Page 1

GE Healthcare

Life Sciences

ÄKTAprime™ plus

Operating Instructions

Original instructions

Page 2

Page 3

Table of Contents

Table of Contents

51 Introduction ..........................................................................................................

61.1 Important user information .............................................................................................................

71.2 Regulatory information ......................................................................................................................

101.3 Instrument ...............................................................................................................................................

131.4 Monitoring and evaluation ...............................................................................................................

141.5 User documentation ...........................................................................................................................

162 Safety instructions ...............................................................................................

162.1 Safety precautions ...............................................................................................................................

242.2 Labels .........................................................................................................................................................

262.3 Emergency procedures ......................................................................................................................

272.4 Recycling information .........................................................................................................................

282.5 Declaration of Hazardous Substances (DoHS) ........................................................................

313 Installation ............................................................................................................

313.1 Site requirements ..................................................................................................................................

313.2 Transport ..................................................................................................................................................

323.3 Unpacking ................................................................................................................................................

323.4 Connections ............................................................................................................................................

323.5 Spare parts and accessories ...........................................................................................................

334 Operation ..............................................................................................................

334.1 Operation overview .............................................................................................................................

334.2 Starting the instrument ......................................................................................................................

344.3 Preparations before start ..................................................................................................................

394.4 Performing a run ...................................................................................................................................

414.5 Procedures after a run .......................................................................................................................

435 Maintenance .........................................................................................................

435.1 General ......................................................................................................................................................

445.2 User maintenance schedule ...........................................................................................................

465.3 Cleaning ....................................................................................................................................................

475.4 Component maintenance ................................................................................................................

475.5 Disassembly and assembly of components and consumables .....................................

485.6 Calibration ................................................................................................................................................

495.7 Storage ......................................................................................................................................................

506 Troubleshooting ...................................................................................................

506.1 UV curve problems ...............................................................................................................................

516.2 Conductivity curve problems ..........................................................................................................

536.3 pH curve problems ...............................................................................................................................

566.4 Pressure curve problems ..................................................................................................................

ÄKTAprime plus Operating Instructions 28-9597-89 AB 3

Page 4

Table of Contents

577 Reference information ........................................................................................

577.1 Specifications .........................................................................................................................................

577.2 Chemical resistance ............................................................................................................................

617.3 System recommendations ...............................................................................................................

627.4 Health and Safety Declaration Form ...........................................................................................

647.5 Ordering information ..........................................................................................................................

65A Connection diagram - Liquid flow path ...........................................................

66B Tubing ....................................................................................................................

4 ÄKTAprime plus Operating Instructions 28-9597-89 AB

Page 5

1 Introduction

Purpose of the Operating

Instructions

The OperatingInstructions provide you withthe instructions needed to handleÄKTAprime

plus in a safe way.

Prerequisites

In order to operate ÄKTAprime plus as is intended, the following pre-requisites must be

fulfilled:

•

The user should have a general understanding of how a PC and the Microsoft™

Windows™ operating system works. (if a computer is used)

•

The user must understand the concepts of liquid chromatography.

•

The user must read and understand the Safety Instructions in this manual.

•

ÄKTAprimeplus andsoftware shouldbe installed, configured and calibratedaccording

to these Operating Instructions.

1 Introduction

About this chapter

This chapter contains important user information, a description of the intended use of

ÄKTAprime plus, regulatory information, list of associated documentation, definitions of

safety notices and so on.

ÄKTAprime plus Operating Instructions 28-9597-89 AB 5

Page 6

1 Introduction

1.1 Important user information

1.1 Important user information

Read this before operating

ÄKTAprime plus

All users must read the entire Operating Instructions before installing, operating or

maintaining ÄKTAprime plus.

Always keep the Operating Instructions at hand when operating ÄKTAprime plus.

Do notoperate ÄKTAprime plusin any otherway than described in the user documentation. If you do, you may be exposed to hazards that can lead to personal injury and you

may cause damage to the equipment.

Intended use

ÄKTAprime plus is a compact liquid chromatography system designed for one-step purification of proteins at laboratory scale.

ÄKTAprime plus is intended for research use only, and shall not be used in any clinical

procedures, or for diagnostic purposes.

Safety notices

This user documentation contains WARNINGS, CAUTIONS and NOTICES concerning the

safe use of the product. See definitions below.

Warnings

WARNING

WARNING indicates a hazardous situation which, if not avoided,

could resultin death or serious injury. It is important not to proceed

until all stated conditions are met and clearly understood.

6 ÄKTAprime plus Operating Instructions 28-9597-89 AB

Page 7

Cautions

Notices

Notes and tips

Note:

Tip:

1 Introduction

1.1 Important user information

CAUTION

CAUTION indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury. It is important not to

proceed untilall stated conditions are metand clearly understood.

NOTICE

NOTICE indicates instructions that must be followed to avoid

damage to the product or other equipment.

A note is used to indicate information that is important for trouble-free and

optimal use of the product.

A tip contains useful information that can improve or optimize your procedures.

Typographical conventions

Software items are identifiedin the text by bold italic text. A colon separates menulevels,

thus File:Open refers to the Open command in the File menu.

Hardware items are identified in the text by bold text (e.g., Power switch).

1.2 Regulatory information

In this section

This section describes the directives and standards that are fulfilled by ÄKTAprime plus.

ÄKTAprime plus Operating Instructions 28-9597-89 AB 7

Page 8

1 Introduction

1.2 Regulatory information

Manufacturing information

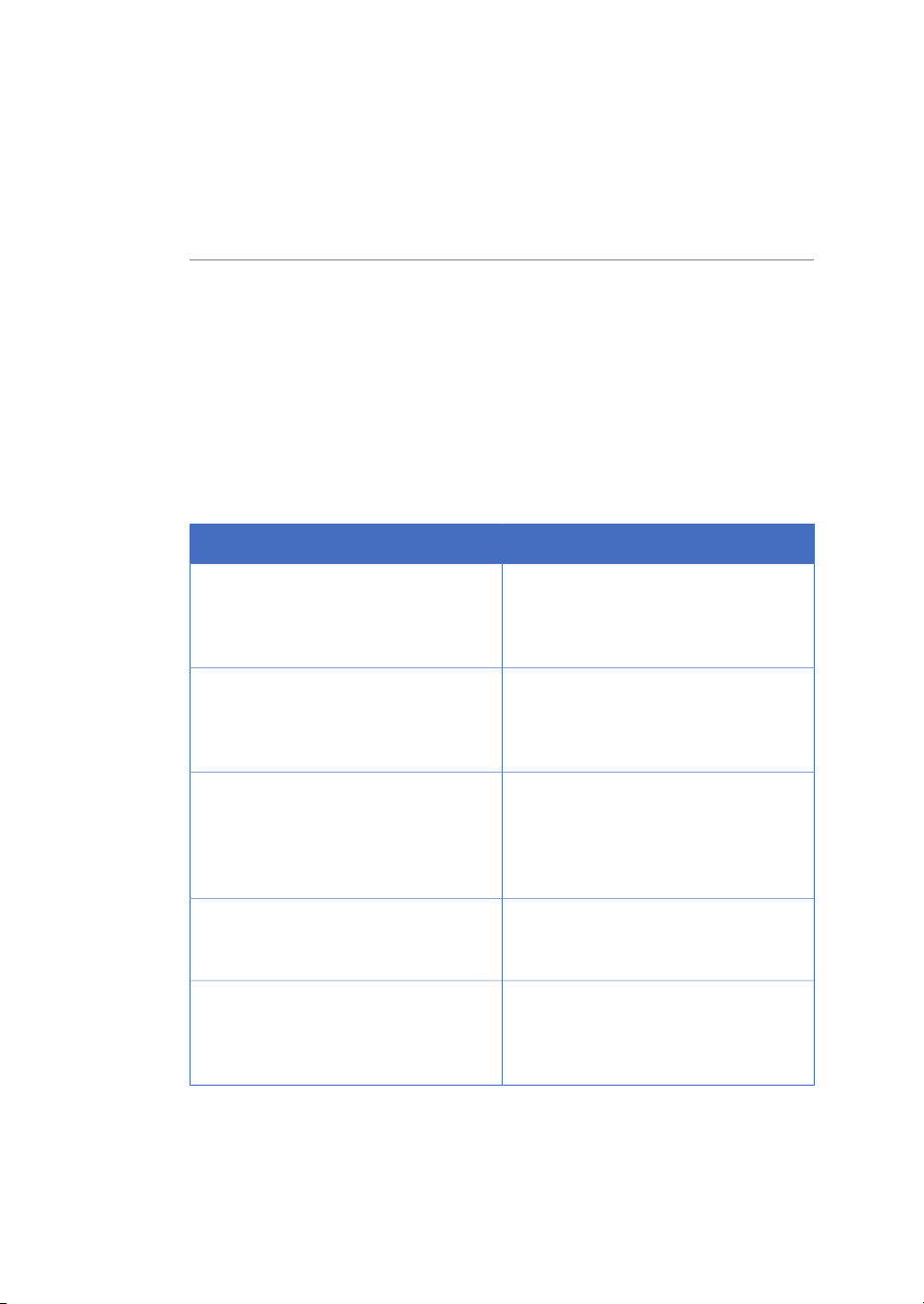

The table below summarizes the required manufacturing information. For further information, see the EC Declaration of Conformity document.

manufacturer

CE conformity

This product complies with the European directives listed in the table, by fulfilling the

corresponding harmonized standards.

A copy of the EC Declaration of Conformity is available on request.

ContentRequirement

GE Healthcare Bio-Sciences AB, Björkgatan 30,Name and address of

SE-751 84 Uppsala, Sweden

TitleDirective

Machinery Directive (MD)2006/42/EC

Low Voltage Directive (LVD)2006/95/EC

CE marking

Electromagnetic Compatibility (EMC) Directive2004/108/EC

The CE marking and the corresponding Declaration of Conformity is valid for the instrument when it is:

•

used as a stand-alone unit, or

•

connected to other CE marked instruments, or

•

connected to other products recommendedor describedin theuser documentation,

and

•

used inthe same stateas it was delivered from GEHealthcare, except for alterations

described in the user documentation.

