Page 1

g

Title P

age

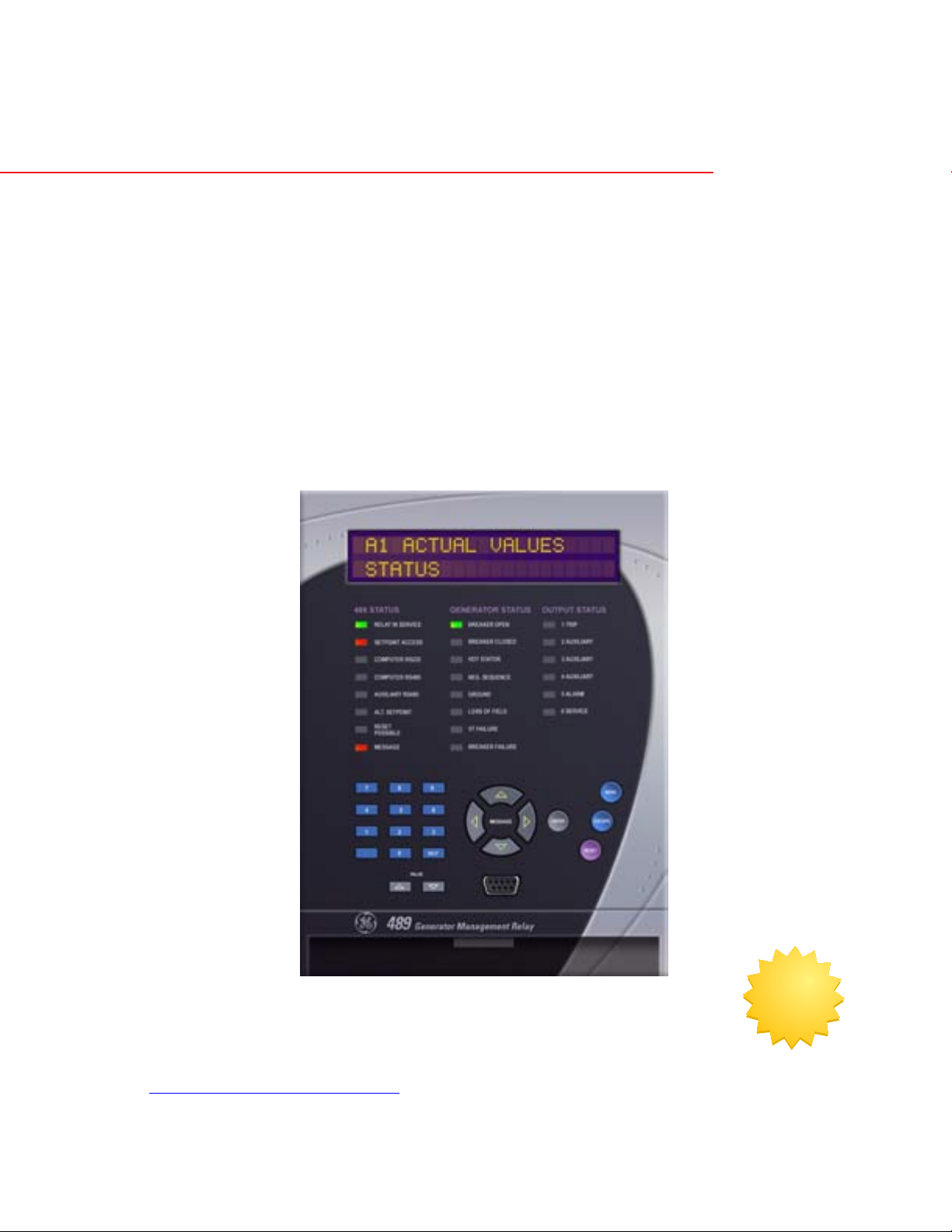

GE Industrial Systems

489

Generator Management Relay

COMMUNICATIONS GUIDE

Software Revision: 3.00

GE Publication Code: GEK-106495A

GE Multilin Part Number: 1601-0149-A2

Copyright © 2004 GE Multilin

GE Multilin

215 Anderson Avenue, Markham, Ontario

Canada L6E 1B3

Tel: (905) 294-6222 Fax: (905) 201-2098

Internet: http://www.GEindustrial.com/multilin

T

E

S

I

R

E

G

D

E

R

ISO9001:2000

G

E

GE Multilin's Quality Management

System is registered to

ISO9001:2000

QMI # 005094

UL # A3775

N

I

M

L

I

U

T

L

Page 2

Page 3

Tabl

e of Contents

Communications Guide

489

Table of Contents

MODBUS PROTOCOL Electrical Interface.................................................................................................................................. 1

MODBUS FUNCTIONS Supported Functions ............................................................................................................................. 3

MODBUS MEMORY MAP Memory Map Information..................................................................................................................... 9

DNP PROTOCOL Device Profile Document..................................................................................................................... 46

DNP POINT LISTS Binary Input / Binary Input Change (Objects 01/02) .......................................................................... 49

Modbus RTU Description...................................................................................................................... 1

Data Frame Format and Data Rate ....................................................................................................... 1

Data Packet Format................................................................................................................................ 2

CRC-16 Algorithm .................................................................................................................................. 3

Timing..................................................................................................................................................... 3

Function Codes 03/04: Read Setpoints / Actual Values ...................................................................... 4

Function Code 05: Execute Operation.................................................................................................. 5

Function Code 06: Store Single Setpoint............................................................................................. 5

Function Code 07: Read Device Status ................................................................................................ 6

Function Code 08: Loopback Test......................................................................................................... 6

Function Code 16: Store Multiple Setpoints........................................................................................ 7

Function Code 16: Performing Commands ......................................................................................... 8

Error Responses..................................................................................................................................... 8

User-Definable Memory Map Area ...................................................................................................... 9

Event Recorder....................................................................................................................................... 9

Waveform Capture .............................................................................................................................. 10

Dual Setpoints...................................................................................................................................... 10

Passcode Operation............................................................................................................................. 10

489 Memory Map................................................................................................................................. 11

Memory Map Data Formats................................................................................................................ 40

Implementation Table ......................................................................................................................... 47

Default Variations ................................................................................................................................ 48

Binary / Control Relay Output Block (Objects 10/12)......................................................................... 51

Binary / Frozen Counter (Objects 20/21)............................................................................................. 52

Analog Input / Input Change (Objects 30/32).....................................................................................53

GE Multilin

http://www.GEindustrial.com/multilin

i

Page 4

Communications Guide

Table of Contents489

ii

http://www.GEindustrial.com/multilin

GE Multilin

Page 5

Modbus Protocol

Communications Guide

489 Communications Guide

GE Publication Code: GEK-106495A

GE Multilin Part Number: 1601-0149-A2

Copyright © 2004 GE Multilin

Modbus Protocol

Electrical Interface The hardware or electrical interface is one of the following: one of two 2-wire RS485

ports from the rear terminal connector or the RS232 from the front panel connector.

In a 2-wire RS485 link, data flow is bidirectional. Data flow is half-duplex for both

the RS485 and the RS232 ports. That is, data is never transmitted and received at

the same time. RS485 lines should be connected in a daisy chain configuration

(avoid star connections) with a terminating network installed at each end of the link,

i.e. at the master end and at the slave farthest from the master. The terminating

network should consist of a 120 Ω resistor in series with a 1 nF ceramic capacitor

when used with Belden 9841 RS485 wire. The value of the terminating resistors

should be equal to the characteristic impedance of the line. This is approximately

120 Ω for standard #22 AWG twisted pair wire. Shielded wire should always be used

to minimize noise. Polarity is important in RS485 communications. Each '+' terminal

of every 489 must be connected together for the system to operate. Refer to the

489 Instruction Manual for correct serial port wiring.

489

Modbus RTU

Description

Data Frame Format and

Data Rate

GE Multilin

The 489 implements a subset of the AEG Modicon Modbus RTU serial communication

standard. Many popular programmable controllers support this protocol directly with

a suitable interface card allowing direct connection of relays. Although the Modbus

protocol is hardware independent, the 489 interfaces include two 2-wire RS485

ports and one RS232 port. Modbus is a single master, multiple slave protocol

suitable for a multi-drop configuration as provided by RS485 hardware. In this

configuration up to 32 slaves can be daisy-chained together on a single

communication channel.

The 489 is always a slave; it cannot be programmed as a master. Computers or

PLCs are commonly programmed as masters. The Modbus protocol exists in two

versions: Remote Terminal Unit (RTU, binary) and ASCII. Only the RTU version is

supported by the 489. Monitoring, programming, and control functions are

performed with read/write register commands.

One data frame of an asynchronous transmission to or from a 489 is default to 1

start bit, 8 data bits, and 1 stop bit. This produces a 10-bit data frame. This is

important for transmission through modems at high bit rates (11 bit data frames are

not supported by Hayes modems at bit rates of greater than 300 bps). The parity bit

is optional as odd or even. If it is programmed as odd or even, the data frame

consists of 1 start bit, 8 data bits, 1 parity bit, and 1 stop bit.

Modbus protocol can be implemented at any standard communication speed. The

489 RS485 ports support operation at 1200, 2400, 4800, 9600, and 19200 baud.

The front panel RS232 baud rate is fixed at 9600 baud.

http://www.GEindustrial.com/multilin

1

Page 6

Modbus Protocol489

Communications Guide

Data Packet Format A complete request/response sequence consists of the following bytes (transmitted

as separate data frames):

1. A Master Query Message consisting of: a 1-byte Slave Address, a 1-byte Func-

tion Code, a variable number of Data Bytes depending on the Function Code,

and a 2-byte CRC code.

2. A Slave Response Message consisting of: a 1-byte Slave Address, a 1-byte

Function Code, a variable number of Data Bytes depending on the Function

Code, and a 2-byte CRC code.

The terms Slave Address, Function Code, Data Bytes, and CRC are explained below:

• SLAVE ADDRESS: This is the first byte of every transmission. This byte

represents the user-assigned address of the slave device that is to receive the

message sent by the master. Each slave device must be assigned a unique

address and only the addressed slave will respond to a transmission that starts

with its address. In a master request transmission the Slave Address represents

the address of the slave to which the request is being sent. In a slave response

transmission the Slave Address represents the address of the slave that is

sending the response. The RS232 port ignores the slave address, so it will

respond regardless of the value in the message. Note: A master transmission

with a Slave Address of 0 indicates a broadcast command. Broadcast commands

can be used for specific functions.

• FUNCTION CODE: This is the second byte of every transmission. Modbus

defines function codes of 1 to 127. The 489 implements some of these

functions. In a master request transmission the Function Code tells the slave

what action to perform. In a slave response transmission if the Function Code

sent from the slave is the same as the Function Code sent from the master

indicating the slave performed the function as requested. If the high order bit of

the Function Code sent from the slave is a 1 (i.e. if the Function Code is greater

than 127) then the slave did not perform the function as requested and is

sending an error or exception response.

• DATA BYTES: This is a variable number of bytes depending on the Function

Code. These may be actual values, setpoints, or addresses sent by the master

to the slave or vice-versa. Data is sent MSByte first followed by the LSByte.

• CRC: This is a two byte error checking code. CRC is sent LSByte first followed

by the MSByte. The RTU version of Modbus includes a two byte CRC-16 (16-bit

cyclic redundancy check) with every transmission. The CRC-16 algorithm

essentially treats the entire data stream (data bits only; start, stop and parity

ignored) as one continuous binary number. This number is first shifted left 16

bits and then divided by a characteristic polynomial (11000000000000101B).

The 16-bit remainder of the division is appended to the end of the transmission,

LSByte first. The resulting message including CRC, when divided by the same

polynomial at the receiver will give a zero remainder if no transmission errors

have occurred.

If a 489 Modbus slave device receives a transmission in which an error is indicated

by the CRC-16 calculation, the slave device will not respond to the transmission. A

CRC-16 error indicates than one or more bytes of the transmission were received

incorrectly and thus the entire transmission should be ignored in order to avoid the

489 performing any incorrect operation. The CRC-16 calculation is an industry

standard method used for error detection. An algorithm is included here to assist

programmers in situations where no standard CRC-16 calculation routines are

available.

2

http://www.GEindustrial.com/multilin

GE Multilin

Page 7

Modbus Functions

Communications Guide

CRC-16 Algorithm Once the following algorithm is complete, the working register “A” will contain the

CRC value to be transmitted. Note that this algorithm requires the characteristic

polynomial to be reverse bit ordered. The MSbit of the characteristic polynomial is

dropped since it does not affect the value of the remainder.

The symbols used in the algorithm are shown below:

--> data transfer

A

; A

; A

low

CRC 16 bit CRC-16 result

i, j loop counters

(+) logical EXCLUSIVE-OR operator

N total number of data bytes

D

i

G 16 bit characteristic polynomial = 1010000000000001 (binary)

shr (x) right shift operator (the LSbit of x is shifted into a carry flag, a '0' is

The CRC algorithm is shown below:

1. FFFF (hex) --> A

2. 0 --> i

3. 0 --> j

4. D

(+) A

i

5. j + 1 --> j

6. shr (A)

7. Is there a carry? No: go to step 8.

8. Is j = 8? No: go to 5.; Yes: continue.

9. i + 1 --> i

10. Is i = N? No: go to 3.; Yes: continue.

11. A --> CRC

16-bit working register; low and high order bytes of A (the 16-bit

high

working register)

i-th data byte (i = 0 to N – 1)

with MSbit dropped and bit order reversed

shifted into the MSbit of x, all other bits are shifted right one

location)

--> A

low

low

Yes: G (+) A --> A and continue.

489

Timing Data packet synchronization is maintained by timing constraints. The receiving

device must measure the time between the reception of characters. If three and one

half character times elapse without a new character or completion of the packet,

then the communication link must be reset (i.e. all slaves start listening for a new

transmission from the master). Thus at 9600 baud a delay of greater than 3.5 × 1/

9600 × 10 = 3.65 ms will cause the communication link to be reset.

Modbus Functions

Supported Functions The following functions are supported by the 489:

• Function Codes 03 and 04: Read Setpoints and Actual Values

• Function Code 05: Execute Operation

• Function Code 06: Store Single Setpoint

• Function Code 07: Read Device Status

• Function Code 08: Loopback Test

• Function Code 16: Store Multiple Setpoints

A detailed explanation of how the 489 implements these function codes is shown in

the following sections.

GE Multilin

http://www.GEindustrial.com/multilin

3

Page 8

Communications Guide

Modbus Functions489

Function Codes 03/04:

Read Setpoints / Actual

Value s

Modbus implementation: Read Input and Holding Registers

489 Implementation: Read Setpoints and Actual Values

For the 489 Modbus implementation, these commands are used to read any setpoint

(‘holding registers’) or actual value (‘input registers’). Holding and input registers

are 16-bit (two byte) values transmitted high order byte first. Thus all 489 setpoints

and actual values are sent as two bytes. The maximum of 125 registers can be read

in one transmission. Function codes 03 and 04 are configured to read setpoints or

actual values interchangeably since some PLCs do not support both function codes.

The slave response to these function codes is the slave address, function code, a

count of the number of data bytes to follow, the data itself and the CRC. Each data

item is sent as a two byte number with the high order byte sent first. The CRC is

sent as a two byte number with the low order byte sent first.

Message Format and Example:

Request slave 11 to respond with 2 registers starting at address 0235. For this

example, the register data in these addresses is:

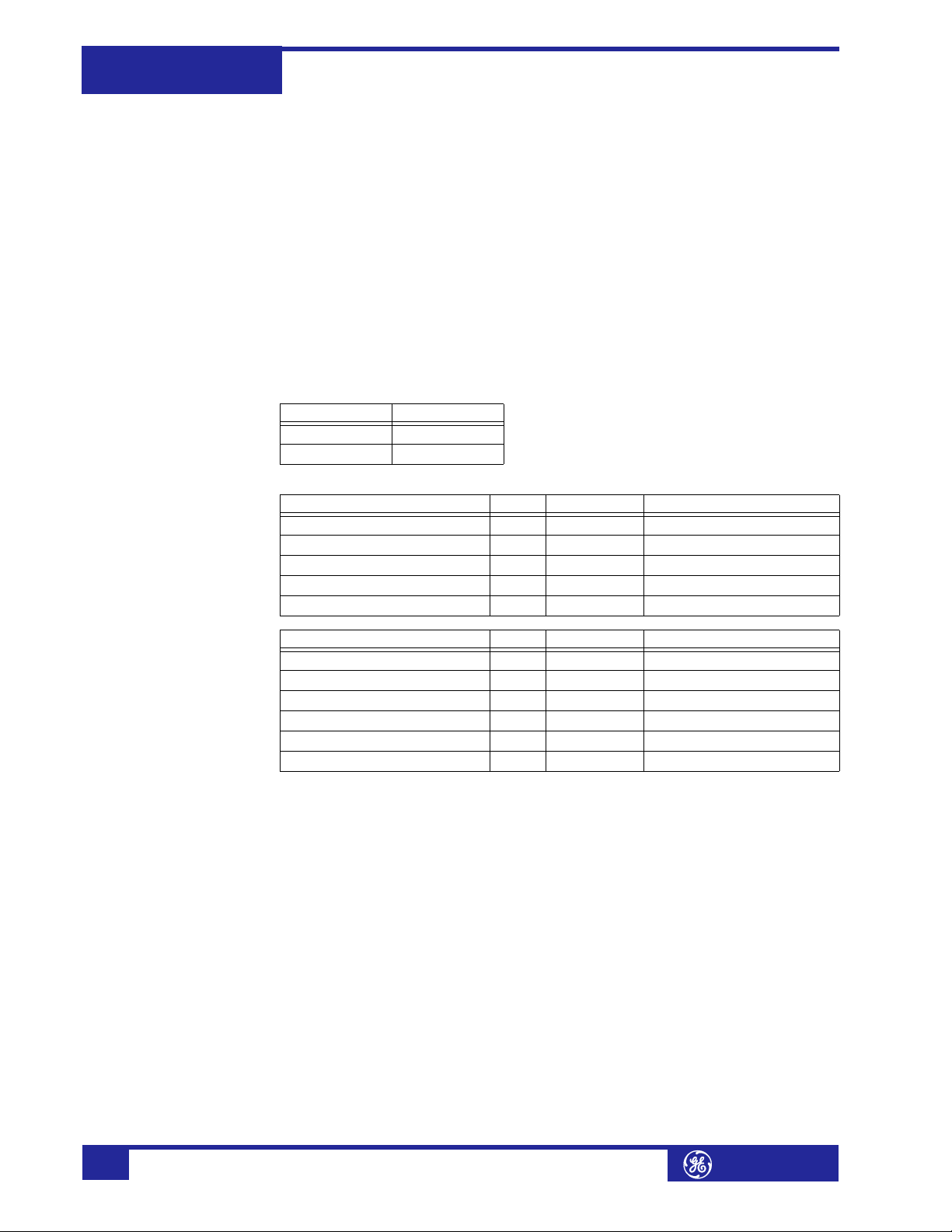

Address Data

0235 0064

0236 000A

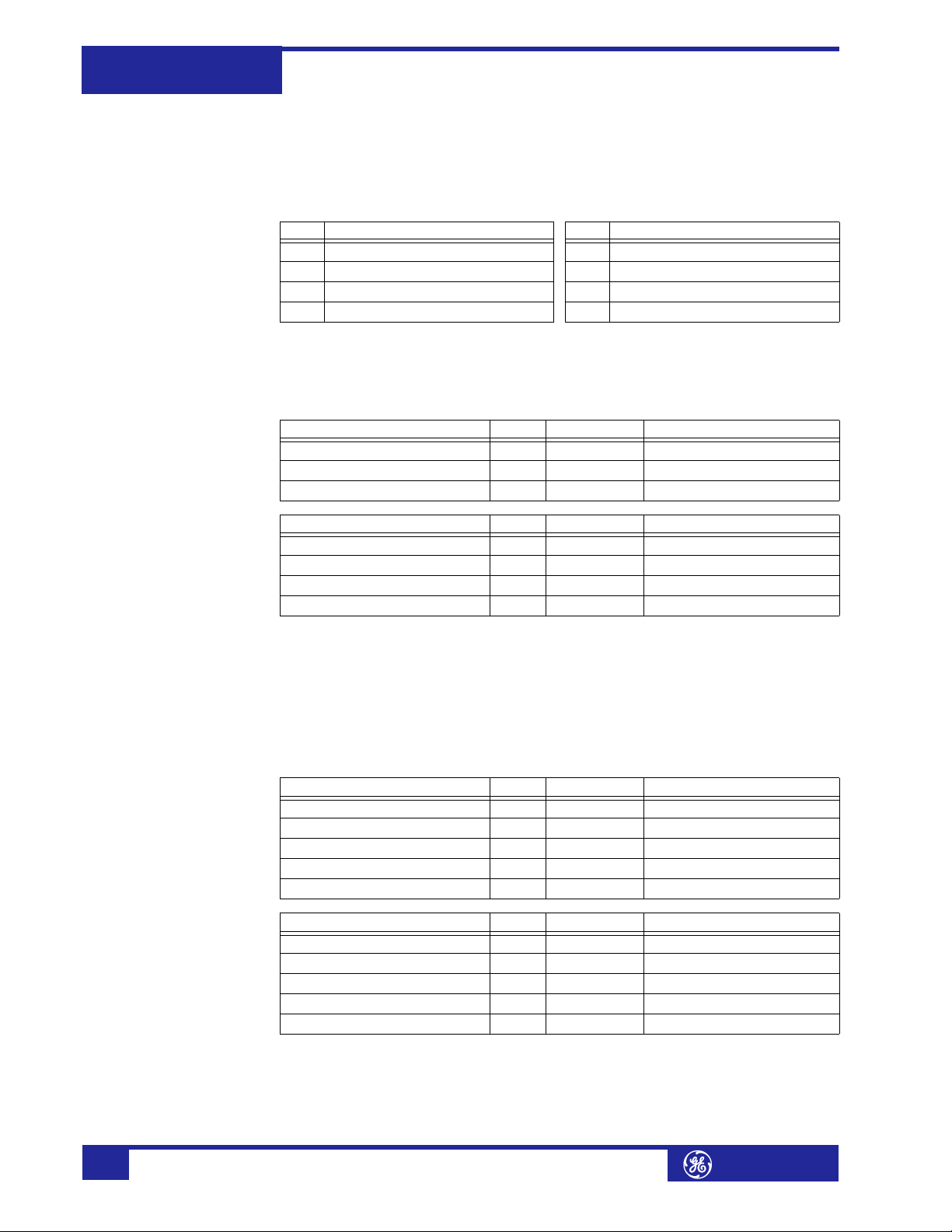

Master Transmission Bytes Example Description

Slave Address 1 0B message for slave 11

Function Code 1 03 read register values

Data Starting Address 2 02 32 data starting at 0235h

Number of Setpoints 2 00 02 2 registers = 4 bytes total

CRC (low, high) 2 D5 17 computed CRC error code

Slave Response Bytes Example Description

Slave Address 1 0B message from slave 11

Function Code 1 03 read register values

Byte Count 1 04 2 registers = 4 bytes total

Data #1 (high, low) 2 00 64 value in address 0235h

Data #2 (high, low) 2 00 0A value in address 0236h

CRC (low, high) 2 EB 91 computed CRC error code

4

http://www.GEindustrial.com/multilin

GE Multilin

Page 9

Modbus Functions

Communications Guide

489

Function Code 05:

Execute Operation

Modbus Implementation: Force Single Coil

489 Implementation: Execute Operation

This function code allows the master to request specific 489 command operations.

The command numbers listed in the Commands area of the memory map

correspond to operation code for function code 05. The operation commands can

also be initiated by writing to the Commands area of the memory map using

function code 16. Refer to Section Function Code 16: Store Multiple Setpoints on

page –7 for complete details.

Supported Operations:Reset 489 (operation code 1); Generator Start (operation

code 2);

Generator Stop (operation code 3); Waveform Trigger (operation code 4)

Message Format and Example:

Reset 489 (operation code 1).

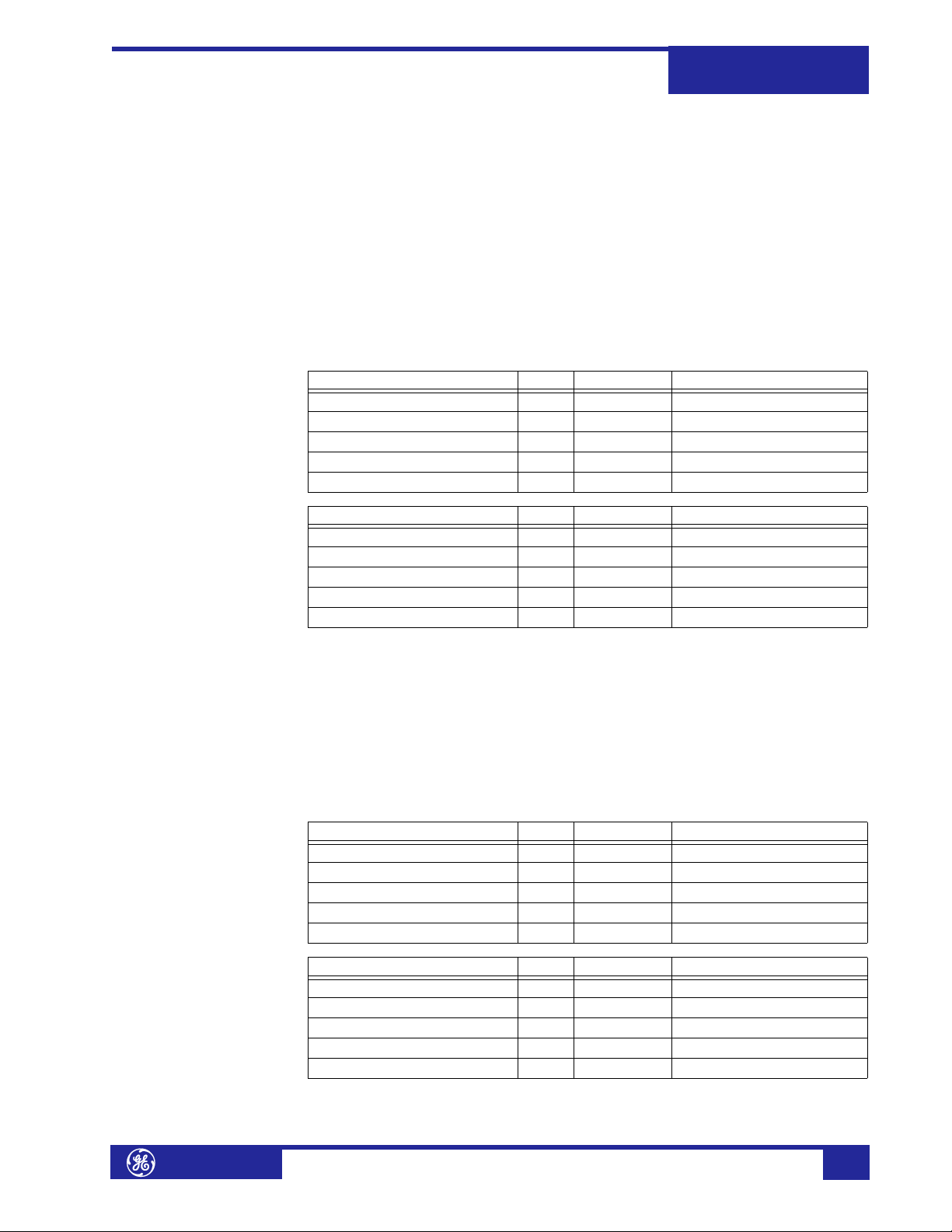

Master Transmission Bytes Example Description

Slave Address 1 0B message for slave 11

Function Code 1 05 execute operation

Operation Code 2 00 01 reset command (op code 1)

Code Value 2 FF 00 perform function

CRC (low, high) 2 DD 50 computed CRC error code

Slave Response Bytes Example Description

Slave Address 1 0B message from slave 11

Function Code 1 05 execute operation

Operation Code 2 00 01 reset command (op code 1)

Code Value 2 FF 00 perform function

CRC (low, high) 2 DD 50 computed CRC error code

Function Code 06: Store

Single Setpoint

Modbus Implementation: Preset Single Register

489 Implementation: Store Single Setpoint

This command allows the master to store a single setpoint into the 489 memory.

The slave response to this function code is to echo the entire master transmission.

Message Format and Example:

Request slave 11 to store the value 01F4 in Setpoint address 1180. After the

transmission in this example is complete, Setpoints address 1180 will contain the

value 01F4.

Master Transmission Bytes Example Description

Slave Address 1 0B message for slave 11

Function Code 1 06 store single setpoint

Data Starting Address 2 11 80 setpoint address 1180h

Data 2 01 F4 data for address 1180h

CRC (low, high) 2 8D A3 computed CRC error code

Slave Response Bytes Example Description

Slave Address 1 0B message from slave 11

Function Code 1 06 store single setpoint

Data Starting Address 2 11 80 setpoint address 1180h

Data 2 01 F4 data for address 1180h

CRC (low, high) 2 8D A3 computed CRC error code

GE Multilin

http://www.GEindustrial.com/multilin

5

Page 10

Communications Guide

Modbus Functions489

Function Code 07: Read

Device Status

Modbus Implementation: Read Exception Status

489 Implementation: Read Device Status

This function reads the selected device status. A short message length allows for

rapid reading of status. The returned status byte has individual bits set to 1 or 0

depending on the slave device status. The 489 general status byte is shown below:

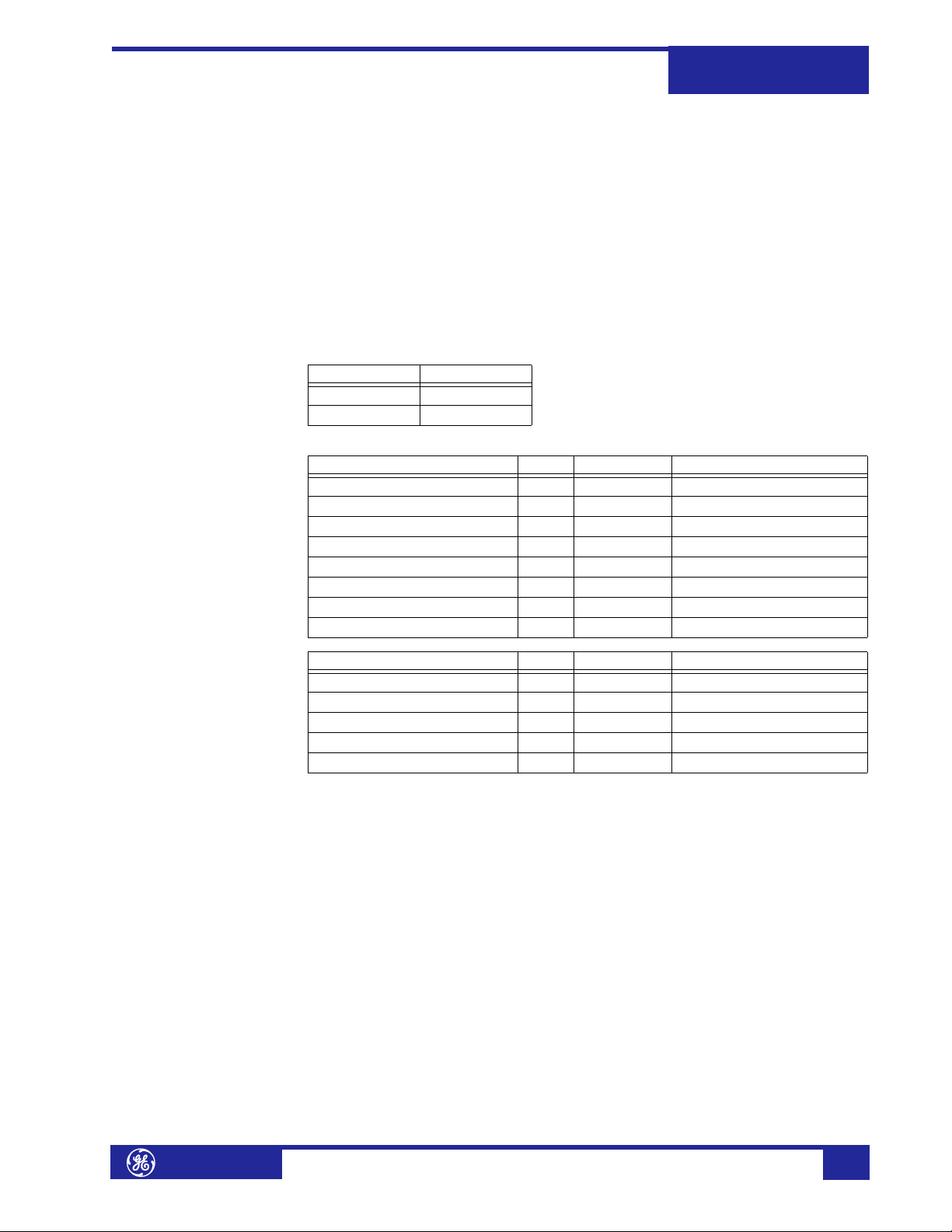

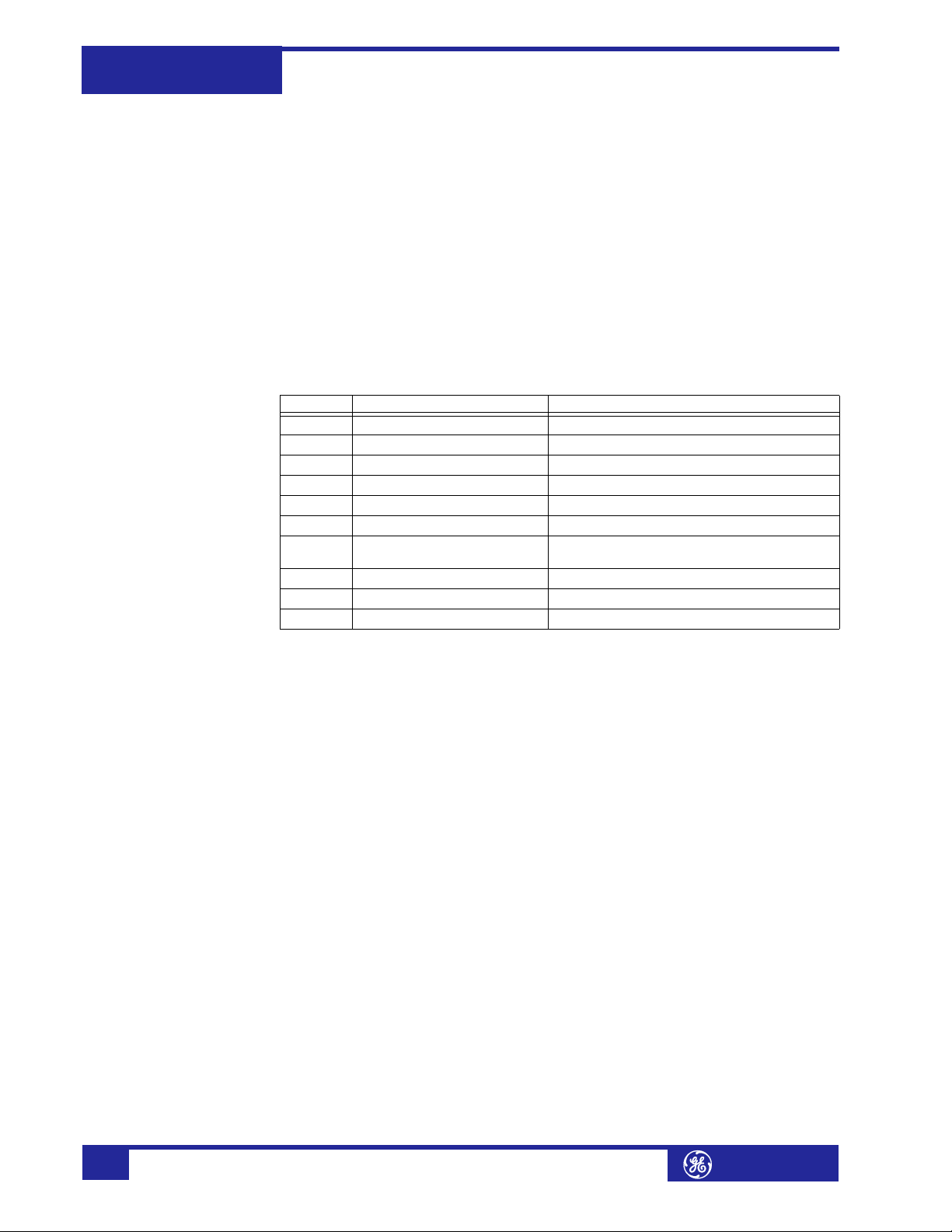

BIT DESCRIPTION BIT DESCRIPTION

B0 1 TRIP relay operated = 1 B4 5 ALARM relay operated = 1

B1 2 AUXILIARY relay operated = 1 B5 6 SERVICE relay operated = 1

B2 3 AUXILIARY relay operated = 1 B6 Stopped = 1

B3 4 AUXILIARY relay operated = 1 B7 Running = 1

Note that if status is neither stopped or running, the generator is starting.

Message Format and Example:

Request status from slave 11.

Master Transmission Bytes Example Description

Slave Address 1 0B message for slave 11

Function Code 1 07 read device status

CRC (low, high) 2 47 42 computed CRC error code

Slave Response Bytes Example Description

Slave Address 1 0B message from slave 11

Function Code 1 07 read device status

Device Status 1 59 status = 01011001b

CRC (low, high) 2 C2 08 computed CRC error code

Function Code 08:

Loopback Test

Modbus Implementation: Loopback Test

489 Implementation: Loopback Test

This function is used to test the integrity of the communication link. The 489 will

echo the request.

Message Format and Example:

Loopback test from slave 11.

Master Transmission Bytes Example Description

Slave Address 1 0B message for slave 11

Function Code 1 08 loopback test

Diagnostic Code 2 00 00 must be 0000h

Data 2 00 00 must be 0000h

CRC (low, high) 2 E0 A1 computed CRC error code

Slave Response Bytes Example Description

Slave Address 1 0B message from slave 11

Function Code 1 08 loopback test

Diagnostic Code 2 00 00 must be 0000h

Data 2 00 00 must be 0000h

CRC (low, high) 2 E0 A1 computed CRC error code

6

http://www.GEindustrial.com/multilin

GE Multilin

Page 11

Modbus Functions

Communications Guide

489

Function Code 16: Store

Multiple Setpoints

Modbus Implementation: Preset Multiple Registers

489 Implementation: Store Multiple Setpoints

This function code allows multiple Setpoints to be stored into the 489 memory.

Modbus “registers” are 16-bit (two byte) values transmitted high order byte first.

Thus all 489 setpoints are sent as two bytes. The maximum number of Setpoints

that can be stored in one transmission is dependent on the slave device. Modbus

allows up to a maximum of 60 holding registers to be stored. The 489 response to

this function code is to echo the slave address, function code, starting address, the

number of Setpoints stored, and the CRC.

Message Format and Example:

Request slave 11 to store the value 01F4 to Setpoint address 1180 and the value

0001 to setpoint address 1181. After the transmission in this example is complete,

489 slave 11 will have the following setpoints information stored:

Address Data

1180 01F4

1181 0001

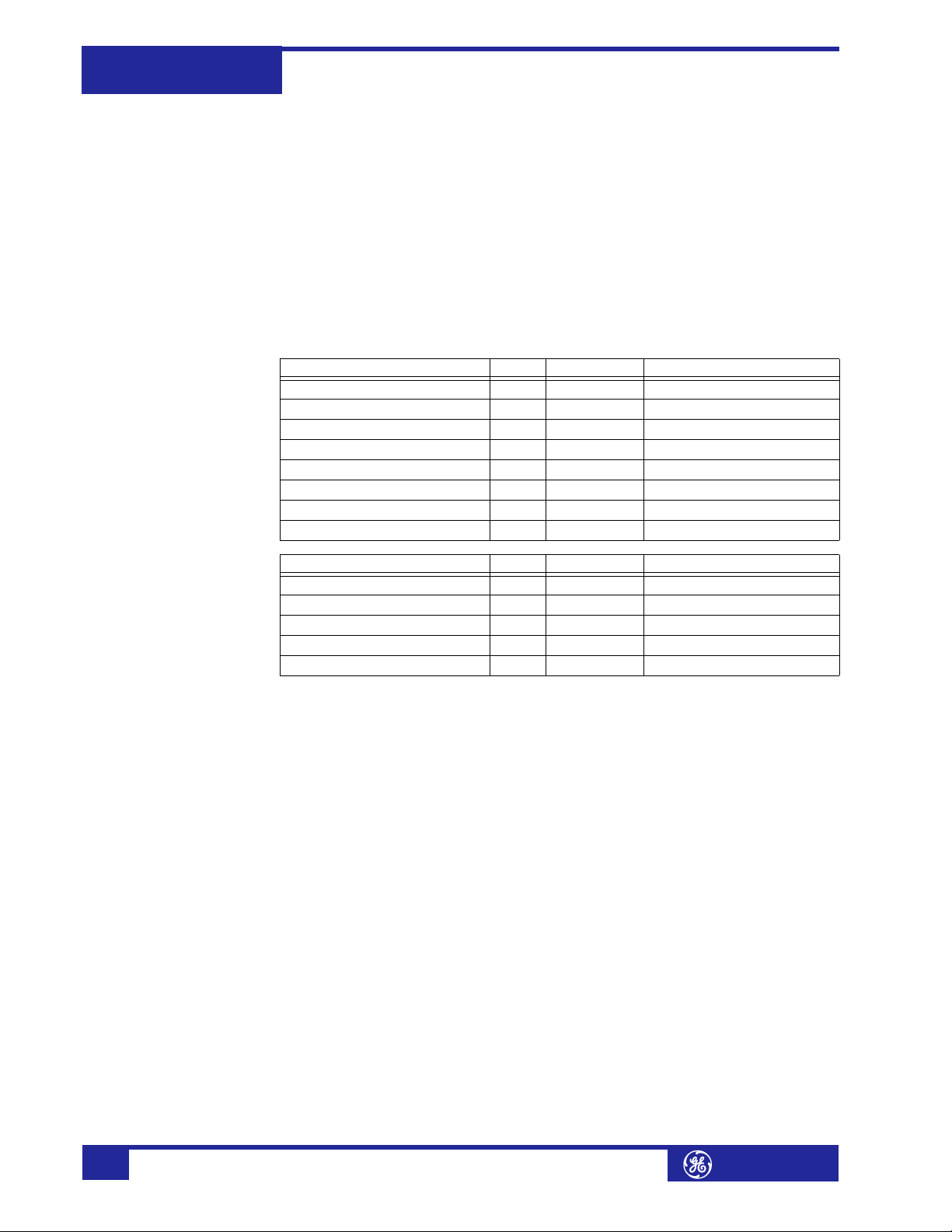

Master Transmission Bytes Example Description

Slave Address 1 0B message for slave 11

Function Code 1 10 store setpoints

Data Starting Address 2 11 80 data starting at 1180h

Number of Setpoints 2 00 02 2 setpoints = 4 bytes total

Byte Count 1 04 2 registers = 4 bytes

Data 1 2 01 F4 data for address 1180h

Data 2 2 00 01 data for address 1181h

CRC (low, high) 2 9B 89 computed CRC error code

Slave Response Bytes Example Description

Slave Address 1 0B message from slave 11

Function Code 1 10 store multiple setpoints

Data Starting Address 2 11 80 data starting at 1180h

Number of Setpoints 2 00 02 2 setpoints (4 bytes total)

CRC (low, high) 2 45 B6 computed CRC error code

GE Multilin

http://www.GEindustrial.com/multilin

7

Page 12

Communications Guide

Modbus Functions489

Function Code 16:

Performing Commands

Some PLCs may not support execution of commands using function code 5 but do

support storing multiple setpoints using function code 16. To perform this operation

using function code 16 (10h), a certain sequence of commands must be written at

the same time to the 489. The sequence consists of: Command Function register,

Command operation register and Command Data (if required). The Command

Function register must be written with the value of 5 indicating an execute operation

is requested. The Command Operation register must then be written with a valid

command operation number from the list of commands shown in the memory map.

The Command Data registers must be written with valid data if the command

operation requires data. The selected command will execute immediately upon

receipt of a valid transmission.

Message Format and Example:

Perform a 489 RESET (operation code 1).

Master Transmission Bytes Example Description

Slave Address 1 0B message for slave 11

Function Code 1 10 store setpoints

Data Starting Address 2 00 80 setpoint address 0080h

Number of Setpoints 2 00 02 2 setpoints = 4 bytes total

Byte Count 1 04 2 registers = 4 bytes

Command Function 2 00 05 data for address 0080h

Command Function 2 00 01 data for address 0081h

CRC (low, high) 2 0B D6 computed CRC error code

Slave Response Bytes Example Description

Slave Address 1 0B message from slave 11

Function Code 1 10 store multiple setpoints

Data Starting Address 2 00 80 setpoint address 0080h

Number of Setpoints 2 00 02 2 setpoints (4 bytes total)

CRC (low, high) 2 40 8A computed CRC error code

Error Responses When a 489 detects an error other than a CRC error, a response will be sent to the

master. The MSbit of the Function Code byte will be set to 1 (i.e. the function code

sent from the slave will be equal to the function code sent from the master plus

128). The following byte will be an exception code indicating the type of error that

occurred.

Transmissions received from the master with CRC errors will be ignored by the 489.

The slave response to an error (other than CRC error) will be:

• SLAVE ADDRESS: 1 byte

• FUNCTION CODE: 1 byte (with MSbit set to 1)

•EXCEPTION CODE: 1 byte

•CRC: 2 bytes

The 489 implements the following exception response codes.

01: ILLEGAL FUNCTION

The function code transmitted is not one of the functions supported by the 489.

02: ILLEGAL DATA ADDRESS

The address referenced in the data field transmitted by the master is not an

allowable address for the 489.

03: ILLEGAL DATA VALUE

The value referenced in the data field transmitted by the master is not within range

for the selected data address.

8

http://www.GEindustrial.com/multilin

GE Multilin

Page 13

Modbus Memory Map

Communications Guide

489

Modbus Memory Map

Memory Map

Information

NOTE

User-Definable

Memory Map Area

The data stored in the 489 is grouped as Setpoints and Actual Values. Setpoints can

be read and written by a master computer. Actual Values are read only. All Setpoints

and Actual Values are stored as two byte values. That is, each register address is

the address of a two-byte value. Addresses are listed in hexadecimal. Data values

(Setpoint ranges, increments, and factory values) are in decimal.

Many Modbus communications drivers add 40001d to the actual address of the

register addresses. For example: if address 0h was to be read, 40001d would be the

address required by the Modbus communications driver; if address 320h (800d) was

to be read, 40801d would be the address required by the Modbus communications

driver.

The 489 contains a User Definable area in the memory map. This area allows

remapping of the addresses of all Actual Values and Setpoints registers. The User

Definable area has two sections:

1. A Register Index area (memory map addresses 0180h to 01FCh) that contains

125 Actual Values or Setpoints register addresses.

2. A Register area (memory map addresses 0100h to 017Ch) that contains the

data at the addresses in the Register Index.

Register data that is separated in the rest of the memory map may be remapped to

adjacent register addresses in the User Definable Registers area. This is

accomplished by writing to register addresses in the User Definable Register Index

area. This allows for improved throughput of data and can eliminate the need for

multiple read command sequences.

For example, if the values of Average Phase Current (register addresses 0412h and

0413h) and Hottest Stator RTD Temperature (register address 04A0h) are required

to be read from an 489, their addresses may be remapped as follows:

1. Write 0412h to address 0180h (User Definable Register Index 0000) using func-

tion code 06 or 16.

2. Write 0413h to address 0181h (User Definable Register Index 0001) using func-

tion code 06 or 16.

(Average Phase Current is a double register number)

3. Write 04A0h to address 0182h (User Definable Register Index 0001) using func-

tion code 06 or 16.

A read (function code 03 or 04) of registers 0100h (User Definable Register 0000)

and 0101h (User Definable Register 0001) will return the Average Phase Current

and register 0102h (User Definable Register 0002) will return the Hottest Stator

RTD Temperature.

Event Recorder The 489 event recorder data starts at address 3000h. Address 3003h is the ID

number of the event of interest (a high number representing the latest event and a

low number representing the oldest event). Event numbers start at zero each time

the event record is cleared, and count upwards. To retrieve event 1, write ‘1’ to the

Event Record Selector (3003h) and read the data from 3004h to 30E7h. To retrieve

event 2, write ‘2’ to the Event Record Selector (3003h) and read the data from

3004h to 30E7h. All 40 events may be retrieved in this manner. The time and date

stamp of each event may be used to ensure that all events have been retrieved in

order without new events corrupting the sequence of events (event 0 should be less

recent than event 1, event 1 should be less recent than event 2, etc.).

If more than 40 events have been recorded since the last time the event record was

cleared, the earliest events will not be accessible. For example, if 100 events have

been recorded (i.e., the total events since last clear in register 3002h is 100),

events 60 through 99 may be retrieved. Writing any other value to the event record

selector (register 3003h) will result in an “invalid data value” error.

GE Multilin

http://www.GEindustrial.com/multilin

9

Page 14

Modbus Memory Map489

Communications Guide

Each communications port can individually select the ID number of the event of

interest by writing address 3003h. This way the front port, rear port and auxiliary

port can read different events from the event recorder simultaneously.

Waveform Capture The 489 stores up to 64 cycles of A/D samples in a waveform capture buffer each

time a trip occurs. The waveform capture buffer is time and date stamped and may

therefore be correlated to a trip in the event record. To access the waveform capture

memory, select the channel of interest by writing the number to the Waveform

Capture Channel Selector (30F5h). Then read the waveform capture data from

address 3100h-31BFh, and read the date, time and line frequency from addresses

30F0h-30F4h.

Each communications port can individually select a Waveform Channel Selector of

interest by writing address 30F5h. This way the front port, rear port and auxiliary

port can read different Waveform Channels simultaneously.

The channel selector must be one of the following values:

VALUE SELECTED A/D SAMPLES SCALE FACTOR

0 Phase A line current 500 counts equals 1 × CT primary

1 Phase B line current 500 counts equals 1 × CT primary

2 Phase C line current 500 counts equals 1 × CT primary

3 Neutral-End phase A current 500 counts equals 1 × CT primary

4 Neutral-End phase B current 500 counts equals 1 × CT primary

5 Neutral-End phase C current 500 counts equals 1 × CT primary

6 Ground current 500 counts equals 1 × CT primary

7 Phase A to neutral voltage 2500 counts equals 120 secondary volts

8 Phase B to neutral voltage 2500 counts equals 120 secondary volts

9 Phase C to neutral voltage 2500 counts equals 120 secondary volts

or 1A for 50:0.025

Dual Setpoints Each communications port can individually select an Edit Setpoint Group of interest

by writing address 1342h. This way the front port, rear port and auxiliary port can

read and alter different setpoints simultaneously.

Passcode Operation Each communications port can individually set the Passcode Access by writing

address 88h with the correct Passcode. This way the front port, rear port and

auxiliary port have individual access to the setpoints. Reading address 0203h,

COMMUNICATIONS SETPOINT ACCESS register, provides the user with the current state

of access for the given port. A value of 1 read from this register indicates that the

user has full access rights to changing setpoints from the given port.

10

http://www.GEindustrial.com/multilin

GE Multilin

Page 15

Modbus Memory Map

Communications Guide

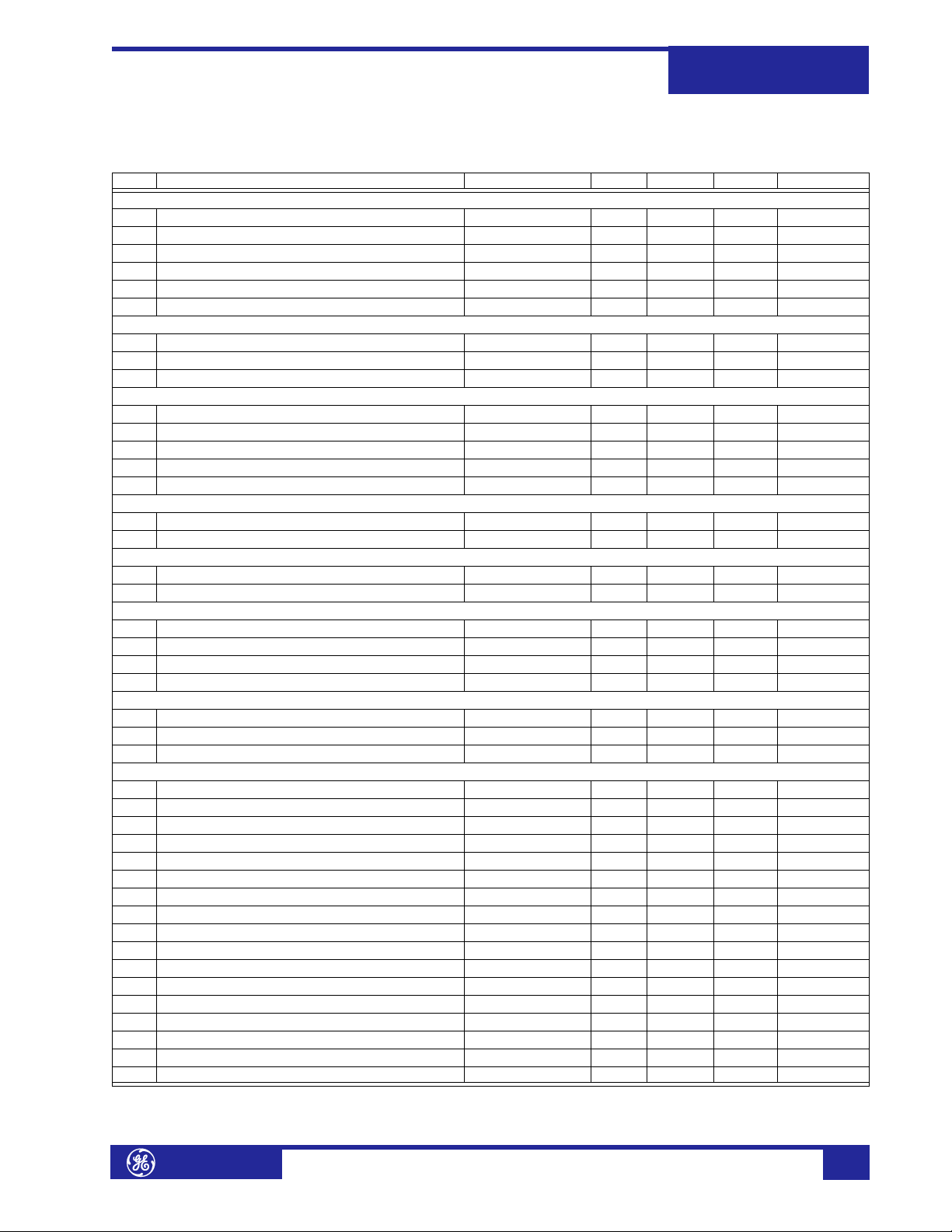

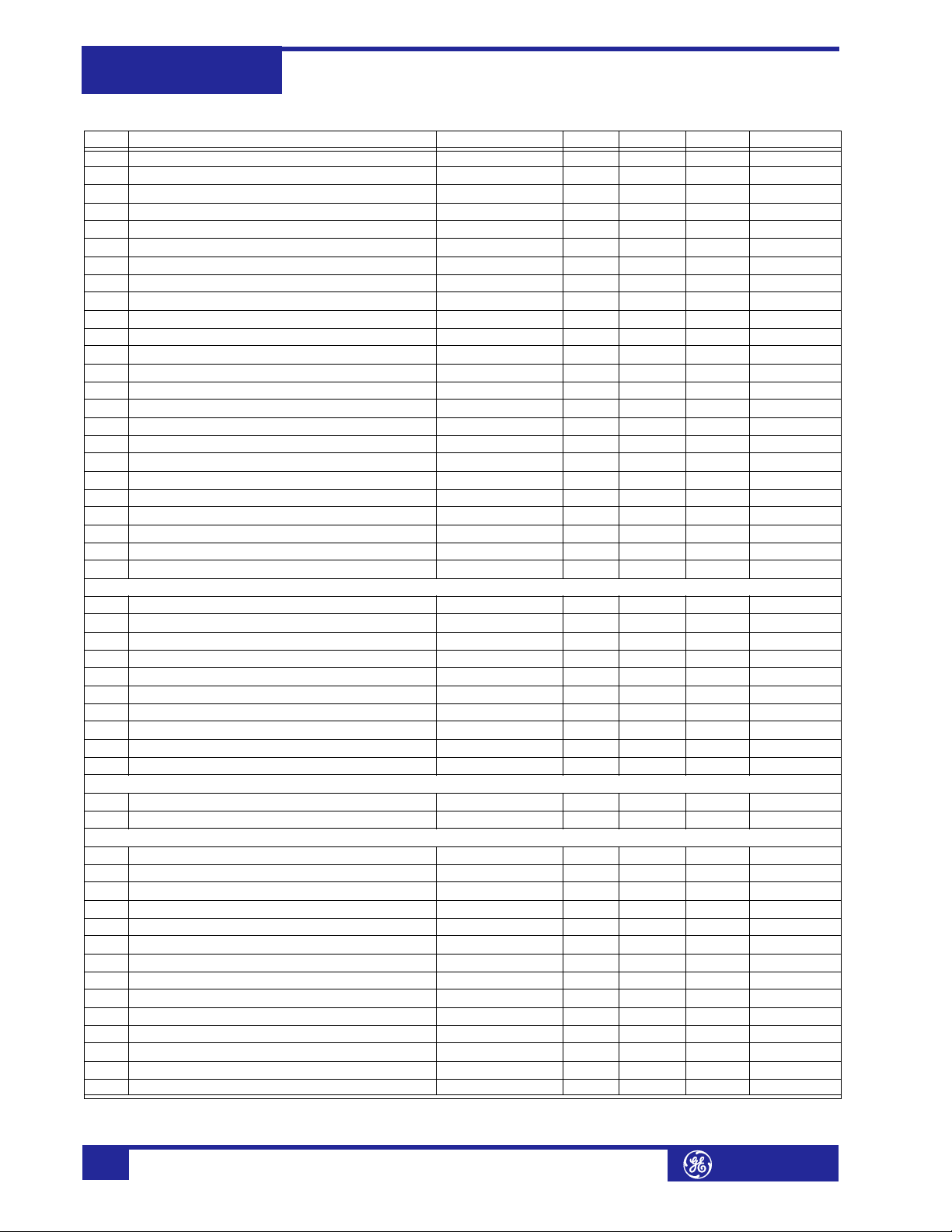

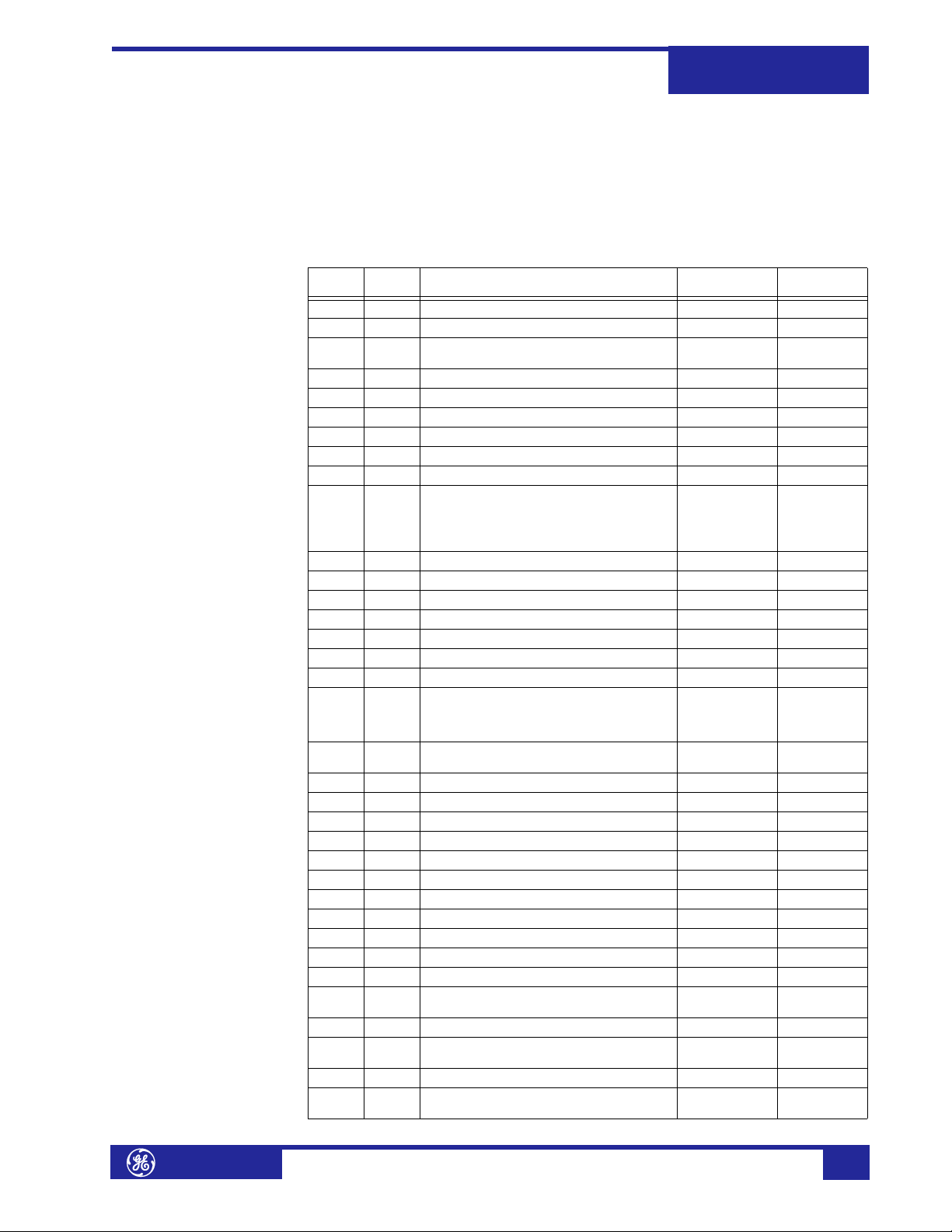

489 Memory Map The 489 memory map is shown in the following table.

Table 1: 489 Memory Map (Sheet 1 of 29)

ADDR NAME RANGE STEP UNITS FORMAT DEFAULT

PRODUCT ID

0000 GE Multilin Product Device Code N/A N/A N/A F1 32

0001 Product Hardware Revision 1 to 26 1 N/A F15 N/A

0002 Product Software Revision N/A N/A N/A F16 N/A

0003 Product Modification Number 0 to 999 1 N/A F1 N/A

0010 Boot Program Revision N/A N/A N/A F16 N/A

0011 Boot Program Modification Number 0 to 999 1 N/A F1 N/A

MODEL ID

0040 Order Code 0 to 16 1 N/A F22 N/A

0050 489 Revision 12 1 N/A F22 N/A

0060 489 Boot Revision 12 1 N/A F22 N/A

COMMANDS

0080 Command Function Code (always 5) 5 N/A N/A F1 N/A

0081 Command Operation Code 0 to 65535 1 N/A F1 N/A

0088 Communications Port Passcode 0 to 99999999 1 N/A F12 0

00F0 Time (Broadcast) N/A N/A N/A F24 N/A

00F2 Date (Broadcast) N/A N/A N/A F18 N/A

USER_MAP / USER MAP VALUES

0100 User Map Value #1 of 125... 5 N/A N/A F1 N/A

017C User Map Value #125 of 125 5 N/A N/A F1 N/A

USER_MAP / USER MAP ADDRESSES

0180 User Map Address #1 of 125... 0 to 3FFF 1 hex F1 0

01FC User Map Address #125 of 125 0 to 3FFF 1 hex F1 0

STATUS / GENERATOR STATUS

0200 Generator Status 0 to 4 1 – F133 1

0201 Generator Thermal Capacity Used 0 to 100 1 % F1 0

0202 Estimated Trip Time On Overload 0 to 65535

0203 Communications Setpoint Access 0 to 1 N/A N/A F126 N/A

STATUS / SYSTEM STATUS

0210 General Status 0 to 65535 1 N/A F140 0

0211 Output Relay Status 0 to 63 1 N/A F141 0

0212 Active Setpoint Group 0 to 1 1 N/A F118 0

STATUS / LAST TRIP DATA

0220 Cause of Last Trip 0 to 139 1 – F134 0

0221 Time of Last Trip N/A N/A N/A F19 N/A

0223 Date of Last Trip N/A N/A N/A F18 N/A

0225 Tachometer Pretrip 0 to 7200 1 RPM F1 0

0226 Phase A Pre-Trip Current 0 to 999999 1 Amps F12 0

0228 Phase B Pre-Trip Current 0 to 999999 1 Amps F12 0

022A Phase C Pre-Trip Current 0 to 999999 1 Amps F12 0

022C Phase A Pre-Trip Differential Current 0 to 999999 1 Amps F12 0

022E Phase B Pre-Trip Differential Current 0 to 999999 1 Amps F12 0

0230 Phase C Pre-Trip Differential Current 0 to 999999 1 Amps F12 0

0232 Negative Sequence Current Pretrip 0 to 2000 1 % FLA F1 0

0233 Ground Current Pretrip 0 to 20000000 1 A F14 0

0235 Pre-Trip A-B Voltage 0 to 50000 1 Volts F1 0

0236 Pre-Trip B-C Voltage 0 to 50000 1 Volts F1 0

0237 Pre-Trip C-A Voltage 0 to 50000 1 Volts F1 0

0238 Frequency Pretrip 0 to 12000 1 Hz F3 0

023B Real Power (MW) Pretrip –2000000 to 2000000 1 MW F13 0

1, 2, 3 See Table footnotes on page 39

1

1sF12 –1

489

GE Multilin

http://www.GEindustrial.com/multilin

11

Page 16

Modbus Memory Map489

Communications Guide

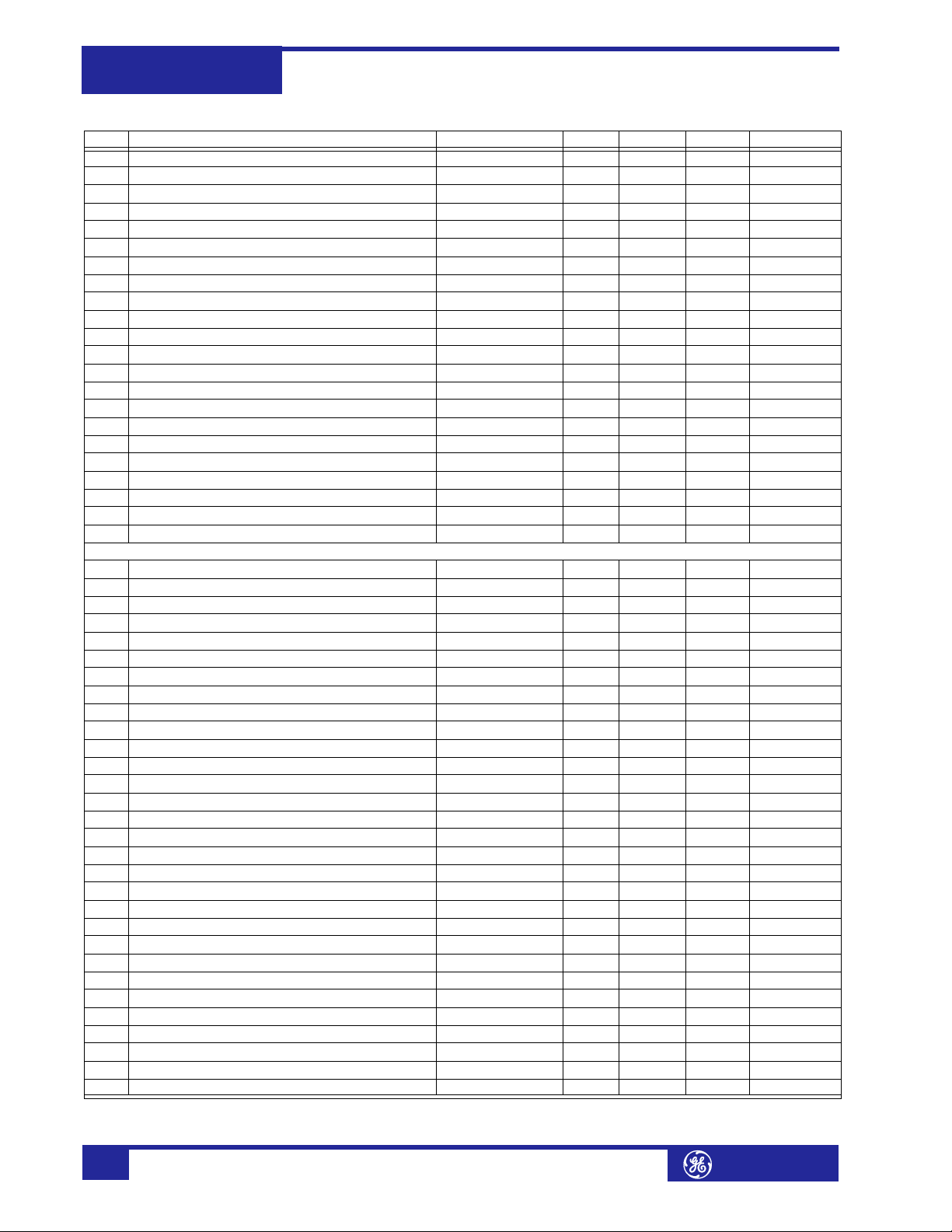

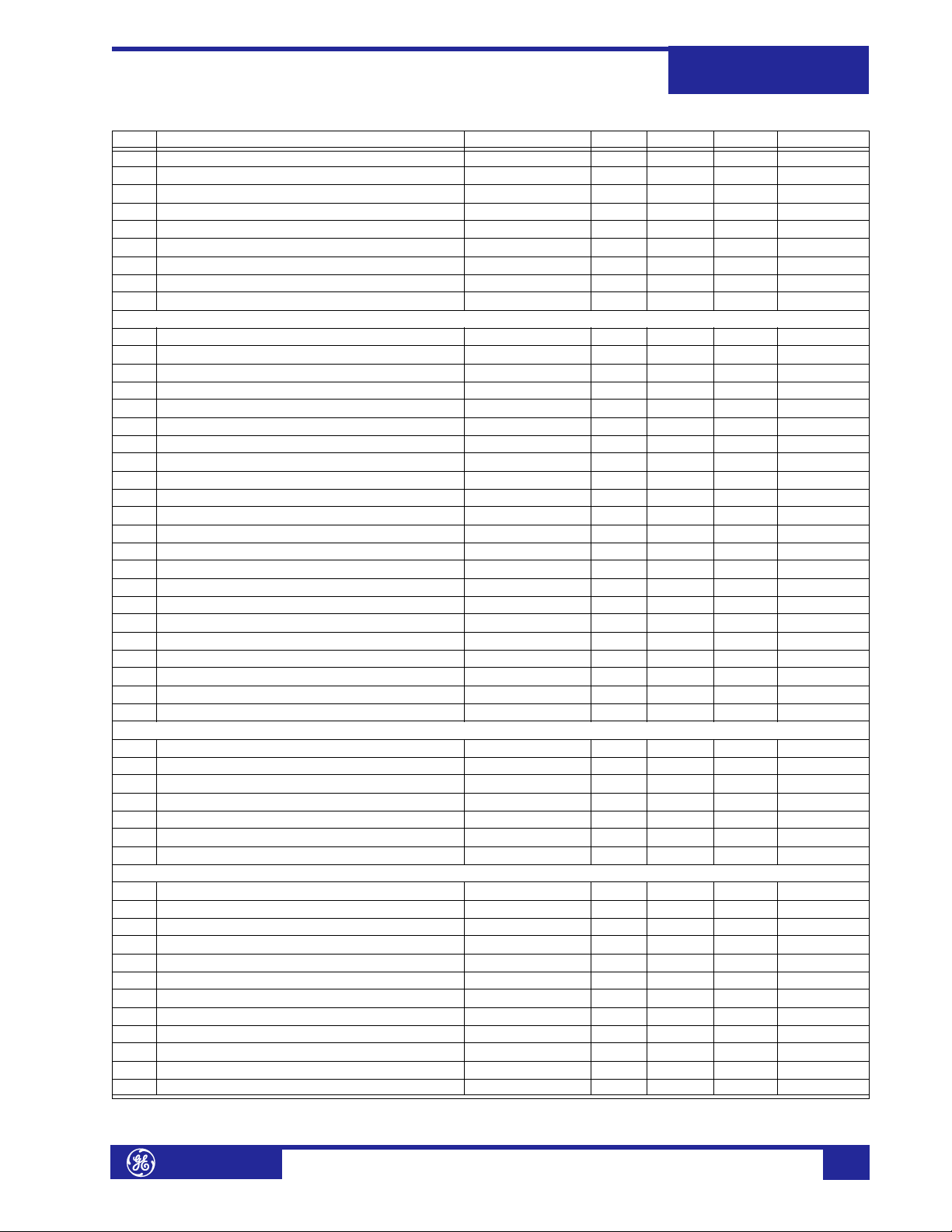

Table 1: 489 Memory Map (Sheet 2 of 29)

ADDR NAME RANGE STEP UNITS FORMAT DEFAULT

023D Reactive Power Mvar Pretrip –2000000 to 2000000 1 Mvar F13 0

023F Apparent Power MVA Pretrip 0 to 2000000 1 MVA F13 0

0241 Last Trip Data Stator RTD 1 to 12 1 – F1 1

0242 Hottest Stator RTD Temperature –50 to 250 1 °C F4 0

0243 Last Trip Data Bearing RTD 1 to 12 1 – F1 1

0244 Hottest Bearing RTD Temperature –50 to 250 1 °C F4 0

0245 Last Trip Data Other RTD 1 to 12 1 – F1 1

0246 Hottest Other RTD Temperature –50 to 250 1 °C F4 0

0247 Last Trip Data Ambient RTD 1 to 12 1 – F1 1

0248 Hottest Ambient RTD Temperature –50 to 250 1 °C F4 0

0249 Analog Input 1 Pretrip –50000 to 50000 1 Units F12 0

024B Analog Input 2 Pretrip –50000 to 50000 1 Units F12 0

024D Analog Input 3 Pretrip –50000 to 50000 1 Units F12 0

024F Analog Input 4 Pretrip –50000 to 50000 1 Units F12 0

025C Hottest Stator RTD Temperature –50 to 250 1 °F F4 0

025D Hottest Bearing RTD Temperature –50 to 250 1 °F F4 0

025E Hottest Other RTD Temperature –50 to 250 1 °F F4 0

025F Hottest Ambient RTD Temperature –50 to 250 1 °F F4 0

0260 Neutral Voltage Fundamental Pretrip 0 to 250000 1 Volts F10 0

0262 Neutral Voltage 3rd Harmonic Pretrip 0 to 250000 1 Volts F10 0

0264 Pre-Trip Vab/Iab 0 to 65535 1 ohms s F2 0

0265 Pre-Trip Vab/Iab Angle 0 to 359 1 ° F1 0

STATUS / TRIP PICKUPS

0280 Input A Pickup 0 to 4 1 – F123 0

0281 Input B Pickup 0 to 4 1 – F123 0

0282 Input C Pickup 0 to 4 1 – F123 0

0283 Input D Pickup 0 to 4 1 – F123 0

0284 Input E Pickup 0 to 4 1 – F123 0

0285 Input F Pickup 0 to 4 1 – F123 0

0286 Input G Pickup 0 to 4 1 – F123 0

0287 Sequential Trip Pickup 0 to 4 1 – F123 0

0288 Field-Breaker Discrepancy Pickup 0 to 4 1 – F123 0

0289 Tachometer Pickup 0 to 4 1 – F123 0

028A Offline Overcurrent Pickup 0 to 4 1 – F123 0

028B Inadvertent Energization Pickup 0 to 4 1 – F123 0

028C Phase Overcurrent Pickup 0 to 4 1 – F123 0

028D Negative Sequence Overcurrent Pickup 0 to 4 1 – F123 0

028E Ground Overcurrent Pickup 0 to 4 1 – F123 0

028F Phase Differential Pickup 0 to 4 1 – F123 0

0290 Undervoltage Pickup 0 to 4 1 – F123 0

0291 Overvoltage Pickup 0 to 4 1 – F123 0

0292 Volts/Hertz Pickup 0 to 4 1 – F123 0

0293 Phase Reversal Pickup 0 to 4 1 – F123 0

0294 Underfrequency Pickup 0 to 4 1 – F123 0

0295 Overfrequency Pickup 0 to 4 1 – F123 0

0296 Neutral Overvoltage (Fundamental) Pickup 0 to 4 1 – F123 0

0297 Neutral Undervoltage (3rd Harmonic) Pickup 0 to 4 1 – F123 0

0298 Reactive Power Pickup 0 to 4 1 – F123 0

0299 Reverse Power Pickup 0 to 4 1 – F123 0

029A Low Forward Power Pickup 0 to 4 1 – F123 0

029B Thermal Model Pickup 0 to 4 1 – F123 0

029C RTD #1 Pickup 0 to 4 1 – F123 0

029D RTD #2 Pickup 0 to 4 1 – F123 0

1, 2, 3 See Table footnotes on page 39

12

http://www.GEindustrial.com/multilin

GE Multilin

Page 17

Modbus Memory Map

Communications Guide

Table 1: 489 Memory Map (Sheet 3 of 29)

ADDR NAME RANGE STEP UNITS FORMAT DEFAULT

029E RTD #3 Pickup 0 to 4 1 – F123 0

029F RTD #4 Pickup 0 to 4 1 – F123 0

02A0 RTD #5 Pickup 0 to 4 1 – F123 0

02A1 RTD #6 Pickup 0 to 4 1 – F123 0

02A2 RTD #7 Pickup 0 to 4 1 – F123 0

02A3 RTD #8 Pickup 0 to 4 1 – F123 0

02A4 RTD #9 Pickup 0 to 4 1 – F123 0

02A5 RTD #10 Pickup 0 to 4 1 – F123 0

02A6 RTD #11 Pickup 0 to 4 1 – F123 0

02A7 RTD #12 Pickup 0 to 4 1 – F123 0

02A8 Analog Input 1 Pickup 0 to 4 1 – F123 0

02A9 Analog Input 2 Pickup 0 to 4 1 – F123 0

02AA Analog Input 3 Pickup 0 to 4 1 – F123 0

02AB Analog Input 4 Pickup 0 to 4 1 – F123 0

02AC Loss Of Excitation 1 Pickup 0 to 4 1 – F123 0

02AD Loss Of Excitation 2 Pickup 0 to 4 1 – F123 0

02AE Ground Directional Pickup 0 to 4 1 – F123 0

02AF High-Set Phase Overcurrent Pickup 0 to 4 1 – F123 0

02B0 Distance Zone 1 Pickup 0 to 4 1 – F123 0

02B1 Distance Zone 2 Pickup 0 to 4 1 – F123 0

STATUS / ALARM PICKUPS

0300 Input A Pickup 0 to 4 1 – F123 0

0301 Input B Pickup 0 to 4 1 – F123 0

0302 Input C Pickup 0 to 4 1 – F123 0

0303 Input D Pickup 0 to 4 1 – F123 0

0304 Input E Pickup 0 to 4 1 – F123 0

0305 Input F Pickup 0 to 4 1 – F123 0

0306 Input G Pickup 0 to 4 1 – F123 0

0307 Tachometer Pickup 0 to 4 1 – F123 0

0308 Overcurrent Pickup 0 to 4 1 – F123 0

0309 Negative Sequence Overcurrent Pickup 0 to 4 1 – F123 0

030A Ground Overcurrent Pickup 0 to 4 1 – F123 0

030B Undervoltage Pickup 0 to 4 1 – F123 0

030C Overvoltage Pickup 0 to 4 1 – F123 0

030D Volts/Hertz Pickup 0 to 4 1 – F123 0

030E Underfrequency Pickup 0 to 4 1 – F123 0

030F Overfrequency Pickup 0 to 4 1 – F123 0

0310 Neutral Overvoltage (Fundamental) Pickup 0 to 4 1 – F123 0

0311 Neutral Undervoltage (3rd harmonic) Pickup 0 to 4 1 – F123 0

0312 Reactive Power Pickup 0 to 4 1 – F123 0

0313 Reverse Power Pickup 0 to 4 1 – F123 0

0314 Low Forward Power Pickup 0 to 4 1 – F123 0

0315 RTD #1 Pickup 0 to 4 1 – F123 0

0316 RTD #2 Pickup 0 to 4 1 – F123 0

0317 RTD #3 Pickup 0 to 4 1 – F123 0

0318 RTD #4 Pickup 0 to 4 1 – F123 0

0319 RTD #5 Pickup 0 to 4 1 – F123 0

031A RTD #6 Pickup 0 to 4 1 – F123 0

031B RTD #7 Pickup 0 to 4 1 – F123 0

031C RTD #8 Pickup 0 to 4 1 – F123 0

031D RTD #9 Pickup 0 to 4 1 – F123 0

031E RTD #10 Pickup 0 to 4 1 – F123 0

031F RTD #11 Pickup 0 to 4 1 – F123 0

1, 2, 3 See Table footnotes on page 39

489

GE Multilin

http://www.GEindustrial.com/multilin

13

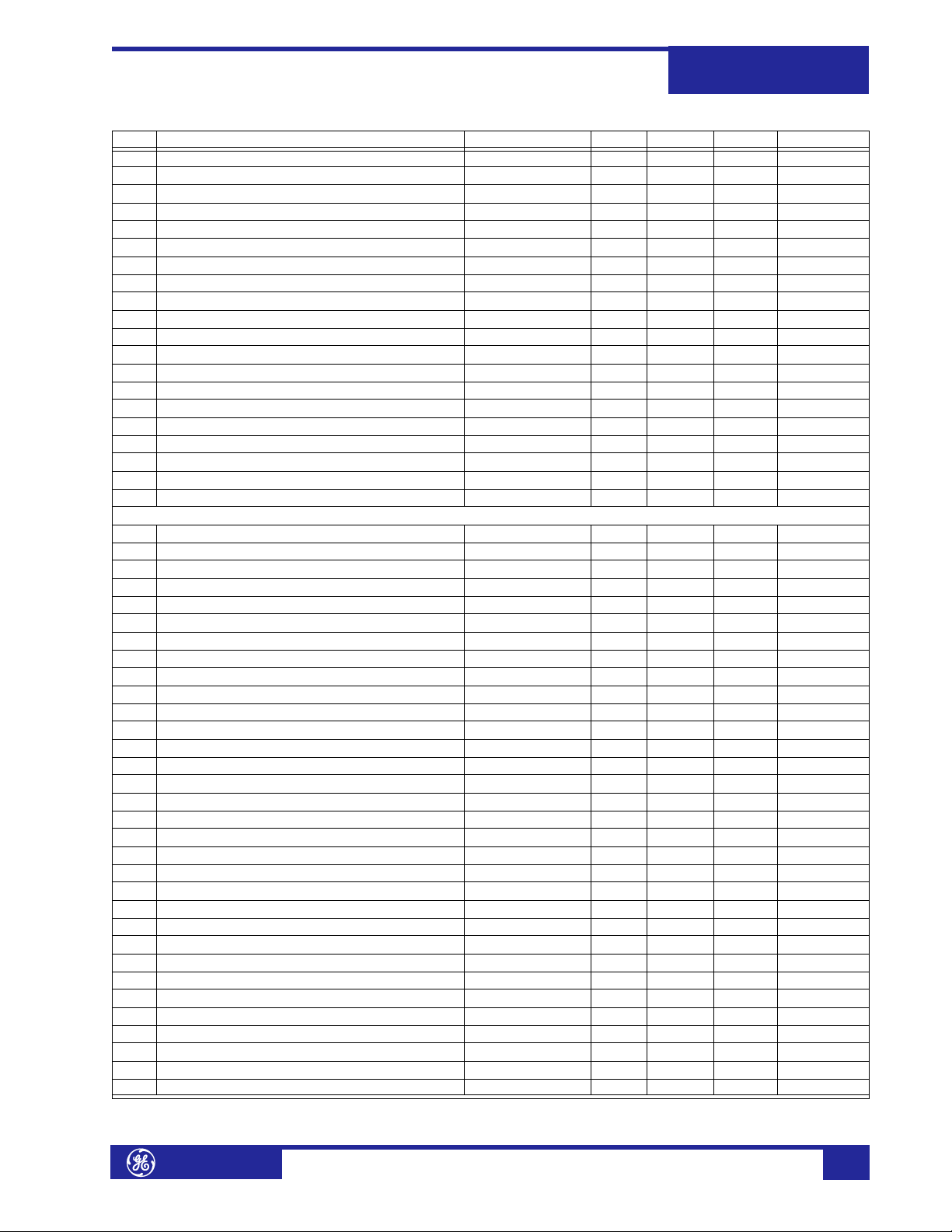

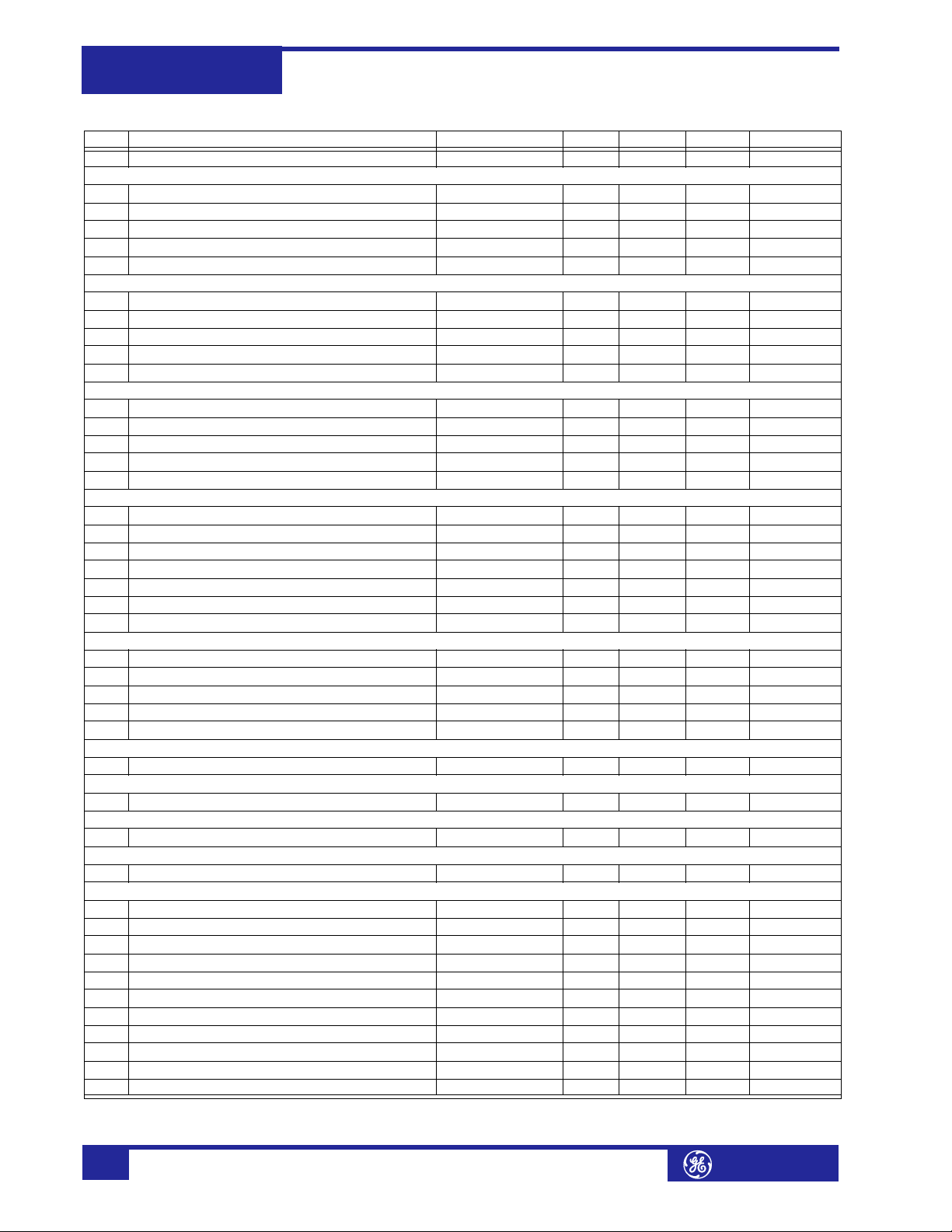

Page 18

Modbus Memory Map489

Communications Guide

Table 1: 489 Memory Map (Sheet 4 of 29)

ADDR NAME RANGE STEP UNITS FORMAT DEFAULT

0320 RTD #12 Pickup 0 to 4 1 – F123 0

0321 Open Sensor Pickup 0 to 4 1 – F123 0

0322 Short/Low Temperature Pickup 0 to 4 1 – F123 0

0323 Thermal Model Pickup 0 to 4 1 – F123 0

0324 Trip Counter Pickup 0 to 4 1 – F123 0

0325 Breaker Failure Pickup 0 to 4 1 – F123 0

0326 Trip Coil Monitor Pickup 0 to 4 1 – F123 0

0327 VT Fuse Failure Pickup 0 to 4 1 – F123 0

0328 Current Demand Pickup 0 to 4 1 – F123 0

0329 MW Demand Pickup 0 to 4 1 – F123 0

032A Mvar Demand Pickup 0 to 4 1 – F123 0

032B MVA Demand Pickup 0 to 4 1 – F123 0

032C Analog Input 1 Pickup 0 to 4 1 – F123 0

032D Analog Input 2 Pickup 0 to 4 1 – F123 0

032E Analog Input 3 Pickup 0 to 4 1 – F123 0

032F Analog Input 4 Pickup 0 to 4 1 – F123 0

0330 Not Programmed Pickup 0 to 4 1 – F123 0

0331 Simulation Mode Pickup 0 to 4 1 – F123 0

0332 Output Relays Forced Pickup 0 to 4 1 – F123 0

0333 Analog Output Forced Pickup 0 to 4 1 – F123 0

0334 Test Switch Shorted Pickup 0 to 4 1 – F123 0

0335 Ground Directional Pickup 0 to 4 1 – F123 0

0336 IRIG-B Alarm Pickup 0 to 4 1 – F123 0

0337 Generator Running Hour Pickup 0 to 4 1 – F123 0

STATUS / DIGITAL INPUTS

0380 Access Switch State 0 to 1 1 – F207 0

0381 Breaker Status Switch State 0 to 1 1 – F207 0

0382 Assignable Digital Input 1 State 0 to 1 1 – F207 0

0383 Assignable Digital Input 2 State 0 to 1 1 – F207 0

0384 Assignable Digital Input 3 State 0 to 1 1 – F207 0

0385 Assignable Digital Input 4 State 0 to 1 1 – F207 0

0386 Assignable Digital Input 5 State 0 to 1 1 – F207 0

0387 Assignable Digital Input 6 State 0 to 1 1 – F207 0

0388 Assignable Digital Input 7 State 0 to 1 1 – F207 0

0389 Trip Coil Supervision 0 to 1 1 – F132 0

STATUS / REAL TIME CLOCK

03FC Date (Read-only) N/A N/A N/A F18 N/A

03FE Time (Read-only) N/A N/A N/A F19 N/A

METERING DATA / CURRENT METERING

0400 Phase A Output Current 0 to 999999 1 Amps F12 0

0402 Phase B Output Current 0 to 999999 1 Amps F12 0

0404 Phase C Output Current 0 to 999999 1 Amps F12 0

0406 Phase A Neutral-Side Current 0 to 999999 1 Amps F12 0

0408 Phase B Neutral-Side Current 0 to 999999 1 Amps F12 0

040A Phase C Neutral-Side Current 0 to 999999 1 Amps F12 0

040C Phase A Differential Current 0 to 999999 1 Amps F12 0

040E Phase B Differential Current 0 to 999999 1 Amps F12 0

0410 Phase C Differential Current 0 to 999999 1 Amps F12 0

0412 Average Phase Current 0 to 999999 1 Amps F12 0

0414 Generator Load 0 to 2000 1 % FLA F1 0

0415 Negative Sequence Current 0 to 2000 1 % FLA F1 0

0416 Ground Current 0 to 10000 1 Amps F14 0

0420 Phase A Current Angle 0 to 359 1 ° F1 0

1, 2, 3 See Table footnotes on page 39

14

http://www.GEindustrial.com/multilin

GE Multilin

Page 19

Modbus Memory Map

Communications Guide

Table 1: 489 Memory Map (Sheet 5 of 29)

ADDR NAME RANGE STEP UNITS FORMAT DEFAULT

0421 Phase B Current Angle 0 to 359 1 ° F1 0

0422 Phase C Current Angle 0 to 359 1 ° F1 0

0423 Phase A Neutral-Side Angle 0 to 359 1 ° F1 0

0424 Phase B Neutral-Side Angle 0 to 359 1 ° F1 0

0425 Phase C Neutral-Side Angle 0 to 359 1 ° F1 0

0426 Phase A Differential Angle 0 to 359 1 ° F1 0

0427 Phase B Differential Angle 0 to 359 1 ° F1 0

0428 Phase C Differential Angle 0 to 359 1 ° F1 0

0429 Ground Current Angle 0 to 359 1 ° F1 0

METERING DATA / VOLTAGE METERING

0440 Phase A-B Voltage 0 to 50000 1 Volts F1 0

0441 Phase B-C Voltage 0 to 50000 1 Volts F1 0

0442 Phase C-A Voltage 0 to 50000 1 Volts F1 0

0443 Average Line Voltage 0 to 50000 1 Volts F1 0

0444 Phase A-N Voltage 0 to 50000 1 Volts F1 0

0445 Phase B-N Voltage 0 to 50000 1 Volts F1 0

0446 Phase C-N Voltage 0 to 50000 1 Volts F1 0

0447 Average Phase Voltage 0 to 50000 1 Volts F1 0

0448 Per Unit Measurement Of V/Hz

0449 Frequency 500 to 9000 1 Hz F3 0

044A Neutral Voltage Fund 0 to 250000 1 Volts F10 0

044C Neutral Voltage 3rd Harmonic 0 to 250000 1 Volts F10 0

044E Neutral Voltage Vp3 3rd Harmonic 0 to 250000 1 Volts F10 0

0450 Vab/Iab 0 to 65535 1 ohms F2 0

0451 Vab/Iab Angle 0 to 359 1 ° F1 0

0460 Line A-B Voltage Angle 0 to 359 1 ° F1 0

0461 Line B-C Voltage Angle 0 to 359 1 ° F1 0

0462 Line C-A Voltage Angle 0 to 359 1 ° F1 0

0463 Phase A-N Voltage Angle 0 to 359 1 ° F1 0

0464 Phase B-N Voltage Angle 0 to 359 1 ° F1 0

0465 Phase C-N Voltage Angle 0 to 359 1 ° F1 0

0466 Neutral Voltage Angle 0 to 359 1 – F1 0

METERING DATA / POWER METERING

0480 Power Factor –100 to 100 1 – F6 0

0481 Real Power –2000000 to 2000000 1 MW F13 0

0483 Reactive Power –2000000 to 2000000 1 Mvar F13 0

0485 Apparent Power –2000000 to 200000 1 MVA F13 0

0487 Positive Watthours 0 to 4000000000 1 MWh F13 0

0489 Positive Varhours 0 to 4000000000 1 Mvarh F13 0

048B Negative Varhours 0 to 4000000000 1 Mvarh F13 0

METERING DATA / TEMPERATURE

04A0 Hottest Stator RTD 1 to 12 1 – F1 0

04A1 Hottest Stator RTD Temperature –52 to 250 1 °C F4 –52

04A2 RTD #1 Temperature –52 to 251 1 °C F4 –52

04A3 RTD #2 Temperature –52 to 251 1 °C F4 –52

04A4 RTD #3 Temperature –52 to 251 1 °C F4 –52

04A5 RTD #4 Temperature –52 to 251 1 °C F4 –52

04A6 RTD #5 Temperature –52 to 251 1 °C F4 –52

04A7 RTD #6 Temperature –52 to 251 1 °C F4 –52

04A8 RTD #7 Temperature –52 to 251 1 °C F4 –52

04A9 RTD #8 Temperature –52 to 251 1 °C F4 –52

04AA RTD #9 Temperature –52 to 251 1 °C F4 –52

04AB RTD #10 Temperature –52 to 251 1 °C F4 –52

1, 2, 3 See Table footnotes on page 39

2

0 to 200 1 – F3 0

489

GE Multilin

http://www.GEindustrial.com/multilin

15

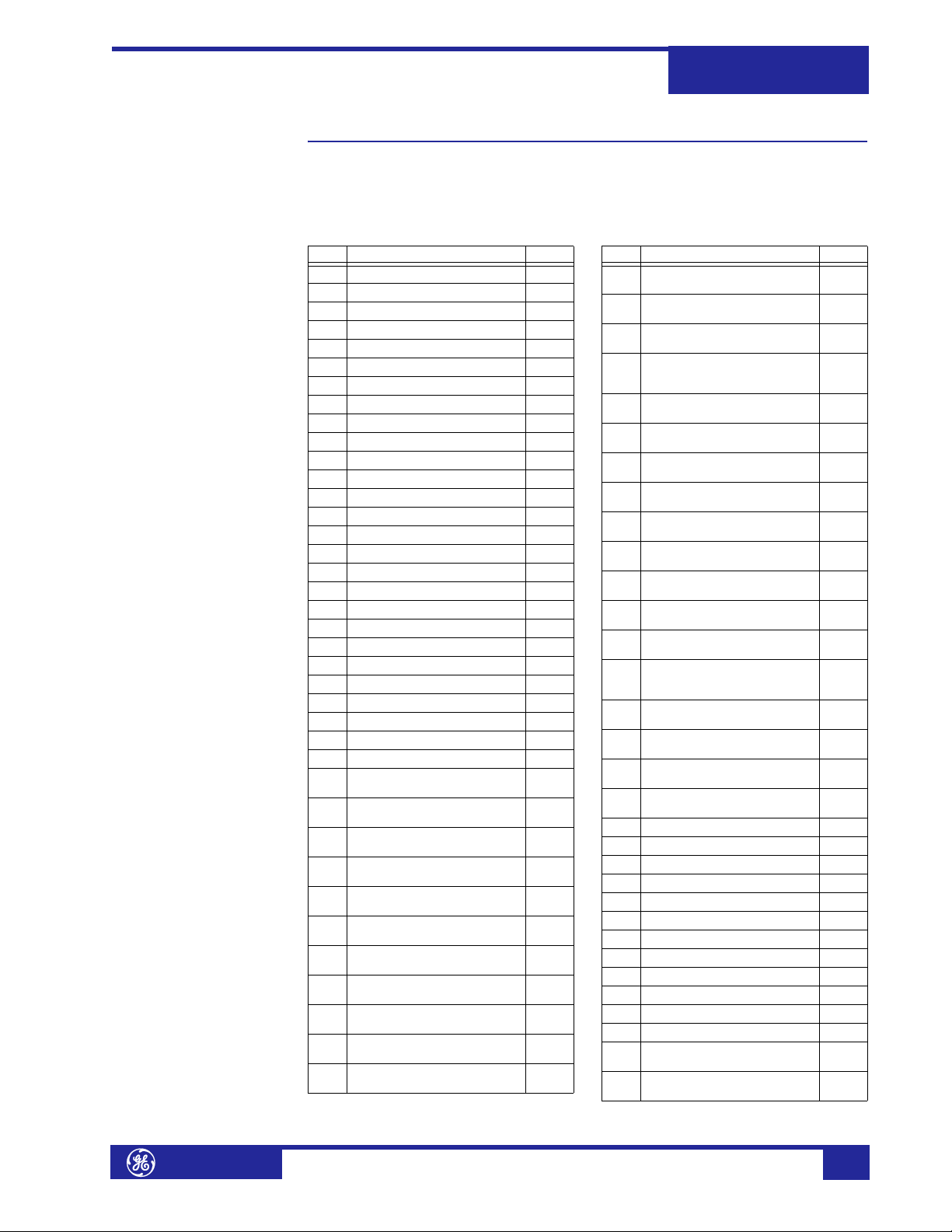

Page 20

Modbus Memory Map489

Communications Guide

Table 1: 489 Memory Map (Sheet 6 of 29)

ADDR NAME RANGE STEP UNITS FORMAT DEFAULT

04AC RTD #11 Temperature –52 to 251 1 °C F4 –52

04AD RTD #12 Temperature –52 to 251 1 °C F4 –52

04C0 Hottest Stator RTD Temperature –52 to 250 1 °F F4 –52

04C1 RTD #1 Temperature –52 to 251 1 °F F4 –52

04C2 RTD #2 Temperature –52 to 251 1 °F F4 –52

04C3 RTD #3 Temperature –52 to 251 1 °F F4 –52

04C4 RTD #4 Temperature –52 to 251 1 °F F4 –52

04C5 RTD #5 Temperature –52 to 251 1 °F F4 –52

04C6 RTD #6 Temperature –52 to 251 1 °F F4 –52

04C7 RTD #7 Temperature –52 to 251 1 °F F4 –52

04C8 RTD #8 Temperature –52 to 251 1 °F F4 –52

04C9 RTD #9 Temperature –52 to 251 1 °F F4 –52

04CA RTD #10 Temperature –52 to 251 1 °F F4 –52

04CB RTD #11 Temperature –52 to 251 1 °F F4 –52

04CC RTD #12 Temperature –52 to 251 1 °F F4 –52

METERING DATA / DEMAND METERING

04E0 Current Demand 0 to 1000000 1 Amps F12 0

04E2 MW Demand 0 to 2000000 1 MW F13 0

04E4 Mvar Demand 0 to 2000000 1 Mvar F13 0

04E6 MVA Demand 0 to 2000000 1 MVA F13 0

04E8 Peak Current Demand 0 to 1000000 1 Amps F12 0

04EA Peak MW Demand 0 to 2000000 1 MW F13 0

04EC Peak Mvar Demand 0 to 2000000 1 Mvar F13 0

04EE Peak MVA Demand 0 to 2000000 1 MVA F13 0

METERING DATA / ANALOG INPUTS

0500 Analog Input 1 –50000 to 50000 1 Units F12 0

0502 Analog Input 2 –50000 to 50000 1 Units F12 0

0504 Analog Input 3 –50000 to 50000 1 Units F12 0

0506 Analog Input 4 –50000 to 50000 1 Units F12 0

METERING DATA / SPEED

0520 Tachometer 0 to 7200 1 RPM F1 0

LEARNED DATA / PARAMETER AVERAGES

0600 Average Generator Load 0 to 2000 1 %FLA F1 0

0601 Average Negative Sequence Current 0 to 2000 1 %FLA F1 0

0602 Average Phase-Phase Voltage 0 to 50000 1 V F1 0

0603 Reserved – – – – –

0604 Reserved – – – – –

LEARNED DATA / RTD MAXIMUMS

0620 RTD #1 Maximum Temperature (Celsius) –52 to 251 1 °C F4 –52

0621 RTD #2 Maximum Temperature (Celsius) –52 to 251 1 °C F4 –52

0622 RTD #3 Maximum Temperature (Celsius) –52 to 251 1 °C F4 –52

0623 RTD #4 Maximum Temperature (Celsius) –52 to 251 1 °C F4 –52

0624 RTD #5 Maximum Temperature (Celsius) –52 to 251 1 °C F4 –52

0625 RTD #6 Maximum Temperature (Celsius) –52 to 251 1 °C F4 –52

0626 RTD #7 Maximum Temperature (Celsius) –52 to 251 1 °C F4 –52

0627 RTD #8 Maximum Temperature (Celsius) –52 to 251 1 °C F4 –52

0628 RTD #9 Maximum Temperature (Celsius) –52 to 251 1 °C F4 –52

0629 RTD #10 Maximum Temperature (Celsius) –52 to 251 1 °C F4 –52

062A RTD #11 Maximum Temperature (Celsius) –52 to 251 1 °C F4 –52

062B RTD #12 Maximum Temperature (Celsius) –52 to 251 1 °C F4 –52

0640 RTD #1 Maximum Temperature (Fahrenheit) –52 to 251 1 °F F4 –52

0641 RTD #2 Maximum Temperature (Fahrenheit) –52 to 251 1 °F F4 –52

0642 RTD #3 Maximum Temperature (Fahrenheit) –52 to 251 1 °F F4 –52

1, 2, 3 See Table footnotes on page 39

16

http://www.GEindustrial.com/multilin

GE Multilin

Page 21

Modbus Memory Map

Communications Guide

Table 1: 489 Memory Map (Sheet 7 of 29)

ADDR NAME RANGE STEP UNITS FORMAT DEFAULT

0643 RTD #4 Maximum Temperature (Fahrenheit) –52 to 251 1 °F F4 –52

0644 RTD #5 Maximum Temperature (Fahrenheit) –52 to 251 1 °F F4 –52

0645 RTD #6 Maximum Temperature (Fahrenheit) –52 to 251 1 °F F4 –52

0646 RTD #7 Maximum Temperature (Fahrenheit) –52 to 251 1 °F F4 –52

0647 RTD #8 Maximum Temperature (Fahrenheit) –52 to 251 1 °F F4 –52

0648 RTD #9 Maximum Temperature (Fahrenheit) –52 to 251 1 °F F4 –52

0649 RTD #10 Maximum Temperature (Fahrenheit) –52 to 251 1 °F F4 –52

064A RTD #11 Maximum Temperature (Fahrenheit) –52 to 251 1 °F F4 –52

064B RTD #12 Maximum Temperature (Fahrenheit) –52 to 251 1 °F F4 –52

LEARNED DATA / ANALOG IN MIN/MAX

0700 Analog Input 1 Minimum –50000 to 50000 1 Units F12 0

0702 Analog Input 1 Maximum –50000 to 50000 1 Units F12 0

0704 Analog Input 2 Minimum –50000 to 50000 1 Units F12 0

0706 Analog Input 2 Maximum –50000 to 50000 1 Units F12 0

0708 Analog Input 3 Minimum –50000 to 50000 1 Units F12 0

070A Analog Input 3 Maximum –50000 to 50000 1 Units F12 0

070C Analog Input 4 Minimum –50000 to 50000 1 Units F12 0

070E Analog Input 4 Maximum –50000 to 50000 1 Units F12 0

MAINTENANCE / TRIP COUNTERS

077F Trip Counters Last Cleared (Date) N/A N/A N/A F18 N/A

0781 Total Number of Trips 0 to 50000 1 – F1 0

0782 Digital Input Trips 0 to 50000 1 – F1 0

0783 Sequential Trips 0 to 50000 1 – F1 0

0784 Field-Breaker Discrepancy Trips 0 to 50000 1 – F1 0

0785 Tachometer Trips 0 to 50000 1 – F1 0

0786 Offline Overcurrent Trips 0 to 50000 1 – F1 0

0787 Phase Overcurrent Trips 0 to 50000 1 – F1 0

0788 Negative Sequence Overcurrent Trips 0 to 50000 1 – F1 0

0789 Ground Overcurrent Trips 0 to 50000 1 – F1 0

078A Phase Differential Trips 0 to 50000 1 – F1 0

078B Undervoltage Trips 0 to 50000 1 – F1 0

078C Overvoltage Trips 0 to 50000 1 – F1 0

078D Volts/Hertz Trips 0 to 50000 1 – F1 0

078E Phase Reversal Trips 0 to 50000 1 – F1 0

078F Underfrequency Trips 0 to 50000 1 – F1 0

0790 Overfrequency Trips 0 to 50000 1 – F1 0

0791 Neutral Overvoltage (Fundamental) Trips 0 to 50000 1 – F1 0

0792 Neutral Undervoltage (3rd Harmonic) Trips 0 to 50000 1 – F1 0

0793 Reactive Power Trips 0 to 50000 1 – F1 0

0794 Reverse Power Trips 0 to 50000 1 – F1 0

0795 Low Forward Power Trips 0 to 50000 1 – F1 0

0796 Stator RTD Trips 0 to 50000 1 – F1 0

0797 Bearing RTD Trips 0 to 50000 1 – F1 0

0798 Other RTD Trips 0 to 50000 1 – F1 0

0799 Ambient RTD Trips 0 to 50000 1 – F1 0

079A Thermal Model Trips 0 to 50000 1 – F1 0

079B Inadvertent Energization Trips 0 to 50000 1 – F1 0

079C Analog Input 1 Trips 0 to 50000 1 – F1 0

079D Analog Input 2 Trips 0 to 50000 1 – F1 0

079E Analog Input 3 Trips 0 to 50000 1 – F1 0

079F Analog Input 4 Trips 0 to 50000 1 – F1 0

MAINTENANCE / GENERAL COUNTERS

07A0 Number Of Breaker Operations 0 to 50000 1 – F1 0

1, 2, 3 See Table footnotes on page 39

489

GE Multilin

http://www.GEindustrial.com/multilin

17

Page 22

Modbus Memory Map489

Communications Guide

Table 1: 489 Memory Map (Sheet 8 of 29)

ADDR NAME RANGE STEP UNITS FORMAT DEFAULT

07A1 Number Of Thermal Resets 0 to 50000 1 – F1 0

MAINTENANCE / TRIP COUNTERS

07A2 Loss Of Excitation 1 Trips 0 to 50000 1 – F1 0

07A3 Loss Of Excitation 2 Trips 0 to 50000 1 – F1 0

07A4 Ground Directional Trips 0 to 50000 1 – F1 0

07A5 High-Set Phase Overcurrent Trips 0 to 50000 1 – F1 0

07A6 Distance Zone 1 Trips 0 to 50000 1 – F1 0

07A7 Distance Zone 2 Trips 0 to 50000 1 – F1 0

MAINTENANCE / TIMERS

07E0 Generator Hours Online 0 to 1000000 1 h F12 0

PRODUCT INFO. / 489 MODEL INFO.

0800 Order Code 0 to 65535 1 N/A F136 N/A

0801 489 Serial Number 3000000 to 9999999 1 – F12 3000000

PRODUCT INFO. / CALIBRATION INFO.

0810 Original Calibration Date N/A N/A N/A F18 N/A

0812 Last Calibration Date N/A N/A N/A F18 N/A

489 SETUP / PREFERENCES

1000 Default Message Cycle Time 5 to 100 5 s F2 20

1001 Default Message Timeout 10 to 900 1 s F1 300

1003 Parameter Averages Calculation Period 1 to 90 1 min F1 15

1004 Temperature Display 0 to 1 1 – F100 0

1005 Waveform Trigger Position 1 to 100 1 % F1 25

1006 Passcode (Write Only) 0 to 99999999 1 N/A F12 0

1008 Encrypted Passcode (Read Only) N/A N/A N/A F12 N/A

100A Waveform Memory Buffer 1 to 16 1 – F1 8

489 SETUP / SERIAL PORTS

1010 Slave Address 1 to 254 1 – F1 254

1011 Computer RS485 Baud Rate 0 to 5 1 – F101 4

1012 Computer RS485 Parity 0 to 2 1 – F102 0

1013 Auxiliary RS485 Baud Rate 0 to 5 1 – F101 4

1014 Auxiliary RS485 Parity 0 to 2 1 – F102 0

1015 Port Used For DNP 0 to 3 1 – F216 0

1016 DNP Slave Address 0 to 255 1 – F1 255

1017 DNP Turnaround Time 0 to 100 10 ms F1 10

489 SETUP / REAL TIME CLOCK

1030 Date N/A N/A N/A F18 N/A

1032 Time N/A N/A N/A F19 N/A

1034 IRIG-B Type 0 to 2 1 – F220 0

489 SETUP / MESSAGE SCRATCHPAD

1060 Scratchpad 0 to 40 1 – F22 _

1080 Scratchpad 0 to 40 1 – F22 _

10A0 Scratchpad 0 to 40 1 – F22 _

10C0 Scratchpad 0 to 40 1 – F22 _

10E0 Scratchpad 0 to 40 1 – F22 _

489 SETUP / CLEAR DATA

1130 Clear Last Trip Data 0 to 1 1 – F103 0

1131 Clear Mwh And Mvarh Meters 0 to 1 1 – F103 0

1132 Clear Peak Demand Data 0 to 1 1 – F103 0

1133 Clear RTD Maximums 0 to 1 1 – F103 0

1134 Clear Analog Inputs Minimums/Maximums 0 to 1 1 – F103 0

1135 Clear Trip Counters 0 to 1 1 – F103 0

1136 Clear Event Record 0 to 1 1 – F103 0

1137 Clear Generator Information 0 to 1 1 – F103 0

1, 2, 3 See Table footnotes on page 39

18

http://www.GEindustrial.com/multilin

GE Multilin

Page 23

Modbus Memory Map

Communications Guide

Table 1: 489 Memory Map (Sheet 9 of 29)

ADDR NAME RANGE STEP UNITS FORMAT DEFAULT

1138 Clear Breaker Information 0 to 1 1 – F103 0

SYSTEM SETUP / CURRENT SENSING

1180 Phase CT Primary 10 to 50001 1 Amps F1 50001

1181 Ground CT 0 to 3 1 – F104 0

1182 Ground CT Ratio 10 to 10000 1 : 1 / :5 F1 100

SYSTEM SETUP / VOLTAGE SENSING

11A0 VT Connection Type 0 to 2 1 – F106 0

11A1 Voltage Transformer Ratio 100 to 30000 1 : 1 F3 500

11A2 Neutral VT Ratio 100 to 24000 1 : 1 F3 500

11A3 Neutral Voltage Transformer 0 to 1 1 – F103 0

SYSTEM SETUP / GEN. PARAMETERS

11C0 Generator Rated MVA 50 to 2000001 1 MVA F13 2000001

11C2 Generator Rated Power Factor 5 to 100 1 – F3 100

11C3 Generator Voltage Phase-Phase 100 to 30001 1 V F1 30001

11C4 Generator Nominal Frequency 0 to 3 1 Hz F107 0

11C5 Generator Phase Sequence 0 to 2 1 – F124 0

SYSTEM SETUP / SERIAL START/STOP

11E0 Serial Start/Stop Initiation 0 to 1 1 – F105 0

11E1 Startup Initiation Relays (2-5) 1 to 4 1 – F50 0

11E2 Shutdown Initiation Relays (1-4) 0 to 3 1 – F50 0

11E3 Serial Start/Stop Events 0 to 1 1 – F105 0

DIGITAL INPUTS / BREAKER STATUS

1200 Breaker Status 0 to 1 1 – F209 1

DIGITAL INPUTS / GENERAL INPUT A

1210 Assign Digital Input 0 to 7 1 – F210 0

1211 Asserted Digital Input State 0 to 1 1 – F131 0

1212 Input Name 0 to 12 1 – F22 _

1218 Block Input From Online 0 to 5000 1 s F1 0

1219 General Input A Control 0 to 1 1 – F105 0

121A Pulsed Control Relay Dwell Time 0 to 250 1 s F2 0

121B Assign Control Relays (1-5) 0 to 4 1 – F50 0

121C General Input A Control Events 0 to 1 1 – F105 0

121D General Input A Alarm 0 to 2 1 – F115 0

121E Assign Alarm Relays (2-5) 1 to 4 1 – F50 16

121F General Input A Alarm Delay 1 to 50000 1 s F2 50

1220 General Input A Alarm Events 0 to 1 1 – F105 0

1221 General Input A Trip 0 to 2 1 – F115 0

1222 Assign Trip Relays (1-4) 0 to 3 1 – F50 1

1223 General Input A Trip Delay 1 to 50000 1 s F2 50

DIGITAL INPUTS / GENERAL INPUT B

1230 Assign Digital Input 0 to 7 1 – F210 0

1231 Asserted Digital Input State 0 to 1 1 – F131 0

1232 Input Name 0 to 12 1 – F22 _

1238 Block Input From Online 0 to 5000 1 s F1 0

1239 General Input B Control 0 to 1 1 – F105 0

123A Pulsed Control Relay Dwell Time 0 to 250 1 s F2 0

123B Assign Control Relays (1-5) 0 to 4 1 – F50 0

123C General Input B Control Events 0 to 1 1 – F105 0

123D General Input B Alarm 0 to 2 1 – F115 0

123E Assign Alarm Relays (2-5) 1 to 4 1 – F50 16

123F General Input B Alarm Delay 1 to 50000 1 s F2 50

1240 General Input B Alarm Events 0 to 1 1 – F105 0

1241 General Input B Trip 0 to 2 1 – F115 0

1, 2, 3 See Table footnotes on page 39

489

GE Multilin

http://www.GEindustrial.com/multilin

19

Page 24

Modbus Memory Map489

Communications Guide

Table 1: 489 Memory Map (Sheet 10 of 29)

ADDR NAME RANGE STEP UNITS FORMAT DEFAULT

1242 Assign Trip Relays (1-4) 0 to 3 1 – F50 1

1243 General Input B Trip Delay 1 to 50000 1 s F2 50

DIGITAL INPUTS / GENERAL INPUT C

1250 Assign Digital Input 0 to 7 1 – F210 0

1251 Asserted Digital Input State 0 to 1 1 – F131 0

1252 Input Name 0 to 12 1 – F22 _

1258 Block Input From Online 0 to 5000 1 s F1 0

1259 General Input C Control 0 to 1 1 – F105 0

125A Pulsed Control Relay Dwell Time 0 to 250 1 s F2 0

125B Assign Control Relays (1-5) 0 to 4 1 – F50 0

125C General Input C Control Events 0 to 1 1 – F105 0

125D General Input C Alarm 0 to 2 1 – F115 0

125E Assign Alarm Relays (2-5) 1 to 4 1 – F50 16

125F General Input C Alarm Delay 1 to 50000 1 s F2 50

1260 General Input C Alarm Events 0 to 1 1 – F105 0

1261 General Input C Trip 0 to 2 1 – F115 0

1262 Assign Trip Relays (1-4) 0 to 3 1 – F50 1

1263 General Input C Trip Delay 1 to 50000 1 s F2 50

DIGITAL INPUTS / GENERAL INPUT D

1270 Assign Digital Input 0 to 7 1 – F210 0

1271 Asserted Digital Input State 0 to 1 1 – F131 0

1272 Input Name 0 to 12 1 – F22 _

1278 Block Input From Online 0 to 5000 1 s F1 0

1279 General Input D Control 0 to 1 1 – F105 0

127A Pulsed Control Relay Dwell Time 0 to 250 1 s F2 0

127B Assign Control Relays (1-5) 0 to 4 1 – F50 0

127C General Input D Control Events 0 to 1 1 – F105 0

127D General Input D Alarm 0 to 2 1 – F115 0

127E Assign Alarm Relays (2-5) 1 to 4 1 – F50 16

127F General Input D Alarm Delay 1 to 50000 1 s F2 50

1280 General Input D Alarm Events 0 to 1 1 – F105 0

1281 General Input D Trip 0 to 2 1 – F115 0

1282 Assign Trip Relays (1-4) 0 to 3 1 – F50 1

1283 General Input D Trip Delay 1 to 50000 1 s F2 50

DIGITAL INPUTS / GENERAL INPUT E

1290 Assign Digital Input 0 to 7 1 – F210 0

1291 Asserted Digital Input State 0 to 1 1 – F131 0

1292 Input Name 0 to 12 1 – F22 _

1298 Block Input From Online 0 to 5000 1 s F1 0

1299 General Input E Control 0 to 1 1 – F105 0

129A Pulsed Control Relay Dwell Time 0 to 250 1 s F2 0

129B Assign Control Relays (1-5) 0 to 4 1 – F50 0

129C General Input E Control Events 0 to 1 1 – F105 0

129D General Input E Alarm 0 to 2 1 – F115 0

129E Assign Alarm Relays (2-5) 1 to 4 1 – F50 16

129F General Input E Alarm Delay 1 to 50000 1 s F2 50

12A0 General Input E Alarm Events 0 to 1 1 – F105 0

12A1 General Input E Trip 0 to 2 1 – F115 0

12A2 Assign Trip Relays (1-4) 0 to 3 1 – F50 1

12A3 General Input E Trip Delay 1 to 50000 1 s F2 50

DIGITAL INPUTS / GENERAL INPUT F

12B0 Assign Digital Input 0 to 7 1 – F210 0

12B1 Asserted Digital Input State 0 to 1 1 – F131 0

1, 2, 3 See Table footnotes on page 39

20

http://www.GEindustrial.com/multilin

GE Multilin

Page 25

Modbus Memory Map

Communications Guide

Table 1: 489 Memory Map (Sheet 11 of 29)

ADDR NAME RANGE STEP UNITS FORMAT DEFAULT

12B2 Input Name 0 to 12 1 – F22 _

12B8 Block Input From Online 0 to 5000 1 s F1 0

12B9 General Input F Control 0 to 1 1 – F105 0

12BA Pulsed Control Relay Dwell Time 0 to 250 1 s F2 0

12BB Assign Control Relays (1-5) 0 to 4 1 – F50 0

12BC General Input F Control Events 0 to 1 1 – F105 0

12BD General Input F Alarm 0 to 2 1 – F115 0

12BE Assign Alarm Relays (2-5) 1 to 4 1 – F50 16

12BF General Input F Alarm Delay 1 to 50000 1 s F2 50

12C0 General Input F Alarm Events 0 to 1 1 – F105 0

12C1 General Input F Trip 0 to 2 1 – F115 0

12C2 Assign Trip Relays (1-4) 0 to 3 1 – F50 1

12C3 General Input F Trip Delay 1 to 50000 1 s F2 50

DIGITAL INPUTS / GENERAL INPUT G

12D0 Assign Digital Input 0 to 7 1 – F210 0

12D1 Asserted Digital Input State 0 to 1 1 – F131 0

12D2 Input Name 0 to 12 1 – F22 _

12D8 Block Input From Online 0 to 5000 1 s F1 0

12D9 General Input G Control 0 to 1 1 – F105 0

12DA Pulsed Control Relay Dwell Time 0 to 250 1 s F2 0

12DB Assign Control Relays (1-5) 0 to 4 1 – F50 0

12DC General Input G Control Events 0 to 1 1 – F105 0

12DD General Input G Alarm 0 to 2 1 – F115 0

12DE Assign Alarm Relays (2-5) 1 to 4 1 – F50 16

12DF General Input G Alarm Delay 1 to 50000 1 s F2 50

12E0 General Input G Alarm Events 0 to 1 1 – F105 0

12E1 General Input G Trip 0 to 2 1 – F115 0

12E2 Assign Trip Relays (1-4) 0 to 3 1 – F50 1

12E3 General Input G Trip Delay 1 to 50000 1 s F2 50

DIGITAL INPUTS / REMOTE RESET

1300 Assign Digital Input 0 to 7 1 – F210 0

DIGITAL INPUTS / TEST INPUT

1310 Assign Digital Input 0 to 7 1 – F210 0

DIGITAL INPUTS / THERMAL RESET

1320 Assign Digital Input 0 to 7 1 – F210 0

DIGITAL INPUTS / DUAL SETPOINTS

1340 Assign Digital Input 0 to 7 1 – F210 0

1341 Active Setpoint Group 0 to 1 1 – F118 0

1342 Edit Setpoint Group 0 to 1 1 – F118 0

DIGITAL INPUTS / SEQUENTIAL TRIP

1360 Assign Digital Input 0 to 7 1 – F210 0

1361 Sequential Trip Type 0 to 1 1 – F206 0

1362 Assign Trip Relays (1-4) 0 to 3 1 – F50 1

1363 Sequential Trip Level 2 to 99 1 × Rated MW F14 5

1365 Sequential Trip Delay 2 to 1200 1 s F2 10

DIGITAL INPUTS / FIELD-BREAKER DISCREPANCY

1380 Assign Digital Input 0 to 7 1 – F210 0

1381 Field Status Contact 0 to 1 1 – F109 0

1382 Assign Trip Relays (1-4) 0 to 3 1 – F50 1

1383 Field-Breaker Discrepancy Trip Delay 1 to 5000 1 s F2 10

DIGITAL INPUTS / TACHOMETER

13A0 Assign Digital Input 0 to 7 1 – F210 0

13A1 Rated Speed 100 to 3600 1 RPM F1 3600

1, 2, 3 See Table footnotes on page 39

489

GE Multilin

http://www.GEindustrial.com/multilin

21

Page 26

Modbus Memory Map489

Communications Guide

Table 1: 489 Memory Map (Sheet 12 of 29)

ADDR NAME RANGE STEP UNITS FORMAT DEFAULT

13A2 Tachometer Alarm 0 to 2 1 – F115 0

13A3 Assign Alarm Relays (2-5) 1 to 4 1 – F50 16

13A4 Tachometer Alarm Speed 101 to 175 1 %Rated F1 110

13A5 Tachometer Alarm Delay 1 to 250 1 s F1 1

13A6 Tachometer Alarm Events 0 to 1 1 – F105 0

13A7 Tachometer Trip 0 to 2 1 – F115 0

13A8 Assign Trip Relays (1-4) 0 to 3 1 – F50 1

13A9 Tachometer Trip Speed 101 to 175 1 %Rated F1 110

13AA Tachometer Trip Delay 1 to 250 1 s F1 1

DIGITAL INPUTS / WAVEFORM CAPTURE

13C0 Assign Digital Input 0 to 7 1 – F210 0

DIGITAL INPUTS / GROUND SWITCH STATUS

13D0 Assign Digital Input 0 to 7 1 – F210 0

13D1 Ground Switch Contact 0 to 1 1 – F109 0

OUTPUT RELAYS / RELAY RESET MODE

1400 1 Trip 0 to 1 1 – F117 0

1401 2 Auxiliary 0 to 1 1 – F117 0

1402 3 Auxiliary 0 to 1 1 – F117 0

1403 4 Auxiliary 0 to 1 1 – F117 0

1404 5 Alarm 0 to 1 1 – F117 0

1405 6 Service 0 to 1 1 – F117 0

CURRENT ELEMENTS / OVERCURRENT ALARM

1500 Overcurrent Alarm 0 to 2 1 – F115 0

1501 Assign Alarm Relays (2-5) 1 to 4 1 – F50 16

1502 Overcurrent Alarm Level 10 to 150 1 × FLA F3 101

1503 Overcurrent Alarm Delay 1 to 2500 1 s F2 1

1504 Overcurrent Alarm Events 0 to 1 1 – F105 0

CURRENT ELEMENTS / OFFLINE OVERCURRENT

1520 Offline Overcurrent Trip 0 to 2 1 – F115 0

1521 Assign Trip Relays (1-4) 0 to 3 1 – F50 1

1522 Offline Overcurrent Pickup 5 to 100 1 × CT F3 5

1523 Offline Overcurrent Trip Delay 3 to 99 1 Cycles F1 5

CURRENT ELEMENTS / INADVERTENT ENERGIZATION

1540 Inadvertent Energize Trip 0 to 2 1 – F115 0

1541 Assign Trip Relays (1-4) 0 to 3 1 – F50 1

1542 Arming Signal 0 to 1 1 – F202 0

1543 Inadvertent Energize O/c Pickup 5 to 300 1 × CT F3 5

1544 Inadvertent Energize Pickup 50 to 99 1 × Rated V F3 50

CURRENT ELEMENTS / PHASE OVERCURRENT

1600 Phase Overcurrent Trip 0 to 2 1 – F115 0

1601 Assign Trip Relays (1-4) 0 to 3 1 – F50 1

1602 Enable Voltage Restraint 0 to 1 1 – F103 0

1603 Phase Overcurrent Pickup 15 to 2000 1 × CT F3 1000

1604 Curve Shape 0 to 13 1 – F128 0

1605 FlexCurve™ Trip Time at 1.03 × PU 0 to 65535 1 ms F1 65535

1606 FlexCurve™ Trip Time at 1.05 × PU 0 to 65535 1 ms F1 65535

1607 FlexCurve™ Trip Time at 1.10 × PU 0 to 65535 1 ms F1 65535

1608 FlexCurve™ Trip Time at 1.20 × PU 0 to 65535 1 ms F1 65535

1609 FlexCurve™ Trip Time at 1.30 × PU 0 to 65535 1 ms F1 65535

160A FlexCurve™ Trip Time at 1.40 × PU 0 to 65535 1 ms F1 65535

160B FlexCurve™ Trip Time at 1.50 × PU 0 to 65535 1 ms F1 65535

160C FlexCurve™ Trip Time at 1.60 × PU 0 to 65535 1 ms F1 65535

160D FlexCurve™ Trip Time at 1.70 × PU 0 to 65535 1 ms F1 65535

1, 2, 3 See Table footnotes on page 39

22

http://www.GEindustrial.com/multilin

GE Multilin

Page 27

Modbus Memory Map

Communications Guide

Table 1: 489 Memory Map (Sheet 13 of 29)

ADDR NAME RANGE STEP UNITS FORMAT DEFAULT

160E FlexCurve™ Trip Time at 1.80 × PU 0 to 65535 1 ms F1 65535

160F FlexCurve™ Trip Time at 1.90 × PU 0 to 65535 1 ms F1 65535

1610 FlexCurve™ Trip Time at 2.00 × PU 0 to 65535 1 ms F1 65535

1611 FlexCurve™ Trip Time at 2.10 × PU 0 to 65535 1 ms F1 65535

1612 FlexCurve™ Trip Time at 2.20 × PU 0 to 65535 1 ms F1 65535

1613 FlexCurve™ Trip Time at 2.30 × PU 0 to 65535 1 ms F1 65535

1614 FlexCurve™ Trip Time at 2.40 × PU 0 to 65535 1 ms F1 65535

1615 FlexCurve™ Trip Time at 2.50 × PU 0 to 65535 1 ms F1 65535

1616 FlexCurve™ Trip Time at 2.60 × PU 0 to 65535 1 ms F1 65535

1617 FlexCurve™ Trip Time at 2.70 × PU 0 to 65535 1 ms F1 65535

1618 FlexCurve™ Trip Time at 2.80 × PU 0 to 65535 1 ms F1 65535

1619 FlexCurve™ Trip Time at 2.90 × PU 0 to 65535 1 ms F1 65535

161A FlexCurve™ Trip Time at 3.00 × PU 0 to 65535 1 ms F1 65535

161B FlexCurve™ Trip Time at 3.10 × PU 0 to 65535 1 ms F1 65535

161C FlexCurve™ Trip Time at 3.20 × PU 0 to 65535 1 ms F1 65535

161D FlexCurve™ Trip Time at 3.30 × PU 0 to 65535 1 ms F1 65535

161E FlexCurve™ Trip Time at 3.40 × PU 0 to 65535 1 ms F1 65535

161F FlexCurve™ Trip Time at 3.50 × PU 0 to 65535 1 ms F1 65535

1620 FlexCurve™ Trip Time at 3.60 × PU 0 to 65535 1 ms F1 65535

1621 FlexCurve™ Trip Time at 3.70 × PU 0 to 65535 1 ms F1 65535

1622 FlexCurve™ Trip Time at 3.80 × PU 0 to 65535 1 ms F1 65535

1623 FlexCurve™ Trip Time at 3.90 × PU 0 to 65535 1 ms F1 65535

1624 FlexCurve™ Trip Time at 4.00 × PU 0 to 65535 1 ms F1 65535

1625 FlexCurve™ Trip Time at 4.10 × PU 0 to 65535 1 ms F1 65535

1626 FlexCurve™ Trip Time at 4.20 × PU 0 to 65535 1 ms F1 65535

1627 FlexCurve™ Trip Time at 4.30 × PU 0 to 65535 1 ms F1 65535

1628 FlexCurve™ Trip Time at 4.40 × PU 0 to 65535 1 ms F1 65535

1629 FlexCurve™ Trip Time at 4.50 × PU 0 to 65535 1 ms F1 65535

162A FlexCurve™ Trip Time at 4.60 × PU 0 to 65535 1 ms F1 65535

162B FlexCurve™ Trip Time at 4.70 × PU 0 to 65535 1 ms F1 65535

162C FlexCurve™ Trip Time at 4.80 × PU 0 to 65535 1 ms F1 65535

162D FlexCurve™ Trip Time at 4.90 × PU 0 to 65535 1 ms F1 65535

162E FlexCurve™ Trip Time at 5.00 × PU 0 to 65535 1 ms F1 65535

162F FlexCurve™ Trip Time at 5.10 × PU 0 to 65535 1 ms F1 65535

1630 FlexCurve™ Trip Time at 5.20 × PU 0 to 65535 1 ms F1 65535

1631 FlexCurve™ Trip Time at 5.30 × PU 0 to 65535 1 ms F1 65535

1632 FlexCurve™ Trip Time at 5.40 × PU 0 to 65535 1 ms F1 65535

1633 FlexCurve™ Trip Time at 5.50 × PU 0 to 65535 1 ms F1 65535

1634 FlexCurve™ Trip Time at 5.60 × PU 0 to 65535 1 ms F1 65535

1635 FlexCurve™ Trip Time at 5.70 × PU 0 to 65535 1 ms F1 65535

1636 FlexCurve™ Trip Time at 5.80 × PU 0 to 65535 1 ms F1 65535

1637 FlexCurve™ Trip Time at 5.90 × PU 0 to 65535 1 ms F1 65535

1638 FlexCurve™ Trip Time at 6.00 × PU 0 to 65535 1 ms F1 65535

1639 FlexCurve™ Trip Time at 6.50 × PU 0 to 65535 1 ms F1 65535

163A FlexCurve™ Trip Time at 7.00 × PU 0 to 65535 1 ms F1 65535

163B FlexCurve™ Trip Time at 7.50 × PU 0 to 65535 1 ms F1 65535

163C FlexCurve™ Trip Time at 8.00 × PU 0 to 65535 1 ms F1 65535

163D FlexCurve™ Trip Time at 8.50 × PU 0 to 65535 1 ms F1 65535

163E FlexCurve™ Trip Time at 9.00 × PU 0 to 65535 1 ms F1 65535

163F FlexCurve™ Trip Time at 9.50 × PU 0 to 65535 1 ms F1 65535

1640 FlexCurve™ Trip Time at 10.0 × PU 0 to 65535 1 ms F1 65535

1641 FlexCurve™ Trip Time at 10.5 × PU 0 to 65535 1 ms F1 65535

1642 FlexCurve™ Trip Time at 11.0 × PU 0 to 65535 1 ms F1 65535

1, 2, 3 See Table footnotes on page 39

489

GE Multilin

http://www.GEindustrial.com/multilin

23

Page 28

Modbus Memory Map489

Communications Guide

Table 1: 489 Memory Map (Sheet 14 of 29)

ADDR NAME RANGE STEP UNITS FORMAT DEFAULT

1643 FlexCurve™ Trip Time at 11.5 × PU 0 to 65535 1 ms F1 65535

1644 FlexCurve™ Trip Time at 12.0 × PU 0 to 65535 1 ms F1 65535

1645 FlexCurve™ Trip Time at 12.5 × PU 0 to 65535 1 ms F1 65535

1646 FlexCurve™ Trip Time at 13.0 × PU 0 to 65535 1 ms F1 65535

1647 FlexCurve™ Trip Time at 13.5 × PU 0 to 65535 1 ms F1 65535

1648 FlexCurve™ Trip Time at 14.0 × PU 0 to 65535 1 ms F1 65535

1649 FlexCurve™ Trip Time at 14.5 × PU 0 to 65535 1 ms F1 65535

164A FlexCurve™ Trip Time at 15.0 × PU 0 to 65535 1 ms F1 65535

164B FlexCurve™ Trip Time at 15.5 × PU 0 to 65535 1 ms F1 65535

164C FlexCurve™ Trip Time at 16.0 × PU 0 to 65535 1 ms F1 65535

164D FlexCurve™ Trip Time at 16.5 × PU 0 to 65535 1 ms F1 65535

164E FlexCurve™ Trip Time at 17.0 × PU 0 to 65535 1 ms F1 65535

164F FlexCurve™ Trip Time at 17.5 × PU 0 to 65535 1 ms F1 65535

1650 FlexCurve™ Trip Time at 18.0 × PU 0 to 65535 1 ms F1 65535

1651 FlexCurve™ Trip Time at 18.5 × PU 0 to 65535 1 ms F1 65535

1652 FlexCurve™ Trip Time at 19.0 × PU 0 to 65535 1 ms F1 65535

1653 FlexCurve™ Trip Time at 19.5 × PU 0 to 65535 1 ms F1 65535

1654 FlexCurve™ Trip Time at 20.0 × PU 0 to 65535 1 ms F1 65535

1655 Overcurrent Curve Multiplier 0 to 100000 1 – F14 100

1657 Overcurrent Curve Reset 0 to 1 1 – F201 0

1658 Voltage Lower Limit 10 to 60 1 % F1 10

CURRENT ELEMENTS / NEGATIVE SEQUENCE

1700 Negative Sequence Alarm 0 to 2 1 – F115 0

1701 Assign Alarm Relays (2-5) 1 to 4 1 – F50 16

1702 Negative Sequence Alarm Pickup 3 to 100 1 %FLA F1 3

1703 Negative Sequence Alarm Delay 1 to 1000 1 s F2 50

1704 Negative Sequence Alarm Events 0 to 1 1 – F105 0

1705 Negative Sequence Overcurrent Trip 0 to 2 1 – F115 0

1706 Assign Trip Relays (1-4) 0 to 3 1 – F50 1

1707 Negative Sequence Overcurrent Trip Pickup 3 to 100 1 %FLA F1 8

1708 Negative Sequence Overcurrent Constant K 1 to 100 1 – F1 1

1709 Negative Sequence Overcurrent Maximum Time 10 to 1000 1 s F1 1000

170A Negative Sequence Overcurrent Reset Rate 0 to 9999 1 s F2 2270

CURRENT ELEMENTS / GROUND O/C

1720 Ground Overcurrent Alarm 0 to 2 1 – F115 0

1721 Assign Alarm Relays (2-5) 1 to 4 1 – F50 16

1722 Ground Overcurrent Alarm Pickup 5 to 2000 1 × CT F3 20

1723 Ground Overcurrent Alarm Delay 0 to 100 1 Cycles F1 0

1724 Ground Overcurrent Alarm Events 0 to 1 1 – F105 0

1725 Ground Overcurrent Trip 0 to 2 1 – F115 0

1726 Assign Trip Relays (1-4) 0 to 3 1 – F50 1

1727 Ground Overcurrent Trip Pickup 5 to 2000 1 × CT F3 20

1728 Curve Shape 0 to 13 1 – F128 0

1729 FlexCurve™ Trip Time at 1.03 × PU 0 to 65535 1 ms F1 65535

172A FlexCurve™ Trip Time at 1.05 × PU 0 to 65535 1 ms F1 65535

172B FlexCurve™ Trip Time at 1.10 × PU 0 to 65535 1 ms F1 65535

172C FlexCurve™ Trip Time at 1.20 × PU 0 to 65535 1 ms F1 65535

172D FlexCurve™ Trip Time at 1.30 × PU 0 to 65535 1 ms F1 65535

172E FlexCurve™ Trip Time at 1.40 × PU 0 to 65535 1 ms F1 65535

172F FlexCurve™ Trip Time at 1.50 × PU 0 to 65535 1 ms F1 65535

1730 FlexCurve™ Trip Time at 1.60 × PU 0 to 65535 1 ms F1 65535

1731 FlexCurve™ Trip Time at 1.70 × PU 0 to 65535 1 ms F1 65535

1732 FlexCurve™ Trip Time at 1.80 × PU 0 to 65535 1 ms F1 65535

1, 2, 3 See Table footnotes on page 39

24

http://www.GEindustrial.com/multilin

GE Multilin

Page 29

Modbus Memory Map

Communications Guide

Table 1: 489 Memory Map (Sheet 15 of 29)

ADDR NAME RANGE STEP UNITS FORMAT DEFAULT