GE AKR-3-50, AKR-3A-50, AKRU-3-50, AKRU-3A-50 Maintenance Manual

MAI NTE NANCE

MAN

UAL

t nc t

t

u de s

s u

ppte

ment8Fi#3;

POTVEN

TYPES

CIRCUIT

BNEAIIERS

AKR.3/3A-50

AND AKRU-3/3A-50

GEilERAr

@

ErECTRlC

GENERAL

General

Breaker

Mounting

Fused Breakers.

Breaker

Breaker

DESCRIPTION. .

Types

Ratings

Description . .

CONTENTS

.

.

.

Page

3

3

3

4

4

4

4

RECEIVING, HANDLING, AND

Receiving

Storage

HandlinC . . .

and

BREAKER OPERATION

Putting the

Breaker in Service

Drawout Breakers

Breaker

Insertion

(Fig.

Breaker Withdrawal

Stationary Breakers

Pre-service

Operating

Manual Closing

Electrical

Openlng

the Breaker

the

Check

Breaker

Closing

Interlocks

Closing

Racking Mechanism

Optional

Accessories .

Shunt Trip

Undervoltage

Static

Electric

Spring Interlock

Interlocks

. .

Device

Time-delay

Lockout

Undervoltage

Device

Interlocks

Auxiliary Switch

BeII Alarm

BREAKER MAINTENANCE.

Safety

Precautions

General

Arranging the Breaker for

Slow Closing

Lubrication

Replacement

Mechanism

Mechanism

and Adjustment of Components

(Figs.

12, 13,

Replaeement

Latch Adjustment

Manual Handle

Adjustment

Contact Maintenance

Contact Replacement

(Fig.

Contact Adjustment

Components and Accessories

Auxiliary Switch

Trip

Shunt

Maintenance of

Electrical

Control

Bell Alarm/Lockout

Drawout

Mechanism

(Fig.

18)

and Undervoltage

Static Delay Device for Undervoltage

C omponents

FiS.

and

AKRU-50 Fused Breaker

Fuse Replacement

Fuse Lockout

Open

Power Sensor Overcument

Tripping

False

Testing

Replacement

Current

Magnetic Trip Device

Selective

Time-current

Tripping

Curves

Device

Caused

Sensors

Trip Device

by Faulty

(Figs.

STORAGE

3)

(Figs.

6A

(F'ig.

. . .

14)

and

(Figs.

Interlocks

17)

.

Device

26).

(Fig.

33

15

32)

Ground

and 38)

68).

and

8)

and

(Figs.

.

.

16)

.

.

and

. .

19

Fault Operation .

. .

Accessories

20).

and

. .

(Figs.

.

.

21

.

and

22)

. .

. . .

5

5

5

5

t

5

5

n

I

7

8

8

8

10

10

10

10

11

11

12

t2

13

13

13

l4

t4

15

15

15

15

16

16

.

.

16

18

19

19

19

19

20

2l

2t

22

24

25

27

28

29

29

31

31

34

34

34

36

36

3?138

IOW-VOLTAGE

TypEs

AKR-3/3A-so

POWER

AND

CIRCUIT

AKRU_3

/ga-so

BREAKERS

Low-voltagepower

controlling

voltage

this

function,

loads

normal

the

more

overloads

The

breakers

protection

mizing

sons

who apply,

will

acquire

information

andprotecting

range

and

automatically

conditions

common

and

proper

is

a

personnel,

of

equipment

the knowledge

contained

(usually

they

undervoltages.

use,

prime

damage

use,

BREAKER

Ali

make, quick-break"

of the

of

storing

lease

in

ferred

for

to an

fast

subject

energy

closing.

opening

tripping.

in

In

GENERAT

circuit

power

up

to

are

a means

clearing

occur.

are

care,

Among

short

and

safety

as

wellas

when

and

service

they need

in

these

TYPES

breakers

descripiion,

a closing

closing,

spring

some

to be used

GENERAT

breakers

circuits

600

of safely

circuits

maintenance

consideration

faults

instructions.

are

having

spring

volts).

circuits

these

and

a means

occur.

these

by

of

the

for

energy

sJbsequenilv

are used

conditions,

gaining

the

for

inthe

low-

In servins

switchin[

when

ab-

sustained

of

these

for

the

mini_

of

per-

breakers

the

"quick_

feature

quick

re_

is trans-

DESCRIPTION

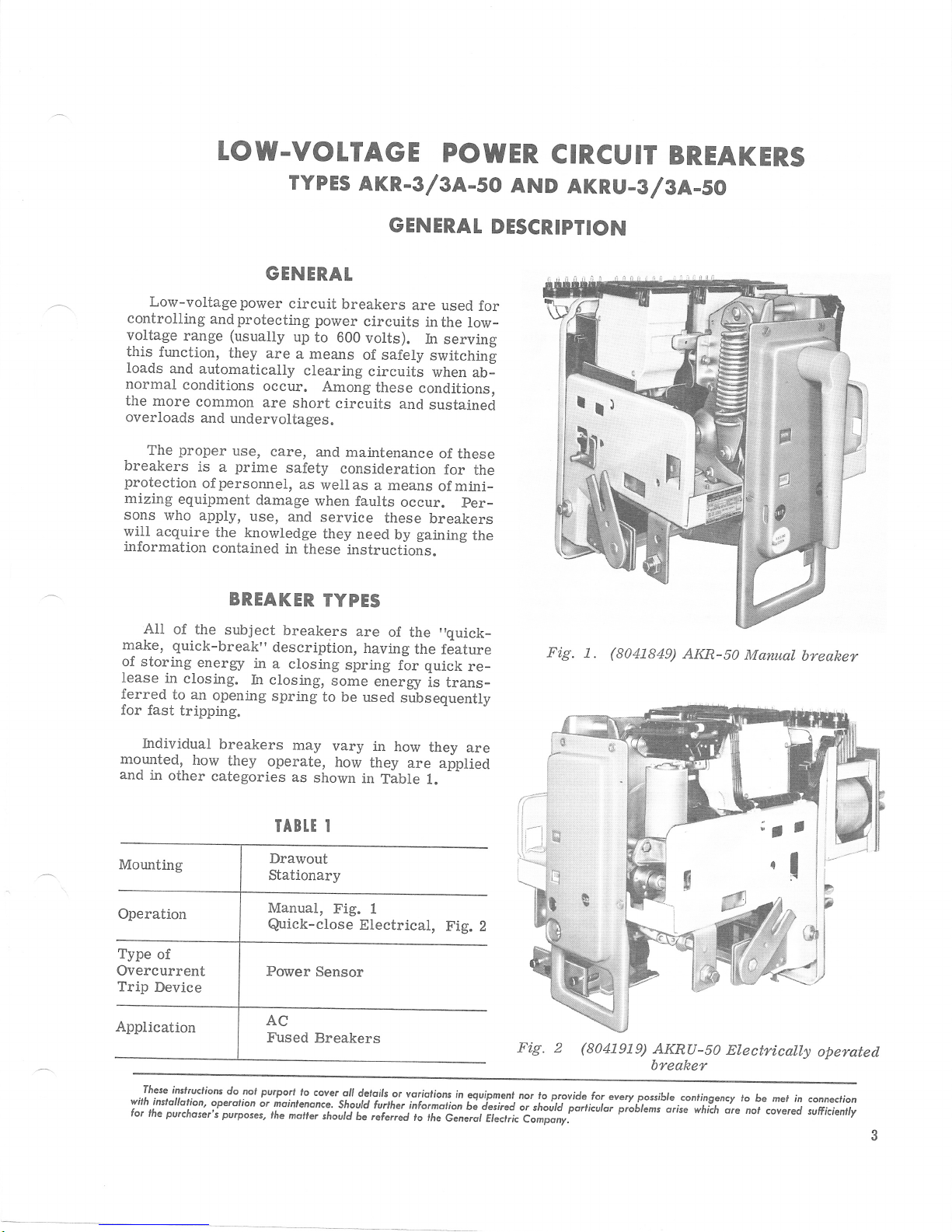

Fig.

