Page 1

-1-

GE Consumer & Industrial Appliances

Service Manual & Installation Manual

Split System Air Conditioner

Model numbers:

GE AIR F24

GE AIR F34

GE AIR F41

Page 2

-2-

Page 3

-3-

Page 4

-4-

IInnttrroodduuccttiioonn aanndd FFeeaattuurrees

s

MMooddeell RReemmaarrkkss

GE AIR F24 1PH 230V 50Hz R407C

Page 5

-5-

MMooddeell

RReemmaarrkkss

GE AIR F34

3PH 400V 50Hz R407C

Page 6

-6-

MMooddeell

RReemmaarrkkss

GE AIR F41

3PH 400V 50Hz R407C

Page 7

-7-

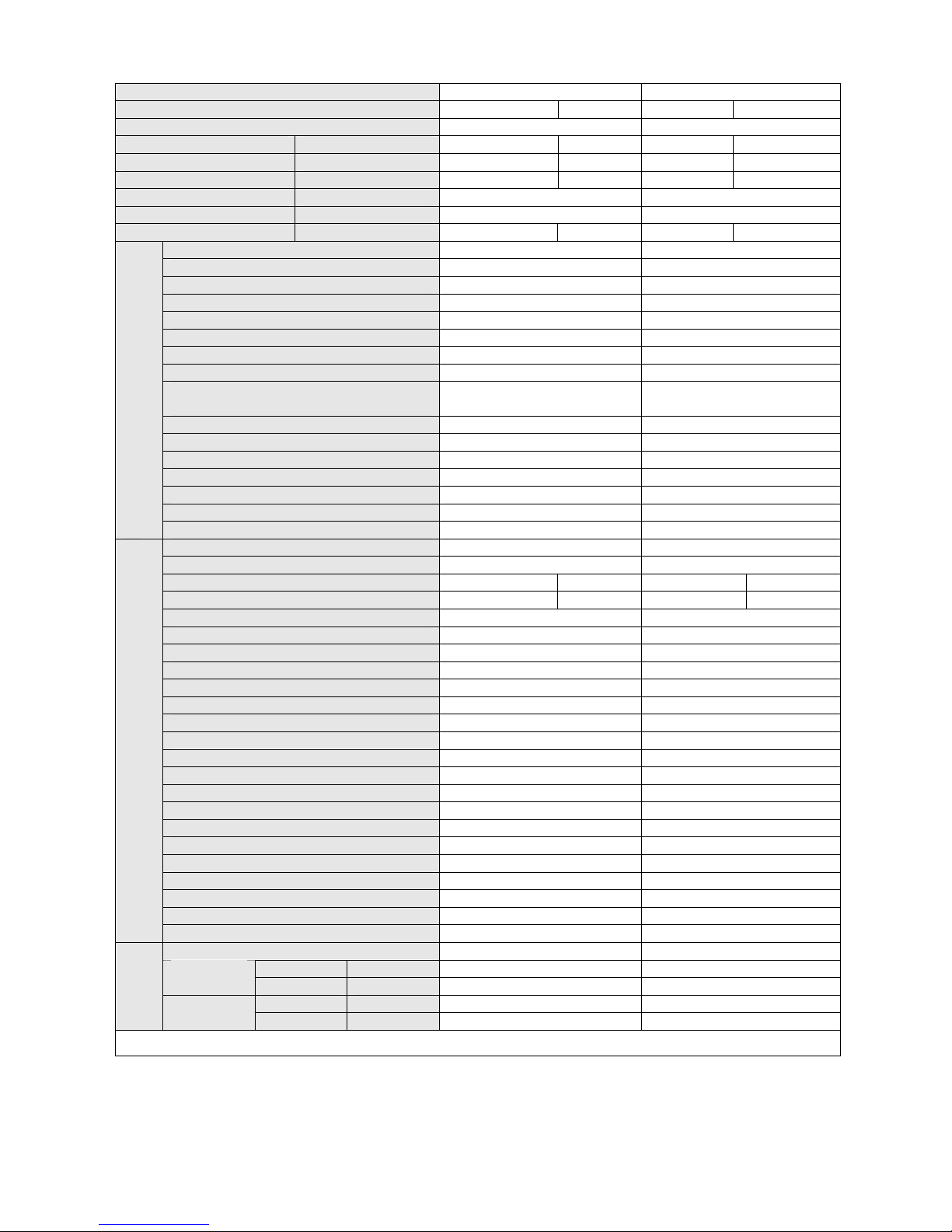

Model GE AIR F24

Function Cooling Heating

Power (Phase-Frequency-Voltage) 1Ph 50Hz 230V

Tot a l C a pa c i t y (W) 7000 8500

Rated power (W) 3000 3050

Rated current (A) 14.6 15.1

Air flow volume (m3/h) 1170

Dehumidify volume (L/h) 2.3

C.O.P/EER (W/W) 2.3 2.79

Model GE AIR F24 IN

Fan motor speed (r/min) (H/M/L) 1360/1280/1240

Output power of motor(W) 100

Fan type-piece Centrifugal Fan-4

Diameter-length (mm) ф125×134

Evaporator Aluminum fin-copper tube

Pipe diameter ф7

Row-fin distance (mm) 3-1.6

Extended area of heat exchange (I×H×L) 1.042×0.19

Swing motor model MP35CA

Power of motor (W) 4

Fuse (A) PCB5A Transformer 0.2A

Sound (pressure level) dB(A) ≤47

Dimension (W/D/H) (mm) 1300×188×600

Dimension of package (W/D/H) (mm) 1414×248×724

Indoor unit

Net weight/gross weight (kg) 32/36

Model GE AIR F24 OUT

Input Power 2900 2950

Running Current 14.2 14.7

Compressor Model C-RN220H5B

Compressor Type Rotary Type

LRA(A) 75

Compressor Overload Protector Type Internal Inherent Protector

Throttle Method Capillary

Starting Method Capacitor

Range of working temperature( )℃ 7≤T≤43℃℃

Condenser Aluminum fin-copper tube

Pipe diameter ф9.52

Row-fin distance (mm) 2-1.8

Extended area of heat exchange

(I×H×L)mm

725×813

Fan motor speed (rpm) 60/780

Fan type-piece Axial Flow Fan-1

Fan Diameter (mm) Ф450

Defrosting Method Auto

Sound (pressure level) dB(A) ≤58

Dimension (W/D/H) (mm) 950×412×840

Dimension of package (W/D/H) (mm) 1100×450×920

Net weight/gross weight (kg) 75/87

Outdoor Unit

Refrigerant/Refrigerant Charge (kg) R407C/2.5

Length 5

Liquid Pipe (mm) Ф9.52(3/8”) Outer

Diameter

Gas Pipe (mm) Ф 16(5/8”)

Height (m) 5

Connecting

Pipe

Max.

Distance

Length (m) 10

Page 8

-8-

Model GE AIR F34 GE AIR F41

Function Cooling Heating Cooling Heating

Power (Phase-Frequency-Voltage) 3Ph - 400V - 50Hz 3Ph - 400V - 50Hz

Tot a l C a pa c i t y (W) 10000 11500 12000 13000

Rated power (W) 4400 4400 5000 4600

Rated current (A) 7.5 7.5 8.3 7.8

Air flow volume (m3/h) 2100 2200

Dehumidify volume (L/h) 2.6 3.4

C.O.P/EER (W/W) 2.27 2.61 2.4 2.83

Model GE AIR F34 IN GE AIR F41 IN

Fan motor speed (r/min) (H/M/L) 1140/1070/980 1110/1000/900

Output power of motor(W) 150 150

Fan type-piece Centrifugal Fan-4 Centrifugal Fan-4

Diameter-length (mm) ф145×175 ф155×175

Evaporator Aluminum fin-copper tube Aluminum fin-copper tube

Pipe diameter ф7 ф7

Row-fin distance (mm) 3-1.6 3-1.6

Extended area of heat exchange

(I×H×L)

1.34×0.25 1.34×0.25

Swing motor model MP35CA MP35CA

Power of motor (W) 4 4

Fuse (A) PCB5A Transformer 0.2A PCB5A Transformer 0.2A

Sound (pressure level) dB(A) ≤52 ≤55

Dimension (W/D/H) (mm) 1590×238×695 1590×238×695

Dimension of package (W/D/H) (mm) 1770×330×830 1714×330×830

Indoor unit

Net weight/gross weight (kg) 42/53 42/51

Model GE AIR F34 OUT GE AIR F41 OUT

Compressor Model C-SBN303H8A C-SBN353H8A

Input Power 4250 4250 4850 4450

Running Current 6.9 7 7.6 7.1

Compressor Type Rotary Type Rotary Type

LRA(A) 42 55

Compressor Overload Protector Type Internal Inherent Protector Internal Inherent Protector

Throttle Method Capillary Capillary

Starting Method Capacitor Capacitor

Range of working temperature( )℃ 2≤T≤43℃℃ 2≤T≤43℃℃

Condenser Aluminum fin-copper tube Aluminum fin-copper tube

Pipe diameter ф9.52 ф9.52

Row-fin distance (mm) 2-1.4 2-1.8

Working Area mm2 813×930 725×1218

Fan motor speed (rpm) 920 840

Fan type-piece Axial Flow Fan-1 Axial Flow Fan-2

Fan Diameter (mm) Ф482 Ф450

Defrosting Method Auto Auto

Sound (pressure level) dB(A) ≤62 ≤63

Dimension (W/D/H) (mm) 1040×410×840 1250×950×412

Dimension of package (W/D/H) (mm) 1100×450×880 1295×1110×450

Net weight/gross weight (kg) 90/105 112/133

Outdoor Unit

Refrigerant/Refrigerant Charge (kg) R407C/3.1 R407C/3.4

Length 5 5

Liquid Pipe (mm) Ф12(1/2”) Ф12(1/2”) Outer

Diameter

Gas Pipe (mm) ф19(3/4”) ф19(3/4”)

Height (m) 5 5

Connecting

Pipe

Max.

