Page 1

MAINTENANCE

LOW-VOLTAGE

..

-POWER

MANUAL

CIR.CUil

BREAKERS

'

GEK

-l

798A

Supersedes

GEH

GEH-1799

GEH-1823A

GEI-50210A

-7303B ·

GEI-50211

GEI-50212A

GEI-67077

GEI-74600

.

·

AK-2/3/2A/3A-50/50S

AK-2/3

AK.:2/3 /2A/3A.;.1QO /100S

/2A/3A-7 5 /7

5S

TYPES

AKT-2/3/50/SOS

AKU-2/3/2A/3A-50/

AKF-2C/2D/2E

_

SOS

:.

.)

GENERAL

f/j

ELECTRIC

Page 2

INTR

ODU

CTION •••••••••••••••••••••••••••

CONTENTS

••

: •••••••••••••••••

••••

•••••••••••••••

~

••••••••••••••••••

••

3

OPERATION ••••••••••••••••••••••••••••••• · •••••••••••••• ~ •••••••••••••••

MA.NUAL

· MANUAL MA.INTENANCE CLOSING

ELECTRICAL CLOSING •• : •••

~tJICIC CLOSE

E

LECTRICAL

MAINTENA

INSERTING

IN

SPECTION •••

TROUBLE

LUBRICATION ••••••••••••

S

EPARATION

..

· BASIC

ELECTRICAL

BREAKER

ARC

POLE

.

OPERATING

QUICIC

AUXILIA.RY SWITCH •••• ~· ••• ; ••

·CLOSIN'G SWITCH ••••••••••••••••••••

CUT-OFF

CON

PROTECTIVE

STATIC

INS

TANTANE

lJND~R\TC>l,1'J\CiE

DffiECT-ACT

S

ERIES

SERIES

REVERSE CURRENT:

POWER SEN

S

ELECTIVE

CLO

SING •••••••••

FOR

ELECTRICAL

TRIPPING

NCE ••• ~ ••••••••••••••••

SAFETY

•••••••••••••••••

SHOOTING~ ••••••••••••••••••••••••

OF

QUENCHERS.

UNIT ASSEMBLY •••••••

CLO

TROL

COMPO

MECHANIS

SE

BREAKE

-CLOSING DEVICES

SWITCHES •••

RELAY

DEViCES ••••••••••••

TIME

OVER

OVERCURRENT

DELAY

dus·uNDER

ING

CURRENT

SOR

TRIPPING

PIN-AIC-50,

FRO

NT AND

NEN

: •••••••••••••• ~ ••

••• ~ •• : ••••

UNDERVOLTAGE

LOCICC>l.J'I'

TRIPP

TRIPP

TRIP •••••••••••••••••

••••••••••••••••••••••••••• -••••••••••••••••••••••••••••••• -••••••••••

••

••••••••

••••••••••••••••

••••

•••••••••••••••••••••• ~ ••••••••••••••••••••••••••••••••••••••••

•••

•••••••••••

••

••••••

•••••••••••••••

TS •••

•••••••••• ; •

MS

••••••• ~ ••••••

R ADJUSTMENTS •••• ~ •••••••••••••••••••••••••••••••••••••

••••

AND

••••

•• : ••••••••••••••••••••••••••••••••••••••••••••••••••••• , ••••••••••

••••

: ••••••••• : ••••••••••••••••••••• •••••••••••••••••••••••••••••••

•••

VOLTAGE

I>~\TICE •••••••••••••••••••••••••

ING DEV

TRIPP

TRIPP

ING

••••••••••••••••••••

OF

ELECTRICAL

••••••••••••••••••••• ~ •••••••••••••••••••••••••••••••••

BREAKERS

••••••• · •••••••••••••••••••••••••••••••••• ; •••••••••••

AIC-

75

•••

•••••••••••••••••••••••••••••••••••••••••• ••• ; ••

••••

REAR

••••••••

•••••••••••••••••••••••

••••••••••••••••••••••.••••••••••••••••••••••••• ; ••••••••••••

ING

FRAM

••••••••••••

•••••• · ....

••••

ING.

DEVICE

................................

••••••••

•••••••••••

CONTROLS ••••

••••••••••••••••••••••• ~ ••••••••••••••••••••••••••••••

TRIPP

ICE-EC-lB ••••

DEVI

DEVICE EC-2/EC-2

••••••

•••••••••••••••• e •••••••••

•••••••••

•••••••••••••••••••••••••••••• ••••••••••

AND A

•••

TRIIPING DEVI

(AIC-50 ON

K-100

•••••••••••••••••••••••••••••••••••••• ••••••

•••••

•• ~ ••••••••••••••••••••••••••••••••• .-•••

ES ••• ; •••••••••••••••••••••••••••••••••••

••••••••

•••••••

.•••• : •••••••••••••••••••••••••••••••••••••

ING

CE E c

· •••••••••••••••••••••••••••••••• ••••••

•••••••••••••••••••••••••••••••••••••••••••

•• ~ ••••••••••••••••••••••••••

BREAKERS •••••••••••••

••••••••••••• •••••••••••.••••••

•••••••• : •••••• -••••••••••••• ; ••••

••••

: •••••••• •••••••••••••••••••••••

••••

••••

••••

••••••••••••••

DEVICE ••••••••••••••••••••••••

:..

1.

••••••••••••••••••••••••• ••••••••

LY) •••

......

....

........

•••••••••••••••• •••••••••

••••

•••••• ~ ••••••••

CE •••••••••••••••••

••••

••••

••••

•••••••••••••••

A •••• ~ ••

••••••••••••••••••

• · •••••••••••• ••••••••••••

••

••••••••••

•••• ••••••••

••

••••

;.

••

••

••

3

3

4

4 -

4

5

5

5·

5

6

7

7

7

.

7

8

13

16

11

23

•

23

25

25

26

29

31

33

33

39

BREAKER

~CE~~()lJS

Th.ue ins

contingency

or

should

be

particul

referred

PRIMA.RY D1SCONN'EC1'S ••••••••

SECONDARY

DRAWOUT MECHANISMS ••

~

SHUNT

~ELL

OPEN FUSE

1'()()1'8 •••••••••••••••••••• •••••••••••••••••••••••••••••

RENEW AL

lrvctiom do· not

to

to

ACCESSORIES ••••••••••••••

DISCONN'ECTS ••

be

t

he

ar

TRIPPING

AI.,AR~

met

in

connection.

problems

General

PART

purpori

Electric

DEVICE

AND

LOCKOUT DEVICE ••••••••••••••••••••••••••••••••••••••••••••••••••••• ••••••

•••••••••••••••••

S ••••••••••••••••••••••••••

to cover

arise

which

Company

LOCl{()tJT

with

installation,

are not cove

•••••••

••••••••••• o••••••••••••••••••••••••••••••••••••••

••••••

•••••••••••••

•••••••••

•••

••••••••••

•••••••••

••••

• ; •••••

all

details

••••

•••

••••••

•••

I)E:\TIC

E: •••

•• ~ ••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••

or

operation

r_

ed

sufficiently lor t~e

. · ·

••••••

•••••••••••••••••••••

••••••••••••••

• ~ ••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••

••••••.•

.••

variations

or

•••

•••

•••••••

•••••••

.••••••••

•.•.•..

in

••••

•••

••••

••.

•••••••••••••••••••••• •••••••••

~ipment

maintenance. Should

purchaser

••••

•••••••••••••

••••••

•••••••••••••••

••••••••••••••••••

••••

•••••••

••••••••

nor

lo pro'!id• lor every possible -

further

's purposes, the matter should

•••

••••••••••

••

••••

••••••••

inlormoli

••

on

42

42

42

43

44

44

45

47

47

47

be

desired

Page 3

LOW-VOLTAGE POWER

CIRCU~T

BREAKERS

-·

TYPES

The

aid

and

Power

designs

designs

extensions

clature

instructions

in

the

accessories

Circuit

The

basic

have

for

including

AK-2-50, AK-2 - 75

standard

mounting

equipment.

AK-2A- 50, AK-2A-75, · AK-2A-100 - The

A

AKD-5 type equipment.

AK-2-50S, AK-2-75S, AK-2-lOOS indicates

close

times

AKU-2-50- fuse

AKF-2C, AKF-2D, AKF-2E . - Are

switches

of

. AK-2-50H -

.

rupting

75,000

AK

the

to

AKT-2- 50 continuous

AK-3-50,

indicates

Power

. AK•SO ,

INTRODUCTION

maintenance and

contained

for

AK-50-75-100 Low Voltage

Breakers.

AK_.50,

been

specific

have

AK-75

expanded

applications.

caused

the

following:

design

or

for

indicates

it

.has_mounting.

breaker

mechanism

of

approximately 5

..

The

breaker

combination:

for

use in.controlling

synchronous

.The

rating

has -been

amp. class.

-2- 50C,-

AK~2-75C-

interrupting

the

rno,ooo

amp.

The

rating

AK-3-75,

the

breaker

Sensor

OVercurrent

herein

repair

and

variations

or

of

breaker

drawout

is

equipped with a quick-

· which

u.

indicates

m~tQ~s and

H Indicates the inter-

. · , _ ·

-

:..

rating

class

· T

indicates

of 2000

AK-3-100 - The 3

ls

AK-100

.

are

of

· AK -100

to

AK-2 - 100 -

use

provides

cycles

increased

The C indicates

has

. .

amps.

equippe!i with the

intended to

basic

breakers

·

include

These

in

the nomen-

for

stationary

in

AKD type

features

(.08 seconds)

an

shunffields

generators.

been

increased

incr~ased. · ·

Trip

breaker

special

design

Basic

The

closing

internal

to the

Device.

fie

for

S

ld

AKF-2C,

;

For

to

ING

a

the

section

THE BREAKER AK-50 and

STORED ENERGY

under

OPERA TING

-'"'

o<:>

a:<(

1-1-

%-'

oo

u>

® •

~

,1,

..

F&G

· + •

SIMPLIFIED ELEMENTARY

INTERNAL WIRING

AKF -

2D,

OPERATION

MANUAL

description

of

these

section

MECHANISMS.

4'

G

G

,fl

LE

GEND

CLOSING

• RELAY

• RELAY CONTACT

• MECHANICALLY

COIL

NOR

MALLY OPEN SWITCH CONTACTS

I • NORMALLY CLOSED SWITCH

L •

AUXILIAAY

AK_:50,

.r

r

"

CLOSING

of manual closing,

instructions

MANUALLY

entitled AK-50-75" AND-100

MANUAL

MOTOR

OPfRATED

SWITCH

CONTACT

DIAGRAM

75,

AND

Fig;l.

lOSING

-

SWITCH

I T ' l

I • I

G

h;

G

l

AKF-2E

entitled

OPERATED

MECHANISM,

-,--

"

E

I

1

:~TRIP

1

I

I

'

[.