(8041849)

1.

AKR-50

Manual

breaker

hdividual

morrnted,

and

in

other

Type

of

Overcurrent

Trip

Device

These

inslruclions

wilh

instollotion'

for

lhe purchoser's

breakers

how

they

categories

do

operdlion

purposes,

may

operate,

as

IABTT I

Drawout

Stationary

Manual,

Quick-close

pvrport

nol

or moinlenonce.

rhe

moner

shown

lo

covsr

shourd

vary

in

how

they

in

Fig.

I

Electrical,

oll

dcloils

should

6e referrd

how

are applied

Table

or

voriolions

furlher

they

L.

Fig.

in

informolion

ri

rhe

c.^irilii".tr;"-t;;;;r:"

are

egurpmenl

bi iesired

Fig. 2

nor lo p.rovide

o,

tno[ii'pirtirutor

(804t9i9)

for

everyposible

pioblams

AKRU-S1

breaker

conlinge

arise

which

Electrically

ncy lo

be mel

nol

in connection

covered

ore

operated

sufficienlly

GEK-731O, Power

Circuit Breokers

IY\OUNTING

Most breakers

type.

These

which make them

from their

features

inserting

mary

part

and

included.

type are interchangeable in their various

in the equipment. This helps breaker maintenance

associated

are

andwithdrawing thebreaker

and controL

automatically. Interlocking

Drawout

in that spare breakers can

breakers

The

mounted

fasteners being

and make

nections

supplied.

FUSED

Fused

in their

breakers are not interchangeable

are

"stationaryf'breakers

on a framework or

powef

are

BREAKERS

breakers

model identification

produced

breakers are

easy to

switchgear equipment.

a racking mechanism

power

breakers

being inspected or serviced.

used

to secure the breaker frame

connections.

needed.

a

are

are

equipped

install

disconnects

the same rating and

of

be

"plugged

are

panel,

control

If

suitable

given

terminal

the

of the

with

in or withdraw

(whichfacilitates

unit) aad

which

designed to be

with

extra letter

number.

with

standard

"dralvout"

features

These

pri-

connect

devices

mechanical

power

Type

are

locations

in"

while

con-

board is

"LI"

AKRU

gen-

eral-purpose drawout breakdrs since their enclos-

ures must be modified

required for

the fuses.

All fused breakers are

fuse lockout

tically trips

fuses open. It

position

atdd.

is

fuse

possibility

phase

energized.

device

the breaker

alsolatches thebreaker

until

a resetting

should not

This

replaced.

of allowing the

This

BREAKER

Type AIG-50

breakers. This represents

size

tinuouscurrent

breakers

theymay

is modified by the rating

device

lovest

device is 200

plied

with which the breaker is

available

As to voltage ratings, the breakers

to 600

up

rating of the

amperes.

volts,

provide

to

equipped with an opened

(OFLO

device).

open

the extra space

automa-

This

when any of the three

inthe

device is manual.ly

be done until the expended

arrangement

circuit to

eliminates

have

only

RATINGS

1600-ampere

are

the maximum

carry.

ac.

This

of the

Power

current value

overcurrent trip

equipped.

Sensor trip

may be

opened

oper-

the

one

frame

con-

The

ap-

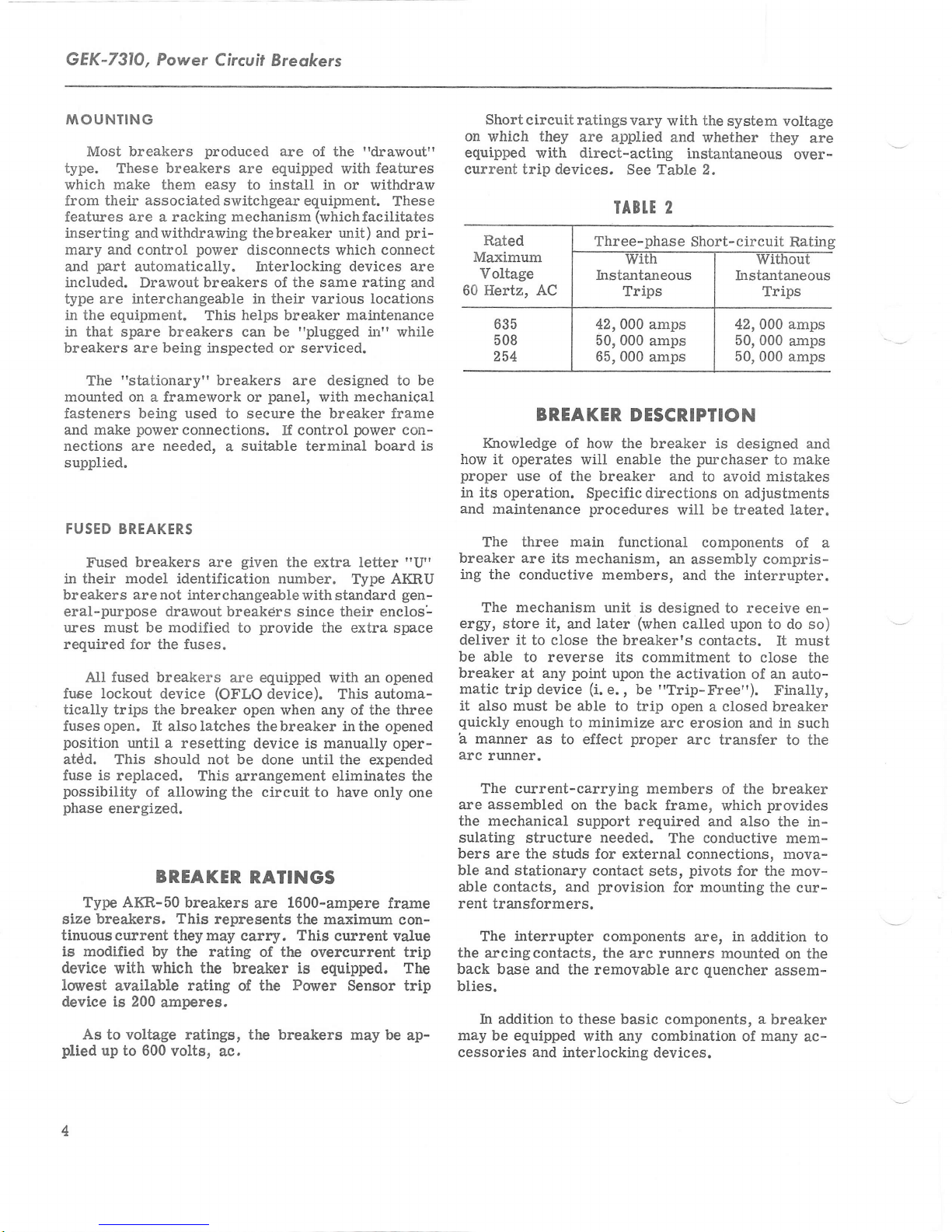

Short

circuit ratings

on which they

equipped

current trip

are

with direct-acting

devices. See Table 2.

BREAKER

IGnowledge

how it

proper

il its

operation.

and

maintenance

operates will

use

of how

of the breaker and

The three main

breaker are

ing

the conductive

The

ergy,

store

deliver

be able

breaker

matic

trip device

it

also

quickly

a

manner as

arc

runner.

The

assembled

are

the mechanical

sulating

bers

are the studs for external connections, mova-

and

ble

able contacts, and

rent

transformers.

The

the

arcingcontacts,

back base and

blies.

In addition to these basic

may

be equipped

cessories and

its mechanism,

mechanism

it,

and

it

to close the breaker's

to reverse its commitment

at any

must

enough

current-carrying

stationary

interrupter

point

be able

to

to effect

on the back

support required and

structure

the removable arc

interlocking devices.

vary

applied

IABI.T

Three-phase

42,000 amps

50,000 amps

65,000

amps

the

with

and whether they

2

system vottage

instantaneous

Short-circuit

42,000 amps

50,000

50,000 amps

DESCRIPTION

breaker

the

enable

is designed and

purchaser

the

to avoid mistakes

Specific

procedures

later

directions

will be

functional

an

assembly

members, and

unit is

designed

(when

called upon to

on

treated later.

components of a

the ilterrupter.

to receive en-

contacts.

