................................................................... 10-11

10.8 Upgrade software.............................................................................................. 10-13

10.9 Upgrade firmware ............................................................................................. 10-13

10.10 Replace front panel ........................................................................................... 10-15

10.11 Replace module ................................................................................................. 10-23

10.12 Battery ................................................................................................................. 10-24

10.12.1 Replace battery for SH/SL power supply ............................................................. 10-24

10.12.2 Dispose of battery ..........................................................................................................10-26

10.13 Clear files and data after uninstall ................................................................ 10-29

10.14 Repairs................................................................................................................. 10-29

10.15 Storage ................................................................................................................ 10-30

10.16 Disposal ............................................................................................................... 10-30

AFLEXANALOG

A.1 FlexAnalog items ................................................................................................... A-1

OPERANDS

B RADIUS SERVER

B.1 RADIUS server configuration ................................................................................B-1

CONFIGURATION

C COMMAND LINE

C.1 Command line interface ....................................................................................... C-1

INTERFACE

D MISCELLANEOUS D.1 Warranty ................................................................................................................. D-1

D.2 Revision history .....................................................................................................D-1

ABBREVIATIONS

INDEX

viii B90 LOW IMPEDANCE BUS DIFFERENTIAL SYSTEM – INSTRUCTION MANUAL

Page 9

B90 Low Impedance Bus Differential System

Chapter 1: Introduction

Introduction

This chapter outlines safety and technical support information.

1.1 Safety symbols and definitions

Before attempting to install or use the device, review all safety indicators in this document to help prevent injury,

equipment damage, or downtime.

The following safety and equipment symbols are used in this document.

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

Indicates practices not related to personal injury.

1.1.1 General cautions and warnings

The following general safety precautions and warnings apply.

Ensure that all connections to the product are correct so as to avoid accidental risk of shock

and/or fire, for example such as can arise from high voltage connected to low voltage terminals.

Follow the requirements of this manual, including adequate wiring size and type, terminal torque settings, voltage,

current magnitudes applied, and adequate isolation/clearance in external wiring from high to low voltage circuits.

Use the device only for its intended purpose and application.

Ensure that all ground paths are uncompromised for safety purposes during device operation and service.

Ensure that the control power applied to the device, the alternating current (AC), and voltage input match the ratings

specified on the relay nameplate. Do not apply current or voltage in excess of the specified limits.

B90 LOW IMPEDANCE BUS DIFFERENTIAL SYSTEM – INSTRUCTION MANUAL 1-1

Page 10

1

FOR FURTHER ASSISTANCE CHAPTER 1: INTRODUCTION

Only qualified personnel are to operate the device. Such personnel must be thoroughly familiar with all safety

cautions and warnings in this manual and with applicable country, regional, utility, and plant safety regulations.

Hazardous voltages can exist in the power supply and at the device connection to current transformers, voltage

transformers, control, and test circuit terminals. Make sure all sources of such voltages are isolated prior to

attempting work on the device.

Hazardous voltages can exist when opening the secondary circuits of live current transformers. Make sure that

current transformer secondary circuits are shorted out before making or removing any connection to the current

transformer (CT) input terminals of the device.

For tests with secondary test equipment, ensure that no other sources of voltages or currents are connected to such

equipment and that trip and close commands to the circuit breakers or other switching apparatus are isolated,

unless this is required by the test procedure and is specified by appropriate utility/plant procedure.

When the device is used to control primary equipment, such as circuit breakers, isolators, and other switching

apparatus, all control circuits from the device to the primary equipment must be isolated while personnel are working

on or around this primary equipment to prevent any inadvertent command from this device.

Use an external disconnect to isolate the mains voltage supply.

Personal safety can be affected if the product is physically modified by the end user. Modifications to the product

outside of recommended wiring configuration, hardware, or programming boundaries is not recommended end-use

practice. Product disassembly and repairs are not permitted. All service needs to be conducted by the factory.

LED transmitters are classified as IEC 60825-1 Accessible Emission Limit (AEL) Class 1M. Class 1M

devices are considered safe to the unaided eye. Do not view directly with optical instruments.

This product is rated to Class A emissions levels and is to be used in Utility, Substation Industrial

environments. Not to be used near electronic devices rated for Class B levels.

1.2 For further assistance

For product support, contact the information and call center as follows:

GE Grid Solutions

650 Markland Street

Markham, Ontario

Canada L6C 0M1

Worldwide telephone: +1 905 927 7070

Europe/Middle East/Africa telephone: +34 94 485 88 54

North America toll-free: 1 800 547 8629

Fax: +1 905 927 5098

Worldwide e-mail: multilin.tech@ge.com

Europe e-mail: multilin.tech.euro@ge.com

Website: http://www.gegridsolutions.com/multilin

When contacting GE by e-mail, optionally include a device information file, which is generated in the EnerVista software by

clicking the Service Report button. When using the optional graphical front panel, the report instead can be generated by

connecting a USB drive to the front panel.

1-2 B90 LOW IMPEDANCE BUS DIFFERENTIAL SYSTEM – INSTRUCTION MANUAL

Page 11

CHAPTER 1: INTRODUCTION FOR FURTHER ASSISTANCE

Figure 1-1: Generate service report in EnerVista software

1

B90 LOW IMPEDANCE BUS DIFFERENTIAL SYSTEM – INSTRUCTION MANUAL 1-3

Page 12

1

FOR FURTHER ASSISTANCE CHAPTER 1: INTRODUCTION

1-4 B90 LOW IMPEDANCE BUS DIFFERENTIAL SYSTEM – INSTRUCTION MANUAL

Page 13

B90 Low Impedance Bus Differential System

Chapter 2: Product description

Product description

This chapter outlines the product, order codes, and specifications.

