Page 1

0

|

0_

0_

0_

0 91wwlmlm

Safety Instructions ............ 2

Operating Instructions

Batteries ............................ 3

Careand Cleaning ............... 6, 7

RemoteControl Features ........ 4, 5

Installation Instructions

AirPurgingand LeakageTest ..... 15

BeforeYouBegin ................... 8

ConnectionTubing ............... 11

Dimensions ........................ 9

Drainage Hose ................... 11

ElectricalRequirements............. 8

ElectricalWiring .............. 12-14

Indoor Unit .................... 12,1:3

Location .......................... 10

Outdoor Unit .................. 14,15

Tubing Hole....................... 11

PowerLine ........................ 14

Mounting Plate ................... 11

TestOperation .................... 16

Wiring Indoor Unit ................ 12

Wiring Outdoor Unit .............. 14

Cool Only Models

AE1CDIOAM / AEOCDIOAM

AE1CD14DM / AEOCD14DM

AE1CD2ODM / AEOCD2ODM

Heat/Cool Models

AE1 RD10AM / AEORD10AM

AE1 RD14DM / AEORD14DM

AE1 RD2ODM / AEORD2ODM

Climatiseurs

inibloc

La section franqaise commence a la page 19

Troubleshooting Tips ........ 17

Normal Operating Sounds........ 17

Consumer Support

ConsumerSupport ...... BackCover

Warrantg ......................... 18

Write the model und seriul numbers here

for the indoor und outdoor units:

Indoor Model #

Indoor Seriul #

Outdoor Model #

Outdoor Seriul #

Find these numbers on a label on the side of

eachunit.

Acondicionadordeaire

desistemaminisplit

La secci6n en espahol empieza en la pdgina 37

49-7600 05-09JR

Page 2

IMPORTANT SAFETYINFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

tl WARNING!

For your safety, the information in this manual must be followed to minimize the risk of fire, electric

shock or personal injury.

SAFETY PRECAUTIONS

Use this equipment onlg for its intended

purpose as described in this Owner's

Manual.

This sgstem must be properlg installed

in accordance with the Installation

Instructions before it is used.

@All wiring should be rated appropriate for

the current value listed on the rating plate.

Use onlg copper wiring.

,tl, WARNING!Riskofelectric

shock. Can cause injurg or death: Earth

connection is essential before connecting

the power supplg.

,_ WAR N ! N G_ Risk of electric

shock. Can cause injurg or death: Disconnect

all remote electric power supplies before

servicing.

WARN!NG!Riskof electric

shock. Can cause injurg or death: Repair or

replace immediatelg all electrical wiring

that has become fraged or otherwise

damaged. Do not use wiring that shows

cracks or abrasion damage along its

length or at either end.

All electrical work must be completed bg a

qualified electrician and completed to local

and national building codes and regulations.

iiiiiiiiiiii_iiii_

Any servicing must be performed by a

qualified individual.

iiiiiiiiiiii_iiii_

iiiiiiiiiiii_iiii_

WARNING!Riskof fire.Can

cause injurg or death: Do not store or use

combustible materials, gasoline or other

flammable vapors or liquids in the vicinitg

of this or ang other appliance.

For any service which requires entry

into the refrigerant sealed system,

Federal regulations require the work

be performed by a technician having

a Class II or Universal certification.

All air conditioners contain refrigerants,

which under federal law must be removed

prior to product disposal. If gou are getting

rid of an old product with refrigerants, check

with the compang handling disposal.

R/410Aair conditioning sgstems require

contractors and technicians to use tools,

equipment and safetg standards approved

for use with this refrigerant. DO NOT use

equipment certified for R22 refrigerant onlg.

READAND FOLLOW THISSAFETY INFORMATION

CAREFULLY.

SAVE THESE INSTRUCTIONS

Page 3

Operating the air conditioner. GEAppliances.com

General Procedure

NOTE:Forbestresults,point the remote control

at the indoor unit.

r-_ Hake surepower isconnected and pressthe

ON/OFFpadto start the sgstem.

F2-] Pressthe NODE pad to selectthe desired

operation mode.

r-_ Pressthe SWINGpad for automatic rotation of

the louvers.Pressagain to stop the rotation.

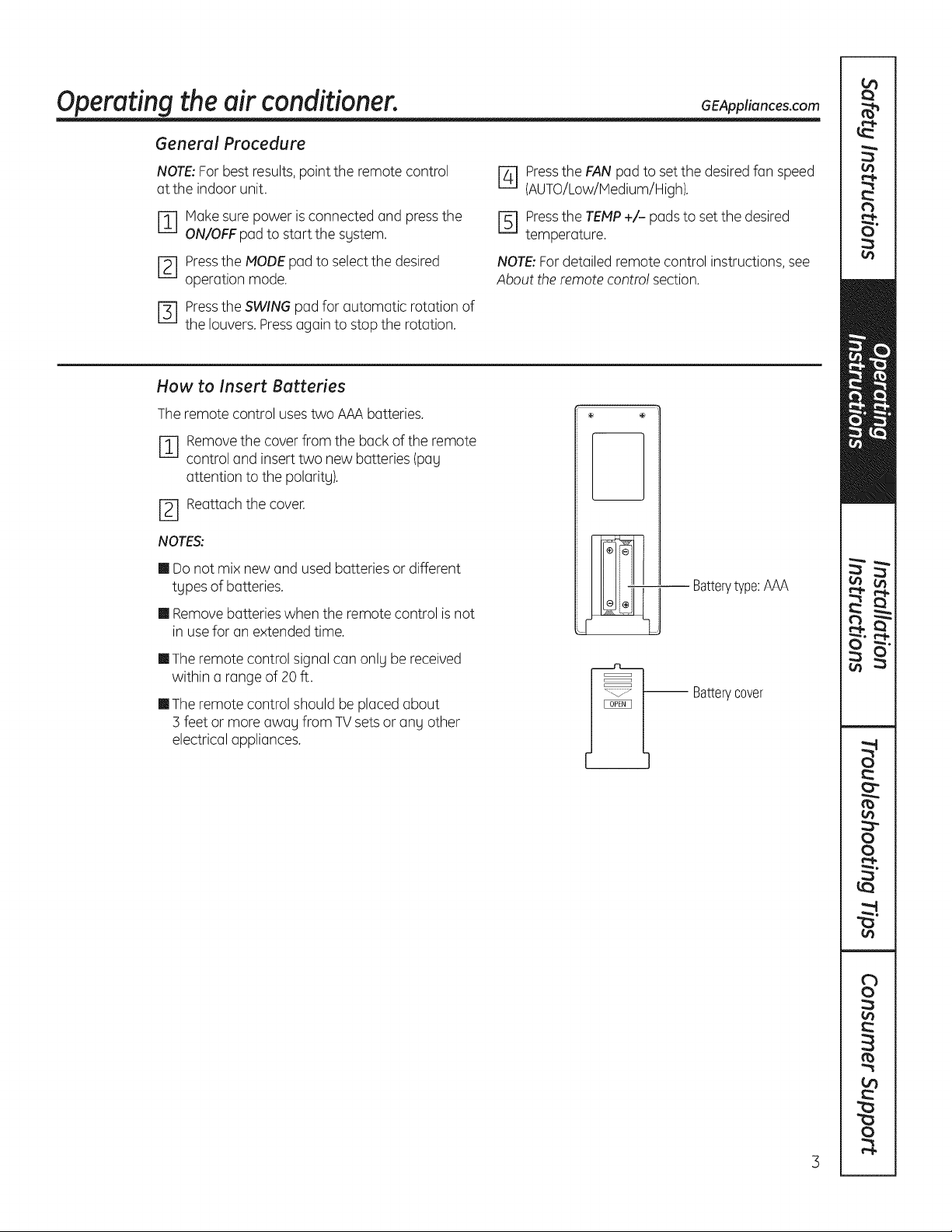

How to Insert Batteries

Theremote control usestwo AM batteries.

r-_ Removethe cover from the back of the remote

control and insert two new batteries (pag

attention to the polaritg).

F2-] Reattachthe cover.

NOTES:

m Do not mix new and usedbatteries or different

tgpes of batteries.

[] Removebatteries when the remote control isnot

in usefor an extended time.

[_] Pressthe FAN pad to setthe desiredfan speed

(AUTO/Low/Medium/High).

[_ Pressthe TENP+/- pads to set the desired

temperature.

NOTE:Fordetailed remote control instructions, see

About the remotecontrol section.

Batterytype:AAA

[] The remote control signal can onlg be received

within a range of 20ft.

[] The remote control should be placed about

] feet or more awag from TVsets or ang other

electrical appliances.

-- Batterycover

]

Page 4

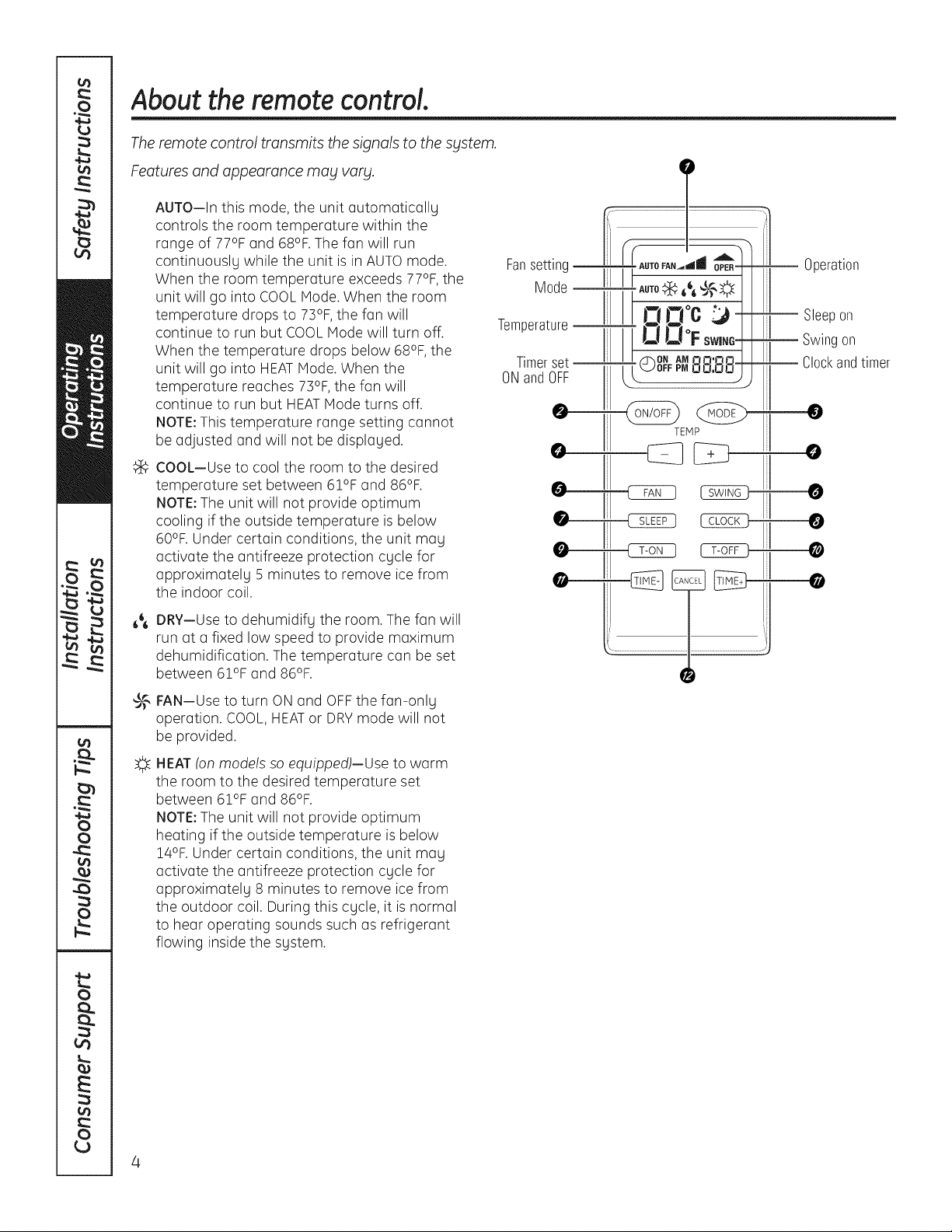

About the remote control.

Theremotecontrol transmitsthe signalsto the system.

Featuresand appearancemay vary.

AUTO--In this mode, the unit automatica%

controls the room temperature within the

range of 77°F and 68°F. The fan will run

continuously while the unit is in AUTOmode.

When the room temperature exceeds 77°F,the

unit will go into COOLMode. When the room

temperature drops to 73°F,the fan will

continue to run but COOLMode will turn off.

When the temperature drops below 68°F,the

unit will go into HEATMode. When the

temperature reaches 73°F,the fan will

continue to run but HEATMode turns off.

NOTE:This temperature range setting cannot

be adjusted and will not be displaged.

¢_ COOL--Use to cool the room to the desired

temperature set between 61°F and 86°F.

NOTE:The unit will not provide optimum

cooling if the outside temperature is below

60°F. Under certain conditions, the unit mag

activate the antifreeze protection cgcle for

approximatelg 5 minutes to remove ice from

the indoor coil.

-- Operation

-- Sleep on

gon

-- Clock andtimer

e

o

______@

@

o

666DRY--Use to dehumidifg the room. The fan will

run at a fixed low speed to provide maximum

dehumidification. The temperature can be set

between 61°F and 86°F.

_€ FAN--Use to turn ON and OFFthe fan-onlg

operation. COOL,HEATor DRYmode will not

be provided.

_X HEAT (onmodels so equipped)--Use to warm

the room to the desired temperature set

between 61°F and 86°F.

NOTE:The unit will not provide optimum

heating if the outside temperature is below

14°F.Under certain conditions, the unit mag

activate the antifreeze protection cgcle for

approximatelg 8 minutes to remove ice from

the outdoor coil. During this cgcle, it is normal

to hear operating sounds such as refrigerant

flowing inside the sgstem.

Page 5

About the remote control. contJ

The remote control transmits the signals to the system.

