GE AGBS300PJ1WW, AGBS300PJ2WW, AGBS300PK1BB, AGBS300PK2BB, JGBS04BPM1WH Installation Guide

...Page 1

Conversion

Instructions

Converting to LP (Propane) Gas or Converting

Back to Natural Gas from LP

30" Standard Twin Burner Gas Range with Pilot Ignition

Beforeyoubegin- Readtheseinstructionscompletelyandcarefully.

IMPORTANT- Savetheseinstructionsfor localinspectorOuse.

IMPORTANT- OBSERVEALLGOVERNINGCODESANDORDINANCES.

NotetoInstaller - Be sureto leavetheseinstructions,orificesand

screwswith the Consumer.

Notetoconsumer- Keeptheseinstructionswith yourOwnerO

Manualforfuture reference.

THISRANGEISFACTORYSETFORUSEWITHNATURALGAS.USE

THESEINSTRUCTIONSWHENCONVERTINGTOLP(PROPANE)GAS

ANDWHENCONVERTINGBACKTONATURALGAS.

WARNING

This conversion kit must be installed by a

qualified service agency in accordance with the

manufacturer's instructions and all applicable codes

and requirements of the authority having jurisdiction.

If the information in these instructions is not followed

exactly, a fire, explosion or production of carbon

monoxide may result, causing property damage,

personal injury or loss of life. The qualified service

agency is responsible for the proper installation of this

kit. The installation is not proper and complete until the

operation of the converted appliance is checked as

specified in the manufacturer's instructions supplied

with the kit.

STEP 11 PREPARE RANGE FOR

CONVERSION

• Disconnect main gas supply to the range.

• Disconnect the electrical power to the range.

- If range has not been connected to the gas supply,

or if a flexible connection was made, the range

may be pulled out from the wall to make conversion

easier.

CAUTION

If the gas supply to the range is discon-

nected for any reason, see the installation instruc-

tions for proper connection and safety precautions.

STEP 21 CONVERT THE PRESSURE

REG U LATOR

WARNING

Do not remove the pressure regulator

from the range.