2.1 Product description

The B90 Low Impedance Bus Differential System is a microprocessor-based architecture that provides protection and

metering for busbars with up to 24 feeders. The B90 protection system is a centralized architecture built on one B90 IED as

per requirements of a particular application. The IED is a full-featured B90 and as such can be accessed and programmed

individually. Protection and supervisory functions of the B90 include:

• Multi-zone differential protection with both restrained (percent, biased) and unrestrained (unbiased, instantaneous)

functions incorporated. Differential protection is fast (typical response time: ¾ of a power cycle; maximum response

time: 1 power cycle) and secure. Security is achieved by using fast and reliable CT saturation detection algorithm and

a second, phase comparison operating principle.

• Check-zone functionality is provided by programming one of the differential zones to enclose the entire bus

• Dynamic bus replica functionality and multi-zone protection allowing application of the B90 to multi-section reconfigurable busbars

• Isolator monitoring feature monitors up to 48 isolators from the B90 IED

• End fault protection (dead zone protection) is provided for up to 24 breakers

• CT trouble monitoring function is provided for each zone of differential protection

• Breaker fail function is provided for up to 24 breakers

• An instantaneous overcurrent function is available per each current input of the B90 system

• A time overcurrent function is available per each current input of the B90 system for backup protection

• An undervoltage function is provided per each voltage input of the B90 system for supervision purposes

Voltage and current metering is built into the relay as a standard feature. Current parameters are available as total

waveform RMS magnitude, or as fundamental frequency only RMS magnitude and angle (phasor).

Diagnostic features include an event recorder capable of storing 1024 time-tagged events and oscillography capable of

storing up to 64 records with programmable trigger, content, and sampling rate. The internal clock used for time-tagging

can be synchronized with an IRIG-B signal, using the Simple Network Time Protocol (SNTP) over the Ethernet port, or using

the Precision Time Protocol (PTP). This precise time stamping allows the sequence of events to be determined between the

B90 IEDs and throughout the system. Events can also be programmed (via FlexLogic

data capture that can be set to record the measured parameters before and after the event for viewing on a computer.

These tools significantly reduce troubleshooting time and simplify report generation in the event of a system fault.

™

equations) to trigger oscillography

B90 LOW IMPEDANCE BUS DIFFERENTIAL SYSTEM – INSTRUCTION MANUAL 2-1

Page 14

2

PRODUCT DESCRIPTION CHAPTER 2: PRODUCT DESCRIPTION

Several options are available for communication. An RS232 port (USB port with the graphical front panel) can be used to

connect to a computer for the programming of settings and the monitoring of actual values. The rear RS485 port allows

independent access by operating and engineering staff. It can be connected to system computers with baud rates up to

115.2 kbps. All serial ports use the Modbus RTU protocol. The IEC 60870-5-103 protocol is supported on the RS485

interface. IEC 60870-5-103, DNP, and Modbus cannot be enabled simultaneously on this interface. Also only one of the

DNP, IEC 60870-5-103, and IEC 60870-5-104 protocols can be enabled at any time on the relay. When the IEC 60870-5-103

protocol is chosen, the RS485 port has a fixed even parity and the baud rate can be either 9.6 kbps or 19.2 kbps. The

100Base-FX or 100Base-TX Ethernet interface provides fast, reliable communications in noisy environments. The Ethernet

port supports IEC 61850, Modbus/TCP, TFTP, and PTP (according to IEEE Std. 1588-2008 or IEC 61588), and it allows access

to the relay via any standard web browser (B90 web pages). The IEC 60870-5-104 protocol is supported on the Ethernet

port. The Ethernet port also supports the Parallel Redundancy Protocol (PRP) of IEC 62439-3 (clause 4, 2012) when

purchased as an option.

Secure Routable GOOSE (R-GOOSE) is supported with software options.

Settings and actual values can be accessed from the front panel or EnerVista software.

The B90 uses flash memory technology that allows field upgrading as new features are added. Firmware and software are

upgradable.

The following single-line diagram illustrates the relay functionality using American National Standards Institute (ANSI)

device numbers.

The available zones of differential protection and their size (maximum number of inputs) are optional and

controlled by the software option portion of the order code. The breaker failure function is also optional. See

the ordering section for information on the maximum number of zones and inputs for a given model. In

addition, different applications can require differing numbers of B90s with different hardware configurations.

Table 2-1: ANSI device numbers and functions supported

Device

number

27 Undervoltage 51 Time overcurrent

50 Instantaneous overcurrent 50BF Breaker failure

50/74 CT trouble 50EF End fault protection

50/87 Unrestrained bus differential

Function Device

number

Function

2-2 B90 LOW IMPEDANCE BUS DIFFERENTIAL SYSTEM – INSTRUCTION MANUAL

Page 15

CHAPTER 2: PRODUCT DESCRIPTION PRODUCT DESCRIPTION

Figure 2-1: Single-line diagram

2

Table 2-2: Other device functions

Function Function

Contact inputs (up to 120 per IED) Modbus communications

Contact outputs (up to 72 per IED) Modbus user map

Control pushbuttons Non-volatile latches

CyberSentry™ security Oscillography

Digital elements (48 per IED) Setting groups (6)

Direct inputs and outputs (256) Time synchronization over IRIG-B or IEEE 1588

DNP 3.0 or IEC 60870-5-104 communications Time synchronization over SNTP

Dynamic bus replica User definable displays

End fault protection User-programmable fault reports

Event recorder User-programmable LEDs

B90 LOW IMPEDANCE BUS DIFFERENTIAL SYSTEM – INSTRUCTION MANUAL 2-3

Page 16

2

SECURITY CHAPTER 2: PRODUCT DESCRIPTION

Function Function

IEC 60870-5-103 communications User-programmable pushbuttons

FlexLogic equations User-programmable self-tests

IEC 61850 communications Virtual inputs (64 per IED)

IEC 62351-9 data and communications security Virtual outputs (96 per IED)

Metering: current, voltage, frequency

2.2 Security

The following security features are available:

• Password security — Basic security present by default

• EnerVista security — Role-based access to various EnerVista software screens and configuration elements. The

feature is present by default in the EnerVista software.

