Page 1

AF-300

MICRO-$AVER

1/4 - 5 Horsepower

Instructions

II

TM

Page 2

General Information – AF-300 Micro-$aver II ™ Drive Instructions

These instructions do not purport to cover all details or variations in equipment, nor to provide for

every possible contingency to be met during installation, operation, and maintenance. Should

further information be desired or should particular problems arise that are not covered sufficiently for

the purchaser's purpose, the matter should be referred to GE Fuji Electric, Customer Service.

This document contains proprietary information of GE Fuji Electric and is furnished to its customers

solely to assist that customer in the installation, testing, and/or maintenance of the equipment

described. This document shall not be reproduced in whole or in part nor shall its contents be

disclosed to any third party without the written approval of GE Fuji Electric.

NOTE: The terms "inverter", "controller", and "drive" are sometimes used interchangeably throughout the industry. We will use the term "Drive" in this document.

AF-300 Micro-Saver II™ and X$D™ are trademarks of General Electric Company. Energy Saver®

is a registered trademark of General Electric Company.

The terms "AF-300 Micro-Saver II" and AF-300M$II will be used interchangeably throughout this

document.

WARNING: Always read the complete instructions

prior to applying power or troubleshooting the equipment

and follow all procedures step by step.

SHOCK HAZARD

voltage may be present. (Refer to Section 1: Safety Precautions for Warnings and Cautions.)

Blank space has been intentionally left at the bottom of each page for the convenience of the user

in documenting notes.

labels may be located on or inside the Drive to alert people that dangerous

i

Page 3

TABLE OF CONTENTS

Section Title Page

1. SAFETY PRECAUTIONS ..........................................................................1-1

2. DESCRIPTION, COMPONENT IDENTIFICATION,

AND SPECIFICATIONS ............................................................................2-1

General Description.................................................................................. 2-1

Delivery Inspection Procedures ............................................................... 2-1

Nameplate Data......................................................................................... 2-1

Drive Keypad Functions and Layout........................................................ 2-2

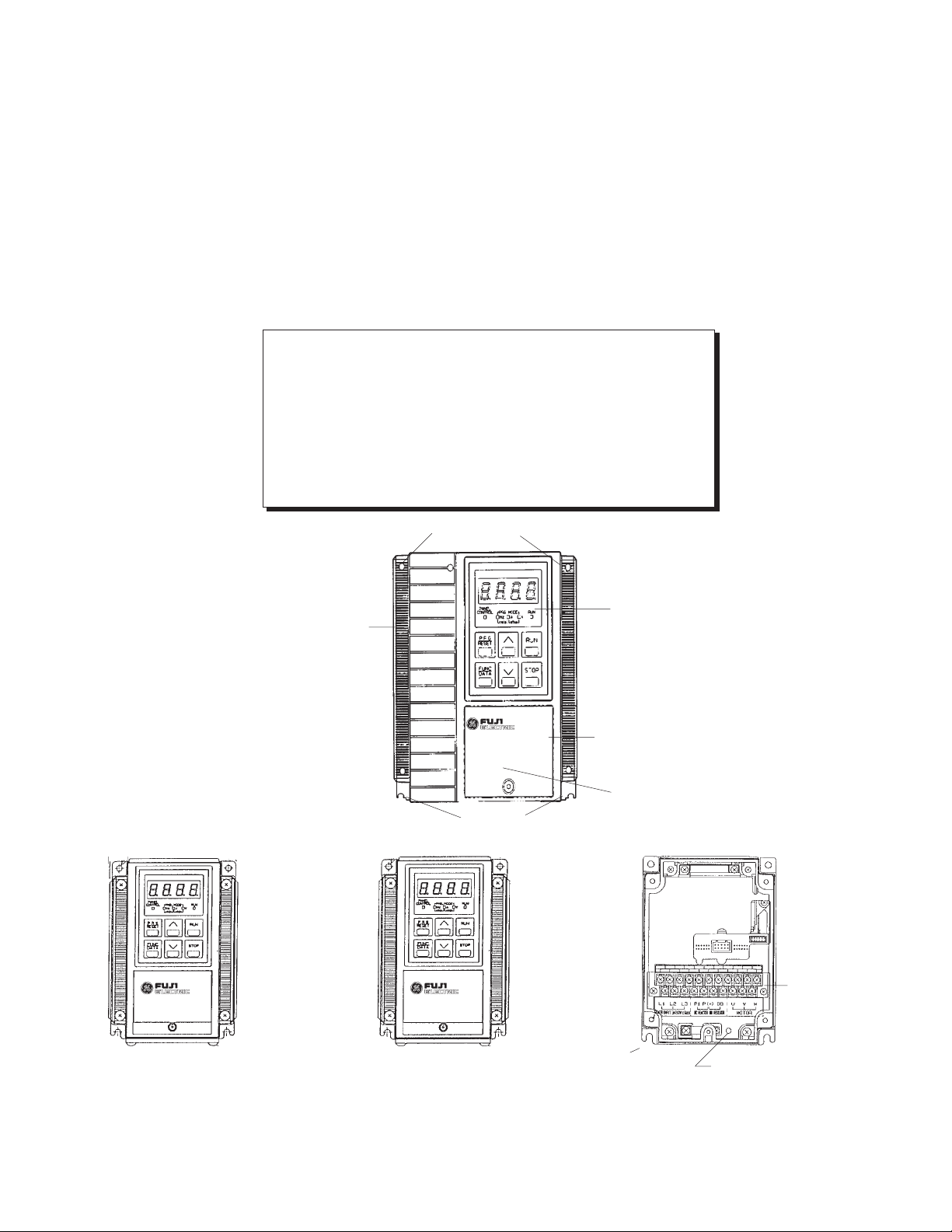

Drive Components .................................................................................... 2-3

Table 1: Standard Specifications.............................................................. 2-4

Table 2: Drive Dimensions ....................................................................... 2-7

Table 3: Drive Ratings, Efficiencies and Watts Loss................................ 2-7

3. INSTALLATION GUIDELINES ..................................................................3-1

Installation Environment.......................................................................... 3-1

Installation Mounting Clearance ............................................................. 3-1

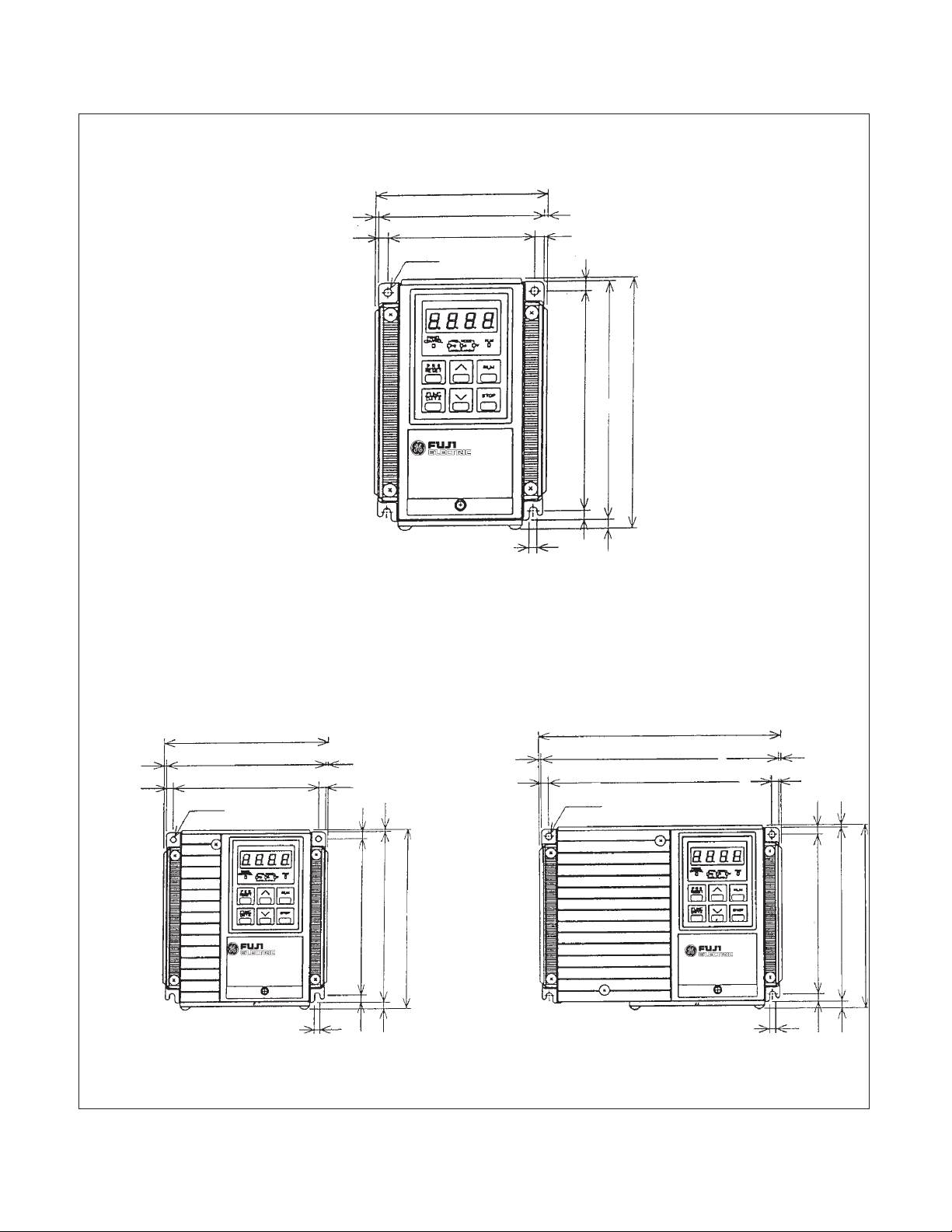

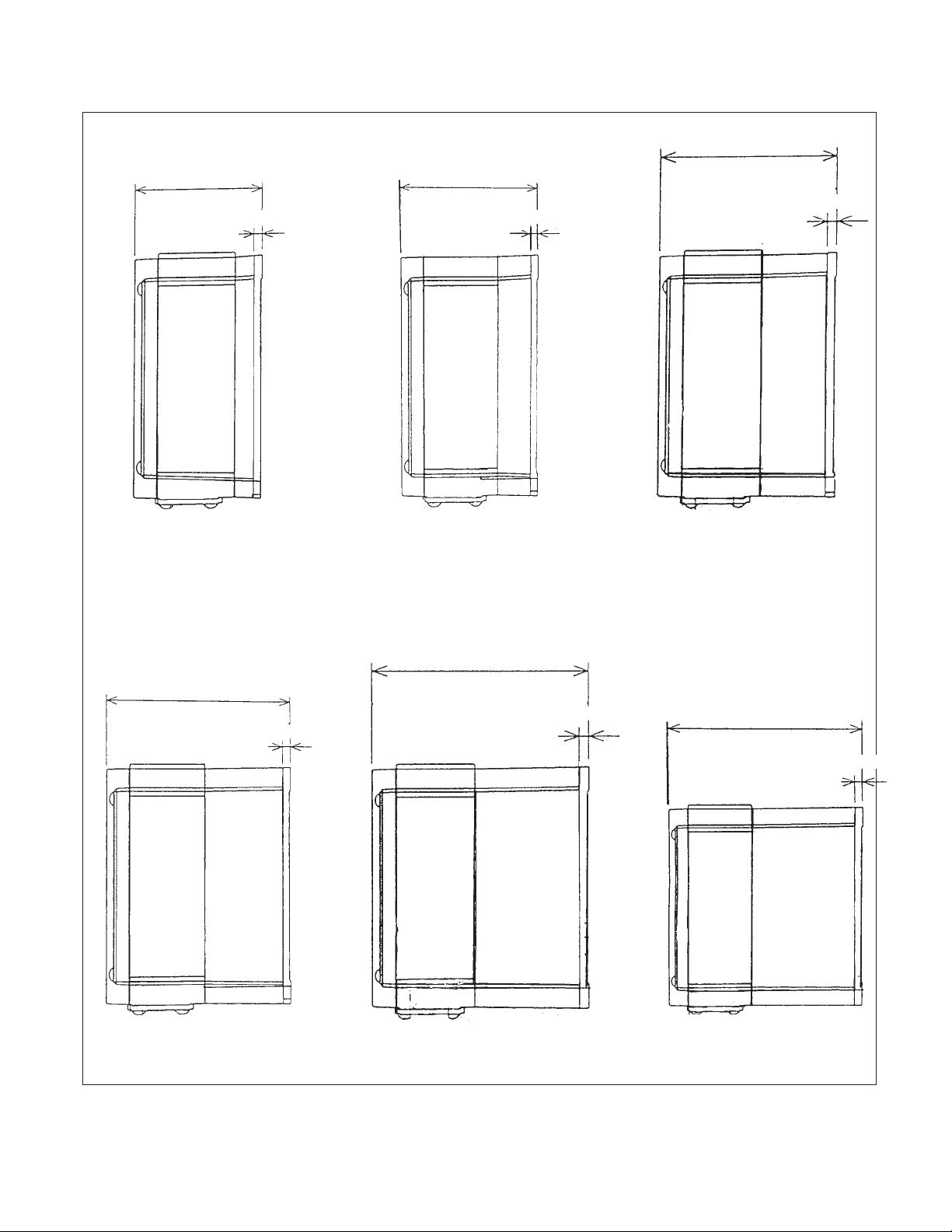

Dimension Drawings................................................................................. 3-2

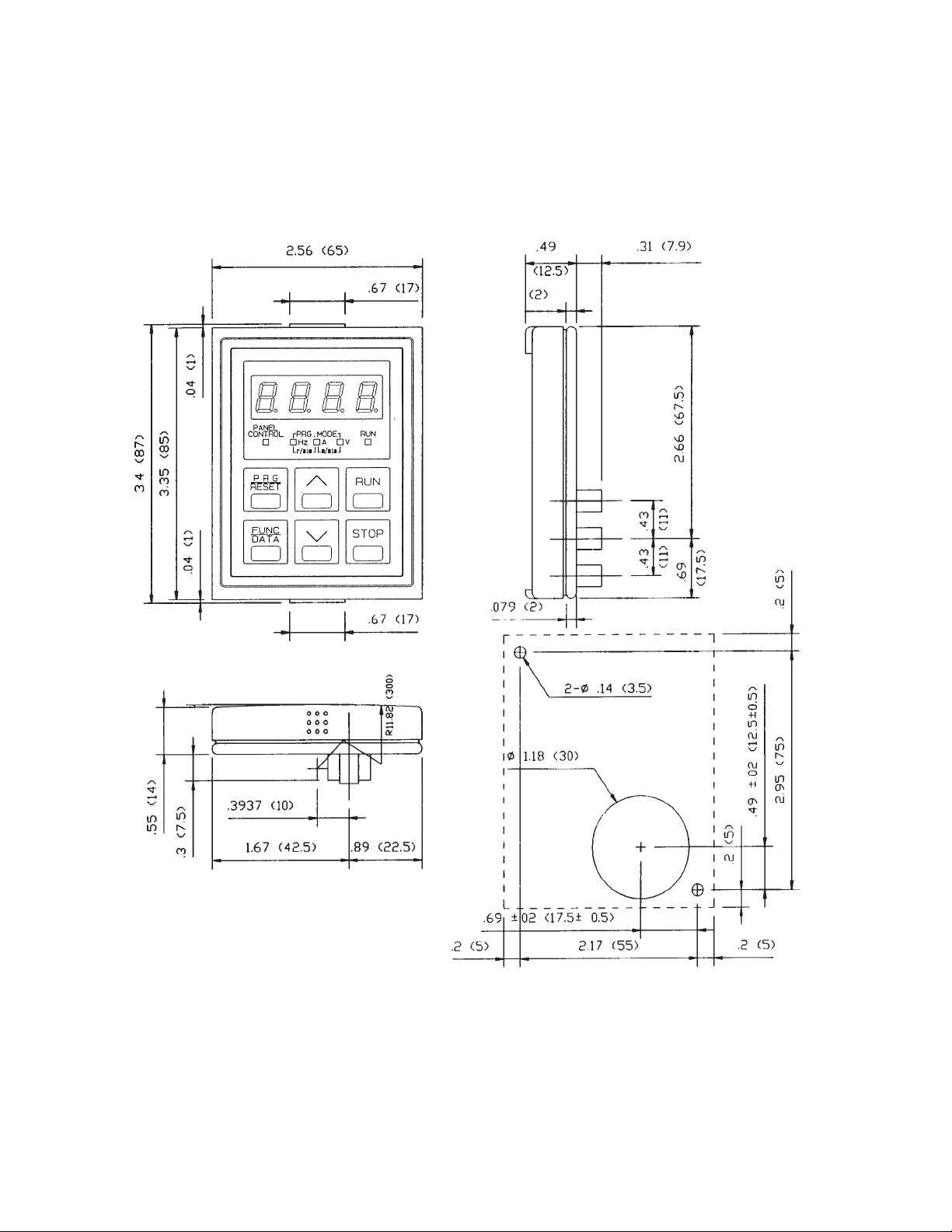

Dimensions of Keypad Mounting Holes.................................................. 3-4