(i.

e., be

upon

activation

the

"Trip-Free").

to trip open a closed breaker

minimize

needed.

contact

provision

components are, in

the

with

arc

proper

erosion and in such

arc

transfer

members

of the breaker

frame, which

conductive

The

pivots

sets,

for mounting the cur-

arc

runners

components,

any combination

mounted

quencher

are

over-

Rating

amps

to make

adjustments

compris-

do so)

must

It

to close

of

an

auto-

Finally,

the

to the

provides

also

the in-

mem-

for t}te mov-

addition to

on the

assem-

a

breaker

of many

ac-

Power

Circuit

Breokers,

GEK-7310

RECEIVING,

RECEIVING

breaker is carefully

Each

before shipment. Immediately

circuit

anydamage

handling

immediately with the

nearest

notified.

during unpacking

that no damage

handling, or from exposure to

Check

that no

service

this is not

betakento insuretheproper storage of

breaker,

sustainedin

is evident,

General

is expected that due

It

parts

all

parts

have been overlooked.

is recommended that the

It

immediately in its

possible,

AND

an

examination

a

damage

transportation company

Electric

installation of the breaker so

and

occur

wi.ll

HANDLING

inspected

upon receipt of the

should be made for

transit. If

claim should

Sales

care

from

damage

Office

will

careless or rough

moisture

against the

packing

list to be sure

STORAGE

breaker

permanent

following

the

precautions

HANDLING, AND

1. The breaker should be

packed

and

rough

or

be filed

and the

should be

be exercised

dirt.

or

put

be

into

location.

must

the breaker:

against

warm dry room, since water

verse

ers for outdoor switchgear should

equi.pment only when

heaters are in

2.

cation

ticular care shouldbe

from moistwe

has

If

STORAGE

condensation,

effect on the insulation

operation

breaker

The

free

from

and

a very

CAUTION:

FOR

BE

THAT RUSTING HAS

TO ASSURE

corrosive effect

IF THE BREAKER

ANY

LENGTH

INSPECTED

DITION. SHOULD

preferably

by

absorption

parts.

be

power

should

corrosive

taken to

cement dust, as

PERIODICALLY TO SEE

GOOD

is available

prevent

to

be stored in a clean lo-

gases

or fumes. Par-

protect

this combination

many

on

IS STORED

OF TIME,IT SHOULD

NOT STARTED AND

MECHANICAL

THE BREAKER BE

STORED UNDER UNFAVORABLE AT-

carefully

MOSPHERIC

BE

CLEANED AND DRIED

BEING

CONDITIONS,

PLACED IN SERVICE.

IT

OUT BEFORE

protected

storing

has an ad-

Circuit

stored in the

and

condensation.

the equipment

parts.

CON-

SHOULD

it in

break-

the

a

BREAKER

PUTTING THE

DRAWOUI BREAKERS

mechanism used

The

force required to overcome the resisting force of

disconnects

the

onthebreaker rather than in the drawout

mechanism

This

mechanism

unit

subassembly and

assembled breaker

work on the breaker.

or

BREAKER

to

on Type AKR

IN

SERVICE

provide

breakers is mounted

mechanical

the

enclosure.

is referred to as the

the

"racking"

can be

without doing any disassembly

mechanism. It is a

added to

a completely

"drawout"

This drawout mechanism consists of a crank-

power

a

and

shaft

fastened to each end of the crankshaJt is

having

arm

in the equipment enclosure.

tates, the crank arms, acting on the stationary

cause

the breaker to move

enclosure.

screw

an open slot

crankshaft

The

which operates

which

with respect to the

engages a fixed

the crankshaJt ro-

As

it.

is driven as the

Rigidly

a

crank

pin

pin,

breaker

power

OPERATION

screw

supported by a centrally located

shaft. The

by means

crank.

will engage the square end of the

breaker. A

be moved aside

screwshaft

clockwise direction moves the breaker into

nected

breaker to move

BREAKER

drawout enclosure

even coating

bars inthe

connects

is turned in an internally

power

screw,

of an external

has,

This

sliding cover in the escutcheon must

end.

position.

|NSERI|ON

procedure

The

1. Before inserting

of D50H47

enclosure

the

of

its

on

so that the handle may engage the

Turning the crank handle in a

reverse

The

out.

(FtG.

for inserting

as

is

the breaker, apply

whichengagethe

breaker.

crank on

jackscrew,

or

handle

a square socket

end,

power

of

3)

a

follows:

grease

to the silver-plated

threaded trunnion

the crank-

is turned

in the form of

which

screw in the

the con-

this

causes the

breaker into its

light,

a

primary

dis-

a

GEK-731O,

Power

Circuif

Breokers

5.

Extend the second rail.

6. Align the

in the rails and

ing

go

move

pins

the

all the

the lifting device.

7. Make

the trip button.

move

the sLiding

racking

clockwise

and remove

remove

the ends of the rackingshaftso that theywill engage

the

has not been

the encloswe, the

to

handle.

8.

itispossibletoturn

If

it. This step is taken to

pins

in

engage

the

pins

on the breaker

carefully

lower

to enter their slots. Make sure the

way down to the bottom of the slots; re-

sure the

breaker

While

is open by

holding in the

with the slots

the breaker, allow-

trip

pins

pushing

button,

cover aside and then engage the

handle

direction, do so

handle.

the

housing.

the

operated while the

pins

andthis stepwillnotbe

If the

arms

will be in theright

the

until

handle

If the racking

in

counter-

the stop is reached

align

breaker is

a

not

does

the arms

mechanism

position

necessary.

turn,

on

out of

9. Make sure that latches on the ends of the ex-

tended

pushing

into the enclosure.

rails are in the unlatched

on the breaker, roll it

position,

as

far

as

and

it will

by

go

10. Put the latches on the ends of the rails into

their locked

position.

in

I.