• CyberSentry security — Advanced security available using a software option. When purchased, the option is

automatically enabled, and the default Password security and EnerVista security are disabled.

2.2.0.1 EnerVista security

The EnerVista security management system is a role-based access control (RBAC) system that allows an administrator to

manage the privileges of multiple users. This allows for access control of UR devices by multiple personnel within a

substation and conforms to the principles of RBAC as defined in ANSI INCITS 359-2004. The EnerVista security

management system is disabled by default to allow the administrator direct access to the EnerVista software after

installation. It is recommended that security be enabled before placing the device in service.

Basic password or enhanced CyberSentry security applies, depending on purchase.

2.2.0.2 Password security

Password security is a basic security feature present by default.

Two levels of password security are provided: command and setting. Use of a password for each level controls whether

users can enter commands and/or change settings.

The B90 supports password entry from a local or remote connection. Local access is defined as any access to settings or

commands via the front panel interface. This includes both keypad entry and the through the front panel RS232 port.

Remote access is defined as any access to settings or commands via any rear communications port. This includes both

Ethernet and RS485 connections. Any changes to the local or remote passwords enables this functionality.

When entering a settings or command password via EnerVista or any serial interface, the user must enter the

corresponding connection password. If the connection is to the back of the B90, the remote password must be used. If the

connection is to the RS232 port of the front panel, the local password applies.

Password access events are logged in the Event Recorder.

2.2.0.3 CyberSentry security

CyberSentry embedded security is available using software options that provide advanced security services. When an

option is purchased, the basic password security is disabled automatically.

CyberSentry provides security through the following features:

• An Authentication, Authorization, Accounting (AAA) Remote Authentication Dial-In User Service (RADIUS) client that is

centrally managed, enables user attribution, provides accounting of all user activities, and uses secure standardsbased strong cryptography for authentication and credential protection

• A Role-Based Access Control (RBAC) system that provides a permission model that allows access to UR device

operations and configurations based on specific roles and individual user accounts configured on the AAA server (that

is, Administrator, Supervisor, Engineer, Operator, Observer roles)

2-4 B90 LOW IMPEDANCE BUS DIFFERENTIAL SYSTEM – INSTRUCTION MANUAL

Page 17

CHAPTER 2: PRODUCT DESCRIPTION SECURITY

• Security event reporting through the Syslog protocol for supporting Security Information Event Management (SIEM)

systems for centralized cybersecurity monitoring

• Strong encryption of all access and configuration network messages between the EnerVista software and UR devices

using the Secure Shell (SSH) protocol, the Advanced Encryption Standard (AES), and 128-bit keys in Galois Counter

Mode (GCM) as specified in the U.S. National Security Agency Suite B extension for SSH and approved by the National

Institute of Standards and Technology (NIST) FIPS-140-2 standards for cryptographic systems

CyberSentry user roles

CyberSentry user roles (Administrator, Engineer, Operator, Supervisor, Observer) limit the levels of access to various UR

device functions. This means that the EnerVista software allows for access to functionality based on the user’s logged in

role.

Example: Administrative functions can be segmented away from common operator functions, or engineering type access,

all of which are defined by separate roles (see figure) so that access of UR devices by multiple personnel within a

substation is allowed.

One role of one type is allowed to be logged in at a time. For example, one Operator can be logged in but not a second

Operator at the same time. This prevents subsets of settings from being changed at the same time.

Figure 2-2: CyberSentry user roles

The table lists user roles and their corresponding capabilities.

2

Table 2-3: Permissions by user role for CyberSentry

Roles Administrator Engineer Operator Supervisor Observer

Complete access Complete access

Device Definition R R R R R

Settings

|---------- Product Setup

|--------------- Security

(CyberSentry)

|--------------- Supervisory See table notes R R See table

|--------------- Display Properties RW RW R R R

|--------------- Clear Relay Records

(settings)