4. WIRING PROCEDURES ...........................................................................4-1

Remove Terminal Top Cover................................................................... 4-1

Control Circuit Wiring.............................................................................. 4-2

Main Circuit Wiring .................................................................................. 4-3

Table 4: Drive Wire Size Recommendations ........................................... 4-4

and Circuit Protection Rating

Control/Circuit Terminal Block.............................................................. 4-5

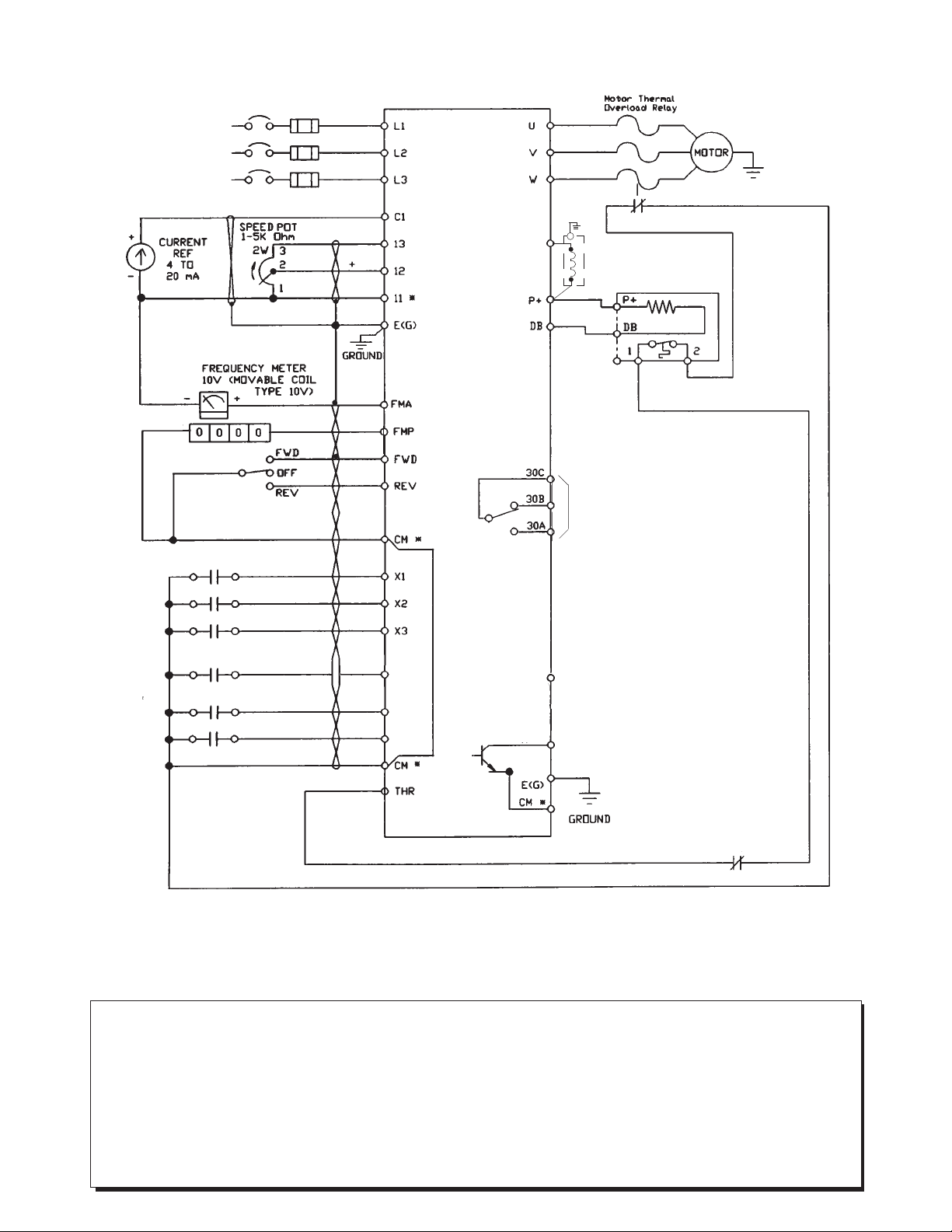

Drive Wiring Diagram............................................................................... 4-6

Table 5: Terminal Identification/Function ............................................ 4-7

Drive Interface Details .............................................................................. 4-9

5. DRIVE OPERATION ..................................................................................5-1

Keypad Panel Identification/Operation ................................................. 5-1

Function Code and Data Code Description/Selection .......................... 5-1

Keypad and Display Operation Programming ........................................ 5-2

Stop Mode ................................................................................................. 5-3

Run Mode.................................................................................................. 5-4

Program Mode while stopped .................................................................. 5-5

Program Mode while running.................................................................. 5-6

Trip Mode.................................................................................................. 5-7

Summary of Operating Modes ................................................................. 5-8

Pre-Operation Inspection......................................................................... 5-9

Table 6: Function Code List..................................................................... 5-10

6. FUNCTION CODE DESCRIPTIONS (01 thru 79) .....................................6-1

(Settings and Diagrams)

7. MAINTENANCE AND INSPECTION .........................................................7-1

Megger Test............................................................................................... 7-1

Periodic Parts Replacement ..................................................................... 7-1

Inspection Items........................................................................................ 7-2

Measurement Points and Meters ............................................................. 7-3

ii

Page 4

TABLE OF CONTENTS (continued)

Section Title Page

8. TROUBLESHOOTING............................................................................. 8-1

Table 8: Fault Condition Description and Operation ............................... 8-1

(1) Overcurrent ............................................................................................8-2

(2) Overvoltage ............................................................................................. 8-3

(3) Undervoltage ..........................................................................................8-4

(4) Drive Overheat........................................................................................ 8-5

(5) External Alarm Input ............................................................................. 8-5

(6) Drive Overload........................................................................................ 8-6

(7) Memory Error, Keypad Communication, CPU Error ..........................8-7

(8) Drive Output Circuit Error....................................................................8-8

(9) Motor will not run ..................................................................................8-9

(10) Motor will run but speed will not change ........................................... 8-10

(11) Motor will stall during acceleration .................................................... 8-11

(12) Motor Heating Abnormal ....................................................................8-12

9. WARRANTY PARTS AND SERVICE ..................................................... 9-1

Warranty Coverage..........................................................................................9-1

Out-of-Warranty Procedure............................................................................9-1

Motors.............................................................................................................. 9-1

In-Warranty Failure Check List................................................................. 9-2

(Data necessary for Warranty Administration)

AF-300M$II Spare Parts List ...........................................................................9-3

10. CE MARK .............................................................................................. 10-1

iii

Page 5

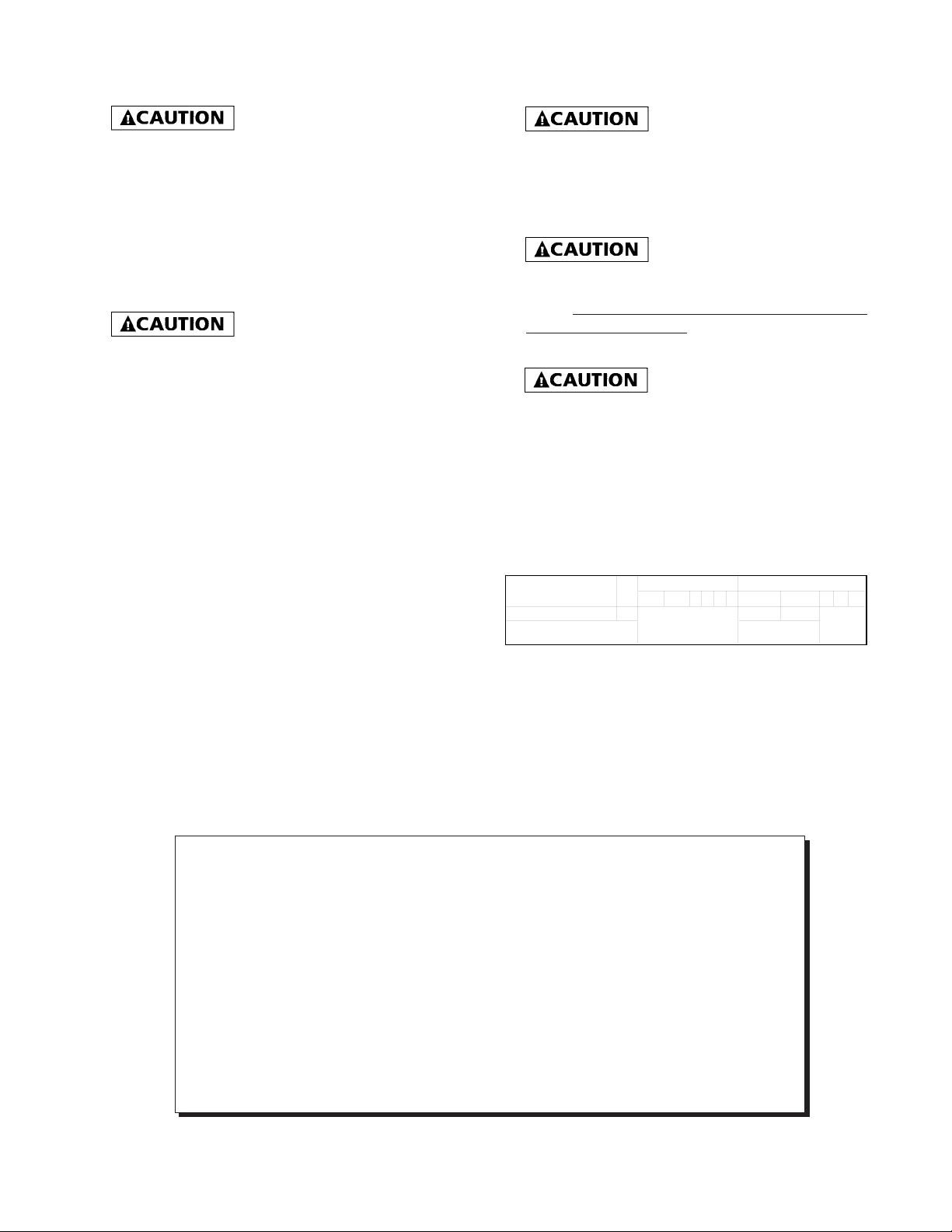

Section 1

SAFETY PRECAUTIONS

DANGER, WARNING, CAUTION AND NOTES

The following format is used on the equipment or found

in this manual. Read all labels and follow the directions

whenever working on the equipment.

WARNS ABOUT HAZARDS THAT

WILL RESULT IN IMMEDIATE SERIOUS PERSONAL

INJURY OR DEATH IF IGNORED.

Denotes operating procedures and

practices that may result in personal injury or loss of

life if not correctly followed.

Denotes operating procedures and

practices that, if not strictly observed, may result in

damage to, or destruction of the equipment.

NOTE: Notes call attention to information that is

especially significant in understanding and operating

the equipment.

DANGER, WARNING, CAUTION

AND NOTE P ARAGRAPHS WITHIN

THIS INSTRUCTION MANUAL

The above paragraphs list some general safety

reminders and safety recommendations to be followed

when operating or installing this equipment. These

safety precautions will be repeated throughout this

instruction book where applicable.

Due to CSA requirements, pertinent warnings are also provided in French and set off by ( )

1-1

Page 6

WARNINGS

MECHANICAL MOTION

HAZARD: Drive systems cause mechanical

motion. It is the responsibility of the user to

insure that any such motion does not result in

an unsafe condition. Customer provided

interlocks, and operating limits should not be

bypassed or modified.

ELECTRICAL SHOCK

AND BURN HAZARD: When using

instruments such as oscilloscopes to work on

live equipment, the oscilloscope’s chassis

should be grounded and a differential amplifier

input should be used. Care should be used in

the selection of probes and leads and in the

adjustment of the oscilloscope so that accurate

readings may be made. See instrument

manufacturer’s instruction book for proper

operation and adjustments to the instrument.

FIRE AND EXPLOSION

HAZARD: Fires or explosions might result

from mounting Drives in hazardous areas such

as locations where flammable or combustible

vapors or dusts are present. Drives should be

installed away from hazardous areas, even if

used with motors suitable for use in these

locations.

STRAIN HAZARD:

Improper lifting practices can cause serious or

fatal injury. Lift only with adequate equipment

and trained personnel.

ELECTRICAL SHOCK

HAZARD: All motor bases and equipment

enclosure housings should be grounded in

accordance with the National Electric Code or

equivalent.

(AVERTISSEMENT)

HAZARD OF ELECTRICAL SHOCK

(RIS QUE DE CHOC ELECTRIQUE)

- Separate motor overcurrent, overload, and

overheating protection is required to be

provided in accordance with the Canadian

Electrical Code, Part 1.

- (Le moteur dolt etre muni d'une protection

distincte contre les surintensites, la

surcharge et la surchauffe confrmement au

Code Canadian de L'electricite, premierb

partie.)

The Drive leakage current to

ground is higher than 3mA. Use grounding

conductor as specified in Table 250-95 of

National Electric Code, ANSI/NFPA 70-1993 or

Table 31 CSA22.2, No. 14-M91.

HAZARD OF MOTOR

OVERSPEED:

ANY APPLICATIONS REQUIRING OPERATION

ABOVE 120 HZ MUST BE APPROVED BY THE

MOTOR MANUFACTURER.

Bias frequency setting is available when analog

frequency setting method (i.e. the Function

code "01" data is set at 1) is selected. At the

stop condition, the reference frequency will be

blinking on the LED display. If the Bias

frequency is set at a certain level and the

reference frequency is Zero, during the stop

condition, the display will be blinking Zero.

Thus, when a RUN command is given to the

Drive, the motor will run at the Bias frequency

setting (up to 400 Hz) even if the reference

frequency is Zero.

With 400 Hz Drive output possible, the Drive will

allow the motor to run up to 6 - 7 times its base

speed. Never operate the motor above its top

mechanical speed or a catastrophic failure may

occur.

Before disassembling,

disconnect and lock out power from the Drive.

Failure to disconnect power may result in death

or serious injury. A bus charge Light "CRG"

provides visual indication that bus voltage is

present; verify the bus voltage level by

measuring the voltage between power terminals

P(+) and N(-) using an analog meter. Do not

attempt to service the Drive until the charge

indicator ("CRG" lamp) has extinguished and

the bus voltage has discharged to zero volts.

Replace all covers before

applying power to the Drive. Failure to do so

may result in death or serious injury.

1-2

Page 7

CAUTIONS

This product is suitable for use

on a circuit capable of delivering not more than

1,000 (1HP or less) or 5,000 (2 HP or more) rms

symmetrical amperes.

AC input fuses to be customer supplied and may

be branch circuit protection fused. The maximum

allowance fuse ratings per TABLE 4.

Do not connect power supply

voltage that exceeds the standard specified

voltage permissible. If excessive voltage is

applied to the Drive, damage to the internal

components will result.

Do not connect power supply to

the output terminals (U, V, W). Connect power

supply only to the power terminals (L1, L2, L3).

Do not connect power supply to

the breaking resistor connection terminals (P (+),

DB). Never short-circuit between P (+) – DB

terminals, and do not connect any resistance with

an ohm and/or wattage value less than standard

application breaking resistor.

Do not connect a power supply

to the control circuit terminals (except 30A, B, C,

maximum rating 250 volts, 0.3A ac/dc).

For RUN and STOP, use the

FWD-CM (forward) and REV-CM (reverse)

terminals. Do not use a contactor (ON/OFF)

installed on the line side of the Drive for RUN and

STOP.

Do not use a switch on the

output side of the Drive for ON/OFF operation.

Do not connect power factor

correcting capacitors on the output side of the

Drive.

Do not operate the Drive

without the ground wire connected. The motor

chassis should be grounded to earth through a

ground lead separate from all other equipment

ground leads to prevent noise coupling. The

grounding connector shall be sized in accordance

with the NEC or Canadian Electrical Code. The

connection shall be made by a UL listed or CSA

certified closed-loop terminal connector sized for

the wire gauge involved. The connector is to be

fixed using the crimp tool specified by the

connector manufacturer.

Do not perform a megger test

between the Drive terminals or on the control

circuit terminals.