8 ÄKTAprime plus Operating Instructions 28-9597-89 AB

Page 9

International standards

This product fulfills the requirements of the following standards:

1 Introduction

1.2 Regulatory information

NotesDescriptionStandard

EN/IEC 61010-1,

UL 61010-1,

CAN/CSA-C22.2

No. 61010-1

EN 61326-1

EN ISO 12100

Regulatory compliance of

connected equipment

Any equipment connected to ÄKTAprime plus should meet the safety requirements of

EN 61010-1/IEC 61010-1, or relevant harmonized standards. Within the EU, connected

equipment must be CE marked.

Environmental conformity

Safety requirements for electrical

equipment for measurement,

control, and laboratory use

Electrical equipmentfor measurement, control and laboratory use

- EMC requirements

Safety of machinery. General

principles for design. Risk assessment and risk reduction.

EN standard is harmonized

with EU directive

2006/95/EC

EN standard is harmonized

with EU directive

2004/108/EC

EN ISO standard is harmonized with EU directive

2006/42/EC

TitleRequirement

Restriction of Hazardous Substances (RoHS) Directive2011/65/EU

2012/19/EU

Regulation (EC) No

1907/2006

ACPEIP

ÄKTAprime plus Operating Instructions 28-9597-89 AB 9

Waste Electricaland ElectronicEquipment (WEEE) Directive

Registration, Evaluation, Authorization and restriction

of CHemicals (REACH)

Administration on the Control of Pollution Caused by

Electronic Information Products, China Restriction of

Hazardous Substances (RoHS)

Page 10

1

2

3

4

5

6 7

8

9

10

17

16

15

14

13

12

11

1 Introduction

1.3 Instrument

1.3 Instrument

Product description

ÄKTAprime plus is a compact liquid chromatography system designed for one-step purification of proteins at laboratory scale.

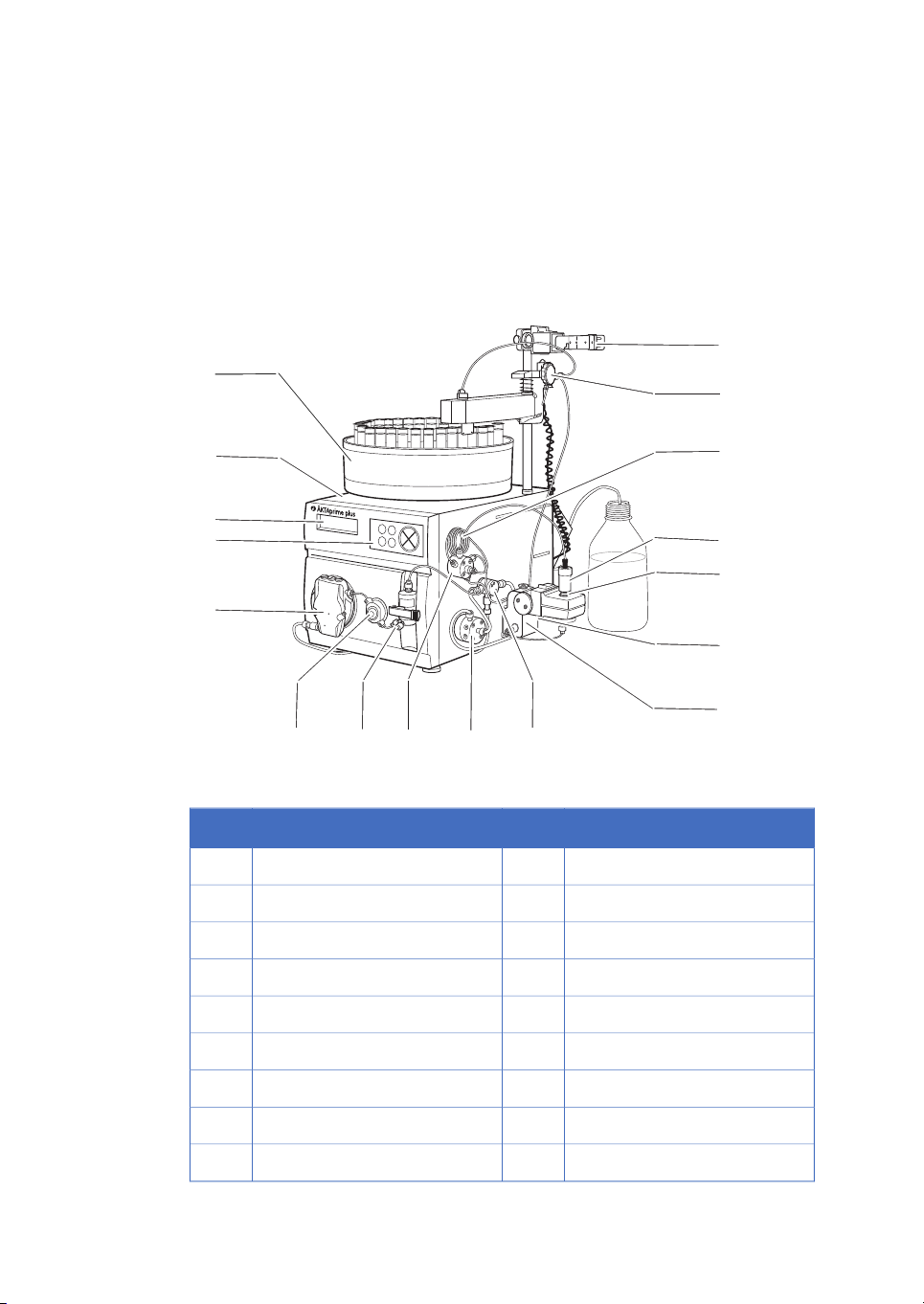

Figure 1.1: The main parts of the instrument.

FunctionPartFunctionPart

Switch valve10Fraction collector1

Conductivity cell11Monitor and controller2

Flow restrictor12LCD display3

UV flow cell13Push buttons4

Column14Pump5

Sample loop15Pressure sensor6

Flow diversion valve16Mixer7

Column holder17Injection valve8

10 ÄKTAprime plus Operating Instructions 28-9597-89 AB

Buffer valve9

Page 11

The Power switch is located at the rear of the system.

l

0

l

0

Drop Sensor

Frac Valve

RS-232

Recorder

Rec. On/off

pH-Ground

pH-Probe

Conductivity Flow Cell

UV

UV-lamp

Mains

Voltage

220-240 V

100-120 /

Power max

90 VA

autorange

~

Frequency

50-60 Hz

(SYSTEM NO.)

(CODE NO.)

1

2

3

4

5

6

7

8

9

10

11

Electrical and communication

connections

1 Introduction

1.3 Instrument

ConnectionNo.ConnectionNo.

pH electrode7RS-232 to computer1

Conductivity flow cell8Flow diversion valve2

Optical unit9Fraction collector3

Power switch10Measurement data to recorder4

Mains power inlet11On/off signals to recorder5

UV lamp6

ÄKTAprime plus Operating Instructions 28-9597-89 AB 11

Page 12

end

OK

Esc

pause

/cont

hold

/cont

feed

tube

1 Introduction

1.3 Instrument

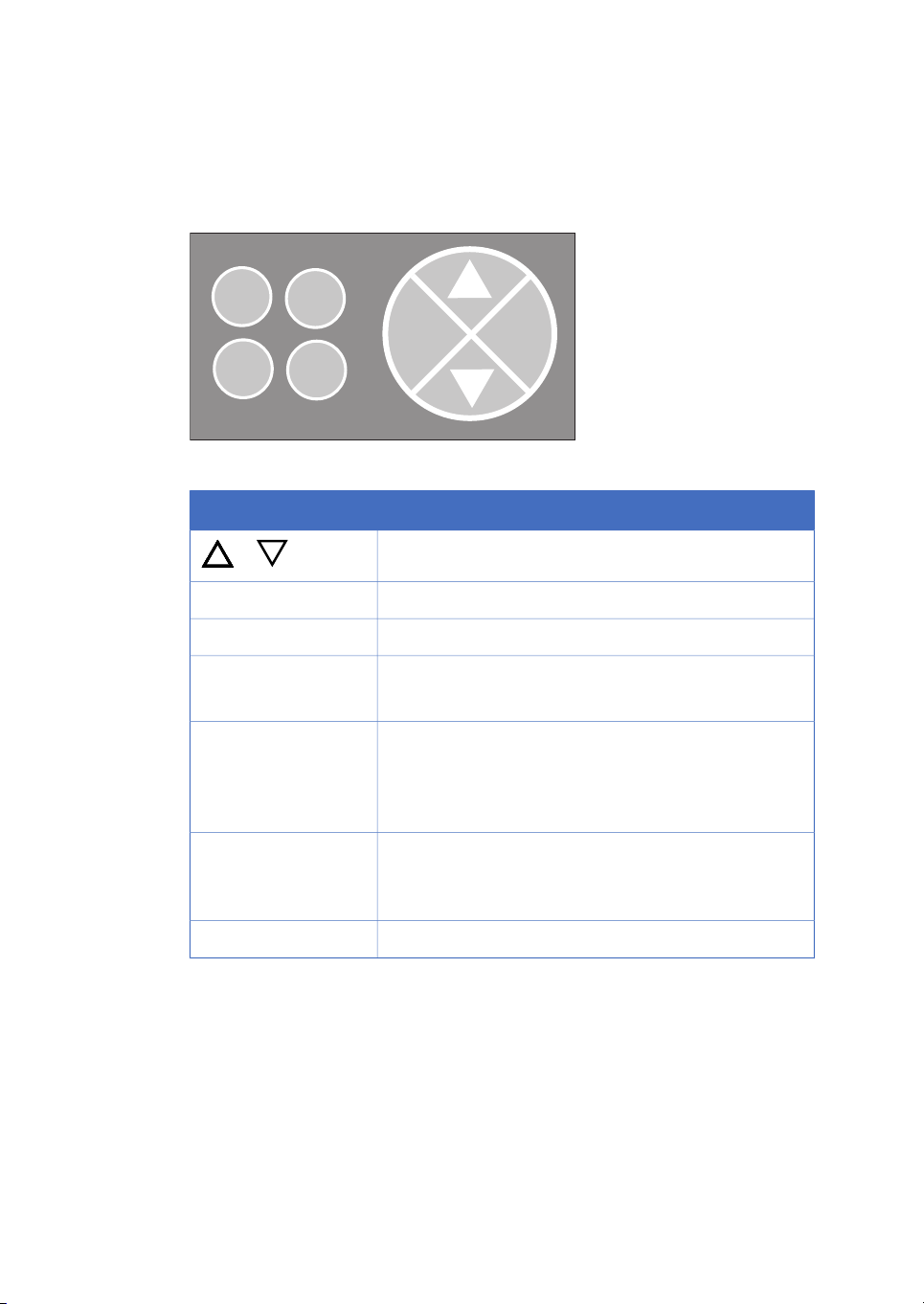

Navigation menu

The system is operated from the push buttons and LCD display at the front panel.

