Page 1

GE Drives

l/4 - 5 HP, 200.23OV’ 3-Phase

l/4 - 3 HP, 200=24OV, I-Phase

lnsbuctions

GEK-85714A

.:~~~~.~-~~~:*~-~~*~~-~~-~~~. . . . . . ,.\ 2.

***.*.*.*.* cs’~.:‘~~.“~‘~‘.~.~.-.~.-.-.-.-*~.-. i.5. . . .*a pg.* .*.*.*.*.*. >*.>; .*.*.*.*.*.*.*.*.*.*.*. 3

..,~-~,-:;~~~~~~~~~-:~~:~~~~~-.~.~ . . . ..A -

. * . . . . . . . . . . . . . . . . . . . . . . . ,.~.*.*.*.*.*.~.~.~,.*.~.~ *.* *.*.*.*.*. >:.:.: .*.*.*.*.~.‘.*.~.*.*” *.*.* *.*. . .*.*.*.* .‘.*.‘.‘.*.*.~.*.*.*.*

.-~:~.~~~:~~.~:.;.~i.: ~~~~~~~I-~~~~~~~-~s;~.;;;;.~.is;~.--~;~.~.;-.~-.~~~~-~.-.-.~-.~.-.-.~~~~~~-~~~~~~~~~~~~~~~~~~

. . . . . .

.;.:.:.:.-~.

..-...

:: .': -----

:*;.:.:.3:.:

7...-.-.:-

. . . . . .

:yy:y$.*

-.-:.-.'.'.'

>.-.-2...*.

<+:.:.:.:.*

. . . . . . .

.~.-.-~-.-.-.-

,....

.- -m-.-.*.-T-

.,..., . . - .% .

.:;;i;.:.:.

>:.:.>>c.

.-.;.ym+..*<*.*

zg?

>y*.

.-+'

.-:

z:*

‘.~.-.-.-.i~.’ ‘...-~:~~~*~~~:!~~~~:.~~~~~~~~?~~,,,~~~~~,~~..s~~~.~.~:~

. - -

~-.-~,-~0~-~~~~~~~~s~~~:-~~~~~~~~s

y. +* .‘:,s\ .‘.....f.......

. . . . . . . . . . . .*

y<ya

-~:y~*-i

y&y..*

A4

<.-;.>; a-i- - -A

-A-s'\

x.:<<<.

<<.-.:.x

-:.:&-.:.

:.:.:+:.s

+x-x

-.-'-.-.-.\

l . . .*.f.

TM Trademark of General Electric Company, U.S.A.

Those kWucbbns do not purport to cw6f ail details of vafiatims in equipment to

cqxxatbn maintenance. Should tbrtbinformatian be desked or should pariicuku problems

rnatw should be reloned to Gene& Electric Cotnpmy

\

.y.:.;.;.;<

-.-.a-.-.-.

il;&$A

>Sk’.\

.-.,-&-.

-A.:.:*

.y.:.:.:.:

-.-.-.a-.-‘;

‘$g$

. .-‘a-. .

:;y::::;:

. . . . .

yy’p

p:.->

-3

.*.:.y.:.:

.-.-.-.-.a

m

,v-:-s

x.:::>;::

.y’y.:<

-.-.a-.-.,

-b.x.-.:.

>-2-3. .*...,..‘..,....

.-z-h*?.-.-.-‘-.-,.-. .~.~..-.-A->.- - * --’ - - - -’ -.-.-.-.‘.-.-.~-.~.-.-.-.-.-.-.-.-.-.~.-.-.-.-.~.~.-.-.-:.-.~.~~

**~*~*~*~~~*~,*~*~,*~~~*,*,*~*~.~~~~*’~~’~~~~:~:‘:~~‘~‘*~* **~~*~~~*~S~*~~S~~*~**.i~.~*~-~~~~~~~~~~~~~~~~

,..... s,.rr,,~r.,,~;.:.:;~.:=-’ ’ -.-t.- * - -.- - *.-.- * - ‘t a.*.-:.* *. .

b

‘. .-.-.-.y -~.-.-.-.-.-.-.-.-.-.~.-.-.,:.:~.:.:.:.:.:.:.:,:.~.:.:.-.:.:.-

.\-‘i-.-. 8~~8~-.~8-.~--~-.-.~- - - -

. . . . . . . . . . . . . . . . . . . . . 1.. . . . . . . . . . . .\-...-.-a

..,~..*~rh,*~S.‘.....~...‘,........ -.

. . , . . . . . . . . . . . . . . . .-. . . .

x-xc-i

.:.::.;.:.:

:.:.:.:...:.

;<:.p-4

:.:.:.:.:.:.

.-.-.-:.-.-

. . . . . .

. . . . . .

. . . . . .

. . . f . .

-... :.:.~.~.:.:~.‘.:.:.:.:-:.:.:.:.:.:.:.:,

. . . . . . . .-. , . . . . . . . . . . .

provide

for overypossibk, cmtingcncy to be met in

ark?

M&h are ruM covered suffkientiy foe the purchasers purposes, the

cowwction with

instaM.bn

Page 2

Page 3

/ f

f

@ .

GE Drive Systems

SUPPLEMENT #l

FOR INSTRUCTION MANUAL GEK-85714A

These instructions do not purport to cover all details or variations in equipment, nor to provide for every possible contingency to be met

during installation, operation, and maintenance. Should &rther information be desired or should particular problems arise that are not

covered suficiently for the purchaser’s purpose, the matter should be referred to GE Drive Systems, Salem, Virginia U.S.A.

This supplement contains additional information

needed when installing and operating the AF-300A

series of inverters. Refer to the information of this

supplement in addition to that contained in GEK85714A for the figures, tables, and paragraphs listed in

this supplement.

Table 3: Application of Wiring and Equipment

The recommended wire sizes shown in Table 3 are

minimum sizes. Due to variations in installation,

check that the recommended wire sizes are adequate

for that particular installation. All inverter installations must meet the applicable national (NEC, CEC)

and local electrical codes. It is the system engineer’s

responsibility to be certain that the inverter installation complies with all applicable electrical codes. (If a

system engineer is not involved, it is the user’s responsibility.) Only adequately trained persons should

install any programmable inverter.

Figure 4-6. Basic Connection Diagram

The 3-phase AC circuit breaker shown in this figure is

incorrectly illustrated as three breakers. It is actually a

single, 3-pole breaker.

Figure 4-6. Basic Connection Diagram

Figures 8-4 and 8-5. Control Block Diagrams

Thermal Relay shown in theses figures is not a standard option kit available from General Electric Drive

Systems. Overload protection is not provided by the

AF-300A and therefore must be provided by the user.

(Typical thermal relay circuit wiring is shown in Figure

4-6.) All inverter installations must meet the applicable national (NEC, CEC) and local electrical codes.

It is the system engineer’s responsibility to be certain

that the inverter installation complies with all applicable electrical codes. (If a system engineer is not

involved, it is the user’s responsibility.)

Table 10: AC Line Fuses and Fuseholders

Due to variations in installation when mounting fuseholders and fuses external to the inverter, check that

the recommended fuse sizes are correct for that

particular installation. When using the recommended

fuse sizes, overload protection must be provided by the

user in order to comply with most electrical codes. All

inverter installations must meet the applicable national (NEC, CEC) and local electrical codes. It is the

system engineer’s responsibility to be certain that the

inverter installation complies with all applicable

electrical codes. (If a system engineer is not involved,

it is the user’s responsibility.)

(10/14/94)

Page 1 of 1

Page 4

Page 5

AF-300A

Inverter

l/4

l/4

to 5 He 200-230\(, 3-Phase

to 3 HP, 200=24OV, 1 -Phase

GEK-85714A

Issue Date: August 1994

These instructions do not purport to cover all details or variations in equipment, nor to provide for

every possible contingency to be met during installation, operation, and maintenance. Should further

information be desired or should particular problems arise that not covered sufficiently for the purchaser’s purpose, the matter should be referred to GE Drive Systems, Salem, Virginia, U.S.A.

This document contains proprietary information of General Electric Company, U.S.A. and is furnished

to its customers solely to assist that customer in the installation, testing, and/or maintenance of the

equipment described. This document shall not be reproduced in whole or in part nor shall its contents be disclosed to any third party without the written approval of GE Drive Systems, 1501 Roanoke

Boulevard, Salem, Virginia 24153, U.S.A.

Page 6

Copyright 1994 by General Electric Company, U.S.A.

All

rights reserved.

Printed in the United States of America.

Page 7

TABLE OF CONTENTS

AF-300A

lnverters GEK-85714

Section

1 .

2 .

3.

4.

5.

Title

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . .

DESCRIPTION, COMPONENT IDENTIF

AND SPECIFICATIONS

General Description

Inspection items Upon Delivery

TABLE 1: AF-300A lnverter Standard Specifications

lnverter Options

INSTALLATION GUIDELINES

Installation Environment

Installation Mounting Clearance

Dimensions Chart:

WIRING PROCEDURES

Remove Terminal Block Cover

Main Circuit Wiring ..................................................................................

Control Circuit Wiring

Optional External Dynamic Braking Resistor Unit Wiring

TABLE 2: Terminal Identification/Function

TABLE 3: Application of Wiring and Equipment

INVERTER OPERATION

Pre-Operation Inspection

Selection of Operating Method

Function Code and Data Setting Procedures

TABLE 4: Operating Methods

Control Circuit Connection and Operation

Multi-Step Operations

TABLE 5: Function Code Settings*

........................................................................

................................................................................

. . . . . . . . . . . . . . . . . . . . . . . ..*............................................................ 2-7

.............................................................. 3-l

........................................................................ 3-1

..................................................................................

......................................................................

............................................................................

......................................................................

......................................................................

............................................................................

. . . . . . . .

ICAT ‘ION,

............................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

............................................................

..............................................................

.......................................... 4-l 0

.................................. 4-l 2

..............................................................

......................................

.............................................................. 5-l

.......................................... 5-4

......................................................

Paae

w

11

2-l

2-1

2-1

3-l

3-2

4-1

4-l

4-l

4-l

.................... 4-8

5-l

5-l

5-l

5-l

5-7

5-9

6 .

7.

*A duplicate of this table

FUNCTION CODE DESCRIPTIONS

TABLE 6: Function Code Descriptions

MAINTENANCE AND INSPECTION

Megger Test

Periodic Parts Replacement

Inspection Items

Measurement Points and Meters

with is also furnished in the back of this instruction (pp. Function Changes I-

2) to record field changes to

............................................................................................

..................................................................

......................................................................................

..........................................................

factory Function Code settings.

....................................................

................................................

....................................................

m

61

6-l

7-l

7-l

7-l

7-l

7-2

Page 8

AF300A /metiers GEK-85714

TABLE OF CONTENTS

Section

8. TROUBLESHOOTING

9 .

10. PARTS REPLACEMENT

Table #

Title

TABLE 7: Fautt Condition Description and Operation ........................

TABLE 8: Fault Condition Display and Corrective Action ....................

WARRANTY PARTS AND SERVICE 91

Warranty Coverage ................................................................................ 9-l

Out-Of-Warranty Procedures .................................................................. 9-l

Motors

TABLE 9:

lnverter Renewal Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-l

TABLE

and Fuseholders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

...................................................................................................... 9-l

10: AF-300A (200.23OV, 3-Phase) Line Fuses

Title Pagg

.......................................................................... 81

....................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 o-1

AF-300A (200-23OV, 3-Phase and 200.24OV, l-Phase)

LIST OF TABLES

Paw

811

8-3

-

1 o-2

TABLE 1:

TABLE 2:

TABLE 3:

TABLE 4:

TABLE 5:

TABLE 6:

TABLE 7:

TABLE 8:

TABLE 9:

TABLE 10:

AF-300A INVERTER STANDARD SPECIFICATIONS

TERMINAL IDENTIFICATION/FUNCTION

APPLICATION OF WIRING AND EQUIPMENT

OPERATING METHODS ................................................................................

FUNCTION CODE SETTINGS

FUNCTION CODE DESCRIPTIONS

FAULT CONDITION DESCRIPTION AND OPERATION

FAULT CONDITION DISPLAY AND CORRECTIVE ACTION

AF-300A INVERTER RENEWAL PARTS

AF-300A (200.23OV, 3-Phase) AC LINE FUSES AND FUSEHOLDERS

...................................................................... 5-9

....................................................