The Drives are an IGBT drive

which develops an adjustable frequency via pulse

width modulation. While this does not present a

problem on 200-240 VAC applications, it may on

380-480 VAC applications. When using the

Drives on 380-480 VAC, get the motor

manufacturer's approval that his insulation system

can withstand the voltage spikes (up to twice the

dc bus voltage 2 x 621 VDC for a 480 VAC power

source of the Drive, in conjunction with the long

motor cable lengths). If the insulation system

does not meet this limit, utilize a RLC filter.

Because the ambient

temperature greatly affects Drive life and

reliability, do not install the Drive in any location

that exceeds the allowable temperature. Leave

the ventilation covers attached for temperatures

of 40 degrees C or below, and remove the

ventilation port side and top covers for

temperatures of between 40 (104° F) and 50

(122° F) degrees C. If the covers need to be

removed, another type of enclosure may be

required for safety purposes.

If the Drive’s Fault Alarm is

activated, consult the TROUBLESHOOTING

section of this instruction book, and after

correcting the problem, resume operation. Do

not reset the alarm automatically by external

sequence, etc.

Be sure to remove the desic-

cant packet(s) when unpacking the Drive. (If not

removed these packets may become lodged in

the fan or air passages and cause the Drive to

overheat.)

1-3

Page 8

CAUTIONS (continued)

AC induction motors require

that they be sized based on the applications speed

range and associated torque requirements for the

motor-Drive system; this is to avoid excessive

motor heating. Observe motor manufacturer's

recommendations when operating any ac induction

motor with the Drive. Also observe motor

manufacturer's recommended voltage/torque boost

at lower operating frequencies.

The available power source con-

nected to the Drive is not to exceed 500KVA. If the

ac power source is greater than 500KVA and the

Drive's rated (HP) is less than 10% of the power

source's KVA; ac line reactors will have to be installed

in L1, L2 & L3 power leads of the Drive.

NOTES

NOTE:

① When terminal operation mode (Function code

F_02 setting is 1) - RUN and STOP are being

controlled by a maintained contact (e.g., selector

switch, toggle switch, etc.) which is connected

between the terminal CM and FWD or REV:

• Closing/opening the maintained contact starts/

stops the Drive.

The Drive must be mounted on

a building or enclosure wall that is constructed of

heat resistant material. While the Drive is operating, the temperature of the Drive's cooling fins can

rise to a temperature of 90°C (194°F.)

If the Drive protective function

is activated, consult Section 8 "Troubleshooting",

and after correcting the problem, resume operation. Do not reset the alarm automatically by

external sequence, etc.

Be sure to provide fuses, as

specified on "Application of Wiring And Equipment"

in Section 4, on line terminals of Drive. Provide

power line disconnect or contactor as needed.

➂ Total wiring between the Drive and the motor must

not exceed the length shown below.

Function 200V Series 400V Series

F_12 data

F_12 = 0, 1, 2 or 3 538 ft. 754 ft.

F_12 = 4 – 15

Hp

1/4 1/21235 1/2 1 2 3 5

1076 ft.

213 ft.

1076 ft.

➁ Function code F_02 setting can be changed only

when connection between the terminals CM and

FWD or REV is open. (i.e. STOP MODE).

Drive ships with shorting bar between

terminals FWD-CM.

UL/CSA Drive Caution Label

Use 60/70°C copper wire only. Use Class 1 wire only.

Suitable for use on a circuit capable of delivering not more than 1,000

(1HP or less) or 5,000 (2 HP or more) rms symmetrical amperes.

WARNING: HAZARD OF ELECTRICAL SHOCK. DISCONNECT INCOMING

POWER BEFORE WORKING ON THIS CONTROL.

ADVERTISSEMENT: RISQUE DE CHOC ELECTRIQUE COUPER

L'ALIMENTATION AVANT LE DEPANNAGE DE CETTE COMMANDE.

CAUTION: DANGEROUS VOLTAGE EXIST UNTIL CHARGE "CRG" LIGHT IS OFF.

ATTENTION: PRESENCE DE TENSIONS DANGEREUSES TANT QUE LE

VOYANT N'EST PAS ETEINT.

WARNING: MORE THAN ONE LIVE CIRCUIT. SEE DIAGRAM.*

AVERTISSEMENT: CET EQUIPEMENT RENFERME PLUSIEURS CIRCUITS

SOUS TENSION. VOIR LE SCHEMA. SA523154-01

*See diagram on page 4-6.

➃ Error in current detection may increase when;

a) A specially designed motor is used.

b) A Drive's capacity is 2 Hp ratings or greater than

the motor capacity.

1-4

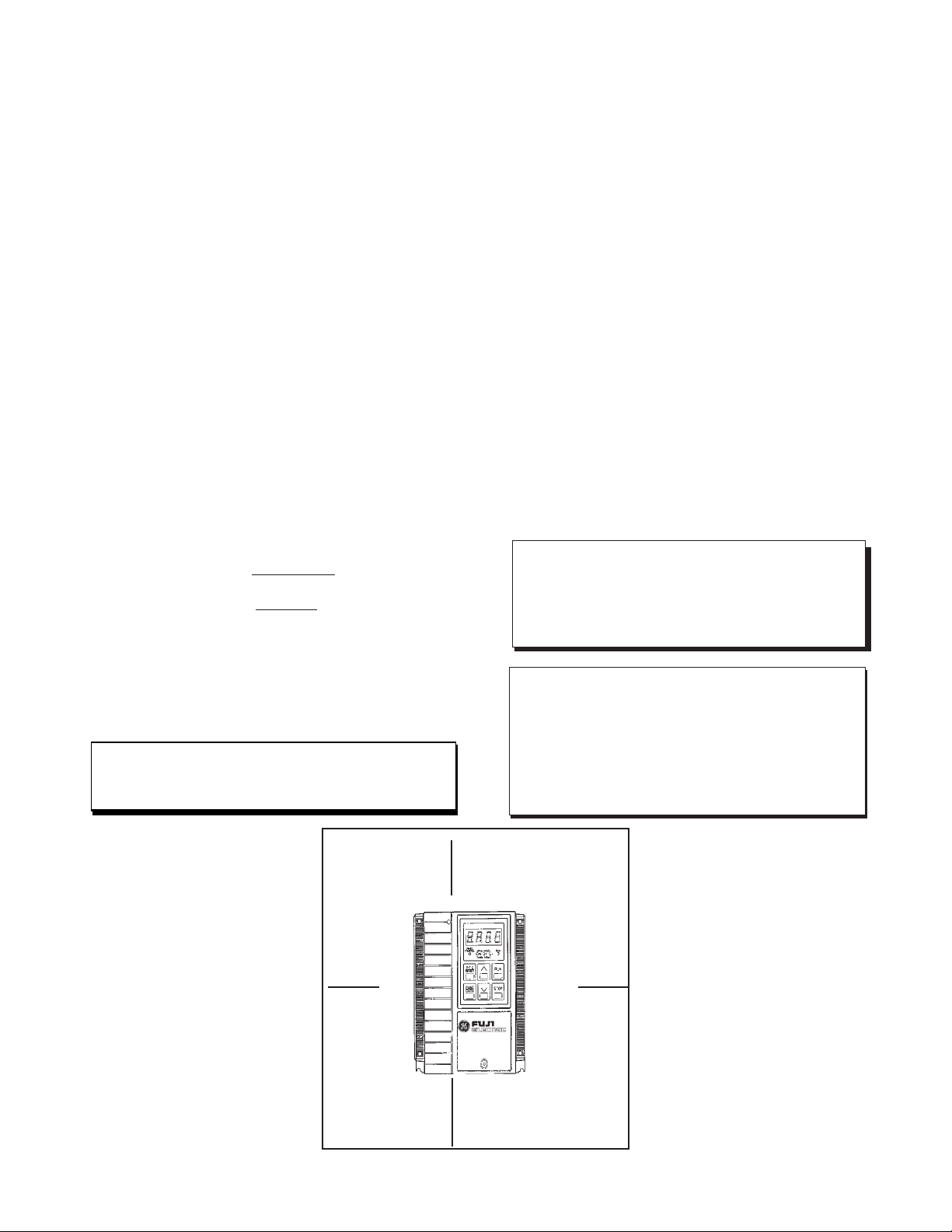

Page 9

Section 2

DESCRIPTION, COMPONENT

IDENTIFICATION, and SPECIFICATION

The Drive is available in ratings of 1/4 to 3 HP 200-240 VAC single phase input, 1/4 to 5 HP 200-230 VAC three phase,

and 1/2 to 5 HP 380-480 VAC three phase. The Drive incorporates advanced Pulse Width Modulated (PWM)

"TORQUE VECTOR" control for high starting torque. The Drives are housed in either a NEMA 1 or NEMA 4 type

enclosure and all Drives are furnished with a detachable cover to allow ease of accessing control and power wiring.

Drive operation and Function Code setting is performed from the “Keypad Panel” that features a Digital Display and

6 dual function keys. The 6 function keys are used for Drive programming and operation.

General data and specifications for each Drive are listed on the nameplate attached to the Drive.

Refer to TABLE 1, for complete Drive specification listing.

INSPECTION PROCEDURES UPON DELIVERY

Upon receipt of your Drive, inspect the equipment for the following items:

1. Check the nameplate to insure that the specifications correspond to those

ordered, and to application requirements.

2. Inspect the unit for any damage that may have occurred during shipment.

– If shipping damage is found or the wrong Drive is received, contact the

Distributor from which the equipment was purchased.

™

AF-300M$

MODEL NO.

SERIAL NO.

INPUT: OUTPUT:

VOLTS VOLTS

*IN CASE OF "L.V. DIRECTIVE 73/23/EEC" FREQ RANGE (HZ)

AMPS HP

FREQ (HZ) AMPS CONT.

PHASE (S) PHASE

ROTATION

MAX 60 SEC. AMPS

INSTRUCTION BOOK GEI-100272 MADE IN JAPAN

All models are UL Listed and CSA Approved. CE MARK applies to the 240 VAC single-phase and 480 VAC 3-phase

Figure 2-1. NAMEPLATE DATA IDENTIFICATION

7898

IND. CONT. EQ.

II

69489

2-1

Page 10

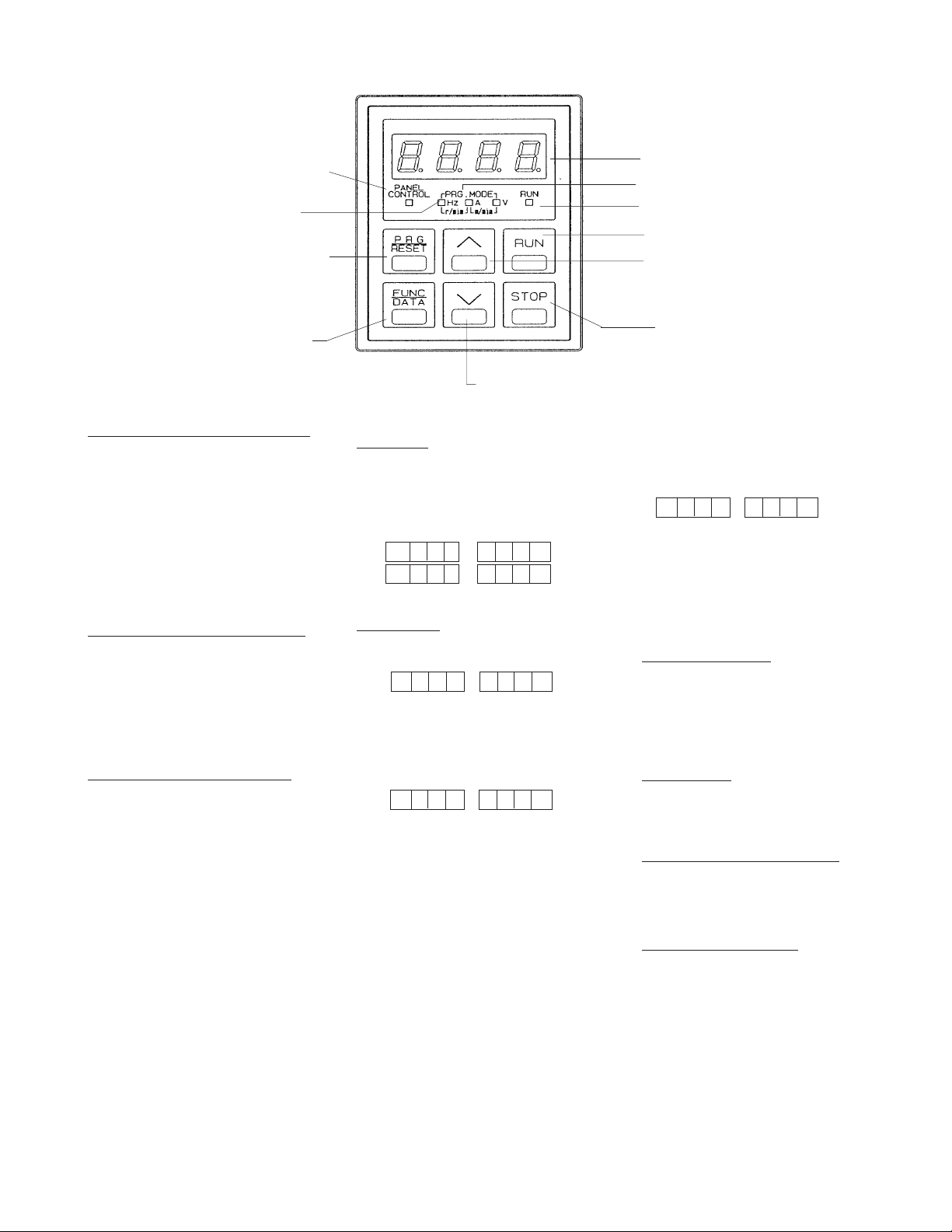

(1) Keypad Part Names and Functions

Operation Mode Indicator

Program Mode

Program/Reset Key

Function Key (Data Key)

Digital Display (4 digits) -

Displays the various Function

Codes and data values during

setting of the program. During

operation, it displays the output

frequency, current, voltage, etc.

If a fault occurs the cause of the

problem will be displayed as a

code.

PROGRAM Key (Reset Key) -

Normal mode or program setting

mode select key. When any of

the protection functions are

activated; this key is used to reset

the fault.

FUNCTION Key (Data Key) -

During the normal mode, this key

can be used to change the display

unit while operation is either

stopped or running.

During the program mode, this

key can be used to read and write

the Function Codes and the data.

DOWN Key

RUN Key - Key used for starting

operation. The LED (green) lights up

during operation.

This key does not function when

terminal operation control is selected.

F 0 2 = 1

or

F 0 2 = 2

STOP Key - This key is used for

stopping drive operation. When set

as follows:

F 0 2 = 0

operation command input is

accepted from the Keypad (RUN

and STOP keys).

When function 2 is set to 1:

F 0 2 = 1

Operation command input by

means of the external signal

terminal (FWD, REV). STOP key

on the keypad is active. If

selection "1" is chosen, and the

stop button is depressed while the

drive is running, the drive will

perform the normal stop

sequence until the output

frequency reaches zero at which

point an "Er6" fault shall be

indicated on the LED. To reset the

Digital Display

Unit Display

Drive RUN Indicator

RUN Key

UP Key

STOP Key

drive you must remove the RUN

command and press RESET.

When function 2 is set to 2:

F 0 2 = 2

operation command input is

accepted by means of the

external signal terminal (FWD,

REV). STOP key on the keypad

is inactive.

UP / DOWN Keys - These keys

increase or decrease the

frequency reference. When unit is

in program setting mode, they

change the Function Code or data

values.

Unit Display - Unit information is

displayed by the LED (red). All

three LEDs flash to indicate that

the unit is in the program mode.

Operation Mode Indicator -

The LED (green) lights up when

keypad panel operation is

selected.

Drive RUN Indicator -

The LED (green) lights up in the

RUN mode.