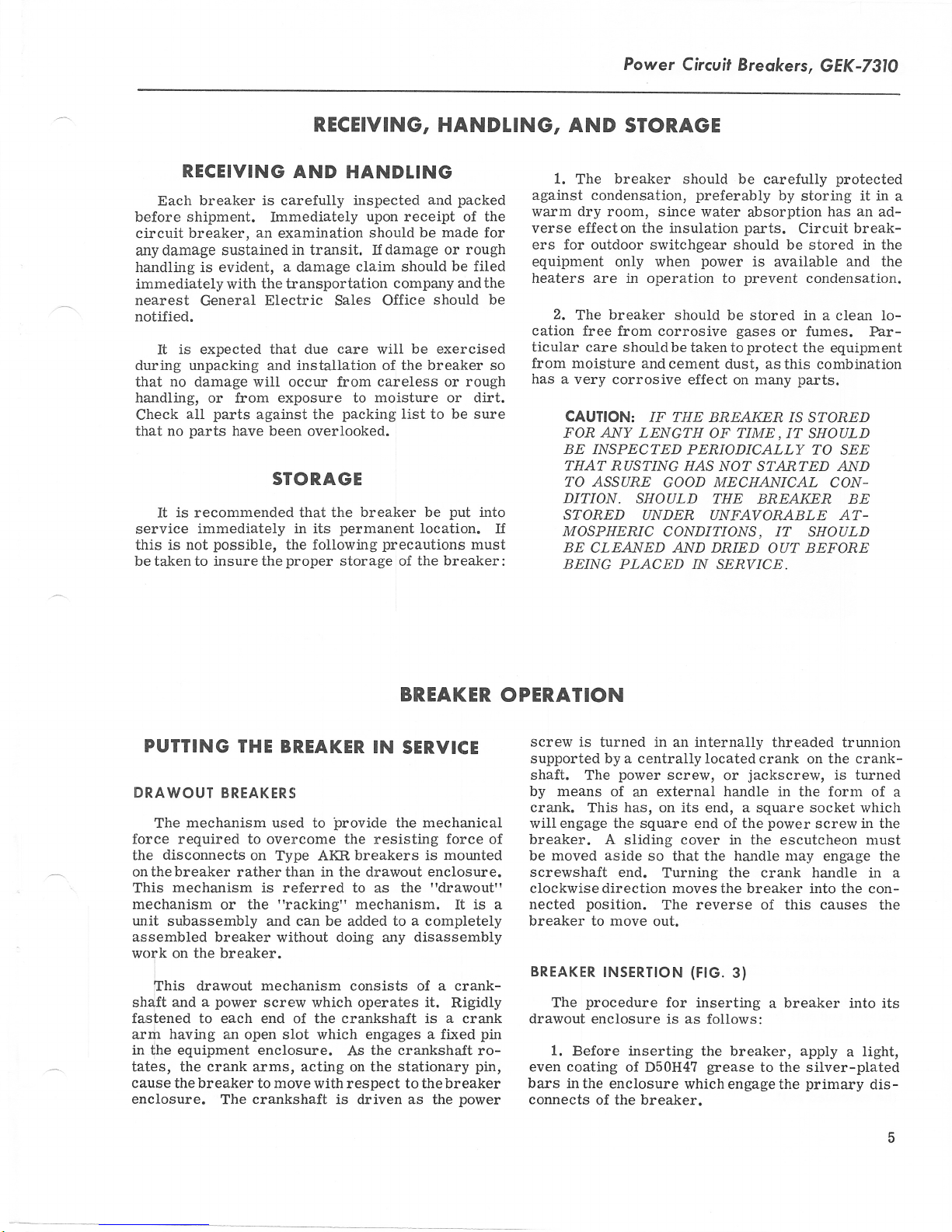

Spreader

2. Drawout Rail

3. Breaker Rail

4. Slots

'

10. Movable

Fig. 3.

5. Trip Button

6.

7. Housing Racking

B. Rail

9.

(8041582)

in

Racking Shaft

Latch Link

Racking

2. Position the breaker

intended

A

3.

forward

sheets for standard

est

unlatchandpull forward

of the cubicle.

breaker

the extended

to receive it and engage

special

The

the back for AKRU fused

3.

4.

"spreader"

hooks of the

square-shaped

the door of the

Open

Raise

the

sides are

breakers,

breaker

a few inches above the slots

rail.

Pins

Rail

Arrns

Pin

Position Indicator

Inner Housing

Inserting

provided

is

spreader are

holes

one of the rails inthe sides

until the rail

the breaker

in front of

lifting device.

the

as shown

placed

in the breaker

and inthe

breakers.

breaker

encloswe,

the cubicle

in

holes near-

pins

Fig.

in the

side

and

in

the

11. Push in on the trip button, move the sliding

cover to the right,

12.

Rotate

revolutions, thebreaker

indicator

The

ment

will

control

the

the

show

circuits

is electrically

secondary

the

on about the third turn

run,

will

off switches

13.

nects,

nected;

connect the

atbd.

the breaker

testing.

charging the

are

h the test

which carry the control.

however,

power

this

At

and engage the racking

handle

left upper

the

in

when this

are

operated, the

disconnects engage.

closing spring, until the

actuated,

position,

primary

the

circuits, are

point,

may

electrical

be operated

14. Further clockwise

handle causesthebreaker to travel

position,

in the

of the racking operation,

in

of the

which also

equipment

primary

will be

compartment. During

disconnects on

handle.

clockwise. After about five

be in the test

will

side of the

position

energized

motor

the handle.

of

and

This

position.

compart-

is reached. If

breaker

the

run when

will

will occur

motor

The

cut-

the secondary discon-

voltage,

disconnects, which

are

con-

still widely separ-

control

for the

rotation of

shown on the indicator

the spring-loaded

the

devices on

purpose

the

racking

to the connected

phase

this

fingers

breaker will en-

of

6

gage

the

stationary bar

The opening of these fingers

springswill

ment

in the racking

fali

off

travel,

About

peak

the

which

the

handle

sal

of the handle motion. Approximately

on the handle

ing cycle.

15.

The first

the enclosure,

and

the marks

grease

tracks

engagement.

attained

BREAKER

cause a noticeablyhigher

to

a lesser force requirement

at which

point

three handle

force requirement

the

ends

movement.

should be removed

are required

time the breaker

it

should

the

of

on the

marks

is

stationary

should

The maximum

g/16-inctr.

WITHDRAWAL

the

in

equipment

against the

effort. This will

a stop will be

turns

will be required

and reaching

Upon

without

for the

be completely

disconnect

bars examined.

indicate no less

amount

enclosure.

force

require-

load

quickly

very

to

the

encountered.

between

the stop

reaching

the

any rever-

24 turns

complete rack-

is introduced

withdrawn

fiagers

than

that

on the

1/4-inch

can

of the

end of

stop,

into

These

be

ers.

They should

easily

enough

the area

Iocation

ject

of the

switchboard

tions

connections

iliary

mountingholes

fastens

vertical

posed

versely

ouiline

gives

and

to

reached

surrounding

is not

chosen

to

extreme

Mounting

breaker to

tothebreaker

to the

switch

the frame

These mounting

plane.

on the breaker

a-ffect

drawing

information

a

cover

parts

live

Power

Circuit

be

situated

for

operation and

free space

troublesome.

should bedry

variations

the

breaker

its supporting

or

enclosure,

studs, andmaking

breaker

terminals,

are

If they

the

which is

or door

of the breaker.

if

required

to its

support.

holes

are not,

structure

operation

preparing

on

suitable

Breakers,

so

that

maintenance,

so

that

If it is

andclean

of temperature.

involves

terminal

these

must

furnished

bolting

structure

making

power

board and

are required.

forthe hardware

all be in

strain may

which could

of the

with the breaker

a mounting

preventing

for

GEK-731O

they can

working

possible,

andnot

the

within

connec-

control

power

the same

be im-

breaker.

structure

access

be

with

in

the

sub-

frame

the

arx-

Four

which

ad-

The

1. Trip

ton,

and move

aside to

2.

counterclockwise

the breaker

the

right.

Engage

the

sliding

the racking

direction.

3. ApproximateLy

complete the

breaker to

shown

be

because

on the

evident to the

further

the

of

racking

willbe

to discharge,

latches

out

Iifted

STATIONARY

activated.

4.

To

onthe

of the compartment.

off the

racking-out

the disconnected position.

indicator

person

stop will

a

movement

be

can

cycle,

This

but

will not

withdraw the

ends

ofthe rails,

rails

by the

BREAKERS

Stationary breakers are

mounting

in an

construction.

the drawout

drawout

and automatic

Careful

lection

on

a framework

enclosure

They

type; however,

features,

disconnects

consideration

a location

of

of the

namely,

for

hold

open,

cover in the

handle

24 turns

operation

in the

operating

encountered

be made.

the

"closing

in

and

the

of

compartment

the mechanism

beyond

Towards

spring

willcause theclosing

close the

breaker

The

lifting

intended

breaker.

completely,

pull

and

breaker

device.

or switchboard

customerts

are the same

own design

breaker unit

they do not have

the

racking mechanism

and

interlocks.

should be

mounting

given

stationary

the trip

escutcheon

crank

handle

and bring the

This

but-

in a

wiII

will be

and will

which no

the

end

interlock"

spring

open the

thebreaker

may now

for

panel,

to the se-

be

separate

or

and

as

the

break-

Another

for

the breaker

stand

and

short-circuit

be subjected.

supportedadequately

of support

enough

is

imposed

Manual

ance is

is

operated.

to the

2-l/2

frame.