Figure 1.2: Push buttons.

DescriptionButton

or

hold /cont

pause /cont

Find a specific menu option

Enter a menu.OK

Return one menu level.Esc

Interrupt method operation before the run is completed.end

Stop manual operation.

Hold method time or volume and the gradient at the current concentration. Pump and fraction collector continue

uninterrupted.

Continue the normal method operation.

Pause all operation without ending the method. All functions, including pump and fraction collector, are stopped.

Continue the normal method operation.

Advance the fraction collector one position.feed tube

12 ÄKTAprime plus Operating Instructions 28-9597-89 AB

Page 13

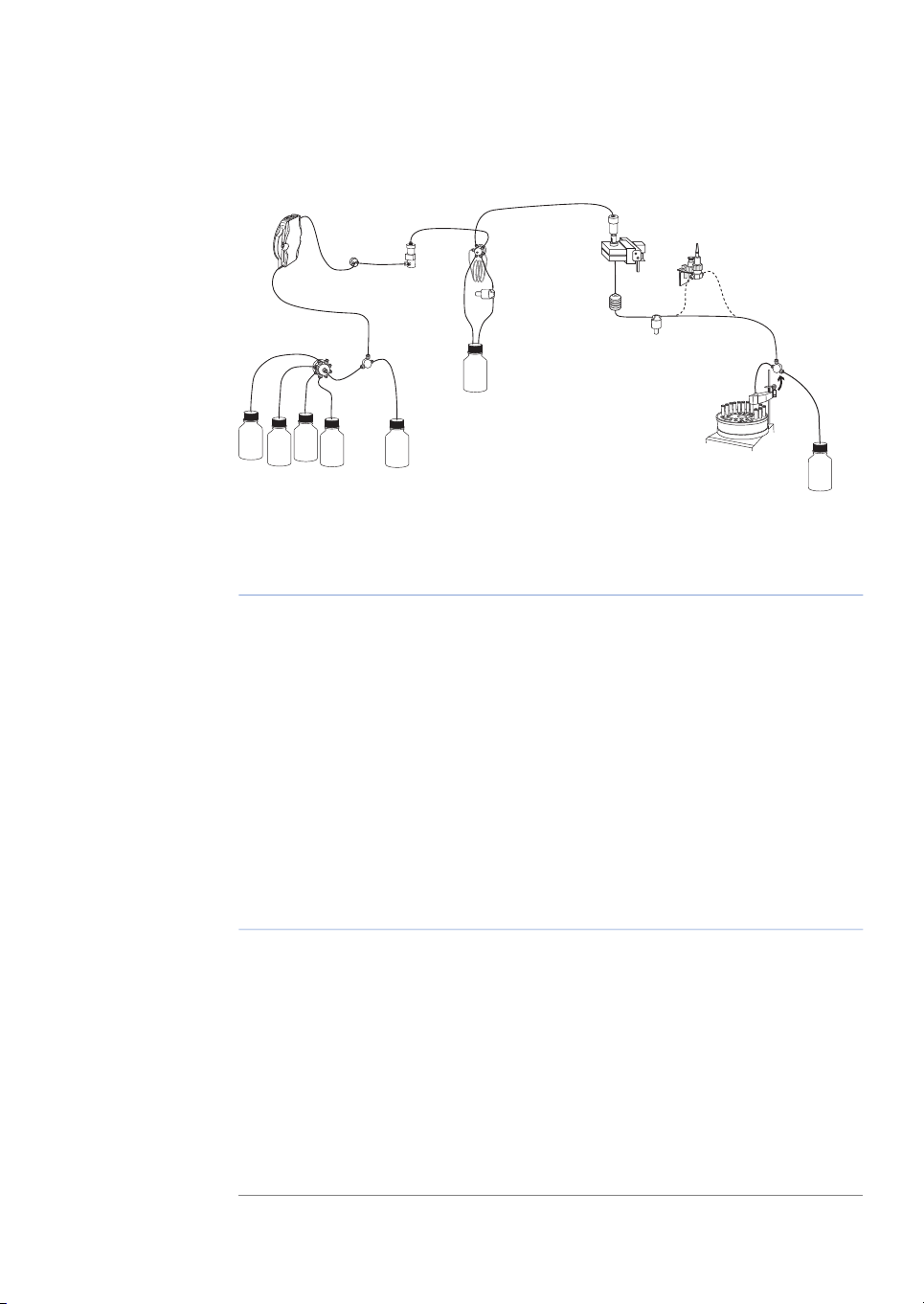

Basic flow path

IN

IN

P

M

UV

C

pH

F

W

V2

V1

B

SW

Figure 1.3: Basic flow path.

1 Introduction

1.3 Instrument

DescriptionPartStage

P, V11

Pump P pumps buffer from a buffer container connected to the

buffer valve V1.

SW, B2

To form a gradientthe switch valve (SW)can be usedto pull liquid

from buffer container (B).

The mixer (M) mixes the buffers.M3

V24

Sample is applied from the sample loop connected to injection

valve (V2)that has been previously filledmanually usinga syringe.

UV, C, pH5

From the injection valve, the flow is directed to the column, and

then to the UV, Conductivity, and optional pH monitor.

F, W6

From the monitors, the flow is directed to the Fraction collector

F or the Waste W.

1.4 Monitoring and evaluation

PrimeView™ software

PrimeView isa softwarethat allows real time monitoring,evaluation andreport generation

on an external computer.

For moreinformation aboutPrimeView evaluationsystem and instructionsfor installation,

see the PrimeView User Manual supplied.

ÄKTAprime plus Operating Instructions 28-9597-89 AB 13

Page 14

1 Introduction

1.4 Monitoring and evaluation

Paper chart recorder

It is possible to connect a chart recorder to ÄKTAprime plus to get real time monitoring.

For more information see the ÄKTAprime plus User Manual.

1.5 User documentation

In addition to these Operating Instructions, the documentation package supplied with

ÄKTAprime plus also includes product documentation binders containing detailed

specifications and traceability documents.

The mostimportant documents in the documentpackage withregard totechnical aspects

of ÄKTAprime plus are:

System-specific documentation

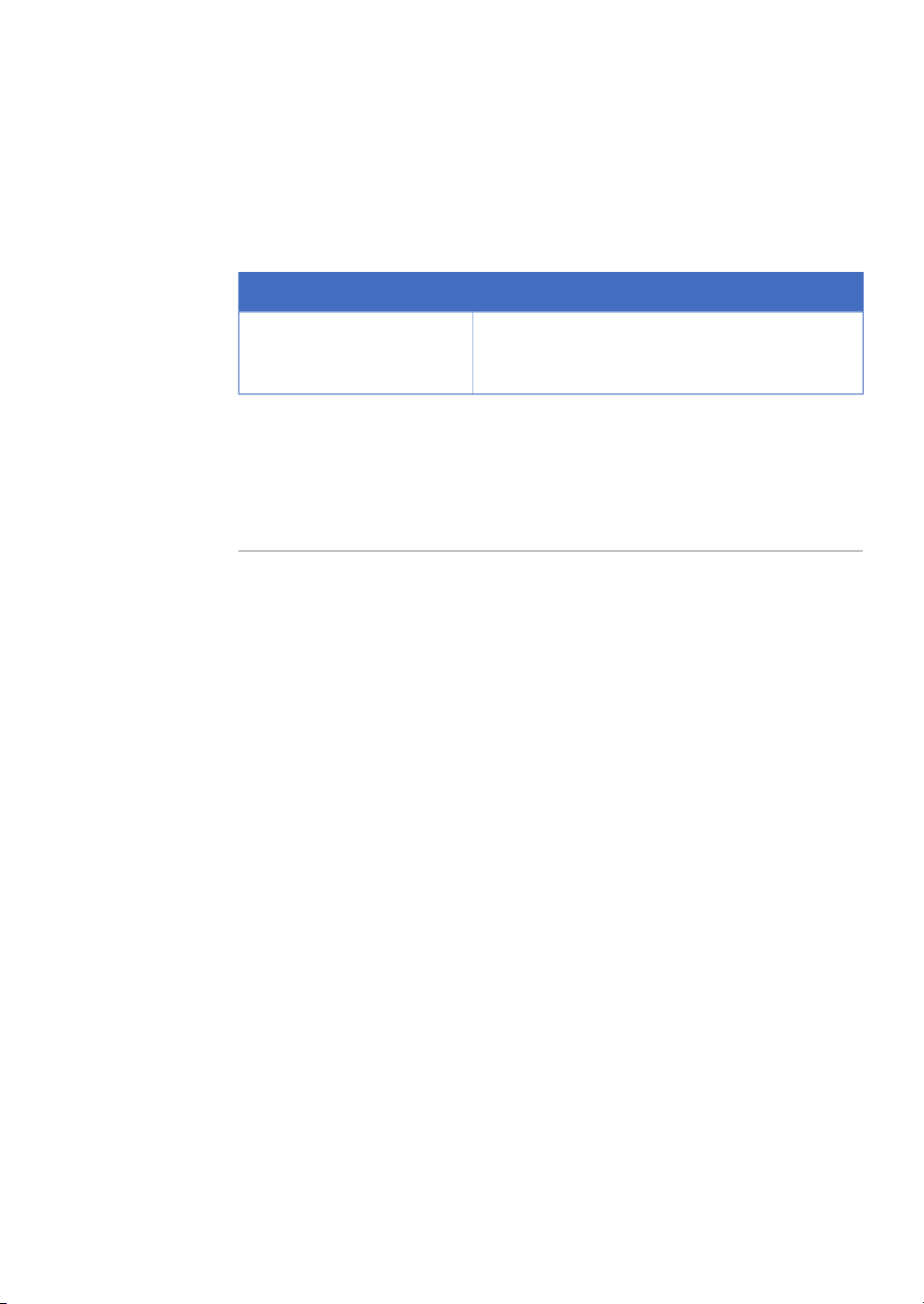

ContentUser documentation

ÄKTAprime plus Operating Instructions

ÄKTAprime plus User Manual

ÄKTAprime plus Cue Cards

ÄKTAprime plus training video

EC Declaration of Conformity for

ÄKTAprime plus

All instructionsneeded to operate the instrument in a safe way, including brief

system description, installation, and

maintenance.