.............................................................. 6-l

...................................................... 10-l

..................................

............................................ 4-l 2

.............................. 8-l

......................

....

2-4

4-l 0

5-l

8-3

IO-2

Page 9

LIST OF FIGURES

AF-300A

/metiers GEK-85714

Figure #

Figure 2-l.

Figure 2-2.

Figure 2-3.

Figure 3-l.

Figure 3-2.

Figure 4-l.

Figure 4-2.

Figure 4-3.

Figure 4-4.

Figure 4-5.

Figure 4-6.

Figure 5-l.

Figure 5-2.

Figure 5-3.

Figure 5-4.

Figure 5-5.

Figure 5-6.

Figure 5-7.

Figure 5-8.

Title

NAMEPLATE DATA IDENTIFICATION

KEYPAD PANEL COMPONENT IDENTIFICATION ......................................

TYPICAL INVERTER COMPONENTS

INVERTER MOUNTING CLEARANCE

INVERTER EXTERNAL DIMENSIONS

TERMINAL BLOCK COVER

POWER CIRCUIT WIRING CONNECTIONS

WIRING CONNECTIONS FOR OPERATION THROUGH

KEYPAD PANEL

WIRING CONNECTIONS FOR EXTERNAL OPERATION THROUGH

CONTROL CIRCUIT TERMINALS

OPTIONAL EXTERNAL DYNAMIC BRAKING RESISTOR UNIT

WIRING CONNECTIONS

BASIC CONNECTION DIAGRAM

KEYPAD PANEL COMPONENT IDENTIFICATION

FACTORY CONNECTIONS

COMMON TERMINAL CONNECTION EXAMPLE

KEYPAD PANEL OPERATION CONNECTIONS

KEYPAD PANEL “RUN” OPERATION EXAMPLE

EXTERNAL SIGNAL OPERATION CONNECTIONS

EXTERNAL SIGNAL “RUN” OPERATION EXAMPLE

MULTI-STEP FREQUENCY OPERATION CONNECTIONS

............................................................................................

.......................................................................... 4-1

. . . . . . . . . . . . . ..I..............................................................

.......................................................................... 5-4

.......................................................... 2-1

.......................................................... 3-l

..........................................................

................................................ 4-2

................................................................ 4-6

..,..,............................,............................. 4-9

...................................... 5-2

......................................

.......................................... 5-5

........................................

....................................

.................................. 5-6

........................ 5-7

2-2

23 - ..........................................................

3-2

4-4

4-8

5-4

5-5

5-6

Figure 5-9.

Figure 5-l 0.

Figure 5-l 1.

Figure 7-l.

Figure 8-l.

Figure 8-2.

Figure 8-3.

Figure 8-4.

Figure 8-5.

MULTI-STEP FREQUENCY “RUN” OPERATION

MULT-STEP ACCELERATION AND DECELERATION

OPERATION CONNECTIONS

MULT-STEP ACCELERATION AND DECELERATION “RUN”

OPERATION EXAMPLE

MAIN CIRCUIT MEGGER TEST CONNECTIONS

MOTOR RUNS BUT SPEED DOES NOT CHANGE

TROUBLESHOOTING CHART

MOTOR ROTATION IS NOT SMOOTH TROUBLESHOOTING CHART . . . . 8-6

MOTOR OVERHEATS TROUBLESHOOTING CHART

CONTROL BLOCK DIAGRAM (l/4 TO 1 .O Horsepower)

CONTROL BLOCK DIAGRAM (2.0 to 5.0 Horsepower)

. . . . . . . . . . . . . . . . . . . . ..*.....................................*.........

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EXAMPLE ...................... 5-7

5-8

5-8

. . . . . . . . . . ..*.........................

................................

............................

..............................

7-1

8-5

8-6

8-7

8-8

Page 10

AF300A /metiers GEK-85714

NOTES=

iv

Page 11

AF300A /metiers

1

m SAFETY PRECAUTIONS

GEK-85714

WARNING, CAUTION AND NOTE

LABELS PLACED ON THE EQUIPMENT

The following format is used on the safety and

informative labels placed on the equipment. Read all

labels and follow the directions on them whenever

working on the equipment.

WARN I NG:

practices that may result in personal injury or loss of

life if not correctly followed.

Denotes operating procedures and

WARNING labels will be red in color with

black or white letterina.

CAUTION:

practices that, if not strictly observed, may result in

damage to, or destruction of the equipment.

Denotes operating procedures and

CAUTION labels will be amber in color with

black lettering.

NOTE:

especially significant in understanding and operating

the equipment.

Notes call attention to information that is

NOTE labels will be white in color with black

letterina.

WARNING, CAUTION AND NOTE

PARAGRAPHS WITHIN THIS

INSTRUCTION

The following paragraphs list some general safety

reminders and safety recommendations to be followed

when operating or installing this equipment. These

safety precautions will be repeated throughout this

instruction book where applicable.

WARNING - STRAIN HAZARD:

lifting practices can cause serious or fatal injury.

Lift only with adequate equipment and trained

personnel.

Improper

WARNING - ELECTRICAL SHOCK AND

BURN HAZARD:

as oscilloscopes to work on live equipment, the

oscilloscope’s chassis should be grounded and a

differential amplifier input should be used. Care

should be used in the selection of probes and

leads and In the adjustment of the oscilloscope so

that accurate readings may be made. See instrument

manufacturers instruction book for proper operation

and adjustments to the instrument.

When using instrumentssuch

WARNING - FIRE AND EXPLOSION

HAZARD:

mounting inverters in hazardous areas such as

locations where flammable or combustible vapors

or dusts are present. lnverters should be installed

away from hazardous areas, even If used with

motors suitable for use in these locations.

WARNING -

HAZARD:

enclosure housings should be grounded in

accordance with the National Electric Code and/or

applicable local codes.

Fires or explosions might result from

ELECTRICAL SHOCK

All motor bases and equipment

WARNING - MOTOR OVERSPEED

HAZARD:

the inverter could cause the motor to run up to

double its base speed. Never operate the motor

above its top mechanical speed or a catastrophic

failure may occur.

With 120 Hz inverter output possible,

WARNING -

HAZARD:

motion. It is the responsibility of the user to insure

that any such motion does not result in an unsafe

condition. Factory provided interlocks and operating

limits should not be bypassed or modified.

WARNING HAZARD:

FWD-CM or REV-CM terminals connected, the

driven motor starts automatically at Power-Up or

by pressing the RESET key to reset the inverter.

(This may not occur due to OH2 trip on later

manufactured inverters .)

MECHANICAL MOTION

tnverter systems cause mechanical

MECHANICAL MOTION

When 2-wire control is used with the

WARNING -

HAZARD:

in the External Signal Mode (Function Code 012

and 013). (Pressing STOP may cause OH2 trip.)

WARNING -

HAZARD:

factory-wired, changing Function Code from the

factory-set Function Code 010 (Keypad Operation)

to Function Code 012 or 013 (External Signal

Operation) without removing the FWD-CM jumper

wire will cause the motor to start.

(This may not occur due to OH2 trip on later

manufactured inverters .)

1-1

MECHANICAL MOTION

RUN and STOP keys do not function

MECHANICAL MOTION

Because the FWD-CM terminal is

Page 12

AF-300A

lnvetters

GEK-85714

WARNING - FIRE HAZARD: Use

namic braking resistors that are provided by GE

Drive Systems. These are special resistors that

have a thermal fuse built in that opens if the

resistor gets too hot. This fuse should only open

if the DB transistor in the inverter or DB unit fails

short circuited. The resistor will need to be replaced if this happens.

WARNING - FIRE HAZARD: User

vide overload protection for the motor and wiring

because this function is not provided by the AF300A. See Figure

for typical wiring of an overload relay. Wire size

recommendations shown in Table 3 and fuse size

recommendations shown in Table 10 of this Instruction Book are based on overload protection

being provided by the user.

CAUTION:

that exceeds the standard specification voltaqe

fluctuation permissible. lf excessive voltaqe is applied

to the inverter, damaqe to the internal components

will

result.

CAUTION:

output terminals (U, V, W). Connect power supply

only to the power terminals (Ll, L2, L3).

CAUTION:

brakinq resistor connection terminals (P, DB). Never

short-circuit between P-N or P-DB terminals, and do

not connect any resistance with a resistance value

less than the standard application brakinq resistor.

4-6

“Basic Connection Diagram”

Do not connect power supply voltaqe

Do not connect power supply to the

Do not connect power supplv to the

only dy-

must pro-

CAUTION:

output side of the invetter.

CAUTION:

ground wire connected.

CAUTION:

consult the TROUBLESHOOTING section of this

instruction book, and after correctinq the problem,

resume operation. Do not reset the alarm automatically

by external sequence, etc.

CAUTION:

the inverter terminals or on the control circuit terminals.

CAUTION:

must be provided, either bv motor thermoswitch,

motor overload relay, or inverter electronic thermal

overload.

CAUTION:

greatly affects inverter

the inverter in anv location that exceeds the allowable

temperature. Leave theventilation cover attached for

temperatures of 40 deqrees C or below, and remove

the cover for temperatures of between 40 and 50

deqrees C.

another type of enclosure may be required for

safety purposes.

CAUTION:

packet(s)

these packets may become lodqed in the fan or air

passages

Do not connect filter capacitors on the

Do not operate the inverter without the

If the invetter’s Fault Alarm is activated,

Do not perform a meqqer test between

Motor Thermal Overload protection

Because the ambient temperature

life and reliability, do not install

If the cover needs to be removed,

Be sure to remove the desicant drver

when unpackinq inverter. (If not removed

and cause the inverter to overheat.)

CAUTION:

control circuit terminals (except 30A and 30C).

CAUTION:

(forward) and REV-CM (reverse) terminals. Avoid

usinq a contactor (ON/OFF) installed on the line side

of the inverter for RUN and STOP.

CAUTION:

of the inverter for ON/OFF operation.

CAUTION:

ratinq should be qreater than 1.5 times the inverter

HP ratinq, but less than 500 KVA. If the AC power

supply transformer is qreater than 500 KVA, install the

AC Line Reactor option on the AC power supply to the

inverter. A Line Reactor is also required if an SCR

Tvpe Controller and/or Power Factor Correction

Capacitors are used on the same power lines.

Do not connect power supplv to the

For RUN and STOP, use the FWD-CM

Do not use a switch on the output side

The AC power supplv transformer KVA

CAUTION:

be of heat resistant material because durinq operation, the temperature of the inverter’s coolinq fins

rises to approximately 90 deqrees C (194 F).

NOTE:

The mountinq wall for the inverter must

Always read the complete instructions prior to

applyingpower or troubleshooting the equipment and

follow a// procedures step by step.

NOTE:

The motor chassis should be grounded to

earth through a separate ground lead from all other

equipment ground leads to prevent noise coupling.

NOTE:

NOTE

l-2

Read and heed a// W’A/WV/NG, CAUTION, and

labels posted on the equipment.