Since eachupper

of two

stud must

parallel

nection.

connector

with

and lower

cable

connects

connectorb:rrs

the end

wards

yond

the

Control

made

frontarea

board

governedby

requirement

is that

the forces

Connectingbus

for buswork

to the

provided

right

arches

separate

connectors

the breaker

to a terminal

may have

breaker

on

the breaker's

breakers

for

This

from

beyond

provide

stud members,

All

members,

stationary

bars

studs.

across

of the

centerline

both halves

may

connecting

connections

of thebreaker

6, 10

the

requirements

that

currents

or busbars.

of

the supporting

it be

rigid

result

from high

to

which thebreaker

or cable

to

resist

these

or cable

so

that no

must

be located

the sweep

requirement

the centerline

the right

studof

a

solid connection

as

appreciable

studs.

of the handle

will be

of

edge

thebreaker

the

connections

well as

breakers

already fastened

These bars

will

If an

of the upper

bedispensed

base no more

the

of

fastener

on stationary breakers

board

located

(front

or 14

with.

bus

should extend in

than 5/8-inctr

hole.

in the upper

view).

points.

of the

structure

enough

forces.

must

to

momentary

must

also be

points

be

strain

so that

the breaker,

of the

11 inches

breaker

is

composed

clear-

when it

to the

across

an external

will

the two

be shipped

to both

accommodate

upper

external bar

studs,

hthis

The terminal

This

control

will

scheme.

with-

may

close

or

con-

the

case,

to-

be-

are

left

be

GEK-731O,

Power

Circuit Breokers

If the breaker

connections

of

switch.

the

PRE-SERVICE CHECK

Before

first time, it

amination

of the breaker.

breaker

an equipment

should consist

1. Attach

onthebreaker afterpushing

ing the cover aside.

til it

Iocks

closing.

and a

on

stops.

which otherwise

has an

may be made

putting

the breaker

would be

preliminary

This

a

workbench or

drawout

the

of

following:

thedrawout

Turn the

This will

auxiliary switch,

well to

may

compartment.

racking handle

deactivate

would keep the breaker

NOTE: Remember, later,

chanism must

position

serted in the

2.

Remove the arc

examine

parts.

the

it for the

Do

preliminary

not

be set

before the

equtpment.

quencher

possibility

replace the arc

examination

directly

be carried

on

thetrip

to the terminaLs

into

service for the

make a

check

the

handle

cursory ex-

the

of

out with the

extended rails

to the shaft

button

clockwise

the various inter-

that this

back to

breaker

i,ts

original

can be in-

from each

of broken or missiqg

quenchers

is

completed.

external

operation

of

The check

slid-

and

un-

from

me-

pole

and

until after

move in

seem

this, refer

tiiled

ping

tivate

Devices

overload

voltage

("wipe")

to

do so, and

at

to the section

"CONTACT

5.

Make

breaker open Erre

the

thesewith thebreaker

in

devices,

device.

6. If the

MAINTENANCE.

swe that a-ll the devices

category are the

this

the

breaker is

the operation of the

Iifting interlock

that

breaker and that the

not be opened if the

the closing

is charged,

far as itwill

as

7.

securely.

8.

should be checked when

ers

able,

drawout equipment

spring

and

Replace

electrical operation

The

with the

wiII

drawout

the

go

inthe counterclockwise direction.

the

breaker in the

least

1/16 inch.

careful measurement

If they do not

of these instructions

"

used for trip-

operable.

closedto establish

shunt trip,

a

drawout breaker, check

Manually ac-

manual trip, the

and the under-

interlock devices. Make

(3),

pin

sliding cover

breaker is closed.

discharge automatically

racking handle is cralked

quenchers,

arc

Fig.

4,

will trip the

(1),

Fig.

Check

clamping

of electricai break-

"test"

power

position

control

compartment.

confirms

en-

this.

sure

8 can-

that

if it

them

is avail-

in the

3.

Charge

manually

as

far as it

motion

and

the closing

operated, turn the handle

(140

go

will

rdturn

it to the vertical

breaker is electrically

nance handle,

charges the

NOTE: It

align the triangular

make it

4.

Close

closed by

eon.

The

closed by

closing

chanism

tangular

This

move

the stationary

and

solenoid which is located beneath

opening

maybe

in closing

Observe

when it is

Fig. 5, to

ciosing

go

the breaker.

pushing

"quick-close"

pulling

and

may bereached throughthe large

done safelysince none

the difference between

spring.

probably

on the

the

CLOSE

forward

in thelower

in this area.

are

contacts

closed.

spring. If the breaker is

degrees), then

eounterclockwise

reverse the

position.

operated,

use

the

turn the camshaft which

nill be necessa',ry to

socket

end of

electrical

when the breaker is

The

in the handle to

the

shaft.

manual breaker is

The

button

on the

end of the escutcheon.

main

in the escutch-

breaker may

armature

parts

the

of

(See

Fig.

position

the

contacts should

If the

mainte-

be

of the

me-

the

rec-

that

64,.)

opened

A breaker may

manually

result in the same

as the

is in the rpay energy

how i.t is released.

and

'NANUAt

Manually

front-mounted

with

the mechanism

sets

spring.

either cranking

degree

The CLOSE

to close

used

button to open

If

of

equipped

breaker

relay.

or

OPERATING

THE BREAKER

be equipped to

or electrically. Both

fast-closing movement as far

contact

swing) or

may beclosed remotelyby a

action is concerned. The variation

is stored in theclosing spring,

CLOSING

operated

AI(R breakers

handles. Handle

and

A complete charge

handle

the

three cycles

the

them.

with

mounted

breaker

closing solenoid, a

a

button,

Before this can be

charges

fully

is

through

(50-degree

on

contacts and

done, however, the

operate either

types of operation

constructed

are

operation re-

the closing

accomplished in

one cycle

the escutcheon,

(135-

swing).

