GE 35002 Brochure

GE Oil & Gas

Masoneilan* Valves

35002 Camflex*II

Rotary Globe Control Valve

The Camflex II eccentric plug control valve effectively

combines enhanced control performance, simplicity

and long-term reliability for a broad range of

applications.

• Design Simplicity

• Long-term Reliability

Camflex II Eccentric Plug

Rotary Control Valve

Setting the Standard

Unlike some valves in the industry, GE’s 35002 Series

Camflex II Eccentric Plug Rotary Control Valve is not an

automated valve pieced together in a valve automation

shop. Its thoughtful design elevates overall product integrity

and reduces the risk of component failure and process

upset. Offering process plant owners and operators an

exceptional control valve choice, GE helps drive results on

your key business metrics:

• Process uptime

• Asset utilization

• Control performance

Simply Reliable

Uncomplicated, yet attentive to all the right details, the

Camflex II Eccentric Plug Rotary Control Valve offers

a universal integrated system of valve, actuator and

positioner. The valve’s key design objectives -- reducing

friction, reducing drive-train slop, and mitigating component

wear -- are accomplished through a standard and simplified

design architecture that helps this control valve reliably

perform the basic functions of shutoff, throttling and

emission control over an extended lifetime.

Employing an Uncomplicated Geometry

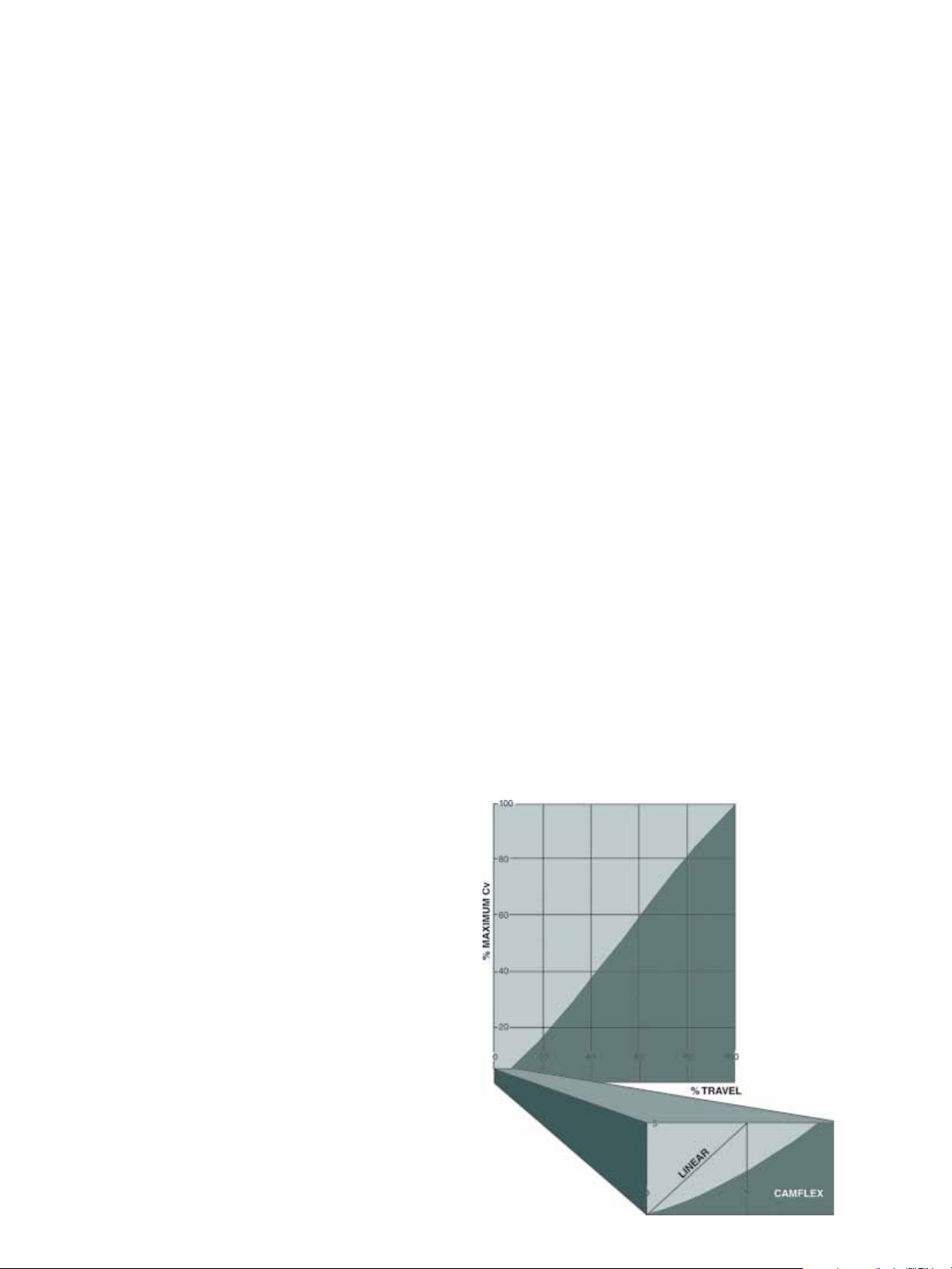

The essentially linear flow characteristic of the Camflex II

Eccentric Plug Rotary Control Valve is established by the

spherical geometry of the eccentric rotating plug. While

the major portion of the flow curve is linear, there is a slight

modification as the plug approaches the seat. As the plug

cams into the seat, the rate of change in flow is gradually

reduced until the plug makes full contact with the seat. This

simple architecture provides the following benefits:

• C

Ratio of 100:1 provides stable operation over a wide

v

range of conditions

• Improved control at startup (low flow/high control

pressure drop)

hardened trim, and high-performance low-emission packing

are all standard, providing exceptional long-term reliability.

In fact, Camflex valves regularly outperform other control

valves in a variety of severely erosive applications where

abrasive solids tend to tear apart other types of valves.

Custom Solutions

Optional constructions, such as the patented DVD™

(Differential Velocity Device) noise reduction trim, alloy