Page 13

AF300A

lnverters GEK-85714

2. DESCRIPTION, COMPONENT

IDENTIFICATION, AND SPECIFICATIONS,

GENERAL DESCRIPTION

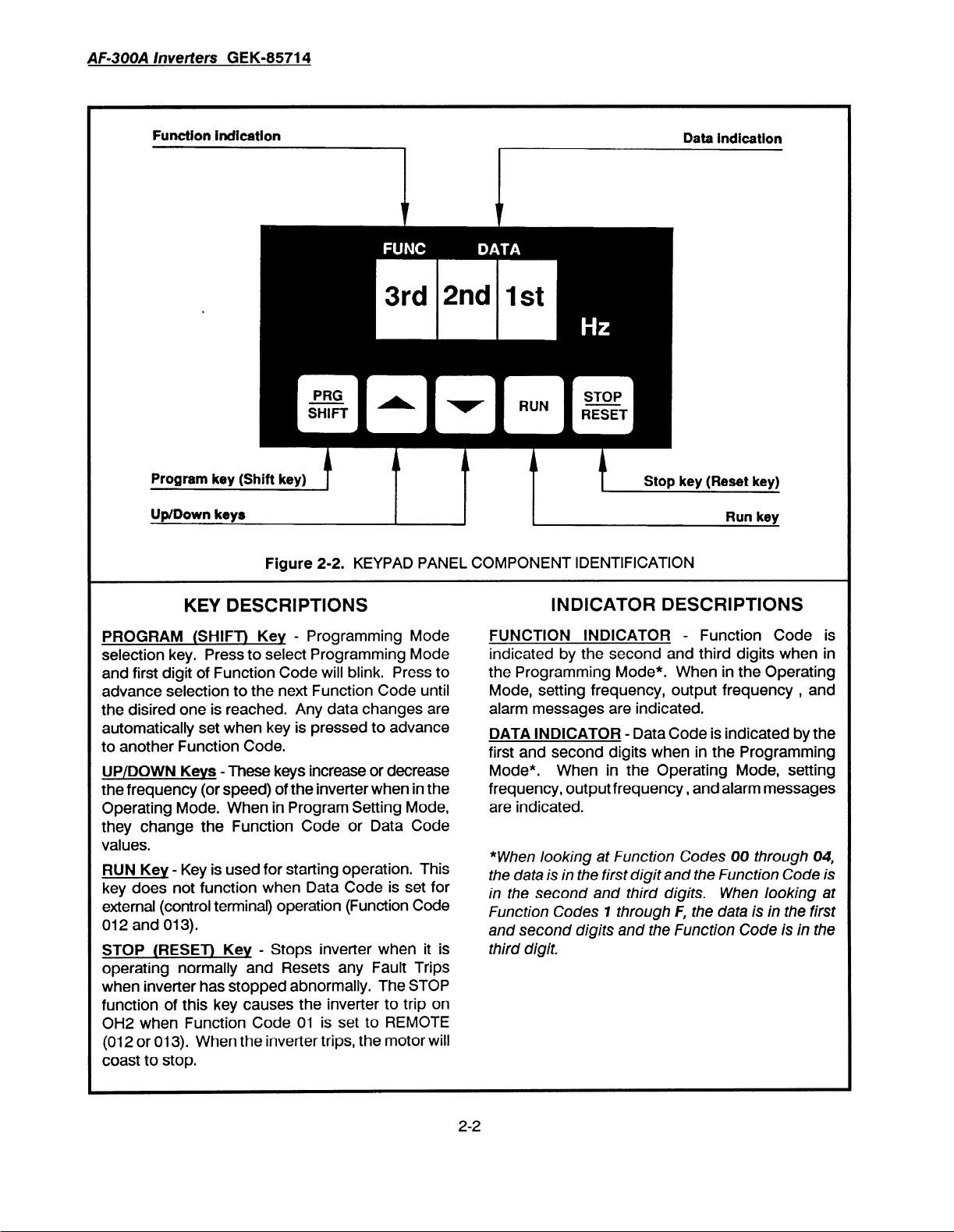

The AF-300ATM inverter is available in l/4 to 5 HP, 200230 VAC 3-Phase and l/4 to 3 HP, 200-240 VAC

Single-Phase versions. The output of the inverters is

3-phase for running a 3-phase motor whether the

input is single-phase or 3-phase. All of the inverters

use 32-bit “Digital Signal Processors” (DSP) for

muttifunction processing to provide high performance

in all applications.

completely enclosed (except for the cooling fan)

construction for improved performance in adverse

environments. All the inverters are furnished with

detachable wiring lead-in plate for access so that

wiring can be easily accomplished. (See Figure 2-3

for inverter external component identification.)

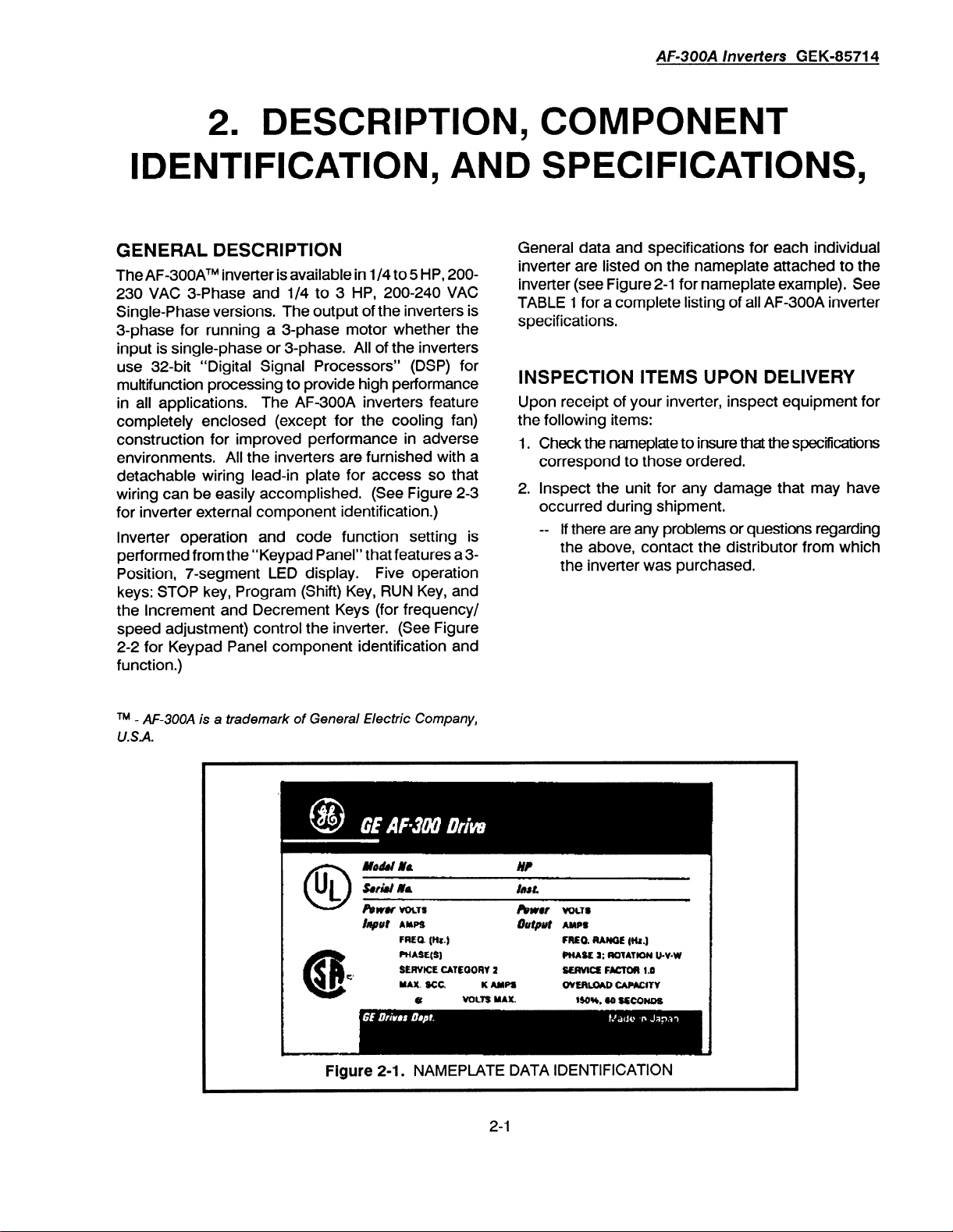

lnverter operation and code function setting is

performed from the “Keypad Panel” that features a 3-

Position, 7-segment LED display. Five operation

keys: STOP key, Program (Shift) Key, RUN Key, and

the Increment and Decrement Keys (for frequency/

speed adjustment) control the inverter. (See Figure

2-2 for Keypad Panel component identification and

function.)

The AF-300A inverters feature

General data and specifications for each individual

inverter are listed on the nameplate attached to the

inverter (see Figure 2-l for nameplate example). See

TABLE 1 for a complete listing of all AF-300A inverter

specifications,

INSPECTION ITEMS UPON DELIVERY

Upon receipt of your inverter, inspect equipment for

the following items:

a

1. Check the nameplate to insure that the specifications

correspond to those ordered.

2. Inspect the unit for any damage that may have

occurred during shipment.

-- If there are any problems or questions regarding

the above, contact the distributor from which

the inverter was purchased.

TM - AF-3OOA is a trademark of General Electric Company,

USA.

Figure 2-l.

NAMEPLATE DATA IDENTIFICATION

2-l

Page 14

AF300A /metiers

GEK-85714

Function indication

Program key (Shift

Up/Down keys

key)

Figure

1

2-2. KEYPAD PANEL

.

1 Stop key (Reset

COMPONENT IDENTIFICATION

Data indication

key)

Run key

KEY DESCRIPTIONS

PROGRAM (SHIFT) Key

selection key. Press to select Programming Mode

and first digit of Function Code will blink, Press to

advance selection to the next Function Code

the disired one is reached. Any data changes are

automatically set when key is pressed to advance

to another Function Code.

UP/DOWN Keys

- These keys increase or decrease

the frequency (or speed) of the inverter when in the

Operating Mode. When in Program Setting Mode,

they change the Function Code or Data Code

values.

RUN Key

- Key is used for starting operation. This

key does not function when Data Code is set for

external (control terminal) operation (Function Code

012 and 013).

STOP (RESET) Key

operating normally and Resets any Fault Trips

when inverter has stopped abnormally. The STOP

function of this key causes the inverter to trip on

OH2 when Function Code 01 is set to REMOTE

(012 or

013).

When the inverter trips, the motor will

coast to stop.

- Programming Mode

until

- Stops inverter when it is

INDICATOR DESCRIPTIONS

FUNCTION INDICATOR

indicated by the second

the

Programming

Mode*. When in the Operating

Mode, setting frequency, output frequency , and

alarm messages are indicated.

DATA INDICATOR

- Data Code is indicated by the

first and second digits when in the Programming

Mode*. When in the Operating Mode, setting

frequency, output frequency, and alarm messages

are indicated.

*When looking at Function Codes 00 through 04,

the data is in the first digit and the Function Code is

in the second and third digits.

Function Codes 7 through f, the data is in the first

and second digits and the Function Code is in the

third digit.

- Function Code is

and third digits when in

When looking at

2-2

Page 15

l/4 to 1.0 HP Units

AF300A /metiers GEK-85714

VENTILATION HOLE

BLIND PLA’TE

VENTILATION HOLE

BLIND PLATE

MOUNTING HOLE

VENTILATION HOLE

BLIND PLATE

CABLE INLET

PLATE

RUBBER BUSHING

(PROVIDED LOOSE)

NAME PLATE

7

pCABLE INLET

PLATE

SCREW

TERMINAL COVER

FOR&

Figure 2-3.