.

1

0

CLOSING

SWITCH

--::-~J

REMOTE

CLOSE

.x

.

SWITQIES

COffTAC_!S

100

·

1

l'l£

MOTE

OSE

w

refer

CLOS

both

..

OIL .

-

AK-2has

two

50X

very

or

previously

When contacting .

to

furnish

the

- -

The

special

more . of

described.

the

complete

x·

indicates

features

the

design

factory'

nameplate

the -breaker

or

it

extensions

- .it

is

important

· information.

"includes_ ·

~C

:

( -

r

tG:

j :

~

=~'l::.W&

<j,

-

'f'

-

INT(~l~.lf1~GC~fi~nt~~~U:icR

LEGEND

~'fc,~l'i,\

ii

t~~

ANTI-PUMP

fo~lTACTS

A£lAT

C<J,ITACTS

https://manualmachine.com/r,:ti~~~~Wc\O.,l~lt>f:S

~~~~1s?ct•r COi

i~'i.1.~

t.ORMAllT

OptN

NORMAU.T

ClOS(O

Fig.

l

~TACT:,

SWITCH

SWITCH

lA.

CONTACTS

CONTACTS

Page 4

GE;K-730~

Low

Voltage

Power

Circuit

Breakers

MANUAL

- .

~

CLOSING

· An electrical

breaker

MAINTENANCE

OF

ELECTRICAL

BREAKE~S

may be closed manually

by _ means of the maintenance handle furnished

'with the

·

out

discharged, proceed

breaker.

To

observe

power, with the

1. · Charge the· closing

te~ance

tor

2. Continue to

until the

3.

Open. ·the

· _·button (4,

The -electrical

~e

operation of the

break~r

as

follows:

han~e

rea~

(1,

"charged": .

operate

breaker

close~.

breaker

"

F~1t.

2)~

ELlCl'.RICAL

c ontrol s·ystem ·

·

breaker

open and

spring

Fig.

with tbe main~

3) until the indica-

with- ·

springs

the.maintenance handle

by . pushing· the

trip

. . .

CLOSIN~

is

comprised

of- an- X relay, two double _contact mechanically

operated

switch

the

voltage

closing s'ignal

switches (F anq G), a push outton closing

and _any means

user

may incorporate into the

is . .first

. applied to the

is

for

remote closing which

breaker,

given) the motor

system.

When

(before any

is

energized

through two of the X relay contacts and the two

a

·.

switch

the closing springs to the

at

which point the mechanically operated F and G

switc~es

·

contacts.· The-.motor then

"pre-charged"

are

ope_

rated.

This ope_

ns

compresses

position

the G contacts,

stop~mg the motor, and closes the F contacts, whicp

readies

breaker

signals ·for

e~ergized, operating the X contacts. This

·

in

and

the

system

for

.. When the push button

a closing operation, the X relay coil

the X relay

tl?,e

closing operation

and energizes the.motor once again

QUt:CK CLOS.E

FOR ELECTRICAL BREAKERS

the. actual closing of the

~r

remote switch ·

seals

takes

place. . .

. Functionally, the ·quick close mechanism differs

from

the

standard

pre-charge

charge

the closing

ing oper~tion,

a

latch

plate

electrical

operation

is

extended · to completely

springs.

w~ch

takes approximately 5 seconds,

engages the prop

mecbanism

At

the end of the

roller

in

that

charg-

to

prevent

_ the closing springs from discharging. .

the

. With

breaker

release

plished

.

lever

the

on. the

remote

. the prop

close

stan~ard

·

the

·

Wi~

. control voltage appli~d, :the motor is·.·

energized

charges

closing

is

ready

of the prop

either

m~ually,

breaker,

closing switch. Upon the

roller

the closing

breaker

electrical

through the . G switch. contacts, · and

the closing springs. When the

springs

for

a closing operation upon

roller.

by

or

in the

same

fully charged the

This

may be accom-

depressi

.ng the closing

electrically

springs

discharge and

manner

breaker.

by closing

release

as

on the

springs

is

the

of

reach

operated

Upon

the

fully charged position; the mechanically

switches

operation

operate,

of

these

reversing

their

switches the

coniact:S.

motor.

stopped by the. opening of the G swit~h. The closing

of the F

closing

operation.

switch

prepares

the

bre.aker

.

Fig.

2 (8939671)-

.

1.

Front

view of AK-2-50

Auxiliary Switch· .

bre~e~

2. Position Indicator

3.

Relay

4. Manual

5. Shaft

Trip

Button

for

Manual Mainte- ·

nance Closing Handle · ·

6.

Spring

Charged-Discharged

Indicator · ·

7. Motor Cut-off ·Switches

8.

Arc

Quenchers

A closing

relay

X whose contacts

circuit

closing

.

as

descr~bed above. At the

l\elay contact

rel~y .causing

the .anti-pump

When the

ted

G switc

. and the F switches open and de-ene:1;gize

trol

relay

is

tripped

the motor

for

the next closing operation.

signal

through the closing

relay

breaker

hes

from

now given ·

energizes

close

relay

coil energized the

same

closes

its c·ontacts

feature.

close

to energize the anti-pU

to re\_'erse

·

closes,

the mechanical

to energize the

being .energized

and

coil.

breaker

time

until

open. With' the . G switc~es c

charges

the closing

sprlngs

the

comple:

. Wi

the·

providing

motor

the

the

brtsed

1s

for- a

cont;;

the

8

clo~e g

clos:P

oper~~

ag~-

:er-

dy'

rea

·

4

Page 5

EL

ECTRICAL TRIPPING

-

The

breaker

of tha

these

instructions.

tripped

current

these

devices

i.e.

·the device

paddles

the

trip

most

The

shunt

as

trip

shown

the shunt

electrical

by the automatic

tripping devices, if

fastened on the

shaft

in

trip

may

be

tripping devices

. The

trip

the

trip

and displacing the

commonly

device connected in the control

Fig.

1.

When a tripping

coil

is

energized through a nortrlally-

open auxiliary switch "

breaker.

· tbe

. .

MAINTENANCE

tripped

electrically

described

breaker

may also

overcurrent

so

equipped. All

breaker

arm

used

inasimilarmanner,

moves

trip

against

shaft

, thus rotating

trip

latch.

tripping device

signal

a"

-contact, thus tripping

or

is

by any

in

be

reverse

the

trip

is

the

circuit

given,

Low Voltage

Power

Circ~it

Breakers

GEK-7303

BEFORE INSPECTION OR

WORK

IS

IS

DONE

BE

SURE THAT THE BREAKER

IN THE OPEN POSITION. ALL ELECTRICAL

POWER, BOTH PRIMARY

SOURCES, SHOULD

Warning: On

ergy

closing mechanisms,

when the

circuit

ALSO

breakers

breaker

and when any inspection

is

being done

open·

position

· being re15trained by

dure

for

inserting