constructions and a cryogenic extension bonnet allow

these valves to be tailored to fit your specific application

needs. All of this combines to offer a low life cycle cost, from

purchase and installation through startup, operation and

maintenance.

• Standard platform

• Wide-ranging applications

• Globe-valve performance

• Customized configurations

Field Proven

More than 1 million Camflex valves have been successfully

installed and operated in a variety of process industries

and applications. The latest Camflex design maintains the

valve’s legendary dependability based on a field-proven

concept that remains a standard of excellence for eccentric

plug rotary control valves.

Broadly Capable

The Camflex II Eccentric Plug Rotary Control Valve is built on

a standard platform with enormous versatility and breadth

of application. Camflex created the eccentric plug, a true

rotary globe control valve that packages the best features

of a globe-style valve within rotary valve architecture. In

addition, high-end features such as the extension bonnet,

2 | GE Oil & Gas

Tackling Key Challenges

Reliable Long-Term Shutoff

With its eccentric rotating valve plug, the Camflex II

Eccentric Plug Rotary Control Valve reduces two common

valve shortcomings: excessive seal ring friction inherent

in ball valves and high actuator forces required for tight

shutoff of either conventional globe valves or butterfly

valves.

Because of its unique seating action, the Camflex plug

makes no contact with the seat until it rotates into its

full closed position. Once seating occurs, continued shaft

rotation causes the plug arm to flex, forcing the plug into

deeper contact with the seat ensuring consistent tight

shutoff. This reliable seating method reduces wear from

rubbing contact, and the tight shutoff performance greatly

reduces the possibility of clearance flow-induced wear or

erosion. Camflex seating mechanics and resulting longterm reliable shutoff offer the following benefits:

• Reduced rubbing – greatly reduced friction and wear

• Improved uptime – extended maintenance cycles

• Reduced unplanned outages and production loss

Environmental Emissions

Compliance

Why pay extra to comply with current environmental

emissions requirements? Unlike some control valves that

require expensive specialized packing systems to satisfy

low emission requirements, Camflex II Eccentric Plug

Rotary Control Valves come standard with GE’s Masoneilan

EF* seal (Emissions Free seal) technology.