Distance

Length (m) 10 10

Page 9

-9-

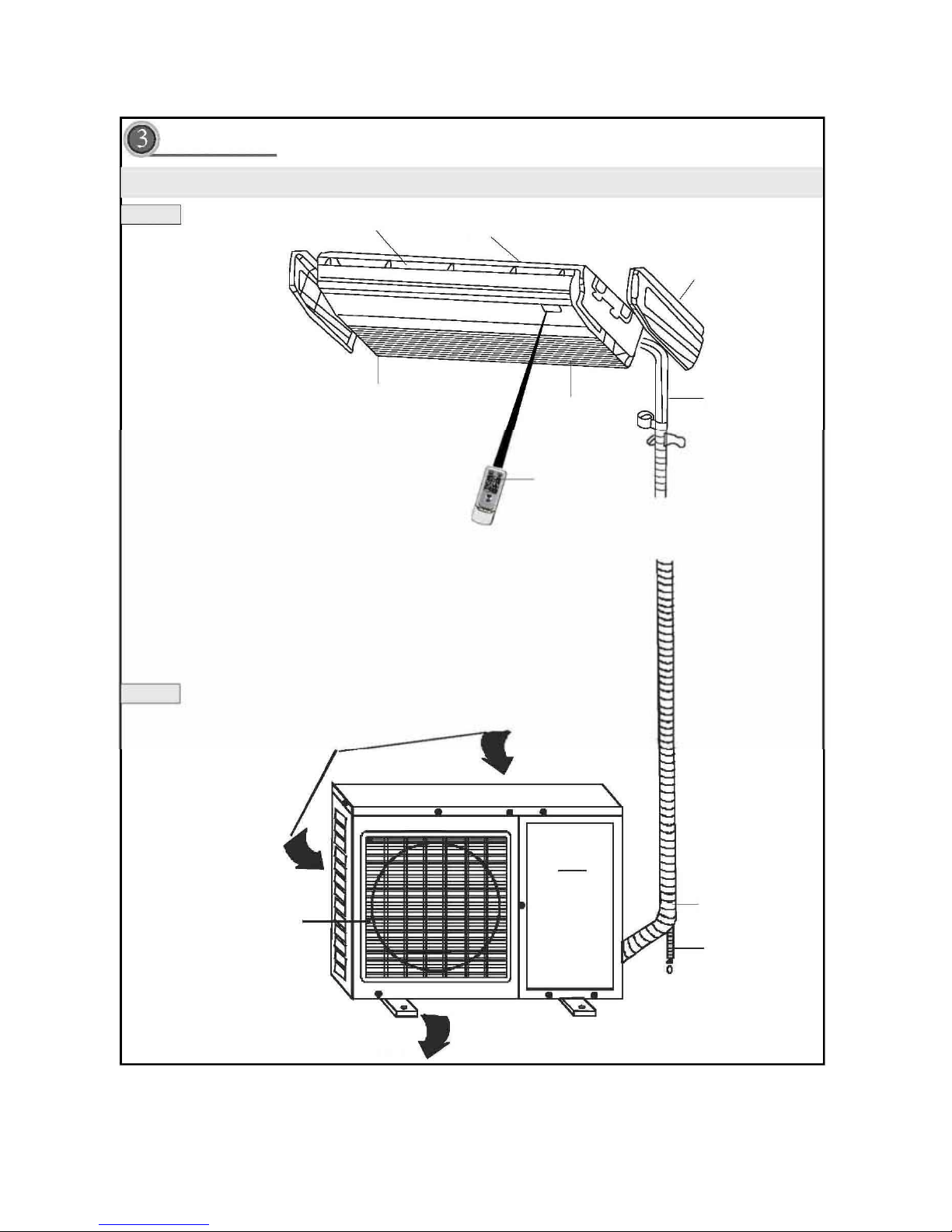

CCoommppoonneenntt NNaammee

Applicable to GE AIR F24/ GE AIR F34

Indoor unit Swing Assy.

