GE 345 Communications Manual

Title page

GE Digital Energy

Multilin

345

Transformer Protection System

Transformer protection and control

SR345 revision: 1.30

Manual P/N: 1601-9099-A1

GE publication code: GEK-113570

Copyright © 2010 GE Multilin

GE Multilin

215 Anderson Avenue, Markham, Ontario

Canada L6E 1B3

Tel: (905) 294-6222 Fax: (905) 201-2098

Internet: http://www.GEmultilin.com

*1601-xxxx-A3*

Communications Guide

GE Multilin's Quality

Management System is

registered to ISO9001:2000

QMI # 005094

© 2010 GE Multilin Incorporated. All rights reserved.

GE Multilin SR345 Transformer Protection System Communications Guide for revision 1.30.

SR345 Transformer Protection System, EnerVista, EnerVista Launchpad, and EnerVista SR3

Setup, are registered trademarks of GE Multilin Inc.

The contents of this manual are the property of GE Multilin Inc. This documentation is

furnished on license and may not be reproduced in whole or in part without the permission

of GE Multilin. The content of this manual is for informational use only and is subject to

change without notice.

Part number: 1601-9099-A1 (February 2010)

TOC

Table of Contents

Communications interfaces ...................................................................................... 1

RS485 interface............................................................................................................ 2

Electrical Interface ...........................................................................................................................................2

MODBUS Protocol.............................................................................................................................................2

Data Frame Format and Data Rate........................................................................................................ 2

Data Packet Format ....................................................................................................................................... 3

Error Checking................................................................................................................................................... 3

CRC-16 Algorithm............................................................................................................................................ 3

Timing....................................................................................................................................................................4

345 supported functions.............................................................................................................................. 4

DNP protocol settings.....................................................................................................................................5

DNP communication...................................................................................................................................... 5

DNP device profile ........................................................................................................................................... 6

DNP implementation...................................................................................................................................... 8

DNP serial EnerVista Setup........................................................................................................................13

DNP general .....................................................................................................................................................15

IEC 60870-5-103 serial communication............................................................................................. 16

Interoperability ............................................................................................................................................... 16

Physical layer...................................................................................................................................................16

Link layer ........................................................................................................................................................... 17

Application layer ............................................................................................................................................ 17

Transmission mode for application data............................................................................................17

Common address of ASDU........................................................................................................................17

Selection of standard information numbers in monitor direction..........................................17

Selection of standard information numbers in control direction............................................20

Basic application functions.......................................................................................................................20

Miscellaneous..................................................................................................................................................21

Application level............................................................................................................................................. 21

Application functions...................................................................................................................................21

Type identification.........................................................................................................................................21

Function type...................................................................................................................................................22

Information number.....................................................................................................................................22

Data management ....................................................................................................................................... 22

Digital states ....................................................................................................................................................23

Measurands......................................................................................................................................................23

Commands....................................................................................................................................................... 24

103 general settings ....................................................................................................................................25

Ethernet interface .....................................................................................................26

SNTP.....................................................................................................................................................................26

SNTP settings...................................................................................................................................................26

SNTP modes .....................................................................................................................................................26

MODBUS TCP/IP.............................................................................................................................................. 27

Data and control functions.......................................................................................................................27

Exception and error responses...............................................................................................................35

Request response sequence ....................................................................................................................35

CRC .......................................................................................................................................................................36

DNP Ethernet protocol settings .............................................................................................................. 38

DNP communication....................................................................................................................................38

DNP device profile .........................................................................................................................................38

DNP port allocation.......................................................................................................................................41

DNP implementation....................................................................................................................................42

DNP Ethernet EnerVista Setup.................................................................................................................47

DNP general .....................................................................................................................................................49

IEC60870-5-104 protocol .......................................................................................................................... 50

IEC 60870-5-104 interoperability...........................................................................................................50

345 TRANSFORMER PROTECTION SYSTEM – COMMUNICATIONS GUIDE toc–1

IEC 60870-5-104 protocol settings........................................................................................................58

IEC 60870-5-104 point lists.......................................................................................................................58

Summary of Ethernet client connections ...........................................................................................60

IEC 61850 GOOSE communications......................................................................................................62

EnerVista SR3 Setup software structure.............................................................................................62

GOOSE transmission.....................................................................................................................................64

GOOSE Rx...........................................................................................................................................................65

GOOSE Rx status ............................................................................................................................................66

GOOSE Rx headers........................................................................................................................................67

GOOSE receive dataset structure...........................................................................................................68

GOOSE remote inputs..................................................................................................................................69

USB interface..............................................................................................................72

MODBUS Protocol ..........................................................................................................................................72

Data Frame Format and Data Rate......................................................................................................72

Data Packet Format......................................................................................................................................72

Error Checking.................................................................................................................................................73

CRC-16 Algorithm ..........................................................................................................................................73

Timing..................................................................................................................................................................74

345 supported functions............................................................................................................................74

MODBUS memory map.............................................................................................75

Format Codes ...............................................................................................................................................128

MODBUS Functions ................................................................................................ 171

Function Code 03H.....................................................................................................................................171

Function Code 04H.....................................................................................................................................171

Function Code 05H.....................................................................................................................................172

Function Code 06H.....................................................................................................................................173

Function Code 07H.....................................................................................................................................173

Function Code 08H.....................................................................................................................................174

Function Code 10H.....................................................................................................................................175

Error Responses........................................................................................................................................... 175

Force coil commands................................................................................................................................176

Performing Commands Using Function Code 10H.....................................................................177

Using the MODBUS User Map............................................................................... 179

MODBUS User Map.....................................................................................................................................179

TOC

toc–2 345 TRANSFORMER PROTECTION SYSTEM – COMMUNICATIONS GUIDE

Digital Energy

Multilin

345 Transformer Protection System

Communications Guide

Communications Guide

Communications interfaces

The 345 has three communications interfaces. These can be used simultaneously:

• RS485

•USB

•Ethernet

345 TRANSFORMER PROTECTION SYSTEM – COMMUNICATIONS GUIDE 1–1

RS485 INTERFACE CHAPTER 1: COMMUNICATIONS GUIDE

NOTE

NOTE

RS485 interface

The hardware or electrical interface in the 345 is two-wire RS485. In a two-wire link, data is

transmitted and received over the same two wires. Although RS485 two wire

communication is bi-directional, the data is never transmitted and received at the same

time. This means that the data flow is half duplex.

NOTE:

Electrical Interface

NOTE:

Polarity is important in RS485 communications. The '+' (positive) terminals of every device

must be connected together.

The hardware or electrical interface in the 345 is two-wire RS485. In a two-wire link, data is

transmitted and received over the same two wires. Although RS485 two wire

communication is bi-directional, the data is never transmitted and received at the same

time. This means that the data flow is half duplex.

RS485 lines should be connected in a daisy chain configuration with terminating networks

installed at each end of the link (i.e. at the master end and at the slave farthest from the

master). The terminating network should consist of a 120 W resistor in series with a 1 nF

ceramic capacitor when used with Belden 9841 RS485 wire. Shielded wire should always

be used to minimize noise. The shield should be connected to all of the 345s as well as the

master, then grounded at one location only. This keeps the ground potential at the same

level for all of the devices on the serial link.

Polarity is important in RS485 communications. The '+' (positive) terminals of every device

must be connected together.

MODBUS Protocol

Data Frame Format

and Data Rate

The 345 implements a subset of the Modicon Modbus RTU serial communication standard.

The Modbus protocol is hardware-independent. That is, the physical layer can be any of a

variety of standard hardware configurations. This includes USB, RS485, fibre optics, etc.

Modbus is a single master / multiple slave type of protocol suitable for a multi-drop

configuration.

The 345 is always a Modbus slave. It can not be programmed as a Modbus master.

Computers or PLCs are commonly programmed as masters.

Both monitoring and control are possible using read and write register commands. Other

commands are supported to provide additional functions.

The Modbus protocol has the following characteristics.

•Address: 1 to 254

• Supported Modbus function codes: 3, 4, 5, 6, 7, 8, 10

One data frame of an asynchronous transmission to or from a 345 typically consists of 1

start bit, 8 data bits, and 1 stop bit . This produces a 10 bit data frame. This is important for

transmission through modems at high bit rates.

Modbus protocol can be implemented at any standard communication speed. The 345

supports operation at 9600, 19200, 38400, 57600, and 115200 baud.

1–2 345 TRANSFORMER PROTECTION SYSTEM – COMMUNICATIONS GUIDE

CHAPTER 1: COMMUNICATIONS GUIDE RS485 INTERFACE

Data Packet Format A complete request/response sequence consists of the following bytes (transmitted as

separate data frames):

Master Request Transmission:

SLAVE ADDRESS: 1 byte

FUNCTION CODE: 1 byte

DATA: variable number of bytes depending on FUNCTION CODE

CRC: 2 bytes

Slave Response Transmission:

SLAVE ADDRESS: 1 byte

FUNCTION CODE: 1 byte

DATA: variable number of bytes depending on FUNCTION CODE

CRC: 2 bytes

SLAVE ADDRESS: This is the first byte of every transmission. This byte represents the userassigned address of the slave device that is to receive the message sent by the master.

Each slave device must be assigned a unique address and only the addressed slave will

respond to a transmission that starts with its address. In a master request transmission the

SLAVE ADDRESS represents the address of the slave to which the request is being sent. In a

slave response transmission the SLAVE ADDRESS represents the address of the slave that is

sending the response.

FUNCTION CODE: This is the second byte of every transmission. Modbus defines function

codes of 1 to 127.

DATA: This will be a variable number of bytes depending on the FUNCTION CODE. This may

be Actual Values, Setpoints, or addresses sent by the master to the slave or by the slave to

the master.

CRC: This is a two byte error checking code.

Error Checking The RTU version of Modbus includes a two byte CRC-16 (16 bit cyclic redundancy check)

with every transmission. The CRC-16 algorithm essentially treats the entire data stream

(data bits only; start, stop and parity ignored) as one continuous binary number. This

number is first shifted left 16 bits and then divided by a characteristic polynomial

(11000000000000101B). The 16 bit remainder of the division is appended to the end of the

transmission, MSByte first. The resulting message including CRC, when divided by the

same polynomial at the receiver will give a zero remainder if no transmission errors have

occurred.

If a 345 Modbus slave device receives a transmission in which an error is indicated by the

CRC-16 calculation, the slave device will not respond to the transmission. A CRC-16 error

indicates than one or more bytes of the transmission were received incorrectly and thus

the entire transmission should be ignored in order to avoid the 345 performing any

incorrect operation.

The CRC-16 calculation is an industry standard method used for error detection. An

algorithm is included here to assist programmers in situations where no standard CRC-16

calculation routines are available.

CRC-16 Algorithm Once the following algorithm is complete, the working register “A” will contain the CRC

value to be transmitted. Note that this algorithm requires the characteristic polynomial to

be reverse bit ordered. The MSBit of the characteristic polynomial is dropped since it does

not affect the value of the remainder. The following symbols are used in the algorithm:

—>: data transfer

A: 16 bit working register

AL: low order byte of A

AH: high order byte of A

CRC: 16 bit CRC-16 value

345 TRANSFORMER PROTECTION SYSTEM – COMMUNICATIONS GUIDE 1–3

RS485 INTERFACE CHAPTER 1: COMMUNICATIONS GUIDE

i, j: loop counters

(+): logical exclusive or operator

Di: i-th data byte (i = 0 to N-1)

G: 16 bit characteristic polynomial = 1010000000000001 with MSbit dropped and bit order

reversed

shr(x): shift right (the LSbit of the low order byte of x shifts into a carry flag, a '0' is shifted

into the MSbit of the high order byte of x, all other bits shift right one location

The algorithm is:

1. FFFF hex —> A

2. 0 —> i

3. 0 —> j

4. Di (+) AL —> AL

5. j+1 —> j

6. shr(A)

7. is there a carry? No: go to 8. Yes: G (+) A —> A

Timing Data packet synchronization is maintained by timing constraints. The receiving device

345 supported

functions

8. is j = 8? No: go to 5. Yes: go to 9.

9. i+1 —> i

10. is i = N? No: go to 3. Yes: go to 11.

11. A —> CRC

must measure the time between the reception of characters. If 3.5 character times elapse

without a new character or completion of the packet, then the communication link must

be reset (i.e. all slaves start listening for a new transmission from the master). Thus at 9600

baud a delay of greater than 3.5 x 1 / 9600 x 10 x = x 3.65 x ms will cause the

communication link to be reset.

The following functions are supported by the 345:

• FUNCTION CODE 03 - Read Setpoints

• FUNCTION CODE 04 - Read Actual Values

• FUNCTION CODE 05 - Execute Operation

• FUNCTION CODE 06 - Store Single Setpoint

• FUNCTION CODE 07 - Read Device Status

• FUNCTION CODE 08 - Loopback Test

• FUNCTION CODE 10 - Store Multiple Setpoints

Refer to section 5 of this guide for more details on MODBUS function codes.

1–4 345 TRANSFORMER PROTECTION SYSTEM – COMMUNICATIONS GUIDE

CHAPTER 1: COMMUNICATIONS GUIDE RS485 INTERFACE

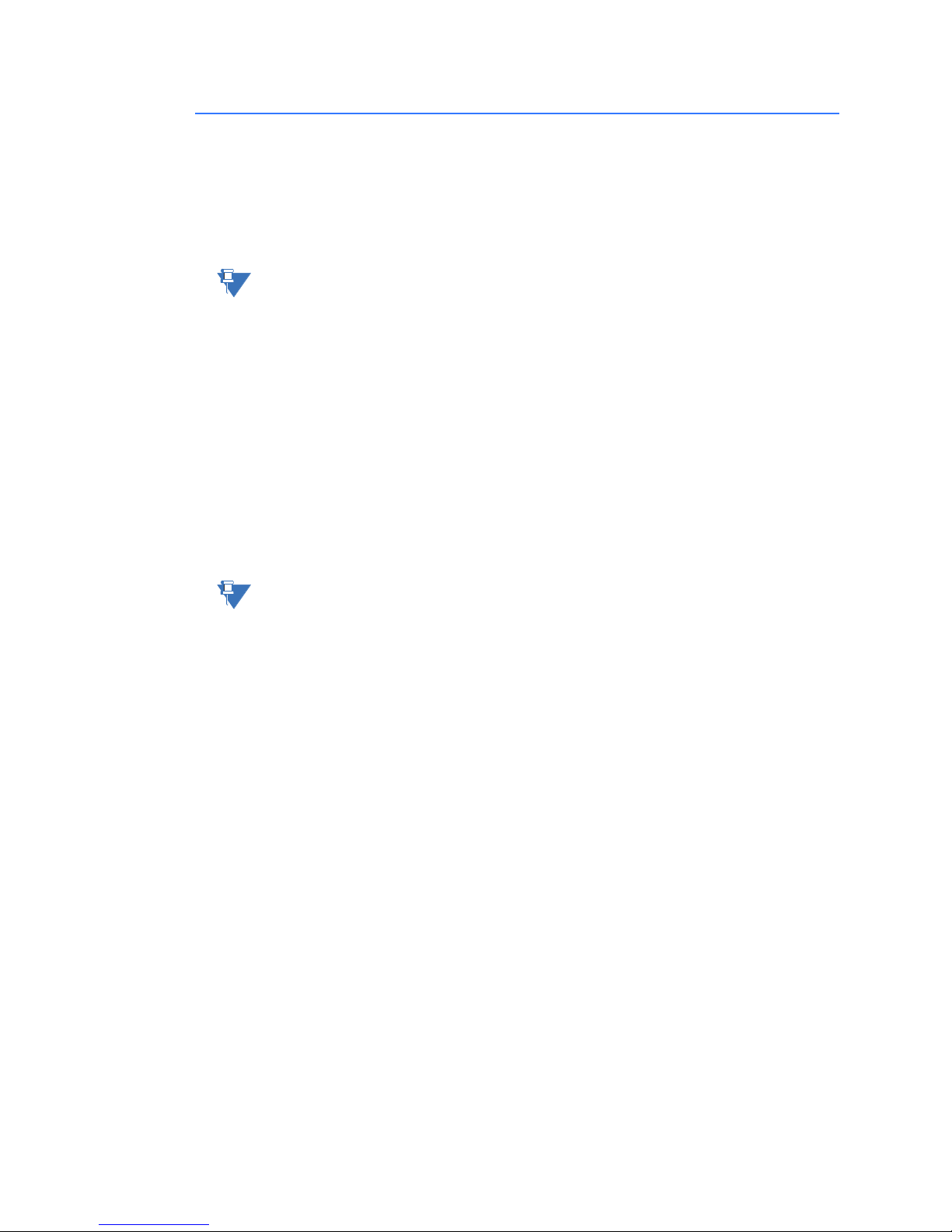

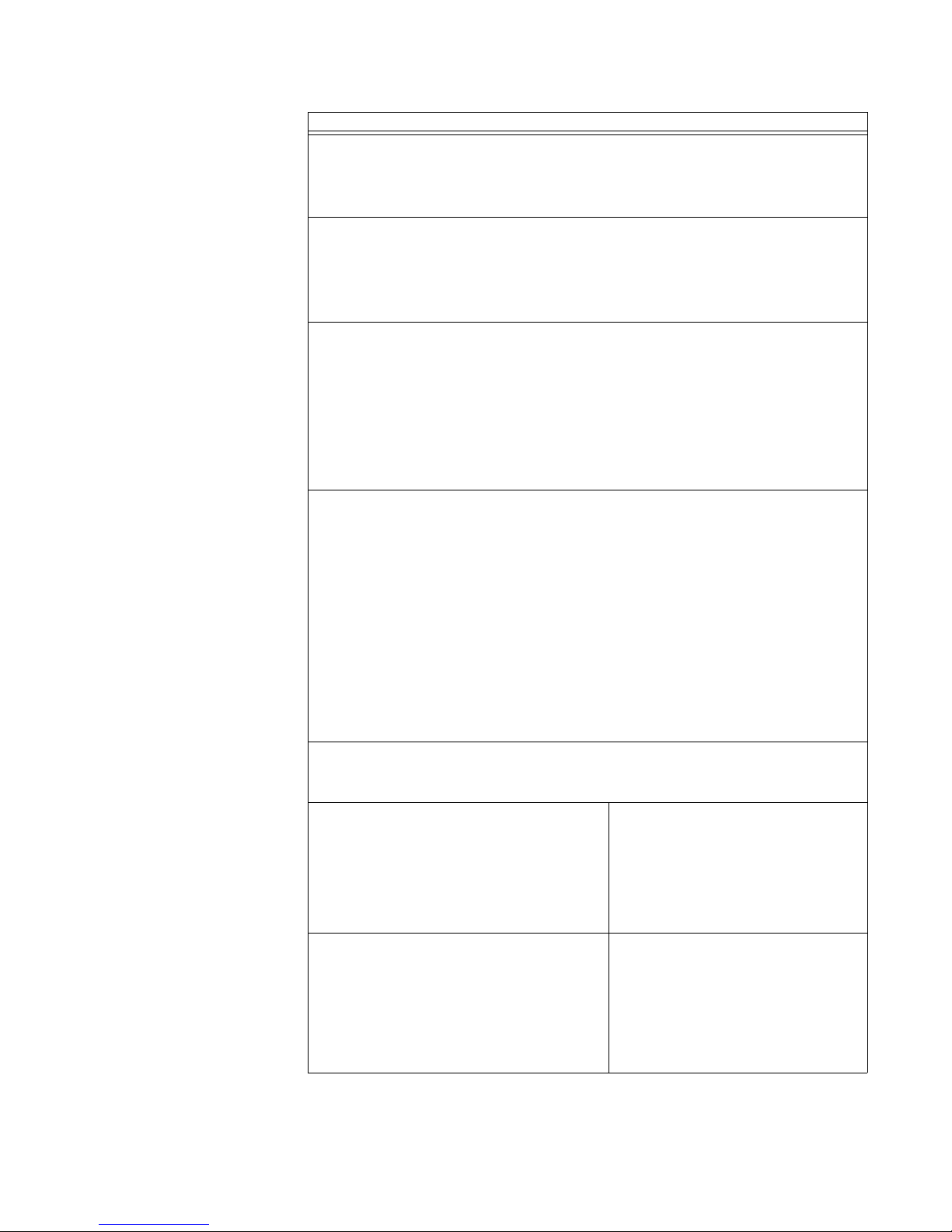

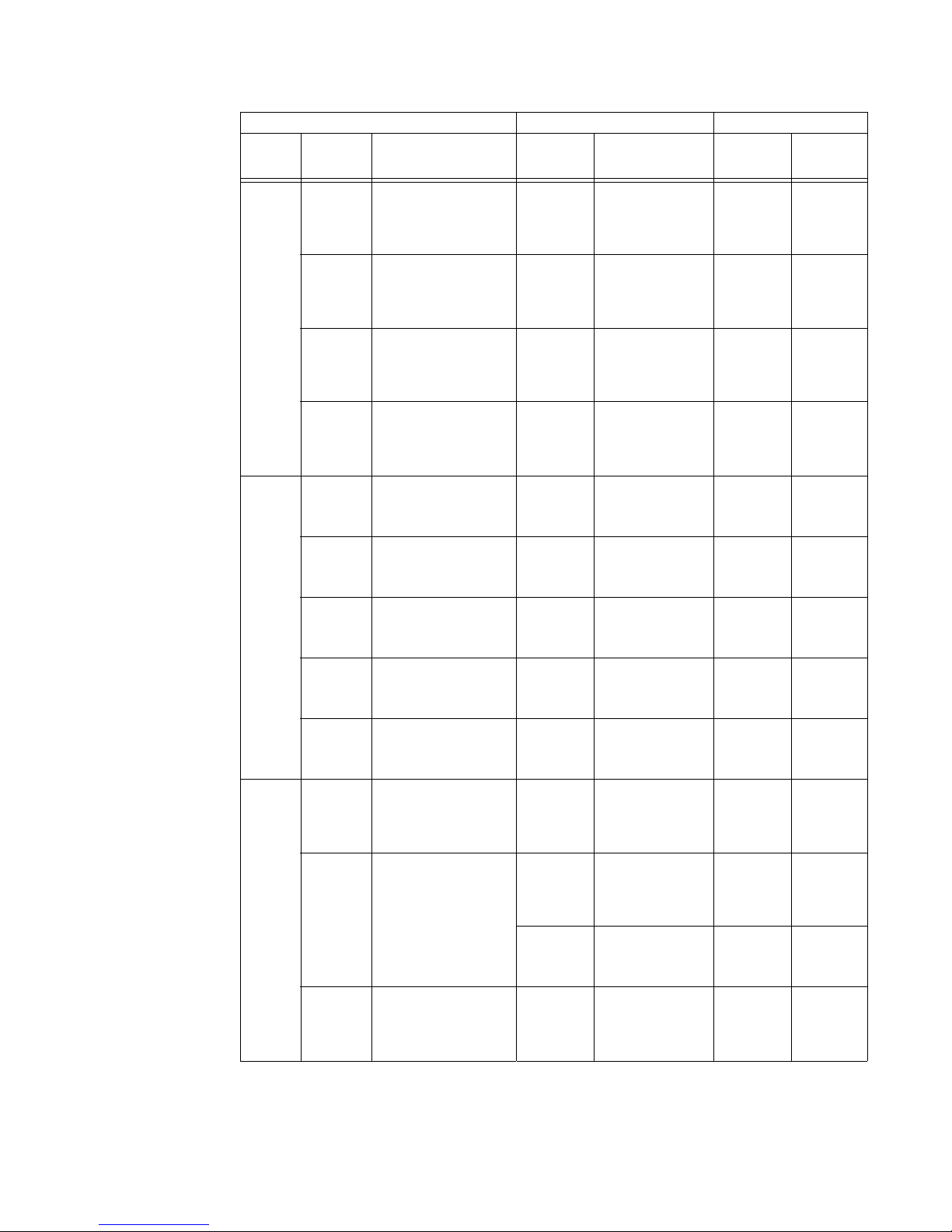

S1 DNP GENERAL

DNP ADDRESS

DNP TCP/UDP PORT

CHANNEL 1 PORT

CHANNEL 2 PORT

TME SYNC IIN PER.

DNP MSG FRAG SIZE

DNP TCP CONN. T/O

▼

S1 DNP

DNP GENERAL

DNP UNSOL RESPONSE*

DEFAULT VARIATION

DNP CLIENT ADDRESS*

DNP POINTS LIST

897769.cdr

DNP CLIENT ADDRESS*

CLIENT ADDRESS 1

CLIENT ADDRESS 2

CLIENT ADDRESS 3

CLIENT ADDRESS 4

CLIENT ADDRESS 5

POINT 0

...

POINT 1

POINT 2

POINT 63

▼

S1 DNP POINTS LIST

BINARY INPUTS

BINARY OUTPUT

ANALOG INPUTS

POINT 0 ENTRY

...

POINT 1 ENTRY

POINT 31 ENTRY

▼

POINT 0 ON

...

POINT 0 OFF

POINT 1 ON

POINT 1 OFF

POINT 15 ON

POINT 15 OFF

▼

DEFAULT VARIATION

DNP OBJECT 1

DNP OBJECT 2

DNP OBJECT 20

DNP OBJECT 21

DNP OBJECT 22

DNP OBJECT 23

DNP OBJECT 30

DNP OBJECT 32

DNP UNSOL RESPONSE*

FUNCTION

▼

TIMEOUT

MAX RETRIES

DEST ADDRESS

* Ethernet only

DNP protocol settings

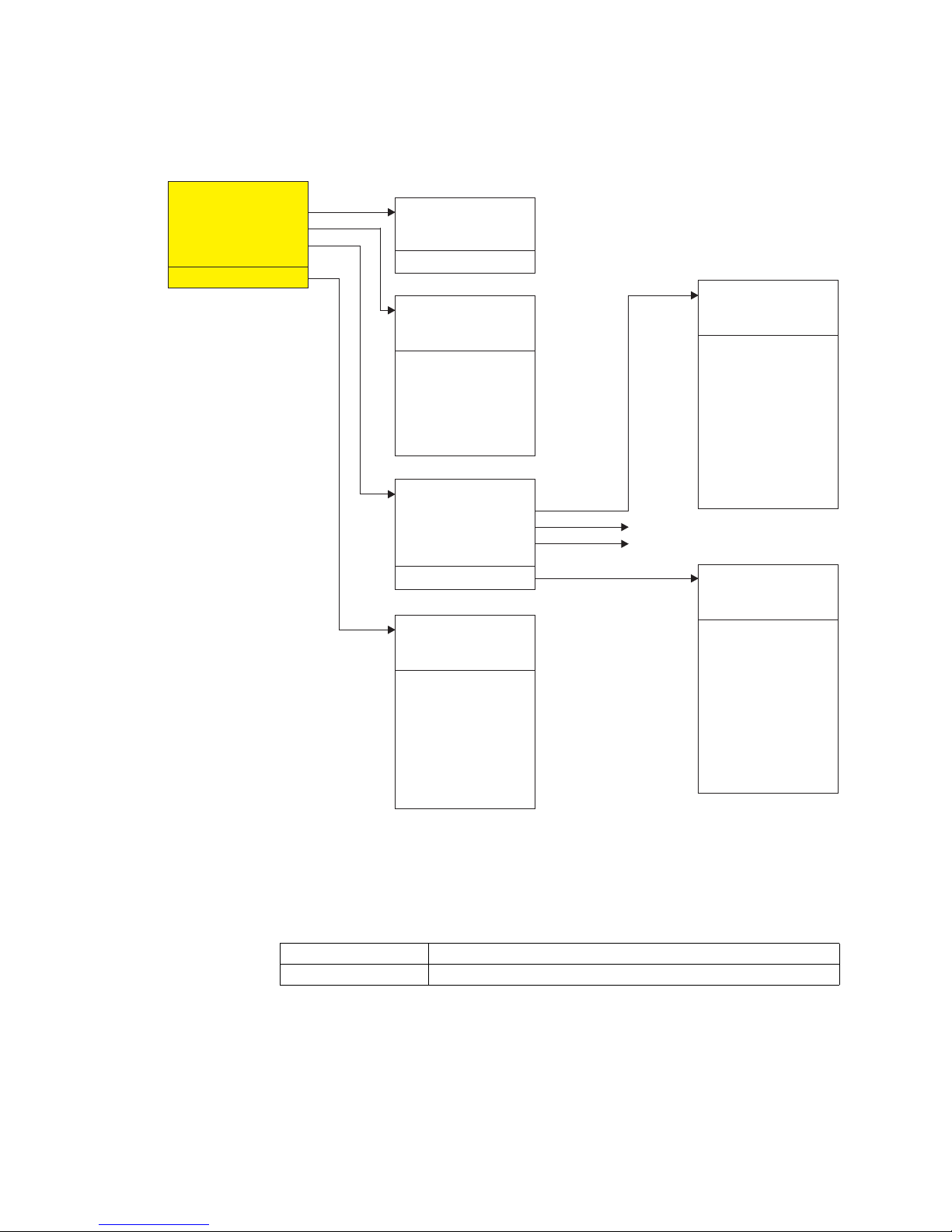

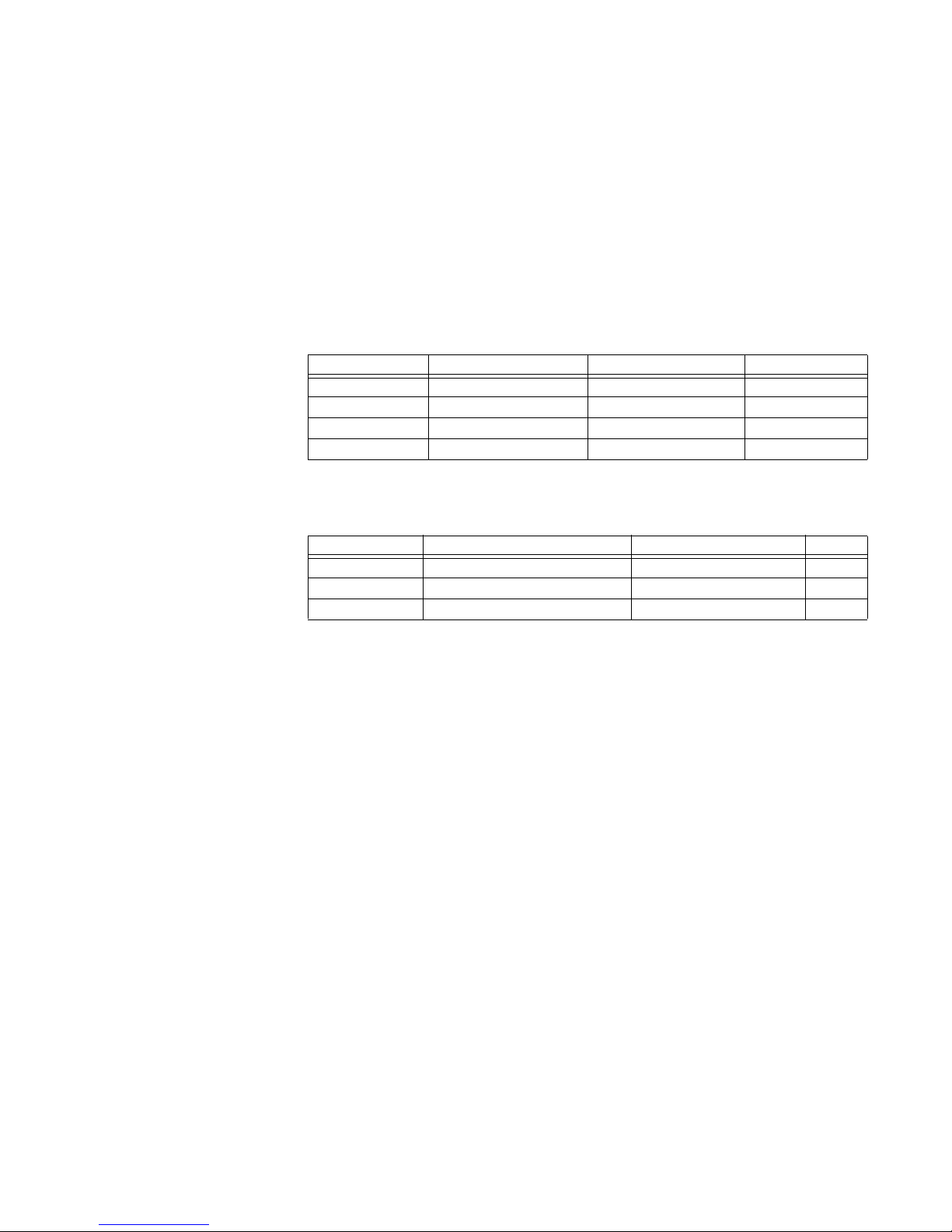

DNP communication The menu structure for the DNP protocol is shown below.

The following path is available using the keypad. For instructions on how to use the

keypad, please refer to Chapter 3 - Working with the Keypad.

PATH:

SETPOINTS > RELAY SETUP > COMMUNICATIONS > DNP PROTOCOL > DNP GENERAL

345 TRANSFORMER PROTECTION SYSTEM – COMMUNICATIONS GUIDE 1–5

RS485 INTERFACE CHAPTER 1: COMMUNICATIONS GUIDE

DNP device profile

DNP 3.0 Device Profile

(Also see the IMPLEMENTATION TABLE in the following section)

Vendor Name: General Electric Multilin

Device Name: SR345 Relay

Highest DNP Level Supported:

For Requests: Level 2

For Responses: Level 2

Device Function:

□ Master

⊠ Slave

Notable objects, functions, and/or qualifiers supported in addition to the Highest DNP Levels

Supported (the complete list is described in the attached table):

Binary Inputs (Object 1)

Binary Input Changes (Object 2)

Binary Outputs (Object 10)

Control Relay Output Block (Object 12)

Binary Counters (Object 20)

Frozen Counters (Object 21)

Counter Change Event (Object 22)

Frozen Counter Event (Object 23)

Analog Inputs (Object 30)

Analog Input Changes (Object 32)

Analog Deadbands (Object 34)

Time and Date (Object 50)

Internal Indications (Object 80)

Maximum Data Link Frame Size (octets): Maximum Application Fragment Size (octets):

Transmitted: 292 Transmitted: configurable up to 2048

Received: 292 Received: 2048

Maximum Data Link Re-tries: Maximum Application Layer Re-tries:

⊠None ⊠ None

□Fixed at 3 □ Configurable

□Configurable

Requires Data Link Layer Confirmation:

⊠ Never

□ Always

□ Sometimes

□ Configurable

Requires Application Layer Confirmation:

□ Never

□ Always

1–6 345 TRANSFORMER PROTECTION SYSTEM – COMMUNICATIONS GUIDE

CHAPTER 1: COMMUNICATIONS GUIDE RS485 INTERFACE

DNP 3.0 Device Profile

⊠ When reporting Event Data

⊠ When sending multi-fragment responses

□ Sometimes

□ Configurable

Timeouts while waiting for:

Data Link Confirm: ⊠ None □ Fixed □ Variable □ Configurable

Complete Appl. Fragment: ⊠ None □ Fixed □ Variable □ Configurable

Application Confirm: □ None ⊠ Fixed at 10 s □ Variable □ Configurable

Complete Appl. Response: ⊠ None □ Fixed at ___ □ Variable □ Configurable

Others:

Transmission Delay: No intentional delay

Need Time Interval: Configurable (default = 24 hrs.)

Select/Operate Arm Timeout: 10 s

Binary input change scanning period: 8 times per power system cycle

Analog input change scanning period: 500 ms

Counter change scanning period: 500 ms

Frozen counter event scanning period: 500 ms

Sends/Executes Control Operations:

WRITE Binary Outputs ⊠ Never □ Always □ Sometimes □Configurable

SELECT/OPERATE □ Never ⊠ Always

□ Sometimes □ Configurable

DIRECT OPERATE □ Never ⊠Always □ Sometimes □ Configurable

DIRECT OPERATE – NO ACK □ Never ⊠ Always □ Sometimes □ Configurable

Count > 1 ⊠ Never □ Always □ Sometimes □ Configurable

Pulse On □ Never □ Always ⊠ Sometimes □ Configurable

Pulse Off □ Never □ Always ⊠ Sometimes □ Configurable

Latch On □ Never □ Always ⊠ Sometimes □ Configurable

Latch Off □ Never □ Always ⊠ Sometimes □ Configurable

Queue ⊠ Never □ Always □ Sometimes □ Configurable

Clear Queue ⊠ Never

□ Always □ Sometimes □ Configurable

Explanation of ‘Sometimes’: Object 12 points are mapped to Virtual Inputs. Both “Pulse On” and

“Latch On” operations perform the same function in the 345; that is, the appropriate Virtual Input is

put into the “On” state. The On/Off times and Count value are ignored. “Pulse Off” and “Latch Off”

operations put the appropriate Virtual Input into the “Off” state.

Reports Binary Input Change Events when no

specific variation requested:

Reports time-tagged Binary Input Change

Events when no specific variation

requested:

□ Never □ Never

⊠ Only time-tagged ⊠ Binary Input Change With Time

□ Only non-time-tagged □ Binary Input Change With Relative Time

□ Configurable □ Configurable (attach explanation)

Sends Unsolicited Responses: Sends Static Data in Unsolicited Responses:

□ Never ⊠ Never

□ Configurable □ When Device Restarts

□ Only certain objects □ When Status Flags Change

⊠ Sometimes No other options are permitted.

⊠ ENABLE/DISABLE unsolicited Function codes

supported

345 TRANSFORMER PROTECTION SYSTEM – COMMUNICATIONS GUIDE 1–7

RS485 INTERFACE CHAPTER 1: COMMUNICATIONS GUIDE

DNP 3.0 Device Profile

Explanation of ‘Sometimes’: It will be disabled for

RS-485 applications, since there is no collision

avoidance mechanism. For Ethernet communication

it will be available and it can be disabled or enabled

with the proper function code.

Default Counter Object/Variation: Counters Roll Over at:

□ No Counters Reported □ No Counters Reported

□ Configurable (attach explanation) □ Configurable (attach explanation)

⊠ Default Object: 20 ⊠ 16 Bits

Default Variation: 1

⊠ Point-by-point list attached □ Other Value: _____

⊠ Point-by-point list attached

Sends Multi-Fragment Responses:

⊠ Yes

□ No

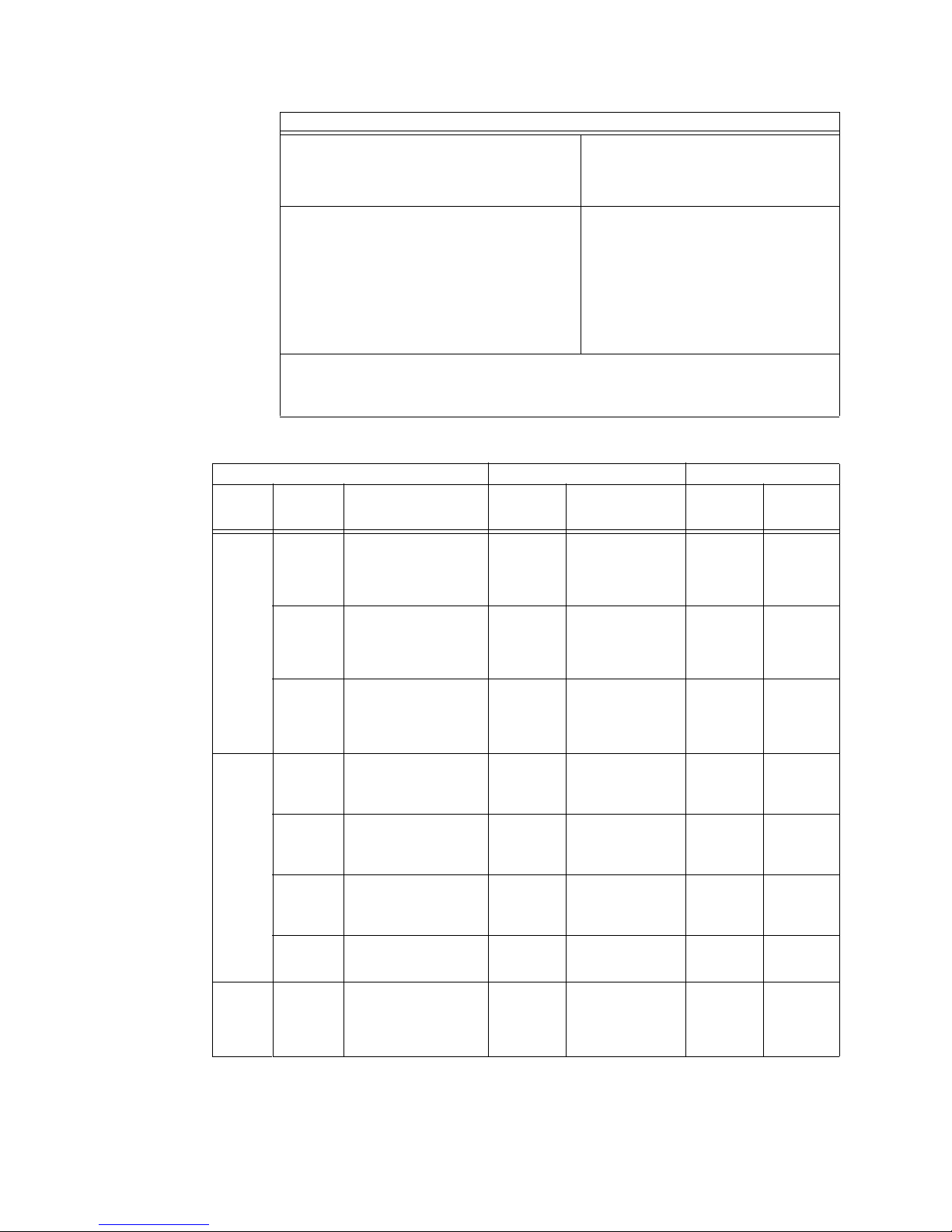

DNP implementation Table 1: DNP Implementation

OBJECT REQUEST RESPONSE

OBJECT

NO.

1 0 Binary Input (Variation 0

2 0 Binary Input Change

10 0 Binary Output Status

VARIATION

NO.

1 Binary Input 1 (read) 22

2 Binary Input with Status 1 (read) 22

1 Binary Input Change

2 Binary Input Change

3 Binary Input Change

DESCRIPTION FUNCTION

is used to request

default variation)

(Variation 0 is used to

request default

variation)

without Time

with Time

with Relative Time

(Variation 0 is used to

request default

variation)

CODES

(DEC)

1 (read) 22

(assign

class)

(assign

class)

(assign

class)

1 (read) 06 (no range, or all)

1 (read) 06 (no range, or all)

1 (read) 06 (no range, or all)

1 (read) 06 (no range, or all)

1 (read) 00, 01(start-stop)

QUALIFIER CODES

(HEX)

00, 01 (start-stop)

06 (no range, or all)

07, 08 (limited

quantity) 17, 28

(index)

00, 01 (start-stop)

06 (no range, or all)

07, 08 (limited

quantity) 17, 28

(index)

00, 01 (start-stop)

06 (no range, or all)

07, 08 (limited

quantity) 17, 28

(index)

07, 08 (limited

quantity)

07, 08 (limited

quantity)

07, 08 (limited

quantity)

07, 08 (limited

quantity)

06 (no range, or all)

07, 08 (limited

quantity) 17, 28

(index)

FUNCTION

CODES

(DEC)

--- ---

129

(response)

129

(response)

--- ---

129

(response)

130 (unsol.

resp.)

129

(response)

130 (unsol.

resp.)

--- ---

--- ---

QUALIFIER

CODES

(HEX)

00, 01

(start-stop)

17, 28

(index) (see

Note 2)

00, 01

(start-stop)

17, 28

(index) (see

Note 2)

17, 28

(index)

17, 28

(index)

1–8 345 TRANSFORMER PROTECTION SYSTEM – COMMUNICATIONS GUIDE

CHAPTER 1: COMMUNICATIONS GUIDE RS485 INTERFACE

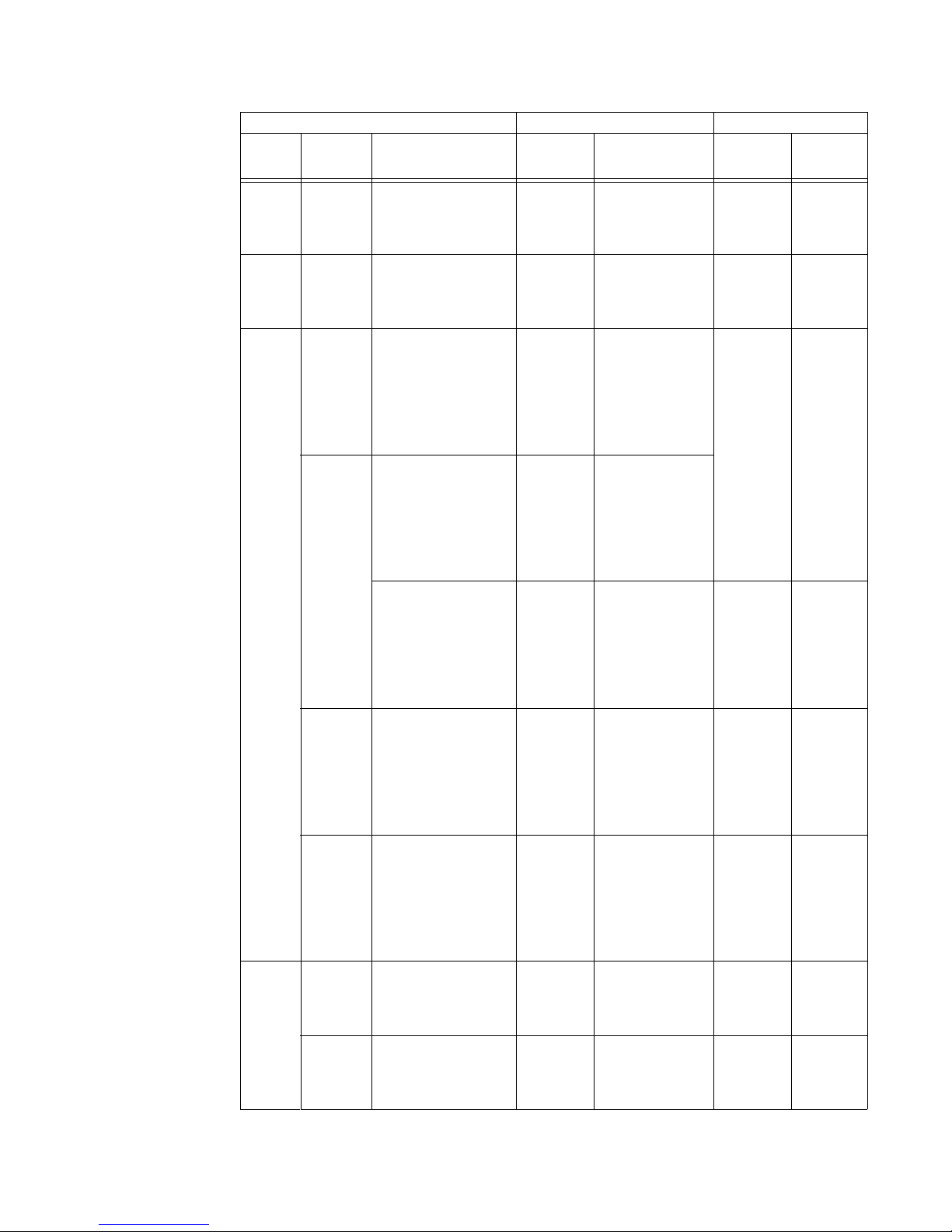

OBJECT REQUEST RESPONSE

OBJECT

NO.

12 1 Control Relay Output

VARIATION

NO.

DESCRIPTION FUNCTION

CODES

QUALIFIER CODES

(HEX)

(DEC)

2 Binary Output Status 1 (read) 00, 01 (start-stop)

06 (no range, or all)

07, 08 (limited

quantity) 17, 28

(index)

Block

3 (select)4

(operate) 5

(direct op) 6

(dir. op,

00, 01 (start-stop)

07, 08 (limited

quantity) 17, 28

(index)

FUNCTION

CODES

(DEC)

129

(response)

129

(response)

QUALIFIER

CODES

(HEX)

00, 01

(start-stop)

17, 28

(index) (see

Note 2)

echo of

request

noack)

20 0 Binary Counter

(Variation 0 is used to

request default

variation)

1 (read) 7

(freeze) 8

(freeze

noack) 9

(freeze clear)

00, 01 (start-stop)

06 (no range, or all)

07, 08 (limited

quantity) 17, 28

(index)

--- ---

10 (frz. cl.

noack) 22

(assign

class)

1 32-Bit Binary Counter 1 (read)7

(freeze) 8

(freeze

noack) 9

(freeze clear)

00, 01 (start-stop)

06 (no range, or all)

07, 08 (limited

quantity) 17, 28

(index)

129

(response)

00, 01

(start-stop)

17, 28

(index) (see

Note 2)

10 (frz. cl.

noack) 22

(assign

class)

2 16-Bit Binary Counter 1 (read) 7

(freeze) 8

(freeze

noack) 9

(freeze clear)

00, 01 (start-stop)

06 (no range, or all)

07, 08 (limited

quantity) 17, 28

(index)

129

(response)

00, 01

(start-stop)

17, 28

(index) (see

Note 2)

10 (frz. cl.

noack) 22

(assign

class)

5 32-Bit Binary Counter

without Flag

1 (read) 7

(freeze) 8

(freeze

noack) 9

(freeze clear)

00, 01 (start-stop)

06 (no range, or all)

07, 08 (limited

quantity) 17, 28

(index)

129

(response)

00, 01

(start-stop)

17, 28

(index) (see

Note 2)

10 (frz. cl.

noack) 22

(assign

class)

6 16-Bit Binary Counter

without Flag

1 (read) 7

(freeze) 8

(freeze

noack) 9

(freeze clear)

00, 01 (start-stop)

06 (no range, or all)

07, 08 (limited

quantity) 17, 28

(index)

129

(response)

00, 01

(start-stop)

17, 28

(index) (see

Note 2)

10 (frz. cl.

noack) 22

(assign

class)

21 0 Frozen

Counter(Variation 0 is

used to request

defaultvariation)

1 (read) 22

(assign

class)

00, 01 (start-stop)

06 (no range, or all)

07, 08 (limited

quantity) 17, 28

--- ---

(index)

1 32-Bit Frozen Counter 1 (read) 22

(assign

class)

00, 01 (start-stop)

06 (no range, or all)

07, 08 (limited

quantity) 17, 28

(index)

129

(response)

00, 01

(start-stop)

17, 28

(index) (see

Note 2)

345 TRANSFORMER PROTECTION SYSTEM – COMMUNICATIONS GUIDE 1–9

RS485 INTERFACE CHAPTER 1: COMMUNICATIONS GUIDE

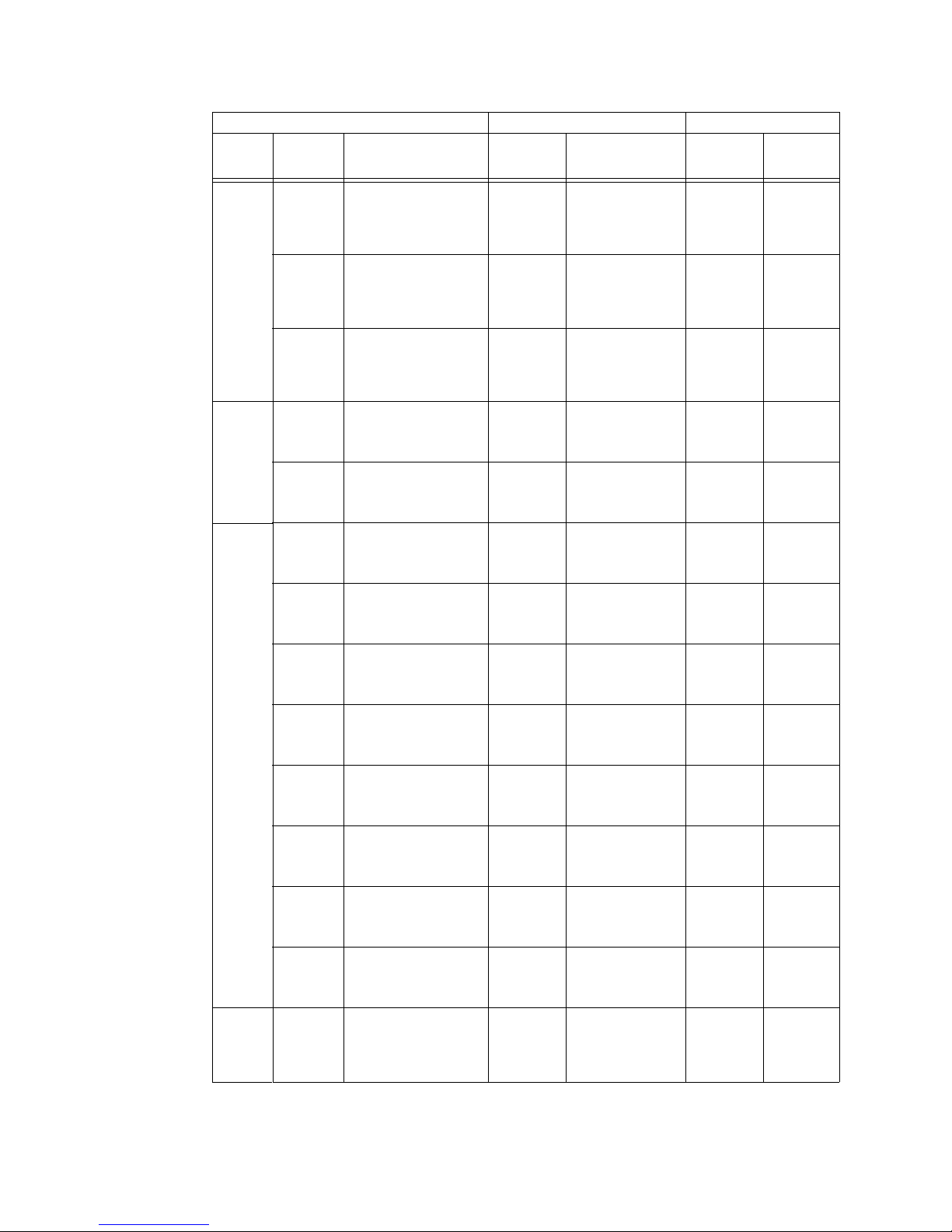

OBJECT REQUEST RESPONSE

OBJECT

NO.

22 0 Counter Change Event

VARIATION

NO.

DESCRIPTION FUNCTION

CODES

(DEC)

2 16-Bit Frozen Counter 1 (read) 22

(assign

class)

9 32-Bit Frozen Counter

without Flag

1 (read) 22

(assign

class)

10 16-Bit Frozen Counter

without Flag

1 (read) 22

(assign

class)

1 (read) 06 (no range, or all)

(Variation 0 is used to

request default

QUALIFIER CODES

(HEX)

00, 01 (start-stop)

06 (no range, or all)

07, 08 (limited

quantity) 17, 28

(index)

00, 01 (start-stop)

06 (no range, or all)

07, 08 (limited

quantity) 17, 28

(index)

00, 01 (start-stop)

06 (no range, or all)

07, 08 (limited

quantity) 17, 28

(index)

07, 08 (limited

quantity)

FUNCTION

CODES

(DEC)

129

(response)

QUALIFIER

CODES

(HEX)

00, 01

(start-stop)

17, 28

(index) (see

Note 2)

129

(response)

00, 01

(start-stop)

17, 28

(index) (see

Note 2)

129

(response)

00, 01

(start-stop)

17, 28

(index) (see

Note 2)

--- ---

variation)

1 32-Bit Counter Change

Event

1 (read) 06 (no range, or all)

07, 08 (limited

quantity)

129

(response)

130 (unsol.

17, 28

(index)

resp.)

23 2 16-Bit Counter Change

Event

1 (read) 06 (no range, or all)

07, 08 (limited

quantity)

129

(response)

130 (unsol.

17, 28

(index)

resp.)

5 32-Bit Counter Change

Event with Time

1 (read) 06 (no range, or all)

07, 08 (limited

quantity)

129

(response)

130 (unsol.

17, 28

(index)

resp.)

6 16-Bit Counter Change

Event with Time

1 (read) 06 (no range, or all)

07, 08 (limited

quantity)

129

(response)

130 (unsol.

17, 28

(index)

resp.)

0 Frozen Counter Event

(Variation 0 is used to

request default

1 (read) 06 (no range, or all)

07, 08 (limited

quantity)

--- ---

variation)

1 32-Bit Frozen Counter

Event

1 (read) 06 (no range, or all)

07, 08 (limited

quantity)

129

(response)

130 (unsol.

17, 28

(index)

resp.)

2 16-Bit Frozen Counter

Event

1 (read) 06 (no range, or all)

07, 08 (limited

quantity)

129

(response)

130 (unsol.

17, 28

(index)

resp.)

5 32-Bit Frozen Counter

Event with Time

1 (read) 06 (no range, or all)

07, 08 (limited

quantity)

129

(response)

130 (unsol.

17, 28

(index)

resp.)

6 16-Bit Frozen Counter

Event with Time

1 (read) 06 (no range, or all)

07, 08 (limited

quantity)

129

(response)

130 (unsol.

17, 28

(index)

resp.)

30 0 Analog Input (Variation

0 is used to request

default variation)

1 (read) 22

(assign

class)

00, 01 (start-stop)

06 (no range, or all)

07, 08 (limited

--- ---

quantity) 17, 28

(index)

1–10 345 TRANSFORMER PROTECTION SYSTEM – COMMUNICATIONS GUIDE

CHAPTER 1: COMMUNICATIONS GUIDE RS485 INTERFACE

OBJECT REQUEST RESPONSE

OBJECT

NO.

32 0 Analog Change Event

VARIATION

NO.

DESCRIPTION FUNCTION

CODES

(DEC)

1 32-Bit Analog Input 1 (read) 22

(assign

class)

2 16-Bit Analog Input 1 (read) 22

(assign

class)

3 32-Bit Analog Input

without Flag

1 (read) 22

(assign

class)

4 16-Bit Analog Input

without Flag

1 (read) 22

(assign

class)

1 (read) 06 (no range, or all)

(Variation 0 is used to

request default

QUALIFIER CODES

(HEX)

00, 01 (start-stop)

06 (no range, or all)

07, 08 (limited

quantity) 17, 28

(index)

00, 01 (start-stop)

06 (no range, or all)

07, 08 (limited

quantity) 17, 28

(index)

00, 01 (start-stop)

06 (no range, or all)

07, 08 (limited

quantity) 17, 28

(index)

00, 01 (start-stop)

06 (no range, or all)

07, 08 (limited

quantity) 17, 28

(index)

07, 08 (limited

quantity)

FUNCTION

CODES

(DEC)

129

(response)

QUALIFIER

CODES

(HEX)

00, 01

(start-stop)

17, 28

(index) (see

Note 2)

129

(response)

00, 01

(start-stop)

17, 28

(index) (see

Note 2)

129

(response)

00, 01

(start-stop)

17, 28

(index) (see

Note 2)

129

(response)

00, 01

(start-stop)

17, 28

(index) (see

Note 2)

--- ---

variation)

1 32-Bit Analog Change

Event without Time

1 (read) 06 (no range, or all)

07, 08 (limited

quantity)

129

(response)

130 (unsol.

17, 28

(index)

resp.)

2 16-Bit Analog Change

Event without Time

1 (read) 06 (no range, or all)

07, 08 (limited

quantity)

129

(response)

130 (unsol.

17, 28

(index)

resp.)

3 32-Bit Analog Change

Event with Time

1 (read) 06 (no range, or all)

07, 08 (limited

quantity)

129

(response)

130 (unsol.

17, 28

(index)

resp.)

4 16-Bit Analog Change

Event with Time

1 (read) 06 (no range, or all)

07, 08 (limited

quantity)

129

(response)

130 (unsol.

17, 28

(index)

resp.)

34 0 Analog Input Reporting

Deadband (Variation 0 is

used to request

defaultvariation)

1 (read) 00, 01 (start-stop)

06 (no range, or all)

07, 08 (limited

quantity) 17, 28

--- ---

(index)

1 16-bit Analog Input

Reporting Deadband

(default - see Note 1)

1 (read) 00, 01 (start-stop)

06 (no range, or all)

07, 08 (limited

quantity) 17, 28

(index)

2 (write) 00, 01 (start-stop)

129

(response)

00, 01

(start-stop)

17, 28

(index) (see

Note 2)

--- --07, 08 (limited

quantity) 17, 28

(index)

2 32-bit Analog Input

Reporting Deadband

1 (read) 00, 01 (start-stop)

06 (no range, or all)

07, 08 (limited

quantity) 17, 28

(index)

129

(response)

00, 01

(start-stop)

17, 28

(index) (see

Note 2)

345 TRANSFORMER PROTECTION SYSTEM – COMMUNICATIONS GUIDE 1–11

RS485 INTERFACE CHAPTER 1: COMMUNICATIONS GUIDE

NOTE

OBJECT REQUEST RESPONSE

OBJECT

NO.

VARIATION

NO.

DESCRIPTION FUNCTION

CODES

(DEC)

2 (write) 00, 01 (start-stop)

QUALIFIER CODES

(HEX)

FUNCTION

CODES

(DEC)

QUALIFIER

CODES

(HEX)

--- --07, 08 (limited

quantity) 17, 28

(index)

50 1 Time and Date (default -

see Note 1)

52 2 Time Delay Fine

(quantity = 1)

60 0 Class 0, 1, 2, and 3 Data 1 (read) 20

1 (read)2

(write)

129

(response)

00, 01 (start-stop)

06 (no range, or all)

07 (limited qty=1) 08

(limited quantity)

17, 28 (index)

129

(response)

00, 01

(start-stop)

17, 28

(index) (see

Note 2)

07 (limited quantity) --- ---

06 (no range, or all) --- ---

(enable

unsol) 21

(disable

unsol) 22

(assign

class)

1 Class 0 Data 1 (read) 22

06 (no range, or all) --- ---

(assign

class)

2 Class 1 Data 1 (read) 20

(enable

unsol)

3 Class 2 Data 21 (disable

06 (no range, or all)

07, 08 (limited

quantity)

--- ---

--- ---

unsol)

4 Class 3 Data 22 (assign

--- ---

class)

80 1 Internal Indications 1 (read) 00, 01 (start-stop)

(index =7)

2 (write) (see

Note 3)

No Object (function

code only) see Note 3

No Object (function

code only)

No Object (function

code only)

NOTE:

1. A default variation refers to the variation response when variation 0 is requested and/

13 (cold

restart)

14 (warm

restart)

23 (delay

meas.)

00 (start-stop)

(index =7)

--- --- ---

--- --- ---

--- --- ---

129

(response)

00, 01

(start-stop)

--- ---

or in class 0, 1, 2, or 3 scans. The default variations for object types 1, 2, 20, 21, 22, 23,

30, and 32 are selected via relay settings. This optimizes the class 0 poll data size.

2. For static (non-change-event) objects, qualifiers 17 or 28 are only responded when a

request is sent with qualifiers 17 or 28, respectively. Otherwise, static object requests

sent with qualifiers 00, 01, 06, 07, or 08, will be responded with qualifiers 00 or 01 (for

changeevent objects, qualifiers 17 or 28 are always responded.)

3. Cold restarts are implemented the same as warm restarts – the 345 is not restarted,

but the DNP process is restarted.

1–12 345 TRANSFORMER PROTECTION SYSTEM – COMMUNICATIONS GUIDE

CHAPTER 1: COMMUNICATIONS GUIDE RS485 INTERFACE

DNP serial EnerVista

Setup

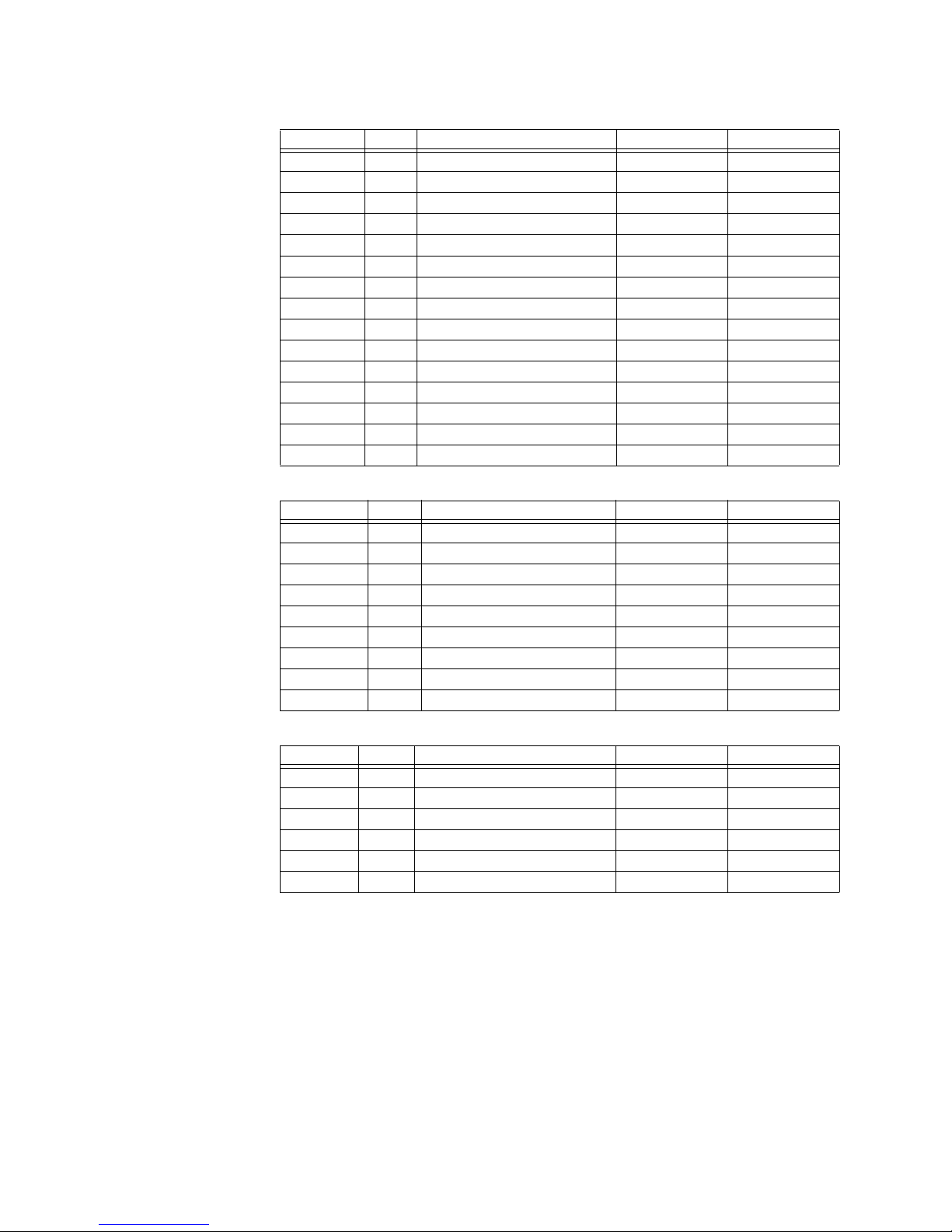

The following tables show the settings needed to configure all the DNP 3.0 implementation

parameters.

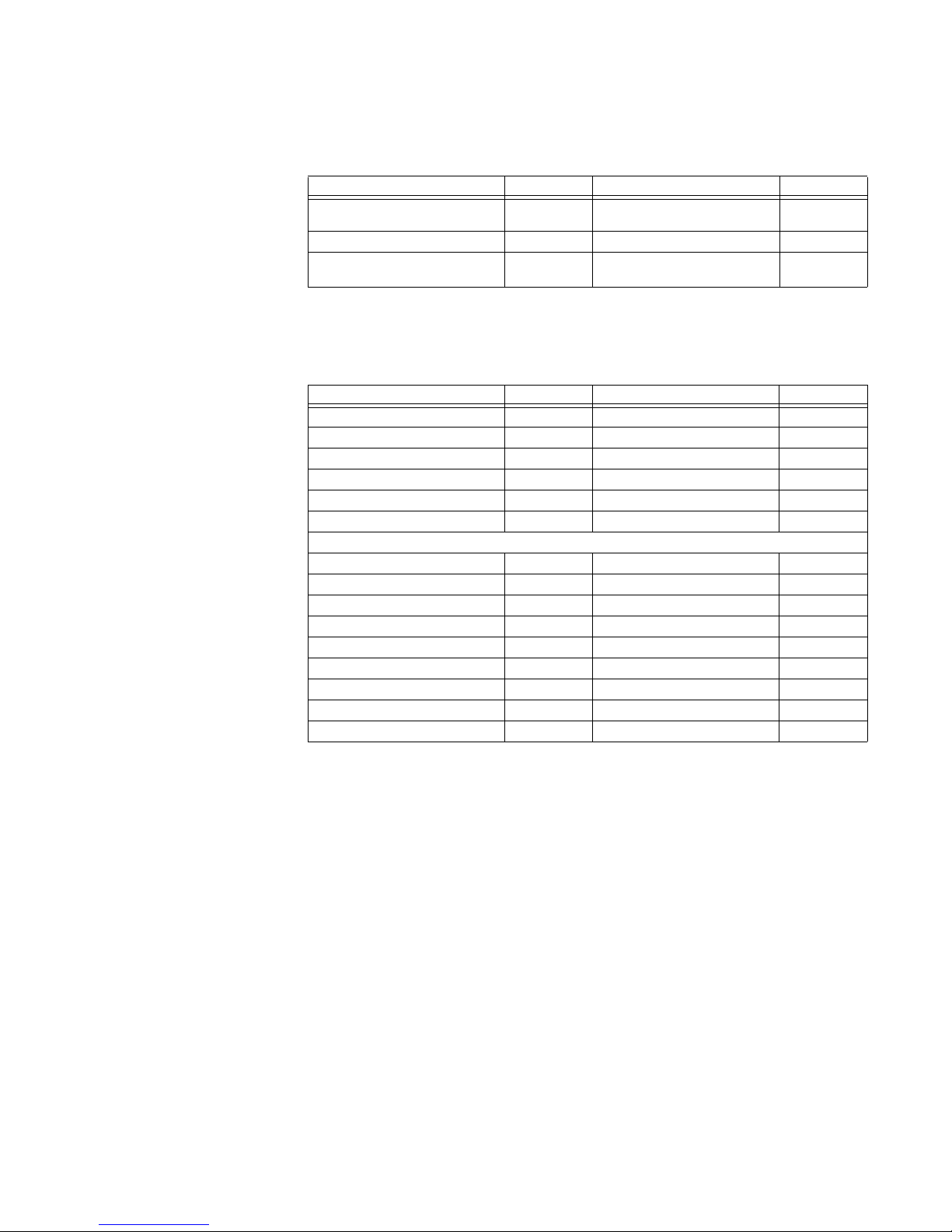

Table 2: RS-485

SETTINGS PARAMETER RANGE FORMAT

RS485 Baud Rate 115200 9600, 19200, 38400, 57600,

115200

RS485 Comm Parity None None, Odd, Even F102

Rear 485 Protocol DNP 3.0 Modbus, IEC60870-5-103, DNP

3.0

F101

F97

In order to activate DNP 3.0 at the RS485 rear port, the setting "Rear 485 Protocol" must be

set to DNP 3.0. Once the setting has been changed, the relay must be switched off, then

switched on.

Table 3: DNP protocol

SETTINGS PARAMETER RANGE FORMAT

DNP Unsol Resp Function Disabled Disabled ; Enabled F126

DNP Unsol Resp Timeout 5 s 0 to 60 s F1

DNP Unsol Resp Max Retries 10 1 to 255 F1

DNP Unsol Resp Dest Addr 1 0 to 65519 F1

DNP Time Sync IIN Period 1440 min 1 to 10080 min F1

DNP Message Fragment Size 240 30 to 2048 F1

DNP Object 1 Default Variation 2 1 ; 2 F1

DNP Object 2 Default Variation 2 1 ; 2 F1

DNP Object 20 Default Variation 1 1 ; 2 , 5 ; 6 F78

DNP Object 21 Default Variation 1 1 ; 2 ; 9 ; 10 F79

DNP Object 22 Default Variation 1 1 ; 2 , 5 ; 6 F80

DNP Object 23 Default Variation 1 1 ; 2 , 5 ; 6 F81

DNP Object 30 Default Variation 1 1 ; 2 ;3 ; 4 F82

DNP Object 32 Default Variation 1 1 ; 2 ;3 ; 4 F83

DNP TCP Connection Timeout 120 s 10 to 300 s F1

345 TRANSFORMER PROTECTION SYSTEM – COMMUNICATIONS GUIDE 1–13

RS485 INTERFACE CHAPTER 1: COMMUNICATIONS GUIDE

Table 4: DNP point list

SETTINGS PARAMETER RANGE FORMAT

Binary Input Point 0 Entry Select entry

from a list

Operands F134

Binary Input Point 63 Entry Select entry

Analog Input Point 0 Entry Select entry

Analog Input Point 0 Scale Factor 1 0.001 ; 0.01 ; 0.1 ; 1 ; 10 ; 100 ;

Analog Input Point 0 Deadband 30000 0 to 100000000 F9

Analog Input Point 31 Entry Select entry

Analog Input Point 31 Scale

Factor

Analog Input Point 31 Deadband 30000 0 to 100000000 F9

Binary Output Point 0 ON Select entry

Binary Output Point 0 OFF Select entry

Binary Output Point 15 ON Select entry

Binary Output Point 15 OFF Select entry

from a list

from a list

from a list

1 0.001 ; 0.01 ; 0.1 ; 1 ; 10 ; 100 ;

from a list

from a list

from a list

from a list

Operands F134

Analog parameters

1000 ; 10000 ; 100000

Analog parameters

1000 ; 10000 ; 100000

Virtual Input 1 to 32 and Force

Coils

Virtual Input 1 to 32 and Force

Coils

Virtual Input 1 to 32 and Force

Coils

Virtual Input 1 to 32 and Force

Coils

F85

F85

F86

F86

F86

F86

• DNP UNSOL RESPONSE FUNCTION should be “Disabled” for RS485 applications, since

there is no collision avoidance mechanism.

• The DNP Time Sync IIN Period setting determines how often the Need Time Internal

Indication (IIN) bit is set by the 345. Changing this time allows the 345 to indicate that

a time synchroniztion command is necessary more or less often

• Various settings have been included to configure Default Variation for the Binary

Inputs, Counters and Analog Inputs Objects. The default variation refers to the

variation response when variation 0 is requested, and/or in class 0, 1, 2, or 3 scans

• Up to 64 Binary Inputs and 32 Analog Input entries can be mapped to an item from a

list of 345 status events and metered values. Status events correspond to Funcion

Code 134B.

• Each Analog Input point Deadband and Scale Factor can be set individually instead of

setting a general deadband or scale for different metering groups. This will avoid scale

and deadband conflicts for different meterings of the same nature.

• Up to 16 Binary/Control Outputs can be configured by selecting a Virtual Input or

Command from a list of 32 Virtual Inputs and Commands (Force Coils). Some legacy

DNP implementations use a mapping of one DNP Binary Output to two physical or

virtual control points. In Order to configure Paired Control Points the source for states

ON and OFF should be set to different Virtual Inputs or Commands.

• The DNP Technical Committee recommends using contiguous point numbers, starting

at 0, for each data type, because some DNP3 Master implementations allocate

contiguous memory from point 0 to the last number for each data type.

1–14 345 TRANSFORMER PROTECTION SYSTEM – COMMUNICATIONS GUIDE

CHAPTER 1: COMMUNICATIONS GUIDE RS485 INTERFACE

NOTE:

Binary Inputs are inputs to the Master. Binary Outputs are outputs from the Master.

DNP general Default variations for Object 1, 2 , 20 , 21 , 22 , 23 , 30 and Object 32 will be set by settings

and returned for the object in a response when no specific variation is specified in a Master

request.

Any change in the state of any binary point causes the generation of an event, and

consequently, if configured, an unsolicited response, or it is returned when the Master asks

for it. The same behaviour will be seen when an analog value changes by more than its

configured deadband limit . There can be up to 3 Masters in total, but only one Serial

Master.

The following Default Classes will be fixed for the different blocks of data:

Binary Input Points Default Class = 1

Analog Input Point Default Class = 2

Counters Default Class = 3

Each Data Point Class can be changed by protocol function code 22 in volatile mode. If a

restart is performed, the new values will be lost.

DNP Object 34 points can be used to change deadband values from the default for each

individual DNP Analog Input point. These new deadbands will be maintained such that in

the case of a relay restart, the values are not lost.

Requests for Object 20 (Binary Counters), Object 21 (Frozen Counters), and Object 22

(Counter Change Events) must be accepted.

Function codes “Immediate Freeze”, “Freeze and Clear” etc. are accepted as well.

345 TRANSFORMER PROTECTION SYSTEM – COMMUNICATIONS GUIDE 1–15

RS485 INTERFACE CHAPTER 1: COMMUNICATIONS GUIDE

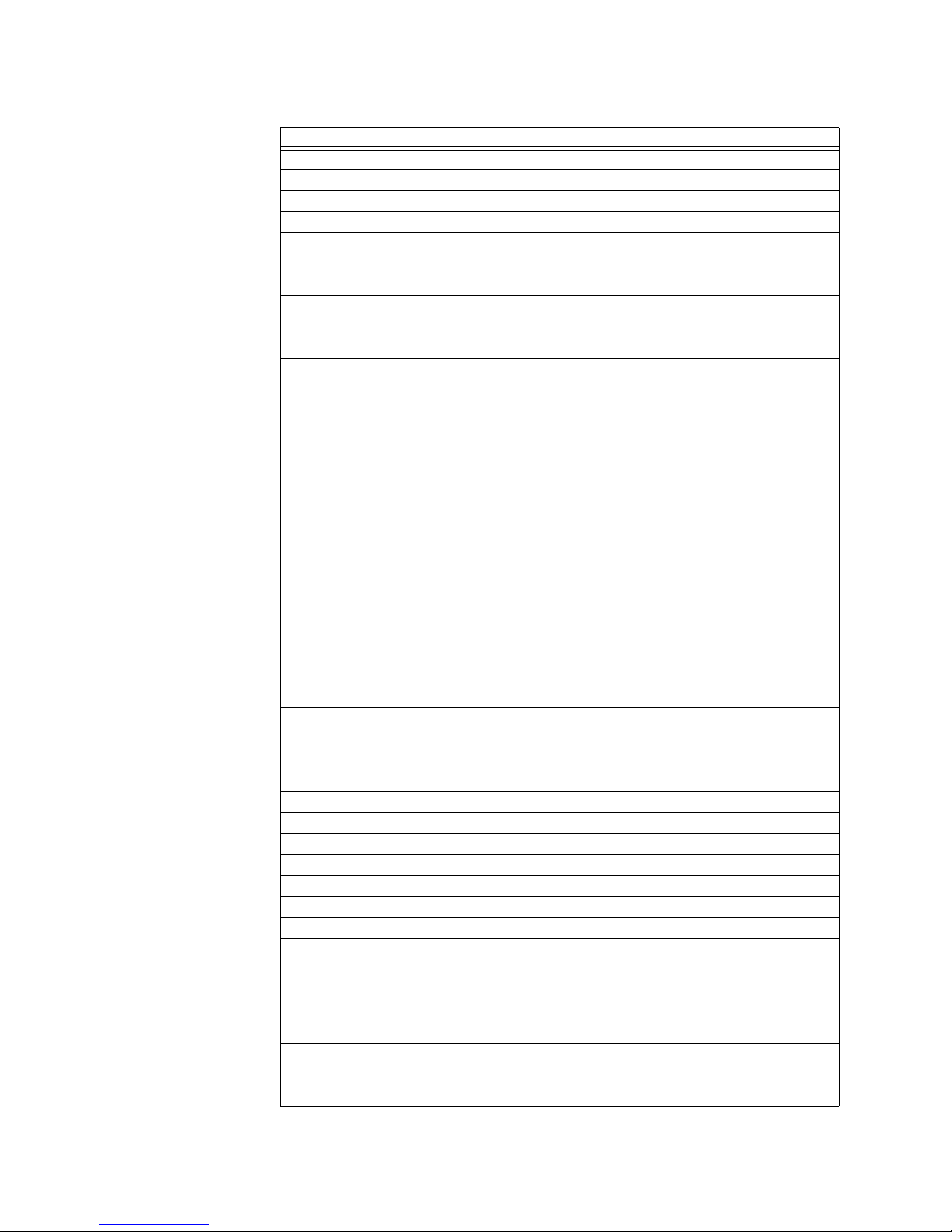

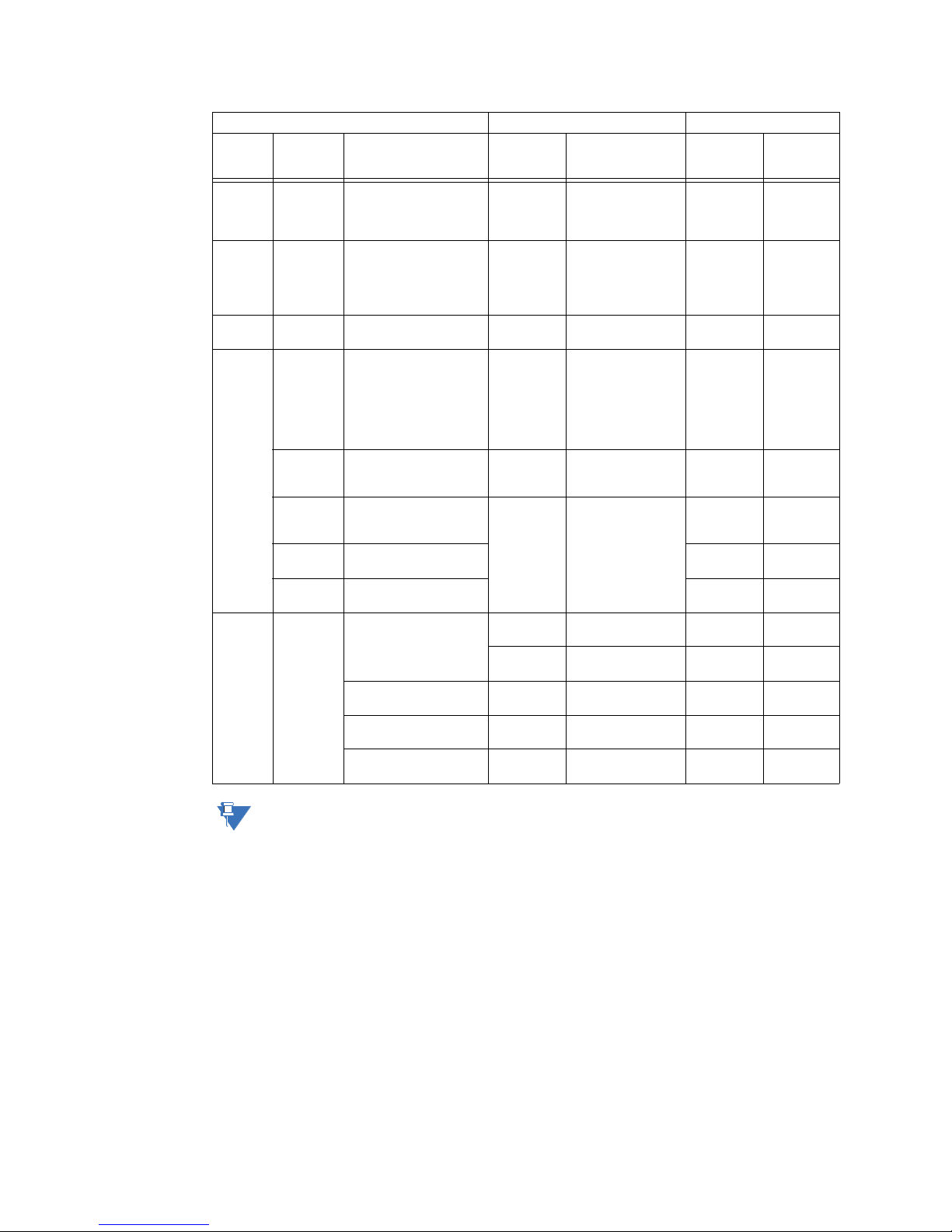

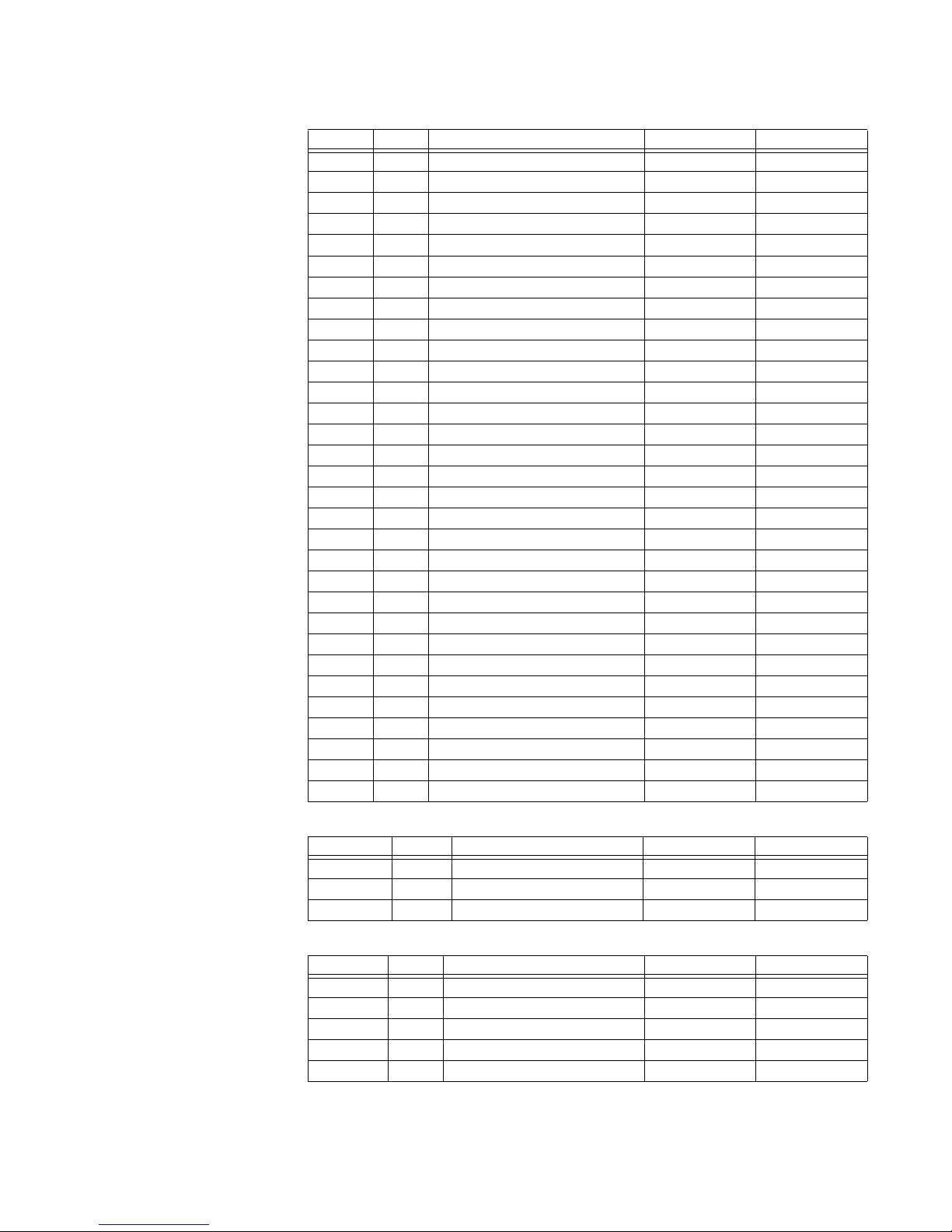

S1 103 FIRST ASDU

ID TYPE

FUNCTION TYPE

INFORMATION NO

SCAN TIMEOUT

FIRST ANLG ENTRY

FIRST ANLG FACTOR

FIRST ANLG OFFSET

...

NINTH ANLG ENTRY

NINTH ANLG FACTOR

NINTH ANLG OFFSET

▼

S1 103 GENERAL

SLAVE ADDRESS

SYNCH TIMEOUT

▼

897770.cdr

S1 103 MEASURANDS

FIRST ASDU

SECOND ASDU

THIRD ASDU

FOURTH ASDU

▼

S1 60870-5-103

GENERAL

BINARY INPUTS

MEASURANDS

COMMANDS

▼

S1 103 COMMANDS

CMD 0 FUNC TYPE

CMD 0 INFO NO:

CMD 0 ON OPER:

CMD 0 OFF OPER:

...

CMD 15 FUNC TYPE:

CMD 15 INFO NO:

CMD 15 ON OPER:

CMD 15 OFF OPER:

▼

S1 103 FOURTH ASDU

ID TYPE

FUNCTION TYPE

INFORMATION NO

SCAN TIMEOUT

FIRST ANLG ENTRY

FIRST ANLG FACTOR

FIRST ANLG OFFSET

...

NINTH ANLG ENTRY

NINTH ANLG FACTOR

NINTH ANLG OFFSET

▼

S1 103 B INPUTS

POINT 0

POINT 0 FUNC TYPE

POINT 0 INFO NO:

...

POINT 63

POINT 63FUNC TYPE

POINT 63 INFO NO:

▼

.

.

.

.

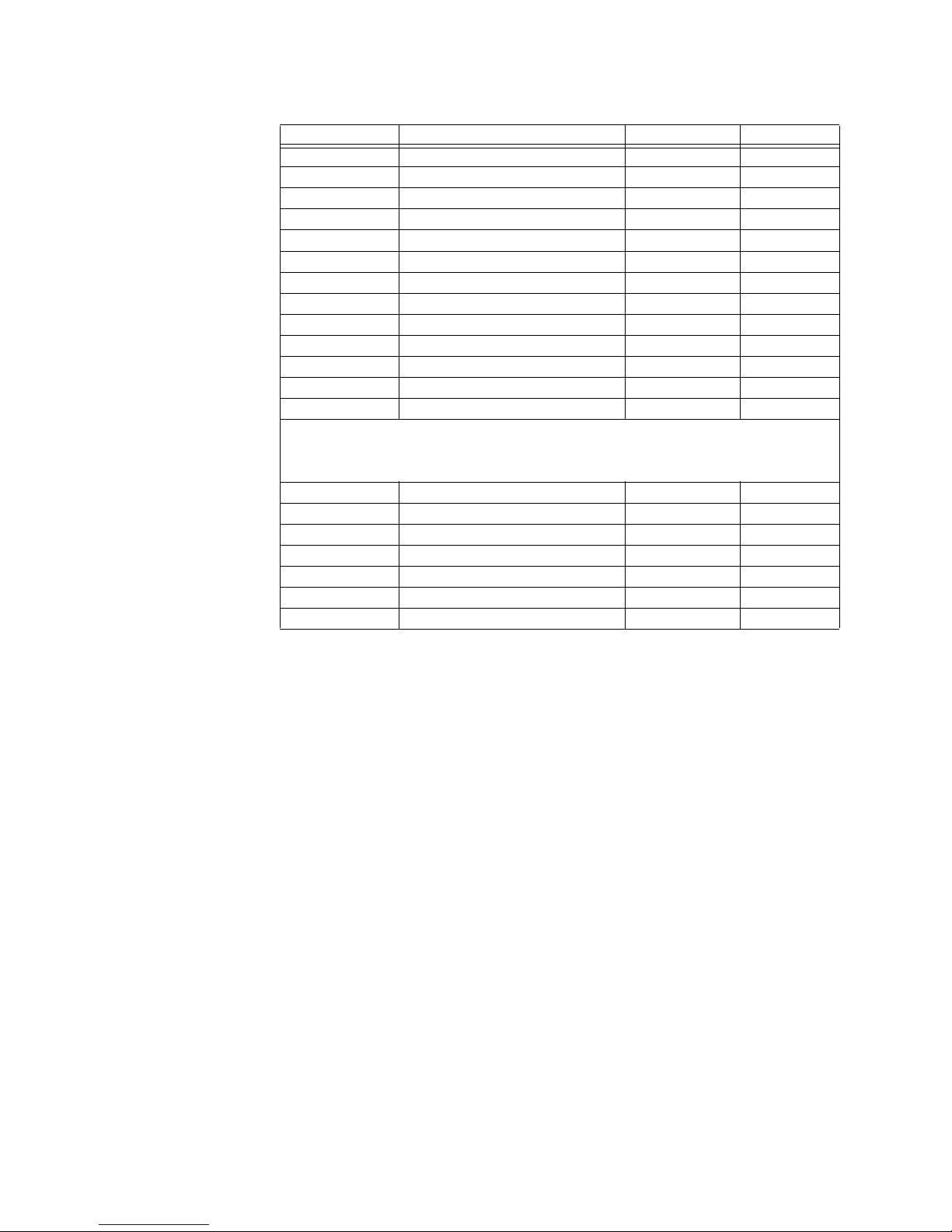

IEC 60870-5-103 serial communication

PATH: SETPOINTS > S1 RELAY SETUP > COMMUNICATIONS > IEC61870-5-103

Interoperability

Physical layer

Electrical interface

⊠ EIA RS-485

32 Number of loads for one protection equipment

1–16 345 TRANSFORMER PROTECTION SYSTEM – COMMUNICATIONS GUIDE

CHAPTER 1: COMMUNICATIONS GUIDE RS485 INTERFACE

Optical interface

□ Glass fibre

□ Plastic fibre

□ F-SMA type connector

□ BFOC/2,5 type connector

Transmission speed

⊠? 9600 bits/s

⊠? 19200 bits/s

Link layer

There are no choices for the Link Layer.

Application layer

Transmission mode

for application data

Common address of

ASDU

Selection of standard

information numbers

in monitor direction

Mode 1 (least significant octet first), is used exclusively in this companion standard.

⊠ One COMMON ADDRESS OF ASDU (identical with station address)

More than one COMMON ADDRESS OF ASDU

Table 5: System functions in monitor direction

INF Semantics

⊠ <0> End of general interrogation

⊠ <0> Time synchronization

⊠ <2> Reset FCB

⊠ <3> Reset CU

⊠ <4> Start/restart

⊠ <5> Power on

345 TRANSFORMER PROTECTION SYSTEM – COMMUNICATIONS GUIDE 1–17

RS485 INTERFACE CHAPTER 1: COMMUNICATIONS GUIDE

Table 6: Status indications in monitor direction

INF Semantics 345 Identifier 345 Data Text

□ <16> Auto-recloser active

□ <17> Teleprotection active

□ <18> Protection active

□ <19> LED reset

□ <20> Monitor direction blocked

□ <21> Test mode

□ <22> Local parameter setting

□ <23> Characteristic 1

□ <24> Characteristic 2

□ <25> Characteristic 3

□ <26> Characteristic 4

□ <27> Auxiliary input 1

□ <28> Auxiliary input 2

□ <29> Auxiliary input 3

□ <30> Auxiliary input 4

Table 7: Supervision indications in monitor direction

INF Semantics 345 Identifier 345 Data Text

□ <32> Measurand supervision I

□ <33> Measurand supervision V

□ <35> Phase sequence supervision

□ <36> Trip circuit supervision

□ <37> I>> back-up operation

□ <38> VT fuse failure

□ <39> Teleprotection disturbed

□ <46> Group warning

□ <47> Group alarm

Table 8: Earth fault indications in monitor direction

INF Semantics 345 Identifier 345 Data Text

□ INF Semantics 345 Identifier 345 Data Text

□ <48> Earth fault L1

□ <49> Earth fault L2

□ <50> Earth fault L3

□ <51> Earth fault forward, i.e. line

□ <52> Earth fault reverse, i.e. busbar

1–18 345 TRANSFORMER PROTECTION SYSTEM – COMMUNICATIONS GUIDE

CHAPTER 1: COMMUNICATIONS GUIDE RS485 INTERFACE

Table 9: Fault indications in monitor direction

INF Semantics 345 Identifier 345 Data Text

□ INF Semantics 345 Identifier 345 Data Text

□ <64> Start / pick-up L1

□ <65> Start / pick-up L2

□ <66> Start / pick-up L3

□ <67> Start / pick-up N

□ <68> General trip

□ <69> Trip L1

□ <70> Trip L2

□ <71> Trip L3

□ <72> Trip I>> (back-up operation)

□ <73> Fault location X in ohms

□ <74> Fault forward / line

□ <75> Fault reverse / busbar

□ <76> Teleprotection signal transmitted

□ <77> Teleprotection signal received

□ <78> Zone 1

□ <79> Zone 2

□ <80> Zone 3

□ <81> Zone 4

□ <82> Zone 5

□ <83> Zone 6

□ <84> General start / pick-up

□ <85> Breaker failure

□ <86> Trip measuring system L1

□ <87> Trip measuring system L2

□ <88> Trip measuring system L3

□ <89> Trip measuring system E

□ <90> Trip I>

□ <91> Trip I>>

□ <92> Trip IN>

□ <93> Trip IN>>

Table 10: Auto-reclosure indications in monitor direction

□ <128> CB ‘on’ by AR

□ <129> CB ‘on’ by long-time AR

□ <130> AR blocked

Table 11: Measurands in monitor direction

□ <144> Measurand I

□ <145> Measurands I, V

□ <146> Measurands I, V, P, Q

□ <147> Measurands In, Ven

□ <148> Measurands IL123, VL123, P, Q, f

345 TRANSFORMER PROTECTION SYSTEM – COMMUNICATIONS GUIDE 1–19

INF Semantics 345 Identifier 345 Data Text

INF Semantics 345 Identifier 345 Data Text

RS485 INTERFACE CHAPTER 1: COMMUNICATIONS GUIDE

Table 12: Generic functions in monitor direction

INF Semantics

□ <240> Read headings of all defined groups

□ <241> Read values or attributes of all entries of one group

□ <243> Read directory of a single entry

□ <244> Read value or attribute of a single entry

□ <245> End of general interrogation of generic data

□ <249> Write entry with confirmation

□ <250> Write entry with execution

□ <251> Write entry aborted

Selection of standard

information numbers

in control direction

Table 13: System functions in control direction

INF Semantics

⊠ <0> Initiation of general interrogation

⊠ <0> T ime synchronization

Table 14: General commands in control direction

INF Semantics

□ <16> Auto-recloser on / off

□ <17> Teleprotection on / off

□ <18> Protection on / off

□ <19> LED reset

□ <23> Activate characteristic 1

□ <24> Activate characteristic 2

□ <25> Activate characteristic 3

□ <26> Activate characteristic 4

Table 15: General functions in control direction

INF Semantics

□ <240> Read headings of all defined groups

□ <241> Read values or attributes of all entries of one group

□ <243> Read directory of a single entry

□ <244> Read value or attribute of a single entry

□ <245> General interrogation of generic data

□ <248> Write entry

□ <249> Write entry with confirmation

□ <250> Write entry with execution

□ <251> Write entry abort

Basic application

functions

1–20 345 TRANSFORMER PROTECTION SYSTEM – COMMUNICATIONS GUIDE

□ Test mode

□ Blocking of monitor direction

□ Disturbance data

□ Generic services

□ Private data

CHAPTER 1: COMMUNICATIONS GUIDE RS485 INTERFACE

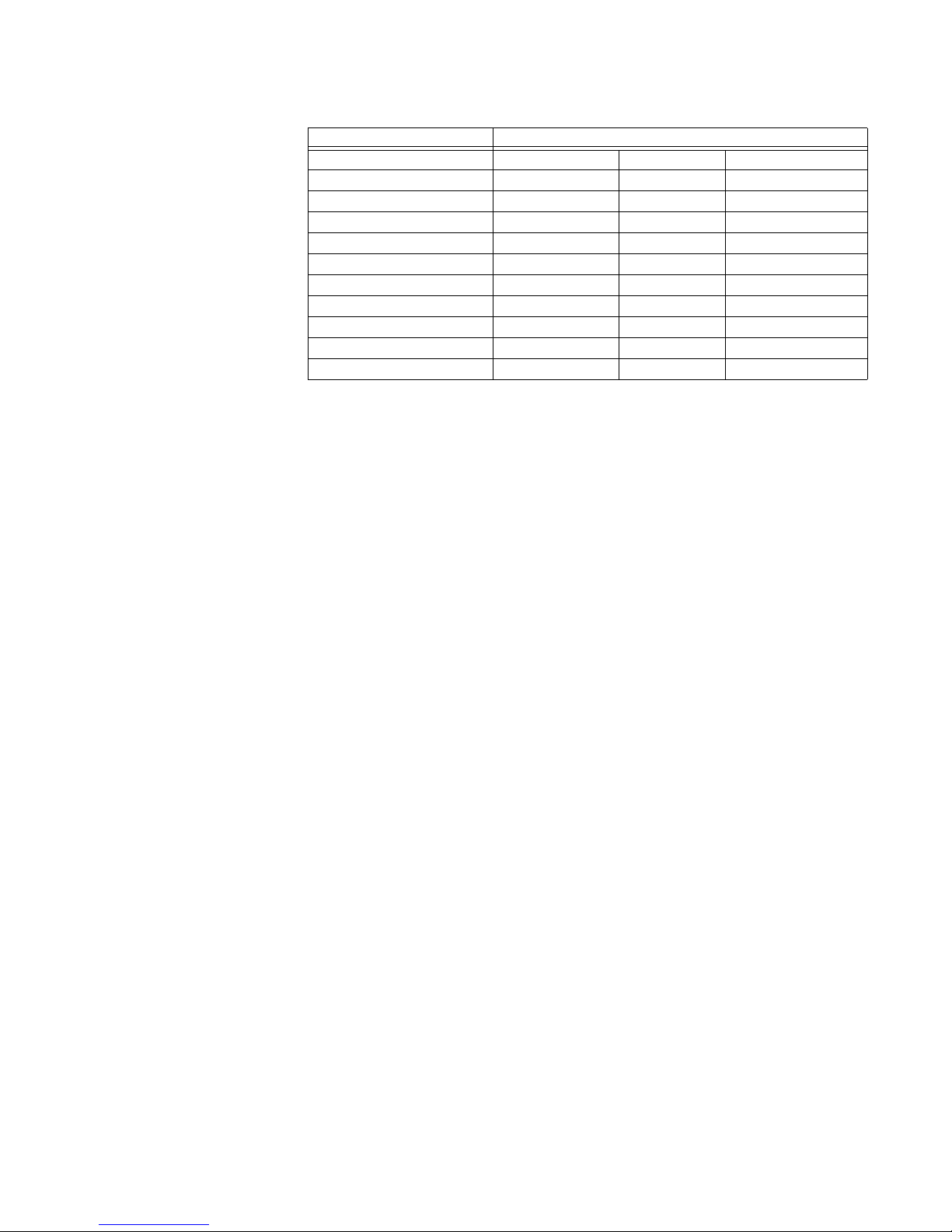

Miscellaneous

Measurand Max. MVAL = times rated value

1,2 or 2,4

Current L1 □⊠

Current L2 □⊠

Current L3 □⊠

Voltage L1-E □□

Voltage L2-E □□

Voltage L3-E □□

Active power P □□

Reactive power Q □□

Frequency f □⊠

Voltage L1-L2 □□

Application level

Application functions The unbalanced transmission mode of the protocol is used to avoid the possibility of more

than one protection device attempting to transmit on the channel at the same time, over

the RS485 port.

Data is transferred to the primary or control station (master) using the “data acquisition by

polling” principle. Cyclically, the master will request class 2 data to the secondary station

(slave).

When slave has class 1 data (high priority) pending, the ACD control bit will be set to 1

demanding the master to request for that data.

Periodically, the master may send a General Interrogation in order to update the complete

database.

The measurands will be sent to the primary station as a response to class 2 request. A

setting (0 to 60 min) is available to configure the desired interval, where 0 means

transmission as fast as possible.

The following functions are supported:

• Initialization

•General Interrogation

•Synchronization

• Commands transmission

Type identification The Type Identification implemented will be:

Information in monitor direction:

Information in control direction:

345 TRANSFORMER PROTECTION SYSTEM – COMMUNICATIONS GUIDE 1–21

TYPE IDENTIFICATION UI8[1..8] <1..255>

<1..31>:= definitions of this companion standard(compatible range)

<32..255>:= for special use (private range)

<1>:= time-tagged message

<3>:= measurands I

<5>:= identification

<6>:= time synchronization

<8>:= general interrogation termination

<9>:= measurands II

<6>:= time synchronization

<7>:= general interrogation

RS485 INTERFACE CHAPTER 1: COMMUNICATIONS GUIDE

<20>:= general command

Function type FUNCTION TYPE UI8 [1..8] <0..255>

<0..127>:= private range

<128..129>:= compatible range

<130..143>:= private range

<144..145>:= compatible range

<146..159>:= private range

<160..161>:= compatible range

<162..175>:= private range

<176..177>:= compatible range

<178..191>:= private range

<192..193>:= compatible range

<194..207>:= private range

<208..209>:= compatible range

<210..223>:= private range

<224..225>:= compatible range

<226..239>:= private range

<240..241>:= compatible range

<242..253>:= private range

<254..255>:= compatible range

The 345 relay is identified in this protocol as “overcurrent protection”, so it will use the

Function Type <160> for all the digital and analogues points proposed by the standard and

mapped in this profile. For the other data supported by the device, the customer will have

the capability to use them by setting a number from the private range.

Information number INFORMATION NUMBER := UI8 [1..8] <0..255>

Monitor direction := <0..255>

<0..15>:=system functions

<16..31>:= status

<32..47>:=supervision

<48..63>:=earth fault

<64..127>:=short circuit

<128..143>:=auto-reclosure

<144..159>:=measurands

<160..239>:=not used

<240..255>:=generic functions

Control direction:=<0..255>

<0..15>:=system functions

<16..31>:=general commands

<32..239>:=not used

<240..255>:=generic functions

Data management

The 345 relay supports a fixed profile and data that is configurable using the EnerVista

SR3 Setup program.

The data that can be configured are:

• digital states

1–22 345 TRANSFORMER PROTECTION SYSTEM – COMMUNICATIONS GUIDE

CHAPTER 1: COMMUNICATIONS GUIDE RS485 INTERFACE

•measurands

•commands.

Digital states Digital states in the relay may be mapped using the EnerVista SR3 Setup program. By

default, states are mapped to information numbers proposed by the standard, but the

user may delete these mappings if desired.

All the mapped information will be sent as a response to a general interrogation like ASDU

1.

For the other states, the customer can assign:

1. Information Number <1..255>

2. Function Type <0..255>.

Settings Digital Status Information Number Function Type

Point 1 Entry Select entry from list <0 – 255 > <0 – 255 >

….

.…

Point 64 Entry Select entry from list <0 – 255 > <0 – 255 >

This means that for each digital point 3 settings are required.

Example:

Modbus Address Description Value Format

43879 Point 1 Entry Digital Status 0x8242 (Undercurrent Trip) FC134

44223 Point 1 Entry Function Type 160 F1

44224 Point 1 Entry Information Number 144 F1

The “Point Entry Digital Status” reuses the DNP Binary Input 43029, 43030, …

Measurands Some analog points are supported by the 345 relay, with compatible information number

that have been identified in the device profile.

For the other measurands, it is possible to use the EnerVista SR3 Setup to select the

desired point and assign the Identification Type (3 or 9), Function Type <0..255>, and

Information Number <1..255>.

If the user selects Identification Type 3 (ASDU 3) only four measurands are available for

configuration, but if Identif ication Type 9 (ASDU 9) is selected, up to nine measurands can

be sent in the IEC103 slave answer. For each measurand, all metering values that the 345

supports, are available in order to be mapped. There are 3 possible configurable ASDUS.

For example, eDataVab is the index in the Modbus Memory Map.

345 TRANSFORMER PROTECTION SYSTEM – COMMUNICATIONS GUIDE 1–23

RS485 INTERFACE CHAPTER 1: COMMUNICATIONS GUIDE

Modbus Address Description Value Format

44384 First ASDU Identification Type 3 or 9 F1

44385 First ASDU Function Type <0 – 255 > F1

44386 First ASDU Information Number < 0 – 255 > F1

44387 First ASDU Scan Timeout < 0 – 1000> secs F1

44388 First ASDU First Analog Entry Vab F1

44389 First ASDU First Analog Factor 1 F3

44390 First ASDU First Analog Offset 0 F1

44391 First ASDU Second Analog Entry Ib F1

44392 First ASDU Second Analog Factor 1 F3

44393 First ASDU Second Analog Offset 0 F1

... ... ... ...

44412 First ASDU Ninth Analog Entry Ib F1

44413 First ASDU Ninth Analog Factor 1 F3

... ... ... ...

44443 Second ASDU Ninth Analogue Entry

44444 Second ASDU Ninth Analogue Factor

44445 Second ASDU Ninth Analogue Offset

... ... ... ...

44446 Third ASDU Identification Type

... … ... ...

44476 Third ASDU Ninth Analogue Offset

In the measurands configuration screen, with each selected measurement, a Factor and

an Offset must be configured.

• The Factor is a multiplier factor.

• The Offset is an offset factor to be applied to the relay measurement to make the final

The factor and offset parameters allow the user to perform different scaling in the relay

measurements. The final measurement sent to the IEC103 master will be: “a*x+b”, where

“x” is the relay measurement, “a” is the multiplier factor and “b” is the offset.

The measurands will be sent to the primary station as a response to a class 2 request.

There is a Timeout configurable with increments of 100 ms, between 0 and 60 min, in order

to configure the desired interval.

Commands

All the commands and virtual inputs are available to be mapped using the EnerVista Setup

program. It is possible to choose the desired command for the ON state and the same or

different command for the OFF state.

The user is able to select the Information Number <1..255> and the Function Type <0..255>

command mappings, but the Identification Type 20 (General Commands) is fixed.++ There

are 32 configurable commands.

In this case it will be necessary to define a new format.

For example, FC500:

measurement calculation to be sent to the master

1–24 345 TRANSFORMER PROTECTION SYSTEM – COMMUNICATIONS GUIDE

CHAPTER 1: COMMUNICATIONS GUIDE RS485 INTERFACE

Description Value

Virtual Input 1 0

Virtual Input 2 1

...

Virtual Input 32 31

Reset 32

Open 35

Close 36

Modbus Address Description Value Format

Command 1 Function Type <0 – 255 > F1

Command 1 Information Number < 0 – 255 > F1

Command 1 Operation ON 2 FC500

Command 1 Operation OFF 8 FC500

...

Command 16 Function Type <0 – 255 > F1

Command 16 Information Number < 0 – 255 > F1

Command 16 Operation ON 6 FC500

Command 16 Operation OFF 34 FC500

The “Command Operations ON and OFF” reuse the DNP Binary Outputs 43189, 43190,

…

103 general settings

Number Value Range

Comms Port COM1 Enum[None,Com1]

Slave Address 1 [0..254]

Synchronization Timeout 30 min [0..1440]min

If Comms Port is set to NONE, the IEC 870-5-103 communication protocol will not be

available.

If the user sets a value other than 0 in the Synchronization Timeout setting, when this time

expires without receiving a synchronization message, the Invalid bit will be set in the time

stamp of a time-tagged message.

It is necessary to configure other port settings: Baud Rate, etc.

345 TRANSFORMER PROTECTION SYSTEM – COMMUNICATIONS GUIDE 1–25

ETHERNET INTERFACE CHAPTER 1: COMMUNICATIONS GUIDE

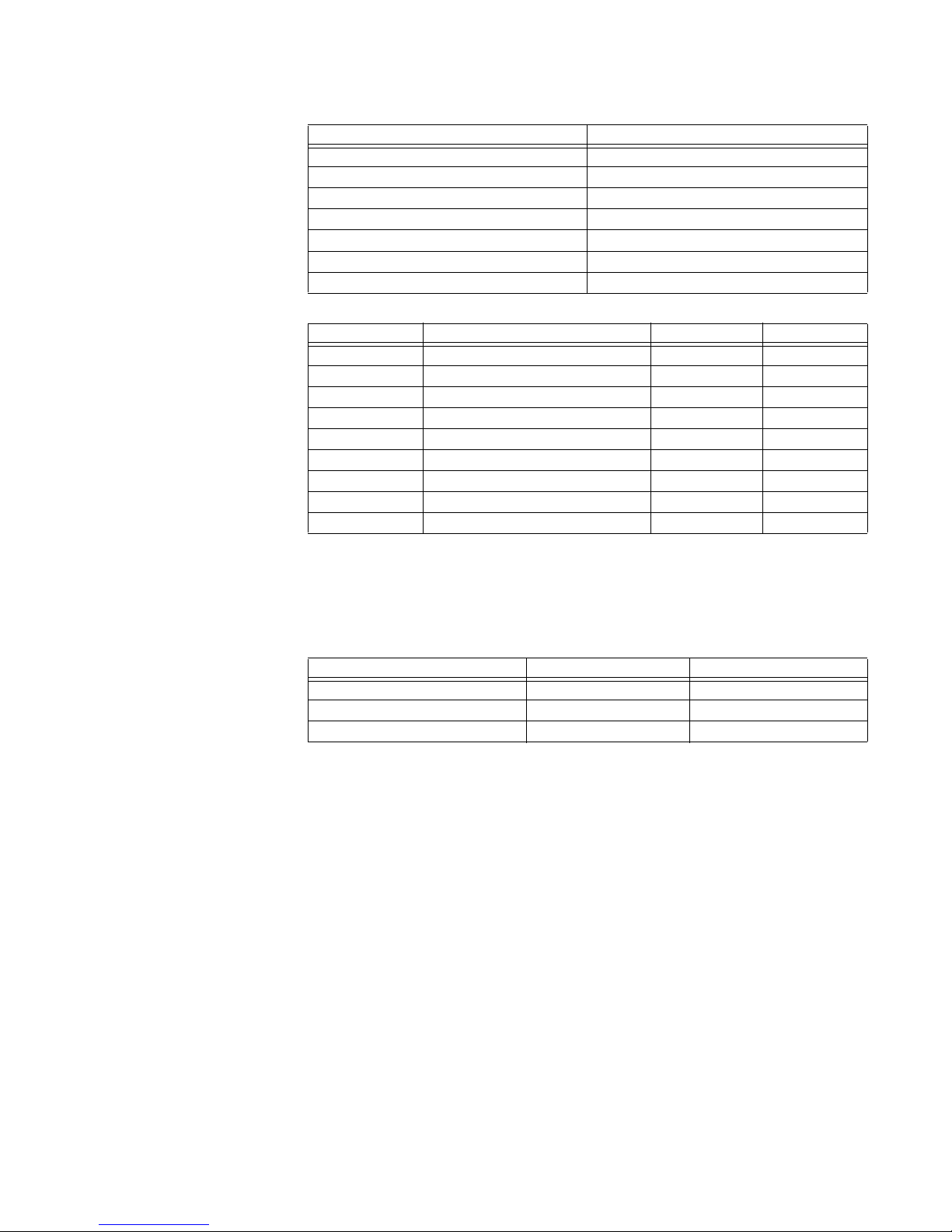

Ethernet interface

The Ethernet option for the 345 provides both a 1300 nm optical interface, and a 10/100

auto-negotiating copper interface. To select which interface is active, a MODBUS setpoint

(see below) must be modified:

MODBUS

Address

40191 BE EthernetConnectionType 0 1 1 FC230 0

Hex

Address

Description Min Max Step Function

Code

Factory

Default

SNTP

SNTP settings With SNTP, the device can obtain the clock time over an Ethernet network, acting as an

SNTP client to receive time values from an SNTP server.

SNTP Port configures the ports that the device uses, so it’s necessary to configure it in all

cases.

The relay binds to the first unicast message (see below) received from any server, then

continues operating with the SNTP server in unicast mode. Any further responses from

other SNTP servers are ignored. In the unicast mode of operation the chosen time server

can go offline, in which case it takes about one minute for the device to signal an SNTP

FAIL state and switch again to anycast mode in order to try to find another time server.

SNTP modes Three different modes of SNTP operation are supported. These modes are unicast,

broadcast and anycast.

To use SNTP in unicast mode, the SNTP IP Address must be set to the SNTP server IP

address. Once this address is set and the function setting is “UNICAST”, the device attempts

to obtain time values from the SNTP server. Since many time values are obtained and

averaged, it generally takes 10 seconds until the clock is synchronized with the SNTP

server.

It may take up to 30 seconds for the device to signal an SNTP FAIL state if the server is offline. In this case the main CPU generates an alarm similar to that of the IRIG-B case.

To use SNTP in broadcast mode, set the function setting to “BROADCAST”. The device

listens to SNTP messages sent to "all" the broadcast addresses for the subnet .

The device waits up to eighteen minutes (>1024 seconds) to receive an SNTP broadcast

message before signaling an SNTP FAIL state.

To use SNTP in anycast mode, set the function setting to “ANYCAST”. Anycast mode is

designed for use with a set of cooperating servers whose addresses are not known

beforehand by the client. The device sends a request to a multicast group address

assigned by IANA for SNTP protocol purposes. This address is 224.0.1.1 and a group of

SNTP servers listens to it . Upon receiving such a request, each server sends a unicast

response to the SNTP client.

The relay binds to the first unicast message received from any server, then it continues

operating with the SNTP server in unicast mode. Any further responses from other SNTP

servers are ignored. In the unicast mode of operation, the chosen time server can go

offline, in which case it takes about one minute for the device to signal an SNTP FAIL state

and to switch again to the anycast mode to try to find another time server.

1–26 345 TRANSFORMER PROTECTION SYSTEM – COMMUNICATIONS GUIDE

Loading...

Loading...