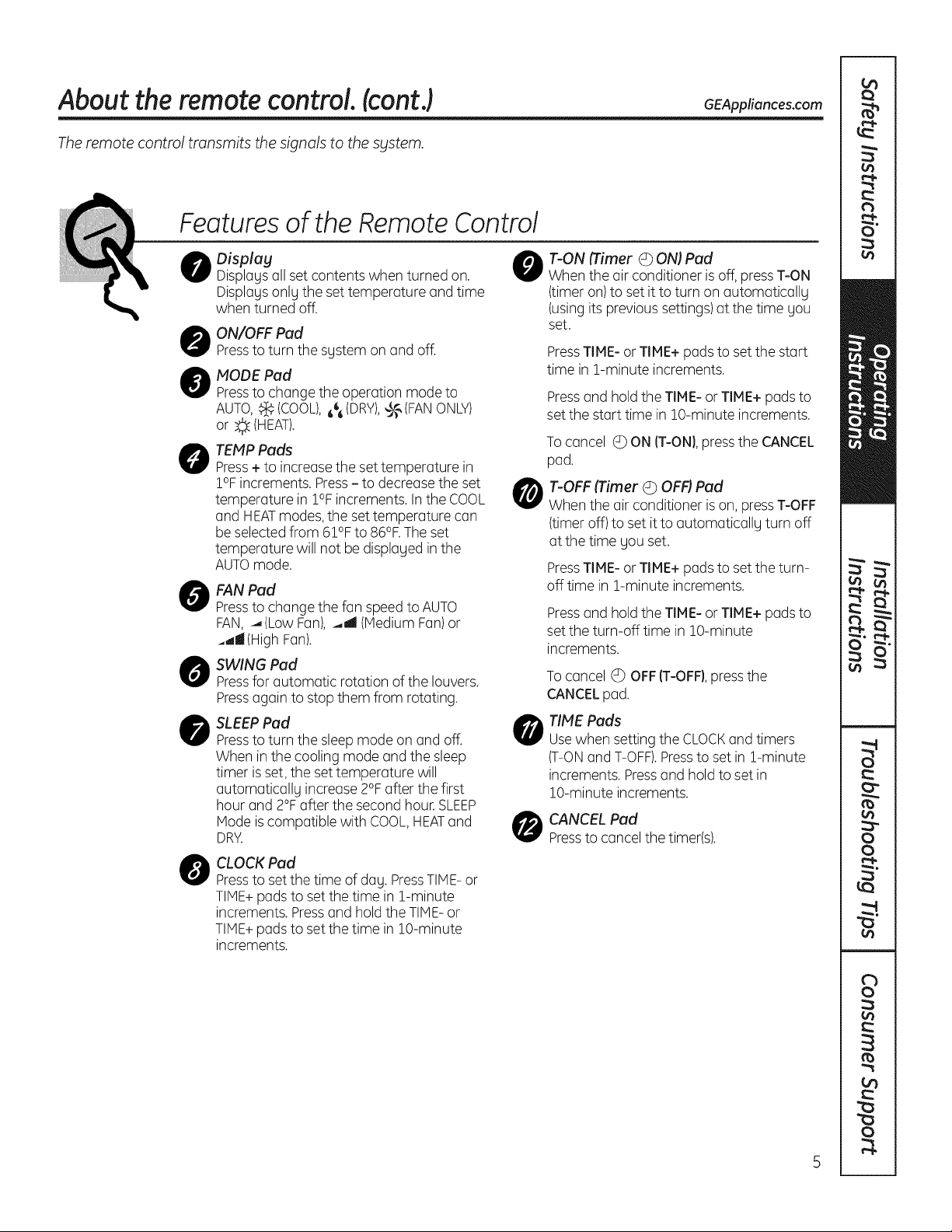

Features of the Remote Control

GEAppliances.com

O isplag 0

Displagsall set contents when turned on.

Displagsonlg the set temperature and time

when turned off.

ON/OFF Pad

Pressto turn the sgstem on and off.

MODE Pad

Pressto change the operation mode to

AUTO,_ (COOL),666(DRY),dSf_(FANONLY)

or _:_(HEAT).

TEMP Pads

O

Press+to increasethe set temperature in

!°F increments. Press- to decrease the set

temperature in !°F increments.In the COOL

and HEATmodes, the settemperature can

be selected from 6!°F to 86°RTheset

temperature will not be displaged inthe

AUTOmode.

FAN Pad

0

Pressto change the fan speedto AUTO

FAN,-,,(LowFan),..,J (Medium Fan)or

_-,IJ (HighFan).

SWING Pad

Pressfor automatic rotation of the louvers.

Pressagain to stop them from rotating.

SLEEPPad

Pressto turn the sleepmode on and off.

When in the cooling mode and the sleep

timer isset,the set temperature will

automaticallg increase 2°Fafter the first

hour and 2°Fafter the second hour. SLEEP

Mode iscompatible with COOL,HEATand

DRY.

CLOCK Pad

0

Pressto set the time of dag. PressTIME-or

TIME+padsto set the time in 1-minute

increments.Pressand hold the TIME-or

TIME+padsto set the time in !0-minute

increments.

T-ON (Timer © ON) Pad

When the air conditioner is off,pressT-ON

(timer on)to set it to turn on automaticallg

(usingits previoussettings)at the time gou

set.

PressTIME- or TIME+pads to set the start

time in 1-minute increments.

Pressand hold the TIME-or TIME+padsto

set the start time in !0-minute increments.

TocancelQ ON (T-ON),pressthe CANCEL

pad.

T-OFF (Timer © OFF) Pad

O

When the air conditioner ison,pressT-OFF

(timer off)to set itto automatically turn off

at the time you set.

PressTIME- or TIME+pads to set the turn-

off time in 1-minute increments.

Pressand hold the TIME-or TIME+padsto

set the turn-off time in !0-minute

increments.

Tocancel © OFF(T-OFF),pressthe

CANCELpad.

TIME Pads

0

Usewhen setting the CLOCKand timers

(T-ONand T-OFF).Pressto set in 1-minute

increments. Pressand hold to set in

!0-minute increments.

CANCEL Pad

0

Pressto cancel the timer(s).

Page 6

Careand cleaning of the air conditioner.

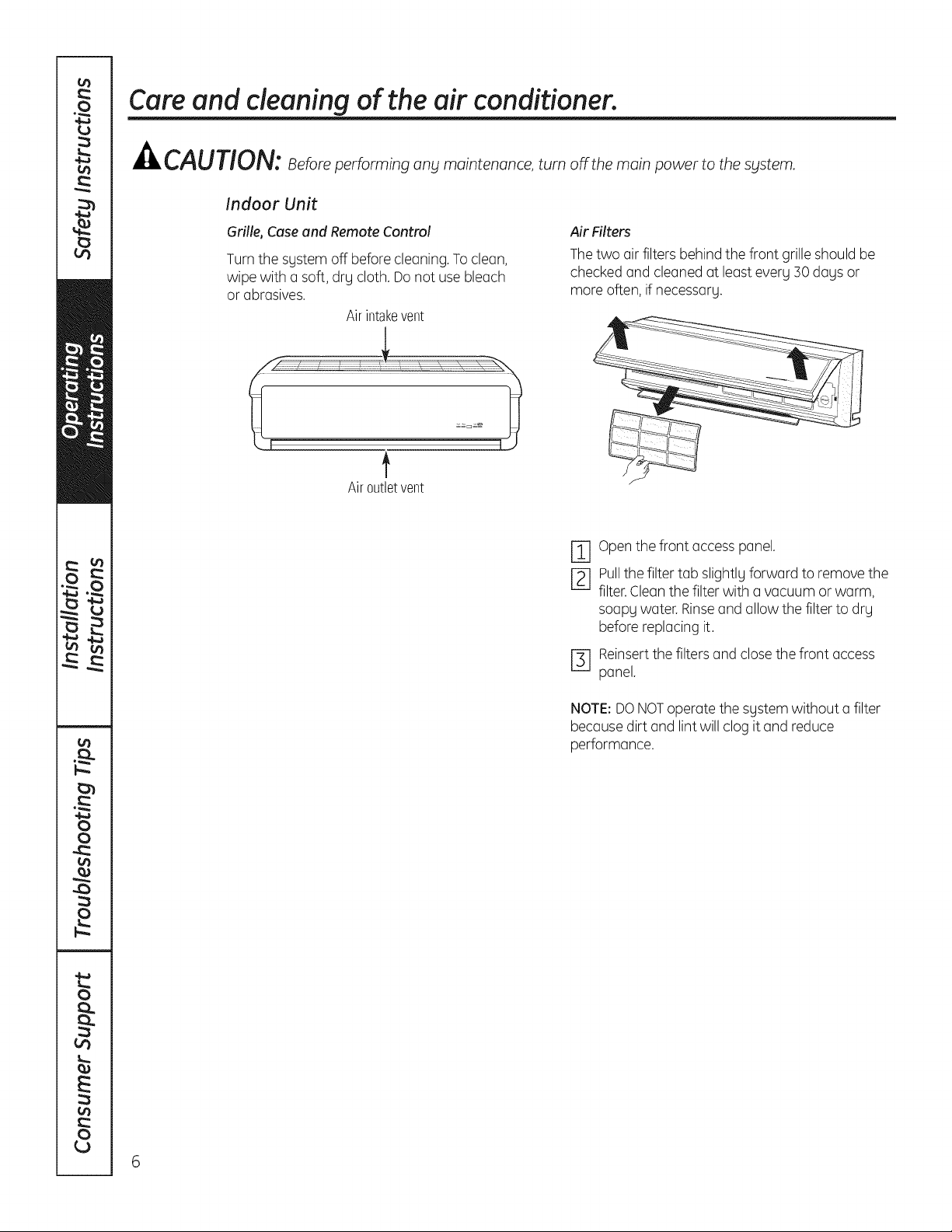

Indoor Unit

Grille, Case and Remote Control

Turn the sgstem off beforecleaning. Toclean,

wipe with a soft, drg cloth. Donot use bleach

or abrasives.

Air intakevent

Airoutletvent

Air Filters

Thetwo air filters behindthe front grilleshould be

checked and cleaned at least everg 30dags or

more often, ifnecessarg.

r_ open the front access panel.

F2-] Pullthe filter tab slightlg forward to remove the

filter.Cleanthe filter with a vacuum or warm,

soapgwater. Rinseand allow the filter to drg

before replacing it.

r_ Reinsertthe filters and closethe front access

panel.

NOTE:DONOToperatethe sgstem without a filter

becausedirt and lint will clog it and reduce

performance.

Page 7

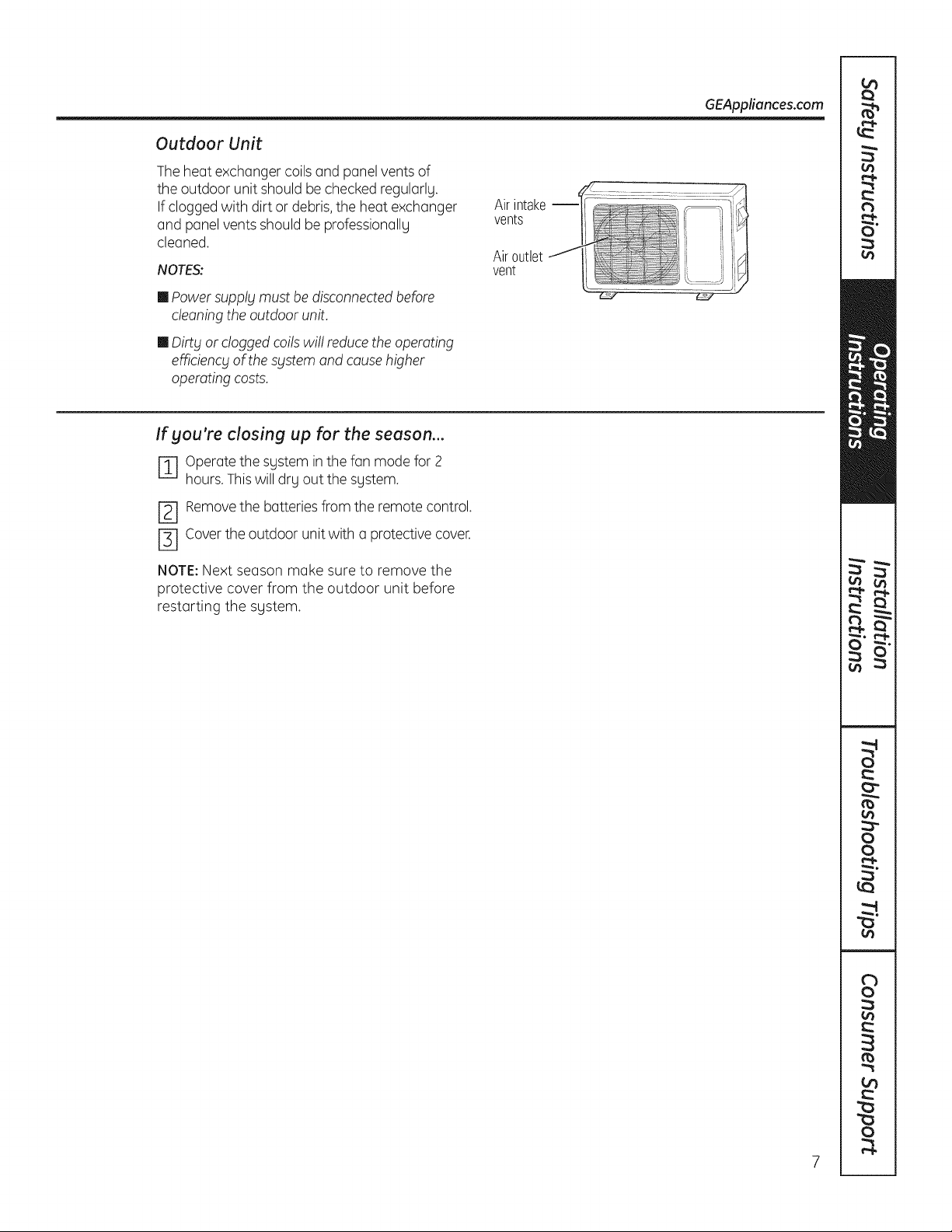

Outdoor Unit

The heat exchanger coils and panel vents of

the outdoor unit should be checked regularlg.

If clogged with dirt or debris, the heat exchanger

and panel vents should beprofessionallg

cleaned.

NOTES:

mPower supplgmust be disconnectedbefore

cleaningthe outdoor unit.

mOirt_lorcloggedcoils wi!!reducethe operating

e_ciency of the sgstem and causehigher

operating costs.

If you're closing up for the season...

IT] Operate the sgstem in the fan mode for 2

hours. This will drg out the sgstem.

[_ Remove the batteries from the remote control.

[_ Cover the outdoor unit with a protective cover.

GEAppliances.com

Airintake

vents

Airoutlet

vent

NOTE: Next season make sure to remove the

protective cover from the outdoor unit before

restarting the sgstem.

Page 8

stall tio

I

Mi

i Split-Sg

te

structio

I

BEFORE YOU BEGIN

Readthese instructions completely and

carefuIIg.

• IMPORTANT - savethese instructions for local

inspector's use.

• IMPORTANT - Observeallgoverningcodes

and ordinances.

• Note to Installer - Besure to leave these instructions

with the Consumer.

• Note to Consumer - Keep these instructions for future

reference.

• Skill level - A licensed, certified (to handle refrigerant-

R410A,recovery, etc.)technician and a qualified

electrician ore required for installation of this split

air conditioning system.

• Completion time - Approximately 2V2hours

• Two people are required to install this unit due to

the weight of the product.

• Proper installation isthe responsibility of the installer.

• Product failure due to improper installation is not

covered under the Warranty.

• For personal safety, this system must be properly

grounded.

• Protective devices (fuses or circuit breakers)

acceptable for installation ore specified on the

nameplate of each unit.

• Servicing and installation of the refrigerant system

must be performed only by a licensed, HVAC-certified

technician.

• Make sure to avoid wiring or plumbing inside the wall

when installing.

• Forany service which requires entry into the refrigerant

sealed system, Federal regulations require the work be

performed by o technician having o Class IIor Universal

certification.

Air

• Becertain all wiring complieswith local building codesand

• Checkthe rating nameplate on the sidepanel of outdoor

• Becertain there is an uninterrupted, unbroken electrical

• Wiring should be encasedin liquid-tight tubing with

Co diti

ELECTRICAL REQUIREMENTS

NECand that the supply voltage for this system iscorrect.

Thesystem supply voltage isconnected to the outdoor

unit only.

unit for requiredcircuit protection rating and required supply

voltage.

UseUL-opprovedelectrical branch circuit disconnect

for providing supplyvoltage to split system indoor and

outdoor units.Locate disconnectwithin sight and readily

accessibleper NECand localcodes.

Allwiring should be rated appropriate for the current value

listed on the rating plate.

ground connection.

connections sealed with liquid-tight connectors.

e

-&CAUTION:

• Do not use on extension cord with this system.

• Aluminum building wiring mag present special

problems-consult a qualified electrician.

• When the unit is in the STOPposition, there is still

voltage to the electrical controls.

• Disconnect the power to the system before

servicing bg removing the branch circuit fuses

or turning the circuit breakers off at the panel.

• DO NOT use equipment certified for R22refrigerant

only.