2-2

Page 11

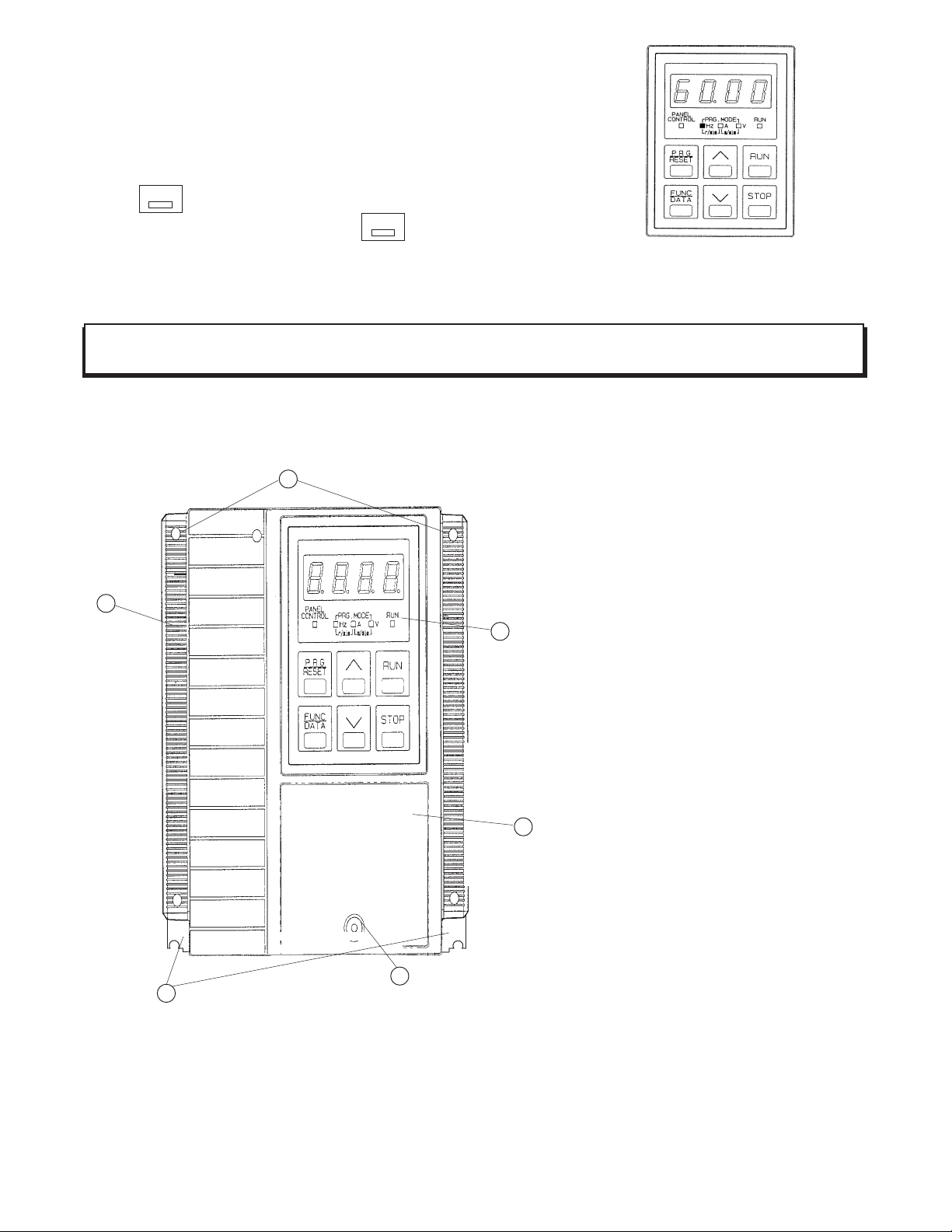

(2) Controlling Method for Keypad Panel

When the power supply is activated, the keypad panel display will be as shown

in the figure on the right (60.00 FLASHING).

RUN

If the key is pressed, the Drive will start and accelerate up to 60 Hz

according to the factory setting. Use the key to stop operation.

STOP

WARNING - RUN and STOP keys function only in Keypad operation mode. (Function Code F_02 setting is 0)

Drive Components

5

1

3

2

6

4

Figure 2-3. TYPICAL DRIVE COMPONENTS

1. Unit Cover (Middle)

2. Unit Cover (Top)

3. Keypad Panel (Optional)

4. Heat Sink and Mounting Tabs

5. Mounting Screw Holes

6. Top Cover Screw

NOTE: NEMA 1 unit does not include keypad. Keypad is sold separately.

Keypad type is 6KM$2KP1 for NEMA 1 unit.

2-3

Page 12

TABLE 1: Standard Specifications

ITEM

SPECIFICATION

Environmental Conditions

Enclosure NEMA 1or NEMA 4

Installation Location: NEMA 1 Suitable for indoor mounting only, less than 1000 meters (3281 feet) elevation,

not in contact with corrosive gas, oil mist, or dust.

NEMA 4

Stored Temperature -20° to +65°C (-4° to +149°F)

Ambient Temperature -10° to +50°C (+14° to +122°

Humidity 20% to 95% relative humidity (non-condensing)

Vibration 0.6G or less

Cooling Method 1/4 to 1 HP – Convection

Suitable for use indoors or outdoors to protect the enclosed equipment against

splashing water, seepage of water, falling or hose directed water and severe

external condensation. Installation should be less than 1000 meters (3281 feet)

elevation, not in contact with corrosive gas, or oil mist.

F) (remove ventilation covers if temperature is

over (+40°C +104° F)

2 HP and greater – Forced air (Integral fan)

Output

Rated Output Voltage 3-Phase, 3-Wire, 80-240 VAC or 160-480 VAC

(Can not exceed power supply voltage)

Frequency Range 0 - 400 Hertz (0.2 to 15 Hz Start Frequency; 15 to 400 Hz Base Frequency)

Above 120 Hz, contact the motor manufacturer for approval of application

Overload Current Rating 150% for 1 minute duration (inverse time characteristic)

200% for 0.5 seconds

Power Supply

Rated Input AC Voltage – 200 to 240 VAC 50/60 Hz, 1 phase (1/4 to 3 HP)

– 200 to 230 VAC 50/60 Hz, 3 phase (1/4 to 5 HP)

– 380 to 480 VAC 50/60 Hz, 3 phase (1/2 to 5 HP)

Voltage: +10% to -15%; Voltage Unbalance: Within 3%; Frequency ±5%

Control System Sinusoidal PWM "TORQUE VECTOR" Control

Control

Frequency Setting – Analog: 0.02 Hz step at Maximum frequency of 60 Hz

Resolution – Digital Keypad: 0.01 Hz Maximum frequency up to 99.99 Hz; 0.1 Hz (100

Hz or more)

Accuracy (Stability) Analog setting: ± 0.2% of Maximum frequency (59° to 95° F)

Digital Keypad setting: ± 0.01% of Maximum frequency (14° to 122° F)

2-4

Page 13

ITEM

SPECIFICATION

Control (continued)

Voltage/Frequency Voltage - 80-240 VAC or 160-480 VAC

Characteristics (V/F) Frequency - 0.2 to 400 Hz

Torque Boost 0: Automatic torque boost or 1 to 31.0 code settings (includes selection for

variable torque load)

Acceleration/Deceleration 0.01 to 3600 seconds (independent acceleration/deceleration)

Characteristics Alternative accel/decel time available as well as linear or 2 S-curves (selectable)

Motor Sound The pitch of the motor sound can be changed by selecting Carrier frequency

(F_12: 0 to 15)

Frequency Meter Adjustment Scale calibration of externally connected analog meter or pulse

frequency

Data Protection Data lock is possible to ensure that the function codes are not changed

High/Low Frequency Limiter Output frequency upper and lower range limit 0 to 400 Hz; 1 Hz step settings

Bias Magnitude of the zero offset can be set from 0 to ±100% of maximum

frequency (1Hz steps)

Gain Output frequency gain corresponding to the reference signal can be

set from 0 to 250%

15 Step Preset Speed 15 programmable preset speeds selectable by 4 contact closures

Maintained Contact Operation Maintained contact operation/stop command (2-wire operation)

Terminal Function Change Multi-Use terminal changed via Function Code settings (X4 input; Y1 output)

Operation

Frequency Reference Signal Speed potentiometer: 0 to +10 VDC 4 to 20 mA [(0 to +5VDC) gain adjust 0-250%]

Input Signal (contact type) Forward, reverse, multistep speed setting, alternate accel/decel time settings,

coast-to-stop, external alarm, 3-wire control and reset

External Output Signals One Dry Form "C" alarm output contact rated 250 VAC, 0.3 amp

1 – Open collector output rated 27 VDC, 50mA from external power

– Drive Run – FDT – FAR – LV– TL – Auto restart mode after momentary

power loss (IP)

Frequency Meter Output Signal Pulse frequency (adjustment to 6 kHz maximum)

Analog - 0 to +10 VDC (adjustment range of 6.5 to 10.3 VDC)

2-5

Page 14

ITEM SPECIFICATION

Operation (continued)

Protective Functions: – Stall prevention – Undervoltage

– Surge input – Overcurrent

– Drive overheating – Overvoltage

– External faults – Short circuit for output terminals

– CPU malfunction – Communication error

– Motor overload – Ground fault (at start)

(electronic thermal) – Output wiring not connected

– Memory error (during auto tuning only)

Keypad Digital Display - 4 digit LED

Drive Operation Output frequency, output current, output voltage, motor speed, line speed

