Page 1

GE Healthcare

Aestiva/5

Operation Manual - Part 2

Software Revision 4.X

Setup, Cleaning, Maintenance, Troubleshooting

Page 2

User Responsibility

w

CAUTION

This Product will perform in conformity with the description thereof contained in

this Operation manual and accompanying labels and/or inserts, when

assembled, operated, maintained, and repaired in accordance with the

instructions provided. This Product must be checked periodically. A defective

Product should not be used. Parts that are broken, missing, plainly worn,

distorted, or contaminated should be replaced immediately. Should repair or

replacement become necessary, Datex-Ohmeda recommends that a telephonic

or written request for service advice be made to the nearest Datex-Ohmeda

Customer Service Center. This Product or any of its parts should not be repaired

other than in accordance with written instructions provided by Datex-Ohmeda

and by Datex-Ohmeda trained personnel. The Product must not be altered

without the prior written approval of Datex-Ohmeda. The user of this Product

shall have the sole responsibility for any malfunction which results from

improper use, faulty maintenance, improper repair, damage, or alteration by

anyone other than Datex-Ohmeda.

U.S. Federal law restricts this device to sale by or on the order of a

licensed medical practitioner. Outside the U.S.A., check local laws

for any restriction that may apply.

Datex-Ohmeda products have unit serial numbers with coded logic which

indicates a product group code, the year of manufacture, and a sequential unit

number for identification.

AAA F 12345

This alpha character indicates the year of product

manufacture and when the serial number was assigned;

“D” = 2000, “E” = 2001, “F” = 2002, etc. “I” and “O” are

not used.

Aestiva, S/5, PSVPro, Tec 5, Tec 6

Datex-Ohmeda Inc.

Other brand names or product names used in this manual are trademarks or

registered trademarks of their respective holders.

and

Tec 7

are registered trademarks of

Page 3

1/Introduction

Table of Contents

2/Cleaning and Sterilization

How to use this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Symbols used in the manual or on the equipment . . . . . . . . . . . . . . . . . . . . 1-3

Maintenance summary and schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Operator maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Datex-Ohmeda approved service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Patient path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Scavenging path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Clean and sterilize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

To wash (by hand or machine) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Autoclave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Special requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Assemble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Disassemble the patient path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

i

3/Setup and Connections

Canister disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Disassemble the scavenging path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

How to clean and disinfect the flow sensors . . . . . . . . . . . . . . . . . . . . . . . .2-13

How to clean and sterilize the optional CO

bypass assembly . . . . . . . . . 2-15

2

Breathing system setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Canister setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Pneumatic and electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

How to install gas cylinders (high-pressure leak test) . . . . . . . . . . . . . . . .3-11

Cylinder yokes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

DIN connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

How to install the gooseneck lamp (12 V) . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

How to attach equipment to the top shelves . . . . . . . . . . . . . . . . . . . . . . .3-15

How to install equipment on the foldout shelf . . . . . . . . . . . . . . . . . . . . . .3-17

Installation notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

1006-0939-000

i

Page 4

Aestiva

4/User Maintenance

ii

Repair policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Manifold maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Expiratory valve maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Receiver maintenance (active gas scavenging only) . . . . . . . . . . . . . . . . . .4-8

Flow sensor maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

Breathing circuit maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Bellows maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Bellows tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

5/Alarms and Troubleshooting

6/Illustrated Parts

sensor calibration - 21% O

O

2

sensor calibration - 100% O

O

2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

2

Flow sensor calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

How to prevent water build-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

About alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Alphabetical list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Breathing system problems (no alarm) . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Electrical problems (power failure, etc.) . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Pneumatic problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

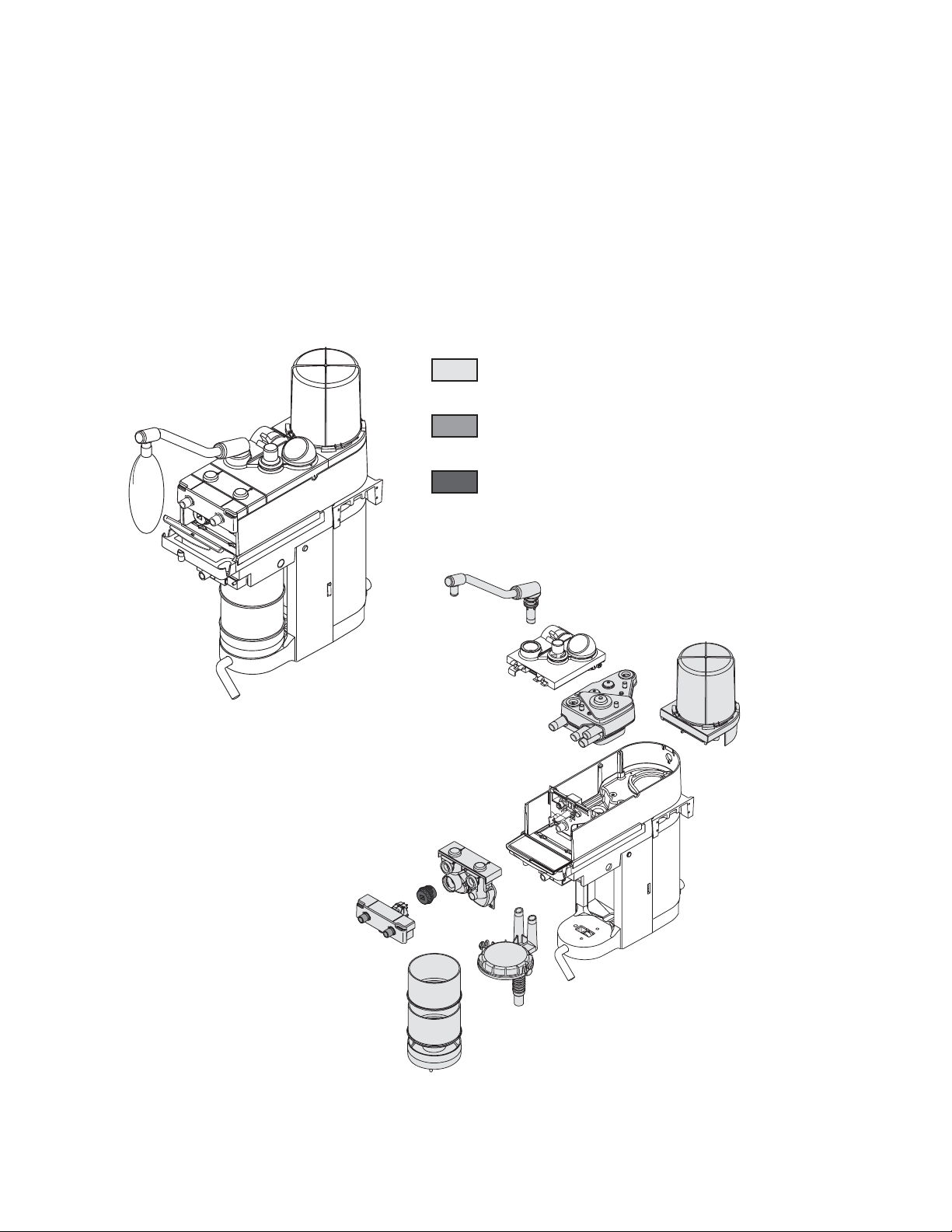

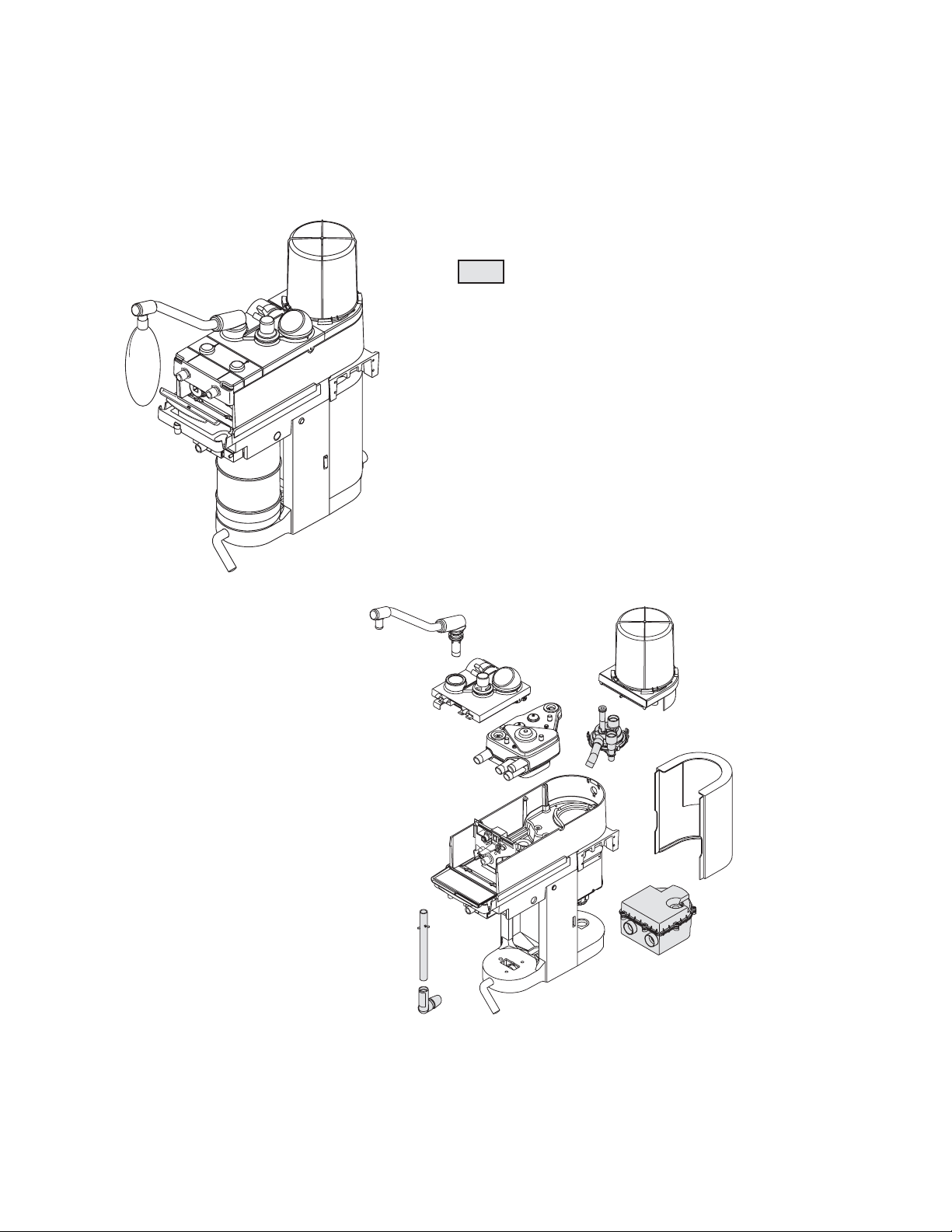

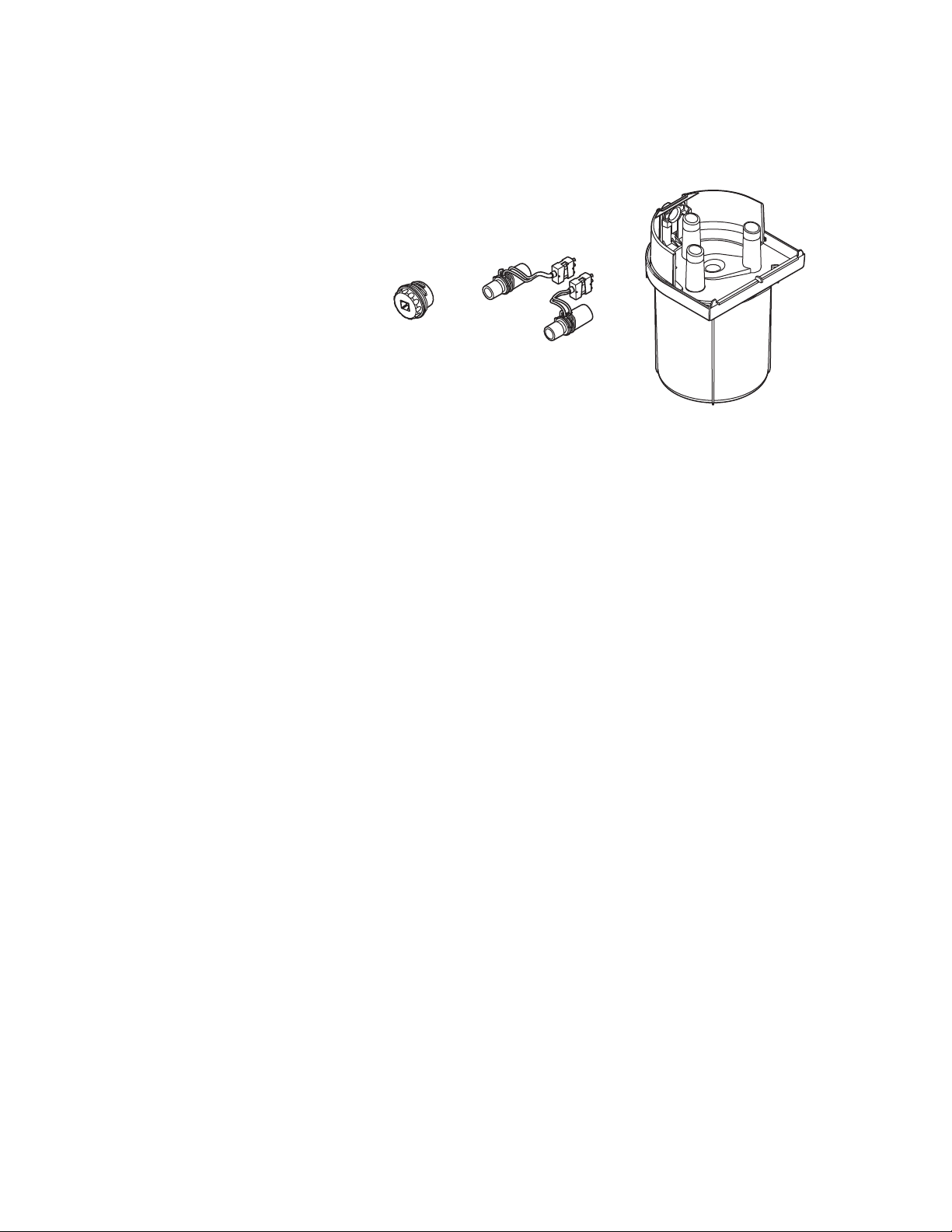

Breathing system parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Top level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Main manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