Page 9

Installation Instructions

PARTS INCLUDED

• Mounting plate

• Sealer

• Screws (5for 10,000 and

la,000 BTUmodels/10 for

20,000 BTUmodels)

• Remote control

• Batteries AAA(2)

• Drainage hose

• Insulation hose

• Two (2)filters

SUPPLIED BY INSTALLER

Adapter: 1/4" male flare with Schrader

valve x 5/16" female (1/2"-20UN)

OPTIONAL ACCESSORY KITS

To aid installation, the following tubing kits may be

ordered:

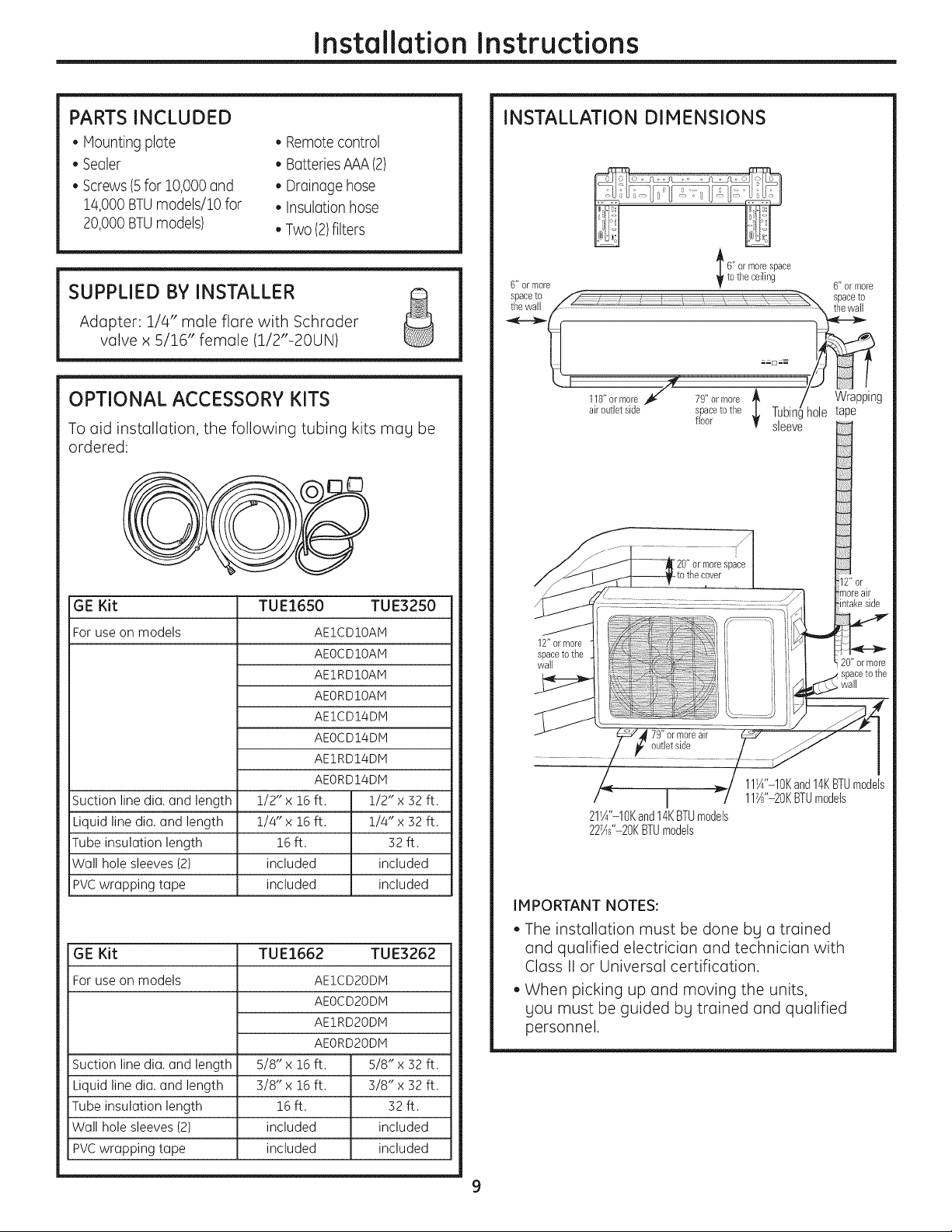

INSTALLATION DIMENSIONS

_6" ormorespace

6" or more _ to the ceiling 6" or more

spaceto f'//' ......................_................... spaceto

thewall f/ " ' "_ tf?e_all

,

118"ormore_ 79"ormore_ // VVrappiFg

airoutletside, hspacetothe --I- TublnoTuhin_holehnb,tapep

T_oor T sleeve

:"20" ormorespace

Ltothecover

GE Kit TUE1650 TUE3250

Foruseon models AE1CD!0AM

AEOCD!0AM

AE1RD10AM

AEORD10AM

AE1CD!4DM

AEOCD14DM

AEIRD14DM

AEORD14DM

Suction line dia. and length 1/2" x 32 ft.

Liquid line dia. and length 1/4" x 32 ft.

Tube insulation length 32 ft.

Wall hole sleeves (2) included

PVCwrapping tape included

GE Kit

For useon models

Suction line dia. and length 5/8" x 16ft. 5/8" x 32 ft.

Liquid line dia. and length 3/8" x 16ft. 3/8" x 32 ft.

Tube insulation length 16 ft. 32 ft.

Wall hole sleeves (2) included included

PVCwrapping tape included included

1/2" x 16 ft.

1/4" x 16 ft.

16 ft.

included

included

TUE1662 TUE3262

AE1CD20DM

AEOCD20DM

AEIRD20DM

AEORD20DM

12"ormore

spacetothe

wall

79"or moreair

outlet side

11¼"-10Kand14KBTUmodels

11_"-20KBTUmodels

21¼"-10Kand14KBTUmodels

22_?'-20KBTUmodels

IMPORTANT NOTES:

,,The installation must be done bg a trained

and qualified electrician and technician with

Class II or Universal certification.

,,When picking up and moving the units,

you must be guided bg trained and qualified

personnel.

Page 10

Installation Instructions

Read these instructions completely and carefully; then follow step by step.

SELECT THE BEST LOCATION

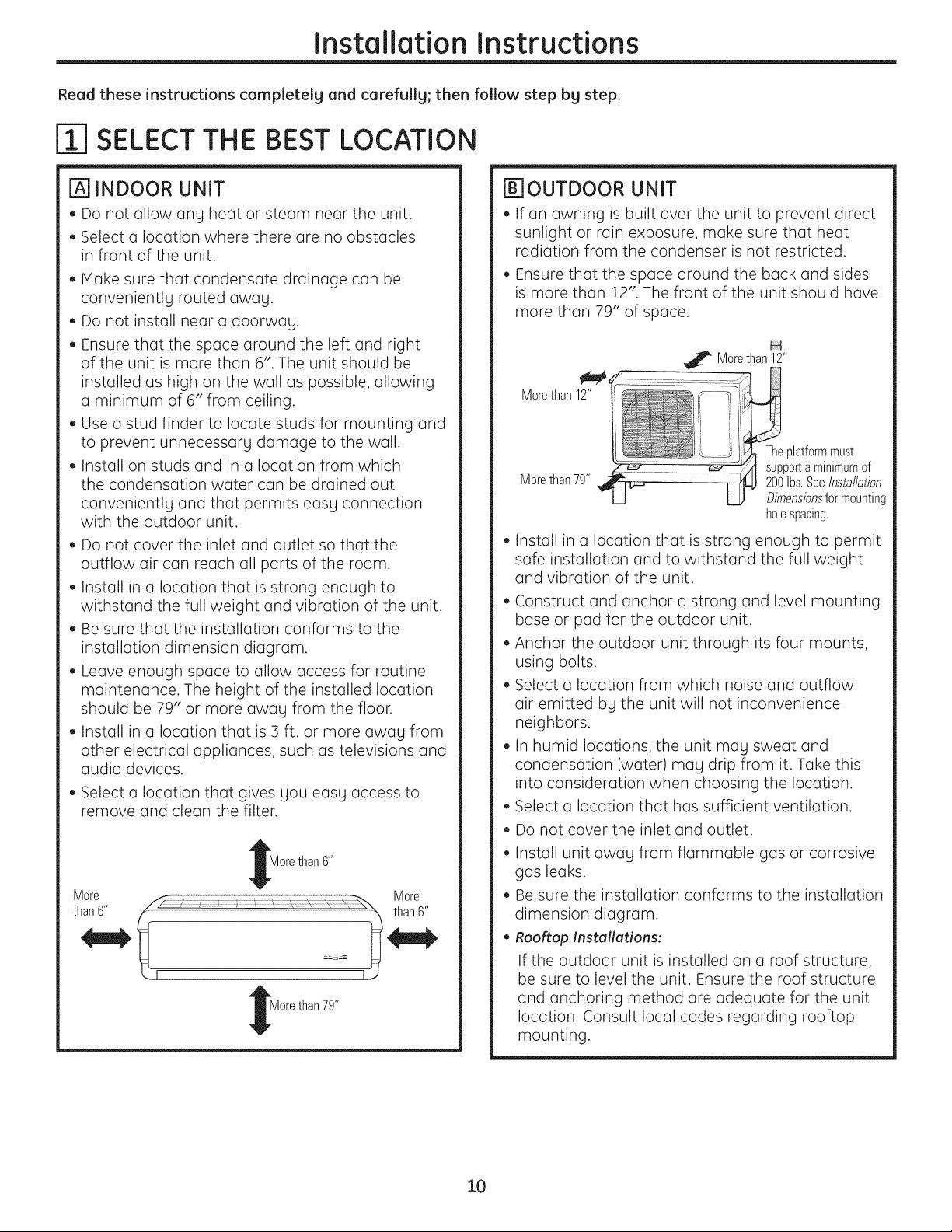

r_ INDOOR UNIT

• Do not allow ang heat or steam near the unit.

• Select a location where there are no obstacles

in front of the unit.

• Make sure that condensate drainage can be

convenientlg routed awag.

• Do not install near a doorwag.

• Ensure that the space around the left and right

of the unit is more than 6". The unit should be

installed as high on the wall as possible, allowing

a minimum of 6" from ceiling.

• Use a stud finder to locate studs for mounting and

to prevent unnecessarg damage to the wall.

• Install on studs and in a location from which

the condensation water can be drained out

convenientlg and that permits easg connection

with the outdoor unit.

• Do not cover the inlet and outlet so that the

outflow air can reach all parts of the room.

• Install in a location that is strong enough to

withstand the full weight and vibration of the unit.

• Be sure that the installation conforms to the

installation dimension diagram.

• Leave enough space to allow access for routine

maintenance. The height of the installed location

should be 79" or more awag from the floor.

• Install in a location that is 3 ft. or more awag from

other electrical appliances, such as televisions and

audio devices.

• Select a location that gives gou easg access to

remove and clean the filter.

Morethan6"

More f, _ , , .... More

Morethan79"

[]OUTDOOR UNIT

• If an awning is built over the unit to prevent direct

sunlight or rain exposure, make sure that heat

radiation from the condenser is not restricted.

• Ensure that the space around the back and sides

is more than 12". The front of the unit should have

more than 79" of space.

H

Morethan12"

Theplatformmust

supporta minimumof

Morethan79" 200Ibs.SeeInstallation

Dimensionsformounting

holespacing.

• Install in a location that is strong enough to permit

safe installation and to withstand the full weight

and vibration of the unit.

• Construct and anchor o strong and level mounting

base or pod for the outdoor unit.

• Anchor the outdoor unit through its four mounts,

using bolts.

• Select o location from which noise and outflow

air emitted bg the unit will not inconvenience

neighbors.

• In humid locations, the unit mog sweat and

condensation (water) mag drip from it. Take this

into consideration when choosing the location.

• Select a location that has sufficient ventilation.

• Do not cover the inlet and outlet.

• Install unit owog from flammable gas or corrosive

gas leaks.

• Be sure the installation conforms to the installation

dimension diagram.

• Rooftop Installations:

If the outdoor unit is installed on a roof structure,

be sure to level the unit. Ensure the roof structure

and anchoring method are adequate for the unit

location. Consult local codes regarding rooftop

mounting.

10

Page 11

INSTALLATION

Installation Instructions

[] INSTALL THE MOUNTING PLATE

• Always mount the mounting plate horizontally.

• Attach the mounting plate at the selected location

with screws supplied with the unit.

• Be sure that the mounting plate has been

attached firmly enough to withstand the weight

of on adult of 130 Ibs. Also, the weight should be

evenly shored by each screw.

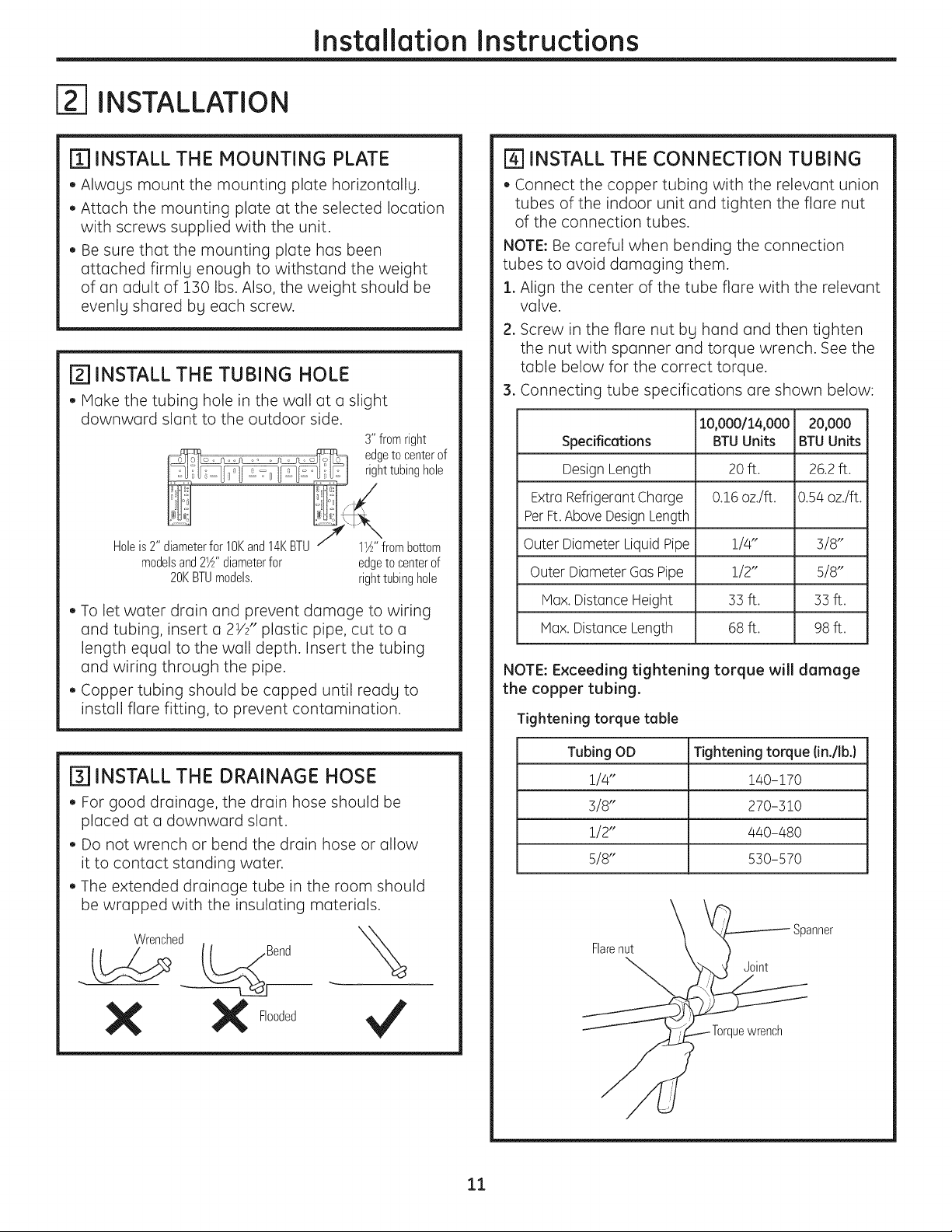

171INSTALL THE TUBING HOLE

• Make the tubing hole in the wall at o slight

downward slant to the outdoor side.