L-

NAM

: PLATE

LCOOLING

FAN

2 to 5 HP Units

TYPICAL INVERTER COMPONENTS

2-3

RUBBER BUSHING

(PROWED LOOSE)

Page 16

AF300A

/metiers GEK-85714

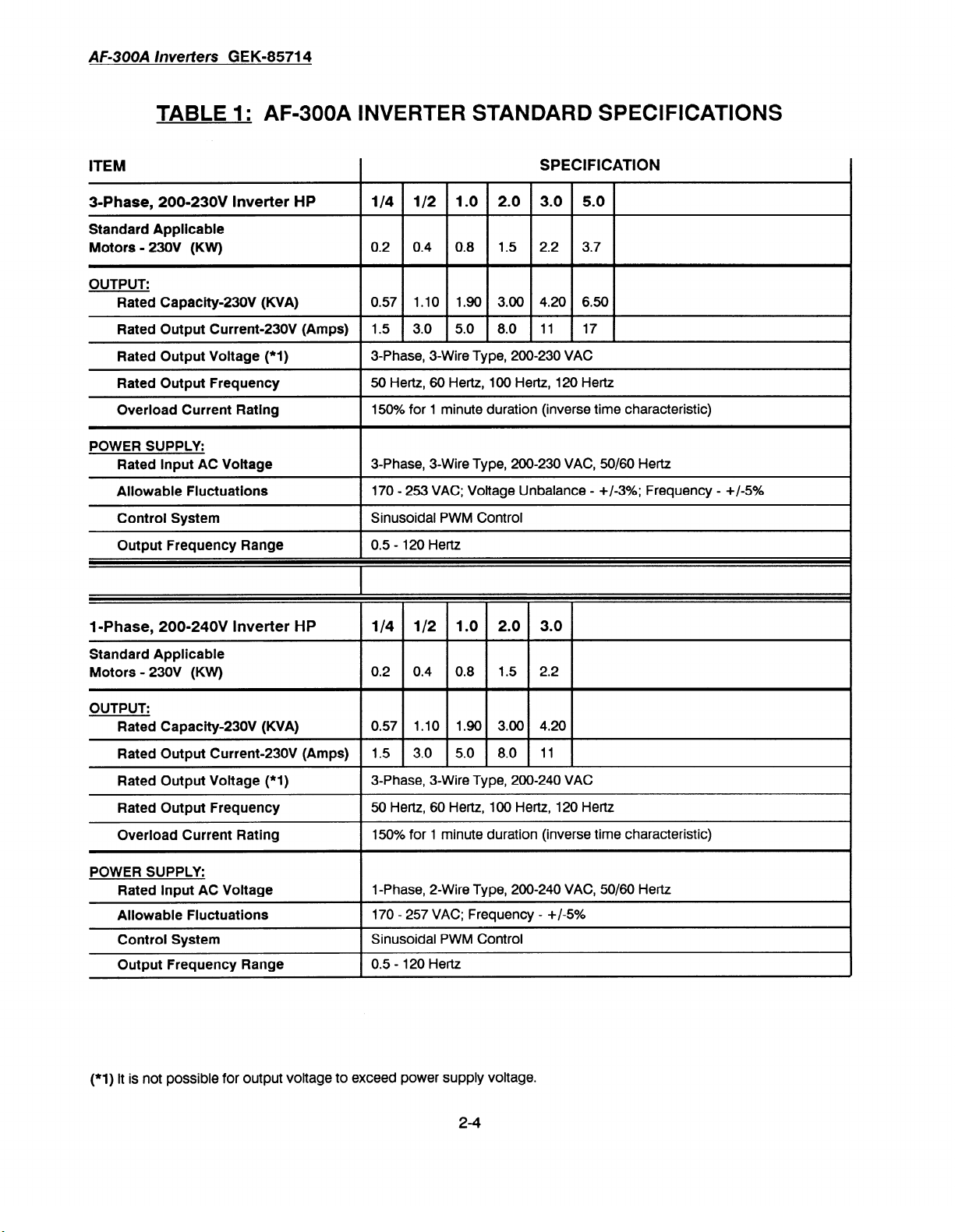

TABLE 1: AF-300A INVERTER STANDARD SPECIFICATIONS

ITEM

3=Phase, 200-230V lnverter HP

Standard Applicable

Motors - 230V (KVV)

OUTPUT:

Rated Capacity-230V (KVA)

Rated Output Current-230V (Amps)

Rated Output Voltage (*I)

Rated Output Frequency

Overload Current Rating

POWER SUPPLY:

Rated input AC Voltage

Allowable

Control System

Output Frequency Range

Fluctuations

I

l/4 l/2 1.0

0.2 0.4 0.8

0.57

1.10 1.90 3.00 4.20

1.5 3.0 5.0

3-Phase, 3-Wire Type, 200-230 VAC

50 Hertz, 60 Hertz, 100 Hertz, 120 Hertz

150% for 1 minute duration (inverse time characteristic)

3-Phase, 3-Wire Type, 200-230 VAC, 50/60 Hertz

170 - 253 VAC; Voltage Unbalance - +/-3%; Frequency - +/-50/o

Sinusoidal PWM Control

I

0.5 - 120 Hertz

I

SPECIFICATION

2.0 3.0 5.0

1.5 2.2 3.7

6.50

8.0 11 17

I

f

I

I

1

1

1

1 -Phase, 200-240V lnverter HP

Standard Applicable

Motors - 230V (KW)

OUTPUT:

Rated Capacity-230V (KVA)

Rated Output Current-230V (Amps)

Rated Output Voltage (*I)

Rated Output Frequency

Overload Current Rating

POWER SUPPLY:

Rated input AC Voltage

Allowable Fluctuations

Control System

Output Frequency Range

l/4

l/2 1.0 2.0 3.0

0.2

0.4 0.8 1.5 2.2

0.57

1.10 1.90 3.00 4.20

1.5

3.0 5.0 8.0 11

3-Phase, 3-Wire Type, 200-240 VAC

I

50 Hertz, 60 Hertz,

150% for 1 minute duration (inverse time characteristic)

1 -Phase, 2-Wire Type, 200-240 VAC, So/60 Hertz

170 - 257 VAC; Frequency - +/-5%

I

Sinusoidal PWM Control

I

0.5 - 120 Hertz

I

100 Hertz, 120 Hertz

1

1

1

1

1

(*l)

It is not possible for output voltage to exceed power supply voltage.

2-4

Page 17

AF-300A lnverters GEK-85714

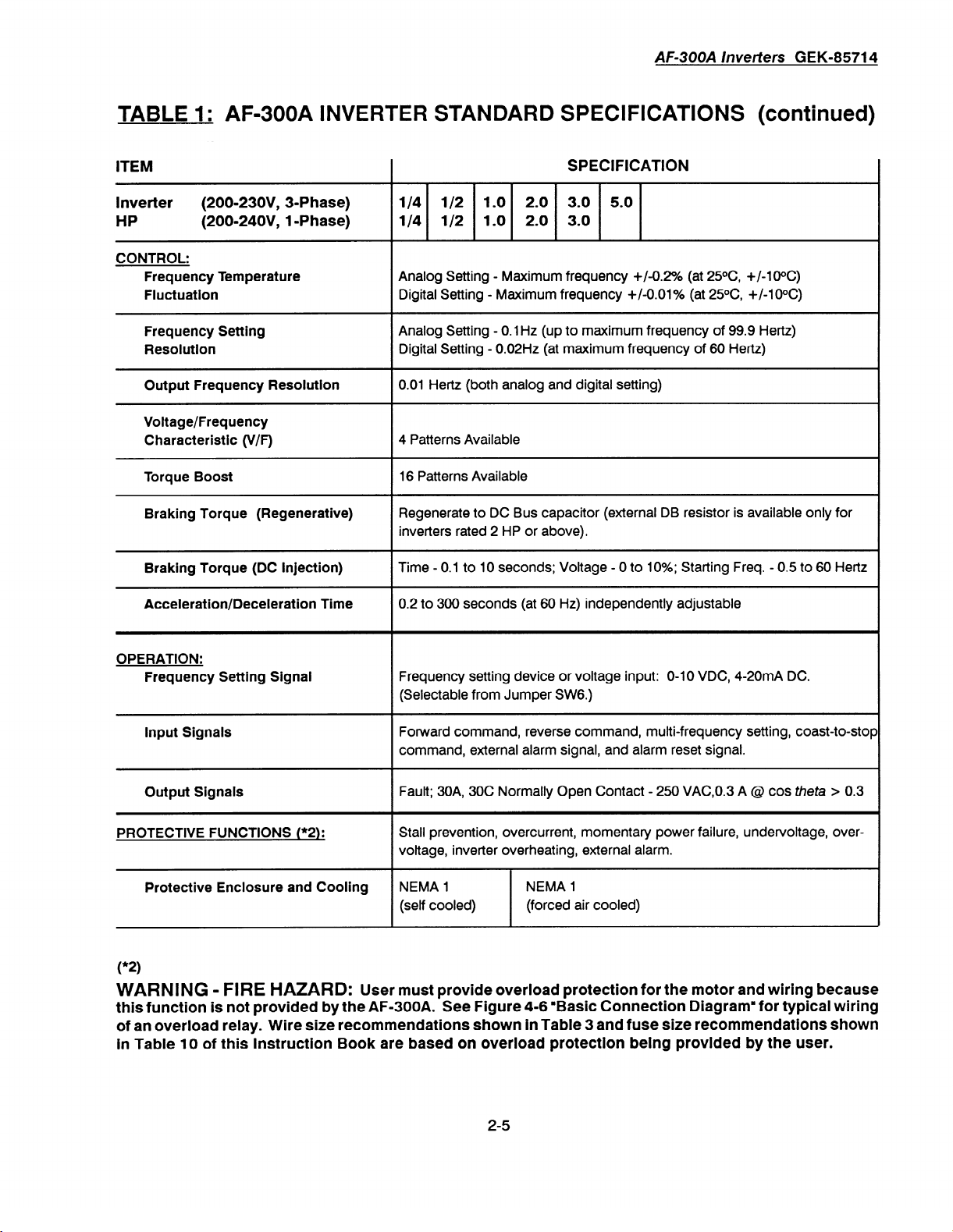

TABLE 1: AF-300A INVERTER STANDARD SPECIFICATIONS (continued)

ITEM

lnverter

HP

CONTROL:

Frequency Temperature

Fluctuation

Frequency Setting

Resolution

Output Frequency Resolution

Voltage/Frequency

Characteristic (V/F)

Torque Boost

Braking Torque (Regenerative)

Braking Torque (DC injection)

Acceleration/Deceleration Time

(200=23OV, 3-Phase)

(200=24OV, 1 -Phase)

SPECIFICATION

l/4 l/2 1 .o 2.0 3.0 5.0

l/4 l/2 1.0 2.0 3.0

Analog Setting - Maximum frequency +/-0.2% (at 25OC, +/-1gOC)

Digital Setting - Maximum frequency +/-0.01% (at 25OC, +/-1oOC)

Analog Setting - 0.1 Hz (up to maximum frequency of 99.9 Hertz)

Digital Setting - 0.02Hz (at maximum frequency of 60 Hertz)

0.01 Hertz (both analog and digital setting)

4 Patterns Available

16 Patterns Available

Regenerate to DC Bus capacitor (external DB resistor is available only for

inverters rated 2 HP or above).

Time - 0.1 to 10 seconds; Voltage - 0 to 10%; Starting Freq. - 0.5 to 60 Hertz

0.2 to 300 seconds (at 60 Hz) independently adjustable

OPERATION:

Frequency Setting Signal

Frequency setting device or voltage input: O-10 VDC, 4-20mA DC.

(Selectable from Jumper SW6.)

input Signals

Fonnrard command, reverse command, multi-frequency setting, coast-to-stop

command, external alarm signal, and alarm reset signal.

Output Signals

PROTECTIVE FUNCTIONS (“2):

Fault; 30A, 30C Normally Open Contact - 250 VACO.3 A @ cos theta > 0.3

Stall prevention, overcurrent, momentary power failure, undervoltage, overvoltage, inverter overheating, external alarm.

Protective Enclosure and Cooling

*

( 2)

WARNING - FIRE HAZARD:

NEMA 1

(self cooled)

User must provide overload protection for the motor and wiring because

NEMA 1

(forced air cooled)

this function is not provided by the AF-300A. See Figure 4-6 “Basic Connection Diagram” for typical wiring

of an overload relay. Wire size recommendations shown In Table 3 and fuse size recommendations shown

in Table 10 of this Instruction Book are based on overload protection being provided by the user.