Exhalation valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

Bellows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

Test tools and system parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

7/Theory of Operation and Specifications

Ventilator Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

ii

1006-0939-000

Page 5

Table of Contents

Breathing system schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Electrical block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Pneumatic circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Suction regulators (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-12

flowmeter (optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-12

O

2

Breathing system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

Breathing system specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-15

Pneumatic specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-17

Flow specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-18

iii

Index

Warranty

Electrical power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Power cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

Electrical fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-20

Battery information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-20

Electro-magnetic compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-20

Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

Environmental requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-22

Ventilation operating specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

Aestiva ventilator accuracy data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-25

1006-0939-000

iii

Page 6

Aestiva

iv

iv

1006-0939-000

Page 7

1 Introduction

1-1

In this section

1006-0939-000

How to use this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Symbols used in the manual or on the equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Maintenance summary and schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1-1

Page 8

Aestiva

How to use this manual

This is part two of the Aestiva operation and maintenance manual. It tells you

how to:

• Remove and clean parts

OO

22

22

mm

sssseeeennnnssssoooorr

ss

rr

••••SSSSeeeetttt uuuupppp tttthhhheeee ssssyyyysssstttteeeemm

••••IIIIddddeeeennnnttttiiiiffffyyyy aaaannnndddd rrrreeeeppppllllaaaacccceeee wwwwoooorrrrnnnn oooorrrr ddddaaaammmmaaaaggggeeeedddd ppppaaaarrrrttttss

••••CCCCaaaalllliiiibbbbrrrraaaatttteeee tttthhhheeee OO

The second half of this section is a maintenance schedule.

The last section, troubleshooting, tells you what causes each alarm and what

you can do about it.

Use this manual together with Part 1, which includes the operating

instructions and preoperative checkout.

w

WARNING If an alarm occurs, safeguard the patient first, before

troubleshooting or repair procedures.

1-2

1006-0939-000

Page 9

N

N

Symbols used in the manual or on the equipment

w

Warnings and

occur if you do not follow all instructions in this manual.

Warnings tell about a condition that can cause injury to the operator or the

patient.

Cautions tell about a condition that can cause damage to the equipment. Read

and follow all warnings and cautions.

Other symbols replace words on the equipment or in Datex-Ohmeda manuals.

No one device or manual uses all of the symbols. These symbols include:

Cautions tell you about dangerous conditions that can

w

1 Introduction

1-3

l

O

o

q

p

œ

†

~

x

On (power)

Not autoclavable

Í

Off (power)

Type B equipment

m

Standby

Type BF equipment

µ

Standby or preparatory state for part of

the equipment

“ON” only for part of the equipment

H

Type CF equipment

Caution, ISO 7000-0434

w

“OFF” only for part of the equipment

wW

Direct current

Alternating current Dangerous Voltage

Protective earth ground

Attention, refer to product

instructions, IEC 601-1

This way up

Earth ground

y

r

1006-0939-000

Electrical input Electrical output

Pneumatic inlet Pneumatic outlet

Frame or chassis ground

REF

Stock Number

1-3

Page 10

Aestiva

å

Y

t

T

+

-

Alarm silence button

Equipotential Systems with this mark agree with

Variability Read top of float

Variability in steps Vacuum inlet

Plus, positive polarity Suction bottle outlet

Minus, negative polarity

SN

O2+

Serial Number

the European Council Directive

(93/42/EEC) for Medical Devices

when they are used as specified in

their Operation and Maintenance

Manuals. The xxxx is the

certification number of the

Notified Body used by DatexOhmeda’s Quality Systems.

O2 Flush button

P

N

ˆ

z

Z

Lamp, lighting, illumination Cylinder

Movement in one direction Isolation transformer

Movement in two directions Linkage system

Lock Risk of Explosion

Unlock Low pressure leak test

1-4

1006-0939-000

Page 11

1 Introduction

134°C

R

u

q

t

Autoclavable

Bag position/ manual ventilation

Mechanical ventilation

r

Open drain (remove liquid)

Close drain

U

Inspiratory flow

Expiratory flow

Q

O2 sensor connection End case

The primary regulator is set to pressure

less than 345 kPa.

European Union Representative

The primary regulator is set to

pressure less than 414 kPa.

1-5

1006-0939-000 1-5

Page 12

Aestiva

Maintenance summary and schedule

These schedules show the minimum frequency. You will have to service the

equipment more frequently if you use it:

• In unusual conditions (dirty gas supplies, high temperature, high humidity,

etc.).

• More frequently than normal.

Operator maintenance

Examine all components and do the maintenance procedures more frequently

if necessary.

Minimum

Frequency

Maintenance

Daily • Clean the external surfaces.

• 21% O

calibration (circuit O2 sensor).

2

• Flow sensor calibration

Two weeks • Drain the vaporizers and discard the agent. This is not

necessary for Tec 6 vaporizers.

Monthly • 100% O

calibration (cIrcuit O2 sensor).

2

• Put Krytox (or a lubricant approved for use with 100%

) on all tee handle threads.

O

2

During cleaning

and setup

• Inspect the parts for damage. Replace or repair as

necessary

Annually • Replace the external o-rings on the vaporizer ports.

As necessary • Install new cylinder gaskets on cylinder yokes.

• Replace the absorbent in the absorber.

• Drain the breathing system.

• Drain the breathing circuit module.

1

• Drain the overflow trap on the optional suction

regulator.

• Replace the circuit O

• Replace the disposable flow sensors (plastic)

sensor.

2

2

• Replace the autoclavable flow sensors (metal)3.

• Replace the receiver filter (active gas scavenging only).

1. This is included in the preoperative test procedure.

2. Under typical use the sensor meets specifications for 3 months

3. Under typical use the sensor meets specifications for 1 year.

1-6 1006-0939-000

Page 13

Datex-Ohmeda approved

service

1 Introduction

Minimum

Frequency Maintenance

6 months Have an approved service person do the service tests

and scheduled service maintenance.

1-7

1006-0939-000 1-7

Page 14

Aestiva

1-8 1006-0939-000

Page 15

WWAAAARRRRNNNNIIIINNNNGGGG

w WW

2 Cleaning and Sterilization

2-1

Obey applicable safety precautions:

• During the cleaning of the liquid collecting tray, avoid skin or eye contact with

the contents of the absorber. In the event of skin or eye contact, immediately

rinse the affected area with water and seek medical assistance.

• Read the material data sheet for each cleaning agent.

• Read the operation and maintenance manual for all sterilization equipment.

• Wear gloves and safety glasses. A damaged O

sensor can leak and cause

2

burns (contains potassium hydroxide).

• Do not breathe the fumes.

CCAAAAUUUUTTTTIIIIOOOONNNN

w CC

To prevent damage:

• Refer to the manufacturer’s data if you have questions about a cleaning agent.

• Do not use organic, halogenated, or petroleum based solvents, anesthetic

agents, glass cleaners, acetone, or other harsh cleaning agents.

• Do not use abrasive cleaning agents (such as steel wool, silver polish or

cleanser).

• Keep all electronic parts away from liquids.

• Do not permit liquid to go into the equipment housings.

• Do not soak synthetic rubber parts for more than 15 minutes. Swelling or faster

aging can occur.

• Only autoclave parts that are marked 134°C.

In this section Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Clean and sterilize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Disassemble the patient path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Canister disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Disassemble the scavenging path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

How to clean and disinfect the flow sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

How to clean and sterilize the optional CO

1006-0939-000 2-1

bypass assembly . . . . . . . . . . . . . . . . . 2-15

2

Page 16

Aestiva

Summary

2-2

Patient path

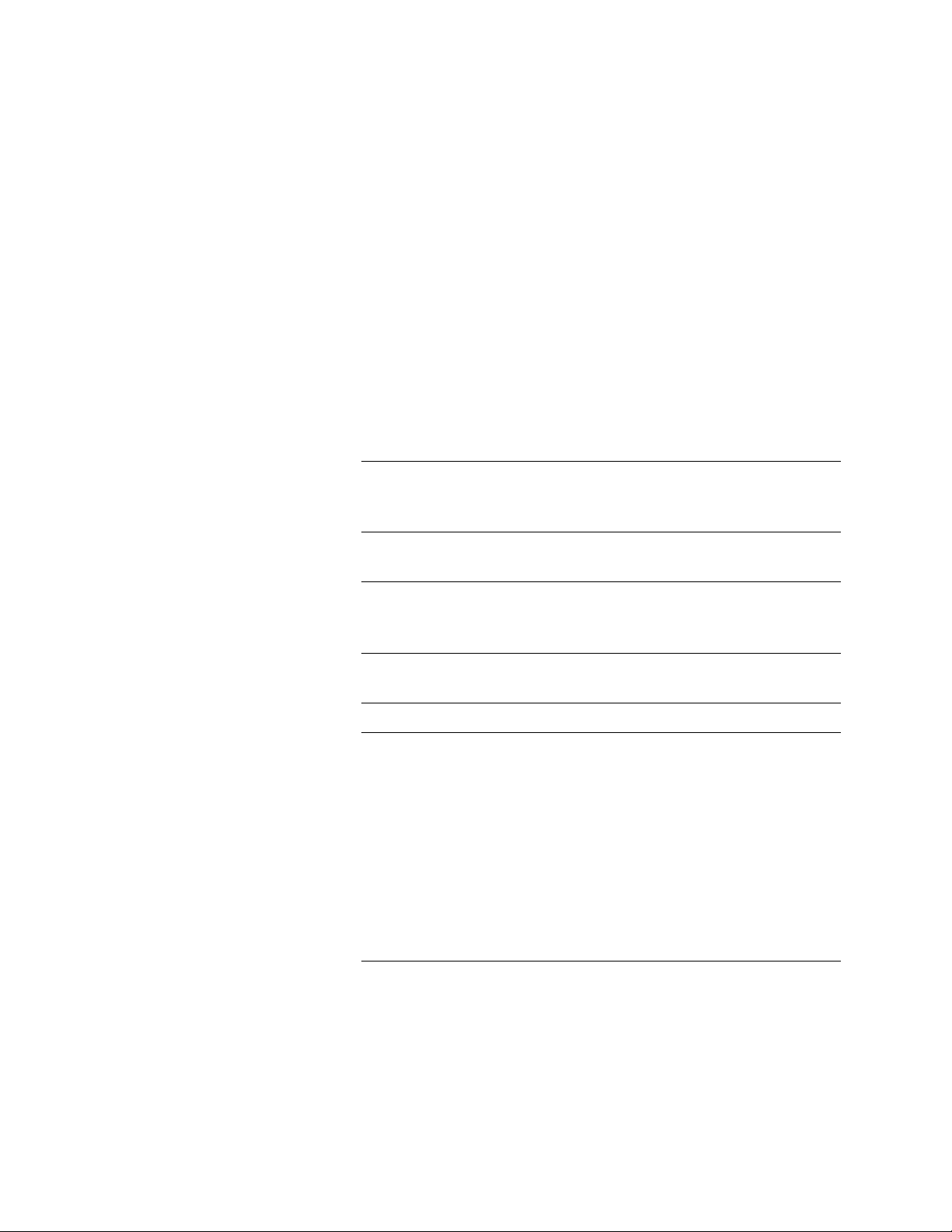

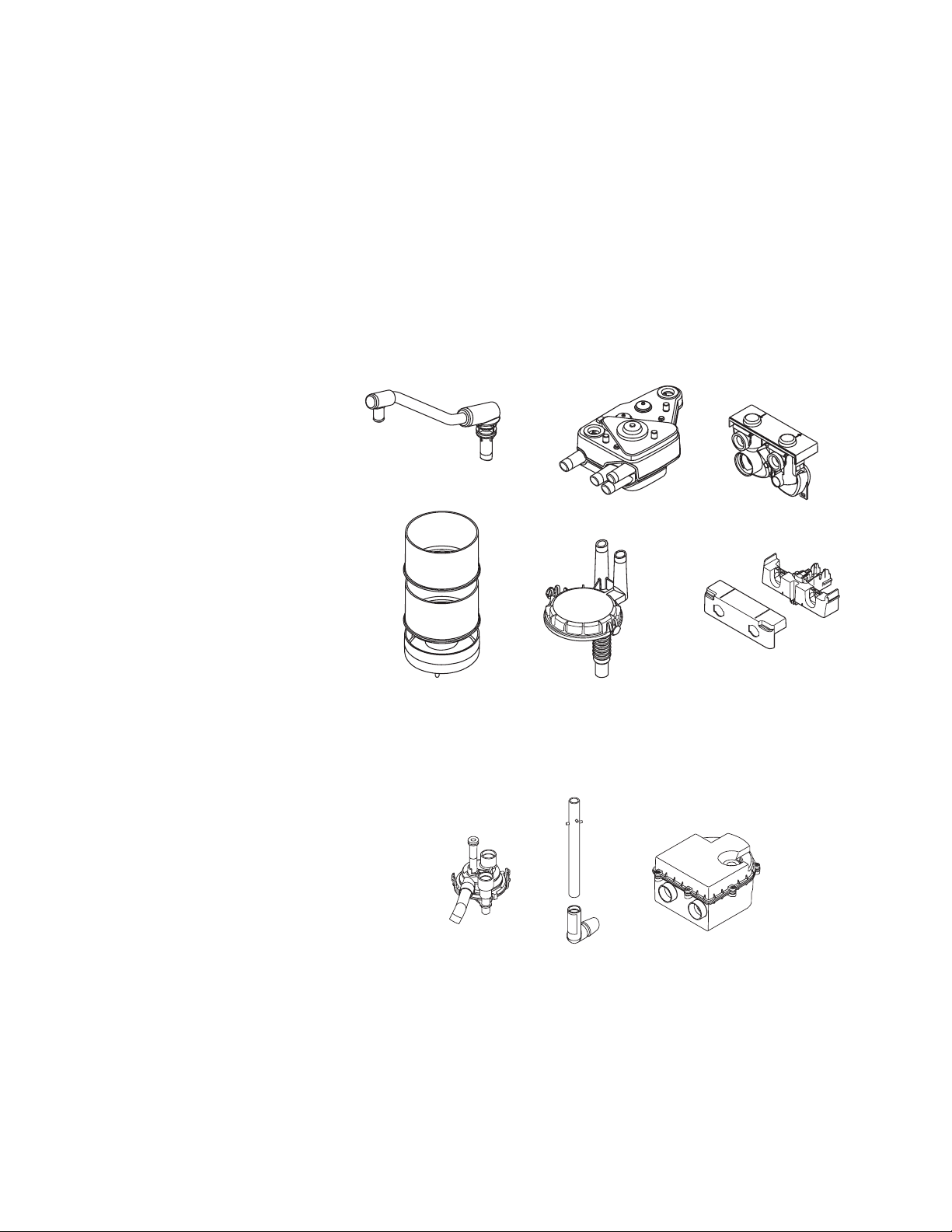

The parts in Figure 2-1 send exhaled gas back to the patient. They may require

more frequent cleaning/sterilization than parts in Figure 2-2. Refer to your

hospital’s infection control policy.