3"fromright

edgetocenterof

righttubinghole

Holeis2"diameterfor1OKand14KBTU l_A''frombottom

modelsand2_''diameterfor edgeto centerof

20KBTUmodels, righttubinghole

• To let water drain and prevent damage to wiring

and tubing, insert o 2V/' plastic pipe, cut to o

length equal to the wall depth. Insert the tubing

and wiring through the pipe.

• Copper tubing should be copped until ready to

install flare fitting, to prevent contamination.

f

\

I_ INSTALL THE CONNECTION TUBING

• Connect the copper tubing with the relevant union

tubes of the indoor unit and tighten the flare nut

of the connection tubes.

NOTE: Be careful when bending the connection

tubes to ovoid damaging them.

1. Align the center of the tube flere with the relevant

velve.

2. Screw in the flare nut by hand end then tighten

the nut with spanner and torque wrench. See the

table below for the correct torque.

3. Connecting tube specifications ere shown below:

10,000/14,00020,000

Specifications BTU Units BTU Units

DesignLength 20 ft. 26.2ft.

Extra Refrigerant Charge 0.16oz./ft. 0.54oz./ft.

PerFt.AboveDesignLength

Outer Diameter Liquid Pipe 1/4" 3/8"

Outer Diameter GasPipe 1/2" 5/8"

Max.Distance Height 33 ft. 33 ft.

Max.Distance Length 68ft. 98ft.

NOTE: Exceeding tightening torque will damage

the copper tubing.

Tightening torque table

[_] INSTALL THE DRAINAGE HOSE

• For good drainage, the drain hose should be

placed at o downward slant.

• Do not wrench or bend the drain hose or allow

it to contact standing water.

• The extended drainage tube in the room should

be wrapped with the insulating materials.

\

X X Flooded

11

Tubing OD

1/4"

3/8"

1/2"

5/8"

Flarenut

Tightening torque(in./Ib.)

140-170

270-310

440-480

530-570

Spanner

Joint

uewrench

Page 12

Installation Instructions

INSTALLATION (cont.}

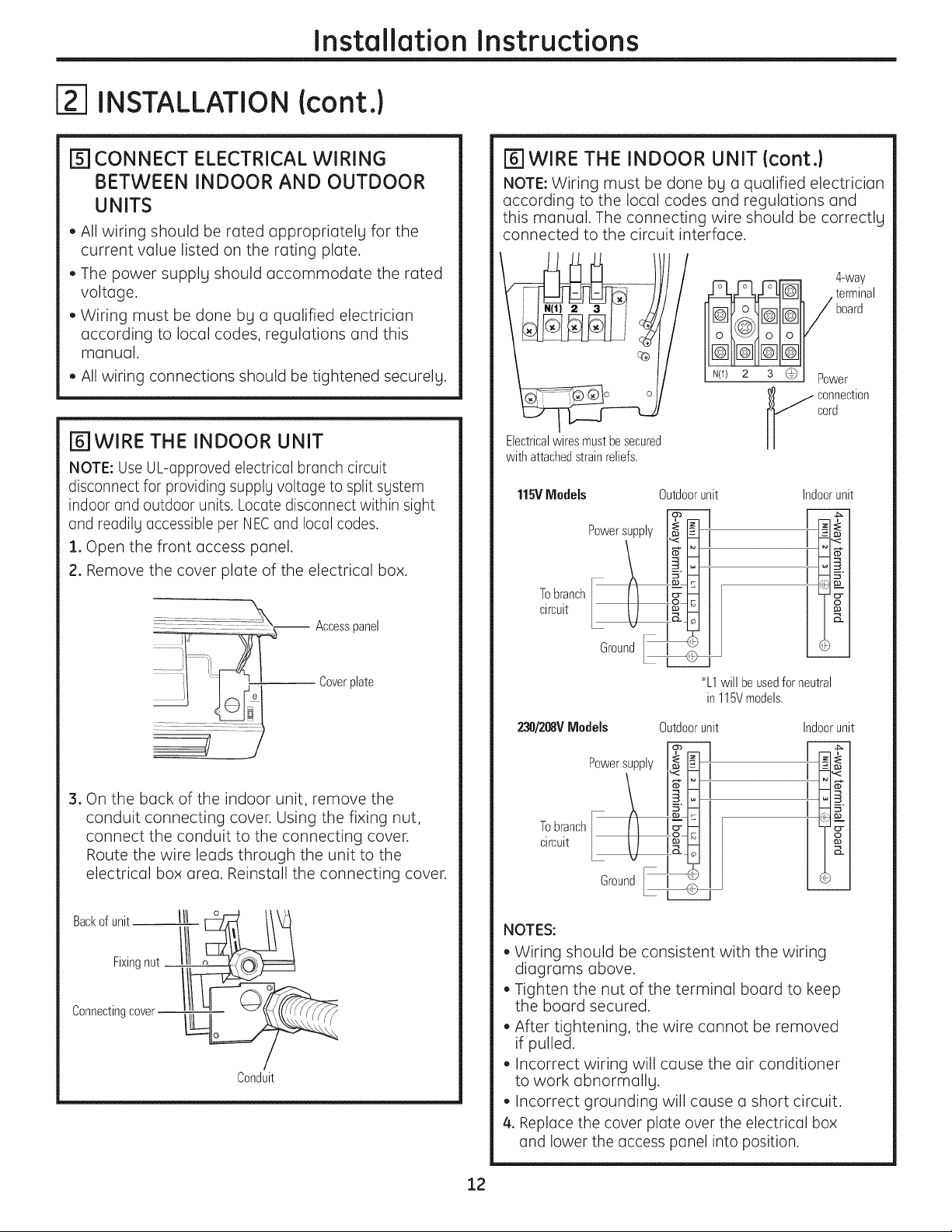

[_] CONNECT ELECTRICAL WIRING

BETWEEN INDOOR AND OUTDOOR

UNITS

• All wiring should be rated appropriately for the

current value listed on the rating plate.

• The power supply should accommodate the rated

voltage.

• Wiring must be done by a qualified electrician

according to local codes, regulations and this

manual.

• All wiring connections should be tightened securely.

[61WIRE THE INDOOR UNIT

NOTE: Use UL-approved electrical branch circuit

disconnect for providing supply voltage to split system

indoor and outdoor units. Locate disconnect within sight

ond readilg occessible per NECand local codes.

1. Open the front access panel.

2. Remove the cover plate of the electrical box.

\

:::::::':_ Accesspanel

F6]WIRE THE INDOOR UNIT {cont.}

NOTE: Wiring must be done by a qualified electrician

according to the local codes and regulations and

this manual. The connecting wire should be correctly

connected to the circuit interface.

_w -way

Electricalwiresmustbesecured

with attachedstrainreliefs.

115VModels Outdoorunit Indoorunit

Powersupply _

Tobranch

circuit

:tI:i!

terminal

board

er

j onnection

cord

3.

o

_3J

B_

roun

i -- Coverplate

J o

3. On the back of the indoor unit, remove the

conduit connecting cover. Using the fixing nut,

connect the conduit to the connecting cover.

Route the wire leads through the unit to the

electrical box area. Reinstall the connecting cover.

Backof unit IIII

Fixingnut /1/

Connecting cover

Conduit

%1will beusedfor neutral

in 115Vmodels.

230/208V Models

Powersupply _1

Tobranch

circuit

NOTES:

• Wiring should be consistent with the wiring

diagrams above.

• Tighten the nut of the terminal board to keep

the board secured.

• After tightening, the wire cannot be removed

if pulled.

• Incorrect wiring will cause the air conditioner

to work abnormally.

• Incorrect grounding will cause a short circuit.

4. Replace the cover plate over the electrical box

and lower the access panel into position.

Outdoorunit

Indoorunit

12

Page 13

Installation Instructions

INSTALLATION (cont.}

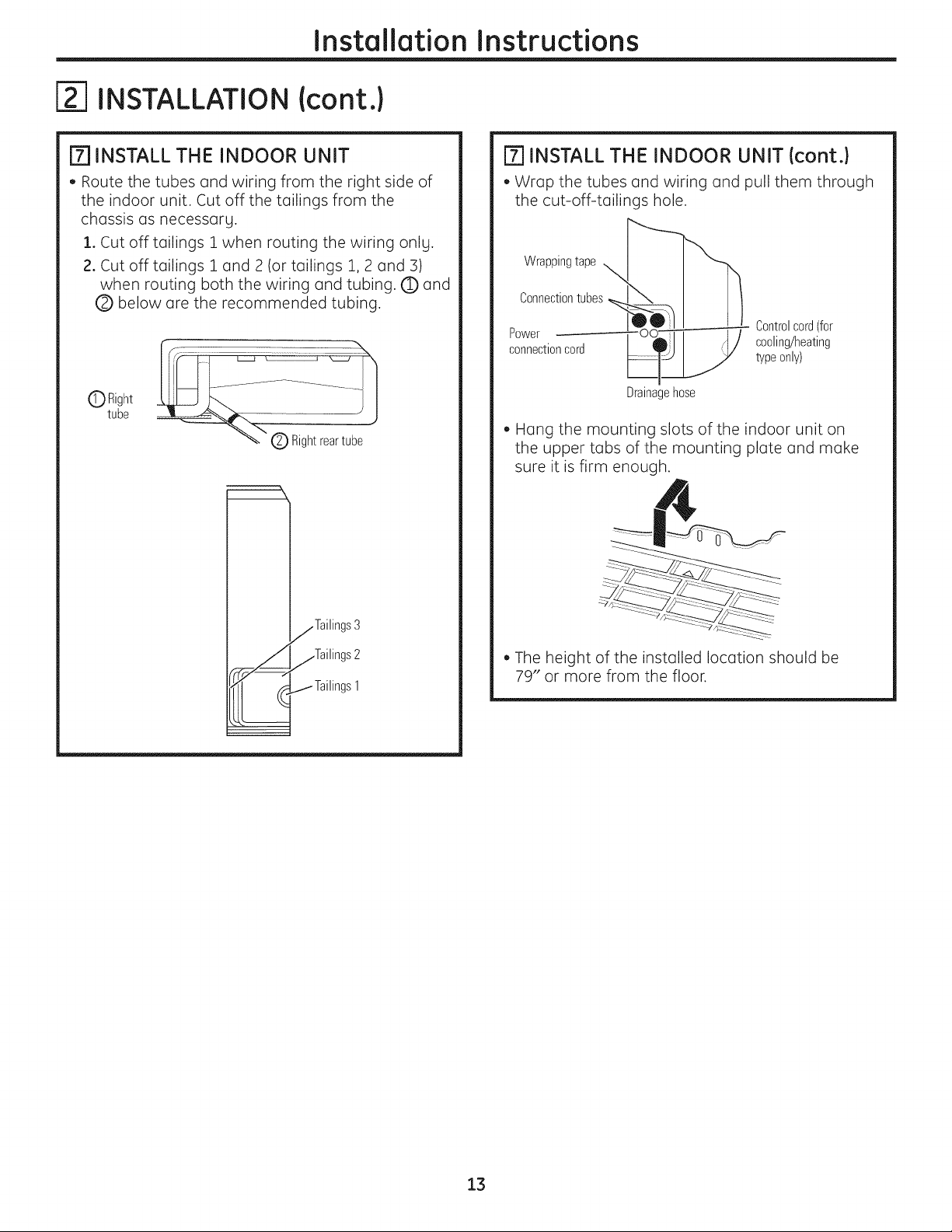

[71INSTALL THE INDOOR UNIT

• Route the tubes and wiring from the right side of

the indoor unit. Cut off the railings from the

chassis as necessary.

1. Cut off tailings 1 when routing the wiring only.

2. Cut off railings 1 and 2 (or railings 1, 2 and 3)

when routing both the wiring and tubing. (_ and

(_ below are the recommended tubing.

C) Right

tube

[2] INSTALL THE INDOOR UNIT (cont.}

• Wrap the tubes and wiring and pull them through

the cut-off-tailings hole.

Wrappingtape

Connectiontubes

Power Controlcord(for

connectioncord cooling/heating

typeonly)

Drainagehose

• Hang the mounting slots of the indoor unit on

the upper tabs of the mounting plate and make

sure it is firm enough.

jTailings 3

I Jl jTailings 2

I_[_ i-- Tailings1

• The height of the installed location should be

79" or more from the floor.

13

Page 14

Installation Instructions

INSTALLATION (cont.}

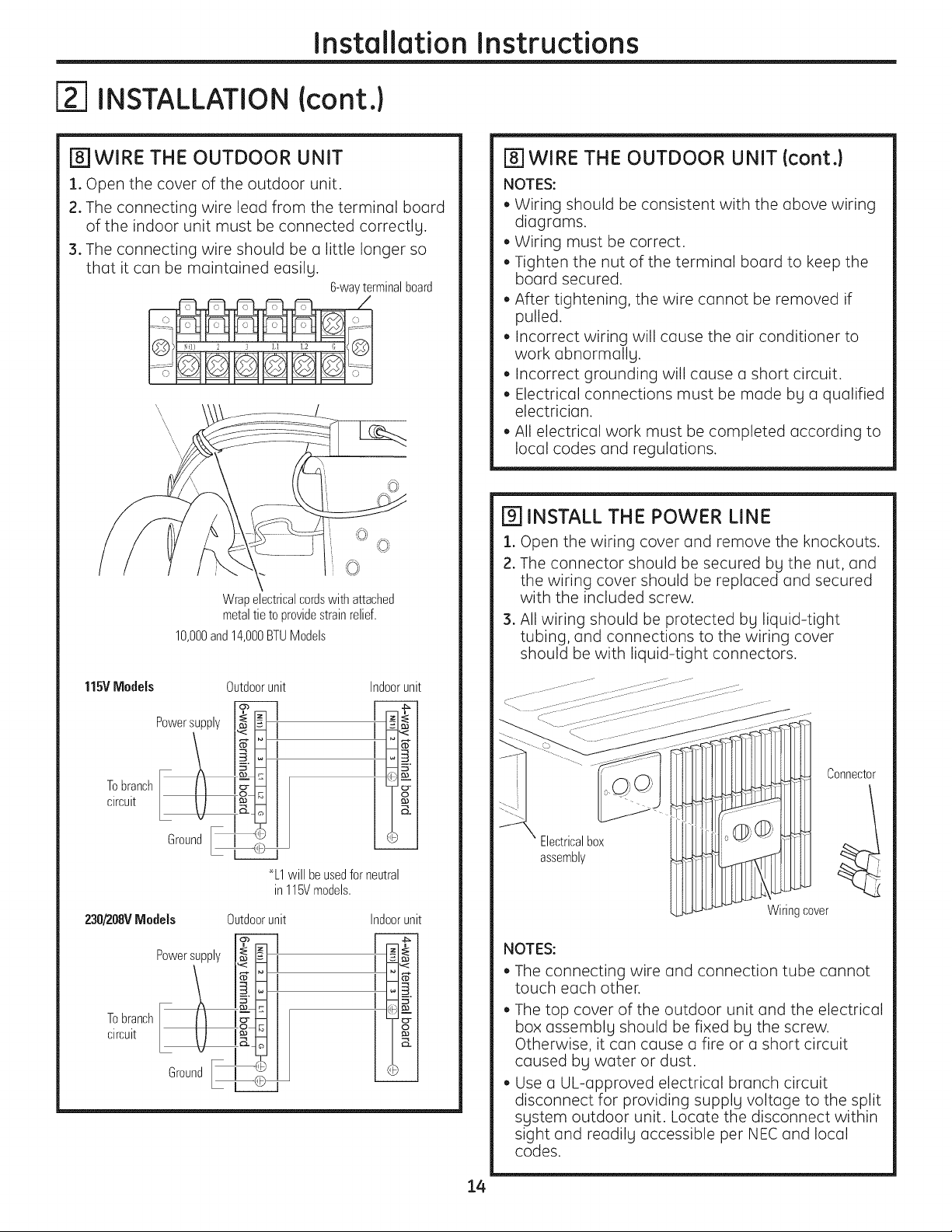

[_]WIRE THE OUTDOOR UNIT

1. Open the cover of the outdoor unit.

2. The connecting wire lead from the terminal board

of the indoor unit must be connected correctly.