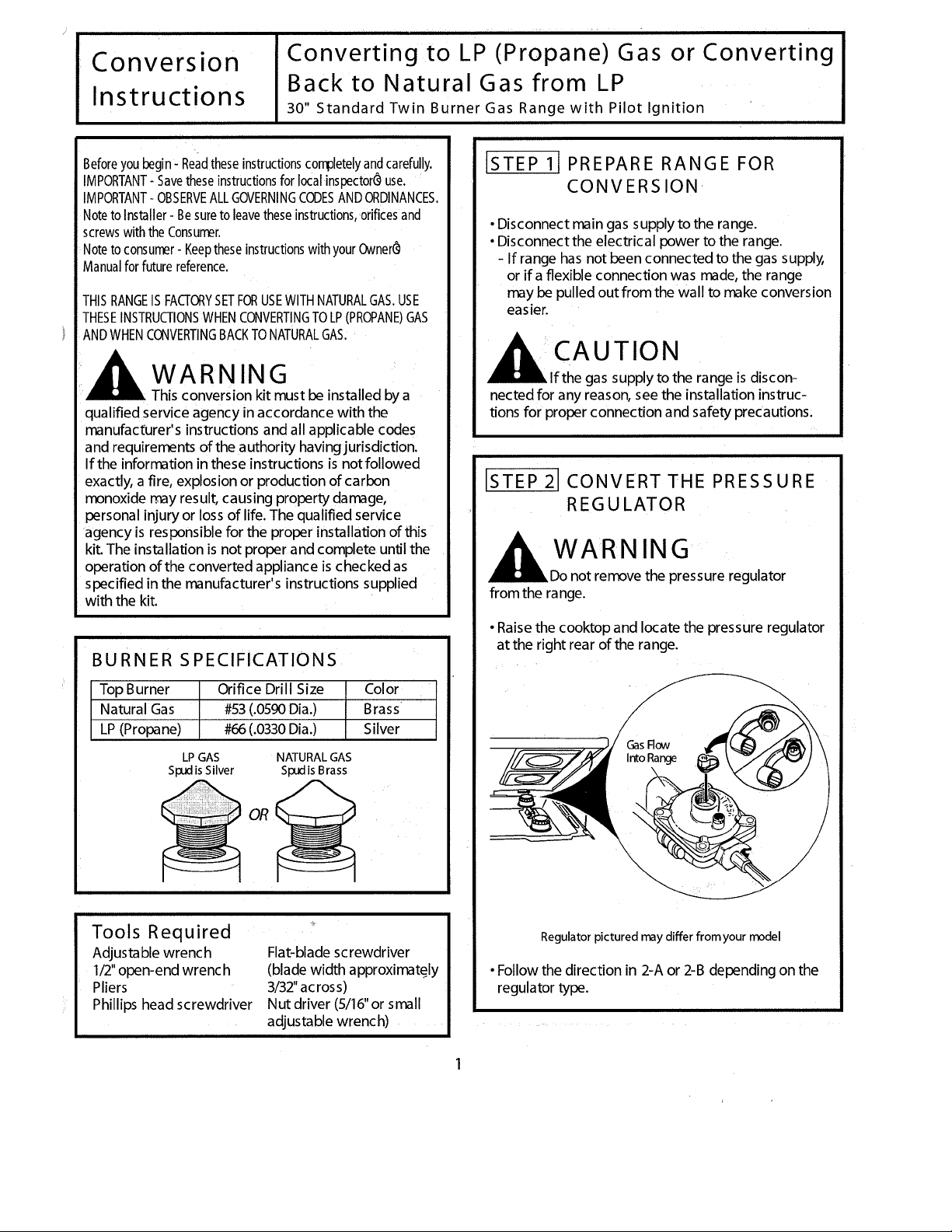

BURNER SPECIFICATIONS

Top Burner Orifice Drill Size

Natural Gas #53 (.0590 Dia.)

LP (Propane) #66 (.0330 Dia.)

LPGAS NATURALGAS

SpudisSilver SpudisBrass

OR

Tools Required

Adjustable wrench

1/2" open-end wrench

Pliers

Phillips head screwdriver

Flat-blade screwdriver

(blade width approximately

3/32"across)

Nut driver (5/16"or small

adjustable wrench)

Color

Brass

Silver

•Raisethe cooktop and locate the pressure regulator

at the right rear of the range.

j_...

/

/-

/

/

/ \

GasRow \

IntoRange \

Regulatorpictured maydiffer fromyour model

• Follow the direction in 2-A or 2-B depending on the

regulator type.