the TRIP

manual

control

switch

is

8

Power Circuit

Breokers, GEK-731O

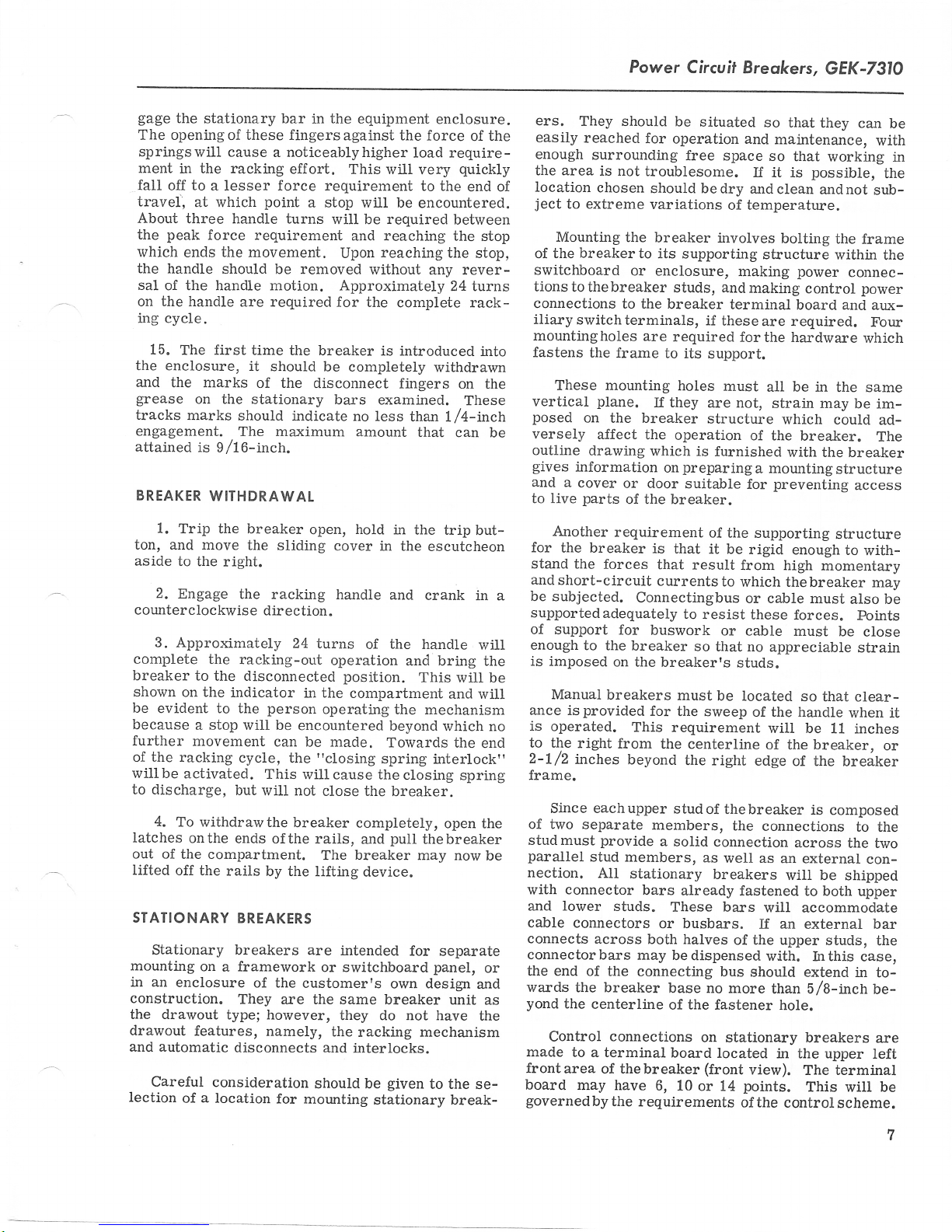

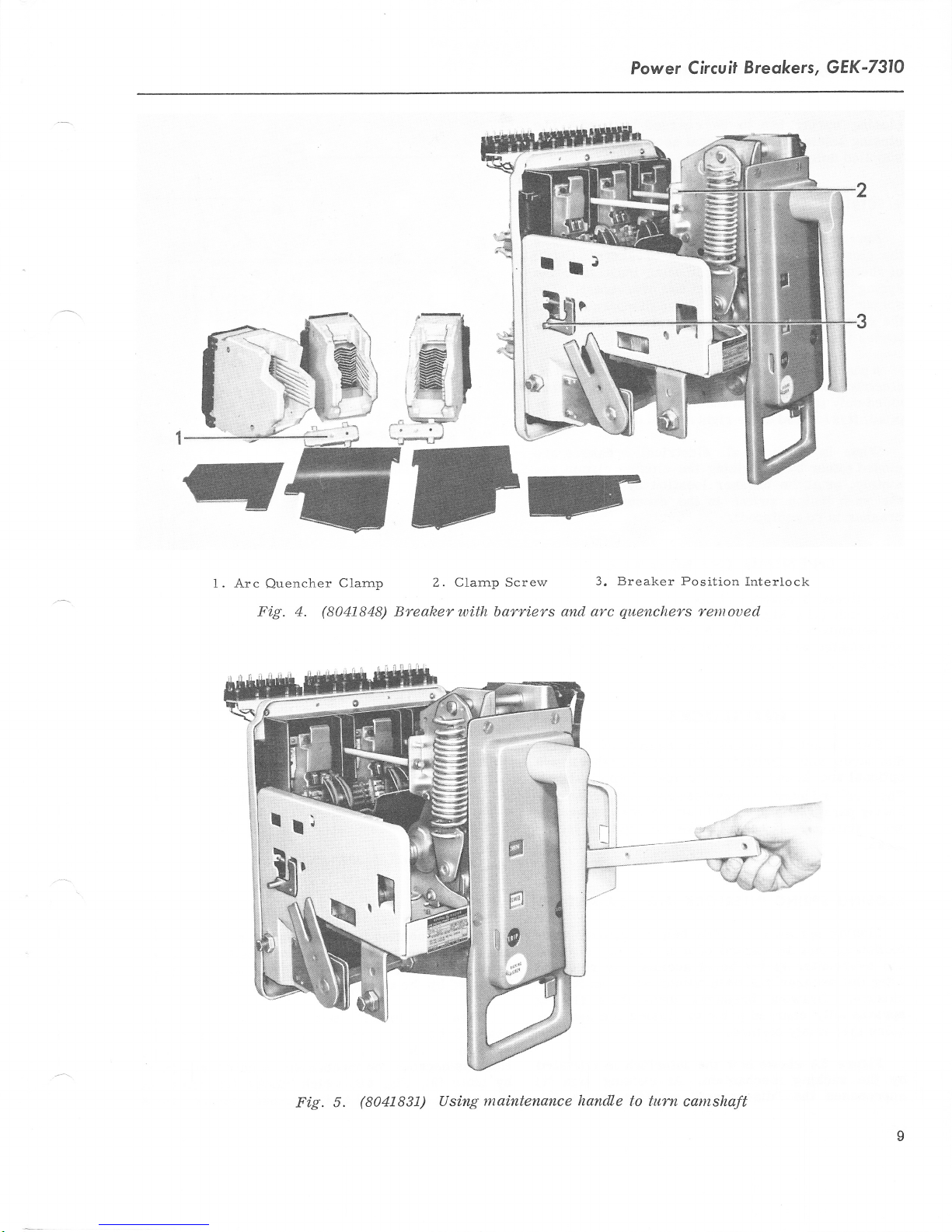

1. Arc

Quencher

Fi.g. 4.

Clarnp

(8041848)

Z. Clarnp Screw

Breaker with bqrriers

3. Breaker Position

and arc

quenchers

Interlock

remoued

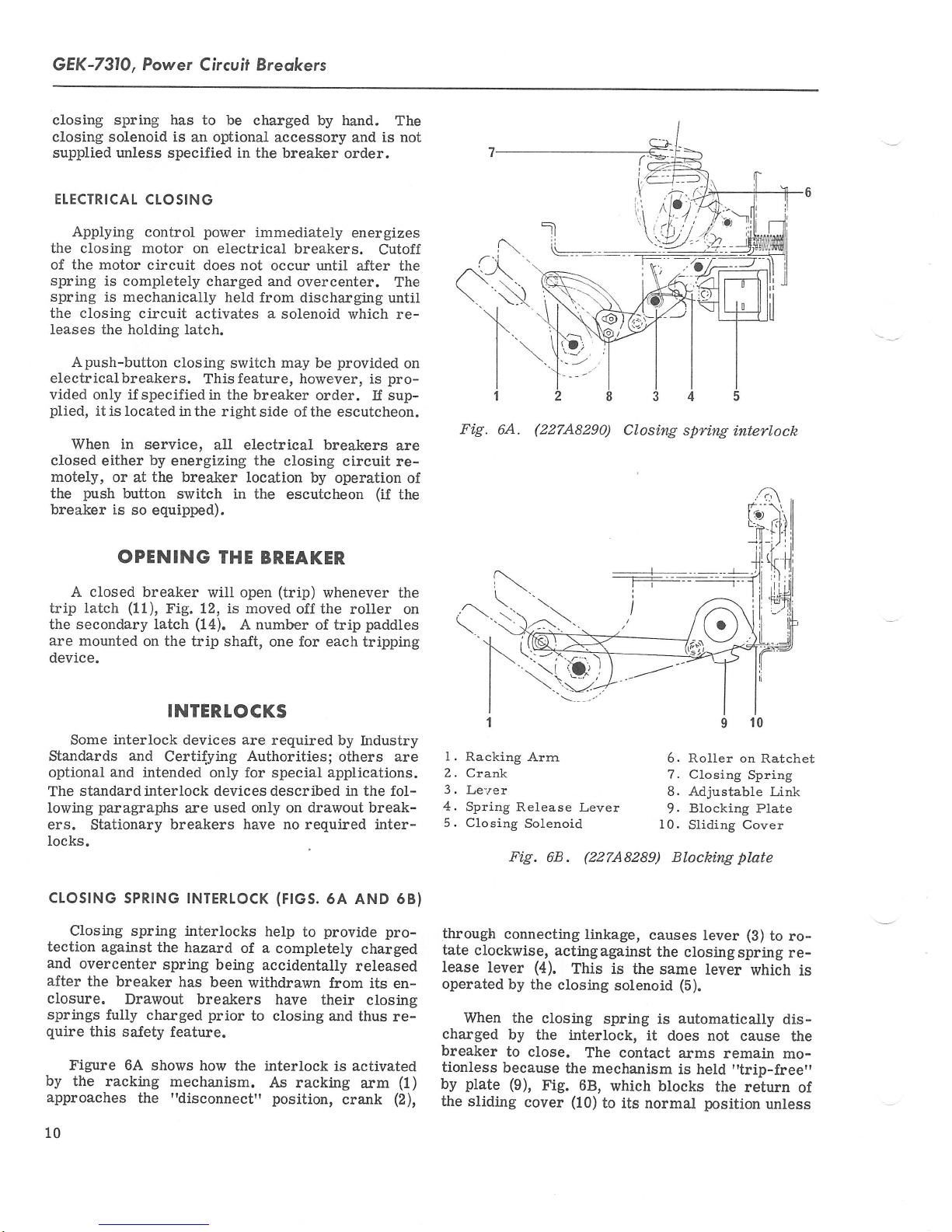

Fig. 5.