- INSERTING

AK-50, -

The closing

maintenance handle

can be

placed

Continue to op

ing the

pin

takes

breaker.

the SJ?ring

- To il)stall the

energy mechanism

STORED- ENERGY MANUAL MECHANISM on page

17

of

these

instrucUons.

so

that

and the closing

the

the safety pin

75

. (Fig

sprini

~hould be charged with the

(1)

in

the hole of the push

er.ate

the maintenance· handle,

This

force

safety

refer

With the safety pin

spring

the

operation

ment

sprmgs

from

ing

force, the. contacts will

breaker

is

manually

of the mechanism and the contact align-

~o

be

visually observed.

. . -

.

!allowing

the inspection

must be recharged, the

the

push

rod, and the pin placed

spring

clip adjacent to the push

ANY

MAINTENANCE

AND

· CONTROL

BE DISCONNECTED.

employing

care

is

or

maintenance work

the

breaker

stored-en-

must

being

springs

safety pin. The

is

given below.

SAFE

TY

PIN

-

and

-100

•.

3)

. .

so

that

is

done

·

the safety pin

so

that

.

pin of the manµal

to the

restraining

operated

section

close

period,

safety

the closing

s.lowly when ·

a1lowing the

the closing

pin

in

the

rod.

be

taken

installed

is

in

the

are

proce-

(3)

rod

(2).

clos-

the safety

stored

-

entitled

removed

retain-

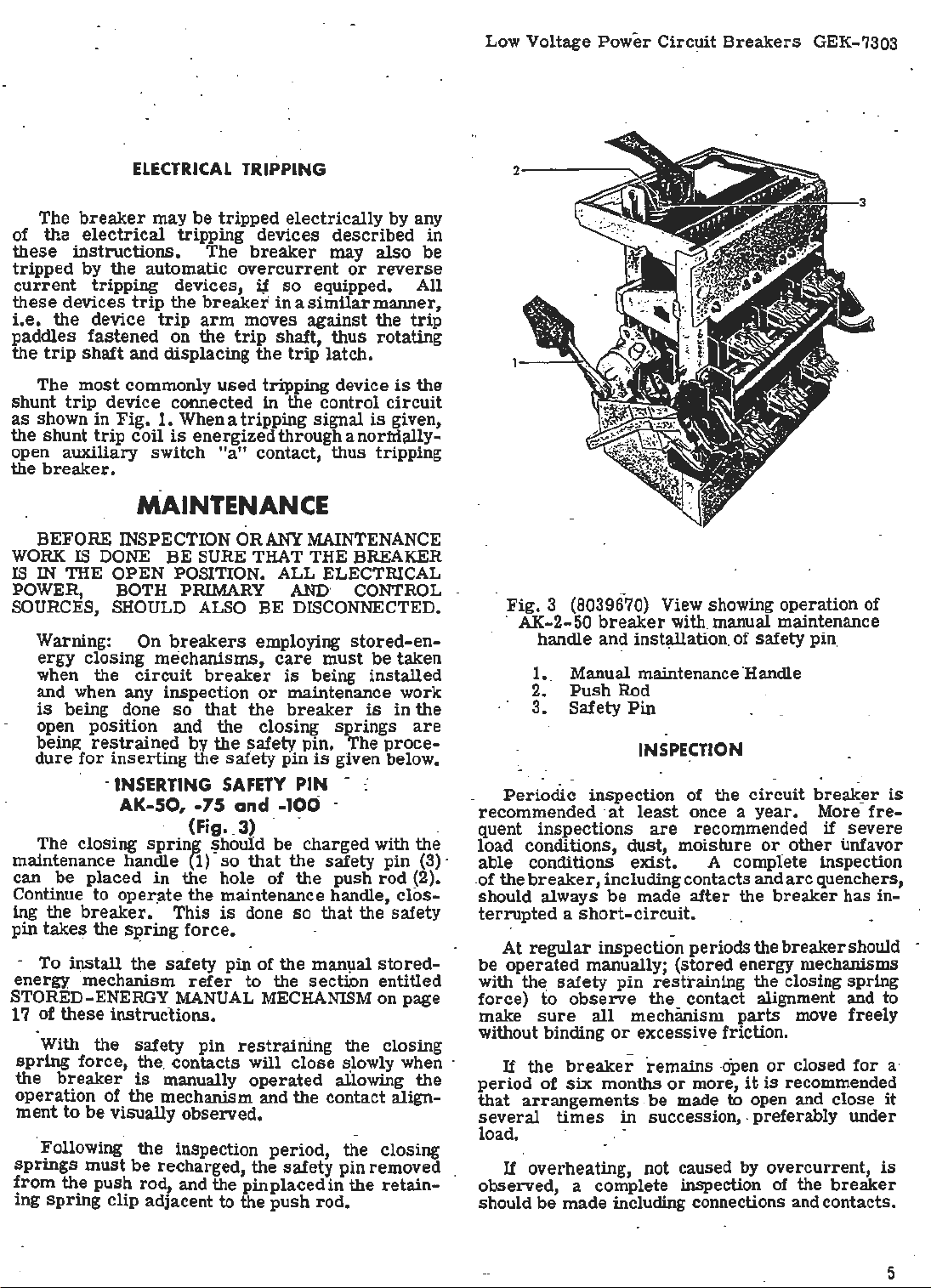

Fig. 3 {8039670) View showing operation of

· AK-2-50 ·

breaker

with manual maintenance

handle and installation. of safety pin,

1.. Manual maintenance 'Handle

2.

Push

Rod

3.

Safety

Periodic

recommended ·

quent inspections

Pin

INSPECTI

inspection of the

at

least

once a

are

recommended

load. conditions, dust, moisture or_

-

able conditions

.of the

breaker,

should always

exist.

A complete inspection

including contacts and

be

made

after

terrupted a short-circuit.

At

regular

be

operated

with the

force)

make

fo

sure

without binding

If

the

period

that

of

arrangements . be

several

inspection periods the

manually; (stored energy mechanisms ·

safety

breaker

pin

observe

all

or

six

months

restraining the closing spring

the contact alignment and to

mechanism

excessive friction.

remains

or

more,

made to open and close

times

in succession, . preferably under.

load.

If overheating, not caused by overcurrent,

observed, a complete inspection

should

be

made including connections and contacts.

ON

parts

-open

circuit

year.

other

arc

the

breaker

breaker

move freely

or

closed

it

is

recommended

of

the

break~r

· More

if

fre-

severe

unfavor

quenchers,

has in-

should -

for

breaker

is

a·

it

is

5

Page 6

GEK-7303 Low Voltage

Power

Circuit

Breakers

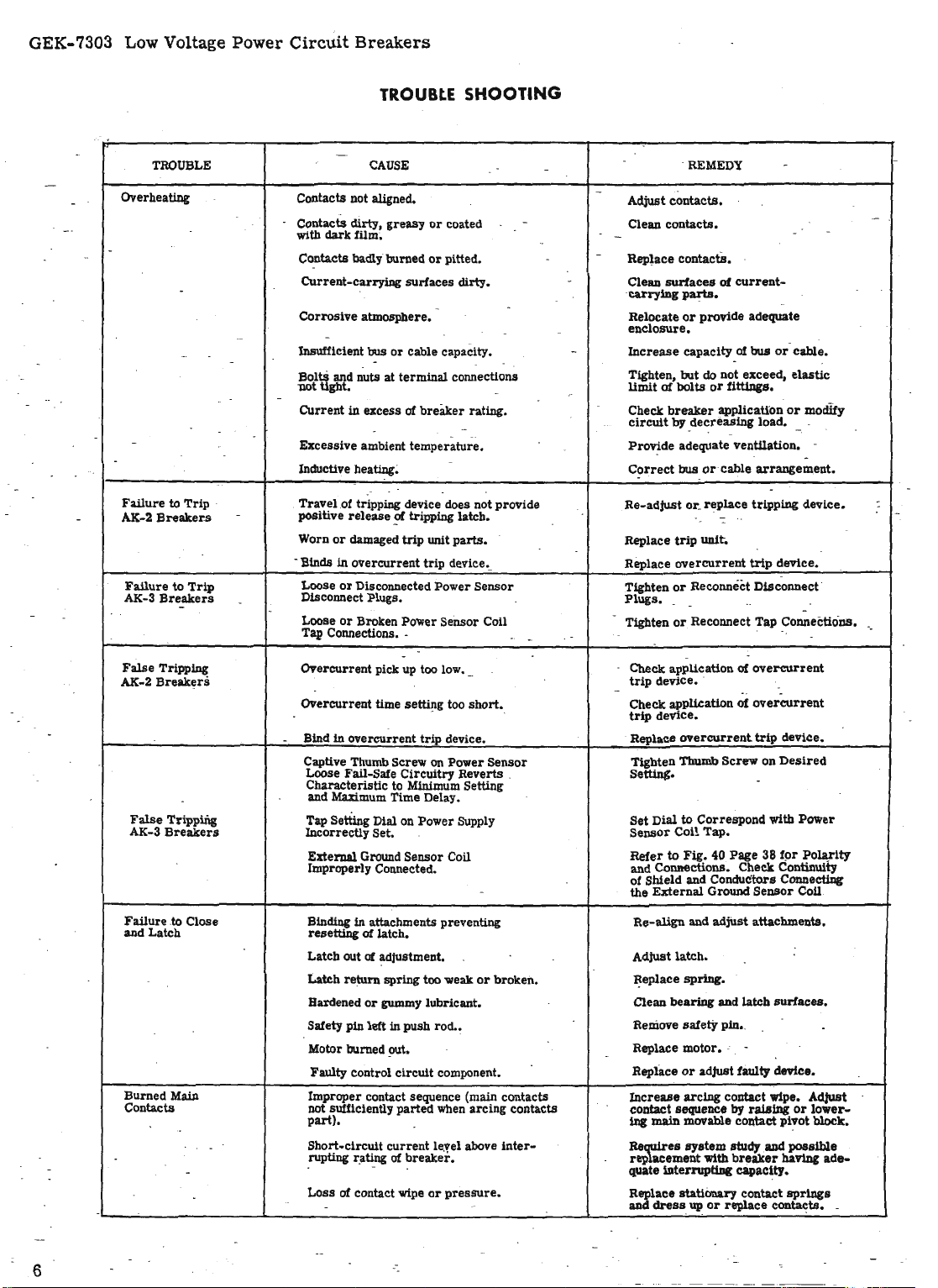

TROUBLE

Overheating

to Trip

Failure

AK-2

Breakers

Failure

to

AK-3

Breakers

Trip

TROUBLE

SHOOTING

CAUSE

Contacts not aligned.

Contacts

with

Contacts

dirty,

greasy

burned

or

or

dark

film;

badly

Current-carrying surfaces

coated

pitted.

dirty.

Corrosive atmosphere.

Insufficient bus

Bolts and nuts at terminal connections

uot

tight.

Current in excess

or

cable capacity.

of

breaker rating.

Excessive ambient temperature.

Inductive heating;

of

Travel

positive release

Worn

- Binds in overcurrent

Loose

Disconnect Plugs.

Loose

Tap Connections. -

tripping device does not provide

gt tripping latch.

or

damaged

or

or

trip

unit

parts.

trip

de.vice._

Disconnected Power Sensor

Broken Power Sensor Coil

·

REMEDY

Adjust contacts.

Clean contacts.

Rep~ace contacts.

Clean

surfaces

carrying

Relocate

enclosure.

Increase

Tighten, but

limit

of

breaker

Check

circuit

of

parta.

or

capacity

bolts

by

current-

proVide adequate

of

bus

do not exceed,

or

fittings.

application

_decreasing load. _

or

or

cable.

elastic

ProVide adequate venWation. C~rrect

bus

or

· cable arrangement.

Re-adjust

Replace

Replace

Tighten

Plugs.

Tighten

or

_ replace tripping device.

trip

unit.

overcurrent

or

Reconnect Disconnect.

or

Reconnect Tap Connections.

trip

device.

modify

__

False

Tripping

AK-2

Breakers

False

AK-3

Failure

and Latch

Burned

Contacts

Tripping

Breakers

.

to

Close

Main

Overcurrent pick

Overcurrent time setti!)g too

Bind

in

overcurrent trip device.

Captive Thumb Screw

Loose Fail-Safe Circuitry Reverts .

Characteristic to Minimum Setting

and Maximum Time Delay.

Tap Setting Dial on Power Supply

Incorrectly Set.

External Ground Sensor Coil

Improperly Connected.

Binding in attachments preventing

resetting

Latch out

return

Latch

Hardened

Safety pin left

up

too low. _

on

of

latch.

of

adjustment.

spring too weak

or

gummy lubricant.

in push rod.,

short.

Power Sensor

or

broken.

Motor burned out.

Faulty control circuit component.

Improper contact sequence

not sufficienUy parted

part).

Short.circuit

rupting r.ating

of

contact wipe

Loss

.

current

of

breaker.

when

leJel

or

pressure.

(main contacts

above

arcing contacts

inter-

Check application

trip

deVice. ·

Check appllcatiOn

trip

deVice.

Replace

Setting.

Set Dial

Sensor Coi! Tap.

Refer

of Shield and Conductors Connecting

the

overcurrent

Tighten Thumb Screw on

to Correspond with Power

to

and Connections. Check Continuity

Fig.

External

of

overeurrent

of

overcurrent

trip

device.

Desired

40 Page 38

Ground Sensor Coil

for

Pola_rity

Re-align and adjust attachments.

Adjust latch,

~eplace

spring.

Clean bearing

and

latch surfaces,

Remove safety pin,

Replace motor.

Replace

Increase

contact sequence by raising

ing

main

ReQuires

replacement

quate interrupting capacity.

Replace

and

dress

,.

-

or

adjuat faulty device.

arcing contact wipe. Adjuat

movable

stationary contact

contact pivot block.

system

study

With

breaker haVing

. up

or

replace contacts. _

and

or

lower-

possible

springs

ade-

6

Page 7

At

all. times

pencil

ials

breaker

lines,

to

remain

as

they may

points of different potential and

electrical

The

at

a

circuits