Page 2

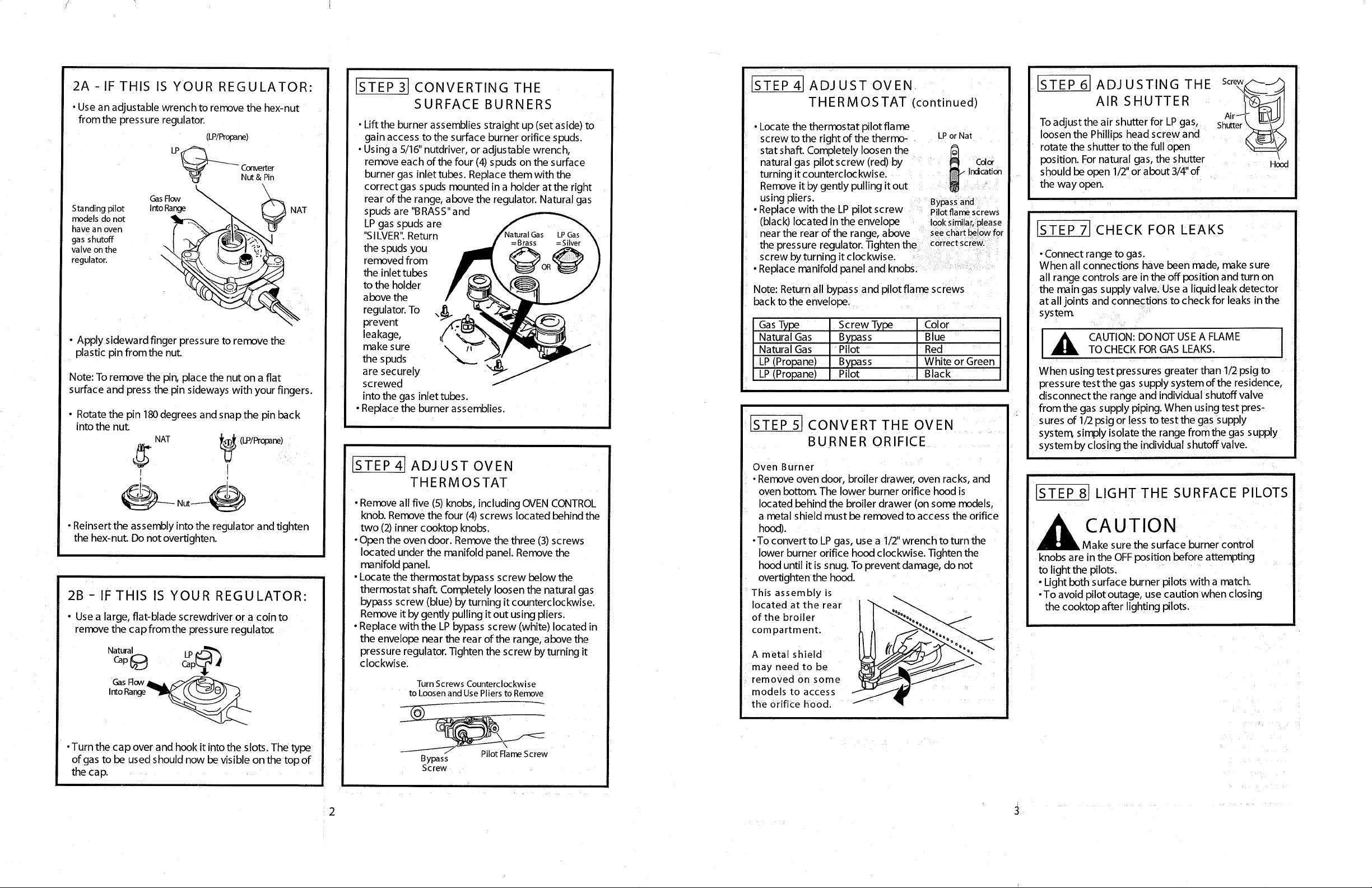

2A-IFTHIS IS YOUR REGULATOR:

•Use an adjustable wrench to remove the hex-nut

from the pressure regulator.

(LP/Proio_ne)

LP

Converter

Nut& Pin

IntoRangeStandingpilot NAT

gas shutoff

valveonthe

regulator. "

GasRow __

vee°n°tanove

• Apply sideward finger pressure to remove the

plastic pin from the nut.

Note:Toremove the pin, place the nut on a fiat

surface and press the pin sideways with your fingers.

• Rotate the pin 180 degrees and snapthe pin back

into the nut.

NAT '_-m_'(LPIPro_ne)

I

l I

• Reinsert the assembly into the regulator and tighten

the hex-nut. Do not overtighten.

2B-IF THIS IS YOUR REGULATOR"

• Use a large, fiat-blade screwdriver or a coin to

remove the cap from the press ure regulator.

Natural

o0÷ 0÷'3

:GasFlow

v,

[STEP 3] CONVERTING THE

SURFACE BURNERS

• Lift the burner assemblies straight up (set aside) to

gain access to the surface burner orifice spuds.

• Using a 5/16" nutdriver, or adjustable wrench,

remove each of the four (4) spuds on the surface

burner gas inlet tubes. Replace them with the

correct gas spuds mounted in a holder at the right

rear of the range, above the regulator. Natural gas

spuds are "BRASS" and

LP gas spuds are

"SILVER". Return

the spuds you

removed from

the inlet tubes

to the holder

above the

regulator. To \_

prevent

leakage,

make sure

the spuds

are securely

screwed

into the gas inlet tubes.

Replacethe burner assemblies.

ISTEP 41ADJ UST OVEN

THERMOSTAT

• Remove all five (5) knobs, including OVEN CONTROL

knob. Remove the four (4) screws located behind the

two (2) inner cooktop knobs.

•Open the oven door. Remove the three (3) screws

located under the manifold panel. Remove the

manifold panel.

• Locate the thermostat bypass screw below the

thermostat shaft. Completely loosen the natural gas

bypass screw (blue) by turning it counterclockwise.

Remove it by gently pulling it out using pliers.

•Replace with the LP bypass screw (white) located in

the envelope near the rear of the range, above the

pressure regulator. Tighten the screw by turning it

clockwise.

Turn Screws Counterclockwise

to Loosen and Use Pliers to Remove

[STEP4 ADJUSTOVEN

THERMOSTAT (continued)

• Locate the thermostat pilot flame

screw to the right of the thermo-

stat shaft. Completely loosen the

natural gas pilot screw (red) by

turning it counterclockwise.

Remove it by gently pulling it out

using pliers.

• Replace with the LP pilot screw

(black) located in the envelope

near the rear of the range, above

the pressure regulator. Tighten the

screw by turning it clockwise.

• Replace manifold panel and knobs.

Note: Return all bypass and pilot fiame screws

back to the envelope.

Gas Type Screw Type Color

Natural Gas Bypass Blue

Natural Gas Pilot Red

LP (Propane) Bypass White or Green

LP (Propane) Pilot Black

1

LPor Nat

Irdcation

Bypassand

Pilotflame screws

looksimilar,please

seechartbelowfor

correct screw.