Air outlet

Decorative panel

Air inlet Water outlet

Front grill

Remote controller

Outdoor Unit

Air outlet

Connecting pipe

Air outlet grill

Drainage pipe

Air outlet

Page 10

-10-

Applicable to GE AIR F41

Indoor unit

Swing Assy. Air outlet

Decorative panel

Air inlet Water outlet

Front grill

Remote controller

Outdoor Unit

Air outlet grill

Air outlet

Connecting pipe

Air outlet grill

Air outlet

Drainage pipe

Page 11

-11-

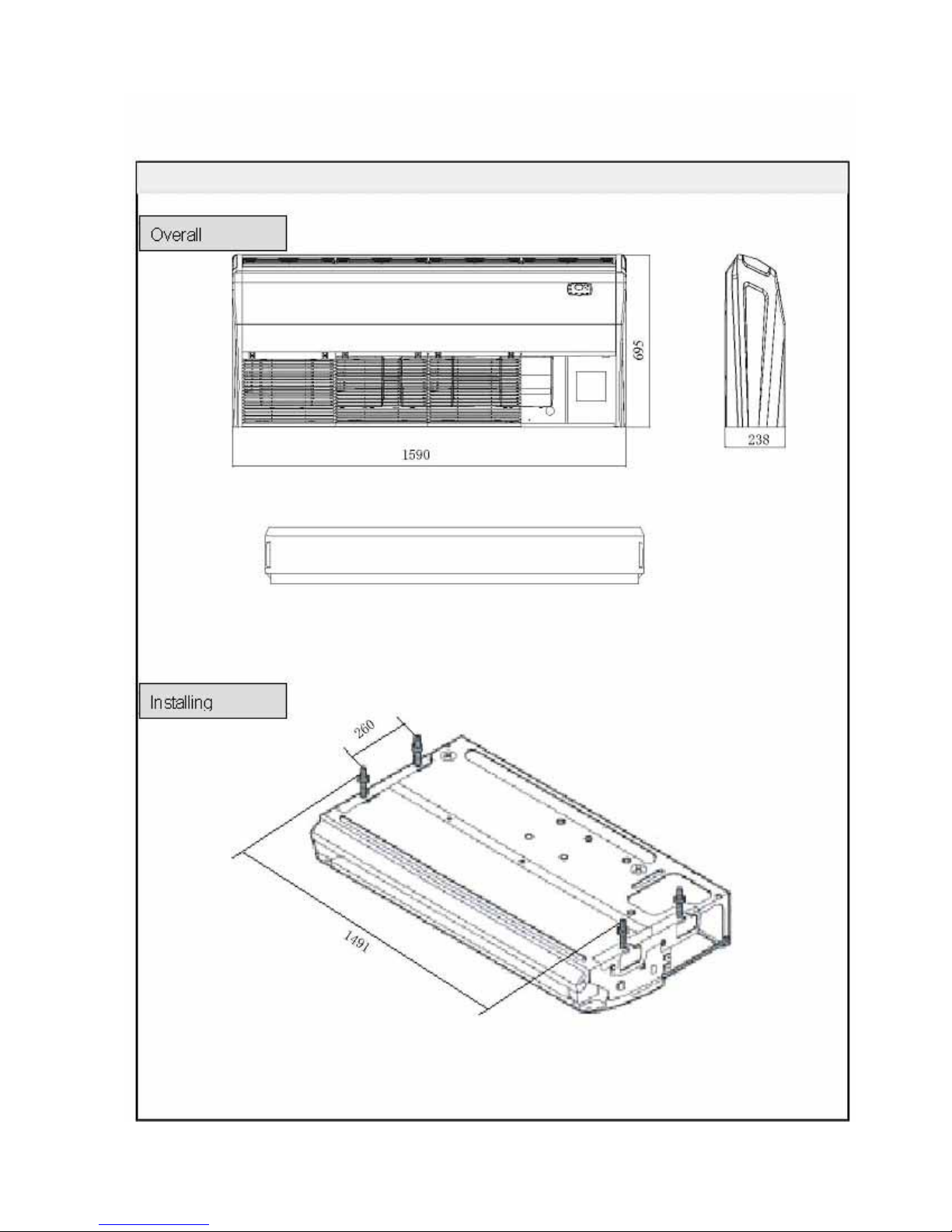

OOvveerraallll aanndd IInnssttaalllliinngg DDiimmeennssiioon

n

Overall and Installing Dimension of Indoor Unit

Applicable to GE AIR F24 IN

Overall dimension

Installing dimension

Page 12

-12-

Applicable to GE AIR F34 IN/ GE AIR F41 IN

Page 13

-13-

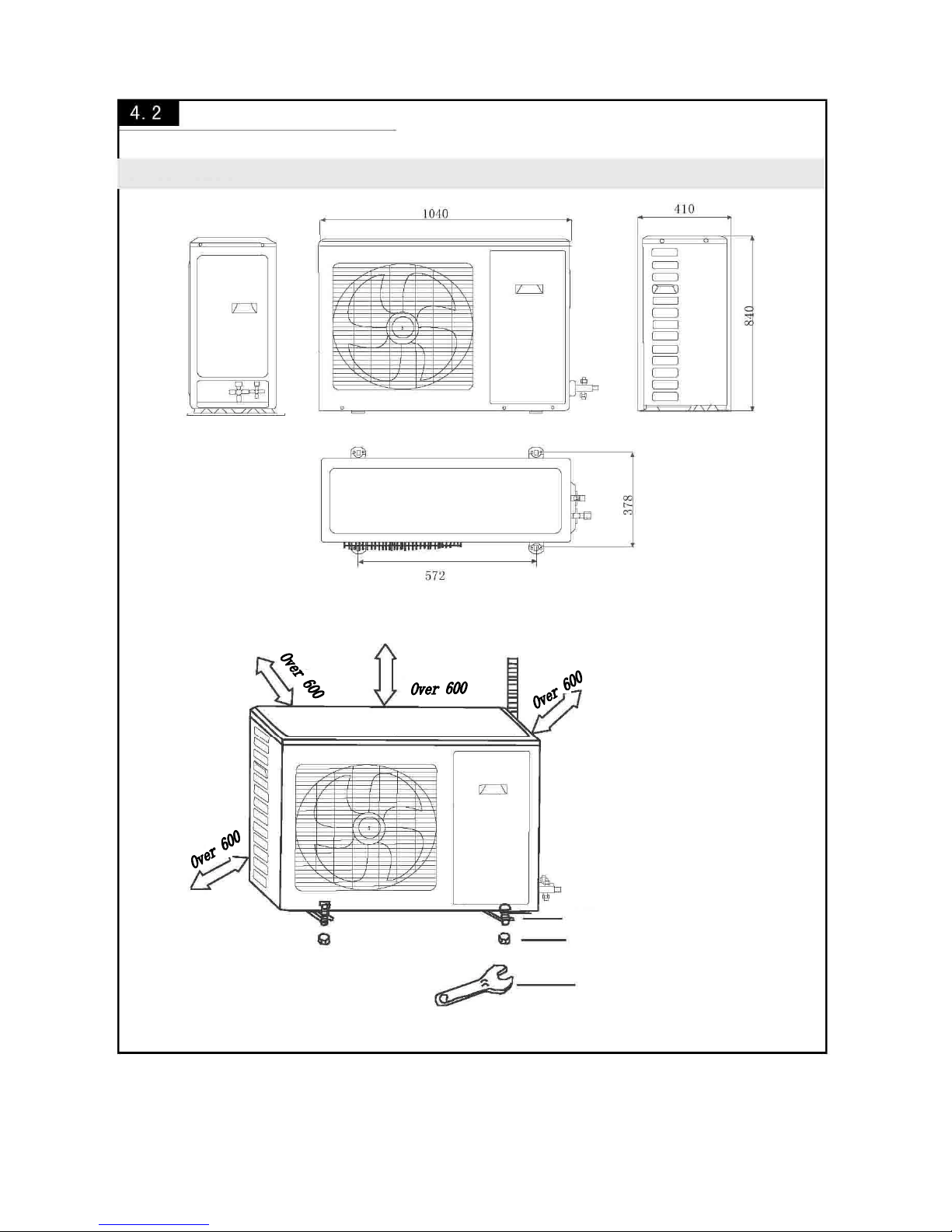

Overall and Installing Dimension of Outdoor Unit

Applicable to GE AIR F24 OUT/ GE AIR F34 OUT

Unit: mm

Bolt

Nut

Wrench

Page 14

-14-

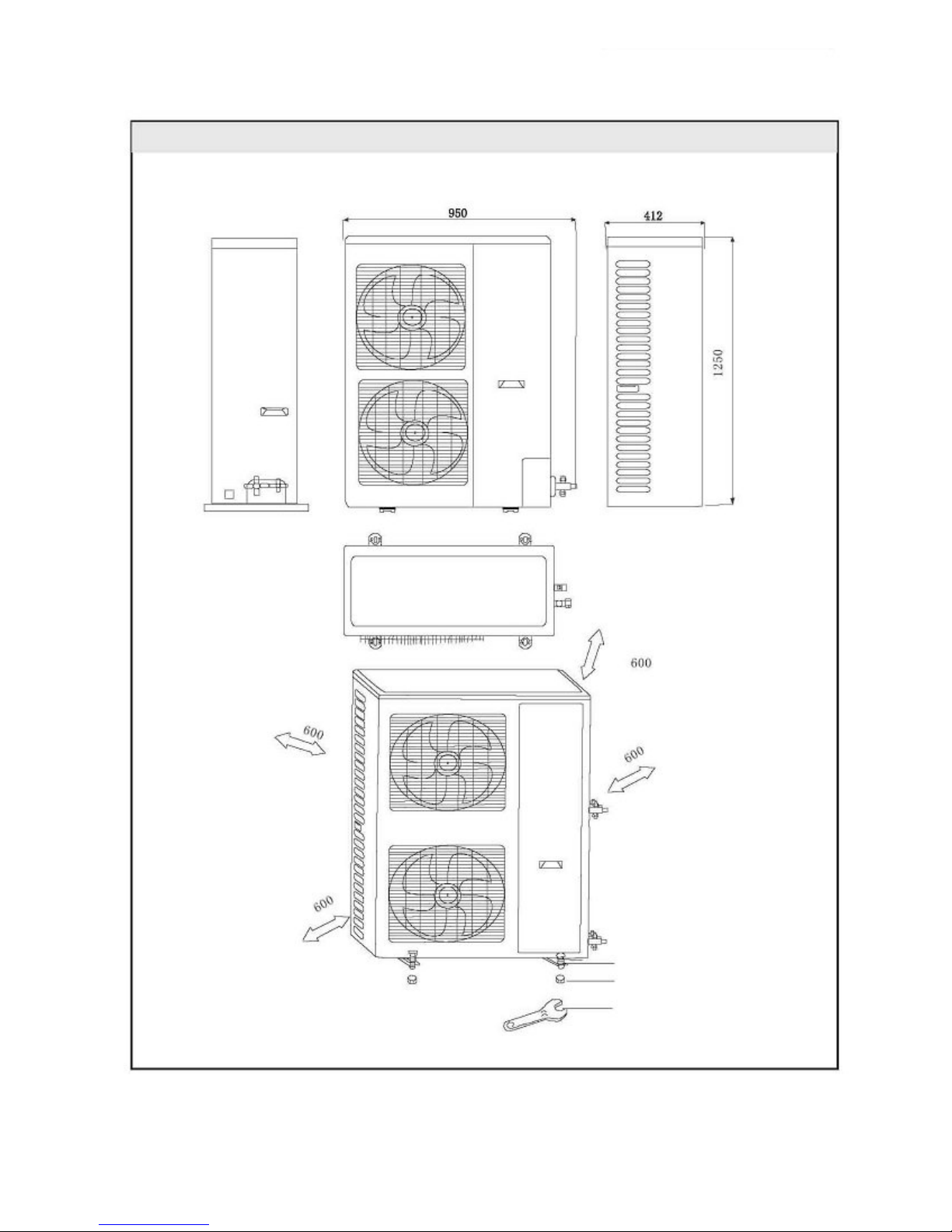

Applicable to GE AIR F41 OUT

Unit: mm

Bolt

Nut

Wrench

Page 15

-15-

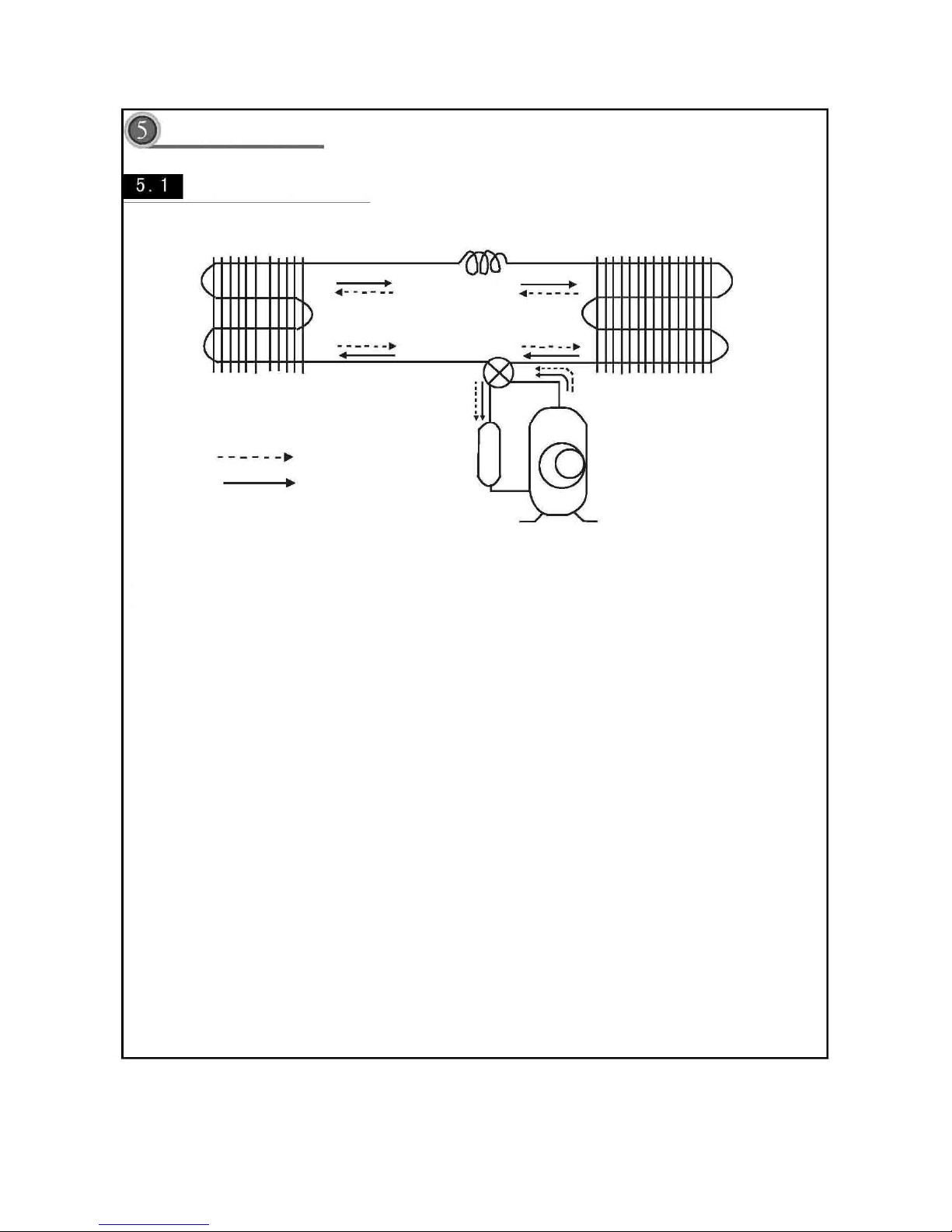

SSyysstteemm DDiiaaggrraamm

System Diagram for Cooling-and-Heating Unit

Capillary

4-way valve

Evaporator Condenser

Gas-liquid

Cooling separator Compressor

Heating

Switch on the power to start the unit. Low-pressure refrigerant vapor from evaporator is absorbed into the

compressor, where it is compressed into high-temp. and high-pressure gas. The gas refrigerant is then

diverted to condenser, where it is liquidized after heat exchange with outdoor air. After that, the liquidized

refrigerant flows through capillary for decrease of temperature and pressure and then enters into

evaporator, where it becomes low-temp. and low-pressure refrigerant vapor after heat exchange with

indoor air to be regulated. This process is repeated in cycle to achieve the purpose of cooling. (Under

heating mode, the 4-way valve will change the flow of refrigerant, so that the condenser absorbs heats

and the evaporator gives out heats, thus to achieve the purpose of heating).

Page 16

-16-

GE AIR F24

GE AIR F34

○

○

66EElleeccttrriiccaall DDiiaaggrraamm

Page 17

-17-

GE AIR F41

In case of any change in the Electrical Diagram shown above, please follow the drawing on cabinet.

Page 18

-18-

T

preset

T

p

reset

T

preset

T

p

reset

CCoonnttrroolllleerr aanndd RReemmoottee CCoonnttrroolllleerr FFuunnccttiioonn MMaannuuaall aan

ndd OOppeerraattiinngg IInnssttrruuccttiioonnss

Controller and Remote Controller Function Manual

7.1.1 Temperature Parameters

Indoor preset temperature (T

preset

)

Indoor ambient temperature (T

amb.

)

Outdoor condenser temperature (T

cond.

)

7.1.2 Basic Functions

Once started under any mode, the compressor will not be stopped within 6 minutes with the change of ambient

temperature. Once stopped, it cannot be restarted unless after 3-minute lag.

7.1.2.1 Cooling Mode

When T

amb.≥Tpreset

+1℃, the unit will run under cooling mode, in which case the compressor and outdoor fan will be

started, the indoor fan will run at preset speed and the swing will run as preset.

When T

amb.≤Tpreset

-1℃, the compressor and outdoor fan will be stopped and the indoor fan will run at preset speed.

When T

preset

-1℃<T

amb.

< T

preset

+1℃, the unit will maintain its original operating status.

Under cooling mode, the temperature can be set within a range from 16 to 30℃. The initial value is 25℃.

T

amb

Start cooling

Maintain original operating status

6 min. 3 min. 6 min. Stop cooling

Compressor

Outdoor fan

Indoor fan Run at preset speed

Run Stop

7.1.2.2 Dehumidifying Mode

When T

amb.≥Tpreset

+2 , the unit will run under coo℃ ling mode, in which case the compressor and outdoor fan will be

started, the indoor fan will run at low speed.

When T

preset

-2 ≤T℃

amb.≤Tpreset

+2 , the compressor, indoor unit and outdoor unit will run 6 minutes and stop 4 ℃

minutes in repeated cycle, while the indoor fan will run at low speed.

When T

amb.

< T

preset

-2 , the compressor and outdoor fan will be stopped, and the indoor ran will keep running at low ℃

speed.

¾ Under dehumidifying mode, the temperature can be set within a range from 16 to 30 . The init℃ ial value is 25 .℃

T

amb

Start cooling

Run under dehumidifying mode

6 min. 4 min. 6 min. 4 min. Stop cooling

Compressor

Outdoor fan

Indoor fan Low speed

Run Stop

Page 19

-19-

T

preset

T

p

reset

7.1.2.3 Heating Mode

When T

amb.≤Tpreset

-1 , the unit will run under heating mo℃ de, in which case the 4-way valve, compressor and

outdoor fan will be started, while the indoor fan will run at preset speed under preset cold air prevention condition.

If T

amb.≥Tpreset

+1 , the compressor and outdoor ℃ fan will be stopped, the 4-way valve is still energized and the indoor

fan will run at low speed for 10 seconds before it is stopped.

When T

preset

-1 <T℃

amb.

< T

preset

+1 , the unit will maintain its original operating status.℃

¾ Under heating mode, the temperature can be set within a range from 16 to 30 . The initial value is 25 .℃℃

¾ If the unit is switched off under heating mode or switched to another mode, the 4-way valve will be de-energized 2

minutes after the compressor is stopped.

Start cooling

Ambient temperature T

amb

Maintain original operating status

6 min. 3 min. 6 min. Stop cooling

Compressor

Outdoor fan

Indoor fan

≤

5 minutes

Preset speed ≤

5 minutes

Preset speed

Louver valve

Run Stop

7.1.2.3.1 Cold Air Prevention Condition

The compressor will start at heat mode, indoor fan will not operate. After 5Min or if the outlet temperature is high, the

indoor fan will run at preset speed. The indoor fan will no longer be stopped once it is started. Once running at preset

speed, it will be impossible to change the speed of the indoor fan.

7.1.2.3.2 Defrosting Conditions

When the condenser is detected to have frost, the system will enter into defrosting mode, in which case the 4-way

valve, indoor fan and outdoor fan will be stopped.

When it is detected that the frost in condenser is completely eliminated, the 4-way valve and outdoor fan will be

started simultaneously, while the indoor fan will start to run under preset cold air prevention condition.

≤10 min.

Compressor

Outdoor fan

Indoor fan ≤

3min.

Preset speed

Run Stop

7.1.2.4 Fan Mode

Indoor fan will run at preset speed

Auto Speed Low Speed Medium Speed High Speed

The temperature can be set within a range from 16 to 30 . The initial value is 25 .℃℃

7.1.2.5 Auto Mode

Under this mode, the system will automatically select its run mode (cooling, dehumidifying, heating or fan) depending on

ambient temperature.

¾ Once a mode is started, the unit will run at least 30 seconds before it can run the status of auto mode depending on

ambient temperature.

7.1.3 AUTO ON/OFF and Sleep Function

7.1.3.1 Sleep

If the controller is under cooling or dehumidifying mode, the preset temperature will be increased by 1 one hour ℃

after running under sleep mode and will be increased by another 1 after two hours. The temperature will increased ℃

by 2 within two hours. After that, the unit will run at this temperature. ℃

Page 20

-20-

T

preset

T

preset

T

preset

T

preset

T

preset

T

preset

Set the Temperature T

preset

1 hours 2 hours Over 2 hours

If the controller is under heating mode, the preset temperature will be decreased by 1 one hour after running under ℃

sleep mode and will be decreased by another 1 after two hours. The temperature will decreased by 2 within two℃℃

hours. After that, the unit will run at this temperature.

1 hours 2 hours Over 2 hours

Set the Temperature T

preset

No sleep function under fan mode or auto mode.

7.1.3.2 AUTO ON

You can set AUTO ON function when the unit is under standby status. Upon the time of AUTO ON, the controller will

run under preset mode. The time interval for AUTO ON is 0.5h, and can be set within 0.5 - 24 hours.

7.1.3.3 AUTO OFF

You can set AUTO OFF function when the unit is under ON status. Upon the time of AUTO OFF< the system will be

switched off. The time interval for AUTO OFF is 0.5h, and can be set within 0.5 - 24 hours.

7.1.4 Other Control

7.1.4.1 Swing Control

You can switch on or off the swing by pressing the SWING key. The swing is valid only when the indoor fan is running.

7.1.4.2 Buzzer Control

When the controller is energized or receives valid key-press signal, the buzzer will give a beep.

7.1.4.3 Automatic Control of Indoor Fan Speed

Under this mode, the indoor fan will automatically select its speed, i.e. high, medium or low, depending on ambient

temperature. Once a speed is activated, the indoor fan will run at least 30 seconds before it can switch over to other

conditions.

7.1.5 Protection

7.1.5.1 Indoor Antifreeze Protection

If E2 is displayed under cooling mode, the compressor, outdoor fan and indoor fan will be stopped, and the swing

motor will maintain its original status. When evaporator temperature is higher than 6 and the compressor has been ℃

stopped for 4 minutes, the display will resume and the controller will run under preset mode.

Under dehumidifying mode (i.e. run 6 minutes and stop 4 minutes), if it is detected within 3 minutes successively that

the tube temperature is lower than -2 after the compressor has been running for 3 minutes, the c℃ ompressor and

outdoor unit will be stopped, the indoor fan will run at low speed, and E2 will be displayed. When tube temperature is

higher than 6 and the compressor has been stopped for 4 minutes, the display will resume and the controller will ℃

run under preset mode.

7.1.5.2 Compressor High-pressure Protection

If high-pressure protection is detected within 3 seconds successively, all loads will be closed, all key-press and remote

control signals will be shielded, and E1 will be displayed. When it is detected within 6 seconds successively that the

compressor has released high-pressure protection, shielding of key-press signal will be removed but E1 will be still

displayed. To clear off E1 display, you have to press ON/OFF key to switch off the unit and press it again to restart.

7.1.5.3 Compressor Low-pressure Protection

When it is detected that the low-pressure switch is off, the complete unit will be stopped and be automatically

restarted after 3 minutes. If E3 is displayed, the unit cannot be restarted automatically, in which case you have to

press ON/OFF key to switch off the unit and press this key again to restart.

Page 21

-21-

If it is detected that the low-pressure switch is off when the compressor is stopped, the complete unit will be stopped,

E3 will be displayed and the unit cannot be restarted automatically. You have to press ON/OFF key to switch off the

unit and press this key again to restart.

7.1.5.4 Exhaust Pipe High-temp. Protection

After the compressor is started, if the exhaust temperature is too high or exhaust sensor is in short circuit (or open

circuit), the unit will be stopped when the indoor ambient temperature reaches the preset value.

After the compressor is stopped for 3 minutes, the complete unit will be restarted when the exhaust temperature is

resumed to normal.

In case of above issue, the complete unit cannot resume its operation and E4 will be displayed. You have to press

ON/OFF key to switch off the unit and press this key again to resume operation under preset mode.

7.1.5.5 Indoor Overtemperature Protection

If it is detected that the evaporator tube temperature is too high under heating mode, the outdoor fan will be stopped.

When the evaporator tube temperature resumes to normal, the outdoor fan will be started.

7.1.5.6 Low-voltage Protection

If the current is detected over 22A as the compressor is started, the unit will be stopped when indoor ambient

temperature reaches preset value. The compressor will automatically resume to its original operating status after it is

stopped for 3 minutes. If E5 is displayed, the compressor cannot resume to its original operating status automatically,

in which case you have to press ON/OFF key to switch off the unit and press this key again.

7.1.5.7 Fault Code and Definition

Fault Code Definition

E1 Compressor High-pressure Protection

E2 Indoor Antifreeze Protection

E3 Compressor Low-pressure Protection

E4 Exhaust Pipe High-temp. Protection

E5 Low-voltage Protection

7.1.5.8 Compulsory Cooling (Heating) Mode

If no valid key-press upon first energization:

① From the remote controller, you can press temperature selection key (+) to enter into compulsory heating mode, in

which case all the keys on front panel and remote controller will be shielded, all loads will be started and the indoor

fan will run at high speed. If it is detected that ambient temperature is in open circuit or higher than 105 , or that ℃

evaporator temperature is in open circuit or higher than 105 , the buzzer will beep. After five minutes, the unit will be ℃

stopped and enter into normal standby status.

② From the remote controller, you can press temperature selection key (-) to enter into compulsory cooling mode, in

which case all the keys on front panel and remote controller will be shielded, all loads except the 4-way valve will be

started and the indoor fan will run at high speed. If it is detected that ambient temperature is in open circuit or higher

than 105 , or that evaporator temperature is in open circuit or higher than 105 , the buzzer will beep. After five ℃℃

minutes, the unit will be stopped and enter into normal standby status.

The functions stated in 1 and 2 are only for test purpose. Compulsory heating function is not available for cooling-only

unit.

7.1.5.9 Indicator

Power indicator: It is bright when energized and black when de-energized. It will blink under indoor antifreeze

protection, compressor high-pressure protection, low-voltage protection and defrosting.

Cooling indicator: It is bright under cooling mode, dehumidifying mode, auto cooling mode or auto dehumidifying

mode. It is black under other modes.

Heating indicator: It is bright under heating mode and auto heating mode. It is black under other modes

7.1.5.10 Power-OFF Memory Function

Memory function includes the mode, swing, preset temperature, preset fan speed, Auto ON/OFF (If the power is cut off

before the preset time for AUTO ON/OFF, the timer will count the time again once the power is resumed. If the power is

cut off after the preset time for AUTO ON/OFF, the unit, once energized again, will run under the mode after preset AUTO

OFF time).

Once energized again after any de-energization, the unit can be automatically restarted according to the memory.

Page 22

-22-

Description and Function of Remote Controller Keys

Notes:

z Make sure that there is no obstruction between remote controller and signal receiving window.

z Do not fall off or throw the remote controller.

z Do not let any liquid flow into remote controller, or expose the remote controller under direct

sunshine or extreme hot temperature.

SWING key

One press of this key will

enable the guide louver to

swing at a specific angle.

Another press will stop the

g

uide louver.

TEMP. key

Each press of (+) key will

increase the preset

temperature by 1 . Each ℃

press of (-) key will

decrease the preset

temperature by 1 .℃

Under “ “ mode,

the indoor temperature can

be adjusted to any value

between 16~30 .℃

MODE key

The run mode will change

sequentially as below with

each press of MODE key.

Auto

FAN ke y

Each press of this key will

change the fan speed

sequentially as below:

Auto Fan

Note: The fan speed is not

adjustable under

Mode.

Cooling mode

Dehumidifying mode

Fan mode

Heating Mode

ON/OFF key

Press this key to start the

air conditioner. Press it

again to stop the air

conditioner.

Page 23

-23-

Description and Function of Remote Controller Keys (After opening the rear cover)

Note: This remote controller is for general use and applicable to multiple types (functions)

of air conditioner. AIR, HUMID, LIGHT, ANION and SAVE buttons are not used for these

models.

LCD display

Display the information

selected by each key

SLEEP key

Press this key to enter into sleep

mode and press it again to exit

sleep mode.

Note: There is no sleep function

under Auto or Fan mode.

AUTO OFF key

Pressing this key when

the unit is running, you

can set the AUTO OFF

time from 0 to 24 hours.

Cancel the AUTO

ON/OFF

Lamp indicator

Press this key to switch on the lamp.

Press it again to switch off the lamp.

AUTO ON key

Pressing this key when the unit is

stopped, you can set the AUTO ON

time from 0 to 24 hours. Each press

of this key will increase the time by

0.5 hour.

Cancel the

AUTO ON/OFF

Page 24

-24-

Battery cover

Installation of Remote Controller Batter

z Operating Guideline

General Procedures:

1. Switch on the power and press ON/OFF key to start the air conditioner.

2. Press MODE key to select your desired run mode.

3. Press SWING key to enable the guide louver to swing at a specific angle. Press it again to stop the

swing.

4. Press FAN key to set the fan speed.

5. Press +/- key to set your desired temperature.

Optional Procedures:

6. Press SLEEP key from remote controller to set the sleep mode.

7. Press AUTO ON/OFF key and then press +/- key to set the timer.

Note: When auto mode is selected, the air conditioner will automatically select an appropriate run mode

according to the indoor temperature, making the environment comfortable.

z Replacement of Remote Controller Battery

Two pieces of 7# alkali dry batteries are used in the remote controller.

1. Slide the battery cover of remote controller downward. Remove the old batteries and replace with two

pieces of new batteries (Take care that the polarity shall be correct)

2. Close the battery cover of remote controller.

Note:

z Do not use new batteries together with old

batteries, or use different types of batteries

together.

z To avoid leakage of liquid and damage to the

remote controller, please take out the batteries

if you will not use the remote controller in

several weeks.

z Operate the remote controller within effective

range.

z Keep the remote controller at least 1 meter

away from television set or sound equipment.

RESET key

Insert two 7# batteries.

Page 25

-25-

Screw

(Fig

8-3

)

DDiissaasssseemmbbllyy aanndd AAsssseemmbbllyy PPrroocceedduurrees

s

Disassembly Procedures of Indoor Unit GE AIR F24 IN, F34 IN & F41

Disassemble Front Grill Sub-Assy

Manually push the clasp of front grill sub-assy

downward to open the front grill. (Fig 8-1)

(Fig 8-1)

Clasp

Disassemble Left and Right Panels

Use screwdriver to screw off the screws shown

in the position, and then move the panels

toward the direction of arrow to Disassemble the

left and right decorative panels. (Fig 8-2)

Screw

(Fig 8-2)

Disassemble Electric Box Assy

A. Use screwdriver to twist off the two screws

shown in the figure and remove the electric box

cover (8-3);

B. Use screwdriver to twist off the screw shown in

the figure, remove the capacitor support, and

disconnect the cables (refer to Figure 8-4);

C. Use screwdriver to twist off the four screws (2

screws at each side), remove the electric box

sub-assy, and disconnect the cables (refer to

Figure 8-5);

(Fig 8-4) Screw Screw (Fig 8-5)

Page 26

-26-

Operating Procedures / Photos

Disassemble Front Panel Assy

Use screwdriver to screw off the six screws

shown in the figure (two screws at the left,

right and rear sides respectively), remove

the front panel assy toward the direction

shown in the figure to remove it (refer to

figures 8-6, 8-7).

Screw Screw

(Fig 8-6) (Fig 8-7)

Disassemble Guide Louver Sub-assy

First remove the guide louver from the fitting

position of the guide louver support, then

remove the two ends of the guide louver

from the fitting position of the swing motor.

(Fig 8-8)

Support

Motor fitting position (Fig 8-8)

Disassemble Water Tray Sub-assy

Use screwdriver to screw off the three

screws shown in the figure so as to remove

the water tray sub-assy (refer to Figure 8-9).

Screw

(Fig 8-9)

Page 27

-27-

Operating Procedures / Photos

Disassemble Mounting Plate Sub-assy of Swing Louver

Use screwdriver to screw off the screws at

both ends of the mounting plate sub-assy of

swing louver. Take the mounting plate

sub-assy of swing louver apart from the guide

louver support. (Fig 8-10)

Screw Support

(Fig 8-10)

Disassemble Evaporator Assy

Use screwdriver to screw off the screw shown

in the figure. Remove the tube-exit clamp

sub-assy of evaporator. (Fig 8-11)

Use screwdriver to screw off the screw shown

in the figure and remove the evaporator assy.

Handle with care. (Fig 8-12、Fig 8-13)

(Fig 8-11) Screw Screw (Fig 8-12)

Screw

(Fig 8-13)

Disassemble Air Outlet Rear Side Plate Sub-assy

First remove the velvet sheet and the left and

right side plate cushions at the air outlet; then

use screwdriver to screw off the screw shown

in the figure. (Fig 8-14)

Screw

(Fig 8-14)

Page 28

-28-

Operating Procedures / Photos

Disassemble Mounting Plate Sub-assy of Swing Motor

Use screwdriver to screw off the screw shown

in the figure. (Fig 8-15)

(Fig 8-15) Screw

Disassemble Left and Right Side Plate Foam Sub-ass

Left Side Plate Foam

Sub-assy

Right Side Plate Foam

Sub-assy

Follow the shown direction to remove the left

and right side plate foam sub-assy. (Fig 8-16)

(Fig 8-16)

Disassemble Fan Motor Assy

Press downward the clasps fitting the front and

rear propeller housings, then pull upward to

remove the front propeller housing (refer to

Figure 8-17).

Hold the clasp position of the rear propeller

housing and pull upward to remove the rear

propeller housing (refer to Figure 8-18).

Use special tool to screw off the two holding

screws at the coupling, move the coupling

toward the fan until the coupling and shaft

sub-assy can be removed; use special tool to

remove the holding screw fixing the fan to

remove the fan (refer to Figure 8-19).

Clasp Position (Fig 8-17) Holding Screw

(Fig 8-18)

(Fig 8-19)

Page 29

-29-

Operating Procedures / Photos

Disassemble Bearing Mounting Plate

Use screwdriver to screw off the four screws

at the bearing mounting plate. (Fig 8-20)

Screw

(Fig 8-20)

Disassemble Motor

Use screwdriver to screw off the screw shown

in the figure to remove the motor clamp and

the motor fixing hoop. (Fig 8-20)

Screw

(Fig 8-20)

Disassemble Motor Mounting Plate Sub-assy

Use screwdriver to screw off the screw at the

motor mounting plate to remove the motor

mounting plate sub-assy. (refer to Figure

8-21).

Motor

Mounting

Plate

Sub-assy

Screw

(Fig 8-21)

Page 30

-30-

Operating Procedures / Photos

Disassemble Supporting Plate of Motor Support

Use screwdriver to screw off the screws

connecting the supporting plate of motor

support and the rear side plate sub-assy with

the motor support. (Fig 8-22)

Tapping Screw

(Fig 8-22)

Disassemble Left and Right Mounting Plates

Use tool to remove the bolts (2 X M8, 2 X M6)

fixing the left and right mounting plates. (Fig.

8-23)

Mounting Plate

M8 Bolt M6 Bolt

(Fig 8-23)

Disassemble Motor Support

Use screwdriver to screw off the screws at the

rear support base plate and at the both sides

of the support as shown in the figure to remove

the motor support. (refer to Fig. 8-24、8-25).

(Fig 8-24)

Screw

(Fig 8-25)

Page 31

-31-

Disassembly Procedures of Indoor Unit

Operating Procedures / Photos Applicable to the models: GE AIR F34 IN/ GE AIR F41 IN

Disassemble Front Grill Sub-Assy

Use tool to push the clasp 1 of front grill

sub-assy downward to open the front grill. (Fig

8-26)

Front Panel Clasp 1

(Fig 8-26)

Disassemble Left and Right Decorative Panels

Screw off the screw in the decorative panel,

and then manually pull toward the direction of

arrow to remove the left and right decorative

panels. (Fig 8-27)

Screw

(Fig 8-27)

Disassemble Electric Box Assy

Use screwdriver to twist off the two screws at the

electric box and manually pull the electric box

cover upward to remove the electric box. (Fig

8-28)

Use screw driver to loosen the two screws at

upper and two screws at lower. Remove the

capacitor board (As shown in Fig. 8-29)

Use screwdriver to twist off the two upper

screws and the two lower screws and remove

the capacitor support. Use screwdriver to

screw off the screw shown in Figure 5 and

disconnect the cables to remove the electric

box sub-assy. (Fig 8-30)

Screw

(Fig 8-28)

Screw

(Fig 8-29)

Screw

(Fig 8-30)

Page 32

-32-

Operating Procedures / Photos

Disassemble Front Panel Assy

Screw off the screws at the front and at the

two sides. Remove the front panel sub-assy.

(Fig 8-31)

Front

Panel

Sub-assy

Screw

(Fig 8-31)

Disassemble Guide Louver Sub-assy

First remove the guide louver from the fitting

position of the guide louver support, then

remove the two ends of the guide louver from

the fitting position of the swing motor. (Fig

8-32)

(Fig 8-32)

Disassemble Water Tray Sub-assy

Use screwdriver to screw off the nut with

washer at the middle of water tray. (Fig 8-33)

Use screwdriver to screw off the two side

screws of the auxiliary water tray. Pull the

auxiliary water tray and the water tray upward

to remove them. (Fig 8-34)

Disassemble Mounting Plate

Sub-assy of Swing Louver

Water Tray

Nut with

Washer

(Fig 8-33)

Auxiliary

Water Tray

Screw

(Fig 8-34)

Use screwdriver to screw off the screws at

both ends of the mounting plate sub-assy of

swing louver. Take the mounting plate

sub-assy of swing louver apart from the guide

louver support. (Fig 8-35)

Screw

(Fig 8-35)

Page 33

-33-

Operating Procedures / Photos

Disassemble Evaporator Assy

Use screwdriver to screw off the two screws at

the tube-exit plate of evaporator. Remove the

tube-exit plate of evaporator. (Fig 8-36)

Use screwdriver to screw off the screw shown

in the figure to remove the evaporator. (Fig

8-37)

Tapping Screw

Tube-exit

Plate of

Evaporator

)

Tapping Screw

Disassemble Left and Right Mounting Plates

(Fig 8-37)

First remove the flocking fabrics and the left

and right side plate cushions at the air outlet;

then use screwdriver to screw off the screw

shown in the figure. (Fig 8-38)

Screw

(Fig 8-38)

Disassemble Mounting Plate Sub-assy of Swing Motor

Use screwdriver to screw off the screw shown

in the figure. (refer to Figure 8-39).

Screw

(Fig 8-39)

Page 34

-34-

Operating Procedures / Photos

Disassemble Mounting Plate

Sub-assy of Swing Motor

Left Side Plate Foam

Sub-assy

Right Side Plate Foam

Sub-assy

Use screwdriver to screw off the screw shown

in the figure. (Fig 8-40)

Disassemble Fan Motor

Assy

(Fig 8-40)

Press downward the clasps fitting the front

and rear propeller housings, then pull upward

to remove the front propeller housing (refer to

Figure 8-41).

Hold the clasp position of the rear propeller

housing and pull upward to remove the rear

propeller housing (refer to Figure 8-42).

Use special tool to screw off the two holding

screws at the coupling, move the coupling

toward the fan until the coupling and shaft

sub-assy can be removed; use special tool to

remove the holding screw fixing the fan to

remove the fan (refer to Figure 8-43).

(Fig 8-41) (Fig 8-42)

Clasp Position Holding Screw

Clasp Position

Disassemble Bearing Mounting Plate

Use screwdriver to screw off the four screws at

the bearing mounting plate. (Figure 8-44).

Disassemble Motor

Use screwdriver to screw off the screw shown

in the figure to remove the motor clamp and

the motor fixing hoop.(Figure 8-45)

Screw Screw

(Fig 8-44) (Fig 8-45)

Page 35

-35-

Operating Procedures / Photos

Disassemble Motor Mounting Plate Sub-assy

Use screwdriver to screw off the six screws

at the motor mounting plate to remove the

motor mounting plate sub-assy. (Fig 8-46)

Motor Mounting

Plate Sub-assy

(Fig 8-46)

Tapping Screw

Disassemble Supporting Plate of Motor Support

Use screwdriver to screw off the screws

connecting the supporting plate of motor

support and the rear side plate sub-assy

with the motor support. (Fig 8-47)

Disassemble Left and

Right Mounting Plates

Tapping Screw

(Fig 8-47)

Use tool to remove the bolts (2 X M8, 2 X

M6) fixing the left and right mounting plates.

(Fig 8-48)

Disassemble Motor Support

Use screwdriver to screw off the screws at

the rear support base plate and at the both

sides of the support as shown in the figure

to remove the motor support.

(Fig 8-48)

Right Mounting Plate Bolt

Left Mounting Plate

Tapping Screw

Bolt

(Fig 8-49)

Page 36

-36-

Disassembly Procedures of Outdoor Unit

Operating Procedures / Applicable Models: GE AIR F24 OUT / GE AIR F34 OUT

Disassemble Front Side Plate

Screw off the four screws around the front

side plate to remove the front side plate. (Fig

8-50)

Front side plate

Screw

(Fig 8-50)

Disassemble Top Cover

Screw off the tapping screws around the top

cover, and then pull the top cover upward to

remove it. (Fig 8-51)

Screw

Top Cover

(Fig 8-51)

Disassemble Rear Grill

Screw off the four screws around the rear grill

to remove the rear grill. (Fig 8-52)

Screw

Rear Grill

(Fig 8-52)

Page 37

-37-

Operating Procedures / Photos

Disassemble Housing

Use screwdriver to screw off the screws

around the cabinet to remove the housing.

(8-53)

Screw

Housing

(Fig 8-53)

Disassemble Electric Box Screw

Use screwdriver to screw off the screws fixing

the electric box, and pull the electric box to

remove it. (Fig 8-54)

Electric Box

Communication Ceiling Type Unit Electric Box

Screw

(Fig 8-54)

Disassemble Right Side Plate

Use screwdriver to screw off the screws at the

right side plat, condenser side plate, gas valve

and liquid valve, and then pull the right side

plate sub-assy upward to remove it. (Fig 8-55)

Screw

Right Side Plate

(Fig 8-55)

Page 38

-38-

Operating Procedures / Photos

Disassemble Axial Flow Fan

Use spanner to remove the nut at the fan to

remove the axial flow fan. (Fig 8-56)

Nut

Axial Flow Fan

(Fig 8-56)

Disassemble Outdoor Motor Motor

Screw off the four tapping screws fixing the

motor, pull out the motor lead-out cable plug,

and remove the motor. Screw off the two

tapping screws fixing the motor support, and

pull the motor support upward to remove it.

(Fig 8-57)

Screw Fixing the Motor

Motor Cable

Motor Support

Fixing Screw

(Fig 8-57)

Disassemble 4-Way Valve

(Only Heating and Cooling Unit has such

valve)

Screw off the holding nut of the 4-way valve

coil and remove the coil. Use wet cotton cloth

to wrap the 4-way valve, unsold the four

soldering points connecting the 4-way valve,

and remove the 4-way valve. Be quick during

the unsoldering process, pay attention to keep

the wrapping cloth wet and do not allow the

soldering flame to burn the compressor

lead-out cable. (Fig 8-58)

4-Way Valve

Soldering

Point

(Fig 8-58)

Page 39

-39-

Operating Procedures / Photos

Disassemble Capillary

Unsold the soldering points at the capillary,

the valve and the condenser to remove the

capillary. Pay attention not to allow the

soldering slag to block the capillary.

(Fig 8-59)

Capillary

Disassemble Valve

Unscrew the two screws fixing the gas valve,

unsolder the soldering point between the gas

valve and the return-air duct and remove the

gas valve (note: when unsoldering the

soldering point, use wet cloth to completely

wrap the gas valve to prevent valve body from

being harmed by high temperature).

Unscrew the two screws fixing the liquid valve,

unsolder the soldering point connecting the

liquid valve and the fork type pipe, and remove

the liquid valve.

(Fig 8-60)

Liquid Valve Screw Gas Valve

Disassemble Compressor

Firstly unsolder the pipes connecting the

compressor, and then unscrew the three foot

nuts at the compressor to remove the

compressor. (Fig 8-61)

Foot Nut

Page 40

-40-

Disassembly Procedures of Outdoor Unit

Operating Procedures/ / Applicable Models: GE AIR F41 OUT

Disassemble Rear Grill

Screw off the tapping screws at the rear side

plate, valve support chassis and condenser

side plate to remove the rear grill. (Fig 8-62)

Rear Grill

Screw

Disassemble Top Cover Plate Screw

Screw off the tapping screws around the top

cover, and then pull the top cover upward to

remove it. (Fig 8-63)

Top Cover

Disassemble Front Side Plate

Screw off the three tapping screws at the front

side plate, and then pull the front side plate

upward to remove it. (Fig 8-64)

Front Side Plate

Screw

Page 41

-41-

Operating Procedures / Photos

Disassemble Housing

Unscrew the screws around the housing to

remove it.

(Fig 8-65)

Screw

Housing

Disassemble Electric Box

Unscrew the screws around the electric box

sub-assy to remove it. (Fig 8-66)

Screw

Communication Cassette Type Unit Electric Box

Screw

Disassemble Right Side Plate

Unscrew the screws around the right side

plate to remover the right side plate. (Fig

8-67)

Right Side Plate

Screw

Page 42

-42-

Operating Procedures / Photos

Disassemble Axial Flow Fan

Use spanner to twist off the nut of the fan and

remove the fan.

(Fig 8-68)

Nut

Nut

Disassemble Outdoor Motor

Screw off the four tapping screws fixing the

motor, pull out the motor lead-out cable plug,

and remove the motor. Screw off the two

tapping screws fixing the motor support, and

pull the motor support upward to remove it.

(Fig 8-69)

Motor

Screw Fixing the Motor

Motor Support

Fixing Screw

Disassemble 4-Way Valve

Screw off the holding nut of the 4-way valve

coil and remove the coil. Use wet cotton cloth

to wrap the 4-way valve, unsold the four

soldering points connecting the 4-way valve,

and remove the 4-way valve. Be quick during

the unsoldering process, pay attention to

keep the wrapping cloth wet and do not allow

the soldering flame to burn the compressor

lead-out cable. (Fig 8-70)

4-Way Valve

Page 43

-43-

Operating Procedures / Photos

Disassemble Valve

Unscrew the screw fixing the valve, unsolder

the connecting pipe of the valve, and remove

the valve.

(Fig 8-71)

Screw Liquid Valve Screw

Gas Valve

Disassemble Capillary

Unsolder the soldering points between the

capillary and other pipes to remove the

capillary. (Fig 8-72)

Capillary

Disassemble Compressor

Unscrew the foot screw of the compressor

and unsolder the connecting pipe to remover

the compressor. (Fig 8-73)

Foot Nut

Page 44

-44-

○

○

99 CCaarree aanndd MMaaiinntteennaannccee

Warning

z Be sure to stop the unit and plug out the power before cleaning your air

conditioner. Otherwise, electric shock may happen.

z Never splash water on the indoor unit, this may cause the risk of

electric shock.

z Volatile liquids such as thinner or gasoline will cause damage to the

appearance of air conditioner. (Only use soft dry cloth or wet cloth

soaked with neutral detergent to clean the indoor unit).

9.1 To clean the filter

Remove the filter and clean with vacuum cleaner. If

very dirty, wash with warm water (below 45℃) that is

added with neutral detergent. Fully dry the filter before

reinstallation.

Suggestion: Too dirty filter will reduce air inflow and result in system overload, causing 6% more

consumption of power. Therefore, it is quite necessary to clean the filter regularly.

9.2 To clean the equipment and components

Use dry and soft cloth or vacuum cleaner to clean the

air conditioner and remote controller. If wet cloth is

used, please wipe it dry after cleaning.

Warning: Never expose the front grill or air filter directly under the sun. Never clean it with hot

water over 45℃ or dry it on fire, (as this will cause decoloring, fire or deformation).

9.3 When using the air conditioner

Check for any foreign articles that may obstruct the air into

or out of the indoor and outdoor unit.

If the unit is operating without air filter, dust will deposit and

cause trouble to the unit. Generally, be sure to install filter

before operating the unit.

Check the drainage pipe for bend or damage.

Check the equipment for normal and correct installation.

9.4 When the air conditioner is out of service

Pull off the plug and disconnect the power.

Clean the filter, equipment and components.

Start the fan for 2 to 3 hours to clean and dry the

inside of the equipment.

Page 45

-45-

Air –conditioning unit

cannot be started

Trip of circuit

breaker or burn-out

of fuse

Check insulation resistance for

grounding; Confirm if

air-conditioning unit has

electrical leakage or is

short-circuited

When set short-circuiter

as “ ON ” , it trips

immediately

When air-conditioning

unit is powered on,

there is no action

(when the unit is

plugged in, buzzer

does not sound and

there is no action

after using the remote

controller to start the

unit)

Remote controller

does not receive

signal (when unit is

powered on, buzzer

shall sound, unless

buzzer is damaged)

No power

supply

Check and secure the plug to

ensure firm contact

Power plug is not

firmly seated or

connection is poor

Replace controller fuse

Controller fuse

burned out

Secure line connections;

measure output voltage of

transformer and replace

transformer if it is incorrect

Connection line of

transformer is loose

or suffers from poor

plugging, or there is

transformer failure

Replace controller

Controller is damaged

Batteries of remote

controller are running

out of

p

owe

r

Remote

controller failure

Receiving head is

loose or plug

connection is

poor

Receiving head is

damaged

Replace battery

First press “AUTO” key of

manual switch. If there is no

action check according to the

above method; if the operation

is normal after pressing the

key, recheck to see if the

mounting position of receiving

head and the line connections

are correct; if they are correct,

replace receiving head or

remote controller.

Check power voltage. If the voltage is 10% than rated

voltage, check the cause, and improve the power

supply conditions such as adding regulated power

supply.

When turning the

air-conditioning unit to

the “ON”status, trip of

circuit breaker occurs

several minutes later

Failure of air-conditioning unit

or component insulation

failure, short circuit or

electricle leakage owing to

insulation puncture after

heating, measure insulation

resistance or check the

components one by one to find

the ones with failure; failure of

circuit breaker itself, replace it.

Power voltage is too low

○

10 Trouble-Shooting

Page 46

-46-

Poor cooling (heating)

effect

Set temperature is not

appropriate

Adjust the set temperature

Check if the cooling (heating)

load is appropriate

Check the forecasted cooling (heating) load

Failure of

refrigerant flow

Leakage of refrigerant or

insufficient refrigerant

Check leakage, carry out

vacuum-pumping after repairing

leakage and charge refrigerant

according to requirements

Leakage between internal

high pressure and low

pressure sections of

compressor

Replace compressor

4-way valve failure

Replace 4-way valve

Partial block in capillary Replace capillary

Block in cooling system

Observe the condensation condition

of evaporator or the reading of high

pressure meter to judge if the system

is blocked; deal with the system

accordingly

Poor thermal insulation of connecting

pipe between indoor unit and outdoor

unit

The thermal insulation of big pipe and small pipe

shall be separate and sound; joint and bare position

of copper pipe shall also have thermal insulation

Insufficient air

circulation volume

Block in outdoor heat

exchanger

Wash away dust on surface

of heat exchanger

Block in air filte

r

Clean filter

Fan speed was set too

lo

w

Set fan speed as high or medium

Fan speed turns

Capacitor

is dama

g

ed

Replace

ca

p

cito

r

Motor is

damaged

Replace

moto

r

Mounting position of

outdoor unit is

inappropriate

Outdoor unit shall be installed in a

p

lace with good ventilation

Outdoor temperature

is too high

Install proper weather screen; it is suggested to replace

air-conditioner unit with one of higher capacity in case the best

available cooling effect does not satisfy needs

Indoor space is not sufficiently closed, or

people enters or leave the room frequently, or

there is heating equipment operating in the

room

Keep the indoor space as closed as

possible, do not use electrical appliance

g

enerating large amount of heat

Page 47

-47-

Indoor fan motor burned out or there

is wire breakage or failure of

overheating protecto

r

Replace fan motor or components

with failure

The internal overheating protector

frequently breaks as overheating is

caused by abnormity of motor

Replace fan motor

Wrong line connection

Correctly connect lines according

to electrical diagram

Open circuit or damage of fan

capacitor

Replace it withfan capacitor of the

same model and spec

When air supply

mode is

selected, the fan

does not

o

p

erate

Outdoor fan motor is damaged

Replace fan motor

Wrong line connection

Correctly connect lines according

to electrical diagram

Outdoor fan capacitor is damaged

Replace fan capacitor

When in cooling

or heating mode,

compressor

operates but

outdoor fan does

not operate

Compressor failure Replace Compressor

Operating capacitor of compressor is

damaged

Replace capacitor

Voltage is too low or too high

It is suggested to equip voltage

regulator

Wrong line connection

Correctly connect lines according

to electrical diagram

When in cooling

or heating mode,

outdoor fan

operates but

compressor

does not o

p

erate

Failure of protector itself

Use universal meter to check if

contacts of compressure not

overheated are conducting;

replace protector in case of

non-conducting conditions

Insufficient or too much refrigerant

Adjust refrigerant amount

Capillary is blocked so air intake

temperature is too high

Replace capillary

Compressor does not operate

smoothly (seized or jammed), air

discharge valve is damaged

Replace Compressor

Failure of protector itself

Replace protector

Compressor is

overheated so

protector is

activated

To rque of swing motor is insufficient

Wrong line connection

Fisrtly check if line connections

have fault, if no, replace

components at failure position

Controller is damaged (IC2003 is

damaged, swing relay cannot close

Swing louver

does not run

Page 48

-48-

In case of the following protection or failures, the indoor unit shall display corresponding codes, which

are explained as follows:

Code Explanation

E1

Compressor High-pressure Protection

E2

Indoor Antifreeze Protection

E3

Compressor Low-pressure Protection

E4

Exhaust Pipe High-temp. Protection

E5

Low-voltage Protection

Fan of indoor unit touches other

positions

Adjust fan position

Foreign articles inside the indoor unit

Remove foreign articles

Vibration of compressor is violent

Adjust support foot mat of

compressor, tighten loose bolts

Abnormal sound

and vibration

Pipes of outdoor unit bump togethe

r

Separate bumping pipes

Metal plates bump together inside the

unit

1. Tighten connection screws

2. Attach vibration damping gum

between metal plates

Indoor fan bumps cabinet

Adjust fan position

Abnormal sound from inside

compressor

Replace Compressor

Abnormal electromagnetic noise from

4-way valve when in heating operation

Internal short circuit of solenoid

valve

,

replace solenoid valve

Water leakage

Block or breakage of drainage pipe

Replace drainage pipe

The refrigerant pipe joint is not

wrapped firmly

Wrap and bind it again firml

y

Loading...

Loading...