(m/min), machine speed (r/min) can be displayed

Drive Setting Function Code and Setting Data can be displayed

Data Initializing Resets all Function Codes to initial factory settings

Drive Fault – OC1 - Acceleration overcurrent

– OC2 - Deceleration overcurrent

– OC3 - Constant speed overcurrent

– LU (LV) - Undervoltage

– OU1 - Overvoltage during acceleration

– OU2 - Overvoltage during deceleration

– OU3 - Overvoltage at constant speed

– OH1 - Drive overheat

– OH2 - External alarm input

– OLU - Electronic Overload - Semiconductor Overload Protection

– OL - Electronic Overload - 4 Pole Motor Overload Protection

– Er1 - Setting error

– Er2 - Communication error

– Er3 - CPU error

– Er4 - Optional circuit board communication error with Drive

– Er5 - Optional Problem - when a link error etc. is detected

– Er6 - Operating Proc. error

– Er7 - Output wiring error

Charge "CRG" Lamp (LED) Illuminates when DC Link capacitor voltage is present

2-6

Page 15

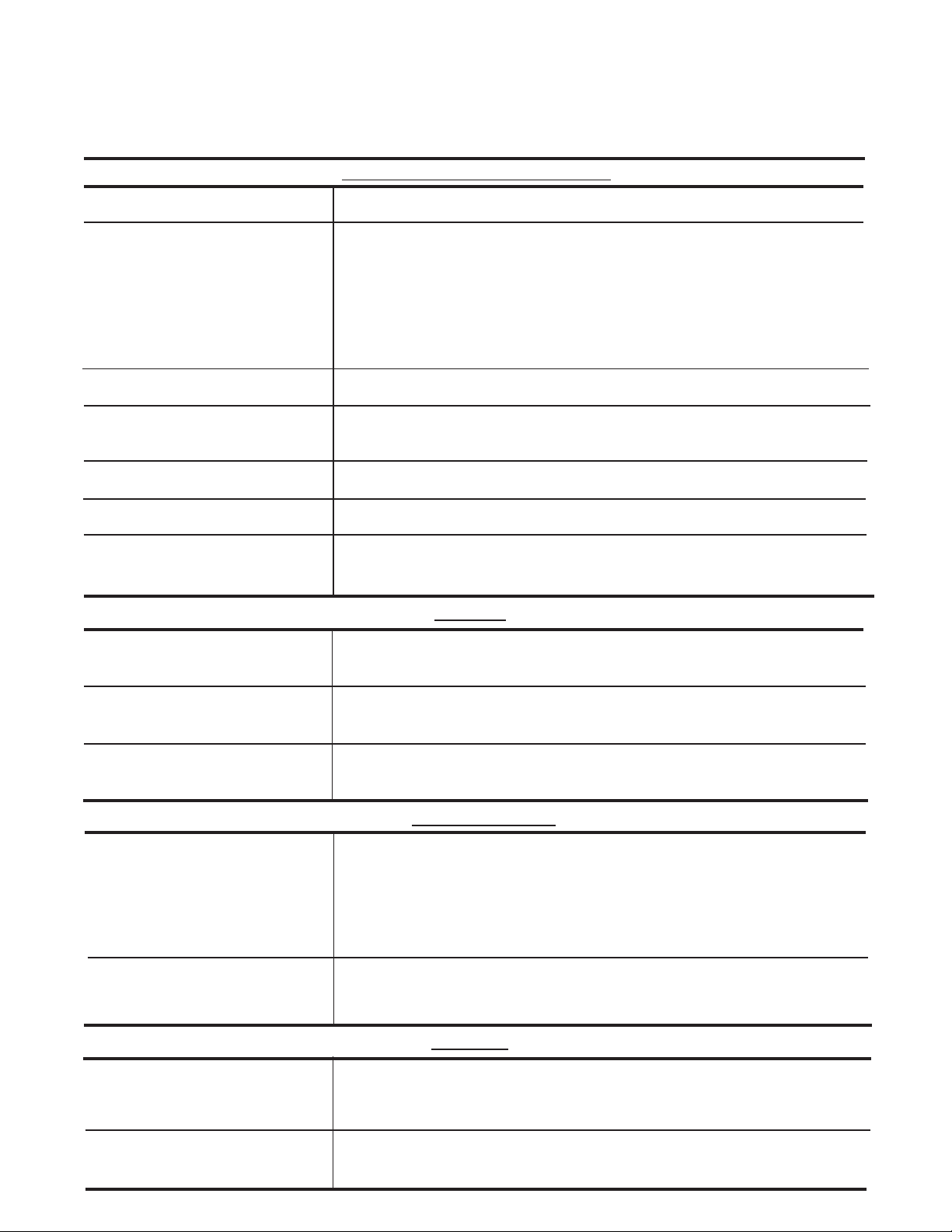

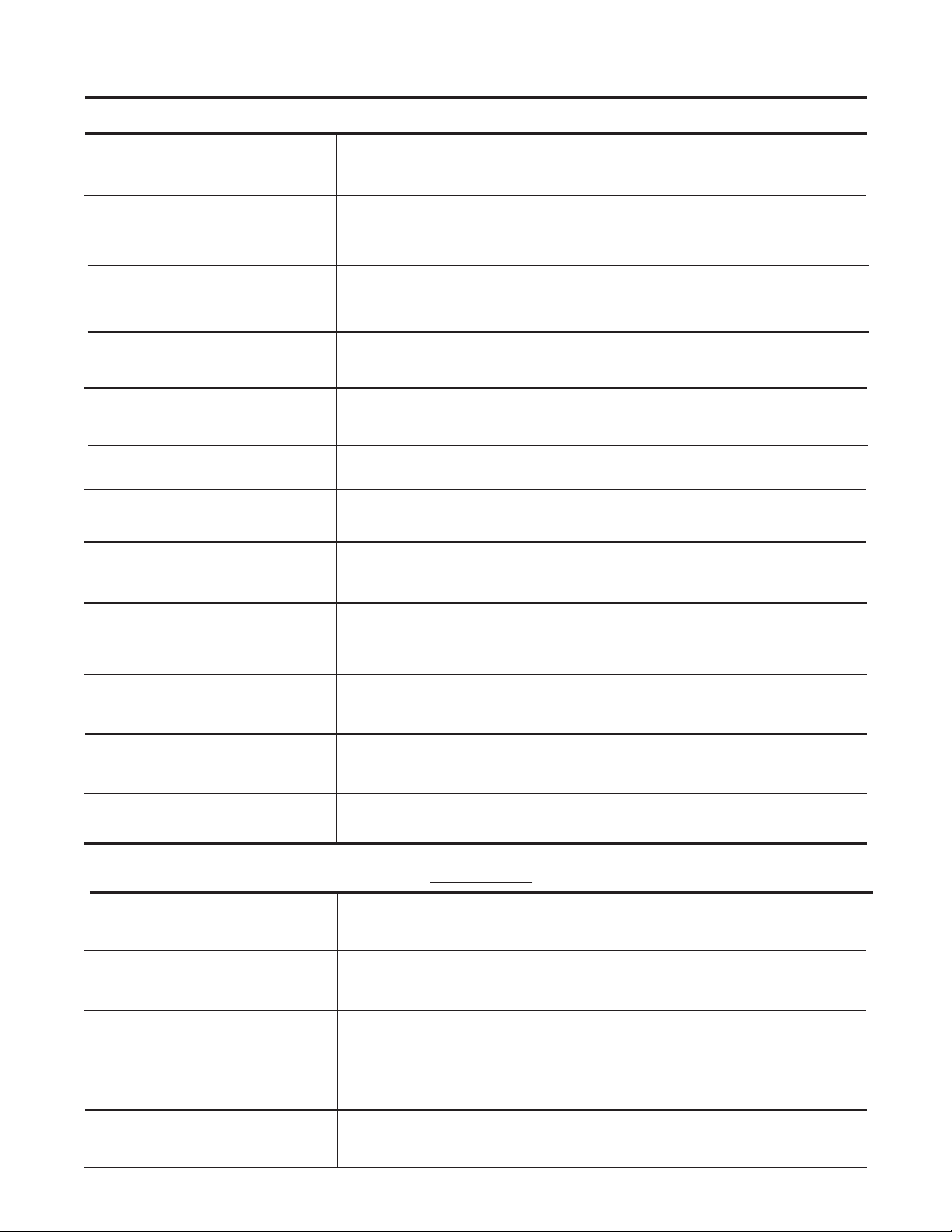

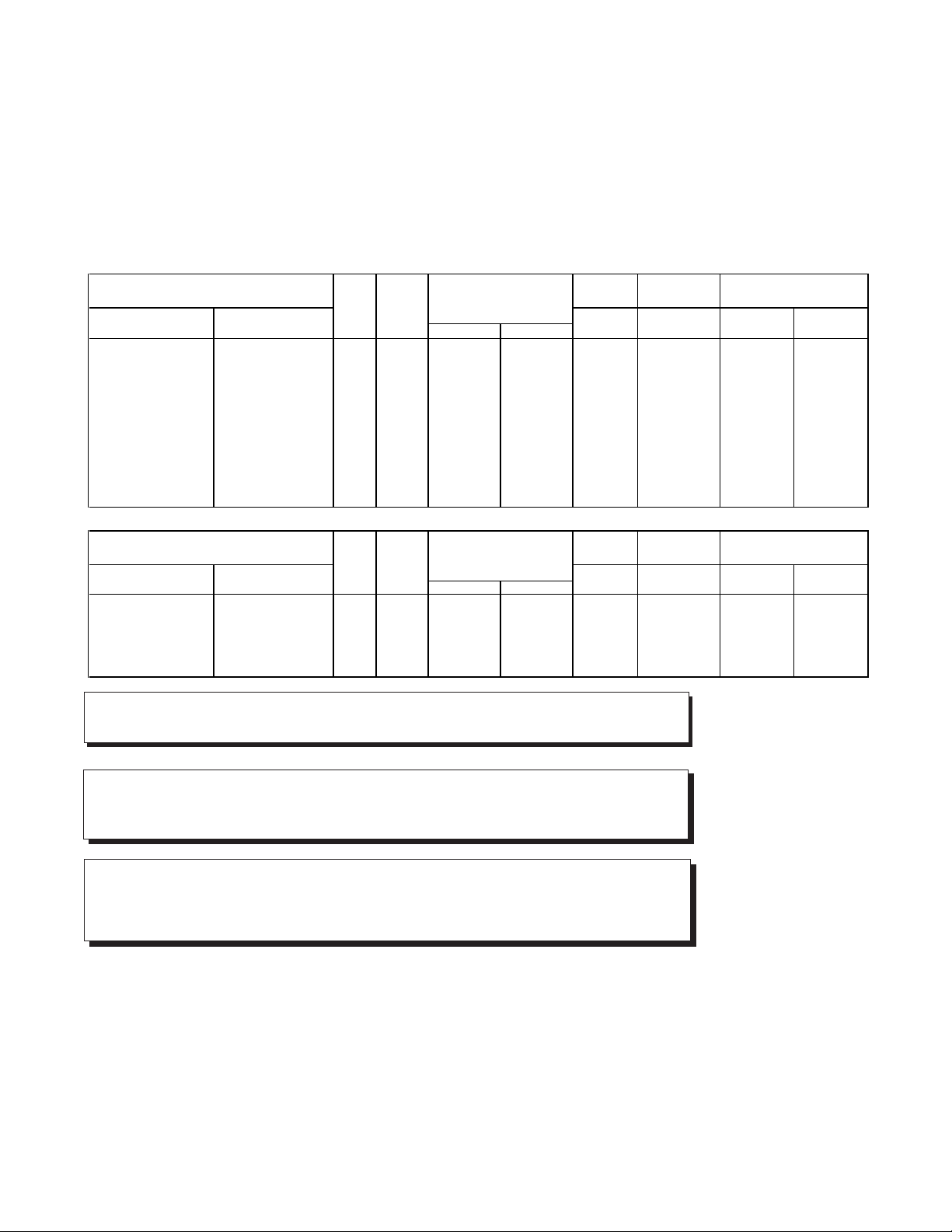

Table 2: Drive Dimensions

240 Volt – Single Phase

HP Weight Height Width Depth Dim. Figure

Model

Const LBS KGS Inches MM Inches MM Inches MM

Pages

NEMA 1 NEMA 4

TRQ

3-2 to 3-5

6KM$221F25N1A1 6KM$221F25X4A1 1/4 2.7 1.2 6.22 158 4.29 109 3.15 80 1 and 4

6KM$221F50N1A1 6KM$221F50X4A1 1/2 3.8 1.7 6.22 158 5.67 144 4.29 109 2 and 6

6KM$221001N1A1 6KM$221001X4A1 1 4.0 1.8 6.22 158 5.67 144 4.29 109 2 and 6

6KM$221002N1A1 6KM$221002X4A1 2 6.2 2.8 6.22 158 8.03 204 5.28 134 3 and 8

6KM$221003N1A1 6KM$221003X4A1 3 6.4 2.9 6.22 158 8.03 204 5.28 134 3 and 8

230 Volt – Three Phase

6KM$223F25N1A1 6KM$223F25X4A1 1/4 2.4 1.1 6.22 158 4.29 109 3.15 80 1 and 4

6KM$223F50N1A1 6KM$223F50X4A1 1/2 2.9 1.3 6.22 158 4.29 109 3.54 90 1 and 5

6KM$223001N1A1 6KM$223001X4A1 1 3.3 1.5 6.22 158 4.29 109 4.69 119 1 and 7

6KM$223002N1A1 6KM$223002X4A1 2 4.6 2.1 6.22 158 5.67 144 4.69 119 2 and 7

36KM$223003N1A1 6KM$223003X4A1 3 6.2 2.8 6.22 158 8.03 204 5.28 134 3 and 8

36KM$223005N1A1 6KM$223005X4A1 5 7.0 3.3 6.22 158 8.03 204 5.87 149 3 and 9

480 Volt – Three Phase

6KM$243F50N1A1 6KM$243F50X4A1 1/2 4.2 1.9 6.22 158 5.67 144 4.29 109 2 and 6

6KM$243001N1A1 6KM$243001X4A1 1 4.2 1.9 6.22 158 5.67 144 4.29 109 2 and 6

6KM$243002N1A1 6KM$243002X4A1 2 6.2 2.8 6.22 158 8.03 204 5.28 134 3 and 8

6KM$243003N1A1 6KM$243003X4A1 3 6.2 2.8 6.22 158 8.03 204 5.28 134 3 and 8

6KM$243005N1A1 6KM$243005X4A1 5 7 3.3 6.22 158 8.03 204 5.87 149 3 and 9

Table 3: Drive Rating Efficiency and Watts Loss Table

240 Volt – Single Phase

Output Current Output Efficiency

Model

NEMA 1 NEMA 4

6KM$221F25N1A1 6KM$221F25X4A1 1/4 1.5 1.3 0.19 87.6 80.9 27 45

6KM$221F50N1A1 6KM$221F50X4A1 1/2 3.0 2.5 0.37 88.1 83.2 50 75

6KM$221001N1A1 6KM$221001X4A1 1 5.0 4.0 0.75 90.4 88.8 80 95

6KM$221002N1A1 6KM$221002X4A1 2 8.0 7.0 1.50 92.9 91.5 115 140

6KM$221003N1A1 6KM$221003X4A1 3 11.0 10.0 2.20 93.6 92.4 150 180

Carrier Frequency

HP

Low High KW Low High Low High

230 Volt – Three Phase

6KM$223F25N1A1 6KM$223F25X4A1 1/4 1.5 1.3 0.20 87.6 80.9 27 45

6KM$223F50N1A1 6KM$223F50X4A1 1/2 3.0 2.5 0.40 88.1 83.2 50 75

6KM$223001N1A1 6KM$223001X4A1 1 5.0 4.0 0.75 90.4 88.8 80 95

6KM$223002N1A1 6KM$223002X4A1 2 8.0 7.0 1.50 92.9 91.5 115 140

36KM$223003N1A1 6KM$223003X4A1 3 11.0 10.0 2.20 93.6 92.4 150 180

36KM$223005N1A1 6KM$223005X4A1 5 17.0 16.5 3.70 94.6 93.4 212 260

6KM$243F50N1A1 6KM$243F50X4A1 1/2 1.6 1.4 0.37 86.0 79.9 60 93

6KM$243001N1A1 6KM$243001X4A1 1 2.5 2.1 0.75 90.4 86.9 80 113

6KM$243002N1A1 6KM$243002X4A1 2 3.7 3.7 1.50 93.2 88.1 110 203

6KM$243003N1A1 6KM$243003X4A1 3 5.5 5.3 2.20 94.4 89.4 130 260

6KM$243005N1A1 6KM$243005X4A1 5 9.0 8.7 3.70 94.9 91.0 200 366

NOTE:

Low setting F_12 = 0

480 Volt – Three Phase

Carrier Frequency: High setting F_12 = 15

2-7

Power Percentage

Watts Loss

Page 16

Section 3

➛

INSTALLATION GUIDELINES

INSTALLATION ENVIRONMENT

Install the Drive in an indoor location that meets the

following requirements:

— The ambient temperature is between -10° C and

+50° C (+14° F to +122° F). Remove the ventilation covers when the temperature exceeds +40° C

[+104° F].

— The relative humidity is between 20% and 95%.

Avoid any location subject to condensation, freezing,

or where the Drive would come in contact with water.

— Do not install in any location subject to direct sunlight,

dust, corrosive gas, inflammable gas, or oil mist.

— Vibration should be less than 0.6G.

— The Drive should be installed at an elevation below

1000 meters (3281 feet). For installation above 1000

meters (3300 feet) the Drive will need to be derated

1% per 333 feet.

Example: 5 HP, 460 VAC, output current 9 amps.

Application altitude 3900 feet.

3900 - 3300

% derate = x 1% = 1.8%

(9 amps) x = 8.84 amps

derated output current.

( )

333

100 - 1.8

( )

100

INSTALLATION MOUNTING

CLEARANCE

— Install at a sufficient distance from other equip-

ment, walls, or wiring ducts as shown in Figure

3-1 (these clearances are required to allow the

heat generated by the Drive to escape).

— Install the Drive perpendicular to the ground and

with the lettering right side up. (If the Drive is

installed upside-down or horizontally, heat buildup will occur.)

— Mounting screws or bolts should be of appropriate

size for weight of Drive.

— See the appropriate figures on pages 3-2 and

3-3 for the location of mounting holes.

— After removing the knockouts in the wiring lead-in

plate, install the rubber bushings supplied to prevent cable damage and to minimize dust entry.

CAUTION: The mounting wall for the Drive must be

constructed of heat resistant material because during

operation, the temperature of the Drive's cooling fins

rises to approximately 90 degrees C (194° F).

Motor derate may also be required,

contact motor manufacturer.

CAUTION: Because the ambient temperature greatly

affects Drive life and reliability, do not install the Drive in

any location that exceeds the allowable temperatures.

2"

or more

➛

5" or more

➛

➛

5" or more

➛

NOTE:

proximity, allow sufficient space as shown in Figure 3-1

and install them in a horizontal row. If they must be

installed in a vertical column, at least 19.7 inches (50cm)

internal space must be provided between each one or a

ventilation baffle should be provided to prevent the

ambient temperature from rising.

When installing two or more Drives in close

2"

or more

➛

Figure 3-1. DRIVE MOUNTING CLEARANCE

3-1

Page 17

NOTE: NEMA 1 unit does not have Keypad.

Shown with optional Keypad

Dimensions

4.29 (109)

4.13 (105)

3.66 (93)

0.24 (6)

5.91 (150)

5.43 (138)

6.22 (158)

0.08 (2)

0.24 (6)

5.67 (144)

5.51 (140)

5.04 (128)

2-ø5 (0.20)

0.08 (2)

0.24 (6)

0.24 (6)

5.43 (138)

0.08 (2)

5.91 (150)

6.22 (158)

Figure 1

0.08 (2)

0.24 (6)

0.20 (5)

0.24 (6)

0.24 (6)

0.20 (2-ø5)

8.03 (204)

7.87 (200)

7.40 (188)

0.08 (2)

0.24 (6)

0.08 (2)

0.24(6)

5.43 (138)

5.91 (150)

6.22 (158)

0.20 (5)

0.24 (6)

0.24 (6)

Figure 2 Figure 3

Note: Inches (MM)

3-2

0.20 (5)

0.24 (6)

0.24 (6)

Page 18

Dimensions

4.29 (109)

3.15 (80)

0.20 (5)

3.54 (90)

0.20 (5)

Figure 4 Figure 5 Figure 6

0.24 (6)

5.28 (134)

4.69 (119)

0.24 (6)

0.24 (6)

Figure 7 Figure 8 Figure 9

Note: Inches (MM)

5.87 (149)

0.24 (6)

3-3

Page 19

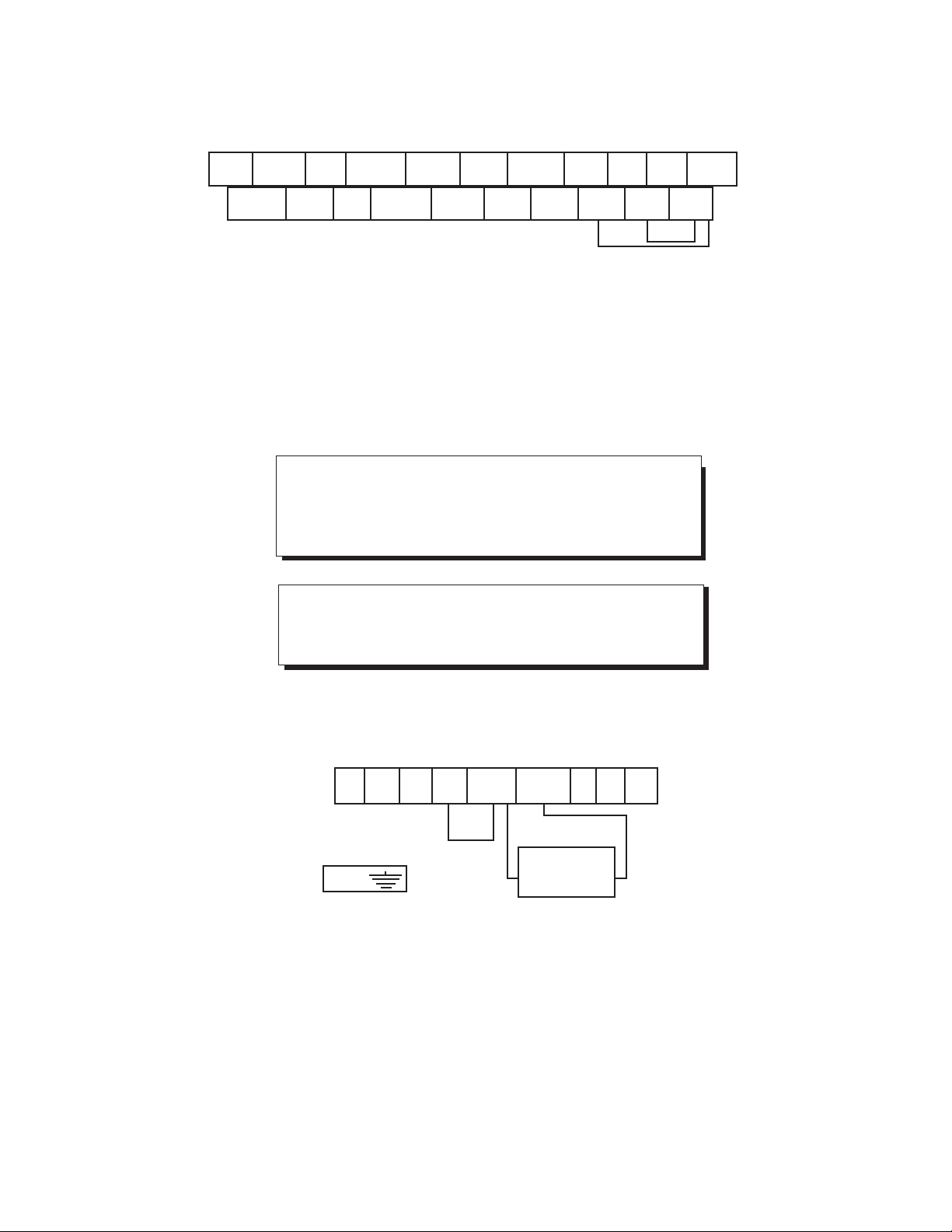

Dimensions of Keypad and Keypad Mounting Holes

Keypad Part # 6KM$2KP1 for NEMA 1 unit

6KM$2KP4 for NEMA 4 unit

3-4

Mounting Hole (panel cut-out)

Inches (MM)

Page 20

Section 4

WIRING PROCEDURES

To access Main and Control Circuit Terminals remove the top

cover as follows (see Figure 4-1):

1. Loosen the screw located at the bottom of the top cover.

2. Press upward on the bottom of the top cover (see arrows

Figure 4-1 step 2) and lift off.