electrical

~reakdown.

breaker

rated

are 'properly

attachments

it

is

important not

paint,

oil

or

on the insulating

cause

should-

voltage

be

to

assure

connected and

are

.other

foreign

surf

low

resistance

result

operated

that the control

functioning

to

·permit

aces

in

several

that

properly.

A complete contact inspection, including con-

tact

wipe and ·

lar

inspection

short

circuit

determine

pitted

or

in

replaced.

quenchers

ing contacts and

replaced

original

erate

and

thickness.

In

general,

lubrication.. _Mechanical bearing points

sliding

regular

G-E

Lubricant

tact

surfaces

ricant

be

using

BE

OF

D50H47. Hardened

removed

kerosene.

REMOVED

DIRT OR

pressure,

periods

current

whether

which

It

to

properly

when they

the

surfaces

inspe

_ction

D50Hl~ . Sli<lingsilver plated con-

should

from

ALL

TO

DUST

should be made

and always

has been

the

contacts

case

is

they should be

necessary

to

inspect the contacts.

arc

quencher

are

LUBRICATION

circuit

barriers

eroded to half

breaker

should be lubricated

periods

be

with a thin film of

lubricated with G-E Lub-

grease

latch

and bearing

EXCESS

AVOID ANY

LUBRICANT

. ·

after

interrupted,

are

worn

remove

should be

requires

and

dirt

surf

ACCUMULATION

mater-

of the

between

eventual

times

all

at

regu

-

a known

to

or

dressed

the

arc

Arctheir

mod-

at

the

should

aces

by

SHOULD

Low Voltage

5. Remove the auxiliary

··

(5-,

Fig.

20).

6. Check along the·

anical

interference

overcurrent

Power

Circuit

or

trip

device and the

Breakers

switch

trip

shaft

connection between the

Remove mechanical · connection if

if

interference

removing

to

avoid mechanical breakage of

or

reassembling

frames

the

should

trip

shaft

NOTE

:

be

fastened to a suitable maouting

the

front

as

the bolts

BASIC

The

arc

regular

cracked

thickness, they should be

inspection

1. Be

or

sure

exists,

re-assembling

use

extreme

front

and

trip

the

front

and

rear

frames,

be

is

hori

zontally aligned.

It

is

recommended

frame

supported by a sling

are

being installed.

BREAKER

ARC QUENCHERS

(Fig •.. 4

positioned

vertically

that

COMPONENTS

and ·5)

quenchers should be inspected

period.

eroded to one-half

REPLACEMENT-AK

the

breaker

If

rep_lacec;i

BREAKERS

is

open.

the

their

.

2. Remove the channel-shaped retaining

by removing two

3.

Lift the quenchers

arcin

g co~tacts.

screws

and two

clear

nuts.

of the· movable

GEK-7303

operating

for

trip

present,

care

back

rod

a mech-

paddles.

or

when

frames

devices. In

the two

so

that

the

breaker

base

with

or

hook

at

the

barriers· are

original

bar

The

use

should

become

destroy

be

entangled

the

On drawout

disconnect

Grease

Specificati~n D50H47. .

To

repair

anism, ox:

frame

must

To -separate

1. · _ The

the

safe!}7

2.

_

part

from

using a

include

Remove ·the two opening

o! the

3.

Remove the clevis pin (14,

the

center

4.

Remove the

socket

the

of

cotton waste to wipe

avoided,

as

under

the cotton ravelings may

the

bearing

bearing

surfac.e of the bearing.

breakers,

studs

SEPARATION OF FRONT

the

should -be

AND

or

replace

overcurrent

be

separated

the two

breaker

pin

in

place.

the contact

greased

REAR

FRAMES

contacts·, operating mech-

devices, the front

from

the

frames

contacts

pro~eed

must

(See MAINTENANCE.)

springs

~reaker)

from

the

outside

Fig.

pole unit.

six

nuts

from

wrench with an extension.

two nuts

at

the top of the

surfaces

surfaces

surface

· with G-E

back

as

follows:

be

open with

(on

pole units.

6)

(13, Fig.

the back

and

of the

frame.

lower

7)

frame

These

frame.

4.

.During _replacement be careful

overtight~n the

shaped retaining

will bow the

cher

loose. · · ·

·

The

is

breakers

except

the

center-pole

similar

that

breaker

to· the

and

the

open and the

Replace the

Type AKF

1. Be

breaker

sure

screw

bar

REPLACEMENT-

arc

is

replaced

breaker

which

bar.

Overtightening the

and leave the

arc

quencher of

·AKF

secure

center

BREA~ERS

these

quenchers of the standard

in a

similar

must be closed. With

closed the center-pole contacts

arc

quencher can be remov.ed.

outer-pole

as

follows:

the

breaker

arc

quenchers of the

is

open.

r.iot

to

the channel-

screws

arc

quen-

breakers

manner,·

are

2. Remove the two channel-shaped r_etaining .-

bars

which

bear

against the front of the

arc

quenchers by removing four -screws, two on each

side.

3.

Lift .the

-

arc

quenchers

clear

of

the movable

arcing contacts.

arc

4. Replace

screws

quenchers and

holding the retaining

insert

bars

the

four

in position.

Page 8

GEK-7303 Low Voltage

Power

Circuit

Breakers

. . . . . .

1·· 2

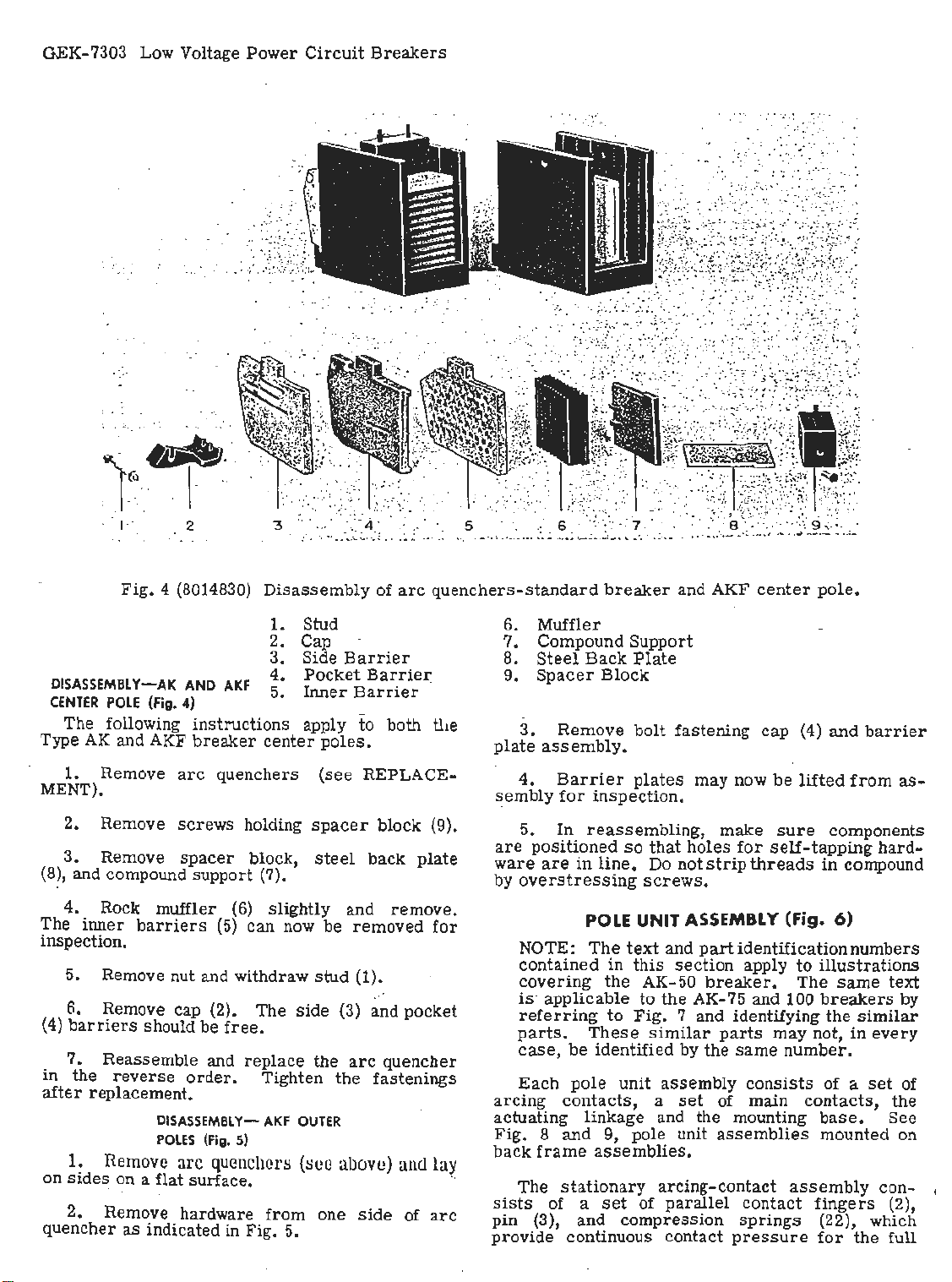

Fig.

4 (8014830)

Disassembly

1. Stud

2. Cap

3. Side

DISASSEMBL

CENTER

POLE

The following

Type

AK

and AKF

1. Remove

MENT).

2. Remove

3. Remove

Y~AK

(Fig.

AND

4) -

instructions

breaker

arc

quenchers

screws

spacer

AKF

holding

block,

4.

5.

center

(8), and compound support (7).

4. Rock muffler

The

inner

barriers

(6)

slightly and

(5)

can now be

inspection.

5. Remove nut and withdraw

6. Remove cap (2). The

(4)

barriers

7.

in

the

after

replacement.

1.

on

sides

2. Remove hardware

quencher

should be

Reassemble and

reverse

DISASSEMBLYPOLES

Remove

order.

(Fig.

arc

quenchers

free.

replace

Tighten

AKF

5)

on a flat surface. ··

from

as

indicated in Fig. 5.

.

..

. :

..

.

. .

,,

, '

Pocket

Inner

apply

poles.

(see

spacer

steel

stud

side

the

OUTER

(8Ce

one

:;.:

:·::··:

~--

.·. : ·· ...

.. .

of

Barrier

Barrie~

Barrier

to

both

REPLACE-

block (9).

back

removed

(1).

(3) and

arc

quencher

the

fastenings

abov

e)

side

. . :

.-

: :

.

arc

quenchers-standard

tl1e

plate

sembly

plate

are

ware

by

remove.

for

pocket