3. The connecting wire should be a little longer so

that it can be maintained easily.

6-wayterminalboard

\

,x

\\

O

©

Wrapelectricalcordswith attached

metaltietoprovidestrainrelief.

10,000and14,000BTUModels

FsqWIRE THE OUTDOOR UNIT (cont.}

NOTES:

• Wiring should be consistent with the above wiring

diagrams.

• Wiring must be correct.

• Tighten the nut of the terminal board to keep the

board secured.

• After tightening, the wire cannot be removed if

pulled.

• Incorrect wiring will cause the air conditioner to

work abnormally.

• Incorrect grounding will cause a short circuit.

• Electrical connections must be made by a qualified

electrician.

• All electrical work must be completed according to

local codes and regulations.

[] INSTALL THE POWER LINE

1. Open the wiring cover and remove the knockouts.

2. The connector should be secured by the nut, and

the wiring cover should be replaced and secured

with the included screw.

3. All wiring should be protected by liquid-tight

tubing, and connections to the wiring cover

should be with liquid-tight connectors.

115VModels Outdoorunit Indoorunit

Powersupply _]

Tobranch

circuit

roun

%1will beusedfor neutral

in 115Vmodels.

230/208VModels Outdoorunit

Powersupply _

circuit

Indoorunit

T° r nchl

Ground_ I

Connector

Electricalbox

assembly

Wiringcover

NOTES:

• The connecting wire and connection tube cannot

touch each other.

• The top cover of the outdoor unit and the electrical

box assembly should be fixed by the screw.

Otherwise, it can cause a fire or a short circuit

caused by water or dust.

• Use a UL-approved electrical branch circuit

disconnect for providing supply voltage to the split

system outdoor unit. Locate the disconnect within

sight and readily accessible per NEC and local

codes.

14

Page 15

Installation Instructions

INSTALLATION (cont.}

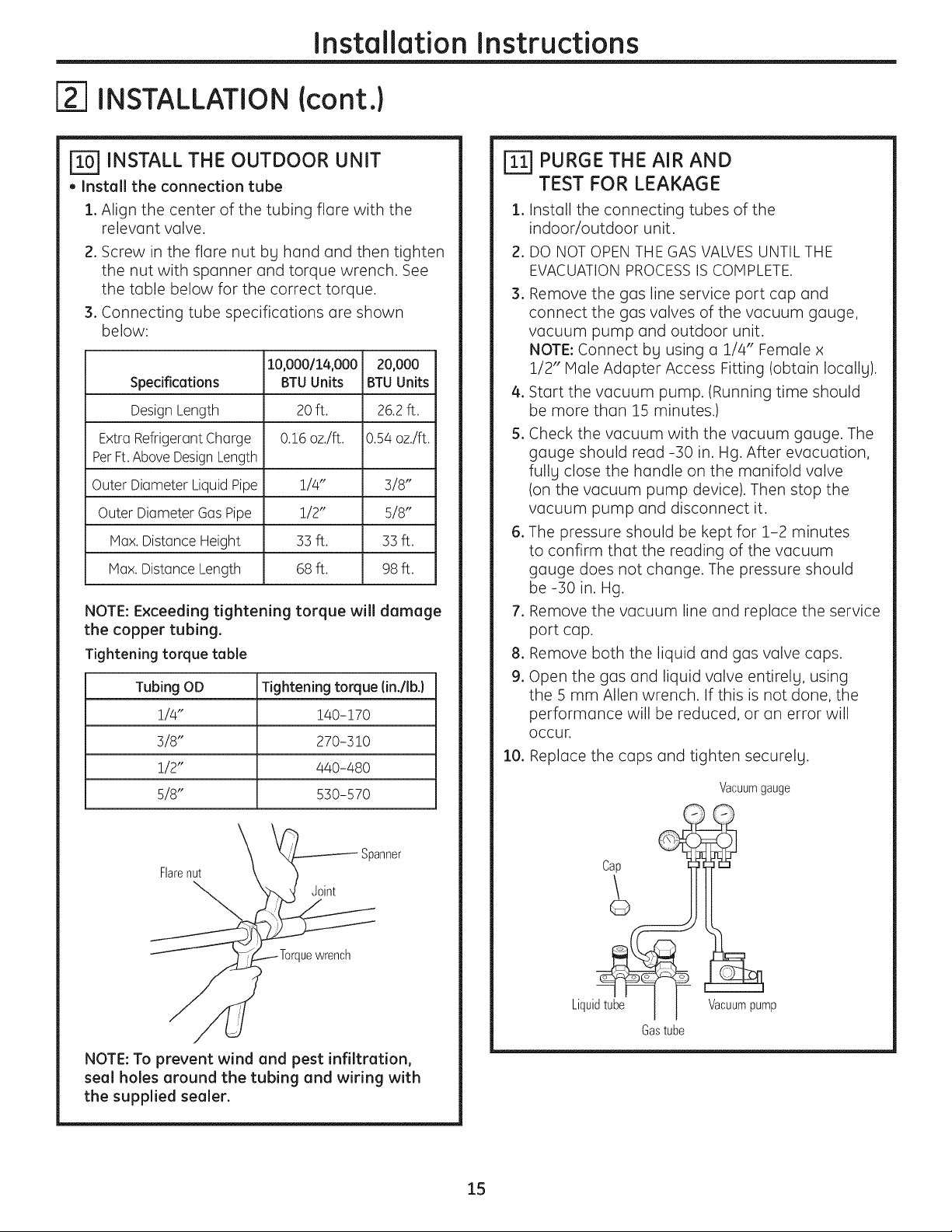

| INSTALL THE OUTDOOR UNIT

• Install the connection tube

i. Align the center of the tubing flare with the

relevant valve.

2. Screw in the flare nut by hand and then tighten

the nut with spanner and torque wrench. See

the table below for the correct torque.

3. Connecting tube specifications are shown

below:

10,000/14,00020,000

Spedficetions BTU Units BTU Units

Design Length 20ft. 26.2ft.

ExtraRefrigerantCharge 0.16 oz./ft. 0.54oz./ft.

PerFt.AboveDesignLength

Outer Diameter LiquidPipe 1/4" 3/8"

Outer Diameter GasPipe 1/2" 5/8"

Max.Distance Height 33 ft. 33ft.

Max.Distance Length 68 ft. 98ft.

NOTE: Exceeding tightening torque will damage

the copper tubing.

Tightening torque table

Tubing OD

1/4"

3/8"

1/2"

5/8"

Tighteningtorque(in./Ib.)

140-170

270-310

440-480

530-570

I-_ PURGE THE AIR AND

TEST FOR LEAKAGE

,

Install the connecting tubes of the

indoor/outdoor unit.

2.

DO NOT OPEN THE GAS VALVES UNTIL THE

EVACUATION PROCESSIS COMPLETE.

3.

Remove the gas line service port cap and

connect the gas valves of the vacuum gauge,

vacuum pump and outdoor unit.

NOTE: Connect bg using a 1/4" Female x

1/2" Male Adapter Access Fitting (obtain Iocallg).

,

Start the vacuum pump. (Running time should

be more than 15 minutes.)

5.

Check the vacuum with the vacuum gauge. The

gauge should read -30 in. Hg. After evacuation,

fulls close the handle on the manifold valve

(on the vacuum pump device). Then stop the

vacuum pump and disconnect it.

6. The pressure should be kept for 1-2 minutes

to confirm that the reading of the vacuum

gauge does not change. The pressure should

be-30 in. Hg.

7. Remove the vacuum line and replace the service

port cap.

8. Remove both the liquid and gas valve caps.

9. Open the gas and liquid valve entirelg, using

the 5 mm Allen wrench. If this is not done, the

performance will be reduced, or an error will

OCCUr.

i0. Replace the caps and tighten securelg.

Vacuumgauge

(

Spanner

Flarenut

Joint

uewrench

NOTE: To prevent wind and pest infiltration,

seal holes around the tubing and wiring with

the supplied sealer.

Cap

Liquid_hp_

Vacuumpump

Gastube

15

Page 16

Installation Instructions

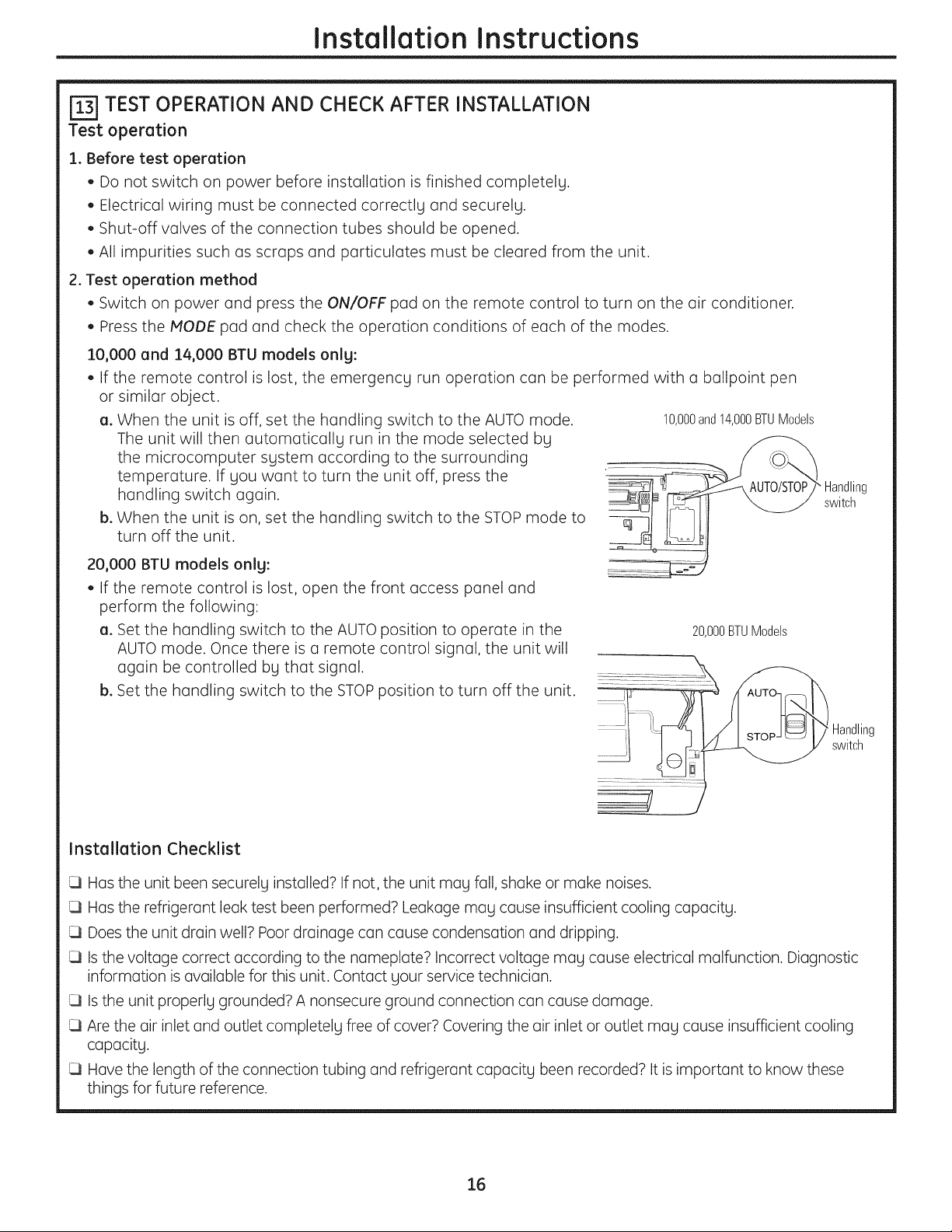

_-_ TEST OPERATION AND CHECK AFTER INSTALLATION

Test operation

1. Before test operation

• Do not switch on power before installation is finished completely.

• Electrical wiring must be connected correctly and securely.

• Shut-off valves of the connection tubes should be opened.

• All impurities such us scraps and particulates must be cleared from the unit.

2. Test operation method

• Switch on power and press the ON/OFF pod on the remote control to turn on the air conditioner.

• Press the MODE pad and check the operation conditions of each of the modes.

i0,000 and 14,000 BTU models onlg:

• If the remote control is lost, the emergency run operation can be performed with a ballpoint pen

or similar object.

a. When the unit is off, set the handling switch to the AUTO mode.

The unit will then automatically run in the mode selected by

the microcomputer system according to the surrounding

temperature. If you want to turn the unit off, press the

handling switch again.

b. When the unit is on, set the handling switch to the STOP mode to q

turn off the unit.

10,000and14,000BTUModels

Handling

switch

20,000 BTU models only:

• If the remote control is lost, open the front access panel and

perform the following:

a. Set the handling switch to the AUTO position to operate in the

AUTO mode. Once there is a remote control signal, the unit will

again be controlled by that signal.

b. Set the handling switch to the STOPposition to turn off the unit.

20,000BTUModels

Installation Checklist

Has the unit been securely installed? If not, the unit may full, shake or make noises.

Has the refrigerant leak test been performed? Leakage may cause insufficient cooling capacity.

Does the unit drain well? Poor drainage con cause condensation and dripping.

Is the voltage correct according to the nameplate? Incorrect voltage may cause electrical malfunction. Diagnostic

information is available for this unit. Contact your service technician.

Is the unit properly grounded? A nonsecure ground connection can cause damage.

Are the air inlet and outlet completely free of cover? Covering the air inlet or outlet may cause insufficient cooling

capacity.

Have the length of the connection tubing and refrigerant capacity been recorded? It is important to know these

things for future reference.

switch

16

Page 17

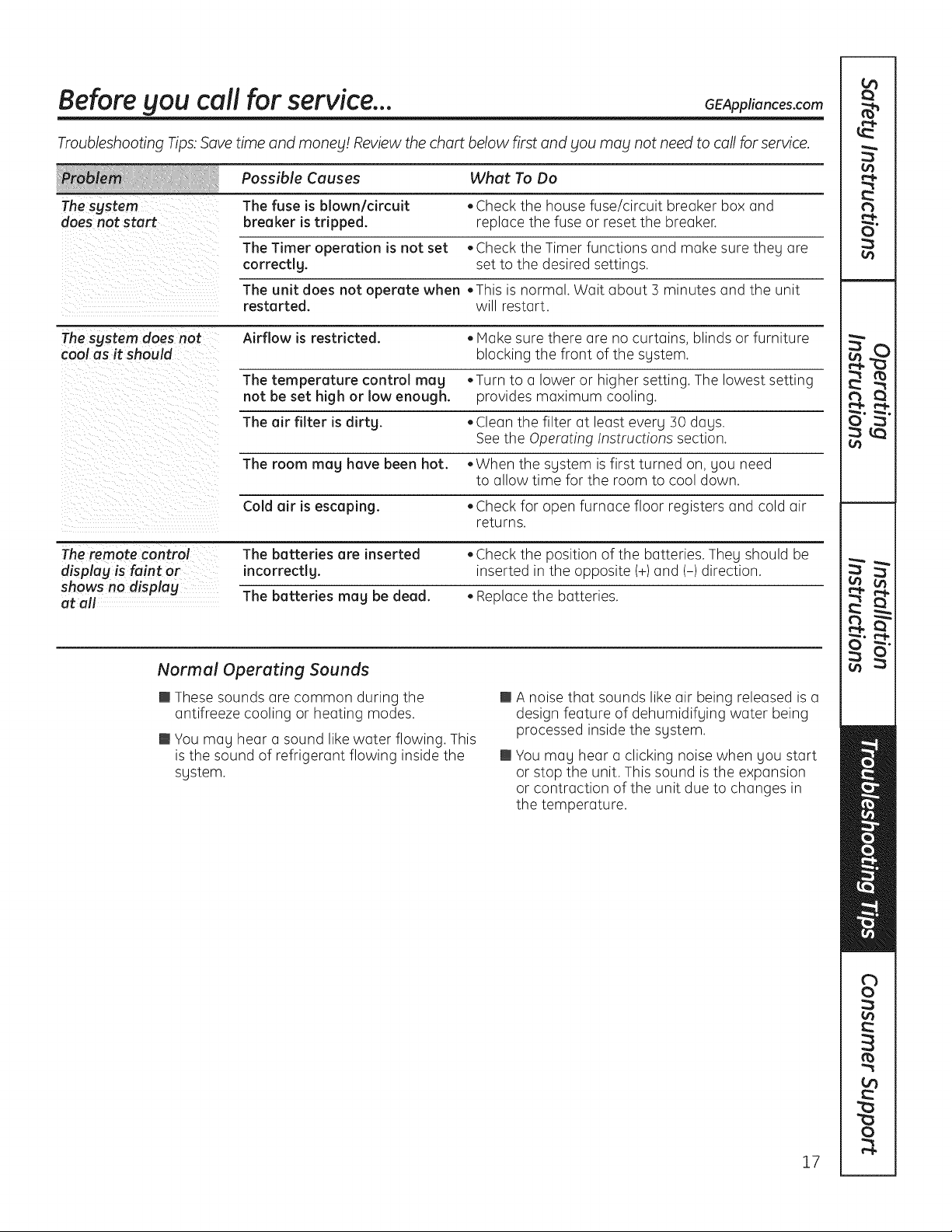

Before gou call for service... GEAppliances.com

Troubleshooting Tips:Save time and moneg! Review the chart below first and gou mag not need to call for service.