Detailed systemdescription. Comprehensive user instructions, method creation,

operation, advanced maintenance and

troubleshooting.

Short step-by-stepinstructions for selected applications using the preprogrammed method templates. System

preparation and value table for the

method templates.

Covers the system introduction, step by

step installation, setting-up the run and

evaluation of results.

Document whereby the manufacturer

ensures that the product satisfies and is

in conformity with the essential requirements of the applicable directives.

14 ÄKTAprime plus Operating Instructions 28-9597-89 AB

Page 15

Software documentation

Together witheach system, the following software documentation is supplied providing

additional information that applies to ÄKTAprime plus, independent of the specific

configuration:

1 Introduction

1.5 User documentation

Purpose/ContentsDocument

PrimeView User Manual

Component documentation

Documentation for components produced both by GE Healthcare and by a third-party

are, if existent, also included in the document package.

A completecontrol software packagefor supervision

of ÄKTAprime plus automated liquid chromatography systems.

ÄKTAprime plus Operating Instructions 28-9597-89 AB 15

Page 16

2 Safety instructions

2 Safety instructions

About this chapter

This chapter describes safety compliance, safety labels, general safety precautions,

emergency procedures, power failure and recycling of ÄKTAprime plus.

2.1 Safety precautions

Introduction

The ÄKTAprime plus instrument is powered by mains voltage and handles pressurized

liquids that may be hazardous. Before installing, operating or maintaining the system,

you must be aware of the hazards described in this manual. Follow the instructions

provided to avoid personal injury or damage to the equipment .

The safety precautions in this section are grouped into the following categories:

•

General precautions

•

Using flammable liquids

•

Personal protection

•

Installing and moving the instrument

•

System operation

•

Maintenance

General precautions

Always follow these General precautions to avoid injury when using the ÄKTAprime plus

instrument.

WARNING

Do not operate ÄKTAprime plus in any other way than described

in the ÄKTAprime plus and PrimeView manuals. If the equipment

is used ina manner not specifiedby the manufacturer,the protection provided by the equipment may be impaired.

16 ÄKTAprime plus Operating Instructions 28-9597-89 AB

Page 17

2 Safety instructions

2.1 Safety precautions

WARNING

Operation anduser maintenanceof the ÄKTAprime plusinstrument

should be performed by properly trained personnel only.

WARNING

Before connecting a column to the ÄKTAprime plus instrument,

read the instructions for use of the column. To avoid exposing the

column to excessive pressure, make sure that the pressure limit is

set to the specified maximum pressure of the column.

WARNING

Do not use any accessories not supplied or recommended by GE

Healthcare.

WARNING

Do not use ÄKTAprime plus if it is not working properly, or if it has

suffered any damage, for example:

•

damage to the power cord or its plug

•

damage caused by dropping the equipment

•

damage caused by splashing liquid onto it

CAUTION

Waste tubesand containers must be secured andsealed to prevent

accidental spillage.

CAUTION

Make sure that the waste container is dimensioned for maximum

possible volume when the instrument is left unattended.

ÄKTAprime plus Operating Instructions 28-9597-89 AB 17

Page 18

2 Safety instructions

2.1 Safety precautions

Using flammable liquids

When usingflammable liquids with theÄKTAprimeplus instrument, followthese precautions to avoid any risk of fire or explosion.

NOTICE

Avoid condensation by letting the unit equilibrate to ambient temperature.

WARNING

Fire Hazard. Before starting the system, make sure that there is

no leakage.

WARNING

A fume hood or similar ventilation system shall be installed when

flammable or noxious substances are used.

Personal protection

WARNING

Always useappropriate PersonalProtective Equipment(PPE) during

operation and maintenance of ÄKTAprime plus system.

WARNING

When using hazardous chemical and biological agents, take all

suitable protective measures, such as wearing protective glasses

and gloves resistant to the substances used. Follow local and/or

national regulations for safe operation and maintenance of

ÄKTAprime plus.

18 ÄKTAprime plus Operating Instructions 28-9597-89 AB

Page 19

Installing and moving the

instrument

2 Safety instructions

2.1 Safety precautions

WARNING

Spread ofbiological agents. Theoperator has to take allnecessary

actions to avoid spreading hazardous biological agents in the

vicinity of the instrument. The facility should comply with the national code of practice for biosafety.

WARNING

High pressure. ÄKTAprime plus operates under high pressure.

Wear protective glasses and other required Personal Protective

Equipment (PPE) at all times.

WARNING

Supply voltage. Make sure that the supply voltage at the wall

outlet corresponds to the marking on the instrument , before connecting the power cord.

WARNING

Protective ground. ÄKTAprime plus must always be connected to

a grounded power outlet.

WARNING

Power cord. Only use power cords with approved plugs delivered

or approved by GE Healthcare.

ÄKTAprime plus Operating Instructions 28-9597-89 AB 19

Page 20

2 Safety instructions

2.1 Safety precautions

WARNING

Access to power switch and power cord with plug. Do not block

access to the power switch and power cord. The power switch

must always be easy to access. The power cord with plug must

always be easy to disconnect.

WARNING

Installing the computer. The computer should be installed and

used according to the instructions provided by the manufacturer

of the computer.

NOTICE

Any computerused withthe equipment shall comply withIEC 60950

and beinstalled and used according tothe manufacturer's instructions.

NOTICE

Disconnect power. Toprevent equipmentdamage, alwaysdiscon-

nect power from the ÄKTAprime plus instrument before an instrument module is removed or installed, or a cable is connected or

disconnected.

System operation

WARNING

Hazardous chemicals during run. When using hazardous chemi-

cals, run System CIP and Column CIP to flush the entire system

tubing with distilled water, before service and maintenance.

20 ÄKTAprime plus Operating Instructions 28-9597-89 AB

Page 21

2 Safety instructions

2.1 Safety precautions

WARNING

Hazardous biological agents during run. When using hazardous

biological agents, run System CIP and Column CIP to flush the

entire system tubing with bacteriostatic solution (e.g. NaOH) followed by a neutral buffer and finally distilled water, before service

and maintenance.

WARNING

There must always be a sample loop connected to ports 2 and 6

of the injection valve. This is to prevent liquid spraying out of the

ports when switching the valve. This is especially dangerous if

hazardous chemicals are used.

CAUTION

Hazardous chemicals in UV flow cell. Make sure that the entire

flow cell has been flushed thoroughly with bacteriostatic solution,

for example NaOH, and distilled water, before service and maintenance.

NOTICE

If the ÄKTAprime plus is kept in acold room, coldcabinet or similar,

keep the system switched on in order to minimize the risk of condensation. (The UV lamp can be turned off to save lamp life time

when the system is not in use.)

NOTICE

When switchingoff the cold cabinet, make surethat youalso switch

off the ÄKTAprime plus system and leave the door to the cold

cabinet open to avoid overheating.

ÄKTAprime plus Operating Instructions 28-9597-89 AB 21

Page 22

2 Safety instructions

2.1 Safety precautions

Maintenance

WARNING

Electrical shock hazard. All repairs should be done by service

personnel authorized by GE Healthcare. Do not open any covers

or replace parts unless specifically stated in the user documentation.

WARNING

Disconnect power.Always disconnect powerfrom the instrument

before replacing any component on the instrument, unless stated

otherwise in the user documentation.

WARNING

Hazardous chemicals during maintenance.When using hazardous

chemicals for system or column cleaning, wash the system or

columns with a neutral solution in the last phase or step.

WARNING

Do not perform any type of maintenance work while the system is

powered electrically or whenthe piping systemis pressurized.Note

that the piping system can be pressurized even when the system

is closed down.

WARNING

Only spare parts and accessories that are approved or supplied

by GE Healthcare may be used for maintaining or servicing

ÄKTAprime plus.

WARNING

Make sure that the piping system is completely leakage free before

performing any CIP on the system.

22 ÄKTAprime plus Operating Instructions 28-9597-89 AB

Page 23

2 Safety instructions

2.1 Safety precautions

WARNING

NaOH is corrosive and therefore dangerous to health. When using

hazardous chemicals, avoid spillage and wear protective glasses

and other suitable Personal Protective Equipment (PPE).

WARNING

After assembly, the piping system must be tested for leakage at

maximum pressure for continued protection against injury risks

due to fluid jets, burst pipes or explosive atmosphere.

WARNING

Before disassembly, check that there is no pressure in the piping

system.

WARNING

Disconnect power.Always disconnect powerfrom the instrument

before replacing fuses.

WARNING

Decontaminate theequipment beforedecommissioning to ensure

that hazardous residues are removed.

CAUTION

Fire hazard. Follow instructions in ÄKTAprime plus Operating

Instructions for correct installation of a new UV-lamp. If the lamp

is not installed properly it may be overheated and cause a fire

hazard.

ÄKTAprime plus Operating Instructions 28-9597-89 AB 23

Page 24

2 Safety instructions

2.1 Safety precautions

2.2 Labels

CAUTION

The systemuses highintensity ultra-violet light. Do not remove the

UV lamp while the system is running. Before replacing a UV lamp,

ensure that the lamp is disconnected to prevent injury to eyes.

If the mercury lamp is broken, make sure that all mercury is removed anddisposed accordingto nationaland local environmental

regulations.

NOTICE

Cleaning. Keep the instrument dry and clean. Wipe regularly with

a softdamp tissue and,if necessary, amild cleaning agent . Let the

instrument dry completely before use.