Autoclave (134°C) or

wash (mild detergent pH <10.5)

AB.23.003

*

If plastic, refer to cleaning/disinfection

procedure. If metal, autoclave (134°C)

Wipe with a damp cloth.

*

Figure 2-1 • These parts return

exhaled

gas to the patient

AB.23.079

2-2 1006-0939-000

Page 17

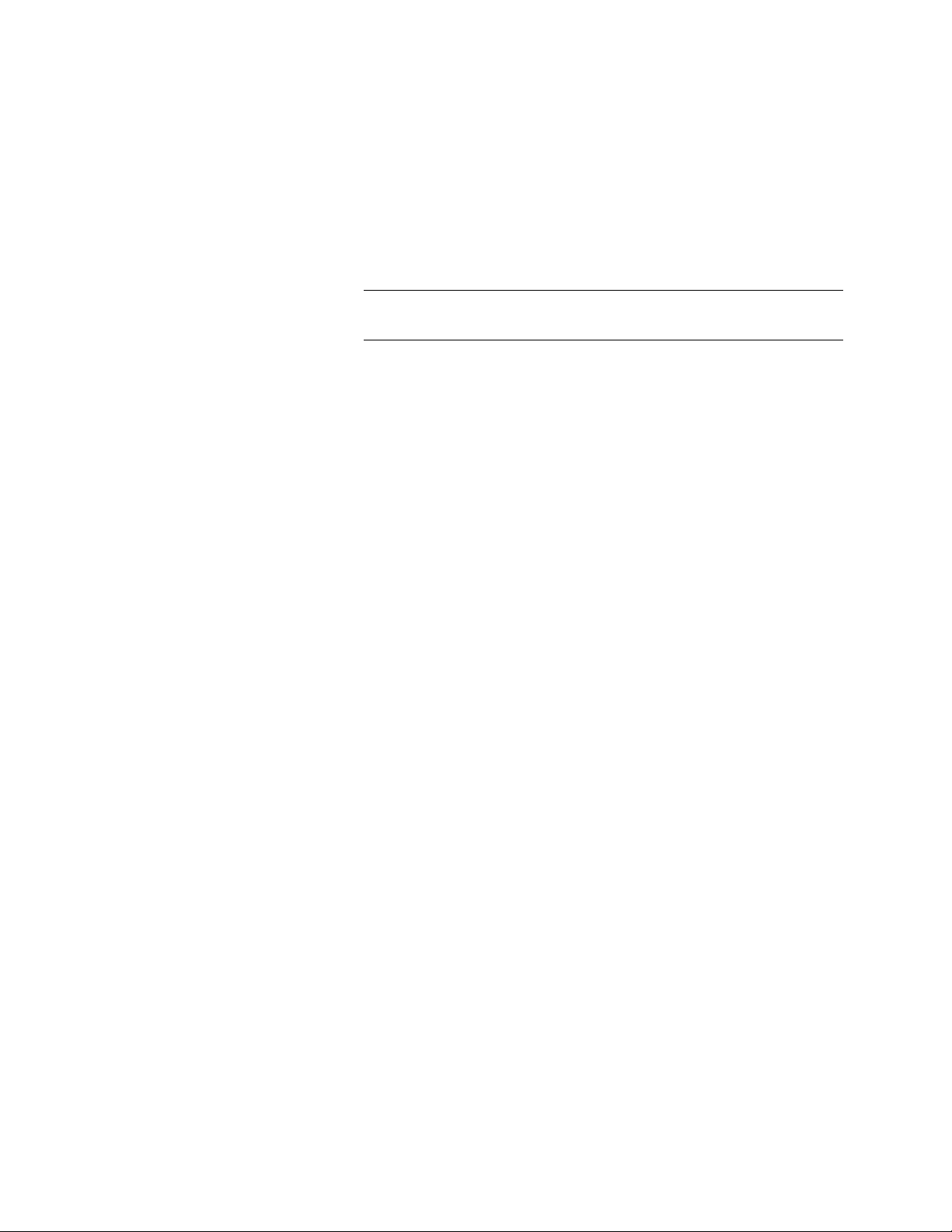

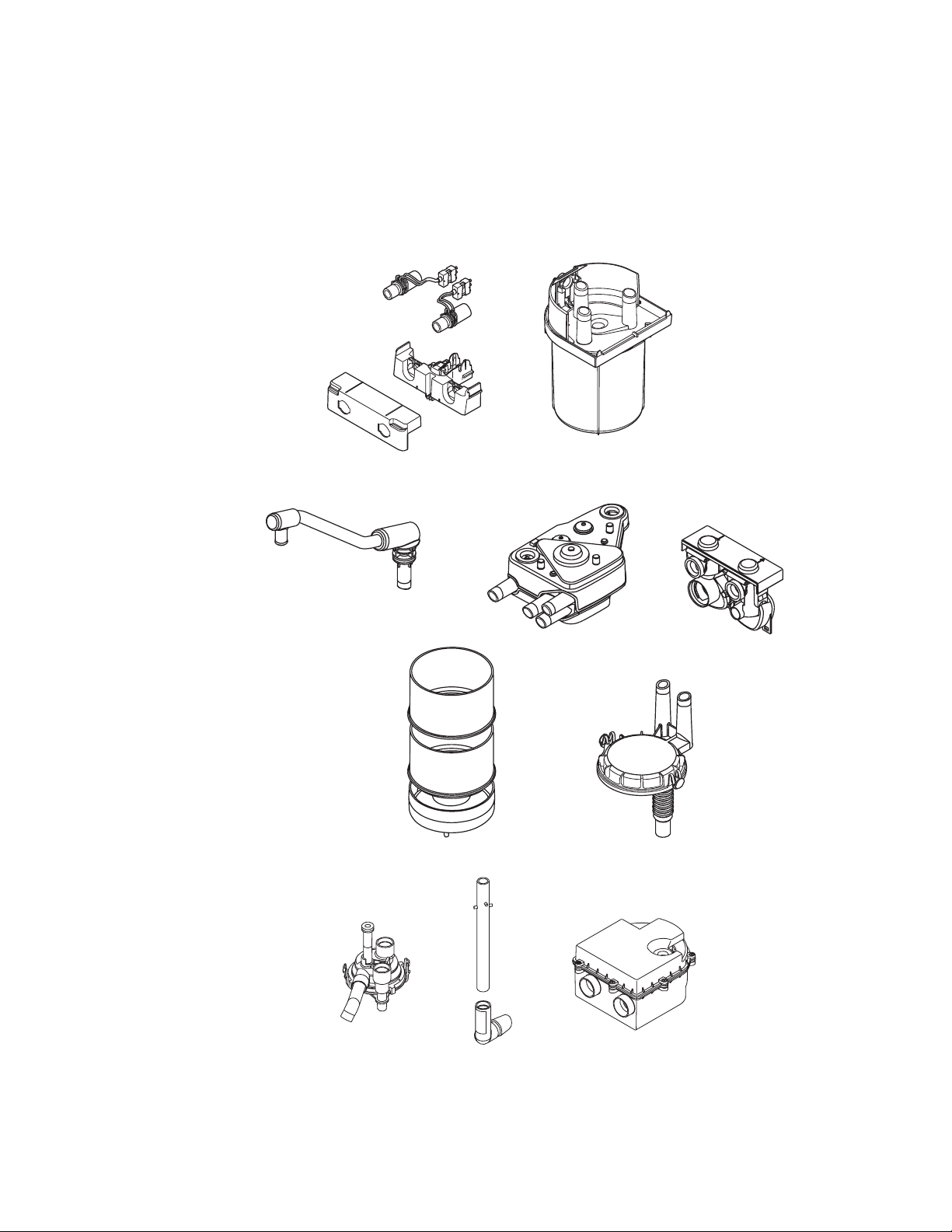

Scavenging path

AB.23.003

2 Cleaning and Sterilization

Autoclave (134°C) or

wash (mild detergent pH <10.5)

2-3

Figure 2-2 • These parts do not send gas back to the patient

AB.23.080

1006-0939-000 2-3

Page 18

Aestiva

Clean and sterilize

2-4

To wash (by hand or

machine)

The Disassembly part of this section tells you how to remove parts for

cleaning.

Patient path

AB.23.085

Scavenging path

AB.23.083

Use a mild detergent (pH <10.5). Then, rinse and dry completely. All parts

except the O

User maintenance tells you how to disassemble parts and clean inside them if

necessary.

2-4 1006-0939-000

sensor, and flow sensors can be washed.

2

Page 19

Autoclave

Metal Only

2 Cleaning and Sterilization

Patient path

2-5

AB.23.087

Upside down

AB.23.086

Scavenging path

AB.23.083

Autoclave at 134°C. Inspect the parts for deterioration. The User Maintenance

section tells you how to do this.

1006-0939-000 2-5

Page 20

2-6

Aestiva

Special requirements

*

AB.23.088

* Hang the bellows upside down

(extended) to dry. If not, the

convolutions can stick together.

•To clean the circuit O2 sensor, wipe it with a damp cloth. Do not put the sensor

in liquid.

• To clean/disinfect metal/or plastic flow sensors, use the flow sensor

cleaning procedure. Do not get the connectors wet.

• Disassemble the bellows before you wash it. If not, it will take a very long time

to dry. Hang the bellows upside down to dry.

• Assemble the bellows before you autoclave. Autoclave the bellows upside

down.

WWAAAARRRRNNNNIIIINNNNGGGG

w WW

CCAAAAUUUUTTTTIIIIOOOONNNN

w CC

Assemble

Do not use talc, zinc stearate, calcium carbonate, corn starch or

equivalent materials to prevent tackiness. These materials can go

into the patient’s lungs and airways and cause irritation or injury.

Do not put the circuit O2 sensor or flow sensor connector in liquid.

w Do not autoclave the Circuit O

sensor or the plastic flow sensors.

2

w Do not clean the interior surfaces of the flow sensors. Use a damp

on external surfaces only.

cloth

The Setup section tells you how to assemble the breathing system.

Inspect all parts for deterioration. Replace them if necessary.

The Preoperative tests in Part 1 (the first half of this manual), tell you how to

test the system for correct operation.