arcing

actuating linkage and the mounting

Fig. 8 and

and

of

lay

arc

back

sists

pin

provide

breaker

6. Muffler

7. Compound

8.

Steel

9.

3.

Back

Spacer

Remove

Block

assembly.

4.

Barrier

for

inspection.

5.

In

reassembling,

positioned

are

in

line.

overstressing

POLE UNIT A

NOTE:

contained

covering

The

in

the

is· applicable

referring

parts.

case,

Each

to

These

be

identified

pole

contacts,

9, pole unit

frame

The

assemblies.

stationary

of a

set

(3), and

continuous contact

and AKF

Support

Plate

bolt

fastening

plates

so

that

holes

Do not

may now

strip

screws.

SSEMB

text

and

this

AK-50

to

Fig.

part

section

breaker.

the AK-

7 and identifying

similar

by the

unit

assembly

a

set

arcing-contact

of

parallel

compression

center

cap

be

make

sure

for

self-tapping

threads

LY

(Fig. 6)

identification

apply

to

The

75

and 100

parts

may not, in

same

number

consists

of mai~

assemblies

assembly

contact

sprin

gs (22), which

pressure

pole

.

(4)

and

barrier

lifted

from

· components

in

compound

numbers

illustrations

same

breakers

the

similar

every

.

of a

set

contacts,

base.

mounted on

fingers

for

the full

as-

hard-

text

by

of

the

See

con- ,

(2),

Page 9

Fig.

5 (8019408) Disassembled

GEK-7303 Low Voltage

arc

quencher- AKF

outer

Power

poles.

Circuit.Breakers

1. Muffler Assembly

2.

3.

Spacer

Inner

Block

Barrier

4. Cap

travel

the pivot pin to

pivot point when interrupting high

earlier

· of · the

model

contacts.

pr

_event possible pitting

breakers

Steel

flexible

springs

(5)

currents. · On

braid

leads

shunt

at

the

were

used.

rhe

movable ~rcing-contact a~sembly consists

of

parallel

·able pivot

contact

pins

arms

(8)

and (19). The

(4)

carried

arcing

on two mov-

con.tacts

interleave the main · contacts and pivot with them

about pin (19).

linkages

from

the

relative

upper

motion

pin

(7)

is

obtained by.

to the

breaker

This

mechanism. . . ·

stationary

Th·e

main and

contact

and will,

and

intermediate

surface

therefore,

break

of contacts

in

Table

I.

after

main contact

contacts. The

assembly

intermediate-

includes

extends beyond the main contacts

make

before

the main contacts

the main contacts. The number

for

each

breaker

rating is· given

The movable main contacts pivof around a

stationary

lower

pin

.(7), connected by an insulated

breaker

shunting

lower

!the

con~cts

liiie

at

the

jassembly

pin (18), which holds

·block. Motion

mechanism.

the

current

is

In

from the contact ·

contact block,

pivot

also

ag~nst

pomt. The movable main contact

the pins to prevent pitting

contains main and intermediate

obtained

addition to

steer

springs

them

from

link

ste·e1

. to the

a second

(12). to tl\e

springs

directly

(17)

force

!contacts.

5. Intermediate

6.

Outer

. 7. Side

In

of contact

Plate

order

Barrier

to function

pressure

between . the movable and

Table I gives the

contact wipe. Both wipe and

cpecked during the_

MEASURING

· 1. Remove

ARC

under

QUENCHER). .

2. With the

zontal distance

contact to the

dim.

for

arcing

contacts). ·

3. Clo.

se

the

difference between the readings in items 2 and 3

to

determines

reasons

breaker.

1. Remove

UNDER

the wipe of the · contacts.

be extremely careful not to trip the

· . ·

MEASURING

(Fig.

ARC

QUENCHER).

2. Close the

"B".

3.

Open the breaker.

Barrier

properly,

a definite amount

and contact wipe must

stationary

figures

for

contact

pressure

regular

CONTACT

arc

quenchers

breaker

from

. the edge of the stationary

stationary

WIPE

(see

open,

block behind

contacts, "C" dim.

breaker

and repeat

inspection period.

(fig. 6)

REPLACEMENT

measure

contacts.

pressure

should be

the hori-

it.

for

item

For

CONTACT

6)

arc

quenchers (see REPLACEMENT

breaker

PRESSURE

and measure dimension

Place

a push-type

exist

and

-:

('.'B"

.main

2. The

safety

scale

Page 10

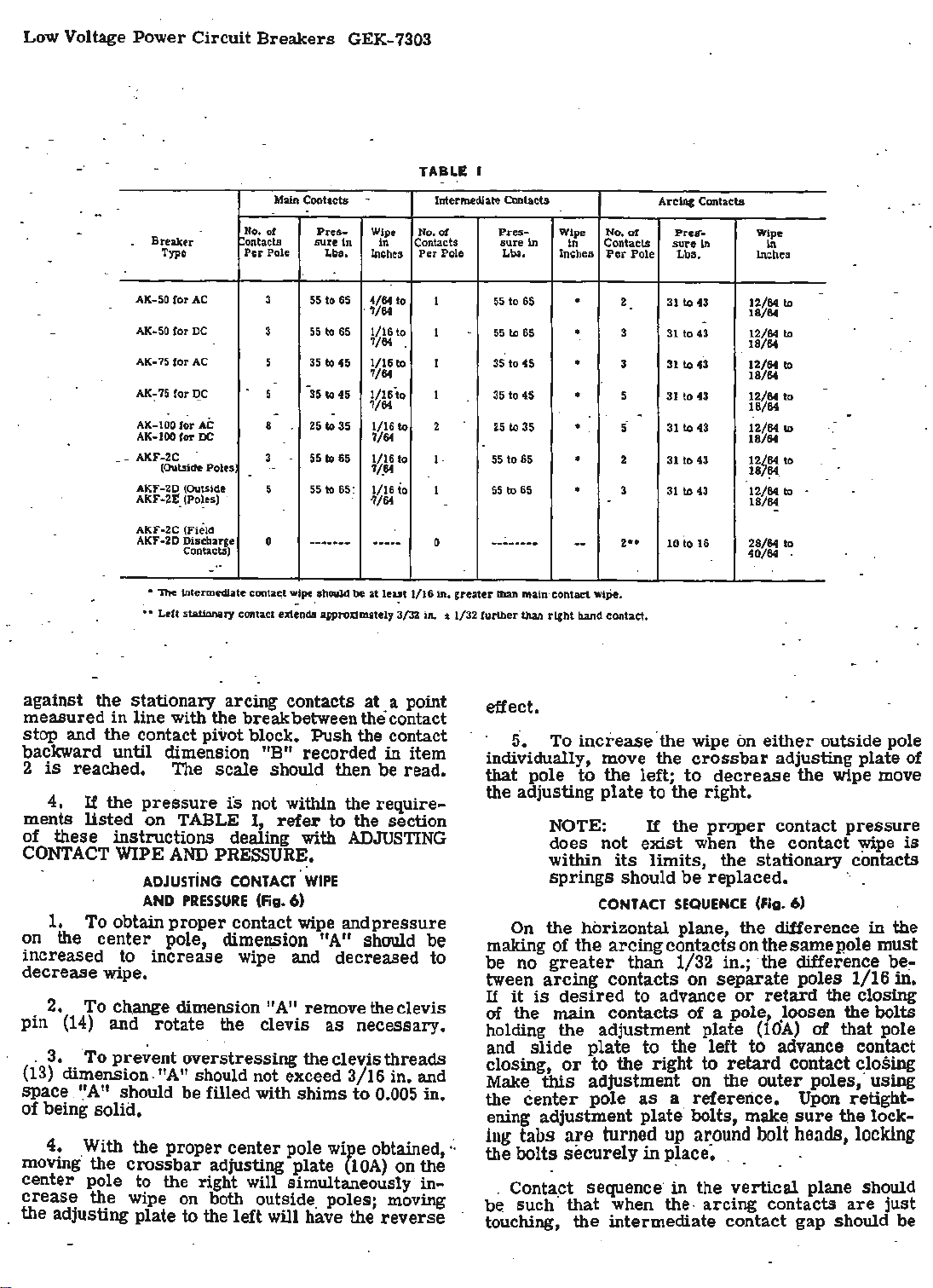

Low Voltage Power Circuit

Breaker ontacts

Type

No.

Per

Breakers

Main Contacts - Intermediate Contacts

or

Pole

GEK-7303

Pres-

sure

In In

Lba,

Wipe

Inches

TABLE

No.

of

Contacts

Per

Pole Lbs,

Pres-

sure

In

Wipe No.

Inches

ln Contacts

of

Per

Pole Lbs,

Arcing Contacts

Pre=r-

sure

In

Wipe

Ill

lnches

AK-SO

tor

AC

AK-SO

tor

DC

tor

AK-75

AK-75

AK-I

AK

_ AKF-2C

-

AKF-2D (Outside

AKF-2£' (Poles)

AKF•2C (Field

AKF-2D Discbarge

AC

tor

DC

00

for

AC

-100

tor

DC

(Oulside Poles

Contacta)

• The intermediate conta~t

~

•

Ldt

stationary contact ext;nda approximately 3/32 in. ~ 1/32 further than right band contact.

-

·:

..

3 55

3

55

5 35 to

-

"

35

5

-

8

25

3 55 to

.•.

.

5 55 to 65:.

0

-------

wipe

to

65

to

65

45

to

45

.

to

35

65

should be

4/64 to

. '1/64

1/16 to

'1/64 .

1/16 to

7/64

1/16

?/64

1/16 to

?/64

1/16 to

'1/.

64

1/16 io

'1/64

-----

at

le~t

to

.

.

1/16

1 55 to

1

1

I 35

2

1,

I

0

in.

against the stationary arcing contacts at . a point

in

measured

line with the breakbetweenthecontact

stop and the contact pivot block. Push the contact

backward until dimension ."B" ·recorded in item

2

is

reached. The

4.

If

the

ments

listed

pressure

on TABLE

of these instructions dealing with

CONTACT

1. To obtain

on the

WIPE

ADJUSTiNG

AND

center

scale

should then be read.

is

not within the

I,

refer

to

require-

the section

ADJUSTING

AND

PRESSURE.

PRESSURE

proper

·coNTACT.

contact wipe andpressure

(Fig.

WIPE

6)

pole, dimension "A" should be

increased to increase wipe and decreased to

decrease wipe.

· 2. To ch.ange dimension "A" remove the clevis

pin

(14)

and rotate the clevis

as

necessary.

. 3. . To prevent overstressing the clevis threads

(13)

dimension. "

space.

'.'A"

should

A"

should not exceed 3/16 in. and

be

filled with shims to 0.005 in.

of being solid.

4.

·