In this section

This sectiondescribes the instrument labels andlabels concerninghazardous substances

that are attached to the ÄKTAprime plus instrument. For information about marking of

the computer equipment, refer to the manufacturer’s instructions.

Labels on the instrument

The illustration below shows an example of the identification label that is attached to

the ÄKTAprime plus instrument .

24 ÄKTAprime plus Operating Instructions 28-9597-89 AB

Page 25

Symbols used in instrument

labels

MeaningLabel

Warning! Read the user documentation before using the system. Do

not open any covers or replace parts unless specifically stated in the

user documentation.

The systemcomplies withthe requirements for electromagneticcompliance (EMC) in Australia and New Zealand.

The system complies with applicable European directives.

This symbol indicates that ÄKTAprime plus has been certified by a Nationally RecognizedTesting Laboratory(NRTL). NRTLmeans an organization, which is recognized by the US Occupational Safety and Health Administration (OSHA) as meeting the legal requirements of Title 29 of the

Code of Federal Regulations (29 CFR), Part 1910.7.

2 Safety instructions

2.2 Labels

Labels concerning hazardous

substances

MeaningLabel

This symbol indicates that the waste of electrical and electronic equipment must not be disposed as unsorted municipal waste and must be

collected separately.Please contactan authorizedrepresentative of the

manufacturer for information concerning the decommissioning of

equipment.

This symbol indicates that the product contains hazardous materials in

excess ofthe limits established by theChinese standardSJ/T11363-2006

Requirements for Concentration Limitsfor Certain Hazardous Substances

in Electronics.

ÄKTAprime plus Operating Instructions 28-9597-89 AB 25

Page 26

2 Safety instructions

2.3 Emergency procedures

2.3 Emergency procedures

In this section

This sectiondescribes howto doan emergencyshutdown of the ÄKTAprime plussystem.

The section also describes the result in the event of power failure.

Emergency shutdown

In an emergency situation, do as follows to stop the run:

ActionStep

Power failure

1

2

The result of a power failure depends on which unit that is affected.

ÄKTAprime plus

Computer

To pause the runwithout ending the method, pressthe Pausebutton located

at the instrument front.

If required, switch off power to the instrument by pressing the Main power

switch to the 0 position. The run is interrupted immediately.

will result in...Power failure to...

The run is interrupted immediately, in an undefined

•

state

The data collected up to the time of the power failure

•

is available in PrimeView

The PrimeViewcomputer shuts downin an undefined

•

state

The run continues, but data cannot be saved in

•

PrimeView.

26 ÄKTAprime plus Operating Instructions 28-9597-89 AB

Page 27

2.4 Recycling information

Decontamination

ÄKTAprime plus shall be decontaminated before decommissioning and all local regulations shall be followed with regard to scrapping of the equipment .

Disposal, general instructions

When taking ÄKTAprime plus out of service, the different materials must be separated

and recycled according to national and local environmental regulations.

Recycling of hazardous

substances

ÄKTAprime plus contains hazardous substances. Detailed information is available from

your GE Healthcare representative.

2 Safety instructions

2.4 Recycling information

Disposal of electrical

components

Waste ofelectrical and electronic equipment must not bedisposed as unsorted municipal

waste and must be collected separately. Please contact an authorized representative

of the manufacturer for information concerning the decommissioning of equipment.

ÄKTAprime plus Operating Instructions 28-9597-89 AB 27

Page 28

2 Safety instructions

2.5 Declaration of Hazardous Substances (DoHS)

2.5 Declaration of Hazardous Substances (DoHS)

Introduction

The following product pollution controlinformation is providedaccording to SJ/T113642006 Marking for Control of Pollution caused by Electronic Information Products.

根据SJ/T11364-2006《电子信息产品污染控制标识要求》特提供如下有关污染 控制

方面的信息

Symbols used in pollution control

label

电子信息产品污染控制标志说明

MeaningLabel

This symbol indicates the product contains hazardous materials in excess ofthe limits established by theChinese standardSJ/T11363-2006

Requirements for Concentration Limits for Certain Hazardous Substances in Electronic Information Products. The number in the symbol

is theEnvironment-friendly UsePeriod (EFUP), which indicates theperiod

during whichthe toxic or hazardous substances or elementscontained

in electronic information products will not leak or mutateunder normal

operating conditions so that the use of such electronic information

products will not result in any severe environmental pollution, any

bodily injury or damage to any assets. The unit of the period is “Year”.

In order to maintain the declared EFUP, the product shall be operated

normally according to the instructions and environmental conditions

as definedin the product manual, and periodic maintenanceschedules

specified in Product Maintenance Procedures shallbe followed strictly.

Consumables or certain parts may have their own label with an EFUP

value lessthan theproduct. Periodicreplacement ofthose consumables

or parts to maintain the declared EFUP shall be done in accordance

with the Product Maintenance Procedures.

This product must not be disposed of as unsorted municipal waste,

and must be collected separately and handled properly after decommissioning.

28 ÄKTAprime plus Operating Instructions 28-9597-89 AB

Page 29

MeaningLabel

该标志表明本产品含有超过SJ/T11363-2006《电子信息产品中有毒

有害物质的限 量要求》中限量的有毒有害物质。标志中的数字为本

产品的环保使用期,表明本 产品在正常使用的条件下,有毒有害物

质不会发生外泄或突变,用户使用本产品 不会对环境造成严重污染

或对其人身、财产造成严重损害的期限。单位为年。

为保证所申明的环保使用期限,应按产品手册中所规定的环境条件

和方法进行正 常使用,并严格遵守产品维修手册中规定的期维修和

保养要求。

产品中的消耗件和某些零部件可能有其单独的环保使用期限标志,

并且其环保使 用期限有可能比整个产品本身的环保使用期限短。应

到期按产品维修程序更换那 些消耗件和零部件,以保证所申明的整

个产品的环保使用期限。

本产品在使用寿命结束时不可作为普通生活垃圾处理,应被单独收

集妥善处理

List of hazardous substances and

their concentrations

产品中有毒有害物质或元素的名称及含量

2 Safety instructions

2.5 Declaration of Hazardous Substances (DoHS)

Indication for each major part if substance exceeds limit

MeaningValue

O

X

ÄKTAprime plus Operating Instructions 28-9597-89 AB 29

Indicates that this toxic or hazardous substance contained in all of the

homogeneous materials for this part is below the limit requirement in

SJ/T11363-2006.

表示该有毒有害物质在该部件所有均质材料中的含量均在SJ/T113632006 标准规定的限量要 求以下

Indicates that this toxic or hazardous substance contained in at least

one of the homogeneous materials used for this part is above the limit

requirement in SJ/T11363-2006.

Data listed in the table represents best information available at the

•

time of publication

表示该有毒有害物质至少在该部件的某一均质材料中的含量超出

SJ/T11363-2006 标准规定的

限量要求

此表所列数据为发布时所能获得的最佳信息

•

Page 30

2 Safety instructions

2.5 Declaration of Hazardous Substances (DoHS)

List of hazardous substances

Component

name

Hazardous substance

有毒有害物质或元素

部件名称

Pb

铅

Hg

汞

Cd

镉

Cr6+

六价铬

PBB

多溴联苯

PBDE

多溴二苯醚

0000XXÄKTAprime plus

1

1

The product has not been tested as per the Chinese standard SJ/T11363-2006 Requirements

for Concentration Limits for Certain Hazardous Substances in Electronic Information Product.

30 ÄKTAprime plus Operating Instructions 28-9597-89 AB

Page 31

3 Installation

ÄKTAprime plus is delivered in protective packing material and shall be unpacked with

great care.

Any equipment connectedto ÄKTAprime plus must fulfill applicablestandards and local

regulations.

A videodescribing theinstallation process,is suppliedwith each ÄKTAprime plus system.

For detailed information on Installation, see ÄKTAprime plus User Manual.

3.1 Site requirements

3 Installation

RequirementParameter

100-240 V, 50-60 HzElectrical power

4°C to 40°CAmbient temperature

3.2 Transport

The equipment can be transported on a trolley capable of supporting at least 20 kg.

Before moving the system:

•

disconnect all cables and tubing connected to peripheral components and liquid

containers.

•

remove any loose items from the top of the instrument.

•

grasp the instrument firmly by placing the fingers under the base of the main unit

and lift.

For more information on transport, see ÄKTAprime plus User Manual.

Stable laboratory bench e.g. 120 × 80 cmPlacement

20% to 95%, non-condensingHumidity

NOTICE

Lift the instrument in the upright position. Do not use the fractionation arm as a lifting handle.

ÄKTAprime plus Operating Instructions 28-9597-89 AB 31

Page 32

3 Installation

3.3 Unpacking

3.3 Unpacking

Check for damage

Check the equipment for damage before starting assembly and installation. There are

no looseparts inthe transport box. All parts are either mounted on thesystem orlocated

in the accessory kit box. If any damage is found, document the damage, and contact

your local GE Healthcare representative.

Unpack the system

Remove straps and packing material. Then set the equipment upright before starting

installation.

3.4 Connections

Communication

Connect thesystem according to the electricaldrawings in Electrical and communication

connections, on page 11.

Flow path

All parts and tubing are mounted on the system at delivery.

Connect a waste tube, buffer and sample bottles, and optional accessories.

Electrical power

Connect the power cord to a grounded power outlet specified in Section3.1 Site requirements, on page 31.

3.5 Spare parts and accessories

For correct up to date information on spare parts and accessories visit:

www.gelifesciences.com/AKTA

32 ÄKTAprime plus Operating Instructions 28-9597-89 AB

Page 33

4 Operation

About this chapter

This chapter provides instructions for the use of ÄKTAprime plus.

4.1 Operation overview

Workflow

The typical workflow in ÄKTAprime plus, after turning on the system, can be divided into

a number of steps.

4 Operation

SectionActionStep

Section 4.3 Preparations before start, on page 34Prepare the system for a run1

Liquid flow path

See Appendix A Connection diagram - Liquid flow path, on page 65 for an illustration of

the liquid flow path in ÄKTAprime plus.

4.2 Starting the instrument

If the system is not already turned on:

1

Turn on the system using the Power switch at the rear panel. The system now performs a self-test.

2

First thesystem name and software version number aredisplayed. Severalmessages

are then shown during the self-test. If an error is detected during the self-test, an

error message is shown.

3

All parameters are automatically set to factory default values during the self-test.

Section 4.4 Performing a run, on page 39Start a run using a method2

Viewing the run, on page 40During arun -view and changeparameters3

Section 4.5 Procedures after a run, on page 41Procedures after a run4

See PrimeView user documentation.Evaluate the results5

ÄKTAprime plus Operating Instructions 28-9597-89 AB 33

Page 34

4 Operation

4.2 Starting the instrument

4

The self-test takes about 30–40 seconds. When the test is completed, the display

shows the Templates menu.

Note:

The system can be used for most applications after 15 min of lamp warm-up

but the full specifications are not obtained until after 1 hour.

4.3 Preparations before start

Buffer preparation

Prepare buffers according to ÄKTAprime plus cue cards.

Sample preparation

1

Adjust the sample composition to the binding buffer by:

•

diluting the sample in binding buffer, or

•

buffer exchange using HiTrap™ Desalting or HiPrep™ 26/10 Desalting column.

2

Filter the sample through a 0.45 µm filter.

Purification setup

Removing storage solution from the flow path

At delivery and during storage, the flow path is filled with 20% ethanol. This should be

removed before continuing the setup.

Note:

To flush out the ethanol using deionized water:

1

2

3

4

5

34 ÄKTAprime plus Operating Instructions 28-9597-89 AB

Do not use buffer with high salt concentration to flush out the ethanol. It might

cause too high backpressure.

Put the inlet tubing A1–A8 that is used and B in deionized water.

Note:

Put all waste capillaries, W1–W3, in waste.

Select Templates in the main menu using the and buttons and press OK.

Select Application Template and press OK.

Select System Wash Method and press OK.

At delivery, only A1 and B are installed.

Page 35

1

2

3

4

5

6

7

8

9

10

ml

4 Operation

4.3 Preparations before start

6

Choose to wash the A2–A8 inlet tubing that is used by pressing OK at those cursor

positions. A1 and B will always be washed.

Note:

7

Scroll to OK and press the OK button.

8

Press OK to start the method.

9

When the method is finished, replace the first collection tube. It will contain a small

At delivery, only A1 and B are installed.

amount of water after the system wash.

Purging the pump and inlet tubing

If there are large amounts of air in the tubing or if you suspect air in the pump, use the

Purge kit to purge the flow path. Air bubbles that still are trapped in the pump (causing

increased pulsation) can beremoved by flushing 100% ethanolthrough thepump. These

two procedures are described in the following two sections.

Purging the flow path using the Purge kit:

1

Remove the stop plug from the pump.

2

Connect the Purge kit to the pump.

3

Put the used inlet tubing in the appropriate buffers.

4

Run the pump at 0.1 ml/min.

Filling inlet tubing A1–A8:

1

Go to Set Buffer Valve using the arrow buttons.

2

Set the chosen A inlet and press OK. The valve switches to the selected port.

3

Draw buffer with the purge syringe until liquid enters the syringe.

4

Repeat step 1–3 until all chosen A inlet tubing is filled.

Filling inlet tubing B:

ÄKTAprime plus Operating Instructions 28-9597-89 AB 35

1

Go to Set Concentration %B and set the concentration to 100%.

Page 36

1

2

3

4

4 Operation

4.3 Preparations before start

2

Press OK. The switch valve turns to the inlet B port.

3

Draw buffer with the purge syringe until liquid enters the syringe.

4

Replace the purge tubing with the stop plug.

5

Stop the pump by pressing end and then OK.

Flushing the pump with 100% ethanol:

1

Put inlet tubing A1 in deionized water.

2

Run the pump at 40 ml/min for 1 min and press pause/cont.

3

Move inlet tubing A1 to 100% ethanol

4

Press pause/cont, run the pump for 10–20 s and press pause/cont.

5

Set the flow rate to 5 ml/min using the arrow buttons.

6

Press pause/cont, run the pump for at least 30 s and press pause/cont.

7

Move inlet tubing A1 to deionized water.

8

Press pause/cont and run the pump for 1 min.

9

Finish by pressing end and then OK.

Preparing the tubing and column

1

Put inlet tubing A1 in the binding buffer.

2

Put inlet tubing B in the elution buffer.

3

Put the threewaste capillaries (brown color)from port 4 and 5 on the injection valve

and port NO on the fraction collector valve in waste.

4

Connect a column, for example a HisTrap™ HP 1 ml column, between port 1 on the

injection valve and the upper port of the UV flow cell. Use a suitable length of PEEK

tubing and 1/16" male connectors.

36 ÄKTAprime plus Operating Instructions 28-9597-89 AB

Page 37

5 mm

1

2

5.

3.

4.

1.

2.

4 Operation

4.3 Preparations before start

DescriptionNo.DescriptionNo.

HisTrap column3Tubing from injection valve1

UV cell41/16" male connector2

Note:

Other unions and connectors might be required for other columns.

Preparing the fraction collector

1

Fill the fraction collector rack with, for example, 18 mm tubes (minimum 40 pcs.).

2

Adjust the height of the delivery arm using the lock knob (1) so that the bottom of

the tubesensor (2) is about 5mm below thetop of the tubes. Thetubes should always

be below the horizontal mark on the tube sensor.

3

If necessary, adjust the length of the tubing exposed according to the sequence

shown below (the hole in the delivery arm used in step 3 and 4 is only used for adjusting the tubing length).

ÄKTAprime plus Operating Instructions 28-9597-89 AB 37

Page 38

2

1

3

4 Operation

4.3 Preparations before start

4

Check that the tube sensor (1) is in the correct position for the tube size. The eluent

tubing should be over the center of the collection tube. Use the red sensor control

knob (2) to position the tube holder (3).

5

Rotate the rack by hand until the rear half of the tube sensor rests against the first

tube.

6

Press feed tube on the front panel (see Figure 1.2). The bowl moves to the correct

position to collect the first fraction in the first tube.

7

Make sure that drop synchronization is turned on.

Note:

Drop synchronization can NOT be used at flowrates above 3 ml/min.

Preparing the monitors

1

Check the UV lamp filter position and the lamp position.

2

Calibrate the pH electrode (optional).

See ÄKTAprime plus User Manual for more information.

Filling the buffer inlet tubing

When running an application templates, the buffer inlet tubing will automatically be

filled with buffer.

For other applications, fill the inlet tubing manually with buffer as described in the

ÄKTAprime plus User Manual.

Filling the sample loop

Using an injection fill port

38 ÄKTAprime plus Operating Instructions 28-9597-89 AB

Page 39

3

1

4 Operation

4.3 Preparations before start

1

Connect a sample loop between port 2 and 6 on the injection valve. Make sure that

the sample loop is large enough for your sample.

2

Connect a luer female/1/16" male union to port 3.

3

Fill a syringe with five loop volumes of deionized water or binding buffer.

4

Fit the syringe in the Luer union (1) and carefully inject the buffer.

5

Remove the syringe and fill it with at least two loop volumes of the sample.

6

Carefully inject the sample into the sample loop. Do NOT remove the syringe after

the injection because the loop might otherwise be emptied due to self-drainage or

air may be introduced in the flow path.

4.4 Performing a run

Selecting template and starting

the run

1

Select Templates in the main menu and press OK.

2

Select Application Template and press OK.

3

Select theappropriate template,for example His Tag Purification HisTrap, and press

OK.

4

Set the sample volume and press OK.

5

Press OK to start the purification run.

ÄKTAprime plus Operating Instructions 28-9597-89 AB 39

Page 40

4 Operation

4.4 Performing a run

Viewing the run

When the pump starts running, the progress of the run can be viewed in the two panes

in PrimeView.

•

The Curves pane displays monitor signal values graphically.

•

The Logbook pane displays all actions (e.g. method start and end, base instructions

and methodinstructions) andunexpected conditions(e.g. warningsand alarms).The

log is saved in the result file.

Selecting curves to be displayed

1

In PrimeView module, select View:Properties.

2

In the Properties dialog, click the Curves tab.

3

In the Display curves list, select the curves you want to display.

4

Click OK.

For more information on customizing the view panes, see PrimeView User Manual.

40 ÄKTAprime plus Operating Instructions 28-9597-89 AB

Page 41

Ending the run

Press OK at the Method Complete prompt. This will cause all valves to return to their

default positions.

To stop the run on a system before it is finished:

1

Press the end button.

2

Select yes and press OK.

Error indication

When a warning or an alarm is issued from a system, an error code is displayed. See

ÄKTAprime plus User Manual for guidance.

Evaluate the results

PrimeView Evaluation module provides facilities for the presentation and evaluation of

separation results.

To start PrimeViewEvaluation module, click PrimeView Evaluationicon on the Windows

desktop.

4 Operation

4.4 Performing a run

See ÄKTAprime plus User Manual and PrimeView User Manual for how to evaluate the

results.

4.5 Procedures after a run

Cleaning after a run

NOTICE

Do not allow solutions which contain dissolved salts, proteins or

other solid solutes to dry out in the UV flow cell.

ÄKTAprime plus Operating Instructions 28-9597-89 AB 41

Page 42

4 Operation

4.5 Procedures after a run

Buffers notcontaining any saltcan be left in the system for ashort time aftera run, even

overnight (not in the pH electrode, see instructions below).

To flush the flow path:

1

Fill a syringe with five times the sample loop volume of deionized water.

2

Rinse the sample loop by injecting the water through the fill port on the injection

valve.

3

Put all used inlet tubings in water.

4

In theTemplates menu,select Application Template and thenSystem Wash Method.

5

Select the used inlet ports. Inlets A1 and B will always be washed.

6

Press OK to start the method. The system flow path is now automatically flushed.

For informationon cleaning andlong-term storage, see Section 5.3 Cleaning, on page46

and Section 5.7 Storage, on page 49.

NOTICE

Do not allow particles to enter the UV flow cell as damage to the

flow cell might occur.

NOTICE

If a buffer containing salt has been used, the flow path must be

flushed with deionized water.

42 ÄKTAprime plus Operating Instructions 28-9597-89 AB

Page 43

5 Maintenance

About this chapter

This chapter provides instructions for routine component maintenance and a maintenance schedule.

5.1 General

Regular maintenanceis important for safe andtrouble-free operationof your instrument.

The usershould perform daily and monthlymaintenance. Preventive maintenanceshould

be performed on a yearly basis by qualified service personnel.

For maintenance of a specific component, carefully read the component manual and

follow the instructions.

WARNING

Electrical shock hazard. All repairs should be done by service

personnel authorized by GE Healthcare. Do not open any covers

or replace parts unless specifically stated in the user documentation.

5 Maintenance

WARNING

Disconnect power.Always disconnect powerfrom the instrument

before replacing any component on the instrument, unless stated

otherwise in the user documentation.

WARNING

Hazardous chemicals during maintenance.When using hazardous

chemicals for system or column cleaning, wash the system or

columns with a neutral solution in the last phase or step.

ÄKTAprime plus Operating Instructions 28-9597-89 AB 43

Page 44

5 Maintenance

5.1 General

WARNING

Do not perform any type of maintenance work while the system is

powered electrically or whenthe piping systemis pressurized.Note

that the piping system can be pressurized even when the system

is closed down.

WARNING

When using hazardous chemical and biological agents, take all

suitable protective measures, such as wearing protective glasses

and gloves resistant to the substances used. Follow local and/or

national regulations for safe operation and maintenance of

ÄKTAprime plus.

CAUTION

Fire hazard. Follow instructions in ÄKTAprime plus Operating

Instructions for correct installation of a new UV-lamp. If the lamp

is not installed properly it may be overheated and cause a fire

hazard.

NOTICE

Cleaning. Keep the instrument dry and clean. Wipe regularly with

a softdamp tissue and,if necessary, amild cleaning agent . Let the

instrument dry completely before use.

5.2 User maintenance schedule

Table 5.1 provides a guide to maintenance operations and intervals at which these operations should be performed by the user. The user is however responsible for deciding

the type of operations and length of intervals necessary to maintain system function

and safety.

44 ÄKTAprime plus Operating Instructions 28-9597-89 AB

Page 45

Table 5.1: User maintenance schedule

5 Maintenance

5.2 User maintenance schedule

Instructions/referenceActionInterval

Visually inspect the system for leaks.Leak inspectionDaily

Wash thesystem flow

path

Calibrate pHelectrode

(optional)

Check inlet filtersWeekly

(if applicable)

Flow restrictorMonthly

For cleaningthe flowpath, seeCleaning-In-

1

Place, on page 46.

For leaving the system for a few days, see

2

Section 5.7 Storage, on page 49.

Calibrate thepH electrode(if applicable) according to Monitor pH/C-900 User Manual.

Check theinlet filters visually and replace them

if necessary.

Replace the on-line filter.Replace on-line filter

Check thatflow restrictor generates the following back-pressure:

FR-904: 0.4 ±0.05 MPa

Check the back-pressure as follows:

Disconnect the flow restrictor.

1

Connect a tubing (approx. 1 m, i.d. 1 mm)

2

to the waste port (port 5) on the injection

valve. Set the injection valve manually to

Waste position.Put the open end ina waste

container.

Run the pump manually at 10 ml/min with

3

water. Note the back-pressure (Bp1) on the

pump display, or in the Run Data window.

Set the system to Pause and connect the

4

flow restrictor to the openend ofthe tubing

(observe theIN marking). Putthe flow restrictor in the waste container.

Press Continue so that the pump run at 10

5

ml/min with water. Note the back-pressure

(Bp2) on the pump display, or in the Run

Data window.

Calculate the back-pressure generated by

6

the flow restrictor (Bp2-Bp1). Replace it if it

is not within limit.

ÄKTAprime plus Operating Instructions 28-9597-89 AB 45

Page 46

5 Maintenance

5.2 User maintenance schedule

Instructions/referenceActionInterval

5.3 Cleaning

Cleaning before planned

maintenance/service

To ensure the protection and safety of service personnel, all equipmentand work areas

must beclean and freeof any hazardous contaminantsbefore a Service Engineerstarts

maintenance work.

Please complete the checklist in the On Site Service Health & Safety Declaration Form or

the Health & Safety Declaration Form for Product Return or Servicing, depending on

whether theinstrument is goingto be serviced on site or returned forservice, respectively.

Copy theform you need from Section7.4 Health and Safety Declaration Form, on page 62

or print it from the PDF file available on the User Documentation CD.

Cleaning-In-Place

All components in the system are designed for ease of CIP.

After repeated separation cycles, contaminating material might progressively build up

in the system and on the column. This material may not have been removed by the

cleaning step described above. The nature and degree of contamination depends on

the sampleand the chromatographic conditions employed.These should be considered

when designing a cleaning protocol.

Routine cleaning should be performed at intervals aimed at prevention rather than

cleaning the system from growth or contamination.

Valve inspectionYearly

Check for external or internal leakage. Replace

channel plate and distribution plate yearly or

when required. Refer to the relevant valve instruction sheet.

WARNING

Make sure that the piping system is completely leakage free before

performing any CIP on the system.

46 ÄKTAprime plus Operating Instructions 28-9597-89 AB

Page 47

5 Maintenance

5.3 Cleaning

Make sure that the process control method for cleaning flushes all possible flow paths

in the system. After cleaning, rinse the entire system with water or suitable liquid until

the piping/tubingsystem iscompletely freefrom theCIP solution(monitors inthe system

can be used as detectors). Do not leave NaOH or other cleaning agents in the system

for long periods.

WARNING

Hazardous chemicals during maintenance.When using hazardous

chemicals for system or column cleaning, wash the system or

columns with a neutral solution in the last phase or step.

WARNING

NaOH is corrosive and therefore dangerous to health. When using

hazardous chemicals, avoid spillage and wear protective glasses

and other suitable Personal Protective Equipment (PPE).

See also Section 5.7 Storage, on page 49.

5.4 Component maintenance

Maintenance andpreventive replacement ofparts of the major componentsare described

in the respective manuals included in the system documentation.

The system documentation also includes a spare part list to be used to find common

spare parts and their code numbers for ordering. This list can also be found online at

www.gelifesciences.com/AKTA.

5.5 Disassembly and assembly of components and consumables

The operator must carefully read and understand the instructions supplied for each

component before disassembly and assembly of the component. When replacing consumables, suchas tubing and tubing connectors,all neccessary safety precautions must

be taken. Contact your local GE Healthcare representative if further information or help

is needed.

WARNING

Disconnect power.Always disconnect powerfrom the instrument

before replacing any component on the instrument, unless stated

otherwise in the user documentation.

ÄKTAprime plus Operating Instructions 28-9597-89 AB 47

Page 48

5 Maintenance

5.5 Disassembly and assembly of components and consumables

WARNING

Before disassembly, check that there is no pressure in the piping

system.

WARNING

After assembly, the piping system must be tested for leakage at

maximum pressure for continued protection against injury risks

due to fluid jets, burst pipes or explosive atmosphere.

5.6 Calibration

The table below lists the type and frequency of calibrations that can be done on the instrument. Refer toPrimeView user documentation and tothe individual component User

Manuals and Instructions for descriptions of how to perform these calibrations. The

calibrations are performed from PrimeView by selecting System:Calibrate in System

Control.

flow cell

Cell constantConductivity

Temperature

Entering a

new cell constant

How oftenComponent

Every day.pH monitor (if applicable)

When required.Pump (if applicable)

When required.Pressure reading

Only necessary if specific conductivity with high

accuracy is measured (Cond_Calib).

Must be done when changing the conductivity

flow cell (Temp).

Must be done when changing the conductivity

flow cell (Cond_Cell).

48 ÄKTAprime plus Operating Instructions 28-9597-89 AB

Page 49

5.7 Storage

General recommendation

For storage, the system must first be cleaned as described in Cleaning-In-Place, on

page 46. After cleaning, the system must be filled with 0.01 M NaOH or 20% ethanol

solution.

Columns and media shall be stored according to their respective instructions.

Storage conditions

The following conditions shall be maintained while the system is in storage:

•

Temperature: 2°C to 30°C (preferably room temperature)

•

Relative humidity: 0% to 95%, non-condensing (preferably low humidity).

After storage,clean the system, calibrate allmonitors, and performa leakage testbefore

using the system.

5 Maintenance

5.7 Storage

ÄKTAprime plus Operating Instructions 28-9597-89 AB 49

Page 50

6 Troubleshooting

6 Troubleshooting

6.1 UV curve problems

Corrective actionPossible causeError symptom

Ghost peak

nal drift or instability

Dirt or residues in the

flow path from previous runs. Air in the

eluents.

Residue inthe column

from previous runs

Incorrect mixer function

Dirty UV cellNoisy UV-signal, sig-

Impure buffer

Air in the pump or in

the UV cell

Clean the system. Make sure air is

removed.

Clean thecolumn according to the

column instructions.

Check the mixer function by placing astirrer baron top of the mixer

housing. The stirrer bar should rotate when the system is in Run

mode. Themixer function can also

be checkedby running the installation test.

Clean the UV cell by flushing

Decon™ 90, Deconex™ 11 or

equivalent.

Check ifthe signalis still noisy with

water.

Purge the pump according to

Pump User Manual. Run a system

wash with buffer.

50 ÄKTAprime plus Operating Instructions 28-9597-89 AB

Page 51

6 Troubleshooting

6.1 UV curve problems

Corrective actionPossible causeError symptom

Aging UV lampLow sensitivity

UV lamp in wrong position

The theoreticalextinction coefficient too

low

6.2 Conductivity curve problems

Baseline drift or noisy

signal

Air in the pump or the

flow cell

Leaking tubeconnections

Incorrect mixer function

Check thelamp runtime according

to and replace if necessary. Refer

to ÄKTAprime plus User Manual.

Check that the lamp position and

the filter position are both set to

the wavelength tobe used, 280 nm

or 254nm. Refer to ÄKTAprimeplus

User Manual.

Calculate thetheoretical extinction

coefficient of the protein. If it is zero or very low at 280 nm, the protein cannot be detected.

Corrective actionPossible causeError symptom

Check the flow restrictor after the

flow cell.

Tighten the clamps. If necessary,

replace the clamps.

Check the mixer function by placing astirrer baron top of the mixer

housing. The stirrer bar should rotate when the system is in Run

mode. Themixer function can also

be checkedby running the installation test.