Possible Causes What To Do

The sgstem

does not start

The sgstem does not Airflow is restricted. • Make sure there are no curtains, blinds or furniture

cool as it should blocking the front of the system.

The remote control The batteries are inserted • Check the position of the batteries. They should be

displag is faint or incorrectlg, inserted in the opposite (+)and (-) direction.

shows no displag

at all The batteries mag be dead. - Replace the batteries.

The fuse is blown/circuit • Check the house fuse/circuit breaker box and

breaker is tripped, replace the fuse or reset the breaker.

The Timer operation is not set • Check the Timer functions and make sure they are

correctly, set to the desired settings.

The unit does not operate when .This is normal. Wait about ] minutes and the unit

restarted, will restart.

The temperature control mag • Turn to a lower or higher setting. The lowest setting

not be set high or low enough, provides maximum cooling.

The air filter is dirty. • Clean the filter at least every ]0 days.

See the Operating Instructions section.

The room mag have been hot. .When the system is first turned on, you need

to allow time for the room to cool down.

Cold air is escaping. • Check for open furnace floor registers and cold air

returns.

Normal Operating Sounds

m These sounds are common during the

antifreeze cooling or heating modes.

m You may hear a sound like water flowing. This

isthe sound of refrigerant flowing inside the

system.

m A noise that sounds like air being released is a

design feature of dehumidifying water being

processed inside the system.

m You may hear a clicking noise when you start

or stop the unit. This sound isthe expansion

or contraction of the unit due to changes in

the temperature.

17

Page 18

Split Sgstem Warrantg.

All warrantg service provided bg our designated service network.

Toschedule service,call 866.404.5245. For service in Canada, contact

Gordon Williams Corp. at 1.888.209.0999. Pleasehave serial number

and model number available when calling for service.

6E Will Replace:

One Year

Fromthe date of the

origina!purchase

Five Years

Fromthe date of the

original purchase

Service trips to gout home to teach you how to use

the product.

Improper installation, delivers or maintenance. If Sou

have an installation problem, or if the air conditioner is

of improper cooling capacity for the intended use,

contact your dealer or installer. You are responsible for

providing adequate electrical connecting facilities.

Failure of the product resulting from modifications to

the product or due to unreasonable use including

failure to provide reasonable and necessary

maintenance.

In commercial locations labor necessary to move the

unit to a location where it is accessible for service by

an individual technician.

Any part of the air conditioner which fails due to a defect in materials or workmanship.

Duringthis limited one-year warranty, GEwill also provide,free of charge, all labor

and related serviceto replacethe defective part.

Any part of the sealed refrigerating system (thecompressor,condenser,evaporator

and all connecting tubing) which fails due to a defect in materials or workmanship.

Duringthis four-year limited additional warranty, GEwill also provide,free of charge,

all labor and related serviceto replace the defective part.

Staple Four receipt here.

Proof of the origina! purchase

date is needed to obtain service

under the warrant F.

Replacement of house fuses or resetting of circuit

breakers.

Failure due to corrosion on models not corrosion-

protected.

Damage to the product caused by improper power

supply voltage, accident, fire, floods or acts of God.

Incidental or consequential damage caused by possible

defects with this air conditioner.

Damage caused after delivery.

Product not accessible to provide required service.

Warranty. Any implied warranties, including the implied warranties of merchantability or fitness for u particular

i XCLUSION OF IMPLIED WARRANTIES--Your sole and exclusive remedy is product repair as provided in this Limited

purpose, are limited to one year or the shortest period allowed bg law.

This warrant_l is extended to the original purchaser and an_l succeeding owner for products purchased

for home use within the USA and Canada. If the product is located in an area where service b!da GE

Authorized Servicer is not available, Sou may be responsible for a trip charge or Sou ma_l be required

to bring the product to an Authorized GE Service location for service. In Alaska, the warrantbt excludes

the cost of shipping or service calls to sour home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warrants

gives Sou specific legal rights, and Sou ma!d also have other rights which vary from state to state. To know

what Four legal rights are, consult btour local or state consumer affairs office or btour state's Attomebt

General.

Warrantor: General Electric Company. Louisville, KV40225

18

Page 19

Consignesdes_cufit_ ........... zo

Condgnes d'utilisation

Entretienet nettouage ................. 24

Fomctionsdelat616commande .... 22, 23

Piles ................................... 21

Instructions de montage

Avant de commencer ................. 25

Branchements ........................ 28

Branchement 61ectrique

de I'unit6 ext6rieure ................... 31

Branchement 61ectrique

de I'unit6 int6rieure.................... 29

C6blage61ectrique................ 29-31

C6ble61ectrique....................... 31

Dimensions ........................... 26

Emplacement ......................... 27

Essaide fonctionnement .............. 33

Exigenceselectriques .................. 25

Plaquede montage ................... 28

Purgede I'airet test defuite .......... 32

Troupour lestugauteries ............. 28

Tugaude vidange ..................... 28

Unit6 ext6rieure ................... 31, 32

Unit int6rieure ..................... 29, 30

Conseilsded_pannage.......... s4

Bruitsnormau×de fonctionnement ... 54

Assistance_ la clientele

Assistance6 la clientele............... 36

Garantie .............................. 35

ModUles de Refroidissement

AE1 CD10API / AEOCD10API

AE1CD14 DM / AEOCD14DM

AE1 CD2ODPI / AEOCD2ODPI

ModUles de Chauffage/Refroidissement

AE1 RDIOAPI / AEORDIOAPI

AE1 RD14DPI / AEORD14DPI

AE1 RD2ODPI / AEORD2ODPI

Inscrivez ici le num_ro de module et le num_ro de s_rie des unit_s

ext_rieures et int_rieures:

Num_ro de module de I'unit_ int_rieure

Num_ro de s_rie de I'unit_ int_rieure

m m

_,_

_ m

_ m

#"% m

Num_ro de module de I'unit_ ext_rieure

Num_ro de s_rie de I'unit_ ext_rieure

Vous trouverez ces num@os sur I'_tiquette appos_e sur le c6t_

de chaque appareil.

19

Page 20

J J

IMPORTANTES CONSIGNES DE SECURITE.

VEUILLEZ LIRE TOUTES LES CONSIGNES AVANT UTILISATION.

AVERTISSEMENT!

Pour votre s4curit4, les informations contenues dans ce manuel doivent 8tre suivies afin

de minimiser les risques d'incendie, de chocs dlectriques ou de blessures corporelles.

CONSIGNESDE SL-CURITE

N'utilisez cet appareil qu'aux fins pr6vues

d6crites dans le manuel d'utilisation.

Ce sgst_me doit @trecorrectement install6

conform6ment aux Consignes de Montage

avant toute utilisation.

@Tousles cOblages devraient @treadapt6s 5

la valeur donn6e sur la plaque signal6tique.

Utilisez uniquement des c@blesen cuivre.

_k AVERTISSEMENT!

Risque de choc #lectrique. Peut provoquer

des blessures voire la mort. IIest important

qua I'appareil soit branch6 6 la terra avant

de le connecter 6 I'alimentation 61ectrique.

_kAVERTISSEMENT!

Risque de choc 61ectrique. Peut provoquer

des blessures voire la mort. D6branchez

routes les alimentations 61ectriques avant

d'effectuer I'entretien de I'appareil.

AkAVERTISSEMENT!

Risque de choc 61ectrique. Peut provoquer

des blessures voire la mort. R6parez ou

remplacez imm6diatement tout cordon

61ectrique us6 ou endommag6. N'utilisez

pas un cordon fissur6 ou pr6sentant des

dommages dus aux frottements soit sur

sa Iongueur ou aux extr6mit6s.

@Tousles travaux 61ectriques doivent

@treeffectu6s par un 61ectricien quali%

conform6ment aux codes de construction

Iocaux et nationaux et @la 16gislation en

vigueur.

La maintenance doit @treeffectu@e par

un technicien qualifi6.

_AVERTISSEMENT!

iiiiiiiiiiii_iiii_

Risque d'incendie. Peut provoquer des

blessures voire la mort. Ne stockez pas et

n'utilisez pas d'essence ou d'autres vapeurs

et liquides inflammables dans les parages

de cat appareil ou de tout autre appareil.

Pour tout entretien demandant

I'ouverture du sgst_me de r_frig_ration

_tanche, il est requis par la I_gislation

f_d_rale que les travau× soient

effectu_s par un technicien certifi_

Class II ou Universal.

Tousles climatiseurs contiennent des

fluides frigorig@nes qui conform6ment @la

16gislation f6d6rale doivent _tre retir6s avant

la mise au rebut de I'appareil. Sivous mettez

au rebus un ancien appareil contenant des

fluides frigorig@nes, v@ifiez la proc6dure @

suivre aupr_s de la compagnie responsable

de I'@limination.

iiiiiiiiiiii_iiii_

Pour les sgst@mes de climatisation

au R410A, il est n@cessaire que les

entrepreneurs etles techniciens utilisent

des outils, un _quipement et des normes de

s@curit@autoris@s pour ce fluide frigorig_ne.

N'utilisez PASd'_quipement certifi@pour

le fluide frigorig@ne R22.

20

LISEZETSUIVEZSOIGNEUSEMENT CESCONSIGNES

DE SL-CURITE.

CONSERVEZ CESINSTRUCTIONS

Page 21

Utilisation du climatiseur, www.electromenagersge.ca

Procedure g_n_rale

REMARQUE:Pourobtenir de meilleursr_sultats,

pointez la t_l_commande en direction de I'unit_

int_rieure.

Assurez-vousque I'appareilest branch_ h

m

I'alimentation _lectrique puisappuyez sur la

touche ON/OFF(Morche/orr_g pour mettre

I'appareilen marche.

Appuyez sur la touche MODE(Node)pour

F2q

s_lectionnezle mode de fonctionnement

appropri&

Appuyez sur la touche SWING (Oriented pour

%

une orientation automatique des persiennes.

Appuyez de nouveau surcette touche pour

arr_ter le mouvement des persiennes.

Comment insurer les piles

Deux pilesAAAsont n_cessairesau fonctionnement

de la t_l_commande.

[] Appugez sur Io touche FAN(VentilationJpour

r_gler IQvitesse souhait_edu ventilateur

(Automatique/Douce/Hogenne/Forte).

r-_ Appuyez sur la touche TEHP+/- (Temperature)

pour r_glerI'appareilh la temperature d_sir_e.

REMARQUE:Pourdes instructions d_taill_essur IQ

t_l_commande, voir la sectionApropos de !o

td_commonde.

r-_ Enlevezle couvercledu Iogement au dosde la

t_l_commande et ins_rezdeux nouvellespiles

(attention aux polarit_s).

[-_ Remettezlecouvercle.

REMARQUES :

m Ne m_langezpas des pilesneuveset despiles

usag_eset n'utilisezpas despilesdiff_rentes.

m Retirezles piles dela t_l_commande sivous

pr_voyez de ne pas utiliser lesyst_me pendant

une Iongue dur_e.

m Lerayon d'action de la t_l_commande s'_tend

jusqu'h 6,1 m (20pieds).

m Lat_l_commande doit _tre plac_e h i m (3 pieds)

ou plus d'un t_l_viseur ou detout autre appareil

_lectrique.

Typedepiles•AAA

-- C0uvercledu10gement

de batterie

21

Page 22

A propos de la t#l#commande.

ka tdl4commande transmet les signaux au sgst_me, kes fonctions et I'apparence peuvent varier.

AUTO (Automatique)--Dans ce mode, I'unit_

maintient la temp@ature de la piece entre

25 °C (77°F)et 20°C (68°F).Leventilateur fonctionne

en continu pendant qua I'unit@est en mode AUTO.

Lorsque la temperature de la piece d@asse

25 °C (77 °F),I'unit_ passe au mode COOL

(Refroidissement).Lorsque la temp@ature de

la piece descend en dessousde 23 °C(73°F),

le ventilateur continue 6 fonctionner mais

le mode COOL(Refroidissement)s'@teint.Lorsque

la temp@ature de la pi@cedescend en dessous

de 20 °C(68°F),I'unit_ passe en mode HEAT

(Chauffage).Lorsque latemp@ature de la piece

attaint 23 °C(73°F),le ventilateur continue 6

fonctionner mais le mode HEAT(Chauffage)s'@eint.

REMARQUE: Ler@glagede cette gamme de

temp@ature ne peut @remodifi_ et ne sera

pas affich&

Marche

Fonctionnuit

-- activ@

FonctionSwing

,activ@

-- Horlogeet

minuterie

O

¢_ COOL(RefroidissementJ--Estutilis6 pour

refroidir la piece 6 destemp6ratures variant

de 16 °C(6! °F)6 30 °C(86°F).

REMARQUE: L'unit@ne donnera pas un

refroidissement optimal si la temp@ature

ext@ieure est inf@ieure 6 15 °C(60°F).Dans

certaines conditions, il est possible qua I'unit6

lance le cgcle de protection contre le gel

pendant environ 5 minutes pour retirer

la glace form_e sur le serpentin int@ieur.

_66DRY(D_shumidification)--Estutilis# pour

d#shumidifier la pi@ce.Leventilateur fonctionne

une vitesse faible et fixe pour donner une

d#shumidification maximale. Lestemp#ratures

peuvent #tre r#gl#es entre !6 °C (61°F)et

50 °C186°F).

'_ FAN(Ventiletion)--Estutilis_pour _teindre ou

mettre en marche la fonction n'utilisant qua le

ventilateur. Lesmodes COOL(Refroidissement),

HEAT(Chauffage)et DRY(D@shumidification)ne

pourront @re utilis@s.

HEAT(Chauffage)(pourlesmo@les @uip_s de

cette fonction)--Est utilis_ pour r@chaufferla

piece6 des temp@raturesvariant de 16 °C(61 °F)

6 30 °C(86OF).