2-5

Page 18

AF-300A

ltwerters GEK-85714

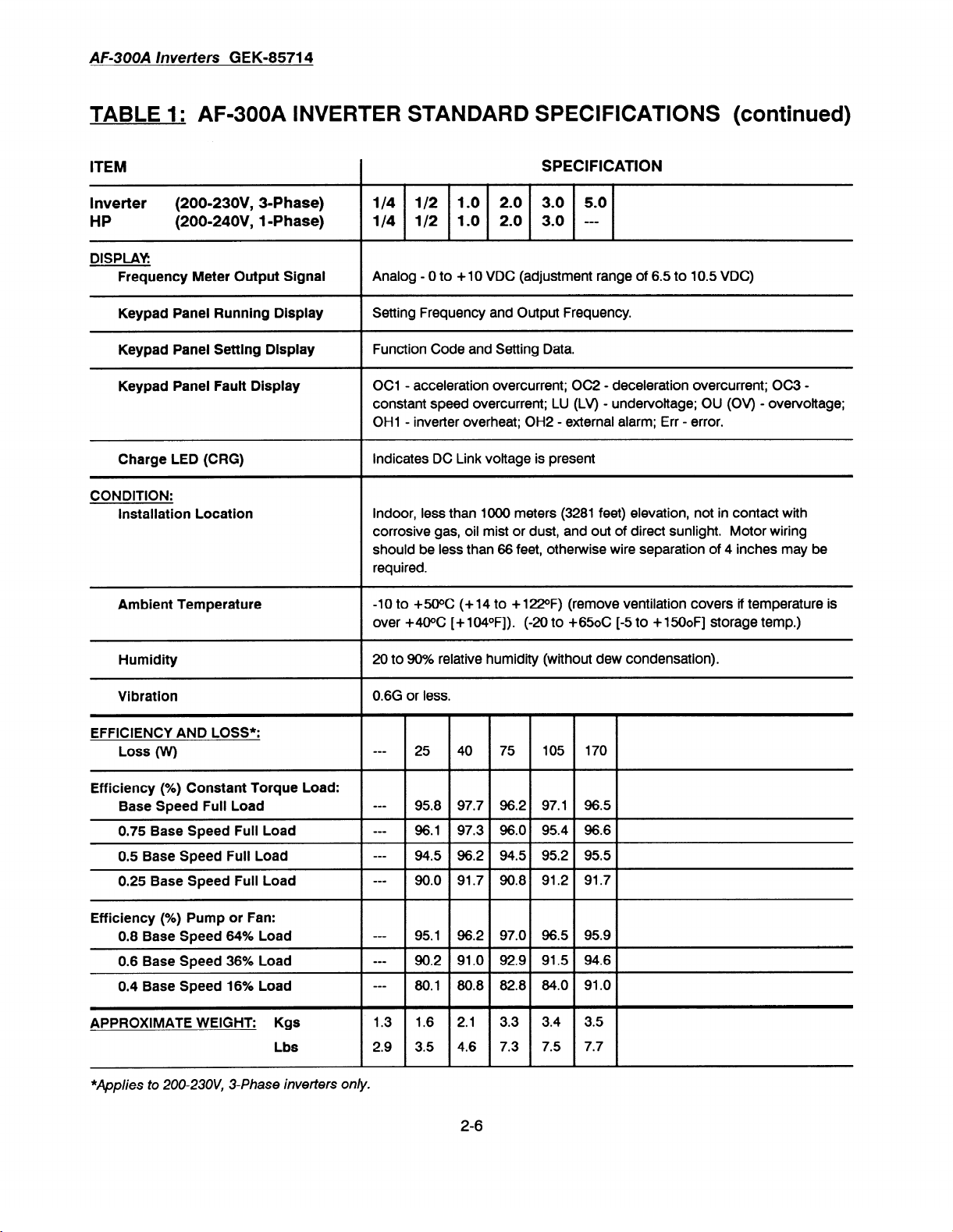

TABLE 1: AF-300A INVERTER STANDARD SPECIFICATIONS (continued)

ITEM

lnverter

HP

(200=23OV, 3-Phase)

(200=24OV, 1 -Phase)

Frequency Meter Output Signal

Keypad Panel Running Display

Keypad

Panel Setting Display

Keypad Panel Fauit Display

Charge LED (CRG)

CONDITION:

installation

Ambient Temperature

Location

SPECIFICATION

l/4 l/2 1.0 2.0 3.0 5.0

l/4 l/2 1 .o 2.0 3.0 ---

Analog - 0 to + 10 VDC (adjustment range of 6.5 to 10.5 VDC)

Setting Frequency and Output Frequency.

Function Code and Setting Data.

OCl - acceleration overcurrent; OC2 - deceleration overcurrent; OC3 constant speed overcurrent; LU (LV) - undervoltage; OU (OV) - overvottage;

OH1 - inverter overheat; OH2 - external alarm; Err - error.

Indicates DC Link voltage is present

Indoor, less than 1000 meters (3281 feet) elevation, not in contact with

corrosive gas, oil mist or dust, and out of direct sunlight. Motor wiring

should be less than 66 feet, otherwise wire separation of 4 inches may be

required.

-10 to +WC (+ 14 to + 122oF) (remove ventilation covers if temperature is

over +40% [ + 1040F]). (-20 to

+650C (-5

to +

1500F]

storage temp.)

Humidity

Vibration

EFFICIENCY AND LOSS*:

Loss (W)

Efficiency (%) Constant Torque Load:

Base Speed Full

0.75 Base Speed Full

0.5 Base Speed Full Load

0.25 Base Speed Full Load

Efficiency (%) Pump or Fan:

0.8

Base Speed 64%

Load

Load

Load

0.6 Base Speed 36% Load

0.4 Base Speed 16% Load

APPROXIMATE WEIGHT: Kgs

Lbs

*Applies to 200-23OV, 3-Phase inverters only.

20 to 90% relative humidity (without dew condensation).

0.6G

or less.

o-0

25 40 75

w-0

95.8 97.7

-00

96.1 97.3 96.0 95.4 96.6

o-0

94.5 96.2 94.5 95.2 95.5

0-a

90.0

91.7 90.8 91.2 91.7

-00

95.1 96.2 97.0 96.5 95.9

m-0

90.2

91.0 92.9 91.5 94.6

o-0

80.1 80.8 82.8 84.0 91 .O

1.3 1.6 2.1

2.9 3.5 4.6 7.3 7.5 7.7

105 170

96.2

97.1 96.5

3.3 3.4 3.5

2-6

Page 19

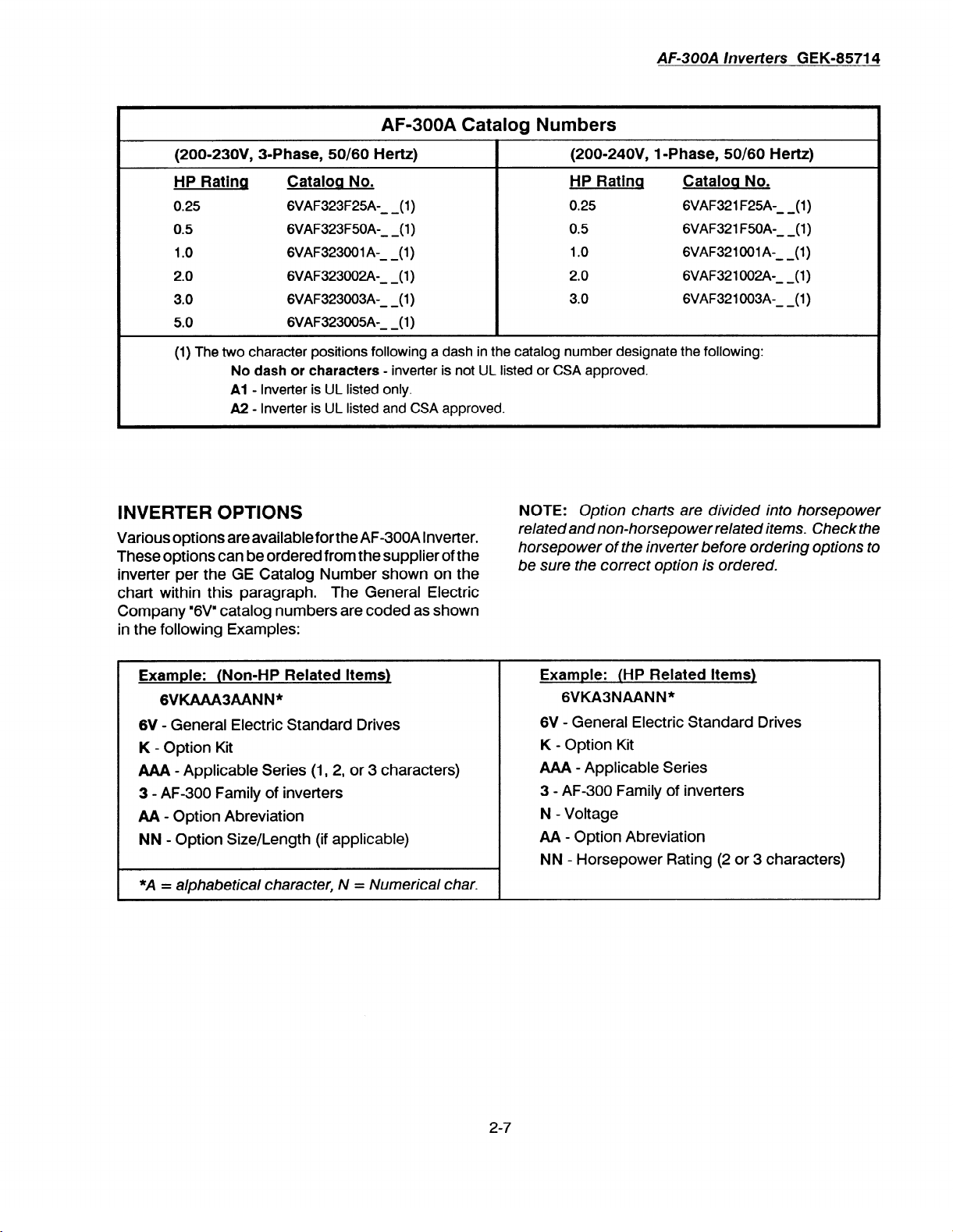

AF-300A Catalog Numbers

AF-300A lnveflers

GEK-85714

(200=23OV, 3=Phase, SO/SO Hertz)

HP Rating

0.25 6VAF323F25A- (1) 0.25

0.5 6VAF323F50A- (1) 0.5

1.0 6VAF323OOlA- (1) 1.0

2.0 6VAF323002A- (1) 2.0

3.0 6VAF323003A- (1) 3.0

5.0 6VAF323005A- (1)

(1) The two character positions following a dash in the catalog number designate the following:

No dash or characters

Al

A2 - lnverter is UL listed and CSA approved.

Catalog No.

--

--

--

--

--

--

- inverter is not UL listed or CSA approved.

- lnverter is UL listed only.

INVERTER OPTIONS

Various options are availableforthe AF-300A Inverter.

These options can be ordered from the supplier of the

inverter per the GE Catalog Number shown on the

chart within this paragraph. The General Electric

Company “6Vn catalog numbers are coded as shown

in the following Examples:

NOTE:

(200.24OV, 1 -Phase,

HP Rating Cataloq No.

Option charts are divided into horsepower

50/60

Hertz)

6VAF321 F25A- (1)

6VAF321 F50A- (1)

6VAF321OOlA- (1)

6VAF321002A- (1)

6VAF321003A- (1)

--

--

--

--

--

related and non-horsepower related items. Check the

horsepower of the inverter before ordering options to

be sure the correct option is ordered.

Example: (Non-HP Related Items)

GVKAAA3AANN*

6V

- General Electric Standard Drives

K

- Option Kit

AAA - Applicable Series (1, 2, or 3 characters)

3 - AF-300 Family of inverters

AA - Option Abreviation

NN - Option Size/Length (if applicable)

*A = alphabetical character, N = Numerical char.