moving·

With the proper

the

crossbar

center pole to the right will simultaneously

crease

the wipe on both outside. poles; moving

the adjusting plate to the left will have the

center

pole

WiJ>e

adjusting plate

obtained,:.

{lOA)

reverse

on the

in-

-

-

to

to

to

-

to

.

greater

.

65

55 to 65'

35 to 45

to

45

25

to 35

55

to

65

55

to

65

-----··--

than main ·contact wipe.

•

.

•

•

•

• ·

--

2 31 to 43

3

31

3

31

5

31

-

5·

31

2 31

3

.

31

2

..

10

12/64 to

18/64

-

to

43 12/64 to

to

43 12/64 to

to

43

to

43

to

43

to

43

io

16

18/64

18/64

12/64

18/64

12/64

18/64

12/64

187?4.

12/64 to

18/64

28/64

40/64

effect.

5.

To

increase

individually, move the

that

pole

to

the

the adjusting

plate

NOTE:

does not

within

springs

CONTACT

On

the

horizontal plane,

making

be

tween

If

of the arcing contacts

no

greater

arcing

it

is

desired

·the wipe on

left;

to

If

exist

its

limits,

crossbar

to

the

right.

the

proper

when

either

outside pole

adjustin~ plate of

decrease

the wipe move

contact

the

contact

the

stationary contacts

should be replaced. ·.

SEQUENCE

(Fig. 6)

the

difference in the

on

the same pole must

than 1/32 in.; the difference

contacts on

to advance

separate

or

retard

poles 1/16

of the main contacts of a pole .loosen the bolts

holding the adjustment plate

slide

and

closing,

Make

center

the

plate

or

this

adjustment on the

pole

to

to

the right to

as

the left to advance

a reference.

ening adjustment plate· bolts,

ing

tabs

are

turned

the bolts

. Contact sequence·

be such ·

touching,

securely

that

when the. arcing contacts

the

intermediate contact gap should be

up

a:r:ound

in

p~ace. . . .

in

the

(10A)

retard

outer

make.

bolt

vertical

of

contact

poles, usmg

Upon

sure

heads,

plane should

pressure

y.,ipe

is

~e~

m.

the closing

that pole

con~ct

~los~g

retight-

the lock-

locking

are

just

Page 11

Low Voltage

Power

Circuit

Breake~s

GEK-7303

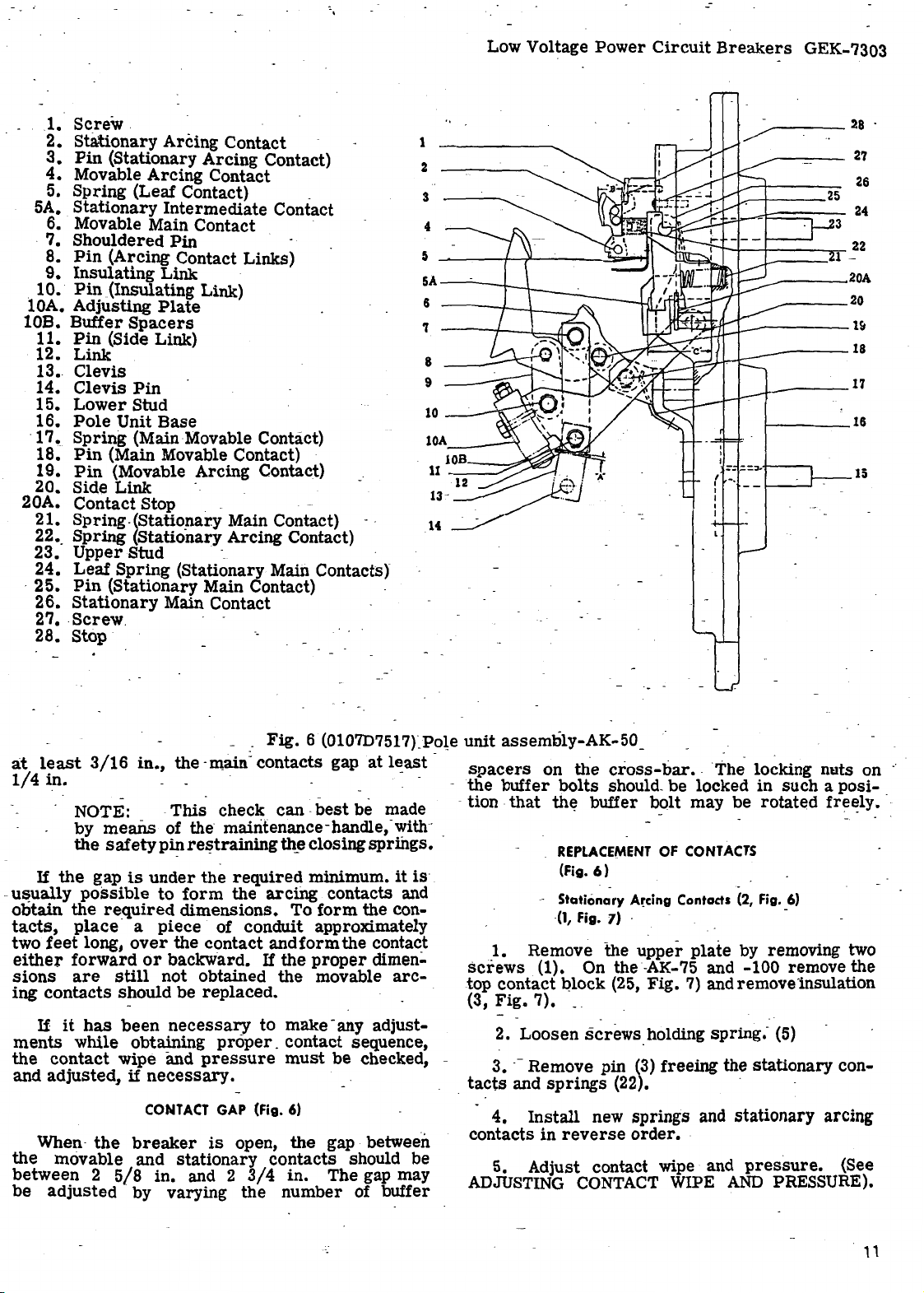

1.

2.

3.

4.

5.

5A.

Screw

Stationary

Pin

Movable

Spring

Stationary

.

Arcing Contact -

(Stationary

Arcing

Arcing

Contact

(Leaf Contact) _

Intermediate

6. Movable Main Contact ·

.

7.

Shouldered

8.

Pin

(Arcing Contact Links)

Insulating

Pin

(Insulating Link)

.

9.

10.

lOA. Adjusting

10B.

Buffer

11.

Pin

12.

13.

14.

15.

16.

·

17.

18.

19.

20. Side

20A.

21.

22 •.

23.

24.

·

25.

26.

27 • .

28.

(Side Link)

Link

Clevis

Clevis

Lower

Pole

Unit

Spring

Pin

(Main Movable Contact) ·

Pin

(Movable Arcing Contact)

Link

Contact

Spring

Spring

Upper

Leaf

Spring

Pin

(Stationary Main Contact) -

Stationary

screw

Stop

Pin

Link ·

Plate

Spacers

Pin

Stud

Base

(Main Movable Contact)

- _

Stop . - · -

-(Statio:f1ar.y Main Contact) - (Stationary Arcing Contact)

Stud -_ ·

(Stationary Main Contacts)

Main Contact

.

Contact)

Contact

1

2

3

4

5

~---t-..,,._---.....::,aa-...,

5A-~--t---\----~-

6

'l

8

9

10

-----

lOA

____

,

-

~

---------

•--r--+---+----...--

~~f/r:J__..-------1~

=-

{ -.

I

I

.J.------~l

______

___

----18

1-----16

.:=.;,,.-i----,

28

27

26

22

-

20A

20

15

·

a:t

least

1/4

3/16

in.

NOTE: -

means

by

the

safety

If

the

-

usually

obtain

tacts,

two

either

sions-are

ing

contacts

If

ments

the

and

When·

the

gap

possible

the

re_quired

place

feet

long,

forward

still

it

has

while obtaining

contact

adjusted,

the

movable and

between 2 5/8

be

adjusted · by

in.,

the ·main: contacts gap

This

of the

pin

is

under

to

form

dimensions.

a

piece

over

the

or

backward.

not

should

been

be

necessary

wipe and

if

necessary.

CONTACT

breaker

stationary

in.

varying

.

Fig.

6 (0107D7517rPote

check

- -

can . best

be made

m~~tenance-h~dle,-~ith

rel?trammg

the

th_e

required

the

arcing

'FO

closing

minimum.

contacts and

form

of conchnt approximately

contact

obtained

and

If

form

the

the

the contact

proper

movable

replaced.

to

make -any adjust-

proper_ contact

pressure

GAP

(Fig.

is

open,

contacts

and 2

3/4

the

must

6)

the

in.

number

sequence,

be

checked, -

gap - between

should be

The gap may

of buffer

at

l~ast

springs.

it

is

~e

con-

dimen-

arc-

unit

-

spacers

-

the

-tion

- _

screws

.top

(3,

tacts

.

contacts

ADJUSTING

assembly-AK-50

on

the

buffer

bolts

that

th~ buffer

REPLACEMENT

(Fig.

- Stationary

(1,

Fig.

1. Remove

_

cross-bar

should.

6)

- .

A~cing

7) -

the

upper

• . The ~ocking nuts

be

locked m

bolt

may

OF

CONTACTS

Contads (2,

plate

be

by removing two

. (1). On the -AK-75 and -100 r~move

contact

Fig.

2.

3 • . - Remove pin

4.

5. Adjust contact wipe and

Qlock (25,

7).

- .

Loosen

and

__

screws

springs

Install

in

reverse

CONTACT

Fig.

7)

and remove insulation

holding

(3)

freeing the

spring.

(22). · ·

new springs and

order.

WIPE

stationary

·

AND

stationary

pressure.

such

rotated

Fig.

a pos1-

fre~ly.

_6)

- (5)

arcing

PRESSURE).

<?D

~e

con-

(See

,,

Page 12

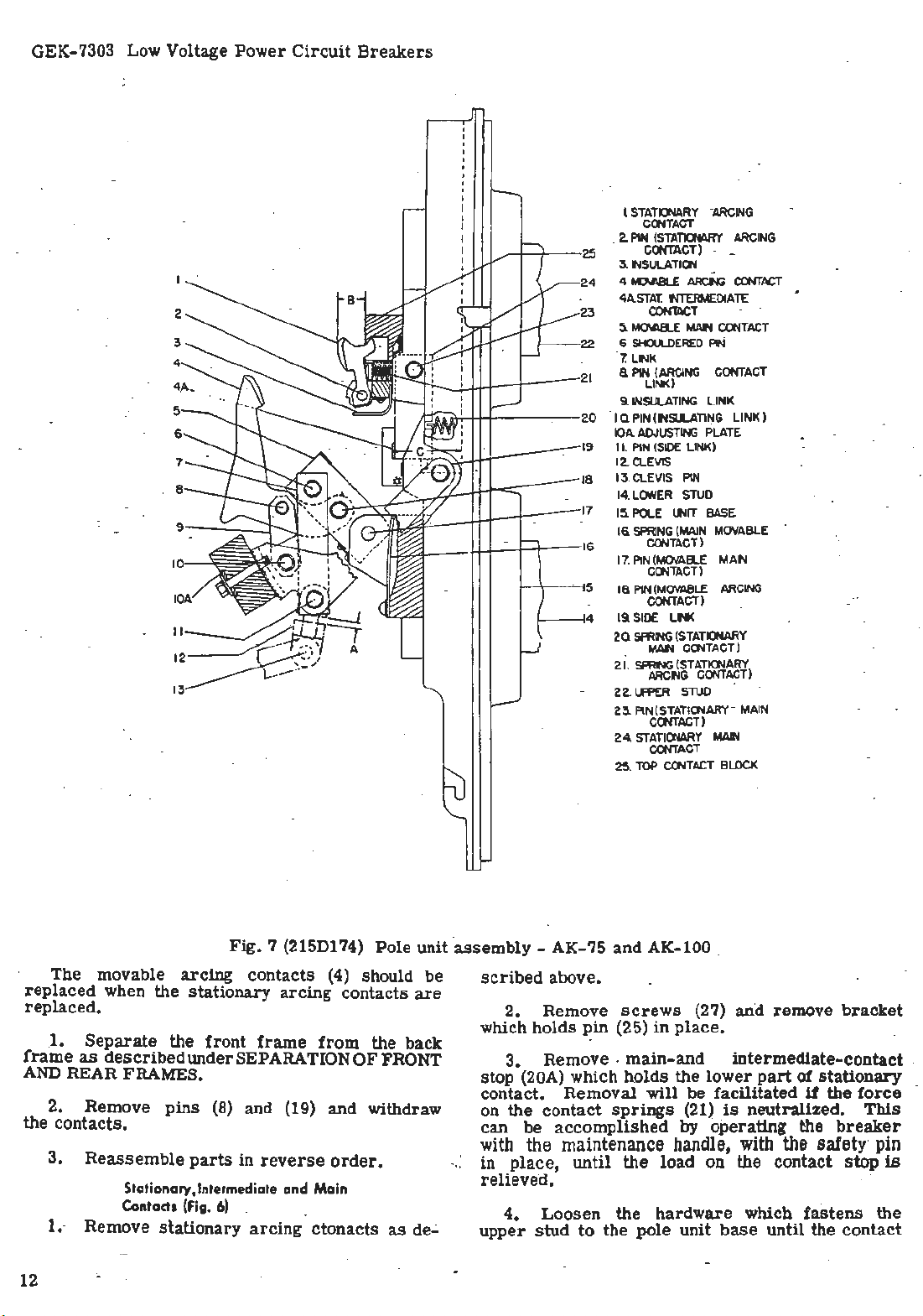

GEK-7303 Low Voltage Power

4

5

Circuit

Breakers

· I

l

I

I

I

I

I

STATIONARY

COOTACT

.

2.

P1N

(STATIONARY

25

24

23

22

21

20

19

18

17

16

5 -

4

-

CONTACT)

3. lNSULATI

4. ID.ABLE

4A.

STA

T.

CON'lllC

5.

MOI.AB.E

6

SHOULDERED

7.

LNK

a

PIN

(ARCING

LINK)

9.

INSULATING

I Q PIN ( INSll.ATING LINK )

IO

A.

A.OJUSTING

II. PI

N (S

12.CLEVIS

13. CLEVIS PIN .

LOWER

14.

15.

POLE

16.

SPRING

CONTACT)

17. PIN(MOVAEl.E MAIN

COOTACT)

1a

P1N(MOV

C

ONTACT)

19 SI

DE

2Q

SPRING (

MAN

2i

. ~ (

ARCING

-22.

Uff>ER

2

3.

PIN(STATIONARY-MAIN

CONTACT)

24.

STATICNARY

CONTACT

25. TOP COOTACT

"ARCING

-

-

OO

ARCf'.lG

NTERMEDIATE

T

MAN

CONTA

PIN

CONTACT

LINK

PLATE

IDE

.LI

NK)

STU

D

UNIT

BASE

(MA

IN

MOVABLE

ARCING

ABLE

LN<

STATIONARY

CONTACT)

STATIONARY)