2-6 1006-0939-000

Page 21

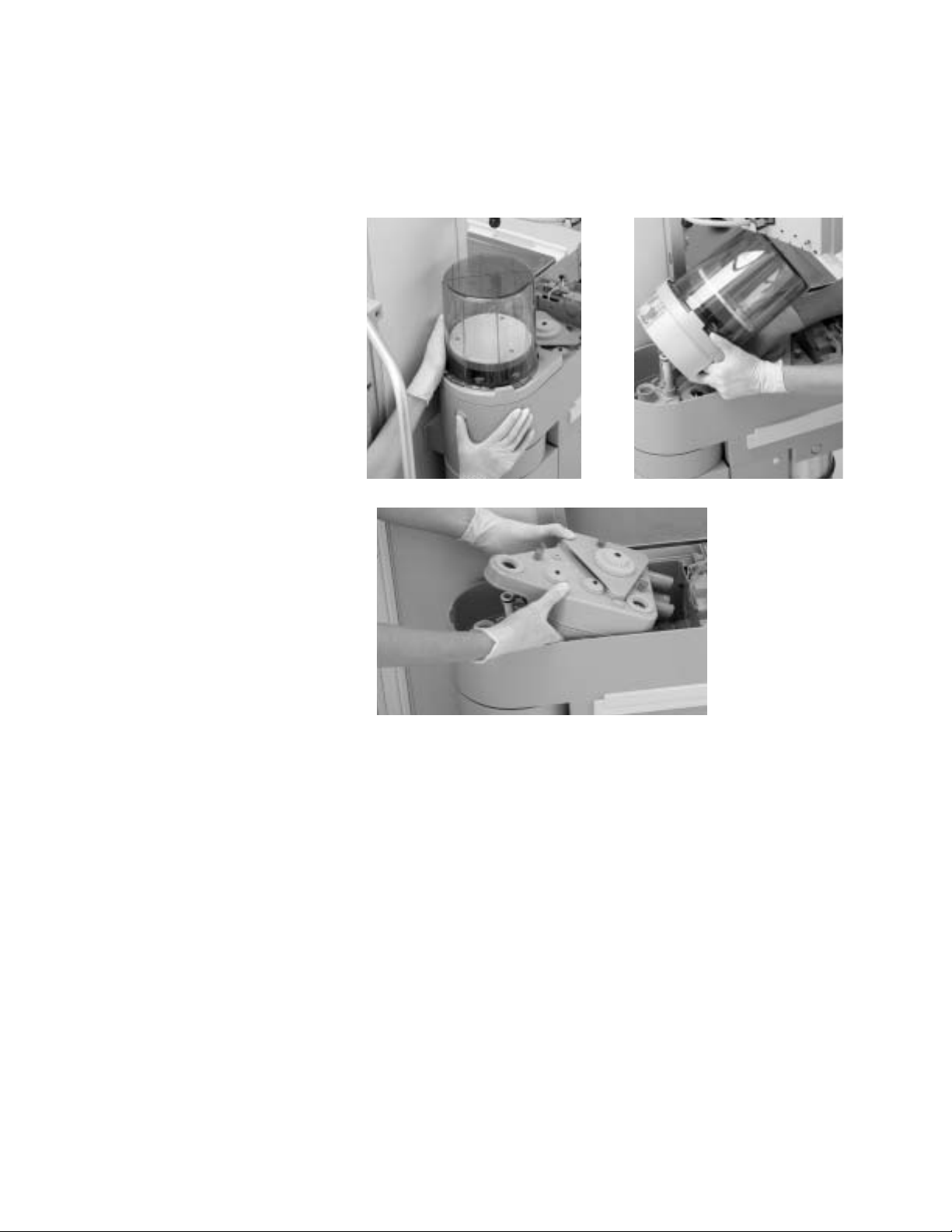

Disassemble the patient path

2 Cleaning and Sterilization

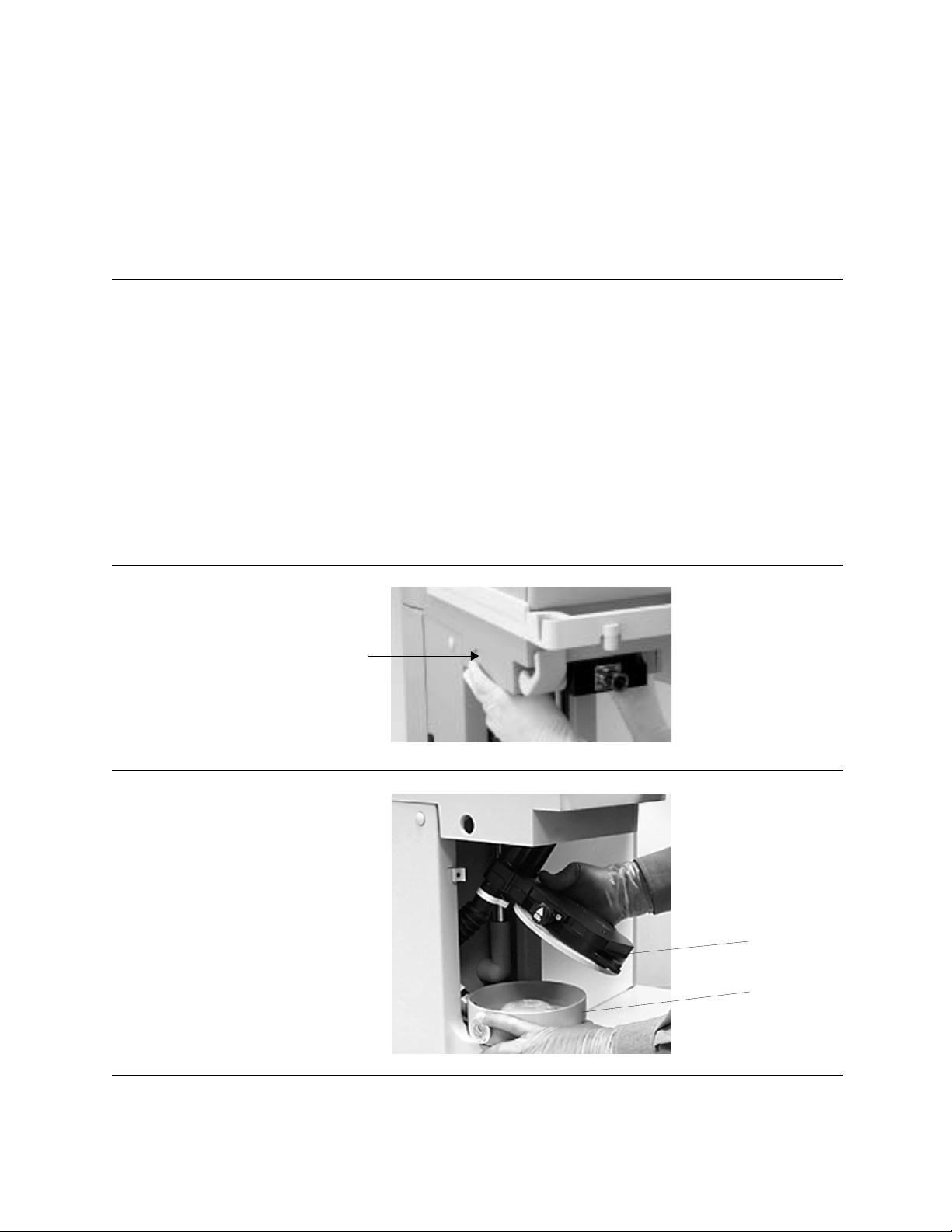

Step 1

Open the access panel.

Step 2

Push up on the latch located under the

flow sensor module.

Step 3

Remove the flow sensor module. You

will feel some resistance. Continue to

pull.

2-7

AA.96p.009

AA.96p.010

AA.96p.011

Step 4

Disconnect the cable and remove the

O

sensor.

2

AA.96p013, 014

1006-0939-000 2-7

Page 22

2-8

Aestiva

Step 5

Completely loosen the thumbscrew on

the breathing circuit module.

AA.96p016

Step 6

Remove the module. You will feel some

resistance. Continue to pull.

Step 7

Push the metal button to the first stop.

Pull out the bag arm.

Step 8

Push the metal button to the

second stop and open the top panel.

AA.96p017

AA.96p018

AA.96p020

2-8 1006-0939-000

Page 23

Step 9

Push the release button and remove

the bellows assembly (pull up).

Step 10

Remove the main manifold.

2 Cleaning and Sterilization

2-9

AA.96p021, 23

AA.96p024

Autoclave assemblies marked 134°C. Refer to the Section “Clean and

sterilize” for complete instructions. To assemble the circuit refer to the Setup

section.

1006-0939-000 2-9

Page 24

Aestiva

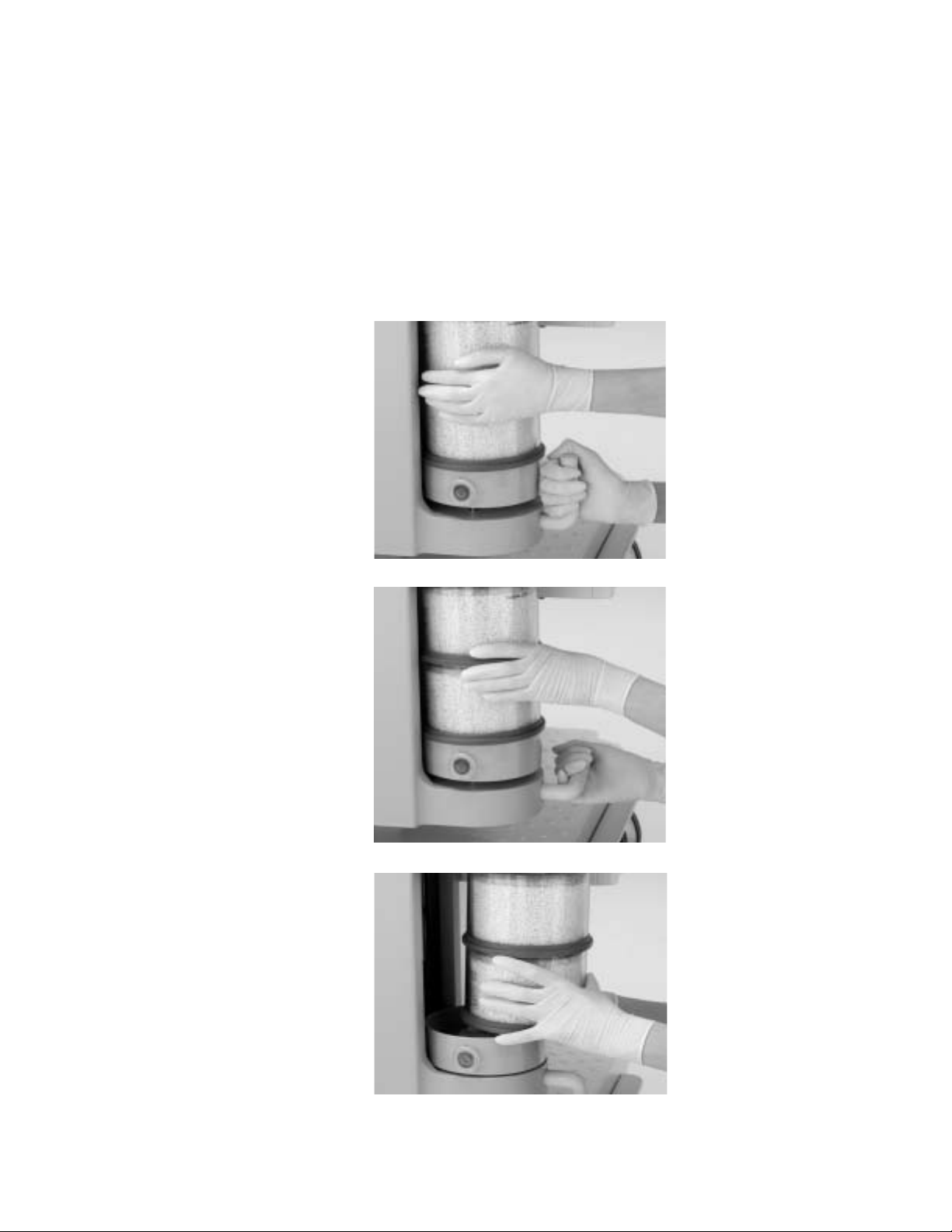

Canister disassembly

2-10

w CCCCAAAAUUUUTTTTIIIIOOOONNNNTo prevent damage, pull the release handle forward. Then turn the handle

Step 1

Pull the release forward.

AA.96p026

wZ

Step 2

Turn the release clockwise.

AA.96p028

Step 3

Pull down and out on the canisters.

AA.96p029

2-10 1006-0939-000

Page 25

Step 4

Push in the buttons on each side of the

top dish.

Step 5

Lift up the drain dish.

Remove the top dish and drain dish.

2 Cleaning and Sterilization

2-11

AA.96p053

AA.96p054

Continue with the next section or go to "Clean and sterilize". To assemble,

refer to the Setup section.

1006-0939-000 2-11

Page 26

Aestiva

Disassemble the scavenging path

These parts send exhaled gas to the disposal system, not the patient.

2-12

Exhalation valve

Complete the basic disassembly

procedure.

Push in the latches and pull out the

exhalation valve.

AB.23.089

Scavenging reservoir

Loosen the knob and remove the rear

cover.

Pull the reservoir up and to the rear.

Twist and pull down to remove the tube.

AB.23.090

2-12 1006-0939-000

Page 27

How to clean and disinfect the flow sensors

wwwwCCCCAAAAUUUUTTTTIIIIOOOONNNNDo not autoclave plastic flow sensors.

wwwwDo not use high-pressure gas, or brushes to clean the flow sensors.

wwwwDo not use cleaning solvents that are not approved for use with

Polycarbonates (e.g. CIDEX Plus).

CIDEX sterilization Both Datex-Ohmeda and the manufacturer of CIDEX (Johnson & Johnson)

have tested this procedure.