Example: (HP Related Items)

6VKA3NAANN*

6V - General Electric Standard Drives

K

- Option Kit

AAA - Applicable Series

3 - AF-300 Family of inverters

N - Voltage

AA - Option Abreviation

NN - Horsepower Rating (2 or 3 characters)

I

2-7

Page 20

AF-300A

lnverters GEK-85714

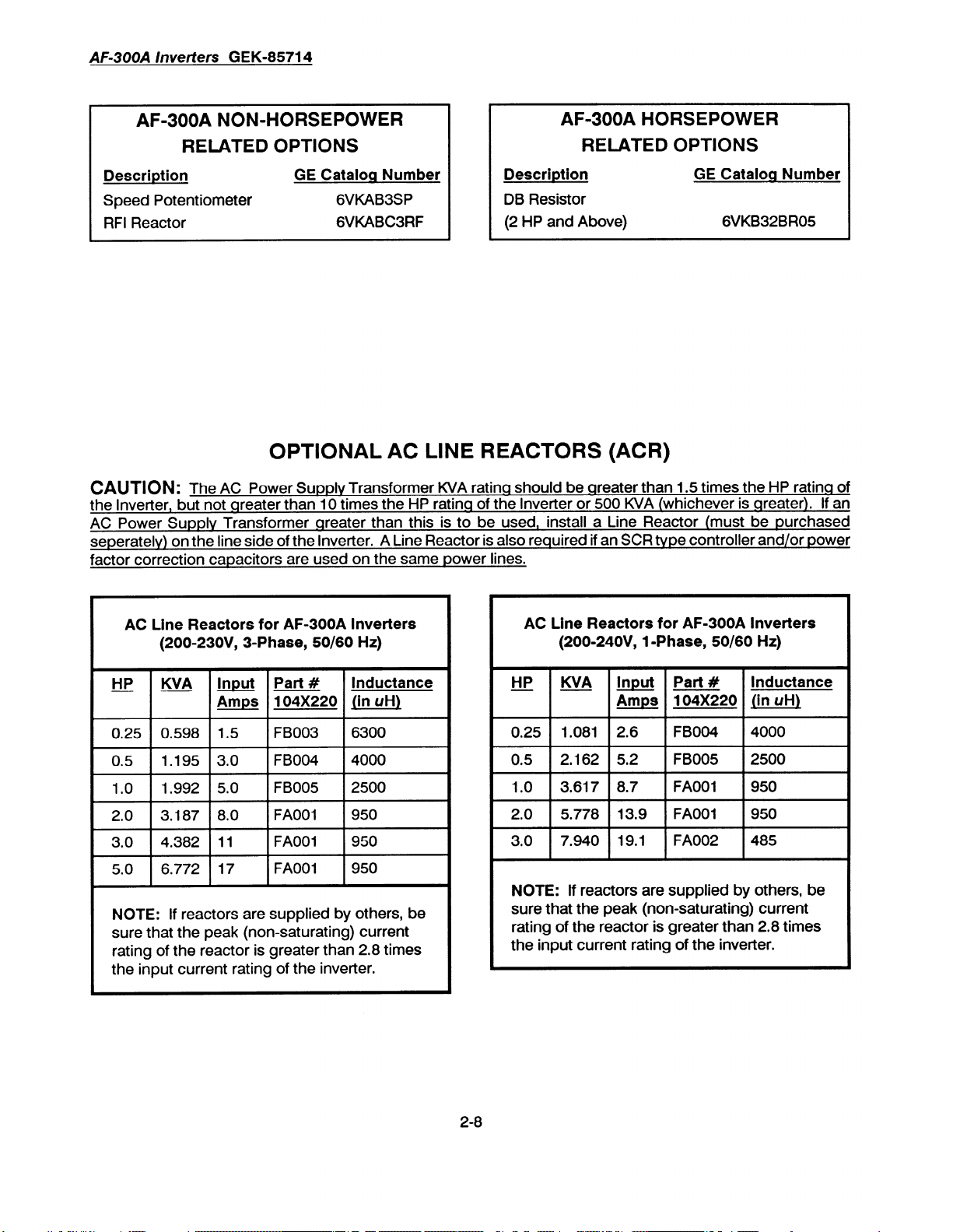

AF-300A NON-HORSEPOWER

RELATED OPTIONS

Description

Speed Potentiometer 6VKAB3SP

RFI Reactor 6VKABC3RF

GE Catalog Number

Description

DB Resistor

(2 HP and Above)

AF=300A HORSEPOWER

RELATED OPTIONS

GE Cataloq Number

6VKB32BR05

OPTIONAL AC LINE REACTORS (ACR)

CAUTION:

the Inverter,

AC Power Supply Transformer qreater than this is to be used, install a Line Reactor (must be purchased

seperately) on the line side of the Inverter. A Line Reactor is also required if an SCR type controller and/or power

factor correction

The AC Power Supply Transformer KVA ratinq should be qreater than 1.5 times the HP ratinq of

but

not qreater than IO times the HP ratinq of the lnverter or 500 KVA (whichever is qreater).

capacitors

are used on the same power lines.

If an

AC Line Reactors for AF-300A lnverters

(200=23OV,

HP WA Input Part #

0.25 0.598

05 . 1.195

10 . 1.992

2.0 3.187

3.0 4.382

5.0 6.772

NOTE:

sure that the peak (non-saturating) current

rating of the reactor is greater than 2.8 times

the input current rating of the inverter.

If reactors are supplied by others, be

3=Phase, SO/SO Hz)

Inductance

Amps lin uH)

1.5 FB003

3.0 FB004

5.0

8.0

11 FAOOI

17 FAOOI

104X220

FBOO5

FAOOI

6300

4000

2500

950

950

950

AC Line Reactors for AF-300A lnverters

(200-24OV,

HP WA Input Part #

0.25

1 1.081 1 2.6

0.5

1 2.162 1 5.2 1 FBO05 1 2500

1 .O 1 3.617 1 8.7

2.0 1 5.778 1 13.9 1 FAOOI

3.0 7.940

NOTE:

sure that the peak (non-saturating) current

rating of the reactor is greater than 2.8 times

the input current rating of the inverter.

If reactors are supplied by others, be

1 -Phase, SO/SO Hz)

104X220

1 FBO04 1 4000

1 FAOOI

19.1 FA002

Inductance

(in uH) Amps

1 950

1 950

485

2-8

Page 21

AF-300A

/metiers GEK-85714

3. INSTALLATION GUIDELINES

INSTALLATION ENVIRONMENT

Install the inverter in a location that meets the following requirements:

-0

The ambient temperature is between -1oOC

and +5OC* (+14oF to +122oF).

-- The relative humidity is between 20% and 90%.

Avoid any location subject to dew condensation, freezing, or where the inverter would come

in contact with water.

-- Do not install in any location subject to direct

sunlight, dust, corrosive gas, inflammable gas,

water vapor, or oil mist.

-0

The inverter should be installed at an elevation

below 1000 meters (3281 feet) and vibration

should be less than 0.6G.

-- Wiring from lnverter to motor should be less

than 66 feet, otherwise a separation of 4 inches

may be required.

INSTALLATION MOUNTING

CLEARANCE

NOTE:

When installing two or more inverters

in close proximity, allow sufficient space as

shown in Figure 3-1 and install them in a horizontal row.

-0

See the appropriate view in Figure 3-2 for the

location and size of mounting holes.

-0

Install the rubber bushings supplied with the

inverter into the cable openings in the wiring

lead-in plate to prevent cable damage and to

minimize dust entry.

*+5(X is the maximum allowable ambient temperature with the ventilation cover removed. When ventilation cover is kept in p/ace, maximum ambient tem-

perature is 40°C (105°F).

CAUTION:

affects inverter life and reliabilitv, do not install the

inverter in anv location that exceeds the allowable

temperatures.

-- Install the inverter perpendicular to the ground

and with the lettering right side up. (If the

inverter is installed up-side-down or horizontally, heat build-up will occur.)

-- Install at a sufficient distance from other equipment, walls, or wiring ducts as shown in Figure

3-l (these clearances are required to allow for

proper cooling air circulation).

CAUTION:

ture of the cooling fins of the inverter rise to

proximatelv 90 degrees C (194 degrees F). For

this reason, the mounting wall must be of heat

resistant material.

Because the ambient temperature greatly

During operation, the tempera-

ap-

Figure 3-l.

Ovw

5’hhe*

(12 cm)

I

INVERTER MOUNTING CLEARANCE

(Open Installation)

3-l

Page 22

AF300A lnverters

GEK-85714

j-244,

(62)

370

'-66.5i-

,1.06

(271

-’ b.25 (61

l/2 HP UNITS*

Cable irdel

mlrl rubber

bus'ling

-6.69 (170 1-q

4

&25(6)

c&Ilk iiu

willl rubber

bushing .

-- .

1

1.32

w S!

l/4

HP UNITS

4 "

Caue nlet

tithrubber

bushirq

-- .

-I

2.70

(se 3

-i

m Rubber

1 .O HP UNITS *

bushing dimensions

Figure

2

to

5 HP UNITS

*For

1 -Phase versions

inverters, the 6.69 inch (170 mm) and 6.10 inch

(155 mm) dimensions are 8.7 inches (221 mm)

and 8.1 inches (206 mm) respectively. All other

dimensions remain as shown.

3-2. INVERTER EXTERNAL DIMENSIONS

3-2

of the l/2 and

1 .O

HP

Page 23

AF300A /metiers

GEK-85714

4.

WIRING PROCEDURES

REMOVE TERMINAL BLOCK COVER

Remove the terminal block cover as follows (see

Figure 4-l):

1. Remove the screw located at the bottom of the

cover (l/4 to 1.0 HP inverters do not have this

screw).

2. Press upward on bottom of cover and lift off.

3. See the appropriate view of Figure 4-1 for the

location of the

the

Control Circuit Terminal Block.

Main Circuit Terminal Block

and

MAIN CIRCUIT WIRING

CAUTION:

connected to the U, V, W terminals or the N, P, P, DB

terminals.

1. Connect the incoming AC power supply wires to

the terminals of the Main Circuit Terminal Block as

shown in the appropriate view of Figure 4-2.

TABLE 2 for description of all terminals and TABLE

3 for application wiring list.)

Be sure that the power supply is never

(See

NOTE:

Motor will rotate counterclockwise when

viewed from the load side when connected normaly.

If the motor rotates in reverse direction, interchange

any two of the U, V, or W terminal connections.

3. Connect the ground terminal as shown in the

appropriate view of Figure 4-2. (Do not operate

without the unit being grounded.)

-- The ground wire must be as large and short as

possible (see TABLE 3 for application wiring

.

.

list)

CONTROL CIRCUIT WIRING

lnverter is wired at shipment for operation and frequency setting through the

is set at 60 Hertz).

-- See Figure 4-3 for wiring connections.

-- See TABLE 2 for description of all terminals.

Make wire connections as shown in Figure 4-4 for

external operation

-- See TABLE 2 for description of all terminals.

through control circuit terminals.

keypad panel

(frequency

2. Connect the 3-phase motor wires to the U, V, and

W terminals of the Main Circuit Terminal Block as

shown in the appropriate view of Figure 4-2.

TABLE 2 for description of all terminals and TABLE

3 for application wiring list.)

Loo*en

SU8W

Figure 4-1.

(See

TERMINAL BLOCK COVER

Push up W@

and the cow

will be refnoved

88SllY

I

Control &cut

A

Main &cut tefmlnal

terminal

4-l

Page 24

AF300A

lnverters GEK-85714

l/4 to 1 .O HP lnverters

I I -

Ll L3

50/60

Hz, l-Phase AC

200-240

f

u v bJ

INDUCTION MOTOR

Volts

2 and 3 HP lnverters

3-Pt-msE

-

- 1

Figure 4-2 (Part 1 of 2).

2

CR

?

W/60

)

200-240 Volts

)

?

Hz, l-Phase AC

Tt-ERMfX

3-WRSE

INDUCTION MOTOR

+

RELAY

POWER CIRCUIT WIRING CONNECTIONS FOR I-PHASE INVERTERS

4-2

Page 25

AF-300A hverters

GEK-85714

l/4 TO 1.0 HP

50/60 HZ, 3-PHRSE AC

288 to 230 VOLTS

2

TO 5 HP

UNITS

3-FvwSE

INDUCTION MOTOR

UNITS

Figure

4-2

(Part 2 of 2).

Ll

L2 L3 N P P DB U V W

1

-

'r'4y?

2

-

- 1

’ ’ ’ - ACR

CB

Y- Y’ Y’

50/60 HZ, 3-PHfSE RC

200 to 230 VCXTS

\

6 \ \

5

\

3-PI-WE

INDUCTION MOTW

THERMFtL

+

RELRY

POWER CIRCUIT WIRING CONNECTIONS FOR 3-PHASE INVERTERS

4-3

Page 26

AF300A /metiers

v t

30C 30A THR RST/BX FWD REV FM Xl X2 1 1 12

I

-

GEK-85714

l/4

TO 1.0 HP UNITS

L

13 CM

2

TO 5 HP UNITS

AF-388FI

CM 11 12 13 FM THR RST/BX FWD REV Xl

c

TOR

FP

T RMAL

RELfW SWITCH

IA/

EXTERNFIL

THERMAL

I

I

X2 30C 30Fl

-

F-

Xl CAUTION:

REMOVE JUMPER FROM BETWEEN

TERMINfXS THR AND CM NHEN

THERMAL INTERLOCKS WE USED.