|--------------- Communications RW RW R R R

|--------------- Modbus User Map RW RW R R R

|--------------- Real Time Clock RW RW R R R

|--------------- Oscillography RW RW R R R

B90 LOW IMPEDANCE BUS DIFFERENTIAL SYSTEM – INSTRUCTION MANUAL 2-5

RW R R R R

RW RW R R R

except for

CyberSentry

Security

Command

menu

Authorizes

writing

notes

Default role

R

Page 18

2

SECURITY CHAPTER 2: PRODUCT DESCRIPTION

Roles Administrator Engineer Operator Supervisor Observer

|--------------- Data Logger RW RW R R R

|--------------- Demand RW RW R R R

|--------------- User-Programmable

LEDs

|--------------- User-Programmable

Self Tests

|--------------- Control Pushbuttons RW RW R R R

|--------------- User-Programmable

Pushbuttons

|--------------- Flex state

Parameters

|--------------- User-Definable

Displays

|--------------- Direct I/O RW RW R R R

|--------------- Teleprotection RW RW R R R

|--------------- Installation RW RW R R R

|---------- System Setup RW RW R R R

|---------- FlexLogic RW RW R R R

|---------- Grouped Elements RW RW R R R

|---------- Control Elements RW RW R R R

|---------- Inputs / Outputs RW RW R R R

|--------------- Contact Inputs RW RW R R R

|--------------- Contact Input

threshold

|--------------- Virtual Inputs RW RW R R R

|--------------- Contact Outputs RW RW R R R

|--------------- Virtual Outputs RW RW R R R

|--------------- Resetting RW RW R R R

|--------------- Direct Inputs RW RW R R R

|--------------- Direct Outputs RW RW R R R

|--------------- Teleprotection RW RW R R R

|--------------- Direct Analogs RW RW R R R

|--------------- Direct Integers RW RW R R R

|---------- Transducer I/O RW RW R R R

|---------- Testing RW RW R R R

|---------- Front Panel Labels Designer NA NA NA NA NA

|---------- Protection Summary NA NA NA NA NA

Commands RW RW RW R R

|---------- Virtual Inputs RW RW RW R R

|---------- Clear Records RW RW RW R R

|---------- Set Date and Time RW RW RW R R

User Displays R R R R R

Targets R R R R R

Actual Values R R R R R

|---------- Front panel labels designer R R R R R

|---------- Status R R R R R

|---------- Metering R R R R R

|---------- Transducer I/O R R R R R

RW RW R R R

RW RW R R R

RW RW R R R

RW RW R R R

RW RW R R R

RW RW R R R

2-6 B90 LOW IMPEDANCE BUS DIFFERENTIAL SYSTEM – INSTRUCTION MANUAL

Page 19

CHAPTER 2: PRODUCT DESCRIPTION ORDER CODES

Roles Administrator Engineer Operator Supervisor Observer

|---------- Records R R R R R

|---------- Product Info R R R R R

Maintenance RW RW R R R

|---------- Modbus Analyzer NA NA NA NA NA

|---------- Change front panel RW RW RW R R

|---------- Update firmware Yes No No No No

|---------- Retrieve file Yes No No No No

Table Notes:

RW = read and write access

R = read access

Supervisor = RW (default), Administrator = R (default), Administrator = RW (only if Supervisor role is disabled)

NA = the permission is not enforced by CyberSentry security

CyberSentry user authentication

The following types of authentication are supported by CyberSentry to access the UR device:

• Device Authentication (local UR device authenticates)

• Server Authentication (RADIUS server authenticates)

The EnerVista software allows access to functionality that is determined by the user role, which comes either from the local

UR device or the RADIUS server.

The EnerVista software has a device authentication option on the login screen for accessing the UR device. When the

"Device" button is selected, the UR uses its local authentication database and not the RADIUS server to authenticate the

user. In this case, it uses its built-in roles (Administrator, Engineer, Supervisor, Observer, Operator, or Administrator and

Supervisor when Device Authentication is disabled) as login names and the associated passwords are stored on the UR

device. As such, when using the local accounts, access is not user-attributable.

In cases where user-attributable access is required especially to facilitate auditable processes for compliance reasons, use

RADIUS authentication only.

When the "Server" Authentication Type option is selected, the UR uses the RADIUS server and not its local authentication

database to authenticate the user.

No password or security information is displayed in plain text by the EnerVista software or UR device, nor is such

information ever transmitted without cryptographic protection.

2

CyberSentry server authentication

The UR has been designed to direct automatically the authentication requests based on user names. In this respect, local

account names on the UR are considered as reserved and not used on a RADIUS server.

The UR detects automatically whether an authentication request is to be handled remotely or locally. As there are five local

accounts possible on the UR, if the user ID credential does not match one of the five local accounts, the UR forwards

automatically the request to a RADIUS server when one is provided.

If a RADIUS server is provided, but is unreachable over the network, server authentication requests are denied. In this

situation, use local UR accounts to gain access to the UR system.

2.3 Order codes

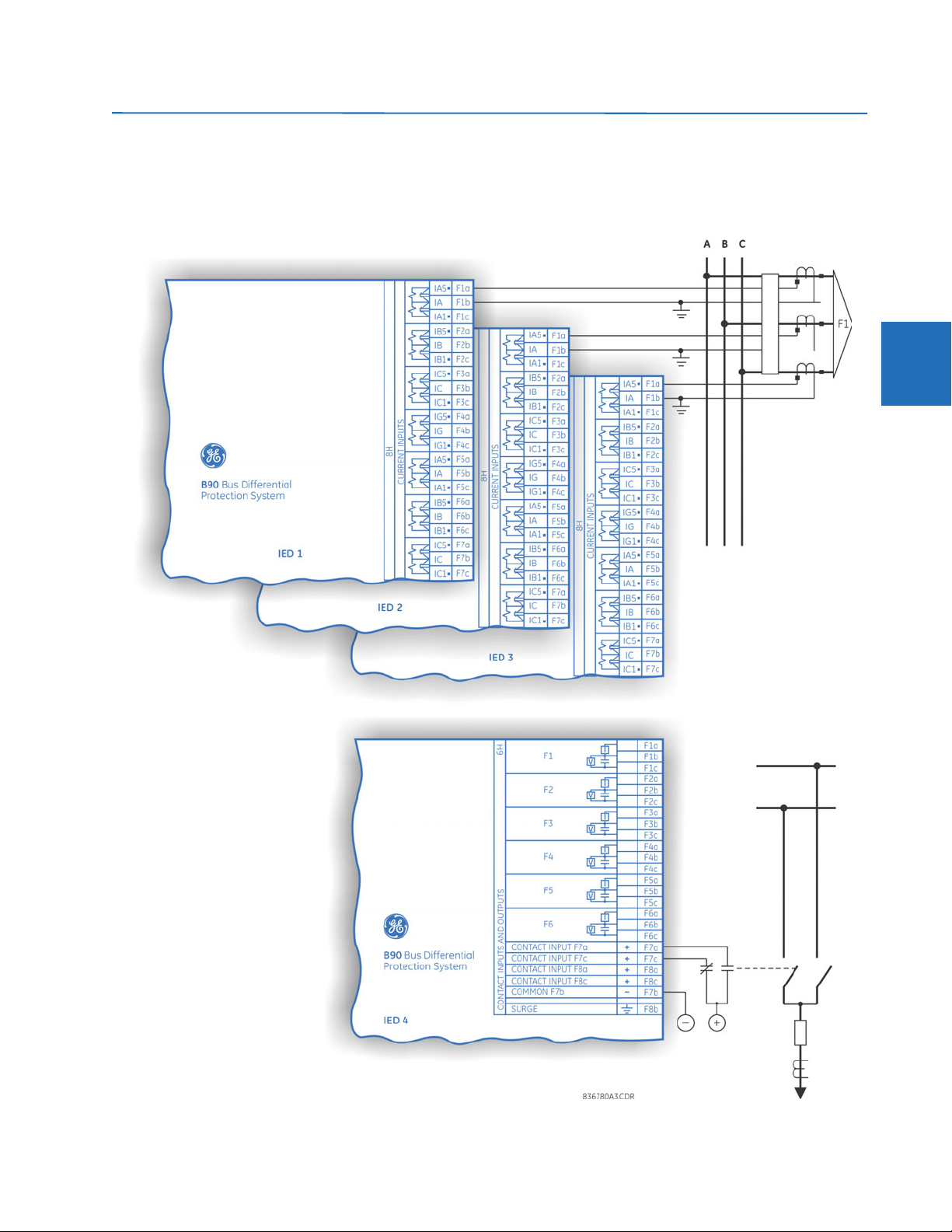

A B90 protection system consists of several UR-series B90 IEDs as per user needs and system configuration. At least three

IEDs are required to provide differential and other protection functions for phases A, B, and C of the busbar. The fourth IED

is required for breaker failure functionality and isolator status monitoring as well as extra input and output capability. A

fifth IED is sometimes required for additional input and output capability.

B90 LOW IMPEDANCE BUS DIFFERENTIAL SYSTEM – INSTRUCTION MANUAL 2-7

Page 20

ORDER CODES CHAPTER 2: PRODUCT DESCRIPTION

Before ordering the B90 system, an analysis of the required protection and monitoring functions is required. Also, detailed

analyses of required AC inputs and input/output contacts must be performed to select appropriate hardware

configurations for each of the B90 IEDs.

The B90 is provided with an option of protecting 8, 16, or 24-feeder busbars. When ordered as an eight-feeder

protection system, the B90 is configurable for up to eight-input bus differential, regardless of the number of

physical current inputs available in the B90 IEDs.

2

The relay is available as a 19-inch rack horizontal mount unit and consists of the following modules: power supply, CPU,

CTs and VTs, contact inputs and outputs, and inter-relay communications. Each of these modules can be supplied in a

number of configurations specified at the time of ordering. The information required to completely specify the relay is

provided in the following tables (see chapter 3 for full details of relay modules).

Order codes are subject to change without notice. See the web page for the product for the latest options.

The R-GOOSE protocol described in IEC 61850-8-1 is available through the IEC 61850 software option. R-GOOSE

security requires the CyberSentry software option.

Table 2-4: B90 order codes

BASE B90 | | | | | | | | | | | | Base Unit

CPU T | | | | | | | | | | | RS485 with 3 100Base-FX Ethernet, multimode, SFP with LC

SOFTWARE OPTIONS 00 | | | | | | | | | | Six-zone 8-feeder bus protection

B90 - * ** - H * * - F ** - H ** - L ** - N ** - S ** - U ** - W/X ** Full Size Horizontal Mount

U | | | | | | | | | | | RS485 with 1 100Base-TX Ethernet, SFP RJ-45 +2 100Base-FX Ethernet ,

V | | | | | | | | | | | RS485 with 3 100Base-TX Ethernet, SFP with RJ-45

01 | | | | | | | | | | Six-zone 16-feeder bus protection

02 | | | | | | | | | | Six-zone 24-feeder bus protection

03 | | | | | | | | | | Single-zone 24-feeder bus protection

04 | | | | | | | | | | Six-zone 8-feeder bus protection + IEC 61850

05 | | | | | | | | | | Six-zone 16-feeder bus protection + IEC 61850

06 | | | | | | | | | | Six-zone 24-feeder bus protection + IEC 61850

07 | | | | | | | | | | Single-zone 24-feeder bus protection + IEC 61850

10 | | | | | | | | | | Six-zone 8-feeder bus protection + breaker failure

11 | | | | | | | | | | Six-zone 16-feeder bus protection + breaker failure

12 | | | | | | | | | | Six-zone 24-feeder bus protection + breaker failure

13 | | | | | | | | | | Single-zone 24-feeder bus protection + breaker failure

14 | | | | | | | | | | Six-zone 8-feeder bus protection + IEC 61850 + breaker failure

15 | | | | | | | | | | Six-zone 16-feeder bus protection + IEC 61850 + breaker failure

16 | | | | | | | | | | Six-zone 24-feeder bus protection + IEC 61850 + breaker failure

17 | | | | | | | | | | Single-zone 24-feeder bus protection + IEC 61850 + breaker failure

A0 | | | | | | | | | | Six-zone 8-feeder bus protection + CyberSentry Lvl 1

A1 | | | | | | | | | | Six-zone 16-feeder bus protection + CyberSentry Lvl 1

A2 | | | | | | | | | | Six-zone 24-feeder bus protection + CyberSentry Lvl 1

A3 | | | | | | | | | | Single-zone 24-feeder bus protection + CyberSentry Lvl 1

A4 | | | | | | | | | | Six-zone 8-feeder bus protection + IEC 61850 + CyberSentry Lvl 1

A5 | | | | | | | | | | Six-zone 16-feeder bus protection + IEC 61850 + CyberSentry Lvl 1

A6 | | | | | | | | | | Six-zone 24-feeder bus protection + IEC 61850 + CyberSentry Lvl 1

A7 | | | | | | | | | | Single-zone 24-feeder bus protection + IEC 61850 + CyberSentry Lvl 1

A8 | | | | | | | | | | Six-zone 8-feeder bus protection + breaker failure + CyberSentry Lvl 1

A9 | | | | | | | | | | Six-zone 16-feeder bus protection + breaker failure + CyberSentry Lvl 1

AA | | | | | | | | | | Six-zone 24-feeder bus protection + breaker failure + CyberSentry Lvl 1

AB | | | | | | | | | | Single-zone 24-feeder bus protection + breaker failure + CyberSentry Lvl 1

AC | | | | | | | | | | Six-zone 8-feeder bus protection + IEC 61850 + breaker failure + CyberSentry Lvl

AD | | | | | | | | | | Six-zone 16-feeder bus protection + IEC 61850 + breaker failure + CyberSentry Lvl

AE | | | | | | | | | | Six-zone 24-feeder bus protection + IEC 61850 + breaker failure + CyberSentry Lvl

AF | | | | | | | | | | Single-zone 24-feeder bus protection + IEC 61850 + breaker failure + CyberSentry

B0 | | | | | | | | | | Six-zone 8-feeder bus protection + IEEE 1588

B1 | | | | | | | | | | Six-zone 16-feeder bus protection + IEEE 1588

B2 | | | | | | | | | | Six-zone 24-feeder bus protection + IEEE 1588

B3 | | | | | | | | | | Single-zone 24-feeder bus protection + IEEE 1588

B4 | | | | | | | | | | Six-zone 8-feeder bus protection + IEC 61850 + IEEE 1588

B5 | | | | | | | | | | Six-zone 16-feeder bus protection + IEC 61850 + IEEE 1588

B6 | | | | | | | | | | Six-zone 24-feeder bus protection + IEC 61850 + IEEE 1588

B7 | | | | | | | | | | Single-zone 24-feeder bus protection + IEC 61850 + IEEE 1588

B8 | | | | | | | | | | Six-zone 8-feeder bus protection + breaker failure + IEEE 1588

B9 | | | | | | | | | | Six-zone 16-feeder bus protection + breaker failure + IEEE 1588

BA | | | | | | | | | | Six-zone 24-feeder bus protection + breaker failure + IEEE 1588

BB | | | | | | | | | | Single-zone 24-feeder bus protection + breaker failure + IEEE 1588

BC | | | | | | | | | | Six-zone 8-feeder bus protection + IEC 61850 + breaker failure + IEEE 1588

BD | | | | | | | | | | Six-zone 16-feeder bus protection + IEC 61850 + breaker failure + IEEE 1588

BE | | | | | | | | | | Six-zone 24-feeder bus protection + IEC 61850 + breaker failure + IEEE 1588

BF | | | | | | | | | | Single-zone 24-feeder bus protection + IEC 61850 + breaker failure + IEEE 1588

C0 | | | | | | | | | | Parallel Redundancy Protocol (PRP) + six-zone 8-feeder bus protection

C1 | | | | | | | | | | PRP + six-zone 16-feeder bus protection

C2 | | | | | | | | | | PRP + six-zone 24-feeder bus protection

C3 | | | | | | | | | | PRP + single-zone 24-feeder bus protection

C4 | | | | | | | | | | PRP + six-zone 8-feeder bus protection + IEC 61850

C5 | | | | | | | | | | PRP + six-zone 16-feeder bus protection + IEC 61850

C6 | | | | | | | | | | PRP + six-zone 24-feeder bus protection + IEC 61850

C7 | | | | | | | | | | PRP + single-zone 24-feeder bus protection + IEC 61850

C8 | | | | | | | | | | PRP + six-zone 8-feeder bus protection + breaker failure

C9 | | | | | | | | | | PRP + six-zone 16-feeder bus protection + breaker failure

multimode, SFP with LC

1

1

1

Lvl 1

2-8 B90 LOW IMPEDANCE BUS DIFFERENTIAL SYSTEM – INSTRUCTION MANUAL

Page 21

CHAPTER 2: PRODUCT DESCRIPTION ORDER CODES

B90 - * ** - H * * - F ** - H ** - L ** - N ** - S ** - U ** - W/X ** Full Size Horizontal Mount

CA | | | | | | | | | | PRP + six-zone 24-feeder bus protection + breaker failure

CB | | | | | | | | | | PRP + single-zone 24-feeder bus protection + breaker failure

CC | | | | | | | | | | PRP + six-zone 8-feeder bus protection + breaker failure + IEC 61850

CD | | | | | | | | | | PRP + six-zone 16-feeder bus protection + breaker failure + IEC 61850

CE | | | | | | | | | | PRP + six-zone 24-feeder bus protection + breaker failure + IEC 61850

CF | | | | | | | | | | PRP + single-zone 24-feeder bus protection + breaker failure + IEC 61850

D0 | | | | | | | | | | Six-zone 8-feeder bus protection + IEEE 1588 + CyberSentry Lvl 1

D1 | | | | | | | | | | Six-zone 16-feeder bus protection + IEEE 1588 + CyberSentry Lvl 1

D2 | | | | | | | | | | Six-zone 24-feeder bus protection + IEEE 1588 + CyberSentry Lvl 1

D3 | | | | | | | | | | Single-zone 24-feeder bus protection + IEEE 1588 + CyberSentry Lvl 1

D4 | | | | | | | | | | Six-zone 8-feeder bus protection + IEC 61850 + IEEE 1588 + CyberSentry Lvl 1

D5 | | | | | | | | | | Six-zone 16-feeder bus protection + IEC 61850 + IEEE 1588 + CyberSentry Lvl 1

D6 | | | | | | | | | | Six-zone 24-feeder bus protection + IEC 61850 + IEEE 1588 + CyberSentry Lvl 1

D7 | | | | | | | | | | Single-zone 24-feeder bus protection + IEC 61850 + IEEE 1588 + CyberSentry Lvl

D8 | | | | | | | | | | Six-zone 8-feeder bus protection + breaker failure + IEEE 1588 + CyberSentry Lvl

D9 | | | | | | | | | | Six-zone 16-feeder bus protection + breaker failure + IEEE 1588 + CyberSentry Lvl