CONTACT

STUD

MAl'l

BLO

ARCING

CO'JT

ACT

CT

CK

The . movable

replaced

replaced

1.

.

frame

AND

as

REAR FRAMES.

2. Remove

the contacts.

3.

1.- Remove

12

·

Fig

arcing

when the

stationary

.

Separate

described

Reassemble

the

front

under SEPARATION

pins

(8) and (19) and withdraw

parts

in

Stotio~ory,lntermediate and Ma

Conta

d1

(Fi

g. 6) _

stationary

. 7 (215D174)

contacts

(4)

arcing

frame

reverse

arcing

from

order

in

ctonacts

Pole

should

contacts

the back

OF

FRONT

.

.

as

unit ·

be

are

de.;.

assembly

scri

- AK-75 and AK-100 .

bed above.

2. Remove

which holds

3.

~in

Remove .

stop (20A) which h.olds

contac

t.

Removal

on the contact

can

be

accomplished

with

the maintenance

in

place,

·

relieved.

until

4. Loosen

upper

stud

to

the pole unit

screws

(25)

(27) and remove

in

place

•

main-and

the

lower

will

be

springs

facilitated

(21)

is

by operating the

handle,

the

load on the contact

· ·

the hardware

base

bracket

intermediate-contact

part

of

stationary

if

the

neutralized.

force

This

breaker

with

the

sa!ety· pin·

stop

is

-which

until

fastens

the

contact

the

.

Page 13

Fig.

8 (8014678)

Front

view of back

assembly

- AK-2-50

frame

Low Voltage

Power

Circuit

Breakers

GEK-7303

Stationary

1.

Contact

Movable

2.

Contact

Stati9nary

3.

Contact

Clamp

4.

Movable Main

.

5.

Contact

spring

lift

5.

out

. ·

load

Remove

contacts.

~--Reassemble

being

in

described

at

th~

·

1.

2.

3.

·

bottom

careful

proper

Remove

above.

Loosen

Remove

of

Arcing

Arcing

Main

:

on

pin

pin

to

position.

Movable

_

Main

the

spring

braid

contact.

(25)

is

(~5i and

contact.s

replace

Intermediate

Contacts

movable

(17).

if

6.

Crossbar

Series

7.

Device

Movable

8.

mediate Contact

Stationary

9.

_mediate Contact

relieved.

screws

in

the

intermediate

(F1g.

and

6) ·

arcing

present

by

· ·

Overcurrent

Inter-

Inter-

(27)

and

reverse. orger,

contact

·

contacts

removing

as

screw

Fig.

9 (8039669)

1.

.

2.

·

3.

ing contact

Power

Disconnect

Tr;msformer

replacement

Front

·. ··

assembly -AK-3-50

Sensor

view of

Coil

Assembly

Plug ·

Taps

in

!

.

back

Amper~s

frame

(See ADJUSTING CONTA_CT WIPE AND PRESSURE).

OPERATING -MECHANISMS

ELECTRICALLY

and

.

The

ele~trically

a

motor

the closing

shaft (14,

with a

closing

closing

llC.

and

center-pole

crossbar

.

of the

contacts

-100;

and a

Fig.

roller

cam

cam

it

OPERATED

MANU~L

gear

springs

10). The

(12,

(2,

Fig.

roller

The

closing

unit

through a

controls

~m

all

AK ·

.AK-50,

-50

-75

·

operated · mechanism

reduction

(16,

Fig.

11).

is

shown in·

unit,

Fig.

10) through a

crank

shaft

10) which

The

which charges ·

ha~ an

rides

position· of

Fig.

11A,

cam is. connected to the

clevis

and through a

the opening and closing

pole

units.

includes

crank

arin

on the

this

11B,

4.

(7).

5.

sid~

to

be

6.

Always

Slide

link

Slide ·pins

to

allow

replaced.

Reassemble

check

(12) to the

(7)

the

movable

parts

contact wi

and (18)

intermediate

in

reverse

pe

and

side

and off of p4l

far

enough

order.

pressure

to

the

contacts

follow-

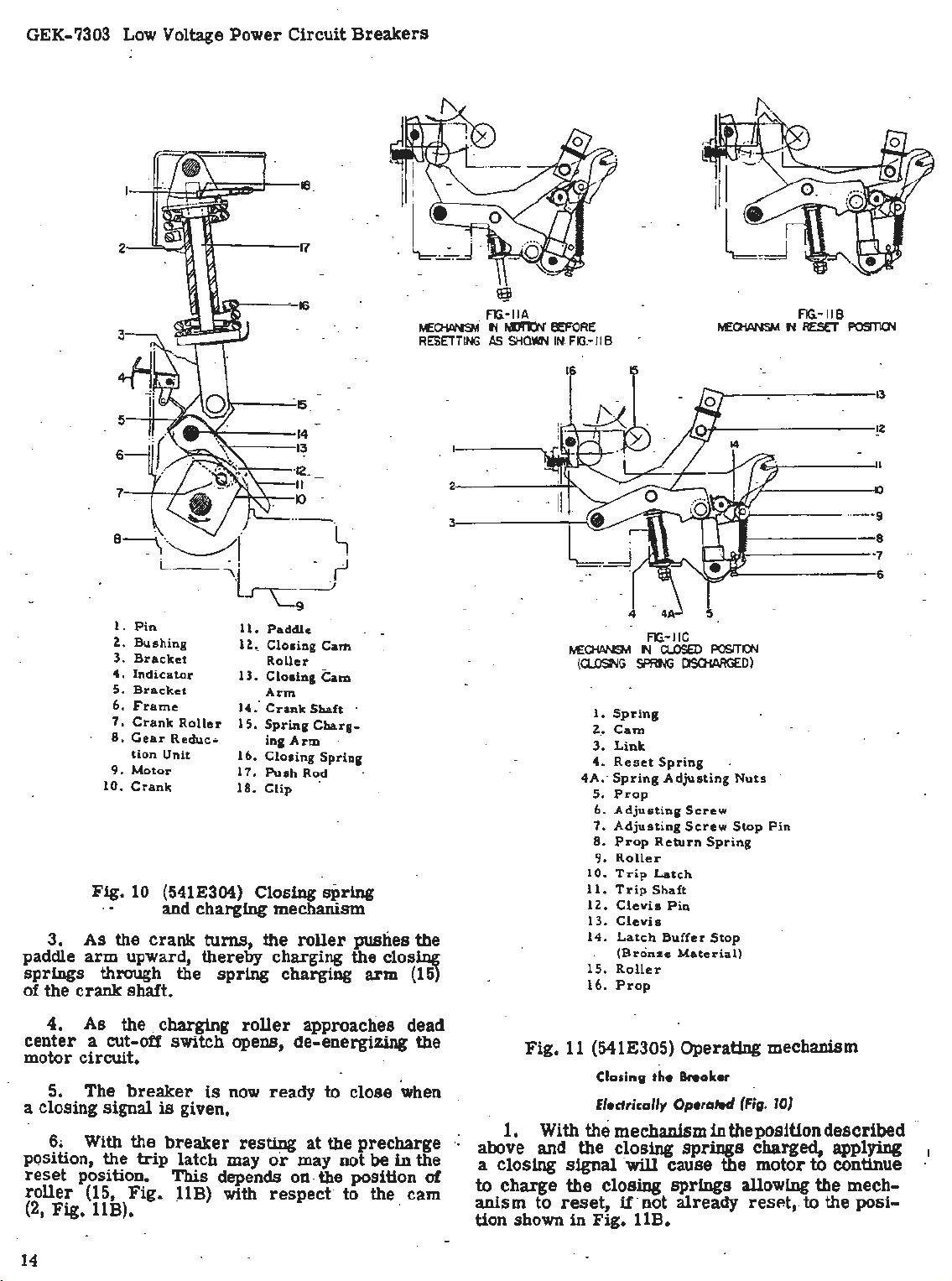

1.

The

Fig.

llA.

2.

The motor turns the crank

is

mounted

tion unit.

face of

on

it.

Chargi

ng

mec~anism

on

The

the

crank,

the Closing Springs (Fig.

in

position

the

output

charging

has

shaft

roller,

paddle

of

arm

10)

is

the

gear

which

(11)

shown

(10)

is

in

which

reduc-

on the

bearing

13

..

Page 14

GEK-7303 Low Voltage

Power

Circuit

Breakers

·

~C>IANSM

RESETTING

FIG

~

·IIA

N

t.1111:lN"

AS

SHOWN IN.

BEFORE

FIG.-

I I B

~CHANSM

FIG.-

N

116

RES€T

POSITlCN

3.

paddle

springs

of the

_5

6

7

Pin

1.

Z..

Bushing

3,

Bracket

4 .

Indicator

5.

Bracket

6.

Frame

7,

Crank

8,

Gear

tion

9.

Motor

10,

Crank

Fig.

10 (541E304) Closing

· · and

As

the

arm

upward, there~y

through the

crank

shaft.

Roller

Reduc

Unit

crank

11,· Paddle

lZ.,

13.

1'4:

15.

..

16.

17,

18,

chargin

turns;

spring

15

14

13

·12_

II

IO

··-

~-

Closing

Roller

Closing

Arm

Crank

Spring

ing

Closing

Push

Clip

g mechanism

the

Cam

Cam

Shaft

Charg-

Arm

Spring

Rod

spring

roller

chargi~

charging

·

pushes the

the closing

arm (15)

13

~2

2

3

Spring

.•

Cam

Link

Reset

Prop

Adjus.ting

Adjusting

Prop

Roller

Trip

Trip

Clevis

Clevis

Latch

(Bronze

Roller

Prop

FIG.-IIC

N

a..osED

SPRf'lG

Spring

Adjusting

Return

Latch

Shaft

Pin

Buffer

POSITl()'.I

ClSOtARGED)

Nuts

Screw

Screw

Stop

Spring

Stop

Material)

Pin

tJE:CHANSM

(CLOONG

1.

z.

3.

4 .

4A,· Spring

5.

6.

7.

8.

9.

10.

11.

lZ..

13.

14.

15.

16.

()

···

--9

-8

·7

6

4.

As

center

motor

5. The

the

a cut-off

circui

t.

breaker

a closing signal

6. With the

· position, the

reset

roller

(2,

14

position.

(15,

Fig

. 11B).

. charging

switch

is

breaker

trip

This

Fig.

llB)

is

roller

opens,

now

approaches

de-energizing

ready

to c

given.

latch

resting

may.

or

at

may

depends on. the position

with

respect· to

lose

the

precharge

not be

the

dead

the

when .

in

the

of

cam

1.

··

above

a

closing

to

charge

anism

tion shown

Fig.

11 (541E305) Operating mechanism

With

and

to

reset,

Closing

Electrically

the

the

signal

the

in

Fig. UB.

the

Operated

mechanism

closing

·

will

cause

closing

springs

u· not

halter

in

the position

springs

the motor

already

(Fig.

charged, applying_

allowing

resP.t, to

10)

described

to

co

ntinue

the

mec~-

the

posi-

Page 15

Low Voltage

•1:

.

Power

Circuit

'

..

Breakers

. . ' ;

.. ~ ..

': .

...

~. ··

GEK-7303

:··

·•. -

Fig.

1i

(8018989)

AK-50 showing

~

2.. As

dead-center

position) the

Crank (10)

motor so-

center

·

3.

the

crank

to

rotate

F.ig.

11).

llC)

in