REMARQUE: Est utilis6pour 6teindre ou

mettre en marche la fonction n'utilisant qua

leventilateur. L'unit@ne donnera pas un

chauffage optimal si la temp6rature ext@ieure

est inf@ieure 6 -!0 °C(1/4°F).Danscertaines

conditions, il est possiblequa I'unit6 lance

le cycle de protection contre le gel pendant

environ 8 minutes pour retirer la glace form6e

sur le serpentin ext_rieur. Pendant ce cgcle, ilest

normal d'entendre des bruits de fonctionnement

tels que le fluide frigorig@necirculant dans

le sgst_me.

e

0

O

CEE_

,O

---0

@

0

22

Page 23

Apropos de la t#l#commande (suite).

La t_l_commande transmet los signaux au s.ust_me.

Fonctionsde la tdldcommande

www.electromenagersge.ca

O ffichoge

Affichelesr@glagesIorsqueI'appareilestmisen

marche.AfficheseulementlerOglagedela

tempOratureetderheureIorsquerappareilest@int.

ToucheON/OFF(Marche/Arr@t)

Appugezsur cette touche pour allumerou _teindre

I'appareil.

ToucheMODE(Mode)

Appuyezsurcettetouchepourpasseradiff@ents

modesdefonctionnementAUTO(Automatique),

¢_ (COOL)(Refroidissement),64 (DRY)

(D@shumidification),_(FANONLY)(Ventilation

uniquement)ou_: (HEAT)(Chauffage).

TouchesTEMP(Temperature)

0

Appugezsur+pouraugmenterlatemp@raturede

r@glageparincr@mentd'l °F.Appugezsur-pour

r@duirelatemp@atureder@glageparincr@mentd'l oF.

EnmodeCOOL(Refroidissement)etHEAT(Chauffage),

ilestpossibledes@lectionnerler@glagedela

temp@ratureentre16°C(61°F)a50°C(86°F).

Laler@glagedetemp@atureneserapasaffich@

enmodeAUTO(Automatique).

ToucheFAN(Ventilation)

0

Appuyezsurcettetouchepourmodifier

lavitesseduventilateuraAUTOFAN(Ventilation

automatique),_,, (LowFan)(Ventilationdouce),

_,J (MediumFan)(Ventilationmoyenne)ou

_41 (HighFan)(Forteventilation).

ToucheSWING(Oriented

0

Appugezsurcette touche pour orienter

automatiquementlespersiennes.Appugez

de nouveausur cettetouche pourarr_ter

lemouvementdespersiennes.

Touche SLEEP(Fonction nun

0

Appugezpouractiverou d_soctiverlemodeSLEEP

(Fonctionnuit).Lorsqueleclimatiseurest en mode

refroidissementet que Iominuteriedenuitest

activ@,latemp@aturefix@augmentera

automatiquementde2°Fapr_slapremiereheure

etde2°Fapr_sladeuxi_meheure.LemodeSLEEP

(Fonctionnuit)estcompatibleaveclesmodesCOOL

(Refroidissement),HEAT(Chauffage)etDRY

(D@shumidification).

ToucheHORLOGE

0

Appuuezsurcettetouchepourr@glerI'heure.

AppuyersurTIME+ ouTIME- pourr@glerI'heure

parincr@mentd'uneminute.Appuyezet maintenez

appuy@slestouchesTIME+ ouTIME- pourr@gler

I'heureparincr@mentde10minutes.

ToucheT-ON(Minuterie© activ_el

0

Lorsqueleclimatiseurest_teint,appugez

surlatoucheT-ON(Hinuterieactiv@)pour

leprogrammerpourqu'ilsemetteenmarche

automatiquement(enutilisantlesr@glages

pr@c@dents)a I'heureprogramm@.

AppuuersurlostouchesTIME-ouTIHE+pour

r@glerI'heuredemiseenmarcheparincr@ment

d'uneminute.

Appuyezetmaintenezappuu@slestouches

TIME-ouTIME+- pourr@glerI'heuredemise

enmarcheparincr@mentde10minutes.

PourannuletQ ON(T-ON)(Minuterieactiv_e),

appuyezsurlatoucheCANCEL(Annuler).

ToucheT-OFF(Minuterie© d#soctiv@)

0

Lorsqueleclimatiseurestallum@,appuuez

surlatoucheT-OFF(Hinuteried@sactiv@)

pourleprogrammerpourqu'ils'arr@te

automatiquementaI'heureprogramm@.

AppuyersurlestouchesTIME-ouTIME+

pourr_glerI'heured'arr_tparincrement

d'uneminute.

Appuuezet maintenezappug@s lestouchesTIME-

ouTIME+pourr@glerI'heured'arr@tpar incr@ment

de 10minutes.

Pourannulet(_ OFF{Minuteried_sactiv_e),

appuuezsurlatoucheCANCEL(Annuler).

TouchesTIME(Heure)

0

Utilisezcestouchespourr@glezI'heuredela

pendule(CLOCK)etdesminuteriesdemisesen

marcheetd'arr@t(T-ONetT-OFF).Appuyezsur

cestouchespourr@glerI'heureparincr@ment

d'l minute.Appuyezetmaintenezappuy@s

cestouchespourr@glerI'heureparincr@ment

de10minutes.

ToucheCANCEL(Annulationl

0

Appugezsur cette touche pourannulerla/les

minuterie(s).

23

Page 24

Entretien et nettoyoge du climotiseur

,_ MISE EN GARDE : Avantd'effectuerI'entretiendevotreappareil, ddbranchezI'alimentationdlectrique.

Unit_ int_rieure

Grille, Logement etT_l_commonde

Eteignezlesgst_me avant de le nettoger.Pourle

nettoger,essugez-leavec unchiffon doux et sec.

N'utilisezpasd'eau de Javelou de nettogants

abrasifs.

Eventd'arriveed'air

f

Eventdesortied'air

Filtres _ Air

Lesdeux filtres h air derrierela grillefrontale doivent

_tre inspect_s et nettog6s au bout de 50jours de

fonctionnement ou plussouvent si n_cessaire.

Ouvrezlepanneau frontal d'acc_s ainsi.

F2-]TirezI_g_rementla languette du filtre vers

I'avantpour retirer lefiltre. Nettogezle filtre

h I'aide d'un aspirateur ou avec de I'eau

savonneusetilde. Rincezlefiltre et laissez-le

s_cher avant de leremettre dans leclimatiseur.

r_] R_ins_rezlesfiltreset fermez lepanneau frontal

d'acc_s.

REMARQUE:NEfaites PASfonctionner le sgst_me

sans un filtre souspeine dele boucher avecde la

poussi_reet de la charpieet de r_duireson efficacit&

24

Unit_ ext_rieure

Lesserpentins _changeurs de chaleur et les

_vents de I'unit_ ext_rieure doivent _treexamines

r_guli_rement. S'ilssont bouch_spar dessalet_sou

desd_bris, lesserpentins_changeurs de chaleur et

les_vents doivent _tre nettog_s par un sp_cialiste.

REMARQUES :

mL'a!imentation dlectriquedoit 8treddbranchdavant

de proc_der 8 !'entretiende!'unitdextdrieure.

mLesserpentinssolesou bouchdsrdduiront

!'efficacit_de votre s_IstSmeetaugmenteront

lescoots de fonctionnement.

Si vous envisegez de ne pus utiliser votre

climetiseur pendent une Iongue dur_e...

Faitesfonctionner votre appareil dans

r-l] lemode de ventilateur pendant 2 heures.

Ceprocessus ass_cheravotre sgst_me.

_-] Retirezles pilesdela t_l_commande.

r_] couvrez I'unit_ ext_rieureavec unehousse

de protection.

Eventde

prised'air

Eventde

sortied'air

REMARQUE:A la saison suivante, assurez-vous

d'avoir retirer la houssede protection de I'unit_

ext_rieure avant de remettre le sgst_me en marche.

.............. ........

Page 25

I structio

tise

ibl c

r$

AVANT DE COMMENCER

Lisezces instructions enti_rement et

ottentivement.

• IMPORTANT- Conservez ces instructions pour

I'inspecteur 61ectrique local.

• IMPORTANT - Respecteztous lescodeset

reglementsenvigueur.

• Remorque pour l'instolloteur- Assurez-vousde

remettre ces instructions au client.

• Remorque pour le client - Conservez ces instructions

pour toute r6f@ence future.

• Niveou de competence - Un technicien agr66 et certifi6

(pour manipuler les frigorig_nes R410A,r6cup6ration,

etc.) et un 61ectricien qualifi6 sont requis pour

I'installation de ce sgst_me de climatisation 6 blocs.

• D_loi d'ex@cution - Environ 2 heures V2.

• A cause du poids du produit, deux personnes sont

requises pour installer cat appareil.

• L'installateur est responsable de I'installation correcte

de I'appareil.

• La panne de I'appareil due 6 une mauvaise installation

n'est pas couverte par la garantie.

• Pour des raisons de s6curit6, cat appareil doit _tre

correctement mis 6 la terra.

• Lesdispositifs de protection (fusibles ou disjoncteurs)

acceptables pour carte installation sont sp6cifi6s sur

la fiche signal6tique de chaque unit6.

• L'entretien et I'installation de ce sgst_me de climatisation

doivent @re effectu6s par un technician qualifi6, certifi6

pour I'installation de chauffage, de ventilation et de

climatisation.

• Evitezd'avoir 6 effectuer des travaux de c_blage et

de plomberie dons le mur au moment de I'installation.

• Pour tout entretien demandant I'ouverture du sgst_me

de rdrig@ation @anche, il est requis par la 16gislation

f6d@ale qua les travaux soient effectu6s par un

technicien certifi6 Class II ou Universal.

MISEENGARDE:

• N'utilisez pos de rollonges ovec cet opporeil.

• Un c6bloge en oluminium dons le domicile peut

occosionner des probl_mes porticuliers-consultez

un @lectricien quolifi&

• Lorsque I'unit_ est en position STOP(Art@t},

les commondes sont toujours sous tension.

• D_bronchez le sgst_me de I'olimentotion @lectrique

ovont d'effectuer I'entretien en retiront les fusibles

du circuit d_riv_ ou en d_clenchont le disjoncteur

ou niveou du tableau _lectrique.

• N'utilisez PASd'_quipement certifi_ pour le fluide

frigorig_ne R22.

E×IGENCES I_LECTRIQUES

• Assurez-vousque lec_blagesoitconforme aux codesde

constructionIocauxet au NECet que latensiond'alimentation

pour ce sgstemesoitcorrecte.Latensiond'alimentationdu

sgstemeestuniquement branch@6 I'unit6ext6rieure.

V@ifiezla plaquesignal6tiquesur lec6t6 deI'unit6ext6rieure

pour connaTtrela protectionet latensiond'alimentation

requise.

Utilisezun sectionneurde circuitd@iv6homologu6ULpour

la tensiond'alimentation aux unit6sext6rieureset int6rieures

du sgsteme 6 blocs.Placezcesectionneur6 port@ devue

et facilementaccessibleselonlescodesIocauxet leNEC.

Tousles cablages devraient @treadapt6saux valeurs

donn@s sur leplaque signal6tique.

Assurez-vousqua le branchement 6 laterra est continuet

non endommag6.

Lec_blagedoit @treprot6g6 dans destubes @anches

6quip6sde connecteurs 6galement @anches.

25

Page 26

Instructions de manta e

PII_CES INCLUSES

• Plaquede montage

• Enduit

. Vis (5pour les modeles (_

i0 000 et 14 000 BTU et

10 pour lesmodules (_

20 000 BTU)

• T616commande

• PilesAAA(2)

• Tugau de vidange

• Tuyau d'isolation

• Deuxfiltres (2)

FOURNIS PAR L'INSTALLATEUR

Adaptateur Soupape Schrader

femelle 5/16 po, filetage male

1/4 po (1/2 po-2OUN)

ACCESSOIRES EN OPTION

Pour fociliter le montage, les accessoires suivants

peuvent @tre command6s '

DIMENSIONS DE L'INSTALLATION

_6 po ouplusentrele

6po ou plus _!'climatiseuretleplafond 6poouplus

entrele entrele

climatiseur_ _ i i _ \, ._ ,\ -,\ <_-- c matseur

etlemur_ J: _%r

e spooup.us 79pooup.us,. / a ded

,_, _A,_,o_,,;_' entrele I /rou pour les orotectlon

_y y........ climatiseur _

d air et lesol T manchons de

:28 po ouplus entrele

Lclimatiseuretlaprotection

tuyauterie

...... J

Trousse GE TUE3250

Pouruneutilisationaveclesmodules

Diam_treettongueur pox 52pi.

duconduitd'aspiration

Diam_treetIongueur pox 52pi.

duconduitdeliquide

Longueurdutube d'isotation 32pi.

Manchonspourtrousdartslemur 12) inclus

BandedeprotectionenPVC inclus

Trousse GE

Pouruneutilisationaveclesmodules

Diam_treetIongueur 5/8 pox 16pi. 5/8 pox 32pi.

duconduitd'aspiration

Diam_treetIongueur 3/8 pox 16pi. 3/8 pox 52pi.

duconduitdeliquide

Longueurdutube d'isotation 16pi. 32pi.

Manchonspourtrousdartslemur (2) inclus inclus

BandedeprotectionenPVC inclus inclus

TUEI650

AE1CDt0AIVi

AEOCDt0AIVl

AEIRDIOAM

AEORDt0AIVi

AE1CDtaDM

AEOCDt4DIVi

AE1RD14DIVi

AEORD14DIVi

1/2 pox 16pi. 1/2

1//4pox16pi. 1//4

16pi.

inclus

inclus

TUEI662 TUE3262

AE1CD20DiVi

AEOCD20DiVi

AE1RD20DiVi

AEORD20DiVi

12po ouplus entrele.

climatiseuret le tour

79 poou plusdu

c6tesortied'air

113_po-Mod_lesb20000BTU

211Apo-Mod_tes_10000et14000BTU

22_6po-Mod_tes_20000BTU

REMARQUES IMPORTANTES :

• L'instollation doit #tre effectu6e por un

61ectricien qualifi6 et par un technicien certi%

Class II ou Universal.

• Lorsque vous soulevez et d6placez des unit6s,

vous devez _tre guid_ par une personne form6e

et quali%e.

26

28poouplus

entreleclimatiseur

etletour

14000BTU

Page 27

Instructions de monta e

Lisez ces instructions enti_rement et attentivement, puis suivez-les _tape par _tape.

CHOISISSEZ L'EMPLACEMENT

LE PLUS APPROPRIE

#

FA]UNITE INTERIEURE

• N'exposez pas votre unit6 5 la chaleur ou la vapeur.

• Choisissez un emplacement sans obstacle devant

I'unit6.

• Assurez-vous que le condensat puisse _tre

facilement @acu&

• N'installez pas I'appareil pr6s d'une ouverture.

• Pr#vogez un espoce d'ou moins 6 po 5 gouche

et 6 droite de I'unit6. Cette unit6 doit #tre instoll6e

le plus hout possible sur lemur, en pr@ogont un

espoce d'ou moins 6 po entre I'unit6 et le plofond.

• Utilisez un d6tecteur de montont pour Iocoliser les

montonts et 6viter tout dommoge inutile ou mur.

• Instollez I'unit6 sur le montonts et dons un

emplocement d'oQ I'eou de condensotion peut #tre

focilement @ocu6e et qui permette une connexion

focile 6 I'unit6 ext@ieure.

• Ne recouvrez pos I'entr6e et Io sortie pour oinsi

permettre 6 Fair d'otteindre toutes les parties de

Io pi@ce.

• Installez I'unit6 dans un emplacement suffisamment

solide pour supporter le poids et les vibrations de

I'appareil.

• Assurez-vous que I'instollation soit conforme aux

dimensions indiqu#es sur le diagramme de

montoge.

• Loissez suffisomment de ploce pour permettre

d'occ6der 6 I'unit6 pour effectuer I'entretien de

routine. L'unit6 dolt _tre install6e 6 une hauteur

minimole de 79 po du sol.

• Installez dons un emplocement 61oign6 d'ou poins

3 pi de tout outre opporeil 61ectrique tel qu'un

t61@iseur et des opporeils oudio.