• CIDEX must be 14 day mixture, with activator vial REF REORDER # 2245

• One liter of this solution cleans four (4) flow sensors

2 Cleaning and Sterilization

2-13

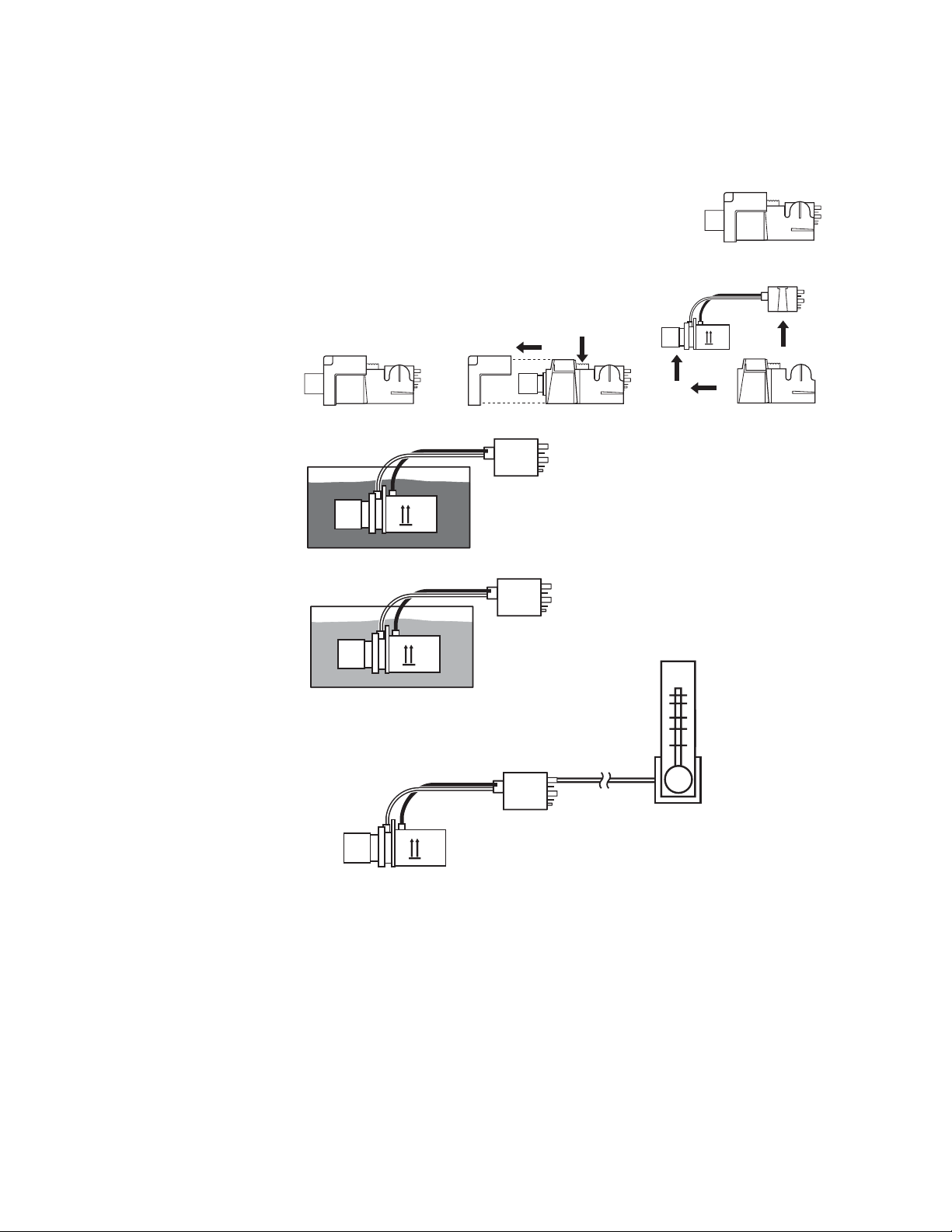

Procedure (Figure 2-3) 1. Remove the flow sensor module from the absorber. Refer to “Disassemble

the patient path” in this section.

2. Remove the flow sensors from the module.

• Push in the latch.

• Pull off the cover.

• Remove the flow sensors.

3. Submerge the flow sensor and tubes in activated CIDEX solution. Keep the

connector dry.

4. Keep the solution in the tubes for the sterilization period.

5. Submerge the flow sensor and tubes in distilled water. Again, do not get the

connector wet.

6. Rinse as indicated in CIDEX instructions.

7. Do steps 5 and 6 again to remove all CIDEX.

8. COMPLETELY dry the flow sensor and the tubes before you use the sensor.

Use a dry syringe, or connect vacuum or pressure to remove all liquid from the

sensor (sensor, tubes, and connector):

•Minimum time: 1 min

•Maximum vacuum: 30 in Hg

•Maximum flow: 10 L/min flow

•Maximum pressure: 345 kPa (50 psi).

1006-0939-000 2-13

Page 28

2-14

Aestiva

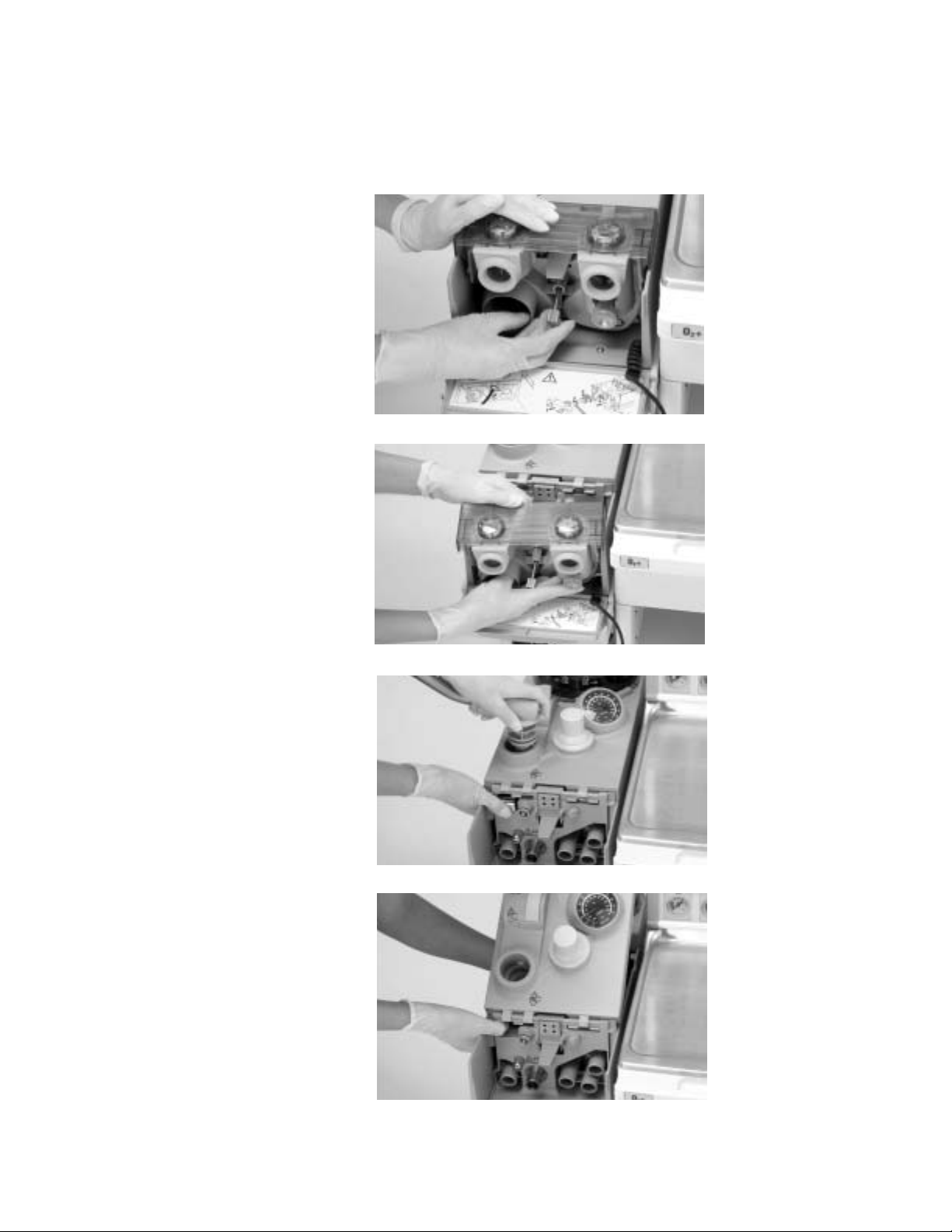

Step 2

Steps 3 and 4

Steps 5, 6 and 7

Step 8

Dry for > 1 min with these precautions:

• Maximum vacuum 30 in Hg

• Maximum flow 10 L/min

• Maximum pressure 345 kPa (50 psi)

Figure 2-3 • Steps 2-8

2-14 1006-0939-000

Page 29

2 Cleaning and Sterilization

HHHHoooowwww ttttoooo cccclllleeeeaaaannnn aaaannnndddd sssstttteeeerrrriiiilllliiiizzzzeeee tttthhhheeee ooooppppttttiiiioooonnnnaaaallll CCCCOO

These instructions assume that the system has the optional CO2 bypass

feature installed.

11

SSSStttteeeepppp 11

Remove the absorber canisters. (Also described in “Canister disassembly” in this section.)

a. Pull the canister release handle forward.

w CCCCAAAAUUUUTTTTIIIIOOOONN

b. Turn the release handle clockwise.

c. Lift out the canisters.

Note: The canisters should drop under their own weight when released. If they do not, clean and lubricate the pins in

the drain dish and sockets in the base.

22

SSSStttteeeepppp 22

Release the CO2 bypass assembly by

pushing both buttons (one on each side

of the assembly).

NN

To prevent damage, pull the canister release handle forward before turning the

handle.

OO

bbbbyyyyppppaaaassssssss aaaasssssssseeeemmmmbbbbllllyy

22

22

yy

2-15

33

SSSStttteeeepppp 33

Pull down on the CO2 bypass assembly

(a) to remove it and lift the drain dish

(b) up.

a

b

1006-0939-000 2-15

Page 30

2-16

Aestiva

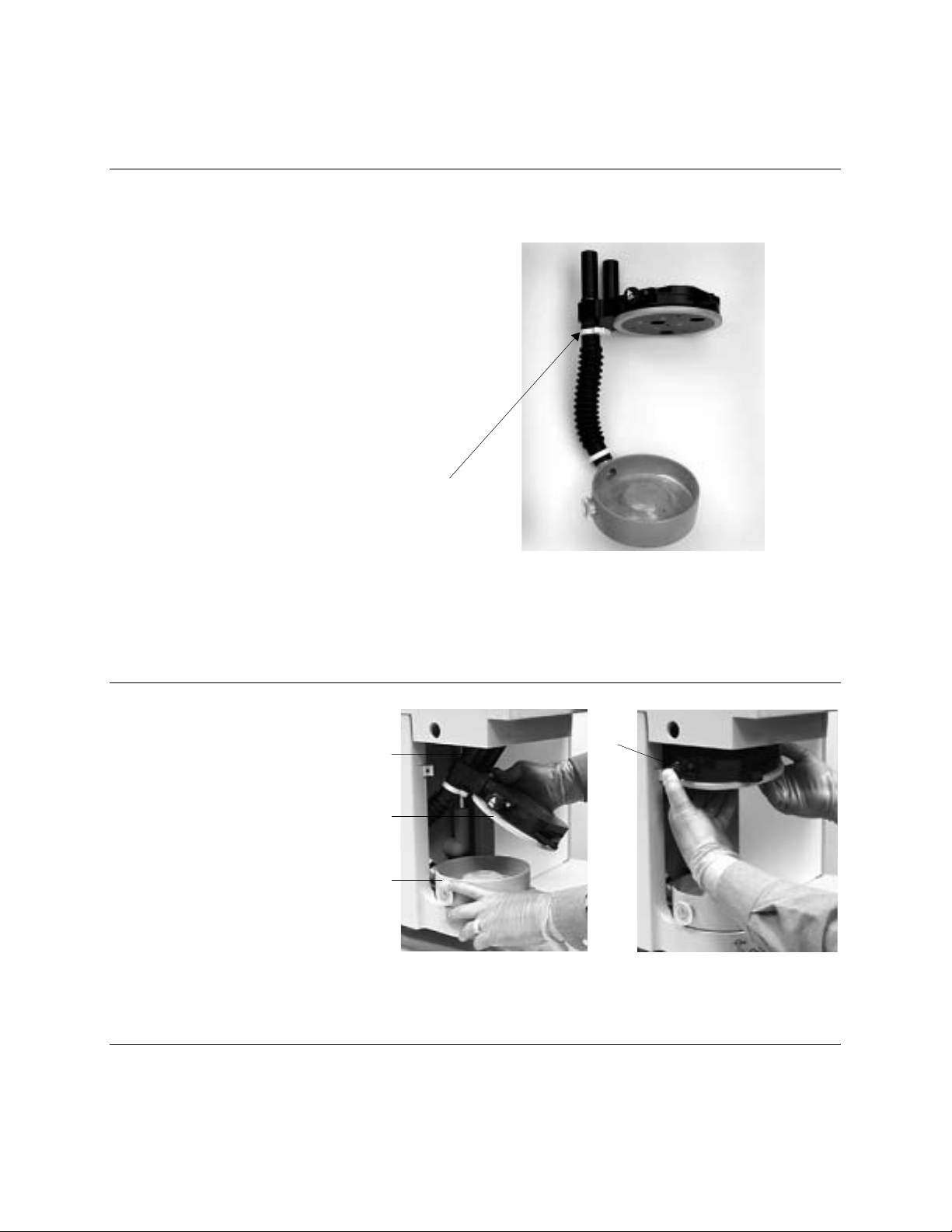

44

SSSStttteeeepppp 44

Clean and sterilize the bypass

assembly:

a. Immerse the assembly into a

solution of mild detergent and

water.

b. Agitate the assembly in the

solution while repeatedly

actuating and releasing the

plate.

c. Rinse the assembly by

immersing it in clean water and

agitating it again with the plate

actuated and released.

d. Autoclave the assembly at

134°C.

e. Cool about 40 minutes at room

temperature.

a

Note: Optionally, the bypass assembly can be divided into two smaller sections for easier cleaning by releasing the

top clamp (a) and pulling the hose from the assembly. When reassembling, reattach the hose to the bottom part of the

assembly. Secure the hose with the clamp and pinch the clamp one notch past finger-tight with pliers.

55

SSSStttteeeepppp 55

Reinstall the bypass assembly:

a. Reinstall the drain dish.

b. Insert the bypass assembly.

c. Push back and adjust to locate

the access holes for the top

ports.

d. Push the buttons on each side of

the assembly and push the

assembly up; both buttons

should snap into place.

e. Pull down on the assembly to

make sure it is locked into place.

c

b

a

d

2-16 1006-0939-000

Page 31

66

SSSStttteeeepppp 66

Reinstall the canisters:

2 Cleaning and Sterilization

a. Ensure seals and rim are free of soda lime dust.

b. Place the canisters in the drain dish.

c. Turn the canister release handle counterclockwise to its locked position while gently applying pressure on the

canisters to hold them against the canister guides.

77

SSSStttteeeepppp 77

Test the Bag circuit for leaks according to the Breathing System tests in the Appendix section of Part 1 of the Operation

manual.

• Do the test in both the Absorber mode and the Bypass mode.

• Ensure the alarm message “No CO

in section 3 of Part 1 of the Operation manual.

88

SSSStttteeeepppp 88

Before you use the system, complete the Preoperative Test procedure. Refer to the ‘Appendix - Preoperative Tests’

section of the Operation Manual Part 1, System Controls, Operation and Checkout.