3. See Figure 4-1 for the location of the Main Circuit

Terminal Block and the Control Circuit Terminal Block.

WARNING: Some printed circuit boards and Drive components may contain hazardous voltage levels. If LED

light "CRG" on the Base Driver Board is illuminated,

hazardous voltages are present in the Drive circuit boards.

Remove and lock out power before you disconnect or

reconnect wires, and before you remove or replace fuses

and circuit boards. Do not attempt to service the Drive

until the "CRG" indicator has extinguished and the bus

voltage has discharged to zero volts.

Removing T op Cover

Mounting Screw

Holes

Step 1:

Loosen Top Cover

screw. (1 to 2 turns)

Unit Cover (Middle)

Step 2:

Press Upward at the locations indi-

cated by the arrows to remove the top

cover.

and Mounting Tabs

→

Heat Sink

→

Keypad Panel

Unit Cover (Top)

Top Cover Screw

Main Circuit

Teminal Block

Control

Circuit

Terminal

Block

Drive

Charge "CRG" Lamp

Figure 4-1. REMOVING THE TOP COVER

4-1

Page 21

Control Circuit Wiring

Drive is wired at shipment for operation and frequency

setting through the keypad panel (frequency is set at 60

Hz.)

– See Figure 4-2, and 4-4 for wiring connections.

– See TABLE 5 for description of all terminals.

Make wire connections as shown in Figure 4-4 through 4-6

for desired mode of external operation through Control

Circuit Terminals.

CAUTION: The Control Circuit Terminal wiring should be

kept as far away as possible from the main power wiring to

prevent operational error due to noise interference. Never

install both types of wiring in the same duct or conduit. (A

separation distance of 4 inches [10 centimeters] or more is

recommended.) If the control circuit wiring must cross the

main power wiring, it should cross at a right angle.

CAUTION: Use shielded or twisted wire for the control

circuit wiring (wiring should be as short as possible, i.e. 65

feet or less [20 meters.]) Connect outer covering of the

shielded wires to the Drive ground terminal and leave the

other end open, but taped with electrical insulating tape.

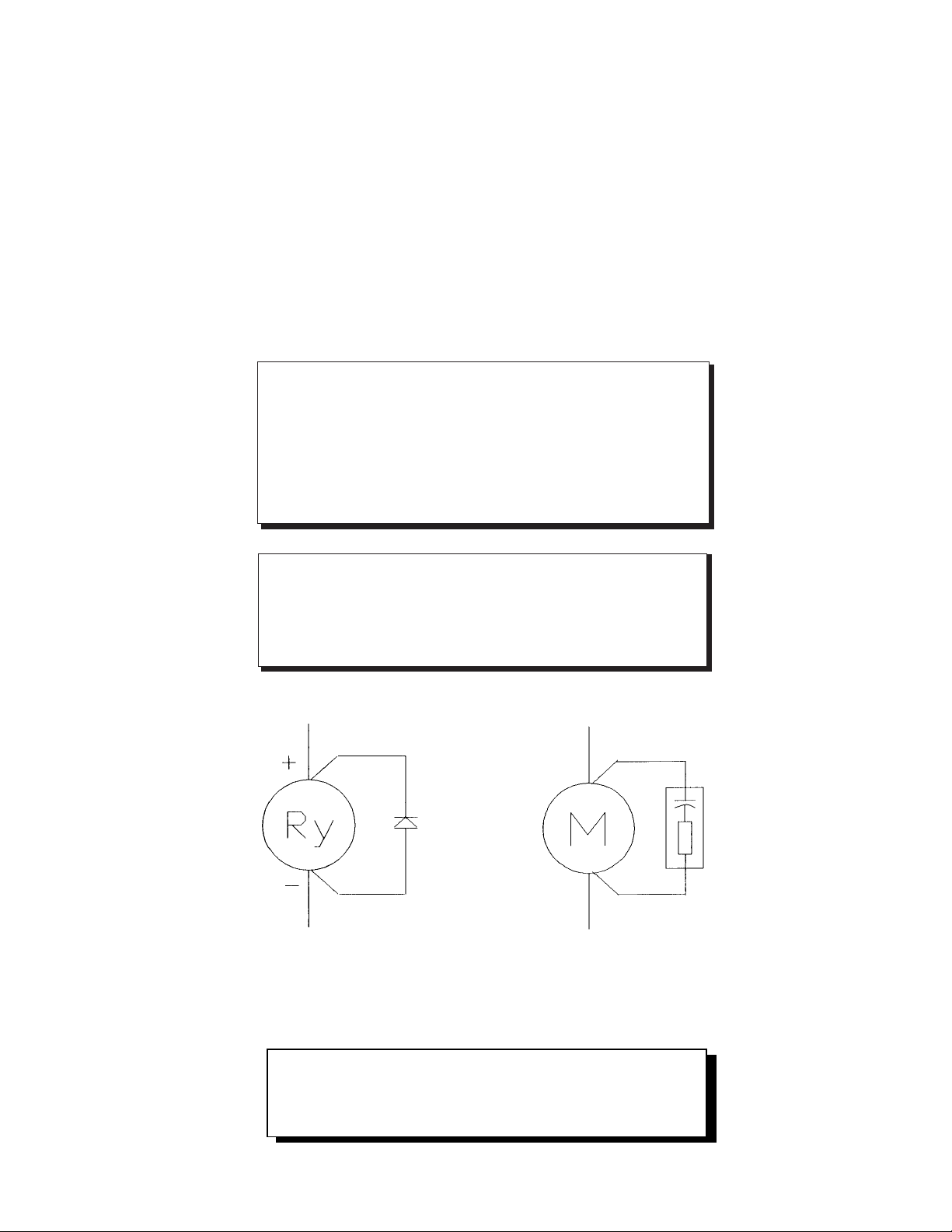

DC RELAY

Figure 4-2. CONNECTION OF SURGE SUPPRESSION DEVICES

AC CONTACTOR

CAUTION: Install a suppressor in parallel with any relay or

solenoid type coil as shown above, that may be close to the

Drive to prevent noise from causing erratic Drive operation.

4-2

Page 22

Main Circuit Wiring

CAUTION: Be sure that the power supply is never

connected to the U, V, W terminals or the P (1), P (+),

DB terminals.

1. Connect the ground terminal as shown in the appropriate view of Figure 4-3. (Do not operate without

the unit being grounded.)

— The ground wire must be minimum 14 AWG

and short as possible

2. Connect the power supply wires to the L1, L2, and

L3 terminals of the Main Circuit Terminal Block as

shown in the appropriate view of Figure 4-3. (See

TABLE 5 for description of all terminals and TABLE

4 for recommended wire sizes.) Note that L1 and L2

terminals only, are available on single phase input

models.

NOTE:

the shaft end when connected normally. If the motor rotates in

reverse direction, interchange any two of the U, V, or W terminal

connections.

Motor will rotate counterclockwise when viewed from

3. Connect the 3-phase motor wires to the U, V, and

W terminals of the Main Circuit Terminal Block as

shown in the appropriate view of Figure 4-3. (See

TABLE 5 for description of all terminals and TABLE

4 for recommended wire sizes.)

4. Suitable for use on a circuit capable of delivering not

more than 1000A (1 HP or less) or 5000A (2 HP or

more) RMS symmetrical.

5. AC input fuses are to be customer supplied and may

be branch circuit protection fuses. The maximum

allowance fuse rating per TABLE 4.

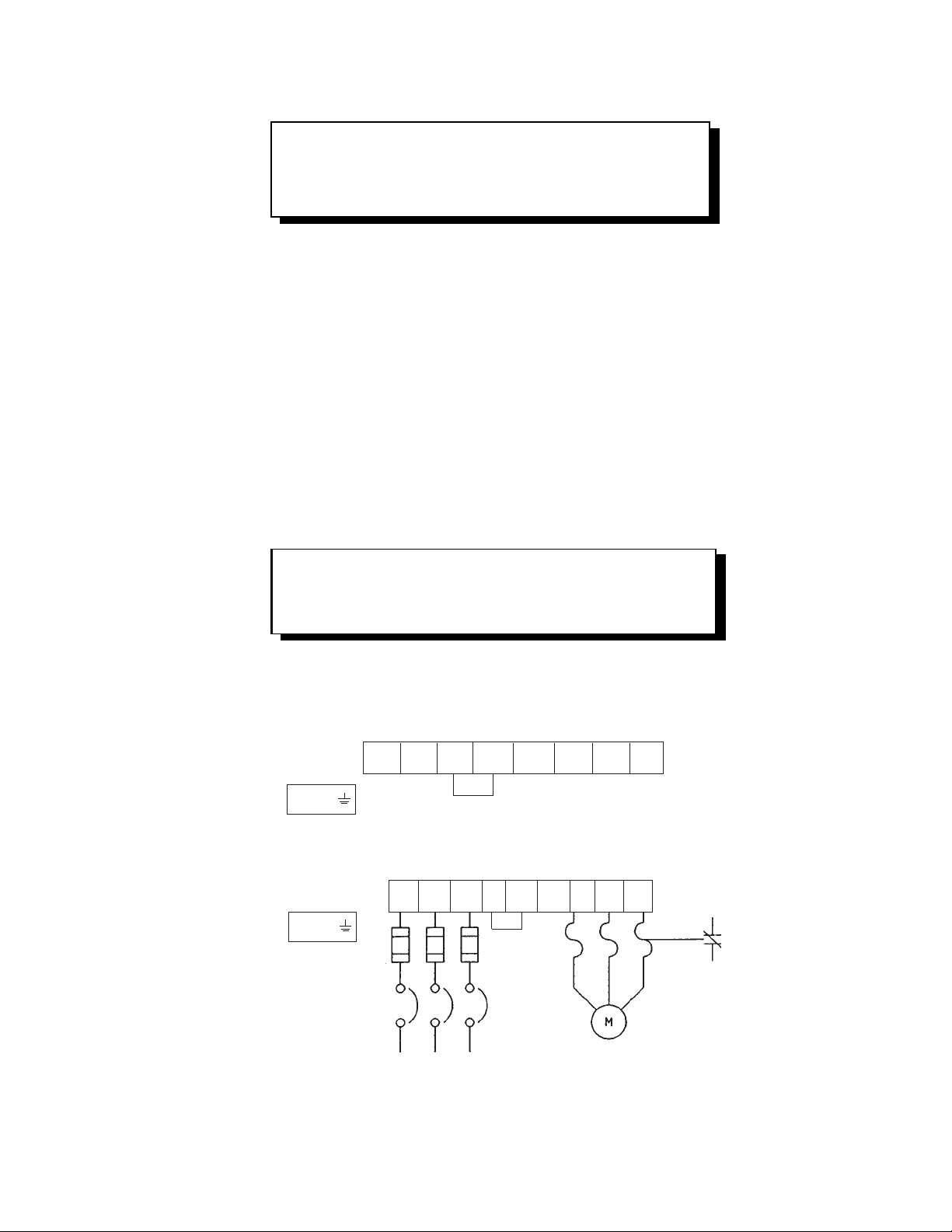

240V – Single Phase 1/4 to 3 HP

L1 L2 P1 P(+) DB* U V W

E (G)

230 & 480V – Three Phase 1/4 to 5 HP

L1 L2 L3 P1 P(+) DB U V W

E (G)

Fuses: Rating per TABLE 4

Reference UL power circuit

protection requirements.

CB

50/60 Hz, 3–Phase AC

✟ Factory installed jumper (Remove when installing DC Reactor)

* The DB resistor connection is not available on models 6KM$221F25X1A1,

6KM$221F25A4A1, 6KM$223F25X1A1, 6KM$223F25A4A1.

# Optional

Figure 4-3. MAIN CIRCUIT TERMINAL LAYOUT

✟

✟

Thermal Relay

3–Phase Motor

#

4-3

Page 23

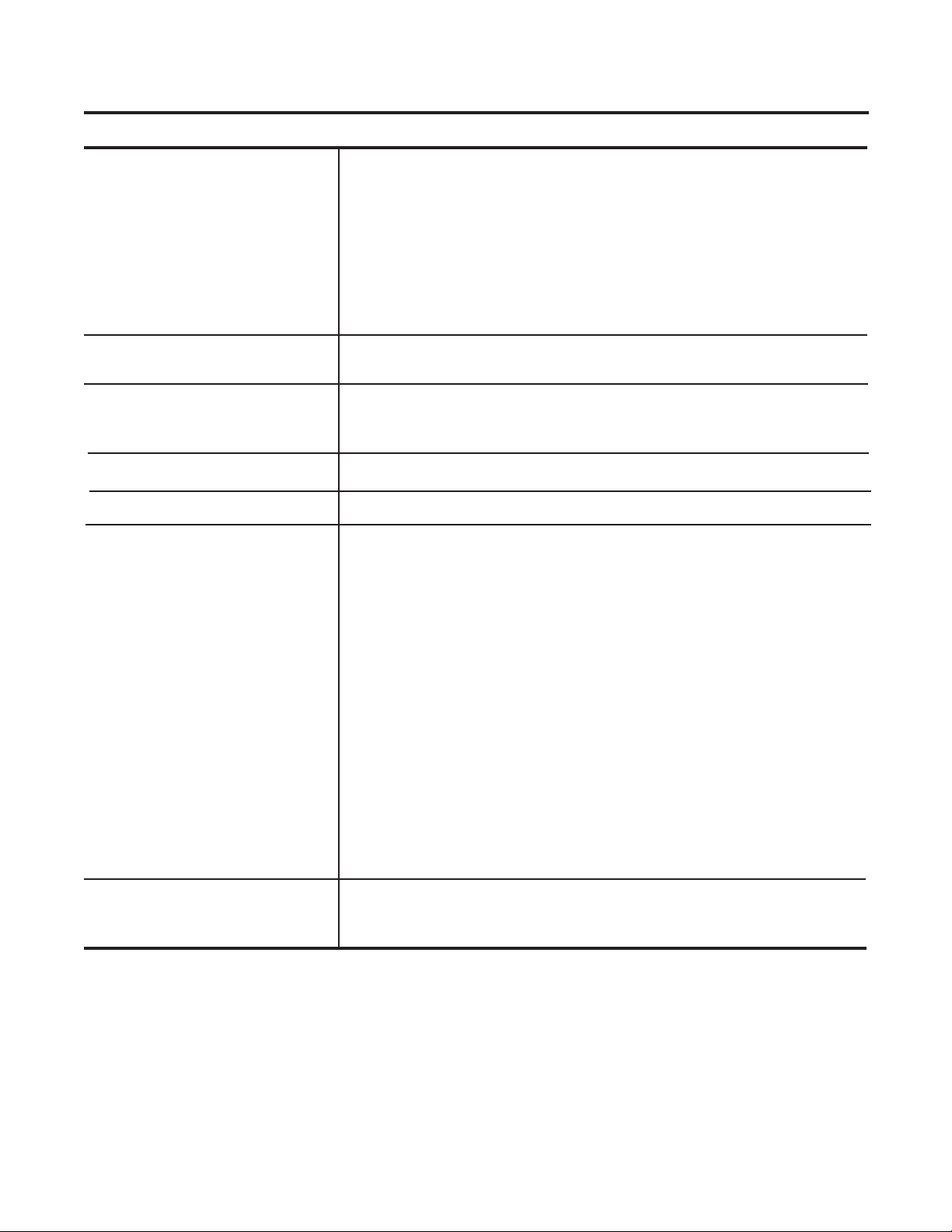

Table 4:

ing

lly

Wire Size Recommendations

& Circuit Protection Ratings

240V – Single Phase and 230V Three Phase

DB Incoming Power

Model PH HP Output Current Power Resistor** AC – Line Devices

NEMA 1 NEMA 4

6KM$221F25N1A1 6KM$221F25X4A1 1 1/4 1.5 1.3 16 - 6 5

6KM$221F50N1A1 6KM$221F50X4A1 1 1/2 3 2.5 16 16 10 10

6KM$221001N1A1 6KM$221001X4A1 1 1 5 4 14 14 15 15

6KM$221002N1A1 6KM$221002X4A1 1 2 8 7 12 12 20 20

6KM$221003N1A1 6KM$221003X4A1 1 3 11 10 10 10 30 30

6KM$223F25N1A1 6KM$223F25X4A1 3 1/4 1.5 1.3 16 - 6 5

6KM$223F50N1A1 6KM$223F50X4A1 3 1/2 3 2.5 16 16 10 5

6KM$223001N1A1 6KM$223001X4A1 3 1 5 4 16 16 15 10

6KM$223002N1A1 6KM$223002X4A1 3 2 8 7 14 14 20 15

6KM$223003N1A1 6KM$223003X4A1 3 3 11 10 14 14 30 20

6KM$223005N1A1 6KM$223005X4A1 3 5 17 16.5 10 10 40 30

480V – Three Phase

Model PH HP Output Current Power Resistor** AC – Line Devices

NEMA 1 NEMA 4

6KM$243F50N1A1 6KM$243F50X4A1 3 1/2 1.6 1.4 16 14 6 5

6KM$243001N1A1 6KM$243001X4A1 3 1 2.5 2.1 16 14 6 5

6KM$243002N1A1 6KM$243002X4A1 3 2 3.7 3.7 16 14 15 10

6KM$243003N1A1 6KM$243003X4A1 3 3 5.5 5.3 16 14 15 15

6KM$243005N1A1 6KM$243005X4A1 3 5 9.0 8.7 14 14 20 15

Const

Input TRQ Low High AWG AWG Fuses* Breaker

Const

Input TRQ Low High AWG AWG Fuses* Breaker

Carrier Frequency

Carrier Frequency

Wire Wire Circuit

DB Incoming Power

Wire Wire Circuit

WARNING - Device ratings such as system coordination, short-circuit

rat

and type must be carefu

NOTE:

75° C for over 100 amps in 30° C ambient and 1.25 times Drive rated amps. These

are minimum wire sizes; consult and conform to local and national codes.