4. Raising

breaker

Tripping the Breaker (Fig.

·Operation

the

trip

to

release

forces

reposition

the

position

the operating ·

Adjustments (Fig.

the

crank. roller

position,

closing

can

be

that

roller

position

As

this

without

the

springs

shaft

cam

Prop

position

'(14)

(2,

(16,

clevis

contacts

of

-any

shaft

(11)

the

latch

of the· contact and opening

the

operating

shown

cycle

11)

Rear

view of

cam

shaft

locking plate

being loosened

(7)

(maximu.m

springs

overdriven

(7)

are

independently of the

assumes

restraint.

free

its

:-

discharge,

causes

Fig.

Fig.

roller

11) and

11) holds

raise

~

(13,

Fig.

llC)

through the pole

11)

of

the

trip

devices

which ;µlows

prop

(5).

the

This

mechanism linkage to

in

Fig.

may

llA,

be

repeated.

In

fronnrame-

passes

spring

its

charge

to

discharge.

top

bottom dead-

the rotation of

(15,

Fig.

11)

clevis

cam

closes

base

(13,

(2,

Fig

the

linkage.

rotates

trip

latch (10)

allows the

springs

this

position,

to

Fig.

manual

and with

roller

1/64 in, and

obtained by

should

.

latch

be

reposition

(3) and

1/

32

the nuts (4A)

.the

Replacement

to the

AND

these

..

.!:.:

Fig.

13

(8018984)

AK-50 showing

~nd

llB.

(The mechanism should

operation

1.

roller

The

(9) of

(15)

gap between.the

the

1/32

turning sc.

2.

·

The

center

pass

through

buffer

stop

adjusted by loosening the retaining

the

3.

The . distance

prop

in.

reset

(5) should be between 1/64 in. and

To

obtain this gap, advance

spring

Rear

view of front

cam

shaft

cam

shaft

removed -

with_ the safety pin

clear

of

cam-(2).

trip

reset

the

latch should be between

in.

This

rew

(6).. - · -

line

of the

center

of the

on the mechanism

latch

with respect to the

between ·the

on

-the bottom of the

(4).

frame-

locking

plate

be

reset

in

latch

(10)

adjustment can be

trip

latch (10)

roller

(9). The

frame

screws

roller

or

~d

When replacing the operating mechanism,

section

BACK

titled

FRAMES

SEPARATION OF FRONT

under

MAINTENANCE

instructions.

by

place

.and the

can

to

roller.

on

link

retard

~ing

refer

in

All

ting

mechanism· in

adjustments

should

the

reset

be

made with the opera-

position

as

shown in

The

motor

is

mounted on the side of

the

g

ear-

15

Page 16

GEK-7303 Low Voltage

Power

Circuit

Breakers

reduction unit and through a worm

planetary

with a reduction 1000:1. To remove the

and gear-reduction unit, _

1 • . Remove the

OF FRONT

2.

as

illustrate~ iii Fig. -

3. Disconnect the

the -wires attached to

4.

front

unit. The.

NOTE

motor unit, disconnect the

remove only the hardware fastening

. - -gear-reduction unit. When removing the motor

· only, the front

· side

. ·

gear

The

similar

oil

HFS

or

· change oil except when the gear'.'.'reduction

unit-and

g~ar

train

drives

proceed

front

frame

AND

R~AR FRAME.)

.Remove closing

Remove four bolts

frame

No.

QUICK

and one

motor

:

down

unit. ·

gear

3.

motor

and

If

it

is

to prevenJ . the oil escaping from the

. reduction

to Atlantic Refining Company's Grade

·n

should not be

are

CLOSE

springs

12

and 13.

leads

gear

bolt

gear

unit may

desired

frame

unit

disassembled •. -·

the

crank

(see

from

motor and remove

unit housing.

at

the bottom of the

at

top of

to

motor

should be placed

contains 4 ounces of

BREAKER

ADJUSTMENTS

gear

(10, Fig. 10)

as

follows:

SEPARATION

and

crank-shaft

gear

reduction

n!JW

be removed .•

replace

necessary

only the

. leads - and

it

.

and a

motor

to the

front

to add

· .

.'

'c"

Fig

. 14A ·

Quick-Closing

Adjust the engagement of the

to 1/8

adjustment

11

±1/64" by

"B". Adjust the

roller

the

Release

is

set,

clearance

to

1/32+0-1/64

Latch -Fig.

turning

lock

the

by

the

between the

turning

14A

roiler

screw

bolt

on the

"A".

with the hex nut

the

screw

After

latch

latch

and

"C".

The quick close

the standard

_ operati<;m

deadAs

_.!tie

bre_aker, the discharge operation

~

pi:ap

closing operation

the

-latch to

the springs

operation and close the

The

is

· not interchangeable with the

uniLon the quick

close

to relieve the

be

. exerted between the output

the prop. . ·

After the· closing springs have been completely

charged and the prop and latch

venting

tion may

relay.

ually- by

mechanically displaces the latch to allow the

break~r to

On

breaker and enclosure

be

discharged before the

from the

is

extended

center

. . .

position of the closing

springs

and latch arrangement. The subsequent

release

to

gear

reduction unit

gear

reduction unit employs a

closure

be

.accomplished by energizing the closing

thni

the control relay contacts,

depressing

close.

drawout

enclosure.

breaker

breaker

start

is

the

continue the interrupted discharging

close

pressure

of

the

the push to

breakers

basically differs

in

that

~e

to

and slightly

. to discharge~ to close the

accomplished · by tripping

prop

which in

breaker.

for

the

unit because the quick

that would otherwise

breaker,

· .

an interlock between the ··

requires

the closing

breaker

p~echarging

past

spring

is

arrested

turn

standard

gear

crank

system

close

lever

the springs

can be removed

from

the top

assembly.

allows

breaker

reduction

slip

clutch

plate and

are

pre-

opera-

or

man-

which

by

to

D

Fig. 14B

Release Arm Adjusting -

Adjust release arm screw

the

armature

roller

over-travel.

NO

·

from

GO

of the closing

the

latch

with a minimum

·Check. by

gauge between

using

Fig.

l4B

"P"

so that

solen<:>id

1/32"

armature

the

stroke of

releases

GO

and

· and magnet.

of

the

1/32"

3/32"

16

.

Page 17

Fig.

14C

Low Voltage

used

on

theAK-50,

closing

manual

··

The

the

breaker,

case

with

breaker

handle

is

!mu

through

position

degrees

then

clockwise

approximately

stroke

have

which have

strokes