Absorption” activates when in Bypass mode. See “CO2 Bypass mode operation”

2

2-17

1006-0939-000 2-17

Page 32

2-18

Aestiva

2-18 1006-0939-000

Page 33

3 Setup and Connections

IIIImmmmppppoooorrrrttttaaaannnnttttDatex-Ohmeda strongly recommends that you use O2 monitoring with this equipment.

Refer to local standards for mandatory monitoring.

IIIImmmmppppoooorrrrttttaaaannnnttttEuropean Standard EN 740 requires anesthetic agent monitoring when anesthetic

vaporizers are in use.

IIIImmmmppppoooorrrrttttaaaannnnttttEuropean Standard EN 740 requires CO2 monitoring during ventilation.

ww

WWWWAAAARRRRNNNNIIIINNNNGGGGSSSSAlways make sure that the pipeline supply hoses and the breathing circuit

ww

components are not toxic and will not:

• Cause an allergic reaction in the patient.

• React with the anesthetic gases or agent to produce dangerous

by-products.

ww

ww

To prevent incorrect values or equipment malfunction, use only

Datex-Ohmeda cables, hoses and tubing.

ww

ww

This system operates correctly at the electrical interference levels of IEC

601-1-2. Higher levels can cause nuisance alarms that may stop

mechanical ventilation.

ww

ww

To help prevent false alarms from devices with high-intensity electrical

fields:

• Keep the electrosurgical leads away from the breathing system and the

flow and oxygen sensors.

• Do not put the electrosurgical leads on any part of the anesthesia system.

3-1

ww

ww

To protect the patient when electrosurgical equipment is used:

• Monitor the correct operation of all life support and monitoring equipment.

• Keep backup manual ventilation available in case the electrosurgical

equipment prevents safe use of the ventilator.

• Do not use conductive masks or hoses.

In this section Breathing system setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Canister setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Pneumatic and electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

How to install gas cylinders (high-pressure leak test) . . . . . . . . . . . . . . . . . . . . . . .3-11

How to attach equipment to the top shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

How to install equipment on the foldout shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Installation notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

1006-0939-000 3-1

Page 34

Aestiva

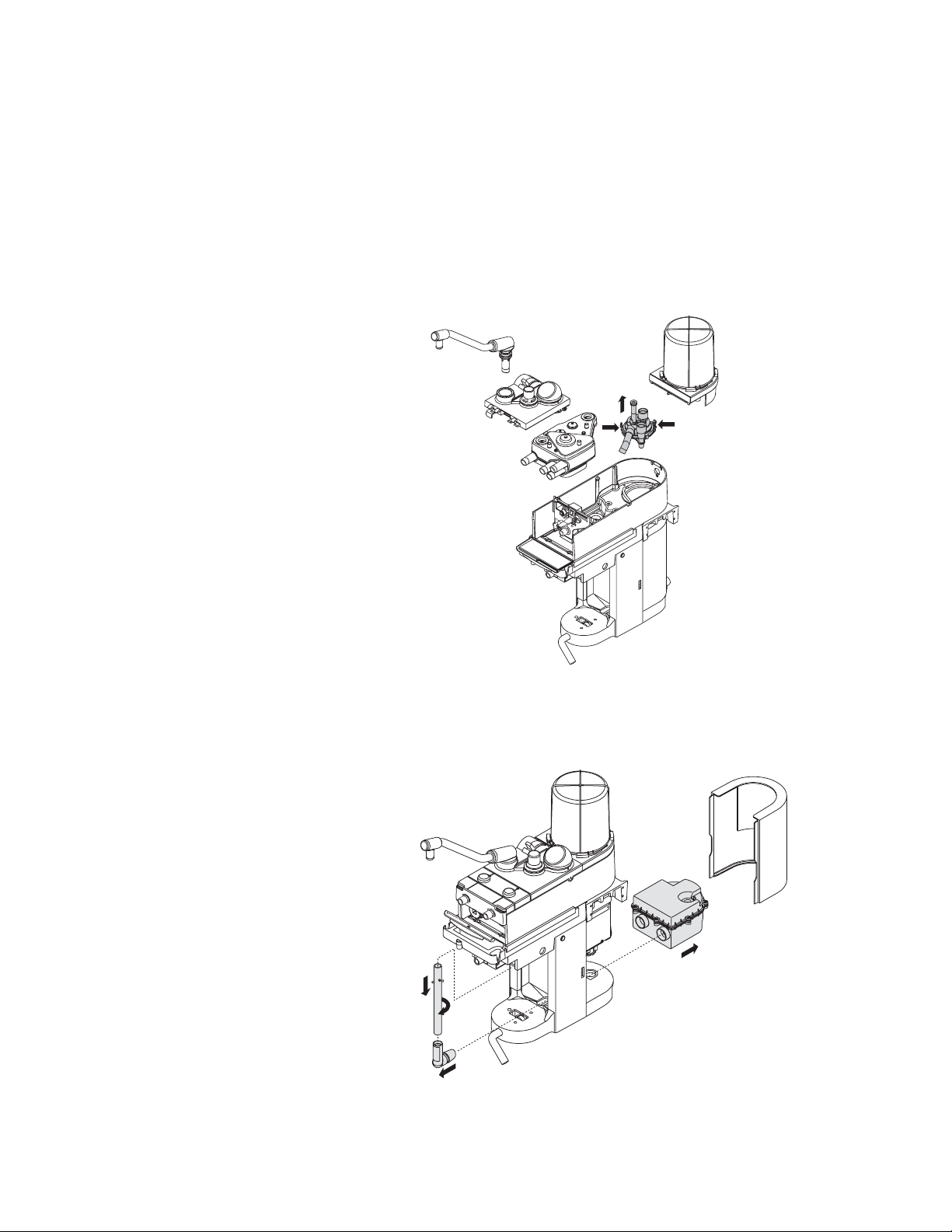

Breathing system setup

Step 1

To assemble the patient circuit, start at step 5.

3-2

Install the main manifold.

AA.96p024

Step 2

Install the Bellows.

•Make sure the release

button aligns correctly.

AA.96p022

Step 3

Gently close the control

panel.

AA.96p012

Step 4

Install the bag arm.

• Install a rebreathing bag

on the bag arm.

AA.96p019

3-2 1006-0939-000

Page 35

Step 5

Identify the breathing circuit

module (Circle or Mapleson).

3 Setup and Connections

Look at the tabs on the rear or

the label on the front.

Step 6

Install the breathing circuit

module. You will feel some

resistance. Continue to push.

Step 7

Completely tighten the

thumbscrew.

AB.23.211

Circle

Mapleson

3-3

AA.96p017

AA.96p016

Step 8

Install the O2 sensor.

• Completely tighten the

sensor.

• Connect the cable.

AA.96p013, 014

1006-0939-000 3-3

Page 36

3-4

Aestiva

Step 9

Install the flow sensor

module.

• You will hear a “click”

when it locks into

position.

• Refer to Note 1 or the User

Maintenance

section.

Step 10

Close the front panel.

AA.96p011

AA.96p009

Step 11

Connect the patient circuit.

Circle Module

AB.23.104

Mapleson D / Bain Module

To-fro

AB.23.152

3-4 1006-0939-000

Page 37

Note 1

Flow sensor assembly

3 Setup and Connections

3-5

AA.96p039

AA.96p038

1006-0939-000 3-5

Page 38

Aestiva

Canister setup

Each canister holds 1.35 kg of loose absorbent or 1.13 kg of commercially

packaged (pre-pack) absorbent. Datex-Ohmeda recommends Sodium or Barium hydroxide based absorbent.

3-6

WWWWAAAARRRRNNNNIIIINNNNGGGG

w

Step 1

Pull the release forward.

Change absorbent often to prevent the build up of non-metabolic gases

when the system is not in use.

Inspect absorbent at the end of a case. During non-use, absorbent can go

back to the original appearance. Refer to the absorbent labeling for more

information about color changes.

If the absorbent completely dries out, it may give off CO (carbon monoxide)

the next time you use it. For safety, replace the absorbent.

AB.23.061

Step 2

Turn the release clockwise.

AB.23.061

3-6 1006-0939-000

Page 39

Step 3

Push in the buttons and install

the top dish and drain dish.

Pull down to make sure the top

dish is locked in place.

Step 4

Fill the canisters with absorbent

and install them. Push down on

the drain dish if necessary.

3 Setup and Connections

AA.96p054

3-7

AA.96p029

Step 5

Turn the release

counter-clockwise.

Step 6

Push in the release.

AA.96p028

AA.96p026

1006-0939-000 3-7

Page 40

Aestiva

Pneumatic and electrical connections

WWAAAARRRRNNNNIIIINNNNGGGG

wWW

Equipment connected to the electrical outlets can increase the leakage

current. Regularly test the leakage current.

3-8

Mains inlet

CCAAAAUUUUTTTTIIIIOOOONNNN

wCC

Use only medical grade gas supplies. Other types of gas supplies may

contain water, oil, or other contaminants.

The Aestiva gas supplies also supply these devices through internal connections:

• The venturi suction regulator (optional)

• The external O

• Ventilator drive gas

• Pneumatic outlets

flowmeter (optional)

2

AA.96.116

Outlets

Labels show outlet voltage

ratings and circuit breaker

amp ratings.

AA.96.116

Tec 6 power

AA.96.095

3-8 1006-0939-000

Page 41

Pipeline inlets

Label identifies the gas.

Pneumatic outlet

Labels identify the gas.

3 Setup and Connections

AA.96.116

3-9

Note: The outlet pressures

range from pipeline pressure

to 550-690 kPa when

cylinder supplies are used.

Scavenging

Adapters may be necessary.

Refer to the Illustrated Parts

section.

AA.96.116

AA.96.137

1006-0939-000 3-9

Page 42

3-10

Aestiva

Suction regulator

Optional item.

Note: Venturi regulators use

the system Air or O

Standard regulators must be

connected to an external

vacuum supply.

supply.

2

External vacuum

(non-venturi)

Filter

Patient

External O2 flowmeter

Optional item.

Serial port

Refer to the communications

appendix for command and

data formats.

Collection Bottle

AA.96.172

AA.96.045

AA.96.116

3-10 1006-0939-000

Page 43

How to install gas cylinders (high-pressure leak test)

3 Setup and Connections

Cylinder yokes

1. Find the cylinder wrench.

AA.96.123

2. Close the cylinder valve on the cylinder to be replaced.

AA.96.122

3. Fully loosen the tee handle.

AA.96.124

4. Open the cylinder yoke.

3-11

AA.96.125

5. Remove the used cylinder and the used gasket.

AA.96.126

6. Remove the cap from the cylinder valve on the new cylinder.

7. Point the cylinder valve away from all flammable items and items that can

be damaged by a release of pressure.

8. Quickly open and close the cylinder valve. This removes dirt from the

cylinder outlet.

1006-0939-000 3-11

Page 44

3-12

Aestiva

w CC

CCAAAAUUUUTTTTIIIIOOOONNNN

No gasket or more than one gasket can cause a leak.

9. Install a new gasket.

10.Align the cylinder post with the index pins.

11.Close the yoke gate and tighten the tee handle.

12.Install a cylinder plug and gasket in all empty cylinder yokes.

13.Do a high-pressure leak test:

• Disconnect pipeline supplies.

• Disconnect all equipment from the pneumatic outlet and turn Off the

auxiliary flowmeter.

• Set the system switch to Standby.

• Open the cylinder.

• Record the cylinder pressure.

• Close the cylinder.

• If the cylinder pressure decreases more than 690 kPa in one minute,

there is a leak.

To repair a leak:

• Install a new cylinder gasket and tighten the tee handle.

• Do this step again. If the leak continues, do not use the system.

ww

ww

WWWWAAAARRRRNNNNIIIINNNNGGGGDo not leave gas cylinder valves open if the pipeline supply is in use. Cylinder supplies

could be depleted, leaving an insufficient reserve supply in case of pipeline failure.

DIN connections

1. Close the cylinder valve on the cylinder to be replaced.

AA.96.127

2. Loosen the adapter and remove the cylinder.

AA.96.129

3. Remove the cap from the cylinder valve on the new cylinder.

4. Point the cylinder outlet away from all items that can be damaged by a

release of high-pressure gas.

3-12 1006-0939-000

Page 45

3 Setup and Connections

5. Open and immediately close the cylinder valve to remove dirt or contaminants.

6. Do a high pressure leak test:

• Disconnect pipeline supplies.

• Disconnect all equipment from the pneumatic outlet and turn Off the

auxiliary flowmeter.

• Set the system switch to Standby.

• Open the cylinder.

• Record the cylinder pressure.

• Close the cylinder.

• If the cylinder pressure decreases more than 690 kPa in one minute,

there is a leak.

To repair a leak:

• Tighten the cylinder connection.

• Do this step again. If the leak continues, do not use the system.

3-13

wwww WWWWAAAARRRRNNNNIIIINNNNGGGGDo not leave gas cylinder valves open if the pipeline supply is in use.

Cylinder supplies could be depleted, leaving an insufficient reserve supply

in case of pipeline failure.

1006-0939-000 3-13

Page 46

Aestiva

How to install the gooseneck lamp (12 V)

wWWWWAAAARRRRNNNNIIIINNNNGGGGUse ONLY 2.4 Watt bulbs. Higher wattage bulbs can get hot enough to burn

you.

3-14

1. Align the connector with the cable towards you.

AA.96.173

2. Push the connector firmly into the socket until you hear a click.

3. Move the light into position.

3-14 1006-0939-000

Page 47

How to attach equipment to the top shelves

The basic system has two straps for equipment. Accessory shelves use clips

and straps.

w CCCCAAAAUUUUTTTTIIIIOOOONNNNEach accessory shelf has a weight limit of 23 kg (50 lb).

w Systems without accessory shelves have a weight limit of 23 kg (50 lb).