STEP 51 CONVERT THE OVEN

BURNER ORIFICE

Oven Burner

• Remove oven door, broiler drawer, oven racks, and

oven bottom The lower burner orifice hood is

located behind the broiler drawer (on some models,

a metal shield must be removed to access the orifice

hood).

•To convert to LP gas, use a 1/2"wrench to turn the

lower burner orifice hood clockwise. Tighten the

hood until it is snug. To prevent damage, do not

overtighten the hood.

This assembly is

located at the rear

of the broiler

compartment.

A metal shield

may need to be

removed on some

models to access

the Orifice hood.

ISTEP61ADJUSTING THE

AIR SHUTTER

Toadjust the air shutter for LPgas,

loosen the Phillips head screw and

rotate the shutter tothe full open

position. Fornatural gas, the shutter

Hood

should be open I12"or about 314"of

the way open.

ISTEP71CHECK FOR LEAKS

• Connect range to gas.

When all connections have been made, make sure

all range controls are in the off position and turn on

the main gas supply valve. Use a liquid leak detector

at all joints and connections to check for leaks in the

syster_

_, AUTION: DONOT USEA FLAME

When using test pressures greater than 1/2psig to

pressure test the gas supply system of the residence,

disconnect the range and individual shutoff valve

from the gas supply piping. When usingtest pres-

sures of 1/2psig or less to test the gas supply

system, simply isolate the range from the gas supply

system by closing the individual shutoff valve.

ISTEP 81 LIGHT THE SURFACE PILOTS

knobs are in the OFF position before attempting

to light the pilots.

• Light both surface burner pilots with a match.

•To avoid pilot outage, use caution when closing

the cooktop after lighting pilots.

TOCHECKFORGASLEAKS.

UTION

Make sure the surface burner control

•Turn the cap over and hook it into the slots. The type

of gas to be used should now be visible on the top of

the cap.....

Bypass PilotFlameScrew

Screw

2 3

Page 3

ISTEP91ADJUSTTHE SURFACE

BURNER PILOTS

[STEP 12] CHECK QUALITY

OF FLAMES

• Locate the pilot adjustment screw. It can be ac=

cessed through the small hole near the center of the

manifold panel.

•To adjust, use a flat-blade screwdriver with a shaft

diameter of less than 3/16". Turn the pilot adjustment

screw until the pilot is 5/16" high. Do not.reduce the

flame to less than 5/16" or a pilot outage may occur.

A pilot flame burning higher than recommended may

generate soot (carbon black) on the bottom of the

cooktop.

STEP ]0J LIGHT THE OVEN PILOT

• Locate the pilot in the back

of the oven botton_ The

pilot is attached to the left

side of the oven burner.

•To light the oven pilot, push

in and hold the oven

control knob while lighting

the pilot with a long match or match holder. Once

the oven pilot is lit, continue holding the oven control

knob for one minute before releasing.

•The pilot flame size should be approximately 3/8 for

LP and 1/2 for natural gas.

STEP 111CHECKING THE

FLAM E S IZE

Turn on oven burner. Check / InnerCone

the flame size for LP _r/ ofFlame

gas,

The flame should have

approximately 1-inch

blue cones. After 30

seconds of burner

operation, check for

flames lifting off the

burner ports. If lifting is ob-

served, gradually reduce the air shutter

opening until flames are stabilized. Some yellow

tipping may be normal on LP gas. See Step 12

Bake/Broiler

Burner

The combustion quality of the burner flames needs to

be determined visually.

(A) Yellow flames-

Further adjustment

required

11111111i

tltt1111

If burner flames look like (A),further air shutter

adjustment is required. Normal burner flamesshould

look like (B) or (C),depending on the type of gas you

use.With LPgas, some yellow tipping on the outer

cones is normal.

ISTEP 131REPLACE OVEN PARTS

Replace oven bottom, ovenracks, oven door and

broiler drawer.

ISTEP 14]COMPLETE AND ADHERE

CONVERSION STICKER

Upon completion of this conversion, fill out the LP

sticker included with the instructions. Once complete,

apply the sticker to the back of the range near the

regulator. The convers ion stic ker must reflect the

change in fuel.

If converting back to natural gas from LP,remove the

LPsticker from the back of the range.

Save these instructions for reference in case the

I

range must be converted back to natural gas.

The conversion to LPgas for the standard twin burner

gas range with standing pilot is now completed.

I

DWG No. 183D5578P057

(B) Yellow tips-

Normal for LPGas

(4) Soft Blue flames-

Normal for Natural Gas

I

I

N.D. 657-04

Loading...

Loading...