• Choisissez un emplocement vous permettont un

acc_s facile pour retirer et nettoger le filtre.

Plusde6po

.-< _ ,, , -,--. Plusde

Plusde79po

[] UNITI_EXTI_RIEURE

• Si une morquise est construite ou dessus de I'unit#

pour Io prot6ger d'une exposition directe ou soleil

ou 6 Io pluie, ossurez-vous que le rogonnement de

choleur en provenance du condenseur ne soit pas

restreint.

• Pr@oyez un espace d'au moins 12 po 5 I'arri@e et

sur les c6t6s de I'unit6. Le devant de I'unit6 dolt

avoir un espace de 79 po.

M

,_ Plusde12po

Plusde12po _ .... _; , ,

' i t;

....... i

I L_ L plateformedoltpouvoirPlusde79po supporterunecharge

• Installez I'unit_ dans un emplacement suffisamment

solide pour permettre une installation sore qui puisse

supporter le poids et les vibrations de I'appareil.

• Construisez et ancrez une base solide et de niveau

pour I'unit6 ext@ieure.

• Ancrez I'unit6 grace 6 ses quatre montants, en

utilisant les boulons.

• Choisissez un emplacement o_ le bruit et I'air 6mis

par I'unit6 ne d@angeront pas les voisins.

•Dans les endroits humides, I'unit6 risque de suinter

et I'eau de condensation peut s'en 6couler. Tenez

compte de ce point Iorsque vous choisissez

I'emplacement.

• Choisissez un emplacement suffisamment ventil6.

• Ne couvrez pas I'entr6e et la sortie.

• Installez I'unit6 6 1'6cart des gaz inflammables ou

des fuites de gaz corrosifs.

• Assurez-vous que I'installation soit conforme aux

dimensions indiqu_es sur le diagramme de

montage.

• Installation sur un toit :

Si I'unit6 ext@ieure dolt 6tre instoll6e sur un toit,

ossurez-vous que I'unit6 est de niveou. Assurez-

vous que Io structure du toit et Io m6thode

d'oncroge soit od6quote pour I'unit6. Consultez

les codes Iocoux concernont une instollotion

sur un toit.

minimalede91kg(200

livres).VoirDimensionsde

/'lnstallationpour

I'espacementdestrous

demontage

27

Page 28

INSTALLATION

Instructions de manta e

[] INSTALLATION DU PLAGUE

DE MONTAGE

• Installez toujours le plaque de montage

horizontalement.

• Fixez le plaque de montage 6 I'emplocement choisi

avec les vis fournies avec I'unit&

• Assurez-vous que le plaque de montage est

correctement fix@pour soutenir le poids d'un adulte

d'environ 60 Kg (130 livres). De plus, tout le poids

dolt @treuniform6ment r6parti sur chaque vis.

[_] INSTALLATION DU TROU POUR

LES CONDUITES

• Le trou pour les conduites dolt @treinclin@ vers

I'ext@ieur.

Trousest2podediam6trespourlesmod61es 1_ podubard

10Ket 14KBTUet2_ popourlesmod61es inf@ieuraucentre

20KBTU. dutroupourles

• Pour permettre 5 I'eau de s'_vacuer et pour 6viter

tout dommage au cablage et aux conduites, ins@ez

un tuLlau en plastique de 2Yz po de diam6tre, coup6

6 une Iongueur 6gale 6 la profondeur du mur.

Ins@ez les conduites et le cablage par ce tuLlau.

• Les tubes en cuivre doivent _tre bouch6sjusqu'6 ce

que vous SOLlezpr6t 6 installez le raccord conique,

pour 6viter toute contamination.

3podubarddroit

au (;entredu trou

pourlesconduites

droite

f

conduites8droite

r_ INSTALLATION DU TUYAU

D'EVACUATION

• Pour une bonne 6vacuation, le tuyau d'6vacuation

doit _tre inclin_ vers le bas.

• Ne vrillez pas ou ne tordez pas le tuyau

d'6vacuation, ne le laissez pas dans I'eau stagnante.

• Le tuLlau d'6vacuation allong6 dans la piece doit

_tre envelopp_ de mat@iau isolant.

Vrill_

r_ INSTALLATION DES TUYAUX

DE CONNEXION

• Branchez les tuLlaux de cuivre de connexion avec

les raccords union de I'unit6 int@ieure et resserrez

le raccord conique des tuLlaux de connexion.

REMARQUE : Courbez d61icatement les tugaux

de connexion pour 6viter de les endommager.

1. Alignez le centre de 1'6vasement du tuLlau avec

le robinet correspondant.

2. Vissez le raccord conique 6 la main, puis serrez-le

6 I'aide d'une cl6 et d'une cl6 dgnamom6trique.

R#f@ez-vous au tableau ci-dessous pour obtenir

le couple de serrage appropri6.

3. Le sp#cification du tugau de connection est

indiqu#e ci-dessous :

ModUles ModUles

Specifications i0 000/14 000BTU20000BTU

Longueurdesignee (pieds) 20 26,2

ExtraCharge Refrigerant 0,16 0,54

par pieds par-dessus

Iongueur designee(oz/ft)

Diam_treext@ieur du 1/4 3/8

tugau de liquide (pouces)

Diam_tre ext@ieurdes 1/2 5/8

tugaus de gaz (pouces)

MaxDistanceHauteur(pieds) 33 33

DistanceMaxLongueur(pieds) 68 98

REMAROUE : Si vous d6passez le couple de

serrage, vous endommagerez les tubes en cuivre.

Tableau de couple de serrage

Diam_tre ext_rieur Couple de serrage

du tugau en cuivre (po/livre)

1/4 po 140-170

3/8 po 270-310

1/2 po 440-480

5/8 po 530-570

Raccordconique

Joint

× ×

\

CI6dynamom6trique

28

Page 29

Instructions de monta e

_] BRANCHEMENT DU C,ABLAGE

I_LECTRIQUE ENTRE LES UNITIES

EXTERIEURE ET INTI_RIEURE

• Tousles c@blagesdevraient _tre adapt_s 6 la valeur

donn6e sur la plaque signal6tique,

• L'alimentation 61ectriquedolt pouvoir accommoder

la tension nominale.

Lec@blagedoit @treeffectu_ par un @ctricien qualifi6

conform6ment aux codes Iocaux,aux I@gislationset 6

cette notice.

• Toutes lesconnexions de c@blagedoivent _tre serr6es

ad@quatement.

B1 CABLAGE DE L'UNITI_ INTI_RIEURE

REMARQUE: Utilisezun sectionneur de circuit d6riv6

homologu6 ULpour la tension d'alimentation aux unit_s

ext_rieures et int6rieuresdu sgst_me 6 blocs. Placezce

sectionneur 6 port6e de vue et facilement accessibleselon

lescodes Iocaux et le NEC.

1. Ouvrezlepanneau d'acc_sfrontal,

2. Retirezle couvercle du coffret de branchement,

'_ ....... Panneaud'acc@s

I_] CABLAGE DE L'UNITI_ INTI_RIEURE(suite}

REMARQUE: Lec_blage doit _tre effectu6 par un @ctricien

qualifi6 conform@mentaux codes Iocaux,aux I_gislationset

6 cette notice. Lefil de branchement doit _tre correctement

branch_ 6 I'interface du circuit.

Bornier

Lesfils@ctriquesdoivent6tres6curis6s

avecdesr6ducteursdetension.

Mod_les 115"V Unit_ext_rieure Unit_int_rieure

Alimentation

@ctrique I_i I

Vers le

circuit de

d6rivation

:ti uIf

j d'alimentation

Couvercle

3.Au dos de I'unit6 int_rieure,retirez le couvercle

de connexion du conduit. A I'aide de 1'6crou

de fixation, branchez le conduit au couvercle

de connexion. Faites passerlesc_bles 6 travers I'unit6

jusqu'au coffret de branchement. R_installezle couvercle

de connexion.

DosdeI'unit6 Ill/

E_'roudefixation tl/

Couverclede

connexion

Conduit

Terre

_LIserautilis@pourleneutre

surlesmodules_ 115Y

Mod_les 230/208V Unit_ext_rieure

Alimentation

@ctrique J_ _ljJ

Terre__

REMARQUES:

• Lec_blage doit suivre lessch6mas de c_blage ci-dessus.

• SerrezIfcrou du bornier pour s'assurerque ce dernier

est bien fix6.

• Apr@sserrage, lefil ne doit pas pouvoir est enlev@en tirant.

• Leclimatiseur fonctionnera de fat:on anormale si lesfils

ne sont pas branch6s correctement.

• Une mauvaisemise6 la terre provoqueradescourts-circuits.

4. Remettezle couverclesur le coffret de branchement et

abaissezle panneau d'acc_sen position ferm_e,

Unit@int@rieure

_J

- o

F--

0 c_,

29

Page 30

Instructions de monto e

[_] INSTALLATION (suite}

[2[]INSTALLATION DE L'UNITI_ INTI_RIEURE

• Foites passer les tuyoux et le cabloge sur Io droite

de I'unit6 int@ieure. D6coupez les parties en exc_s

du chassis si n6cessoire.

1. D6coupez le rejet 1 Iorsque vous faites

seulement passer le cablage.

2. D6coupez les rejets 1 et 2 (ou rejets 1, 2 et 3)

Iorsque vous fakes passer le cablage et les

tuLlauteries. (_) et (_) ci-dessous sont les

tULlauteries recommond_es.

(]) Tuyauterie i .................................

"_-" C) Tuyauteriearriiredroite

t......................

[2[]INSTALLATION DE L'UNITI_

INTI_RIEURE (suite}

• Enveloppez les tULlauteries et le cabloge et tirez-les

au travers du trou d#coup#.

protection.

Bandede i-'_--"_

Cordondecommande

(seulementpour

Cordon----------7-, oc _

d'alimentation

Tuyaud'@acuation

• Accrochez les fentes de montage de I'unit_

int@ieure oux Ionguettes sup#rieures de Io plaque

de montage et ossurez-vous que le sLIst_me soit

r6sistant.

lesmod61eschauffage/

refroidissement)

/ Bejet3

I /1_%_

_ mejet1

• L'unit6 doit _tre install6e 6 une hauteur minimale

de 79 po du sol.

3O

Page 31

Instructions de monta e

I-8]C#,BLAGE DE L'UNITI_ E×TI_RIEURE

1. Ouvrez le couvercle de I'unit6 ext@ieure.

2. Le c_ble de connexion provenant du bornier de

I'unit6 int@ieure doit _tre branch6 correctement.

3. Ce c_ble doit _tre un peu plus long que n6cessaire

pour permettre un entretien facile.

Bornier86p61es

\\

\

.\

\

O

iO

I

Enveloppezlescordons_lectriques_I'aidedesattachesm6talliques

servantder6ducteursdetension.

Mod61es8 10000et14000BTU

Meddles 115V Unit6ext6rieure Unit6int6rieure

_J

- o

Alimentation

_lectrique J_l _

Vers le

circuit de

d6rivation

F __

J

[] C#,BLAGE DE L'UNITI_ E×TI_RIEURE

{suite}

REMARQUES:

• Lec6blagedoitsuivrelessch6masdec6blageci-dessus.

• Serrez1'6croudu bornier pour s'assurerque ce dernier est

bien fix&

• Apr6s serrage,le fil ne doit pas pouvoir est enlev6 entirant.

• Le climatiseur fonctionnera de faqon anormale si lesills

ne sont pas branch6s correctement.

• Une mauvaisemise6 la terreprovoquera descourts-circuits.

• Les branchements 61ectriquesdoivent @reeffectu6s par

un _lectricien qualifi&

• Tousles travaux _lectriques doivent @reeffectu_s

conform_ment 6 la I_gislation et aux codes Iocaux.

[] INSTALLATION DU CABLE

D'ALI MENTATION

1.Ouvrez le couvercle de protection des cablages

et retirez les pastilles poinqonn_es.

2. Le connecteur doit _tre fix_ 6 I'aide de I'_crou et

le couvercle du cablage doit _tre remis en place

et fix_ 6 I'aide de la vis fournie.

3. Tout le cablage doit _tre prot_g_ dans un

tugau _tanche et les connexions au couvercle

du c_blage doivent _tre faites 6 I'aide de connecteurs

_tanches.

iii

Connecteur

Nlod_les230/208V

Alimentation_or_--_q

_lectrique I__ I

Vers le

circuit de

d6rivation

Terre ___

%1serautilis6pourle neutre

surlesmod61es_115M

Unit6ext6rieure

Unit6int6rieure

_2J

- 0

r-

- ©_

I =

Coffretde

branchement

Couvercle

de@blage

REMARQUES:

• Lefil de connexion et le tugau de connexion ne doivent

pas _tre en contact.

• Lecouvercle sup_rieur de I'unit_ ext@ieure et

le coffret de branchement doivent _tre fixes par une vis.

Dans le contraire, il peut en r_sulter un incendie ou un

court-circuit provoqu_ par la poussi_re ou I'eau.

• Utilisez un sectionneur de circuit d_riv_ homologu_ UL

pour la tension d'alimentation aux unit_s ext@ieures du

sgst_me 6 blocs. Placez ce sectionneur 6 port_e de vue

et facilement accessible selon les codes Iocaux et le NEC.

31

Page 32

Instructions de manta e

INSTALLATION (suite}

| INSTALLATION DE L'UNITI_

E×TI_RIEURE

• Installez le tugau de connexion

i. Alignez le centre de l'#vasement du tugau avec

le robinet correspondant.

2. Vissez le raccord conique 6 la main, puis

serrez-le 6 I'aide d'une cl@et d'une cl@

dgnomom#trique. R6f@ez-vous au tableau

ci-dessous pour obtenir le couple de serrage

appropri@.

3. Le sp@cificotion du tugau de connection est

indiqu@e ci-dessous :

ModUles ModUles

Sp@cifications io ooo/14 000BTU20000BTU

Longueur designee (pieds) 20 26,2

ExtraCharge Refrigerant 0,16 0,54

par pieds par-dessus

Iongueurdesignee(oz/ft)

Diam6tre ext@ieurdu !/4 3/8

tugau de liquide(pouces)

Diam6tre ext@ieurdes 1/2 5/8

tugaus de gaz (pouces)

MaxDistanceHauteur(pieds) 33 33

DistanceMaxLongueur(pieds) 68 98

REMARQUE : Si vous d_passez le couple de serrage,

vous endommagerez les tubes en cuivre.

Tableau de couple de serrage

Diam_tre ext6rieur Couple de serrage

du tuyau en cuivre (po/livre}

1/4 po 140-170

3/8 po 270-310

1/2 po 440-480

5/8 po 530-570

[i_ PURGE DE L'AIR ET TEST DE FUITES

i. Installez les tugaux de connexion des unit6s

int@ieure et ext@ieure.

,

N'OUVREZ PAS LESROBINETS DE GAZ AVANT

OUE LE PROCESSUS DE PURGE NE SalT TERHIN@

3.

Retirez le bouchon du port de maintenance

de la conduite de gaz et branchez le robinet de

gaz au videm@tre, 6 la pompe 6 vide et 6 I'unit6

ext@ieure.

REMARQUE : Effectuez le branchement 6 I'aide

d'un adaptateur 1/4 po femelle x 1/2 po male,

obtenu Iocalement.

,

Lancez la pompe 6 vide. (La pompe doit

fonctionner un minimum de 15 minutes.)

5.

V@ifiez le vide 6 I'aide du videm_tre. La jauge

doit indiquer -30 po Hg. Apr_s la purge, fermez

compl_tement la poign6e du robinet

d'intercommunication (sur le dispositif de pompe

6 vide). Puis arr@tez la pompe 6 vide et

d@branchez-la.

6. Le sgst_me doit @re gard6 sous pression

pendant 1 6 2 minutes pour confirmer que

la valeur affich6e au videm_tre ne change pas.