XZ CWTION:

REMOVE 3UMfER FROM BETWEEN

TERMINALS FWD f3ND CM.

NOTE: SET FUNCTION CODE 01= 0.

Figure 4-3

Operation From Keypad

(Part 1 of 2). CONNECTIONS FOR OPERATION THROUGH KEYPAD PANEL

4-4

Page 27

RF-388A

30C

l

I

-

AF-3OOA Invertem

l/4

TO 1.0 HP UNITS

~.

30A

THR RST/BX FWD REV FM Xl X2 1 1 12 13 CM

*2

FWD

MOTOR

TmF7-

A’

kr

*1

GEK-85714

.

>

HF-388A

CM 11 12

2

TO 5 HP UNITS

13 FM THf? RST/BX FWII REV Xl

1

X2 30C 30R

Xl

CRUTION:

REMOVE JJUMPER FROM BETWEEN

TERPlINflLS THR AND CM WHEN

THERMFtL INTERLOCKS FRE USED.

X2 CFlUTION:

REMOVE JUMPER FROM BETWEEN

TEf?MINALS

NOTE: SET FUNCTION CODE 01s 0.

FWD f'3ND

CM.

Operation From Keypad With Reversing Capability

Figure 4-3

(Part 2 of 2). CONNECTIONS FOR OPERATION THROUGH KEYPAD PANEL

4-5

Page 28

AF-300A

/metiers GEK-85714

l/4

TO

1.0

HP UNITS

r

30C 30FI THR RST/BX FWD REV FM Xl X2 1 1 12

I

I

MOTOR

THERMFIL

RELfIY

XTERNFIL

F

l-l RMRL

SW TCH 5

I

*1

2

TO 5 HP UNITS

RF-38WI

1

CM

1 I

11 12

1 I I

13 FM THR RST/BX FWD REV Xl

I

I

13 CM

I I

SPEED

lKR, 1/2W

1

POT

X2 30C 30A

*

+

.

t

i

w

FLED1 /p2owT

9

MOTOR EXTERML

THERMAL

RELFIY

THERMRL

SWITCH

Xl

CAUTION:

REMOVE JUMPER FROM BETWEEN

TERMINRLS THR AND CM WHEN

THERMAL

X2

CFKJTION:

REMOVE JUMPER

TERMINFILS FWD

NOTE: SET FUNCTION CODE 81= 3.

INTERLOCKS

r

ARE

USED.

FROM BETWEEN

F)ND

CM.

Operation From Remote

Figure

4-d (Part 1 of 2). CONNECTIONS FOR CONTROL CIRCUIT TERMINAL OPERATION

4-6

Page 29

l/4

TO 1.0 HP UNITS

.

30C 30A THR RST/BX FWD REV FM

1

I

*2

AF-300A

Xl X2 11 12

SPEED POT

lKn,

/metiers GEK-85714

13

.

143

CM

RF-388A

CM I1 12

(XX9

I

2

TO 5 HP UNITS

.

13 FM THR RST/BX FWD REV Xl

*2

1

x2 30c 3OA

I

-

#l

CRUTION:

REMOVE JUMPER FROM BETEEN

TERMINF)LS THR

THERMHm INTEf?LOCKS f+?E USED.

#2

CHJTION:

REMOVE JUMPER FROM BETEEN

TERMINFILS FWD fbdl CM.

NOTE: SET FUNCTION CODE 81~ 3.

AND

CM I44EN

Figure

Operation From Remote With Reversing Capability

4-4 (Part 2 of 2). CONNECTIONS FOR CONTROL CIRCUIT TERMINAL OPERATION

4-7

Page 30

AF-300A lnverters GEK-85714

CAUTION:

The contrd circuit terminal wiring should

be kept as far awav as possible from the main power

wirino to prevent operational error due to noise interference. Never install both tvpes of wiring in the same

duct or conduit. (A separation distance of 10 centimeters [4 inches] or more is recommended.) If the

control circuit wiring must cross the main power wiring, it should cross at a right angle.

CAUTION:

Use shielded or twisted wire for the

control circuit wiring (wiring should be as short as

possible, i.e. 20 meters 165 feet] or less). (Connect

outer covering of the shielded wires to the inverter

ground terminal and leave the other end open, but

taped.)

CAUTION:

Install a suppressor in parallel with any

relays or solenoid type coils, etc. that may be close to

the inverter.

OPTIONAL EXTERNAL DYNAMIC

BRAKING RESISTOR UNIT WIRING

NOTE:

CM - THR terminals. If the jumper is not removed, the

OH2 alarm will not function during operation.

When frequent braking or high torque braking is

required, connect the optional braking resistor as

shown in Figure

OWL

CAUTION:

nals are inadvertently short-circuited, damage to the

inverter will result.

CAUTION:

used except for inverters above 1.5 KW (2 HP).

WARNING - FIRE HAZARD: Use

namic braking resistors that are provided by GE

Drive Systems. These are special resistors that

have a thermal fuse built in that opens if the

resistor gets too hot. This fuse should only open

if the DB transistor in the inverter or DB unit fails

short circuited. The resistor will need to be replaced if this happens.

Remove the factory installed jumper from the

4-5

(available for

If the P-DB terminals or the P-N termi-

The external braking resistor cannot be

2-5

HP inverters

only dy-

Figure

\

2 TO 5 HP UNITS ONLY

CM [

Ll L2 L3 N P P DE U V W

THERMAL

FUSE

1 THR 1

I

P DB 1 2

.

I

BRAKING

RESISTOR

I I

L

L

THERMAL

SWITCH

1

/

4-5. OPTIONAL EXTERNAL DYNAMIC BRAKING RESISTOR UNIT WIRING CONNECTIONS

4-8

Page 31

AF300A lnverters GEK-85714

* THERWiL RELAY

Ll

I

*-OPTION

RF-300fl

3

n

13

12

11

E(G)

E(G)

DB

N

SISTOR UNIT

P

P

Q

AND

,-----e---w-,

-

GROUND

FIBOVE 1

ANY F)DDITICMK

NOfWRLY CLOSED

INTERLOCKS

BE ADCUI

8

I

:

I

f

I

SHOULD ’

IN

SERIES

I 3:

Figure 4-6.

BASIC CONNECTION DIAGRAM

4-9

Page 32

AF-300A hverters GEK-85714

TABLE 2: TERMINAL IDENTIFlCATION/FUNCTlON

Terminal Terminal

Label

MAIN

CIRCUIT:

L1 J-a

L3

Name

AC Supply Line

Input Terminals

Function

Connection for commercial power (ZOO-230 VAC).

ww

P,DB

W

E (G)

CONTROL

INPUT:

11

12

13

lnvefter

Terminals

External Braking

Resistor Terminals

External DC Bus

Terminals

Ground Terminal

Frequency Setting

Common Terminal

Frequency Setting

Signal Input

Frequency Setting

Power Supply Term.

Control Circuit

Common Terminal

Output

Connection for 3-phase induction motor.

Connection for external braking resistor (1.5 KW (2 HP] or more).

May be used to check DC bus voltage. Not present on

on l/4 to 1 .O HP inverters.

Connection for ground.

Voltage setting and current setting common terminal. (Do not

connect to CM terminal as they are not isolated.)

0 to + IO VDC input when SW6 is in the 2-3 position.

4 to 20 milliamp input when SW6 is in the 1-2 position.

Regulated + 10 VDC power supply for speed pot only, 1 OmA

maximum output current (with respect to terminal 11).

Common terminal for control input/output commands. (Do not

connect to terminal 11 as they are not isolated.)

FWD

REV

RST/BX

THR

Forward Command

Input Terminal

Reverse Command

Input Terminal

~-

External RESET and/

or Coast-To-Stop

External thermal relay,

external braking resis-

tor thermostat terminal

Forward command via FWD-CM (closed). Reverse command via

REV-CM (closed). When FWD-CM is closed and REV-CM is closed

at the same time, the inverter will decelerate to stop.

Signal during STOP due to fault - Alarm RESET

Signal during Act. and steady state running to STOP - Inactive

Signal during Dec.

With THR-CM (open), motor will coast-to-stop.

NOTE:

thermostat, the THR-CM terminals must be closed or the inverter will

not operate.

With no external thermal relay or external braking resistor

4-l 0

- Motor will coast-to-stop

Page 33

AF300A /metiers GEK-85714

TABLE 2: TERMINAL lDENTIFICATION/FUNCTlON

Terminal

Label

CONTROL

INPUT:

(cont.)

Xl, x2

Terminal

Name

Multi-step Frequency

Operation Command

Input Terminals

Number 2 Acc./Dec.

Selection (when set as

poq, [900])

Function

Xl -CM

X2-CM

Selected

Freq.

Xl -CM

X2-CM

Selected

Freq.

Acc./Dec.

OFF

OFF

Touch Panel/

Terminal 12

OFF

OFF

Touch Panel/

Terminal 12

Act. (F.C. 4)

Dec. (F.C. 5)

ON

OFF

Multi-Freq.

Setting 1

(F.C. 7)

ON

OFF

Multi-Freq.

Setting 1

(F.C. 7)

Act. (F.C. 4)

Dec. (F.C. 5)

(continued)

OFF

ON

Multi-Freq.

Setting 2

(F.C. 8)

OFF

ON

Touch Panel/

Terminal 12

Number 2

AccJDec.

(F.C. 6)

ON

ON

Multi-Freq.

Setting 3

(F.C. 9)

ON

ON

Multi-Freq.

Setting 1

(F.C. 7)

Number 2

Acc./Dec.

(F.C. 6)

CONTROL

OUTPUT:

30A

3oc

Analog Frequency

Meter Terminal

Fault Relay Output

Terminals

Outputs + 10 VDC at maximum frequency and is proportional to

output frequency down to 0 VDC. Adjustable maximum voltage of

+6.5 to + 10.5 VDC.

DC Volt Meter internal impedance over 1 OK ohm can be connect-ted

to this terminal (maximum two).

During normal operation, the relay is not energized. When a fault

is detected, the relay is energized and contact is made between 30A

and 30C. (Contact rating resistive load: 250 VAC, 0.3 Amps @ cos

theta > 0.3)

4-l 1

Page 34

AF300A

lnverters GEK-85714

WARNING - FIRE HAZARD:

User must provide overload protection for the motor and wiring because

this function is not provided by the AF-300A. See Figure 4-6 “Basic Connection Diagram” for typical wiring

of an overload relay. Wire size recommendations shown in Table 3 and fuse size recommendations shown

in Table 10 of this Instruction Book are based on overload protection being provided by the user.

TABLE 3: APPLICATION OF WIRING AND EQUIPMENT

I

ITEM

Inverter

HP

,

Standard Applicable

Motor Output-230v (KW)

Rated

Capacity-230V (KVA) (*I)

Applicable

Main Circuit Wiring (200-23OV, 3-Ph.)

Main Input Circuit Wiring

(200=24OV,

Main Output Circuit Wiring

(200,24OV, I-Phase)

Control Circuit Wiring

.

Wire Sizes (AWG) (*2)

l-Phase)

114

0.2 0.4 0.8

0.57 1.1 1.9

14 14 14

14 14 14

14 14 14

m

20 (twisted, shielded)

SPECIFICATION

1.0

2.0 3.0 5.0

1.5 2.2 3.7

3.0 4.2 6.5

14 14 12

12 10 N/A

14 14 N/A

”

I

(*I)

Indicates rated capacity when rated output voltage is 230

(*2) Standard wire is 600V vinyl wire.

VAC.

4-12

Page 35

AF-300A lnverters

5. INVERTER OPERATION

GEK-85714

PRE-OPERATION INSPECTION

After mounting and wiring has been completed, check

the

inverter for the following items before applying AC

power:

--

Check for

wiring).

-- Verify that there are no wiring chips, screws,

etc. remaining in the inverter.

-- Check that all screw and terminal connections

are

-- Verify that no exposed wire ends are touching

other terminals.

WARNING -

HAZARD:

FWD-CM or REV-CM terminals connected, the

driven motor starts automatically at Power-Up or

by pressing the RESET key to reset the inverter.

When AC

RUN

key is pressed,

according to the

(Use

the

STOP

If a test run is desired,

frequency of around

a safe manner and

-- Smooth

-- Correct direction

-- Any abnormal vibration or noise in the motor.