*NOTE: AC input fuses are required to validate the drive's UL and CSA approvals.

** Optional Item.

Wire size from NEC table 310-16. Copper wire rated 60° C for 100 amps or less,

The fuse should be Class J type such as Bussman, JKS or equivalent. Circuit breaker

ratings are shown for reference, but UL and CSA approval can only be validated by

the use of Class J fuses.

reviewed by the user.

4-4

Page 24

30A 30B Y1 FMA PLC BX RST C1 13 12 11

30C FMP X1 X2 X3 X4 REV FWD THR CM

#1

*

* Factory installed jumper

*

CONTROL CIRCUIT TERMINAL BLOCK LAYOUT

#1 CAUTION:

Remove jumper from between terminals THR and CM when

a motor overload or a motor temperature switch is used.

Wire the device thermal switch in series with the THR and

CM terminals.

#2 NOTE:

FWD to CM jumper required for operation using keypad

RUN-STOP.

#2

Figure 4-4.

L1 L2 L3 P1 P(+) DB* U V W

DB

E(G)

* Not available on 6KM$221F25X1A1, 6KM$221F25A4A1, 6KM$223F25X1A1, 6KM$223F25A4A1.

Figure 4-5. DYNAMIC BRAKING RESISTOR CONNECTIONS

RESISTOR

4-5

Page 25

1 or 3PH

50/60 Hz

230/480 Vac

(Based on

Model selected)

DIGITAL METER

DISCONNECT/

CIRCUIT

BREAKER #

FUSE

✟

DO NOT CONNECT

TO CM

DC REACTOR #

P1

BRAKING RESISTOR

1/2 TO 5HP #

BRAKING RESISTOR

THERMAL SWITCH

ALARM RELAY OUTPUT

#

GROUND

BX

RST

X4(HLD)

PROGRAMMABLE LOGIC

PLC

CONTROL POWER

Y1

ANY ADDITIONAL NORMALLY

CLOSED PROTECTIVE

INTERLOCKS SHOULD BE

ADDED IN SERIES

* Terminal 11 should not be connected to CM.

✟ L3 not supplied on single phase units.

# Optional

Figure 4-6. WIRING DIAGRAM

CAUTION:

1. The Control Circuit Terminal wiring should be kept as far as possible from the main circuit wiring to prevent

operation error due to noise interference. Never install them in the same duct or conduit. A separation distance

of 4 inches or more is recommended. If the control circuit wiring must cross the main circuit wiring, make sure

it crosses at a right angle.

2. Use shielded wire for the control circuit wiring, which should be as short as possible (66 feet or less). Connect

shield to the Drive ground terminal and leave the other end open but taped.

3. Install a surge protector in parallel with any magnetic contactors, solenoids, relays or timer coils which are close

to the Drive.

4-6

Page 26

TABLE 5: Terminal Identification/Function

Terminal Terminal

Label Name Function

POWER TERMINAL BOARD

L1, L2, AC Supply Line Connection for 200-230 VAC or 380-480 VAC, 3-phase, 50/60 Hz;

L3 Input Terminals L1 & L2 for single phase input, 200-240 VAC 50/60 Hz

U, V, W Drive Output Connection for 3-phase induction motor

Terminals

P+, DB External Braking Connection for external braking resistor option for single phase and

Resistor Terminals three phase drives (Only on 1⁄2 HP to 5 HP; not on 1/4 HP)

P1, P+ DC Reactor Terminals Connection for external DC reactor for power factor improvement

(Option). (Remove factory installed jumper)

CONTROL TERMINAL BOARD

11 Frequency Setting & Common connector for terminals 12, 13, C1 and FMA (Do not

Analog Freq. Meter connect to CM terminal or electrical noise immunity may be lost).

Common Terminal

12 Frequency Setting When 0 to +10 VDC (0 to 5V*) is applied, the maximum frequency is

Voltage Input reached at +10 VDC (5V*) and is proportional to output frequency

down to 0 VDC. Input impedance is 22K ohm ( *250% gain setting F_35)

13 Frequency Setting Regulated +10 VDC power supply for frequency setting potentiometer,

Voltage Output Term. 10mA or less (13 to terminal 11)

C1 Frequency Setting When the input signal is +4 to +20mA dc, the maximum frequency is

Current Input (+) reached at 20mA and is proportional down to a minimum frequency

setting at 4mA. Input impedance is 250 ohm, must be isolated source

CM Control Circuit Common terminal for control input commands, X1-X4, FWD, REV, BX,

Common Terminal RST, THR, Y1 and FMP pulse output signal

(Do not connect to terminal 11)

FWD Forward Command

Input Terminal Forward command via FWD-CM (closed). Reverse command via

REV-CM (closed). When FWD-CM and REV-CM are closed

Reverse Command at the same time, the Drive will decelerate to stop

REV Input Terminal

BX Motor Coast-To-Stop Motor will coast-to-stop with BX-CM (closed). (For use when

Command Input applying mechanical brake with Drive in operation.) Note: If BX-CM is

Terminal opened with FWD or REV closed, the Drive will start the motor

RST Fault Reset Input After removal of fault condition, Faults are reset when a momentary

Terminal contact closure is made between the RST-CM terminals for more

than 0.1 seconds

If there is an input to the FWD or REV terminals with F_02 = 1 OR

2 and F_14 = 4 or 5 the Drive will suddenly restart.

4-7

Page 27

TABLE 5: Terminal Identification/Function (continued)

Terminal Terminal

Label Name Function

CONTROL TERMINAL BOARD (Continued)

THR External thermal trip With THR-CM (open), OH trip will occur and the motor will

command coast-to-stop.

NOTE:

thermostat, the THR-CM terminals must be closed or the Drive

will not operate. THR-CM is factory pre-jumpered, remove prior to

connecting an external NC contacts.

FMA* Analog Frequency Provides an output of 0 to +10 VDC (+10VDC at max frequency),

Meter Connection available for connection of a voltmeter with internal resistance of

F_40=0 10K ohms. See Function Code 41 for monitoring selection. Meter

connects between terminal FMA & 11. Note: FMP cannot be used

FMP* Digital Frequency Pulse frequency output equal to Drive output frequency.

Meter Connection Pulse voltage: Peak 5 VDC, 50% duty, Adjustable range = 600 to

F_40=1 6000 Hz (Max) See Function Code 42 Pulse Rate Multiplier.

Meter connects between FMP and CM. Note: FMA cannot be used

With no external thermal relay or external braking resistor

30A Fault Relay Output During normal operation, the relay is not energized and contact is made

30B Terminals between 30B and 30C. When a fault is detected, the relay is energized

30C and contact is made between 30A and 30C. (Contact rating resistive

load: 250 VAC, 0.3 Amps)

X1-X3 Multistep Frequency Seven individual preset frequency selections via binary combination

Input Function (closure) between X1, X2, X3, and CM.

Selection Frequency selections determined using functions F_21 thru F_27.

X4 Function Extension F_43=0 acceleration/deceleration time #2 is selected when X4-CM is

(Input) closed. When not closed #1 setting is activated.

(F_43=1) 8 additional frequencies can be selected by X1, X2, X3 and X4.

(F_43=2) 2nd Motor selection when X4 - CM is closed.

(F_43=3) Functions as hold signal if 3-wire operation is desired.

Y1 Output Function Outputs one of the following signals depending on setting of F_54;

(Programmable) 0: Drive running (RUN) 3: Undervoltage stop mode (LV)

1: Frequency level detection (FDT) 4: Torque limiting mode (TL)

2: Frequency equivalence (FAR) 5: Auto restart mode after

momentary power loss (IP)

Allowable load: Maximum 27VDC, 50mA or less

PLC PLC Prevents PLC fault caused by leakage current from the drive. (See Drive

interface details, Figure 4-7)

* Either an analog (FMA) or digital (FMP) frequency meter, not both.

4-8

Page 28

Output Terminal Y1

CM

Drive Interface Details

27 Vdc MAX Load

50 mA MAX

Y1

Input Terminal FWD, REV, X1-X4, BX, RST, THR

DC24 - 27V

6 mA MAX

Input Terminal

22K Ohms

250 Ohms

CM

Reference Input

1 - 5K Ohms

2 WATT

+4 to +20 mA dc

With PLC Terminal Connection Between PLC and Drive

PLC Drive

Note: Do Not

Connect

Figure 4-7. DRIVE INTERFACE DETAILS

4-9

Page 29

Section 5

DRIVE OPERATION

PRE-OPERATION INSPECTION

After mounting and wiring has been completed, check the Drive for the following items before applying AC power:

— Check for wiring errors.

— Verify that there are no wiring chips, screws, etc. remaining in the Drive.

— Check that all screw and terminal connections are tight.

— Verify that no exposed wire ends are touching other terminals.

KEYPAD PANEL IDENTIFICATION / OPERATION

See the following diagrams for Display and Keypad Operation description when in the Operation Mode, Program

Mode or Trip Mode.

FUNCTION CODE AND DATA CODE DESCRIPTION / SELECTION

When AC power is applied to the Drive, the keypad panel display will be as shown in Figure 5-1 and will be

flashing on and off. If the RUN key is pressed at this point, operation will be at 60 Hertz according to the

Function Code set at the factory. (Use the STOP key to halt operation.)

-- A Flashing display indicates when a run command is not present.

-- A Solid display indicates the actual output when the Drive is running.

If a test run is desired, press the key to change the flashing display of 60.00 Hz frequency setting to

5.00 Hz. Press RUN to conduct the test run and check for smooth motor operation and direction of rotation.

Removal of AC power will store a frequency reference in memory.

Figure 5-1. KEYPAD PANEL DISPLAY WHEN AC POWER IS APPLIED

5-1

Page 30

Keypad and Display Operation Programming

Mode Selection

The Drive has five (5) modes as shown below. The mode can be changed with the keys on the keypad panel.

(1) Stop Mode: Drive stopped (4) Program Mode: Motor Running

(2) Run Mode: Drive operational (5) Trip Mode: Drive system faults

(3) Program Mode: Motor Stopped

Data Setting

Changing Function Codes in the STOP Mode

➀

Stop mode

PRG

RESET

FUNC

DATA

1

Stop Mode

3

All Function Codes

Can Be Changed

2

Run Mode

5

Trip Mode

PRG

RESET

PRG

RESET

4

Restricted Function

Code Access

RUN

PRG

RESET

This is the state in which all operation signals ( signal)

[Keypad operation], FWD and REV signals (Terminal operation)

are OFF.

The last keypad display (frequency, amps, volts etc.) flashes

repeatedly.

The mode is switched to Function Code setting mode (All

Function Code settings can be changed).

Each time the key is pressed, the display changes between

indication of a Function Code and its data.

When these keys are pressed while the Function Code is displayed, the Function Code number will change. By pressing

them while data is displayed, the data can be changed.

FUNC

DATA

The data is stored and the Function Code advances to the next

Function Code number.

Are

there any

more functions

To change other data, repeat the above procedure.

to change?

PRG

RESET

Changing Function Codes in the RUN Mode (See TABLE 6)

➁

The program mode is ended and the Drive returns to STOP

mode.

5-2

Page 31

Display and Key Operation

1. Operations and displays in each mode

The keypad panel modes can generally be classified into five types. The operation method and the display

contents of each mode are shown below.

NOTE:

STOP Mode (Display continually flashes)

➀

Hz display

Following examples are with maximum frequency, F_03 set higher than 60 Hz

A display

FUNC

DATA

➛➛

PRG

Reset

To PROGRAM

mode while stopped

➛

➛

PRG

Reset

To PROGRAM

mode while stopped

➛

➛

FUNC

DATA

➛

FUNC

DATA

r/min display

PRG

Reset

To PROGRAM

mode while stopped

➛

FUNC

DATA

V display

PRG

Reset

To PROGRAM

mode while stopped

➛

➛➛

m/min display

➛

PRG

Reset

➛

➛

To PROGRAM

mode while stopped

➛

RUN

Keypad panel

operation:

➛➛

Drive will run

Display = Hz

Terminal operation:

Not operational.

STOP

➛

➛

RUN

Terminal operation:

Not operational.

STOP

Not effectiveNot effective

Keypad panel

operation:

Drive will run

Display = A

➛

RUN

Keypad panel

➛

STOP STOP

operation:

Drive will run

Display = V

Terminal operation:

Not operational.

Not effective

➛➛

5-3

RUN

➛

Keypad panel

➛

operation:

Drive will run

Display = r/min

Terminal operation:

Not operational.

Not effective

➛

➛

RUN

Keypad panel

➛

Drive will run

Display = m/min

Terminal operation:

Not operational.

STOP

Not effective

➛

operation:

Page 32

RUN Mode

➁

Hz display A display

FUNC

DATA

➛

PRG

*

Reset

PROGRAM Mode

while running

➛

➛

PRG

Reset

PROGRAM Mode

➛

➛

FUNC

DATA

➛

while running

V display

PRG

Reset

PROGRAM Mode

➛

➛

FUNC

DATA

➛

while running

r/min display

PRG

Reset

PROGRAM Mode

while running

➛

➛

FUNC

DATA

➛

m/min display

PRG

Reset

PROGRAM Mode

while running

➛

➛

➛

RUN

➛

Keypad panel

operation:

Drive will stop

➛

STOP

Display = Hz

Terminal operation:

F_02=1 Drive will stop

LED will show Er6

F_02=2 Stop key not

operational

➛

RUN

Not effectiveNot effective

➛

Keypad panel

Drive will stop

➛

STOP

Display = A

Terminal operation:

F_02=1 Drive will stop

LED will show Er6

F_02=2 Stop key not

operation:

operational

➛ ➛

RUN

Not effective

➛

Keypad panel

operation:

Drive will stop

➛

STOP STOP

Display = V

Terminal operation:

F_02=1 Drive will stop

LED will show Er6

F_02=2 Stop key not

operational

➛

RUN

Not effective

➛

Keypad panel

operation:

Drive will stop

➛

Display = r/min

Terminal operation:

F_02=1 Drive will stop

LED will show Er6

F_02=2 Stop key not

operational

* NOTE: See TABLE 6 (page 5-12) for Functions that can be changed while in RUN Mode.

RUN

Not effective

➛

Keypad panel

operation:

Drive will stop

➛

STOP

Display = m/min

Terminal operation:

F_02=1 Drive will stop

LED will show Er6

F_02=2 Stop key not

operational

5-4

Page 33

PROGRAM mode while stopped (example: changing the Torque Boost 1data)

➂

➛

➛

➛

FUNC

DATA

Data is Stored*

FUNC

DATA

➛

➛

PRG

Reset

Exit PROGRAM mode

➛

to keypad display**

RUN

Not effective

➛

STOP

Not operational

➛

FUNC

DATA

➛

PRG

Reset

Exit PROGRAM mode

➛

to keypad display**

RUN

Not effective

➛

STOP

Not operational

➛

Data is Stored*

FUNC

DATA

Data is Stored*

➛

➛

→

*NOTE: After changing function data with keys, the key must be pressed. If this is not

done, the data will not be stored. If the key is pressed before key is pressed, the

PRG

Reset

FUNC

DATA

FUNC

DATA

changed data will be canceled and operation will continue with the previous data.