• Standard at no extra cost

• Satisfies global low emissions standards requirements

• Simple and reliable with long life

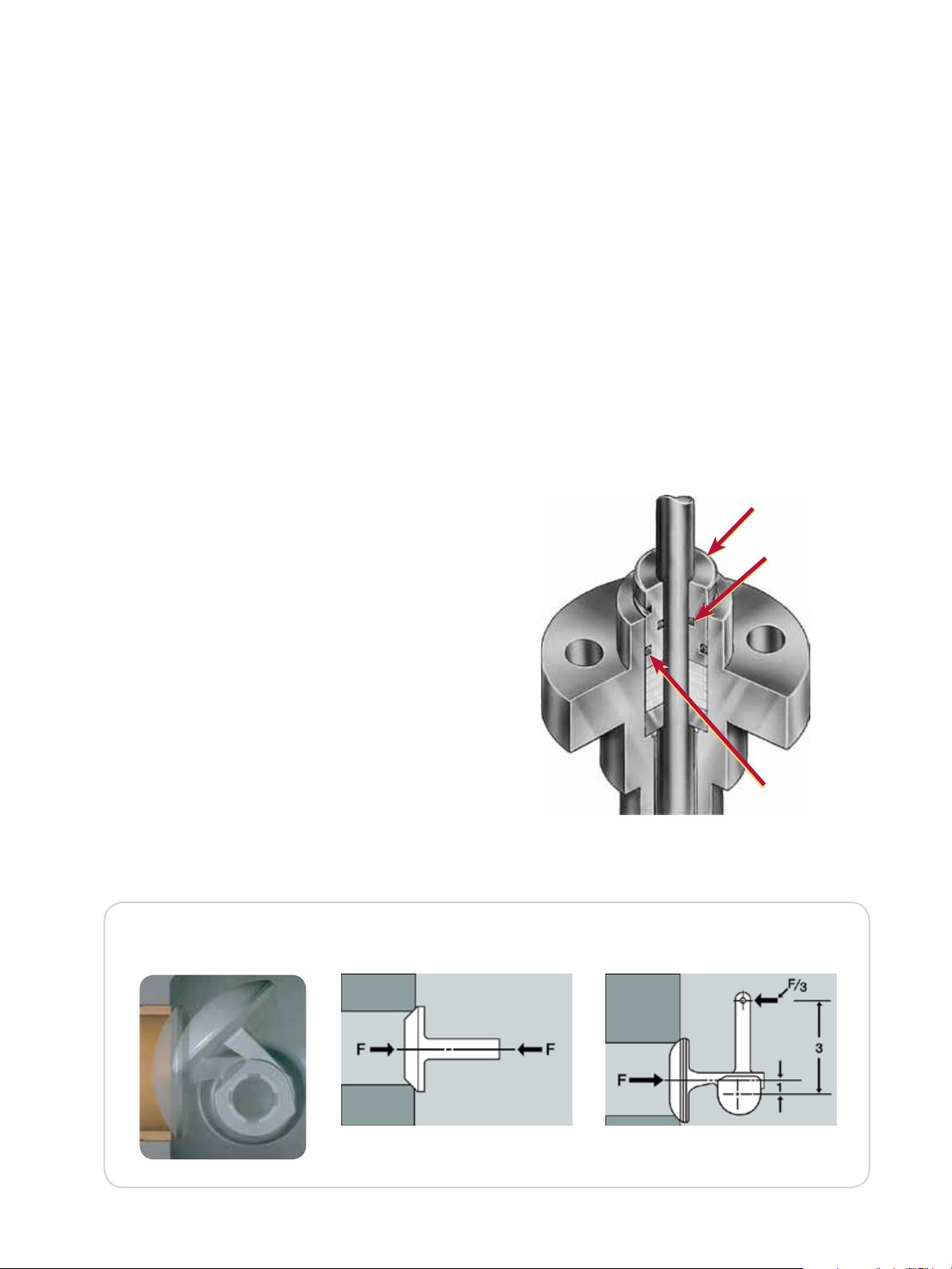

Packing Follower

O-Ring

By combining eccentric plug action with a long actuation

lever, this valve achieves a 3:1 force multiplication. This

means that only one-third of the force required to stroke a

conventional single-seated globe valve is required for the

Camflex actuator to stroke against a given pressure drop.

• Smaller actuator size

• Faster response speed

• Improved control performance

The Camflex plug makes no contact with the seat until it rotates into its full closed position.