(8041831)

maintenance handle

Using

to turn

camshaft

GEK-731O, Power

Circuit Breokers

closing spring has to

closing solenoid is

supplied unless specified in the breaker

ELECIRICAL

Applying

the closing motor

the motor

of

spring is completely

spring

the closing

leases

Apush-button

CTOSING

control

circuit

is mechanically

circuit activates a

holding latch.

the

closing

electricalbreakers.

vided

only ifspecified in

plied,

it is located

When

closed

motely,

the

breaker is

either

or at

push

inthe right

in service,

by

energizing the closing

the

button

switch

so equipped).

OPENING

A closed breaker

trip latch

the secondary latch

are mounted

device.

(11),

Fig. 12, is moved

on the trip shaft,

be charged by

optiona-l

an

power

on electrical

does not

charged and

held from discharging

This

the breaker

accessory

immediately

breakers.

occur until a-fter the

overcenter. The

solenoid

switch

may

feature,

be

however, is

order. If sup-

side of the escutcheon.

all electrical breakers

breaker location

in the

THE

BREAKER

will

open

(14).

A number of trip

by

escutcheon

(trip)

off the

one for each tripping

hand. The

is not

and

order.

energizes

Cutoff

which re-

provided

circuit

operation of

(if

whenever

roller on

paddles

until

on

pro-

are

re-

ttre

the

\ri

/-

"l

a\^.

\

\N

\\l

It\

tl

12

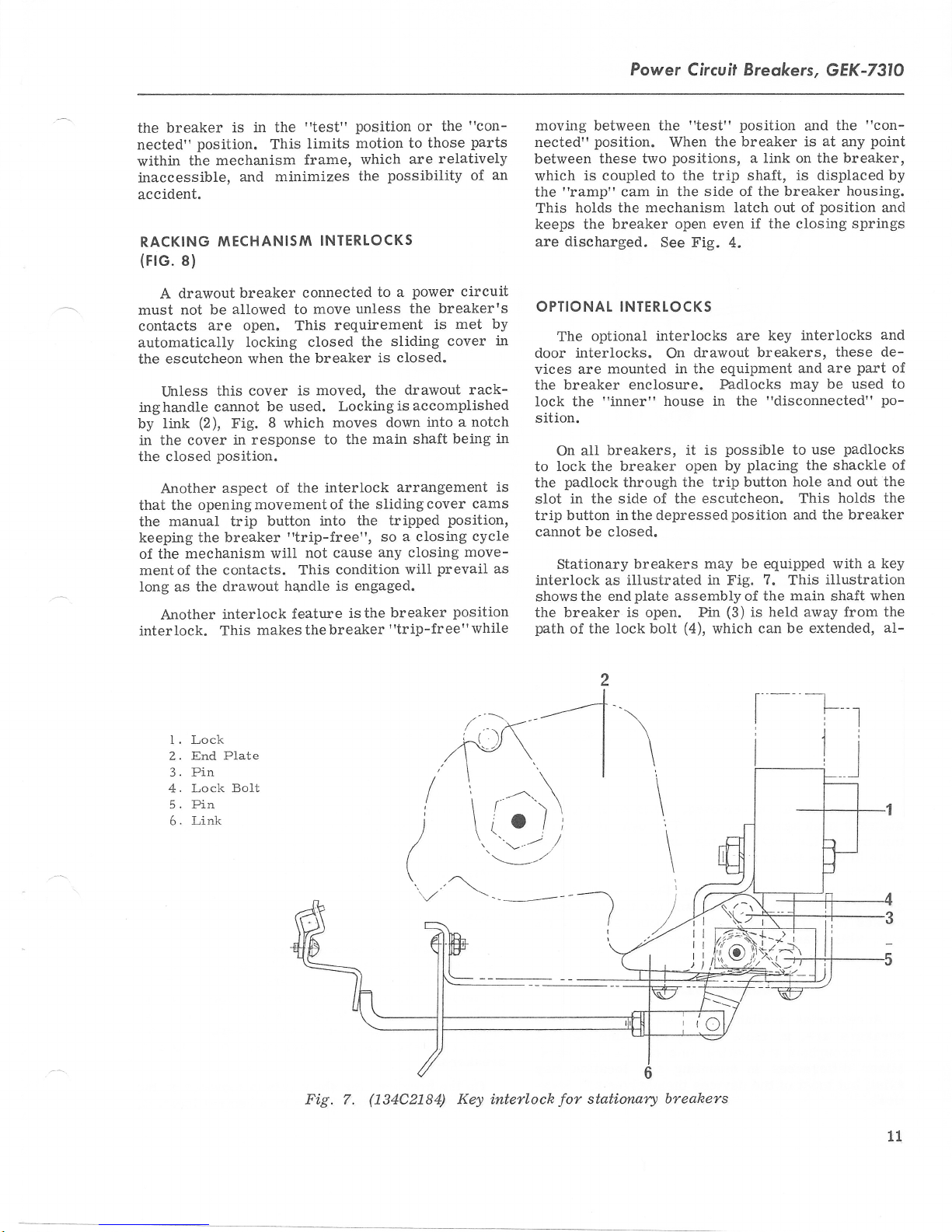

Fig.

6A.

a\

t\

\'\

\-

f..

I

.rm

(227A8290)

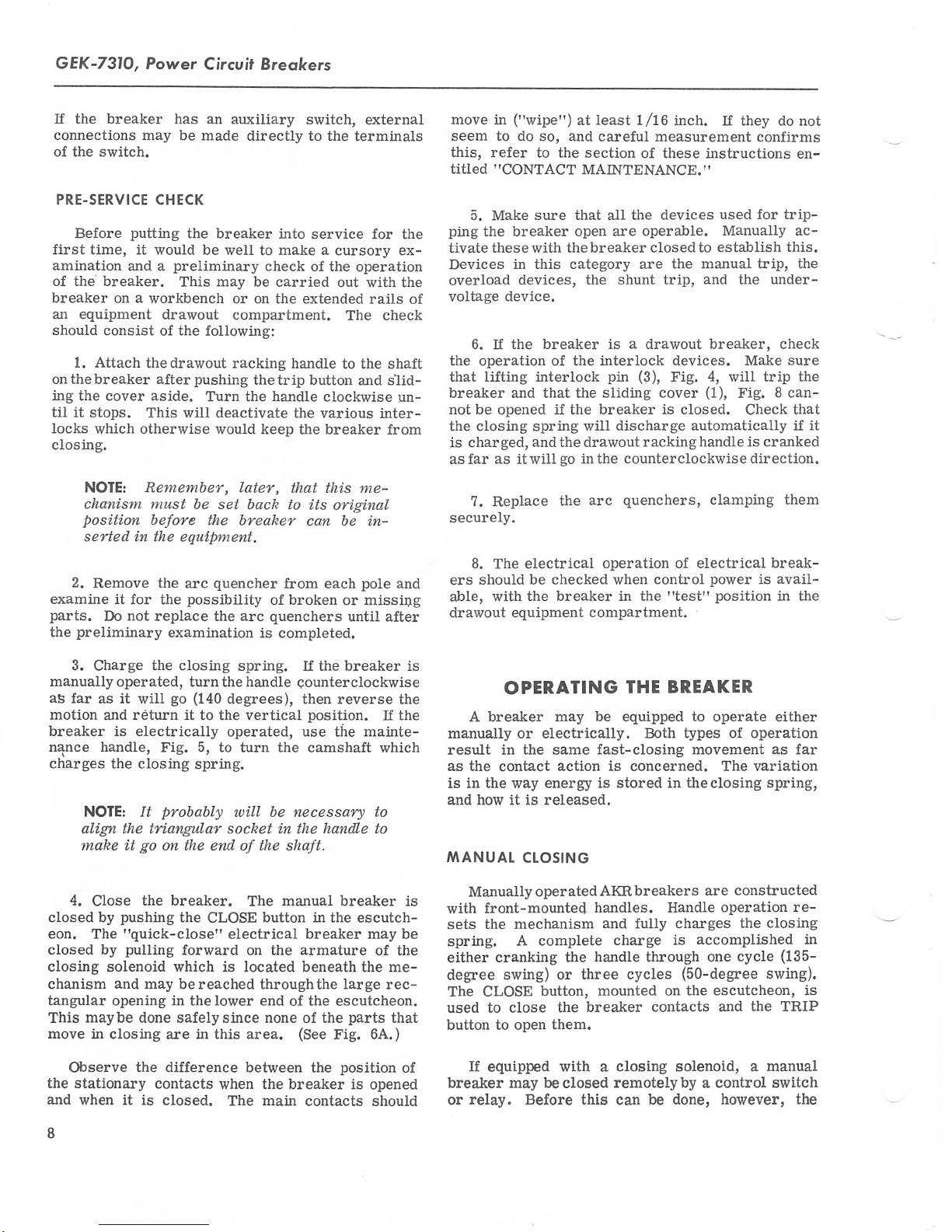

Closi.ng

spri.ng

interlock

INTERTOCKS

interlock

Some

Standards

optional

standard interlock devices described in the fol-

The

Iowing

ers.

locks.

cLoSrNG

Closing spring interlocks

tection

and

overcenter

after

closure.

springs

quire

Figure 6A shows

by

the racking

approaches

10

and

and

paragraphs

Stationary

SPRTNG

against

the breaker

Drawout breakers

fully charged

this

sa-fety

devices are

required by

Certifying Authorities;

intended only for

used only on drawout break-

are

breakers

INTERTOCK

the hazard

spring

has

feature.

mechalism.

the

"disconnect"

have no

of a

being

been

withdrawn

prior

to closing and

how

the interlock

help

accidentally

As

special

(F|GS.

completety

have

applications.

required inter-

6A AND 68)

provide

to

from

their

is

racking

position,

Industry

others are

pro-

charged

released

its en-

ciosing

thus re-

activated

(1)

arm

crank

(2),

I

'l

l.

Racking

2. Crank

3.

Le:'er

4.

Spring

5. Closing

through

tate

clockwise,

lease

lever

operated

When the

charged

breaker

tionless

plate (9),

by

the

sliding

Arrn

Release

Solenoid

Fig.

68.

connecting

actingagainst

(4).

by

the

closing

closing

by

the interlock,

to close.

because

the mechanism

Fig.

cover

Lever

(22748289)

linkage,

This is

The contact

68,

(10)

the same

solenoid

spring is

which

to its

6. Roller on

7.

Closing

8. Adjustable

Blocking Plate

9.

10.

Sliding

Blocking

causes

lever

the

closingspring

lever

(5).

automatically

it

does not

arms remain

is held

blocks

normal

position

10

Ratchet

Spring

Link

Cover

plate

(B)

to

which is

dis-

cause the

mo-

"trip-free"

the return

unless

rore-

of

Power

Circuit

Breokers,

GEK-731O

breaker

the

nected"

within

inaccessible,

accident.

RACKING'NECHANISIYT

(FtG.

8)

A drawout

not be

must

contacts

automatically

the escutcheon

Unless

inghandle

link

by

in the cover

the closed

Another

that the

manual trip

the

keeping the

of the

ment of

Iong as the

Another

interlock. This

is in the

position.

mechanism

the

This

minimizes

and

breaker connected

allowed

to

are open. This

locking closed

the breaker

when

cover

this

cannot be

(2),

Fig.

ia response

positi.on.

aspect of

openingmovementof

breaker

mechanism

the contacts. This

drawout

interlock

used. Lockingisaccomplished

8

which

button

"trip-free",

will

handle is engaged.

featwe

makes thebreaker

"test"

limits

frame,

position

motion to

which

the

INIERLOCKS

to a

move unless

requirement

the

is closed.

is moved,

to the

the interlock

the drawout

moves

down

main

the slidingcover

into the tripped

so a closing

not cause

any closing

condition

is the

or the

are

possibility

power

the breaker's

sliding

"con-

those

relatively

circuit

met by

is

cover

parts

of

rack-

into a notch

being

shaft

arrangement

cams

position'

cycle

move-

prevail

will

breaker

position

"trip-free"while

moving between the

nected"

between these

an

which

the

This

keeps the breaker open even

position.

two

is coupled to the trip

"ramp"

cam

holds the mechanism latch out of

are discharged.

OPTIONAT INTERTOCKS

optional

in

in

is

as

The

interlocks.

door

mounted in the equipment

are

vices

the breaker

Iock

the

sition.

all breakers,

On

lock the breaker

to

padlock

the

in

slot

trip button

cannot be closed.

Stationary

interlock

the

shows

the breaker is open. Pin

path

of

enclosure. Padlocks

t'inner"

through

side of the escutcheon. This

the

inthe depressedposition and

breakers

illustrated in Fig.

as

plate

end

the lock bolt

"test"

When

positions,

position

the breaker is

a link on the breaker,

shaft, is displaced by

in the side of

if the closing

See Fig.

interlocks are

On

house in the

assembly

4.

drawout breakers.

possible

is

it

open by

placing

the trip button

may be

of the

(3)

(4),

is held away from the

which

the

and

the breaker

interlocks

key

and

may

"disconnected"

use

to

the shackle

hole

equipped

7.

This

main

can be extended,

"con-

at

any

housing.

position

springs

these de-

part

are

be used to

padlocks

and

out the

holds the

the breaker

with a

illustration

shaft

point

and

and

of

po-

of

key

when

aI-

1 . Lock

End Plate

2.

3. Pin

4. Lock BoIt

5. Pin

Link

6.

Fig. 7.

i

)

\

(134C2184)

Key inteflock

stati.orwrl

for

-t-

\

\

\

\

\

I

6

breahers

11

GEK-7310,

Power Circuit

Breokers

l.

Sliding

lowing

makes it

this

sible

sembly

causes

bolt, which cannot

breakers

used

Minor differences in

exist, but most of the devices

the key to be removed. Extending

push

moves

against

breaker latch, and

the

pin

(5).

to close the breaker.

When

is

away

(3)

pin

Accessories

from link

to move into the

then be extended.

ACCESSORTES

available

(6)

for use on the AIG-50

breaker is closed, the

the

are, in most cases, the same devices

throughout

the entire line of AK

mounting and location may

tical.

L2

Cover 2. Locking Link

Fig. 8.

(134C2179)

Drawout interlocks

the bolt

Through

the

makes it impos-

linkage,

placing,

dealt

structions; only

function it serves

SHUNT TRIP

and

metal

torsion spring

the

path

of the

plate

lock's

as-

its coil

which

in series with

made

ondary disconnects

arxiliary switch and

breakers.

bottom

themselves

breakers.

are

iden-

3. Trip

Maintenance operations, such

adjusting

and

in

with

The

is

the

shunt trip device opens

energized.

is

closed only

Button

these components wili be

maintenance

description

a

be

will

dealt with

An

when the breaker

portion

the device

of

the breaker when

frA't

the device coil.

the external tripping source

to

on

drawout

breakers, or to the

terminal board on

the breaker,

On

the

of

breaker frame in

the

shunt

trip

a

as adding, re-

of these in-

and

the

here.

auxiliary switch,

is

closed,

Connections

through sec-

stationary

is mounted

central location.

are

on the

is

Loading...

Loading...