* * NOTE: Keypad displays Frequency, Amps, Voltage, etc. based on selection.

5-5

Page 34

PROGRAM mode while running (example: changing the Torque Boost 1data)

➃

*NOTE: After changing function data with keys, the key must be pressed. If this is not done,

the data will not be stored. If the key is pressed before key is pressed, the changed data

PRG

Reset

FUNC

DATA

FUNC

DATA

will be canceled and operation will continue with the previous data.

* * NOTE: Keypad displays Frequency, Amps, Voltage, etc. based on selection.

See Table 6 for Functions that can be changed while in RUN mode.

5-6

Page 35

TRIP mode

➄

NOTE: Past fault records also can be displayed with Function Code 29.

Display of

present fault

status

PRG

Reset

Resets Fault

➛

Not effective

➛

Display of

previous fault

status

PRG

Reset

Resets Fault

➛

Display of

second- to-last

fault status

PRG

Reset

Resets Fault

➛

Display of

third-to-last

fault status

PRG

Reset

➛

Resets Fault

MECHANICAL MOTION

HAZARD: If there is an input to the FWD-CM or REV-CM

with F_02 = 1 or 2 and F_14 + 4 or 5 (Terminal

Mode) the Drive will suddenly restart.

END

PRG

Reset

➛

➛

Resets Fault

Not effective

FUNC

DATA

➛

➛

STOP

Not effective

➛

Not effective

Not effective

FUNC

DATA

Not effective

➛

Not effective

➛

STOP

Not effective Not effective

➛

FUNC

DATA

➛

➛

STOP STOP STOP

➛

Not effective

Not effective

FUNC

DATA

Not effective

➛

RUNRUNRUNRUN

Not effective

➛

Not effective Not effective

➛

FUNC

DATA

RUN

➛

➛

➛

Not effective

Not effective

5-7

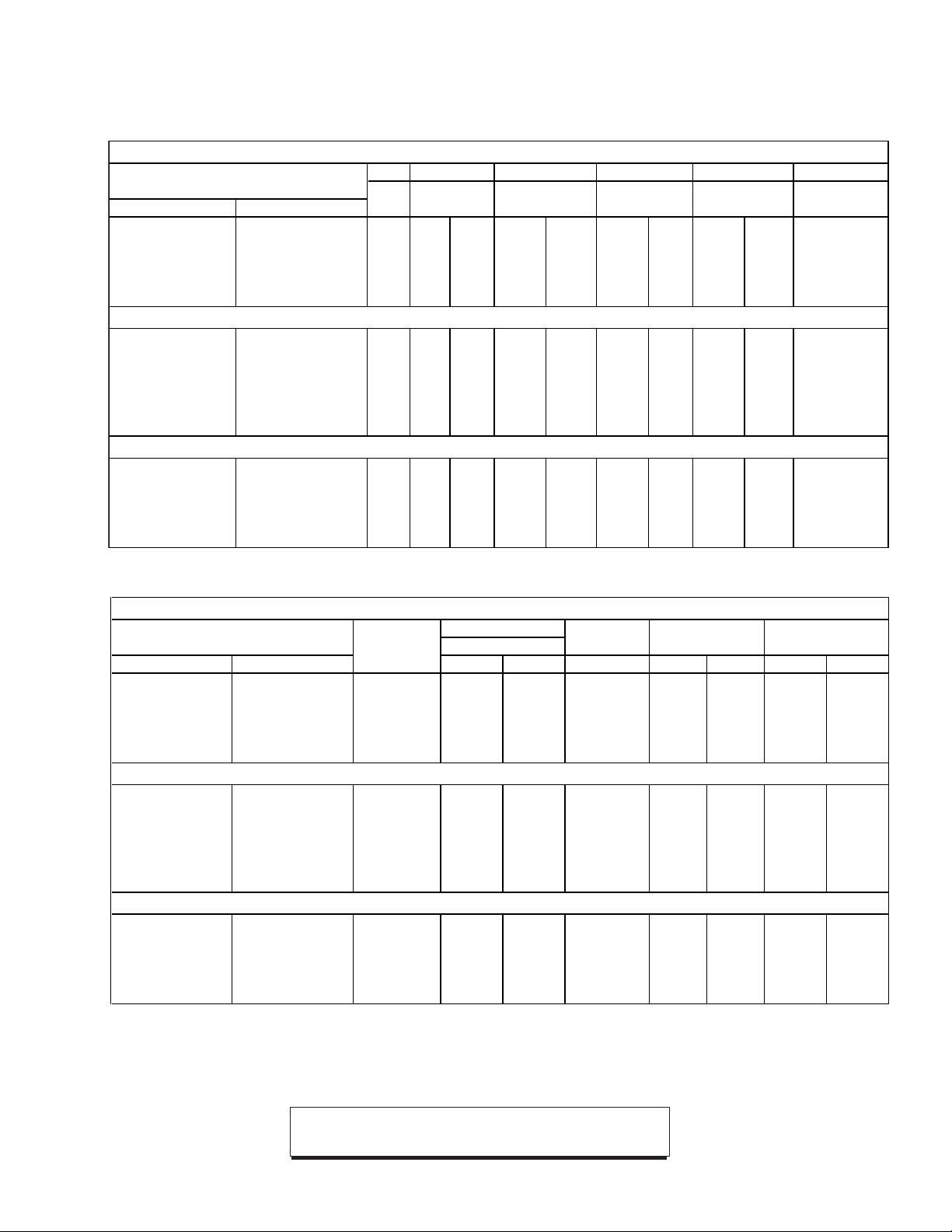

Page 36

PROGRAM Mode PROGRAM Mode

Keys and Indicators Mode STOP Mode RUN Mode While Stopped While Running TRIP Mode

Function Display output frequency, current, Display function codes and data Display fault status

voltage, motor speed or line speed and fault memory listing

Indication Repeated Flashing Lit

Function Unit display for output frequency, current, Indicates PROGRAM mode None

voltage, motor speed or line speed

Indication Not Lit

PANEL

Function Indicates whether Keypad Panel or Terminal Operation Selected None

CONTROL

Indication Lit during Keypad Panel Operation Lit

Function Indicates Stopped Indicates Running Indicates Stopped Indicates Running Indicates Fault

Indication Not Lit Lit Not Lit Lit Not Lit

Function Program Mode Program Mode Stop Mode Run Mode Indicates Fault

Switches Digital Monitor & LED's

•

Change Display between Function Code and data

Function Unit indicates displayed values

•

Data setting and incrementing Function Code

Not Effective

•

Stores data and renews Function Code

Increases and decreases Increases and Increases and decreases

Function frequency, motor speed decreases Function Function Codes Displays Fault Memory

or line speed settings Codes and data and Data (stores data

values. temporarily)

Function Change to Run Mode Not Effective

Change to

Change to Program

Function Not Effective Stop Mode Not Effective Mode while Stopped Not Effective

(F_02 = 0)

(F_02=0)

Summary of each operation mode : The following table shows a summary of the various modes.

Lit

Repeated Flashing

Lit

Repeated Flashing

PRG. MODE

Hz A V

r /min m /min

PRG. MODE

Hz A V

r /min m /min

Change to

Stop Mode or 1

(F_02=0) or

(F_02=1)

PRG. MODE

Hz A V

r /min m /min

5-8

RUN

PRG

RESET

FUNC

DATA

RUN

STOP

Page 37

Operation

Pre-Operation Inspection

After completion of installation and wiring work, inspect the following items before the power supply to the Drive is

switched on.

CAUTION:

1. Check for wiring errors. (Especially the main circuit wiring: connection of the three

(single) phase AC power supply to the terminals L1, L2, L3 (L1, L2)).

2. Check that all loose wire strands, metal chips and unnecessary screws, etc. have been removed.

3. Check that all screws, terminals, and components are tight.

4. Check that the wire ends of crimp terminals are not in contact with other terminals.

CAUTION: Megger Test:

Do not conduct megger tests between the Drive main circuit terminals, or control circuit terminals.

Refer to Section 7 "Maintenance and Inspection."

Test Run Check Points

Use a low frequency reference setting of about 5 Hz to test Drive operation.

The following operating conditions must be confirmed:

1. Smooth motor rotation.

2. Correct direction of equipment rotation.

3. No abnormal vibrations and noise from the motor over full speed range.

4. Smooth acceleration and deceleration over full speed range.

Selecting Operation Method

The following methods can be selected to input the RUN/STOP signals and for frequency setting.

Keys

Analog signal (4 to 20 mA dc)

RUN

STOP Keys

*3

or

or (0 to 10Vdc)

Keys

Analog signal (4 to 20 mA dc)

or (0 to 10Vdc)

2

NOTES:

*1: F_02 cannot be changed when there is a short circuit (jumper)between either FWD-CM or REV-CM.

*2: Multistep speed operation (up to 8 steps are possible)

The frequencies of step 1 to step 7 are set with the Function Codes F_21 to F_27 and selected

with the terminals X1, X2 and X3 (Additional 8 steps available with F_43 = 1 and F_44 to F_51

using X4).

If input signals are provided to terminals X1, X2 and X3, then data setting of F_01 (settings made by

keypad panel or analog signal are ignored) and multistep speed operation is controlled by these

terminal signals.

*3: F_02 =1 Stop key on the keypad active

F_02 = 2 Stop key on the keypad inactive

5-9

Page 38

TABLE 6: Function Codes

Function Code Numbers Followed by Function Descriptions

* Function can be changed while the Drive is operating.

Basic Functions

–

00 Data Protection 1

01 Frequency Command 1

02 Operation Command 3

03 Maximum Frequency 3

04 Base Frequency 1 3

05 Maximum Output Voltage 4

06 *Acceleration Time 1 4

07 *Deceleration Time 1 4

08 *Torque Boost 1 4

09 *FMA Terminal Voltage 5

Adjustment

10 *Number of Motor Poles 5

11 *Line Speed Display 5

Coefficient

12 *Motor Sound (Carrier Freq.) 5

13 Number of Restart Attempts 6

Page 6 –

Basic Functions (cont'd)

22 *Multistep Frequency 10

Setting 2

23 *Multistep Frequency 10

Setting 3

24 *Multistep Frequency 10

Setting 4

25 *Multistep Frequency 10

Setting 5

26 *Multistep Frequency 10

Setting 6

27 *Multistep Frequency 10

Setting 7

28 S-curve Acceleration/ 11

Deceleration

(Operation Selection)

29 * Fault Memory/History 12

30 Starting Frequency 12

31 * (During Accel/Decel) 12

Torque Limit

32 * (At Constant Speed) 12

Page 6 –

Basic Functions (cont'd)

43 X4 Terminal Function 17

44 *Multistep Frequency Setting 8 17

45 *Multistep Frequency Setting 9 17

46 *Multistep Frequency Setting 10 17

47 *Multistep Frequency Setting 11 17

48 *Multistep Frequency Setting 12 17

49 *Multistep Frequency Setting 13 17

50 *Multistep Frequency Setting 14 17

51 *Multistep Frequency Setting 15 17

52 *Signal Filter 18

Frequency Setting

53 Timer 18

54 Y1 Terminal (Function) 19

55 *Frequency Level Detection 19

(FDT Operation Level)

56 *Hysteresis Width 20

Page 6 –

14 Restart After Momentary 6

Power Failure

15 Electronic Overload 1 7

Selection

16 Electronic Overload 8

Setting 1

17 DC Brake Operation 9

18 *DC Brake Starting Frequency 9

19 *DC Braking Level 9

20 *DC Braking Time 9

21 *Multistep Frequency 10

Setting 1

33 Braking Torque 13

Selection

34 * Bias Frequency 13

35 * Gain for Frequency Setting 14

Signal

36 * High Frequency Limiter 15

37 * Low Frequency Limiter 15

38 * Motor Characteristics 15

39 Data Initialization (Default 15

Settings)

40 FMA, FMP terminals 16

(Operation Selection)

41 FMA Terminal (Function) 16

42 * FMP Pulse Rate Multiplier 16

5-10

57 THR Terminal (Function) 20

58 *Jump Frequency Hysteresis 21

59 *Jump Frequency 1 21

60 *Jump Frequency 2 21

61 *Jump Frequency 3 21

62 Base Frequency 2 21

63 *Acceleration Time 2 21

64 *Deceleration Time 2 21

65 *Torque Boost 2 22

cont'd on next page

Page 39

TABLE 6: Function Codes (Cont'd)

Function Code Numbers Followed by Function Descriptions

* Function can be changed while the Drive is operating.

Basic Functions

–

66 Electronic Overload 2 22

Selection

67 Electronic Overload 22

Setting 2

68 *Slip Compensation 22

69 Torque Vector Control 23

70 Motor HP Capacity 1 23

71 Rated Current 1 23

72 No-load Current 1 23

73 Rated Current 2 23

74 Automatic Tuning 24

75 Motor 1 (%R1 Setting) 24

76 Motor 1 (%X Setting) 25

Page 6 –

Basic Functions (cont'd)

Page 6 –

Basic Functions (cont'd)

Page 6 –

77 *Torque Limiting Response 25

at Constant Speed

78 *Torque Limiting Response 25

During Acceleration/

Deceleration

79 Option Card Selection 25

5-11

Page 40

LED

Data Factory Customer

Display Setting Description Setting Setting

Section 6

FUNCTION CODE DESCRIPTIONS

Basic Functions

NOTE: * = Function can be changed while Drive is operating.

LED

Data Factory Customer

Display Setting Description Setting Setting

F_00 DATA PROTECTION 0

This Function protects the data setting from

accidental changes.

F_01

0 Data Changeable

1 Data Protected

To change the Data Protection Setting,

simultaneously press the

STOP

key and either the or key.

FREQUENCY COMMAND 0/1*

The frequency reference setting method can be selected.

0 Using the Keypad Panel and keys

1 Using analog signal input

Note: The frequency setting will be the sum of the

values at terminal 12 (0 to 10 VDC) and terminal C1

(4 to 20mA dc).

2 UP/DOWN Control

Output frequency can be increased or decreased by signal

input to the terminals X1 and X2.

The adjustable range is from minimum frequency to max

frequency. If the terminals X1-CM is held closed, output

frequency increases by F63 (2nd acceleration time). When

the terminals X2-CM is held closed, output frequency

decreases by F64 (2nd deceleration time). The rotation

direction can not be changed. The rotation direction

depends on input to the terminal FWD or REV.

*Default value = 0

Factory setting for NEMA1 = 1. Will reset to 0 when default is selected

6-1

Page 41

LED

Data Factory Customer

Display Setting Description Setting Setting

The initial value for frequency setting is always zero after

the drive is stopped by operation command or after power

shut off.

3 Same as data setting 2 except the initial value for frequency

setting is the previous value before the drive is stopped by

operation command or power shut off.

Example of UP/DOWN control operation

*1) Initial value = 0

*2) Initial value = prevous value

*3) 1st Acc. time by F06

*4) 1st Dec. time by F07

*5) 2nd Acc. time by F63

*6) 2nd Dec. time by F64

Data 2

Output

freq.

FWD-CM

X1-CM

X2-CM

Data 3

Output

freq.

FWD-CM

Max. frequency

*4

*4

Max. frequency

*4

*3

*4

*6

*5

*6

*6

*4

*4

*5

*1

*5

*2

*3

*5

*5

*1

0

*5

*2

*3

0

X1-CM

X2-CM

*Default value = 0

Factory setting for NEMA1 = 1. Will reset to 0 when default is selected

6-2

Page 42

LED

Data Factory Customer

Display Setting Description Setting Setting

F_02 OPERATION COMMAND 0/1*

Selection of the input method for operation commands

0 Operation command input using the keypad

(RUN and STOP keys)

1 Operation command input by means of the

external signal terminal (FWD, REV). STOP key on

the keypad is active.

2 Operation command input by means of the

external signal terminal (FWD, REV). STOP key on

the keypad is inactive.

If selection "1" is chosen, and the stop button is depressed

while the drive is running, the drive will perform the

normal stop sequence until when the output frequency

reaches zero at which point an "Er6" fault shall be

indicated on the LED.

NOTE: To change the Operation Command Setting

the following three conditions must be met:

1. Remove jumper between CM to FWD

2. Open between CM to FWD and CM to REV

3. F_43 = 3 for Three Wire Control

cannot be selected.

F_03 MAXIMUM FREQUENCY 60

50 Maximum operating frequency can be set within

to the range of 50 to 400 Hz in steps of 1 Hz.

400

WARNING: Prior to operating a motor above its base

frequency, you must review the operational capabilities

of the motor. Failure to do so could result in severe

damage to the motor and could result in injury to