DA | | | | | | | | | | Six-zone 24-feeder bus protection + breaker failure + IEEE 1588 + CyberSentry Lvl

DB | | | | | | | | | | Single-zone 24-feeder bus protection + breaker failure + IEEE 1588 + CyberSentry

DC | | | | | | | | | | Six-zone 8-feeder bus protection + IEC 61850 + breaker failure + IEEE 1588 +

DD | | | | | | | | | | Six-zone 16-feeder bus protection + IEC 61850 + breaker failure + IEEE 1588 +

DE | | | | | | | | | | Six-zone 24-feeder bus protection + IEC 61850 + breaker failure + IEEE 1588 +

DF | | | | | | | | | | Single-zone 24-feeder bus protection + IEC 61850 + breaker failure + IEEE 1588 +

E0 | | | | | | | | | | IEEE 1588 + PRP + six-zone 8-feeder bus protection

E1 | | | | | | | | | | IEEE 1588 + PRP + six-zone 16-feeder bus protection

E2 | | | | | | | | | | IEEE 1588 + PRP + six-zone 24-feeder bus protection

E3 | | | | | | | | | | IEEE 1588 + PRP + single-zone 24-feeder bus protection

E4 | | | | | | | | | | IEEE 1588 + PRP + six-zone 8-feeder bus protection + IEC 61850

E5 | | | | | | | | | | IEEE 1588 + PRP + six-zone 16-feeder bus protection + IEC 61850

E6 | | | | | | | | | | IEEE 1588 + PRP + six-zone 24-feeder bus protection + IEC 61850

E7 | | | | | | | | | | IEEE 1588 + PRP + single-zone 24-feeder bus protection + IEC 61850

E8 | | | | | | | | | | IEEE 1588 + PRP + six-zone 8-feeder bus protection + breaker failure

E9 | | | | | | | | | | IEEE 1588 + PRP + six-zone 16-feeder bus protection + breaker failure

EA | | | | | | | | | | IEEE 1588 + PRP + six-zone 24-feeder bus protection + breaker failure

EB | | | | | | | | | | IEEE 1588 + PRP + single-zone 24-feeder bus protection + breaker failure

EC | | | | | | | | | | IEEE 1588 + PRP + six-zone 8-feeder bus protection + breaker failure + IEC 61850

ED | | | | | | | | | | IEEE 1588 + PRP + six-zone 16-feeder bus protection + breaker failure + IEC

EE | | | | | | | | | | IEEE 1588 + PRP + six-zone 24-feeder bus protection + breaker failure + IEC

EF | | | | | | | | | | IEEE 1588 + PRP + single-zone 24-feeder bus protection + breaker failure + IEC

F0 | | | | | | | | | | PRP + CyberSentry Lvl 1 + six-zone 8-feeder bus protection

F1 | | | | | | | | | | PRP + CyberSentry Lvl 1 + six-zone 16-feeder bus protection

F2 | | | | | | | | | | PRP + CyberSentry Lvl 1 + six-zone 24-feeder bus protection

F3 | | | | | | | | | | PRP + CyberSentry Lvl 1 + single-zone 24-feeder bus protection

F4 | | | | | | | | | | PRP + CyberSentry Lvl 1 + six-zone 8-feeder bus protection + IEC 61850

F5 | | | | | | | | | | PRP + CyberSentry Lvl 1 + six-zone 16-feeder bus protection + IEC 61850

F6 | | | | | | | | | | PRP + CyberSentry Lvl 1 + six-zone 24-feeder bus protection + IEC 61850

F7 | | | | | | | | | | PRP + CyberSentry Lvl 1 + single-zone 24-feeder bus protection + IEC 61850

F8 | | | | | | | | | | PRP + CyberSentry Lvl 1 + six-zone 8-feeder bus protection + breaker failure

F9 | | | | | | | | | | PRP + CyberSentry Lvl 1 + six-zone 16-feeder bus protection + breaker failure

FA | | | | | | | | | | PRP + CyberSentry Lvl 1 + six-zone 24-feeder bus protection + breaker failure

FB | | | | | | | | | | PRP + CyberSentry Lvl 1 + single-zone 24-feeder bus protection + breaker failure

FC | | | | | | | | | | PRP + CyberSentry Lvl 1 + six-zone 8-feeder bus protection + breaker failure + IEC

FD | | | | | | | | | | PRP + CyberSentry Lvl 1 + six-zone 16-feeder bus protection + breaker failure +

FE | | | | | | | | | | PRP + CyberSentry Lvl 1 + six-zone 24-feeder bus protection + breaker failure +

FF | | | | | | | | | | PRP + CyberSentry Lvl 1 + single-zone 24-feeder bus protection + breaker failure

G0 | | | | | | | | | | IEEE 1588 + PRP + CyberSentry Lvl 1 + six-zone 8-feeder bus protection

G1 | | | | | | | | | | IEEE 1588 + PRP + CyberSentry Lvl 1 + six-zone 16-feeder bus protection

G2 | | | | | | | | | | IEEE 1588 + PRP + CyberSentry Lvl 1 + six-zone 24-feeder bus protection

G3 | | | | | | | | | | IEEE 1588 + PRP + CyberSentry Lvl 1 + single-zone 24-feeder bus protection

G4 | | | | | | | | | | IEEE 1588 + PRP + CyberSentry Lvl 1 + six-zone 8-feeder bus protection + IEC

G5 | | | | | | | | | | IEEE 1588 + PRP + CyberSentry Lvl 1 + six-zone 16-feeder bus protection + IEC

G6 | | | | | | | | | | IEEE 1588 + PRP + CyberSentry Lvl 1 + six-zone 24-feeder bus protection + IEC

G7 | | | | | | | | | | IEEE 1588 + PRP + CyberSentry Lvl 1 + single-zone 24-feeder bus protection + IEC