-- Smooth speed increase and speed reduction.

wiring errors (especially main circuit

tight.

MECHANICAL MOTION

When &wire control is used with the

power is

applied to the inverter and the

operation will be at 60 Hertz

Function Code set at the factory.

key to

halt operation.)

run the inverter at a low

5 Hertz. Conduct the test run in

check for the following:

rotation of motor.

of rotation.

CAUTION:

the inverter terminals or control circuit terminals. For

meooer testing method, refer to Section 6, Maintenance and Inspection.

Do not conduct meager tests between

SELECTION OF OPERATING METHOD

The AF-300A provides five type of operating methods. See TABLE 4

for list of operating methods and

refer to Figure 5-1 for identification of the components

of

the Keypad Panel.

FUNCTION CODE AND DATA

SETTING PROCEDURES

In order that the inverter (including the motor) may

operate under optimum conditions, Function Code

data setting changes may be required. This

graph is a general explanation of the Function Code

data setting methods.

NOTE: Complete details

are shown in TABLE

10:

Function Code Descriptions. Be sure to fully

for Function Code settings

9:

Function Codes, and TABLE

understand all Function Codes.

para-

TABLE

Method # RUN & STOP

RUN Key

,

STOP/RESET Key

External Signal

FWD and REV Term.

Multi-Frequency Setting (maximum of 4 steps)

-- #I Frequency is set by Function Code

-- #2, #3, and #4 Frequencies are set by Function Codes [7 - -1, [8 - -1,

and [9 - -1 and selected by external signal combinations of Xl and X2.

I

4:

OPERATING METHODS

Frequency Setting

Increment and Decrement Keys

Potentiometer or Analog Signal

Increment and Decrement Keys

Potentiometer or Analog Signal

[Ol -1

5-1

Function Code

[Ol 0] (Factory Set)

Wll

P121

co1 31

Page 36

AF-300A lnverters

GEK-85714

Function indication

Up/Down keys

Figure

$ Program key (Shift key)

’

5-1. KEYPAD PANEL COMPONENT IDENTIFICATION

Data indication

KEY DESCRIPTIONS

PROGRAM (SHIFT) Key

selection key. Press to select Programming Mode

and first digit of Function Code will blink. Press to

advance selection to the next Function Code until

the disired one is reached. Any data changes are

automatically set when key is pressed to advance

to another Function Code.

UP/DOWN Keys

- These keys increase or decrease

the frequency (or speed) of the inverter when in the

Operating Mode. When in Program Setting Mode,

they change the Function Code or Data Code

values.

RUN Key

- Key is used for starting operation. This

key does not function when Data Code is set for

external (control terminal) operation (Function Code

012 and 013).

STOP (RESET) Key

operating normally and Resets any Fault Trips

when invetter has stopped abnormally. The STOP

function of this key does not function when Data

Code is set for external (control terminal) operation

(Function Code 012 and 013). (Pressing may

cause OH2 trip.)

- Programming Mode

- Stops inverter when it is

INDICATOR DESCRIPTIONS

FUNCTION INDICATOR

indicated by the first and second digits when in the

Programming Mode. When in the Operating Mode,

setting frequency, output frequency , and alarm

messages are indicated.

DATA INDICATOR - Data Code is indicated by the

second and third digits when in the Programming

Mode*. When in the Operating Mode, setting

frequency, output frequency, and alarm messages

are indicated.

*When looking at Function Codes

the data is in the first digit and the Function Code is

in the second and third digits. When looking at

Function Codes I through F, the data is in the first

and second digits and the Function code is in the

third digit.

- Function Code is

00

through 04,

5-2

Page 37

AF3OOA lnverters

GEK-85714

Chanqinq Function Code

Mode:

NOTE: Function

Code setting will be disp/ayed in the

Settinqs In STOP

following order when inverter is stopped:

76.

7. [00 -1

2. [Ol -1

3. [02 -1 8. [3 - -1 73. [8 - -1

4. [03-l

5. [04 -1

6. [l - -1 77. [6 - -1

7. [2 - -1 72. [7 - -1

9. [4 - -1 74. [9 - -1

70. [5 - -1 75.

[A - -1

[b - -1

77. [C - -1

78.

[d--l

79.

[E - -1

20.

[F - -1

See TABLE 5 forwfiich Function Codes can be changed

while inverter is operating.

1.

Verify operation signal

terminal signals) is completely in

(RUN

key, FWD and REV

OFF

mode.

-- The frequency that has been set will blink on

the display.

-- If display shows Function Code [030], press

STOP

key, then press and hold

PRG/SHIFT

key until the set frequency is shown (blinking).

2.

Press

PRG/SHIFT

key to change to Function Code

Setting Mode.

-- When key is pressed, Function Code will activate and display will show [000] (first digit will

be blinking).

3.

Continue to press

PRG/SHIFT

key to advance

Function Code (advances each time key is pressed)

until desired one is reached.

-- First digit of Function Code will be blinking.

4.

Press

Increment or Decrement

keys to change

data value of the selected Function Code.

-- Data will be shown in the second and third

positions of the display

Chanqinq Function Code Settinqs In RUN Mode:

NOTE:

Function Code setting will be displayed in the

following order when inverter is running:

7. [03 -1 3. [3 - -1 5. [5 - -1

2. [2 - -1 4. [4 - -1 6. [6 - -1

These are the on/y Function Codes can be changed

while inverter is operating (see TABLE

1. Press

PRG/SHIFT

key to change to Function Code

5).

Setting Mode.

-- When key is pressed, Function Code will activate and display will show [030] (first digit will

be blinking).

2.

Continue to press

PRG/SHIFT

key to advance

Function Code (advances each time key is pressed)

until desired one is reached.

-- First digit of Function Code will be blinking.

3.

Press

Increment or Decrement

keys to change

data value of the selected Function Code.

-- Data will be shown in the second and third

positions of the display

4.

Press

PRG/SHIFT

key to enter data (set in step 3)

into memory and advance to next Function Code.

-- Display will show existing data.

5. Repeat steps 2 through 4 until all desired data

changes have been completed.

-- Display will show any adjustments as they are

made.

6. Press and hold the

PRG/SHIFT

key to store the

data adjusted in step 5 and advance display to the

set frequency (not blinking).

5.

Press

PRG/SHIFT

key to enter data (set in step

into memory and advance to next Function Code.

-- Display will show existing data.

6.

Repeat steps 3 through 5 until all desired data

changes have been completed.

-0

Display will show any adjustments as they are

made.

7.

Press and hold the

PRG/SHIFT

key to store the

data adjusted in step 6 and advance display to the

set frequency (shown blinking).

lnverter is now ready for operation again.

4)

5-3

lnverter is now in Operation

Mode again.

Page 38

CONTROL CIRCUIT CONNECTION

AND OPERATION

Basic connections

Codes

[OlO]

(these connections are done at factory).

Common terminal connections

regardless of Function Code are shown in Figure

Connection description is as follows:

--

30A, 30C

circuits, etc.

--

FM

- Used for external analog meter when fre-

quency indication is needed.

- THR

- Connected to CM terminal at factory.

Connects to a normally closed contact. When

inverter STOP is desired through external alarm,

(thermal overload relay for motor, heat sensor

for DB resistor, etc.)open this contact.

RST/BX

mentary contact for resetting a fault externally

during stop.

CM

- Zero volt terminal (common).

that are required for Function

and

[Ol l]

are shown in Figure 5-2

that are required

- Fault Relay Output used for alarm

- Connects to a normally open mo-

5-3.

Keypad Panel Operation [Ol 01, [Ol l] terminal connections

that are required are shown in Figure 54.

Connection description/operation is as follows:

-- Wiring shown for this operation is FWD to CM Do Not remove this wiring.

-- Frequency Setting - If the Function Code setting is

[Oil],

the following three frequency

setting methods are available:

Connect potentiometer (1 K ohm. l/2 watt) to

terminals.1 3,

Input of 0 to +

12 (12

12,

10

is positive).

and

1 i. ’ *

VDC signal to terminals

,

11,

Connect analog current signal of 4 to 20mA

DC current signals to terminals

12, 11 (12

positive).

-- See Figure

5-5

for

RUN

Operation example.

is

l/4 to 1.0 HP Units

J--l- .

#K: 3oA THR RST!BX FWD

.

.

l/4 to 1.0 HP Units

4

? -

REV FM Xl X2 11 I2 13 CM

I I I

Figure 5-2.

i t _ A

FACTORY CONNECTIONS

CM 1 I 12 13

2 to 5 HP Units

p-7

FM THR

1

c

RST.‘BX FWD REV Xl X2 30C

I

6

3OA

4

2 to 5 HP Units

Figure 5-3.

COMMON TERMINAL CONNECTION EXAMPLE

5-4

Page 39

*

38C 38fi

CM

L

i

11

1

*

4

4

I

I

1

4

t

1

i

4

I

I

'Ax

l/4 to 1.0 HP Units

THR RST/BX FhID REV FM

A

2 to 5 HP Units

12

1

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

13

-a

b

I

4

I

I

I

t

I

I

I

#

I

I

I

I

I

FM THR

RST/BX FWD

AF-300A lnverters GEK-85714

Xl XZ 1 1 12

v

I

I

I I

I b

I I

I I

I I

I I

I

I

I b

I

I

!-xK

1

8

I

I

I

I

I

I

I

REV

A

Xl

x2 q38c 3im

13 CM

4

I

I

I

I

I

I

4

I

I

I

I

I

I

I

I

-.

4

.

.

NOTE: A/so

Figure 5-4.

refer to the respective

KEYPAD PANEL OPERATION CONNECTIONS

Function Codes as shown in Table 6.

Acceleration Time

Set By

Fun.

Code

4

RUN

I

Figure

5-5. KEYPAD PANEL WUNn OPERATION EXAMPLE

setting frequency

Deceleration Time

Set By Fun. Code 5

STOP

RESET

5-5

Page 40

AF’300A

lnverters GEK-85714

External Signal Operation [012], [013] terminal

connections

.

6

that are required are shown in Figure 5

Connection description/operation is as follows:

-- Remove factory installed wire from FWD to CM.

- Rotation Direction tary) between

between

NOTE:

the same time, the inverter will stop.

FWD-CM

REV-CM

If FWD and REVsignals are applied at

30C 30A THR RST/BX

,

CM 11

l

Make contact (momen-

for forward rotation or

for reverse rotation.

13 FM

12

.

.

L

,

*

8

.

:

,

n

8

e

8

t

t

t

b

t

t

t

b

t

.

t

8

,

,

t

8

t

8

t

t

t

#

I

,

I

*

I

,

8

-.

l/4 to 1.0 HP Units

r

FWD

REV FM Xl X2 11 12

2 to 5 HP Units

1

THR

RST/BX FWD REV X1

-- Frequency Setting - If the Function Code setting is

[013],

the following three frequency set-

ting methods are available:

Connect potentiometer (1 K ohm, l/2 watt) to

terminals 13,

12,

and

11.

Input of 0 to + 10 VDC signal to terminals

12 (12

is positive).

Connect analog current signal of 4 to 20mA

DC current signals to terminals

12, 11 (12

positive).

- See Figure

5-7

for

RUN

Operation example .

T

13

1

- -

-

I

t

I

x2 3BC 38fl

CM

,

I

4

11,

is

frequency

forword

reverse

1

Figure

Forward

Figure

*

w

5-6. EXTERNAL SIGNAL OPERATION CONNECTIONS

Reversible operation

5-7. EXTERNAL SIGNAL “RUN” OPERATION EXAMPLE

5-6

Page 41

AF-300A

/metiers GEK-85714

MULTI-STEP OPERATIONS

Terminal connections and Function Code selections

for Multi-Step Frequency Operation and Multi-Step

Acceleration and Deceleration Operation are as

described in the following subparagraphs.

Multi-Step Frequency Operation

terminal connections (Xl, X2 terminals) that are required are shown in

Figure 5-8. Multi-step Frequency Operation can be

used to select one of four different speed settings .

l/4 to

3BC 38A

CM

THR RST/BX FWD REV FM

2

to 5 HP Units

11

13 FM THR

12

Operation is as follows: