Page 1

GE Oil & Gas

Masoneilan* Valves

28000 Series Varipak

Control Valves

Precise Microflow Valves

with Compact Design

and Flexible Capabilities

Technical Specifications

10/2012

Page 2

Table of Contents

Numbering System ............................................................................................2

Anti-Cavitation Varipak .................................................................................9

Varilog

Micro-flow Control Innovation .....................................................................3

General Data ........................................................................................................4

Materials of Construction .......................................................................... 5-6

Standard Flangeless Varipak ......................................................................................7

Standard Flanged Varipak ........................................................................................... 8

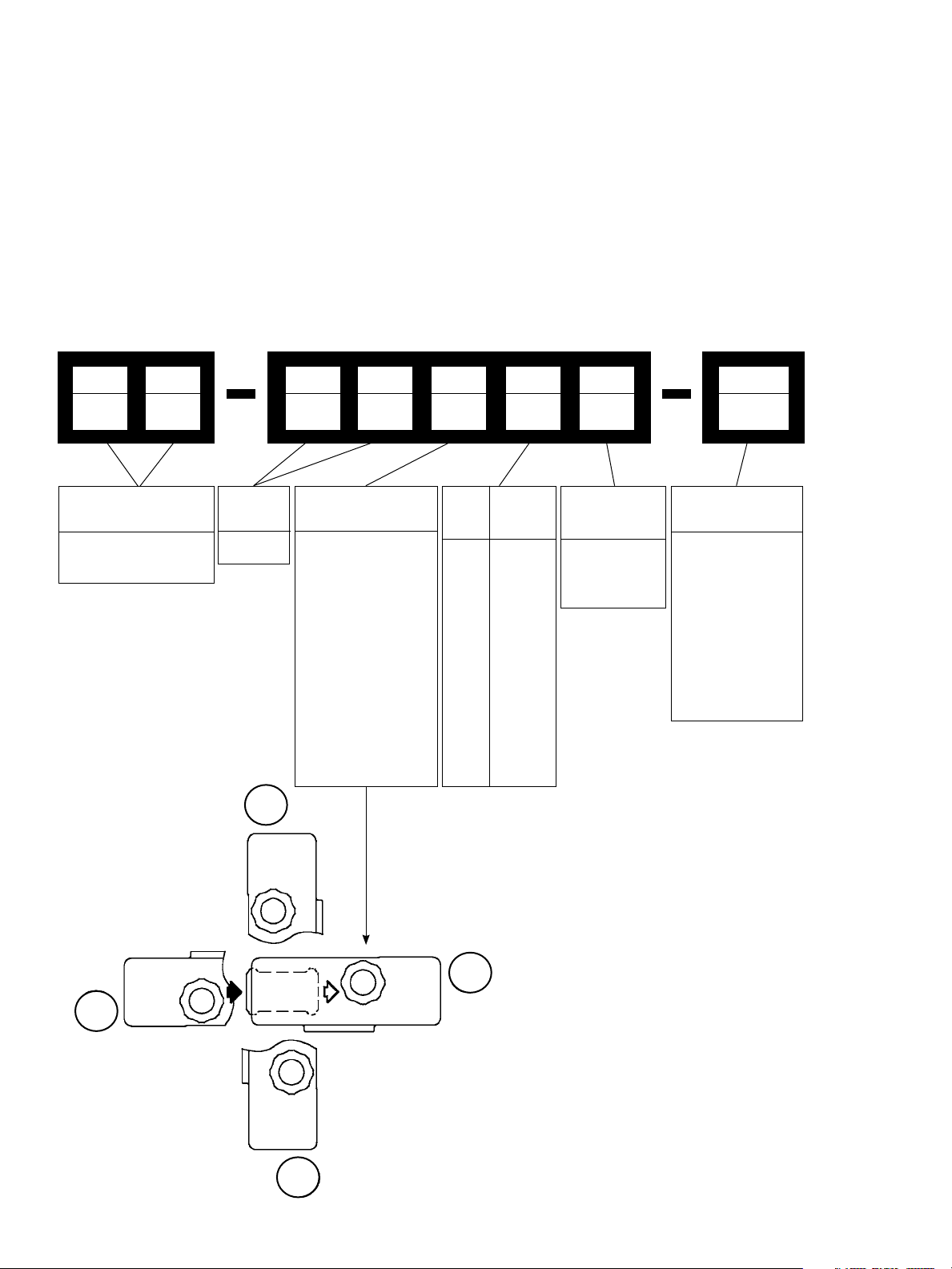

Numbering System

1st

2

Actuator Type

27 Air-to-Close

28 Air-to-Open

Body

Series

28

1st

2

8

Actuator Mounting

Position

0 Undefined

1 (*) (**)

2 (**)

3

4

*

Standard actuator

mounting

arrangement

**

Flanged valve

mounting position

Face-to-face =

102 mm (4.02")

High Pressure Varipak ................................................................................................ 10

Bellows Seal Varipak ................................................................................................... 11

Cryogenic Varipak ........................................................................................................ 12

Accessories and Options ........................................................................................... 13

Standard Actuator Options ...................................................................................... 14

Suffix2nd 2nd 3rd 4th 5th

Trim N°Max.

C

v

0 3.8

1 2.3

2 1.2

3 0.6

4 0.25

5 0.10

6 0.050

7 0.025

8 0.010

9 0.004

Adjustable

C

v

0 Undefined

1 Without

2 With

Construction

Option

Standard

A Angle

BS Bellows seal

EB Cryogenic

HP High pressure

MS Anti-cavitation

SP Special

2

Figure 2:

Actuator Mounting Positions

2 | GE Energy

3

4

1

Information contained in this publication is for general information only and

GE reserves the right to modify the contents without prior notice.

No warranty either expressed or implied is either given or intended.

Page 3

Microflow Control Innovation

Optimized CV Characteristics

The VariPak valve outshines conventional microflow valves with its support of a wide range of nominal Cv values (from 0.0016 to 3.8), using only

eight plugs and five seats.

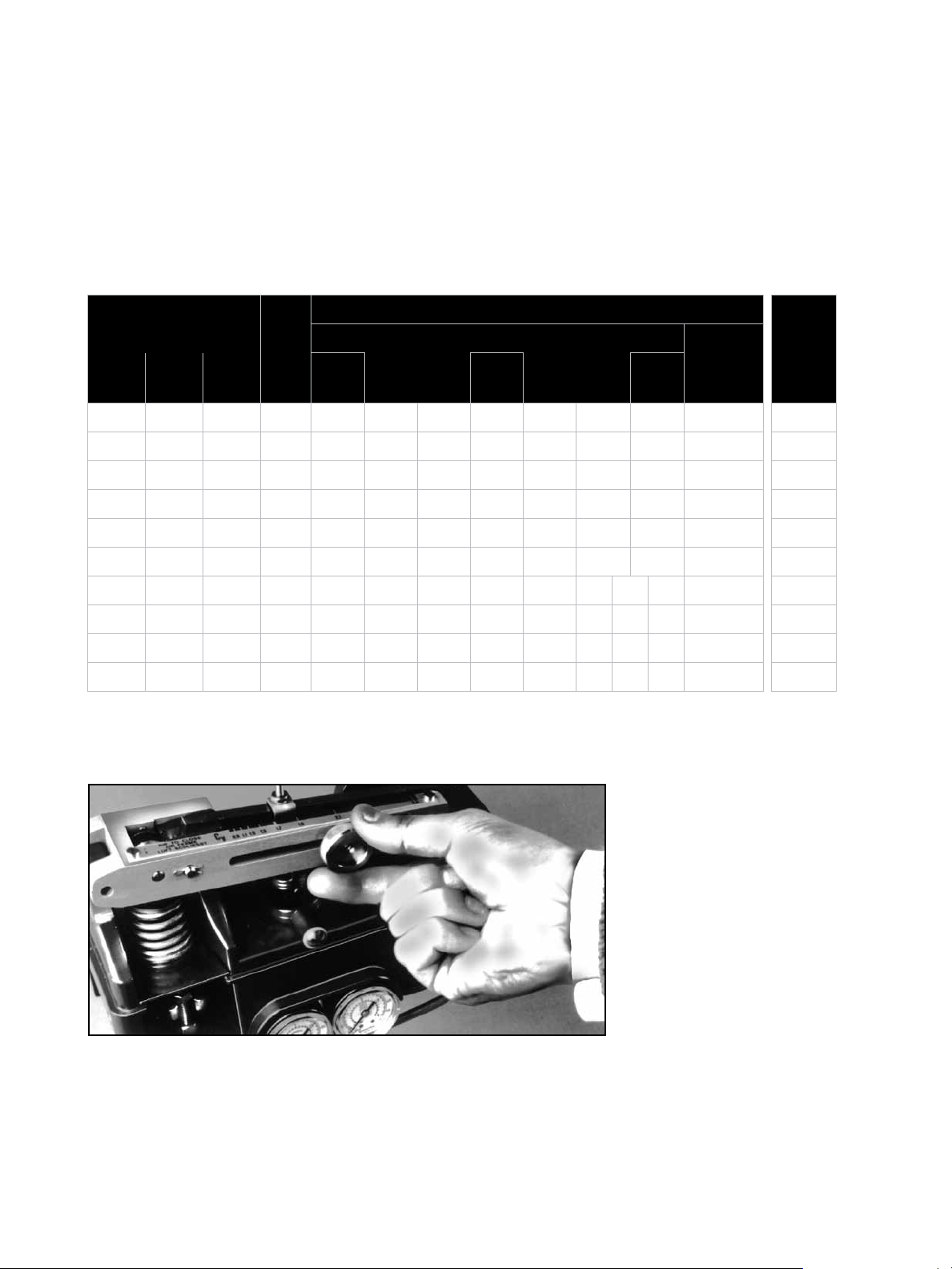

Precise Cv Calibration and Selection - CV and F

Valve Sizes

Trim

.5"

(15mm)

• • • 9 0.0016 0.0020 0.0024 0.0028 0.0032 0.0036

• • • 8 0.004 0.005 0.006 0.007 0.008 0.009

• • • 7 0.010 0.013 0.016 0.019 0.021 0.023

• • • 6 0.020 0.025 0.030 0.035 0.040 0.045

• • • 5 0.04 0.05 0.06 0.07 0.08 0.09

• • • 4 0.10 0.13 0.16 0.19 0.21 0.23

• • • 3 0.25 0.30 0.35 0.40 0.45 0.50 0.55

• • • 2 0.5 0.6 0.7 0.8 0.9 1.0 1.1

• • • 1 1.9 1.1 1.3 1.5 1.7 1.9 2.1

(1) Flangeless, flanged or threaded connections.

(2) Flangeless or threaded connections.

(3) The “Risk-free” setting allows for easy valve capacity adjustments in the field to meet changing service conditions.

.75"

(20mm)

• • 0 1.5 1.9 2.3 2.6 2.9 3.2 3.5

1"

(25mm)

(2) (1)

No.

Min.

With Adjustable CV Function

Flow Coefficient C

Risk-

(3)

Free

V

L

Max.

0.0040 0.0040

0.010 0.010

0.025 0.025

0.050 0.050

0.10 0.10

0.25 0.25

0.60 0.60

1.2 1.2

2.3 2.3

3.8 3.8

Without

Adjustable

C

V

Function

Critical

Flow

Factor

F

L

0.85

0.85

0.85

0.85

0.85

0.90

0.90

0.92

0.92

0.92

Figure 3: Flow Coefficient Adjustment

28000 Series Varipak Control Valves | 3

Page 4

General Data

Body

Type: globe style

angle style optional

Sizes: 1" (DN 25) standard

1/2" (DN 15) and 3/4" (DN 20) optional

Materials: Standard: type 316L St. St.

Optional: Monel®, Hastelloy® C,

Alloy 20, others

Options: Flanged valve

Anti-cavitation Varilog

High pressure

Bellows seal

Cryogenic

Angle valve

NACE version

Trim

Plug type: contoured, heavy top guided

multi-staged anti-cavitation (Varilog) optional

Seat type: metal seat

CV ratio: 500/1 at max. C

Flow characteristics: linear (trim No. 0 to 5)

modified linear (trim No. 6 to 9)

Flow Direction: flow-to-open

flow-to-close optional

Actuator

Type: spring-opposed rolling diaphragm

Action: direct or reverse, easily performed without

additional parts

CV adjustment: optional adjustable knob/lever

Handwheel: optional top mounted

Air connection: 1/8" NPT

Temperature Range/Seat Leakage

Valve Type Temperature Range Seat Class

200/1 at min. C

(1) (2)

V

V

Standard and High Pressure Valves

Cryogenic Valves

Varilog Anit-Cavitation Valves

(1) Please consult GE for applications outside the temperature ranges noted.

(2) Class IV seat leakage is standard and Class V is optional. Seat leakage class ratings per IEC 534-4 and ANSI/FCI 70-2.

-320°F to +650°F (-192°C to +343°C)

-455°F to +300°F (-270°C to +150°C)

-20°F to +650°F (-29°C to +343°C)

IV V

Rating/End Connections**

Valve Sizes

Maximum

C

inches mm Flangeless Threaded SW BW

V

ASME Class 150-1500

ISO PN 20-250

Flanged

Face-to-Face:

6.3” (160mm)

.5 15 2.3 • • • • •

.75 20 2.3 • • • • •

1 25 3.8 • • • • • •

** Please consult GE for applications requiring ASME Class 2500/ISO PN 420 rating.

ASME Class 150-600

ISO PN 20-100

Flanged

Face-to-Face:

4” (102mm)

4 | GE Energy

Page 5

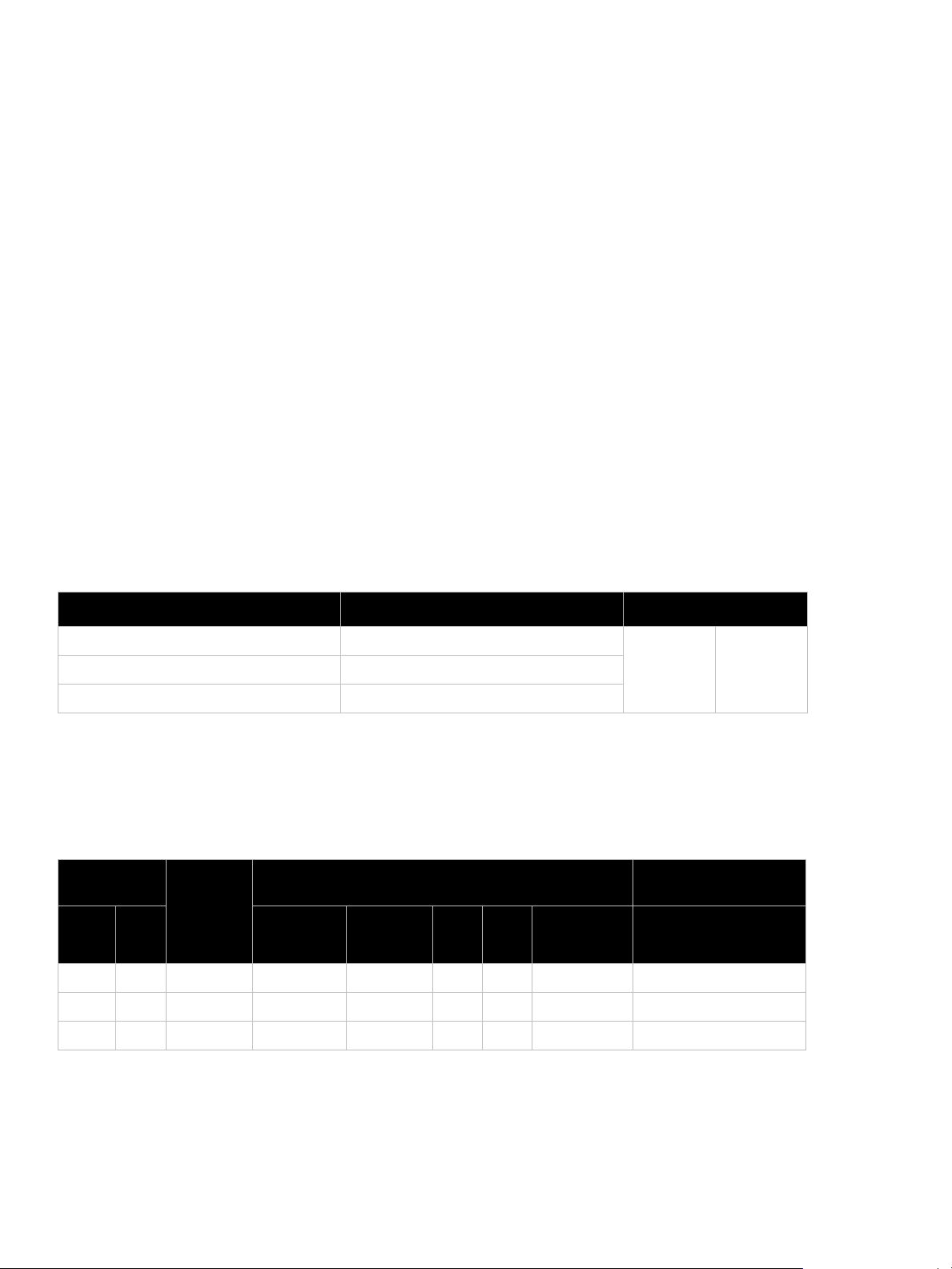

Materials of Construction

11

9

10

7

15

14

13

6

8

3

2

1

12

5

Figure 4: Sectional View

4

28000 Series Varipak Control Valves | 5

Page 6

Materials of Construction

+650°F

+343°C

(1)

-20°F

-29°C

Materials* (Standard and NACE Construction)

Ref.

No.

Temperature Range

-320°F

-196°C

∇ ∇ ∇ ∇

+450°F

+232°C

Description Standard Materials (Optional Materials) NACE Materials

1 Body

2 Seat

316L St. St. ASTM A182 Gr. F 316L (forging)

316L St. St. ASTM A351 Gr. CF3M (casting)

Optional: Monel

®

, Hastelloy® C, Alloy 20

17-4 PH St. St. ASTM A564 Gr. 630 Condition H900

(Max CV ≥ 0.10, trims No. 0 to 5)

Solid Stellite No. 6

or Equivalent

(Max CV ≤ 0.05, trims No. 6 to 9)

22 HRC Max.

MONEL K 500 35 HRC Max.

35 HRC Max.

Optional: 440C St. St. Monel®, Hastelloy® C, Alloy 20

No. 6

Plug Solid Stellite

or Equivalent

(Max CV >_ 0.10, trims No. 0 to 5)

3

Plug and

Stem S/A

Stem 316 St. St. (Max Cv >_ 0.10, trims No. 0 to 5)

One Piece Solid Stellite No. 12 or Equivalent

(Max CV ≤ 0.05, trims No. 6 to 9)

22 HRC Max.

Optional: 440C St. St., Monel®, Hastelloy® C, Alloy 20

4 Seat Ring Gasket

316 St. St. with Flexible Graphite Filler (Spiral Wound) with

316 St. St. inserts

PTFE Fiberglass Reinforced

5 Seat Ring Retainer 17-4 PH St. St. ASTM A564 Gr. 630 Condition H1075 MONEL K 500 35 HRC Max.

PTFE (standard up to

ASME Class 1500)

PTFE (standard up to

ASME Class 1500)

6 Packing

Lattyflon

®

(with optional Viton® O-rings)

Lattyflon® (with optional

Viton® O-rings)

7 Packing Follower 303 St. St. ASTM A582 TY 303 ASTM A479 TY 304 22 HRC Max.

8 Packing Spacer 316 St. St. ASTM A479 TY 316 22 HRC Max.

9 Packing Flange 304 St. St. AISI 304 ASTM A743 Gr. CF8 22 HRC Max.

304 St. St. ASTM A193 Gr. B8

10 Packing Flange Studs 304 St. St. ASTM A193 Gr. B8

304 St. St. ASTM A193 Gr. B8

(Class III)

(Class I or II) 22 HRC Max.

304 St. St. ASTM A194 Gr. 8

11 Packing Flange Nuts 304 St. St. ASTM A193 Gr. 8

304 St. St. ASTM A194 Gr. 8A

(Class III)

(Class I or II) 22 HRC Max.

12 Safety Pin 316 St. St. ASTM A479 TY 316 22 HRC Max.

13 CV Adjustment Knob Stainless Steel Stainless Steel

14 Actuator Cover

Polycarbonate Polycarbonate

Optional: Stainless Steel Optional: Stainless Steel

15 Handwheel (optional) Lexan® + Austenitic St. St. Lexan® + Austenitic St. St.

+450°F

+232°C

(1) Materials and processes in accordance with the requirements of NACE specification MR0103.

Applications requiring compliance to MR0175, 2003 Rev. or ISO 15156 would require engineering review.

(2) Materials designated for these parts conform to NACE Class III bolting requirements.

(3) Materials designated for these parts conform to NACE Class I or Class II bolting requirements.

(4) Consult GE for NACE Applications above ASME Class 600 rating.

* Materials noted throughout this text are for reference only. GE reserves the right to supply trade name material or equivalent

6 | GE Energy

Material not applicable

Page 7

Standard Flangeless Varipak

28000 Series

Due to its simple, compact, and versatile stainless-steel body design,

the standard flangeless Varipak valve is widely used across a variety of

industries.

Figure 5:

Standard Flangeless Varipak

Rated Cv Range/Weight

Body/Actuator Assembly Weight Rated CV Range

15.4 lbs (7 kg) 3.8 to 0.0040 (trim No. 0 to 9)

Dimensions – inches (mm)

Standard Varipak (Stainless Steel) Bar Stock Body

(For Non-Castable Material)

4.13

(105)

10.24

(260)

Handwheel (optional)

12.80

(325)

11.10

(282)

2 holes tapped

5/16" – 18 UNC

depth 11 (7/16")

1/2" NPT

Optional

3/4" NPT

1" NPT

Provide a removal clearance of 5.5 inches (140 mm)

1.30

(33)

4.02

(102)

8.56

(217.5)

1.77

1.10

(28)

28000 Series Varipak Control Valves | 7

(45)

Page 8

Standard Flanged Varipak

28000 Series

The Varipak is also available in flanged configurations with connections and ratings as indicated in the following table.

Flange Ratings/Weight

Figure 6:

Standard Flanged

Varipak

Face-to-Face Dimensions Flange Ratings Body/Actuator S/A Weight* Rated CV Range

4" (102mm)

ASME Class 150-600

ISO PN 20-100

(raised face only)

8 to 10 kg

(17.4 to 22 lbs)

3.8 to 0.0040

6.3" (160mm)

ASME Class 150-1500

ISO PN 20-250

DIN PN 10-250

10 to 12 kg

(22 to 26.5 lbs)

(trim No. 0 to 9)

(RF, FF, RTS, etc...)

* depending on rating.

Dimensions – inches (mm)

10.24

(260)

Handwheel (optional)

12.80

(325)

11.10

(282)

2 holes tapped

5/16" – 18 UNC

depth 11 (7/16")

4.13

(105)

Provide a removal clearance of 5.5 inches (140 mm)

8 | GE Energy

6.30

(160)

8.56

(217.5)

4.02

(102)

Page 9

Varilog* Anti-Cavitation Varipak

28000 MS Series

The Varilog multi-stage trim design for the Varipak control valve provides

unmatched anti-cavitation performance in low flow applications.

By reducing erosion and vibrations, this design helps minimize failure that is often

associated with conventional single-seated valves. The Varilog trim is available

with the standard Varipak body designs in either the flanged or flangeless

configurations.

Figure 7: Varilog Trim Subassembly

Specific Characteristics

Rated CV Range Critical Flow Factor FLTemperature Range Materials

ASTM A 564 Gr. 630 Condition H900

No. 12

0.60 to 0.050

(trim No. 3 to 6)

0.98

-20°F to +660°F

(-29°C to +350°C)

Seat

Plug

Other Parts Standard Construction: see page 6

Dimensions – inches (mm)

Standard Varipak (Stainless Steel) Bar Stock Body

(For Non-Castable Material)

4.13

(105)

10.24

(260)

Handwheel (optional)

12.80

(325)

11.10

(282)

2 holes tapped

5/16" – 18 UNC

depth 11 (7/16")

Type 17-4 PH St. St.

One piece from solid Stellite

or Equivalent

or ASTM A 276 type

440 C St. St.

1/2" NPT

Optional

3/4" NPT

1" NPT

Provide a removal clearance of 5.5 inches (140 mm)

1.30

(33)

4.02

(102)

8.56

(217.5)

1.77

1.10

(28)

28000 Series Varipak Control Valves | 9

(45)

Page 10

High Pressure Varipak

28000 HP Series

The high-pressure Varipak valve design is recommended for applications

involving conditions with very high upstream pressure or pressure drop

that exceeds the pressure rating of the standard Varipak body design.

Specific Characteristics

Figure 8:

High Pressure Varipak

Rated CV Range Body Rating Seat Leakage Materials

0.60 to 0.0040

(trim No. 3 to 9)

ASME Class 2500

ISO PN 420

Class IV

Body

Other Parts Standard Construction: see page 6

Dimensions – inches (mm)

Handwheel (optional)

4.13

(105)

2.24

(57)

2 holes tapped

5/16" – 18 UNC

depth 11 (7/16")

1/2" NPT

Optional

3/4" NPT

1" NPT

Provide a removal clearance of 5.5 inches (140 mm)

6.38

(162

1.10

(28)

10.24

(260)

8.56

(217.5)

11.10

(282)

12.80

(325)

Valve Sizes X

inches mm inches mm

.5 15 3.15 80

.75 20

1 25

ASME A 182 Gr. F 316L

Optional: ASTM A182 Gr. F 316

1/4" NPT

1

Supply Connection

1/4" NPT

2

Instrument Connection

4.02 102

10 | GE Energy

Page 11

Bellows Seal Varipak

28000 BS Series

For applications that require no leakage at the packing box, the Varipak

valve is available with a bellows seal. This design is ideal for applications

that involve the handling of flammable, toxic, or explosive fluids.

Specific Characteristics

Figure 9A:

Bellows Seal Varipak

Rated CV

Range

2.3 to 0.0040

(trim No. 1 to 9)

Body Rating

ASME Class 150-600

ISO PN 10-100

Dimensions – inches (mm)

4.13

(105)

2 holes tapped

5/16" – 18 UNC

depth 11 (7/16")

1/2" NPT

Optional

3/4" NPT

1" NPT

Provide a removal clearance of 5.5 inches (140 mm)

1.30

(33)

4.02

(102)

Seat

Leakage

Class IV

10.24

(260)

8.56

(217.5)

Operating

Pressures

800 psi at +212°F

(55 bar at +100°C)

580 psi at +392°F

(40 bar at +200°C)

Handwheel (optional)

12.80

(325)

11.10

(282)

Materials

Body

Plug/Bellows

Subassembly

ASTM A 182 Gr. F 316L

Optional: A182 Gr. F 316

Plug and Seat: Standard Materials

Bellows Assembly: 316L St. St.

Viton

®

O-rings

Other Parts Standard Construction: see page 6

Figure 9B:

Plug and Bellows Subassembly

28000 Series Varipak Control Valves | 11

Page 12

Cryogenic Varipak

28000 EB Series

Simplified maintenance

This Varipak control valve design meets the requirements of cryogenic processes that require thermal insulation. An insulating interface sets up between the

valve body (cold zone) and the body extension located in the higher temperature

area (warm zone). The valve body assembly and its thermal extension are positioned inside the cold box, and the plug can easily be removed and inspected

without disturbing the valve body. This eliminates the need for any preliminary,

complicated dismounting, and more importantly, prevents any interference

with the cold box.

Body

Manufactured from a material suitable for low temperatures, the valve body

maintains ductility in service. It can be conveniently mounted to suit specific

piping needs, as long as the angle between the valve axis and vertical does not

exceed 60°.

Specific Characteristics

The bonnet is located away from the cryogenic fluid, which means that the body

gasket is not inside the cold zone. This design prevents any leakage

of the cryogen into the insulated zone.

Body extension

To reduce the inflow of head by conduction, thin-walled metal tubes are used

for the body extension and coupling sleeve. In addition, the annular space is

reduced to exclude convection currents.

Plug

The design of the plug allows the working parts to be accurately centered in

relation to the seat and provides a uniform temperature zone for the guiding.

Rated CV

Range

3.8 to 0.10

(trim No. 0 to 5)

Temperature

Range

-455°F to +300°F

(-270°C to + 150°C)

Dimensions – inches (mm)

10.24

(260)

8.56

(217.5)

2 holes tapped

5/16" – 18 UNC

depth 11 (7/16")

4.13

(105)

2.24

(57)

15.71

(399)

Body

Rating

ASME Class 150-600

ISO PN 20-100

excepted trim No. 0:

ASME Class 150-300

ISO PN 20-50

Handwheel (optional)

1

2

22.13

(562)

20.43

(519)

Seat

Leakage

Plug/Stem Standard Material

Class IV

O-ring Seat

Other Parts Standard Construction: see page 6

1/4" NPT

Supply Connection

1/4" NPT

Instrument Connection

Body and

Extension

Seat

Gasket

Materials

ASTM A 182 Gr. F 316L

Trim No. 0: Standard Material

Trim No. 1 to 5: ASTM A 564 Gr. 630

Condition H900 Type 17-4 PH. St. St.

PTFE

1.30 (33)

Provide a removal clearance of 5.5 inches (140 mm)

12 | GE Energy

4.02

(102)

Figure 10: Cryogenic Varipak

Page 13

Accessories and Options

Pneumatic Positioner (Model 7700P)

Type

pneumatic, force balance

Mounting

built-in bracket in actuator

Action

direct: increasing instrument signal

increases air output

Characteristics

linear

Instrument signal

3 to 15, 6 to 30 or 3 to 27 psi

200 to 1000, 400 to 2050 or

(200 to 1850 mbar)

3 to 9, and 9 to 15 psi

(200 to 600 and 600 to 1000 mbar)

split range

Connections

1/4" NPT instrument and supply –

1/8" NPT output

Average air consumption

0.15 scfm at 30 psi supply

Figure 11: Model 7700P Pneumatic

Positioner

(0.26 Nm3/h at 2.1 bar supply)

Max. air output

4.20 scfm (7 Nm3/h)

Supply pressure effect

0.05 percent of full stroke variation per

psi supply pressure change

(0.07 percent per 100 mbar)

Open loop gain

70

Linearity

± 0.5 percent

Sensitivity

0.1 percent

Repeatability

0.1 percent

Full stroke time

less than one second

Weight

3.3 lbs (1.5 kg)

Other Accessories

Proximity sensors and limit switches

Digital positioners – HART® and

Fieldbus Foundation

Handwheel, airsets and solenoid valves

Figure 12: Model 7700E

Electropneumatic Positioner

Electropneumatic Positioner (Model 7700E)

Type

electropneumatic, force balance

Mounting

compact, without external linkage

to the actuator (see Fig. 15)

Action

direct: increasing instrument signal

increases air output

Characteristics

linear

Instrument signal

4-20 mA

Air Connections

1/4" NPT supply – 1/8" NPT output

Average air consumption

0.24 scfm (0.4 Nm3/h)

Electrical connections

1/2" NPT or M20

Weight

7.7 lbs (3.5 kg)

Hazardous Location Protection

ATEX Approvals (94/9/EC Directive)

Explosionproof

No. SIRA 02 ATEX 1274

Intrinsic Safety

No. SIRA 02 ATEX 2277 X

FM (Factory Mutual) Approvals

Explosionproof

Intrinsic Safety

Non-incendive and

Dust-ignitionproof

CSA Approvals

(Canadian Standards Association)

Explosionproof

Intrinsic Safety

Non-incendive

28000 Series Varipak Control Valves | 13

Page 14

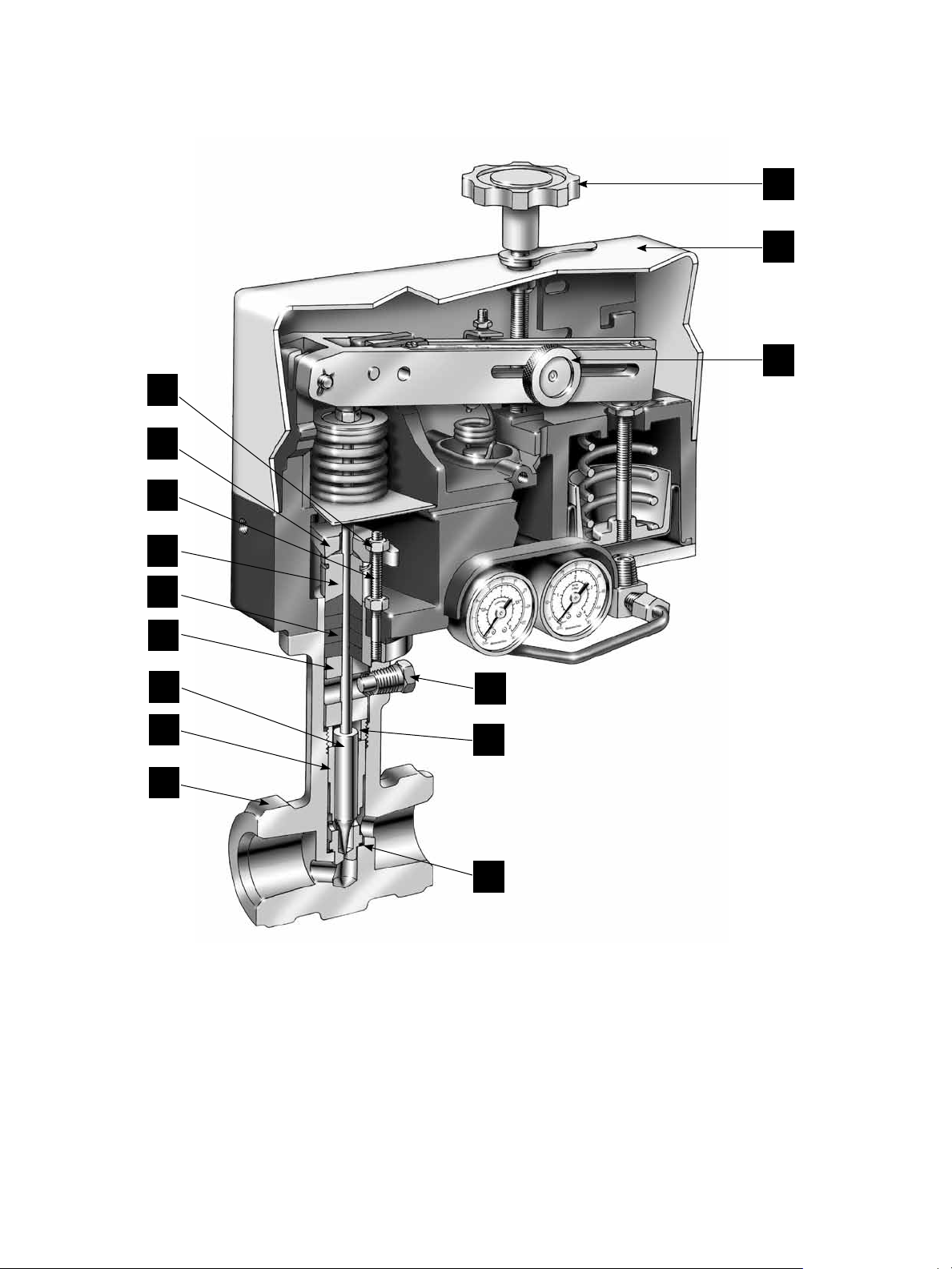

Standard Actuator Options

Figure 14: Varipak with Non-Adjustable

C

Actuator (cover removed)

V

Figure 13: Non-Adjustable CV Actuator

Figure 15: Varipak with 7700E

Electropneumatic Positioner

Figure 16: Adjustable CV Actuator

14 | GE Energy

Page 15

DIRECT SALES OFFICE LOCATIONS

AUSTRALIA

Brisbane:

Phone: +61-7-3001-4319

Fax: +61-7-3001-4399

Perth:

Phone: +61-8-6595-7018

Fax: +61 8 6595-7299

Melbourne:

Phone: +61-3-8807-6002

Fax : +61-3-8807-6577

BELGIUM

Phone: +32-2-344-0970

Fax: +32-2-344-1123

BRAZIL

Phone: +55-11-2146-3600

Fax: +55-11-2146-3610

CHINA

Phone: +86-10-8486-4515

Fax: +86-10-8486-5305

FRANCE

Courbevoie

Phone: +33-1-4904-9000

Fax: +33-1-4904-9010

GERMANY

Ratingen

Phone: +49-2102-108-0

Fax: +49-2102-108-111

INDIA

Mumbai

Phone: +91-22-8354790

Fax: +91-22-8354791

New Delhi

Phone: +91-11-2-6164175

Fax: +91-11-5-1659635

ITALY

Phone: +39-081-7892-111

Fax: +39-081-7892-208

JAPAN

Chiba

Phone: +81-43-297-9222

Fax: +81-43-299-1115

KOREA

Phone: +82-2-2274-0748

Fax: +82-2-2274-0794

MALAYSIA

Phone: +60-3-2161-0322

Fax: +60-3-2163-6312

MEXICO

Phone: +52-5-310-9863

Fax: +52-5-310-5584

THE NETHERLANDS

Phone: +0031-15-3808666

Fax: +0031-18-1641438

RUSSIA

Veliky Novgorod

Phone: +7-8162-55-7898

Fax: +7-8162-55-7921

Moscow

Phone: +7 495-585-1276

Fax: +7 495-585-1279

SAUDI ARABIA

Phone: +966-3-341-0278

Fax: +966-3-341-7624

SINGAPORE

Phone: +65-6861-6100

Fax: +65-6861-7172

SOUTH AFRICA

Phone: +27-11-452-1550

Fax: +27-11-452-6542

SOUTH & CENTRAL

AMERICA AND THE CARIBBEAN

Phone: +55-12-2134-1201

Fax: +55-12-2134-1238

SPAIN

Phone: +34-93-652-6430

Fax: +34-93-652-6444

UNITED ARAB EMIRATES

Phone: +971-4-8991-777

Fax: +971-4-8991-778

UNITED KINGDOM

Wooburn Green

Phone: +44-1628-536300

Fax: +44-1628-536319

UNITED STATES

Massachusetts

Phone: +1-508-586-4600

Fax: +1-508-427-8971

Corpus Christi, Texas

Phone: +1-361-881-8182

Fax: +1-361-881-8246

Deer Park, Texas

Phone: +1-281-884-1000

Fax: +1-281-884-1010

Houston, Texas

Phone: +1-281-671-1640

Fax: +1-281-671-1735

California

Phone: +1-562-941-7610

Fax: +1-562-941-7810

* Masoneil an, Varipak, Va rilog and LE Pac king are regist ered tradema rks of the Gener al Electric C ompany.

Other company names and product names used in this document are the registered trademarks or trademarks of their respective owners.

© 2012 General El ectric Comp any. All rights re served.

GEA19708 10/2012

Loading...

Loading...