G8 | | | | | | | | | | IEEE 1588 + PRP + CyberSentry Lvl 1 + six-zone 8-feeder bus protection + breaker

G9 | | | | | | | | | | IEEE 1588 + PRP + CyberSentry Lvl 1 + six-zone 16-feeder bus protection +

GA | | | | | | | | | | IEEE 1588 + PRP + CyberSentry Lvl 1 + six-zone 24-feeder bus protection +

GB | | | | | | | | | | IEEE 1588 + PRP + CyberSentry Lvl 1 + single-zone 24-feeder bus protection +

GC | | | | | | | | | | IEEE 1588 + PRP + CyberSentry Lvl 1 + six-zone 8-feeder bus protection + breaker

GD | | | | | | | | | | IEEE 1588 + PRP + CyberSentry Lvl 1 + six-zone 16-feeder bus protection +

GE | | | | | | | | | | IEEE 1588 + PRP + CyberSentry Lvl 1 + six-zone 24-feeder bus protection +

GF | | | | | | | | | | IEEE 1588 + PRP + CyberSentry Lvl 1 + single-zone 24-feeder bus protection +

J0 | | | | | | | | | | IEC 60870-5-103 + six-zone 8-feeder bus protection

1

1

1

1

Lvl 1

CyberSentry Lvl 1

CyberSentry Lvl 1

CyberSentry Lvl 1

CyberSentry Lvl 1

61850

61850

61850

61850

IEC 61850

IEC 61850

+ IEC 61850

61850

61850

61850

61850

failure

breaker failure

breaker failure

breaker failure

failure + IEC 61850

breaker failure + IEC 61850

breaker failure + IEC 61850

breaker failure + IEC 61850

2

B90 LOW IMPEDANCE BUS DIFFERENTIAL SYSTEM – INSTRUCTION MANUAL 2-9

Page 22

2

ORDER CODES CHAPTER 2: PRODUCT DESCRIPTION

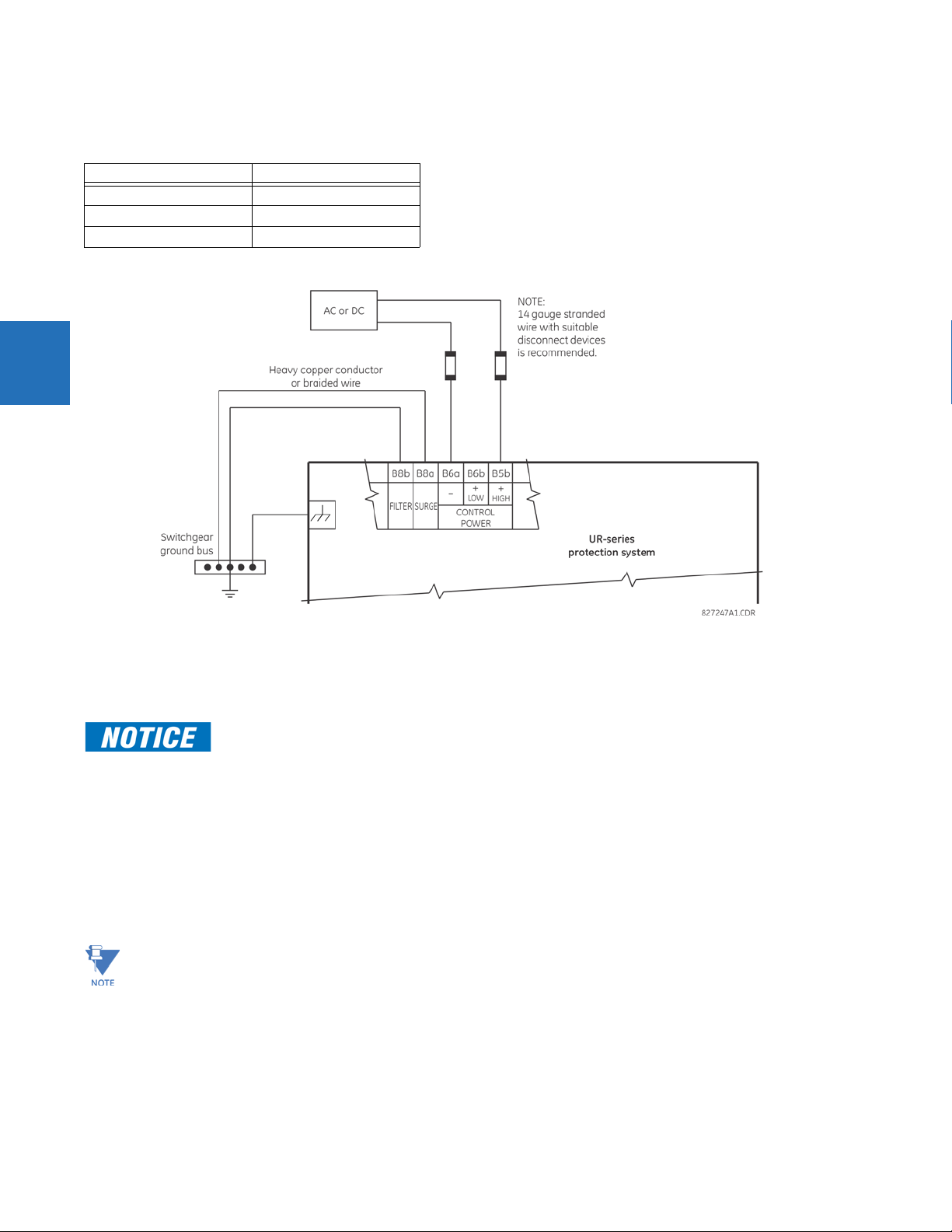

B90 - * ** - H * * - F ** - H ** - L ** - N ** - S ** - U ** - W/X ** Full Size Horizontal Mount