Conventional Valve Design

1:1 Ratio of Forces Requires Large Actuator

O-Ring

The Camflex Principle

3:1 Multiplication of Forces

Masoneilan 35002 Series Camflex® II - Universal Control Valve | 3

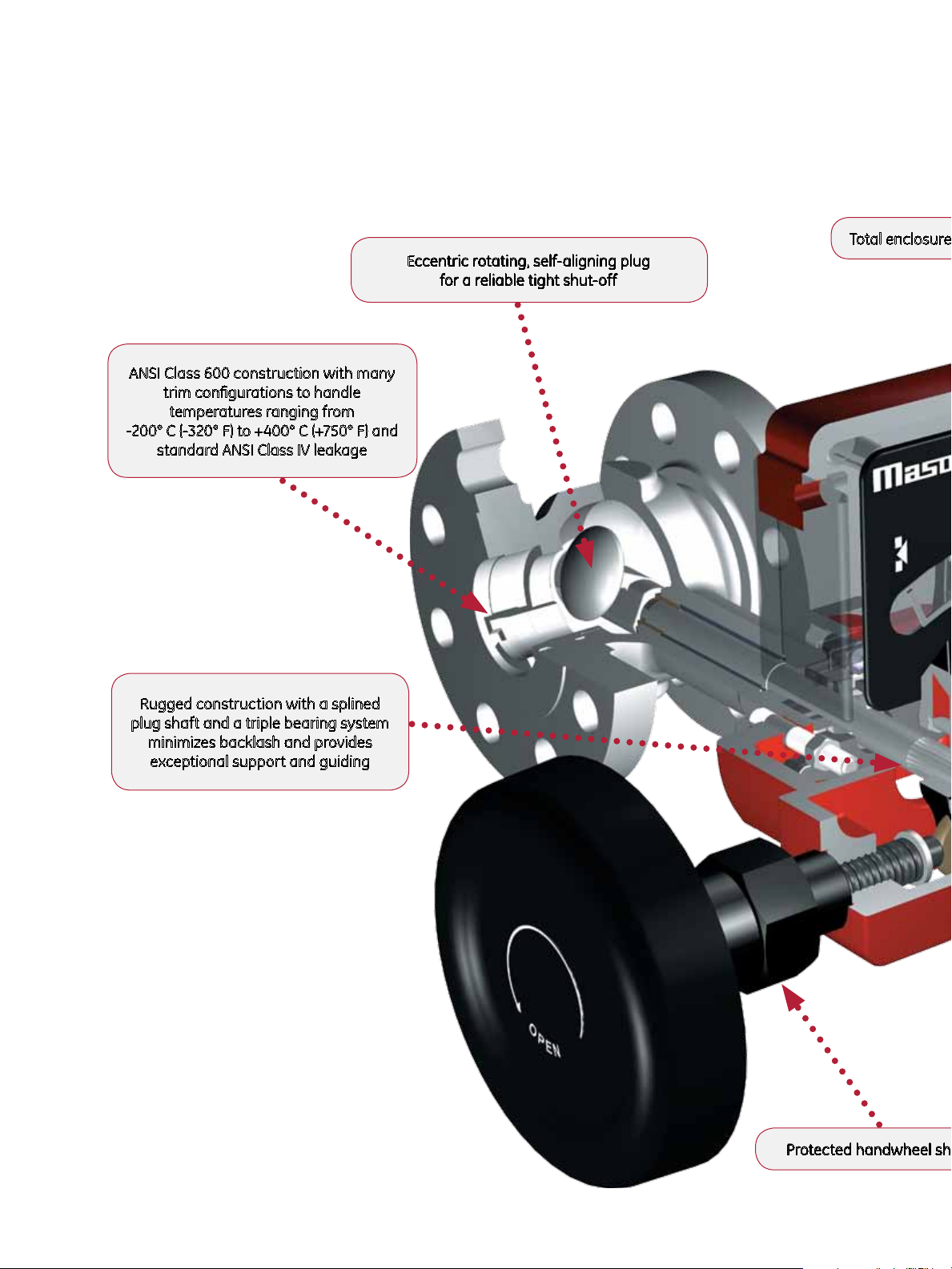

Camflex II Eccentric Plug Rotary Control Valve

ANSI Class 600 construction with many

trim configurations to handle

temperatures ranging from

-200° C (-320° F) to +400° C (+750° F) and

standard ANSI Class IV leakage

Total enclosure provides complete protection

Eccentric rotating, self-aligning plug

for a reliable tight shut-off

Rugged construction with a splined

plug shaft and a triple bearing system

minimizes backlash and provides

exceptional support and guiding

Protected handwheel shaft

4 | GE Oil & Gas

Loading...

Loading...