Dirty conductivity cell

Column notequilibrated

Dirty flow cellConductivity measurement with the same

buffer appears to decrease over time

ÄKTAprime plus Operating Instructions 28-9597-89 AB 51

Decrease in ambient

temperature

Clean the conductivity cell by

flushing 1M NaOH or 20% ethanol.

Equilibrate the column. If necessary, clean the column using a

method plan for column cleaning.

Clean the flow cell according to

procedure in Monitor User Manual.

Use a temperature compensation

factor. See Monitor User Manual.

Page 52

6 Troubleshooting

6.2 Conductivity curve problems

Corrective actionPossible causeError symptom

Waves on the gradient

in the gradient profile

slow response to %B

changes

Incorrect pump function

Dirty mixing chamber

Insufficient mixing

chamber volume

Incorrect motor function

Air in the flow cellGhost peaks appear

Dirty tubingUnlinear gradients or

ume

Check that the pump is operating

and is programmed correctly.

Check that the mixing chamber is

free from dirt or particles.

Change to a larger mixing chamber volume if necessary.

Check the motor operation. Place

a hand on the mixer and start it by

starting the pump at a low flow

rate. You shouldboth hear and feel

the mixer motor and stirrer when

they are spinning.

Check for loose tubing connections. Use the flow restrictor.

Wash the tubing and check pump

is operating properly.

Change to smaller mixer volume.Incorrect mixer vol-

52 ÄKTAprime plus Operating Instructions 28-9597-89 AB

Page 53

6 Troubleshooting

6.2 Conductivity curve problems

Corrective actionPossible causeError symptom

Incorrect or unstable

reading

6.3 pH curve problems

Loose connection of

conductivity flow ca-

ble

Incorrect pump and

valves function

Incorrect temperature

compensation factor

Dirty or incorrectly

equilibrated column

Incorrect mixer func-

tion

Check that the conductivity flow

cell cable is connected properly.

Check that the pump and valves

operate correctly.

If temperature compensation is

being used,check thatthe temperature sensoris calibrated, and that

the correct temperature compensation factor is in use.

Check thatthe columnis equilibrated. If necessary clean the column.

Check the operation of the mixer.

The mixer function is checked by

placing a stirrer bar on top of the

mixer housing. The stirrer bar

should rotate when the system is

in Run mode. The mixer function

can also be checked by running

the installation test.

Corrective actionPossible causeError symptom

No response to pH

changes

changes

ÄKTAprime plus Operating Instructions 28-9597-89 AB 53

Faulty electrode con-

nection

Damaged electrode

Incorrectly connected

pH monitor

Dirty pH electrodeSmall response to pH

Check that the electrode cable is

connected properly.

The electrode glass membrane

may becracked. Replace the electrode.

Check that the pH monitor is correctly connected according to the

ÄKTAprime plus User Manual.

Clean thepH electrode as detailed

in Monitor pH/C-900 User Manual.

If theproblem remains,replace the

pH electrode.

Page 54

6 Troubleshooting

6.3 pH curve problems

Corrective actionPossible causeError symptom

Slow pH response or

Calibration impossible

Contaminated electrode glass membrane

Membrane has dried

out

Check the electrode glass membrane. If it is contaminated, clean

the electrodefollowing theinstructions in Monitor pH/C-900 User

Manual.

If themembrane has dried out, the

electrode may be restored by

soaking it in buffer overnight.

54 ÄKTAprime plus Operating Instructions 28-9597-89 AB

Page 55

6 Troubleshooting

6.3 pH curve problems

Corrective actionPossible causeError symptom

Incorrect or unstable

pH reading

Problem with elec-

trode

Check that the electrode cable is

connected properly.

Check thatthe electrodeis correctly inserted in the flow cell and, if

necessary, hand-tighten the nut.

Check that the pH electrode is not

broken.

Calibrate the pH electrode.

Clean the pH electrode if required,

see MonitorpH/C-900 User Manual.

Compare the response of the pH

electrode with that of another pH

electrode. If the response differ

greatly, the electrode may require

cleaning or replacement.

In organic solvents such as

ethanol, methanoland acetonitrile,

stable pH measurements are not

possible since dehydration of the

membrane will occur. It is recommended that the pH electrode is

not used in applications using organic solvents. Mount the dummy

electrode instead.

Incorrect pump or

valve operation

Air in the flow cell

Check that the pump and valves

operate correctly.

If air in the flow cell is suspected,

tap the flow cell carefully or tilt it

to remove the air. Alternatively,

flush the cell with buffer at 20

ml/min (E100 system)or 10 ml/min

(E 10 system) for 1/2 min. Use the

flow restrictor FR-902 after the pH

electrode.

Static interference

There may be interference from

static fields. Connect the pH flow

cell and the rear panel of the

monitor usinga standardlaboratory 4 mm “banana plug” cable.

ÄKTAprime plus Operating Instructions 28-9597-89 AB 55

Page 56

6 Troubleshooting

6.3 pH curve problems

Corrective actionPossible causeError symptom

pH values vary with

varied back pressure

electrode

6.4 Pressure curve problems

Erratic flow, noisy

baseline signal,irregular pressure trace

through or trapped in

the pump

Inlet or outlet check

valves notfunctioning

correctly

Piston seal leaking

Replace the pH electrode.Problem with the

Corrective actionPossible causeError symptom

Check all connections for leaks.Air bubbles passing

Check thatthere is sufficient eluent

present in the reservoirs.

Use degassed solutions.

Purge the pump.

Follow the instructions in

ÄKTAprime plus User Manual.

Clean the valves according to

Pump P-920 User Manual.

Clean the valves according to

ÄKTAprime plus User Manual.

Replace the piston seal according

to the instructions in .ÄKTAprime

plus User Manual.

Flush through to clear blockage.Blockage or part

blockage of flowpath

56 ÄKTAprime plus Operating Instructions 28-9597-89 AB

If necessary, replace tubing.

Check inlet tubing filter. It can become clogged if unfiltered buffers

or samplesare applied.See instructions for flushing through at the

end of the run in ÄKTAprime plus

User Manual.

Page 57

7 Reference information

About this chapter

This chapter contains technical data, regulatory and other information.

7.1 Specifications

ValueParameter

Housing: IP20Ingression protection

Flow cells: IP44

100-120/220-240 V ~, 50 to 60 HzSupply voltage

90 VAPower consumption

T 1.0 AH 250 VFuse specification

7 Reference information

7.2 Chemical resistance

Chemical

Exposure

< 1 day

up to 2

months

OKOKAcetaldehyde

OKOKAcetic acid, < 5%

530 × 400 × 450 mmDimensions (H × W × D)

13 kgWeight

4°C to 40°CAmbient temperature

10% to 95%Relative humidity tolerance (non-condensing)

84 to 106 kPa (840 to 1060 mbar)Atmospheric pressure

CommentsEEC no.CAS no.Exposure

200-580-764-19-7OKOKAcetic acid, 70%

200-835-275-05-8OKOKAcetonitrile

FFKM, PP and PE

swell.

ÄKTAprime plus Operating Instructions 28-9597-89 AB 57

Page 58

7 Reference information

7.2 Chemical resistance

Chemical

ride

bonate

phate

Exposure

< 1 day

up to 2

months

AvoidOKAcetone, 10%

OKOKAmmonium bicar-

OKOKAmmonium nitrate

OKOK1-Butanol

OKOK2-Butanol

AvoidOKChloroform

CommentsEEC no.CAS no.Exposure

PVDF is affected by

long term use.

231-635-37664-41-7OKOKAmmonia, 30%

Silicone is affected

by long-term use.

235-186-412125-02-9OKOKAmmonium chlo-

231-984-17783-20-2OKOKAmmonium sul-

249-576-729340-81-6OKOKCitric acid

Kalrez™, CTFE, PP

and PE are affected

by long term use.

OKOKCyclohexane

OKOKDetergents

200-664-367-68-5AvoidAvoidDimethyl sulphox-

ide

AvoidAvoid1, 4-Dioxane

PVDF is affected by

long term use.

ETFE, PP, PE and

PVDF are affected

by long term use.

200-837-375-08-1OKOKEthanol, 100%

AvoidOKEthyl acetate

Silicone not resistant. Pressure limit

for PEEKdecreases.

203-473-3107-21-1OKOKEthylene glycol,

100%

58 ÄKTAprime plus Operating Instructions 28-9597-89 AB

Page 59

7 Reference information

7.2 Chemical resistance

Chemical

drochloride

0.1 M

> 0.1 M

Exposure

< 1 day

up to 2

months

OKOKGuanidinium hy-

AvoidOKHexane

AvoidOKHydrochloric acid,

CommentsEEC no.CAS no.Exposure

200-579-164-18-6OKOKFormic acid, 100%

Silicone not resistant.

200-289-556-81-5OKOKGlycerol, 100%

Silicone not resistant. Pressure limit

for PEEKdecreases.

231-595-77647-01-0OKOKHydrochloric acid,

Silicone not resistant.

Silicone not resistant. Titanium isaffected bylong term

use.

200-661-767-63-0OKOKIsopropanol, 100%

200-659-674-93-1OKOKMethanol, 100%

AvoidOKNitric acid, diluted

Silicone not resistant.

AvoidAvoidNitric acid, 30%

Elgiloy™ is affected

by long term use.

231-633-27664-38-2AvoidOKPhosphoric acid,

10%

Titanium, aluminium oxide and glass

are affected by

long term use.

209-529-3584-08-7OKOKPotassium carbon-

ate

231-211-87447-40-7OKOKPotassium chloride

AvoidAvoidPyridine

ETFE, PP and PE not

resistant.

OKOKSodium acetate

ÄKTAprime plus Operating Instructions 28-9597-89 AB 59

Page 60

7 Reference information

7.2 Chemical resistance

Chemical

ate

2 M

ed

medium concentration

Exposure

< 1 day

up to 2

months

OKOKSodium bicarbon-

OKOKSodium bisulphate

OKOKSodium borate

OKOKSodium carbonate

AvoidOKSulphuric acid, dilut-

AvoidAvoidSulphuric acid,

CommentsEEC no.CAS no.Exposure