1. Install or find the clips:

•With an accessory shelf, install the clips in the two slots nearest to the

equipment.

3 Setup and Connections

3-15

• Systems without accessory shelves have the clips attached.

AA.96.130

AA71.145

1006-0939-000 3-15

Page 48

3-16

Aestiva

2. Install the straps:

•With an accessory shelf:

A

Large equipment.

Loop one time

(A, B, C)

A

Small equipment.

Loop two times

(A, B, C, D)

B

C

B

C

AA.50.015

D

A

A

B

B

C

C

•Without an accessory shelf:

D

C

B

A

3. Fully tighten the straps.

4. Make sure that the straps hold the equipment in position.

AA.96.135

WWAAAARRRRNNNNIIIINNNNGGGG

w WW

3-16 1006-0939-000

If you do not fully tighten the strap, equipment can fall off the shelf.

Page 49

How to install equipment on the foldout shelf

This is a hidden shelf for equipment that you do not need to look at, adjust, or

touch. To access the shelf, you must remove the cylinders.

1. Make sure you have a cylinder wrench (if necessary).

2. Close the valves on all gas cylinders.

3. Remove all gas cylinders.

4. Loosen the thumbscrews and open the rear door.

3 Setup and Connections

3-17

AA.96.118

AA.96.119

AA.96.120

5. Put the equipment on the shelves.

6. Make sure the item does not hang over the raised edge.

7. Connect all cables and route them through the cutouts in the door.

8. Close the door.

9. Test the equipment.

AA.96.114

10.Install the cylinders.

WWAAAARRRRNNNNIIIINNNNGGGG

w WW

1006-0939-000 3-17

Items that hang over the raised edge can fall off.

Page 50

Aestiva

Installation notes

When the system is installed the service representative will check these settings and change them if necessary.

3-18

wWWWWAAAARRRRNNNNIIIINNNNGGGGThese settings can only be changed by Qualified Service personnel.

• Language

• Power up defaults: When you turn the system off, should it save the current

settings or go back to the facility defaults.

• Automatic calculation of

• Altitude

• Ventilator drive gas

• Heliox mode availability

◊E alarm limits during mechanical ventilation.

3-18 1006-0939-000

Page 51

WWAAAARRRRNNNNIIIINNNNGGGG

w WW

WWAAAARRRRNNNNIIIINNNNGGGG

w WW

4 User Maintenance

TO PREVENT FIRES:

• Use lubricants approved for anesthesia or O2 equipment, such as Krytox

• Do not use lubricants that contain oil or grease. They burn or explode

in high O

concentrations.

2

• All covers used on the system must be made from antistatic (conductive)

materials. Static electricity can cause fires.

Obey infection control and safety procedures. Used equipment may

contain blood and body fluids.

®

4-1

1

.

In this section Repair policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Manifold maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Expiratory valve maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Receiver maintenance (active gas scavenging only) . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Flow sensor maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Breathing circuit maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Bellows maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Bellows tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

sensor calibration - 21% O2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

O

2

sensor calibration - 100% O2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

O

2

Flow sensor calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

How to prevent water build-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

1.

® Krytox is a registered trademark of Dupont de Nemours E.I. & Company Inc

1006-0939-000 4-1

Page 52

4-2

Aestiva

Repair policy

CCAAAAUUUUTTTTIIIIOOOONNNN

w CC

Do not use malfunctioning equipment. Make all necessary repairs or have the

equipment serviced by an authorized Datex-Ohmeda service representative. After repair,

test the equipment to ensure that it is functioning properly, in accordance with the

manufacturer’s published specifications.

To ensure full reliability, have all repairs and service done by an authorized DatexOhmeda service representative. If this cannot be done, replacement and maintenance

of those parts listed in this manual may be undertaken by a competent, trained

individual having experience in the repair of devices of this nature.

No repair should ever be attempted by anyone not having experience in the

repair of devices of this nature.

Replace damaged parts with components manufactured or sold by Datex-Ohmeda.

Then test the unit to ascertain that it complies with the manufacturer’s published

specifications.

Contact the Datex-Ohmeda Customer Service Center for service assistance. In all cases,

other than where Datex-Ohmeda’s warranty is applicable, repairs will be made at DatexOhmeda’s current list price for the replacement part(s) plus a reasonable labor charge.

4-2 1006-0939-000

Page 53

Manifold maintenance

Step 1

Complete the basic

disassembly (Refer to the

Cleaning and Sterilization

section).

4 User Maintenance

AB.23.094

4-3

Step 2

(APL valve)

Remove the diaphragm.

Replace it if:

• The disk, cage, or

diaphragm is damaged.

• The diaphragm looks

worn.

• The diaphragm fits over

the rim.

1

Step 3

(Seals)

Loosen the thumbscrew and

remove the plate.

• Replace the seal if

damaged or worn.

AB.23.069

AB.23.070

1006-0939-000 4-3

Page 54

Aestiva

Step 4

(Seals con.)

Loosen the thumbscrews.

4-4

AB.23.073

Step 5

(Seals con.)

Open the manifold (top

middle, and bottom parts).

AB.23.074

Step 6

(Seals con.)

Replace the parts if they are

damaged or worn.

Top

4-4 1006-0939-000

Bottom

Side

AB.23.071

Page 55

Step 7

(Bag/Vent)

Replace the parts if they are

damaged or worn.

2

4 User Maintenance

4-5

AB.23.077

Step 8

Put the parts together

•Make sure all gaskets are

fully seated.

• Fully tighten the

thumbscrews.

AB.23.075

1. When you turn the APL knob, you change the pressure that is necessary to push the disk up and permit gas

to exit.

2. The Bag/Vent switch pushed down plungers to close the other path. In the Bag position, the vent path is

closed, etc.

Before you use the system, complete the preoperative test procedure. Refer to

"Appendix - Preoperative Tests" section of Part 1 of the Operation Manual.

1006-0939-000 4-5

Page 56

4-6

Aestiva

Expiratory valve maintenance

Disassemble the manifold and examine the seals at 12 autoclave cycles.

These conditions indicate a possible leak in the exhalation valve:

•A decrease in airway pressure during the inspiratory pause in the volume control

mode of ventilation.

• Alarms for low tidal volume.

• The ventilator circuit has a leak, but the bellows pass the bellows tests in this

section.

Step 1

Remove the exhalation valve

(Cleaning and Sterilization

section).

AB.23.089

Step 2

Remove the top cover.

AB.23.093

4-6 1006-0939-000

Page 57

Step 3

Unscrew the lock ring (one

quarter turn) and remove the

cap.

Step 4

4 User Maintenance

AB.23.072

4-7

Put the parts together

• Align the dimples in the

cap with the valve seat.

• To install the top, align it

with the base and push

down.

AB.23.021

Dimples

Before you use the system, complete the preoperative test procedure. Refer to

"Appendix - Preoperative Tests" section of Part 1 of the Operation Manual.

1006-0939-000 4-7

Page 58

Aestiva

Receiver maintenance (active gas scavenging only)

A blocked filter decreases flow through the scavenging system. In extreme cases this can

open the high-pressure relief valve and vent to room air.

Note: Passive gas scavenging does not require maintenance.

Step 1

4-8

Remove the receiver:

• Loosen the thumbscrew.

• Remove the rear cover.

• Pull out and up on the

receiver.

Step 2

Replace the filter (friction fit

with gasket).

AB.23.091

AB.23.092

Filter

WWAAAARRRRNNNNIIIINNNNGGGG

w WW

This system operates correctly at the electrical interference levels of IEC

601-1-2. Higher levels can cause nuisance alarms that may stop

mechanical ventilation.

• Always make sure that the rear cover is installed.

• Completely tighten the thumbscrew.

Before you use the system, complete the preoperative test procedure. Refer to

"Appendix - Preoperative Tests" section of Part 1 of the Operation Manual.

4-8 1006-0939-000

Page 59

Flow sensor maintenance

Step 1

Remove the flow sensor

module (Cleaning and

Sterilization section).

Push in the tab and remove

the cover.

Step 2

4 User Maintenance

4-9

AA.96p.037

Install the new sensor with

the arrows up.

Keep the tubes straight.

Step 3

Slide on the cover. Do not

pinch the tubes.

AA.96p.039AA.96p.038

Before you use the system, complete the preoperative test procedure. Refer to

"Appendix - Preoperative Tests" section of Part 1 of the Operation Manual.

1006-0939-000 4-9

Page 60

Aestiva

Breathing circuit maintenance

Disassemble the patient circuit module to replace check valves or seals.

Step 1

4-10

Remove the patient circuit

module (Cleaning and

Sterilization section).

AA.96p.017

Step 2

Hold in the tab.

AA.96p.041

Step 3

Remove the rear cover.

Note: The rear seal is keyed

to fit a specific module.

AA.96p.042

4-10 1006-0939-000

Page 61

Step 4

Push in the tabs and remove

the top cover.

Step 5

Remove the seals.

Turn and pull to remove the

check valves.

4 User Maintenance

AA.96p.043

4-11

AA.96p.044

AA.96p.045

Do the steps in the opposite order to assemble the module.

Before you use the system, complete the preoperative test procedure. Refer to

"Appendix - Preoperative Tests" section of Part 1 of the Operation Manual.

1006-0939-000 4-11

Page 62

4-12

Aestiva

Bellows maintenance

Step 1

Remove the bellows from the

breathing system.

AA.96p.023

Step 2

Turn the housing

counter-clockwise and lift.

Step 3

Remove the bottom edge of

the bellows from the rim.

AA.96p.051

AA.96p.052

4-12 1006-0939-000

Page 63

Step 4

Remove the disk from the

bellows.

4 User Maintenance

AA.96p.031

Step 5

Remove the ring from inside

the top of the bellows.

Step 6

Push the latch toward the

center and remove the rim.

4-13

AA.96p.032AA.96p.033

Step 7

Remove the pressure relief

assembly.

AA.96p.034

WWAAAARRRRNNNNIIIINNNNGGGG

w WW

1006-0939-000 4-13

Do not disassemble the pressure relief valve. This can damage the seat or

diaphragm and cause injury to the patient.

Page 64

Aestiva

Step 8

Push the latch towards the

center and remove the

locking tabs.

4-14

AA.96p.035

Step 9

Remove the seal.

AA.96p.036

Do these steps in the opposite order to assemble the bellows. If you see a dust-like

powder on the housing or the bellows, apply a thin layer of KRYTOX lubricant to the ribs

of the bellows housing. Make sure the lubricant is applied smoothly and there are no

lumps.

Make sure that:

• The arrow on the seal points up.

• You hear a double click when you install the rim.

• The rim is locked in position.

• The inner ring is correctly installed inside the top of the bellows.

• Only the bottom ring of the bellows fits over the rim.

• The housing is locked in position. You cannot lift it off.

4-14 1006-0939-000

Page 65

Bellows tests

WWAAAARRRRNNNNIIIINNNNGGGG

w WW

WWAAAARRRRNNNNIIIINNNNGGGG

w WW

4 User Maintenance

Objects in the breathing system can stop gas flow to the patient. This can

cause injury or death:

• Do not use a test plug that is small enough to fall into the breathing

system.

4-15

• Make sure that there are no test plugs or other objects caught in the

breathing system.

The bellows assembly test does not replace the preoperative tests. Always

complete the tests in the section Preoperative Tests before you use the

system with a patient.

Step 1

Hold the bellows assembly

vertical and close the

ports (A and B).

This test makes sure that all components are correctly assembled. It is not an alternative

to a complete system checkout.

If the bellows operates correctly, install it in the system.

If there is a problem, disassemble the bellows. Look for and replace damaged parts.

A

B

1006-0939-000 4-15

Page 66

4-16

Aestiva

Step 2

Invert the bellows. They must

not fall more than

100 mL/min.

If it does:

• The ports are not tightly

sealed.

• The bellows is incorrectly

installed.

• The seal inside the

bellows is not correctly

installed (with its groove

pointed up).

• Parts are damaged.

Step 3

Remove the plugs from the

ports. Permit the bellows to

fully extend.

Step 4

Close port C.

C

AA.96p.124

4-16 1006-0939-000

Page 67

Step 5

The bellows must not fall

more than 100 mL/min.

If it does:

• The port is not tightly

sealed.

• The bellows or the

pressure relief valve is

not correctly installed.

• Parts are damaged.

4 User Maintenance

4-17

If the result for all the bellows tests was “passed,” install it in the system.

Before you use the system, complete the preoperative test procedure. Refer to

"Appendix - Preoperative Tests" section of Part 1 of the Operation Manual.

1006-0939-000 4-17

Page 68

Aestiva

4-18

O2 sensor calibration - 21% O

Note: The 21% O2 calibration must be done before the 100% O2 calibration. During O2

calibration the screen replaces O

perform calibration.

This procedure takes three minutes or less.

Step 1

Push the menu key.

AB.29.013

Step 2

Turn the knob to select

Setup/Calibration (highlight).

AB.90.036

2

data with - - -. Mechanical ventilation must be off to

2

AB29.002

Step 3

Push the knob to show the

next screen.

AB.90.037

AB.90.091

4-18 1006-0939-000

Page 69

Step 4

Tur n, then push the knob to

select O

2 Sensor Cal.

Step 5

Select 21%. Then, push the

knob.

4 User Maintenance

AB29.002

AB.90.048

AB.29.012

4-19

AB.90.049

Step 6

Complete the steps shown on

the screen.

• Remove the O

sensor from

2

the circuit.

• Do not twist or stress the

cable.

•Make sure the cable is

connected.

Step 7

Select Start Cal.

Then, push the knob.

AB.48.080

The screen shows “Calibrating. . .”, followed by the result (“Complete” or “Failure”).

1006-0939-000 4-19

Page 70

Aestiva

If the calibration fails:

• perform the calibration again.

• do a 100% O

sensor calibration. If this passes, repeat the 21% O2 calibration.

2

4-20

If the calibration passes, install the O

sensor. If necessary, do the 100% O2 calibration.

2

Before you use the system, complete the preoperative test procedure. Refer to

"Appendix - Preoperative Tests" section of Part 1 of the Operation Manual.

4-20 1006-0939-000

Page 71

O2 sensor calibration - 100% O2

Note: If w appears on the screen, the 21% O2 calibration must be completed before the

100% O

This procedure takes three minutes or less.

Step 1

calibration. Mechanical ventilation must be off to perform calibration.

2

4 User Maintenance

Push the menu key.

Step 2

Turn the knob to select

Setup/Calibration (highlight).

Step 3

Push the knob to show the

next screen.

4-21

AB.29.003

AB29.002

AB90.036

AB90.037

1006-0939-000 4-21

Page 72

Aestiva

Step 4

Tur n, then push the knob to

select O

2 Sensor Cal.

AB29.002

AB90.048

4-22

Step 5

Select 100%. Then, push the

knob.

Step 6

With the O2 sensor in the

circuit, fill the circuit with

100% O2:

• Push the flush button.

• Then flow 100% O2 at

5 L/min. (circuit should

be open).

AB.29.046

AB.90.050

AB.90.088

Step 7

Select Start Cal.

Then, push the knob.

AB48.081

4-22 1006-0939-000

Page 73

4 User Maintenance

The screen shows “Calibrating . . . ”, followed by the result (“Complete” or “Failure”).

If the calibration fails,

• perform the calibration again.

• decrease the airway pressure, and repeat the calibration.

Before you use the system, complete the preoperative test procedure. Refer to

"Appendix - Preoperative Tests" section of Part 1 of the Operation Manual.

4-23

1006-0939-000 4-23

Page 74

4-24

Aestiva

Flow sensor calibration

Minimum Frequency: Weekly

The system automatically corrects for zero offset when you unplug the flow sensor

connectors with power on. You must stop mechanical ventilation before you calibrate the

flow sensors.

Step 1

Push up on the latch under

the flow sensor module.

AA.96p.010

Remove the flow sensor

module. You will feel some

resistance. Continue to pull.

Step 2

When calibration is complete,

the screen shows, "No Insp

flow sensor" and "No Exp

flow sensor".

No Insp Flow Sensor

No Exp Flow Sensor

Step 3

• Install the flow sensor

module.

4-24 1006-0939-000

Page 75

How to prevent water build-up

WWAAAARRRRNNNNIIIINNNNGGGG

w WW

During the cleaning of the liquid collecting tray, avoid skin or eye contact with the

contents of the absorber. In the event of skin or eye contact, immediately rinse the

affected area with water and seek medical assistance.

4 User Maintenance

Why is water buildup a

problem?

How much water is too

much?

Where does the water

come from?

Solutions • Drain the absorber each morning.

Pooled water in the sensor or water in the sensing lines causes false alarms.

A thin layer of water or a foggy look in the flow sensors is OK. Drops of water is too much.

Water comes from exhaled gas and a chemical reaction between CO2 and the soda lime

in the absorber.

At lower fresh gas flows more water builds up because less gas is scavenged and:

•More CO

•More moist, exhaled gas stays in the absorber.

• Drain all hoses as necessary.

• Flow sensor tubes must point up so that they do not collect water.

•With a circle breathing circuit, push the drain button before every case (listed in

preoperative procedures).

• If Check Flow Sensors alarm occurs during a VERY LONG case, replace the flow

sensors. Allow the original flow sensors to dry before you use them again.

stays in the absorber to react and produce water.

2

4-25

1006-0939-000 4-25

Page 76

4-26

Aestiva

4-26 1006-0939-000

Page 77

CCAAAAUUUUTTTTIIIIOOOONNNN

wCC

5 Alarms and

Troubleshooting

5-1

No repair should ever be attempted by anyone not having experience in the

repair of devices of this nature.

In this section About alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Alphabetical list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Breathing system problems (no alarm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

Electrical problems (power failure, etc.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16

Pneumatic problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-18

1006-0939-000 5-1

Page 78

5-2

Aestiva

About alarms

WWAAAARRRRNNNNIIIINNNNGGGG

w WW

If an alarm occurs, safeguard the patient first, before troubleshooting

or repair procedures.

Two areas on the screen show alarms. The area at the top of the display shows

most alarms. If there are more than 4 alarms at the same time, the lower priority

alarms cycle every two seconds.

During severe malfunctions that prevent mechanical ventilation and/or

monitoring, the area under the waveform shows minimum system messages.

During normal operation, this area shows instructions (push the knob, etc.).

Alarms

Alarm priority depends on the level of danger to the patient. High priority alarms

require immediate attention.

Priority Alarm tone Alarm silence Note

High 10 tones,

10 second pause,

repeat

Medium 3 tones,

25 second pause,

repeat

Low Single tone Tone does not repeat ---

120 seconds or

cannot be silenced

120 seconds ---

Reverse video

AB.90.025

5-2 1006-0939-000

Page 79

5 Alarms and Troubleshooting

Alarm messages have three general causes.

• Malfunctions: Some malfunctions cause reduced function (for example, no

PEEP). Others prevent mechanical ventilation (Minimum shutdown).

• Patient monitoring: These are high and low limit settings that you adjust.

• Informational: Control settings or system conditions can change operation. For

example, if the audible circuit leak alarm is Off, the screen shows “Circuit Leak

Audio Off” as a low priority alarm.

5-3

1006-0939-000 5-3

Page 80

5-4

Aestiva

Alphabetical list

The instructions in this section tell you what you can do:

• During a case to protect the patient

• After the case to repair a problem

This table does not include operator instructions.

There are two special types of alarms:

•Minimum monitoring alarms stop mechanical ventilation.

• Minimum shutdown alarms stop mechanical ventilation and monitoring.

Message Priority Cause Action/Concerns Repair

+15V Analog Outof-Range

-15V Analog Outof-Range

12 Hour Test Low System in use for more

A/D Converter

Failure

Absorber panel

open

Adjust Low Ve Limit Medium The audible circuit leak

Min. shutdown

(High)

Min. shutdown

(High)

Min. shutdown

(High)

Medium The top panel is not

Ventilator malfunction. Ventilate manually.

Ventilator malfunction. Ventilate manually.

than 12 hours without a

power-up self test.

Ventilator malfunction. Ventilate manually.

completely closed.

alarm is Off (Alarm menu)

but the low VE alarm is not

set.

Contact a qualified

Monitoring is not reliable.

Monitoring is not reliable.

To do the test, move the

system switch from Standby

to On.

Monitoring is not reliable.

Close the panel. - - -

Set the low VE alarm. - - -

service

representative.

Contact a qualified

service

representative.

Not necessary,

informational.

Contact a qualified

service

representative.

VE alarm is Off in SIMV or

PSVPro modes.

5-4 1006-0939-000

Page 81

5 Alarms and Troubleshooting

Message Priority Cause Action/Concerns Repair

Apnea Alarm

Standby

Low Normal condition after

End Case, power-up, or

ACGO change from On to

Off

Apnea Alarm Off Low The cardiac bypass option

is selected (alarm limit

menu).

Aux Gas Outlet On Medium

(low after

acknowledged)

The outlet selection

switch is set to the

auxiliary common gas

outlet.

Backup Mode

Active

Battery Charger

Fail

Low SIMV-PC + PSV mode

entered.

Low The current in the battery

charging circuit is too

high.

Monitoring resumes after first

breath (mechanical) or 2

breaths within 30 seconds

(non-mechanical).

Apnea alarms are normally

turned off when this option is

selected.

Connect the patient circuit to

the auxiliary outlet. For

mechanical ventilation or

manual ventilation with

monitoring, select the

common gas outlet.

Spontaneous breath rate fell

below the set breath rate

The system is operational, but

may fail later depending on

what caused this alarm.

- - -

- - -

- - -

5-5

- - -

Contact a qualified

service

representative.

Battery Charging Low The battery is not fully

charged. If power fails,

the total backup time will

be less than 30 minutes.

Battery Current

High

Battery Failure

High

Low Battery current >

6 amps

for 10 seconds.

Low Battery voltage > 16 V for

10 seconds.

Battery Failure Low Low The battery voltage is too

low (<7 V) to supply the

system if power fails.

Leave the system plugged in

to charge the battery.

The system continues to

operate, but may fail.

The system continues to

operate, but may fail.

The battery does not have

enough charge to power the

equipment if power fails.

Leave the system plugged in

to charge the battery.

- - -

Contact a qualified

service

representative.

Contact a qualified

service

representative.

If the battery does

not charge in 24

hours, contact a

service

representative.

1006-0939-000 5-5

Page 82

Aestiva

Message Priority Cause Action/Concerns Repair

5-6

Cal Flow Sensors Low The last flow sensor

calibration failed.

Calibrate O2

Low O

%>110% Does the sensor measure

2

Sensor

Canister open Medium The canister release is

open (large leak) without

a bypass mechanism.

Cannot Drive

Bellows

Low The internal manifold

pressure is higher than

Paw + tolerance.

Cardiac Bypass Low The alarm limit settings

are set for a patient on

cardiac bypass. Apnea

alarms are off.

Check Flow

Sensors

Medium

(low after

acknowledged)

No flow or negative flow

on inspiratory sensor

during inspiration in a

circle system or negative

flow on expiratory sensor

in expiration (for 6

breaths in a row).

Calibrate the flow sensors.

Look for water in the flow

sensor tubes. Dry if

Contact a qualified

service

representative.

necessary.

sensor.

2

21% O

in room air?

2

Calibrate O

Close the canister release. A switch checks the

release position.

Fill the bellows if empty. - - -

Use the alarm limits menu to

- - -

change this setting.

Are the flow sensors correctly

installed?

Inspect one way

valves (breathing

circuit module).

Water build-up in the flow

sensor tubes?

Replace flow sensor

module with the

Is a flow sensor tube cracked

or broken?

spare. Check the

condition of the flow

sensor and its tubing.

Circuit Leak Audio

Off

Low Control setting on the

Alarm limit menu.

This message tells you that

the audio alarm for circuit

- - -

leaks was turned off.

Connect O

Sensor Low The O2 sensor is not

2

connected to the cable.

Connect the sensor. Contact a qualified

service

representative to

replace the cable.

5-6 1006-0939-000

Page 83

5 Alarms and Troubleshooting

Message Priority Cause Action/Concerns Repair

Control Settings

Input has Failed

Minimum

monitoring

(Medium)

CPU Failure Minimum

shutdown

(High)

CPU Internal Error Minimum

shutdown

(High)

Display Voltage

Out-Of-Range

Minimum

shutdown

(High)

Exp Flow Sensor

Low The system cannot read

Fail

Exp Reverse Flow Medium

(low after

acknowledged)

Ventilator malfunction. Ventilate manually.

Monitoring is still available.

Ventilator malfunction. Ventilate manually.

Monitoring is not reliable.

Ventilator malfunction. Ventilate manually.

Monitoring is not reliable.

Ventilator malfunction. Ventilate manually.

Monitoring is not reliable.

Operation continues with

the calibration data

stored in the sensor.

Flow through the

default values.

Replace the flow sensor.

Look at the check valves.

expiratory sensor during

inspiration (for 6 breaths

in a row).

Water build-up in the flow

sensor tubes?

Is a flow sensor tube cracked

or broken?

Contact a qualified

service

representative.

Contact a qualified

service

representative.

Contact a qualified

service

representative.

Contact a qualified

service

representative.

- - -

Replace the

expiratory check

valve.

Check the condition

of the flow sensor.

5-7

Flow Valve (DAC)

Failure

Flow Valve (current)

Minimum

monitoring

(Medium)

Ventilator malfunction. Ventilate manually.

Monitoring is still available.

Contact a qualified

service

representative.

Failure

Gas Inlet Valve

Failure

Hardware

Watchdog Failure

1006-0939-000 5-7

Minimum

shutdown

1

(High)

Minimum

shutdown

(High)

Ventilator malfunction. Ventilate manually.

Monitoring is still available.

Ventilator malfunction. Ventilate manually.

Monitoring is not reliable.

Contact a qualified

service

representative.

Contact a qualified

service

representative.

Page 84

Aestiva

Message Priority Cause Action/Concerns Repair

5-8

Heliox Mode is On Low Control setting on

ventilation setup menu.

High O

2

Medium O2% > alarm high limit

setting.

High Paw High Paw is greater than Plimit.

The ventilator cycles to

expiration.

High Ve Medium The minute volume is

greater than the set high

limit. This alarm is

suspended for 9 breaths

after you change the

ventilator settings.

When Heliox is used, the

ventilator must adjust volume

calculations.

Is the limit set correctly? What

is the O

flow?

2

Did you just push Flush? Does

the sensor see 21% O2in

room air?

Are Plimit and other controls

set correctly? Look for

blockages.

Check the patient connection.

Check patient for

spontaneous breathing.

Adjust control settings.

- - -

Calibrate O

Replace O

sensor.

2

sensor.

2

Calibrate the flow

sensors.

Replace the receiver

filter.

- - -

High Vte Medium VTE is greater than high

alarm limit. This alarm is

suspended for 9 breaths

after you change the

ventilator settings.

Insp Flow Sensor

Fail

Low The system cannot read

the calibration data

stored in the sensor.

Inspiration

Stopped

Insp Reverse Flow Medium

High Drive gas safety switch

activated (high pressure)

Flow through the

(low after

acknowledged)

inspiratory sensor during

expiration (for 6 breaths

in a row).

Check patient for

spontaneous breathing.

Check ventilator and alarm

settings.

Operation continues with

default values.

Replace the flow sensor.

Adjust controls. Check

systems for blockages.

Look at the check valves.

Water build-up in the flow

sensor tubes?

Is a flow sensor tube cracked

or broken?

- - -

- - -

- - -

Replace the

inspiratory check

valve.

Check the condition

of the flow sensor.

5-8 1006-0939-000

Page 85

5 Alarms and Troubleshooting